Page 1

RETURN TO CD-ROM TABLE OF CONTENTS

North

American

Vitalert3000ServiceManualTableofContents

Dräger

Summary of what's new in Revision L

DESCRIPTION PAGE

SECTION1:

Introduction........................................................1-1

SECTION2:

Diagnostics.........................................................2-1

2.1 MainServiceScreen........................................2-2

2.2 PMSSchedule............................................2-3

2.3 Monitors................................................2-4

2.4 Keys....................................................2-8

2.5 SecondaryServiceScreens...................................2-9

SECTION3:

Troubleshooting......................................................3-1

3.1 PowerSupplyandVoltageDistribution.........................3-1

3.2 TroubleshootingGuides.....................................3-2

SECTION4:

ReplacementProcedures...............................................4-1

4.1 VITALERT3000Cover.....................................4-2

4.2 ProcessorAssembly........................................4-4

4.3 PowerSupply.............................................4-7

4.4 FrontBezelAssembly......................................4-9

4.5 SpO

Assembly...........................................4-11

2

4.6 NIBPModule............................................4-13

4.7 GasAnalyzerAssembly....................................4-15

4.8 SamplePump............................................4-17

4.9 Firmware...............................................4-19

SECTION5:

AdjustmentandCalibrationProcedures...................................5-1

5.1 SpO

MonitorCalibrationCheck..............................5-2

2

5.2 NIBPCuffInflationPressureCheck...........................5-4

5.3 GasSampleLineFlowCalibration.............................5-6

5.4 GasAnalyzerSpanCalibration...............................5-8

5.5 TiltBezelFrictionAdjustment...............................5-11

SECTION6:

PMSProcedure......................................................6-1

6.1 SafetyandElectricalTesting.................................6-2

6.2 ServiceScreen............................................6-3

6.3 SpO

/Pulse...............................................6-4

2

6.4 NIBP...................................................6-5

6.5 CO

/SampleLine..........................................6-6

2

6.6 AlarmCircuitDelayTest....................................6-8

Rev.H

i

Page 2

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

CONTENTS (continued) VA3000

DESCRIPTION PAGE

6.7 System Configuration ............................................ 6-8

6.8 Reset/PMS Criteria ............................................. 6-9

6.9 Accessory Attachments ...................................... 6-9

6.10 Visual Inspection .......................................... 6-9

6.11 Operator Manual .......................................... 6-9

SECTION 7:

Spare and Replacement Parts

ASSEMBLY/PART PAGE

Cabinet Assembly (Cover), Water Trap & Air Filter ...................... 7-2, 7-3

Front Bezel and Related Items ...................................... 7-4, 7-5

NIBP Pump, Bracket, Interface Panel ................................. 7-6, 7-7

Assembly (incl. Bracket and Modules), Interface Panel ................ 7-8, 7-9

SpO

2

Processor Assembly, Speakers, Mains Filter, Circuit Breaker ..............7-10, 7-11

Gas Analyzer Assembly and Sample Pump ............................7-12, 7-13

Power Supply, Input and Output Wire Harnesses,

Touch-up paint: Euro white, Euro blue ..........................7-14, 7-15

ii

Rev. L

Page 3

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Page 4

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

VITALERT 3000 SERIES MONITORING SYSTEM

RETURN TO CD-ROM TABLE OF CONTENTS

MAIN KEY

PANEL

WATER

TRAP

AIR

FILTER

SAMPLE

LINE

NIBP

INTERFACE

PANEL

PULSE OXIMETE R

INTERFACE PANEL

MONITOR

ALARM

LIMITS

MONITOR

SETUP

SYSTEM

CONFIG

DATA

ALARMS

STBY

NIBP CONTROL

KEYS

CONTROL

NIBP

START

LOG

NIBP

DATA

STOP

NIBP

AUTOSET

STAT

KEYS

SELECTION

DIAL

LOG

ON

STBY

SV30123

1-0 Rev. C

Page 5

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 INTRODUCTION

1.0 Recommendations

Because of the sophisticated nature of Draeger Medical, Inc. monitoring equipment and its critical

importance in the operating room setting, it is highly recommended that only appropriately

trained and experienced professionals be permitted to service and maintain this equipment.

Please contact DrägerService at (800) 543-5047 for service of this equipment.

Draeger Medical, Inc. also recommends that its monitoring equipment be serviced at three-month

intervals. Periodic Manufacturer’s Service Agreements are available for equipment manufactured

by Draeger Medical, Inc.. For further information concerning these agreements, please contact

us at (800) 543-5047.

Draeger Medical, Inc. products/material in need of factory repair shall be sent to:

DrägerService

3124 Commerce Drive

Telford, PA 18969

(Include RMA Number)

HOW TO USE THIS MANUAL

The manual is divided into several sections. The DIAGNOSTICS section describes self-test and

service diagnostics for checking the system functions. An understanding of the on-board service

capabilities is necessary before any attempt is made to troubleshoot the unit. The

TROUBLESHOOTING section provides troubleshooting guides to assist the TSR in locating the

source of a problem. The REPLACEMENT PROCEDURES section contains instructions for

removal and replacement of the assemblies that are considered field-replaceable. The

ADJUSTMENT AND CALIBRATION PROCEDURES section contains the field procedures needed

to restore original system specifications. The Periodic Manufacturer’s Service (PMS)

PROCEDURE section outlines the steps required to verify the electrical, mechanical and

pneumatic safety of the unit and also identifies components requiring periodic replacement.

GENERAL TROUBLESHOOTING GUIDELINES

Troubleshooting the VITALERT 3000 should always begin by communicating with those who

observed or experienced the problem with the unit. This may eliminate unnecessary

troubleshooting steps. Once a general problem is identified, refer to the troubleshooting flow

charts in Section 3 of this manual to determine proper corrective action.

After a component is replaced, verify that the unit is operating properly by running the

appropriate diagnostic procedure. The PMS PROCEDURE in Section 6 must also be performed

after any component has been replaced, removed, calibrated or adjusted.

The general arrangement of a VITALERT 3200 Monitor is shown on the opposite page.

WARNINGS are used in this manual before procedures which if not performed correctly could

result in personal injury.

CAUTIONS are used in this manual to alert service personnel to the possibility of damage to the

equipment if a procedure is not performed correctly.

EQUIPMENT CLASS: IEC 601 Class 1, Type BF, continuous

Rev. H

1-1

Page 6

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

INTRODUCTION (continued) VA3000

Copyright

Copyright © 1999 by Draeger Medical, Inc. All rights reserved. No part of this publication

may be reproduced, transmitted, transcribed, or stored in a retrieval system in any form or

by any means, electronic or mechanical, including photocopying and recording, without the

written permission of Draeger Medical, Inc.

Trademark Notices

CliniDAS, Datagrip, NAD Information Systems, NAD Logo, Narkomed, O.R. Data Manager,

O.R. Link, ORM, PC Prep/View, Quality Service For Life, Vigilance Audit, Vitalert, and

Vitalink are registered trademarks of Draeger Medical, Inc. Trademark application has been

made for NMGS and registration is pending. All other products or name brands are

trademarks of their respective owners.

Disclaimer

The content of this manual is furnished for informational use only and is subject to change

without notice. Draeger Medical, Inc. assumes no responsibility or liability for any errors or

inaccuracies that may appear in this manual.

1-2

Rev. H

Page 7

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 DIAGNOSTICS

2.0 DIAGNOSTICS

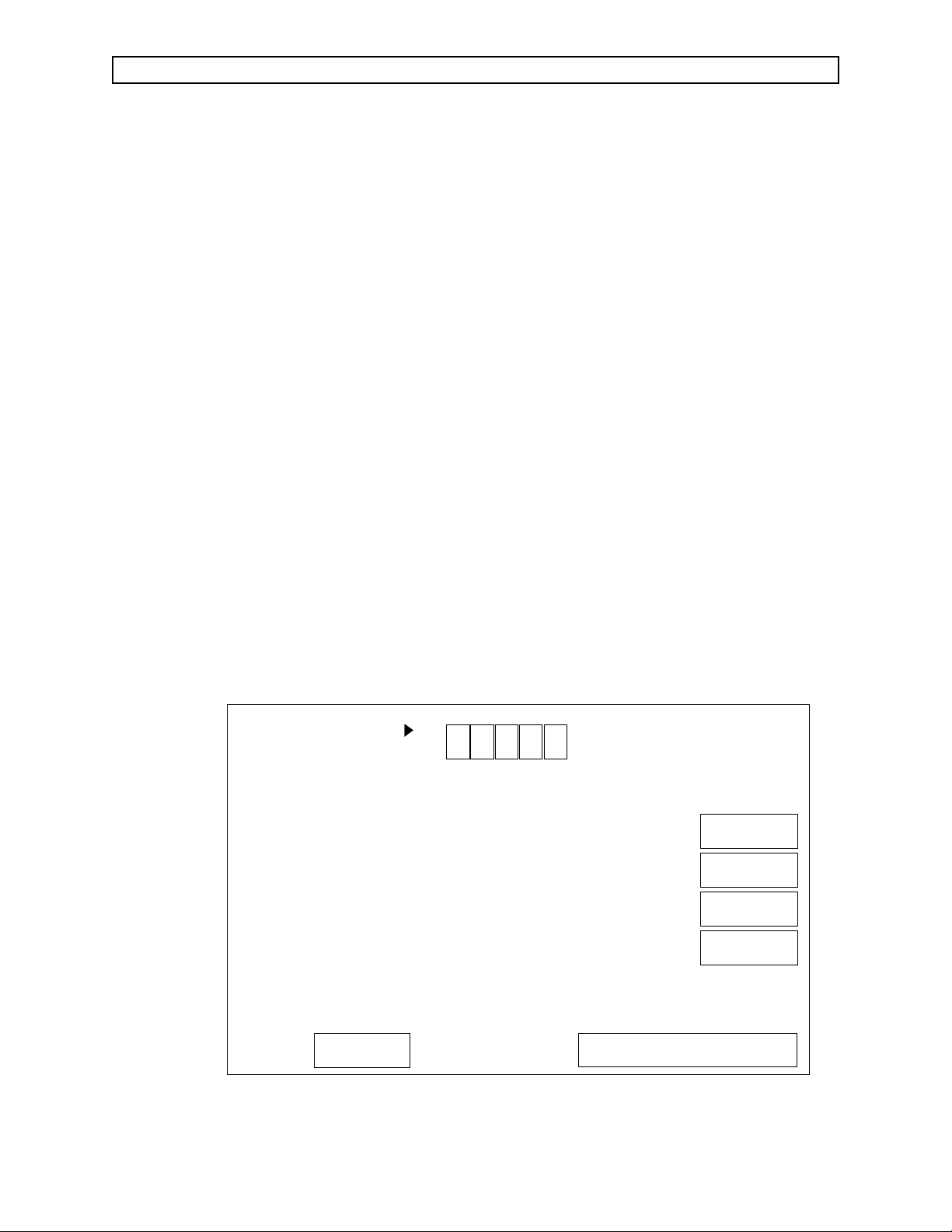

The VITALERT 3000 Series contains a diagnostic system that monitors certain system

functions and records their operational status. A series of tests is performed when the

instrument is powered up and the results are displayed on the diagnostics screen shown in

Figure 2-1. If any of these tests fail, consult Section 3 for proper corrective action.

The operational status of the VITALERT 3000 Series is shown at the end of the power-up

self-diagnostics and will be one of the following:

FUNCTIONAL: All self-diagnostic tests pass, and the instrument begins normal

monitoring operation.

CONDITIONALLY A non-critical fault has been detected, and the MONITOR key

FUNCTIONAL must be pressed to continue operation. The instrument may

continue to be used in this situation, but steps shall be taken to

eliminate the problem.

NON-FUNCTIONAL: The self-diagnostic tests reveal a problem in the instrument. A

summary of the diagnostic results is posted and normal

operation is inhibited. The instrument cannot be operated until

the problem is corrected.

Further diagnostic functions are available through service screens that can be accessed as

described on the following pages. If no display is present upon system power-up, refer to

Section 3 of this manual for troubleshooting assistance.

DIAGNOSTIC TESTS

FIRMWARE

VIDEO

MEMORY

TIMER

AUDIO - PRI MARY

BACK UP

SpO2

SERIAL I/O

CLOCK

NVRAM

PASS

PASS

PASS

PASS

PASS

PASS

PASS

PASS

PASS

PASS

VITALERT 3000

COPYRIGHT 1993, NAD INC.

VERSION 1.03

Rev. H

FUNCTIONAL

SV30101

Figure 2-1: POWER-UP DIAGNOSTICS SCREEN

2-1

Page 8

SYSTEM CONFIG

MONITOR

3

MAIN

PMS

SCHEDULE

MONITORS

KEYS

SERVICE

RESET

HOURS

ROTATE DIAL TO MOVE CURSOR

PRESS TO ACTIVATE FEATURE

3 3 3

SV30104

MACHINE SERIAL NUMBER

LAST SERVICE DATE

HOURS RUN SINCE LAST SERVICE

TOTAL HOURS RUN

VA3:14900

07-14-93

97

3383

OXIM SW VERSION:

GAI SW VERSION:

GAS BENCH SW VERSION:

V 1.0.7

V 1.2.3

V 1.0.1

SERVICE PERSON

IDENTIFICATION

SERVICE TYPE

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) VA3000

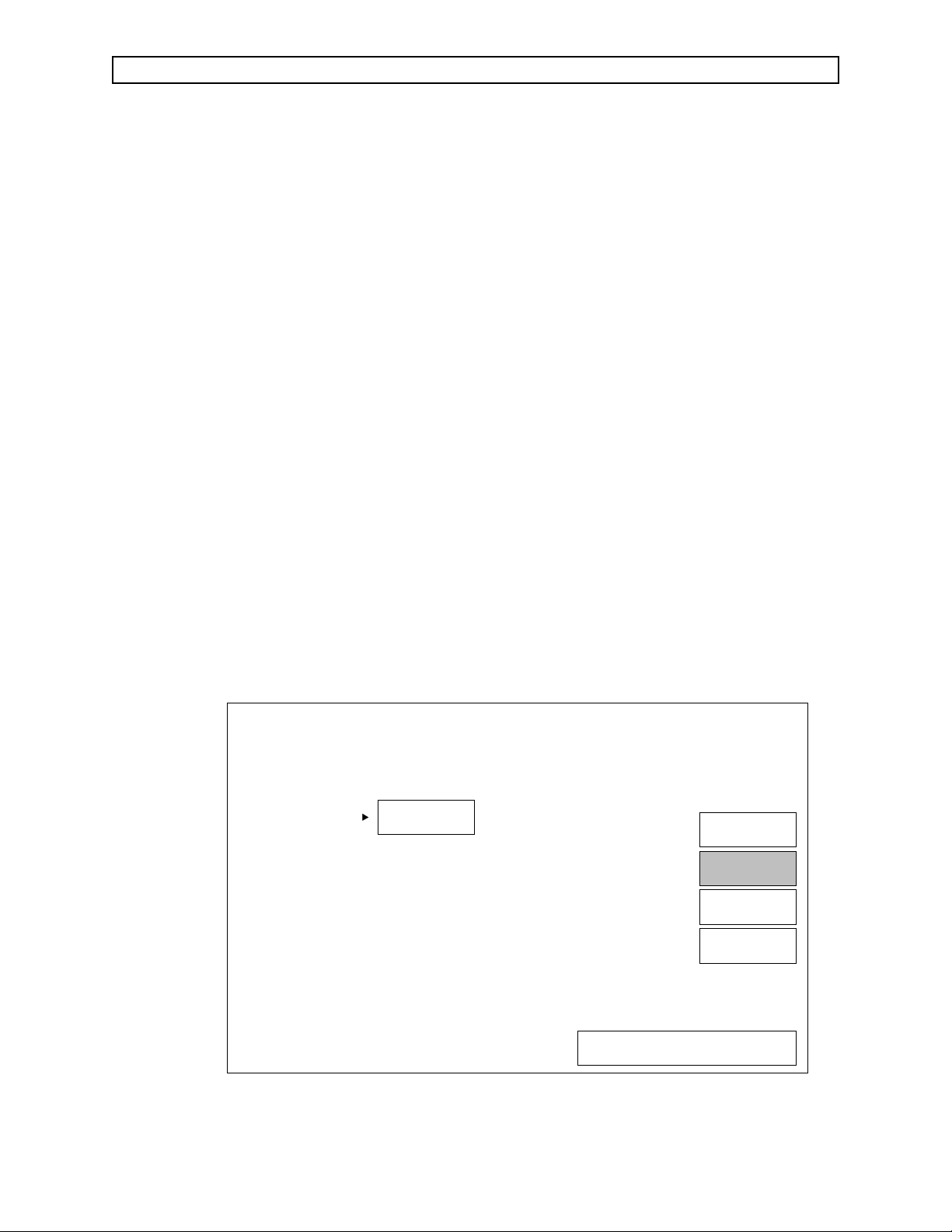

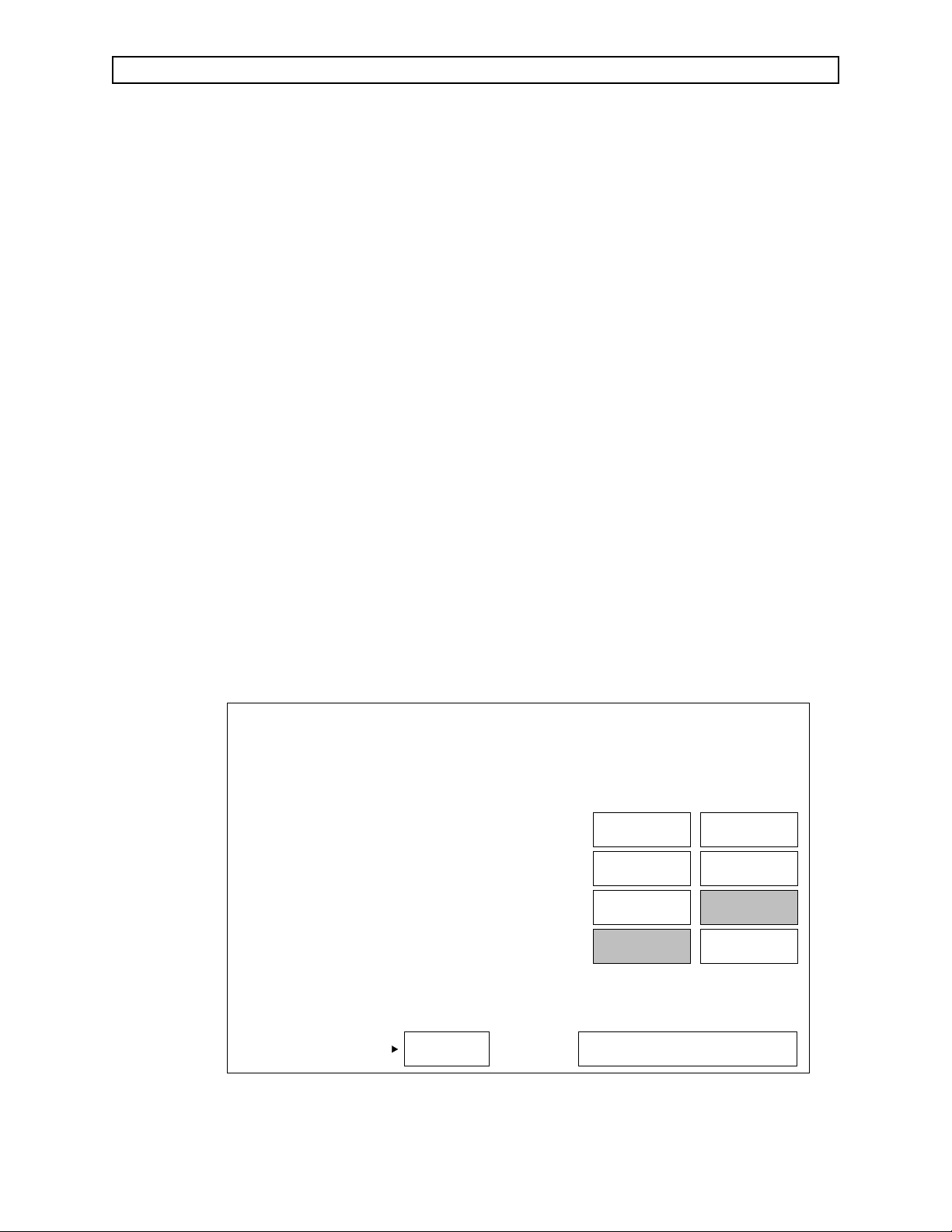

2.1 Main Service Screen

The VITALERT 3000 Series monitors include a maintenance mode that allows

the setting of gas sample flow rates, gas analyzer calibration, diagnostic testing

of the NIBP and SpO

monitors. A Preventive Maintenance Schedule (PMS)

2

screen is also provided for setting the next PMS due date. These maintenance

functions are represented by a series of screens described on following pages,

that can be accessed from the Main Service Screen shown in Figure 2-2. In

addition to these functions, a series of Secondary Service screens allows

viewing of the machine’s service log and making service entries.

The Main Service Screen displays the serial number, the date that the

instrument was last serviced, the hours since last service, total hours on the

instrument and the version number for each software set in the instrument.

To access the Main Service Screen, simultaneously press and hold the

MONITOR

and keys. While holding the keys, press the rotary dial.

With the rotary dial, set the cursor to the Service Person Identification box and

press the dial. Scroll to the first character of your Service I.D., then enter the

selection by pressing the dial. Enter the three remaining I.D. characters in the

same manner.

Use the rotary dial to select the service screens described in the following

paragraphs. Selecting RESET and pressing the dial will set the last service

date to the current date, and the hours run since last service to zero. Pressing

the key on the front panel will return the instrument to normal

operation.

Figure 2-2: MAIN SERVICE SCREEN

2-2

Page 9

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 DIAGNOSTICS (continued)

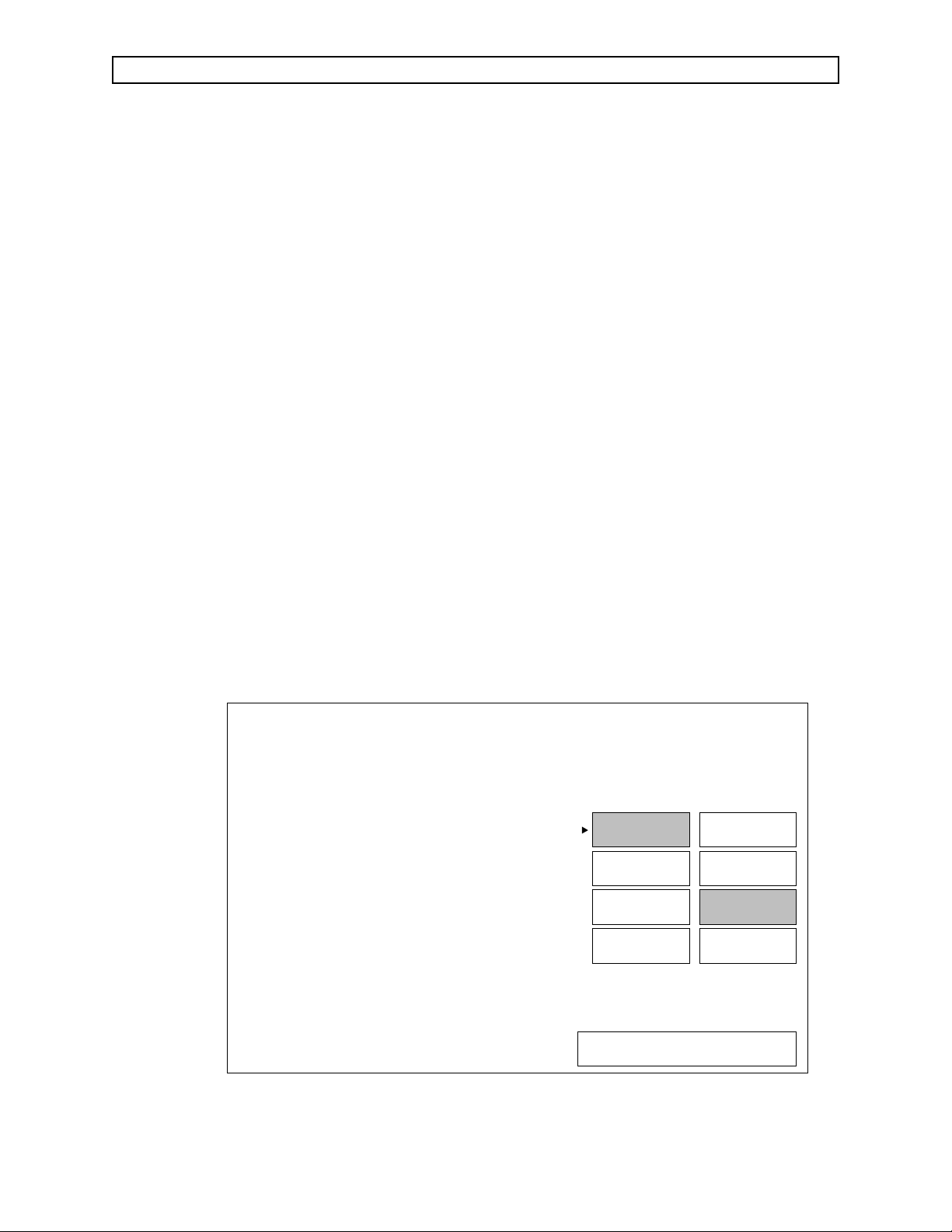

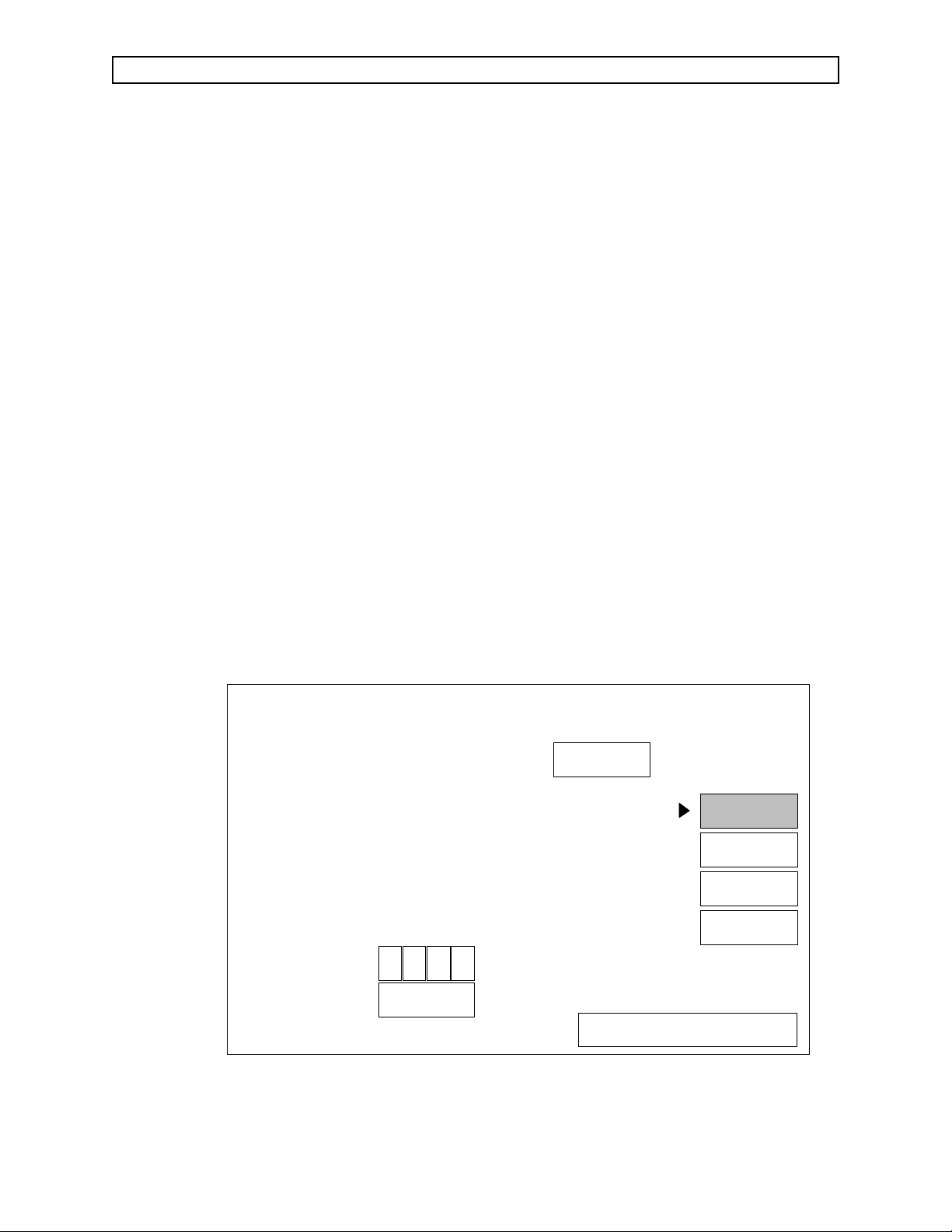

2.2 PMS Schedule

To enter the PMS Screen from the Main Service Screen:

- Use the rotary dial to position the cursor at PMS SCHEDULE, and

press the dial. The cursor will then move to the Month function as

shown in Figure 2-3.

- Press the dial to highlight the function.

- Rotate the dial to select the desired month for the next PMS reminder,

and press the dial to save the setting.

The recommended PMS interval for the Vitalert 3000 Series monitors is three

months. If the current date exceeds that which has been selected and entered,

a Preventive Maintenance Due message will appear on the power-up

diagnostics screen.

Following the PMS month selection:

- Use the rotary dial to set the cursor on MONITORS to proceed with

other maintenance screens . (Selecting MAIN will return you to the

Main Service Screen.)

- Press the dial to enter the selected screen.

SELECT MONTH OF NEXT SCHEDULED PMS

MAR

1993

MAIN

PMS

SCHEDULE

MONITORS

KEYS

Rev. H

ROTATE DIAL TO MOVE CURSOR

PRESS TO ACTIVATE FEATURE

SV30041

Figure 2-3: PMS SCHEDULE SCREEN

2-3

Page 10

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) VA3000

2.3 Monitors

When the cursor is set to MONITORS and the dial is pressed, a second column

of selections is displayed. These are used to select specific monitors as

described in the following paragraphs.

2.3.1 SpO2Service Screen

While still in the Main Service Screen, note the "OXIM SW VERSION"

number. It should be of the form "V x.x.x" or "Vx.x.x.x". The former

indicates that a Nellcor MP-202 is installed. The latter indicates a MP-

203.

Set the cursor to SPO2 and press the dial. A typical SpO

service screen

2

is shown in Figure 2-4.

This screen displays the current values for SpO

and Pulse to verify

2

that the pulse oximeter is operational. A calibration check can be made

by disconnecting the SpO

sensor prior to power up, and connecting a

2

Nellcor® model PT-2500 Pocket Tester. The screen should then display

an SpO

value of 81 ± 1, and a Pulse value of 61 ± 1 for a MP-202, 40

2

± 1 for a MP-203. Connection details are illustrated in Section 5.

To enter another service screen, set the cursor to the desired selection,

and press the dial. (Selecting MAIN and pressing the dial will return

you to the Main Service Screen.)

SPO2 VALUE: 81

PULSE VALUE: 61

SPO2

MAIN

SV30042

Figure 2-4: SpO2SERVICE SCREEN

2-4

NIBP

SAMPLE

LINE

GAS

ANALYZER

ROTATE DIAL TO MOVE CURSOR

PRESS TO ACTIVATE FEATURE

PMS

SCHEDULE

MONITORS

KEYS

Rev. A

Page 11

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 DIAGNOSTICS (continued)

2.3.2 NIBP Service Screen

Set the cursor to NIBP and press the dial. A typical NIBP service

screen is shown in Figure 2-5.

This screen indicates the cuff inflation pressure and also provides a

timing period after inflation for leak testing. On-screen instructions

provide a method of checking pressure calibration with an external

gauge. Connection details are illustrated in Section 5.

- Connect a BP cuff to the patient interface panel on the left side of the

instrument, and wrap the cuff around a cylindrical object.

- Use the rotary dial to position the cursor at TEST, and press the dial

to begin cuff inflation.

- Wait one minute, then compare the test gauge reading with the

displayed CUFF PRESSURE VALUE. The readings should agree

within±5mmHg.

The Cuff Pressure Value will be displayed until the cuff deflates

(approximately four minutes after the start of inflation). The STATUS

line will then display the result of the test.

NOTE: With software version 1.05 the sensitivity of the automatic test

may be too high. If a "FAIL" message appears, perform the leak test

described in Section 5 before making repairs.

To enter another service screen, set the cursor to the desired selection,

and press the dial. (Selecting MAIN and pressing the dial will return

you to the Main Service Screen.)

CUFF PRESSURE VALUE: 300

NIBP CUFF PRESSURE CHECK PROCEDURE:

-PLACE T FITTING INLINE WITH THE BP CUFF

-CONNECT A CALIBRATED PRESSURE GAUGE TO T

-SELECT 'TEST' KEY AND PRESS THE ROTARY

DIAL TO INFLATE CUFF

-VERIFY THAT THE CUFF INFLATES TO 300 MM HG

-WAIT FOR STATUS MESSAGE TO APPEAR BELOW

STATUS: PASS

SPO2

NIBP

SAMPLE

LINE

GAS

ANALYZER

MAIN

PMS

SCHEDULE

MONITORS

KEYS

Rev. A

TEST

SV30043

Figure 2-5: NIBP SERVICE SCREEN

2-5

ROTATE DIAL TO MOVE CURSOR

PRESS TO ACTIVATE FEATURE

Page 12

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) VA3000

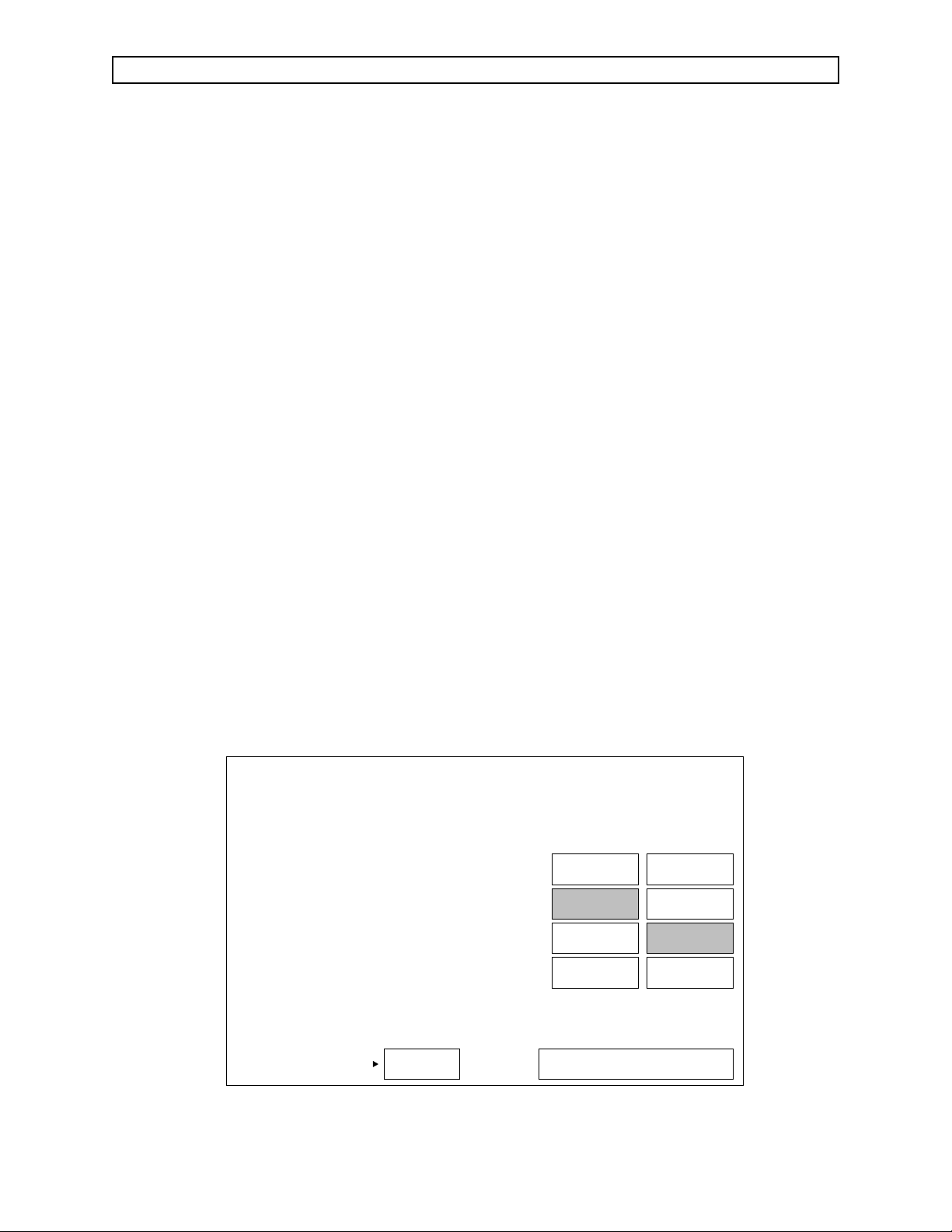

2.3.3 Sample Line Flow Service Screen

Set the cursor to SAMPLE LINE and press the dial. A typical Sample

Line service screen is shown in Figure 2-6.

This screen allows gas sample flow rates (100 ml/min. and 200 ml/min.)

to be set using an external flow meter connected to the exhaust port on

the rear panel of the instrument.

A calibration procedure for the Low Flow and High Flow is displayed

on-screen. A more complete calibration procedure for the low and high

flow rates is given in Section 5 along with a calibration verification and

line block alarm test.

To enter another service screen, set the cursor to the desired selection,

and press the dial. (Selecting MAIN and pressing the dial will return

you to the Main Service Screen.)

ALLOW UNIT TO WARM UP FOR 10 MINUTES

LOW FLOW CALIBRATION PROCEDURE

-PLACE A FLOW METER AT THE EXHAUST PORT

-SELECT 'ADJUST FLOW' KEY AND PRESS DIAL

-ADJUST FLOW WITH DIAL UNTIL FLOW METER

INDICATES DESIRED FLOW THEN PRESS DIAL

-BLOCK SAMPLE LINE THEN SELECT 'STORE LOW'

KEY. PRESS THE ROTARY DIAL TO CALIBRATE

HIGH FLOW CALIBRATION PROCEDURE

-PLACE A FLOWMETER AT THE EXHAUST PORT

-SELECT 'ADJUST FLOW' KEY AND PRESS DIAL

-ADJUST FLOW WITH DIAL UNTIL FLOW METER

INDICATES DESIRED FLOW THEN PRESS DIAL

-BLOCK SAMPLE LINE THEN SELECT 'STORE HIGH'

KEY. PRESS THE ROTARY DIAL TO CALIBRATE

ADJUST

FLOW

SV30044

STORE

LOW

STORE

HIGH

SPO2

NIBP

SAMPLE

LINE

GAS

ANALYZER

ROTATE DIAL TO MOVE CURSOR

PRESS TO ACTIVATE FEATURE

Figure 2-6: SAMPLE LINE FLOW SERVICE SCREEN

2-6

MAIN

PMS

SCHEDULE

MONITORS

KEYS

Page 13

MAIN

PMS

SCHEDULE

MONITORS

KEYS

ROTATE DIAL TO MOVE CURSOR

PRESS TO START CALIBRATION

SV30102

SPAN

SPO2

NIBP

SAMPLE

LINE

GAS

ANALYZER

-IN MONITOR SETUP SET FLOW TO MAXIMUM

-MEASURE THE FLOW RATE AT EXHAUST

-WAIT FOR MODE = 'READY'

-ATTACH GAS SAMPLE LINE TO CAL GAS BOTTLE

-SET FLOW ON BOTTLE EQUAL TO EXHAUST FLOW

-SELECT THE 'SPAN' KEY AND PRESS THE

ROTARY DIAL

-MESSAGES APPEAR AS PROCEDURE IS

PERFORMED BY THE MONITOR

CURRENT CO2: 0.0

CURRENT N2O: 0

CURRENT AGENT:

SPAN CALIBRATION PROCEDURE

MODE: READY

STATUS: IDLE

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 DIAGNOSTICS (continued)

2.3.4 Gas Analyzer Service Screen

Set the cursor to GAS ANALYZER and press the dial. A typical Gas

Analyzer service screen is shown in Figure 2-7.

This screen displays current values for CO

O and anesthetic agent,

2,N2

along with a procedure for performing a span calibration of the gas

analyzer using a certified gas sample of known accuracy.

Before performing a span calibration, an accuracy test should be

performed to determine whether a span calibration is needed.

Refer to Section 5 for the complete calibration procedure, including an

accuracy test, equipment required and test connections.

To enter another service screen, set the cursor to the desired selection,

and press the dial. (Selecting MAIN and pressing the dial will return

you to the Main Service Screen.)

Figure 2-7: GAS ANALYZER SERVICE SCREEN

Rev. A

2-7

Page 14

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) VA3000

2.4 Keys

At the time of this writing, the software has not yet been implemented for

producing the test pattern to verify operation of the front panel keys.

Figure 2-8: KEY TEST SCREEN

2-8

Page 15

MAIN

PMS

SCHEDULE

MONITORS

KEYS

SERVICE

RESET

HOURS

ROTATE DIAL TO MOVE CURSOR

PRESS TO ACTIVATE FEATURE

SV30103

MACHINE SERIAL NUMBER

LAST SERVICE DATE

HOURS RUN SINCE LAST SERVICE

TOTAL HOURS RUN

VA3:00004

07-14-93

97

3383

OXIM SW VERSION:

GAI SW VERSION:

GAS BENCH SW VERSION:

V 1.0.7

V 1.2.3

V 1.0.1

SERVICE PERSON

IDENTIFICATION

SERVICE TYPE

2

33 3 3

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 DIAGNOSTICS (continued)

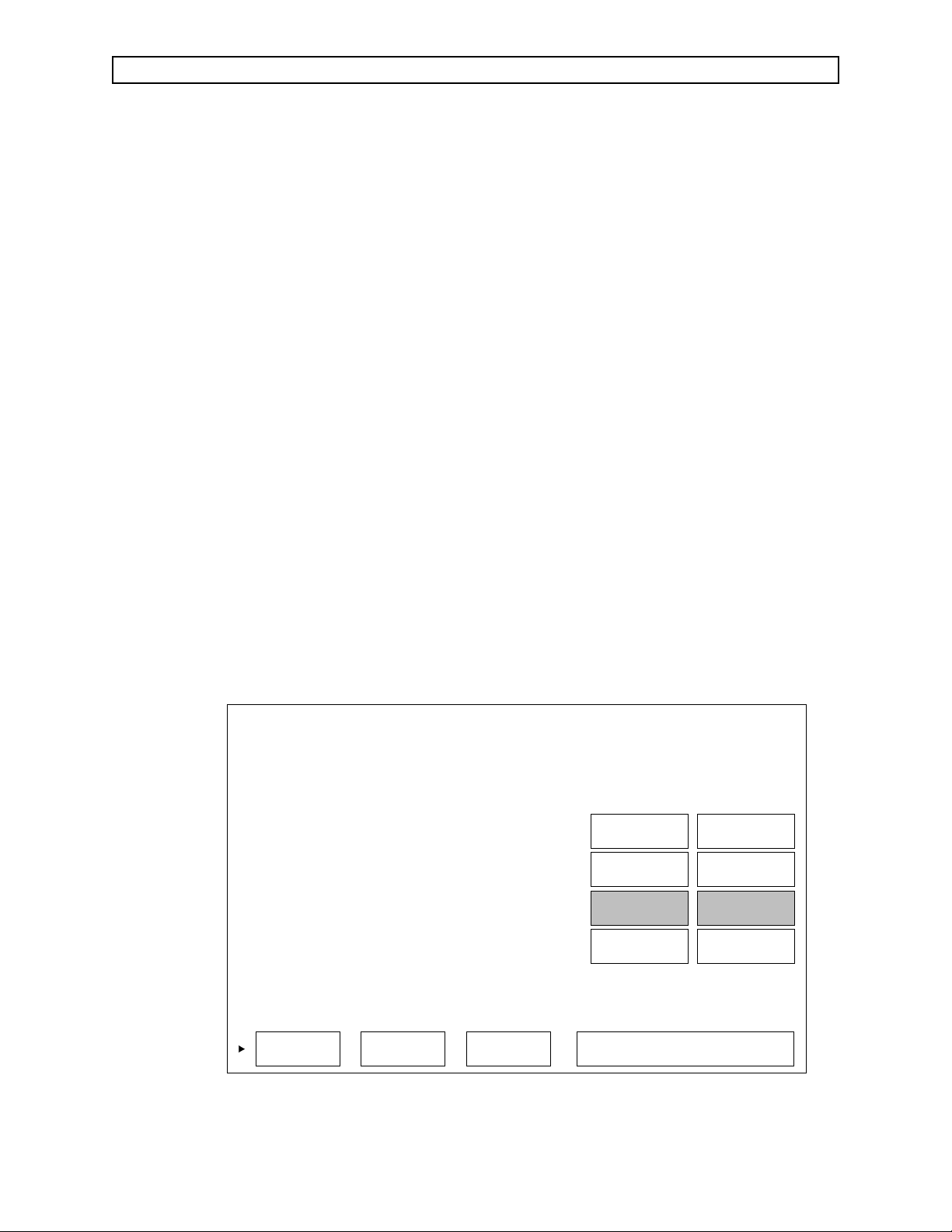

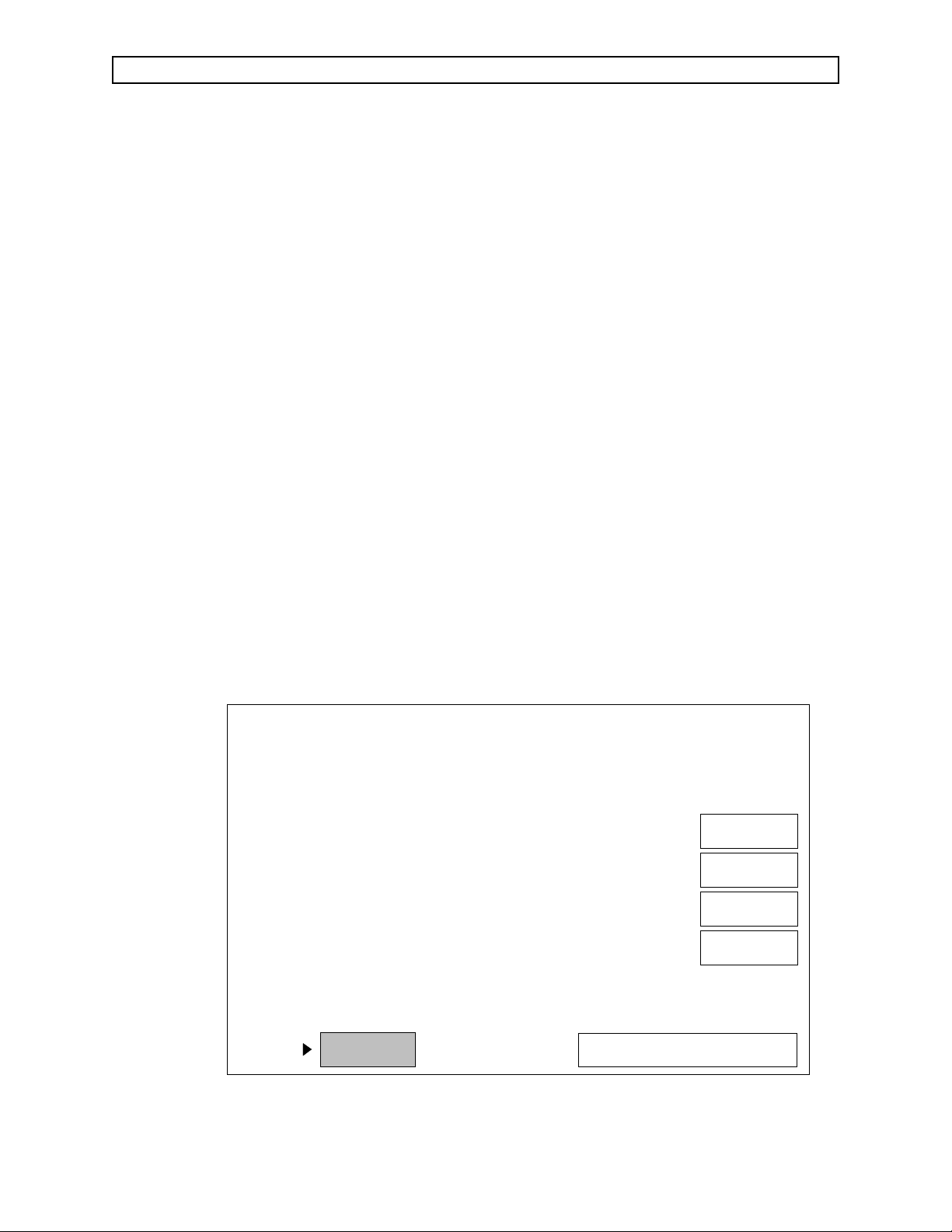

2.5 Secondary Service Screens

The secondary service screens are described on the following pages. These

screens allow viewing and making entries into the service log, and include a

setup screen to turn monitoring functions on or off.

To enter the Secondary Service screens from the Main Service Screen:

- A Service Person Identification must be entered as described under

Paragraph 2.1.

- Using the rotary dial, set the cursor to MAIN, and press the dial to

illuminate the box.

- Slowly turn the dial clockwise until a numeral

2appears at the bottom

of the screen as shown in Figure 2-9.

- Slowly turn the dial counter-clockwise until the numeral

- Slowly turn the dial clockwise until the numeral

6 appears.

5 appears.

- Press the dial to bring up the Service Log Screen (described on the next

page).

Figure 2-9: MAIN SERVICE SCREEN -

SECONDARY SERVICE SCREEN ENTRY

2-9

Page 16

MAIN

SERVICE

LOG

CODES

SETUP

SCROLL

ROTATE DIAL TO MOVE CURSOR

PRESS TO ACTIVATE FEATURE

SV30105

DATE TIME PARAMETER CODE EVENT

06-07-93

06-07-93

06-07-93

06-11-93

06-14-93

06-14-93

11:47

11:50

11:50

15:26

06:57

06:57

1234

00000000

00000820

00000021

00000021

1234

S002 PMS

NIBP MONITOR ERROR

"ENTERING FULL ACCURACY"

"GASBENCH STATUS REPORT"

"GASBENCH STATUS REPORT"

S004 SECONDARY SRVC SCREEN ENTRY

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) VA3000

2.5.1 Service Log Screen

Set the cursor to SERVICE LOG and press the dial to enter the Service

Log Screen.

The Service Log Screen presents a chronological listing of operational

and service events as shown in Figure 2-10. When this screen appears,

the most recent entries are displayed.

To scroll through the complete list, set the cursor to SCROLL and press

the dial. Turning the dial clockwise or counter-clockwise will allow you

to scroll backward or forward through the list.

To add a service entry to the log, refer to the Codes screen described on

the next page.

To enter another secondary service screen, set the cursor to the desired

selection, and press the dial. (Selecting MAIN and pressing the dial will

return you to the Main Service Screen.)

Figure 2-10: SERVICE LOG SCREEN

2-10

Page 17

MAIN

SERVICE

LOG

CODES

SETUP

ENTER INTO LOG? YES NO

ROTATE DIAL TO MOVE CURSOR

PRESS TO ACTIVATE FEATURE

SV30106

EVENTCODE

R001

R002

R003

R004

R005

R006

R007

R008

R009

R010

R011

R012

R013

R014

R015

R016

PRESSED MASTER RESET

REPLACE CORD SET

REPLACE BREAKER

REPLACE POWER SUPPLY

REPAIR POWER SUPPLY

REPLACE MAIN CPU

REPAIR MAIN CPU

UPDATE MAIN SW

REPLACE BEZEL ASM

REPLACE KEYBOARD

REPAIR KEYBOARD

REPLACE DISPLAY PANEL

REPLACE SPO2/ISO ASM

REPLACE SPO2 PCB

REPLACE ISO PCB

REPLACE GAS SUB ASM

EVENTCODE

R017

R018

R019

R020

R021

R022

R023

R024

R025

R026

R027

REPLACE ANALYZER

REPAIR ANALYZER

REPLACE GAI PCB

REPAIR GAI PCB

REPLACE FAN

REPLACE SOLENOID

REPLACE HOSE(S)

REPLACE NIBP ASM

REPLACE CABLE(S)

REPLACE COVER

REPLACE BEZEL

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 DIAGNOSTICS (continued)

2.5.2 Codes Screen

Set the cursor to CODES and press the dial to enter the Codes screen.

The Codes Screen presents a list of service codes and related events

that can be selected and entered into the service log. See Figure 2-11.

To place an entry into the service log:

- Turn the dial to scroll through the list, and set the cursor in

front of the selected entry.

- Press the dial.

- Position the cursor at YES or NO, as desired, and press the dial.

If YES is chosen, the selected entry will be placed in the service

log. If NO is chosen, the selected entry will be cancelled and

another selection can be made.

To enter another secondary service screen, set the cursor to the desired

selection, and press the dial. (Selecting MAIN and pressing the dial will

return you to the Main Service Screen.)

Figure 2-11: CODES SCREEN

2-11

Page 18

MAIN

SERVICE

LOG

CODES

KEYS

FACTORY

RESET

ROTATE DIAL TO MOVE CURSOR

PRESS TO ACTIVATE FEATURE

SV30107

MACHINE SERIAL NUMBER: VA3

WARNING:

THE FACTORY RESET IS TO BE DONE

ONLY BY NORTH AMERICAN DRAGER.

ALL SETTINGS AND CALIBRATIONS MUST

BE REDONE FOLLOWING A FACTORY RESET.

IMPORTANT SERVICE DATA WILL BE LOST.

MONITORING FUNCTIONS

NIBP

SPO2

SEVO

DES

ON

ON

ON

ON

914 0

0

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) VA3000

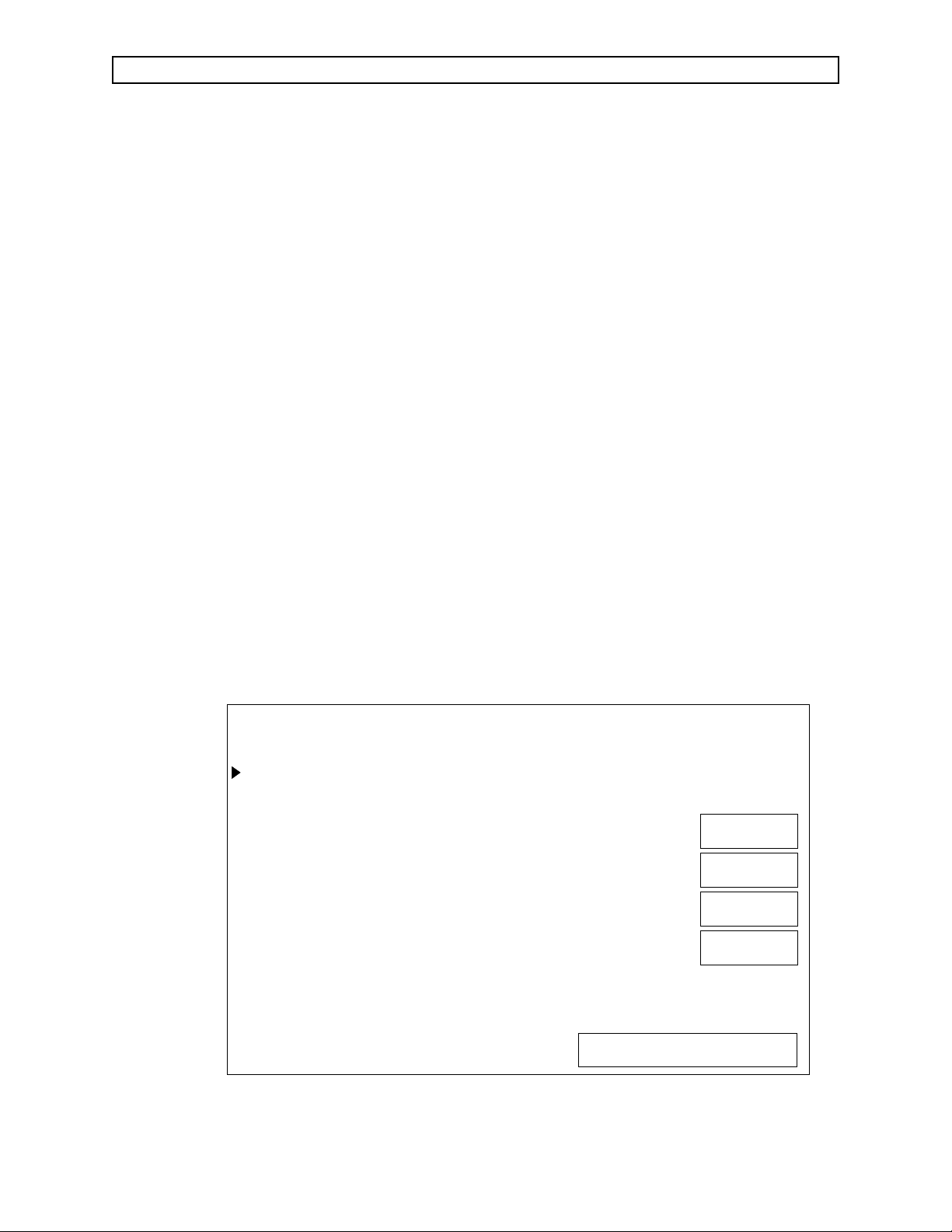

2.5.3 Setup Screen

Set the cursor to SETUP and press the dial to enter the Setup screen.

The Setup screen, shown in Figure 2-12, provides the following

functions:

- Allows entry of the machine serial number (for display on the

Main Service Screen). This needs to be done when a processor

board is replaced, and may also need to be done when software

is updated.

- Allows monitoring functions to be turned OFF or ON.

- Allows Factory Reset to delete the calibration settings and clear

the service log.

WARNING: The factory reset is to be done only by Drägerservice. All

settings and calibrations must be redone following a

factory reset. Important service data will be lost.

To enter another secondary service screen, set the cursor to the desired

selection, and press the dial. (Selecting MAIN and pressing the dial will

return you to the Main Service Screen.)

Figure 2-12: SETUP SCREEN

2-12

Page 19

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 TROUBLESHOOTING GUIDE

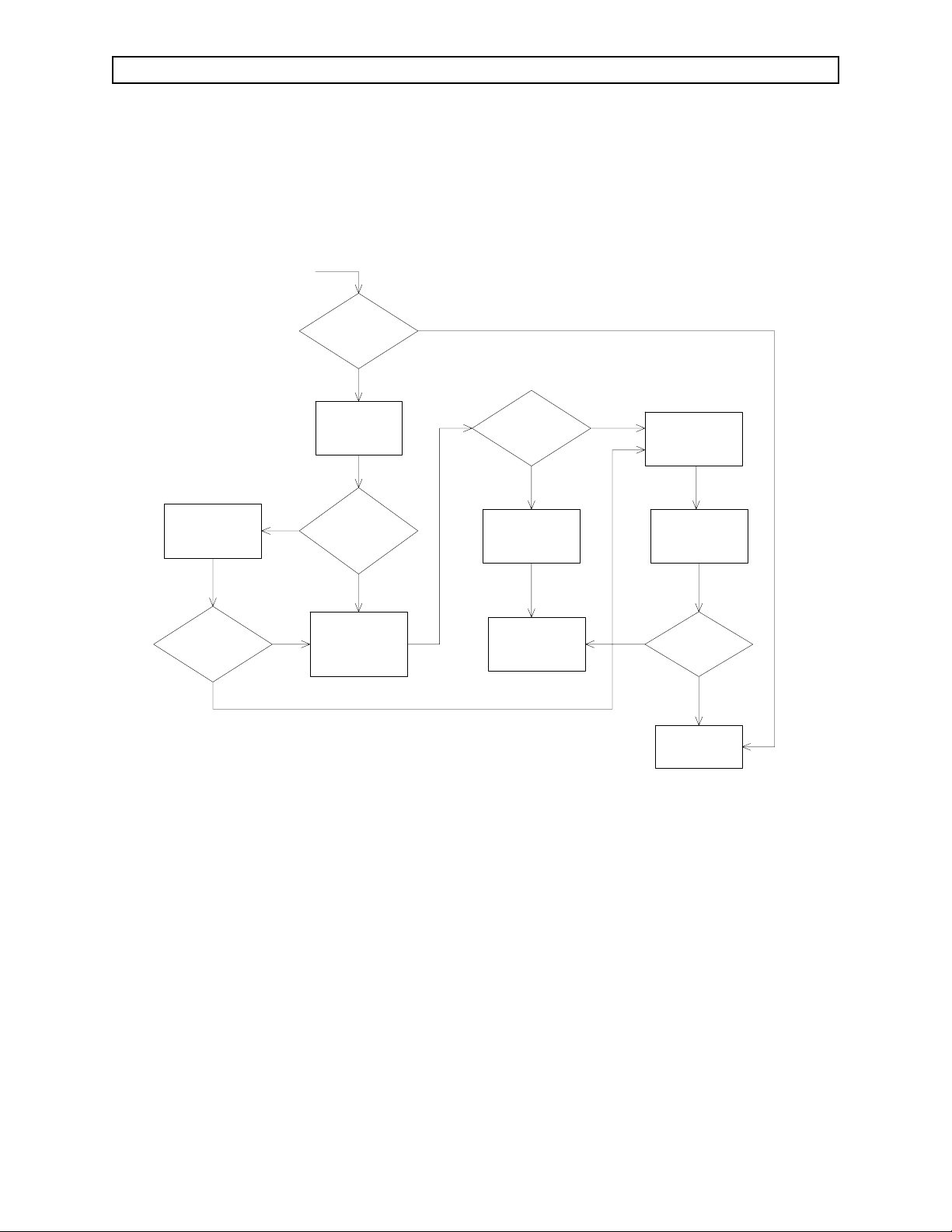

3.0 TROUBLESHOOTING

This section contains information to assist the Technical Service Representative (TSR)

in locating electrical faults affecting the VITALERT 3000 Series monitors. Since most

troubleshooting efforts begin with verifying power supply voltages, the following

paragraph outlines the voltage distribution scheme within the instrument along with

cable connector identification.

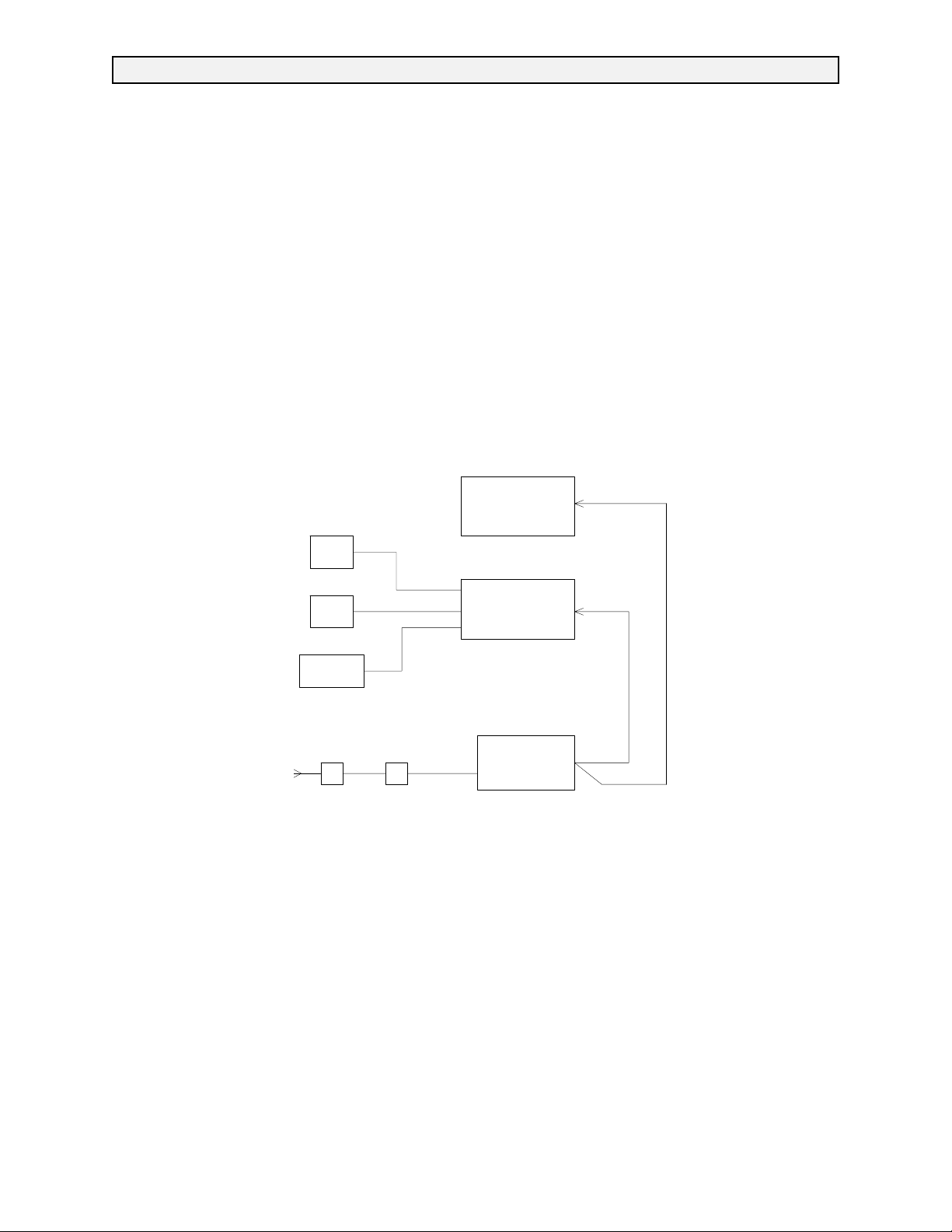

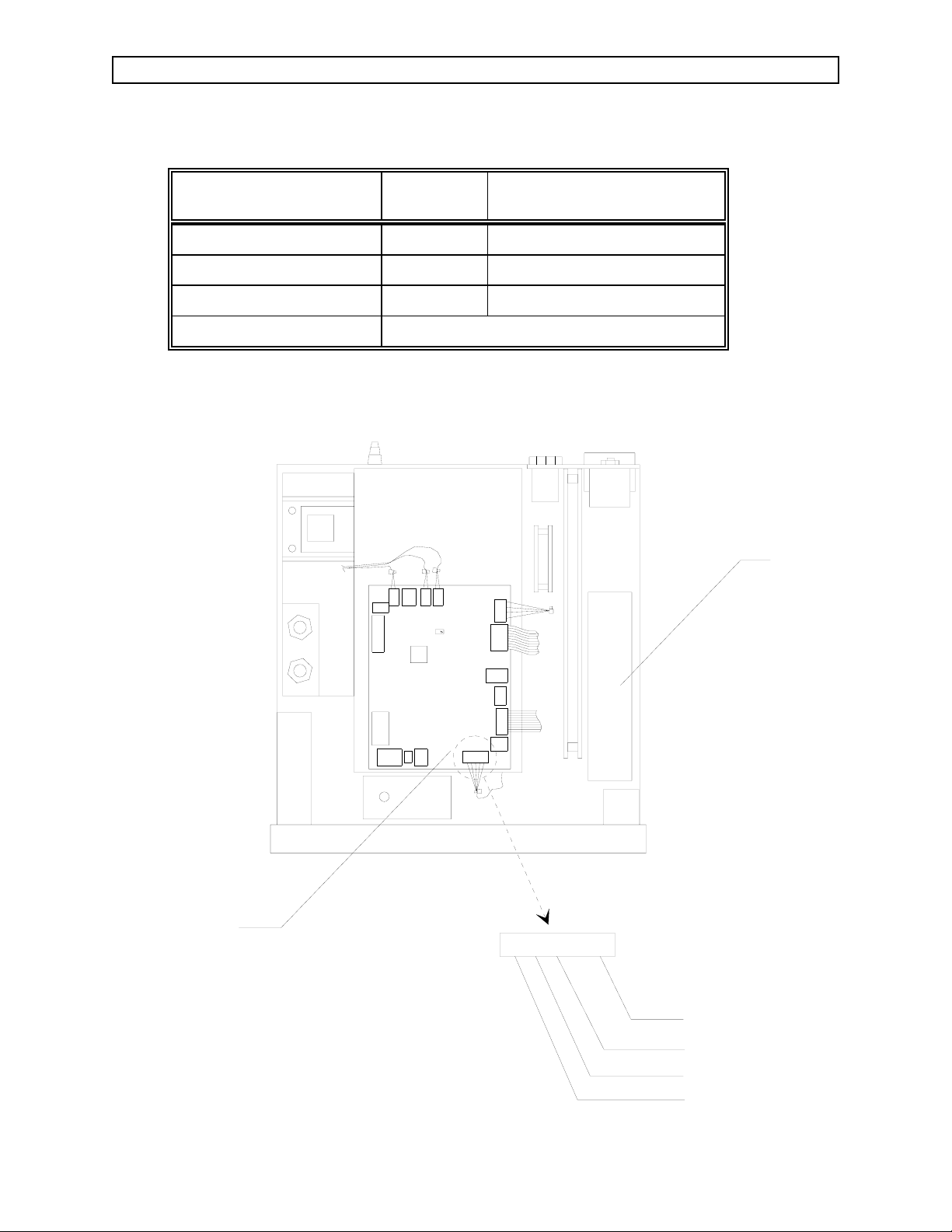

3.1 Power Supply and Voltage Distribution

Figure 3-1 shows a block diagram of the voltage distribution within the

VITALERT 3000 from the power supply. J7 on the Gas Analyzer Interface PCB

(see Figure 3-2) provides the safest, most convenient point to measure power

supply voltages. The voltages are given in Table 3-1 along with their allowable

tolerances. Refer to Section 4 of this manual for appropriate removal and

replacement procedures.

J7

J12

J3

MAINS

SPO2

ASM

NIBP

DISPLAY

FILTER

GAS

ANALYZER

J1

J5

J4

J14

CB1

J1

PROCESSOR

POWER

SUPPLY

Figure 3-1: VITALERT 3000 VOLTAGE DISTRIBUTION

Rev. G

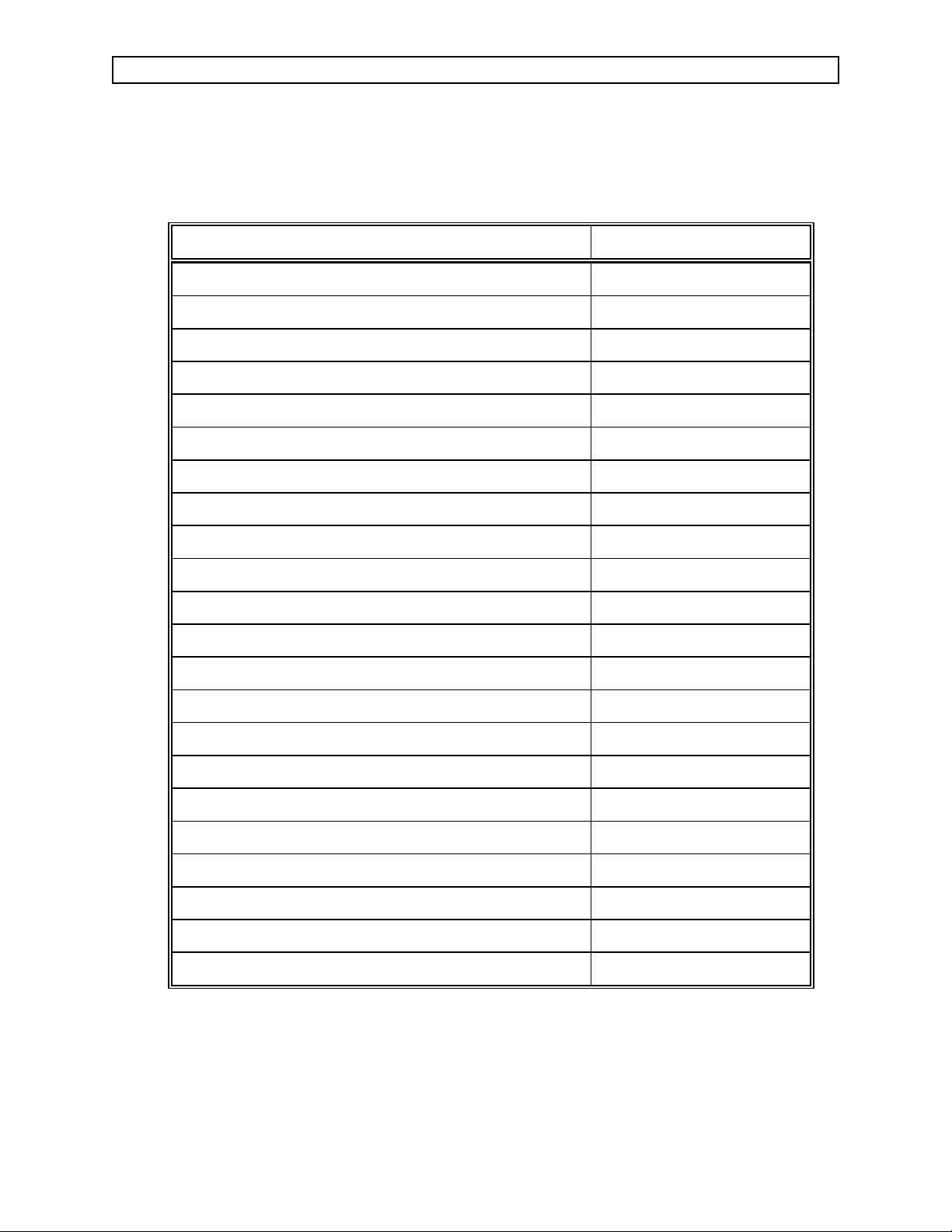

3.2 Troubleshooting Guides

Table 3-2 lists common failure modes and symptoms (excluding simultaneous

multiple faults) for the Vitalert 3000 Series monitors. Each failure mode or

symptom is keyed to a troubleshooting guide flow chart on the following pages

to assist the TSR in locating a problem.These flow charts assume that the

instrument is plugged into an AC outlet with the correct voltage. If a problem

occurs that cannot be corrected by following these guides, call DrägerService

for support.

3-1

Page 20

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) VA3000

TABLE 3-1: POWER SUPPLY VOLTAGES AND TOLERANCES

GAS IF PCB, PWR SUPP

VOLTAGE ACCEPTABLE RANGE

WIRE HARNESS

J7-5 (Pur) + 5 VDC 4.85 to 5.15 VDC

J7-3 (Yel) +12VDC 11.76 to 12.24 VDC

J7-1 (Yel/Wht) -12VDC -11.76 to -12.24 VDC

J7-4 (Blk) Common

TOP VIEW OF VITALERT 3000

WITH COVER REMOVED

J4

J8

J14

J1

J6

J2

U3

J3

J12

J5

J11

J16

J18

J15

J10

J13

J7

J9

POWER

SUPPLY

GAS ANALYZER

INTERFACE BOARD

TEST POINTS

FOR POWER

SUPPLY VOLTAGE

SV30130

Figure 3-2: POWER SUPPLY TEST POINTS

3-2

54321

(YEL/ WH) - 12 VDC

(YEL) + 12 VDC

(BLK) COMMON

(PUR) + 5 VDC

Rev. G

Page 21

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 TROUBLESHOOTING GUIDE (continued)

TABLE 3-2: VITALERT 3000 TROUBLESHOOTING GUIDES

FAILURE MODE / SYMPTOM CORRECTIVE ACTION

Display blank upon system power-up Guide 1

Firmware Test fails upon system power-up Guide 2

Video Test fails upon system power-up Guide 3

Memory Test fails upon system power-up Guide 4

Timer Test fails upon system power up Guide 5

Audio Test - Primary fails upon system power-up Guide 6

Audio Test - Backup fails upon system power-up Guide 7

Audio Test - SpO2fails upon power-up Guide 8

Serial I/O Test fails upon system power-up Guide 9

Clock Test fails upon system power-up Guide 10

NVRAM Test fails upon system power-up Guide 11

"SERVICE GAS MON" Advisory error Guide 12

"SERVICE NIBP MON" Advisory error Guide 13

"SERVICE SPO2 MON" Advisory error Guide 14

Vitalink failure Guide 15

Low or No Flow at CO2exhaust port Guide 16

Line Block message displayed Guide 17

Instrument will not power-up Guide 18

Front Keys and/or Rotary Dial not functional Guide 19

NIBP readings inacurate Guide 20

Instrument is performing intermittent resets Guide 21

Analyzer fails Span Cal Guide 22

3-3

Page 22

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) VA3000

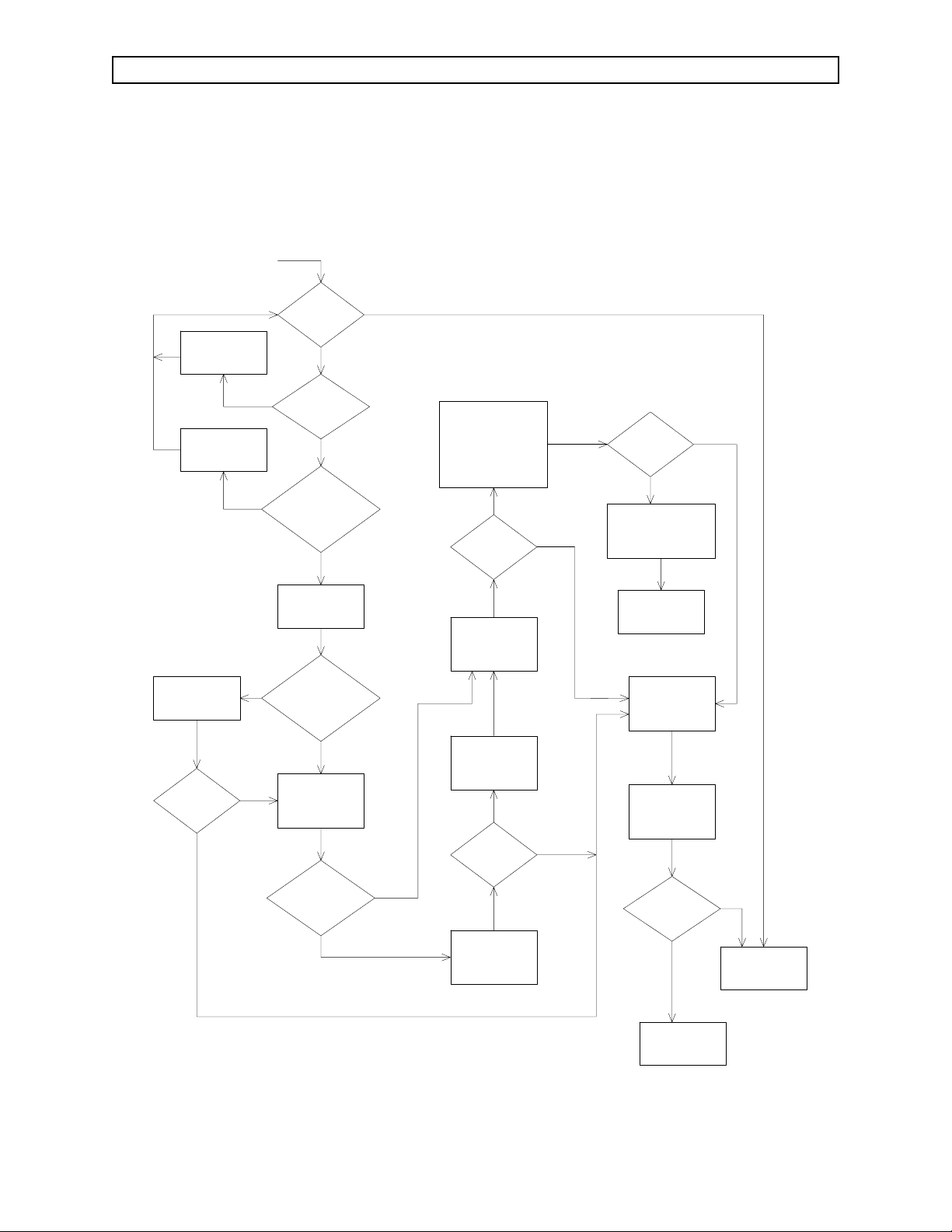

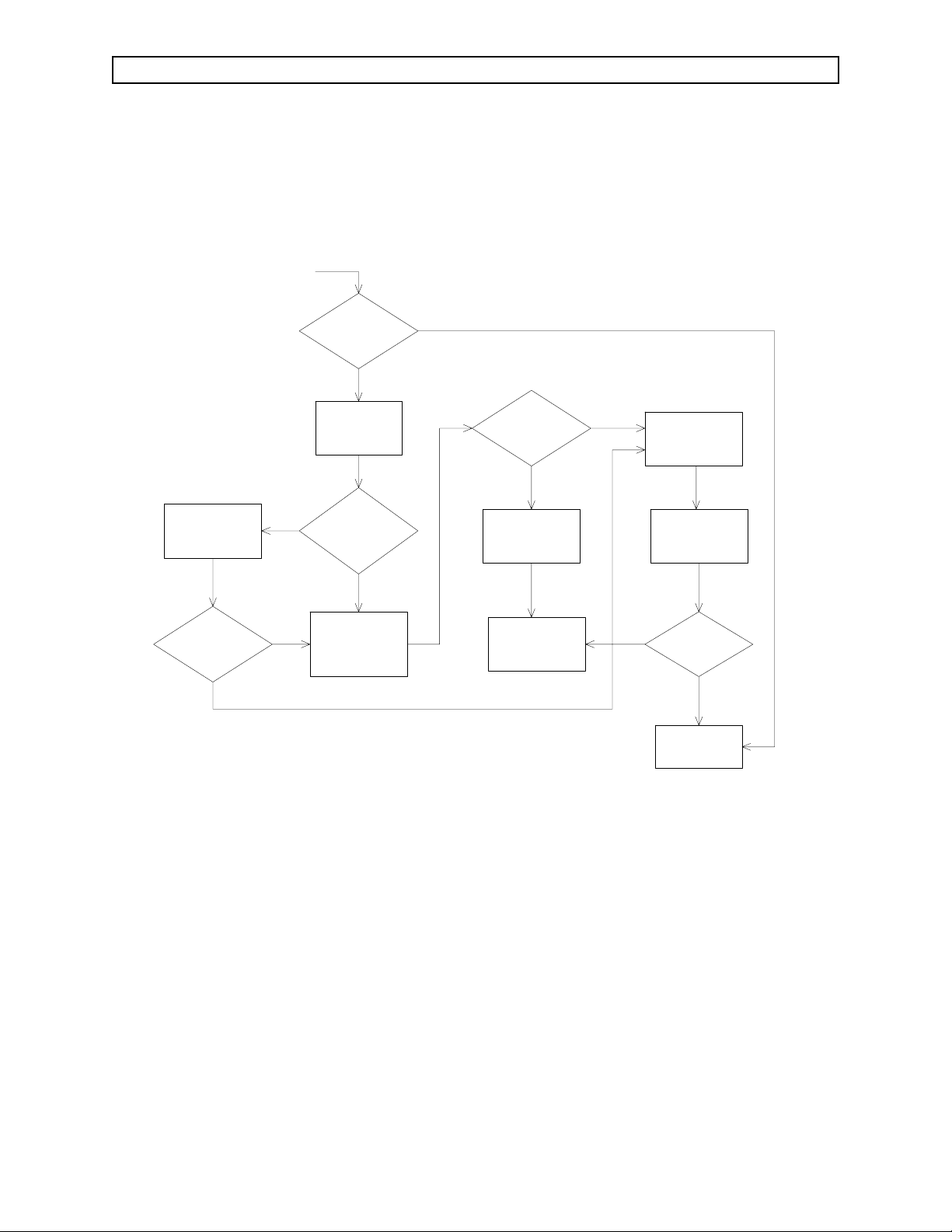

GUIDE 1: Display blank upon system power-up

START

ENABLE

CIRCUIT

BREAKER

PLUG VA3000

INTO A LIVE

AC RECEPTACLE

CONNECT

CABLES

SECURELY

IS

DISPLAY

BLANK?

DISPLAY

N

CIRCUIT BREAKER

ENABLED?

N

PLUGGED INTO LIVE

AC RECEPTACLE?

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

N

ALL INTERNAL CABLES

CONNECTED?

Y

CHECK POWER

SUPPLY VOLTAGES

AS OUTLINED IN

SECTION 3.1

IS

BLANK?

Y

IS

Y

IS

VA3000

Y

ARE

Y

N

REINSTALL ORIGINAL

MONITOR BEZEL

------------------------------REPLACE

PROCESSOR ASSEMBLY

AS OUTLINED IN

PROCEDURE 4.2

Y

IS

DISPLAY

BLANK?

REPLACE

MONITOR BEZEL

AS OUTLINED IN

PROCEDURE 4.4

REINSTALL ORIGINAL

POWER SUPPLY

ASSEMBLY

N

Y

IS

DISPLAY

BLANK?

REINSTALL ORIGINAL

PROCESSOR ASSEMBLY

AND COVER

CONTACT NAD

SERVICE DEPT.

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

PERFORM A

COMPLETE PMS

N

Y

N

ARE

VOLTAGES WITHIN

SPEC?

N

Y

IS

DISPLAY

BLANK?

REPLACE POWER

SUPPLY ASSEMBLY

AS OUTLINED IN

PROCEDURE 4.3

N

DOES

UNIT PASS

PMS?

CONTACT NAD

SERVICE DEPT.

Y

N

UNIT IS

FUNCTIONAL

3-4

Page 23

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 TROUBLESHOOTING GUIDE (continued)

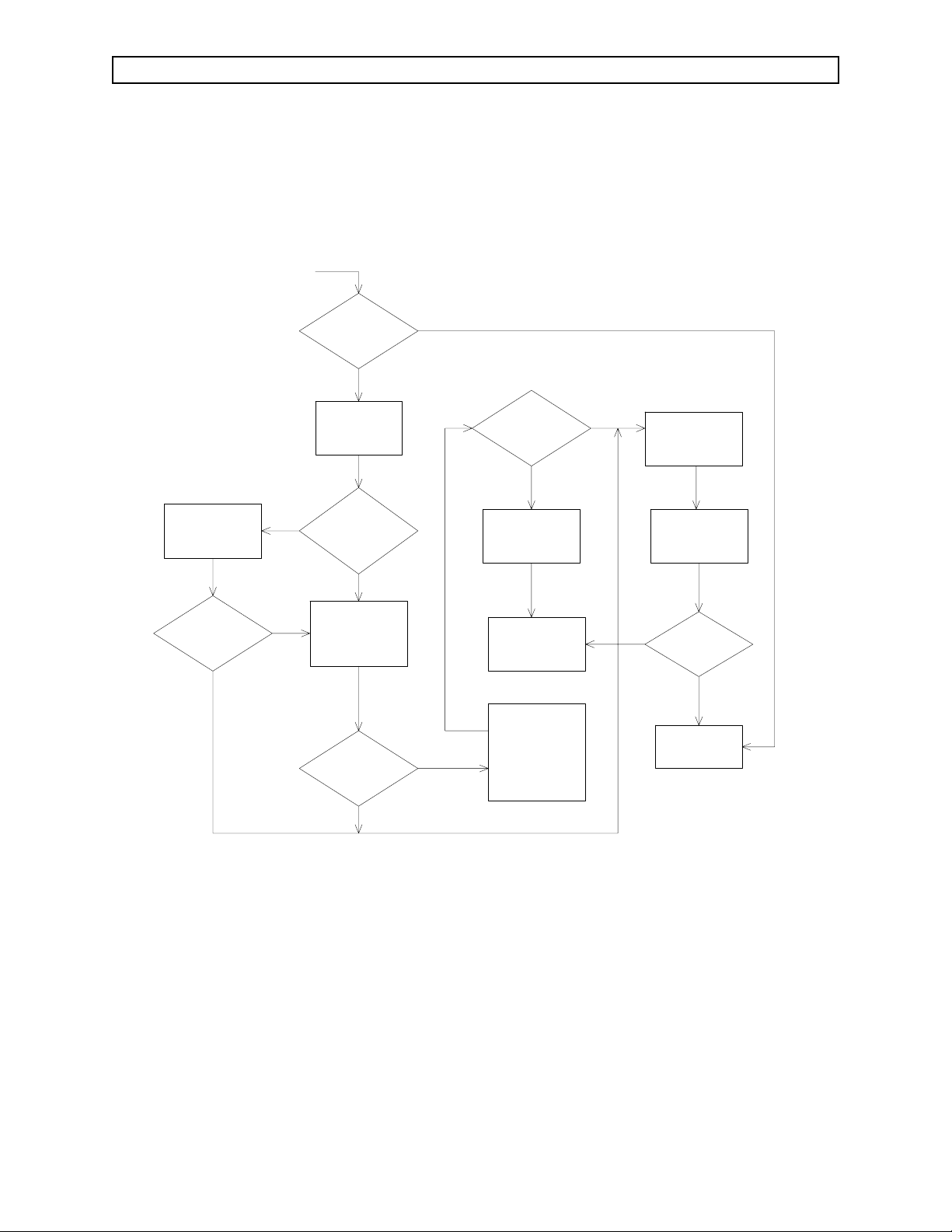

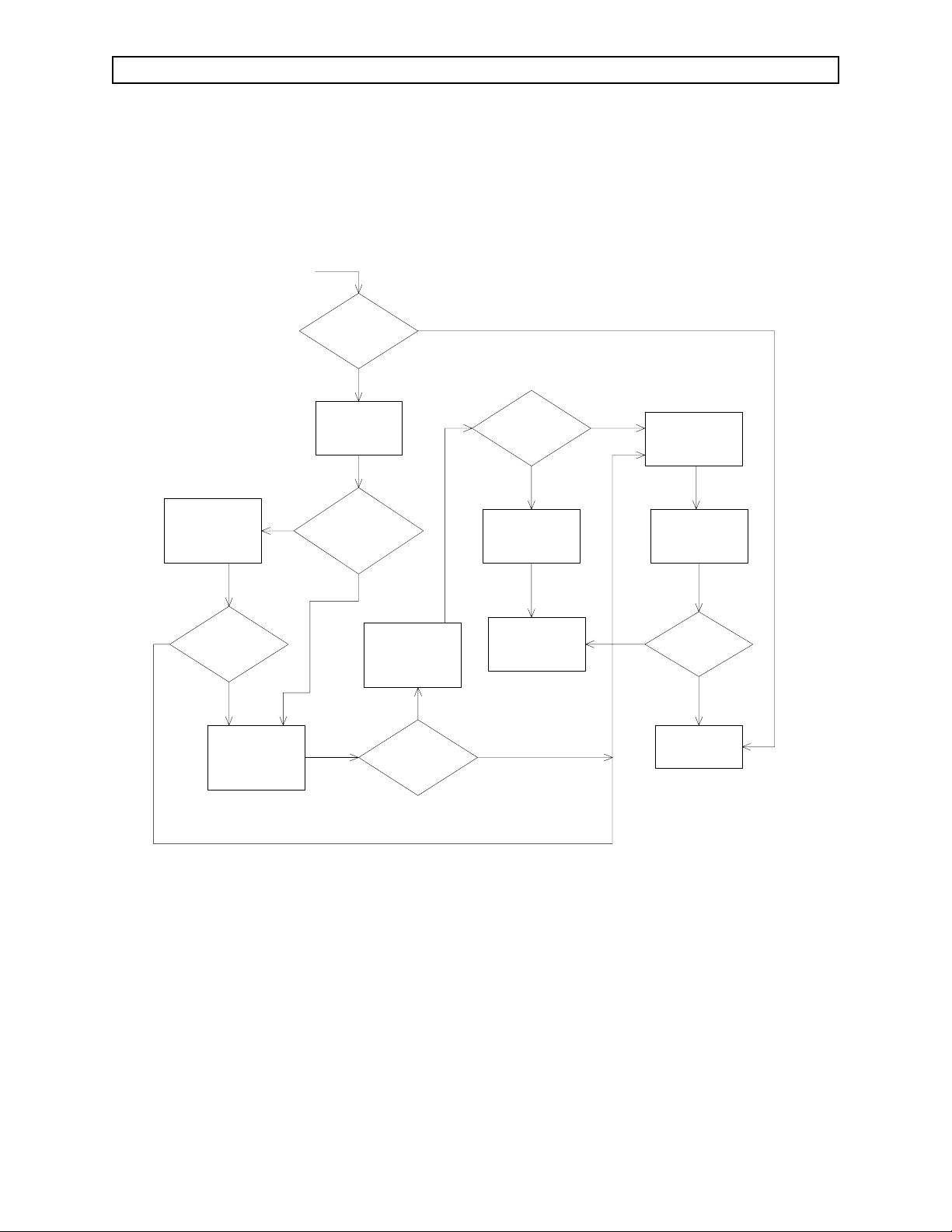

GUIDE 2: Firmware Test fails upon system power-up

START

CONNECT ALL

PROCESSOR BOARD

AND INTERNAL CABLES

DOES

FIRMWARE TEST

FAIL UPON SYSTEM

POWER-UP?

N

N

Y

DOES

FIRMWARE TEST

FAIL UPON SYSTEM

POWER-UP?

Y

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

ARE

ALL CABLES

CONNECTED TO

PROCESSOR

BOARD?

Y

REPLACE

FIRMWARE

AS OUTLINED IN

PROCEDURE 4.9

DOES

FIRMWARE TEST

FAIL UPON SYSTEM

POWER-UP?

N

DOES

FIRMWARE TEST

FAIL UPON SYSTEM

POWER-UP?

Y

REINSTALL ORIGINAL

PROCESSOR BOARD

AND COVER

CONTACT NAD

SERVICE DEPT.

REINSTALL ORIGINAL

FIRMWARE

----------------------------------

Y

REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.2

N

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

PERFORM A

COMPLETE PMS

ON UNIT

N

DOES

UNIT PASS

PMS?

UNIT IS

FUNCTIONAL

Y

N

3-5

Page 24

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) VA3000

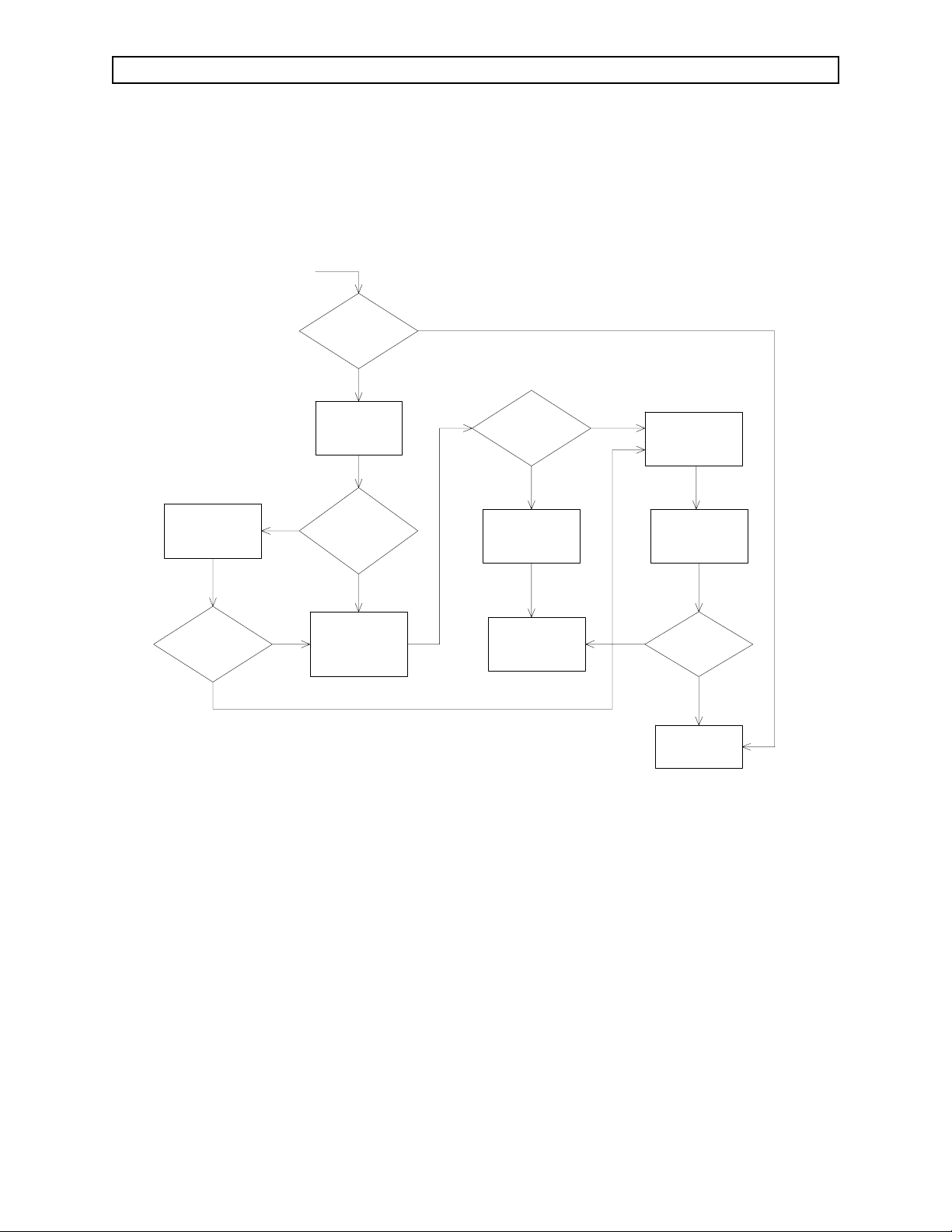

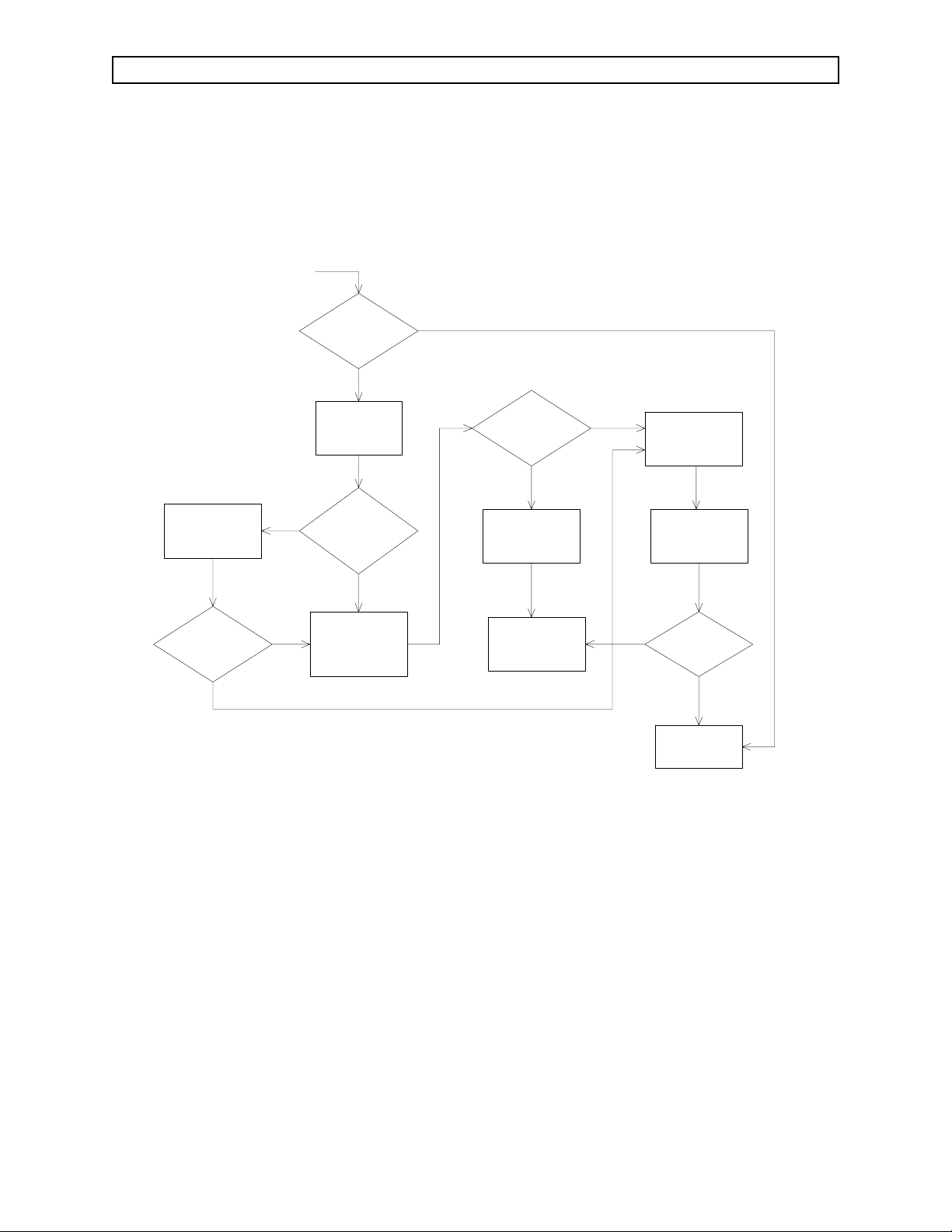

GUIDE 3: Video Test fails upon system power-up

START

CONNECT ALL

PROCESSOR BOARD

AND INTERNAL CABLES

DOES

VIDEO TEST

FAIL UPON SYSTEM

POWER-UP?

N

N

Y

DOES

VIDEO TEST

FAIL UPON SYSTEM

POWER-UP?

Y

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

ARE

ALL CABLES

CONNECTED TO

PROCESSOR

BOARD?

Y

REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.2

N

DOES

VIDEO TEST

FAIL UPON SYSTEM

POWER-UP?

Y

REINSTALL ORIGINAL

PROCESSOR BOARD

AND COVER

CONTACT NAD

SERVICE DEPT.

N

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

PERFORM A

COMPLETE PMS

ON UNIT

N

DOES

UNIT PASS

PMS?

UNIT IS

FUNCTIONAL

Y

3-6

Page 25

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 TROUBLESHOOTING GUIDE (continued)

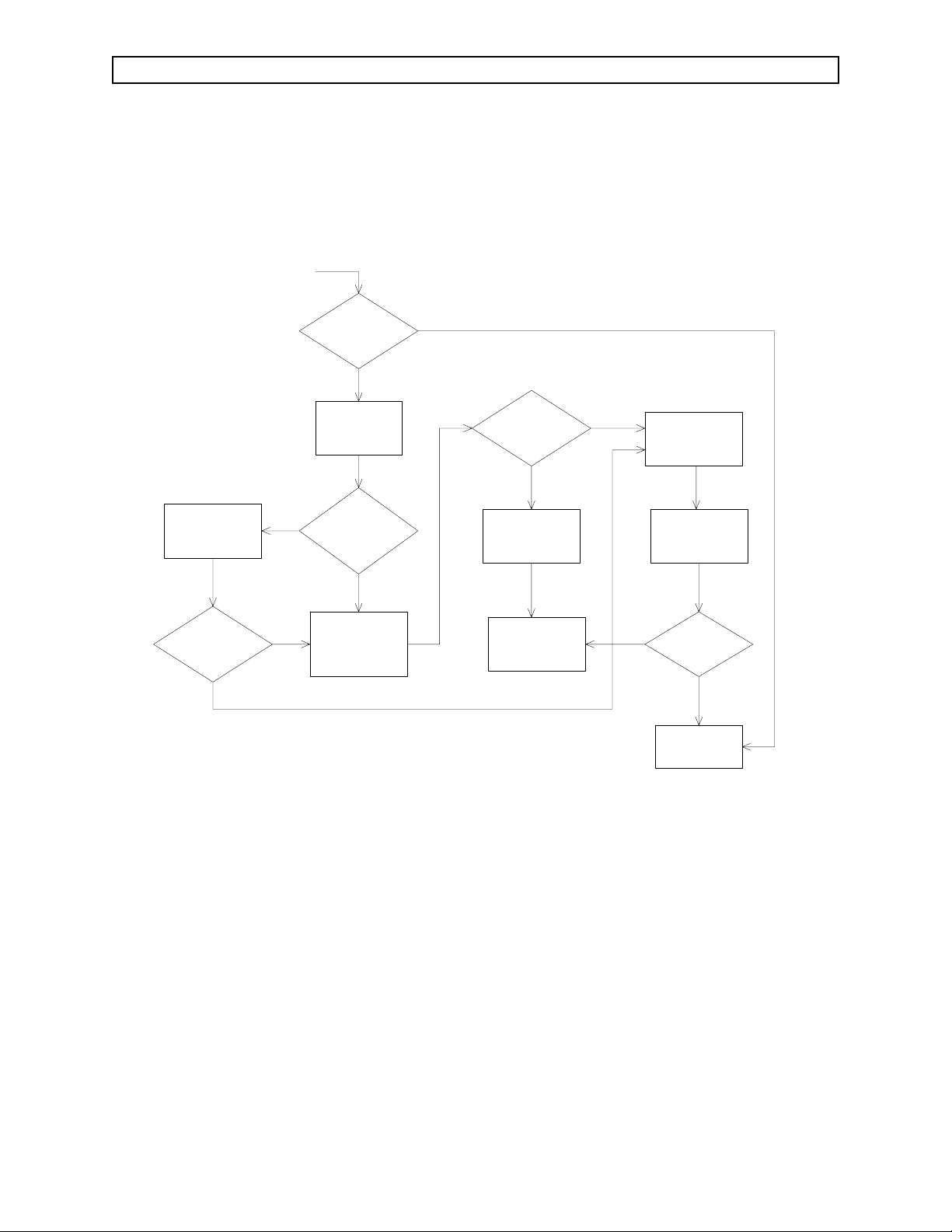

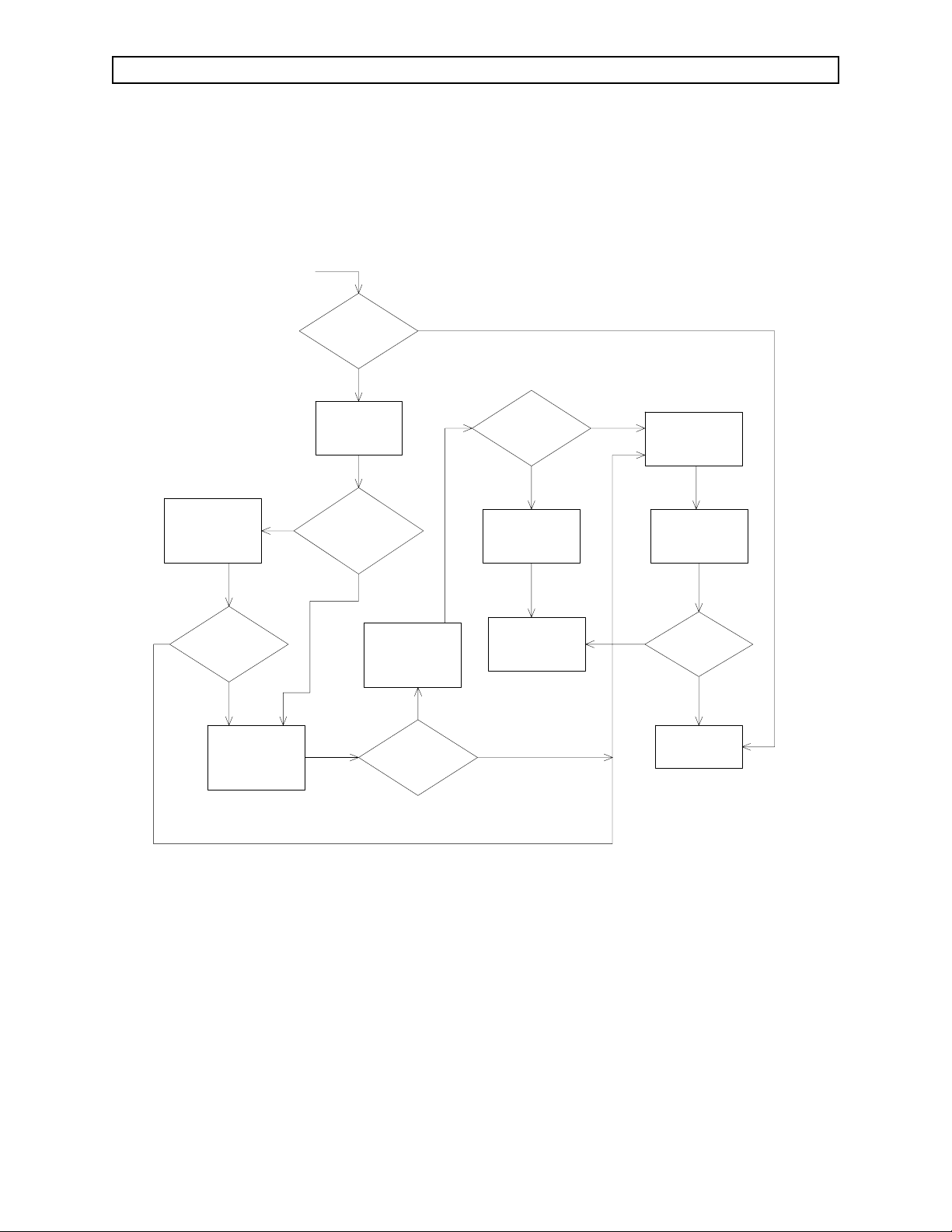

GUIDE 4: Memory Test fails upon system power-up

START

CONNECT ALL

PROCESSOR BOARD

AND INTERNAL CABLES

DOES

MEMORY TEST

FAIL UPON SYSTEM

POWER-UP?

N

N

Y

DOES

MEMORY TEST

FAIL UPON SYSTEM

POWER-UP?

Y

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

ARE

ALL CABLES

CONNECTED TO

PROCESSOR

BOARD?

Y

REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.2

N

DOES

MEMORY TEST

FAIL UPON SYSTEM

POWER-UP?

Y

REINSTALL ORIGINAL

PROCESSOR BOARD

AND COVER

CONTACT NAD

SERVICE DEPT.

N

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

PERFORM A

COMPLETE PMS

ON UNIT

N

DOES

UNIT PASS

PMS?

UNIT IS

FUNCTIONAL

Y

3-7

Page 26

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) VA3000

GUIDE 5: Timer Test fails upon system power up

START

CONNECT ALL

PROCESSOR BOARD

AND INTERNAL CABLES

DOES

TIMER TEST

FAIL UPON SYSTEM

POWER-UP?

N

N

Y

DOES

TIMER TEST

FAIL UPON SYSTEM

POWER-UP?

Y

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

ARE

ALL CABLES

CONNECTED TO

PROCESSOR

BOARD?

Y

REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.2

N

DOES

TIMER TEST

FAIL UPON SYSTEM

POWER-UP?

Y

REINSTALL ORIGINAL

PROCESSOR BOARD

AND COVER

CONTACT NAD

SERVICE DEPT.

N

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

PERFORM A

COMPLETE PMS

ON UNIT

N

DOES

UNIT PASS

PMS?

UNIT IS

FUNCTIONAL

Y

3-8

Page 27

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 TROUBLESHOOTING GUIDE (continued)

GUIDE 6: Audio Test - Primary fails upon system power-up

START

CONNECT PRIMARY

SPEAKER CABLE TO

J15 ON PROCESSOR

BOARD

N

DOES

AUDIO TEST-PRIMARY

FAIL UPON SYSTEM

POWER-UP?

Y

REPLACE PRIMARY

SPEAKER (TOP)

AS OUTLINED IN

PROCEDURE 4.2

DOES

AUDIO TEST-PRIMARY

FAIL UPON SYSTEM

POWER-UP?

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

N

IS

PRIMARY SPEAKER

CABLE CONNECTED TO

J15 ON PROCESSOR

BOARD?

N

Y

Y

REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.2

Y

DOES

AUDIO TEST-PRIMARY

FAIL UPON SYSTEM

POWER-UP?

DOES

AUDIO TEST-PRIMARY

FAIL UPON SYSTEM

POWER-UP?

Y

REINSTALL ORIGINAL

PROCESSOR BOARD

AND COVER

CONTACT NAD

SERVICE DEPT.

N

N

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

PERFORM A

COMPLETE PMS

ON UNIT

N

DOES

UNIT PASS

PMS?

UNIT IS

FUNCTIONAL

Y

3-9

Page 28

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) VA3000

GUIDE 7: Audio Test - Backup fails upon system power-up

START

CONNECT ALL

PROCESSOR BOARD

AND INTERNAL CABLES

DOES

AUDIO BACKUP TEST

FAIL UPON SYSTEM

POWER-UP?

N

AUDIO BACKUP TEST

N

Y

PROCESSOR BOARD

DOES

FAIL UPON SYSTEM

POWER-UP?

Y

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

ARE

ALL CABLES

CONNECTED TO

PROCESSOR

BOARD?

Y

REPLACE

AS OUTLINED IN

PROCEDURE 4.2

N

DOES

AUDIO BACKUP TEST

FAIL UPON SYSTEM

POWER-UP?

Y

REINSTALL ORIGINAL

PROCESSOR BOARD

AND COVER

CONTACT NAD

SERVICE DEPT.

N

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

PERFORM A

COMPLETE PMS

ON UNIT

N

DOES

UNIT PASS

PMS?

UNIT IS

FUNCTIONAL

Y

3-10

Page 29

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 TROUBLESHOOTING GUIDE (continued)

CONNECT SPO2

SPEAKER CABLE TO

J16 ON PROCESSOR

BOARD

START

DOES

AUDIO TEST-SPO2

FAIL UPON SYSTEM

POWER-UP?

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

N

IS

SPO2 SPEAKER

CABLE CONNECTED TO

J16 ON PROCESSOR

BOARD?

GUIDE 8: Audio Test - SpO

N

Y

DOES

AUDIO TEST-SPO2

FAIL UPON SYSTEM

POWER-UP?

Y

REINSTALL ORIGINAL

PROCESSOR BOARD

AND COVER

Y

N

fails upon power-up

2

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

PERFORM A

COMPLETE PMS

ON UNIT

N

DOES

AUDIO TEST-SPO2

FAIL UPON SYSTEM

POWER-UP?

REPLACE SPO2

SPEAKER (BOTTOM)

AS OUTLINED IN

PROCEDURE 4.2

REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.2

Y

Y

DOES

AUDIO TEST-SPO2

FAIL UPON SYSTEM

POWER-UP?

CONTACT NAD

SERVICE DEPT.

N

N

DOES

UNIT PASS

PMS?

Y

UNIT IS

FUNCTIONAL

3-11

Page 30

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) VA3000

GUIDE 9: Serial I/O Test fails upon system power-up

START

CONNECT ALL

PROCESSOR BOARD

AND INTERNAL CABLES

DOES

SERIAL I/O TEST

FAIL UPON SYSTEM

POWER-UP?

N

N

Y

DOES

SERIAL I/O TEST

FAIL UPON SYSTEM

POWER-UP?

Y

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

ARE

ALL CABLES

CONNECTED TO

PROCESSOR

BOARD?

Y

REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.2

N

DOES

SERIAL I/O TEST

FAIL UPON SYSTEM

POWER-UP?

Y

REINSTALL ORIGINAL

PROCESSOR BOARD

AND COVER

CONTACT NAD

SERVICE DEPT.

N

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

PERFORM A

COMPLETE PMS

ON UNIT

N

DOES

UNIT PASS

PMS?

UNIT IS

FUNCTIONAL

Y

3-12

Page 31

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 TROUBLESHOOTING GUIDE (continued)

GUIDE 10: Clock Test fails upon system power-up

START

CONNECT ALL

PROCESSOR BOARD

AND INTERNAL CABLES

DOES

CLOCK TEST

FAIL UPON SYSTEM

POWER-UP?

N

N

Y

DOES

CLOCK TEST

FAIL UPON SYSTEM

POWER-UP?

Y

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

ARE

ALL CABLES

CONNECTED TO

PROCESSOR

BOARD?

Y

REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.2

N

DOES

CLOCK TEST

FAIL UPON SYSTEM

POWER-UP?

Y

REINSTALL ORIGINAL

PROCESSOR BOARD

AND COVER

CONTACT NAD

SERVICE DEPT.

N

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

PERFORM A

COMPLETE PMS

ON UNIT

N

DOES

UNIT PASS

PMS?

UNIT IS

FUNCTIONAL

Y

3-13

Page 32

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) VA3000

GUIDE 11: NVRAM Test fails upon system power-up

START

CONNECT ALL

PROCESSOR BOARD

AND INTERNAL CABLES

DOES

NVRAM TEST

FAIL UPON SYSTEM

POWER-UP?

N

N

Y

DOES

NVRAM TEST

FAIL UPON SYSTEM

POWER-UP?

Y

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

ARE

ALL CABLES

CONNECTED TO

PROCESSOR

BOARD?

Y

REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.2

N

DOES

NVRAM TEST

FAIL UPON SYSTEM

POWER-UP?

Y

REINSTALL ORIGINAL

PROCESSOR BOARD

AND COVER

CONTACT NAD

SERVICE DEPT.

N

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

PERFORM A

COMPLETE PMS

ON UNIT

N

DOES

UNIT PASS

PMS?

UNIT IS

FUNCTIONAL

Y

3-14

Page 33

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 TROUBLESHOOTING GUIDE (continued)

GUIDE 12: "SERVICE GAS MON" Advisory error

START

ATTACH ALL

CABLES TO GAS

ANALYZER

DOES

ADVISORY COLUMN

DISPLAY "SERVICE

GAS MON"?

PERFORM SPAN

CALIBRATION

AS OUTLINED IN

PROCEDURE 5.4

DOES

ADVISORY COLUMN

DISPLAY "SERVICE

GAS MON"?

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

N

ARE

ALL CABLES

CONNECTED TO GAS

ANALYZER?

N

Y

N

Y

DOES

ADVISORY COLUMN

DISPLAY "SERVICE

GAS MON"?

Y

REINSTALL ORIGINAL

GAS ANALYZER ASM

---------------------------REPLACE

PROCESSOR ASM

AS OUTLINED IN

PROCEDURE 4.2

PERFORM SPAN

CALIBRATION

AS OUTLINED IN

PROCEDURE 5.4

DOES

ADVISORY COLUMN

DISPLAY "SERVICE

GAS MON"?

N

N

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

DOES

ADVISORY COLUMN

DISPLAY "SERVICE

GAS MON"?

N

REPLACE GAS

Y

AS OUTLINED IN

PROCEDURE 4.7

N

ADVISORY COLUMN

DISPLAY "SERVICE

PERFORM SPAN

AS OUTLINED IN

PROCEDURE 5.4

Y

ANALYZER

DOES

GAS MON"?

Y

CALIBRATION

REINSTALL ORIGINAL

PROCESSOR ASM

CONTACT NAD

SERVICE DEPT.

3-15

Y

PERFORM A

COMPLETE PMS

ON UNIT

N

DOES

UNIT PASS

PMS?

Y

UNIT IS

FUNCTIONAL

Page 34

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) VA3000

GUIDE 13: "SERVICE NIBP MON" Advisory error

START

ENSURE THAT NIBP

FUNCTION IS "ON"

VIA SERVICE SCREEN

(SEE SECTION 2.5)

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

IS

CABLE CONNECTED

FROM PROCESSOR J4

TO NIBP PUMP?

Y

REPLACE NIBP PUMP

AS OUTLINED IN

PROCEDURE 4.6

DOES

ADVISORY COLUMN

DISPLAY MESSAGE

"SERVICE NIBP

MON"?

Y

N

DOES

NIBP MONITOR

SECTION APPEAR

ON DISPLAY?

Y

N

CONNECT CABLE

BETWEEN

PROCESSOR AND

NIBP PUMP

YN

ADVISORY COLUMN

DISPLAY MESSAGE

"SERVICE NIBP

DOES

MON"?

N

DOES

ADVISORY COLUMN

DISPLAY MESSAGE

"SERVICE NIBP

MON"?

REINSTALL ORIGINAL

NIBP PUMP

---------------------------------REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.2

ADVISORY COLUMN

DISPLAY MESSAGE

"SERVICE NIBP

MON"?

Y

DOES

N

N

Y

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

3-16

REINSTALL ORIGINAL

PROCESSOR BOARD

AND COVER

CONTACT NAD

SERVICE DEPT.

PERFORM A

COMPLETE PMS

N

UNIT PASS

FUNCTIONAL

ON UNIT

DOES

PMS?

Y

UNIT IS

Page 35

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 TROUBLESHOOTING GUIDE (continued)

GUIDE 14: "SERVICE SPO2 MON" Advisory error

START

ENSURE THAT SPO2

FUNCTION IS "ON"

VIA SERVICE SCREEN

(SEE SECTION 2.5)

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

IS

CABLE CONNECTED

FROM PROCESSOR J5

TO SPO2 ASM?

Y

REPLACE SPO2 ASM

AS OUTLINED IN

PROCEDURE 4.5

DOES

ADVISORY COLUMN

DISPLAY MESSAGE

"SERVICE SPO2

MON"?

Y

N

DOES

SPO2 MONITOR

SECTION APPEAR

ON DISPLAY?

Y

N

CONNECT CABLE

BETWEEN

PROCESSOR AND

SPO2 ASM

YN

ADVISORY COLUMN

DISPLAY MESSAGE

"SERVICE SPO2

DOES

MON"?

N

DOES

ADVISORY COLUMN

DISPLAY MESSAGE

"SERVICE SPO2

MON"?

REINSTALL ORIGINAL

SPO2 ASM

---------------------------------REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.2

ADVISORY COLUMN

DISPLAY MESSAGE

"SERVICE SPO2

MON"?

Y

DOES

N

N

Y

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

3-17

REINSTALL ORIGINAL

PROCESSOR BOARD

AND COVER

CONTACT NAD

SERVICE DEPT.

PERFORM A

COMPLETE PMS

N

UNIT PASS

FUNCTIONAL

ON UNIT

DOES

PMS?

Y

UNIT IS

Page 36

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) VA3000

GUIDE 15: Vitalink failure

START

CONNECT EXTERNAL

CABLE SECURELY

AT BOTH ENDS

N

CONNECTED AT BOTH

CHECK CONFIGURATION

SETTINGS ON VA3000

AND EXTERNAL DEVICE

N

VA3000 COMMU NICATE

WITH ANOTHER VITALINK

CAPABLE PRODUCT?

APPLICABLE SERVICE

FURTHER ASSISTANCE

ON ISOLATING FAILURE

DOES

VA3000 FAIL

TO COMMUNICATE

TO EXTERNAL

DEVICE?

Y

IS

SERIAL PORT

CABLE SECURELY

ENDS?

Y

DOES

VA3000 FAIL

TO COMMUNICATE

TO EXTERNAL

DEVICE?

Y

DOES

Y

REFER TO

MANUAL FOR

N

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.2

REATTACH

SERIAL CABLE AND

CONFIGURE SERIAL

PORTSOF VA3000 AND

EXTERNAL DEVICE

DOES

VA3000 FAIL

TO COMMUNICATE

TO EXTERNAL

DEVICE?

Y

REINSTALL ORIGINAL

PROCESSOR BOARD

AND COVER

N

CONTACT NAD

SERVICE DEPT.

N

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

PERFORM A

COMPLETE PMS

N

UNIT PASS

FUNCTIONAL

ON UNIT

DOES

PMS?

Y

UNIT IS

3-18

Page 37

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 TROUBLESHOOTING GUIDE (continued)

WAIT FOR

WARM-UP MESSAGE

TO CLEAR

REPLACE

WATER TRAP AND

SAMPLE LINE

N

IS

FLOW LOW OR

ABSENT?

START

FLOW LOW OR

Y

IS

ABSENT?

Y

IS

ANALYZER

IN WARM-UP

MODE?

N

GUIDE 16: Low or No Flow at CO

N

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

ARE

THERE SIGNS OF

FLUID/CONTAMINATION

IN INTERNAL

TUBING?

N

REPLACE

SAMPLE PUMP

AS OUTLINED IN

PROCEDURE 4.8

Y

REINSTALL ORIGINAL

SAMPLE PUMP

REPLACE

GAS ANALYZER

AS OUTLINED IN

PROCEDURE 4.7

PERFORM

SAMPLE LINE FLOW

CALIBRATION

AS OUTLINED IN

SECTION 5.3

exhaust port

2

Y

PERFORM

SAMPLE LINE FLOW

CALIBRATION

AS OUTLINED IN

SECTION 5.3

NY

IS

FLOW LOW OR

ABSENT?

PERFORM

SAMPLE LINE FLOW

CALIBRATION

AS OUTLINED IN

SECTION 5.3

IS

FLOW LOW OR

ABSENT?

N

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

PERFORM A

COMPLETE PMS

ON UNIT

IS

FLOW LOW OR

ABSENT?

REINSTALL ORIGINAL

GAS ANALYZER

Y

AND COVER

CONTACT NAD

SERVICE DEPT.

DOES

UNIT PASS

PMS?

UNIT IS

FUNCTIONAL

N

Y

N

Y

3-19

Page 38

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) VA3000

GUIDE 17: Line Block message displayed

START

IS LINE

BLOCK MESSAGE

DISPLAYED?

Y

REPLACE

SAMPLE LINE

AND WATER TRAP

IS LINE

BLOCK MESSAGE

DISPLAYED?

Y

PERFORM SAMPLE LINE

FLOW CALIBRATION

AS OUTLINED IN

PROCEDURE 5.3

IS LINE

BLOCK MESSAGE

DISPLAYED?

IS FLOW

WITHIN SPEC?

LO=100+/-25

HI=200+/-25

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

ARE

THERE SIGNS OF

FLUID/CONTAMINATION

IN INTERNAL

TUBING?

N

Y

N

N

N

N

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

Y

Y

REPLACE

SAMPLE PUMP

AS OUTLINED IN

PROCEDURE 4.8

PERFORM SAMPLE LINE

FLOW CALIBRATION

AS OUTLINED IN

PROCEDURE 5.3

IS FLOW

WITHIN SPEC?

LO=100+/-25

HI=200+/-25

Y

IS LINE

BLOCK MESSAGE

DISPLAYED?

Y

REINSTALL ORIGINAL

SAMPLE PUMP

REINSTALL ORIGINAL

PROCESSOR BOARD

AND COVER

CONTACT NAD

SERVICE DEPT.

REPLACE

GAS ANALYZER

AS OUTLINED IN

PROCEDURE 4.7

PERFORM SAMPLE LINE

FLOW CALIBRATION

AS OUTLINED IN

PROCEDURE 5.3

IS LINE

BLOCK MESSAGE

DISPLAYED?

Y

REINSTALL ORIGINAL

N

N

GAS ANALYZER

----------------------------------REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.2

PERFORM SAMPLE LINE

FLOW CALIBRATION

AS OUTLINED IN

PROCEDURE 5.3

YN

IS LINE

BLOCK MESSAGE

DISPLAYED?

N

DOES

UNIT PASS

PMS?

N

REINSTALL

COVER

PERFORM A

COMPLETE PMS

ON UNIT

3-20

Y

UNIT IS

FUNCTIONAL

Page 39

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 TROUBLESHOOTING GUIDE (continued)

GUIDE 18: Instrument will not power-up

START

ENABLE

CIRCUIT BREAKER

PLUG UNIT

INTO LIVE AC

RECEPTACLE

NB

DOES UNIT

POWER UP?

N

IS

CIRCUIT BREAKER

ENABLED?

IS

UNIT PLUGGED

INTO LIVE AC

RECEPTACLE?

REPLACE

POWER CORD

ASSEMBLY

DOES UNIT

POWER UP?

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

Y

N

Y

Y

Y

N

REPLACE

POWER SUPPLY

AS OUTLINED IN

PROCEDURE 4.3

ARE

VOLTAGES WITHIN

SPEC?

Y

DOES UNIT

POWER UP?

N

REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.2

REINSTALL ORIGINAL

N

Y

POWER SUPPLY

AND COVER

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

Y

DOES UNIT

POWER UP?

N

CONTACT NAD

SERVICE DEPT.

PERFORM A

COMPLETE PMS

ON UNIT

CHECK

VOLTAGES PER

SECTION 3.1

N

ARE

VOLTAGES WITHIN

SPEC?

Y

3-21

REINSTALL ORIGINAL

PROCESSOR BOARD

AND COVER

CONTACT NAD

SERVICE DEPT.

N

DOES

UNIT PASS

PMS?

Y

UNIT IS

FUNCTIONAL

Page 40

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) VA3000

GUIDE 19: Front Keys and/or Rotary Dial not functional

START

ARE FRONT

KEYS/ROTARY DIAL

FUNCTIONAL?

N

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

REPLACE

FRONT BEZEL

AS OUTLINED IN

PROCEDURE 4.4

ARE FRONT

KEYS/ROTARY DIAL

FUNCTIONAL?

N

REINSTALL ORIGINAL

FRONT BEZEL

-----------------------------REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.2

Y

Y

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

Y

ARE FRONT

KEYS/ROTARY DIAL

FUNCTIONAL?

N

PERFORM A

COMPLETE PMS

ON UNIT

DOES

UNIT PASS

PMS?

N

Y

UNIT IS

FUNCTIONAL

REINSTALL ORIGINAL

PROCESSOR BOARD

AND COVER

3-22

CONTACT NAD

SERVICE DEPT.

Page 41

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 TROUBLESHOOTING GUIDE (continued)

GUIDE 20: NIBP readings inacurate

START

ARE

NIBP READINGS

ACCURATE?

N

PERFORM

CUFF PRESSURE TEST

AS OUTLINED IN

SECTION 5.2

DOES

THE SYSTEM

LEAK?

REPLACE

CUFF AND

EXTENSION HOSE

DOES

THE SYSTEM

LEAK?

N

Y

Y

N

Y

REPLACE

NIBP PUMP

AS OUTLINED IN

PROCEDURE 4.6

DOES

THE SYSTEM

LEAK?

Y

REINSTALL ORIGINAL

NIBP PUMP

CONTACT NAD

SERVICE DEPT.

N

ARE

NIBP READINGS

ACCURATE?

Y

N

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

PERFORM A

COMPLETE PMS

ON UNIT

ARE

NIBP READINGS

ACCURATE?

Y

N

N

DOES

UNIT PASS

PMS?

Y

UNIT IS

FUNCTIONAL

3-23

Page 42

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) VA3000

GUIDE 21: Instrument is performing intermittent resets

START

IS V3000

PERFORMING

INTERMITTENT

RESETS?

Y

IS V3000

INTERFACED TO A

HOST MACINE?

N

REPLACE AC

POWER CORD

IS V3000

PERFORMING

INTERMITTENT

RESETS?

Y

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

N

REMOVE

HOST CONNECTIONS,

Y

N

RECONFIGURE

BOTH UNITS,

RECONNECT

SERIAL CABLE

IS V3000

YN

PERFORMING

INTERMITTENT

RESETS?

REINSTALL ORIGINAL

PROCESSOR BOARD

------------------------------REPLACE

POWER SUPPLY

AS OUTLINED IN

PROCEDURE 4.3

IS V3000

PERFORMING

INTERMITTENT

RESETS?

Y

REINSTALL ORIGINAL

POWER SUPPLY

AND COVER

N

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

PERFORM A

COMPLETE PMS

ON UNIT

ARE

ALL INTERNAL

CABLES CONNECTED

SECURELY?

CONNECT ALL

CABLES SECURELY

IS V3000

PERFORMING

INTERMITTENT

RESETS?

N

Y

REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.2

Y

YN

IS V3000

PERFORMING

INTERMITTENT

RESETS?

3-24

CONTACT NAD

SERVICE DEPT.

N

N

DOES

UNIT PASS

PMS?

Y

UNIT IS

FUNCTIONAL

Page 43

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 TROUBLESHOOTING GUIDE (continued)

GUIDE 22: Analyzer fails Span Cal

START

DOES

UNIT FAIL SPAN

CAL?

IS

CAL GAS

CORRECT?

NAD P/N

4110599

IS

SAMPLE FLOW

WITHIN

SPEC?

REPLACE

GAS ANALYZER

AS OUTLINED IN

PROCEDURE 4.7

PERFORM SAMPLE LINE

FLOW CALIBRATION

AS OUTLINED IN

PROCEDURE 5.3

N

Y

Y

Y

REPEAT SPAN CAL

N

N

WITH CORRECT

GAS CYLINDER

YN

DOES

UNIT FAIL SPAN

CAL?

PERFORM SAMPLE LINE

FLOW CALIBRATION

AS OUTLINED IN

PROCEDURE 5.3

DOES

UNIT FAIL SPAN

CAL?

REMOVE COVER

AS OUTLINED IN

PROCEDURE 4.1

N

Y

REINSTALL ORIGINAL

GAS ANALYZER

------------------------------REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.2

Y

DOES

UNIT FAIL SPAN

CAL?

PERFORM SAMPLE LINE

FLOW CALIBRATION

AS OUTLINED IN

PROCEDURE 5.3

REINSTALL ORIGINAL

SAMPLE PUMP

-----------------------------------

REPLACE

GAS ANALYZER

AS OUTLINED IN

PROCEDURE 4.7

N

PERFORM SAMPLE LINE

FLOW CALIBRATION

AS OUTLINED IN

PROCEDURE 5.3

N

DOES

UNIT FAIL SPAN

CAL?

Y

REINSTALL ORIGINAL

PROCESSOR BOARD

AND COVER

CONTACT NAD

SERVICE DEPT.

REINSTALL COVER

AS OUTLINED IN

PROCEDURE 4.1

DOES

UNIT FAIL SPAN

CAL?

N

ARE

THERE SIGNS OF

FLUID/CONTAMINATION

IN INTERNAL

TUBING?

DOES

UNIT FAIL SPAN

CAL?

N

NYY

REPLACE

SAMPLE PUMP

AS OUTLINED IN

PROCEDURE 4.8

PERFORM SAMPLE LINE

FLOW CALIBRATION

AS OUTLINED IN

PROCEDURE 5.3

SAMPLE FLOW

WITHIN

SPEC?

3-25

PERFORM A

COMPLETE PMS

ON UNIT

DOES

UNIT PASS

PMS?

CONTACT NAD

SERVICE DEPT.

IS

NYY

UNIT IS

FUNCTIONAL

Y

N

Page 44

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Page 45

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 REPLACEMENT PROCEDURES

4.0 REPLACEMENT PROCEDURES

This section outlines removal and replacement procedures for the field-replaceable

assemblies of the VITALERT 3000 Series Monitoring System.

All procedures are to be performed only by a Draeger Medical, Inc. qualified Technical

Service Representative (TSR).

The following replacement procedures are the only procedures authorized by Draeger

Medical, Inc. to be performed in the field. All others shall be referred to Draeger

Medical Inc.’s Technical Service Department.

NOTE: The PMS Procedure provided in Section 6 must be performed

after any replacement, removal, calibration, or adjustment

procedure.

Rev. G

4-1

Page 46

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued) VA3000

4.1 VITALERT 3000 Cover

The VITALERT 3000 cover is secured to the underside of the chassis by four

button head screws, and to the rear panel by four button head screws. The

general arrangement of the cover is shown in Figure 4-1.

4.1.1 Place the instrument in the standby mode, and remove the AC power

cord from the instrument.

4.1.2 Disconnect any data cables at the rear panel, and disconnect the

exhaust line at the rear panel.

4.1.3 If applicable, disconnect the Pulse Oximeter cable and the BP cuff

hose from the patient interface panel on the left side of the

instrument.

4.1.4 Disconnect the PVC sample line and remove the air filter from the

water trap housing.

4.1.5 Remove the water trap from its holder.

4.1.6 Remove the four button head screws and lockwashers securing the

cover to the rear panel.

4.1.7 On a clean working surface, turn the instrument onto its side.

4.1.8 Remove the four button head screws and lockwashers securing the

cover to the bottom of the chassis.

4.1.9 Carefully rotate the instrument back to an upright position.

4.1.10 On the left side of the instrument, pull the bottom of the cover

outward far enough to clear the water trap housing while sliding the

cover towards the rear of the chassis until the cover is clear of the

chassis.

...............................................................................................................................

4.1.11 Following adjustment or repair, position the cover at the rear of the

chassis and slide it towards the front. Pull the left side of the cover

outward as needed to guide it past the water trap housing.

4.1.12 Turn the instrument onto its side and reinstall the four button head

screws and lock washers that were previously removed.

4.1.13 Rotate the instrument back to an upright position.

4.1.14 Reinstall the four button head screws and lock washers that were

previously removed at the rear of the cover.

4-2

Page 47

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 REPLACEMENT PROCEDURES (continued)

NOTE: On later model gas analyzers the Luer fitting in the water trap

housing and the Luer fitting on the PVC sample line have a different

gender arrangement than previous models. The later arrangement

prevents connection of the PVC sample line to the water trap

housing without an air filter. (The same air filter is used - oriented

180° from the previous arrangement.)

4.1.15 Reinstall the water trap and the air filter, and reconnect the PVC

sample line.

4.1.16 If applicable, reconnect the Pulse Oximeter cable and the BP cuff

hose at the patient interface panel.

4.1.17 Connect the AC power cord to the instrument.

SCREW (4X)

LOCKWASHER

(4X)

COVER

SV30118

REAR VIEW OF

VITALERT 3000

LOCK-WASHER (4X)

Figure 4-1: VITALERT 3000 COVER REMOVAL

Rev. E

4-3

MOUNTING

SCREW (4X)

Page 48

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued) VA3000

4.2 Processor Assembly

The VITALERT 3000 processor assembly includes the processor board and the

rear panel components - speakers, mains filter and circuit breaker - which are

replaceable without removing the processor assembly from the chassis. (The

serial port connecting through the rear panel are part of the processor board.)

Figures 4-2 and 4-2A illustrate the mounting arrangement and connections to

the processor assembly.

CAUTION: The processor board contains static-sensitive devices. Use ESD

protection when handling this assembly.

NOTE: If possible, document Standard Site and all other stored default

template parameters for restoring in replacement processor.

4.2.1 Remove the cover as outlined in Procedure 4.1.

4.2.2 Disconnect the following from the processor board:

J11 (Wire harness - front panel encoder)

J13 (Ribbon cable - front switch panel)

J14 (Ribbon cable - display)

J10 (Ribbon cable - gas analyzer)

J12 (Wire harness - power supply): cut the tie strap

J4 (Ribbon cable - NIBP module)

J5 (Ribbon cable - SpO

assembly)

2

4.2.3 Disconnect the input wire harness at J1 on the power supply.

4.2.4 Disconnect the ground wires at the right rear corner of the chassis.

4.2.5 Remove the processor assembly mounting screws from the underside

of the chassis, and carefully lift the processor assembly from the

chassis.

Speaker Replacement Only:

- Carefully disconnect the wire harness from the speaker to be

replaced. Note the wire color and (+) terminal mark on the speaker

so that the replacement speaker can be installed in the same

manner.

- Un-screw the speaker mounting ring and remove the speaker from

the back panel.

- Install the replacement speaker in the back panel of the processor

assembly and secure it with its mounting ring.

- Connect the wire harness to the replacement speaker.

4-4

Rev. G

Page 49

SV30110

SPEAKERS

SPEAKER

MOUNTING

NUTS

J16

J15

CHASSIS

(UNDERSIDE VIEW)

J5 (SPO2 ASSEMBLY)

J14 (FRONT BEZEL-

DISPLAY)

J13 (FRONT BEZEL-

SWITCH PANEL)

J10 (GAS ANALYZER)

J11 (FRONT BEZEL-

ENCODER)

J12 (POWER SUPPLY)

J4 (NIBP MODULE)

LOCKWASHER (2X)

MOUNTING

SCREW (2X)

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 REPLACEMENT PROCEDURES (continued)

4.2.6 Position the replacement processor assembly in the chassis, and

secure the assembly with the screws and lock washers that were

previously removed.

4.2.7 Reconnect the ground wires in the same manner as original.

4.2.8 Reconnect the input wire harness to J1 on the power supply.

4.2.9 Reconnect all cables and wire harnesses that were previously

disconnected from the processor board.

4.2.10 Install a new tie strap at J12 in the same manner as the original.

4.2.11 Reinstall the cover as outlined in Procedure 4.1.

Rev. G

Figure 4-2: REPLACEMENT OF PROCESSOR ASSEMBLY

4-5

Page 50

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued) VA3000

4.2.12 Restore power to the instrument and observe the power-up

diagnostics screen (see Section 2) to verify that the replacement

processor board is working properly.

4.2.13 Enter the System Configuration screen (ref. OPERATOR’S

INSTRUCTION MANUAL, VITALERT 3000 SERIES) and verify

that the date and time are set correctly.

4.2.14 Enter the Secondary Service setup screen (see Section 2) and perform

the following:

- Reset hours since last serviced

- Make appropriate entry in service log

- Enter Machine serial number

- Enable functions appropriate to unit (NIBP, SpO

, SEVO, DES)

2

- Verify correct SW version numbers

SV30111

NOTE: Restore any default templates documented from original processor.

If these parameters were unavailable because of a board fault,

attempt to reprogram the standard site template (check another

VA3000 or inquire of hospital personnel). If no templates are

reprogrammed, advise hospital personnel of this fact.

4.2.15 Perform the PMS Procedure given in Section 6.

PROCESSOR

ASSEMBLY

VITALERT 3000 RIGHT SIDE VIEW

CIRCUIT

BREAKER

MAINS

FILTER

J3

J1

NUT w/CAPTIVE

LOCKWASHER

(2X)

POWER

SUPPLY

POWER SUPPLY

INPUT CONNECTOR

Figure 4-2A: REPLACEMENT OF PROCESSOR ASSEMBLY (continued)

4-6

GROUND

WIRE

LOCKWASHER

(2X)

GROUND

STUD

Rev. G

Page 51

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 REPLACEMENT PROCEDURES (continued)

4.3 Power Supply

The power supply is not field serviceable and is replaced as a unit. Figure 4-3

shows the electrical connections and mounting arrangement of the power

supply.

4.3.1 Remove the cover as outlined in Procedure 4.1.

4.3.2 Disconnect the input wire harness at J1, and disconnect the output

wire harness at J3.

4.3.3 Remove the power supply mounting screws from the underside of the

chassis, and carefully lift the power supply fron the chassis.

4.3.4 Transfer the piece of gromet strip to the replacement power supply

as shown in the illustration.

4.3.5 Position the replacement power supply in the chassis and secure it

with the two screws and lock washers that were previously removed.

4.3.6 Reconnect the output wire harness to J3, and the input wire harness

to J1 on the power supply.

4.3.7 Restore AC power to the instrument and verify that the DC voltages

are within their allowable range. See Section 3.

4.3.8 Disconnect the AC power cord and reinstall the cover as outlined in

Procedure 4.1.

4.3.9 Enter the service screens (see Section 2) and make an appropriate

entry in the service log.

4.3.10 Perform the PMS Procedure given in Section 6.

4-7

Page 52

SV30112

VITALERT 3000 RIGHT SIDE VIEW

GROMMET

STRIP

FUSE F1

LOCKWASHER

(2X)

MOUNTING

SCREW (2X)

OUTPUT

CONNECTOR

INPUT

CONNECTOR

POWER

SUPPLY

J3

J1

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued) VA3000

Figure 4-3: REPLACEMENT OF POWER SUPPLY

4-8

Page 53

RETURN TO THIS MANUAL’S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VA3000 REPLACEMENT PROCEDURES (continued)

4.4 Front Bezel Assembly

The front bezel assembly includes the display panel, key switches and rotary

encoder. These internal components are not field serviceable, and the bezel is

replaced as a complete assembly. Figure 4-4 illustrates the mechanical

arrangement of the front bezel and its connections.

CAUTION: The front bezel contains static-sensitive devices. Use ESD

protection when handling this assembly.

4.4.1 Remove the cover as outlined in Procedure 4.1.

4.4.2 Disconnect the following from the processor board:

J11 (Wire harness - front panel encoder)

J13 (Ribbon cable - front switch panel)

J14 (Ribbon cable - display)

4.4.3 Disconnect the front bezel ground wire from the ground tab behind

the patient interface panel.

4.4.4 Remove the delrin friction disk from the tilt panel friction

adjustment mechanism on each side of the bezel. Do not mis-place

the panel connecting links.

4.4.5 Position the chassis with its front feet at the edge of a table, so that

the bezel overhangs the table.

4.4.6 While holding the front bezel, loosen the two stop plate screws, and

slide the stop plate downward.

4.4.7 Carefully swing the bezel assembly downward until its hinge hooks

disengage the hinge pins, and lift off the bezel assembly.

4.4.8 Set the replacement bezel assembly hinge hooks onto the hinge pins,

and swing the bezel up into its normal position.

4.4.9 Raise the stop plate into position and tighten its screws.