Page 1

WARNING

Strictly follow the Instructions for Use.

The user must fully understand and strictly observe the

instructions. Use the product only for the purposes specified

in the Intended use section of this document.

Dräger Polytron 8700/8720

Instructions for Use

i

!

Page 2

Page 3

Contents

Contents

1 For your safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.1 General safety statements . . . . . . . . . . . . . . . . . . . .4

1.2 Definitions of alert icons . . . . . . . . . . . . . . . . . . . . . .4

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1 Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Functional description . . . . . . . . . . . . . . . . . . . . . . . .6

2.3 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.4 Intended area and conditions of use . . . . . . . . . . . . .6

2.5 Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.6 Device marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.1 General information for the installation . . . . . . . . . . .7

3.2 Restrictions on the installation . . . . . . . . . . . . . . . . .7

3.3 Impedance range of the signal loop . . . . . . . . . . . . .8

3.4 Mechanical installation . . . . . . . . . . . . . . . . . . . . . . .8

3.5 Electrical installation without e-Box . . . . . . . . . . . . . .8

3.6 Electrical installation with e-Box . . . . . . . . . . . . . . .10

3.7 Connecting the device to a Dräger control unit . . . .10

3.8 Connecting the device to a PC . . . . . . . . . . . . . . . .10

3.9 PolySoft 8000 PC software (optional) . . . . . . . . . . .10

3.10 Installing software dongles . . . . . . . . . . . . . . . . . . .10

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4.1 Operating fundamentals . . . . . . . . . . . . . . . . . . . . .11

4.2 Display and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . .11

4.3 Activating the Info mode . . . . . . . . . . . . . . . . . . . . .12

4.4 Switching to the Quick Menu mode . . . . . . . . . . . .13

4.5 Switching to Menu mode (password protected) . . .13

4.6 Measurement mode . . . . . . . . . . . . . . . . . . . . . . . .13

5 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

5.1 Calibrating the device . . . . . . . . . . . . . . . . . . . . . . .14

5.2 Performing Auto Calibration . . . . . . . . . . . . . . . . . .15

6 Menu overview . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

7 Information menu. . . . . . . . . . . . . . . . . . . . . . . . . .17

7.1 Device settings . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

7.2 Sensor information . . . . . . . . . . . . . . . . . . . . . . . . .17

7.3 Datalogger information (only with data dongle) . . .17

8 Settings menu . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

8.1 Switching SIL lock on or off . . . . . . . . . . . . . . . . . . .18

8.2 Device settings . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

8.3 Communication settings . . . . . . . . . . . . . . . . . . . . .21

8.4 Sensor settings . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

8.5 Datalogger settings (only with data dongle) . . . . . .25

9 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . .27

9.1 Fault reference: . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

9.2 Warning reference . . . . . . . . . . . . . . . . . . . . . . . . .28

10 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

10.1 Maintenance intervals . . . . . . . . . . . . . . . . . . . . . . .29

10.2 Changing the sensor . . . . . . . . . . . . . . . . . . . . . . . .29

10.3 Changing the main electronics . . . . . . . . . . . . . . . .29

11 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

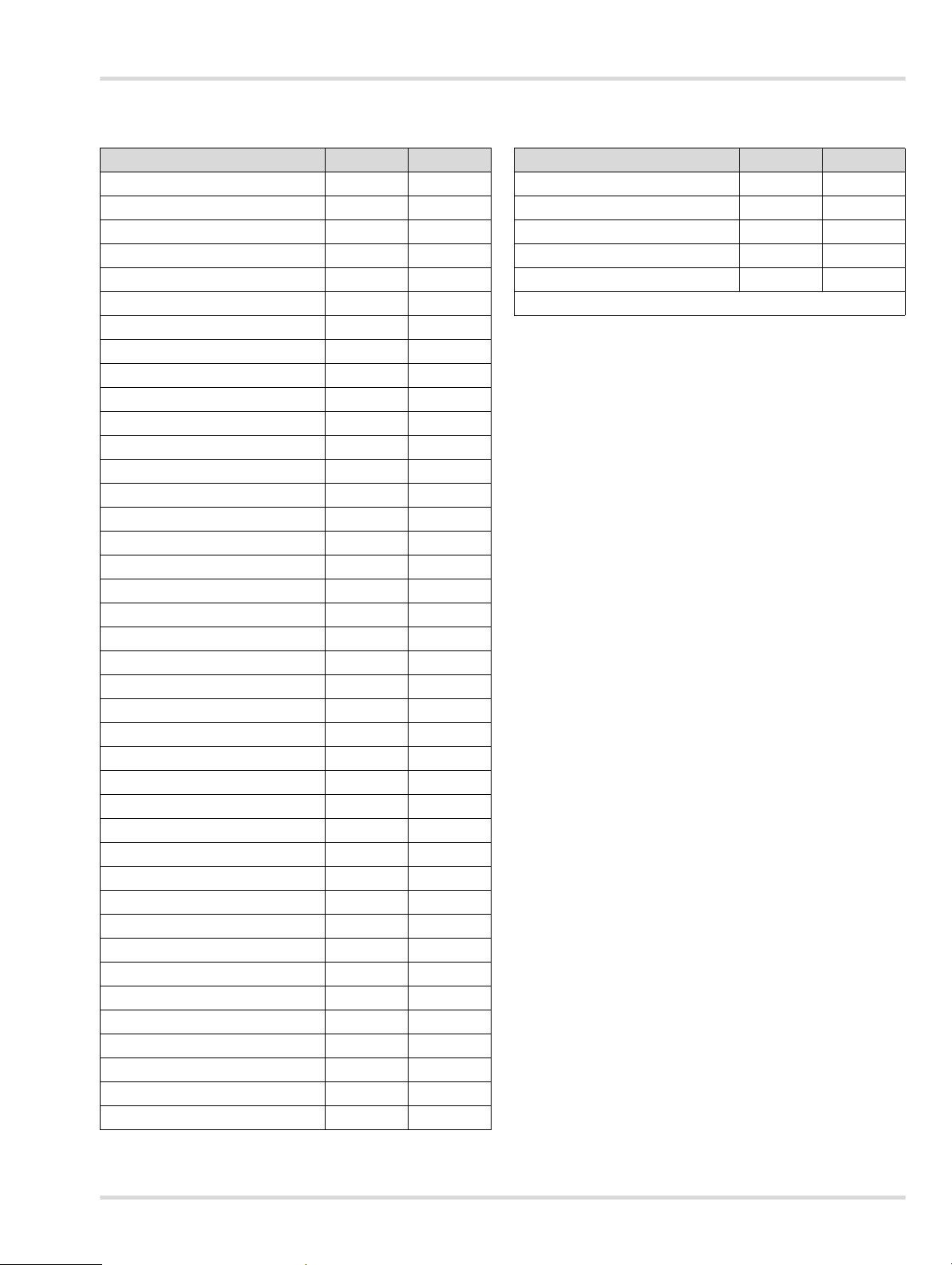

12 Substances in the gas library (PIR 7000). . . . . . 30

12.1 Polytron 8700 Type 334 . . . . . . . . . . . . . . . . . . . . 30

12.2 Polytron 8700 Type 340 . . . . . . . . . . . . . . . . . . . . 31

13 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

13.1 Torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

13.2 Tightening torque and cable size for field wiring termi-

nals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

13.3 Factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

14 Order list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

14.1 Dräger Polytron 8700 Type 334 . . . . . . . . . . . . . . 34

14.2 Dräger Polytron 8700 Type 340 . . . . . . . . . . . . . . 34

14.3 Dräger Polytron 8720 . . . . . . . . . . . . . . . . . . . . . . 34

14.4 Sensors for remote versions . . . . . . . . . . . . . . . . . 34

14.5 Replacement sensors (except for remote versions) 35

14.6 Accessories for Polytron 8700/8720 . . . . . . . . . . . 35

14.7 Replacement parts . . . . . . . . . . . . . . . . . . . . . . . . 35

15 Declaration of Conformity. . . . . . . . . . . . . . . . . . 36

Dräger Polytron 8700/8720 3

Page 4

For your safety

1 For your safety

1.1 General safety statements

z Before using the product, carefully read the Instructions

for Use.

z Strictly follow the Instructions for Use. The user must fully

understand and strictly observe the instructions. Use the

product only for the purposes specified in the Intended use

section of this document.

z Do not dispose of the Instructions for Use. Ensure that they

are retained and appropriately used by the product user.

z Only fully trained and competent users are permitted to use

this product.

z Comply with all local and national rules and regulations

associated with this product.

z Only trained and competent personnel are permitted to

inspect, repair and service the product as detailed in these

Instructions for Use. Further maintenance work that is not

detailed in these Instructions for Use must only be carried

out by Dräger or personnel qualified by Dräger. Dräger

recommend a Dräger service contract for all maintenance

activities.

z Properly trained service personnel must inspect and

service this product as detailed in the Maintenance section

of this document.

z Use only genuine Dräger spare parts and accessories, or

the proper functioning of the product may be impaired.

z Do not use faulty or incomplete products, and do not modify

the product.

z The threads for the explosion proof enclosure do not

conform to the minimum/maximum values in EN/IEC

60079-1. The threads must not be reworked by the user.

z The measuring function of the transmitter for explosion

protection according to Annex II, Clauses 1.5.5, 1.5.6 and

1.5.7 of Directive 94/9/EG is not covered at present.

z Only operate the product within the framework of a risk-

based alarm signalling concept.

Safe coupling with electrical devices

z Electrical connections to devices which are not listed in

these Instructions for Use should only be made following

consultation with the respective manufacturers or an

expert.

Use in areas subject to explosion hazards

z Devices or components for use in explosion-hazard areas

which have been tested and approved according to

national, European or international Explosion Protection

Regulations may only be used under the conditions

specified in the approval and with consideration of the

relevant legal regulations. The devices or components may

not be modified in any manner. The use of faulty or

incomplete parts is forbidden. The appropriate regulations

must be observed at all times when carrying out repairs on

these devices or components.

1.2 Definitions of alert icons

The following alert icons are used in this document to provide

and highlight areas of the associated text that require a greater

awareness by the user. A definition of the meaning of each

icon is as follows:

WARNING

!

IIndicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury.

CAUTION

!

Indicates a potentially hazardous situation which, if not

avoided, could result in physical injury, or damage to

the product or environment. It may also be used to

alert against unsafe practices.

NOTICE

i

i

Indicates additional information on how to use the

product.

4 Dräger Polytron 8700/8720

Page 5

2 Description

001233300.eps

4

6

5

1

3

2

7

002233300.eps

4

8

5

1

6

7

3

2

2.1 Product overview

Description

2.1.1 Explosion proof device

2.1.2 Explosion proof device with increased safe wiring compartment (e-Box)

1 Housing cover

2 Clip

3 Enclosure with main electronics (and optional relay)

4 Lower part of housing

5 Dräger PIR 7000/7200

6 Assembled device

7 Mounting spacer

1 Housing cover

2 Clip

3 Enclosure with main electronics (and optional relay)

4 Lower part of housing

5 Dräger PIR 7000/7200

6 Feed through cable

7e-Box

8 Assembled device

Dräger Polytron 8700/8720 5

Page 6

Description

D

Polytron 8700

ITR 0421

Dräger Safety 23560 Lübeck, Germany

II 2G

II 2D

WARNING: Do not open when energized

I

S

F

S

I

E

A

D

L

C

9N54

0158

Class I, Div 1, Groups A,B,C,D | Class II, Div 1, Groups E,F,G

Class I, Zone 1, Group IIC | T-Code T6/T4 | Type 4X | C22.2 No. 152

Supply: 10...30 VDC, 0.1...0.75 A | Relays: 5 A, 30 VDC or 230 VA C

CAUTION: Do not open cover. Opening

cover with circuits alive provokes risk of

Ignition of Hazardous Atmospheres.

W

ARNING: To reduce the risk of Ignition

of Hazardous Atmospheres, the conduit

must be sealed within 18’’ of the enclosure.

WARNING: Read Manual before operating.

Gas Detector for Use in Hazardous Locations as to

Fire, Electrical Shock and Explosion Hazards only

Part No: 4544638

Serial No. XXXX-9999

Ex d IIC T6/T4 Gb

Ex tb IIIC T80/130°C Db

-40°C ≤ Ta ≤ +40/+80°C

PTB 11 ATEX 1005X

IECEx PTB 11.0005X

IP6x | P ≤ 5 W

Sample

2.2 Functional description

The device is operated from a 10 to 30 volt DC supply.

The current gas concentration, status messages and menu

items are shown on a backlit LCD display and by three colored

LEDs. The measured gas concentration is output as a 4 to

20 mA analog signal or a digital HART

®

signal1 After the power

is switched on, the device detects whether the 4-20 mA

interface is to be operated as a current source or a current

sink. The flexible design permits fitting even in places that are

difficult to access. The Dräger PIR 7000/7200 can be fitted on

either side of the of the equipment and installation with up to

30 m between the sensing head and the PIR 7000/7200 is

possible. In the variant with the integrated e-Box with the

"increased safety" protection class, the device can be easily

connected to the electrical field wiring. The device can be

configured, calibrated and serviced without declassification of

the area.

2.3 Intended use

The Dräger Polytron 87x0 is an explosion proof transmitter for

continuous monitoring of the concentration of gases and vapors

containing hydrocarbons or carbon dioxide. The housing for the

device consists of robust, non-corroding stainless steel or

aluminum and is suitable for indoor or outdoor applications.

The unit can be connected to a Dräger monitoring system or

a programmable logic controller (PLC) by means of a sealed

conduit or an appropriately approved cable gland. With the

optionally integrated relay module, the device can be operated

without a central controller (with additional local alarm

signalling). The device is designed for fixed installation and is

approved for use in potentially explosive atmospheres,

see chapter 2.5 on page 6.

2.3.2 Dräger Polytron 8720 with PIR 7200 infrared gas

sensor Type CO

2

For monitoring carbon dioxide.

z Measuring range (IDS 01x5): 0 to 0.2 up to 30 vol% CO

2

WARNING

!

Explosive. Not to be used in oxygen enriched

atmospheres. None of the Polytron 8000 transmitters

is certified and approved to be operated in oxygen

enriched atmospheres.

2.4 Intended area and conditions of use

Hazardous areas classified by zones:

The device is only designed for use in Zone 1 or Zone 2

potentially explosive atmospheres for which a temperature

range as specified on the device must be observed and in which

gases of Explosion Groups IIA, IIB or IIC and Temperature

Classes T4 or T6 (depending on maximum ambient

temperature) or dust of Groups IIIA, IIIB or IIIC may occur.

Hazardous areas classified by divisions:

The device is only designed for use in potentially explosive

atmospheres of Classes I&II, Div. 1 or 2, for which

a temperature range as specified on the device must be

observed and in which gases or dust of Groups A, B, C, D or

E, F, G and Temperature Classes T4 or T6 (depending on

maximum ambient temperature) may occur.

2.5 Approvals

WARNING

!

To prevent ignition of explosive atmospheres, strictly

follow the warnings below:

Not tested in oxygen enriched atmospheres (>21%

O2). High off-scale readings may indicate an explosive

concentration.

Exchanging components may compromise the intrinsic

safety. This only applies if the device is intrinsically

safe.

2.3.1 Dräger Polytron 8700 with PIR 7000 infrared gas sensor Types 334 and 340

For monitoring flammable gases and vapors containing

hydrocarbons

z Measuring range of Type 334 (IDS 01x1): 0 to 20 up to

100 %LEL

z Measuring range of Type 340 (IDS 01x2): 0 to 5 up to

100 %LEL

2

, for CH4 (methane) also 0 to 100 vol.%

2

See printed version for approval markings.

2.6 Device marking

The device marking is reproduced on a separate document

shipped with the device.

Key to the Serial Number: The third letter of the Serial Number

specifies the year of manufacture: A = 2009, B = 2010, C = 2011,

D = 2012, E = 2013, F = 2014, H = 2015, J = 2016, K = 2017 etc.

Example: Serial Number ARBH-0054: The third letter is B,

i.e. the device was manufactured in 2010.

2 Lower Explosive Limit depending on the substance and the locally

applicable regulations.

6 Dräger Polytron 8700/8720

1HART® is a registered trademark of HCF, Austin, Texas, USA

Page 7

Installation

3 Installation

3.1 General information for the installation

The selection of a suitable mounting location is crucial for the

effectiveness and performance of the entire system.

Considerable thought must be given to every detail of

installation, particularly:

z the local and national rules and regulations for the

installation of gas monitoring systems,

z the applicable regulations for running and connecting

power and signal cables to gas monitoring systems,

z the full extent of environmental influences to which the

device will be subjected,

z the physical properties of the gases and vapors to be

measured,

z the details of the particular application (e.g., potential

leaks, air movements/flows, etc.),

z accessibility for required maintenance activities,

z the geometric of the accessories that are used with

the system,

z all other limiting factors and stipulations that may affect the

installation of the system.

z For installation without a conduit, an approved cable gland

(e.g. Hawke A501/421/A/¾" NPT or equivalent) must be

used (see chapter 13 on page 32). To increase the RF

interference immunity, it may be necessary to connect the

cable screen to the cable gland and to the control unit.

z The explosion proof enclosure has three ¾" NPT

connections, which can be used for field wiring, the direct

attachment of a sensor or wiring an external sensor. For the

correct tightening torques for cable bushings, plugs and

sensors, see chapter 13 on page 32.

z The secondary are supposed to be supplied from an

isolating source (does not apply to relay contacts).

z The optional e-Box has up to four 20 mm connections,

which can be used for field wiring or wiring an external

sensor. The permissible cable diameter is 7 to 12 mm.

z If the device is installed in locations where ambient

temperatures of over 55 °C prevail, appropriate cables

which are designed for use at temperatures of 25 °C above

the maximum ambient temperature must be used.

z Strip back the insulation on conductors by 5 to 7 mm.

z Connect the cable as shown in Chapter 3.5 on page 8

(shown here also with protective ground).

z The use of a mounting spacer (Order Number 68 12 617)

is recommended as a matter of principle if the device is to

be mounted on a wall or on a very uneven substrate.

z The connecting wires for the optional relay module must be

selected and fused according to the rated voltages,

currents and environmental conditions.

z When stranded conductors are used, an end ferrule must

also be used.

3.2 Restrictions on the installation

z The device requires a DC voltage between 10 and 30 V.

The minimum supply voltage of 10 V and the cross-section

of the conductors used determine the distance of the

device from the supply or the central controller

(see chapter 13 on page 32). The device is designed for

cables of sizes 12 to 24 AWG (0.2 to 2.5 mm

2

). A three-

wire, screened cable must be used as a minimum.

z The device must not be subjected to any radiant heat

(e.g. direct sunlight) as this may result in a temperature rise

above the specified thresholds (see chapter 13 on

page 32). The use of a reflective screen is recommended.

z If a splash guard (Order Number 68 11 911 or 68 11 912) is

used, it is essential to make sure that the LEDs on the

status display are aligned vertically and the "Dräger" logo

on the splash guard is aligned horizontally. A maximum

deviation of ±10 degrees from the horizontal position is

permissible. Greater deviations will increase the response

time (see Instructions for Use for the PIR 7000/7200).

z Observe the preferred position: The PIR 7000/7200 must

be aligned so that the lights on the status display are above

one another. At the same time, the "Dräger" lettering on the

splash guard must read horizontally. A deviation from the

horizontal of ±10° maximum is permissible.

1

00333300.eps

z Any other alignment is only permissible if the PIR 7000/

7200 is used without a splash guard, e.g. applications in

exhaust ducts. When the sensor is fitted in an exhaust duct,

there is an increased risk that residues will form on the

optical surfaces.

z The housing is weather resistant and suitable for outdoor

applications. The use of the optional splash guard is

recommended to protect the sensor from water and dust.

z The device must be installed and operated in an

environment which conforms to the stated specifications

(see chapter 13 on page 32).

z To insure proper operation of the device, the impedance of

the 4 to 20 mA signal loop must not exceed 500 ohms.

Depending on the operating voltage and according to the

application (e.g. HART operation), certain minimum

impedances must be adhered to (see chapter 3.3 on

page 8). The conductors for the power supply must have

an adequately low resistance to insure the correct supply

voltage at the device.

Dräger Polytron 8700/8720 7

Page 8

Installation

01133300.eps

VDC

+

-

mA

01033300.eps

VDC

+

-

mA

NOTICE

i

i

A dust cap can be fitted to the cable entry of the device.

This cap is only used for transport purposes and must

be removed before the device is connected to a sealed

conduit.

3.3 Impedance range of the signal loop

Devices with a HART interface can be operated with HART

communication or in HART Multidrop mode.

Operating mode

Operation

without HART

communication

Operation with

HART

communication

(HART mode)

HART Multidrop

operation

Impedance range of the

signal loop

0 to 230 Ω at 10 V DC

Rising linearly with the

supply voltage from:

0 to 230 Ω at 10 V to

0 to 500 Ω at 16 V

0 to 500 Ω 18 to 30 V DC

230 to 270 Ω at 13 V DC

Rising linearly with the

supply voltage from:

230 to 270 Ω at 11 V to

230 to 500 Ω at 16 V

230 to 500 Ω 18 to 30 V DC

230 to 500 Ω 10 to 30 V DC

Supply

voltage range

10 to 18 V DC

11 to 16 V DC

3.5 Electrical installation without e-Box

CAUTION

!

First connect the cables for the relays and make

the connections to the sensor before connecting the

device to the power supply.

Connection diagram for operation as a current source

Connection diagram for operation as a current sink

3.4 Mechanical installation

z Use the supplied drilling template for mounting on a wall.

z The mounting surface should be even and free of

sharp edges.

z Dräger recommends using M6 Allen bolts.

z Take care that the conditions at the mounting location do

not result in the gas feed openings of the PIR 7000/7200

being covered or obstructed.

z The openings must be readily accessible to the

surrounding atmosphere.

NOTICE

i

i

There must be a free space of 5 cm next to the

PIR 7000/7200 to permit fitting/removal of the splash

guard and the later fitting of accessories.

To ensure an adequate distance between the

PIR 7000/7200 and the wall, use the mounting

spacer (Order Number 68 12 617).

8 Dräger Polytron 8700/8720

Page 9

Installation

00933300.eps

1

3.5.1 Power and signal cables

1. Release the retaining

screw (1) and unscrew the

housing cover from the

device.

2. Lift the handle and remove

the enclosure with the main

electronics.

3. Connect the device

electrically to ground.

4. Rotate the main electronics

and disconnect the 5-way

plug.

5. Connect the three cables for

the power supply and the

signal to the corresponding

terminals (see following

table of connections for the 5-way plug).

Connections for 5-way plug (power supply and signal):

5-way plug (power supply and signal)

Terminal 1 2 3 4 5

Ident. PWR+ PWR- PWR- 4 to 20 mA signal PE

Function V+ V- V- 4 to 20 mA signal

(Operation as

source or sink)

PE

NOTICE

i

i

For clear and far-ranging detection of a device fault,

an alarm device should be switched by the fault relay.

Connections for 9-way plug (relays):

9-way plug (relays)

Fault relay A2 relay A1 relay

Terminal123456789

Ident. FLTNOFLTCFLTNCA2NOA2CA2NCA1NOA1CA1

(NO = Normally open, NC = Normally closed, C = Common)

3.5.3 Remote sensor

The remote junction box (Order Number 45 44 098 for

stainless steel / Order Number 45 44 099 for aluminum)

permits the installation of the sensors remote from the device

electronics. This installation enables operation of the device in

difficult to access or unfavourable positions (see the

Instructions for Use for the Dräger Polytron 5000 Junction Box

in this respect). The maximum permissible distance between

the Polytron 87X0 and the PIR 7000/7200 is 30 m.

NC

6. For operation without a central controller: connect

Terminal 3 to Terminal 4.

7. Fit the plug back in the socket and tighten the screws.

8. The screen of the cable must only be connected to the

control unit.

9. Insert the main electronics back in the housing.

10. Screw the cover on again and tighten the retaining screw.

3.5.2 Version with relays

WARNING

!

At voltages >30 V AC or >42.4 V DC, the relay cables

must be enclosed in protective tubing, or doubleinsulated cables must be used.

When the relay module is fitted, the wires for the alarm device

are connected to the 9-way plug.

1. Disconnect the 9-way plug on the rear of the main

electronics.

2. Connect the wires for Alarm Relay 1, Alarm Relay 2 and the

Fault relay to the corresponding terminals, (see following

table of connections for the 9-way plug).

3. The relays are energized when the default settings are used

and in the measurement mode. This insures "fail-safe"

operation. The terminal assignments in the connection table

below apply when the default settings are used and in

measuring mode (see chapter 4.6 on page 13).

4. Fit the plug back in the socket and tighten the screws.

5. Fit the enclosed protective cover over the plug and secure

it with cable ties if necessary.

Dräger Polytron 8700/8720 9

Page 10

Installation

00833300.eps

3.6 Electrical installation with e-Box

z Install the e-Box in accordance with the Installation

Instructions for the Polytron 5000/8000 e-Box.

NOTICE

i

i

The e-Box can be pre-installed, wired and closed off

with the supplied cover. As soon as the installation is

ready for commissioning, the device is connected to

the e-Box and put into operation. This prevents the

device from being damaged during the construction

phase.

3.7 Connecting the device to a Dräger control unit

NOTICE

i

i

Information on connection can be found in the

Instructions for Use accompanying the particular

Dräger control unit (e.g. Regard, QuadGard).

Electrical connections to the control unit

z Connect the screen for the wires to the grounding point in

the control unit (e.g., chassis, grounding rail).

3.10 Installing software dongles

The following SW dongles are available for the device:

Datalogger dongle

83 17 618

Sensor test dongle

83 17 619

Diagnostic dongle

83 17 860

Combi-dongle (datalogger and sensor test dongle)

83 23 218

Combi-dongle (datalogger and diagnostic dongle)

83 23 219

Enables the datalogger and the

graphic display of concentrations.

Enables the sensor self test

(for certain versions only)

Enables the sensor self test,

the display of the remaining

sensor activity and the sensor

diagnostic function

(for certain functions only)

3.8 Connecting the device to a PC

The separately available Polytron 5000/8000 IR connection kit

is intended for use with the Polytron 5000/8000 and enables

communication between the Polytron 5000/8000 and a PC.

3.9 PolySoft 8000 PC software (optional)

The PolySoft 8000 PC software is used to display device

information, edit configuration settings and read out from the

measurements memory.

To install a SW dongle:

1. Switch off the power to the unit or declassify the area

according to the local regulations.

2. Release the retaining screw and unscrew the housing

cover from the device.

3. Lift the handle and remove the enclosure with the main

electronics.

4. Insert the dongle in the slot with the Dräger lettering facing

upwards.

5. Insert the main electronics back in the housing.

6. Screw the cover on again and tighten the retaining screw.

The dongle is installed.

7. Switch on the power.

10 Dräger Polytron 8700/8720

Page 11

Operation

M

OK

M

OK

M

OK

OK

OK

4 Operation

4.1 Operating fundamentals

4.1.1 Menu navigation

00733300.eps

It is possible to scroll throught he menu items by tapping the

and symbols with the magnetic wand (Part Number

4544101, blue). confirms a function.

NOTICE

i

i

The housing cover should be fitted when using the

magnetic wand. If the housing cover is not fitted,

the magnetic wand might activate two or more buttons

at the same time (crosstalk).

List closed below / complete

There are no further functions, menus or sub-menus

listed below.

List can be scrolled downwards

There are further functions, menus or sub-menus

listed below.

Next

Perform context-related action.

3/3

Number / total number of steps (screens) within

the function.

2/2

Entry

Enter data with » « and » «.

M

4.1.2 Changing parameter values or the parameter status

1. Select the desired menu item with and .

2. Confirm the menu item with .

The current value or status will be displayed.

3. Using and , the value of a numerical parameter can

be changed or preset values can be selected.

4. As soon as the desired value or the selection is displayed,

tap to validate/confirm the new parameter.

5. Tap to access the next higher level.

z If exiting using Back to menu or Previous, all changes will

be discarded.

4.1.3 Exiting menus

z Ta p Back to measurement and to exit the menu.

4.2 Display and LEDs

In measurement mode, the current gas concentration,

the name of the gas and the measurement units are shown on

the display. The green LED lights.

Graphic symbols facilitate navigation in the various menus.

Together with the text » Back «, » Menu «, etc., exit the

menu or go back 1 step.

Closed folder

Further functions or sub-menus are located under

this item.

Opened folder

The functions and sub-menus available here are listed

under this item.

Function

When activated, functions can be executed in one or

more steps.

Selection activated

For functions that can be selected and activated,

the activation is initiated by pressing » «.

OK

List closed above / complete

There are no further functions, menus or sub-menus

listed above.

List can be scrolled upwards

There are further functions, menus or sub-menus

listed above.

In addition, the following symbols may be displayed:

z " ", if the measurement range is exceeded

z " - - - - " and " X " in the event of a malfunction. The yellow

LED lights, (see chapter 4.2.2 on page 12).

z "SIL", when SIL status is activated.

When the optional relay PCB is used:

z If the first alarm has been triggered, the red LED gives

single flashes.

z If the second alarm has been triggered, the red LED gives

double flashes.

Dräger Polytron 8700/8720 11

Page 12

Operation

M

OK

4.2.1 Special symbols

The following special symbols, which indicate the device state,

may be displayed on the right hand side in measurement

mode.

Warning message present – to display warnings,

see chapter 7.1.1 on page 17.

Information can be called up in Info mode, see chapter 4.3

on page 12.

Error message present – to display the error,

see chapter 7.1.2 on page 17

Maintenance signal will be output on the interface,

see chapter 8.3.2 on page 21.

Measurement range of analog interface exceeded

Measurement less than range of analog interface

Analog interface is set to a fixed value (e.g. Multidrop HART

communication) and is not transmitting any measurements.

"Preventive" maintenance: The sensor is ready for operation.

"Preventive" maintenance: The sensor is ready for operation

but is close to the end of its life cycle.

"Preventive" maintenance: The sensor is still ready for

operation but should be changed as soon as possible.

The datalogger is active in rolling mode.

To activate/deactivate, see chapter 8.5.2 on page 25.

The datalogger is active in stacking mode.

To activate/deactivate, see chapter 8.5.2 on page 25.

SIL

SIL is activated (observe Safety Manual - Order Number

9033307).

4.2.2 LED symbols

Symbol LED Description

red Alarm triggered

yellow Malfunction / Warning

green

Switched on

Measurement mode

NOTICE

i

i

The alarm triggering function is only available when

the optionally integrated relay module is used.

When the optional relay PCB is used:

z If the first alarm has been triggered, the red LED gives

single flashes. A1 relay is activated.

z If the second alarm has been triggered, the red LED gives

double flashes. A2 relay is activated.

z If an alarm can be acknowledged and is acknowledged,

the LED stops flashing and lights continuously instead until

the alarm condition is no longer present. The corresponding

relay is deactivated.

4.3 Activating the Info mode

The Info mode is used to present information about the central

device settings and states.

z Tap and hold for 3 seconds.

The device information appears on several displays.

No changes can be made.

z Tap or briefly to switch between the displays.

z The Info mode can be ended at any time by selecting .

z If no button is selected within 30 seconds, the device

reverts automatically to the measurement mode.

Example of the Info mode

(Displays vary depending on sensor):

1. Display - Device information:

07.11.2003 12:34

SW Version

Part No.

Serial No.

DeviceCode: 00006317

Instrument Info

z Date and Time

z Software version

z Part number of the device

z Serial number of the device

z Device code

2. Display - Sensor information:

Sensorname: O

Part No. : 6809630

Serial No.

EEPROM Typ

EEPROM Vers.: 1

Sensor Info

z Sensor description

z Part number of sensor

z Serial number of the sensor

z Software version

z Software revision

3. Display - Sensor configuration:

Gasname : O

Range : 25.00 Vo

4–20 SP

Alarm A1

Alarm A2

Sensor Config.

z Gas description

z Maximum measurement limit and measurement units for

the sensor

z Measurement range and measurement units for the analog

interface. Only displayed when the 4-20 mA interface is

enabled.

: 1

: 8317778

: ARUA0001

2

: XXXXXXX

: 1

2

: 25.00 Vo

: 19.00 Vo

: 23.00 Vo

1/3

A001.eps

2/3

A002.eps

3/3

A003.eps

12 Dräger Polytron 8700/8720

Page 13

Operation

M

M

z A1 Alarm limit and measurement units

z A2 Alarm limit and measurement units

1

1

4.4 Switching to the Quick Menu mode

z Tap and hold for 1 to 2 seconds.

The Quick Menu will open. This menu is displayed without

any password request. No changes can be made.

The selected information about status and device settings

can be retrieved (e.g. warning messages, error messages,

installed modules and calibration data).

4.5 Switching to Menu mode (password protected)

1. Tap and hold for longer than 3 seconds.

The password request will be displayed.

2. Enter the password and confirm.

The screen for password entry will be displayed.

3. Set the password and confirm the entry.

The menu hierarchy corresponding to the entered password

will open.

z An error message will be displayed if the entered password

is invalid.

Password presets:

Password for the Calibration menu: _ _ _ 1

Password for the Settings menu: _ _ _ 2

4.6.1 Analog signals

In measurement mode the output current of the device is

between 4 and 20 mA and is proportional to the measured gas

concentration.

The device uses various current values to indicate different

operating modes. This conforms to the NAMUR NE43

recommendation. The 4-20 mA interface on the device can be

customized and configured to individual requirements.

The device is provided with suitable standard settings at the

factory (see chapter 13.3 on page 33).

4.6 Measurement mode

WARNING

!

The configuration and calibration settings must be

checked before the device is operated in measurement

mode.

z Switch on the power.

{ The device runs through a start-up sequence (LCD test

by inverting the video, LED test, software version and

initialization) and starts the warm-up phase. The display

indicates that the sensor is ready to start in hh:mm:ss

(the countdown begins) and the Polytron 87X0 sends

the Maintenance signal.

{ After the warm-up phase, the device passes into the

measurement mode.

{ The current gas concentration, the selected gas and

the units of measure appear on the display.

{ The LED lights green.

NOTICE

i

i

The correct date and time settings are important for

many functions (see chapter 8.2.3 on page 20).

1 Only displayed when relay is configured.

Dräger Polytron 8700/8720 13

Page 14

Calibration

5 Calibration

Repeat the calibration of the device at regular intervals as

specified in the particular sensor data sheet.

CAUTION

!

Danger to health! Do not inhale the test gas. Observe

the hazard information in the corresponding safety

data sheets. Provide venting into a fume cupboard or

outside the building.

Always calibrate the zero point first before the

sensitivity. Otherwise the calibration will be faulty!

NOTICE

i

i

Calibration is not possible if the date and time are not

set (see chapter 8.2.3 on page 20).

5.1 Calibrating the device

NOTICE

i

i

To perform a zero point or span calibration of the

Polytron 87X0 with a PIR 7000/7200, the PIR 7000/

7200 must be adequately warmed up. Dräger

recommends performing a calibration no sooner

than 3 hours after the device is switched on. For

a calibration, use the splash guard (Order Number:

68 11 911/68 11 912) and the calibration adapter

(Order Number: 68 11 610) (does not apply for duct

mounting or when the process cuvette / process

adapter is used) Observe the installation instructions

for the PIR 7000/7200 accessories.

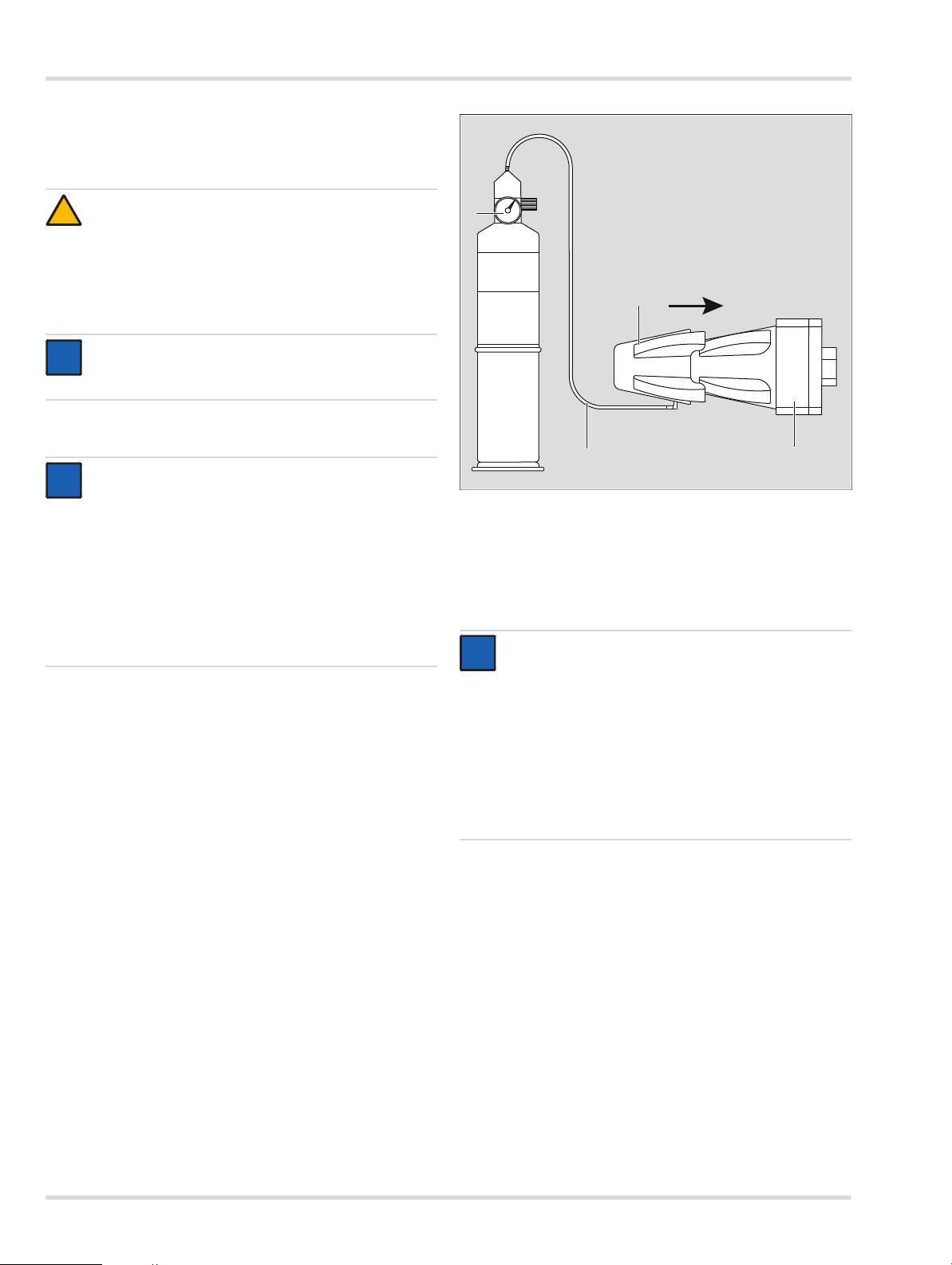

1. Connect the pressure reducer to the calibration gas cylinder.

2. Attach the calibration adapter to the sensor.

3. The gas flow should be between 0.5 and 2.0 l/min.

4. Connect the hose to the calibration adapter.

2

4

1

3

1 Test gas cylinder

2 Pressure reducer

3Hose

4 Calibration adapter

5.1.1 Zero point calibration

NOTICE

i

i

Ambient air can also be used instead of nitrogen or

synthetic air to zero the sensor, provided it is insured

that the ambient air contains no measured gas or any

other gas for which the sensor may exhibit crosssensitivity (see the details in the sensor data sheet).

In this case, neither a gas cylinder nor a calibration

adapter is required for the zero point calibration.

PIR 7000

00433300.eps

For the Polytron 8720 (with PIR 7200 to detect carbon

dioxide), only nitrogen or synthetic air without any CO

content may be used for a zero point calibration.

1. Select Calibration > Zero Calibration and confirm.

The Maintenance signal is transmitted.

The message Apply zero gas is displayed.

2. Connect zero gas (synthetic air or nitrogen) to the sensor.

3. Select Next and confirm.

The current value is displayed.

After the displayed value is stable:

4. Select Calibrate and confirm.

The message Please wait… is displayed.

The actual value is displayed.

14 Dräger Polytron 8700/8720

2

Page 15

Calibration

z Actual value within the permissible range:

{ Select Next and confirm.

{ Shut off the test gas and remove the calibration adapter

from the PIR 7000/7200.

z Actual value outside the permissible range:

{ Select Next and confirm.

{ Wait until the measurement is stable.

5.1.2 Span calibration

1. Select Calibration > Span calibration and confirm.

The Maintenance signal is transmitted.

The values for the calibration gas are displayed, e.g.:

Gas Methane

Unit %LEL

Conc. 50.0

All three paramrters can be changed:

z Select Gas and confirm.

{ Select the desired calibration gas from the list and

confirm.

z Select Unit and confirm.

{ Select the desired unit from the list and confirm.

z Select Conc. and confirm.

{ Set the desired concentration of the calibration gas.

When the settings are correct:

2. Select Next and confirm.

A message such as, e.g. Gas flow to METHANE

is displayed.

3. Connect the calibration gas to the sensor.

4. Select Next and confirm.

The current value is displayed.

After the displayed value is stable:

5. Select Next and confirm.

The message Please wait… is displayed.

The actual value is displayed.

z Actual value within the permissible range:

{ Select Next and confirm.

{ Shut off the test gas and remove the calibration adapter

from the PIR 7000/7200.

z Actual value outside the permissible range:

{ Select Next and confirm.

{ Wait until the measurement is stable.

z A calibration can be aborted at any time.

5.2 Performing Auto Calibration

The device offers the option of an automatically sequenced

calibration. This reduces the number of otherwise manual

interactions with the device. The auto calibration is only

suitable for experienced users, as calibration errors can occur

here as a result of tightened procedures.

NOTICE

i

i

Not all of the available sensors and gases support auto

calibration. If the function is not available, a manual

calibration must be performed.

1. Select Settings > Sensor > Autocal. set. to enable or

disable the function.

2. Supply fresh air or feed nitrogen or compressed air at

a flow rate of 0.5 - 2.0 L/min to the sensor.

WARNING

!

It must be insured that during the zero point calibration,

no measured gas is present in the supplied calibration

gas. Particularly with a fresh air calibration, Dräger

recommends performing a second, independent

measurement. Some sensors may only be calibrated

with synthetic air or nitrogen (observe the relevant

sensor data sheets).

3. Select Calibration > Auto cal. and confirm.

{ Please wait... is displayed and a calibration of the zero

point is performed automatically.

{ After a successful zero point calibration, the span

calibration is started.

{ The calibration gas concentration, the units and, where

appropriate, the calibration gas are displayed and can

be changed.

4. Start the calibration with Next; Back to menu aborts the

calibration.

NOTICE

i

i

After 10 minutes without confirmation, the device

reverts to measurement mode without performing

a calibration.

5. Feed the relevant calibration gas to the sensor at a flow

rate of 0.5 - 2.0 L/min.

{ When the measured value is stable, the device performs

the calibration automatically.

{ After a successful calibration, the measurement and

the message Value OK? are displayed.

6. When the measurement is stable, shut off the calibration

gas and wait until the measurement is below any possible

alarm thresholds again.

z The calibration is performed again with Redo.

z Complete the calibration with Accept value.

The device returns to the measurement mode.

Dräger Polytron 8700/8720 15

Page 16

Menu overview

6 Menu overview

Back to

◄

measure

Information page 17 Instrument page 17

Sensor page 17

Calibration page 14 Data logger page 17

Settings page 18

Zero calibration page 14

Span calibration page 15

Auto CAL page 15

SIL activation page 18

Instrument page 18

Communication page 21

Sensor page 24

Data logger

Datalogr. on/off

Set Datalogger

Clear datalogr

Sample time

Peak/Average

Trigger on/off

Trigger value

Stack/Roll

Warnings

Faults

Device codes

Modules

Last cal. date

Next cal. date

Logger status

Graph

Alarm

Passwords

Date and time

Language

Function key

Device init

SW dongle

Display

HART interface

Analog interface

Profibus address

Auto CAL

Sensortest

Sensor lock

Sensor type

Gas settings

Reset sensor

required!

Cal. interval

Set Sensortest

Fast response

page 17

page 17

page 17

page 17

page 17

page 17

page 17

page 17

page 18

page 20

page 20

page 20

page 20

page 20

page 20

page 20

page 21

page 21

page 23

page 24

page 24

page 23

page 23

page 23

page 23

page 23

page 23

page 23

Alarm on/off

Relay A1

Relay A2

Alarm A1

Alarm A2

Set alarm A1

Set alarm A2

Set fault

Calibration PWD

Settings PWD

Display contrast

Operating mode

Display test

Polling address

Unique identifier

Tag

Dräger REGARD

Fault current

Warning

Warning interval

Warning current

Maintenance signal

Maintenance current

Beamblock on/off

Beambl. current

Analog offset

Set current

Set concentr.

Set fault

Set warning

Set mainten.

Set beamblock

page 18

page 18

page 18

page 18

page 19

page 19

page 19

page 19

page 20

page 20

page 20

page 20

page 21

page 21

page 21

page 21

page 21

page 21

page 21

page 21

page 22

page 22

page 22

page 22

page 22

page 22

page 23

page 23

page 23

page 23

page 23

page 23

16 Dräger Polytron 8700/8720

Page 17

Information menu

OK

7 Information menu

Specific data about the device, the sensor used and the

measured gas are summarized in this menu. The menu can be

accessed without a password. Changes to the data are not

possible.

7.1 Device settings

7.1.1 Displaying warning messages

To display warnings in plain text with warning numbers,

see chapter 9 on page 27.

The symbol is displayed when there is a warning present.

z Select Information > Instrument > Warnings and confirm.

Warnings are displayed in plain text.

If several warnings are present, this is indicated in the upper

right-hand corner of the display, e.g., 1/3 = Screen 1 of 3.

7.1.2 displaying fault messages

To display faults present in plain text with fault numbers,

see chapter 9 on page 27.

The symbol is displayed when there is a fault present.

z Select Information > Instrument > Faults and confirm.

Faults are displayed in plain text.

If several faults are present, this is indicated in the upper

right-hand corner of the display, e.g., 1/2 = Screen 1 of 2.

7.1.3 Displaying device codes

Display of codes for faults/warnings in a numerical table

(hexadecimal).

The symbol is displayed when there is a fault present.

z Select Information > Instrument > Device codes and

confirm.

Faults are displayed as a hexadecimal numerical code in

tabular form. If all the numerical groups are displayed as 00,

there are no faults or warnings present.

7.2 Sensor information

This menu contains the functions for retrieving the calibration

data.

7.2.1 Display last calibration date

Display the date of the last calibration.

z Select Information > Sensor > Last cal. date and confirm.

The date of the last calibration is displayed

7.2.2 Display next calibration date

Display the date of the next calibration.

z Select Information > Sensor > Next cal. date and confirm.

The date when the next calibration of the sensor is due is

displayed.

7.3 Datalogger information (only with

data dongle)

This menu contains the functions for querying the datalogger.

7.3.1 Displaying the datalogger status

z Select Information > Datalogger > Logger status

and confirm.

The current status of the datalogger is displayed: Datalogr. :

on or off (datalogger on or off)

z To switch the datalogger on/off, see chapter 8.5.1 on

page 25.

7.3.2 Displaying a graph of measured values

Show the measurements from the sensor on a 15-minute

time axis.

z Select Information > Datalogger > Graph and confirm.

NOTICE

i

i

The fault code is very helpful for technical support and

should always be stated in full in the event of a fault.

7.1.4 Displaying installed modules

Display of the installed hardware modules.

z Select Information > Instrument > Modules and confirm.

A list of all possible modules is displayed. The installed

modules are identified by a , those not installed by a .

z Mark a module and request detailed information with .

Dräger Polytron 8700/8720 17

Page 18

Settings menu

8 Settings menu

This menu contains all the functions that are required for the

individual configuration of the device.

8.1 Switching SIL lock on or off

NOTICE

i

i

SIL lock is only available for certain sensors (see also

the sensor data sheets or the Dräger Polytron 8X00

Safety Manual).

With this function, the device can be protected against

unauthorized changes to the configuration with a password.

Changing the configuration (e.g., changing the measurement

range from 100 %LEL to 50 %LEL) will cause the device to

display all the safety-relevant parameters to the user once

more before it returns to the measurement mode. The

correctness of the parameters and settings must be confirmed.

1. Select Settings > Instrument > Set SIL.

2. Select the desired state On or Off and confirm.

NOTICE

i

i

When SIL is activated, the device displays all the

important parameters and setting before returning to

measurement mode. Check the parameters and

settings carefully and confirm.

8.2 Device settings

8.2.1 Alarm settings (only with installed relay module)

Alarms issued via relays and LEDs.

CAUTION

!

In the normal state, the relays in the relay module are

energized. That is, the relays change their state if the

power supply is interrupted!

Switching the alarm on or off

1. Select Settings > Instrument > Alarm > Alarm on/off.

2. Select the desired state On or Off and confirm.

CAUTION

!

If the alarm is inactive, the alarm state will not be

issued by the LEDs or the relay interface! A warning

message will be shown on the display!

Configuring Relay A1 or A2

This function is used to define whether the alarm relay is

energized in standard operation or in an alarm state. If the

configuration of the relay is set to "Normally energized", the

corresponding relay contact is closed in the normal case and

drops out in the event of an alarm. This configuration results in

an alarm being triggered in the event of a loss of power to the

transmitter (fail-safe). The fault relay is factory-configured to

"Normally energized" and cannot be changed.

1. Select Settings > Instrument > Alarm > Relay A1 or

Relay A2 and confirm.

2. Select Normal energy supply oder Energy supply

during alarm and confirm.

Configuring Alarm A1 or A2

1. Select Settings > Instrument > Alarm > Alarm A1 or

Alarm A2 and confirm.

2. Select the line for entering the alarm limit and confirm.

3. Set the threshold and confirm.

The setting for the alarm threshold is displayed.

4. Select Next and confirm.

The setting for the alarm direction is displayed.

5. Select Rising or Falling and confirm.

6. Select Next and confirm.

The setting for the alarm direction is displayed.

7. Select Latching or Non Latching and confirm.

8. Select Next and confirm.

The setting for the acknowledgement is displayed.

9. Select Acknowledgeable or NonAcknowledgeabl or

PreAcknowledgeabl and confirm.

10. Select Next and confirm.

The functional relationship between the various settings is

explained in the following table:

Latching and

acknowledgeable

Latching and not

acknowledgeable

Latching and preacknowledgeable

Non-latching and

acknowledgeable

Non-latching and not

acknowledgeable

Non-latching and preacknowledgeable

The alarm must be acknowledged

manually. The alarm can be

acknowledged when the alarm

condition is still present.

The alarm must be acknowledged

manually. The alarm can only be

acknowledged when the alarm

condition is no longer present.

The alarm must be acknowledged

manually. The alarm can be

acknowledged when the alarm

condition is still present but will only

be reset when the alarm condition is

no longer present.

The alarm is acknowledged

automatically when there is no longer

any alarm condition present, or it can

be acknowledged manually.

The alarm is acknowledged

automatically when there is no longer

any alarm condition present.

The alarm cannot be acknowledged

manually.

Corresponds to the alarm behavior

for "Non-latching" and "Not

acknowledgeable".

18 Dräger Polytron 8700/8720

Page 19

Settings menu

Overview of standard alarm settings (for Polytron 8700

with PIR 7000, configured for methane, full scale reading

of 100 %LEL)

A1/Relay 1 A2/Relay 2

Alarm threshold 20 %LEL 40 %LEL

Hysteresis 0 %LEL 0 %LEL

Relay Normally

Relay alarm:

Direction

Latching mode Non-latching Latching

Acknowledgement

mode

The function for setting the A1 hysteresis is opened.

This function permits the setting of a zone within which

a triggered relay maintains its status until the gas concentration

is outside the zone. This function prevents relays from

chattering at an alarm threshold.

Example: A2 at 40 %LEL methane

Maximum possible hysteresis: 3 %LEL

Alarm activation at measured values ≥40 %LEL

Alarm deactivation at measured values ≤37 %LEL (40 %LEL 3 %LEL)

energized

Rising Rising

Acknowledgeable Not

Normally

energized

acknowledgeable

1. Select Settings > Instrument > Alarm > Set Alarm A2

and confirm.

2. Select On or Off and confirm.

When the function is activated, the relay and the interface are

set to the A2 alarm status and the red LED gives double flashes.

Testing Fault status

NOTICE

i

i

When the function Set fault is exited in the menu,

the Polytron 87X0 reverts automatically to measurement

mode.

This function simulates the Fault alarm.

1. Select Settings > Instrument > Alarm > Set fault

and confirm.

2. Select On or Off and confirm.

When the function is activated, the Fault relay and the 4-20 mA

interface are set to the fault current and the yellow LED lights.

11. Select the line for entering the hysteresis and confirm.

12. Set the hysteresis for A1 and confirm.

The hysteresis setting for A1 is displayed.

13. Select Next and confirm.

The settings for A1 are displayed.

14. Select and confirm with Confirm.

The settings for the A1 alarm are now complete.

Testing Alarm A1

NOTICE

i

i

When the function Set Alarm A1 is exited in the menu,

the Polytron 87X0 reverts automatically to measurement

mode.

This function simulates the A1 alarm status.

1. Select Settings > Instrument > Alarm > Set Alarm A1

and confirm.

2. Select On or Off and confirm.

When the function is activated, the relay and the interface are

set to the A1 alarm status and the red LED gives single flashes.

Testing Alarm A2

NOTICE

i

i

When the function Set Alarm A2 is exited in the menu,

the Polytron 87X0 reverts automatically to measurement

mode.

This function simulates the A2 alarm status.

Dräger Polytron 8700/8720 19

Page 20

Settings menu

OK

8.2.2 Changing passwords

The passwords for calibration (zero and span calibrations) and

for the settings (full configuration) can be defined in this menu.

1. Select Settings > Instrument > Passwords > Calibration/

Settings PWD and confirm.

2. Select the line for the password settings and confirm.

3. Set the password and confirm.

The setting for the password is displayed.

4. Select Confirm and confirm.

8.2.3 Setting the date and time

1. Select Settings > Instrument > Date and time and confirm.

2. Select the desired line and confirm in order to switch to the

Change mode.

3. Set each digit and confirm each setting.

4. Select Confirm and confirm.

8.2.4 Changing the display language

1. Select Settings > Instrument > Language and confirm.

2. Select the desired language from the list and confirm.

8.2.5 Configuring the function key

This function is used to assign a predefined function to the

key. The selected function is activated by briefly taping the

key.

8.2.6 Resetting the device to factory settings

The following device parameters are reset to the factory

settings with this function (see chapter 13.3 on page 33).

z Alarm parameters

z Passwords

z Language

z Function key

z HART interface

z Data logger

z Analog interface

z Relay configuration

1. Select Settings > Instrument > Device init. and confirm.

2. Select Confirm and confirm in order to reset the device to

the factory settings.

8.2.7 Deactivating the software dongle

This function allows the SW dongles to be deactivated before

they are removed or in the event of a fault.

A dongle can only be reactivated by switching the power to the

device off and on.

1. Select Settings > Instrument > SW dongle > Dongle

datalogger/Dongle sensortest/Dongle diagnostic and

confirm.

2. Select Deactivate func. and deactivate Dongle datalogger/

Dongle sensortest/Dongle diagnostic with .

1. Select Settings > Instrument > Function key and confirm.

2. Select the desired function and confirm.

z Repeating the confirmation deactivates the selected

function.

z If Bumptest is selected:

The maintenance symbol is shown on the right hand

side of the display and the maintenance signal is output.

Repeating the confirmation ends the bump test and the

device reverts to the normal measurement mode.

z In measurement mode, the selected function can be

activated by briefly pressing .

Selection options:

Graph (only with

data logging)

The measurements from the sensor

are displayed graphically on a time axis

(see chapter 7.3.2 on page 17).

Faults Faults are displayed in plain text

(see chapter 7.1.2 on page 17).

Warnings Warnings are displayed in plain text

(see chapter 7.1.1 on page 17).

Bump test The bump test allows gas to be applied

without an alarm being issued. The

maintenance signal is output on the

4-20 mA output.

Sensor vitality Shows the remaining sensor vitality

(only available for certain sensors).

8.2.8 Display settings

Changing the contrast

1. Select Settings > Instrument > Display > Display contrast

and confirm.

2. Change the contrast and confirm.

Changing the display mode

The display of measured values can be turned on or off with

this function.

1. Select Settings > Instrument > Display > Display mode

and confirm.

2. Select Standard or Non display and confirm.

If "Non display" has been selected, the display shows the start

screen and the symbols.

If the relay option is set and an alarm is triggered, the display

shows the current gas concentration and the red LED flashes,

regardless of the selected display mode.

20 Dräger Polytron 8700/8720

Page 21

Settings menu

Switching the display test on or off

The function of the display and the LEDs is tested with

this function.

1. Select Settings > Instrument > Display > Displaytest

and confirm.

2. Select On or Off and confirm.

When this function is activated, the display is shown inverted

and all the LEDs are lit.

8.3 Communication settings

8.3.1 Settings for the HART interface (only for devices with the optional HART interface)

This group contains the setting functions for the HART interface.

Setting the polling address

The polling address configures the device for analog operation

(4 to 20 mA) or multidrop operation. Analog operation (4 to

20 mA) is activated by setting the polling address to 0.

For multidrop operation the polling address must be

configured to a value between 1 and 15, which will result in the

analog interface being deactivated and set to a constant

current of approx. 1 mA. To allow the control unit to request the

Unique Identifier (unique HART address) with HART command

#0, all the devices on a line must be configured with different

polling addresses. It is advisable to choose a sequence

starting with 1 and incrementing continuously.

This setting corresponds to HART command #6 (Write Polling

Address).

1. Select Settings > Communication > HART interface >

Polling address and confirm.

2. Select the address line for the entry and confirm in order to

switch to the Change mode.

3. Set the polling address and confirm.

4. Select Confirm and confirm.

Displaying the Unique Identifier

This function enables reading of the Unique Identifier (unique

HART address), which has to be known for almost all the

HART addressing commands. However this information is only

required for those systems that are not able to read back the

Unique Identifier using HART command #0 in Short-Frame

Format or HART command #11. The display corresponds to

the address for HART command #0 (Read Unique Identifier) or

#11 (Read Unique Identifier associated with Tag).

z Select Settings > Communication > HART interface >

Unique Identifier and confirm.

The Unique Identifier is displayed.

Changing the measuring point name

The tag can be used to identify special devices. It can contain

up to 8 alphanumeric characters. The tag can also function as

an address for reading the unique identifier from the device

using HART command #11 (Read Unique Identifier Associated

With Tag), even when the polling address is unknown.

This requires that a unique tag has previously been configured.

1. Select Settings > Communication > HART interface >

Tag and confirm.

2. Select the tag line for the entry and confirm.

3. Set the tag and confirm.

4. Select Confirm and confirm.

Selecting Dräger REGARD

This function enables switching between different HART

protocols.

NOTICE

i

i

REGARD SW 2.0 is the standard setting. REGARD

SW 1.4 must be set on REGARD controllers with

SW 1.4.

1. Select Settings > Communication > HART interface >

Dräger REGARD and confirm.

2. Select REGARD SW 2.0 or REGARD SW 1.4 and confirm.

8.3.2 Settings for the analog interface

The test and setting functions for the analog interface are

summarized in this menu.

Setting the fault current

This function is used to define the current for the fault signal on

the analog interface.

1. Select Settings > Communication > Analog interface >

Fault current and confirm.

2. Select the fault current line and confirm.

3. Set the currrent and confirm.

4. Select Confirm and confirm.

Switching the warning signal on or off

This function is used to switch the warning signal on the analog

interface on and off. If an existing warning is to be output over

the analog interface, the warning signal must be turned on.

During a warning, the current on the analog interface is

switched to the "Warning" status for one second.

The measurement is transmitted for the rest of the time.

The interval between warning signals and the analog signal

phase can be customized.

To switch the warning signal on or off:

1. Select Settings > Communication > Analog interface >

Warning and confirm.

2. Select On or Off and confirm.

Setting the warning interval

This function is used to set the interval between the warning

signals and the analog interface.

1. Select Settings > Communication > Analog interface >

Warning interval and confirm.

2. Select line T1 for the entry and confirm.

3. Set the time and confirm.

The setting for Time T1 is displayed.

4. Select Next and confirm.

5. Select line T2 for the entry and confirm.

6. Set the time and confirm each setting.

The setting for Time T2 is displayed.

7. Select Confirm and confirm.

Dräger Polytron 8700/8720 21

Page 22

Settings menu

Value

0633300.eps

t

[s]

1,1

[mA]

0,7

5

3

[mA]

20

4

3

T

T

2

1

t

[s]

0533300.eps

Setting the warning current

This function is used to define the current for the warning

signal on the analog interface.

1. Select Settings > Communication > Analog interface >

Warning current and confirm.

2. Select the current line for the entry and confirm.

3. Set the currrent and confirm.

The setting for the warning current is displayed.

4. Select Confirm and confirm.

Changing the maintenance signal type

This function is defines the type of signal used on the analog

interface for the maintenance signal.

1. Select Settings > Communication > Analog interface >

Maint. signal and confirm.

2. Select static or dynamic signal type and bestätigen.

NOTICE

i

i

The static signal type is a constant current. The current

can be configured.

The dynamic signal type is a square wave signal with

the following characteristics:

Setting the maintenance current

This function is used to define the current for the maintenance

signal on the analog interface.

1. Select Settings > Communication > Analog interface >

Maint. current and confirm.

2. Select the current line for the entry and confirm.

3. Set the currrent and confirm.

The setting for the maintenance current is displayed.

4. Select Confirm and confirm.

NOTICE

i

i

The maintenance current can only be set if the

maintenance signal has been set to static. This function

is not available otherwise.

Switching Beam Block on or off (for PIR 7000/7200 only)

If the Beam Block signal is enabled and the optical surfaces of

the PIR 7000 or PIR 7200 are dirty, a Beam Block signal will be

output over the analog output of the transmitter. In the case of

a high and potentially dangerous gas concentration of more

than 15 % LEL (PIR 7000) or 15 % of the full-scale reading

(PIR7200), the device will switch back to the normal measuring

mode. If the contamination on the surfaces increases and

correct measurement is not possible, the device transmits

a fault signal.

1. Select Settings > Communication > Analog interface >

Beamblock on/off and confirm.

2. Select On or Off and confirm.

Setting the beam block current (for PIR 7000/7200 only)

This function is used to define the current for the beam block

signal on the analog interface.

1. Select Settings > Communication > Analog interface >

Beambl. current and confirm.

2. Select the current line for the entry and confirm.

3. Set the currrent and confirm.

The setting for the beam block current is displayed.

4. Select Confirm and confirm.

Setting the 4-20 mA offset

This function can be used to set an adjustable offset current on

the analog interface. The offset is constant over the entire

range of the output signal.

1. Select Settings > Communication > Analog interface >

Analog offset and confirm.

2. Select the current line for the entry (max. range: -0.2 to

1.5 mA) and confirm.

3. Set the currrent and confirm.

The setting for the 4-20 mA offset is displayed.

4. Select Confirm and confirm.

22 Dräger Polytron 8700/8720

Page 23

Settings menu

Test functions for the analog interface

NOTICE

i

i

Alarms in the central controller may be triggered by

these functions! If necessary, the alarms in the central

controller must be disabled beforehand.

Setting current signals

Using this function, various currents in the range from 0 to

22 mA can be set on the analog interface.

1. Select Settings > Communication > Analog interface >

Set current and confirm.

2. If the alarm in the control unit is disabled, confirm the

message Inhibit all alarms.

3. Select the current line for the entry and confirm.

4. Set the currrent and confirm.

The setting for the current is displayed.

5. Select Next and confirm.

6. Select Set current out or Current off and confirm.

7. Select Next and confirm. The function is terminated.

8. After the alarm settings in the control unit have been reenabled, confirm the Enable all alarms message.

Setting the concentration

This function is used to simulate various concentrations in the

range between 0 and 100 % of the selected unit of measure.

The current output is set to correspond to the selected

concentration.

1. Select Settings > Communication > Analog interface >

Set concentr. and confirm.

2. If the alarm in the control unit is disabled, confirm the

message Inhibit all alarms.

3. Select the concentration line for the entry and confirm.

4. Set the concentration and confirm.

The setting for the concentration is displayed.

5. Select Next and confirm.

6. Select Set concentr. or Concentration of and activate.

7. Select Next and confirm. The function is terminated.

8. After the alarm settings in the control unit have been reenabled, confirm the Enable all alarms message.

Testing the maintenance signal

This function is used to set the analog interface to the

maintenance signal.

1. Select Settings > Communication > Analog interface >

Set mainten. and confirm.

Select On or Off and confirm.

2.

{ The current for the maintenance signal will be

transmitted on the analog interface.

Testing the beam block signal (for PIR 7000/7200 only)

This function is used to set the analog interface to the beam

block signal.

1. Select Settings > Communication > Analog interface >

Set beamblock and confirm.

2. Select On or Off and confirm.

{ The current for the beam block signal will be

transmitted on the analog interface.

8.3.3 Profibus address

Not yet active - for future functions.

Testing the Fault signal

This function is used to set the analog interface to the

fault current.

1. Select Settings > Communication > Analog interface >

Set fault and confirm.

2. Select On or Off and confirm.

The current for the Fault signal will be transmitted on the

analog interface.

Testing the warning signal

This function is used to set the analog interface to the

warning signal.

1. Select Settings > Communication > Analog interface >

Set warning and confirm.

2. Select On or Off and confirm.

The current for the warning signal will be transmitted on the

analog interface.

Dräger Polytron 8700/8720 23

Page 24

Settings menu

8.4 Sensor settings

8.4.1 Switching Auto CAL on or off

NOTICE

i

i

The auto-calibration from the Calibration menu is only

available if this function is enabled.

1. Select Settings > Sensor > Set auto calibration and

confirm.

2. Select On or Off and confirm.

8.4.2 Sensor testsettings

NOTICE

i

i

The sensor test settings are only available for certain

sensors.

The setting functions for the sensor self test are summarized

in this group of functions.

8.4.3 Switching the sensor test on or off (for EC

When the sensor self test is enabled, the device continuously

checks the sensor to insure reliable functioning. If the sensor

does not pass the self test, an appropriate warning or fault

indication is issued.

1. Select Settings > Sensor > Sensor test and confirm.

2. Select On or Off and confirm.

8.4.4 Switching the sensor lock on or off (for EC sensors

This function is used to activate or deactivate the sensor

interlock.

1. Select Settings > Sensor > Sensor lock and confirm.

2. Select On or Off and confirm.

sensors only)

and PIR 7000/7200 only)

Standard

setting

On = The device will only accept a new sensor if

Off = The device will also accept other sensor

=Off

the Part Number (= Dräger Order Number),

and hence the sensor type, is identical to

that of the previous sensor.

types and with thus adopt the default

settings for the sensor, i.e., in this case the

configuration of the device will be altered.

8.4.6 Changing the gas settings

Settings for gas type, measuring range and measurement

units can be made in this menu.

1. Select Settings > Sensor > Gas setting and confirm.

2. Select the measured gas from the list and confirm.

The measurement units display will be shown.

3. Select the measurement units and confirm.

The full scale reading display will be shown.

4. Set the full scale reading and confirm.

The setting for the full scale reading is displayed.

5. Select Next and confirm.

an overview of the new gas settings is displayed.

z Return to the previous view with Previous or confirm the

settings with Confirm.

Information about the measured gas

If the PIR 7000/7200 sensor is used, the measured gas can be

selected from many different gases. These substances are

already stored in the PIR 7000/7200 as library substances.

Selecting a library function has the following effects: