Dräger Cato Instructions For Use Manual

Cato edition

Anaesthetic Workstation

Instructions for Use

Software versions:

Ventilator: ...................... 7.n

Monitor: ......................... 2.n

MT-439-2000

D

Working with these Instructions for Use

In the header line...

the subject of the main section

The sub-section title is given underneath the main title to

help you find your way rapidly through the manual.

Page body

Instructions for Use

in text-graphic combination. The information is translated

directly into physical actions that teach the user in practical steps how to use the apparatus.

Left-hand column...

the text

contains explanations and guides the user in the operation of the product with concise, clear and unmistakable

instructions in ergonomic sequence.

The bullets (dots) indicate separate steps, and, when

several steps are described, the numbers indicate details

in the illustrations and also specify the order of action.

Right-hand column...

the illustrations

provide a visual reference for the text and make it easier

to locate the various parts of the equipment. Details

mentioned in the text are highlighted. Irrelevant details are

omitted.

The user is also prompted by screen displays which

confirm the operating sequence.

Working with these Instructions for Use

Manual / Spontaneous

Before connecting a patient

● Check workstation with checklist (see page 21).

– Check that breathing system is complete

(see page 20) and

– perform leakage test (see page 31).

Select Manual / Spontaneous mode

1 Press »MAN/SPONT« on ventilator for at least one

second –

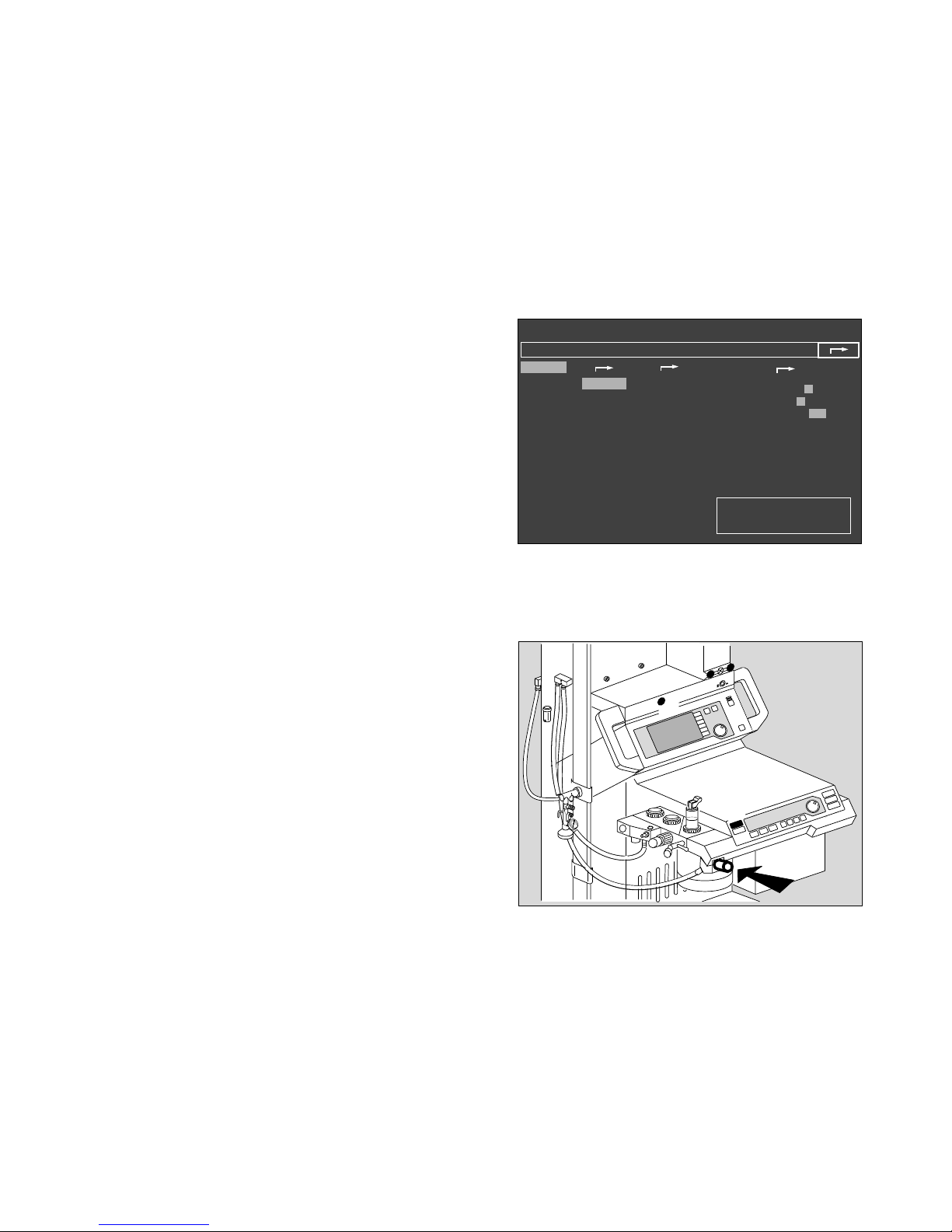

2 Display in dialogue field:

MAN/SPONT

The standard screen appears with the alarm limits

for MAN/SPONT mode.

Spontaneous breathing

»PEEP« and pressure limitation »Pmax« are inactive.

3 Set pressure limiting valve APL to »SPONT«.

It is now open, regardless of the set pressure.

To fill system:

4 Press »O2 +« to inflate the breathing bag rapidly –

5 Set fresh gas –

detailed information on setting the fresh gas flow

can be found in the Annex on page 130.

1

2

Operation

Manual / Spontaneous

Select Manual / Spontaneous mode

Spontaneous breathing

alarm

limits

CO

2

al. off

curve

list

alarm

info

Man./spont. alarm limits

SpO2 98 67

etCO2 38

MV 6.0 freq 10

Fi Fet

O

2

29 25

Hal. 0.8 0.6

N2O 70 68

20

18

V

T

0.35

PAW

0

0

Volumeter 27s

5.5

05

10

0.5

1

Volumeter started.

Re-start: confirm !

40

20

CO

2

40

0

config

.

3

4

5

2

00128971 2402897000137224

3

Contents

Index 143

Contents

For your safety and that of your patients 4

Quick start in an emergency 7

Operating concept 9

Preparing for use 17

Operation 35

Monitor functions 49

Troubleshooting (messages - cause - remedy) 71

Care 79

Check operational readiness 101

What's what 107

Technical data 115

Descriptions 123

Intended use 5

For Your Safety and that of Your

Patients

Strictly follow the Instructions for Use

Any use of the apparatus requires full understanding and

strict observation of these instructions. The apparatus is

only to be used for purposes specified here.

Maintenance

The apparatus must be inspected and serviced regularly

by trained service personnel at six monthly intervals

(and a record kept).

Repair and general overhaul of the apparatus may only be

carried out by trained service personnel.

We recommend that a service contract be obtained with

DrägerService and that all repairs also be carried out by

them. Only authentic Dräger spare parts may be used for

maintenance.

Observe chapter "Maintenance Intervals".

Accessories

Do not use accessory parts other than those in the order

list.

Not for use in areas of explosion hazard

This apparatus is neither approved nor certified for use in

areas where combustible or explosive gas mixtures are

likely to occur.

Safe connection with other electrical equipment

Electrical connections to equipment which is not listed in

these Instructions for Use should only be made following

consultations with the respective manufacturers or an

expert.

Liability for proper function or damage

The liability for the proper function of the apparatus is

irrevocably transferred to the owner or operator to the

extent that the apparatus is serviced or repaired by

personnel not employed or authorized by DrägerService

or if the apparatus is used in a manner not conforming to

its intended use.

Dräger cannot be held responsible for damage caused

by non-compliance with the recommendations given

above. The warranty and liability provisions of the terms

of sale and delivery of Dräger are likewise not modified

by the recommendations given above.

Dräger Medizintechnik GmbH

For Your Safety and that of Your Patients

4

Intended use

Anaesthetic Workstation Cato

Universally applicable anaesthetic workstation for

● Inhalation anaesthesia in semi-closed systems

● Inhalation anaesthesia in virtually closed systems with

»low flow« and »minimal flow« techniques for minimum

gas and anaesthetic consumption, with:

● Inhalation anaesthesia in non-rebreathing systems

with separate fresh gas outlet for connecting e.g.

Kuhn system.

● Automatic ventilation (IPPV)

● Synchronized intermittent mandatory ventilation

(SIMV)

● Manual ventilation (MAN)

● Spontaneous breathing (SPONT)

The workstation must only be used under the

supervision of qualified medical staff, so that help is

available immediately if any faults or malfunctions

occur.

Explosive anaesthetic agents, such as ether or

cyclopropane, must not be used due to the risk of fire!

The equipment cannot distinguish between different

anaesthetics. Dräger cannot accept any liability if the

wrong anaesthetic is used!

Additional electric devices clipped into the top of

the unit must be connected to the base unit via an

equipotential bonding (earthing) conductor.

Do not use mobile phones within a distance of

10 metres from the machine.

Mobile phones can cause interference to electrical and

electronic medical appliances, thereby putting patients at

risk.*

Do not use Cato for nuclear spin tomography.

The functioning of the apparatus may be impaired.

Since this equipment is not approved for use with inflammable anaesthetics (ether, cyclopropane, etc.), it is not

necessary to use antistatic (conductive) breathing hoses

or face masks.

Conductive breathing hoses and face masks may cause

burns during high-frequency surgery and are therefore

not recommended for this equipment.

The workstation should be moved using the handles

only.

* Dräger medical appliances comply with the interference immunity

requirements of the specific standards for the products or

EN 60601-1-2 (IEC 601-1-2). However, depending on the design

of the mobile phone and situation of use, field strengths may occur

in the immediate environment of a mobile phone that exceed the

values of the standards quoted and therefore cause interference.

Measurement and monitoring functions:

● Measurement of the ventilation parameters:

pressure, flow, O2 concentration (inspiratory and

expiratory)

● Continuous measurement of the CO2 concentration

and N2O/anaesthetic concentration (halothane, enflurane, isoflurane, sevoflurane, desflurane). The flow

rate for sampling the measuring gas can be varied

and is returned to the circulation.

● Automatic adjustment of the alarm limits for automatic

ventilation IPPV.

● Anaesthetic vaporizer with automatic Vapor

recognition1).

Optional:

❍ Continuous non-invasive measurement of the

functional O2 saturation.

❍ Measurement of the inspiratory breathing gas

temperature.

❍ Expiratory O2 value.

The following values are indicated:

● Continuous curve for airway pressure, peak and

plateau pressure, mean pressure and PEEP.

● Patient compliance.

● Expiratory minute volume, tidal volume and respiration

rate.

● Expiratory flow curve.

● Inspiratory and expiratory O2 concentration.

● Inspiratory and expiratory concentration of N2O and

anaesthetic halothane, enflurane, isoflurane, sevoflurane and desflurane.

● Inspiratory and end-expiratory CO2 concentration

(inCO2 and etCO2).

● Continuous CO2 curve.

● List entries and trend displays.

Optional:

❍ Functional O2 saturation, pulse rate, plethysmogram.

❍ Inspiratory breathing gas temperature.

❍ Expiratory O2 value.

1) Refer to the separate Instructions for Use for the Vapor!

5

Intended use

Anaesthetic Workstation Cato

The following parameters are monitored:

● Airway pressure.

● Expiratory minute volume.

● Inspiratory O2 concentration.

● Inspiratory and expiratory CO2 concentration.

● Inspiratory anaesthetic concentration.

Optional:

❍ Functional O2 saturation and pulse.

❍ Inspiratory breathing gas temperature with invariable

upper alarm limit.

Accessories

– Patient monitoring

Optional monitor PM 8060 vitara1).

Parameter box for patient monitoring and measurement of the haemodynamic patient values.

● ECG/arrhythmia analysis.

● Pulse rate.

● Respiration.

● Invasive (2 channels) and non-invasive blood

pressure.

● Functional O2 saturation and pulse.

● Body temperature (2 channels).

– Aquapor

1)

for humidifying and heating the breathing gas.

– Secretion aspirator

1)

– Vapor

1)

Anaesthetic vaporiser for halothane, enflurane,

isoflurane and sevoflurane.

– Connection for two "Vapor" anaesthetic vaporisers

1)

– Devapor

1)

Anaesthetic vaporiser for desflurane.

– Anaesthetic gas scavenging system

1)

– Uninterruptible power supply

1)

1) Refer to the separate Instructions for Use for this equipment!

Intended use

Anaesthetic Workstation Cato

Accessories

6

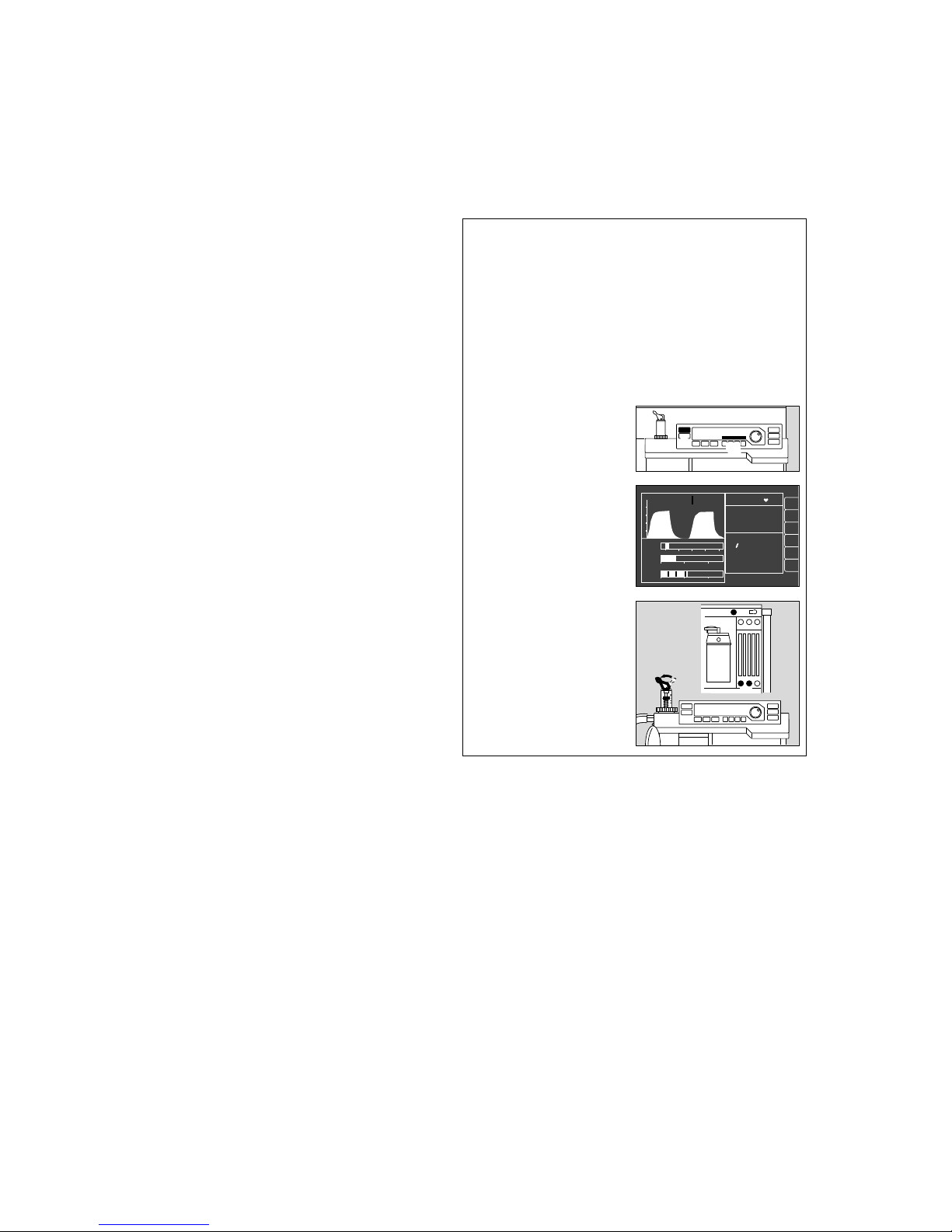

Quick start in an emergency

● Plug the gas connectors into the gas supply wall

sockets.

1 The O2, AIR and N2O pressure gauges must be in

the green range.

● Plug the power plug into the mains.

2 Press the master switch.

All the LEDs on the ventilator light up.

3 Press the key for the desired operating mode on the

ventilator –

Recommendation: hold down M for longer than

1 second.

4 The following message is displayed in the display

window of the ventilator:

Test 3 x discont (example)

Number of times that the self-test has been interrupted for a quick start since it was last completed

successfully.

● Set the selector switch to »N2O« or »AIR«.

5 Deliver fresh gas.

6 Press O2 flush – if necessary –

to fill the system and the breathing bag rapidly.

7 Switch the pressure limiting valve (APL) to »MAN«.

8 Set maximum pressure. Turn the lever of the pressure

limiting valve clockwise until the indicator (plate)

stands at maximum pressure.

No more than ten consecutive quick-starts are allowed

between two complete self-tests. This maximum is only

permitted if the previous completed self-test revealed no

fault.

After the 10th consecutive quick-start, the following

message appears in the ventilator display window:

last cancel

If a further attempt is made to cancel the self-test and carry

out a quick start, the following message is displayed:

COMPLETE TEST

Quick-start not permitted.

A complete self-test must be carried out before startup is possible.

However, in all cases, manual ventilation is always

possible.

Quick-start can be started at any time, even while a selftest is in progress.

D

1

7

8

6

2

5

3

4

3

Cato edition

7

Quick start in an emergency

00237224

Power failure (manual ventilation is still possible)

● The master power switch must be pressed.

The audible power failure warning is muted after

45 seconds.

● Deliver fresh gas and set the pressure limiting valve

(APL). If necessary press the O2 Flush key (»O2 +«).

If there is a power failure, the ventilator piston is

forced back to its end position by the airway

pressure, thereby increasing the system volume

by max. 1.4 litre.

Gas failure

If AIR (medical compressed air) fails

– Cato automatically switches over to O2.

If O2 fails

– Cato automatically switches over to AIR. An audible

warning is emitted (O2 shortage warning). N2O

delivery is blocked:

If O2 and air fail:

Ventilate the patient immediately with the

separate emergency ventilation bag!

Auto-WakeUp

Manual ventilation cannot be performed in standby mode.

Any attempt to perform manual ventilation in standby

mode is detected by the system on account of the

pressure thrust in the breathing bag and it automatically

switches to »MAN/SPONT« mode in which manual

ventilation can then be performed. The background

lighting of the flow measuring tubes goes on at the same

time.

The system is protected against excess static pressures:

The system pressure is relieved automatically if an excess

static pressure of more than 30 mbar is present for more

than 60 seconds.

Dräger recommends that manual ventilation should

always be started by pressing the »MAN/SPONT« key.

8

Quick start in an emergency

Power failure

Gas failure

Auto-WakeUp

[

[

Contents

Page

Operating concept, general ................................................................... 10

Master switch for electricity supply .......................................................... 10

Operating concept of the ventilator ...................................................... 11

Keys with dedicated function ................................................................... 11

Display window without dialogue function ................................................ 12

Display window with dialogue function .................................................... 12

Operating concept of the monitor ......................................................... 13

Keys with dedicated function ................................................................... 13

Displays .................................................................................................. 13

Measured values with grey numerals ....................................................... 13

Screen structure ..................................................................................... 14

Screen saver ........................................................................................... 14

Rotary control.......................................................................................... 14

The various screen displays .................................................................... 16

9

Operating concept

Contents

Operating concept

Operating concept, general

Master switch for electricity supply

Master switch

1 Press to switch on

Dialogue:

Monitor and ventilator feature a dialogue with the user

mediated by:

● keys,

● rotary controls,

● displays and

● beeps.

Basic conditions of the operating state are

established by adjusting the delivery valves

or pressure limitation (e.g. APL valve).

● Keys: For direct command input

● Rotary control:

For selection by ...

... turning

This causes a cursor frame (on the screen)

to be moved or a variable numerical value

(on the display window of the ventilator or

on the screen) to be changed.

... pressing

The value selected with the rotary control

is adopted as a valid parameter or a

process is started or ended.

● Displays: For presenting all information on the

screen and on the display windows of the

ventilator.

● Tone sequences:

As an acoustic supplement to the

messages. They are coupled with certain

sounds or tone sequences, according to

priority classes.

Tone sequences accompanying warnings

are output continuously, every 30 seconds

with caution messages and only once in

conjunction with advisory messages.

These are to draw the user's attention to

the messages which appear simultaneously in the displays.

European Standard EN 740 stipulates use

of EN tones.

Alternatively there are tones in keeping

with Dräger conventions available.

1

Operating concept

Operating concept, general

Master switch for electricity supply

10

IPPV

MAN

SPONT

003372242432897000328970

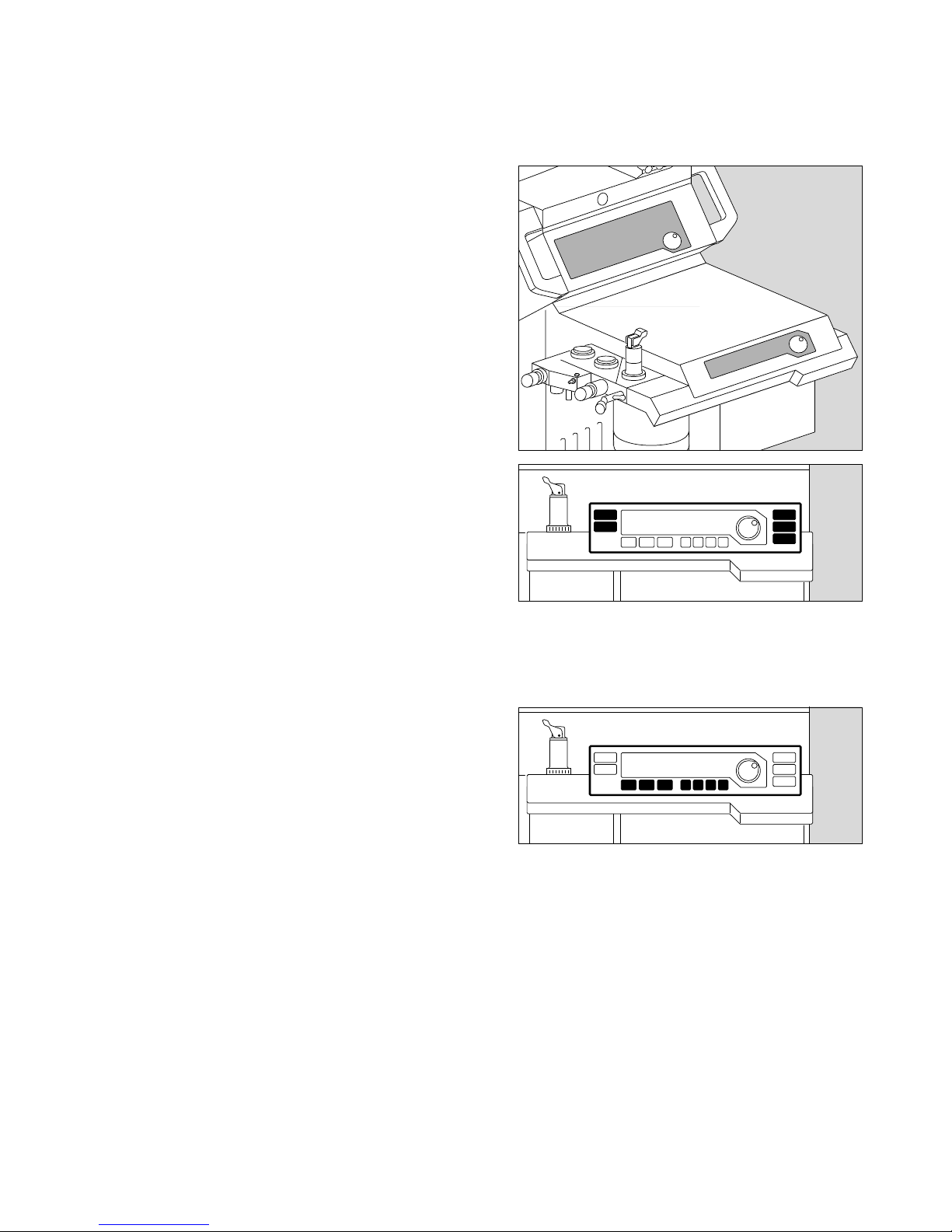

Operating concept of the ventilator

Keys with dedicated function –

for setting the operating modes

Left-hand side:

Key for manual ventilation or

spontaneous breathing.

Key for IPPV mode.

Right-hand side:

Key for leakage test and compliance

measurement.

Key for SIMV mode.

Standby key.

for setting ventilation parameters

Below the display window:

Key for setting the maximum pressure

for IPPV and SIMV ventilation.

Key for setting the tidal volume.

Key for setting the ventilation frequency

in IPPV mode.

Key for setting the time ratio between

inspiration and expiration.

Key for setting the relative inspiratory

pause.

Key for setting the PEEP pressure for

IPPV mode.

Key for setting the ventilation frequency

in SIMV mode.

11

Operating concept

Operating concept of the ventilator

Keys with dedicated function

M

I

T

S

A

p

B

F

t

†

P

f

G

A

S

004372240052897000628970

Operating concept

Operating concept of the ventilator

Display window without and with dialogue function

12

Display window without dialogue function

Top left:

Continuous indication of the relative piston movement

(in % referred to the set stroke volume VT)

The set operating parameters correspond with the keys

below:

– Indication of the maximum pressure Pmax in mbar.

– Indication of the tidal volume VT in mL or L.

– Indication of the ventilation frequency fIPPV in breaths

per minute.

Display window with dialogue function

(in combination with the rotary control)

Example: adjusting the maximum pressure

In the black field, beside the rotary control:

1 The set value appears on the right and left-hand sides

of the field when a parameter key (Pmax, VT, fIPPV) is

pressed. Here: »23«.

2 The value on the right-hand side is changed by turning

the rotary control. Here: »28«.

The old and new values are consequently always

displayed together.

3 The value on the right («28«) is confirmed as the

definitive value by pressing the control.

If the rotary control is not pressed and not turned again,

the machine is reset after 10 seconds without changing

the setting.

● This dialogue window also displays advisory messages

(see page 78) –

Example: »Paed. hoses !«:

23 Pmax / mbar 28

Paed. hoses !

2

3

1

0% 100%

Pmax

23

VT

600

fIPPV

12

mbar ml/L 1/min

0072897000828970009289700102897001128970

Operating concept of the monitor

Keys with dedicated function (Hardkeys)

The right-hand side is reserved for operating elements,

the left-hand side for displays.

This key switches the monitor from standby to

measuring mode and vice versa.

The monitor mode depends on the ventilator

mode:

Standby can only be selected on the monitor if

the ventilator is also in standby.

The monitor starts up when the ventilator is

started.

This key is used to deactivate the alarm tone for

two minutes. It is reactivated by pressing the key

again. The yellow LED in the key lights up while

alarms are suppressed.

Inside the dark area, there are two keys acting directly on

the screen contents:

This key is used to switch directly from one

screen to the next in succession.

This key is always used to call up the »Standard

screen« (see page 57).

Displays

Two bar-shaped indicator lamps are located above

the G key: these lamps continue to indicate the

alarm states even when the acoustic alam is

switched off.

Red (upper) lamp, flashing: Warning !!!

Yellow (lower) lamp, flashing: Caution !!

Yellow lamp, constant: Advisory !

Measured values with grey numerals

Measured values generated by an uncalibrated sensor

are shown in grey type. This may be due to the following

causes:

– Self-test has been aborted.

– Automatic sensor calibration is in progress.

– The measuring equipment for the anaesthetic gas

composition has not yet reached the required working

temperature when the system is started.

13

Operating concept

Operating concept of the monitor

Keys with dedicated function, Displays

Measured values with grey numerals

E

G

W

Q

E

G

QW

G

QW

01228970

00537224

01428970

Operating concept

Operating concept of the monitor

Screen structure, Screen saver

Rotary control

14

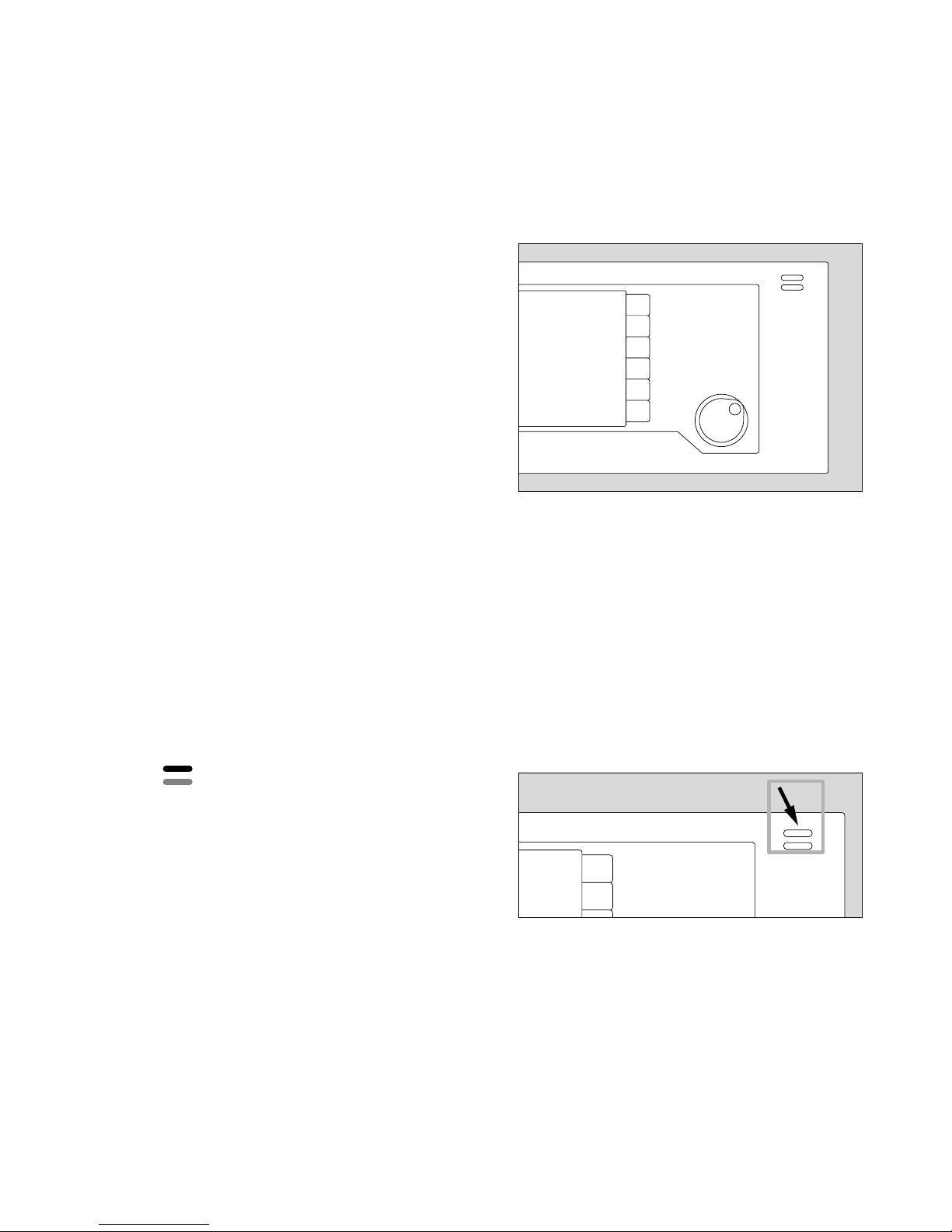

Screen structure

● Status field top:

contains information on the current alarm mode

of the monitor.

● Alarm field top:

indicates any alarms and their priority.

● Graphic field left:

for curves and bar graphs.

● Measured value field right:

for the most important numerical values.

● Operator prompts bottom right:

prompts to guide the operator.

● Softkeys right:

for rapid selection of the functions displayed on the

screen.

Screen saver

If none of the operating elements on the monitor is

operated in »standby« for approx. 2 minutes, the screen

switches off and becomes dark. The yellow LED in the

standby key and the word »standby« on the ventilator

light up. The monitor display is immediately restored as

soon as any key is pressed.

Rotary control

Selection and adjustment with a single control.

For example:

Adjusting the volume of the pulse tone

after calling up the menu of default values via the softkey

»config.« in standby (after entering a code).

● Turn rotary control = selection.

The cursor frame moves horizontally in the dashed

area.

● Press rotary control = confirm selection.

The selection is confirmed and appears in dark type

on a light background. The cursor frame is positioned

over the arrow symbol ( z) to the next higher menu.

● Turn rotary control = the cursor frame moves vertically

inside the dashed area.

Select pulse tone.

anaesth. gas

warning calibrating

defaults

Standby / Configuration

Alarms inactive!

anaesth. gas

warning calibrating

defaults

pulse tone

0 1 2 3 4 5 6 7 8 9

alarm tone 1 2 3 4 5 6 7 8 9

mode adult Neo.

parameters

record

interfaces

alarm limits

curves

basic configuration

Standby / Configuration

Alarms inactive!

anaesth. gas

warning calibrating

defaults

pulse tone

0 1 2 3 4 5 6 7 8 9

alarm tone 1 2 3 4 5 6 7 8 9

mode adult Neo.

parameters

record

interfaces

alarm limits

curves

basic configuration

Menu for setting

pulse tone volume.

Status field Alarm field

Measured

value field

Operator prompts

Graphic field

Softkeys

002289710032897100428971

00528971

01628970

● Press rotary control = confirm selection.

The selection is confirmed and appears in dark type

on a light background.

● Turn rotary control = select new setting.

● Press rotary control = confirm selection.

The cursor frame is now on the arrow symbol ( z)

to the next higher menu.

● Turn rotary control = select new setting.

Or:

● Press rotary control again = close submenu

»defaults«.

The cursor frame is on the arrow symbol ( z)

to the next higher menu.

The current configuration is indicated by the fields with

grey background.

● Press rotary control again = exit menu.

15

Operating concept

Operating concept of the monitor

Rotary control

Standby / Configuration

✓

anaesth. gas

Halothane

Enflurane

Isoflurane

Sevoflurane

Desflurane

no

anaesth. gas

warning

default

✓

calibrating

O

2

-sensor

21 Vol.%

flow sensor

Ventilator

start up test

more

✓

Alarms inactive!

defaults

pulse to.

0 1 2 3 4 5 6 7 8 9

alarm tone 1 2 3 4 5 6 7 8 9

mode adult Neo.

parameters

record

interfaces

alarm limits

curves

basic configuration

Standby / Configuration

Alarms inactive!

anaesth. gas

warning calibrating

defaults

pulse tone

0 1 2 3 4 5 6 7 8 9

alarm tone 1 2 3 4 5 6 7 8 9

mode adult Neo.

parameters

record

interfaces

alarm limits

curves

basic configuration

Menu for setting

pulse tone volume.

Standby / Configuration

Alarms inactive!

anaesth. gas

warning calibrating

defaults

pulse tone

0 1 2 3 4 5 6 7 8 9

alarm tone 1 2 3 4 5 6 7 8 9

mode adult Neo.

parameters

record

interfaces

alarm limits

curves

basic configuration

006289710072897100828971

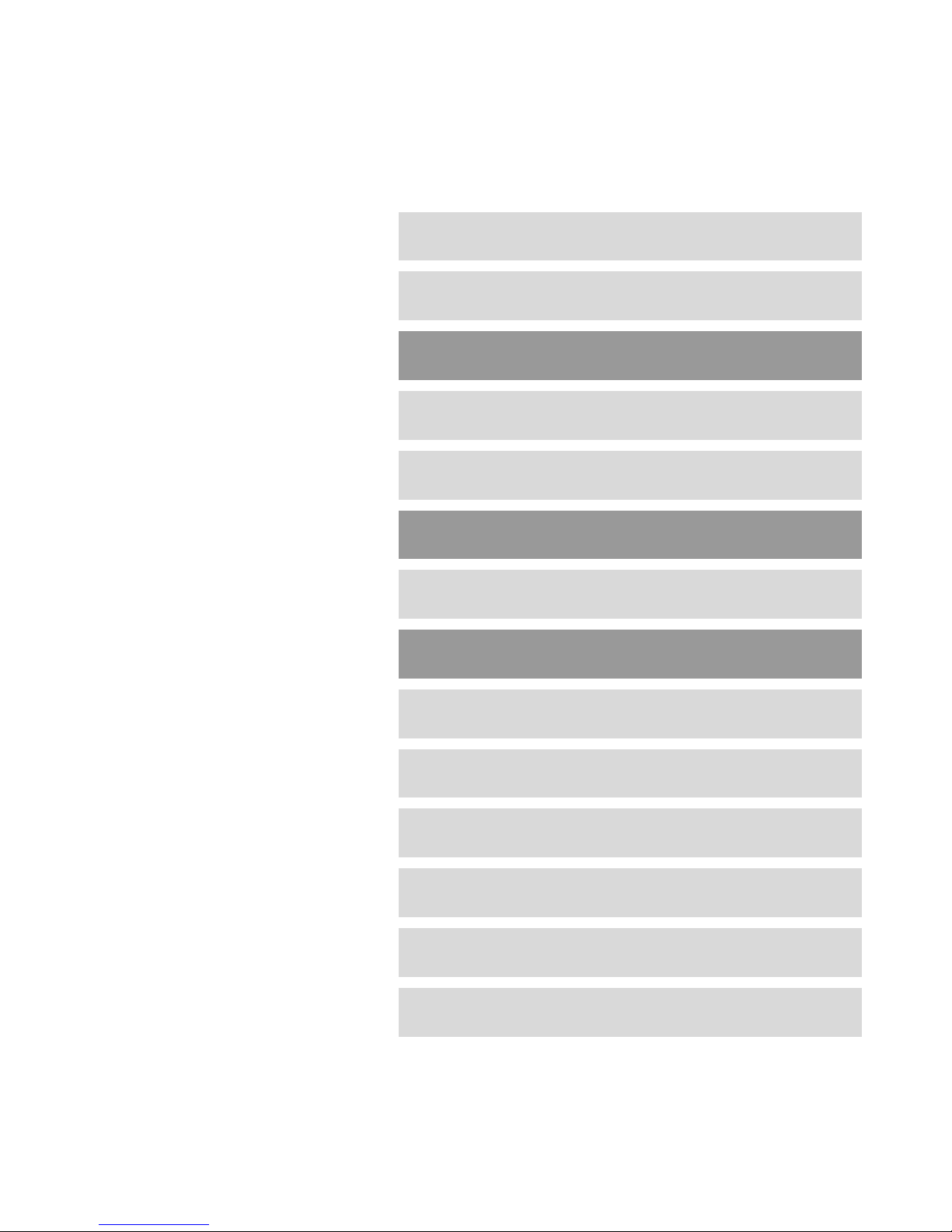

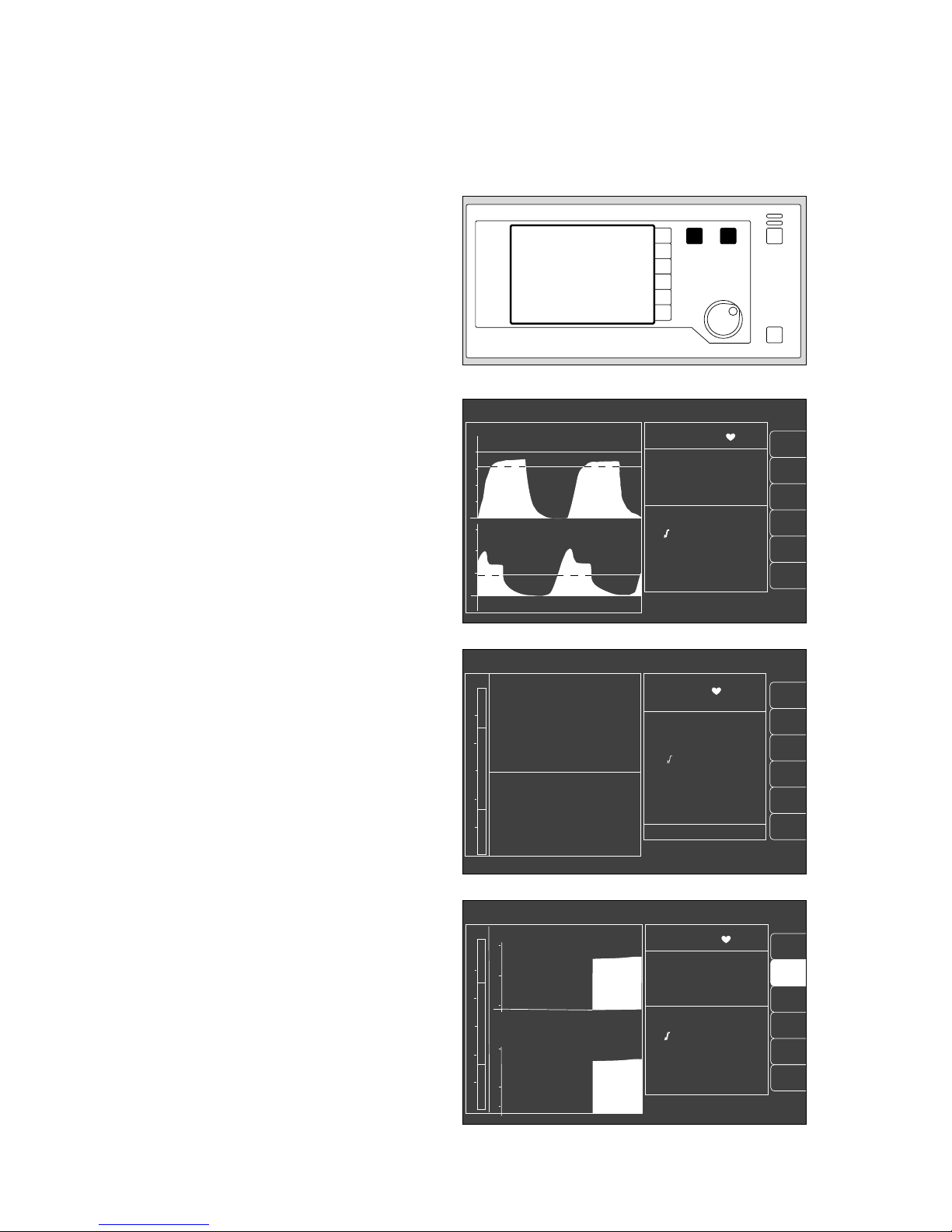

The various screen displays

1 The three different screen displays are invoked by

pressing W.

2 Press Q to return to the standard screen from any

screen display.

The standard screen

with the CO2 curve and another selectable curve. The

most important measured values are grouped together

on the right.

The data screen

contains all measured values with their units of measure;

simplifies the completion of the anaesthesia record.

The trend screen

for displaying the changes in measured values since

measurement started.

The current measured values are shown on the right.

Operating concept

Operating concept of the monitor

The various screen displays

16

alarm

limits

auto set

vent. al.

list

IPPV alarm limits

alarm

info

10 - 03 - 97 8:00

PAW

peak 37 mbar

plat. 30

PEEP 5

mean 20

compliance 15 ml/mbar

MV 6.0 L/min

V

T

0.60 L

freq 10 1/min

AW-temp 38

o

C

20

40

0

Fi Fet

SpO

2

98 67

% 1/min

0 36

29 25

0.8 0.6

70 68

CO

2

mmHg

O

2

%

Hal.

%

N2O

%

sys-compl. 1.5 from 10-03

leakage 5 8 : 00

18

config.

alarm

limits

auto set

vent. al.

curve

list

config.

alarm

info

IPPV alarm limits

SpO

2

98 67

etCO

2

38

MV 6.0 freq 10

Fi Fet

O

2

29 25

Hal. 0.8 0.6

N

2

O 70 68

CO

2

40

0

PAW

20

0

20

18

SpO

2

pulse

AGas

N

2

O

IPPV alarm limits

CO

2

MV

O

2

compl.

SpO

2

98 67

etCO

2

38

MV 6.0 freq 10

Fi Fet

O

2

29 25

Hal. 0.8 0.6

N

2

O 70 68

18

MV

15

5

0

CO

2

60

30

0

11:00 12:00 13:00

PAW

20

40

0

10

full

trend

alarm

limits

12

009289710102897101128971 02328970

Contents

Page

Connecting the equipment .................................................................... 18

Electricity and gas supply ........................................................................ 18

Auxiliary electrical equipment ................................................................... 18

Anaesthetic gas scavenging system (AGS) ............................................. 19

Anaesthetic agent vaporiser .................................................................... 19

Uninterruptible power supply ....................................................................20

External equipment .................................................................................. 20

Checking readiness for operation with checklist .................................. 21

Vapor ...................................................................................................... 22

Anaesthetic gas scavenging .................................................................... 22

Breathing system .................................................................................... 23

Soda lime ................................................................................................ 23

Emergency ventilation bag ....................................................................... 23

Water traps ............................................................................................. 24

Reserve gas cylinders (optional) .............................................................. 24

Pipelinie gas supply ................................................................................. 24

Gas delivery ............................................................................................ 24

Oxygen Ratio Control (ORC) .................................................................. 25

O2 Flush ................................................................................................. 25

Secretion aspirator (optional) .................................................................. 25

Power supply .......................................................................................... 26

Self-test .................................................................................................. 26

Fresh gas - External outlet (optional) ........................................................ 27

Selecting anaesthetic agent ..................................................................... 28

Automatic calibration of O2/flow sensors ................................................. 29

Manual calibration of the O2 sensor ......................................................... 29

Manual calibration of the flow sensor ....................................................... 30

Ventilator start-up test ............................................................................. 31

17

Preparing for use

Contents

Preparing for use

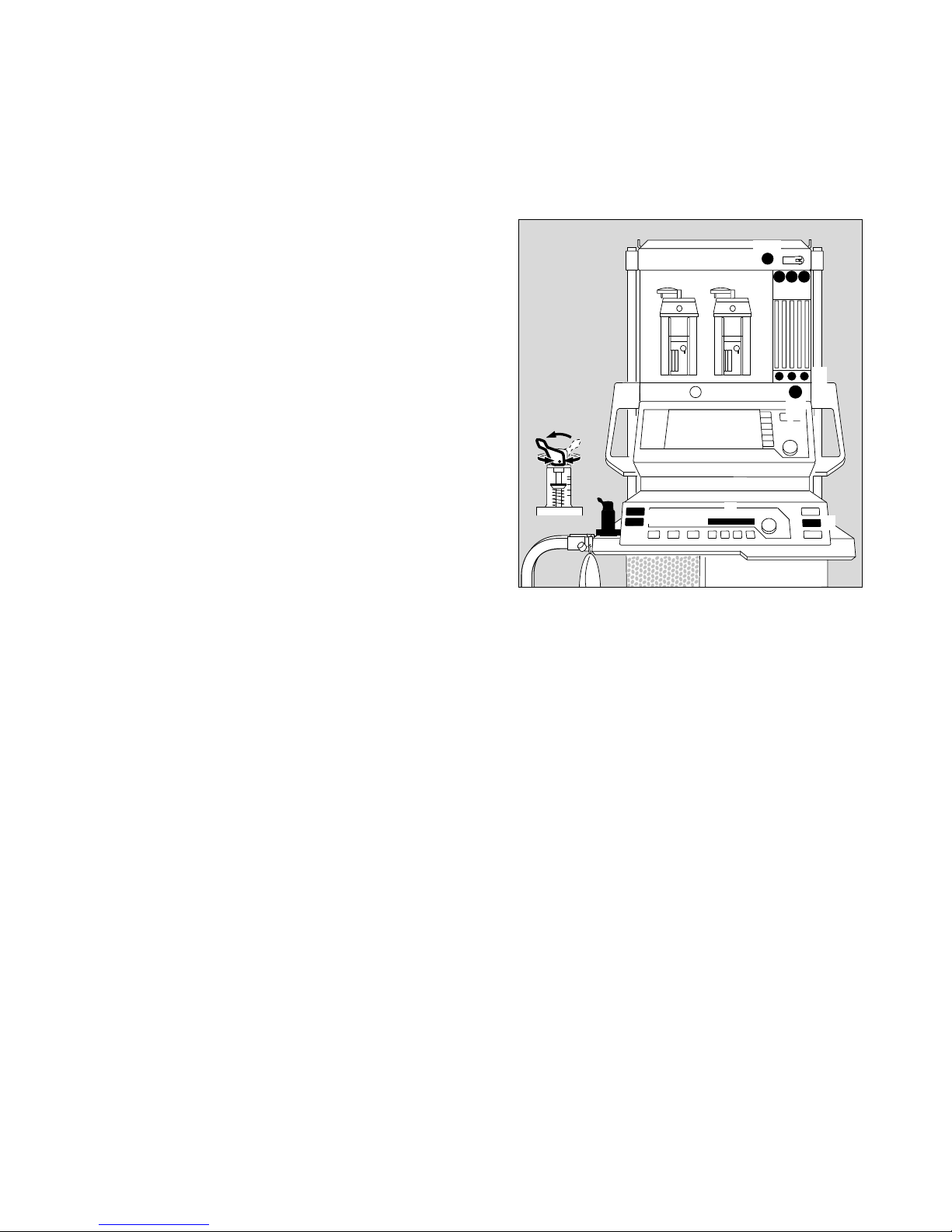

Connecting the equipment

The equipment must have been stripped down and tested

beforehand!

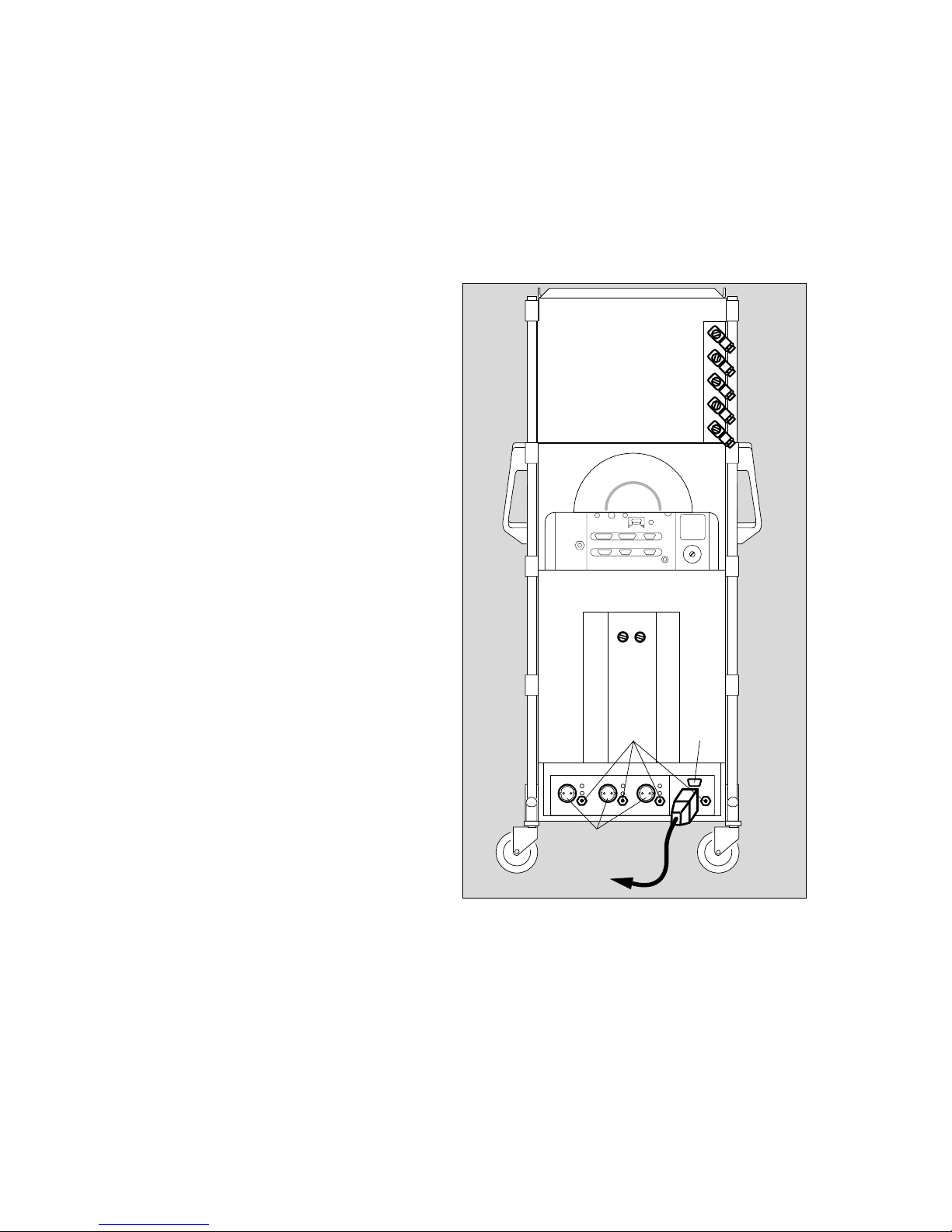

Electricity and gas supply

1 Plug the power cable into the mains socket.

2 Connect a ground lead for equipotential bonding to

one of the four pins on the rear of the workstation

when it is used for intracranial or intracardiac surgery.

The other end must be connected to the specified

point in the operating theatre.

3 Screw hoses for O2, AIR and N2O into the rear of the

equipment and plug connectors into the wall sockets.

● Check that the supply pressure is adequate on the

pressure gauges on the front (pointers must be in the

green area).

4 Holder for anaesthetic gas scavenging.

Auxiliary electrical equipment

5 Connect to the three auxiliary power sockets

(max. current per socket: 2 A). The auxiliary power

sockets are not controlled by the main switch.

If there is a power failure, the auxiliary power sockets

will be de-energised, because they are not powered

by the uninterruptible power supply (UPS).

Do not connect high-frequency surgery appliances to

the auxiliary power sockets.

Do not connect any other multiple sockets, e.g.

multiple socket adapters, to the auxiliary sockets.

The connection of equipment to the auxiliary sockets

causes an increase in leakage current.

The total leakage current in the power line must not

exceed 500 uA (EN 60601-1).

6 Sub-D socket for connecting the uninterruptible

power supply (UPS), see page 20.

On connection to the Sub-D socket, the UPS can be

switched off using the main switch.

The auxiliary power sockets and UPS are not

installed in the Cato ceiling version.

Preparing for use

Connecting the equipment

Electricity and gas supply

Auxiliary electrical equipment

18

1

2P

3

4

6

5

04237224

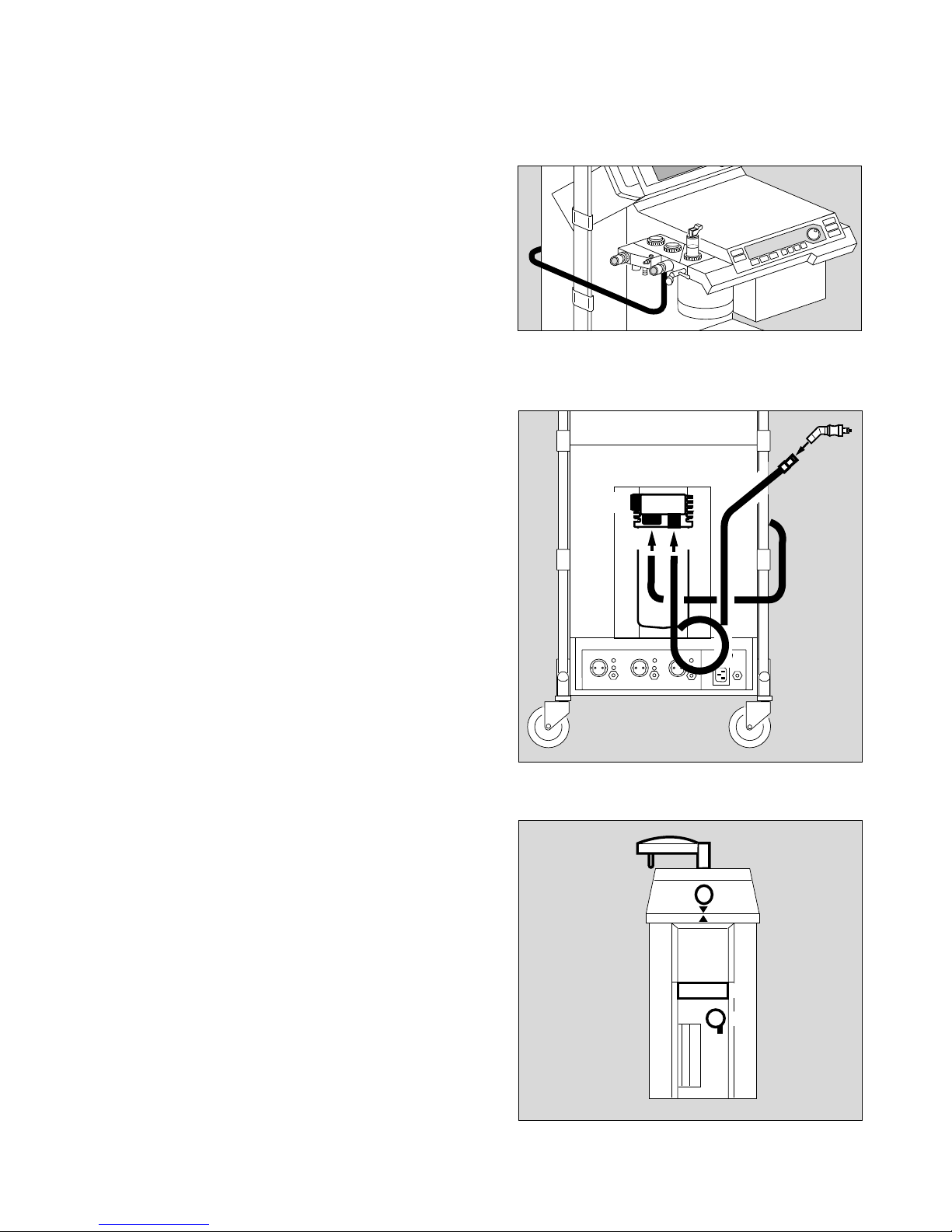

Anaesthetic gas scavenging system (AGS)

● Connect the transfer hose to the scavenging adapter

– first time only, it then remains in place.

1 Insert the scavenging adapter in the breathing system

from below until it engages.

2 Route the transfer hose round the equipment to the

rear.

3 Plug the transfer hose to the port on the collecting

system.

4 Connect the suction hose (sampling hose) to the port

on the collecting system.

5 Connect the anaesthetic scavenging connector to the

sampling hose.

6 Make sure that the second connector on the collecting

system is sealed with the screw plug.

● Follow the specific Instructions for Use of the

anaesthetic gas scavenging system.

Anaesthetic agent vaporiser

The illustration shows a Vapor 2000

● If using the double connector for two Vapors, the

automatic Vapor identification system is disabled.

● Only use Vapors listed in the Order List.

● Follow the specific Instructions for Use of the Vapor.

● For each anaesthetic agent, only use the specified

Vapor.

7 Always insert the sealing plug and

8 secure with lever.

9 Engage control dial at »0« when no fresh gas is set.

10 Always secure the Vapor with the locking lever (turn

lever to the left as far as it will go).

19

Preparing for use

Connecting the equipment

Anaesthetic gas scavenging system (AGS)

Anaesthetic agent vaporiser

10

9

8

7

0

5

6

34

0292897000637224

G

A

S

1

2

02828970

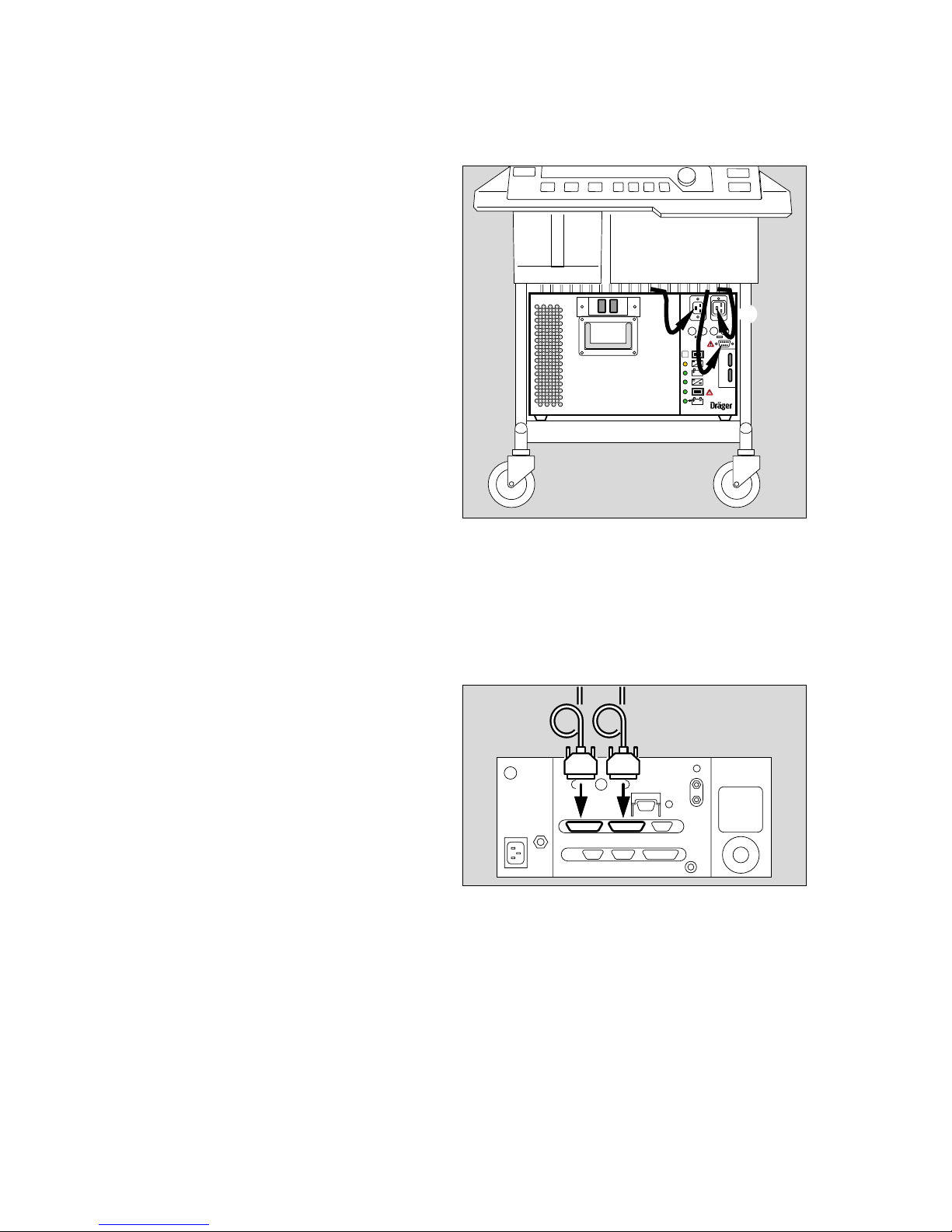

Uninterruptible power supply

(optional, see separate Instructions for Use)

Make sure that the status line is connected, so that the

uninterruptible power supply (UPS) is controlled by Cato.

In the event of power failure, the machine is powered

by the battery of the UPS, but the auxiliary mains

socket on the back of the Cato will be de-energised.

However, auxiliary equipment powered by the refrigerator

connector on the side of the Cato will still be powered.

1 Plug the power plug of the Cato into the socket of the

UPS.

2 Plug the power plug of the UPS into the mains

socket.

The UPS can supply the Cato and connected auxiliaries

with electrical energy for about 45 minutes. It is automatically activated in the event of a power failure.

External equipment

See page 53 for the configuration of the interfaces.

Connection via the protocol interface

3 with data cable for printers with serial interface, e.g.

Desk-Jet (Hewlett-Packard)

or

e.g. the PM 8060 Vitara Patient Monitor with the

MEDIBUS protocol.

See page 53 for configuration.

Connection via the Dräger RS 232 C MEDIBUS

interface

e.g. to connect the PM 8060 Vitara Patient Monitor.

4 Connect with data cable.

● The equipment plugs must be secured with the

screws provided.

Preparing for use

Connecting the equipment

Uninterruptible power supply

External equipment

20

34

g

USV - Ein / On

manuell

S 3 S 4

S 5

S 6

I

0

F2 F2 F3 F4

1

2

0312897003228970

Checking readiness for operation

with checklist

It is assumed that the following conditions have

been met:

● The equipment and its accessory parts have been

cleaned and disinfected –

refer to page.......................................... 83 onwards

● The unit is fully equipped for the application in

question –

refer to page.......................................... 89 onwards

● The user has a good knowledge of the Instructions for

Use and has been trained to use the equipment.

● An emergency ventilation bag with appropriate mask is

available on the equipment.

● A checklist is affixed to the equipment.

The equipment must always be checked against the

checklist before it is used!

This check is mandatory as specified by EN 740!

Duration: approx. 5 minutes (depending on the scope

of calibration).

The equipment is subsequently in »standby« mode

when ready for use. Anaesthesia ventilation can

immediately be started at any time in this mode –

refer to page.......................................... 36 onwards

● Update the checklist by adding or deleting points

in accordance with the Instructions for Use, the

equipment type and configuration concerned and the

various supplementary units connected. It will then

contain all the requisite checks.

● Enter the model designation and serial number of the

equipment.

● Tick off ✔ the results of the checks in the ACTUAL

column.

● Remember to sign and date the checklist!

Test sequence

– Note any alterations and additions!

– Note the Instructions for Use of the individual units!

– If the checks do not proceed as planned, restore the

required status.

21

Preparing for use

Checking readiness for operation with checklist

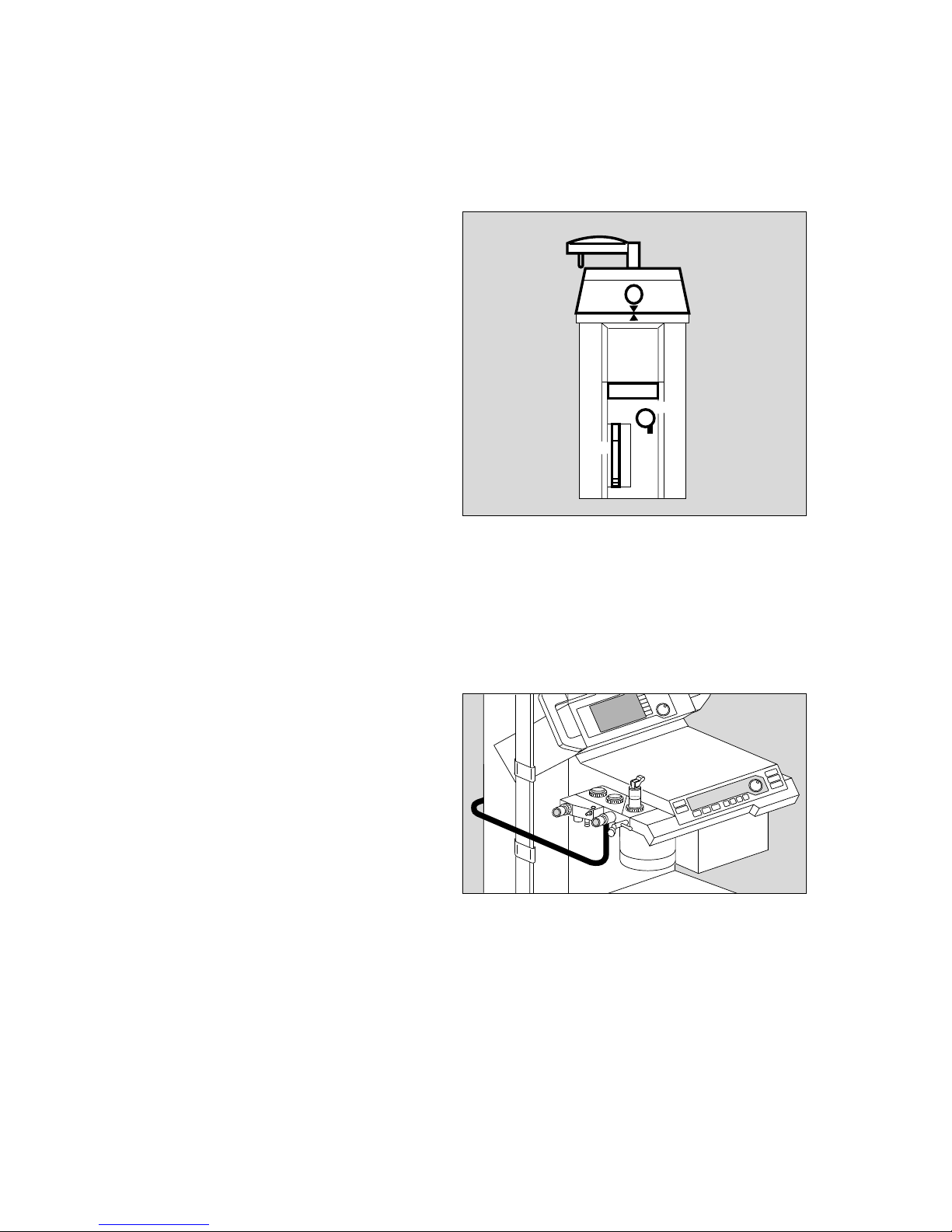

Vapor

The illustration shows a Vapor 2000

1 The control dial is engaged at »0«.

2 Filling level OK – check filling level in viewglass.

– Last inspection less than six months ago.

Safety fill:

3 The sealing plug is inserted and secured with

the lever.

Plug adapter:

– The plug adapter lies horizontally and flush all round

on the sealing rings of the plug connection.

Interlock:

4 Plug-in system is locked – locking lever turned

clockwise until it engages.

Anaesthetic gas scavenging

– Is indicator in wall socket green? (Only when using

Dräger systems; note sounds of gas flow in other

cases.)

– Hose connector engaged below breathing system?

– The auxiliary air holes in the tube below the connector

must not be sealed, otherwise the breathing system

will be drained!

● Note the separate Instructions for Use for the

anaesthetic gas scavenging system.

22

Preparing for use

Checking readiness for operation with checklist

Vapor

Anaesthetic gas scavenging

0

1

4

2

3

D

G

A

S

0073722403428970

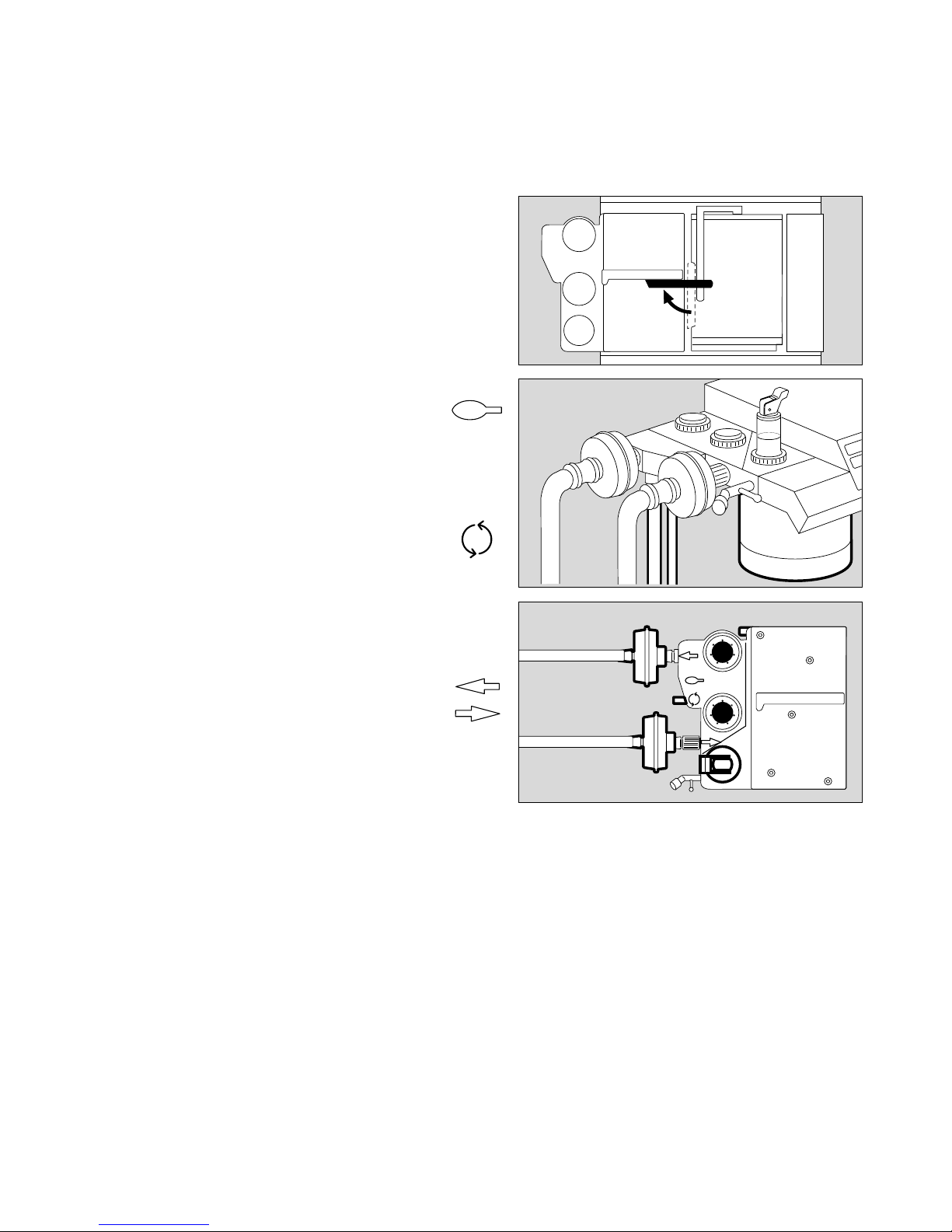

Breathing system

Lift off table top:

1 Lever set to the position shown in black.

The following are complete:

2 Hose with manual ventilation bag Symbol:

(Connected from below – not shown)

– Correct breathing hoses installed.

(Adult or infant hoses)

3 Pressure measuring hose with filter connected.

4 Measured gas return hose Symbol:

connected.

5 Fresh gas hose plugged in.

(Connected from below – not shown)

6 Valve discs inserted.

– Pressure limiting valve (APL) present.

– Inspiratory microbial filter. Symbol:

– Expiratory microbial filter. Symbol:

Soda lime

7 Lime has not noticeably changed colour (purple).

– Filling level adequate (up to the mark).

– Soda lime container is securely tightened – up to the

end stop (clockwise).

Emergency ventilation bag

(not shown)

– Bag is complete with mask and hung from the side

of the Cato.

– Bag functions correctly.

✔Check and tick off.

23

Preparing for use

Checking readiness for operation with checklist

Breathing system, Soda lime

Emergency ventilation bag

1

275

APL

3

4

6

035289700362897003728970

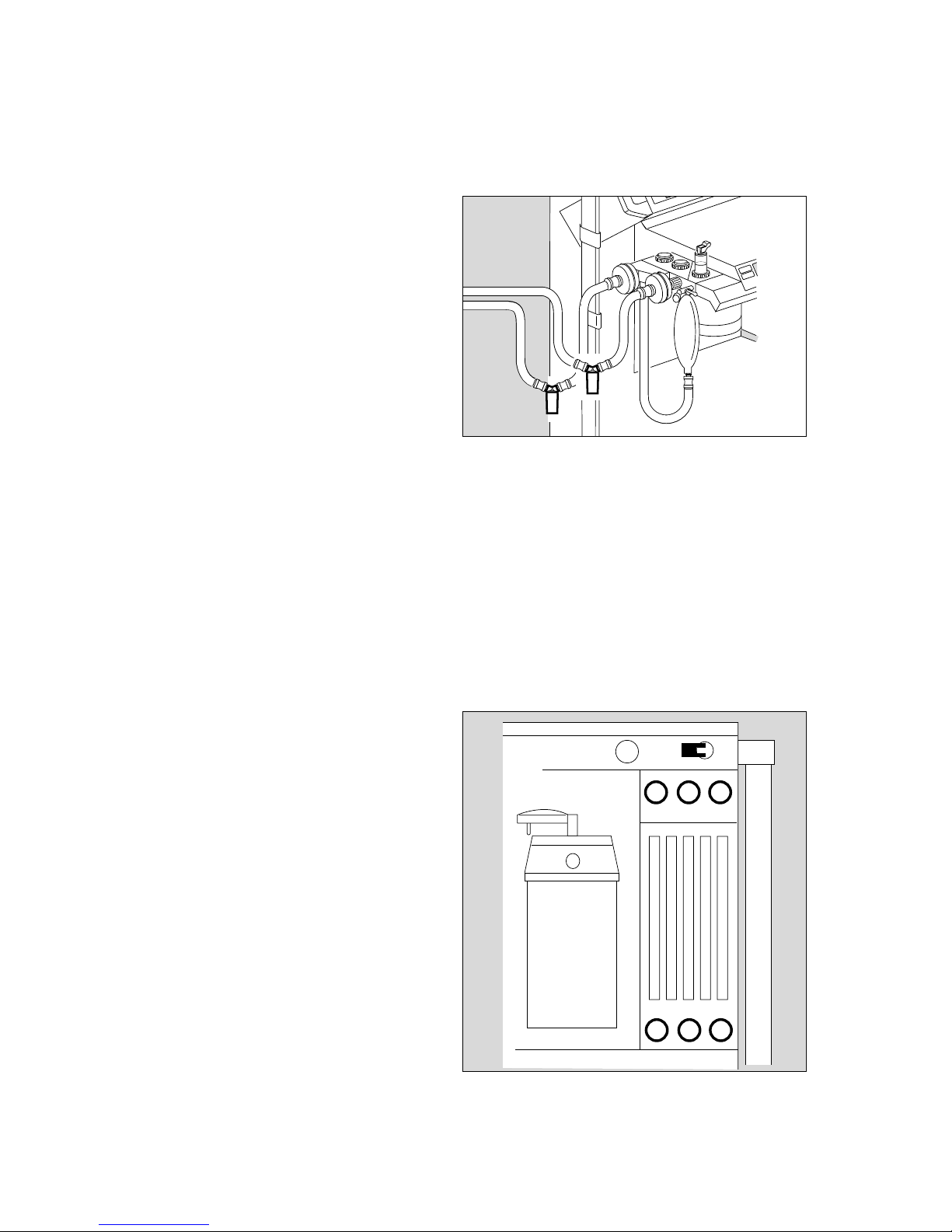

Water traps

1 Water traps are recommended in both the inspiratory

and the expiratory lines during prolonged anaesthesia,

low-flow anaesthesia and when using humidified

breathing gas.

– Water traps must be fitted at the lowest point in the

hose and hang downwards.

– Check regularly and drain if necessary.

Observe hygiene regulations –

risk of infection!

The hose system remains sealed. The container must

be replaced securely!

»Tips on reducing condensation« on page 136.

Reserve gas cylinders (optional)

● Open cylinder valves.

✔Check and tick off:

● Pressure indicator on O2 cylinder exceeds 50 bar? –

Pressure indicator on N2O cylinder exceeds 30 bar? –

Replace cylinders if not.

● Close cylinder valves!

Pipelinie gas supply

● Have connectors been pressed right into the wall

sockets for O2, AIR and N2O (not in holding

position!)?

✔Check and tick off:

2 Pointers of all three pressure indicators are in the

green range.

Gas delivery

3 Switch over to AIR.

4 Open O2 and AIR delivery valves until more than

9 L/min are indicated!

5 Open N2O delivery valve completely.

✔Check and tick off:

Does N2O measuring tube indicate 0?

3 Switch over to N2O.

✔Check and tick off:

Does N2O measuring tube indicate more than 9 L/min?

Does AIR measuring tube indicate 0?

24

Preparing for use

Checking readiness for operation with checklist

Water traps, Reserve gas cylinders

Pipelinie gas supply, Gas delivery

G

A

S

1

1

3

2

445

[

0382897000837224

Oxygen Ratio Control (ORC)

1 Slowly close O2 delivery valve –

– check:

the N2O flow decreases to less than 0.8 L/min

proportionally with the O2 flow for ORC low-flow,

the N2O flow decreases to »O« proportionally with

the O2 flow for S-ORC.

2 Switch over to »AIR«.

N2O flow decreases to »O«.

● Close N2O and AIR delivery valve.

O2 flush

3 Press button »O2+« –

– Is there a distinctly audible flow noise?

– Does the manual ventilation bag inflate?

✔Check and tick off!

Secretion aspirator (optional)

4 Open ejector valve –

5 Seal the aspiration holes on aspirator hose with your

finger (or fold over the hose).

Negative pressure indicated approx. – 0.8 bar?

✔Check and tick off!

● Close ejector valve.

Secretion aspirator may only be used in

»MAN/SPONT« mode or with disconnected

Y-piece.

25

Preparing for use

Checking readiness for operation with checklist

Oxygen Ratio Control (ORC)

O2 Flush, Secretion aspirator

D

G

A

S

5

4

2

1

3

[

0093722401037224

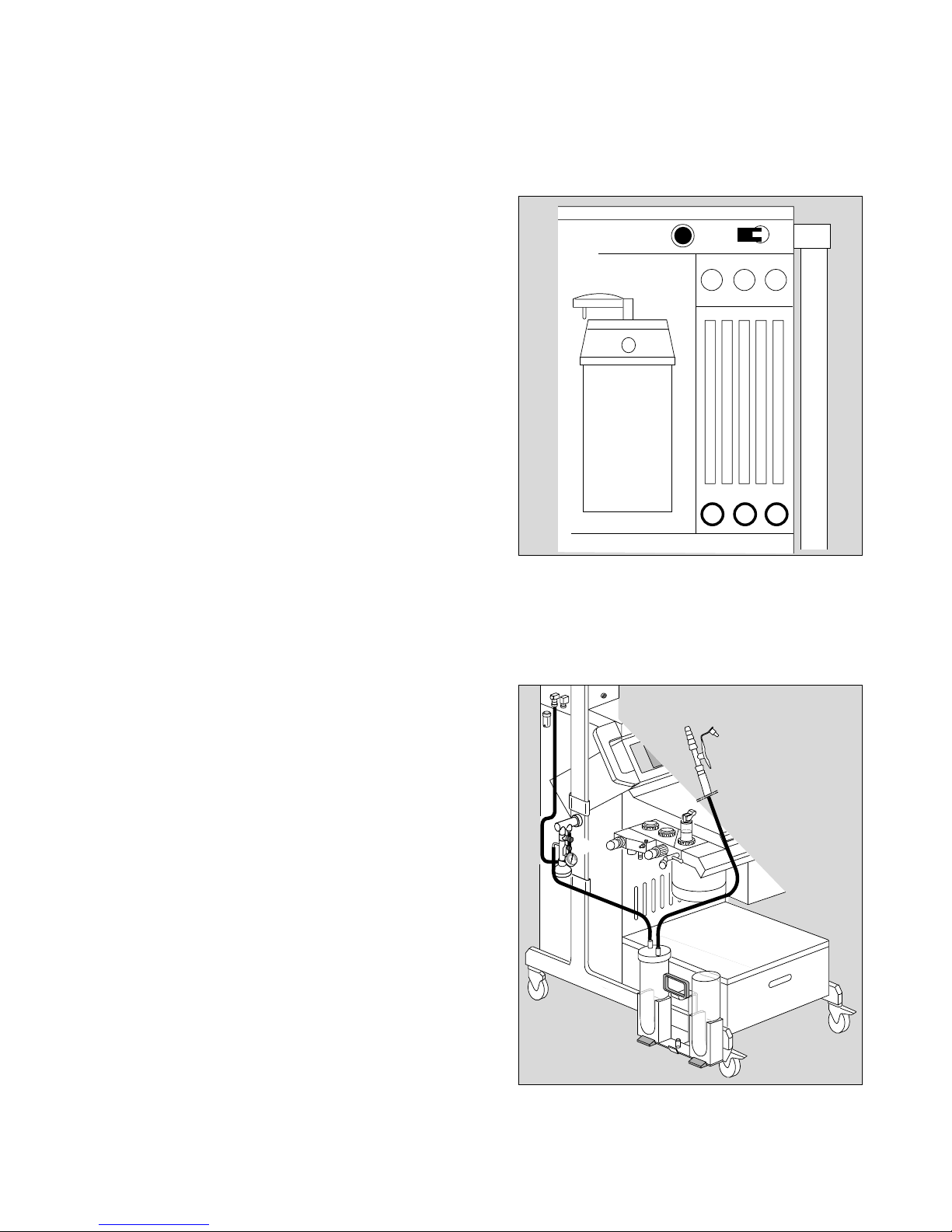

Power supply

● Equipotential bonding conductor connected?

● Mains plug connected?

1 Switch on equipment –

Press main switch to I.

Self-test

✔Check the signals and tick off the following on the

checklist:

● Lamp and alarm test, in succession:

Ventilator:

– Indication of the software version, all indicators light

up for approx. 2 seconds while a single tone sounds.

Monitor:

– The machine runs through the self-test:

All LEDs and display elements light up for

approx. 2 seconds. The LED in the Standby key E

continues to light up.

– Two alarm tones sound.

– The internal program memories are tested.

– The self-test is completed after approx. 1 minute.

The following display appears on the monitor:

»Self-test«

is displayed on the ventilator.

If the self-test reveals a fault of no relevance to the

safety of the equipment and not affecting any of the

measuring functions, the following message appears on

the monitor:

»Ready within limits«

together with a specific error message (refer to

pages 74 onwards). However, the equipment can be

operated nevertheless.

● Press the rotary control.

Call DrägerService.

26

Preparing for use

Checking readiness for operation with checklist

Power supply

Self-test

1

Technology for life

Cato

D

SW-Version 2.05

02-05-00

self-test

00137225 0113722404428970

If the self-test reveals a fault impairing the equipment's

safety, the following message appears on the monitor:

»Not ready«.

The machine cannot switch to Standby and cannot be

switched to measuring mode. DrägerService must be

called immediately.

● The configuration menu is displayed after the self-test

(example):

Fresh gas - External outlet (optional)

Fresh gas outlet for connecting to semi-open systems.

1 Fit the hose of the semi-open system to the external

fresh gas outlet.

● Make sure the anaesthetic gas scavenging hose is

connected.

2 Set the desired O2 and N2O flow-rates on the

flowmeter block.

3 Press »MAN SPONT« on the ventilator.

4 The lamp in the »FRESH GAS OUTLET« key does not

light up.

● Check that pressure is building up in the circle system.

4 Switch on the fresh gas outlet –

Press »FRESH GAS OUTLET« key.

The lamp in the key lights up.

● Check that pressure builds up in the semi-open

system.

27

Preparing for use

Checking readiness for operation with checklist

Self-test

Fresh gas - External outlet

Standby / Configuration

✓

anaesth. gas

Halothane

Enflurane

Isoflurane

Sevoflurane

Desflurane

no

anaesth. gas

warning

default

✓

calibrating

O

2

-sensor

21 Vol.%

flow sensor

Ventilator

start up test

more

✓

Alarms inactive!

defaults

pulse to.

0 1 2 3 4 5 6 7 8 9

alarm tone 1 2 3 4 5 6 7 8 9

mode adult Neo.

parameters

record

interfaces

alarm limits

curves

basic configuration

D

P

M

8

050

0

I

G

A

S

1

3

4

2

0132897101237224

Selecting anaesthetic agent

The machine automatically identifies the newer Vapor

models with code for

halothane, enflurane and isoflurane,

sevoflurane and desflurane.

Sevoflurane and desflurane are only identified by

equipment built after July 1994 or which has been

upgraded.

Uncoded Vapors must be selected via the configuration

menu on the monitor.

The setting »no anaesth. gas« must be selected in

the configuration menu for ventilation without volatile

anaesthetic. This setting is activated automatically if a

Vapor is not connected.

The plug-in system of the new Vapor models features an

optical code allowing the machine to identify the Vapor:

– when the equipment is started up

– when the Vapor is changed during operation.

Incorrect anaesthetics are not detected!

However, the user can quite deliberately select a

different Vapor instead of that identified automatically.

The following advisory message is then displayed in

the alarm field on the monitor:

»AGT NOT SEL !«

If the Vapor has not been encoded:

The message

»Vapor not identified«

is displayed in the user advisory field of the configuration

menu in »standby« mode.

● Set the appropriate anaesthetic for the Vapor used.

If a Vapor has not been connected:

The message

»Vapor not present«

is displayed in the user advisory field of the configuration

menu in »standby« mode.

28

Preparing for use

Checking readiness for operation with checklist

Selecting anaesthetic agent

Automatic calibration of the O2/flow sensors

Sidestream calibration of the O2 measurement

(O2 sampling) and flow measurement are performed

automatically.

Automatic flow calibration is performed during the first

breaths after starting ventilation. There is therefore no

cause for panic if the measured values for the minute

ventilation still appear in grey (i.e. uncalibrated values,

see page 13) immediately after the self-test.

CO2 measurement must function correctly before

automatic flow calibration can be performed, otherwise

the flow sensor must be calibrated by hand.

Manual calibration of the O2 sensor

The O2 sensor must be calibrated by hand if

O2 measurement has been set in the inspiratory line

(see “Parameters“ on page 53).

Calibrate O2 sensor with 21% O2 by volume = air

– The O2 sensor can be calibrated while flow calibration

is still in progress.

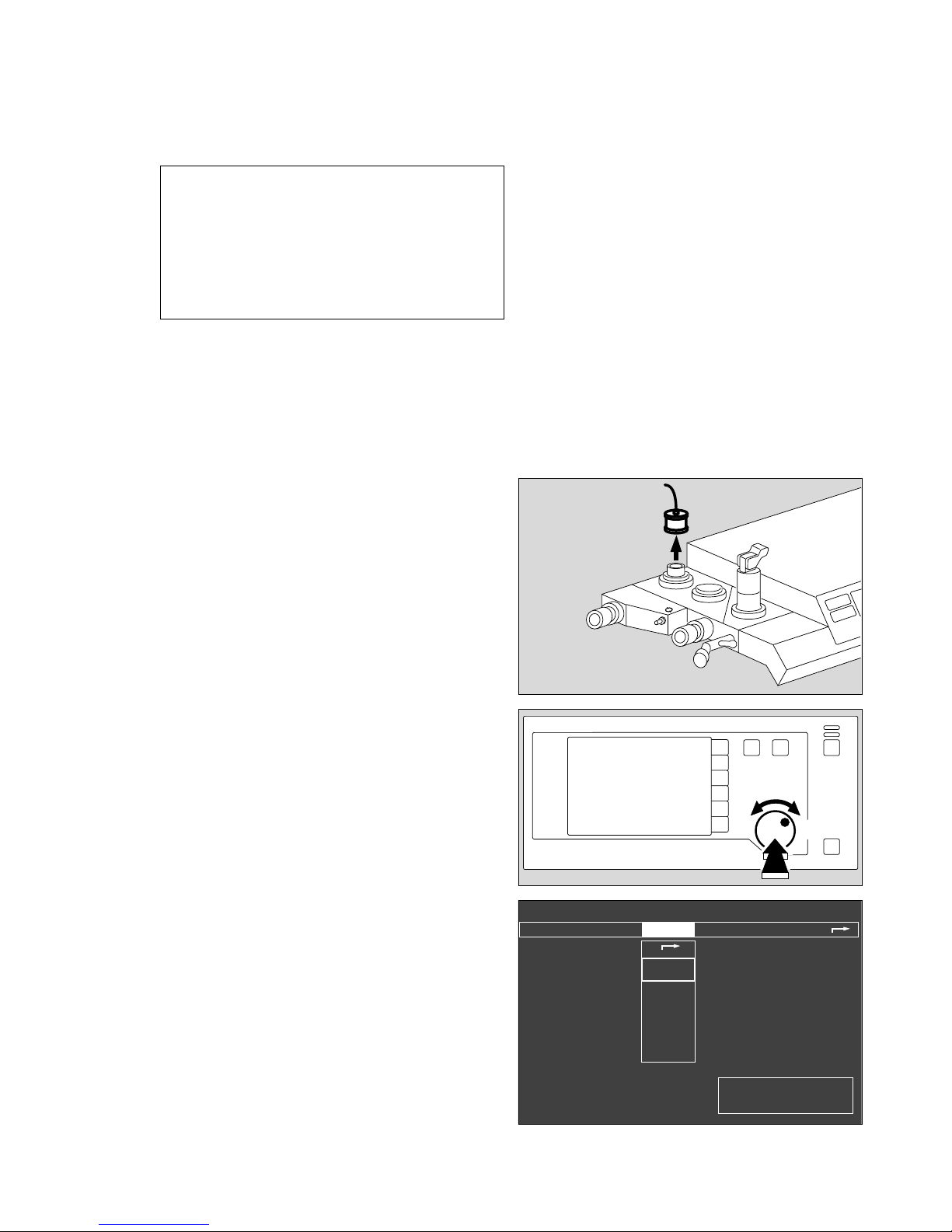

1 Remove the sensor from the inspiratory valve and

expose it to the ambient air – place it on the table and

wait at least two minutes.

2 Use the rotary control to select »calibrating« in the

»Standby/Configuration« menu and press to confirm.

● Move the cursor frame to

»O2 sensor

21Vol.%« by means of the rotary control.

● Press rotary control to confirm:

calibration starts.

1 Then plug O2 sensor onto the inspiratory valve again.

✔ Tick off in checklist.

29

Preparing for use

Checking readiness for operation with checklist

Automatic calibration of the O2/flow sensors

Manual calibration of the O2 sensor

The following symbols are used:

? = Enquires whether an action has been performed

or a setting made.

u

= Waiting period. The selected test step is being

performed by the machine.

✔ = The action has been completed successfully or

is not required.

Standby / Configuration

Alarms inactive!

calibrating

O

2

-sensor

21 Vol.%

flow sensor

Ventilatorstart up test

more

✓

Calibrate O

2

sensor after

replacing sensor and after 24 hrs.

Detach O

2

sensor and expose

for 2 min. to ambient air.

confirm !

✓

✓

2

G

A

S

1

01428971 0472897004828970

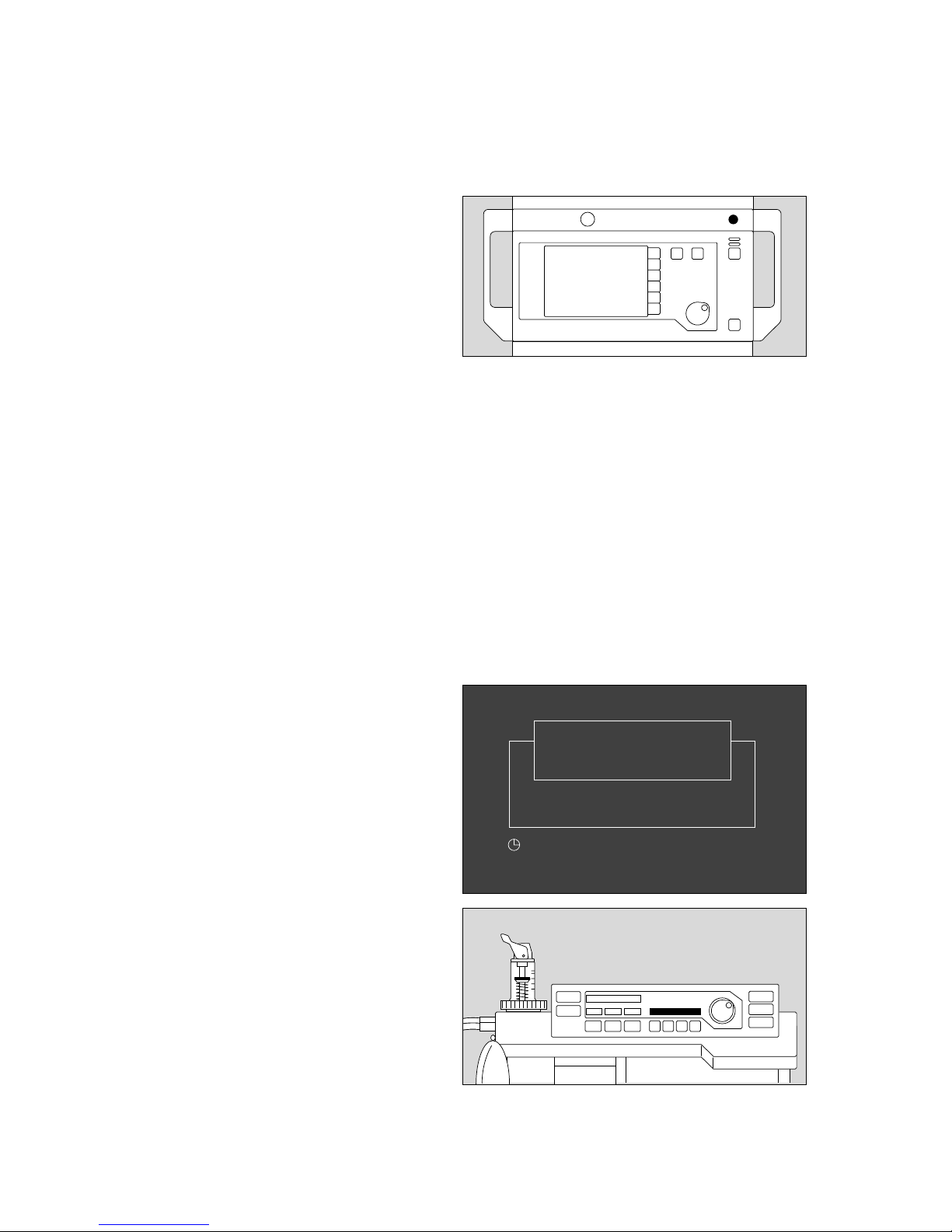

Manual calibration of the flow sensor

– The flow sensor can be calibrated by hand while O2

calibration is still in progress, either in the machine or

after being removed from the machine.

Without removal:

On the anaesthetic unit:

1 Set AIR/N2O selector to »AIR«.

2 Close the delivery valves for O2 and N2O, open the

delivery valve for air and thoroughly flush the

breathing system with air.

3 Close the delivery valve for air.

● Press the rotary control on the monitor to start

calibration.

The question mark (?) disappears and is replaced by

a timer icon ( u) on the screen.

A tick ( ✔ ) appears on the screen when calibration

has been completed correctly.

✔Tick off in checklist.

The cursor frame has automatically jumped to

»Ventilator start-up test«.

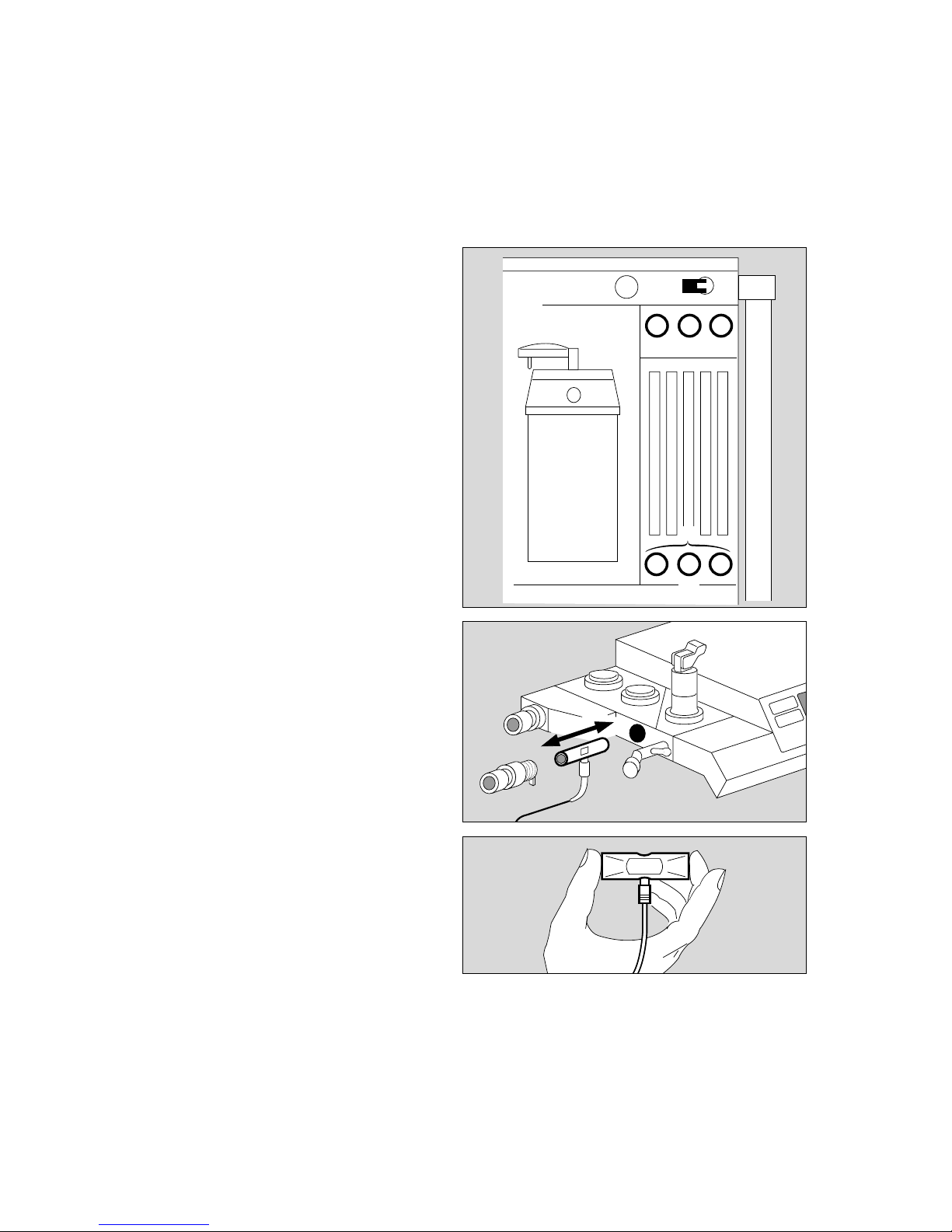

With removal:

4 Remove flow sensor:

– Unscrew expiration nozzle

– Remove flow sensor

– Briefly swing it to flush with ambient air

– Hold it horizontally with the cable connection pointing

downwards (calibration in installation position

improves the measuring accuracy)

– Seal off one or both sides as shown on the right,

preferably with your thumb or palm.

● Press the rotary control on the monitor to start

calibration; continue as above.

4 Replace flow sensor!

30

Preparing for use

Checking readiness for operation with checklist

Manual calibration of the flow sensor

4

2

1

3

2

013372240512897005228970

Loading...

Loading...