Page 1

DR

SAFETY & OPERATING INSTRUCTIONS

®

REDI-PLOW™ PLUS

DR Power Equipment

Serial No.

Order No.

Read and understand this manual and all instructions before operating the DR® REDI-PLOW™ PLUS.

Original Language

Toll-free phone: 1-800-DR-OWNER (376-9637)

Fax: 1-802-877-1213

Website: www.DRpower.com

Page 2

Table of Contents

y

Chapter 1: General Safety Rules ............................................................................................................................................................ 4

Chapter 2: Setting Up The DR® REDI-PLOW™ PLUS.......................................................................................................................... 6

Chapter 3: Operating The DR® REDI-PLOW™ PLUS .......................................................................................................................... 12

Chapter 4: Parts Lists and Schematic Diagrams .................................................................................................................................. 14

Conventions used in this manual

This indicates a hazardous situation, which, if not avoided, could result in death or serious injury.

This indicates a hazardous situation, which, if not avoided, could result in minor or moderate injury.

This information is important in the proper use of your machine. Failure to follow this instruction could result in damage

to

our machine or property.

Serial Number and Order Number

A Serial Number is used to identify your machine and is located on the Serial Number Label on your machine. An Order Number

is used to check and maintain your order history and is located on your packing slip. For your convenience and ready reference,

enter the Serial Number and Order Number in the space provided on the front cover of this manual.

Additional Information and Potential Changes

DR Power Equipment reserves the right to discontinue, change, and improve its products at any time without notice or obligation

to the purchaser. The descriptions and specifications contained in this manual were in effect at printing. Equipment described

within this manual may be optional. Some illustrations may not be applicable to your machine.

2 DR

®

REDI-PLOW™ PLUS

Page 3

CONTACT US AT www.DRpower.com 3

Page 4

Chapter 1: General Safety Rules

Read this safety & operating Instructions manual before you use the REDI-PLOW. Become familiar with the operation and

service recommendations to ensure the best performance from your machine. If you have any questions or need assistance,

please contact us at www.DRpower.com or call toll-free 1-800-DR-OWNER (376-9637) and one of our Technical Support

Representatives will be happy to help you.

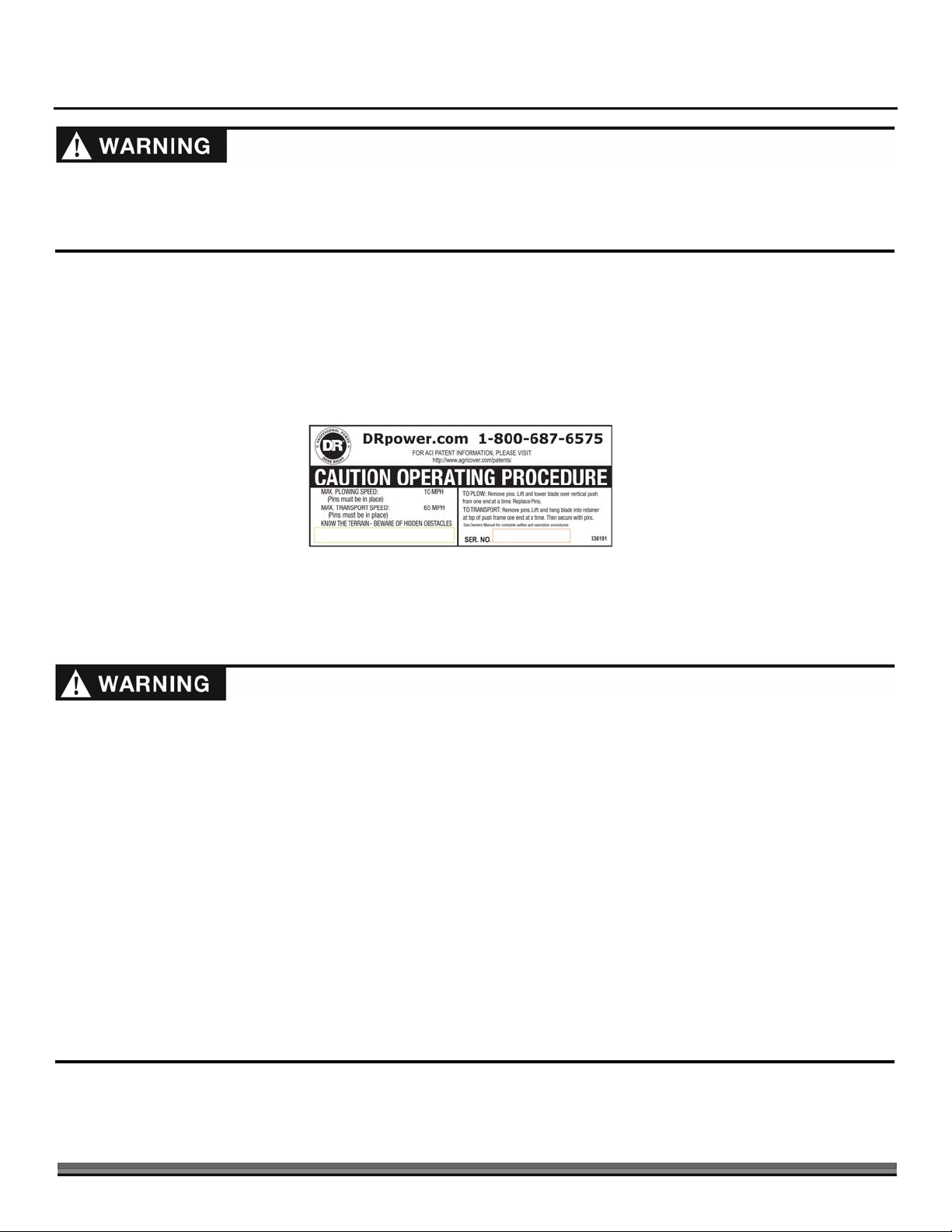

Labels

Your REDI-PLOW carries prominent labels as reminders for its proper and safe use. Shown below are copies of the Safety and

Information labels that appear on the equipment. Take a moment to study them and make a note of their location on your REDIPLOW as you set up and before you operate the unit. Replace damaged or missing safety and information labels immediately.

#33619

Operating the Plow Safely

The vehicle the plow is attached to is a heavy, high-powered machine. You must operate the vehicle safely. Unsafe operation can

create a number of hazards for you, as well as anyone else in the nearby area. Always take the following precautions when using

this vehicle and Plow:

Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people, their property, and

themselves.

Keep bystanders at least 50 feet away from your work area at all times. Stop and shut off the vehicle engine when another

person or pet approaches.

Remember – always exercise safety, courtesy, and common sense.

Avoid overloading your equipment - push only enough snow with each pass to get the job done.

When transporting blade, secure it to hanger brackets with pins or locks.

Do not exceed 65 MPH when transporting plow.

Do not exceed 10 MPH when plowing.

Never pile snow on someone else’s property, on street or sidewalks, by fire hydrants, mailboxes, water drains or electrical

boxes.

Check with local regulations before pushing snow across roads-it may be illegal.

Do not pile snow near handicapped or parking areas.

Plow snow during low-traffic hours - be cautious of pedestrians and vehicles.

Never pile snow where it obstructs visibility of traffic.

4 DR

®

REDI-PLOW™ PLUS

Page 5

Operating the Plow Safely (continued)

Use lowest transmission gear, on 4WD select low range if equipped.

On manual transmission avoid riding the clutch.

Be aware of engine temperature - avoid overheating.

When backing up don’t rely on rear view mirrors-turn around and look where you are going.

Never plow with your head out of the window-an unexpected sudden stop could result in personal injury.

Always wear your seat belt-even when plowing snow.

Follow vehicle manufacturers specifications for snowplowing.

Never operate the machine when under the influence of alcohol, drugs, or medication.

Keep all nuts and bolts tight and keep the equipment in good operating condition.

When pushing snow onto a pile, always do so with blade in the straightforward position. Piling snow with blade angled may

cause damage to plow or vehicle components.

Use caution when plowing next to a building wall. Make first pass about 3 feet away, make second pass about 2 feet away and

third pass about 1 foot away.

Safety for Children and Pets

Tragic accidents can occur if the operator is not alert to the presence of children and pets. Children are often attracted to the

machine and the plowing activity. Never assume that children will remain where you last saw them. Always follow these

precautions:

Keep children and pets out of the working area and under the watchful care of a responsible adult.

Be alert and turn the vehicle off if children or pets enter the work area.

Never allow children to operate the REDI-PLOW.

Use extra care when approaching blind corners, shrubs, trees, or other objects that may obscure your vision.

A Note to All Users

No list of warnings and cautions can be all-inclusive. If situations occur that are not covered by this manual, the operator must

apply common sense and operate this REDI-PLOW in a safe manner. Contact us at www.DRpower.com or call 1-800-DR-OWNER

(376-9637) for assistance.

CONTACT US AT www.DRpower.com 5

Page 6

Chapter 2: Setting Up The DR

®

REDI-PLOW™ PLUS

Assembly

Tools and Supplies needed:

Ft. lb. Torque Wrench

Impact or Ratchet with 9/16” and 3/4” Socket

Drill with 3/16” and 5/16” Drill Bit

#3 Phillips Driver Bit

Box Wrench 3/4”

Open Wrench 5/16”

Allen Wrench 3/16”

2 Short Pcs. of 2 X 4 Blocking

Bubble Level

Protective Eyewear

Note: Prior to plow assembly, park vehicle on level grade and install plow mount

receiver (shipped separately). Clearance under receiver should measure

between 8 to 16 inches above grade (Figure 1). Interceptor can be installed

with leg turned up or down as needed for proper push frame clearance

(Shown turned up in illustrations).

1. Insert interceptor into receiver – leg up. Secure with pins (interceptor has

choice of holes to allow for clearance when aligning blade). Hold push frame

against interceptor. Select 4 bolt hole pattern that positions push frame 8"

to 10" above grade. If lowest bolt pattern is too high, remove interceptor

and turn leg down. Bolt push frame (4 bolts 1/2" x 4" w/flat washers and

lock nuts) to proper hole height on interceptor – leave bolts snug tight for

now.

Receiver Clearance

8" - 16"

Figure 1

Interceptor

Push Frame

4 Bolts 1/2" x 4",

8 Flat Washers,

4 Lock Nuts

Push Frame

Clearance 8" - 10"

2. Push set collar tight against receiver – hold and tighten set screw with 3/16"

Allen wrench (Figure 2).

3. With bolts snug tight, level push frame horizontally (Figure 3).

4. Check push frame for vertical plumb (Figure 4). If plumb, tighten 4 bolts

now and go to step 5. If not plumb, refer to the following shim procedure.

Bubble

Plumb

Figure 2

Figure 3

8" - 10"

Bubble Level

8" - 10"

Figure 4

6 DR

®

REDI-PLOW™ PLUS

Page 7

Figure 5

A

A

A

A

d

J

Shim Here

5. If the push frame leans towards front of vehicle. Shim at top pair of bolts

(Figure 5). If the push frame leans away from front of vehicle. Shim at

bottom pair of bolts (Figure 6).

WHEN SHIMMING IS COMPLETE – TIGHTEN ALL BOLTS.

6. Refer to exploded view components for plow blade parts before performing

next step (Figure 7).

Note: Rubber Blade should be room temperature before assembly.

7. Apply soapy water solution to channel areas of the Rubber Blade and bottom

section of Aluminum Blade where they will mate together (Figure 8).

8. Slide end of rubber edge with matching channel in bottom half of aluminum

blade and center on bottom half.

9. Turn bottom half of blade over and set it on wood blocks, one at each end as

shown (Figure 9). Take top half and connect tongue and groove joint with

bottom half. Slide top half until centered with bottom half of blade.

Figure 6

End Plate

Bottom

Section of

luminum

Blade

Figure 7

Shim Here

Blade Marker

Rubber Blade

Slide Hinge

Box End

Top

Section of

luminum

Blade

Rubber

Blade

Figure 8

Tongue an

Groove

oint

Figure 9

Bottom Section of

luminum Blade

pply Soapy

Water Solution

Use 2x4 to prop

bottom of Blade

up at both ends

CONTACT US AT www.DRpower.com 7

Page 8

10. Place each side hinge on blade and align edge of hinge with factory mark on

A

A

A

A

blade (Figure 10).

11. When both hinges are properly aligned – they should measure 22 1/2" apart

(Figure 11).

12. At end of blade, insert two square nuts in each channel – flat side facing out.

Slide nuts over to hinge and align them with holes at top and bottom (Figure

12).

13. Turn 3/8" x 3/4" hex bolts with flat washer into nuts on top section of blade

and leave loose (Figure 13). Turn 3/8" x 3/4" hex bolts into nuts on bottom

section of blade and leave loose.

14. Make sure slide hinge is lined up with mark (Figure 10). Using 9/16"

wrench, tighten hex bolts in top section first (Figure 14). Then tighten hex

bolts on bottom section.

15. Using 5/16" bit, drill a hole through blade in each factory punched hole on

slide hinge (Figure 15). Turn a (short) 3/8" self threading bolt into each

drilled out hole and tighten. Repeat steps to attach opposite slide hinge.

lign this edge of each Slide

Hinge with Factory mark

Slide Hinge

Factory Marks

on Blade

22-1/2" apart

Figure 10

22-1/2"

Tighten these

bolts second

Figure 14

Drill 5/16" Hole

in Blade

Figure 15

Tighten these

bolts first

Factory

Hole in

Slide

Hinge

Figure 11

lign Square Nut here at bottom

lign edge

with Factory

Mark

lign Square

Nut here at top

Figure 12

Bottom

Hex Head

Bolt

w/Flat

Washer

Top Hex Head Bolt w/Flat

Washer (loose for now)

Figure 13

8 DR

®

REDI-PLOW™ PLUS

Page 9

Drill 5/16" Hole at

#

Factory Mark (1 at

each end)

Figure 16

16. At tongue and groove joint, drill a 5/16" pilot hole at factory mark in v-

groove at each end of blade (Figure 16).

17. Using a 9/16" wrench, turn a (short) 3/8" self threading bolt into 5/16" pilot

hole and tighten (Figure 17). Repeat at other end.

18. Using torque wrench, tighten all (6) bolts on each slide hinge to 31 ft/lbs.

(Figure 18).

19. At bottom of blade, check to make sure rubber edge is centered, then drill a

3/16" pilot hole at factory mark in v-groove (4 locations) – drill only through

first layer of aluminum and into rubber (Figure 19). Repeat this drilling

procedure for three remaining marks.

20. Using Phillips #3 bit, run a self drilling screw into each of the four pilot holes

(Figure 20). This prevents rubber from movement.

21. Hang blade on push frame in the transport position and insert key hole pins

(Figure 21).

22. Attach tether cord to pins by feeding end of cord through hole in pin and

tying a square knot (Figure 22).

3 Philips

Self Drilling

Screw

3/8" Self

Threading Bolt

Figure 17

*Torque Bolts to 31 ft/lb.

Figure 18

3/16" Drill Bit

Factory

Mark

(4X)

Figure 20

Keyhole Pin

Slide Hinge

Figure 21

Tether

Cord

Square

Figure 19

Figure 22

CONTACT US AT www.DRpower.com 9

Knot

Page 10

23. Insert two square nuts into top channel (Figure 23). Turn a hex head jam

r

J

f

nut onto the stud of blade marker and align marker with hole on lift handle

and bolt marker and handle to blade using square nut in channel.

24. Turn 3/8" x 3/4" bolt into other hole on handle and thread to nut in channel

(Figure 24). Position the handle flush with blade edge. Then tighten both

bolts on lift handle. Repeat at other end.

25. Attach rubber end and metal cap plate to end of blade with four long self

threading bolts (Figure 25).

26. Tighten all bolts until rubber begins to compress to blade. Insert a 5th bolt

to tighten bottom of rubber to bottom of end plate. Use flat washer and lock

nut (Figure 26).

27. Tighten all bolts equally. Repeat box end assembly at opposite end (Figure

27).

Blade

Marke

Hex Head

am Nut

2 Square Nuts

in Channel

lat side up

Figure 23

Bolt

Figure 26

Lock Nut

Flat

Washer

Figure 24

Four Long Self

Threading Bolts

Metal End Cap

Rubber Box End

Figure 27

10 DR

®

REDI-PLOW™ PLUS

Figure 25

Page 11

CONTACT US AT www.DRpower.com 11

Page 12

Chapter 3: Operating The DR® REDI-PLOW™ PLUS

Basic Snowplowing Practices and Tips

The REDI-PLOW is designed to make moving snow convenient and easy. By following these simple practices, snow removal can

be safe and enjoyable.

If blade is kept in warm storage, set blade outside and allow to cool-this prevents snow from freezing to blade when plowing.

Setting the blade straight forward is the most efficient way to move snow.

Always keep current with fresh snowfall, it’s easier to plow fresh snow. Wet snow can compact and freeze which requires

chipping to break it loose before attempting to move it.

From the start of the season, push the snow far enough out to allow for future snowfalls.

Avoid overloading your equipment-push only enough snow with each pass to get the job done.

When pushing snow onto a pile, always do so with blade in the straight forward position. Piling snow with blade angled may

cause damage to plow or vehicle components.

When pushing new snow to stack up against hardened piles, start a new pile first and then push it up on to hard pile.

Use caution when plowing next to a building wall. Make first pass about 3 feet away, make second pass about 2 feet away and

third pass about 1 foot away.

When transporting blade, secure it to hanger brackets with pins or locks.

On 4WD select low range, if equipped.

Always know the terrain before plowing.

Operating instructions

The design of your plow is for pushing snow. Do not use it for any other purpose as it could cause damage to the plow or

machine.

Before performing any adjustments to the plow or any other procedure or inspection, stop the vehicles engine, set the parking

brake and remove the key.

Read and understand all safety warnings listed in Chapter 2 “General Safety

Keyhole Pins Secure Blade

During Transporting

Figure 28

Keyhole Pins Reinstalled To

Secure Blade During Plowing

Rules” before using your REDI-PLOW.

Note: If blade is kept in warm storage, set blade outside and allow to cool - this

prevents snow from freezing to blade when plowing.

LOWERING THE BLADE FOR PUSHING SNOW:

1. Step behind the Plow and remove the keyhole pin (Figure 28).

2. Lift one side of the blade out of retainer until the slide hinge fits over the

push bar, then lower blade to ground.

3. Re-insert keyhole pin (Figure 29). Repeat same procedure for other side of

blade.

TO PUSH SNOW:

Follow vehicle manufacturers’ specifications for snowplowing.

Note: Do not exceed 10 MPH when plowing.

Figure 29

12 DR

®

REDI-PLOW™ PLUS

Use lowest transmission gear, on 4WD select low range if equipped.

Page 13

4. To start a pass, Drive forward slowly allowing for tire traction and for the

A

A

A

blade to accumulate snow.

5. As you come to the end of the pass, reduce speed and start applying brakes

as needed.

6. Back up to disengage the blade and continue backing up until you are

realigned for next push.

7. Repeat this procedure until job is finished. Deep and/or compacted snow

may require several passes.

The blade can be angled by removing swivel pin, turning blade to desired angle

position and reinserting pin (Figure 30).

Angled Interceptor Note: There are two holes in the interceptor shaft. When

inserting angle interceptor into front mount receiver,

select the hole which allows blade to swing as far as

possible without contacting vehicle.

TO STORE BLADE FOR TRANSPORTING:

Reverse procedure from “Lowering the Blade for Pushing Snow” and re-insert

keyhole pins (Figure 28).

Do not exceed 65 MPH when transporting plow.

Note: When transporting blade, secure it to hanger brackets with pins or locks.

Swivel Pin

ngle

Interceptor

Push Frame

Straight Position

ngled to Right

ngled to Left

Figure 30

CONTACT US AT www.DRpower.com 13

Page 14

Chapter 4: Parts Lists and Schematic Diagrams

Parts List – DR® REDI-PLOW™ PLUS

Note: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

1 33601 Aluminum Blade, Top, 82"

2 33602 Aluminum Blade, Bottom, 82"

3 33603 Rubber Cutting Edge, 82"

4 33604 Rubber Box End

5 33605 Metal End Cap

6 33606 Slide Hinge

7 33607 Bolt, Self Threading, 3/8" x 1" ZP

8 33608 Bolt, Hex Head, 3/8" x 3/4" ZP

9 33609 Washer, Flat, 3/8" ZP

10 33610 Push Frame w/Hardware Kit

33611 Hardware Kit, Push Frame

11 33612 Keyhole Pin

12 33613 Lift Handle

13 33614 Bolt, Self Threading, 3/8" x 2- 1/2" ZP

14 33615 Bolt, Hex, 1/2" x 4" GR 8 ZP

Ref# Part# Description

15 33616 Nut, Lock, 1/2'' ZP

16 33617 Washer, Flat, 1/2" ZP

17 33618 Nut, Square, 3/8'' ZP

18 33619 Label, Operation & S/N, RDP Plus

19 33620 Leveling Shim

20 33621 Hitch Pin

21 33622 Hair Pin

22 33623 Blade Marker Kit, Top Mount

23 33624 Angle Interceptor Kit

24 33625 Swivel Pin

25 33626 Set Collar

26 33627 Bolt, 3/8" x 1- 3/4" GR 5 ZP

27 33628 Nut, Nylon Lock, 3/8'' ZP

28 33629 Screw, Self Drilling, #14 x 1" ZP

- 34007 Label, RDP Plus Logo

14 DR

®

REDI-PLOW™ PLUS

Page 15

DR

®

REDI-PLOW™ PLUS

2-Year Limited Warranty

Terms and Conditions

The DR

to ordinary and normal consumer use; ninety (90) days for any other use.

For the purposes of all the above warranties, “ordinary and normal consumer use” refers to non-commercial

residential use and does not include misuse, accidents, or damage due to inadequate maintenance.

DR

this type is used. DR

duration to a period of two (2) years in consumer use, ninety (90) days for any other use.

The 2-Year Limited Warranty on the DR

The 2-Year Limited Warranty is applicable only to the original owner.

The warranty holder is responsible for the performance of the required maintenance as defined by the manufacturer's

owner's manuals. This warranty does not cover attachments and accessories to the machine.

REDI-PLOW™ PLUS is warranted for two (2) years against defects in materials or workmanship when put

Power Equipment certifies that the DR

Power Equipment however, limits the implied warranties of merchantability and fitness in

REDI-PLOW™ PLUS is fit for ordinary purposes for which a product of

REDI-PLOW™ PLUS starts on the date the machine ships from our factory.

During the warranty period, the warranty holder is responsible for the machine transportation charges, if required.

During the warranty period, warranty parts will ship by standard method at no charge to the warranty holder.

Expedited shipping of warranty parts is the responsibility of the warranty holder.

SOME STATES DO NOT ALLOW LIMITATIONS ON THE LENGTH OF IMPLIED WARRANTIES, SO THE ABOVE

LIMITATIONS MAY NOT APPLY TO YOU.

DR

Power Equipment shall not be liable under any circumstances for any incidental or consequential damages or

expenses of any kind, including, but not limited to, cost of equipment rentals, loss of profit, or cost of hiring services

to perform tasks normally performed by the DR

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU HAVE OTHER RIGHTS, WHICH VARY FROM

STATE TO STATE.

REDI-PLOW™ PLUS.

15 DR

®

REDI-PLOW™ PLUS

Page 16

Daily Checklist for the DR® REDI-PLOW™ PLUS

To help maintain your REDI-PLOW for optimum performance, we recommend you follow this checklist each time you use your machine.

Before performing any adjustments to the plow or any other procedure or inspection, stop the vehicles engine, set the parking

brake and remove the key.

[ ] RUBBER BLADE: Check the Blade for wear or damage.

[ ] GENERAL CONDITION: Check the general condition of the machine, e.g.; nuts, bolts, welds etc.

End of Season and Storage

Before performing any adjustments to the plow or any other procedure or inspection, stop the vehicle’s engine, set the parking

brake and remove the key.

For maximum blade life, periodically retighten bolts and protect blade from sun by storing it inside or covered.

75 MEIGS ROAD, P.O. BOX 25, VERGENNES, VERMONT 05491

©2013 Country Home Products, Inc. All rights reserved PN 80771_ 090113 / CHP 336491

Loading...

Loading...