Page 1

®

8-TON DR

WOOD SPLITTER

SAFETY & OPERATING INSTRUCTIONS

DR Power Equipment

Serial No.

Order No.

READ AND UNDERSTAND THIS MANUAL AND ALL INSTRUCTIONS BEFORE OPERATING THIS 8-TON

DR WOOD SPLITTER.

Toll-free phone: 1-800-DR-OWNER (376-9637)

Fax: 1-802-877-1213

Website: www.DRpower.com

Page 2

Table of Contents

Chapter 1: General Safety Rules..........................................................................................................4

Chapter 2: Setting Up Your 8-Ton DR Wood Splitter .........................................................................9

Chapter 3: Operating Your Wood Splitter.........................................................................................18

Chapter 4: Inspection And Maintenance .......................................................................................... 22

Chapter 5: Troubleshooting...............................................................................................................27

Chapter 6: Class II Receiver Mount Accessory .................................................................................29

Chapter 7: Parts Lists, Schematic Diagrams And Warranty............................................................. 32

Conventions used in this manual

THIS INDICATES A HAZARDOUS SITUATION, WHICH, IF NOT FOLLOWED, WILL RESULT IN DEATH

OR SERIOUS INJURY.

THIS INDICATES A HAZARDOUS SITUATION, WHICH, IF NOT AVOIDED, COULD RESULT IN DEATH

OR SERIOUS INJURY.

THIS INDICATES A HAZARDOUS SITUATION, WHICH, IF NOT AVOIDED, COULD RESULT IN MINOR

OR MODERATE INJURY.

THIS INFORMATION IS IMPORTANT IN THE PROPER USE OF YOUR MACHINE. FAILURE TO FOLLOW

THIS INSTRUCTION COULD RESULT IN DAMAGE TO YOUR MACHINE OR PROPERTY.

2 8-TON DR

®

WOOD SPLITTER

Page 3

Serial Number and Order Number

A Serial Number is used to identify your machine and is located on the Serial Number Label on your

machine. An Order Number is used to check and maintain your order history and is located on the

upper left portion of your packing slip. For your convenience and ready reference, enter the Serial

Number and Order Number in the space provided on the front cover of this manual.

Additional Information and Potential Changes

DR Power Equipment reserves the right to discontinue, change, and improve its products at any time

without notice or obligation to the purchaser. The descriptions and specifications contained in this

manual were in effect at printing. Equipment described within this manual may be optional. Some

illustrations may not be applicable to your machine.

Specifications

MECHANICAL SPECIFICATIONS

Slide Rail...................................................................... 4" x 4", reinforced, heavy duty, steel tube

Wedge.......................................................................... high-carbon steel, 3/4" thick

Force/Tonnage............................................................ 8 ton

Cylinder Stroke ............................................................ 18"

Log Opening ............................................................... 18" maximum

Operating Weight........................................................ 138 LBS

Engine.......................................................................... 475 Power Built series Briggs & Stratton; 4.75 ft. lbs.

torque (148cc)

HYDRAULIC SPECIFICATIONS

Cylinder Size................................................................ 3" x 18", trunnion mount cylinder, 1.25" rod

Hydraulic System Capacity

(including cylinder, tank, and hoses)......................... 154 oz. (4.5 liters)

Safety Release Control Valve ...................................... Detent, auto return

Gear Pump .................................................................. single-stage, 2.7 GPM

Hydraulic Fluid

Above 30° F ................................................................. Use AW-32, 10W tractor hydraulic oil (non foaming)

or ATF Dextron III

Below 30° F.................................................................. Use only ATF Dextron III

SHIPPING SPECIFICATIONS

Shipping Weight.......................................................... 148 LBS

Contact us at www.DRpower.com 3

Page 4

Chapter 1: General Safety Rules

READ THIS SAFETY AND OPERATING MANUAL BEFORE YOU USE THE 8-TON DR WOOD SPLITTER.

BECOME FAMILIAR WITH THE SERVICE RECOMMENDATIONS TO ENSURE THE BEST

PERFORMANCE FROM YOUR SPLITTER.

DO NOT ATTEMPT TO ASSEMBLE, OPERATE, OR MAINTAIN OUR PRODUCT WITHOUT FULLY

UNDERSTANDING ALL OUR INSTRUCTIONS AND SAFETY PRECAUTIONS. DO NOT OPERATE THE

WOOD SPLITTER UNLESS YOU READ AND UNDERSTAND THE INSTRUCTIONS AND WARNINGS IN

THIS MANUAL. IF YOU ARE EVER UNSURE ABOUT AN ACTION YOU ARE ABOUT TO TAKE, DON’T

DO IT. CONTACT US AT WWW.DRPOWER.COM OR CALL DR POWER EQUIPMENTS’ TOLL-FREE

SUPPORT AT 1-800-DR-OWNER (376-9637) FOR HELP OR INFORMATION.

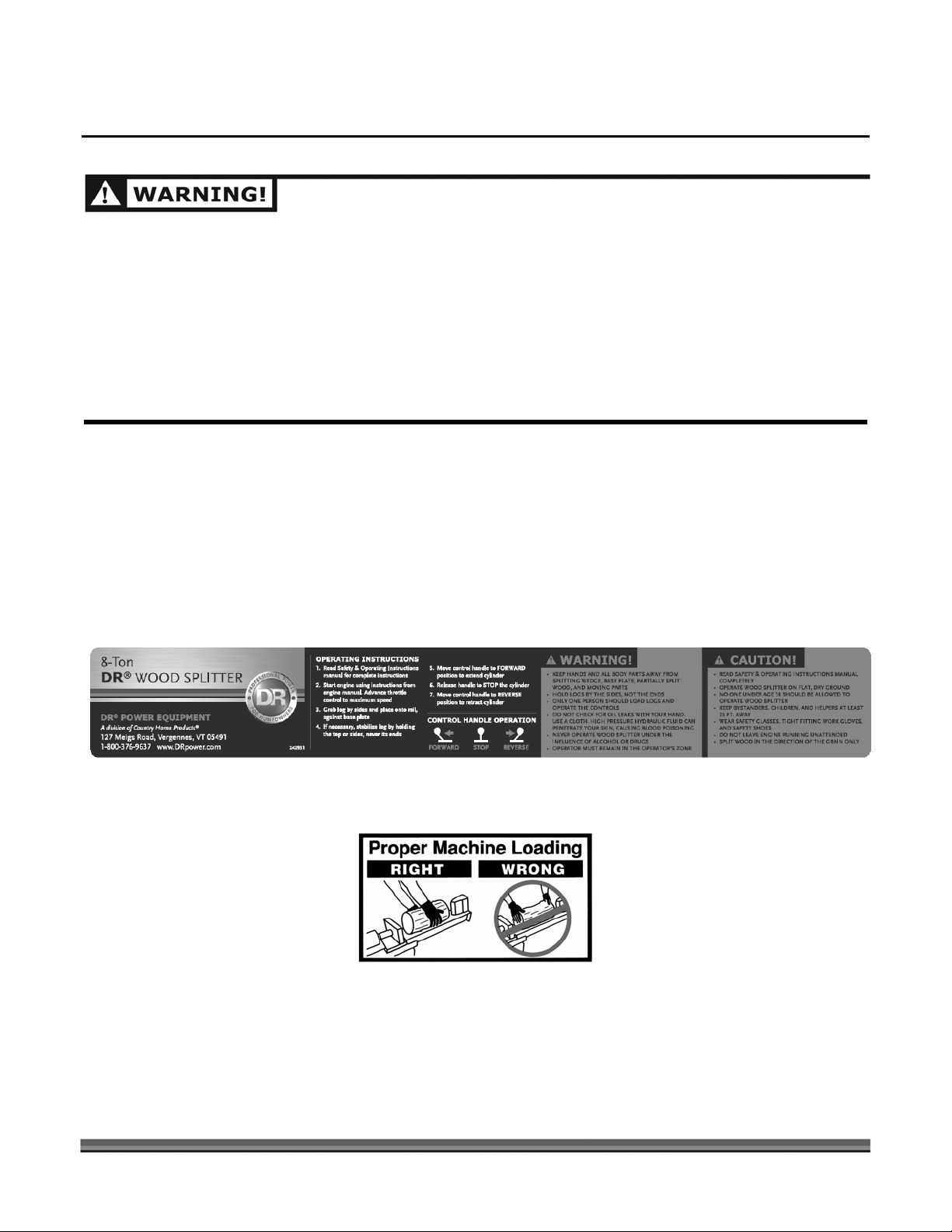

Labels

Your 8-TON DR WOOD SPLITTER carries prominent labels as reminders for its proper and safe use.

Shown below are copies of all the safety and operation labels that appear on the equipment. Take a

moment to study them and make a note of their location on your 8-TON DR WOOD SPLITTER as you

assemble and before you operate the unit. Replace damaged or missing safety and operation labels

immediately.

4 8-TON DR

®

WOOD SPLITTER

242931

265941

Page 5

Personal Protection

• TO AVOID PERSONAL INJURY OR DEATH, CAREFULLY READ AND UNDERSTAND ALL

INSTRUCTIONS PERTAINING TO THE WOOD SPLITTER INCLUDING THE ENGINE

MANUFACTURER’S OPERATING AND MAINTENANCE INSTRUCTION MANUAL.

• ALWAYS WEAR PROTECTIVE GEAR, SUCH AS SAFETY GOGGLES, TIGHT-FITTING GLOVES

WITHOUT DRAW STRINGS OR LOOSE CUFFS, STEEL-TOED SHOES, AND A PROTECTIVE HEARING

DEVICE.

• TO PREVENT INJURY, MAKE SURE ALL DECALS ARE ATTACHED TO THE WOOD SPLITTER AND

ARE LEGIBLE AT ALL TIMES.

Worksite Safety

NEVER OPERATE THE ENGINE IN AN ENCLOSED AREA. EXHAUST FUMES CONTAIN CARBON

MONOXIDE THAT CAN BE DEADLY WHEN INHALED. MAKE SURE THE AREA IS WELL VENTILATED.

• TO AVOID TRIPPING, DO NOT LEAVE TOOLS, LOGS, OR OTHER ITEMS LYING AROUND THE

WORK AREA.

• NEVER OPERATE YOUR WOOD SPLITTER ON SLIPPERY, WET, MUDDY, OR ICY SURFACES. THE

LOCATION YOU CHOOSE SHOULD BE SOLID, LEVEL, DRY, AND FREE FROM ANY TALL GRASS,

BRUSH, OR OTHER INTERFERENCES.

• NEVER USE YOUR WOOD SPLITTER AT NIGHT.

Operating Safety

• ALLOW ONLY ONE (1) PERSON TO LOAD AND OPERATE THE WOOD SPLITTER.

• ALLOW ONLY ADULTS TO OPERATE THE WOOD SPLITTER. NO ONE UNDER THE AGE OF 18

SHOULD BE ALLOWED TO OPERATE THE WOOD SPLITTER.

• ALWAYS KEEP BYSTANDERS, INCLUDING CHILDREN AND PETS, AT LEAST TWENTY-FIVE (25)

FEET AWAY FROM THE WORK AREA. ONLY THE OPERATOR SHOULD STAND NEAR THE

EQUIPMENT AND ONLY WITHIN THE SAFE OPERATING AREA PRESCRIBED IN THIS MANUAL

(SEE THE PHOTOS ON SAFE AND UNSAFE OPERATING ZONES IN THE “OPERATING YOUR

WOOD SPLITTER” SECTION IN CHAPTER 4.)

Contact us at www.DRpower.com 5

Page 6

• WHEN THE RAM OF THE WOOD SPLITTER IS IN THE RETURN MODE, KEEP YOUR HANDS OFF

THE MACHINE — THE WOOD SPLITTER IS DESIGNED TO AUTOMATICALLY STOP THE RAM

WHEN THE CYLINDER IS FULLY RETRACTED.

• ALWAYS DISCONNECT THE SPARK PLUG WIRE WHEN THE WOOD SPLITTER IS NOT IN

OPERATION.

• DO NOT ALLOW ANY PERSON TO OPERATE THE WOOD SPLITTER UNTIL THEY HAVE READ

AND UNDERSTOOD THE SAFE OPERATING INSTRUCTIONS CONTAINED IN THIS MANUAL.

• DO NOT, UNDER ANY CIRCUMSTANCES, ALTER YOUR WOOD SPLITTER. THIS EQUIPMENT

WAS DESIGNED AND ENGINEERED TO BE USED IN ACCORDANCE WITH THE OPERATING

INSTRUCTIONS. ALTERING THE EQUIPMENT, OR USING THE EQUIPMENT IN SUCH A WAY AS

TO CIRCUMVENT ITS DESIGN CAPABILITIES AND CAPACITIES, COULD RESULT IN SERIOUS OR

FATAL INJURY AND WILL VOID THE WARRANTY.

• NEVER OPERATE, OR ALLOW ANYONE ELSE TO OPERATE, THIS EQUIPMENT WHILE UNDER

THE INFLUENCE OF MEDICATION, DRUGS, OR ALCOHOL.

• NEVER WEAR LOOSE CLOTHING OR JEWELRY THAT MAY GET CAUGHT OR BECOME

ENTANGLED IN THE WOOD SPLITTER.

• NEVER PLACE HANDS OR FEET BETWEEN LOG AND SPLITTING WEDGE OR BETWEEN LOG

AND RAM DURING THE FORWARD OR REVERSE STROKE.

• DO NOT STRADDLE OR REACH ACROSS THE SPLITTING AREA WHEN OPERATING THE WOOD

SPLITTER.

• DO NOT STEP OVER YOUR WOOD SPLITTER WHEN THE ENGINE IS RUNNING, BECAUSE YOU

MAY TRIP OR ACCIDENTALLY ENGAGE THE RAM.

• NEVER ATTEMPT TO LOAD YOUR WOOD SPLITTER WHILE THE RAM IS IN MOTION.

• ONLY USE YOUR HAND TO OPERATE THE CONTROL VALVE HANDLE.

Log Splitting Safety

• ALWAYS KEEP YOUR FINGERS AWAY FROM ANY CRACKS THAT OPEN IN THE LOG DURING THE

SPLITTING OPERATION.

• ALWAYS MAKE SURE THAT BOTH ENDS OF THE LOG YOU ARE SPLITTING ARE CUT AS SQUARE

AS POSSIBLE. THIS WILL PREVENT THE LOG FROM SLIDING OUT OF POSITION WHILE UNDER

PRESSURE. LOGS SHOULD BE 18 INCHES OR SHORTER IN LENGTH.

• NEVER PILE LOGS TO BE SPLIT IN A MANNER THAT WILL CAUSE YOU TO REACH ACROSS THE

WOOD SPLITTER.

6 8-TON DR

®

WOOD SPLITTER

Page 7

Maintenance and Repair

• FOLLOW ALL SAFETY RULES. MOST ACCIDENTS INVOLVING THE OPERATION, MAINTENANCE, OR

REPAIR OF PRODUCTS OCCUR BECAUSE THE ASSEMBLER/OWNER/OPERATOR FAILED TO OBSERVE

BASIC SAFETY RULES OR OPERATING INSTRUCTIONS.

• ALWAYS INSPECT YOUR WOOD SPLITTER BEFORE EACH USE. MAKE SURE ALL NUTS, BOLTS,

SCREWS, HYDRAULIC FITTINGS, HOSE CLAMPS, ETC. ARE SECURELY TIGHTENED.

• ALWAYS CHECK THE FLUID LEVEL IN THE HYDRAULIC FLUID TANK AND ENGINE OIL RESERVOIR

BEFORE EACH USE.

• NEVER OPERATE YOUR WOOD SPLITTER WHEN IT IS IN NEED OF REPAIR OR IS IN POOR

MECHANICAL CONDITION.

• NEVER TAMPER WITH THE ENGINE TO RUN IT AT EXCESSIVE SPEEDS. THE MAXIMUM ENGINE

SPEED IS PRESET AND IS WITHIN SAFETY LIMITS.

• NEVER MAKE ALTERATIONS TO YOUR WOOD SPLITTER IN ANY MANNER. SUCH ALTERATIONS MAY

CAUSE THE WOOD SPLITTER TO BECOME UNSAFE AND WILL VOID THE WARRANTY.

• ALWAYS CLEAN THE UNIT AFTER EACH USE. IF POSSIBLE, STORE THE UNIT INSIDE OR COVER IT

COMPLETELY IF STORED OUTSIDE.

Refueling

• ONLY REFUEL THE WOOD SPLITTER OUTDOORS IN A CLEAR AREA VOID OF GAS FUMES OR

SPILLED GASOLINE.

• ALWAYS USE AN APPROVED FUEL CONTAINER TO CARRY GASOLINE.

• ALWAYS REPLACE THE WOOD SPLITTER GAS CAP AND THE FUEL CONTAINER CAP SECURELY.

• IF GASOLINE IS SPILLED, MOVE THE MACHINE AWAY FROM THE AREA OF THE SPILL AND AVOID

CREATING ANY SOURCE OF IGNITION UNTIL THE SPILLED GASOLINE HAS COMPLETELY

EVAPORATED.

• TAKE A CLASS B FIRE EXTINGUISHER WITH YOU WHEN OPERATING THE WOOD SPLITTER IN DRY

AREAS AS A PRECAUTIONARY MEASURE AGAINST POSSIBLE FLYING SPARKS.

• ALWAYS STORE GASOLINE IN AN APPROVED, TIGHTLY SEALED CONTAINER. STORE THE

CONTAINER IN A COOL, DRY PLACE. DO NOT STORE THE CONTAINER IN A HOUSE OR NEAR ANY

HEATING APPLIANCE.

• DO NOT SMOKE OR HAVE OPEN FLAMES WHEN REFUELING THE ENGINE. DO NOT SPILL FUEL. IF

FUEL SHOULD SPILL, QUICKLY WIPE UP THE SPILL AND ALLOW THE EXCESS TO EVAPORATE

BEFORE CONTINUING. MAKE SURE GASOLINE SOAKED RAGS ARE PROPERLY DISPOSED OF.

• DO NOT FILL THE GAS TANK WHILE THE ENGINE IS HOT OR RUNNING. ALLOW TIME FOR THE

ENGINE TO COOL DOWN BEFORE REFUELING.

Contact us at www.DRpower.com 7

Page 8

Preventing Fires

• NEVER OPERATE THE WOOD SPLITTER NEAR A FLAME OR SPARK. OIL AND GASOLINE ARE

FLAMMABLE AND CAN EXPLODE.

• NEVER SMOKE WHILE OPERATING OR REFUELING THE WOOD SPLITTER. GASOLINE, OIL, AND

EVEN GAS FUMES CAN EXPLODE.

• THE WOOD SPLITTER IS EQUIPPED WITH AN INTERNAL COMBUSTION ENGINE AND SHOULD

NOT BE USED ON OR NEAR ANY UNIMPROVED FOREST-COVERED, BRUSH-COVERED, OR

GRASS COVERED LAND UNLESS THE ENGINE’S EXHAUST SYSTEM IS EQUIPPED WITH A SPARK

ARRESTER MEETING LOCAL OR STATE LAWS (IF ANY). IF A SPARK ARRESTER IS USED, IT

SHOULD BE MAINTAINED IN EFFECTIVE WORKING ORDER BY THE OWNER AND/OR

OPERATOR.

Hydraulic Safety

HIGH FLUID PRESSURES ARE DEVELOPED IN HYDRAULIC LOG SPLITTERS. PRESSURIZED

HYDRAULIC FLUID ESCAPING THROUGH A PIN HOLE OPENING CAN PUNCTURE SKIN AND CAUSE

SEVERE BLOOD POISONING. THEREFORE, THE FOLLOWING INSTRUCTIONS SHOULD BE HEEDED

AT ALL TIMES.

• DO NOT OPERATE THE UNIT WITH FRAYED, KINKED, CRACKED OR DAMAGED HOSES, FITTINGS,

OR TUBING. (B) STOP THE ENGINE AND RELIEVE HYDRAULIC SYSTEM PRESSURE BEFORE

CHANGING OR ADJUSTING FITTINGS, HOSES, TUBING, OR OTHER SYSTEM COMPONENTS.

• DO NOT ADJUST THE PRESSURE SETTINGS OF THE PUMP OR VALVE.

• DO NOT CHECK FOR LEAKS WITH YOUR HAND. LEAKS CAN BE LOCATED BY PASSING

CARDBOARD OR WOOD OVER THE SUSPECTED AREA: LOOK FOR DISCOLORATION. IF INJURED

BY ESCAPING FLUID, SEE A DOCTOR AT ONCE. SERIOUS INFECTION OR REACTION CAN

DEVELOP IF PROPER MEDICAL TREATMENT IS NOT ADMINISTERED IMMEDIATELY.

A Note to All Users

Under California law, and the laws of some other states, you are not permitted to operate an internal

combustion engine using hydrocarbon fuels without an engine spark arrester. This also applies to

operation on US Forest Lands. All 8-TON DR WOOD SPLITTERS shipped to California, New Mexico and

Washington State are provided with spark arresters. Failure of the owner or operator to maintain this

equipment in compliance with state regulations is a misdemeanor under California law and may be in

violation of other state and/or federal regulations. Contact your State Park Association or the

appropriate state organization for specific information in your area.

8 8-TON DR

®

WOOD SPLITTER

Page 9

Chapter 2: Setting Up Your 8-Ton DR Wood Splitter

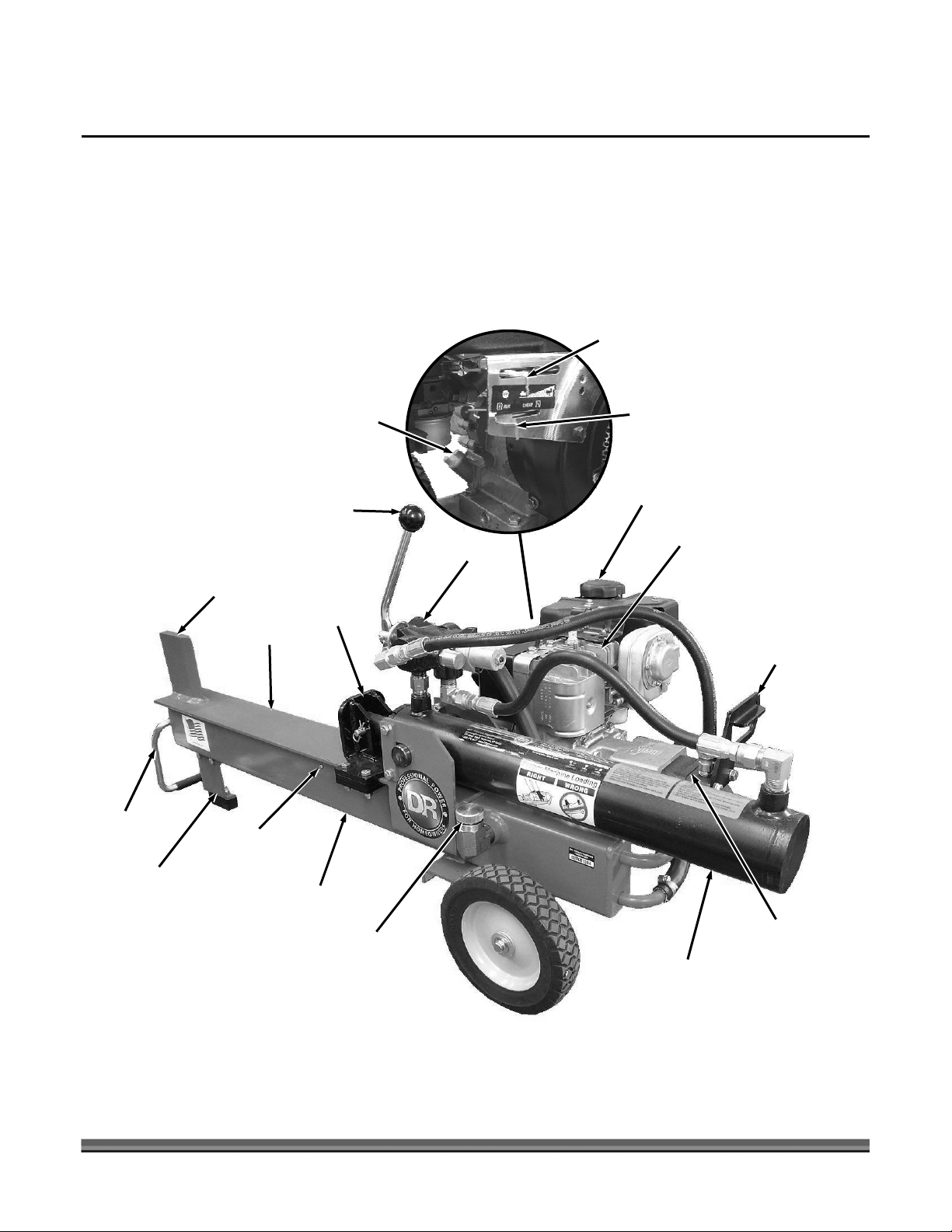

It may be helpful to familiarize yourself with the controls and features on your Splitter by reviewing the

picture in Figure 1 before beginning the steps outlined in this chapter.

8-Ton DR Wood Splitter Controls and Features

Engine Oil

Fill Cap

Valve

Control

Handle

Splitting

Wedge

Push

Plate

Rail

Throttle

Choke

Fuel Tank

Cap

Engine

Valve

Rear Lift

Handle

Front Lift

Handle

Front Leg

with Rubber

Foot

Hydraulic

Fluid Level

Screw

Hydraulic

Tank

Hydraulic Tank

Fill Cap

Hydraulic

Pump

Cylinder

Figure 1

Contact us at www.DRpower.com 9

Page 10

Tools needed:

y

y

• 10" crescent wrench

• Flathead Screwdriver

• 7/16" open-end wrenches

• 1/2" open-end wrenches

• Utility Knife

• Hammer

• Long-necked Funnel

• Tin Cutters

Supplies needed:

• Hydraulic fluid (see “Specifications”, page 2)

• Engine oil (see engine manual)

• General purpose grease

Shipping List

The following chart lists the parts that are shipped with the

8-TON DR WOOD SPLITTER.

DESCRIPTION

Base Unit (engine) 1

Cylinder and Push Plate Assembl

Parts Box Contents

Front Leg Assembl

Tire, 8" 2

Hardware Bag 1

Hardware Bag Contents

Bolt (5/16-18 x 1") 1

Bolt (5/16-18 x 3/4") 4

Nut, Push-on 2

Nut, Nylon Lock (5/16")

Plate, Cylinder Retainer 2

Washer, Flat (1/2") 4

Users Manual Bag Contents

Handle Assembly Kit (includes

Handle, Knob, Clevis Pins and

Hairpin Clips)

S & O Manual 1

Engine Users Manual 1

1

QTY

1

5

1

10 8-TON DR

®

WOOD SPLITTER

Page 11

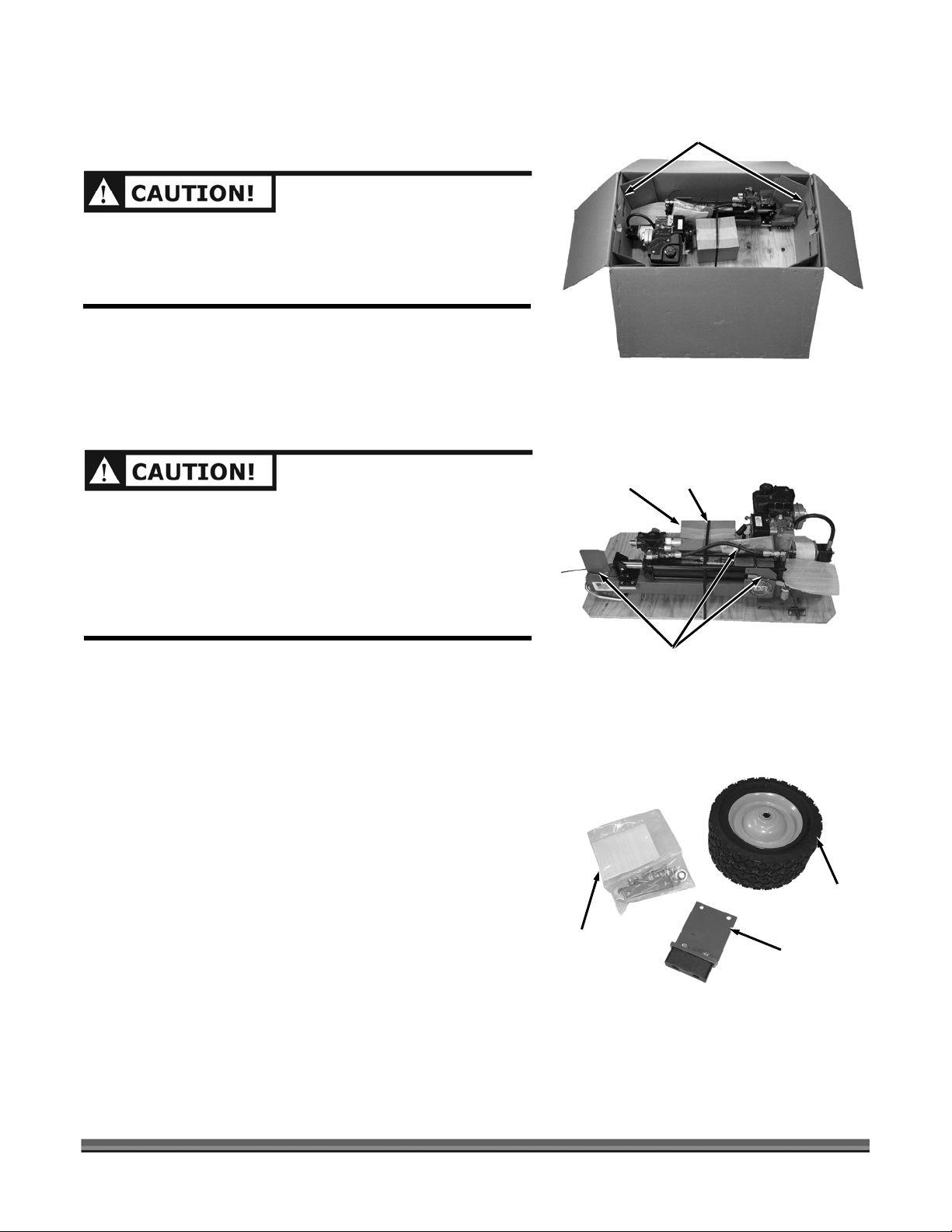

Unpacking the Crate

WEAR EYE PROTECTION WHEN CUTTING THE BANDING.

THE BANDING MAY HAVE A LOT OF TENSION ON IT AND

MAY SNAP AND CUT YOU. ALWAYS STAND TO ONE SIDE

WHEN CUTTING THE BANDING.

1. Cut the banding (tin cutters) and pull the box off the

pallet.

2. Cut the tape (utility knife) and open the box. Pull out

both Support Inserts (Figure 2).

THE WOOD SPLITTER WEIGHS APPROXIMATELY 140

LBS. WE RECOMMEND TWO PEOPLE FOR STEP 3.

BE CAREFUL WHEN WORKING NEAR THE SPLITTING

WEDGE. THE WEDGE CAN EASILY CUT OR PUNCTURE

THE SKIN IF YOU CONTACT IT AT THE POINTED TOP

CORNER OR SHARP FRONT EDGE.

Figure 2

Parts

Box

Support

Inserts

Plastic

Banding

3. With a person at each end of the box, lift the plywood

base that the Splitter is attached to, out of the box.

4. Cut the remaining banding strap and Cable Ties (tin

cutters) (Figure 3).

5. Open the Parts box, and make sure all the smaller

parts have been shipped (Figure 4). The chart in the

“Shipping List” (previous page) provides a complete

list of all the parts shipped with your Wood Splitter. If

you have any questions, please contact us at

www.DRpower.com or call DR Power Equipment at 1–

800-DR-OWNER (376-9637).

Figure 3

Hardware

Package

Figure 4

Cable

Ties

Two 8"

Tires

Front Leg

with Rubber

Foot

Contact us at www.DRpower.com 11

Page 12

Assembly Procedure

READ ALL INSTRUCTIONS AND SAFETY RECOMMENDATIONS BEFORE ASSEMBLING OR OPERATING

THIS WOOD SPLITTER.

Cylinder and

Push Plate

Assembly

Figure 5

Bolt and

Locknut

Trunnion

Pins

Securing the Cylinder and Push Plate Assembly

6. Slide the Cylinder and Push Plate Assembly towards

the Engine until the Trunnion Pins on the side of the

Cylinder fit into the slots of the Cylinder Mounting

Bracket (Figure 5).

Cylinder

Mounting

Bracket

7. Install the two Cylinder Retainer Plates using four 5/16

x 3/4 inch long Hex Bolts and Locknuts (Figure 6).

Tighten the Nuts securely (1/2 inch wrenches).

Cylinder

Retainer

Plate

Figure 6

High -Pressure

Hose

Figure 7

12 8-TON DR

®

WOOD SPLITTER

Low -Pressure

Hose

Hose

Clamp

8. Push the Low-Pressure Hose onto the Fitting (Figure

7).

9. Loosen the Hose Clamp (flathead screwdriver) and

slide it up over the end of the Low-Pressure Hose and

tighten.

10. Thread the High-Pressure Hose onto the Control

Valve Fitting and tighten (crescent wrench).

Page 13

Attaching the Valve Control Handle to the Valve

1. Install the Clevis Pin and Hairpin Clip through the

bottom hole on the Valve (Figure 8).

2. Insert the forked end of the Valve Control Handle over

the Clevis Pin.

3. Align the hole in the Handle with the top hole in the

Valve and insert the top Clevis Pin and Hairpin Clip.

4. Remove the Bolt and Locknut that is securing the

wedge end of the Splitter to the shipping Bracket

(1/2" wrenches) (Figure 9).

NOTE: Set the Bolt and Locknut that was removed in the last

step aside to be used when you install the Front Leg.

Valve

Control

Handle

Clevis

Pin

Figure 8

Hairpin

Clip

Clevis

Pin

Valve

Hairpin

Clip

Bolt and

Locknut

5.

Remove the Two Carriage Bolts and Locknuts that secure

the Shipping Bracket to the Plywood Base (1/2" wrenches)

and remove the Shipping Bracket (Figure 10).

6. Slide the Splitter out of the Shipping Bracket that is on the

opposite side and set the Splitter on a flat, clean surface.

Shipping

Bracket

Figure 9

Carriage

Bolts and

Locknuts

Figure 10

Shipping

Bracket

Contact us at www.DRpower.com 13

Page 14

Installing the Tires and Front Leg

1. Raise one side of the Wood Splitter and slide two

Large Washers over the Axle then install a Tire onto

the axle (Figure 11).

Axle

Figure 11

Figure 12

Front

Handle

Figure 13

2 Large

Washers

Push-on

Nut

Front

Leg

Tire

Rail

Bolts and

Locknuts

2. Install a Push-on Nut and tap it in place (hammer)

(Figure 12). Repeat the process for the other wheel.

NOTE: Placing a socket over the push nut and tapping on the socket

will make it easier to install the push nut.

3. Unfold the Front Handle from under the Rail (Figure

13).

4. Attach the Front Leg to the Rail using two 5/16" x 1"

Hex Bolts and Locknuts. One Bolt/Locknut is in the

parts box; the other you already removed from the Rail

and the Shipping Bracket.

Your 8-Ton DR Wood Splitter is now fully assembled.

14 8-TON DR

®

WOOD SPLITTER

Page 15

Start-Up Procedure

w

(

READ AND FOLLOW ALL OF THE INSTRUCTIONS IN THE “START-UP PROCEDURE” BEFORE STARTING

THE ENGINE AND OPERATING THE WOOD SPLITTER. FAILURE TO FOLLOW THIS RECOMMENDATION

WILL RESULT IN ENGINE AND HYDRAULIC PUMP DAMAGE.

BEFORE STARTING THE ENGINE, READ THE ENGINE MANUFACTURER’S OPERATING AND

MAINTENANCE INSTRUCTION MANUAL. IF YOU HAVE ANY QUESTIONS, PLEASE CONTACT US AT

WWW.DRPOWER.COM OR CALL OUR CUSTOMER SERVICE REPRESENTATIVES AT OUR TOLL-FREE

NUMBER: 1-800-DR-OWNER

NOTE: Place a clean container under Hydraulic Fluid

Overflow Screw to catch any overflow of Hydraulic

Fluid. Do not allow excess Fluid to spill onto the

ground.

1. Ensure that the Splitter is on a flat, level surface and

remove the Hydraulic Tank Cap and the Hydraulic

Fluid Overflow Screw from the Hydraulic Tank (Figure

14).

376-9637).

2. Using a long-neck funnel, slowly pour approximately

114 oz. (3.3 liters) of SAE 10W tractor hydraulic Fluid

or automatic transmission fluid, such as Dextron III,

into the hydraulic tank. Pour the fluid slowly, allowing

air to escape as you fill the tank.

3. When Fluid begins coming out of the Overflow Hole,

stop pouring and wait for the Fluid to stop flowing

from the hole. reinstall the Hydraulic Fluid Overflow

Screw.

4. Screw on the Hydraulic Tank Cap and hand tighten.

NOTE: The total hydraulic system fluid capacity is 154 oz.

(4.5 liters), but only add 114 oz. (3.3 liters) for now.

5. Lubricate the underside of the rail with grease (Figure

15). This will help to prevent wear between the Slide

Plates and the Rail.

Figure 14

Figure 15

Hydraulic

Fluid

Overflow

Scre

Underside

of Rail

Hydraulic

Tank Cap

Slide

Plate

Contact us at www.DRpower.com 15

Page 16

Crank Case

Fill Cap

Figure 16

6. Remove the Crank Case Fill Cap (Figure 16) and Fill

the engine’s crankcase with 20 ounces (approximately

2/3 of a quart) of the engine manufacturer’s

recommended oil. Pour slowly and fill to the point of

overflowing. You may want to use a long-neck funnel

to help reach the fill opening. 10W 30 is a general

purpose motor oil, however refer to the Oil Chart in

the engine manual for different viscosities and types to

use for different Starting temperatures.

7. Replace the Crank Case Fill Cap.

Gas Cap

Figure 17

BE CAREFUL NOT TO SPILL FUEL WHEN FILLING THE

ENGINE. IF FUEL SHOULD SPILL, QUICKLY WIPE OFF AND

ALLOW THE EXCESS FUEL TO EVAPORATE BEFORE

CONTINUING. FUEL AND FUEL VAPORS ARE HIGHLY

FLAMMABLE AND CAN CAUSE PERSONAL INJURY OR EVEN

DEATH WHEN IGNITED.

DO NOT MIX OIL WITH THE GASOLINE. USING MIXED

OIL/GASOLINE IN A FOUR CYCLE ENGINE CAN CAUSE

ENGINE DAMAGE.

8. Remove the Gas Cap (Figure 17) and fill the engine’s

fuel tank with fresh, clean, lead-free automotive

gasoline to approximately 1-1/2" below top of neck to

allow for expansion.

9. Replace the Gas Cap.

10. Move the throttle to FAST and the Choke Lever to

CHOKE (Figure 18).

Throttle

Choke

Lever

Figure 18

16 8-TON DR

Starter

Cord

®

WOOD SPLITTER

11. Pull the starter cord and start the engine.

12. Allow the engine to warm up, then adjust the choke

towards the RUN position until the engine runs

smoothly.

Page 17

KEEP ALL BODY PARTS AWAY FROM THE SLIDE AREA WHEN CYCLING THE CYLINDER.

13. Push the Valve Control Handle, with one hand, to the

forward (extend) position (towards the front of the

cylinder) (Figure 19).

14. When the Push Plate is fully extended, push the Valve

Control Handle to the retract position and retract the

Cylinder Piston (Figure 20). The Cylinder Valve will

automatically stop the Cylinder from retracting when it

reaches the end of its stroke. Fully cycle the Cylinder 2

to 3 times.

NOTE: Extending and retracting the cylinder piston draws the

hydraulic fluid through the system and expels any

trapped air from the system.

Valve

Control

Handle

Push

Plate

Figure 19

Valve

Control

Handle

Extend

Retract

Cylinder

Valve

15. Turn off the engine.

16. Remove the Hydraulic Fluid Overflow Screw from the

side of the Tank (Figure 21).

17. Remove the Hydraulic Tank Cap and slowly start

adding the remaining 40 oz. (1.2 liters) of Hydraulic

Fluid until Fluid comes out of the Overflow Screw

Hole. DO NOT OVERFILL THE HYDRAULIC TANK.

18. Wait until the Fluid stops flowing from the hole and

reinstall the Overflow Screw.

19. Screw on and tighten the Hydraulic Tank Cap.

20. Check all fittings and hoses for leaks and tighten as

needed.

Your 8-Ton DR Wood Splitter is now ready to use.

Figure 20

Hydraulic

Fluid

Overflow

Screw

Figure 21

Hydraulic

Tank

Contact us at www.DRpower.com 17

Hydraulic

Tank Cap

Fluid Fill

Elbow

Page 18

Chapter 3: Operating Your Wood Splitter

TOP VIEW

Operator

Zone

Figure 22

DO NOT ATTEMPT TO OPERATE THE WOOD SPLITTER

WITHOUT FULLY UNDERSTANDING ALL INSTRUCTIONS,

SAFETY PRECAUTIONS, AND/OR WARNINGS. IF ANY DOUBT

OR QUESTION ARISES ABOUT THE CORRECT OR SAFE

METHOD OF PERFORMING ANYTHING FOUND IN THIS

MANUAL, PLEASE CONTACT OUR CUSTOMER SERVICE

REPRESENTATIVES AT OUR TOLL FREE NUMBER: 1-800-DROWNER (376-9637).

WHEN OPERATING THE WOOD SPLITTER, MAKE SURE YOU

ARE IN THE SAFE OPERATING AREA (OPERATOR ZONE) AS

SHOWN IN FIGURE 22. YOU MUST STAY IN THE SAFE

OPERATING AREA AT ALL TIMES WHEN THE SPLITTING

WEDGE IS IN MOTION (WHETHER EXTENDING OR

RETRACTING). NEVER PLACE ANY PART OF YOUR BODY

INTO A POSITION THAT CAUSES AN UNSAFE OPERATING

CONDITION.

BEFORE LOADING AND OPERATING THE WOOD SPLITTER,

ALWAYS WEAR PROTECTIVE GEAR, INCLUDING SAFETY

GOGGLES, HEARING PROTECTION, TIGHT-FITTING GLOVES

WITHOUT DRAW STRINGS OR LOOSE CUFFS, AND STEELTOED SHOES.

Splitting

Wedge

Figure 23

18 8-TON DR

®

WOOD SPLITTER

Hands

on Sides

of Wood

USE THE FOLLOWING PHOTOS FOR THE CORRECT AND

INCORRECT METHODS OF SPLITTING LOGS. NEVER SPLIT A

LOG USING AN INCORRECT OR UNSAFE METHOD.

1. Set your Wood Splitter on flat, dry ground. Make sure

you read all the recommendations from the “General

Safety Rules” in Chapter 2 before using the Wood

Splitter.

2. Start the engine using the instructions from the engine

manual. If the Wood Splitter has not been running

(cold engine), warm up the engine and hydraulic

system by running the engine at half throttle for 3 to 4

minutes, then advance the engine throttle control to

maximum speed.

3. Place the log on the Wood Splitter. Grasp the log on

the sides near the middle of the block (Figure 23).

Center the log, side-to-side, on the rail of the Wood

Splitter, making sure that one end is against the

Splitting Wedge.

Page 19

J

DO NOT PLACE YOUR HANDS ON THE ENDS OF THE LOG

NDS

(FIGURE 24)

.

WHEN LOADING THE WOOD SPLITTER. THIS IS A VERY

UNSAFE METHOD AND COULD RESULT IN INJURY TO YOUR

HA

DO NOT REACH OR STEP ACROSS THE RAIL WHILE THE

WOOD SPLITTER IS RUNNING. THIS IS A VERY UNSAFE

METHOD WHICH COULD CAUSE PERSONAL INJURY OR

EVEN DEATH (FIGURE 25).

4. Make sure both ends of the log you are splitting are

cut as square as possible. This will prevent the log

from sliding out of position while under pressure. All

logs should be no longer than 18" (Figure 26).

NEVER ATTEMPT TO SPLIT WOOD ACROSS THE GRAIN. THE

WOOD SPLITTER WAS NOT DESIGNED FOR CROSS-GRAIN

SPLITTING. DOING SO WILL DAMAGE THE WOOD SPLITTER

AND MAY CAUSE PERSONAL IN

URY (FIGURE 27).

5. Using only your hand, push the Valve Control Handle

forward (towards the log) (Figure 28). If the log moves

before it is contacted by the Push Plate, release the

Valve Control Handle and then reposition the log.

Operate the Wood Splitter only when in the safe

operating area, as shown in Figure 22.

Figure 24

Figure 25

Figure 28

Figure 26

Valve

Control

Handle

Push Plate

Figure 27

Contact us at www.DRpower.com 19

Page 20

Figure 29

Push

Plate

Hold

Side

Valve

Control

Handle

IF YOU FIND YOU MUST HOLD THE LOG UNTIL THE PUSH

PLATE TOUCHES IT AND HOLDS IT IN PLACE, BE VERY

CAREFUL NOT TO PUT YOUR HAND BETWEEN THE LOG

AND THE PUSH PLATE OR THE LOG AND THE SPLITTING

WEDGE. IF YOU MUST, HOLD THE LOG FROM THE SIDE

AND IN THE MIDDLE (FIGURE 29). REMOVE YOUR HAND

IMMEDIATELY WHEN THE PUSH PLATE ENGAGES THE LOG.

NEVER USE YOUR KNEE OR ANY EXTENSION DEVICE TO

OPERATE THE VALVE CONTROL HANDLE.

6. Hold the Valve Control Handle, extending the Push

Plate (Figure 30), until the log is split or the cylinder

rod stops at its maximum travel position. Stop the

Wood Splitter (forward movement), at any point in the

splitting process, if you feel an unsafe splitting

condition is occurring. As the log is being split, DO

NOT reach forward and attempt to catch the split

wood — let it fall to the ground.

Figure 30

Figure 31

Push Plate

Valve

Control

Handle

7. Once the Push Plate reaches its full forward travel,

pull back on the Valve Control Handle to the full

retract position (Figure 31). The ram of the cylinder

will automatically retract into the cylinder.

20 8-TON DR

®

WOOD SPLITTER

Page 21

NOTE: It is not necessary to hold the Valve Control Handle as

J

the cylinder retracts (Figure 32). Stop the Push Plate

if the log sticks (see caution on next page). When the

Valve

Control

Handle

cylinder is fully retracted, the Control Valve will

automatically shift to a neutral position.

Control

Valve

Figure 32

DEPENDING ON THE TYPE OF WOOD BEING SPLIT, A LOG MAY NOT ALWAYS SPLIT INTO TWO

PIECES AND FALL TO THE GROUND. IF A LOG STICKS TO THE WEDGE OR PUSH PLATE, MOVE THE

VALVE CONTROL HANDLE IN THE CENTER (NEUTRAL) POSITION TO STOP THE PUSH PLATE FROM

RETRACTING, STOP THE ENGINE, AND CAREFULLY REMOVE THE LOG FROM THE WEDGE OR PUSH

PLATE. ALLOWING THE LOG TO REMAIN ATTACHED TO THE PUSH PLATE WHEN IT IS FULLY

RETRACTED COULD LEAD TO POSSIBLE IN

URY AND/OR DAMAGE TO THE WOOD SPLITTER.

8. DO NOT load another log or remove split pieces until the Push Plate has completely stopped and

the Valve Control Handle automatically returns to the neutral position.

Splitting Large Logs

When splitting a large log, or one in which the wood is

extremely tough or stringy (such as elm), the first pass

through the Splitter may not split the log into two sections.

If this happens, turn the log and split off small sections.

Repeat this process as necessary to split the entire log

(Figure 33).

Figure 33

Contact us at www.DRpower.com 21

Page 22

Chapter 4: Inspection And Maintenance

This chapter covers regular maintenance procedures that will ensure the best performance and long life

of your machine. For engine maintenance, please refer to the engine owner’s manual that came with

your Splitter. Service intervals listed in the check list below supercede those listed in the engine owner’s

manual.

Maintenance Kits and Accessories are available through our website at www.DRpower.com.

Regular Maintenance Check List

NOTE: Service intervals shown are considered maximum under normal operating conditions. Increase

frequencies under extremely dirty or dusty conditions.

Procedure

Check Hydraulic Fluid Level

Check Engine Oil Level

Check General Equipment Condition

Check Wedge for Sharpness

Grease Bottom Surface of Slide Rail

Clean Engine Exterior and Cooling Fins

Before Each Use Every 25 Hours Every 100 Hours

▲

▲

▲

▲

▲

▲

Change Engine Oil 1st time 5 hours

Replace Air Filter

Change Hydraulic Fluid

Replace Spark Plug

▲

▲

▲

▲

22 8-TON DR

®

WOOD SPLITTER

Page 23

General Maintenance Check (before operating)

The hydraulic system (hoses, cylinder, and pump) should be carefully inspected before each use. Also,

inspect the mechanical parts at the same time. Make sure all clamps, nuts, bolts, fittings, etc. are

properly installed and tightened.

DO NOT CHECK FOR LEAKS WITH YOUR HAND. LEAKS CAN BE LOCATED BY PASSING A PIECE OF

CARDBOARD OR WOOD AROUND THE SUSPECTED LEAK AND LOOKING FOR DISCOLORATION.

HIGH-PRESSURE FLUID ESCAPING FROM A VERY SMALL HOLE CAN BE ALMOST INVISIBLE. ESCAPING

FLUID UNDER PRESSURE CAN HAVE SUFFICIENT FORCE TO PENETRATE SKIN, CAUSING SERIOUS

INJURY OR EVEN DEATH. IF FLUID IS INJECTED INTO YOUR SKIN, IT MUST BE TREATED IMMEDIATELY

BY A DOCTOR FAMILIAR WITH THIS TYPE OF INJURY.

Always replace frayed, kinked, or cracked hoses and/or other damaged hydraulic components with DR

Power Equipments authorized parts and components specified in the “Parts” section (Chapter 8) of this

manual. Replacement parts from secondary suppliers (not original DR Power Equipments replacement

parts) can lead to product damage and/or personal injury, and will void the warranty.

DO NOT REMOVE THE CAP FROM THE HYDRAULIC TANK OR RESERVOIR WHILE THE WOOD

SPLITTER IS RUNNING. HOT FLUID, UNDER PRESSURE, COULD BE EXPELLED RESULTING IN SERIOUS

INJURY.

Should it become necessary to loosen or remove any hydraulic fitting or line, be sure to relieve all

hydraulic pressure by shutting off the engine, removing the spark plug wire, and moving the valve

control handle back and forth several times until no cylinder movement is visible.

Engine Service

Refer to the engine manufacturer’s manual for engine maintenance, repair and storage.

Rail Maintenance

Between each use of the WOOD SPLITTER, we recommend applying a rust preventative (Fluid Film or

equivalent) to any bare metal areas on the top of the rail. This will assure the longest possible service life

of the Slide Plates.

Contact us at www.DRpower.com 23

Page 24

Hydraulic Fluid Change

Tools needed:

• Flat Head Screwdriver

• Spark plug socket and Ratchet

1. Drain the hydraulic tank.

a. Place a waste fluid container under the inlet hose.

b. Loosen the Hose Clamp on the end of the inlet hose

(Flat Head Screwdriver) (Figure 34).

c. Remove the Inlet Hose from the Tank.

d. Completely drain the Tank.

e. Reconnect the Inlet Hose to the Tank.

Figure 34

Figure 35

Hose

Clamp

Hose

Clamp

Inlet

Hose

Return

Hose

f. Tighten the Hose Clamp on the end of the Inlet Hose

(Flat Head Screwdriver).

2. Drain the head end of the cylinder.

a. Remove the spark plug wire and spark plug to help

reduce the back pressure on the engine and to prevent

it from starting.

NOTE: The total amount of hydraulic fluid in the system is 1.5

gallons.

b. Loosen the Hose Clamp on the end of the Return

Hose (Figure 35)

c. Disconnect the Return Hose (low pressure) from the

Hydraulic Tank and direct it into a waste fluid

container. (Please properly dispose of the waste

hydraulic fluid per local regulations.)

d. Extend the cylinder by holding the Valve Control

Handle forward and pulling on the engine’s pull start

cord until fluid from the return line stops flowing. This

step drains the head end of the cylinder.

24 8-TON DR

®

WOOD SPLITTER

e. Do not replace the Return Hose at this time.

Page 25

DO NOT MIX TRACTOR HYDRAULIC FLUID WITH TRANSMISSION FLUID. USE ONE OR THE OTHER.

3. Refill the hydraulic tank.

a. Remove the Hydraulic Tank Cap and the Hydraulic

Fluid Overflow Screw from the Hydraulic Tank (Figure

36).

b. Using a long-neck funnel, slowly pour approximately

114 oz. (3.3 liters) of SAE 10W tractor hydraulic Fluid

or automatic transmission fluid, such as Dextron III,

into the hydraulic tank. Pour the fluid slowly, allowing

air to escape as you fill the tank.

c. When Fluid begins coming out of the Overflow Hole,

stop pouring and wait for the Fluid to stop flowing

from the hole. reinstall the Hydraulic Fluid Overflow

Screw.

d. Screw on the Hydraulic Tank Cap and hand tighten

Hydraulic

Fluid

Overflow

Screw

Figure 36

Hydraulic

Tank

Hydraulic

Tank Cap

Fluid Fill

Elbow

4. Drain and refill the piston end of the cylinder.

a. Hold the Valve Control Handle in the retract position

and pull the engine pull start cord until the cylinder rod is fully retracted. This step removes the old

fluid from the piston end of the cylinder.

b. Reconnect the Return Hose to the Hydraulic Tank (Figure 35).

c. Extend the cylinder by holding the Valve Control Handle forward and pulling on the engine’s pull

start cord until the cylinder is completely extended. This step refills the piston end of the cylinder.

5. Start the engine and cycle the cylinder.

a. Replace the spark plug and spark plug wire.

b. Start the engine and cycle the cylinder several times (see “Operating Your Wood Splitter”, Chapter

4).

c. Retract the cylinder and shut off the engine.

d. Recheck the Hydraulic Tank to make sure fluid is up to the Hydraulic Fluid Overflow Screw.

Hydraulic Fluid Specifications

Above 30˚ F . . . . . . . . . AW-32, 10W (non-foaming) or ATF DEXTRON III

Below 30˚ F . . . . . . . . . use only ATF DEXTRON III

Hydraulic Fluid Capacities

Hydraulic System (including cylinder, tank, and hoses) . . . . . . . 154 oz. (4.5 liters)

Contact us at www.DRpower.com 25

Page 26

End of Season and Storage

BEFORE PERFORMING ANY MAINTENANCE PROCEDURE, STOP THE ENGINE AND

DISCONNECT THE SPARK PLUG WIRE.

NOTE: Please refer to the engine owner's manual for engine-specific procedures.

• Change the engine oil.

• Remove the spark plug and pour about 1 ounce of motor oil into the cylinder hole. Replace the plug

and pull the recoil starter rope until you feel strong resistance. This will coat the piston and seat the

valves to prevent moisture buildup.

• Clean/replace the air filter.

• Clean dirt and debris from the cylinder head cooling fins and muffler area of the engine.

• If your 8-TON DR WOOD SPLITTER will be idle for more than 30 days, we recommend using a gas

stabilizer. This will prevent sediment from gumming up the carburetor. If there is dirt or moisture in

the gas or tank, remove it by draining the tank. Completely fill the tank with fresh, unleaded gas and

add the appropriate amount of stabilizer or gasoline additive. Run the engine for a short time to

allow the additive to circulate. Close the fuel shut-off valve to prevent carburetor overflow and

leakage.

• Check the wedge for nicks and wear. Sharpen if needed.

• Apply Fluid Film to areas where the paint has worn or chipped off to bare metal.

• If possible, store the unit inside or cover it completely if stored outside.

• Grease bottom surface of Slide Rail.

26 8-TON DR

®

WOOD SPLITTER

Page 27

Chapter 5: Troubleshooting

Most problems are easy to fix. Consult the troubleshooting table for common problems and their

solutions. If you continue to experience problems contact us at www.DRpower.com or call DR Power

Equipment Toll Free at 1-800-DR-OWNER (376-9637) for support.

BEFORE PERFORMING ANY MAINTENANCE PROCEDURE, STOP THE ENGINE AND

DISCONNECT THE SPARK PLUG WIRE.

Troubleshooting Table

SYMPTOM POSSIBLE CAUSE

When the valve

control handle is

pushed forward

(extend), the push

plate does not

move.

⇒ Check the hydraulic tank to make sure the fluid level is up to the hydraulic fluid

overflow screw hole. If the fluid is not up to the overflow hole, fill with hydraulic

fluid until it is up to the overflow hole.

⇒ If the fluid level is OK then contact us at www.DRpower.com or call 1 (800) DR-

OWNER (376-9637) for assistance.

The engine won’t

start.

(Please refer to the

engine owner’s

manual for enginespecific procedures.)

The engine lacks

power or is not

running smoothly.

(Please refer to the

engine owner’s

manual for enginespecific procedures.)

⇒ Are you using fresh, clean gas? If the gas is old, change it. Use a fuel stabilizer if

you keep gas longer than 30 days.

⇒ Is the spark plug clean? If the spark plug is dirty or cracked, change it. If it’s oily,

leave it out, hold a rag over the plug hole and pull the recoil cord several times to

blow out any oil in the cylinder, then wipe off the plug and reinsert it.

⇒ If your engine still won’t start, contact us at www.DRpower.com or call 1(800) DR-

OWNER (376-9637) for assistance.

⇒ Check that the Throttle Lever is in the “Run” position.

⇒ Is the air filter clean? If it’s dirty, change it following the procedure in the engine

manufacturer’s owner’s manual.

⇒ Is the spark plug clean? If it’s fouled or cracked, change it. If it’s oily, leave it out,

hold a rag over the plug hole and pull your recoil cord several times to blow out

any oil in the cylinder, then wipe off the plug and reinsert it.

⇒ Are you using fresh, clean unleaded gas? If it’s old, change it. Use a fuel stabilizer

if you keep gas longer than 30 days.

⇒ Does your engine have the right amount of clean oil? If it’s dirty, change it

following the procedure in the engine manufacturer’s owner’s manual.

⇒ Check the oil level and adjust as needed.

⇒ If your engine still lacks power, contact us at www.DRpower.com or call 1(800)

DR-OWNER (376-9637) for assistance.

Contact us at www.DRpower.com 27

Page 28

SYMPTOM POSSIBLE CAUSE

Engine smokes.

(Please refer to the

engine owner’s

manual for enginespecific procedures.)

⇒ Check the oil level and adjust as needed.

⇒ Check the air filter and clean or replace if needed.

⇒ You may be using the wrong oil—too light for the temperature. Refer to your

Engine Owner’s Manual for detailed information.

⇒ Clean the cooling fins if they’re dirty.

⇒ If the engine still smokes, contact us at www.DRpower.com or call 1(800) DR-

OWNER (376-9637) for assistance.

The engine stalls

when the push plate

engages the wood.

The pusher plate

moves slowly, but

will split wood.

The ram will not

automatically

retract.

Hydraulic fluid

squirts from the fill

plug during

operation.

⇒ The engine may not be properly adjusted. Contact us at www.DRpower.com or call

1(800) DR-OWNER (376-9637) for assistance.

⇒ Check the hydraulic fluid level in the hydraulic tank and fill if necessary.

⇒ Check the high-pressure hose, fittings, and valve openings for dirt and debris that

may have obstructed the openings.

⇒ Check the slide rail or push plate for damage.

⇒ Push the valve control handle to the retract position. If the handle will not stay in

this position, contact us at www.DRpower.com or call 1(800) DR-OWNER (376-

9637) for assistance.

⇒ The hydraulic fluid tank may be over-filled. Drain fluid down to the overflow screw.

⇒ The WOOD SPLITTER is not level. Make sure the WOOD SPLITTER is on level

ground.

28 8-TON DR

®

WOOD SPLITTER

Page 29

Chapter 6: Class II Receiver Mount Accessory

The Receiver Mount Accessory mounts to your 8-Ton DR

Wood Splitter so that it can be installed on a vehicle with a

Class II 2" x 2" Trailer Hitch Receiver. This is a convenient

and efficient way to transport your Wood Splitter to the job

site for two reasons:

a. It provides a handy operating position from the

back of your vehicle.

b. It allows more space in your vehicle for hauling

split firewood.

1. Position your Wood Splitter so you can easily access

the underside of the engine mount.

2. Unpack all parts from the shipping box and place the

Receiver Attachment Bracket in the orientation shown

(Figure 37). (the bracket will be mounted under the

frame of the Wood Splitter using the same bolts that

hold the engine in place.)

3. Reach under the frame of your Wood Splitter and use

a 1/2" wrench to remove the Hex Nuts, Lock Washers,

and Flat Washers from the Engine Mount Bolts. Leave

the Bolts in place.

4. Position the Receiver Attachment Bracket under the

frame. Align the holes in the Bracket over the ends of

the exposed Engine Mount Bolts and install Flat

Washers, Lock Washers, and Hex Nuts. Tighten

securely.

5. Make sure you remove the Clip and Clevis Pin from

the adjustable Receiver Bar (Figure 38), then insert the

long straight end

of the Bar into the Bracket (Figure

39).

Engine

Mount

Hardware

Figure 37

Figure 38

Receiver

Attachment

Bracket

Clevis

Pin

Receiver

Bar

Clip

NOTE: The end of the Receiver Bar should just go through the

other side of the Receiver Attachment Bracket to have

room to install the Clevis Pin and Clip.

6. Insert Clevis Pin and Clip into the end of the Receiver

Bar.

7. Screw the L-Shaped Tensioning Bolt into the threaded

hole in the Receiver Attachment Bracket and tighten

by hand.

Figure 39

Clevis Pin

and Clip

Receiver

Receiver

Bar

Contact us at www.DRpower.com 29

Attachment

Bracket

L-Shaped

Tensioning

Bolt

Page 30

Receiver

Hitch

Figure 40

Receiver

Bar

Vehicle

Hitch

High Position

Receiver

Bar

Low Position

8. Position the Wood Splitter behind the vehicle with the

engine of your Wood Splitter on the right-hand side

(Figure 40).

NOTE: The end of the Receiver Bar that inserts into your vehicle

hitch features a dual-height positioner. By turning the Bar 180˚ (up

or down) in the vehicle hitch, your Wood Splitter can be oriented in

a high or low position (Figure 41). Use the HIGH position when

transporting your Wood Splitter, and use either the HIGH or LOW

position when splitting wood.

Figure 41

Class ll

Receiver

Figure 42

THE WOOD SPLITTER WITH THE RECEIVER MOUNT

ACCESSORY WEIGHS APPROXIMATELY 160 LBS. WE

RECOMMEND TWO PEOPLE FOR THIS NEXT OPERATION.

9. Lift the end of the Receiver Bar and start it into the

Vehicle Hitch (Figure 42).

Receiver

Bar

30 8-TON DR

®

WOOD SPLITTER

Page 31

10. Pick up your Wood Splitter up and slide the unit

forward into the Vehicle Hitch until the Lock Pin holes

line up (Figure 43). (Due to the weight, we

recommend two people for this operation). Lock the

Receiver Bar into position with your Vehicle Hitch

Lock Pin.

Vehicle Hitch

Lock Pin

Figure 43

NOTE: When you have the Wood Splitter adjusted to the end

of the Receiver Bar (with the Clevis Pin and Clip

installed at the end of the Receiver Bar and the LShaped Tensioning Bolt is hand tight) you will have

room to drop down the tailgate of the vehicle for easy

loading (Figure 44). This is the operating position.

The Wood Splitter should be secured in a stable and

level position for best splitting performance. When

positioning a heavy log on the Wood Splitter, it may

be necessary to support the Front Leg to maintain a

level position.

NOTE: When transporting your Wood Splitter, be sure to

carry it in the HIGH position (Figure 41) and slide it

as close to your vehicle as possible without hitting any

part of the vehicle. Secure it in position by hand

tightening the L-Shaped Tensioning Bolt (Figure 45).

Always be sure to have the Clevis Pin and Clip

inserted into the end of the Receiver Bar.

Vehicle Hitch

Lock Pin

Figure 44

L-Shaped

Tensioning

Bolt

Operating

Position

Clevis Pin

and Clip

Transport

Position

Observe the posted speed limits when transporting the

Wood Splitter with the receiver mount properly

installed and the Wood Slitter properly attached.

When traveling over rough terrain, drive slowly to

prevent undue stress to the Receiver Bar.

Figure 45

L-Shaped

Tensioning

Bolt

Contact us at www.DRpower.com 31

Clevis Pin

and Clip

Page 32

Chapter 7: Parts Lists, Schematic Diagrams And Warranty

Parts List and Schematic – Base Unit

NOTE: Part numbers listed are available through DR Power Equipment

Ref# Part# Description

1 235571 Rail Weldment

2 235581 Nut, Push-On, 1/2"

3 235591 Handle

4 235601 Black Grip, 1/2" diameter

5 235611 Front Leg

6 235621 Bolt, 5/16-18 x 1"

7 235631 Locknut, 5/16-18

8 235641 Pan head Screw, 1/4-20 x 1"

9 235651 Locknut, 1/4-20

10 235661 Bolt, 5/16-18 x 1-1/2"

11 235671 Slide Weldment

12 235681 Slide Guide Plate

13 235691 Slide Retainer Plate

Ref# Part# Description

14 235701 Lock Washer, 5/16"

15 235711 Nut, 5/16-18

16 235721 Clevis Pin, 3/8 x 2-1/2"

17 235731 Hairpin Clip, 3/32 x 1-5/8"

18 235741 Bolt, 5/16-18 x 3/4"

19 235751 Cylinder Retainer Plate

20 235761 Vented Fill Plug

21 235771 O-ring for Vented Plug

22 235781 Vented Fill Plug Breather

23 237911 Fitting, Street Elbow

24 237921 Tire, 8"

25 237931 Rubber Foot

26 265951 Screw, Hydraulic Fluid Overflow

32 8-TON DR

®

WOOD SPLITTER

Page 33

Parts List and Schematic – Pump and Piston Assembly

NOTE: Part numbers listed are available through DR Power Equipment

Ref# Part# Description

1 237951 Engine, Briggs, 4.75 ft. lbs. Torque

2 237961 Bolt, 5/16-18 x 1-3/4”

3 237971 Washer, 5/16"

4 237981 Lock Washer, 5/16”

5 237991 Nut, 5/16-18

6 238001 Square Key, 3/16”

7 238011 Set Screw, 1/4-20 x 1/2”

8 238021 Engine Coupling

9 238031 Spider

10 238041 Pump Coupling

11 238051 Engine Flange

12 238061 Pump Key

13 238071 Bolt, 5/16-24 x 3/4”

14 238081 Hydraulic Pump

15 238091 Bolt, 5/16-24 x 3-1/2”

16 238101 High-Pressure Hose

(pump to side of valve)

17 238111 Elbow , 90 Degree

Ref# Part# Description

18 238121 Hose Clamp, 5/8”

19 238131 Low-Pressure Hose 5/8” x 5”

20 238141 Low-Pressure Hose 5/8” x 15”

21 238151 Cylinder, 3” x 18”

22 238161 Elbow, 90 Degree

23 238171 High-Pressure Hose (cylinder to

bottom of valve)

24 238181 Elbow, 90 Degree

25 238191 Valve

26 238201 Handle Assembly Kit (includes

handle, clevis pins, and hairpin

clips)

27 238211 Straight Fitting

28 265961 Handle, Rear

Safety & Information Labels (not shown)

238221 Label, Operator Safety

265941 Label, Proper Machine Loading

Contact Us At www.DRpower.com 37

Page 34

Parts List and Schematic – Class II Receiver Hitch Accessory

NOTE: Part numbers listed are available through DR Power Equipment

1 240261 Bracket, Receiver Attachment

2 240271 Bar, Receiver

3 240281 Bolt, Tensioning, L-Shaped

4 240291 Pin, Clevis

5 240301 Clip

38 8-TON DR

®

WOOD SPLITTER

Page 35

8-TON DR® WOOD SPLITTER

2-Year Limited Warranty

The 8-TON DR

to ordinary and normal consumer use; ninety (90) days for any other use. The engine manufacturer warrants the engine

separately.

For the purposes of all the above warranties, “ordinary and normal consumer use” refers to non-commercial residential

use and does not include misuse, accidents or damage due to inadequate maintenance.

DR Power Equipment certifies that the 8-TON DR

this type is used. DR Power Equipment however, limits the implied warranties of merchantability and fitness in duration

to a period of two (2) year in consumer use, ninety (90) days for any other use.

The 2-Year Limited Warranty on the 8-TON DR

factory. The 2-Year Limited Warranty is applicable only to the original owner.

The warranty holder is responsible for the performance of the required maintenance as defined by the manufacturer's

owner's manuals. The warranty holder is responsible for replacement of normally wearing parts such as the air filter,

spark plug, and tires. Attachments and accessories to the machine are not covered by this warranty.

During the warranty period, the warranty holder is responsible for the machine transportation charges, if required.

During the warranty period, warranty parts will be shipped by standard method at no charge to the warranty holder.

Expedited shipping of warranty parts is the responsibility of the warranty holder.

SOME STATES DO NOT ALLOW LIMITATIONS ON THE LENGTH OF IMPLIED WARRANTIES, SO THE ABOVE

LIMITATIONS MAY NOT APPLY TO YOU.

DR Power Equipment shall not be liable under any circumstances for any incidental or consequential damages or

expenses of any kind, including, but not limited to, cost of equipment rentals, loss of profit, or cost of hiring services to

perform tasks normally performed by the 8-TON DR

®

WOOD SPLITTER is warranted for two (2) year against defects in materials or workmanship when put

®

WOOD SPLITTER is fit for ordinary purposes for which a product of

®

WOOD SPLITTER starts on the date the machine ships from our

®

WOOD SPLITTER.

Terms and Conditions

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU ALSO HAVE OTHER RIGHTS, WHICH VARY

FROM STATE TO STATE.

Warranty

Page 36

Daily Checklist for the 8-TON DR WOOD SPLITTER

To help maintain your 8-TON DR WOOD SPLITTER for optimum performance, we recommend you

follow this checklist each time you use your machine.

[ ] OIL: With the machine on a level surface, check the engine oil level with the dipstick and add more if

necessary (only add oil to the level indicated on the dipstick - DO NOT OVERFILL). Use SAE 10W

30 high detergent motor oil.

[ ] GAS: Fill the gas tank with clean, fresh, unleaded gasoline.

[ ] HYDRAULIC FLUID: Check hydraulic fluid level and fill as needed.

[ ] HYDRAULIC HOSES: Check hydraulic hoses for cracks or wear.

[ ] ENGINE AIR COOLING SYSTEM: It is very important to keep the engine clean of debris. Remove wood

chips and other built-up materials from the air intake screen before, during and after you run the

Splitter. Regularly remove debris from the cooling fins. A dirty engine retains heat and can cause

damage to the internal engine parts.

[ ] WEDGE: Check the wedge for tightness, nicks and wear.

[ ] GENERAL CONDITION: Check the general condition of the machine ( e.g.; nuts, bolts, welds etc.).

[ ] SLIDE RAIL: Apply a rust preventative (Fluid Film or equivalent) to any bare metal areas on the top of the

rail. This will assure the longest possible service life of the wear pads.

DR POWER EQUIPMENT

MEIGS ROAD, P.O. BOX 25, VERGENNES, VERMONT 05491

1-800-DR-OWNER (376-9637) • www.DRpower.com ©2009 CHP, Inc. 235491A

Loading...

Loading...