Page 1

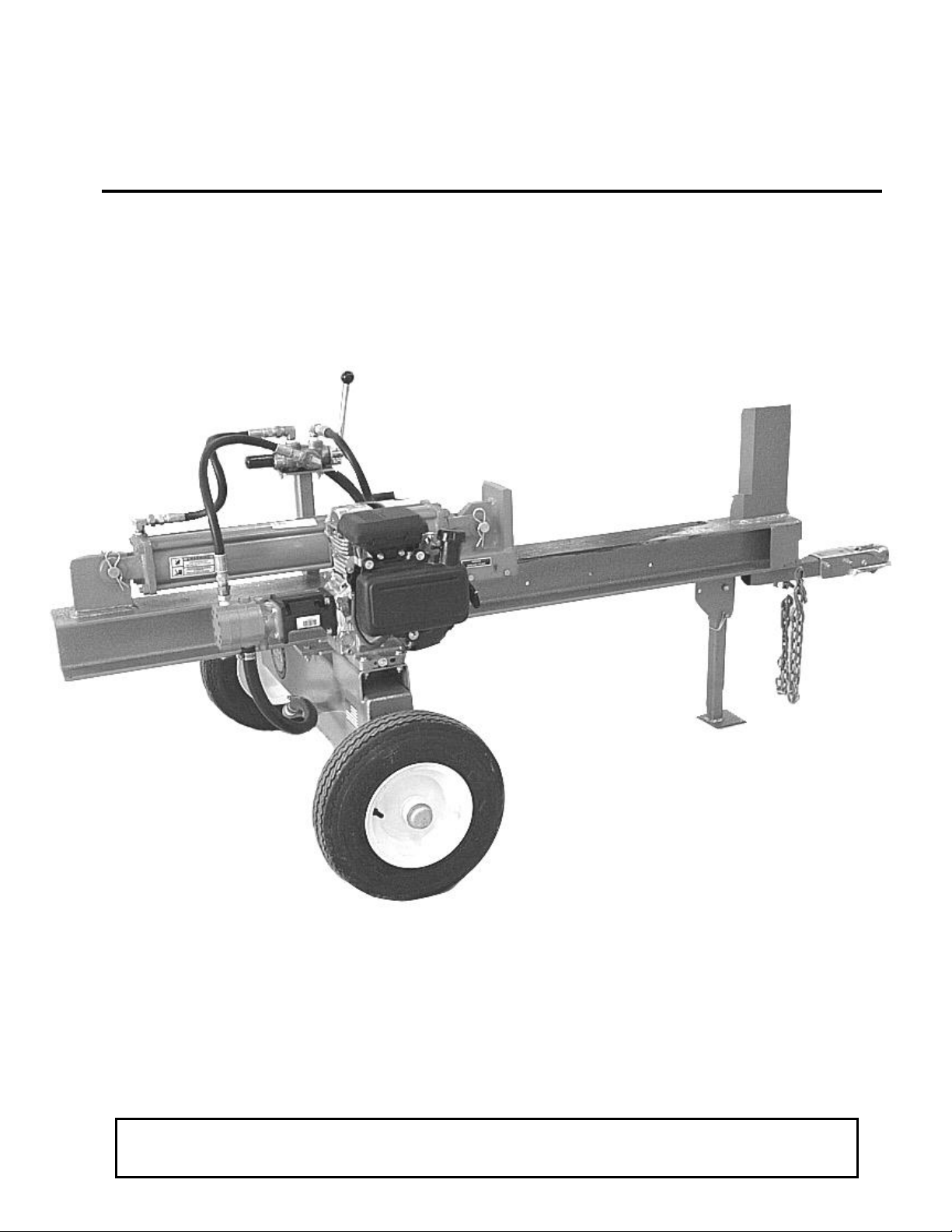

DR 20-Ton WOOD SPLITTER

Safety & Operating Instructions

Please read instructions before operating machine

Page 2

And congratulations on your purchase of a new DR 20-Ton WOOD SPLITTER!

We have done our utmost to ensure that your DR 20-Ton WOOD SPLITTER will be

one of the most trouble-free and satisfying pieces of equipment you have ever owned.

Please let us know of any questions or problems you may have. We want to answer or

correct them as quickly as possible. (When you do call or write, please have your serial

number and/or order number handy—it will speed things up!) We also hope to hear

from you on how much you like your new helper.

And, please tell your friends about your new DR 20-Ton WOOD SPLITTER! Having

DR Owners spread the word about our products and our way of doing business is the

best advertising we can have, and the best way to help us provide even better service in

the years to come.

Thanks once again!

for all of us at

Country Home Products, Inc

.

S

ALES MANAGER

COPYRIGHT

2004 Country Home Products, Inc. All rights reserved.

Country Home Products, Inc.

Meigs Road

P.O. Box 25

Vergennes, VT 05491

Toll-free phone: 1-800-DR-OWNER (376-9637)

Fax: 1-802-877-1213

Web site: www.dr-owner.com

E-mail: info@chp.com

ii DR

20-Ton WOOD SPLITTER Safety & Operating Instructions

Page 3

Table of Contents

Chapter 1: Introducing the DR 20-Ton WOOD SPLITTER.................................... 1

Conventions used in this manual.................................................................................................... 1

Chapter 2: Safety Considerations.......................................................................... 3

Preparing to Use the DR 20-Ton WOOD SPLITTER ..................................................................... 3

Safety Information Labels............................................................................................................... 3

Protecting Yourself ......................................................................................................................... 5

Operating the Machine Safely ........................................................................................................ 5

Safety with Gasoline-Powered Machines ....................................................................................... 6

Hydraulic Safety ............................................................................................................................. 7

A Note to All Users ......................................................................................................................... 8

Additional Information and Potential Changes................................................................................ 8

Chapter 3: Setting Up Your DR 20-Ton WOOD SPLITTER................................... 9

DR 20-Ton WOOD SPLITTER Controls and Features................................................................... 9

Unpacking the Splitter and Installing the Wheels ..........................................................................10

Check the Tire Pressure................................................................................................................11

Log Cradle Installation (Optional) ..................................................................................................12

Manual Log Lift Installation (Optional) ...........................................................................................12

Table Grate Installation (Optional).................................................................................................14

Four-way, Reversible, Slip-on Wedge Installation (Optional) ........................................................15

Transporting the Splitter ................................................................................................................16

Towing Safety................................................................................................................................16

Checking the Engine Oil and Adding Gasoline..............................................................................17

Chapter 4: Operating Your DR 20-Ton WOOD SPLITTER.................................. 19

Before Starting the Engine ............................................................................................................19

Starting..........................................................................................................................................19

Splitting Safety ..............................................................................................................................20

Loading and Wedge Positioning....................................................................................................20

Operating the Wood Splitter ..........................................................................................................21

Chapter 5: Maintaining the DR 20-Ton WOOD SPLITTER .................................23

Regular Maintenance Checklist.....................................................................................................23

Lubrication.....................................................................................................................................24

Removing and Replacing the Engine Oil .......................................................................................25

Removing and Replacing the Hydraulic Fluid and Filter ................................................................26

Removing and Replacing the Hydraulic Hoses .............................................................................28

Adjusting the Hydraulic Control Valve ...........................................................................................29

End of Season & Storage ..............................................................................................................30

Chapter 6: Troubleshooting and Warranty .........................................................31

Troubleshooting Table...................................................................................................................31

DR 20-Ton WOOD SPLITTER Safety & Operating Instructions iii

Page 4

iv DR 20-Ton WOOD SPLITTER Safety & Operating Instructions

Page 5

r

Chapter 1: Introducing the DR 20-Ton WOOD

SPLITTER

This manual will help you set up and safely operate your new DR 20-Ton WOOD

SPLITTER. Careful adherence to the safety and operating instructions in this manual will

ensure many years of productive use.

Please let us know if you have any questions or problems by contacting Technical Support

via our toll-free phone number. Our contact information is listed inside the front cover of

this manual. When you call or write, please have your serial number or order number

available so we can help you quickly.

Conventions used in this manual

WARNING! The exclamation point within a triangle alerts you to

essential operating, safety, maintenance and servicing instructions.

Important! This information is important in the proper use of you

machine. Failure to follow this instruction could result in injury to you and

others or damage to your splitter.

Tip: This is a helpful hint to guide you in getting the most out of your splitter.

Tools Needed: This indicates you will need a special tool to perform a maintenance

function on your machine.

Note: This information may be helpful to you.

If you are ever unsure about an action you are about to take, don’t do it. Contact Country

Home Products’ toll-free support at 1-800-DR-OWNER (376-9637) for help or

information.

DR 20-Ton WOOD SPLITTER Safety & Operating Instructions 1

Page 6

2 DR 20-Ton WOOD SPLITTER Safety & Operating Instructions

Page 7

Chapter 2: Safety Considerations

Taking the time to read and observe all safety instructions will ensure many years of

productive use from your DR 20-Ton WOOD SPLITTER and help you avoid injury.

Please take a few moments to read the following guidelines for safely operating your new

machine.

Preparing to Use the DR 20-Ton WOOD SPLITTER

Read these Safety & Operating Instructions and the engine owner manual before you use

the DR 20-Ton WOOD SPLITTER. Become familiar with the controls, engine and

service recommendations to ensure the best performance from your machine.

Inspect the area in which you will be working. Locate the wood splitter only on firm,

level ground. The site must be free of slippery surfaces and potentially hazardous

obstacles.

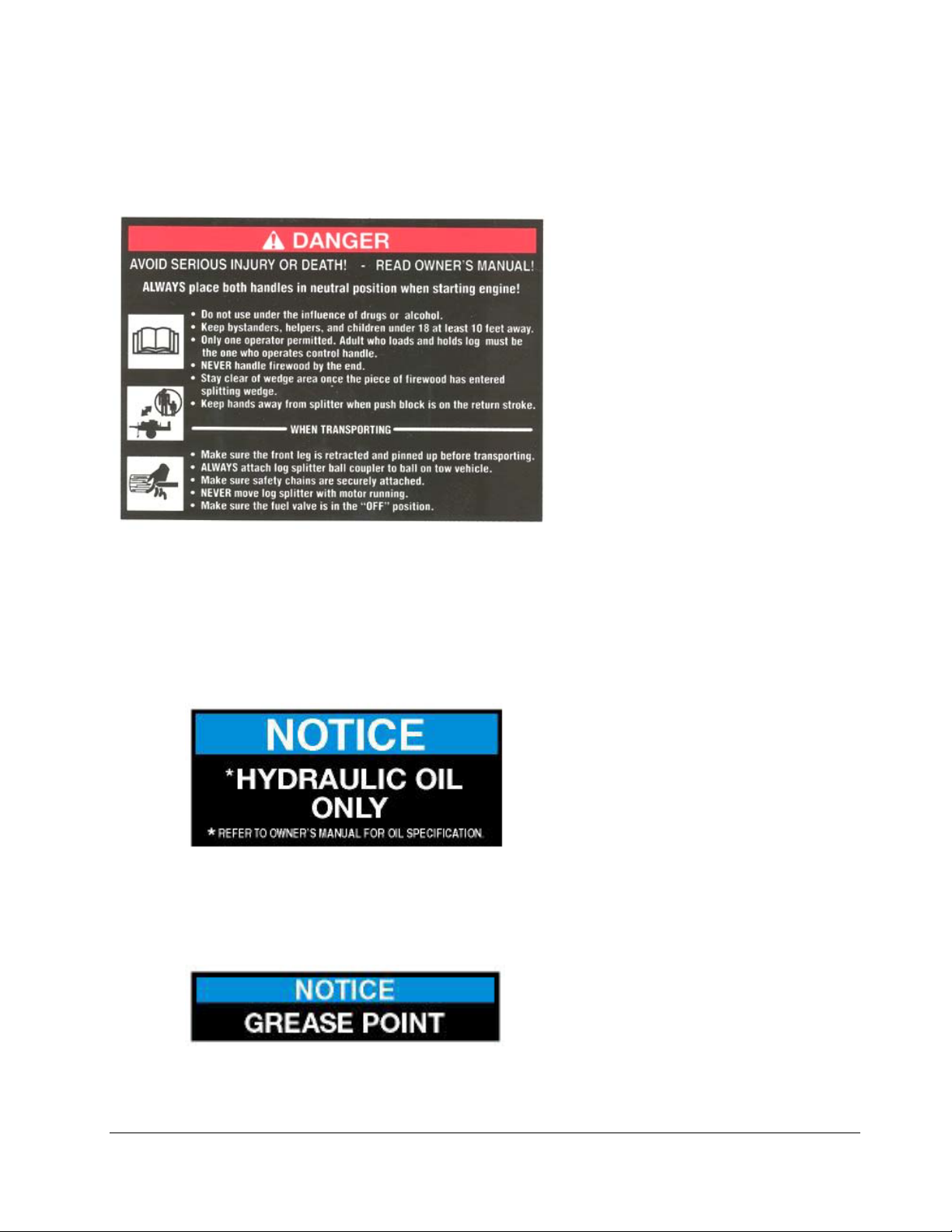

Safety Information Labels

Take some time to become familiar with the following standard safety cautions applicable

to your splitter. Replace damaged or missing safety labels immediately.

Keep combustible substances away from

the engine when it is hot. (#136831)

Keep hands, feet, hair and clothing

away from moving parts. (#199240)

DR 20-Ton WOOD SPLITTER Safety & Operating Instructions 3

Page 8

T

u

f

g

g

f

e

his label reminds yo

about the importance o

reading and understandin

the Safety & Operatin

Instructions manual and o

paying attention to th

safety warnings. (#199250)

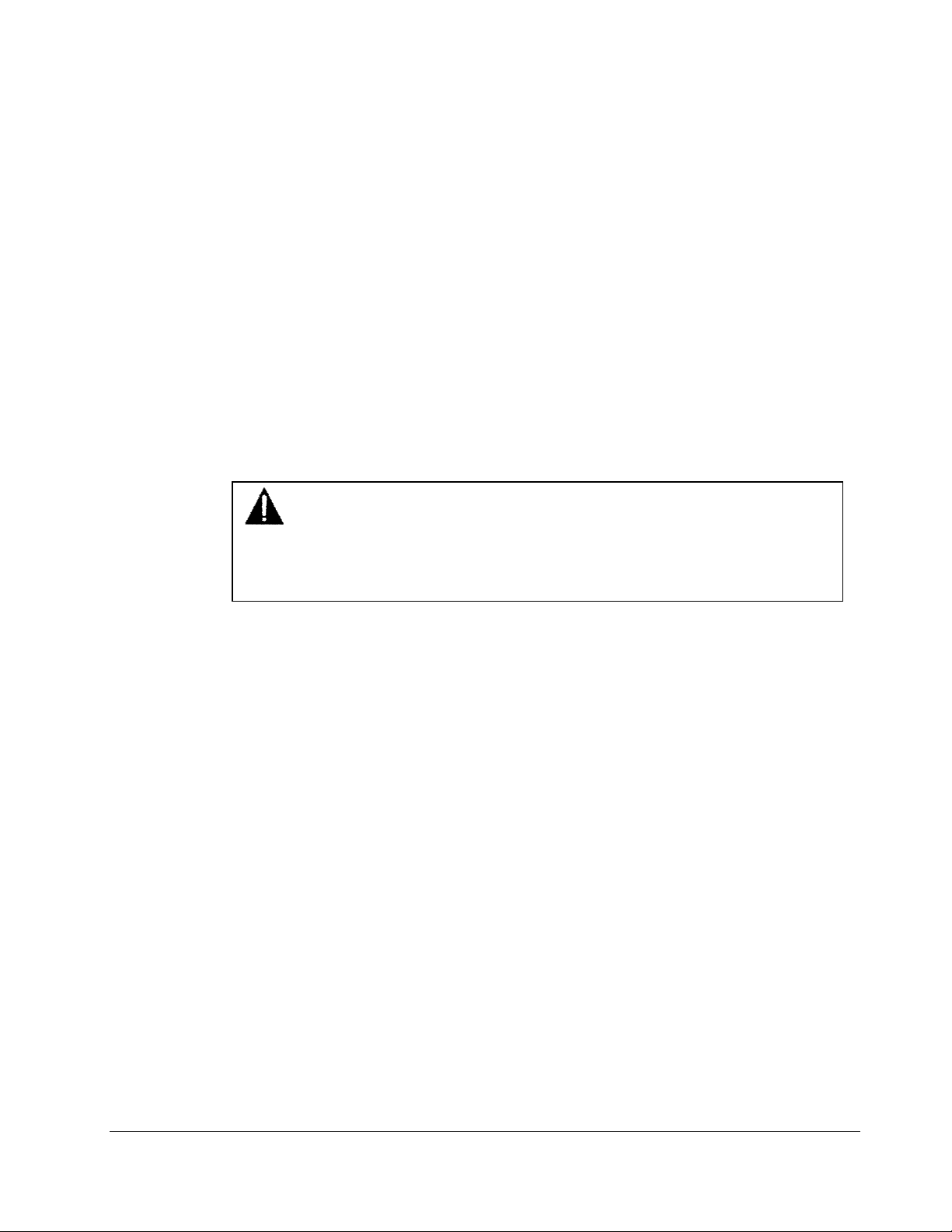

This label cautions to use only

hydraulic fluid. (#199230)

This label indicates a

lubrication point. (#199200)

4 DR 20-Ton WOOD SPLITTER Safety & Operating Instructions

Page 9

r

p

Protecting Yourself

Always wear protective goggles while splitting wood to protect your eyes from possible

thrown bits of wood.

Wear shoes with non-slip treads when using your DR 20-Ton WOOD SPLITTER. If

you have safety shoes, we recommend wearing them. Do not use the machine while

barefoot or wearing open sandals.

Wear long pants while splitting wood.

Avoid wearing loose clothing or jewelry, which might be caught on the splitter’s

moving parts.

Use hearing protection or earplugs to protect your hearing.

We recommend wearing snug-fitting work gloves while splitting wood.

Operating the Machine Safely

To be safe, do not operate the machine near children or pets, and never allow children

Keep your hands and feet clear of the splitting area while the push block is in motion.

ALWAYS shut off the engine and remove the spark plug wire before adjusting the

The exhaust area on the engine becomes very hot with use. Allow the engine to cool

Keep combustible substances away from the engine when it is hot.

Use the machine only in daylight or good artificial light.

Do not use in wet or slippery conditions.

ALWAYS OPERATE THE SPLITTER FROM THE OPERATOR ZONE. (Figure

Use only your hands to operate the splitter controls.

Do not place your hands at pinch points where they can get caught between a log and

Do not put any part of yourself, your clothing, or your personal protective equipment

WARNING! The items listed in this section will help you keep you

DR 20-Ton WOOD SPLITTER running smoothly and, most importantly,

revent injury to yourself or others. Please review them carefully before

starting your machine.

to operate the splitter.

machine. If you have to stop to remove any debris from the machine, ALWAYS retract

the ram and disconnect the spark plug wire first.

before doing maintenance or making adjustments.

19) Never straddle or climb over the wood splitter at any time.

the wedge, push block, or log cradle.

into a crack in a log that is being split; it might close suddenly with great force.

DR 20-Ton WOOD SPLITTER Safety & Operating Instructions 5

Page 10

Never split anything other than logs.

Always cut the ends of the log to be split, as

squarely as possible.

Never split more than one log at a time unless

the ram has been fully extended and a second log

is needed to complete the split of the first log.

Do not handle logs by their ends when you

position them on the splitter.

Do not put anything between the log cradle and the side of a log; logs spread as they

are forced against the wedge.

Do not move or reposition the wood splitter with the motor running.

Do not, under any conditions, remove, bend, cut, fit, weld, or otherwise alter standard

parts on the DR 20-Ton WOOD SPLITTER. Modifications to your machine could

cause personal injuries and will void your warranty.

While using the DR 20-Ton WOOD SPLITTER, don't hurry or take things for

granted.

Never team up with another person to operate the wood splitter controls – this is a one

person job.

Never allow people who are unfamiliar with these instructions to use the DR 20-Ton

WOOD SPLITTER.

Never leave the wood splitter unattended with its motor running.

Do not operate the machine when under the influence of alcohol or medication.

Always make certain nuts & bolts are tight to assure a safe working condition.

Safety with Gasoline-Powered Machines

Do not run the engine in an enclosed area or without proper ventilation.

Store all fuel in containers specifically designed for this purpose.

Fill the gasoline tank outdoors with the engine off. Don't handle gasoline if you or

If you spill gasoline, do not attempt to start the engine. Move the machine away from

Allow the engine to cool completely before storing in any enclosure. Never store the

Do not change the engine governor settings or modify the engine speed.

WARNING! The items listed in this section will help you keep your

DR 20-Ton WOOD SPLITTER running smoothly and, most importantly,

prevent injury to yourself or others. Please review them carefully before

starting your machine.

anyone nearby is smoking, or if you are near anything that could cause the gasoline to

ignite or explode.

the area of the spill and avoid creating any source of ignition until the gas vapors have

dissipated. Wipe up any spilled fuel to prevent a fire hazard and properly dispose of the

waste.

machine near an open flame or spark with gasoline in the tank.

6 DR 20-Ton WOOD SPLITTER Safety & Operating Instructions

Page 11

R

r

Hydraulic Safety

Inspect hydraulic hoses every day – check for worn, frayed, kinked, and cracked areas.

Replace any damaged or worn hoses.

Periodically check for hydraulic leaks by placing a sheet of cardboard under the splitter

Please follow these steps to depressurize system and release residual hydraulic energy

Do not make any adjustments to the pressure relief valve.

Never remove cap from the hydraulic tank while motor is running or while tank is still

WARNING! The items listed in this section will help you keep your D

20-Ton WOOD SPLITTER running smoothly and, most importantly, prevent

injury to yourself or others. Please review them carefully before starting you

machine.

WARNING! Escaping pressurized fluid from hydraulic system leaks can

have enough force to penetrate skin and cause serious injury or death.

Hydraulic fluid can remain highly pressurized while the splitter motor is off.

- Never use your hand or any part of your body to check for hydraulic system

leaks while the system is pressurized.

- Get professional medical help at once if hydraulic oil penetrates anyone's skin.

- Always release residual energy from pressurized hydraulic fluid and allow the

fluid to cool before doing any maintenance or repair work on the log splitter.

while the system is running.

before starting any repairs.

1. Shut off splitter motor and disconnect the spark plug wire.

2. Move control valve handle back and forth, from one limit of travel to the other, at

least four times and holding the valve for three seconds at each limit of travel. The

ram should not move during the 4th cycle.

3. Call 1(800) DR-OWNER (376-9637), or a qualified hydraulic mechanic, to replace

worn components or for assistance.

warm after motor is shut off. Hot pressurized fluid can cause serious injury, so wait for

hydraulic tank to cool before removing cap.

Important! Use only DR replacement connectors, valves, or fittings on your

machine. They have been thoroughly tested and proven for many hours of use.

DR 20-Ton WOOD SPLITTER Safety & Operating Instructions 7

Page 12

A Note to All Users

Under California law, and the laws of some other states, you are not permitted to operate

an internal combustion engine using hydrocarbon fuels without an engine spark arrester.

All DR 20-Ton WOOD SPLITTERS shipped to California and Washington State are

provided with spark arresters. Failure of the owner / operator to maintain this equipment

in compliance with state regulations is a misdemeanor under California law and may be in

violation of other state and/or federal regulations. Contact your local fire marshal or forest

service for specific information in your area.

Additional Information and Potential Changes

Country Home Products, Inc. reserves the right to discontinue, change, and improve its

products at any time without notice or obligation to the purchaser. The descriptions and

specifications contained in this manual were in effect at printing. Equipment described

within this manual may be optional. Some illustrations may not be applicable to your

machine.

8 DR 20-Ton WOOD SPLITTER Safety & Operating Instructions

Page 13

Chapter 3: Setting Up Your DR 20-Ton WOOD

SPLITTER

This chapter outlines a few simple steps you will need to follow to set up your new machine

before you use it. It may be helpful to familiarize yourself with the controls and features on

your splitter by reviewing the picture below before beginning the steps outlined in this

chapter.

4-Way, Slip-On,

Wedge (Optional)

Table Grate

(Optional)

DR 20-Ton WOOD SPLITTER Controls and

Features

Control

Valve

Handle

Log Lift

(Optional)

5 HP OHC

Honda Engine

Log Cradle

(Optional)

Hydraulic

Cylinder

Hydraulic Tank

2" Ball Coupler

Trailer Hitch

DR 20-Ton WOOD SPLITTER Safety & Operating Instructions 9

Swing down

Support Leg

Figure 1

Page 14

Unpacking the Splitter and Installing the Wheels

The DR 20-Ton WOOD SPLITTER is shipped from the factory with the wheels

dismounted from the axles. The following instructions will detail how to unpack the

machine and assemble the wheels to the axles prior to use.

Tools & Supplies Needed:

Flat blade screwdriver

Pliers

Hammer

Knife

Gloves

Eye protection

Metal shears

Parts supplied in the plastic bag tied to the large hydraulic cylinder:

(2) Slotted Retaining Nuts

(2) Cotter Pins

(2) Hub Caps

Two wheels with inner and outer bearings are strapped to the shipping pallet and prelubricated.

banding may have a lot of tension on it and may snap, striking you when cut.

Always stand to one side when cutting the band.

attempting to unpack and install the wheels.

1. Stand to one side and cut the banding.

2. Remove the top of the carton. Separate the

3. Pry off the fasteners and cut any ties holding the

4. Cut the straps holding the wheels to the pallet.

Note: The rear axle of the splitter has been raised to

5. With the valve stem facing out, slide the wheel on the axle, making certain the

WARNING! Always wear eye protection when cutting the banding. The

WARNING! Always stabilize the splitter on flat terrain before

Bearing

stapled vertical cardboard ends from the pallet to

access the pallet straps. The staples are sharp so

be careful.

splitter to the pallet.

Axle

allow for installation of the wheels while the

unit remains on the pallet.

Figure 2

inside and outside bearings remain seated in place in the wheel hub (Figure 2).

10 DR 20-Ton WOOD SPLITTER Safety & Operating Instructions

Page 15

6. Install the retaining nut by hand. To

tighten the nut, insert a screwdriver blade

into a slot on the nut and tap gently with a

hammer (Figure 3) until the nut is seated

firmly against the bearing. Use care not to

damage the axle threads. A slot in the nut

must

be aligned with the cotter pin hole in

the axle. Either tighten slightly or loosen to

align a slot with the hole. Check to be sure

that the wheel spins freely.

7. Insert the cotter pin through the aligned

slot and the hole in the axle (Figure 4).

8. Bend the top of the cotter pin over to

retain it in the assembly (Figure 4). Tap the

hubcap into place on the wheel hub.

9. Repeat steps 5 through 8 for the second wheel.

10. Do not discard your pallet and packaging material until you are fully satisfied with

your machine.

Figure 3

Slot

Check the Tire Pressure

There should be 60 psi in each tire.

Bend over

Cotter Pin

Figure 4

DR 20-Ton WOOD SPLITTER Safety & Operating Instructions 11

Page 16

Log Cradle Installation (Optional)

The following procedure includes all of the steps necessary for the installation of the

optional Log Cradle on the DR 20-Ton WOOD SPLITTER.

Tool Needed:

9/16" wrench or socket

1. Mount the Log Cradle on the

WARNING! Before performing any maintenance procedure, stop the

engine and disconnect the spark plug wire.

Log Cradle (2 shown)

operators side of the wood

splitter (Figure 5) and the Log

Cradle retaining panel on the

opposite side of the H-beam

using the three 3/8" bolts and

nuts. Tighten the bolts using the

3 Bolts

9/16" socket.

Figure 5

Manual Log Lift Installation (Optional)

The following procedure includes all of the steps necessary for the installation of the

optional lever-action Manual Log Lift (Figure 6) on the DR 20-Ton WOOD SPLITTER.

Tools Needed:

1/2" wrench or

socket

9/16" wrench or

socket

1. If the optional Log

Cradle is employed,

remove the three

bolts that hold it on

(Figure 5).

2. Replace the Log

Cradle retaining

panel with the Log

Lift mounting plate,

then re-insert and

tighten the three

bolts and nuts. See

Figure 7 on page 13.

Figure 6

12 DR 20-Ton WOOD SPLITTER Safety & Operating Instructions

Page 17

Lo

g

Lift Mounting Plate

3. Hook the Lift Support Bracket

over the lower edge of the Hbeam frame on the Operator’s

side and insert the bracket's

threaded rod through the tab

that extends down from the

Tab

mounting plate (Figures 7 & 8).

Secure with a nut using a 9/16"

Figure 7

socket.

4. Bolt left end of the multi-position Lift Support into the bracket on the Lift Arm

Assembly's crosspiece using 5/16" bolts and

1/2" socket or wrench, making sure that the

slots in the Lift Support face down (Figure 9).

5. Attach the Lift Arm Assembly to the

Threaded Rod

Mounting Plate using two retaining pins and

spring clips (Figure 10).

6. Hold the Lift Support up between the arms of

the Lift Support Bracket and install a 5/16"

bolt through the lower set of holes in the

bracket below the right end of the Lift Support

and tighten with a 1/2" socket (Figure 9).

Lift Support

Bracket

Lift Arm Assembly

Cross Piece

Slots facing down

Figure 9

5/16" Bolts and

Nuts here

Lift Support

Bracket

Lift Support

Figure 8

Mounting Plate

Spring

Clip

Lift Arm

Assembly

Figure 10

Spring Clip

Retaining

Pins here

WARNING! Always remove the Log Lift before transporting the splitter and

never let anyone ride on the Log Lift.

DR 20-Ton WOOD SPLITTER Safety & Operating Instructions 13

Page 18

Table Grate Installation (Optional)

The following procedure is for the installation of the optional Table Grate (Figure 11) on

the DR 20-Ton WOOD SPLITTER.

Figure 11

The tubular steel Table Grate installs behind the splitting wedge by simply sliding the boxshaped grate supports into the open end of the wood splitter frame (Figure 12). This enables

convenient repositioning for the second pass on large pieces. Wood chips and debris will

fall through the grate, providing a cleaner finished product.

Grate Supports

Figure 12

WARNING! Always remove the Table Grate before transporting the splitter.

14 DR 20-Ton WOOD SPLITTER Safety & Operating Instructions

Page 19

Four-way, Reversible, Slip-on Wedge Installation

(Optional)

The following procedure is for the installation of the optional Four-Way Wedge (Figure 13)

for the DR 20-Ton WOOD SPLITTER.

Each DR 20-Ton WOOD SPLITTER has a permanently installed, 12 " single-blade,

fixed wedge. The fixed wedge splits logs into two pieces.

The fixed wedge also serves as a mounting for the optional Four-way Wedge (Figure

13).

The optional Four-way Wedge will split a log (up to 24 inches in diameter) into 4 pieces

on each push block cycle.

To vary the size of the resulting split pieces of wood, simply turn the Four-way Wedge

over and slip it back on the fixed wedge (Figure 13).

Important! Do not use a slip-on wedge with logs that have more than one knot or

that have twisted grain.

4-Way Wedge

Single Blade

Fixed Wedge

Figure 13

WARNING! Always remove the Slip-on Wedge before transporting the splitter.

DR 20-Ton WOOD SPLITTER Safety & Operating Instructions 15

Page 20

Transporting the Splitter

1. Remove the optional Four-Way Wedge, Table Grate, Log Lift (see Chapter 3) and

2. Make sure there are no loose parts or debris on the wood splitter that will fall off while

3. Never tow the wood splitter with a log on it.

4. Make sure the wood splitter's 2" ball coupler is firmly attached

c.) Lower the hitch latch into the locked position and secure

6. Make sure that the safety chains on the wood splitter’s hitch

7. Make sure the front swing-down support leg is retracted and

WARNING! NEVER move the wood splitter with the engine running.

WARNING! Do not rely on the Log Lift support to keep the Log Lift

raised while transporting the wood splitter.

transport them separately in the tow vehicle.

the machine is being towed.

to the 2" ball on the tow vehicle hitch:

a.) Raise hitch latch to the unlocked position (Figure 14).

b.) Place the wood splitter hitch onto the 2" ball of the tow

vehicle's trailer hitch.

with locking pin (Figure 14).

are securely attached to your tow vehicle, with sufficient slack

to allow for turning.

pinned up before transporting the wood splitter.

Figure 14

Latch Raised

Locking Pin

Towing Safety

Never allow anyone to ride on the wood splitter.

Never transport anything on the wood splitter.

Obey local, state, and federal regulations when you tow the wood splitter on public

roads and highways.

Note: Some states may require the wood splitter to be registered with the State

Department of Motor Vehicles.

Fenders and light kits, required in some states, are available from Country Home

Products as optional equipment.

Do not exceed 30 MPH while towing the wood splitter.

Towing the wood splitter can affect handling:

□ The wood splitter might track at an angle the tow vehicle.

□ The wood splitter can turn tighter than the tow vehicle does.

Never back up the tow vehicle with the wood splitter attached. The wood splitter can

jackknife, causing damage to itself and/or the tow vehicle.

Long distance towing is not recommended. The wood splitter does not have springs to

absorb road shock. Extended towing can cause unnecessary wear

16 DR 20-Ton WOOD SPLITTER Safety & Operating Instructions

.

Page 21

Checking the Engine Oil and Adding Gasoline

The DR 20-Ton WOOD SPLITTER is shipped with the engine oil already added.

Important! To get an accurate reading when checking the engine oil; the

machine should be on a level surface.

Capacities

Honda 5.0 HP OHC Engine SAE 10W-30W HD, .61 US qt. (0.58 L)

Gasoline Tank Unleaded gasoline, .53 US gal. (2 L)

Tip: To avoid confusion, we recommend leaving the caps on the fuel and engine oil fills

and only removing one cap each time when you are ready to pour gasoline or oil into the

correct fill.

Use only SAE 10W-30W high detergent oil. Other types of oil could cause problems

operating your machine. Please refer to your engine owner manual for detailed oil

information.

1. To check the engine oil

level, remove the oil

filler cap/dipstick and

wipe it clean.

2. Insert the oil filler

cap/dipstick into the

oil filler neck (Figure

Figure 15

Dipstick

Oil Fill

Upper Limit

Lower Limit

15), but do not screw it

in. Remove the dipstick and check the oil level. If the oil level is near or below the

lower limit mark on the dipstick, add SAE 10W-30W high detergent oil (recommended

by the engine manufacturer) to the upper limit mark (bottom edge of the oil fill hole).

Be careful not to overfill (Figure 15).

3. Remove the fuel tank cap and add

fresh, unleaded gas to the bottom

of the fuel level limit in the neck

Max Fuel

Level

of the fuel tank. Do not overfill

(Figure 16). See your engine owner

manual for more information.

Fuel

Level

Mark

Figure 16

DR 20-Ton WOOD SPLITTER Safety & Operating Instructions 17

Page 22

18 DR 20-Ton WOOD SPLITTER Safety & Operating Instructions

Page 23

Chapter 4: Operating Your DR 20-Ton WOOD SPLITTER

This chapter covers the procedures for starting and stopping your new DR 20-Ton WOOD

SPLITTER and also discusses basic operation features.

Before Starting the Engine

1. Inspect the area in which you will be working. Locate the wood splitter only on firm,

level ground in a well lit and well ventilated spot. The site must be free of slippery

surfaces and potentially hazardous obstacles. Also make sure there won't be people

or animals in the area around the wood splitter.

2. Take out cotter pin holding the hitch support leg in the raised position, swing leg

down, and insert cotter pin in the hole for the down position. (Figure 1 on page 9)

3. Check the engine oil level every time you use the machine (See Figure 15 on page 17).

4. Check the gasoline level (Figure 16 on page 17).

5. Check the hydraulic fluid level. See page 26.

Starting

1. When starting a cold engine; pull the

choke rod (Figure 17) to the Closed

position.

2. Move the throttle lever (gray) up from the

Stop position to about 1/3 of the way

toward the Fast position (Figure 18).

3. Grasp the recoil starter handle and slowly

pull until you feel resistance. Let the cord

retract a little bit, then pull the cord rapidly

to start the engine. One or two pulls

usually starts the DR 20-Ton WOOD

SPLITTER.

4. After the engine starts, return the choke to

the Open (Run) position (Figure 17).

5. Allow the engine to run at idle for 10 to 15

minutes to let the hydraulic fluid warm up.

6. For best engine performance, it is

recommended the engine be operated with

the throttle in the Fast position (Figure 18).

7. To stop the engine, move the throttle to

the Slow position allowing the engine to

idle, then move the lever to Stop position.

Choke Rod

Open (Run)

Closed

Figure 17

Throttle Lever (gray)

Fast

Slow

Stop

Figure 18

DR 20-Ton WOOD SPLITTER Safety & Operating Instructions 19

Page 24

Splitting Safety

The DR 20-Ton WOOD SPLITTER has a push block with 20 tons of force and a 13second cycle time.

Note: Always be sure to stand inside the Operator Zone to run the wood splitter

(Figure 19). This is the area between the hydraulic tank and the optional Log Cradle.

Never operate the wood splitter from anyplace else.

Handle logs only from the

Control Valve

sides, never by the ends.

For best splitting results, place

log on the beam with butt end

toward hydraulic cylinder push

block.

Be very careful to keep arms

Operator

Zone

and fingers away from the

wedge and push block.

Figure 19

Keep hands and fingers clear

at all times. Many wood

splitting accidents happen on

the return portion of the stroke.

Do not put any part of your body within the splitting area. Use a stick if you need

to remove debris from the splitting area.

Loading and Wedge Positioning

1. The optional Four-Way Wedge can be installed with either end up. The installed

position determines height of split cross pieces (Figure 13 on page 15).

2. Optional Manual Log Lift operation: (Figure 6 on page 12)

a.) With the lift fully lowered, go around the wood splitter and roll a log up to

200 lbs. MAX onto the lifting platform (Figure 1 on page 9).

b.) Return to the “Operator Zone” and pull back on the Log Lift handle (Figure

1) to raise the lift until the log rolls onto the splitter H-beam. The Lift

Support will engage in multiple positions as the Log Lift is raised (Figure 9

on page 13).

c.) Keep lift raised until log is securely held between push block and wedge.

d.) Pull up and hold the support release while lowering Log Lift Handle.

20 DR 20-Ton WOOD SPLITTER Safety & Operating Instructions

Page 25

Operating the Wood Splitter

1. To activate the control valve – push the handle forward and hold.

Note: The hydraulic control is a single handle

valve (Figure 20). The Push Block travels

forward only while valve handle is held in

the forward position. The cylinder

automatically completes return stroke

when valve handle is pushed back to the

locked (detent) position and released.

2. Put one hand on top of log, in the middle, to

keep it steady until the log is held firmly

between the Push Block and the wedge – then

remove your hand from the log.

3. Keep holding the valve handle forward until

the split pieces of the log fall away or Push

Block reaches full extension, one or two inches

from the wedge.

Figure 20

Note: The DR 20-Ton WOOD SPLITTER uses a two-stage hydraulic pump that

normally moves the Push Block at high speed with low force and will shift

automatically to low speed and high force when the wood splitter encounters

more resistance. This shift in speed may occur two or three times while

splitting some logs. If the two-stage hydraulic pump stays in one stage all the

time, call 1(800) DR-OWNER (376-9637) for assistance.

Back

Forward

4. Before starting the return stroke, let the hydraulic system recover by moving the

valve handle to the neutral position (straight up) for a moment.

5. Make sure nothing will interfere with the Push Block while it retracts.

6. Press the valve handle backward into the locked (detent) position and let go. The

Push Block will return by itself.

7. The valve handle will stay in the locked position until the Push Block is fully

retracted.

Note: To stop the Push Block or reverse direction:

During the forward stroke, release the control valve handle.

During the return stroke, pull the control valve handle forward to release it

from the locked (detent) position.

Operate the hydraulic control valve smoothly. Allow a short pause when

reversing directions, then press lever firmly in direction you need to go.

Rapidly or forcefully moving the control valve lever in either direction will

cause the system to wear prematurely.

DR 20-Ton WOOD SPLITTER Safety & Operating Instructions 21

Page 26

22 DR 20-Ton WOOD SPLITTER Safety & Operating Instructions

Page 27

Chapter 5: Maintaining the DR 20-Ton WOOD

SPLITTER

Regular maintenance is the way to ensure the best performance and long life of your

splitter. Please refer to this manual and the engine owner manual for maintenance

procedures. Service intervals listed in the checklist below supercede those listed in the

engine owner manual.

WARNING! When performing any maintenance, you must first shut off

the engine, disconnect the spark plug wire, make sure the hydraulic system is

depressurized and the fluid has cooled. Read the "Safety Considerations"

section of this manual before performing any repairs or maintenance.

Regular Maintenance Checklist

Note: Service intervals shown are considered maximum under normal operating

conditions. Increase frequencies under extremely dirty or dusty conditions.

Procedure

Check Engine Oil Level

Check Hydraulic Fluid Level

Lubricate Push Block and H-beam

Check Wedge(s) for sharpness

Check Hydraulic Hoses for wear,

fraying, kinking or abraded areas

Check the general condition of the

splitter, e.g.; nuts, bolts, welds etc.

Check Tire Pressure

Clean Engine Air Filter

Change Engine Oil

Note: 1st time after 5 hours of operation

Change Hydraulic Fluid

Note: If the hydraulic fluid becomes contaminated, change it immediately.

Change Hydraulic Fluid Filter

Note: 1st time after 20 hours of operation, or if the pressure

gauge indicates “Service Filter” (red area).

Clean Engine Exterior & Cooling Fins

Before

Each

Use

▲

▲

▲

▲

▲

▲

▲

Every

20

Hours

▲

▲

▲

Every

50

Hours

▲

Every

100

Hours

Every

200

Hours or

Annually

▲

Replace Spark Plug

Replace Engine Air Filter

DR 20-Ton WOOD SPLITTER Safety & Operating Instructions 23

▲

▲

Page 28

Lubrication

Your DR 20-Ton WOOD SPLITTER was lubricated at the Factory. The operator

needs to provide engine lubrication and lubricate the Push Block H-Beam periodically.

Tools & Supplies Needed:

#2 Lithium Grease

9/16" wrench

WARNING! Before performing any maintenance procedure, stop the

engine and disconnect the spark plug wire.

1. The Push Block should be lubricated daily to reduce wear on the H-Beam and sides.

Use #2 Lithium grease on the fittings, one on each side (Figure 21).

Note: Replace the Push Block Wear Plates (one on each side) if the Push Block can be

raised more than 1/4" off the H-Beam. Use a 9/16" wrench to remove the retaining bolts

(Figure 21).

2. The top of the H-Beam should be lubricated daily by coating it with #2 Lithium grease.

3. The wheel bearings should be lubricated (hand packed) with #2 Lithium grease

annually or after any trip longer than 50 miles. Refer to section “Unpacking the Splitter

and Installing the Wheels” on pages 10 & 11. Perform steps 5 thru 8 in the reverse

order to remove the wheels. Slide out the inner and outer bearings and hand pack them

with the #2 Lithium grease. Re-insert the bearings and replace the wheels per steps 5

thru 8 on pages 10 & 11.

Grease

Fitting

Retaining

Bolts

Wear Plate

Figure 21

24 DR 20-Ton WOOD SPLITTER Safety & Operating Instructions

Page 29

Removing and Replacing the Engine Oil

WARNING! Before performing any maintenance procedure, stop the

engine and disconnect the spark plug wire.

Tools & Supplies Recommended:

1/2" wrench

SAE 10W-30W HD, .61 US qt. (0.58 L)

CHP Liquid Vac Oil Drainer, item # 16145 (Optional)

Note: Drain the oil when the engine is warm. Warm oil drains quickly and completely.

1. Position a suitable oil receptacle under the engine oil drain and remove the engine oil

filler cap (Figure 22).

2. Remove the engine oil drain plug using the 1/2" wrench (Figure 22).

3. Allow the used oil to drain completely, then reinstall the drain plug with washer and

tighten securely.

4. Replace the engine oil using SAE 10W-30W HD oil. See page 17.

Optional Method

1. Remove the engine oil Fill Cap and vacuum the oil from the engine through the oil fill

tube using the recommended CHP oil drainer.

2. Replace the engine oil using SAE 10W-30W HD oil. See page 17.

Note: If the oil is not to be reused, be sure to use environmentally safe disposal

procedures in the disposing of the used oil.

Oil Filler

Cap/Dipstick

Drain Plug

Washer

Figure 22

Important! Be certain to fill with oil before starting the engine. See Page 17.

DR 20-Ton WOOD SPLITTER Safety & Operating Instructions 25

Page 30

Removing and Replacing the Hydraulic Fluid and

Filter

Tools & Supplies Needed:

WARNING! Before performing any maintenance procedure, stop the

engine and disconnect the spark plug wire.

WARNING! Escaping pressurized fluid from hydraulic system leaks can

have enough force to penetrate skin and cause serious injury or death.

Hydraulic fluid can remain highly pressurized while the splitter motor is off.

- Never use your hand or any part of your body to check for hydraulic system

leaks while the system is pressurized.

- Get professional medical help at once if hydraulic oil penetrates anyone's skin.

- Always release residual energy from pressurized hydraulic fluid and allow the

fluid to cool before doing any maintenance or repair work on the log splitter.

Important! Use only Rando 46 (Texaco) hydraulic fluid or equivalent.

Fill Plug

Rando 46 (Texaco) 4.5 gallons (17L)

Pipe wrench

Screwdriver

Filter element, 198980

1. With the engine stopped, release any

residual hydraulic pressure by moving

the control lever back and forth a

Filter inside filler tube

couple of times.

2. Remove the filler plug and then

Figure 23

remove the filter element inside the filler opening (Figure 23).

3. Place a suitable container under the drain elbow of the hydraulic fluid tank (Figure 24).

4. Loosen the pump hose clamp from the pump hose (Figure 24), at the pump end, using

the screwdriver. Then remove the hose from the nipple.

5. While holding the hose up, turn the tank drain elbow 180° counterclockwise using the

pipe wrench and then lower the hose into the fluid container allowing the fluid in the

tank to drain completely (Figure 24).

6. Turn the drain elbow 180° clockwise, reattach the hose to the pump connection nipple

and tighten the clamp.

26 DR 20-Ton WOOD SPLITTER Safety & Operating Instructions

Page 31

7. Fill the hydraulic tank with fresh fluid to about 1" from the top of the tank.

8. Insert a new filter element in the filler opening and replace the filler cap.

9. Start the splitter engine and operate the ram back and forth a couple of times to bleed

the air from the hydraulic system.

10. The pressure gauge should now indicate a pressure in the “green” area of the pressure

gauge dial (0-25 psi).

11. Recheck and adjust the hydraulic fluid level per step 7.

Pump Hose Clamp

Drain Elbow

Figure 24

DR 20-Ton WOOD SPLITTER Safety & Operating Instructions 27

Page 32

Removing and Replacing the Hydraulic Hoses

Tools & Supplies Needed:

1" wrench (fitting)

7/8" wrench (hose)

Rando 46 (Texaco) hydraulic fluid

Screwdriver

1. With the engine stopped, release any

2. Use the 7/8" wrench to hold the

3. Install the new hose in the reverse order.

4. To replace a low pressure hose, loosen the hose clamp with a screwdriver and slip the

5. Install the new hose in the reverse order.

WARNING! Before performing any maintenance procedure, stop the

engine and disconnect the spark plug wire.

WARNING! Escaping pressurized fluid from hydraulic system leaks can

have enough force to penetrate skin and cause serious injury or death.

Hydraulic fluid can remain highly pressurized while the splitter motor is off.

- Never use your hand or any part of your body to check for hydraulic system

leaks while the system is pressurized.

- Get professional medical help at once if hydraulic oil penetrates anyone's skin.

- Always release residual energy from pressurized hydraulic fluid and allow the

fluid to cool before doing any maintenance or repair work on the log splitter.

Important! Use only Rando 46 (Texaco) hydraulic fluid and DR replacement

hoses, connectors, valves, or fittings on your machine. They have been

thoroughly tested and proven for many hours of use.

1" wrench here

Low

High

Pressure Hose

Pressure

(approx. 1 qt. to refill)

residual hydraulic pressure by

Hose

7/8" wrench here

moving the control lever back and

forth a couple of times.

Screwdriver here

high pressure hose end being

replaced while loosening the fitting

Figure 25

with the 1" wrench. (Figure 25)

hose off the connector nipple.

28 DR 20 - Ton WOOD SPLITTER Safety & Operating Instructions

Page 33

6. Check and adjust the hydraulic fluid to be about 1" from the top of the tank.

7. Start the splitter engine and operate the ram back and forth a couple of times to bleed

any air from the hydraulic system.

8. The pressure gauge should indicate a pressure in the “green” area of the pressure gauge

dial (0-25 psi).

9. Recheck and adjust the hydraulic fluid level per step 6.

Adjusting the Hydraulic Control Valve

Tools Needed:

7/16" wrench

1/8" (9mm) Hex wrench

If the hydraulic push ram will not return all the way back to it’s retracted position, the

locked position (detent) on the right side (Operator’s side) of the control valve may have to

be adjusted.

1. Pull off the black protective cap (Figure 26) on the right side of the control valve and

loosen the jam nut with the 7/16" wrench (Figure 27).

2. Using the Hex wrench, turn the screw on the control valve clockwise, a quarter turn at

a time (Figure 27), until the push ram will return to it’s fully retracted position. Re-

tighten the jam nut and replace the protective cap.

Jam Nut Hex Screw

Protective

Cap

Figure 26 Figure 27

DR 20-Ton WOOD SPLITTER Safety & Operating Instructions 29

Page 34

End of Season & Storage

WARNING! Before performing any maintenance procedure, stop the

engine and disconnect the spark plug wire.

Note: Please refer to the engine owner manual for engine-specific procedures.

Change the oil.

If your DR 20-Ton WOOD SPLITTER will be idle for more than 30 days, we

recommend using a gas stabilizer. This will prevent sediment from gumming up the

carburetor. If there is dirt or moisture in the gas or tank, remove it by draining the

tank. Completely fill the tank with fresh, unleaded gas and add the appropriate

amount of stabilizer or gasoline additive. Run the engine for a short time to allow

the additive to circulate.

Remove the spark plug and pour about 1 ounce of motor oil into the cylinder hole.

Replace the plug and pull the recoil starter rope until you feel strong resistance.

This will coat the piston and seat the valves to prevent moisture buildup.

Clean/replace the air filter.

Clean dirt and debris from the cylinder head cooling fins, blower housing, debris

screen and muffler area of the engine.

30 DR 20-Ton WOOD SPLITTER Safety & Operating Instructions

Page 35

Chapter 6: Troubleshooting and Warranty

Most problems are easy to fix. Consult the troubleshooting table for common problems

and their solutions. If you continue to experience problems, call Country Home Products,

Inc. for support.

Troubleshooting Table

WARNING! Before performing any maintenance procedure, stop the

engine and disconnect the spark plug wire.

S

YMPTOM

P

Recoil will not

pull out or is

difficult to pull.

The engine

won’t start.

(Please refer to

the engine

manufacture’s

owner’s manual

for enginespecific

procedures.)

OSSIBLE CAUSE

⇒ Check the engine oil level, the engine may be seized.

⇒ There may be an oil compression lock in the cylinder.

Take out the spark plug, hold a rag over the spark

plug hole and pull the recoil cord several times to blow

out any oil in the cylinder. Wipe off the spark plug and

reinsert it.

⇒ The recoil may be broken or jammed. Call 1(800) DR-

OWNER (376-9637) for assistance.

⇒ Check the oil level. See page 17.

⇒ Are you using fresh, clean gas? If the gas is old,

change it. Use a fuel stabilizer if you keep gas longer

than one month.

⇒ Check the throttle adjustment and travel. See page 19.

⇒ Is the spark plug clean? If the spark plug is dirty or

cracked, change it. If it’s oily, leave it out, hold a rag

over the plug hole and pull the recoil cord several

times to blow out any oil in the cylinder, then wipe off

the plug and reinsert it.

⇒ If your engine still won’t start, call 1(800) DR-OWNER

(376-9637) for assistance.

DR 20-Ton WOOD SPLITTER Safety & Operating Instructions 31

Page 36

Symptom Possible Cause

The engine

lacks power or

is not running

smoothly.

(Please refer to

the engine

manufacturer’s

owner’s manual

for enginespecific

procedures.)

⇒ Check the throttle travel. See page 19.

⇒ Is the choke pushed all the way in (Open)? See page

19.

⇒ Is the air filter clean? If it’s dirty, change it following the

procedure in the engine manufacturer’s owner’s

manual.

⇒ Is the spark plug clean? If it’s fouled or cracked,

change it. If it’s oily, leave it out, hold a rag over the

plug hole and pull your recoil cord several times to

blow out any oil in the cylinder, then wipe off the plug

and reinsert it.

⇒ Are you using fresh, clean unleaded gas? If it’s old,

change it. Use a fuel stabilizer if you keep gas longer

than one month.

⇒ Does your engine have the right amount of clean oil?

If it’s dirty, change it following the procedure in the

engine manufacturer’s owner’s manual.

⇒ Check the oil level and adjust as needed.

⇒ If your engine still lacks power, call 1(800) DR-

OWNER (376-9637) for assistance.

Engine smokes.

Splitter wheels

tracking left or

right while being

towed.

Push Ram will

not move or is

slow to respond.

⇒ Check the oil level and adjust as needed.

⇒ Check the air filter and clean or replace if needed.

⇒ You may be using the wrong oil—too light for the

temperature. Refer to your Engine Manufacturer's

Owner’s Manual for detailed information.

⇒ Clean the cooling fins if they’re dirty.

⇒ If the engine still smokes, call 1(800) DR-OWNER

(376-9637) for assistance.

⇒ Check the tire pressure. There should be 60 psi in

each tire.

⇒ The hydraulic fluid may be low. Check and adjust the

level as required. See page 26.

⇒ The hydraulic fluid filter may be dirty or plugged. See

page 26.

32 DR 20-Ton WOOD SPLITTER Safety & Operating Instructions

Page 37

Notes

DR 20-Ton WOOD SPLITTER Safety & Operating Instructions 33

Page 38

Notes

34 DR 20-Ton WOOD SPLITTER Safety & Operating Instructions

Page 39

1-Year Limited Warranty

Terms and Conditions

The DR 20-Ton WOOD SPLITTER is warranted for one (1) year against defects in materials or workmanship when put to

ordinary and normal consumer use; ninety (90) days for any other use. The engine is warranted separately by the engine

manufacturer.

For the purposes of all the above warranties, “ordinary and normal consumer use” refers to non-commercial residential use and

does not include misuse, accidents or damage due to inadequate maintenance.

Country Home Products, Inc. certifies that the DR

product of this type is used. Country Home Products, Inc. however, limits the implied warranties of merchantability and fitness

in duration to a period of one (1) year in consumer use, ninety (90) days for any other use.

The 1-Year Limited Warranty on the DR 20-Ton WOOD SPLITTER starts on the date the machine ships from our factory.

The 1-Year Limited Warranty is applicable only to the original owner.

The warranty holder is responsible for the performance of the required maintenance as defined by the manufacturer's owner's manuals.

The warranty holder is responsible for replacement of normally wearing parts such as the hydraulic hoses, wear plates, and spark plug.

Attachments and accessories to the machine are not covered by this warranty.

During the warranty period, the warranty holder is responsible for the machine transportation charges, if required. During the warranty

period, warranty parts will be shipped by standard method at no charge to the warranty holder. Expedited shipping of warranty parts is

the responsibility of the warranty holder.

SOME STATES DO NOT ALLOW LIMITATIONS ON THE LENGTH OF IMPLIED WARRANTIES, SO THE ABOVE

LIMITATIONS MAY NOT APPLY TO YOU.

20-Ton WOOD SPLITTER is fit for ordinary purposes for which a

Country Home Products, Inc. shall not be liable under any circumstances for any incidental or consequential damages or

expenses of any kind, including, but not limited to, cost of equipment rentals, loss of profit, or cost of hiring services to

perform tasks normally performed by the DR

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

20-Ton WOOD SPLITTER.

Customer Service Hotline

Country Home Products, Inc.’s objective is to have 100% satisfied customers. For that reason, we operate a 6-day-a-week

Technical Service Department for our Owners. You can access a Representative by dialing our TOLL-FREE Hotline at 1-800DR-OWNER (376-9637). The sole job of our well-trained and friendly folks is to ensure that you get any help you need in a

timely fashion. They are there to answer all your questions including: (1) inquiries on any of the above warranties, (2) inquiries

about replacement parts, or (3) your questions regarding service, maintenance and operation.

Our Customer Service Representatives will also be happy to answer any of your questions regarding the separate warranties on

all engines. However, to obtain service, repair or replacement of any engine within the time period covered by the

manufacturer’s limited warranty, follow the instructions and warranty information specifically pertaining to those items

provided by their separate manufacturers.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU ALSO HAVE OTHER RIGHTS, WHICH VARY

FROM STATE TO STATE.

COUNTRY HOME PRODUCTS, Inc.

MEIGS ROAD, P.O. BOX 25, VERGENNES, VERMONT 05491

1-800-DR-OWNER (376-9637) • www.dr-owner.com

©2003 CHP, Inc. 178901

Page 40

Daily Checklist for the DR 20-Ton WOOD

SPLITTER

To help maintain your DR 20-Ton WOOD SPLITTER for optimum performance, we

recommend you follow this checklist each time you use your machine.

[ ] OIL: With the splitter on a level surface, remove the oil fill cap and check the oil

level. Fill the reservoir according to the dipstick with SAE 10W-30W HD motor oil.

(See page 17)

[ ] GAS: Fill the gas tank with fresh, unleaded gasoline. See page 17.

[ ] ENGINE: It is very important to keep the engine clean. Remove dirt and other

debris from the engine cooling fins and debris guard. A dirty engine retains heat

and can cause damage to internal engine components.

[ ] HARDWARE: Check all nuts and bolts to be sure that the components are secure.

[ ] FRAME: Check all welds to be sure that the frame is in tact and secure.

[ ] WEAR PLATES: Make sure that the Wear Plates attached to the Push Block are

firmly bolted into place. (See page 24)

[ ] GREASE: Make sure that Push Block and the top of the H-Beam are well

lubricated with grease. (See page 24)

[ ] HYDRAULIC HOSES: Inspect the hydraulic hoses for frayed, worn, kinked, or

abraded areas. Replace any damaged or worn hoses immediately. (See page 28)

COUNTRY HOME PRODUCTS, Inc.

MEIGS ROAD, P.O. BOX 25, VERGENNES, VERMONT 05491

1-800-DR-OWNER (376-9637) • www.dr-owner.com

©2004 CHP, Inc. 186501

Loading...

Loading...