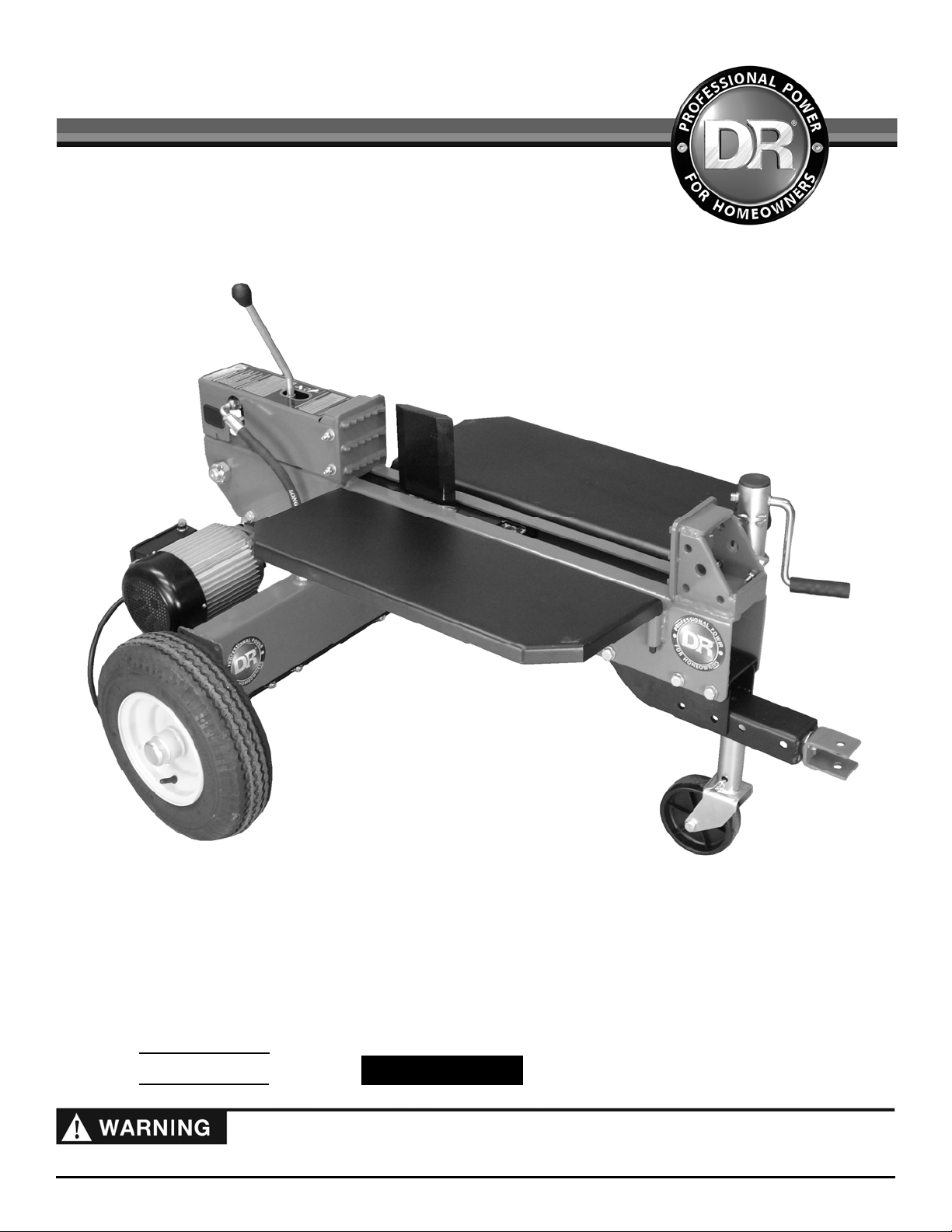

Page 1

`

DR

SAFETY & OPERATING INSTRUCTIONS

®

DUAL-ACTION ELECTRIC LOG SPLITTER

DR Power Equipment

Serial No.

Order No.

Read and understand this manual and all instructions before operating the DR Dual-Action Electric Log Splitter.

Original Language

Toll-free phone: 1-800-DR-OWNER (376-9637)

Fax: 1-802-877-1213

Website: www.DRpower.com

Page 2

Table of Contents

Chapter 1: General Safety Rules ............................................................................................................................................................ 3

Chapter 2: Setting Up The DR DUAL-ACTION ELECTRIC LOG SPLITTER ......................................................................................... 7

Chapter 3: Operating Your DR DUAL-ACTION ELECTRIC LOG SPLITTER ........................................................................................ 14

Chapter 4: Maintaining The DR DUAL-ACTION ELECTRIC LOG SPLITTER ...................................................................................... 18

Chapter 5: Troubleshooting .................................................................................................................................................................. 21

Chapter 6: DR DUAL-ACTION ELECTRIC LOG SPLITTER Road Towable Kit ..................................................................................... 24

Chapter 7: Parts Lists, Schematic Diagrams And Warranty ................................................................................................................ 28

Conventions used in this manual

This indicates a hazardous situation, which, if not avoided, could result in death or serious injury.

This indicates a hazardous situation, which, if not avoided, could result in minor or moderate injury.

This information is important in the proper use of your machine. Failure to follow this instruction could result in damage to

your machine or property.

Serial Number and Order Number

A Serial Number is used to identify your machine and is located on the Serial Number Label on your machine. An Order Number

is used to check and maintain your order history and is located on your packing slip. For your convenience and ready reference,

enter the Serial Number and Order Number in the space provided on the front cover of this manual.

Additional Information and Potential Changes

DR Power Equipment reserves the right to discontinue, change, and improve its products at any time without notice or obligation

to the purchaser. The descriptions and specifications contained in this manual were in effect at printing. Equipment described

within this manual may be optional. Some illustrations may not be applicable to your machine.

2 DR

®

DUAL-ACTION ELECTRIC LOG SPLITTER

Page 3

Chapter 1: General Safety Rules

#

Read this safety & operating Instructions manual before you use the DR DUAL-ACTION ELECTRIC LOG SPLITTER. Become

familiar with the operation and service recommendations to ensure the best performance from your machine. If you have any

questions or need assistance, please contact us at www.DRpower.com or call toll-free 1-800-DR-OWNER (376-9637) and one of

our Technical Support Representatives will be happy to help you.

Labels

Your DR DUAL-ACTION ELECTRIC LOG SPLITTER carries prominent labels as reminders for its proper and safe use. Shown

below are copies of all the Safety and Information labels that appear on the equipment. Take a moment to study them and make a

note of their location on your Log Splitter as you set up and before you operate the unit. Replace damaged or missing safety and

information labels immediately.

# 27609

# 29395

29394

CONTACT US AT www.DRpower.com 3

Page 4

Protect Yourself and Those Around You

This is a high-powered machine, with moving parts operating with high energy. You must operate the machine safely. Unsafe

operation can create a number of hazards for you, as well as anyone else in the nearby area. Always take the following precautions

when using this machine:

Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people, their property, and

themselves.

Always wear protective goggles or safety glasses with side shields while using the Log Splitter to protect your eyes from possible

thrown debris.

Avoid wearing loose clothing or jewelry, which can catch on moving parts.

We recommend wearing gloves while using the Log Splitter. Be sure your gloves fit properly and do not have loose cuffs or

drawstrings.

Wear shoes with non-slip treads when using your Log Splitter. If you have safety shoes, we recommend wearing them. Do not

use the machine while barefoot or wearing open sandals.

Wear long pants while operating the Log Splitter.

Use ear protectors or ear plugs rated for at least 20 dBA to protect your hearing.

Keep bystanders at least 50 feet away from your work area at all times. Stop the motor when another person or pet approaches.

Hydraulic Safety

High fluid pressures are developed in hydraulic machines. Pressurized hydraulic fluid escaping through a pin hole opening can

puncture skin and cause severe blood poisoning. Therefore, the following Instructions should be heeded at all times.

Do not operate the unit with frayed, kinked, cracked or damaged hoses, fittings, or tubing. Stop the motor, wait 5 minutes and

relieve hydraulic system pressure before changing or adjusting fittings, hoses, tubing, or other system components.

The relief valve settings are set at the factory for best Splitter performance and safety. Make sure other factors such as using an

extension cord that is not rated for this application is not the problem before adjusting valve settings.

Do not check for leaks with your hand. Leaks can be located by passing cardboard or wood over the suspected area: Look for

discoloration. If injured by escaping fluid, see a doctor at once. Serious infection or reaction can develop if proper medical

treatment is not administered immediately.

Always wear safety glasses to protect your eyes from hydraulic fluid.

Safety for Children and Pets

Tragic accidents can occur if the operator is not alert to the presence of children and pets. Children are often attracted to the

machine and the splitting activity.

precautions:

Keep children and pets at least 50 feet from the working area and ensure they are under the watchful care of a responsible

adult.

Be alert and turn the machine off if children or pets enter the work area.

Never allow children to operate the Log Splitter.

Never

assume that children will remain where you last saw them. Always follow these

4 DR

®

DUAL-ACTION ELECTRIC LOG SPLITTER

Page 5

Safety with Electric - Powered Machines

Never overlook the hazards of electricity. Always follow these precautions:

Never open the switch box or motor cover. Never attempt any electrical repairs yourself. If in doubt, consult a qualified

electrician, visit our website at www.DRpower.com or contact DR Power Equipment for toll-free support at: 1-800-dr-owner

(376-9637) for help or information.

Never use an extension cord that is not rated for outdoor use.

Never operate the Log Splitter if there is an electrical hazard present.

Never operate the Log Splitter in wet conditions and always store under cover.

Never operate the Log Splitter with a damaged electrical cord or damaged extension cord.

Never pull on the electrical cord to move the machine.

Always grasp the electrical cord plug when unplugging the cord from the outlet; never pull the plug out by the cord. Make

sure your fingers do not touch the metal prongs when plugging or unplugging.

Never operate the Log Splitter unless the electrical cord is plugged into a properly grounded GFCI protected electrical outlet,

which supplies 110-120v power, and is protected by a 20-amp circuit breaker.

Never tamper with safety devices. Check their proper operation regularly.

If you are using an extension cord, keep the connection between the electrical cord and the extension cord well away from any

water.

Never use an extension cord longer than 25 feet and smaller than 12 awg in diameter, or longer than 50 feet and smaller than

10 awg in diameter; the cord will produce a voltage drop that will prevent the motor from supplying full power and may cause

damage to the motor. Use of a smaller diameter (larger awg number) extension cord could result in melting of the insulation

or even create a fire.

Always keep the electrical cord and/or extension cord away from excessive heat, oil, and sharp objects.

Towing (optional Road Tow Kit)

ALWAYS check before towing to make certain your splitter is correctly and securely attached to the towing vehicle. Be sure

that the ball hitch you are using is the proper size for the hitch coupler on the splitter. Be sure the safety chains are properly

hooked to the vehicle leaving enough slack for turning.

ALWAYS raise the jack to the highest setting before transporting the splitter.

ALWAYS use accessory lights and devices when transporting on a road or highway to warn operators of other vehicles. Check

your local government regulations for DOT information.

ALWAYS allow for added length of the splitter when turning, parking, crossing intersections, and in all driving situations.

ALWAYS be careful when backing up. You could jackknife your splitter if care is not taken.

ALWAYS travel slowly over rough terrain, on hillsides, and around curves to prevent tipping.

NEVER exceed 30 mph. when towing your splitter. Obey all state and local regulations when towing on state and local roads

and highways. Adjust your speed for terrain and conditions, as needed. Be extra cautious when towing over rough terrain,

especially over a railroad crossing.

NEVER allow anyone to sit or ride on your splitter.

NEVER carry any cargo on your splitter.

NEVER tow the splitter near the edge of a ditch.

General Safety

Operating this Log Splitter safely is necessary to prevent or minimize the risk of death or serious injury. Unsafe operation can

create a number of hazards for you. Always take the following precautions when operating this Log Splitter:

Your Log Splitter is a powerful tool, not a plaything. Exercise extreme caution at all times. The machine is designed to Split

Logs. Do not use it for any other purpose.

CONTACT US AT www.DRpower.com 5

Page 6

Allow only one person to operate the Log Splitter at any time.

If the machine should start making an unusual noise or vibration, turn the machine off and unplug the electrical cord and

allow the machine to cool, then inspect for damage. Vibration is generally a warning of trouble. Check for damaged parts and

clean, repair and/or replace as necessary.

Never tamper with safety devices. Check their proper operation regularly.

Never allow people who are unfamiliar with these instructions to use the Log Splitter. Allow only responsible individuals who

are familiar with these rules of safe operation to use your machine.

Never overload or attempt to split logs beyond the manufacturer’s recommendation. Personal injury or damage to the

machine could result.

While using the Log Splitter, don't hurry or take things for granted. When in doubt about the equipment or your surroundings

stop the machine and take the time to look things over.

Never operate the machine when under the influence of alcohol, drugs, or medication.

Use the machine only in daylight.

Keep all nuts and bolts tight and keep the equipment in good operating condition.

Always cut the ends of the log you are splitting as squarely as possible.

Never split more than one log at a time unless you fully extended the ram and you need a second log to complete the split of

the first log.

Never put anything between the log trays and the side of a log; logs spread as they are forced against the wedge.

Never operate the wedge in a stalled position for more than five (5) seconds. The hydraulic fluid may overheat and damage

the machine. If the wood being split is excessively hard, stop the machine, rotate the log 180 and try again. If you still

cannot split the log, reject the log as it exceeds the capacity of the machine.

Never leave the Log Splitter unattended while plugged in. If you leave the area, unplug from the power source.

Clean up as you work; accumulated split wood and wood chips can create a hazardous work environment.

Keep your hands and feet away from the splitting area while the wedge is in motion.

Use only your hands to operate the Log Splitter controls.

Do not place your hands at pinch points where they can catch between a log and the wedge, log trays or the ram.

Do not put any part of yourself, your clothing, or your personal protective equipment into a crack in a log that you are

splitting; it might close suddenly with great force.

Never split anything other than logs free of nails, wires, and branches. Maximum log length is 20" with a maximum diameter

of 24" for the DR DUAL-ACTION ELECTRIC LOG SPLITTER.

Never operate the Log Splitter in an area of natural gas or flammable liquids.

Always operate the Log Splitter from the operator zone (Chapter 3). Never stand on, straddle, or climb over the Log Splitter

at any time.

Do not handle logs by their ends when you position them on the Log Splitter. Handle from the sides of the log.

Always unplug the Log Splitter from the power source before adjusting or servicing the machine. If you have to stop to

remove any debris from the machine, always retract the ram and unplug the machine.

Do not move or reposition the Log Splitter with its motor running.

Check the Log Splitter before turning it on. Never use the machine without ensuring that all guards and shields are in place.

Replace damaged, missing or failed parts before using the Splitter.

Never, under any conditions, remove, bend, cut, fit, weld, or otherwise alter standard parts on the Log Splitter. This includes

all shields and guards. Modifications to your machine could cause personal injuries and property damage and will void your

warranty.

Know how to stop the Log Splitter quickly; see “Stopping the Log Splitter” in Chapter 3.

Never operate your unit on a slippery, wet, muddy, or icy surface. Exercise caution to avoid slipping or falling.

A Note to All Users

No list of warnings and cautions can be all-inclusive. If situations occur that are not covered by this manual, the operator must

apply common sense and operate this DR DUAL-ACTION ELECTRIC LOG SPLITTER in a safe manner. Contact us at

www.DRpower.com or call 1-800-DR-OWNER (376-9637) for assistance.

6 DR

®

DUAL-ACTION ELECTRIC LOG SPLITTER

Page 7

Jack

Chapter 2: Setting Up The DR DUAL-ACTION ELECTRIC LOG SPLITTER

ff

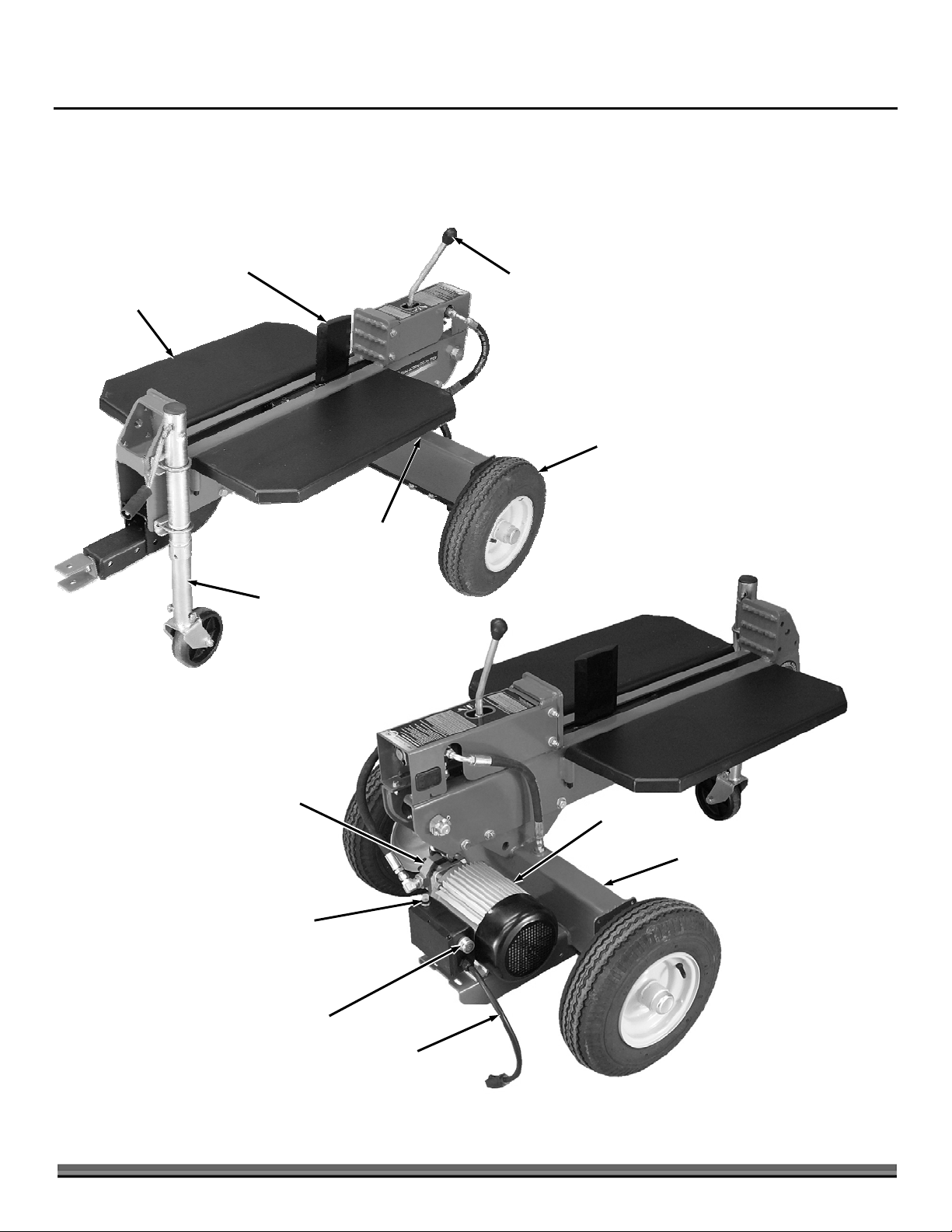

It may be helpful to familiarize yourself with the controls and features of your DR DUAL-ACTION ELECTRIC LOG SPLITTER as

shown in Figure 1 before beginning these procedures. If you have any questions at all, please feel free to contact us at

www.DRpower.com.

DR DUAL-ACTION ELECTRIC LOG SPLITTER Controls and Features

Splitting Wedge

Log Tray

Dipstick/Hydraulic

Fluid Fill

Operator Lever

Pneumatic

Tires

Hydraulic

Fluid Pump

Assembly

Reset

Button

Electric Motor

On-O

Switch

Electric Motor

Hydraulic

Fluid Tank

Electrical Cord

Figure 1

CONTACT US AT www.DRpower.com 7

Page 8

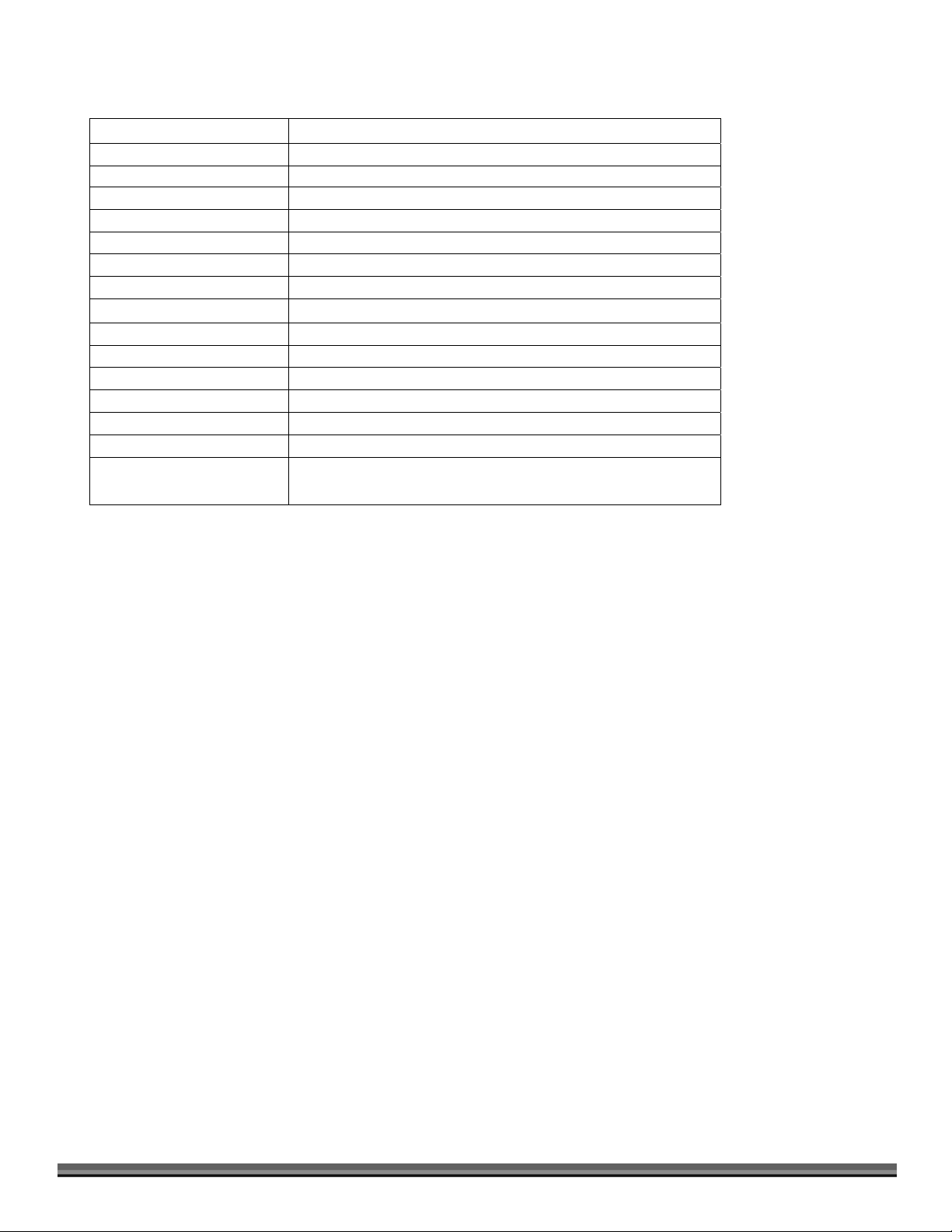

Specifications

(

Motor

Bed height

Wedge

Log Trays

Force/Tonnage

Log Length

Log Diameter*

Cycle Time

Wheels & Tires

Weight

Dimensions

Cylinder Size

Hydraulic Tank

Pump

Control Valve

Hydraulic Fluid

*The diameter listed is indicative of the maximum suggested size - a small log can be difficult to split when it contains knots or a

particularly tough fiber. On the other hand, it may not be difficult to split logs with regular fibers even if its diameter exceeds the

maximum indicated above.

1.8kW, 110V AC Motor

24" (610mm)

168mm) h, .75" (19mm) w/high carbon steel.

6.61"

27.45in (697mm) L x 11.45in (290mm) W

10 ton

20 inches

24 inches

Approx. 21 seconds

Dot Approved, 4.8/4-8, Steel Wheel With Taper Roller Bearings

298 lbs (150kg)

64"L X 40.5"W X 38.5"H

3" (76mm) Bore, 18.51" (470mm) Stroke

6 Quarts

Single Stage, 1.58 Gal/min (6 L/minute)

Integrated Pressure Relief

See Table-1 on page 10

Assembling the DR DUAL-ACTION ELECTRIC LOG SPLITTER

Tools and Supplies Needed:

Two 3/4" Wrenches

1-1/2" Wrench

Pliers

Soft Face Hammer

Two 1/2" Wrenches

7/8" Wrench

17mm Wrench

Two 7/16" Wrenches

Jack Stands

Utility Knife

Wire Cutters

Safety Glasses

8 DR

®

DUAL-ACTION ELECTRIC LOG SPLITTER

Page 9

1. Open the Parts Box and lay them out on a clean flat area (Figure 2).

A

A

A

s

3 4 5

8 9 10 11 12 13 14 15 16

Note: For assembly location, the part numbers in the following list can be

referenced to the Parts List and illustrations in Chapter 6.

Parts Box (Figure 2):

Item #

Part # Description Qty

1 ............. 13443 .............. Bolt, HCS, 5/16-18 X 1-1/2, Gr5, ZP .............. 4

2 ............. 11238* ............ Washer, Flat, 1/4" USS .................................. 12

3 ............. 11076 .............. Nut, Nylon Lock, 5/16-18, ZP ........................ 4

4 ............. 29054 .............. Mount, Tow Hitch, Rear ................................. 1

5 ............. 29367 .............. Dipstick ........................................................... 1

6 ............. 27610 .............. Abrasion Resistant Sheathing, 15.5in ............ 1

7 ............. 11214 .............. Cable Tie, 7-1/2 Long ..................................... 2

8 ............. 25616 .............. Hyd Adapter jcm08-obm08-90 ....................... 1

9 ............. 15192 .............. Pin, Hitch Clip, 5/16" - 3/8" ........................... 4

10 ........... 25311 .............. Pin, Cotter, 3/16" X 2.5" ................................. 2

11 ........... 25310 .............. Nut, Slotted, 1-14, ZP ..................................... 2

12 ........... 25318 .............. Cap, Dust ........................................................ 2

13 ........... 11075 .............. Nut, Nylon Lock, 3/8-16, ZP .......................... 4

14 ........... 11241 .............. Washer, Flat, 5/16 USS, ZP ........................... 4

15 ........... 29377 .............. Clamp, 2 inch, Jack ......................................... 2

16 ........... 29378 .............. U-bolt, 3/8-16 X 2 X 4, ZP .............................. 2

* Only 8 are used for this model.

2

Figure 2

1

6

7

Compare the contents of the Parts Box, Product Pack and Shipping Box with the

“Parts Supplied” list above. If you have any questions please contact us at

www.DRpower.com or call 1-800-DR-OWNER (376-9637) for assistance.

Assembly

We recommend two people when handling assemblies during the following

procedures. The assemblies involved are heavy and could cause injury when

lifting or if dropped.

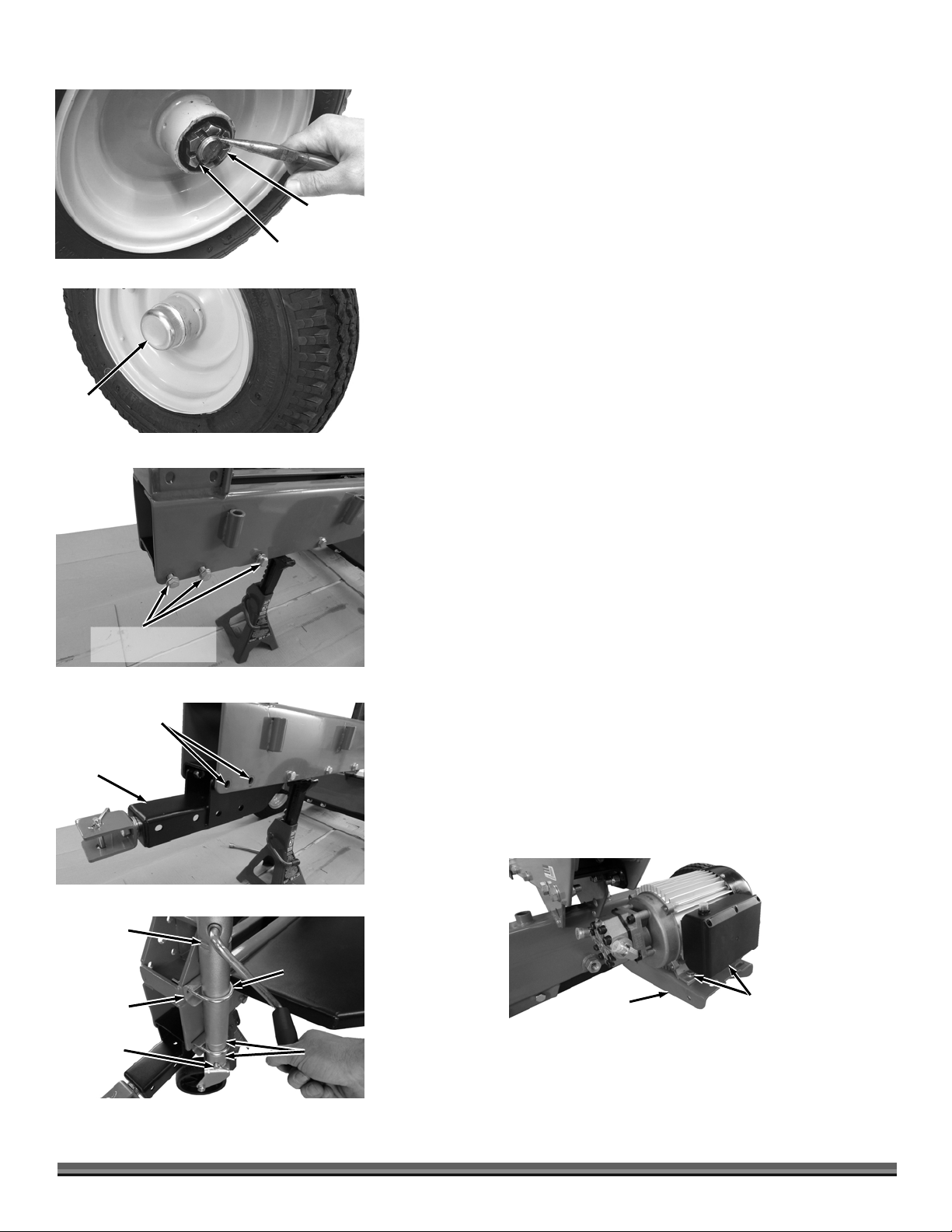

1. Position the Beam at the center of the pallet and lay it on its side to remove

the four sets of Bolts, Flat Washers and Locknuts where the Axle assembly

attaches (Figure 3).

2. Set the Beam assembly onto the Axle assembly and align the holes (Figure

4).

3. Insert the four Bolts, Flat Washers (outside of main Beam) and Locknuts

and tighten with two 3/4" Wrenches.

4. Place Jack Stands under the Axle assembly to allow room to install the

Wheels.

5. Place a Wheel onto the Axle with the Valve Stem facing out and the loose

Tapered Bearing on the outside (Figure 5).

Note: Make sure the rollers of the Tapered Bearing are facing in. The Hub and

Bearing were greased at the factory. Do not remove the grease.

Bolts, Washers

and Locknuts

Figure 3

Beam

ssembly

Bolts, Flat

Washers and

Locknut

xle

ssembly

Figure 4

Taper

Bearing

Figure 5

CONTACT US AT www.DRpower.com 9

Page 10

A

Jack

Figure 6

Dust

Cap

Figure 7

Cotter Pin

Castle

Nut

6. Install the Castle Nut onto the Axle Threads with a 1-1/2" Wrench until the

Tapered Bearing is just pushing against the inside of the Wheel Hub but not too

tight (Figure 6). There should be minimal amount of drag on the Wheel when

rotated by hand.

7. Turn the Castle Nut back only as far as needed to align the closest slot in the

Nut with the Hole in the Axle. Insert the Cotter Pin and bend the ends around

with Pliers to secure the Nut. Check that the wheel will rotate freely and does

not wobble on the axle.

8. Install the Dust Cap with a soft face Hammer (Figure 7).

9. Repeat steps 5 thru 8 for the second Wheel.

10. Use a Jack Stand to raise the front of the Splitter allowing room for installing

the Tow Hitch and Jack.

11. Remove the six sets of hardware (three per side) that are installed at the

front of the Beam assembly (Figure 8).

12. Position the Tow Hitch and secure the right side with three sets of the Bolts,

Lock Washers and Locknuts and one set on the left side using two 3/4"

Wrenches (Figure 9).

13. Install the Jack, Spacers and U-Bolts with the lower Clamp and U-Bolt

located between the two positioning rings of the Jack Housing (Figure 10).

Note: The Jack must be installed at a 45° angle for Handle clearance. Temporarily

install a Tray as a guide for checking Handle clearance.

Bolts, Washers and

Locknuts (both sides)

Figure 8

Leave These Out

Tow Hitch

ssembly

Figure 9

Clamp

Hitch Pin

U-Bolt

Position

Rings

Tray

14. Secure the U-Bolts with Flat Washers and Locknuts using a 9/16" Wrench.

15. Remove the Jack Stand and roll the Splitter from the Pallet.

Note: The Slots of the Engine Mount are for Gas Engine mounting and the round

holes are for Electric Motor mounting.

16. Position the Motor onto the Bracket and align the Motor Base holes with the

holes of the Bracket (Figure 11).

17. Install the four sets of Bolts, Flat Washers (top and bottom) and Locknuts to

secure the Motor to the Mount using two 1/2" Wrenches.

Motor

Mount

Figure 11

Motor

Hardware

Figure 10

10 DR

®

DUAL-ACTION ELECTRIC LOG SPLITTER

Page 11

J

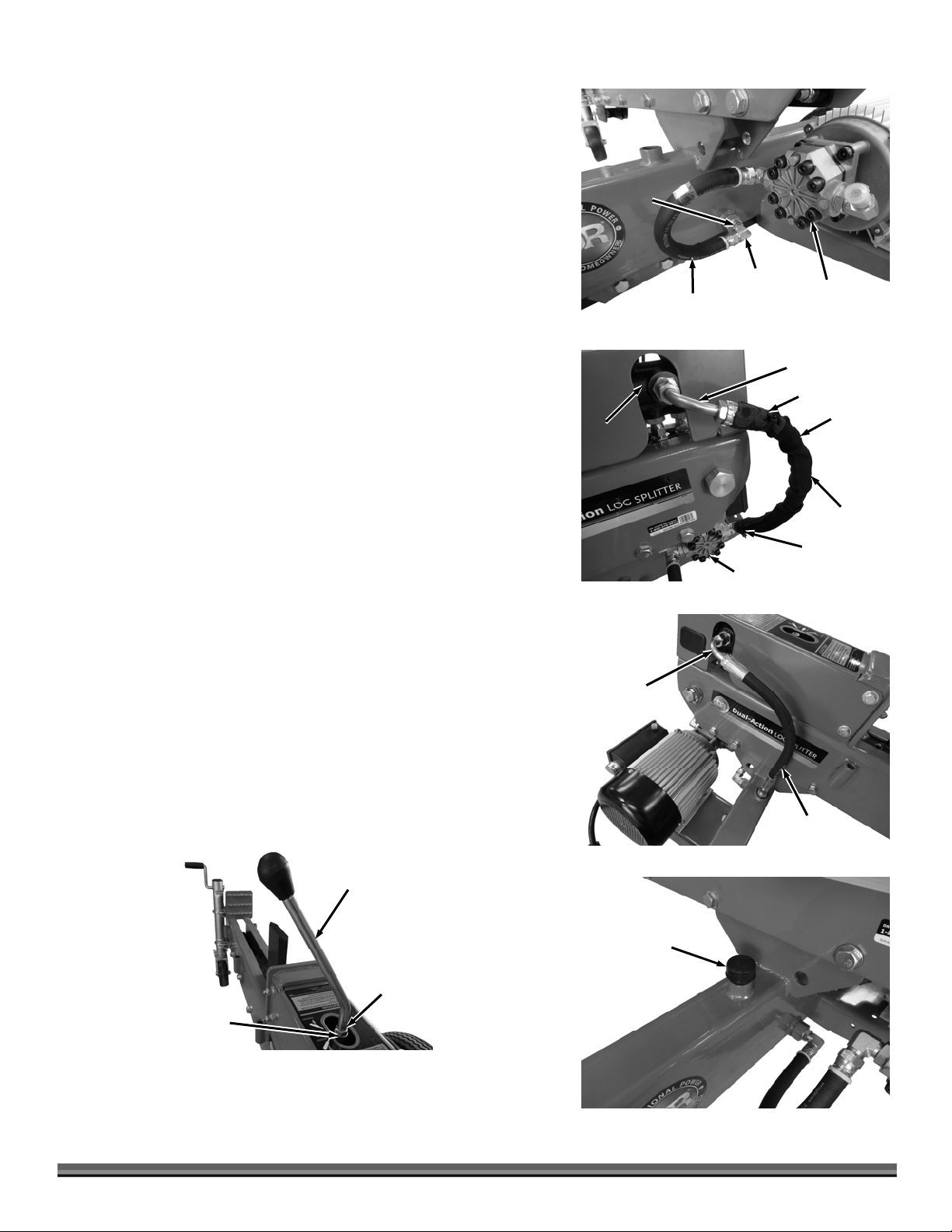

Note: Remove protective Caps as needed for the following Hydraulic Hose

J

connections.

18. Install the Elbow Hydraulic Fitting into the Tank assembly by hand until it

cannot be turned any more with your hand. If needed, turn the Elbow back

to align it parallel with the ground and facing out (Figure 12).

19. Tighten the Elbow Jam Nut against the Tank with a 7/8" Wrench.

20. Use Wire Cutters to cut the Cable Ties holding the Hydraulic Hoses

together.

21. Install the Fluid Suction Hose onto the Pump and Tank fittings using a 7/8"

Wrench.

22. Slide the Sheathing over one of the Pressure Hoses and secure it to the

Hose with a Cable Tie near each end (Figure 13).

Note: When installing the following Hose fittings they should be tight, but try not

to over tighten. Start with a snug fit and if leaking is detected then tighten a

bit more until no leaks are detected.

23. Install the Hose with Sheathing to the Control Valve (long elbow end) and

Pump using a 7/8" Wrench.

24. Install the Fluid Return Hose to the Control Valve (long elbow end) and top

of the Tank using a 7/8" Wrench (Figure 14).

25. Install Hydraulic Cap/Dipstick into the hole on top of the Tank (Figure 15).

26. Remove the Nut and Flat Washer from the Control Lever threads and

reinstall the Nut all the way onto the threads (Figure 16).

27. Place the Washer onto the threads and screw the Control Lever into the top

of the Control Valve as far as it will go. Turn it back to the desired position

depending of your preference to split on the right or left side of the splitter.

Tighten the Jam Nut against the Valve to secure the Lever using a 17mm

Wrench.

28. Install the Trays onto the sides of the Beam assembly and secure with the

Hitch Clips (Figure 17).

am Nut

Figure 12

Control

Valve

Figure 13

Long Elbow

Suction Hose

Elbow

Pump

Pump

Long Elbow

Cable Tie

Pressure

Hose

Sheathing

Cable Tie

Tank

Control

Lever

am Nut

Flat Washer

Figure 16

Figure 14

Hydraulic

Cap/Dipstick

Figure 15

CONTACT US AT www.DRpower.com 11

Fluid Return

Hose

Page 12

Receiving

s

Tube

29. Install the Trays onto the sides of the Beam assembly by aligning the legs

with the receiving tubes and secure with the Hitch Clips (Figure 18).

30. Remove the two left side Bolts, Flat Washers and Locknuts from the Tank

and Axle using two 3/4" Wrenches. Position the Tow Bracket and secure with

the hardware you just removed (Figure 18).

31. Raise the Jack so the Wood Splitter is parallel with the ground.

Figure 17

Figure 18

Trays

Bolts, Washers

and Locknuts

Hydraulic Fluid

Fill Cap

Fluid Half

Way on the

Steel Rod

Tow

Bracket

Adding Hydraulic Fluid

Tools and Supplies Needed:

Paper Towels

Hydraulic Fluid

You must add hydraulic fluid before using the splitter. This machine is

shipped without hydraulic fluid in the hydraulic tank. When performing

the following procedures, fill the hydraulic tank slowly, checking the level

frequently to avoid overfilling.

To get an accurate reading when checking the hydraulic fluid level:

- the machine should be on a level surface.

- the dipstick should be pushed in fully to ensure an accurate fluid level

reading.

TIP: Check the Fluid level by removing the Hydraulic Fluid Filler Cap and wiping

the steel rod of the Dipstick with a Paper Towel. Reinsert the Cap fully (Figure

19). Remove the Cap and lay the Steel Rod onto a dry Paper Towel and read the

level by the wet mark that is transferred from the Steel Rod to the Paper Towel.

1. Remove the Hydraulic Fluid Fill Cap Dipstick and fill the Hydraulic Tank with

the recommended fluid (see Table-1).

NOTE: The tank is full when the fluid level is within the recommended level on the

Dipstick. The recommended level is in the middle of the two marks on the Steel Rod.

Do not deviate past the marks up or down from that point. If the fluid level is not

within this range, fluid must be added or removed to bring it within that range.

Figure 19

HYDRAULIC OIL ISO RECOMMENDATIONS

NOTE: The operator should initially only need to add about 5 quarts before

checking the level because some fluid has already been added to the Cylinders.

2. Start the Motor and cycle the cylinder several times (see “Operating

Your DR Dual-Action Log Splitter”, Chapter 3).

ISO 68

3. Retract the cylinder and shut off the Motor and recheck Fluid level.

4. Adjust level as needed.

ISO 46

ISO 32

ISO 22

0°

10°

20°

30°

40°

50°

60°

70°

80°

(-18°)

(-12°)

(-7°)

(-1°)

(4°)

(10°)

(16°)

(21°)

TEMPERATURE FAHRENHEIT (CELSIUS)

Table-1

12 DR

®

DUAL-ACTION ELECTRIC LOG SPLITTER

(27°)

90°

(32°)

Page 13

Check the Tire Pressure

Do not over inflate the tires. Inflate to the manufacturers recommended

pressure found on the tires.

Tools Needed:

Tire Pressure Gauge

Air Compressor

5. Remove the Valve Stem Protective Cap (Figure 20) and check the tire

pressure with a Tire Pressure Gauge.

6. Check what the manufacturers recommended pressure is that is stamped

on the side of the Tire.

7. If the pressure is too low, add air through the Valve Stem with an air hose.

8. Replace the Valve Stem Protective Cap when finished.

Valve Stem

Protective Cap

Figure 20

CONTACT US AT www.DRpower.com 13

Page 14

Chapter 3: Operating Your DR DUAL-ACTION ELECTRIC LOG SPLITTER

It may be helpful to better familiarize yourself with the features of your Log

Splitter by reviewing Figure 1 in Chapter 2 before beginning the steps outlined

in this chapter.

Read and understand all instructions, safety precautions, and/or

Operator

Zone

Figure 21

Operator

Zone

TOP VIEW

warnings listed in “Chapter 1 General Safety Rules” before operating this

DR Dual-action electric log splitter. If any doubt or question arises about

the correct or safe method of performing anything found in this manual,

please contact our Customer Service Representatives at our toll free

number: 1-800-DR-OWNER (376-9637).

When operating the Log Splitter, make sure you are standing in the safe

operating area (OPERATOR ZONE) as shown in Figure 21. You must stay

in the safe operating area at all times when the splitting wedge is in

motion (whether extending or retracting). Never place any part of your

body into a position that causes an unsafe operating condition.

Before loading and operating the Log Splitter, always wear protective

gear, INCLUDING safety goggles, hearing protection, tight-fitting gloves

without draw strings or loose cuffs, and steel-toed shoes.

Use the following photos for the correct and incorrect methods of

splitting logs. Never split a log using an incorrect or unsafe method.

Circuit

Breaker

Switch

Figure 22

On/Off

Switch

Starting

1. Position your Log Splitter on flat, dry ground and block the two back Wheels

and the Jack Wheel to prevent it from moving.

2. Make sure the Log Splitter is plugged into a properly grounded 15 Amp,

GFCI protected outlet.

3. Push the On/Off Switch all the way in and then pull finger away to start the

Motor (Figure 22).

Stopping

1. Push the On/Off Switch all the way in and then pull finger away to stop the

Motor.

2. When not using the Splitter unplug the Cord.

14 DR

®

DUAL-ACTION ELECTRIC LOG SPLITTER

Page 15

A

Splitting

Note: All logs should be no longer than 20".

Do not place your hands on the ends of the log when loading the Log

Splitter. This is a very UNSAFE method and could result in injury to your

hands (Figure 23).

Do not reach or step across the rail while the Log Splitter is running. This

is a very UNSAFE method which could cause personal injury or even

death.

Never attempt to split wood across the grain. The Log Splitter was not

designed for cross-grain splitting. Doing so could damage the Log

Splitter and may cause personal injury (Figure 24).

Make sure both ends of the log you are splitting are cut as square as

possible. This will prevent the log from sliding out of position while under

pressure (Figure 25)

Figure 23

Never run the Log Splitter unless the hydraulic fluid tank is at the proper

level.

1. Place the log on the Log Splitter. Grasp the log on the sides near the

middle of the block (Figure 26). Center the log, side-to-side, on the rail of

the Log Splitter, making sure that one end is against the Stop Base.

2. Using only your hand, push the Valve Control Handle forward (towards the

log) (Figure 27). If the log moves before it is contacted by the Wedge,

release the Valve Control Handle and then reposition the log.

Valve

Control

Handle

Wedge

Figure 24

Figure 25

Hands

on Sides

of Wood

Wood

gainst

Stop Base

Figure 27

Figure 26

CONTACT US AT www.DRpower.com 15

Page 16

If the log does not split immediately, do not continue the forward thrust of the ram for more than five (5) seconds. This can

damage the splitter. Try repositioning the log on the splitter or set the log aside.

3. Hold the Valve Control Handle, moving the Wedge towards the Log until the log is split or the cylinder rod stops at its

maximum travel position. Stop the Log Splitter (forward movement), at any point in the splitting process, if you feel an unsafe

splitting condition is occurring. As the log is being split, DO NOT reach forward and attempt to catch the split wood — let it

fall to the Tray.

4. Once the Wedge reaches its full forward travel, let go of the Valve Control Handle and the Wedge will stay at that position.

5. Load another log on the other side of the Wedge and pull the Valve Control Handle, moving the Wedge towards you and the

Log until the log is split or the cylinder rod stops at its maximum travel position.

Depending on the type of wood being split, a log may not always split into two pieces and fall onto the trays. If a log sticks to the

wedge, move the wedge away from the base, stop the motor, and carefully remove the log from the wedge. If the log is stuck onto

the wedge and you can’t remove it by hand, a piece of wood cut into a wedge shape can be used between the log and base to lift

the log from the machine as you actuate the lever.

Splitting Large Logs

When splitting a large log, or one in which the wood is extremely tough or stringy (such as elm), the first pass through the Splitter may not

split the log into two sections. If this happens, turn the log and split off small sections. Repeat this process as necessary to split the entire

log.

16 DR

®

DUAL-ACTION ELECTRIC LOG SPLITTER

Page 17

CONTACT US AT www.DRpower.com 17

Page 18

Chapter 4: Maintaining The DR DUAL-ACTION ELECTRIC LOG SPLITTER

Regular maintenance is the way to ensure the best performance and long life of your machine. Please refer to this manual for

maintenance procedures.

Before performing any repairs or maintenance procedure, unplug the wood splitter power cord from the power source.

Regular Maintenance Checklist

PROCEDURE BEFORE

EACH USE

Clean around the splitting Wedge, Ram and Trays.

Check the Splitting Wedge for sharpness.

Check the general condition of the Log Splitter (e.g. nuts, bolts, welds, etc).

Check the Wedge for smooth travel.

Check the condition of the electrical cord.

Check the hydraulic fluid level (See “Adding Hydraulic Fluid” in Chapter 2).

Check Tire pressure

Change the hydraulic fluid (See “Changing the Hydraulic Fluid”). 1st Time 25

Hours

VERY 150

E

HOURS

General Maintenance Check (before operating)

The hydraulic system (hoses, cylinder, and pump) should be carefully inspected before each use. Also, inspect the mechanical

parts at the same time. Make sure all clamps, nuts, bolts, fittings, etc. are properly installed and tightened.

Do not check for leaks with your hand. Leaks can be located by passing a piece of cardboard or wood around the suspected leak

and looking for discoloration. High-pressure fluid escaping from a very small hole can be almost invisible. Escaping fluid under

pressure can have sufficient force to penetrate skin, causing serious injury or even death. If fluid is injected into your skin, it must

be treated immediately by a doctor familiar with this type of injury.

Always replace frayed, kinked, or cracked hoses and/or other damaged hydraulic components with DR Power Equipments

authorized parts and components specified in the “Parts” section (Chapter 7) of this manual. Replacement parts from secondary

suppliers (not original DR Power Equipments replacement parts) can lead to product damage and/or personal injury, and will void

the warranty.

Do not remove the cap from the hydraulic tank or reservoir while the Log Splitter is running. Hot fluid, under pressure, could be

expelled resulting in serious injury.

Should it become necessary to loosen or remove any hydraulic fitting or line, be sure to relieve all hydraulic pressure by shutting

off the Motor, and moving the valve control handle back and forth several times until no cylinder movement is visible.

18 DR

®

DUAL-ACTION ELECTRIC LOG SPLITTER

Page 19

Hydraulic Fluid Change

r

Tools and Supplies Needed:

Adjustable Wrench

Clean Rags

Approved Container (8 quart capacity)

Small funnel

Never run the Log Splitter unless the hydraulic fluid tank is at the proper

level.

Hydraulic Fluid Specifications

See Table-1 on page 10

1. Drain the hydraulic tank.

a. Place an approved container under the inlet hose.

b. Disconnect the Inlet Hose at the Pump Elbow using an Adjustable

Wrench and lower the Hose to drain the Fluid into the Container

(Figure 28).

c. Remove the Hydraulic Fluid Dipstick to let air in to improve fluid flow.

d. Completely drain the Tank.

e. Disconnect the Inlet Hose at the Tank Elbow using an Adjustable

Wrench.

f. Remove the Screen (with elbow) from the Tank with an Adjustable

Wrench and clean any debris from the Screen or replace as needed

(Figure 29).

g. Reinstall the Screen (with elbow).

h. Reconnect the Inlet Hose at the Tank Elbow using an Adjustable

Wrench.

i. Reconnect the Inlet Hose at the Pump Elbow using an Adjustable

Wrench.

2. Refill the hydraulic tank.

a. Remove the Hydraulic Fluid Dipstick from the Hydraulic Tank (Figure

28).

b. Fill the Hydraulic Tank as described in the “Adding Hydraulic Fluid”

section in Chapter 2.

3. Start the engine and cycle the cylinder.

Dipstick

Screen

Filte

Inlet Hose

to Pump

Inlet Hose

to Tank

Figure 28

Filter

Screen

Elbow

Figure 29

a. Start the Motor and cycle the cylinder several times (see “Operating Your Log Splitter”, Chapter 3).

b. Retract the cylinder and shut off the Motor.

c. Recheck the Hydraulic Tank to make sure fluid is up to the proper level.

Hydraulic Fluid Capacities

Hydraulic Tank . . . . . . . 6 quarts (5.6 liters)

CONTACT US AT www.DRpower.com 19

Page 20

Dust Cap

Replacing the Wheels

Tools and Supplies needed:

Channel lock Pliers

Clean Rags

Adjustable Wrench

Needle Nose Pliers

Jack and Jack Stands

Soft Face Hammer

1. Jack the Splitter off the ground and secure with Jack Stands.

Figure 30

Figure 31

Cotter Pin

Taper

Bearing

Castle

Nut

2. Remove the Dust Cap from the Wheel Assembly with Channel Lock Pliers

(Figure 30).

3. Straighten the ends of the Cotter Pin with Needle nose Pliers so the Cotter

Pin can be pulled from the hole in the Axle (Figure 31).

4. Remove the Castle Nut with the Channel Lock Pliers.

5. Pull the Wheel assembly and Taper Bearing from The Axle (Figure 32).

6. Slide a Wheel Assembly onto the Axle Shaft. Make sure the open side of the

Wheel Hub with the loose Taper Bearing is facing towards you.

7. Screw the Castle Nut onto the Axle and tighten it with an adjustable wrench

to seat the Bearings (Figure 31).

8. Back the Castle Nut off and then snug it up to the Bearing lightly.

9. Insert a Cotter Pin through the slots of the Castle Nut and into the hole in

the Axle.

10. Bend the ends of the Cotter Pin with Needle nose Pliers to secure it.

11. Place the Dust Cap onto the Wheel Assembly Hub and work it into the Hub

using a soft face Hammer (Figure 30).

12. Jack the back of the Splitter up and remove the jack Stands.

13. Lower the Splitter to the ground.

Figure 32

20 DR

®

DUAL-ACTION ELECTRIC LOG SPLITTER

Page 21

Adjusting the Pressure Valve

p

r

Jam

The Log Splitter is set at the factory to optimize splitting force. The following

adjustment should only be performed if the splitter Breaker or house Breaker is

being tripped excessively while splitting Logs. Adjusting to less pressure should

lessen the Breaker problem but will also lessen splitting force.

Tools needed:

Two 9/16" Wrenches

Two 1/2" Wrenches

10mm Wrench

4mm Allen Wrench

1. Remove the Operator Lever Knob by unscrewing it counterclockwise.

2. Remove the front hardware from the Valve Cover using Two 9/16" Wrenches

(Figure 33).

3. Remove the rear hardware from the Valve Cover using Two 1/2" Wrenches.

4. Remove the Valve Cover.

5. Remove the Valve Plug using a 10mm Wrench (Figure 34).

Note: Only turn the Pressure Screw 1/4 turn at a time to prevent over adjustment.

6. Adjust the Pressure Screw by turning it counterclockwise 1/4 turn (less

pressure) or clockwise 1/4 turn (more pressure) with a 4mm Allen Wrench

(Figure 35).

Front Bolts,

Washers and

Locknuts

Nut

Figure 33

Valve Plug

erator Leve

O

Valve Cover

Rear Bolts,

Washers and

Locknuts

Pressure

Valve

If you turn the pressure screw out too far and it comes out of the valve, screw

it back in all the way as you count the number of full turns until it stops. Turn

it back out half the number of turns to position the screw at the central

pressure location. Use this position to start pressure adjustment again.

7. Replace the Valve Plug and operate the Log Splitter to check the setting and

adjust further as needed.

Valve plug should always be installed before testing pressure to protect

yourself from high pressure fluid.

8. Position the Valve Cover.

9. Install the rear hardware of the Valve Cover using Two 1/2" Wrenches.

10. Install the front hardware of the Valve Cover using Two 9/16" Wrenches.

11. Install the Operator Lever Knob by screwing it on clockwise.

Figure 34

Pressure

Screw inside

Figure 35

CONTACT US AT www.DRpower.com 21

Page 22

22 DR

®

DUAL-ACTION ELECTRIC LOG SPLITTER

Page 23

Chapter 5: Troubleshooting

Most problems are easy to fix. Consult the Troubleshooting Table below for common problems and their solutions. If you

continue to experience problems, contact us at www.DRpower.com or call toll-free 1-800-DR-OWNER (376-9637) for support.

Before performing any repairs or maintenance procedure, unplug the Log Splitter power cord from the power source.

Troubleshooting Table

SYMPTOM POSSIBLE CAUSE

With Motor running and

the valve control handle

is pushed, the wedge

does not move or is slow

to respond.

The Motor does not run

Log fails to split.

Air in the system; Bleed any accumulated air from the hydraulic system.

The Log Splitter may not be on a level surface.

Make sure the voltage at the outlet or extension cord connection to the DR DUAL-ACTION

ELECTRIC LOG SPLITTER is 110-120VAC.

If you are using an extension cord, make sure that the cord is no more than 25 feet long, is

not smaller than 12 AWG wire or no more than 50 feet long, and is not smaller than 10 AWG

wire.

The hydraulic fluid may be low. Check and adjust the level as required.

In extreme high temperature and heavy rapid use, the hydraulic fluid may have overheated.

Allow the machine to cool.

The wood you are splitting may be too hard, it has knots, or its fiber is very tough.

Check the high-pressure hose, fittings, and valve openings for dirt and debris that may have

obstructed the openings.

If the Wedge will still not move or is slow to respond, Visit our website at www.DRPower.com,

call 1-800-DR-OWNER (376-9637), or call a qualified hydraulic mechanic for assistance to

replace worn components. Be sure to reference Hydraulic Safety in Chapter 1.

Splitter unplugged; plug Splitter in.

Splitter Cord may be damaged; visit our website at www.DRPower.com or call 1-800-DR-

OWNER (376-9637) for assistance.

The motor Reset has tripped; push the Reset Button.

If the above causes are not the problem, a circuit breaker might need to be reset; Reset Circuit

Breaker.

If the Motor still does not run, visit our website at www.DRPower.com or call 1-800-DR-

OWNER (376-9637) for assistance.

Check the possible causes for the previous Wedge operation symptom.

Incorrect positioning of the log; re-position the log flat on the splitting beam with the end

squarely against the Base.

Log exceeds permitted dimensions or the wood is too hard for the capacity of the machine.

The maximum log length is 20" with a maximum diameter of 24" for the DR DUAL-ACTION

ELECTRIC LOG SPLITTER.

There may be a hydraulic fluid leak. Locate the leak using a piece of cardboard under the

machine. Visit our website at www.DRPower.com, call 1-800-DR-OWNER (376-9637), or call a

qualified hydraulic mechanic for assistance to replace worn components. Be sure to reference

Hydraulic Safety in Chapter 1.

Hydraulic pressure is too low. Visit our website at www.DRPower.com, call 1-800-DR-

OWNER (376-9637), or call a qualified hydraulic mechanic for assistance to replace worn

components. Be sure to reference Hydraulic Safety in Chapter 1.

CONTACT US AT www.DRpower.com 23

Page 24

Troubleshooting Table (Continued)

Before performing any repairs or maintenance procedure, unplug the Log Splitter power cord from the power source.

SYMPTOM POSSIBLE CAUSE

Ram advances with a

jerky motion or with

strong vibrations.

Hydraulic fluid leaking

from the ram or other

external parts.

Check the possible causes for the Ram operation symptom in “Log fails to split” above.

Check the hydraulic fluid level.

Bleed any accumulated air from the hydraulic system. To bleed, make sure the fluid level is

correct, cycle in one direction, bottom out, hold for 5 seconds, retract fully, bottom out, hold

for 5 seconds, repeat 10 times. If the problem persists, visit our website at

www.DRPower.com or call 1-800-DR-OWNER (376-9637) for assistance.

The hydraulic fluid seals may be worn. Visit our website at www.DRPower.com or call 1-800-

DR-OWNER (376-9637), or call a qualified hydraulic mechanic for assistance to replace worn

components. Be sure to reference Hydraulic Safety in Chapter 1.

Splitter Breaker or house

Breaker is being tripped

excessively.

Pressure Valve set too high; Adjust Valve pressure by performing adjustment on page 18.

24 DR

®

DUAL-ACTION ELECTRIC LOG SPLITTER

Page 25

Chapter 6: DR DUAL-ACTION ELECTRIC LOG SPLITTER Road Towable Kit

Tools and Supplies Needed:

Two 7/16" Wrenches

Two 1/2" Wrenches

Two 9/16" Wrenches

Two 3/4" Wrenches

15/16" Wrench

15/16" Socket with 1/2" Ratchet

Original

Tow Hitch

Installing the Road Towable Kit

12. Remove the existing Hitch from the Splitter by removing the large Bolt,

Washers and Locknut using a 15/16" Wrench and Ratchet with a 15/16"

Socket (Figure 36).

13. Attach the new Tow Hitch to the Frame with the two 1/2-13 x 4" Bolts and

Locknuts using two 3/4" Wrenches (Figure 37).

14. Position the Safety Chains at the holes in the Frame and secure with two

3/8-16 x 1-1/2" Bolts, four Washers (one on Bolt side and one on Locknut

side) and Locknuts using two 9/16" Wrenches.

15. Place the Vehicle Connector end of the Wire Harness near the Tow Hitch

and let it extend about two feet past the Hitch. Place the 7/16" Tube Clamp

around the Harness and secure the Clamp to the Frame using two 7/16"

Wrenches (Figure 38).

Note: Make sure there is enough of the Harness past the Tube Clamp to be

connected to the tow vehicle.

16. Guide the other end of the Harness behind the Hitch and under the Frame.

Feed the Harness over the center of the Hydraulic Tank so it is at the Back of

the machine.

17. Remove a Bolt, Washer and Locknut at the center of the Frame on the Left

side with two 9/16" Wrenches (Figure 39). Place the large Tube Clamp over

the Harness and secure to the Frame with the Bolt, Washer and Locknut

from the kit. Tighten the Clamp Hardware with two 1/2" Wrenches.

Hardware

Figure 36

Hitch

Hardware

New Tow

Hitch

Chain

Hardware

Safety

Chains

Figure 37

Small Tube

Clamp

Vehicle Connector

This End

Figure 38

Tube Clamp

Hardware

Hose

Clamp

Figure 39

CONTACT US AT www.DRpower.com 25

Page 26

(

Roadside

Tail Light

Figure 40

Nylon Locknut

Roadside

Fender

Cable Ties

Carriage

Bolts and

Locknuts

Yellow and

Brown Wires

(roadside)

18. Assemble the Fenders to the Frame with eight 5/16-18 x 3/4" Carriage Bolts

(fender side) and Locknuts using a 1/2" Wrench (Figure 40).

19. Position the roadside Tail Light (yellow/brown wires) and curbside Tail Light

(green/brown wires) onto the Fenders and secure with one of the 1/4-20

Locknuts on the outside stud using a 7/16" Wrench.

20. Route the Yellow/Brown Wire Connector with a White Ground Wire behind

the Tank on the roadside (left side) of the Splitter.

21. Plug in the Connector, place the Ground Wire onto the inner Stud and

secure it with a 1/4-20 Locknut using a 7/16" Wrench (Figure 41).

22. Route the Green/Brown Wire Connector with a White Ground Wire behind

the Tank on the curbside (right side) of the Splitter.

23. Plug in the Connector, place the Ground Wire onto the inner Stud and

secure it with a 1/4-20 Locknut using a 7/16" Wrench.

24. Use the Cable Ties to secure the excess Harness to the Engine Mount hole.

Secure the center portion of Harness to the two holes in the Frame. Trim all

Cable Ties with Wire Cutters.

Figure 41

Green and

Brown Wires

(curbside)

White

Ground Wire

both sides)

Locknut

26 DR

®

DUAL-ACTION ELECTRIC LOG SPLITTER

Page 27

Attaching to Tow Vehicle

A

A

A

Making sure the Splitter is securely attached to the vehicle is the responsibility of the owner/operator. Failure to securely attach

the Splitter can cause loss of control of the vehicle or the Splitter being separated from the towing vehicle, resulting in serious

injury or death. ALWAYS use accessory lights and devices when transporting on a road or highway to warn operators of other

vehicles. Check your local government regulations.

25. Close the Latch Assembly on the Tow Hitch Assembly to lock the Tow

Hitch Assembly onto the Tow Ball (Figure 42). Attach the towing Safety

Chains to the tow vehicle ensuring there is enough slack for turning.

26. Make sure the hitch coupler is properly and securely attached to the tow

ball.

27. Insert the Locking Pin into the hole of the Latch Assembly to lock it in the

closed position (Figure 43).

28. For extra safety and security, you may want to purchase a lock to install into

the hole of the latch assembly.

29. Plug the Harness Connector to the Tow Vehicle.

Hitch Coupler Adjustment Check

30. Place a 2" ball in the socket of the coupler and close the latch assembly

(Figure 44). Verify that the locking trigger is properly engaged in its detent.

31. Pull on the ball and/or coupler, trying to remove the ball from the socket. If

the ball moves more than 1/16" in the coupler’s socket, the clamp requires

adjustment. Follow the proper adjustment procedure in the following steps.

Hitch Coupler Adjustment

32. With the proper size ball in the socket of the hitch coupler, close the latch of

the coupler completely (Figure 45). Verify that the locking trigger is properly

engaged in its detent.

33. Tighten the lock nut on the underside of the coupler until the spring

between the nut and the clamp is fully compressed. Then back off the lock

nut 1/2 turn or just enough that the latch is able to clamp and unclamp

from the ball.

Latch

ssembly

Figure 42

Figure 43

Latch

ssembly

Tow Hitch

ssembly

Safety

Chains

Locking Pin

Locking

Pull

Spring

Lock Nut

Ball Clamp

Figure 45

1/16"

Movement

Figure 44

CONTACT US AT www.DRpower.com 27

Trigger

Page 28

Chapter 7: Parts Lists, Schematic Diagrams And Warranty

Parts List - FRAME ASSEMBLY

NOTE: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

1 11241 Washer, Flat, 5/16", USS

2 29387 Beam Assembly, With Labels

3 11075 Nut, Nylon Lock, 3/8-16

4 22909 Bolt, HHCS, 1/2-13 X 1.5" Gr5, ZP

5 23499 Washer, SAE Flat, 1/2", ZP

6 11072 Nut, Nylon Lock, 1/2-13

7 21155 Pin, Snap Safety, 3/8" X 2.75"

8 29367 Dipstick

9 19295 Clevis, Hitch

10 15745 Washer, Flat, 5/8", USS

11 29054 Mount, Tow Hitch, Rear

12 25297 Wheel And Tire Assembly, W/ Dust cap

13 29045 Axle

Ref# Part# Description

14 29386 Reservoir, With Labels

15 29053 Mount, Hitch, Tow

16 29382 Jack, Trailer, Wheeled

17 19296 Bolt, HCS, 5/8-11 X 1.75", Gr5, ZP

18 10174 Washer, .640" ID X 1.5" OD X .25"

19 10131 Nut, Nylon Lock, 5/8-11

20 29378 U--bolt, 3/8-16 X 2" X 4", ZP

21 19202 Label, DR Logo, 4.0", 4 Color

22 29377 Clamp, 2", Jack

23 25310 Nut, Slotted, 1-14, ZP

24 25311 Pin, Cotter, 3/16" X 2.5"

25 25318 Dust cap

28 DR

®

DUAL-ACTION ELECTRIC LOG SPLITTER

Page 29

Schematic – FRAME ASSEMBLY

CONTACT US AT www.DRpower.com 29

Page 30

Parts List – BEAM ASSEMBLY

NOTE: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

1 16003 Pin, Hitch Clip, 1/2" To 9/16", .12" Wire

2 11241 Washer, Flat, 5/16", USS

3 29047 Valve, Hyd, 3200 Psi

4 29043 Cylinder Assembly, Hydraulic

5 11158 Bolt, HCS, 5/16-18 X 1"

6 11243 Washer, Lock, Split, 5/16"

7 11072 Nut, Nylon Lock, 1/2-13

8 29502 Washer, 26mm X 44mm X 3.5mm

9 29375 Bolt, HHCS, 1-14 X 6", Gr5, ZP

10 23499 Washer, SAE Flat, 1/2", ZP

11 25311 Pin, Cotter, 3/16 X 2.5"

12 25346 Hyd Adapter, Jcm06-Obm08

13 29371 Hyd Adapter, Obm08-Jcsf06

14 22909 Bolt, HHCS, 1/2-13 X 1.5", Gr5, ZP

15 25310 Nut, Slotted, 1-14, ZP

Ref# Part# Description

16 29046 Brace, Lower Cylinder

17 29370 Guard, Seal

18 29519 Label, DR Branding

19 29395 Label, Warning, Do Not Sit or Stand

20 29389 Tray, Log, With Labels

21 29388 Cover, Valve, With Label

22 29394 Label, Controls

23 29373 Bolt, HCS, 3/8-16 X 5.5", Gr5, ZP

24 15131 Plug, Hour Meter Hole, 2" X 1-1/4"

25 11075 Nut, Nylon Lock, 3/8-16

26 11238 Washer, Flat, 1/4", USS

27 12321 Bolt, HCS, 5/16-18 X .75"

28 11076 Nut, Nylon Lock, 5/16-18

29 29513 Handle Assembly, Control Valve

30 29503 O-ring, 22mm X 2.4mm

30 DR

®

DUAL-ACTION ELECTRIC LOG SPLITTER

Page 31

Schematic – BEAM ASSEMBLY

CONTACT US AT www.DRpower.com 31

Page 32

Parts List – MOTOR AND PUMP ASSEMBLY

NOTE: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

1 27610 Sheathing, Abrasion Resistant, 15.5"

2 11214 Tie, Cable, 7 1/2"L

3 25616 Hyd Adapter, Jcm08-Obm08-90

4 25346 Hyd Adapter, Jcm06-Obm08

5 25348 Hyd Adapter, Jcm06-Obm08-90

6 25333 Hose Assembly, Hyd, Tank-Pump, 12.5"

7 29364 Hose, Hyd, 15"

8 11238 Washer, Flat, 1/4", USS

9 11076 Nut, Nylon Lock, 5/16-18

10 29512 Filter, Hyd, In tank

Ref# Part# Description

11 11158 Bolt, HCS, 5/16-18 X 1"

12 29511 O-ring, 28.5mm X 2.4mm

13 29358 Pump, Hyd, 6L/Min

14 29366 Motor, 1.8kw, 120V, 60Hz

15 11243 Washer, Lock, Split, 5/16"

16 27629 Bolt, SHCS, M8-1.25 X 20

17 27609 Label, Motor, Electric

18 29503 O-ring, 22mm X 2.4mm

Items Not shown in illustration

29381 Pump Assembly, Motor

32 DR

®

DUAL-ACTION ELECTRIC LOG SPLITTER

Page 33

Schematic – MOTOR AND PUMP ASSEMBLY

CONTACT US AT www.DRpower.com 33

Page 34

Parts List – ROAD-TOW ACCESSORY

NOTE: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

1 11072 Nut, Nylon Lock, 1/2-13

2 11073 Nut, Nylon Lock, 1/4-20

3 11075 Nut, Nylon Lock, 3/8-16

4 11076 Nut, Nylon Lock, 5/16-18

5 11149 Bolt, HCS, 1/4-20 X 1.00", Gr5, ZP

6 11238 Washer, Flat, 1/4", USS

7 11239 Washer, Flat, 3/8, USS

8 11985 Bolt, HCS, 3/8-16 X 1.5"

9 14529 Bolt, Carriage, 5/16-18 X .75"

10 24648 Receiver, 2", Class ll

Ref# Part# Description

11 24666 Bolt, HHCS, 1/2-13 X 4", Gr8

12 25305 Fender, Curbside

13 25308 Fender, Roadside

14 25312 Chain, Safety, Pair, 36"

15 25351 Tail Light, Roadside

16 25352 Tail Light, Curbside

17 28320 Tube Clamp, 7/16", Vinyl Coated

18 29379 Tube Clamp, 3/4", Vinyl Coated

Items Not shown in illustration

25353 Wire Harness, Tow Kit

34 DR

®

DUAL-ACTION ELECTRIC LOG SPLITTER

Page 35

Schematic – ROAD TOW ACCESSORY

CONTACT US AT www.DRpower.com 35

Page 36

Daily Checklist for the DR DUAL-ACTION ELECTRIC LOG SPLITTER

To help maintain your DR DUAL-ACTION ELECTRIC LOG SPLITTER for optimum performance, we recommend you follow

this checklist each time you use your Log Splitter.

Before performing any repairs or maintenance procedure, unplug the Log Splitter power cord from the power source.

[ ] Clean and Wood Chips from the machine.

[ ] Check the Splitting Wedge for damage and sharpness.

[ ] Check the general condition of the Log Splitter, e.g.; nuts, bolts, welds, etc.

[ ] Check the Wedge for smooth travel.

[ ] Check the condition of the electrical cord.

[ ] Check the hydraulic fluid level

End of Season and Storage

Before performing any repairs or maintenance procedure, unplug the Log Splitter power cord from the power source.

Fully retract the Cylinder so the Rod is not visible.

Wipe down the DR DUAL-ACTION ELECTRIC LOG SPLITTER to remove any moisture, wood chips, and dirt that may have

accumulated on the Log Trays and Operating Handle.

Apply a thin coating of oil or #2 Lithium Grease to the leading edge of the Splitting Wedge.

Relieve any internal air pressure by moving the Operator Handle back forward and backwards.

If possible, store the Log Splitter in a dry, protected place. If it is necessary to store the Log Splitter outside, cover it with a

protective material (especially the Motor).

Do not store the log splitter in wet conditions. This can cause damage to the motor

75 MEIGS ROAD, P.O. BOX 25, VERGENNES, VERMONT 05491

©2013 Country Home Products, Inc. All rights reserved 276151A

Loading...

Loading...