Page 1

DR

®

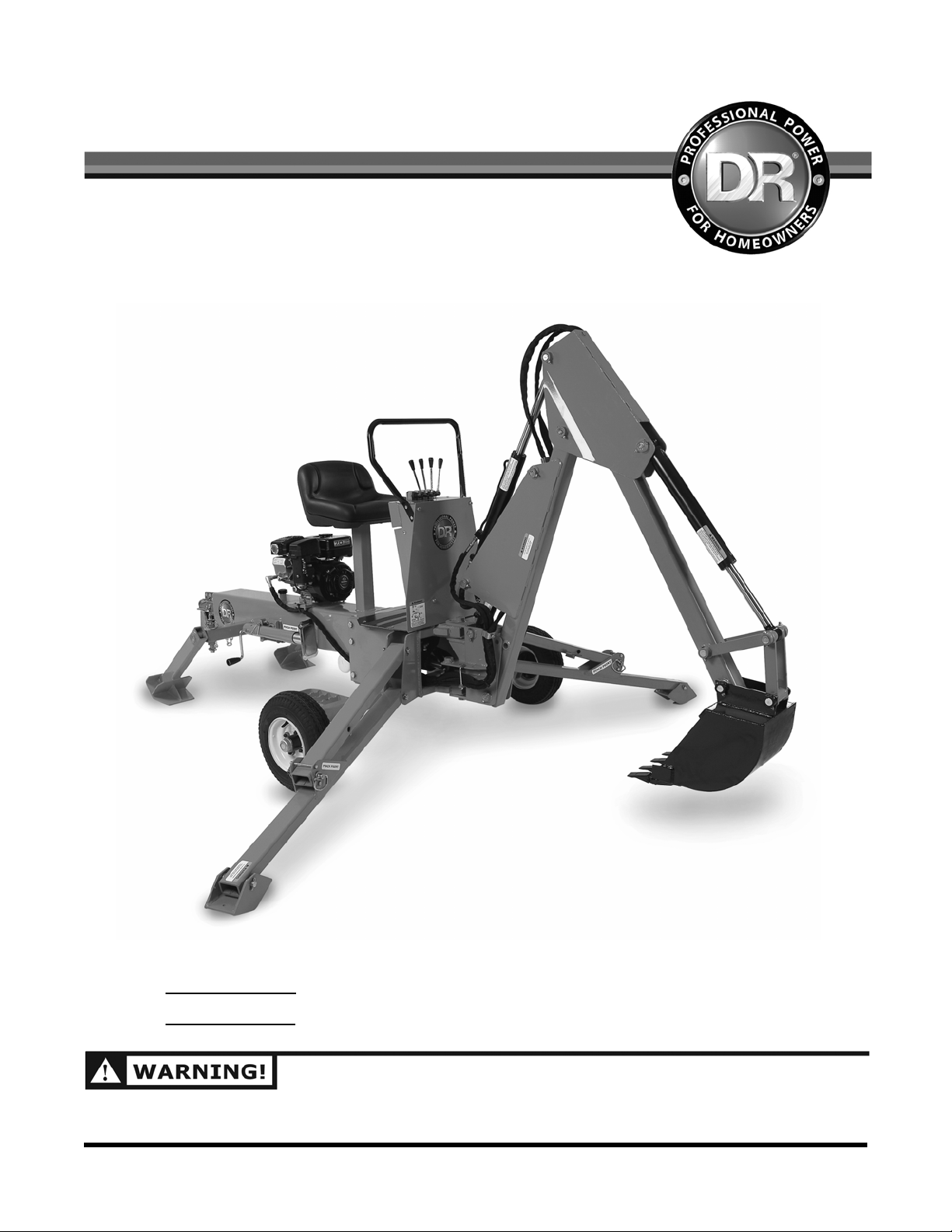

DIRT BOSS™ TOWABLE BACKHOE

SAFETY & OPERATING INSTRUCTIONS

Serial No.

Order No.

READ AND UNDERSTAND THIS MANUAL AND ALL INSTRUCTIONS BEFORE OPERATING THIS DR

BACKHOE.

Page 2

Congratulations on your purchase of a new DR DIRT BOSS TOWABLE BACKHOE!

We have done our utmost to ensure that your DR DIRT BOSS TOWABLE BACKHOE will be one of the most

trouble-free and satisfying pieces of equipment you have ever owned. Please let us know of any questions you

may have. We want to answer them as quickly as possible. When you do call, please have your order number

handy. For technical assistance, please contact us at www.DRpower.com call Toll-Free 1-800-DR-OWNER

(376-9637) and one of our Technical Support Representatives will be happy to help you. We also hope to hear

from you on how much you like your new helper.

In addition, please tell your friends about your new DR DIRT BOSS TOWABLE BACKHOE! Having DR Owners

spread the word about our products and our way of doing business is the best advertising we can have, and

the best way to help us provide even better service in the years to come.

Thanks once again!

for all of us at

DR Power Equipment

Sales Manager

COPYRIGHT

©2008 Country Home Products, Inc. All rights reserved.

®

DR

Power Equipment

A division of Country Home Products

®

127 Meigs Road

Vergennes, VT 05491

Toll-free phone: 1-800-DR-OWNER (376-9637)

Fax: 1-802-877-1213

Web site: www.DRpower.com

ii DR® DIRT BOSS™ TOWABLE BACKHOE

Page 3

Table of Contents

CHAPTER 1 ..........................................................................................................................................1

INTRODUCING THE DR DIRT BOSS TOWABLE BACKHOE.....................................................1

Conventions used in this manual.................................................................................................1

Specifications ................................................................................................................................2

Serial Number ...............................................................................................................................3

Order Number...............................................................................................................................3

CHAPTER 2 ..........................................................................................................................................5

GENERAL SAFETY RULES ............................................................................................................5

Labels.............................................................................................................................................5

Protecting Yourself and Those Around You.................................................................................7

Safety for Children and Pets..........................................................................................................7

Safety with Gasoline - Powered Machines ...................................................................................8

Hydraulic Safety.............................................................................................................................9

Safety When Digging Near Utilities..............................................................................................9

Towing ........................................................................................................................................10

General Safety..............................................................................................................................11

A Note to All Users......................................................................................................................13

Additional Information and Potential Changes .........................................................................13

CHAPTER 3 ........................................................................................................................................15

SETTING UP YOUR DR DIRT BOSS TOWABLE BACKHOE.....................................................15

DR Dirt Boss Towable Backhoe Controls and Features.............................................................15

Adding Oil and Gasoline............................................................................................................. 16

Adding Hydraulic Fluid ...............................................................................................................17

Check the Tire Pressure ..............................................................................................................18

CHAPTER 4 ........................................................................................................................................19

OPERATING YOUR DR DIRT BOSS TOWABLE BACKHOE .....................................................19

Control Levers .............................................................................................................................19

Starting the Engine...................................................................................................................... 19

Stopping the Engine....................................................................................................................20

Stabilizing the Backhoe for Digging ...........................................................................................20

Digging with the Backhoe ...........................................................................................................23

Preparing the Backhoe for Towing .............................................................................................24

Towing the Backhoe ....................................................................................................................27

Hitch Coupler Adjustment Check...............................................................................................29

Hitch Coupler Adjustment..........................................................................................................29

CHAPTER 5 ........................................................................................................................................31

MAINTAINING THE DR DIRT BOSS TOWABLE BACKHOE.................................................... 31

Regular Maintenance Checklist ..................................................................................................31

Greasing the Backhoe .................................................................................................................32

End of Season and Storage.........................................................................................................33

CHAPTER 6 ........................................................................................................................................35

TROUBLESHOOTING ................................................................................................................35

Troubleshooting Table ................................................................................................................35

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER iii

Page 4

CHAPTER 7 ........................................................................................................................................37

DR DIRT BOSS TOWABLE BACKHOE ACCESSORIES .............................................................37

Installing a Bucket or Digging Tooth.......................................................................................... 37

CHAPTER 8 ........................................................................................................................................40

PARTS LIST AND SCHEMATIC DIAGRAMS..............................................................................40

Parts List - LINKAGE, CROWD ARM AND BOOM ASSEMBLY................................................40

Schematic – LINKAGE, CROWD ARM AND BOOM ASSEMBLY .............................................41

Parts List – SWIVEL, MAIN BOX AND STABILIZER ASSEMBLY..............................................42

Schematic – SWIVEL, MAIN BOX AND STABILIZER ASSEMBLY ............................................ 43

Parts List – HANDLE GUARD, VALVE MOUNT AND PANELS ASSEMBLY............................44

Schematic – HANDLE GUARD, VALVE MOUNT AND PANELS ASSEMBLY ..........................45

Parts List – CYLINDERS, PINS AND FITTINGS ASSEMBLY ....................................................46

Schematic – CYLINDERS, PINS AND FITTINGS ASSEMBLY................................................... 47

Parts List – HYDRAULIC HOSES AND CYLINDERS ASSEMBLY ............................................. 48

Schematic – HYDRAULIC HOSES AND CYLINDERS ASSEMBLY ...........................................49

Parts List – VALVE AND FITTINGS ASSEMBLY ........................................................................ 50

Schematic – VALVES AND FITTINGS ASSEMBLY ....................................................................51

Parts List – HOSE CONNECTION DETAIL ...............................................................................52

Schematic – HOSE CONNECTION DETAIL..............................................................................53

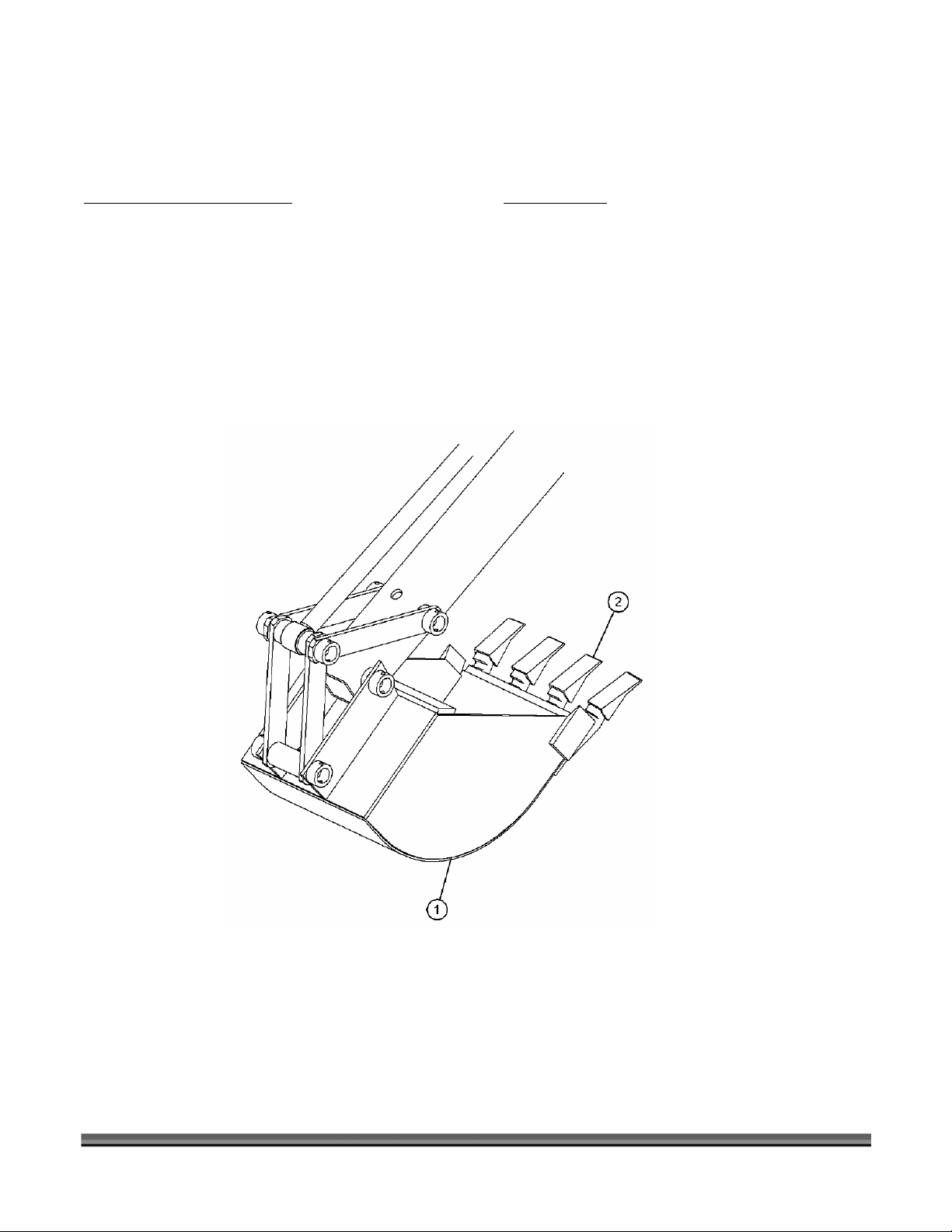

Parts List – BUCKET AND TEETH ASSEMBLY ..........................................................................54

Schematic – BUCKET AND TEETH ASSEMBLY ........................................................................54

Parts List – TONGUE AND AXLE ASSEMBLY ...........................................................................56

Schematic – TONGUE AND AXLE ASSEMBLY .........................................................................57

Parts List – ENGINE AND PUMP ASSEMBLY...........................................................................58

Schematic – ENGINE AND PUMP ASSEMBLY .........................................................................59

Notes ...........................................................................................................................................61

Daily Checklist for the DR DIRT BOSS TOWABLE BACKHOE..................................................64

iv DR® DIRT BOSS™ TOWABLE BACKHOE

Page 5

CHAPTER 1

INTRODUCING THE DR DIRT BOSS TOWABLE BACKHOE

This manual will help you set up and safely operate your new DR DIRT BOSS TOWABLE BACKHOE.

Careful adherence to the safety and operating instructions in this manual will ensure many years of

productive use.

Please let us know of any questions you may have. We want to answer them as quickly as possible.

When you do call, please have your order number handy. For technical assistance, please contact us at

www.DRpower.com or call Toll-Free 1-800-DR-OWNER (376-9637) and one of our Technical Support

Representatives will be happy to help you.

Conventions used in this manual

THIS INDICATES A HAZARDOUS SITUATION, WHICH, IF NOT FOLLOWED, WILL RESULT IN DEATH

OR SERIOUS INJURY.

THIS INDICATES A HAZARDOUS SITUATION, WHICH, IF NOT AVOIDED,

OR SERIOUS INJURY

THIS INDICATES A HAZARDOUS SITUATION, WHICH, IF NOT AVOIDED,

OR MODERATE INJURY.

THIS INFORMATION IS IMPORTANT IN THE PROPER USE OF YOUR MACHINE. FAILURE TO FOLLOW

THIS INSTRUCTION COULD RESULT IN DAMAGE TO YOUR MACHINE OR PROPERTY.

Tip: This is a helpful hint to guide you in getting the most out of your BACKHOE.

Tools Needed: This indicates you will need a special tool to perform a maintenance function on your

Backhoe.

NOTE:

This information may be helpful to you.

.

COULD RESULT

COULD RESULT

IN

IN

DEATH

MINOR

If you are ever unsure about an action you are about to take, don’t do it. Contact us at www.DRpower.com or

call DR Power Equipments’ toll-free support at 1-800-DR-OWNER (376-9637) for help or information.

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 1

Page 6

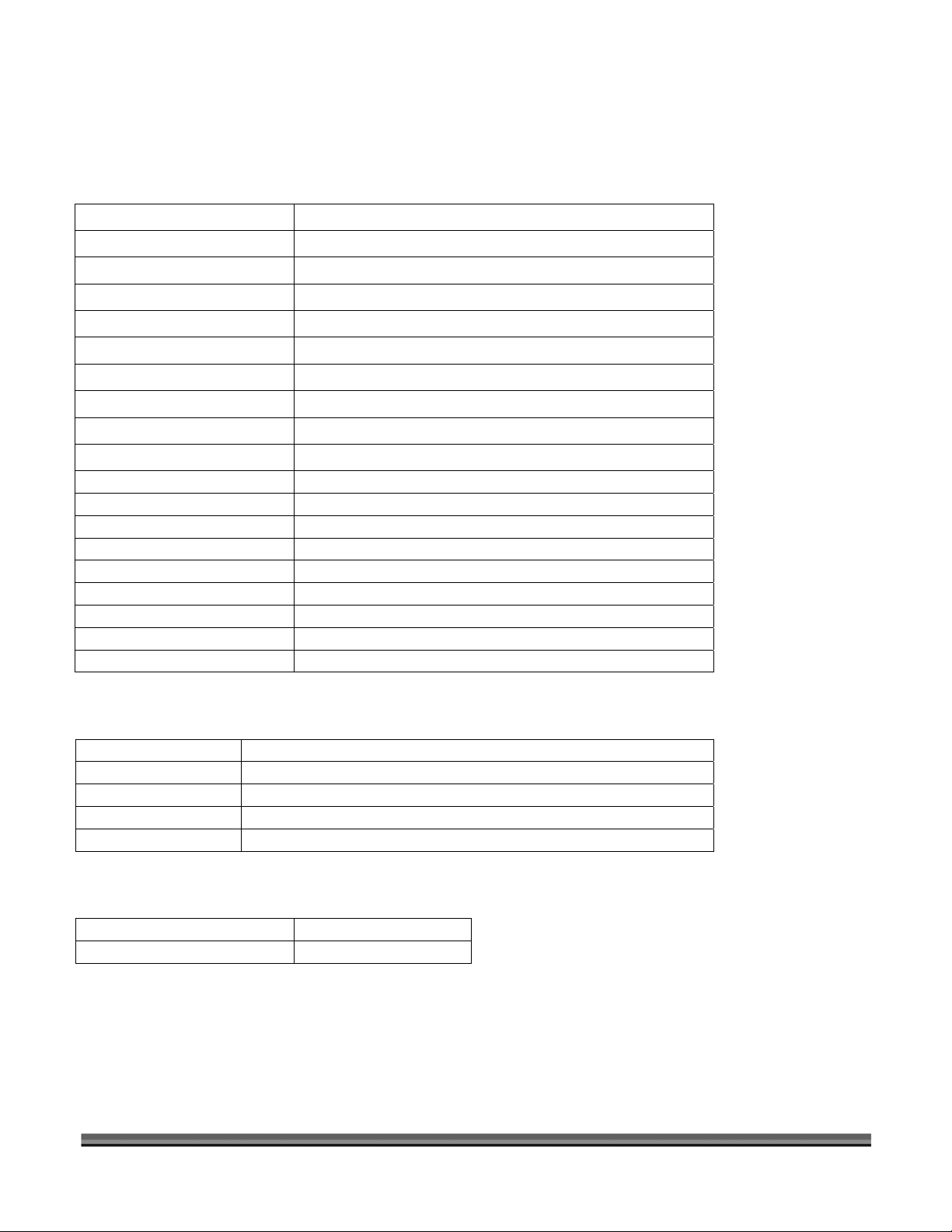

Specifications

g

g

g

p

y

pping

/

MECHANICAL SPECIFICATIONS

Engine

Series

Max. HP

Torque

Fuel Capacity

Oil Capacity

Tire Size

Digging Depth

Horizontal Reach

Ripping Force

Bucket Size - Standard

Max. Digging Radius

Lubrication

Bucket Rotation

Tow Ball Size

Towing Speed

Front Stabilizers Width

Dry Weight

Operating Weight

Subaru Manual Start

EX21 Robin

7.0 (5.1 kW)/4000 rpm.

10.26 ft. pds. (13.9 N.m.)/2500 rpm.

.7 Gal (2.7 L)

1.3 pt. (0.60 L)

4.80/4.00-8 Pneumatic

78"

100"

1,950 lbs.

12"

140 de

17 Grease Fittin

147 de

rees

s at pivot points

rees

2" Ball

h. max.

45 m

Down 117"…UP 44"

1,175 lbs.

1,260 lbs.

HYDRAULIC SPECIFICATIONS

Hydraulic Tank

Hydraulic System

Hydraulic Fluid Filter

Gear Pump

Hydraulic Fluid

12.46 gallon capacity

13.72 gallon capacity (including tank, cylinder, hoses, filter)

Spin-on type, 10 micron filter

Single stage, 2.788 GPM

Universal H

SHIPPING SPECIFICATIONS

Shi

Dimensions

Shipping Weight

2 DR

®

DIRT BOSS™ TOWABLE BACKHOE

draulic Fluid (all temps)

119" x 64" x 69 1

1,175 lbs

2"

Page 7

Serial Number

A Serial Number is used to identify your machine. The number is located on the serial number label on

your machine. For your convenience and ready reference, enter the Identification number in the space

provided on the front cover of this manual.

Order Number

An Order Number is used to check and maintain your order history. The number is located on the

upper left portion of your packing slip. For your convenience and ready reference, enter the order

number in the space provided on the front cover of this manual.

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 3

Page 8

4 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 9

CHAPTER 2

GENERAL SAFETY RULES

READ THIS SAFETY & OPERATING MANUAL BEFORE YOU USE THE DR BACKHOE. BECOME FAMILIAR

WITH THE OPERATION AND SERVICE RECOMMENDATIONS TO ENSURE THE BEST PERFORMANCE

FROM YOUR MACHINE. IF YOU HAVE ANY QUESTIONS OR NEED ASSISTANCE, PLEASE CONTACT US

AT WWW.DRPOWER.COM OR CALL TOLL FREE 1-800-DR-OWNER (376-9637) AND ONE OF OUR

TECHNICAL SUPPORT REPRESENTATIVES WILL BE HAPPY TO HELP YOU.

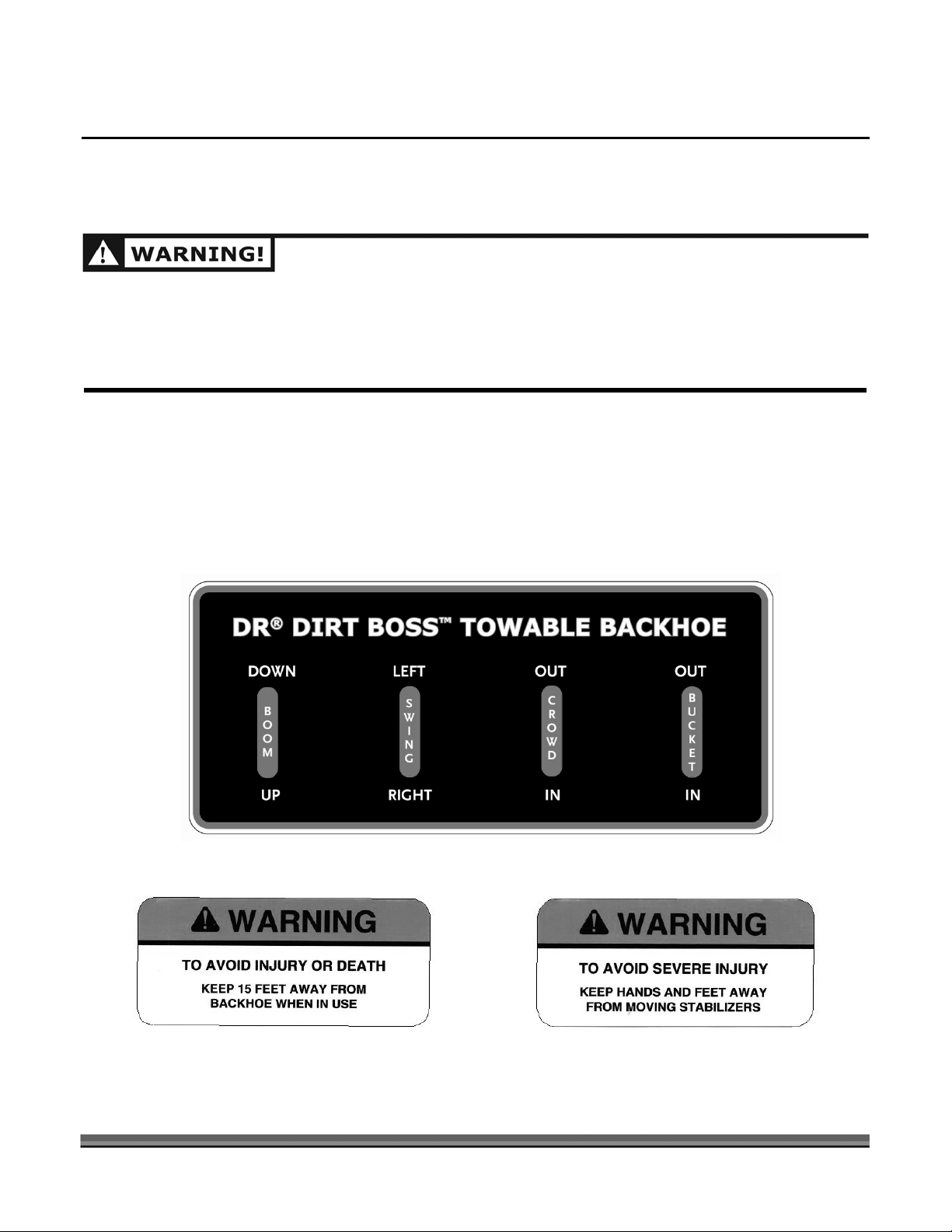

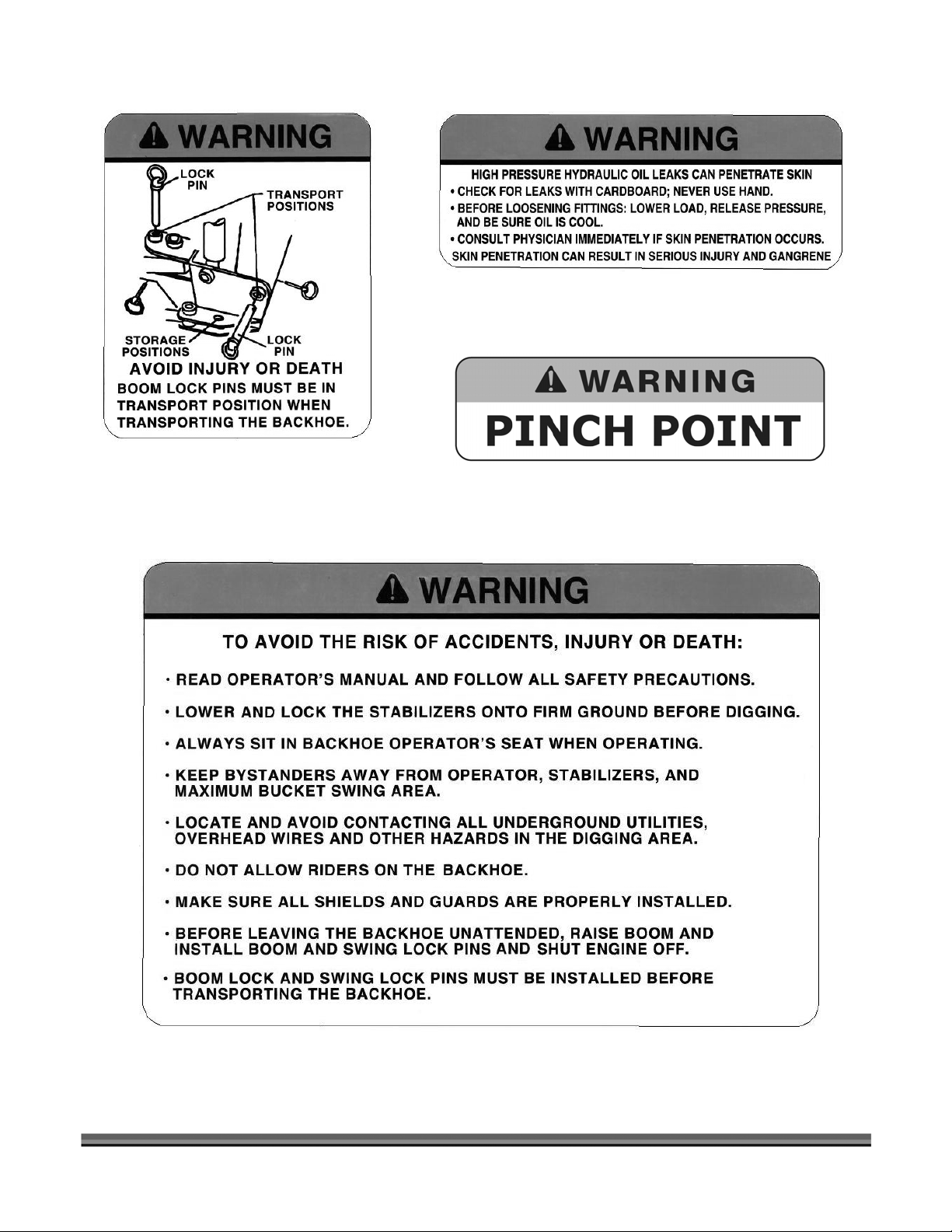

Labels

Your DR DIRT BOSS TOWABLE BACKHOE carries prominent labels as reminders for its proper and safe

use. Shown below are copies of all the Safety and Information labels that appear on the equipment.

Take a moment to study them and make a note of their location on your Backhoe as you set up and

before you operate the unit. Replace damaged or missing safety and information labels immediately.

#250451

#245441

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 5

#245701

Page 10

#245871

#246041

#250441

6 DR

®

DIRT BOSS™ TOWABLE BACKHOE

#245851

Page 11

Protecting Yourself and Those Around You

K

THIS IS A HIGH-POWERED MACHINE, WITH MOVING PARTS OPERATING WITH HIGH ENERGY. YOU

MUST OPERATE THE MACHINE SAFELY. UNSAFE OPERATION CAN CREATE A NUMBER OF HAZARDS

FOR YOU, AS WELL AS ANYONE ELSE IN THE NEARBY AREA. ALWAYS TAKE THE FOLLOWING

PRECAUTIONS WHEN USING THIS MACHINE:

• KEEP IN MIND THAT THE OPERATOR OR USER IS RESPONSIBLE FOR ACCIDENTS OR HAZARDS

OCCURRING TO OTHER PEOPLE, THEIR PROPERTY, AND THEMSELVES.

• ALWAYS WEAR PROTECTIVE GOGGLES OR SAFETY GLASSES WITH SIDE SHIELDS WHILE USING

THE BACKHOE TO PROTECT YOUR EYES FROM POSSIBLE THROWN DEBRIS.

• AVOID WEARING LOOSE CLOTHING OR JEWELRY, WHICH CAN CATCH ON MOVING PARTS.

• WE RECOMMEND WEARING GLOVES WHILE USING THE BACKHOE. BE SURE YOUR GLOVES FIT

PROPERLY AND DO NOT HAVE LOOSE CUFFS OR DRAWSTRINGS.

• WEAR SHOES WITH NON-SLIP TREADS WHEN USING YOUR BACKHOE. IF YOU HAVE SAFETY

SHOES, WE RECOMMEND WEARING THEM. DO NOT USE THE MACHINE WHILE BAREFOOT OR

WEARING OPEN SANDALS.

• WEAR LONG PANTS WHILE OPERATING THE BACKHOE.

• USE EAR PROTECTORS OR EAR PLUGS RATED FOR AT LEAST 20 DBA TO PROTECT YOUR HEARING.

• KEEP BYSTANDERS AT LEAST 100 FEET AWAY FROM YOUR WORK AREA AT ALL TIMES. LOWER THE

BUCKET AND STOP THE ENGINE WHEN ANOTHER PERSON OR PET APPROACHES.

• POSITION A BARRICADE AROUND THE WORK AREA.

• NEVER ALLOW A PERSON TO WORK UNDER A RAISED BUCKET.

• NEVER LIFT A PERSON WITH THE BACKHOE.

Safety for Children and Pets

TRAGIC ACCIDENTS CAN OCCUR IF THE OPERATOR IS NOT ALERT TO THE PRESENCE OF CHILDREN

AND PETS. CHILDREN ARE OFTEN ATTRACTED TO THE MACHINE AND THE DIGGING ACTIVITY.

NEVER

THESE PRECAUTIONS:

• KEEP CHILDREN AND PETS AT LEAST 100 FEET FROM THE WORKING AREA AND ENSURE THEY

• BE ALERT AND TURN THE MACHINE OFF IF CHILDREN OR PETS ENTER THE WORK AREA.

ASSUME THAT CHILDREN WILL REMAIN WHERE YOU LAST SAW THEM. ALWAYS FOLLOW

ARE UNDER THE WATCHFUL CARE OF A RESPONSIBLE ADULT.

• NEVER ALLOW CHILDREN TO OPERATE THE BAC

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 7

HOE.

Page 12

Safety with Gasoline - Powered Machines

GASOLINE IS A HIGHLY FLAMMABLE LIQUID. GASOLINE ALSO GIVES OFF FLAMMABLE VAPOR THAT

CAN BE EASILY IGNITED AND CAUSE A FIRE OR EXPLOSION. NEVER OVERLOOK THE HAZARDS OF

GASOLINE. ALWAYS FOLLOW THESE PRECAUTIONS:

• NEVER RUN THE ENGINE IN AN ENCLOSED AREA OR WITHOUT PROPER VENTILATION AS THE

EXHAUST FROM THE ENGINE CONTAINS CARBON MONOXIDE, WHICH IS AN ODORLESS,

TASTELESS, AND DEADLY POISONOUS GAS.

• STORE ALL FUEL AND OIL IN CONTAINERS SPECIFICALLY DESIGNED AND APPROVED FOR THIS

PURPOSE AND KEEP AWAY FROM HEAT AND OPEN FLAME, AND OUT OF THE REACH OF

CHILDREN.

• REPLACE RUBBER FUEL LINES AND GROMMETS WHEN WORN OR DAMAGED AND AFTER 5 YEARS

OF USE.

• FILL THE GASOLINE TANK OUTDOORS WITH THE ENGINE OFF AND ALLOW THE ENGINE TO

COOL COMPLETELY. DON'T HANDLE GASOLINE IF YOU OR ANYONE NEARBY IS SMOKING, OR IF

YOU'RE NEAR ANYTHING THAT COULD CAUSE IT TO IGNITE OR EXPLODE. REINSTALL THE FUEL

TANK AND FUEL CONTAINER CAPS SECURELY.

• IF YOU SPILL GASOLINE, DO NOT ATTEMPT TO START THE ENGINE. MOVE THE MACHINE AWAY

FROM THE AREA OF THE SPILL AND

AVOID CREATING ANY SOURCE OF IGNITION UNTIL THE GAS

VAPORS HAVE DISSIPATED. WIPE UP ANY SPILLED FUEL TO PREVENT A FIRE HAZARD AND

PROPERLY DISPOSE OF THE WASTE.

• ALLOW THE ENGINE TO COOL COMPLETELY BEFORE STORING IN ANY ENCLOSURE. NEVER

STORE A MACHINE THAT HAS GAS IN THE TANK, OR A FUEL CONTAINER, NEAR AN OPEN FLAME

OR SPARK SUCH AS A WATER HEATER, SPACE HEATER, CLOTHES DRYER OR FURNACE.

• NEVER MAKE ADJUSTMENTS OR REPAIRS WITH THE ENGINE RUNNING. SHUT DOWN THE

ENGINE, DISCONNECT THE SPARK PLUG WIRE, KEEPING IT AWAY FROM THE SPARK PLUG TO

PREVENT ACCIDENTAL STARTING, WAIT 5 MINUTES BEFORE MAKING ADJUSTMENTS OR REPAIRS.

• NEVER TAMPER WITH THE ENGINE’S GOVERNOR SETTING. THE GOVERNOR CONTROLS THE

MAXIMUM SAFE OPERATION SPEED AND PROTECTS THE ENGINE. OVER-SPEEDING THE ENGINE

IS DANGEROUS AND WILL CAUSE DAMAGE TO THE ENGINE AND TO THE OTHER MOVING PARTS

OF THE MACHINE. IF REQUIRED, SEE YOUR AUTHORIZED DEALER FOR ENGINE GOVERNOR

ADJUSTMENTS.

• KEEP COMBUSTIBLE SUBSTANCES AWAY FROM THE ENGINE WHEN IT IS HOT.

• NEVER COVER THE MACHINE WHILE THE MUFFLER IS STILL HOT.

• DO NOT OPERATE THE ENGINE WITH THE AIR CLEANER OR THE CARBURETOR AIR INTAKE COVER

REMOVED. REMOVAL OF SUCH PARTS COULD CREATE A FIRE HAZARD. DO NOT USE

FLAMMABLE SOLUTIONS TO CLEAN THE AIR FILTER.

• THE MUFFLER AND ENGINE BECOME VERY HOT AND CAN CAUSE A SEVERE BURN; DO NOT

TOUCH.

8 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 13

Hydraulic Safety

HIGH FLUID PRESSURES ARE DEVELOPED IN HYDRAULIC MACHINES. PRESSURIZED HYDRAULIC

FLUID ESCAPING THROUGH A PIN HOLE OPENING CAN PUNCTURE SKIN AND CAUSE SEVERE

BLOOD POISONING. THEREFORE, THE FOLLOWING INSTRUCTIONS SHOULD BE HEEDED AT ALL

TIMES.

• DO NOT OPERATE THE UNIT WITH FRAYED, KINKED, CRACKED OR DAMAGED HOSES, FITTINGS,

OR TUBING. STOP THE ENGINE, WAIT 5 MINUTES AND RELIEVE HYDRAULIC SYSTEM PRESSURE

BEFORE CHANGING OR ADJUSTING FITTINGS, HOSES, TUBING, OR OTHER SYSTEM

COMPONENTS.

• DO NOT CHANGE ANY BACKHOE NEEDLE VALVE SETTINGS. THEY ARE SET AT THE FACTORY

FOR BEST BACKHOE PERFORMANCE AND SAFETY.

• DO NOT CHECK FOR LEAKS WITH YOUR HAND. LEAKS CAN BE LOCATED BY PASSING

CARDBOARD OR WOOD OVER THE SUSPECTED AREA: LOOK FOR DISCOLORATION. IF INJURED

BY ESCAPING FLUID, SEE A DOCTOR AT ONCE. SERIOUS INFECTION OR REACTION CAN

DEVELOP IF PROPER MEDICAL TREATMENT IS NOT ADMINISTERED IMMEDIATELY.

• ALWAYS WEAR SAFETY GLASSES TO PROTECT YOUR EYES FROM HYDRAULIC FLUID.

Safety When Digging Near Utilities

CALL 811 BEFORE YOU BEGIN ANY DIGGING PROJECT. A NEW, FEDERALLY-MANDATED NATIONAL

"CALL BEFORE YOU DIG" NUMBER, 811 WAS CREATED TO HELP PROTECT YOU FROM

UNINTENTIONALLY HITTING UNDERGROUND UTILITIES WHILE WORKING ON DIGGING PROJECTS.

EVERY DIGGING JOB REQUIRES A CALL. IF YOU HIT AN UNDERGROUND UTILITY LINE WHILE

DIGGING, YOU CAN HARM YOURSELF OR THOSE AROUND YOU, DISRUPT SERVICE AND

POTENTIALLY BE RESPONSIBLE FOR FINES AND REPAIR COSTS.

• THERE MAY BE BURIED POWER, GAS, AND/OR TELEPHONE LINES IN THE WORK AREA. ELECTRIC

SHOCK, DEATH, OR EXPLOSION MAY OCCUR.

• HAVE THE PROPERTY OR WORK AREA MARKED FOR BURIED LINES AND DO NOT DIG IN

MARKED AREAS.

• THERE MAY ALSO BE OVERHEAD POWER LINES IN THE WORK AREA. ELECTRIC SHOCK OR

DEATH MAY OCCUR IF A POWER LINE IS TOUCHED BY THE BACKHOE.

• SURVEY AND MARK THE AREA WHERE THERE ARE OVERHEAD POWER LINES AND DIG WITH

CAUTION UNDER POWER LINES TO ENSURE THAT YOU DO NOT TOUCH THEM WITH THE

BACKHOE.

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 9

Page 14

To w in g

• ALWAYS CHECK BEFORE TOWING TO MAKE CERTAIN YOUR BACKHOE IS CORRECTLY AND

SECURELY ATTACHED TO THE TOWING VEHICLE. BE SURE THAT THE BALL HITCH YOU ARE

USING IS THE PROPER SIZE FOR THE HITCH COUPLER ON THE BACKHOE. BE SURE THE SAFETY

CHAINS ARE PROPERLY HOOKED TO THE VEHICLE LEAVING ENOUGH SLACK FOR TURNING.

• ALWAYS INSTALL THE SWING AND BOOM TRANSPORT HITCH PINS AND LYNCH PINS BEFORE

TRANSPORTING THE BACKHOE.

• ALWAYS USE ACCESSORY LIGHTS AND DEVICES WHEN TRANSPORTING ON A ROAD OR

HIGHWAY TO WARN OPERATORS OF OTHER VEHICLES. CHECK YOUR LOCAL GOVERNMENT

REGULATIONS.

• ALWAYS ALLOW FOR ADDED LENGTH OF THE BACKHOE WHEN TURNING, PARKING, CROSSING

INTERSECTIONS, AND IN ALL DRIVING SITUATIONS.

• ALWAYS BE CAREFUL WHEN BACKING UP. YOU COULD JACKKNIFE YOUR BACKHOE IF CARE IS

NOT TAKEN.

• NEVER EXCEED 45 M.P.H. WHEN TOWING YOUR BACKHOE. OBEY ALL STATE AND LOCAL

REGULATIONS WHEN TOWING ON STATE AND LOCAL ROADS AND HIGHWAYS. ADJUST YOUR

SPEED FOR TERRAIN AND CONDITIONS, AS NEEDED. BE EXTRA CAUTIOUS WHEN TOWING

OVER ROUGH TERRAIN, ESPECIALLY OVER A RAILROAD CROSSING.

• NEVER ALLOW ANYONE TO SIT OR RIDE ON YOUR BACKHOE.

• NEVER CARRY ANY CARGO ON YOUR BACKHOE.

• TRAVEL SLOWLY OVER ROUGH TERRAIN, ON HILLSIDES, AND AROUND CURVES TO PREVENT

TIPPING.

• DO NOT TOW THE BACKHOE NEAR THE EDGE OF A DITCH OR EXCAVATION.

10 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 15

General Safety

OPERATING THIS BACKHOE SAFELY IS NECESSARY TO PREVENT OR MINIMIZE THE RISK OF

OR SERIOUS INJURY

ALWAYS TAKE THE FOLLOWING PRECAUTIONS WHEN OPERATING THIS BACKHOE:

• YOUR BACKHOE IS A POWERFUL TOOL, NOT A PLAYTHING. EXERCISE EXTREME CAUTION AT

ALL TIMES. THE DESIGN OF THIS MACHINE IS TO DIG HOLES. DO NOT USE IT FOR ANY OTHER

PURPOSE.

• KNOW HOW TO STOP THE BACKHOE QUICKLY; SEE “STOPPING THE ENGINE” IN CHAPTER 4.

• OPERATE THIS MACHINE ON A LEVEL SURFACE ONLY. NEVER OPERATE YOUR UNIT ON A

SLIPPERY, WET, MUDDY, OR ICY SURFACE. EXERCISE CAUTION TO AVOID SLIPPING OR

FALLING.

• SEE MANUFACTURER’S INSTRUCTIONS FOR PROPER OPERATION AND INSTALLATION OF

ACCESSORIES. ONLY USE ACCESSORIES APPROVED BY DR POWER EQUIPMENT.

• NEVER USE THE MACHINE WITHOUT ENSURING THAT ALL GUARDS AND SHIELDS ARE IN

PLACE.

• NEVER, UNDER ANY CONDITIONS, REMOVE, BEND, CUT, FIT, WELD, OR OTHERWISE ALTER

STANDARD PARTS ON THE BACKHOE. THIS INCLUDES ALL SHIELDS AND GUARDS.

MODIFICATIONS TO YOUR MACHINE COULD CAUSE PERSONAL INJURIES AND PROPERTY

DAMAGE AND WILL VOID YOUR WARRANTY.

• ALWAYS OPERATE THE BACKHOE FROM THE OPERATOR SEAT ONLY.

. UNSAFE OPERATION CAN CREATE A NUMBER OF HAZARDS FOR YOU.

DEATH

• ALLOW ONLY ONE PERSON TO OPERATE THE BACKHOE AT ANY TIME.

• NEVER DIG WITH THE BACKHOE UNLESS THE STABILIZERS ARE PROPERLY SET.

• DO NOT DIG UNDER THE STABILIZERS. SOFT GROUND OR SANDY SOIL CAN CAUSE CAVE-INS.

• DO NOT USE THE BACKHOE BUCKET AS A BATTERING RAM.

• ALWAYS LOWER THE BUCKET TO THE GROUND BEFORE LEAVING THE OPERATOR’S SEAT.

• NEVER LEAVE THE BACKHOE WITH THE ENGINE RUNNING. STOP THE ENGINE AND TURN THE

IGNITION SWITCH TO “OFF”.

• BE SURE THE AREA IS CLEAR OF UNDERGROUND OBSTRUCTIONS. CALL “811” BEFORE YOU DIG.

• USE THE STEPS PROVIDED WHEN CLIMBING ON OR OFF THE BACKHOE TO PREVENT SLIPPING.

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 11

Page 16

• IF THE MACHINE SHOULD START MAKING AN UNUSUAL NOISE OR VIBRATION, SHUT DOWN

THE ENGINE, DISCONNECT THE SPARK PLUG WIRE, KEEPING IT AWAY FROM THE SPARK PLUG

TO PREVENT ACCIDENTAL STARTING, WAIT 5 MINUTES, THEN INSPECT FOR DAMAGE.

VIBRATION IS GENERALLY A WARNING OF TROUBLE. CLEAN, REPAIR AND/OR REPLACE

DAMAGED PARTS.

• NEVER TAMPER WITH SAFETY DEVICES. CHECK THEIR PROPER OPERATION REGULARLY.

• BEFORE PERFORMING ANY MAINTENANCE/INSPECTION PROCEDURE OR BEFORE LEAVING THE

BACKHOE UNATTENDED, RAISE AND CENTER THE BOOM, LOWER THE CROWD ARM, PULL IN

THE BUCKET, ADJUST THE THROTTLE CONTROL LEVER TO IDLE, TURN THE IGNITION SWITCH

TO “OFF”, REMOVE THE SPARK PLUG WIRE, AND INSTALL THE SWING AND BOOM TRANSPORT

HITCH PINS AND LYNCH PINS.

• NEVER ALLOW PEOPLE WHO ARE UNFAMILIAR WITH THESE INSTRUCTIONS TO USE THE

BACKHOE. ALLOW ONLY RESPONSIBLE INDIVIDUALS WHO ARE FAMILIAR WITH THESE RULES

OF SAFE OPERATION TO USE YOUR MACHINE.

• NEVER OVERLOAD OR ATTEMPT TO MOVE MATERIAL BEYOND THE MANUFACTURER’S

RECOMMENDATION. PERSONAL INJURY OR DAMAGE TO THE MACHINE COULD RESULT.

• WHILE USING THE BACKHOE, DON'T HURRY OR TAKE THINGS FOR GRANTED. WHEN IN

DOUBT ABOUT THE EQUIPMENT OR YOUR SURROUNDINGS, STOP THE MACHINE AND TAKE

THE TIME TO LOOK THINGS OVER.

• NEVER OPERATE THE MACHINE WHEN UNDER THE INFLUENCE OF ALCOHOL, DRUGS, OR

MEDICATION.

• USE THE MACHINE ONLY IN DAYLIGHT.

• STAY ALERT FOR HIDDEN HAZARDS OR TRAFFIC.

• KEEP ALL NUTS AND BOLTS TIGHT AND KEEP THE EQUIPMENT IN GOOD OPERATING

CONDITION.

• NO LIST OF WARNINGS AND CAUTIONS CAN BE ALL-INCLUSIVE. IF SITUATIONS OCCUR THAT

ARE NOT COVERED BY THIS MANUAL, THE OPERATOR MUST APPLY COMMON SENSE AND

OPERATE THIS BACKHOE IN A SAFE MANNER. CONTACT US AT WWW.DRPOWER.COM OR CALL

1 (800) DR-OWNER (376-9637) FOR ASSISTANCE.

12 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 17

A Note to All Users

Under California law, and the laws of some other states, you are not permitted to operate an internal

combustion engine using hydrocarbon fuels without an engine spark arrester. This also applies to

operation on US Forest Lands. All DR

®

DIRT BOSS™ TOWABLE BACKHOES shipped to California, New

Mexico and Washington State are provided with spark arresters. Failure of the owner or operator to

maintain this equipment in compliance with state regulations is a misdemeanor under California law

and may be in violation of other state and/or federal regulations. Contact your State Park Association or

the appropriate state organization for specific information in your area.

Additional Information and Potential Changes

DR Power Equipment reserves the right to discontinue, change, and improve its products at any time

without notice or obligation to the purchaser. The descriptions and specifications contained in this

manual were in effect at printing. Equipment described within this manual may be optional. Some

illustrations may not be applicable to your machine.

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 13

Page 18

14 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 19

l

CHAPTER 3

SETTING UP YOUR DR DIRT BOSS TOWABLE BACKHOE

This chapter outlines unpacking and a few simple steps you will need to follow to set up your new

machine before you use it. It may be helpful to familiarize yourself with the controls and features of your

DR DIRT BOSS TOWABLE Backhoe as shown in Figure 1 before beginning these procedures. If you have

any questions at all, please feel free to contact us at www.DRpower.com or call our Customer Service

Representatives at our toll free number: 1-800-DR-OWNER (376-9637).

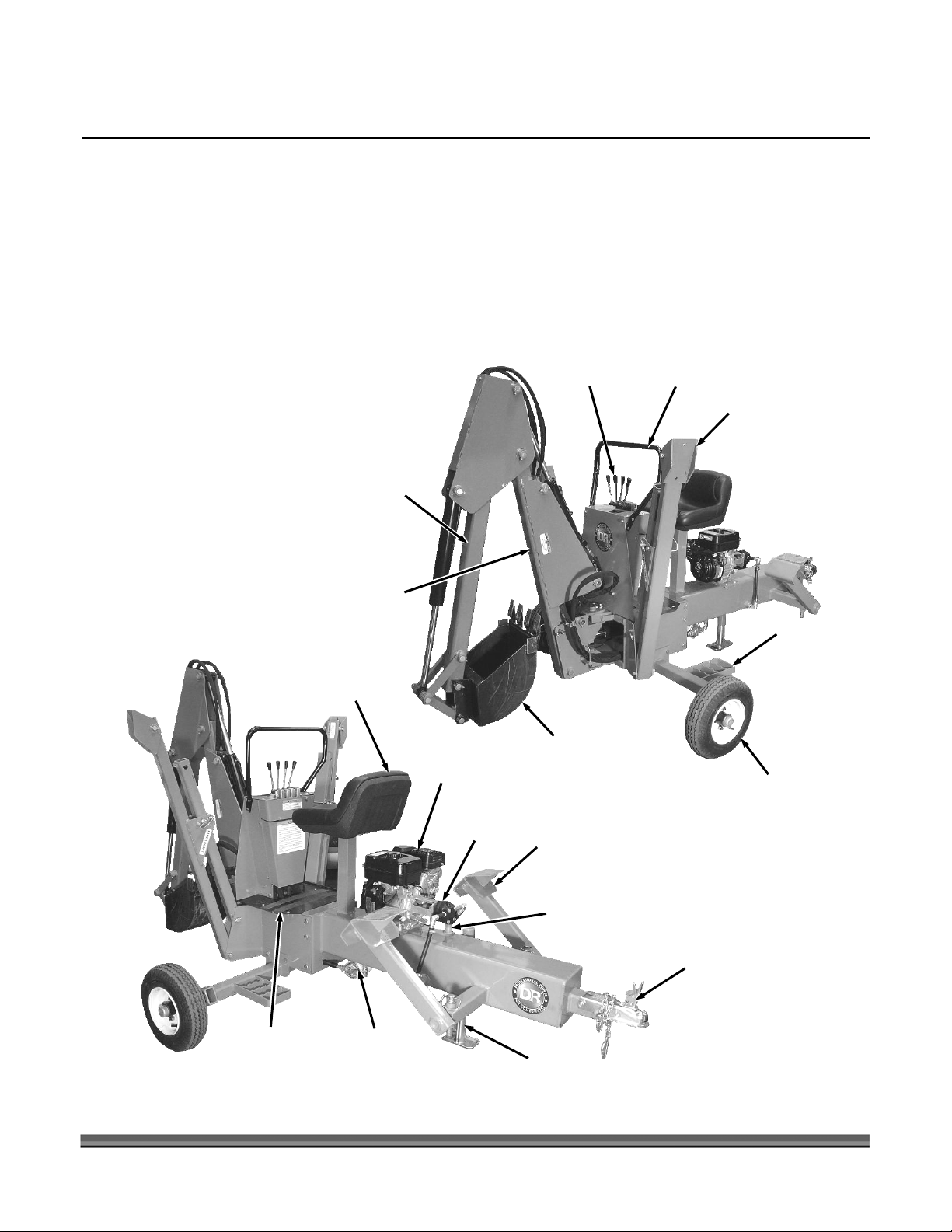

DR DIRT BOSS TOWABLE Backhoe

Controls and Features

Crowd

Arm

Boom

Operator

Seat

Engine

Hydraulic

Pump

Control Valve

Assembly

12" Bucket

(9" and 16" Bucket

and Tooth Optional)

Rear

Stabilizers

Handle

Guard

Front

Stabilizer

Operator

Step

Pneumatic

Wheel

Hydraulic

Tank Fil

Foot

Plate

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 15

Hydraulic

Filter

Jack

Figure 1

Tow

Hitch

Page 20

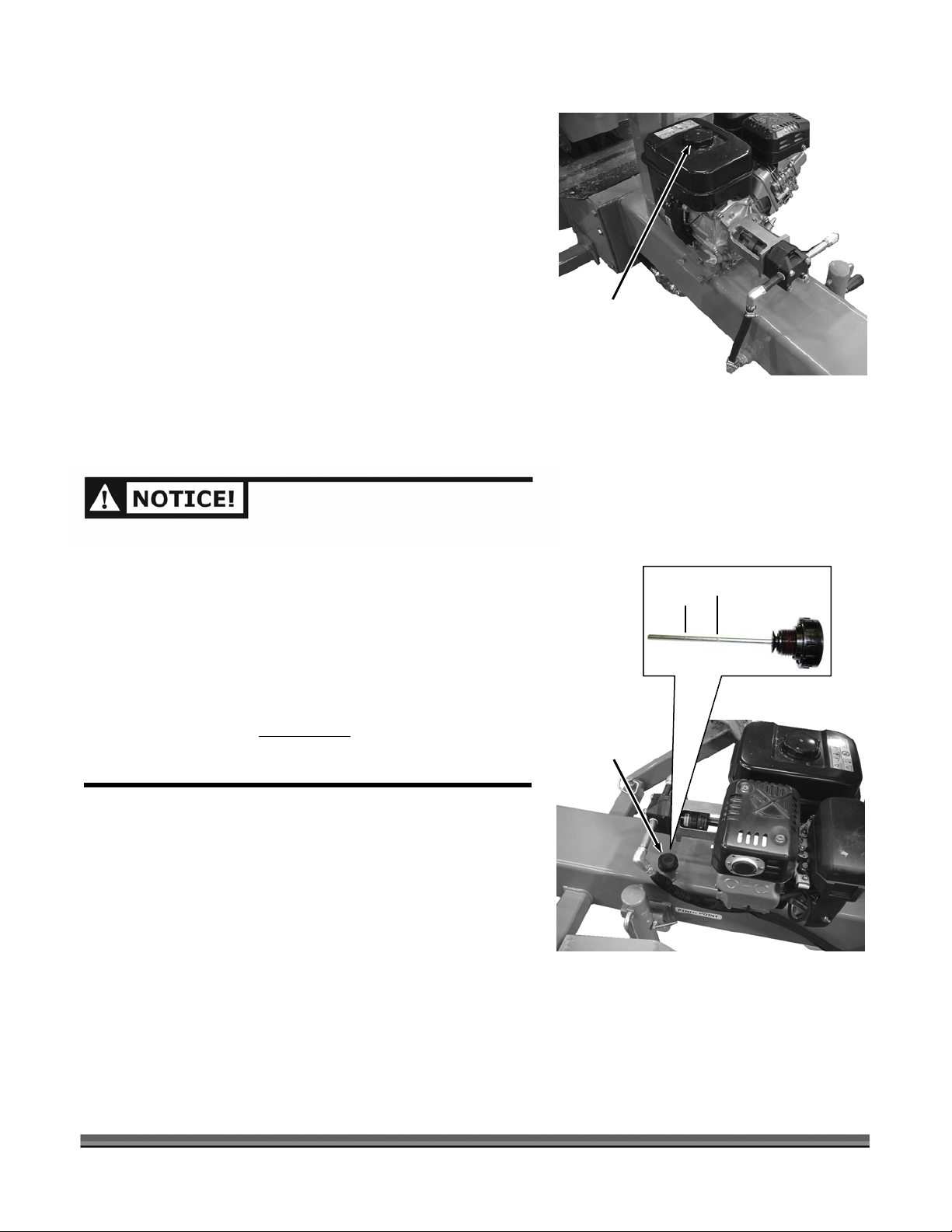

Adding Oil and Gasoline

Capacities

Engine

1.3 pt. (0.60 L) - SAE 30 for temp. 50 deg. F. or above,

10w-30 for 10-90 deg. F., 5w-30 for 30 deg. F. or below

Fuel Tank

Unleaded gasoline, .7 Gal (2.7 L)

• YOU MUST ADD OIL BEFORE STARTING THE ENGINE. THIS MACHINE IS SHIPPED WITHOUT

OIL. TRACES OF OIL MAY BE IN THE RESERVOIR FROM FACTORY TESTING, BUT YOU MUST ADD

OIL BEFORE STARTING THE ENGINE. FILL THE RESERVOIR SLOWLY, CHECKING THE LEVEL

FREQUENTLY TO AVOID OVERFILLING.

• TO GET AN ACCURATE READING WHEN CHECKING THE OIL LEVEL:

- THE MACHINE SHOULD BE ON A LEVEL SURFACE.

- THE DIPSTICK SHOULD NOT

Full

Low

READING.

BE SCREWED DOWN TO ENSURE AN ACCURATE OIL LEVEL

NOTE: Use only the recommended high detergent oil. Other types

of oil could cause problems operating your machine. Please refer to

your Engine Owner’s Manual for detailed oil information.

Oil Fill/Dipstick

Figure 2

16 DR

®

DIRT BOSS™ TOWABLE BACKHOE

1. Place the machine on a level surface, remove the Oil

Fill/Dipstick (Figure 2) and clean the end of it with a

rag.

2. Machines are shipped with no oil. Initially add 16 oz.

of the oil recommended by the Engine Manufacturer.

Wait one minute for the oil to settle.

3. Replace the Dipstick, but DO NOT

screw it in, to

ensure an accurate reading and then remove it to

check the oil level (clean the Dipstick with the rag after

checking).

4. Continue adding a few ounces of oil at a time,

rechecking the Dipstick until the oil reaches the fill

mark. Be careful not to overfill.

5. Replace the Dipstick and screw all the way down when

full.

Page 21

6. Remove the Gas Fill Cap and fill the Gas Tank with

fresh, unleaded gas (with a minimum of 85 Octane) to

approximately 1" to 1-1/2" below the top of the fill

neck to allow for fuel expansion (Figure 3). Be careful

not to overfill and reinstall the Gas Fill Cap before

starting the engine. See your Engine Owner’s Manual

for more detailed information.

NOTE: To refill the gas tank, turn the engine OFF and let the

engine cool at least five minutes before removing the

gas fill cap.

Adding Hydraulic Fluid

• YOU MUST ADD HYDRAULIC FLUID BEFORE USING THE

BACKHOE. THIS MACHINE IS SHIPPED WITHOUT

HYDRAULIC FLUID. FILL THE HYDRAULIC TANK

SLOWLY, CHECKING THE LEVEL FREQUENTLY TO AVOID

OVERFILLING.

Gas Fill Cap

Figure 3

Low

Full

• TO GET AN ACCURATE READING WHEN CHECKING THE

HYDRAULIC FLUID LEVEL:

- THE MACHINE SHOULD BE ON A LEVEL SURFACE.

- THE DIPSTICK SHOULD BE

SCREWED ALL THE WAY

DOWN TO ENSURE AN ACCURATE FLUID LEVEL

READING.

1. Remove the Hydraulic Fluid Fill Cap Dipstick and fill

the Hydraulic Tank (Figure 4) with the recommended

fluid (see the “specifications” section, page 2). The

tank is full when the fluid level is at the full mark on

the Dipstick.

NOTE: The total hydraulic system fluid capacity is 13.72

gallons.

Hydraulic Fluid

Fill Cap

Hydraulic

Tank

Figure 4

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 17

Page 22

Check the Tire Pressure

Tools Needed:

• Tire Pressure Gauge

• Air Compressor

DO NOT OVER INFLATE THE TIRES. INFLATE TO THE

MANUFACTURERS RECOMMENDED PRESSURE FOUND ON

THE TIRES.

Valve Stem

Protective Cap

Figure 5

1. Remove the Valve Stem Protective Cap (Figure 5) and

check the tire pressure with a tire pressure gauge.

2. If the pressure is too low, add air with an air hose

through the Valve Stem.

3. Replace the Valve Stem Protective Cap when finished.

18 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 23

r

CHAPTER 4

OPERATING YOUR DR DIRT BOSS

TOWABLE BACKHOE

This chapter discusses the basic operation of your new DR

DIRT BOSS TOWABLE BACKHOE. It may be helpful to

better learn the features of your Backhoe by reviewing

Figure 1 in Chapter 3 before beginning the steps outlined

in this chapter.

READ AND UNDERSTAND THE DANGERS LISTED IN THE

“SAFETY WHEN DIGGING NEAR UTILITIES” SECTION IN

CHAPTER 2, GENERAL SAFETY RULES, BEFORE OPERATING

THIS BACKHOE.

READ AND UNDERSTAND THE WARNINGS LISTED IN

CHAPTER 2, GENERAL SAFETY RULES, BEFORE OPERATING

THIS BACKHOE.

Boom

Control

Lever

Figure 6

Swing

Control

Leve

Boom

Down

Boom

Up

Swing

Left

Swing

Right

Crowd Arm

Control

Lever

Crowd

Out

Crowd

In

Bucket

Control

Lever

Bucket

Out

Bucket

In

Control Levers

1. Familiarize yourself with all of the Control Levers

(Figure 6)and all of their functions (Figure 7) before

operating the Backhoe.

Starting the Engine

1. Turn the Ignition Switch to the “ON” position (Figure

8).

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 19

Figure 7

Off

Ignition

Switch

On

Figure 8

Page 24

Throttle

Lever

2. Make sure the Fuel Shut-off is in the “OPEN” position

(Figure 9).

3. Move the Choke Control Lever to the left to the choke

Choke

Lever

position (leave in the run position to the right if the

engine is already warm).

4. Move the Throttle Control Lever to about half way

between Slow and Fast position.

Fuel

Shut-off

5. Slowly pull the Starter Cord until you feel resistance,

then pull quickly. The Cord will recoil back into

position.

6. As the engine warms up, slowly adjust the Choke to

the right towards the run position. Wait until the

engine runs smoothly before each Choke adjustment.

7. When the Engine is warmed up and running smoothly

with the Choke in the run position, move the Throttle

Control Lever to the fast position for operating the

Backhoe.

Figure 9

Figure 10

Rear

Stabilizers

Hitch

Pin

Lynch Pin

Starter

Cord

Stopping the Engine

1. Slowly move the Throttle Control Lever to the idle

position (Figure 9).

2. Turn the Ignition Switch to the “Off” position (Figure

8).

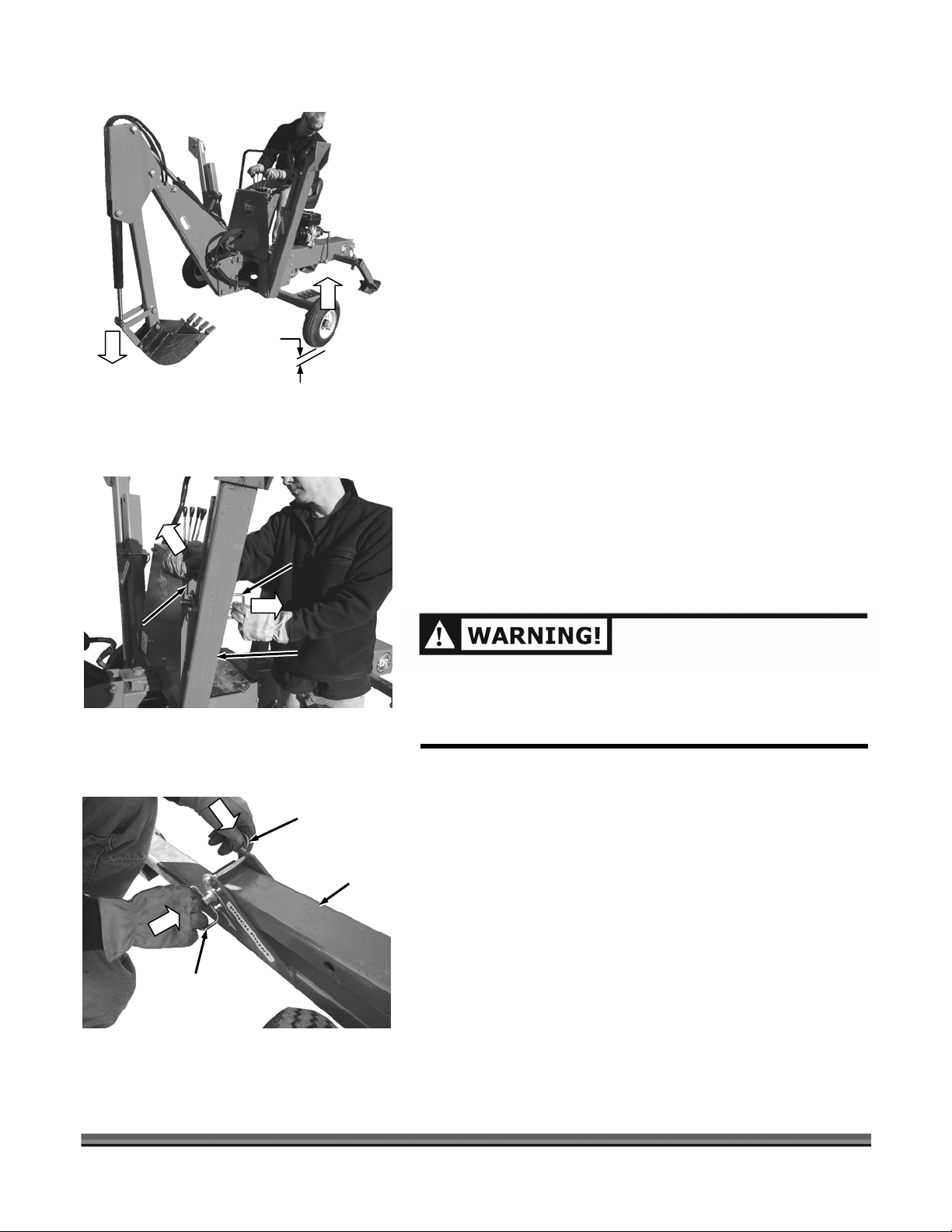

Stabilizing the Backhoe for Digging

A. LOWERING THE REAR STABILIZERS

1. Pull the Rear Stabilizer Lynch-Pin from the Hitch pin

and remove the Hitch Pin (Figure 10).

2. Rotate the Rear Stabilizer towards the Tow Hitch

until the holes line up and allow you to reinstall the

Hitch Pin. Secure the Hitch Pin with the Lynch Pin.

NOTE: If the Stabilizer hits the ground before the holes line up,

then the Jack must be jacked up more to provide the needed

clearance.

20 DR

®

DIRT BOSS™ TOWABLE BACKHOE

3. Repeat for the other Rear Stabilizer.

Page 25

4. Lower the rear of the Backhoe to the ground by

cranking the Jack Handle counterclockwise (Figure

11).

Jack

Figure 11

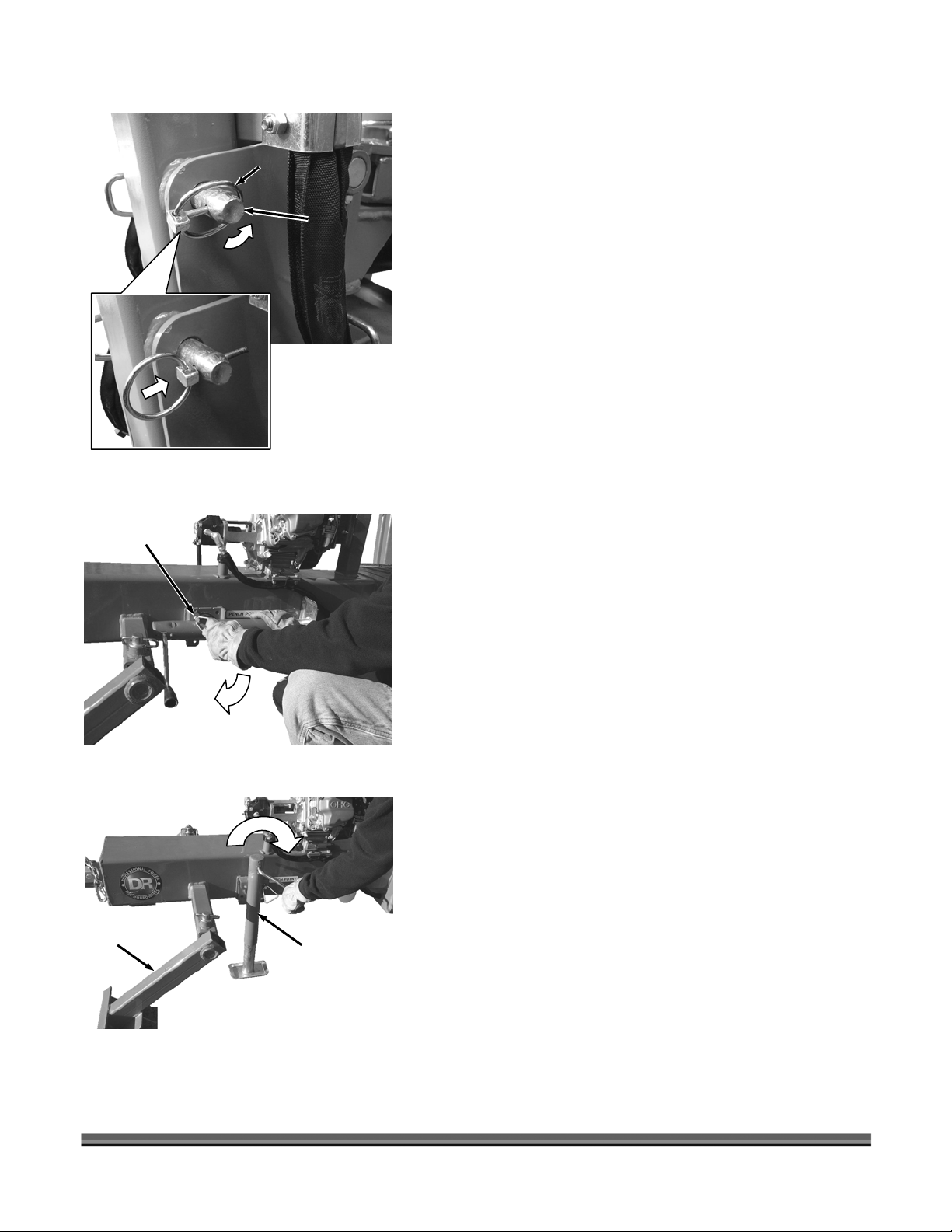

5. Pull the Lock Pin of the Jack and rotate the Jack

counterclockwise until the Lock Pin locks the Jack into

the horizontal position (Figure 12).

B. LOWERING THE FRONT STABILIZERS

NOTE: When using the Backhoe for the first time after initial

setup, you must first cycle the Hydraulic Fluid into the

cylinders before you can control the Boom effectively

and have it stay in position when the Control Levers

are released.

1. Start the Engine as instructed in the “Starting the

Engine” section in this chapter.

NOTE: Refer to Figures 6 and 7 for Control Lever functions.

2. Pull back on the Boom Control Lever until you see the

Boom move towards you. When the Boom is moved to

this position, pressure is removed from the Boom

Hitch Pins.

Jack

Locking Pin

Figure 12

Hitch

Pin

Hitch

Pin

3. Remove the Lynch Pins from the two Hitch Pins and

remove the Hitch Pins from the Boom (Figure 13).

4. Install the two Hitch Pins into the storage holes in the

Boom and secure with the Lynch Pins.

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 21

Hitch Pin

Storage

Figure 13

Page 26

5. Push the Swing Control Lever slowly all the way

forward and pull all the way back four to six times to

fill the Swing Cylinder with fluid.

6. Push the Bucket Control Lever slowly all the way

forward and pull all the way back four to six times to

fill the Bucket Cylinder with fluid.

7. Push the Crowd Arm Control Lever slowly all the way

forward and pull all the way back four to six times to

fill the Crowd Arm Cylinder with fluid.

Figure 14

Lynch

Pin

Figure 15

Approx.

6" off

ground

Hitch

Pin

Front

Stabilizer

Lynch

Pin

8. Push the Boom Control Lever slowly forward (do not

push full forward) to slowly fill the Boom Cylinder the

rest of the way and lower the Boom.

9. Pull the Boom Control Lever slowly all the way back

and push all the way forward four to six times to fill

the Boom Cylinder with fluid.

10. Center the Boom and slowly lower the Bucket to the

ground and lift the front of the Backhoe until the

Wheels are about 6" off the ground (Figure 14).

11. Carefully get off the Backhoe and shut down the

engine.

WHEN THE FRONT STABILIZERS ARE LOWERED OR RAISED

THERE IS A HAZARD OF PINCHING YOUR HANDS. KEEP

YOUR HANDS CLEAR OF THE PINCH POINT AREAS AS

INDICATED BY THE LABELS.

12. Pull the Front Stabilizer Lynch-Pin from the Hitch pin

and remove the Hitch Pin (Figure 15).

13. Lower the Front Stabilizer to the ground.

Figure 16

22 DR

Front

Stabilizer

Hitch

Pin

®

DIRT BOSS™ TOWABLE BACKHOE

14. Line up the holes in the Front Stabilizer and insert the

Hitch Pin. Secure the Hitch Pin with the Lynch Pin

(Figure 16).

15. Repeat the last three steps for the other Front

Stabilizer.

Page 27

16. Start the Backhoe engine and get into the Operator

seat to raise the Boom to lower the Backhoe onto the

Front Stabilizers (Figure 17).

Digging with the Backhoe

It is not difficult (but it does take practice) to become an

efficient operator. A control lever operating decal is located

just forward of the control levers. Study this decal; it will

help you become familiar with the controls. See Figures 6

and 7 for control locations and functions.

Smooth, light handling of the controls will result in the

most efficient machine operation. Operate the backhoe

control levers to become familiar with their speed and

movements. The engine speed will determine the speed of

the cylinder operation.

Swing the boom several times to practice controlling the

speed of the swing. Do not operate the swing more than

45 degrees each way for the first few times. Gradually

increase the arc.

Best results are obtained by digging near the center of the

swing arc so material can be dumped to either side.

Figure 17

18" to 24"

TO AVOID DAMAGE TO THE BACKHOE, DO NOT SLAM THE

SWING UNIT INTO THE END OF THE SWING CYLINDER

STROKE.

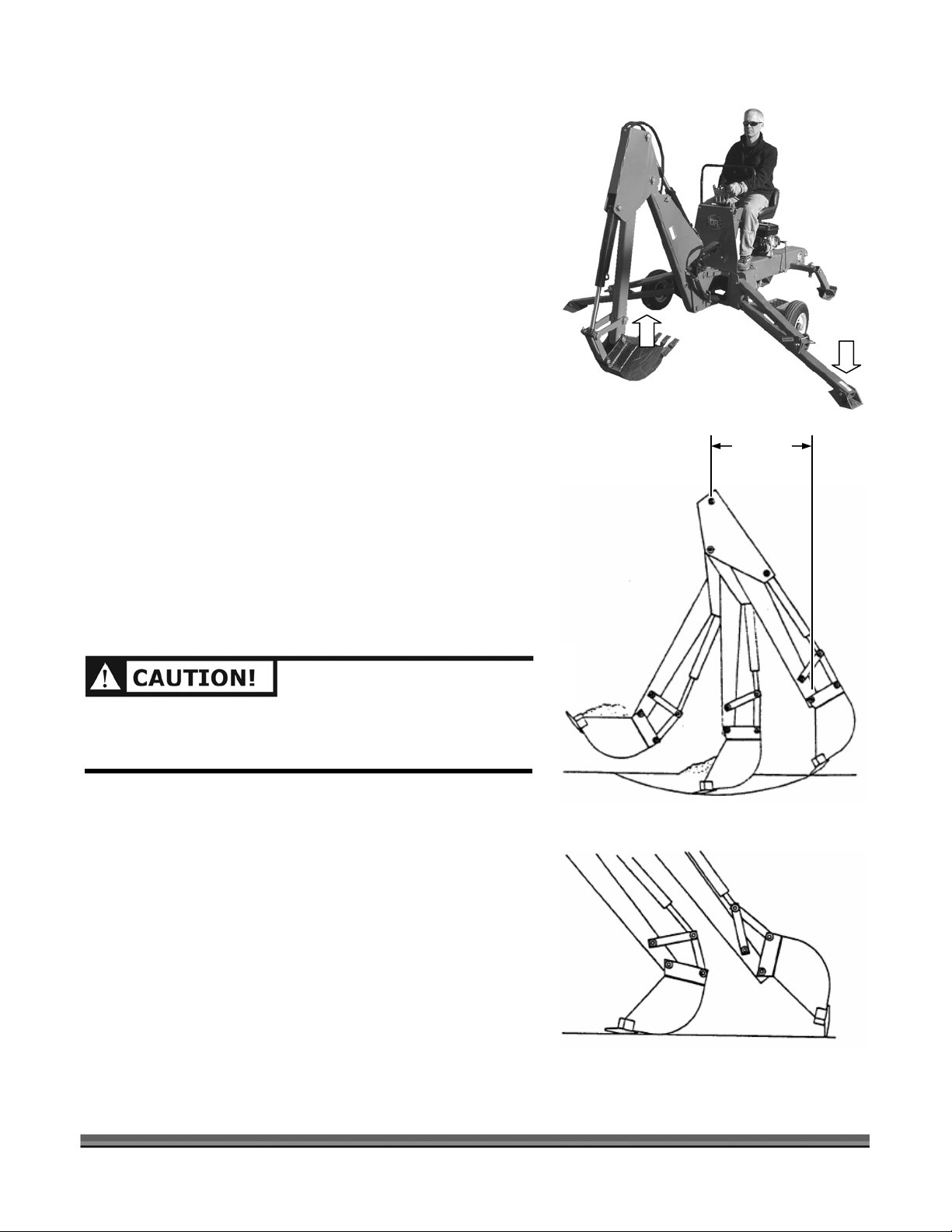

Bucket Digging

1. Lower the Bucket to the digging area with the Bucket

pivot 18" to 24" forward of the Boom/Crowd Arm pivot

(Figure 18).

NOTE: It is important for the Bucket to be in the proper

position for digging efficiency. The Bucket will not dig

as well if you attempt to dig with the Bucket in the

wrong position, tilted too far forward or too far back

(Figure 19).

2. Using down pressure on the Bucket bottom, force the

Bucket into the ground.

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 23

Figure 18

Too Far Forward

Figure 19

Too Far Back

Page 28

3. With the Bucket in the ground, simultaneously retract the Crowd Arm and load the Bucket until it is

full (Figure 18).

4. If the Bucket stalls, raise the Boom slightly and continue to dig until the Bucket is full.

5. Raise the Bucket to the top of the trench and dump it on the spoil pile.

6. When lifting the loaded Bucket high, continue rolling the Bucket in as it is being raised to prevent

spilling the contents.

NOTE: With a little practice, raising, swinging, and dumping can be accomplished in one smooth operation.

Crowd Arm Digging

1. Lower the Bucket to the digging area with the Bucket

pivot 18" to 24" forward of the Boom/Crowd Arm

pivot.

2. Rotate the Bucket until the cutting edge teeth are flat

on the ground.

3. Using only the Crowd Arm Control Lever, retract the

Crowd Arm, dragging the Bucket through the trench

until it is about half full. Roll the Bucket as you

continue to retract the Crowd Arm.

Figure 20

Figure 21

Hitch

Pin

4. Raise the Bucket and swing the Boom until the Bucket

can be dumped in the spoil area.

Preparing the Backhoe for Moving/Towing

1. Lift the front of the Backhoe by lowering the Boom

until the Front Stabilizers lift slightly off the ground

(Figure 20).

2. Move the Throttle Lever to the idle position (Figure 9)

and turn the Ignition Switch of the Engine to the

“OFF” position (Figure 8).

Lynch

Pin

Front

Stabilizer

WHEN THE FRONT STABILIZERS ARE LOWERED OR RAISED

THERE IS A HAZARD OF PINCHING YOUR HANDS. KEEP

YOUR HANDS CLEAR OF THE PINCH POINT AREAS AS

INDICATED BY THE LABELS.

3. Pull the Front Stabilizer Lynch-Pins from the Hitch

pins and remove the Hitch Pins (Figure 21).

24 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 29

g

4. Raise the Front Stabilizers to the Vertical position

(Figure 22).

5. Line up the holes in the Front Stabilizers and insert

the Hitch Pins. Secure the Hitch Pins with the Lynch

Pins.

6. Start the Backhoe Engine and raise the Boom to lower

the Backhoe onto the Wheels (Figure 23).

Lynch

Pin

Figure 22

Hitch

Pin

Front

Stabilizer

7. Use the Controls to center and pull in the Boom, pull

the Crowd arm all the way towards you, and pull the

Bucket in. This will line up the holes for the next step.

NOTE: You may need to check that the holes are aligned

properly before you shut down the Engine.

8. Move the Throttle Control Lever to the idle position

and turn the Engine Ignition Switch to “OFF”.

9. Remove the Lynch Pins from the Hitch Pins and then

remove the two Hitch Pins from the storage area.

Install the Hitch Pins into their positions to lock the

Boom in place (Figure 24).

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 25

Figure 23

Hitch

Pin

Hitch Pin

Storage

Fi

ure 24

Hitch

Pin

Page 30

Figure 25

Boom

Assembly

Linchpin

10. Insert the Lynch Pins into the Hitch Pins and secure

them by snapping the Lynch Pin Ring over the Hitch

Pin (Figure 25).

Hitch

Pin

Jack

Locking Pin

Figure 26

Rear

Stabilizer

11. Pull the Jack Spring Pin out and rotate the Jack until it

locks into the vertical position (Figure 26).

12. Rotate the Jack Handle clockwise until the Rear

Stabilizers are lifted off the ground (Figure 27).

Jack

Figure 27

26 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 31

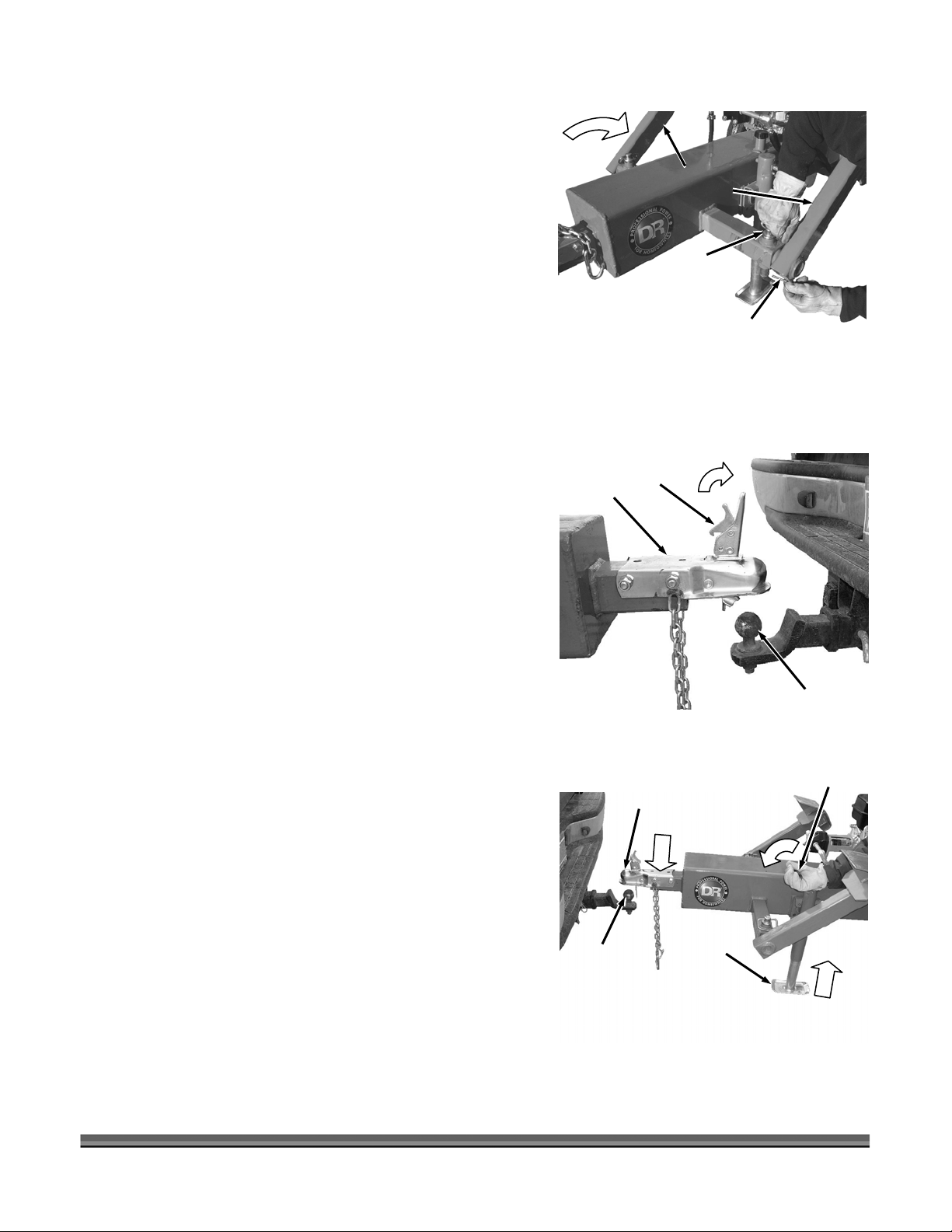

13. Remove the Hitch Pins of the Rear Stabilizers and

rotate them into their upright position until the

holes are aligned (Figure 28).

14. Reinstall Hitch Pins into the Rear Stabilizers and

secure with the Lynch Pins.

Towing the Backhoe

Rear

Stabilizers

Hitch

Pin

Lynch Pin

Figure 28

The Backhoe must be prepared for towing by following the

procedures in the previous “Preparing the Backhoe for

Towing” section first.

1. Position the Backhoe behind the tow vehicle and raise

or lower the Jack to position the Tow Hitch just over

the Tow Ball (Figure 29).

2. Pull the Latch Assembly of the Tow Hitch Assembly up

and into the open position.

3. Lower the Hitch Coupler of the Backhoe onto the tow

vehicle’s Tow Ball (must be a 2" tow ball) by lowering

the Jack until all the weight is on the Tow Ball and the

Jack Base comes off the ground (Figure 30).

Tow

Hitch

Assembly

Figure 29

Latch

Assembly

Tow Hitch

Assembly

2" Tow Ball

Jack Handle

Jack

Tow Ball

Figure 30

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 27

Base

Page 32

Latch

k

Assembly

4. Close the Latch Assembly on the Tow Hitch Assembly

to lock the Tow Hitch Assembly onto the Tow Ball

(Figure 31). Attach the towing Safety Chains to the tow

vehicle ensuring there is enough slack for turning.

Figure 31

Jac

Figure 32

Tow Hitch

Assembly

Spring Pin

Locking Pin

Safety

Chains

5. Rotate the Jack to the towing position by pulling the

spring pin and rotating the Jack until it locks into the

tow position (Figure 32). Make sure the hitch coupler

is properly and securely attached to the tow ball.

6. Insert the Locking Pin into the hole of the Latch

Assembly to lock it in the closed position.

7. For extra safety and security, you may want to

purchase a lock to install into the hole of the latch

assembly (Figure 33).

Latch

Assembly

MAKING SURE THE BACKHOE IS SECURELY ATTACHED TO

THE VEHICLE IS THE RESPONSIBILITY OF THE

OWNER/OPERATOR. FAILURE TO SECURELY ATTACH THE

Figure 33

BACKHOE CAN CAUSE LOSS OF CONTROL OF THE VEHICLE

OR THE BACKHOE BEING SEPARATED FROM THE TOWING

VEHICLE, RESULTING IN SERIOUS INJURY OR DEATH.

ALWAYS USE ACCESSORY LIGHTS AND DEVICES WHEN

TRANSPORTING ON A ROAD OR HIGHWAY TO WARN

OPERATORS OF OTHER VEHICLES. CHECK YOUR LOCAL

28 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 33

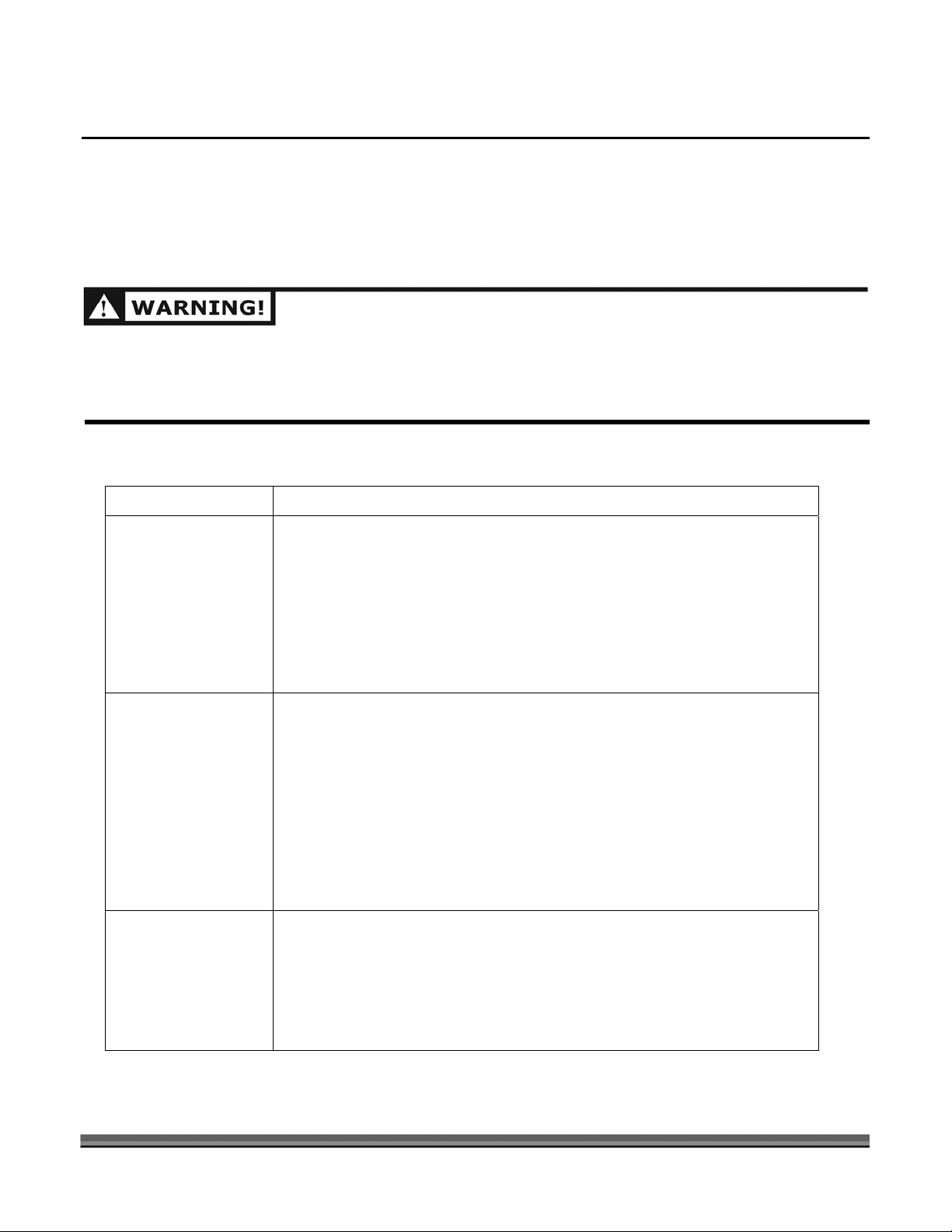

Hitch Coupler Adjustment Check

1. Place the proper size ball in the socket of the

coupler and close the latch assembly (Figure 34).

Verify that the locking trigger is properly engaged

in its detent.

2. Pull on the ball and/or coupler, trying to remove

the ball from the socket. If the ball moves more

than 1/16" in the coupler’s socket, the clamp

requires adjustment. Follow the proper

adjustment procedure in the following steps.

Hitch Coupler Adjustment

1. With the proper size ball in the socket of the hitch

coupler, close the latch of the coupler completely

(Figure 35). Verify that the locking trigger is properly

engaged in its detent.

2. Tighten the lock nut on the underside of the coupler

until the spring between the nut and the clamp is

fully compressed. Then back off the lock nut 1/2 turn

or just enough that the latch is able to clamp and

unclamp from the ball.

Pull

1/16"

Movement

Figure 34

Figure 35

Locking

Trigger

Spring

Lock Nut

Ball Clamp

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 29

Page 34

30 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 35

CHAPTER 5

MAINTAINING THE DR DIRT BOSS TOWABLE BACKHOE

Regular maintenance is the way to ensure the best performance and long life of your machine. Please

refer to this manual and the engine manufacturer's owner's manual for maintenance procedures.

Service intervals listed in the checklist below supersede those listed in the engine manufacturer's

owner's manual.

CENTER THE BOOM. RETRACT THE BOOM, CROWD ARM AND BUCKET. INSTALL THE BOOM HITCH

PINS AND LYNCH PINS TO LOCK THE BOOM IN PLACE. SHUT DOWN THE ENGINE, REMOVE THE

SPARK PLUG WIRE AND WAIT 5 MINUTES BEFORE PERFORMING ANY MAINTENANCE PROCEDURE

OR INSPECTION ON THE BACKHOE.

Regular Maintenance Checklist

ROCEDURE BEFORE EACH USE EVERY 25 HOURS EVERY 100 HOURS

P

Check Engine Oil Level

Check General Equipment Condition

Check Tire Pressure

Check Hydraulic Fluid Level

Check Hydraulic Hoses and Connections

Lubricate Grease Fittings

Clean Air Filter

Change Engine Oil 1st time 5 hours

Clean Engine Exterior & Cooling Fins

Replace Spark Plug

Replace Hydraulic Fluid and Filter

Replace Air Filter

*Lubricate grease fittings after every four hours of use.

S

S

S

S

S

S*

S

S

S

S

S

S

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 31

Page 36

Greasing the Backhoe

Economical and efficient operation of any machine is dependant upon regular and proper lubrication of

all moving parts with a quality lubricant. All parts provided with grease fittings should be lubricated with

a good quality chassis lube type grease. If any grease fittings are missing, replace them immediately.

Tools and Supplies Needed:

• Grease Gun (general purpose grease)

• Rags

1. Wipe any grease or dirt from all Grease Fittings with a rag.

2. Grease the Backhoe at all seventeen Grease Fittings (Figure 36) until you notice grease escaping

from the joint.

3. Wipe off any excess grease with a rag.

32 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Figure 36

Page 37

Changing the Hydraulic Fluid and Filter

Tools needed:

• 3/4"Wrench

• 7/8" Wrench

• Filter Wrench

1. Place a waste fluid container under Filter and

Connections. Your container must be large enough to

hold the 12.46 gallons of fluid in the Tank.

2. Slightly raise the hitch end of the Backhoe by turning

the Jack Handle clockwise. The hitch end of the

Hydraulic Tank should be slightly higher than the Filter

end.

3. Remove the existing Hydraulic Fluid Filter and properly

dispose of it (Figure 37).

4. Let the Hydraulic Fluid drain into the container.

5. Apply a thin coat of fresh hydraulic fluid to the Rubber

Seal of the new Hydraulic Fluid Filter.

Remove

Install

Hydraulic

Fluid Filter

Figure 37

6. Screw the filter onto the filter head. Once the filter seal

makes contact with the filter head, turn it an additional

¾ turn. Hand-tighten only.

7. Remove the Hydraulic Tank Fill Cap/Dipstick and fill

the Hydraulic Tank with the recommended type and

quantity of hydraulic fluid until the level reaches the fill

mark on the Dipstick (Figure 38). Refer to the Spec

sheet on page 2.

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 33

Hydraulic Fluid

Fill Cap

Hydraulic

Tank

Figure 38

Low

Full

Page 38

End of Season and Storage

CENTER THE BOOM. RETRACT THE BOOM, CROWD ARM AND BUCKET. INSTALL THE BOOM HITCH

PINS AND LYNCH PINS TO LOCK THE BOOM IN PLACE. SHUT DOWN THE ENGINE, REMOVE THE

SPARK PLUG WIRE AND WAIT 5 MINUTES BEFORE PERFORMING ANY MAINTENANCE PROCEDURE

OR INSPECTION ON THE BACKHOE.

• Coat the exposed piston rods of all hydraulic cylinders with a grease or corrosion preventative.

• Lubricate all grease fittings (See page 32).

• Clean the exterior of the unit to remove all dirt, grease, and any other foreign material. To prevent

rust, touch up painted surfaces that have been scratched or chipped.

• If possible, store the Backhoe in a dry, protected place. If it is necessary to store the Backhoe

outside, cover it with a protective material (especially the Engine and Seat).

34 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 39

CHAPTER 6

TROUBLESHOOTING

Most problems are easy to fix. Consult the Troubleshooting Table below for common problems and their

solutions. If you continue to experience problems, call DR Power Equipment for support.

CENTER THE BOOM. RETRACT THE BOOM, CROWD ARM AND BUCKET. INSTALL THE BOOM HITCH

PINS AND LYNCH PINS TO LOCK THE BOOM IN PLACE. SHUT DOWN THE ENGINE, REMOVE THE

SPARK PLUG WIRE AND WAIT 5 MINUTES BEFORE PERFORMING ANY MAINTENANCE PROCEDURE

OR INSPECTION ON THE BACKHOE.

Troubleshooting Table

SYMPTOM POSSIBLE CAUSE

Backhoe fails to lift or

swing.

Backhoe lifting or

swinging too slowly.

Backhoe fails to hold

up the load.

NOTE: All loads will

settle down over a

period of time. This is

normal.

⇒ Low hydraulic fluid supply; Add fluid.

⇒ Pump not running; Start engine.

⇒ Worn control valve; Replace or repair worn valve.

⇒ Pump damaged or worn; Replace pump.

⇒ Broken hydraulic line; Check for leaks, replace line.

⇒ Faulty relief valve; Clean or replace relief valve.

⇒ Bent piston rod; repair or replace cylinder.

⇒ Cold hydraulic fluid; Warm fluid with engine at idle.

⇒ Engine speed too low; Open throttle

⇒ Hydraulic fluid leaking past control valve; repair or replace worn valve.

⇒ Hydraulic fluid too heavy; Use recommended fluid.

⇒ Scored Cylinder; Replace cylinder.

⇒ Pump damaged or worn; Repair or replace pump.

⇒ Hydraulic fluid leaking past cylinder packings; Replace packings.

⇒ Pinched supply hose; Replace hose, rout to prevent kinking or

pinching.

⇒ Broken hydraulic lines; Check for leaks and replace line.

⇒ Hydraulic fluid leaking past cylinder packings; Replace packings.

⇒ Hydraulic fluid leaking past control valve; repair or replace worn valve.

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 35

Page 40

CENTER THE BOOM. RETRACT THE BOOM, CROWD ARM AND BUCKET. INSTALL THE BOOM HITCH

PINS AND LYNCH PINS TO LOCK THE BOOM IN PLACE. SHUT DOWN THE ENGINE, REMOVE THE

SPARK PLUG WIRE AND WAIT 5 MINUTES BEFORE PERFORMING ANY MAINTENANCE PROCEDURE

OR INSPECTION ON THE BACKHOE.

Troubleshooting Table (continued)

SYMPTOM POSSIBLE CAUSE

Hydraulic Fluid

Heating.

⇒ Dirty hydraulic fluid; Drain fluid and refill.

⇒ Control valve handle held open too long; Return control valve handle

to neutral position when not in use.

⇒ Hydraulic fluid too light in hot weather; Use recommended fluid.

⇒ Engine running too fast; Reduce throttle.

⇒ Damaged hydraulic lines; Replace damaged lines.

External leakage.

Swing cylinder

malfunctioning.

Control valve sticking

or working hard.

Spongy or jerking

action of cylinders

and/or very noisy

pump action.

⇒ Damaged O-rings on valve spools; Repair control valve.

⇒ Cylinder seals damaged; Repair cylinder.

⇒ Broken hydraulic line; Check for leaks and replace line.

⇒ Hydraulic fluid leaking past packing or seals; Replace packing or seals.

⇒ Faulty cross-over relief valve; Clean or replace.

⇒ Scored bore or bent spool; Repair or replace worn valve.

⇒ Control linkage misaligned; Correct misalignment.

⇒ Return spring binding or broken; Replace spring.

⇒ Foreign matter in spool bore; Clean valve.

Dirty hydraulic fluid; Drain fluid and refill.

⇒

⇒ Low hydraulic fluid supply; Add fluid.

⇒ Cold hydraulic fluid too stiff; Use recommended fluid.

⇒ Air in system; Purge system of air by operating machine at maximum

hydraulic fluid flow and through full movements.

⇒ Pinched suction line to pump; Replace hose, rout to prevent kinking or

pinching.

36 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 41

CHAPTER 7

DR DIRT BOSS TOWABLE BACKHOE ACCESSORIES

The optional Buckets and Digging Tooth provide more options for the type of digging you do by

enabling a choice of larger or smaller amounts of earth that can be loosened or moved.

CENTER THE BOOM. RETRACT THE BOOM, CROWD ARM AND BUCKET. INSTALL THE BOOM HITCH

PINS AND LYNCH PINS TO LOCK THE BOOM IN PLACE. SHUT DOWN THE ENGINE, REMOVE THE

SPARK PLUG WIRE AND WAIT 5 MINUTES BEFORE PERFORMING ANY MAINTENANCE PROCEDURE

OR INSPECTION ON THE BACKHOE.

Tools and Supplies Needed:

• Two 7/16" wrenches

• Hammer

• Brass Drift Punch

• Wood Blocks

• Safety Glasses

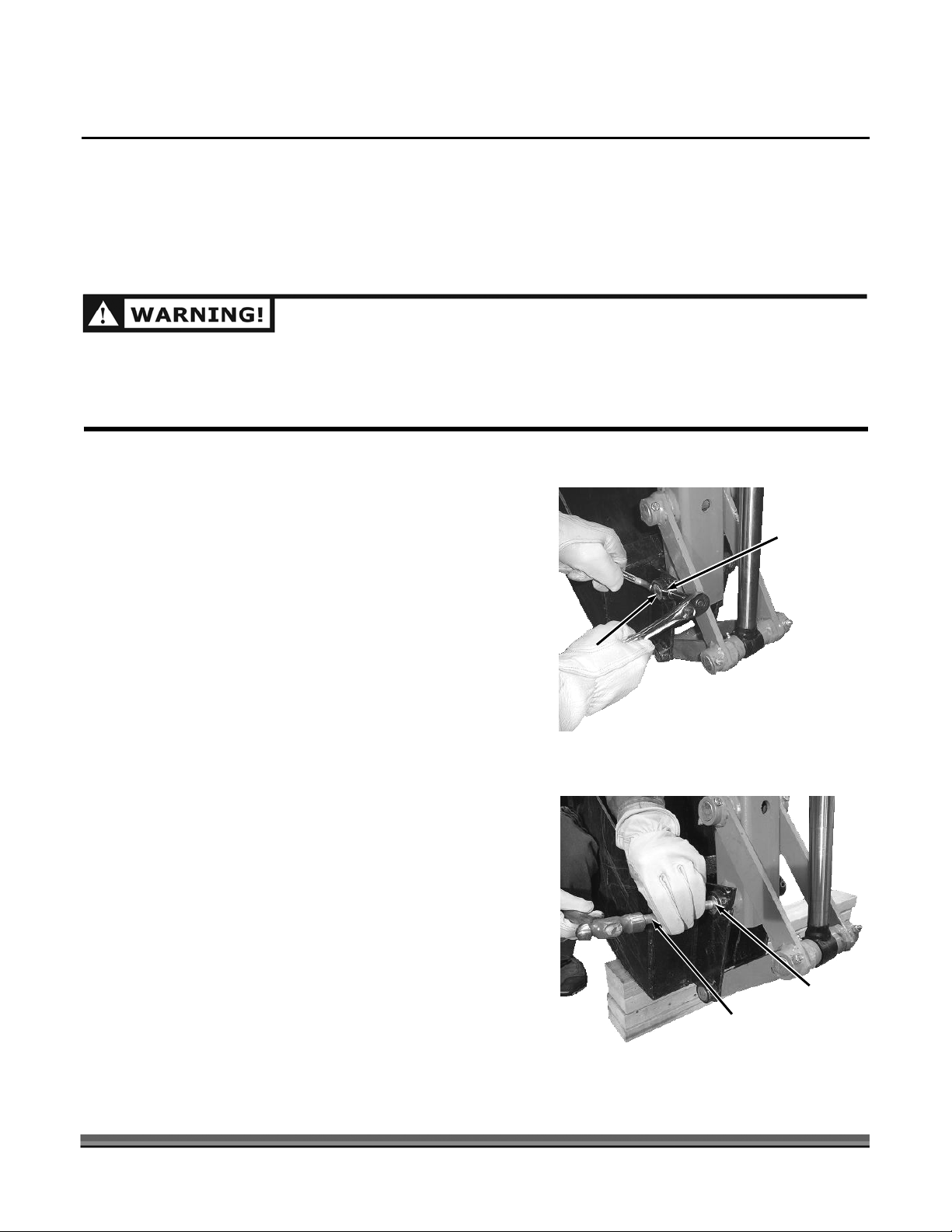

Installing a Bucket or Digging Tooth

1. Insert Wood Blocks under the Bucket for support.

2. Remove the four Bolts and Locknuts from the Bucket

Linkage Pins (Figure 37).

3. Use a Drift Punch to remove the two Linkage Pins

from the Bucket (Figure 38).

Bucket

Bolt and

Locknut

Linkage

Pin

Figure 37

Linkage

Drift

Punch

Figure 38

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 37

Pin

Page 42

Accessory

(Digging

Tooth

Shown)

Linkage

Pin

Figure 39

Wood

Block

Bolt and

Locknut

4. Remove the Bucket and position the accessory Bucket

or Digging Tooth at the same orientation as the

original Bucket.

5. Install the two Linkage Pins into the Bucket or Digging

Tooth and Linkage (Figure 39).

NOTE: Do not hammer directly on the Linkage Pin. Use a block of

wood so you do not damage the end of the Pin. Make sure the holes

in the Linkage Pins are aligned with the holes in the Accessory.

6. Install the four Bolts into the Linkage and Bucket or

Digging Tooth and secure with four Locknuts (Figure

40).

If you have any questions or need assistance, Please contact us

at www.Drpower.com or call toll free 1-800-DR-OWNER (376-

9637).

Figure 40

38 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 43

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 39

Page 44

CHAPTER 8

PARTS LIST AND SCHEMATIC DIAGRAMS

Parts List - LINKAGE, CROWD ARM AND BOOM ASSEMBLY

NOTE: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

01 245291 Crowd Arm

02 245301 Boom

03 245311 Linkage

04 245321 Strap, Linkage

05 245331 Bracket, Hose

06 245341 Bracket, Hose

07 245351 Pin

08 245361 Pin, Linkage

09 245371 Pin, Hitch, 3/4" x 6"

10 245381 Linchpin, 3/16" x 9/16"

Ref# Part# Description

11 245391 Screw, Hex Head Cap, 5/16-18 x

1-1/4"

12 245401 Locknut, 5/16-18

13 245411 Screw, Hex Head Cap, 1/4-20 x

2"

14 245421 Locknut, 1/4-20

15 245431 Fitting, Grease, 1/4-28

Safety & Information Labels

245441 Label, Warning

40 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 45

Schematic – LINKAGE, CROWD ARM AND BOOM ASSEMBLY

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 41

Page 46

Parts List – SWIVEL, MAIN BOX AND STABILIZER ASSEMBLY

NOTE: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

01 245451 Swivel

02 245461 Box, Main

03 245471 Plate, Foot

04 245481 Stabilizer

05 245491 Tube, Lock, Stabilizer

06 245501 Foot, Stabilizer

07 245511 Pin, Foot

08 245521 Pin, Stabilizer

09 245351 Pin

10 245541 Pin, Pivot

11 245551 Pin, Hitch 3/4" x 4-3/4"

12 245381 Linchpin, 3/16" x 1-9/16"

13 245571 Screw, Hex Head Cap, 3/8-16 x

4"

14 245581 Locknut, 3/8–16

15 245591 Bushing, 3/4"

16 245601 Holder, Hose

Ref# Part# Description

17 245611 Pin, Spring, 1/4" x 1-1/2"

18 245621 Washer, Thrust

19 245631 Locknut, 5/16–18

20 245801 Locknut, 5/16–18

21 245411 Screw, Hex Head Cap, 1/4-20 x

2"

22 245811 Screw, Slotted Truss Head, 1/4-

20 x 3/4"

23 245421 Locknut, 1/4-20

24 245681 Strip, Anti Skid

25 245431 Fitting, Grease 1/4-28

Safety & Information Labels

245701 Label, Warning

250441 Label, Pinch Point

42 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 47

Schematic – SWIVEL, MAIN BOX AND STABILIZER ASSEMBLY

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 43

Page 48

Parts List – HANDLE GUARD, VALVE MOUNT AND PANELS ASSEMBLY

NOTE: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

01 245731 Guard, Handle

02 245741 Cover, Valve

03 245751 Guard, Hose

04 245761 Mount, Valve

05 245771 Panel, Front

06 245781 Locknut, 3/8–16

07 246791 Screw, Hex Head Cap, 5/16–18 x

3/4"

08 245801 Locknut, 5/16–18

09 245811 Screw, Slotted Truss Head, 1/4-

20 x 3/4"

Ref# Part# Description

10 245821 Screw, Slotted Truss Head, 1/4-

20 x 1/2"

11 245421 Locknut, 1/4-20

Safety & Information Labels

250451 Label, Operator

245851 Label, Warning

246041 Label, Warning

245871 Label, Pin Placement

44 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 49

Schematic – HANDLE GUARD, VALVE MOUNT AND PANELS ASSEMBLY

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 45

Page 50

Parts List – CYLINDERS, PINS AND FITTINGS ASSEMBLY

NOTE: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

01 245881 Cylinder, Bucket

02 245891 Cylinder, Crowd Arm

03 245901 Cylinder, Boom

04 245911 Cylinder, Swing

05 245361 Pin

06 245931 Pin

07 245351 Pin

08 245951 Pin

09 245961 Pin

10 245971 Connector, 9/16-18 ORFS x 7/16

-20 ORB

11 245981 Elbow, Short, 9/16-18 ORFS x

7/16-20 ORB x 90 deg.

Ref# Part# Description

12 245431 Fitting, Grease, 1/4-28

13 245411 Screw, Hex Head Cap, 1/4-20 x

2"

14 245421 Locknut, 1/4-20

15 246021 Fitting, Grease, 1/4-28 x 45 deg

16 246031 Fitting, Grease, 1/4-28 x 90 deg

Safety & Information Labels

246041 Label, Warning

46 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 51

Schematic – CYLINDERS, PINS AND FITTINGS ASSEMBLY

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 47

Page 52

Parts List – HYDRAULIC HOSES AND CYLINDERS ASSEMBLY

NOTE: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

01 246051 Hose, Hydraulic, 1/4 x 130"

02 246061 Hose, Hydraulic, 1/4 x 127"

03 246071 Hose, Hydraulic, 1/4 x 78-1/2"

04 246081 Hose, Hydraulic, 1/4 x 75"

05 246091 Hose, Hydraulic, 1/4 x 78-1/2"

Ref# Part# Description

06 246201 Hose, Hydraulic, 1/4 x 84-1/2"

07 246211 Hose, Hydraulic, 1/4 x 27"

08 246221 Hose, Hydraulic, 1/4 x 21"

09 246231 Tie, Nylon

48 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 53

Schematic – HYDRAULIC HOSES AND CYLINDERS ASSEMBLY

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 49

Page 54

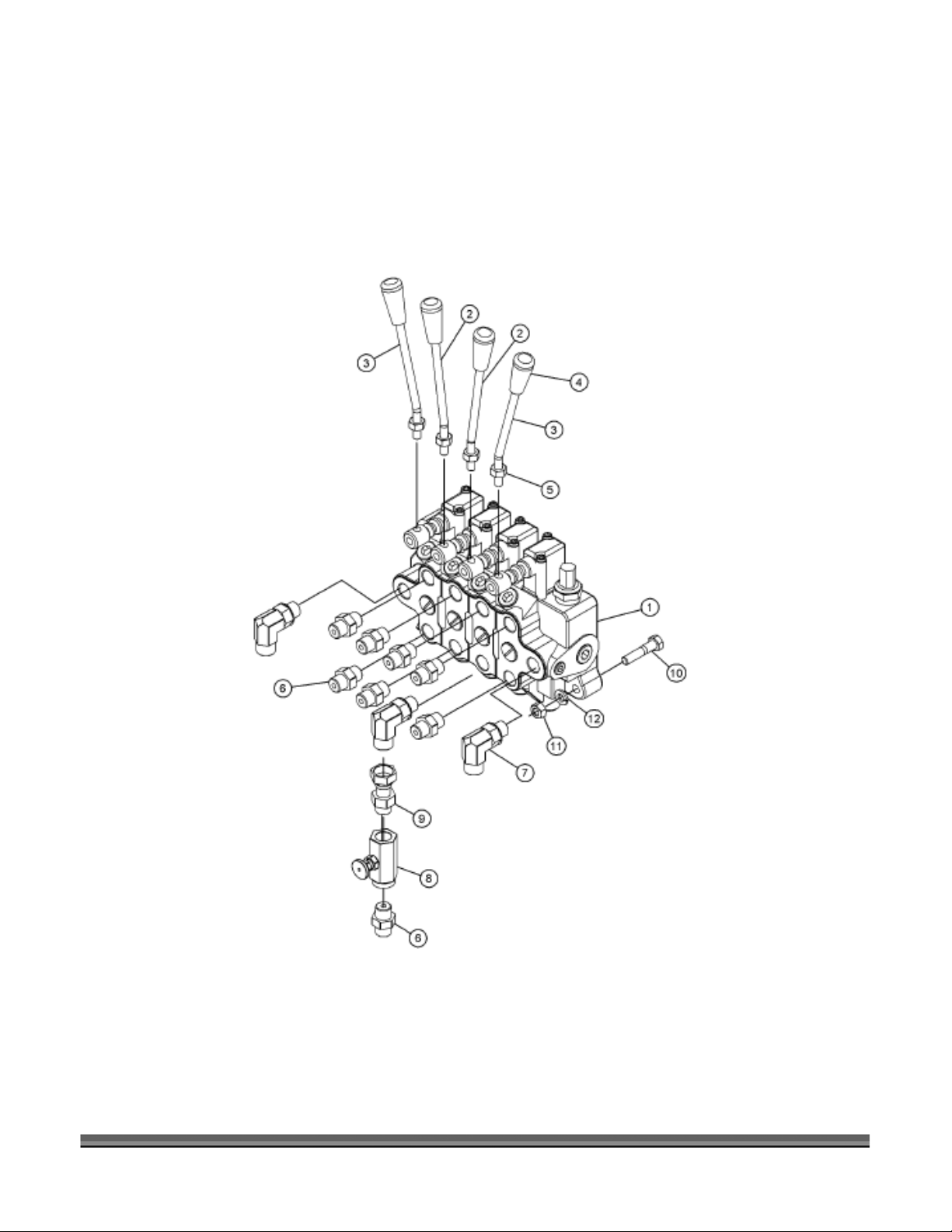

Parts List – VALVE AND FITTINGS ASSEMBLY

NOTE: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

01 246241 Valve, 4 Spool

02 246251 Handle Assembly

03 246261 Handle Assembly

04 246271 Knob

05 246281 Nut, Hex, 8mm–1.25

06 246291 Connector, Straight Thread

07 246301 Elbow, Straight Thread, 90 deg.

Ref# Part# Description

08 246311 Valve, Needle

09 246321 Connector, Swivel, Straight

Thread

10 246331 Screw, Hex Head Cap, 5/16–18 x

1-1/2"

11 245631 Nut, Hex, 5/16–18

12 246351 Lock Washer, 5/16

50 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 55

Schematic – VALVES AND FITTINGS ASSEMBLY

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 51

Page 56

Parts List – HOSE CONNECTION DETAIL

NOTE: This list and schematic are reference for attaching hose ends. Part numbers are listed on other

schematics.

Ref# Description

01 Hose, Hydraulic, 1/4 x 130"

02 Hose, Hydraulic, 1/4 x 127"

03 Hose, Hydraulic, 1/4 x 75"

04 Hose, Hydraulic, 1/4 x 78-1/2"

05 Hose, Hydraulic, 1/4 x 27"

Ref# Description

06 Hose, Hydraulic, 1/4 x 21"

07 Hose, Hydraulic, 1/4 x 78-1/2"

08 Hose, Hydraulic, 1/4 x 84-1/2"

09 Hose, Hydraulic, 3/8 x 43"

10 Hose, Hydraulic, 3/8 x 70"

52 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 57

Schematic – HOSE CONNECTION DETAIL

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 53

Page 58

Parts List – BUCKET AND TEETH ASSEMBLY

NOTE: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

01 246311 Bucket, Standard, 12”

02 246331 Tooth

Schematic – BUCKET AND TEETH ASSEMBLY

Not Illustrated

246301 Bucket, Standard, 9”

246321 Bucket, Standard, 16”

54 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 59

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 55

Page 60

Parts List – TONGUE AND AXLE ASSEMBLY

NOTE: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

01 246361 Weldment, Axle

02 246371 Hub

03 246381 Seal

04 246391 Bearing

05 246401 Washer

06 246411 Nut

07 246421 Pin, Cotter

08 246431 Cap-Dust

09 246441 Wheel

10 246451 Tire, 4.80-8

11 246461 Nut, Stud, Hub

12 246471 Weldment, Tongue

13 246481 Coupler

14 246491 Chains

15 246501 Jack

16 246511 Seat

17 246521 Stablizer, Rear, R.H.

18 246531 Stablizer, Rear, L.H.

19 246541 Cap, Vent, w/Dipstick

20 246551 Pin, Hitch, 1" x 5-3/4"

21 246561 Linchpin

Ref# Part# Description

22 246571 Screw, Hex Head Cap 1/2-13 x 1-

1/2"

23 246581 Locknut, 1/2-13

24 246591 Lockwasher, 1/2"

25 246601 Screw, Hex Head Cap, 3/8–16 x

1"

26 246611 Washer, Flat, 3/8"

27 246621 Lockwasher, 3/8"

28 246631 Screw, Hex Head Cap, 5/8–11 x

1-1/2"

29 246641 Locknut, 5/8–11

30 246651 Lockwasher, 5/8"

31 246661 Screw, Hex Head Cap, 1/2-13 x

4"

32 246671 Screw, Hex Head Cap, 3/8–16 x

4-1/2"

33 245581 Locknut, 3/8–16

Safety & Information Labels

250441 Label, Pinch Point

56 DR

®

BACKHOE

Page 61

Schematic – TONGUE AND AXLE ASSEMBLY

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 57

Page 62

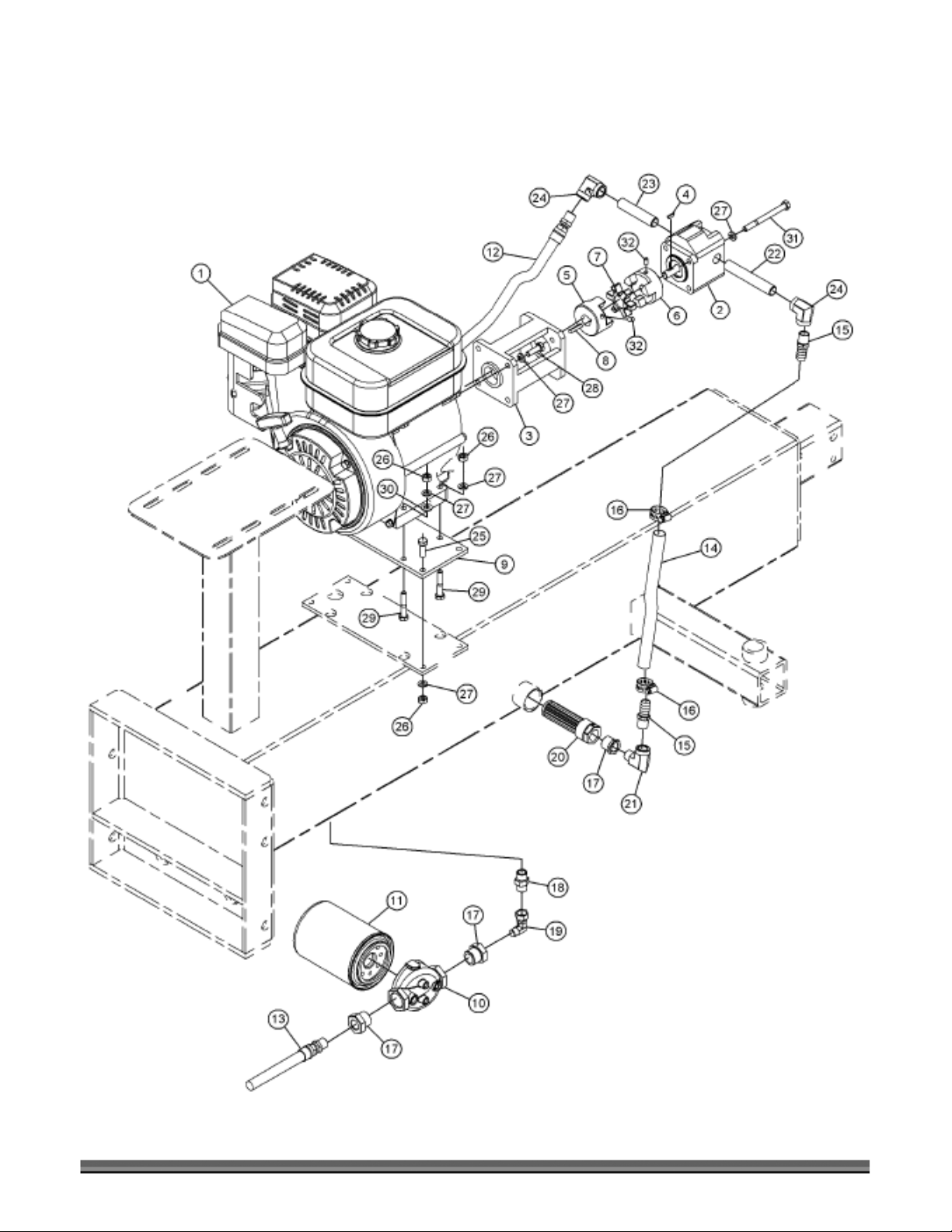

Parts List – ENGINE AND PUMP ASSEMBLY

NOTE: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

01 246701 Engine

02 246711 Pump, W/Key

03 246721 Mount, Pump-Engine

04 246731 Key, Woodriff, #2

05 246741 Coupler, 3/4"

06 246751 Coupler, 7/16"

07 246761 Spider

08 246771 Key, Square, 3/16" x 3/16" x 1"

09 246781 Plate, Mount, Engine

10 246001 Mount, Filter

11 245991 Filter

12 246011 Hose, Hydraulic, 3/8" x 70"

13 246241 Hose, Hydraulic, 3/8" x 43"

14 245531 Hose, Suction, 1/2" x 9"

15 246681 Fitting, Barb, Hose

16 246691 Clamp, Hose, #8

17 245651 Bushing, Reducer, 1/2" To 3/8"

18 245861 Nipple, Pipe, Ext., 3/8" x 3/8"

Ref# Part# Description

19 245661 Union, Swivel, 3/8" MNPT x 3/8"

FNPT, 90 Deg.

20 250561 Filter, Tank

21 245711 Elbow, Steel, 3/8" x 90 Deg.

22 245641 Nipple, 3/8" x 4"

23 245941 Nipple, 3/8" x 3"

24 245921 Elbow, Steel, 3/8" x 90 Deg.

25 245561 Screw, Hex Head Cap, 5/16–18 x

1"

26 245631 Nut, Hex, 5/16-18

27 246351 Washer, Lock, 5/16"

28 250571 Screw, Hex Head Cap, 5/16–24 x

1"

29 245691 Screw, Hex Head Cap, 5/16–18 x

1-3/4"

30 245671 Washer, Flat, 5/16"

31 245841 Screw, Hex Head Cap, 5/16-18 x

3-1/2"

32 245831 Screw, Set, 1/4-20 x 3/8"

58 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 63

Schematic – ENGINE AND PUMP ASSEMBLY

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 59

Page 64

Notes:

60 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 65

Notes:

CONTACT US AT www.DRpower.com or CALL TOLL FREE 1-800-DR-OWNER 61

Page 66

62 DR

®

DIRT BOSS™ TOWABLE BACKHOE

Page 67

D

R

BACKHOE

2-Year Limited Warranty

Terms and Conditions

The DR® BACKHOE is warranted for two (2) years against defects in materials or workmanship when put to ordinary

and normal consumer use; ninety (90) days for any other use.

For the purposes of all the above warranties, “ordinary and normal consumer use” refers to non-commercial residential

use and does not include misuse, accidents or damage due to inadequate maintenance.

®

®

DR Power Equipment certifies that the DR

used. DR Power Equipment however, limits the implied warranties of merchantability and fitness in duration to a period

of two (2) years in consumer use, ninety (90) days for any other use.

The 2-Year Limited Warranty on the DR® BACKHOE starts on the date the machine ships from our factory. The 2-Year

Limited Warranty is applicable only to the original owner.

The warranty holder is responsible for the performance of the required maintenance as defined by the manufacturer's

owner's manuals. The warranty holder is responsible for replacement of normally wearing parts such as the Filters,

Bucket Teeth and Wheels. Accessories to the machine are not covered by this warranty.

BACKHOE is fit for ordinary purposes for which a product of this type is

During the warranty period, the warranty holder is responsible for the machine transportation charges, if required.

During the warranty period, warranty parts will be shipped by standard method at no charge to the warranty holder.

Expedited shipping of warranty parts is the responsibility of the warranty holder.

SOME STATES DO NOT ALLOW LIMITATIONS ON THE LENGTH OF IMPLIED WARRANTIES, SO THE ABOVE

LIMITATIONS MAY NOT APPLY TO YOU.

DR Power Equipment shall not be liable under any circumstances for any incidental or consequential damages or

expenses of any kind, including, but not limited to, cost of equipment rentals, loss of profit, or cost of hiring services to

perform tasks normally performed by the DR

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

®

BACKHOE.

Customer Service Hotline

DR Power Equipment’s objective is to have 100% satisfied customers. For that reason, we operate a 6-day-a-week

Technical Service Department for our Owners. You can access a Representative by dialing our TOLL-FREE Hotline at 1800-DR-OWNER (376-9637). The sole job of our well-trained and friendly folks is to ensure that you get any help you

need in a timely fashion. They are there to answer all your questions including: (1) inquiries on any of the above

warranties, (2) inquiries about replacement parts, or (3) your questions regarding service, maintenance and operation.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU ALSO HAVE OTHER RIGHTS, WHICH VARY

FROM STATE TO STATE.

Page 68

Daily Checklist for the DR DIRT BOSS TOWABLE BACKHOE

To help maintain your DR DIRT BOSS TOWABLE BACKHOE for optimum performance, we recommend

you follow this checklist each time you use your Backhoe.

CENTER THE BOOM. RETRACT THE BOOM, CROWD ARM AND BUCKET. INSTALL THE BOOM HITCH

PINS AND LYNCH PINS TO LOCK THE BOOM IN PLACE. SHUT DOWN THE ENGINE, REMOVE THE

SPARK PLUG WIRE AND WAIT 5 MINUTES BEFORE PERFORMING ANY MAINTENANCE PROCEDURE

OR INSPECTION ON THE BACKHOE.

BE SURE THE AREA IS CLEAR OF UNDERGROUND OBSTRUCTIONS. CALL “811” BEFORE YOU DIG.

[ ] Check the engine oil level.

[ ] Check the general condition of the Backhoe, e.g.; nuts, bolts, welds etc.

[ ] Check Tire Pressure

[ ] Check Hydraulic Hoses and Connections

[ ] Lubricate Grease Fittings

DR® Power Equipment

75 MEIGS ROAD, P.O. BOX 25, VERGENNES, VERMONT 05491

1-800-DR-OWNER (376-9637) • www.DRpower.com ©2008 CHP, Inc. 247111

Loading...

Loading...