Page 1

DR STUMP GRINDER

Safety & Operating Instructions

Model: 9 HP CPSC92CHP

This manual contains information concerning proper and improper operating

procedures, warnings, maintenance, troubleshooting, assembly, and tips.

Everyone who operates this machine should read these instructions and be

thoroughly familiar with them.

Form 807-0151

03/26/04

Page 2

SECTION I - SAFETY

WARNING

Rules for Safe Operation

WARNING: To reduce the potential for any injury, comply with the

Read this owner’s manual carefully in its entirety before attempting to assemble or operate this machine. Keep

this manual in a safe place for future and regular reference and for ordering replacement parts. The operator

must familiarize themselves with the controls when the handle is swung from the front to the rear position, as

the throttle and brake controls are reversed.

Never use your stump grinder for any purpose other than chipping or cutting

stumps and roots. It is designed for this use and any other use may cause injury.

instructions in this manual. Failure to comply with the

instructions may result in personal injury.

TRAINING

INTENDED USE

DANGER

DANGER: Rotating cutting teeth. Keep hands and feet out from under the machine when running.

DANGER: This machine can CUT and SEVER parts of your body if they are placed in the area of the

cutter head while the unit is running.

2

Page 3

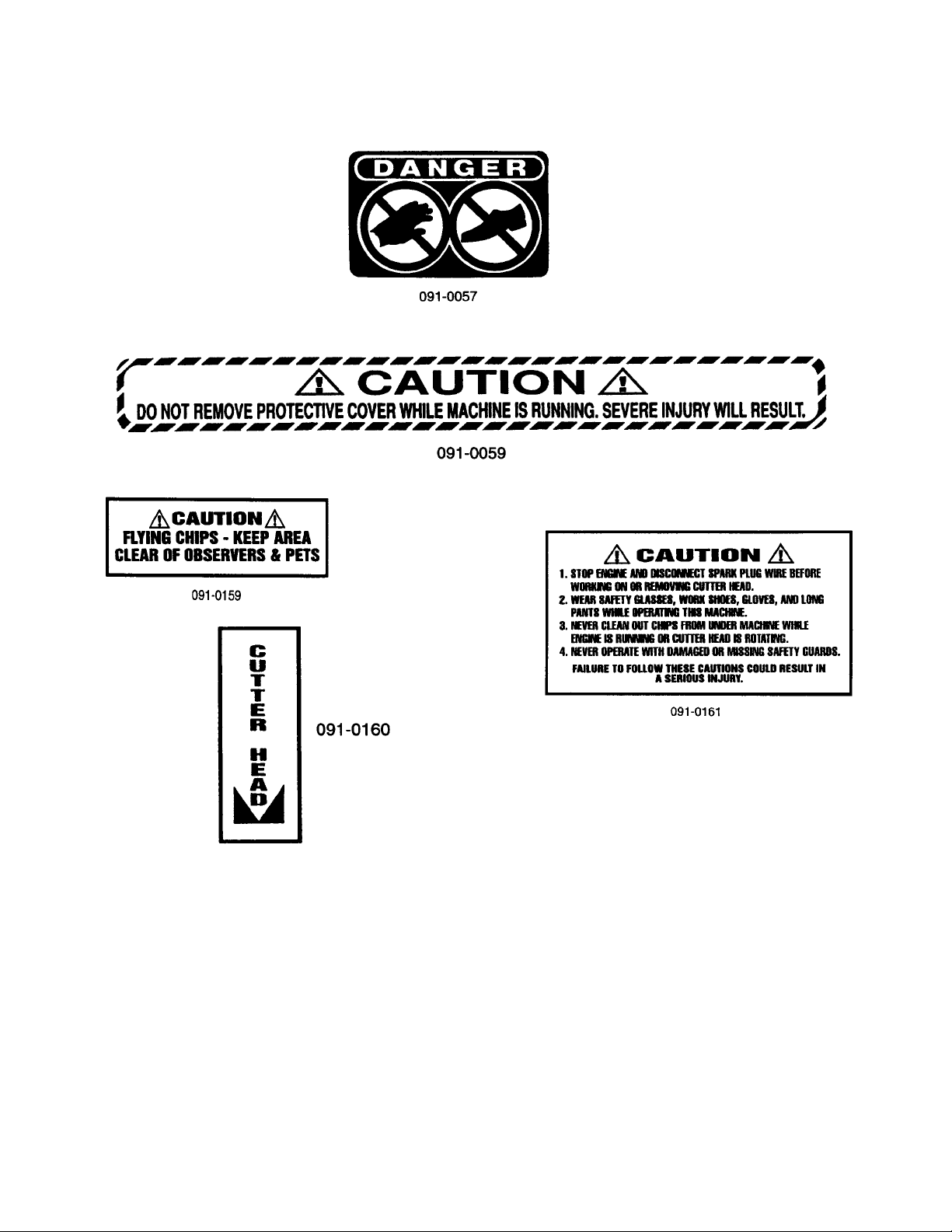

Make certain that all safety labels on this equipment are kept clean and in good

condition. If you need replacement labels, please order by part number.

OPERATOR’S RESPONSIBILITY

• Never allow children to operate your stump cutter, or adults without the proper instructions. Keep children,

pets, and bystanders a minimum of 20 feet away from your work area. Flying chips can be hazardous.

• Never run this machine in an enclosed area since the exhaust from the engine contains carbon monoxide,

which is an odorless, tasteless, and deadly poisonous gas.

• Never put your hands, feet, face, or any other part of your body near the cutter head while the engine is

running.

• Never operate your stump cutter while under the influence of alcohol, drugs, or medication. A clear mind is

essential for safety.

• Never allow a person who is tired or otherwise not alert to operate this machine.

• Never operate this machine with any damaged parts or guarding removed.

3

Page 4

SAFETY WEAR

Never wear loose clothing or jewelry that can be caught by moving parts of your stump cutter and

pull you into it. Keep all clothing away from moving parts. Wear proper headgear to keep hair

away from moving parts.

Always wear safety glasses provided with your unit at all times while operating your stump

cutter. A chip could fly out and hit you in the eye. Be sure your glasses fit properly.

SAFETY OPERATING PROCEDURE

If it is necessary for any reason to inspect or repair any part of the machine, stop the machine, allow it to cool,

disconnect the spark plug wire from the spark plug and move it away from the spark plug before attempting

such inspection or repair. Whenever you operate your stump cutter, wearing safety glasses is required.

Before each use, check all three controls; brake, throttle, clutch, to be sure they are functioning properly.

The operation of any stump cutter can result in foreign objects being thrown into the eyes, which can result in

severe eye damage. Always wear the safety glasses provided with the stump cutter or eye shields before

chipping or while performing any adjustments or repairs.

OPERATE IN A SAFE ENVIRONMENT

Operate equipment only in daylight or in good artificial light.

Extreme care must be taken when operating your machine on a side hill. It could tip, or poor footing could

cause an accident. Do not operate the machine parallel to the hill. Always stand uphill from the stump.

A. Secure handle in front or rear position.

B. Do not use your machine on muddy or icy surfaces.

C. Never leave your machine unattended with the engine running.

Thoroughly inspect and clear work area of objects that might be picked up and thrown. Remove all stones,

sticks, wires, bones and other foreign objects. Beware of hidden objects located above or below ground, such

as electric wires, gas or water lines, and sprinkler systems. DO NOT BEGIN TO CHIP STUMPS unless you are

sure the area is clear.

1. Know how to turn the machine off.

2. HANDLE GASOLINE WITH CARE as it is an extremely flammable fuel.

3. Check the fuel before starting the engine. Do not fill the fuel tank indoors, while the engine is running, or

while the engine is still hot. Turn the unit off and let the engine cool for at least three minutes before

refueling. Fuel your stump cutter in a clean area to avoid getting dirt in the gas tank. Do not smoke while

refueling. Fuel tank cap must be secure at all times except during refueling. Avoid spilling gasoline or oil.

Wipe the unit clean of any spilled fuel or oil.

4. Store fuel and oil in approved containers, away from heat or open flame, and out of reach of children.

Leave 1/2-inch air space at top of fuel tank to allow for expansion of fuel.

REPAIR AND MAINTENANCE SAFETY

Never operate your stump cutter in poor mechanical condition. Periodically check that all nuts,

bolts, screws, and belts are tightened to specifications. Be sure all safety guards and shields are

in proper position. These safety devices are for your protection.

Be sure to read and follow engine owner’s manual for engine maintenance and repair.

BEFORE STARTING ENGINE, ALWAYS CHECK OIL LEVEL

4

Page 5

SECTION II - ASSEMBLY INSTRUCTIONS

PACKAGE CONTENTS

SKID POLYBAG

STUMP GRINDER OWNER’S MANUAL

HANDLE ASSEMBLY ENGINE MANUAL

POLYBAG SAFETY GLASSES

ALLEN WRENCH

4 EA – CABLE TIES

STEP 1 - UNPACKING AND CHECKING CONTENTS

1. Remove all pieces from the skid.

2. Compare all items with the list above.

3. If any parts appear missing or damaged, contact Country Home Products at 1-800-376-9637.

4. Assembly should be done on a clean and level surface.

STEP 2 - INSTALLING HANDLE SUPPORT

1. Loosen and remove the two bolts mounting the handle support (item #23, pg. 15) to the bumper straps (item

#22, pg. 15).

2. Flip the handle support to the upright position with the six adjustment holes above the bumper straps.

3. Replace and tighten the bolts through the bumper straps to the handle support that were removed in step 1

STEP 3 - INSTALLING HANDLE ASSEMBLY

The handle assembly is packed with the cables attached, so be careful not to over extend the handle away from

the stump grinder and break them loose.

1. Remove bolt and nut (items #50 & #64, pg. 15) from the pivot pin weldment (item #13, pg. 15) and pull it out

of the pivot bracket.

2. Carefully pick up the handle assembly (item #14, pg. 15) and put it in place so that the bend is down and the

handle grips are at the cutter head end (rear position). NOTE: Care needs to be taken to prevent the

cables from being torn loose, dislodged, or pinched.

3. Insert pivot pin through the first hole on the handle mount plate (item #9, pg. 15), through the lower handle

tube, and into the other hole on the handle mount plate.

4. Secure the pivot pin with the hardware you removed in step 1.

5

Page 6

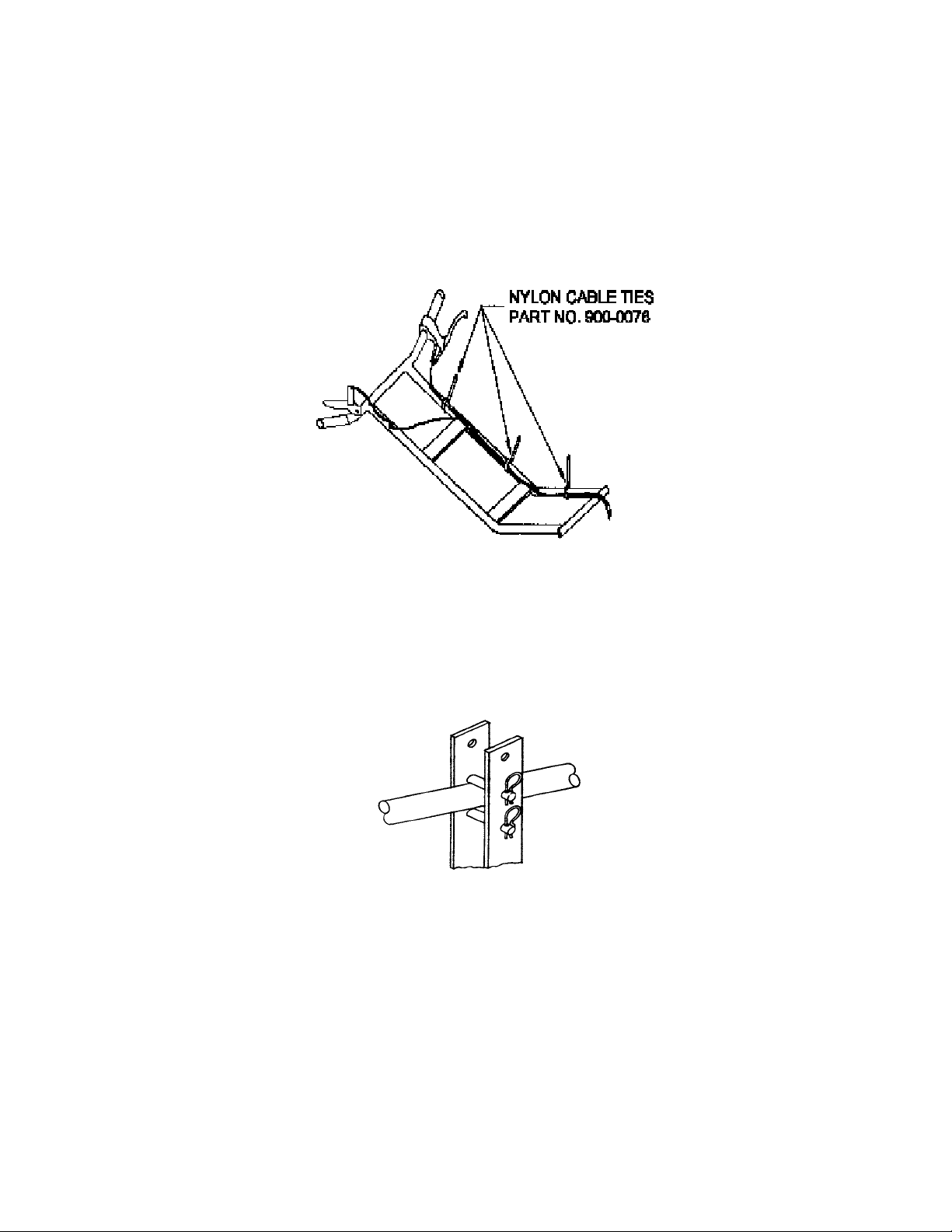

STEP 4 - SECURING THE CABLES

1. Four cable ties have been provided for fastening the cables to the handlebar after it has been installed.

Refer to figure 2 for the correct mounting points of the cable ties.

2. Attach the clutch cable in the center of the handlebar mounting pivot at point #1. Loop the cable so it

provides plenty of clearance from the belt guard and does not bind when the handle is rotated to the front

position. This attachment also keeps the cable away from the idler pulley.

3. With the handle in the rear position, opposite the cutter head, install the other cable ties at points 2, 3 and 4

(fig. 2).

4. Swing the handles from the front to the rear position while checking to make sure the cables do not bind or

become kinked.

fig. 2

STEP 5 - POSITIONING THE HANDLE

1. You can secure the handle in the front or rear position as well as adjust for height with the clevis pins (item

#78, pg. 15) and hair cotters (item #79, pg. 15) provided as shown in figure 3.

2. Note: Brake, throttle and clutch controls will be reversed when handle is switched from front to rear

position.

fig. 3

BEFORE STARTING ENGINE, ALWAYS CHECK OIL LEVEL

GREASE CUTTER HEAD BEARINGS

SEE MAINTENANCE SECTION FOR INSTRUCTION

6

Page 7

SECTION III - LUBRICATION & ENGINE START UP

FOR INFORMATION ABOUT:

1. OIL

2. FUEL

3. STARTING

4. STOPPING

5. RECOMMENDED MAINTENANCE

6. SERVICE

7. STORAGE

8. ENGINE WARRANTY INFORMATION

REFER TO THE ENGINE OWNER’S MANUAL.

THE ENGINE ON YOUR STUMP GRINDER HAS BEEN SHIPPED DRY.

BE SURE TO SERVICE THE ENGINE ACCORDING TO THE

ENGINE OWNER’S MANUAL PRIOR TO STARTING.

FAILURE TO DO SO CAN RESULT IN DAMAGE NOT WARRANTIED BY

THE ENGINE MANUFACTUROR.

WARNING: Do not fill closer than ½” from the top of the fuel tank to prevent spills and to allow for fuel

expansion. If gasoline is accidentally spilled, move the mower away from the area of the spill. Avoid creating

any source of ignition until gasoline vapors have disappeared.

CAUTION: Experience indicates that alcohol blended fuels (gasohol, ethanol, methanol) can attract moisture

which leads to separation and formation of acids during storage. Acidic gas can damage the fuel system or an

entire engine while in storage. To avoid engine problems, the fuel system should be empty before storage for

periods over 30 days. For more information, refer to the engine owner’s manual. Use fresh fuel each season.

Never use engine or carburetor cleaner products in the fuel tank or permanent damage may result.

ALWAYS CHECK OIL LEVEL PRIOR TO STARTING

THE STUMP GRINDER.

7

Page 8

SECTION IV-OPERATION

These operating instructions are designed to help you get the most out of your stump cutter.

1. It is suggested that tall stumps always be cut to near ground level with a chain saw prior to cutting with this

machine. This is a big time saver.

2. Use a mattock or other digging tool to remove dirt and stones from around the stump as deep as you intend

to cut. This is important to prolong the life of the cutter teeth. Stones that are solidly embedded in the

stump and can’t be seen will only dull the cutting teeth. The loose stones should be removed since they

can chip a tooth or be thrown by the cutter head. Your cutter head is affixed with teeth of a mining grade

tungsten carbide. It will continue to cut in spite of stones, but the fewer stones it strikes-the better.

3. Select the desired handle location for the job. Remove the hair cotter and the clevis pin (items #78, #79, pg.

15). Swing the handle (item #14, pg. 15) over to convert the stump cutter to a front or rear cutter. If the

stump is close to a building or fence, have the cutter head in front. If the stump is in the open, you may find

it is easier to chip with the cutter head in the rear. You can also change the height of the handles by

positioning the clevis pin in one of several locations. Always secure the clevis pin with the hair cotter pins.

(Figure 3 pg. 6).

NOTE: Front Position

head.

Rear Position

4. If the ground is very soft, place a sheet of plywood around the stump, especially on the sides. Pull or push

the machine up onto the stump so that about 1/3 (3” or 4”) of the cutter head is nearly touching the stump.

5. Once the machine is positioned over the stump, squeeze the brake handle to lock the wheel. The brake

locks one wheel only and allows you to make a sweeping motion with the cutter head. You can hold the

brake on with one hand or lock it in position by depressing the brake handle lock (item C, Figure 6). To

unlock the brake, simply squeeze the lever and release.

– Operator position and handle on engine end of machine, farthest from cutter

– Operator position and handle on cutter head end of machine.

fig. 6

8

Page 9

1. Move kickstand to mid-position for rear-cutting and top position for front cutting. While not in use, move the

kickstand to the down position. This keeps the cutter head off the ground, preventing damage to the cutter

teeth.

NOTE: Never adjust the kickstand while the cutter head is in motion.

1. Move throttle control to the run position. The engine will stall if you engage the cutter head while the engine

is in idle.

2. Hold operator presence handle down against the rest of handle. This will engage the cutter head. When

the operator presence handle is released, the cutter head will stop in less than two seconds. Test the unit

before operating to make sure the clutch is performing properly. If the clutch does not perform properly

discontinue use immediately.

fig. 7

1. Start to cut the stump at the extreme left (rear position) or extreme right (front position). Swing the cutter

head across the stump, cutting approximately 2” of wood at each pass. As you become more familiar with

your machine, you will be able to cut left to right and right to left. The hardness of the wood and the

sharpness of the teeth will dictate how deep and how fast you cut. See figure 8.

fig. 8

1. At the end of each pass, allow the engine to recover to full speed. Release the brake to push or pull the

cutter further into the stump, re-lock the brake and continue cutting.

2. Continue to cut across the stump until entire stump is at ground level. To cut below ground level, position

cutter head in the center of the stump and work towards the outer edges.

9

Page 10

HELPFUL HINTS

1. Chips are contained by the rubber guards and may begin to build up between the wheels.

Should there be excessive build-up, release throttle and move unit out of position and rake or

shovel away the chip build-up. A power blower or vacuum works well.

2. On larger stumps, if you continue to cut from one location, eventually a wheel may want to roll

into the hole. Before this happens, move to a different side of the stump to continue cutting.

3. It is a good idea to never operate the machine with the engine more than 30 degrees from

horizontal. This could cause engine damage due to lack of lubrication. This problem could

happen when a stump is on a steep hill. Try to cut the stump with the least amount of tilt.

WARNING

If the cutting head strikes a rock or curb and starts making an unusual noise or vibrating excessively:

1. Stop the engine immediately.

2. Disconnect the spark plug wire from the spark plug.

3. Allow the engine to cool.

4. Inspect for obvious damage.

5. Check for loose parts and tighten to assure continued safe operation.

6. Replace or repair any damaged parts.

10

Page 11

SECTION V - MAINTENANCE

LUBRICATION OF THE ENGINE

Check engine oil level regularly-WHILE THE UNIT IS IN A LEVEL POSITION. Check the oil every five hours of

operation and before each usage. Stop engine and wait several minutes before checking oil level. With engine

level:

1. Remove the oil filler plug and check oil level. It should be to the top of the fill plug.

2. If the level is low, fill to the top of the fill plug.

Change oil after the first five hours of operation and every 25 hours thereafter. Refer to the engine manual

enclosed with this unit for additional information on your engine.

AIR CLEANER

Refer to the engine manual for additional information on the air filter

1. Do not operate engine if air cleaner or cover directly over carburetor air intake is removed. Removal of

such parts could create a fire hazard.

2. Do not use flammable solutions to clean the air filter.

BEARINGS

Grease cutter head bearings after every use. Greasing should be done after unit has been washed down as

water pressure can remove grease from the bearings. The greasing process will remove any water that has

penetrated the bearing. Lubricate bearings with a #2 lithium based grease while manually rotating cutter head

until fresh clean grease is seen purging from the bearing seals.

BELT TENSION

Check belt tension frequently. This is especially important in the first one hour of use. Once the belt is “seated”

and initially stretched (approximately two hours), recheck the tension. You should check the tension each time

you use the machine. To test belt tension, push down on the belt at mid span with moderate pressure. The belt

should move approximately 1/2”.

To adjust belt tension:

1. Loosen the four motor bolts

2. Tighten or loosen the adjustment nut on the belt tensioner (item #36, pg. 15) until desired belt

tension is reached.

3. Retighten the four motor bolts.

CALIPER BRAKES

The brake is needed to prevent the machine from moving away from the stump during cutting. To adjust the

brake:

1. Loosen the locking nut on the brake handle. (Item B, fig. 9)

2. Turn the brake adjuster (Item A, fig. 9) out, away from the handle, a few turns.

3. Continue to check to see if the brake is holding.

4. When the brake “holds”, the correct adjustment is reached. Re-tighten the locking nut. (Item B, fig. 9).

fig. 9

11

Page 12

1. If correct adjustment cannot be achieved at the handle, turn the brake adjuster all the way in and adjust

brake tension at the brake caliper.

2. To adjust brake at caliper (item #26, pg. 15), loosen locking nut (Item B, fig. 10). Turn adjusting screw (Item

A, fig. 10) in until brake is holding. Retighten locking nut (Item B, fig. 10).

fig. 10

CLUTCH ADJUSTMENT

Your Stump Grinder is equipped with a brake clutch that controls the motion of the cutter head. When engaged

the clutch allows the cutter head to spin, when disengaged the clutch will stop the cutter head in under 2

seconds. It is critical that the clutch control cable be adjusted properly.

To adjust the clutch control cable:

1. Remove belt guard and disconnect clutch control cable from spring attached to clutch engagement lever

(item C, fig. 11).

2. With engagement lever fully forward measure 1 ½ “ backwards from the left hand edge of the lever and

make a mark on the clutch housing.

3. Re-connect the clutch control cable and adjust the jam nuts (item A, fig. 11) forwards or backwards as

necessary so that the lever does not pull backwards.

4. Compress the operator presence handle and check that left hand edge on the engagement lever moves

to the mark on the clutch housing.

5. Adjust cable accordingly if lever moves to the left or right of the mark.

6. If more adjustment is needed, move the cable end support (item B, fig. 11) as necessary.

Clutch cable tension should be checked periodically along with belt tension.

fig. 11

CLUTCH SERVICING

The clutch is shipped from the factory assembled and adjusted. No internal adjustment is available to the end

user. For service, return the clutch to the factory.

STORAGE

Never store your stump grinder indoors or in an enclosed, poorly ventilated area if gasoline remains in the tank.

Fumes may reach an open flame, spark or pilot light from a furnace, water heater, clothes dryer, cigarette, etc.

When not in use, your machine should be stored out of reach of children with the spark plug removed. Always

allow the engine to cool before storing of covering. For long periods of storage (over winter), please refer to the

engine owner’s manual.

12

Page 13

SECTION VI – CUTTER HEAD

The cutter head is fastened to the mounting flange on the spindle with four 3/8-16 x 1-3/4” bolts. Be sure to

check them frequently for tightness. (Figure 12)

TEETH

Your stump cutter is equipped with carbide tipped teeth. (Items 24d, 24e, 24f, pg. 15) Carbide retains its

sharpness longer, cuts faster and smoother and can withstand heat, but they will wear. Sharpen the teeth

before excessive wear or when they look dull or rounded. Check the teeth on the cutter head after each use.

Always check the 45-degree tooth first because it is the most abused being a “digger and leader”. Any cutter

tooth with less than a 10-degree relief (see fig. 15, pg. 14) will cause poor performance, smoke and burn marks.

By keeping the teeth sharp, you will prevent frustration at the job site. It only takes a few minutes to touch them

up before you go out on a job. If the unit receives heavy use, a second cutter head assembly can be purchased

as a back up while the other head is being sharpened.

fig. 12 fig. 13

FOR PROPER OPERATION:

1. Teeth should be installed according to the pattern shown in Figure 13 above.

2. Cutter head must never be run with a missing or damaged tooth.

CAUTION: Excessive vibration is usually a result of broken or missing teeth. Stop engine, disconnect spark

plug wire and inspect.

TO SHARPEN

Teeth can be removed and sharpened individually or while still attached to the cutter head.

1. Remove entire cutter head (see figure 12) by removing the four 3/8”-16 nuts and bolts.

2. To remove the teeth from the cutter head, remove the 9 cap screws using the 5/16” Allen wrench

provided.

3. Tap any of the 9 teeth with a soft hammer to “pop” the cover off the cutter body.

4. Remove the 9 teeth from their slots.

WARNING: WHEN SHARPENING TEETH, ALWAYS WEAR EYE PROTECTORS AND A

DUST MASK OR RESPIRATOR. CARBIDE DUST CAN BE DANGEROUS IF INHALED.

13

Page 14

5. Any bench-type or pedestal style grinder with a “Green wheel” (silicon carbide grinding wheel or

diamond wheel) may be used on the carbide teeth. A regular gray wheel (coarse grinding wheel) is

needed for grinding the steel relief. It is best if you can set up the grinder with a coarse wheel on one

side and “Green Wheel” on the other side.

6. Teeth may be ground free hand since precision is not important. Any variance between teeth will not be

noticed.

7. Using the “Green Wheel”, grind the end of the carbide until the edge is sharp. Avoid grinding on the

face of the carbide, which would reduce its thickness and weaken it, making it more susceptible to

cracking and chipping. (Figure 14)

fig. 14

8. As the end of the carbide is ground away, you will have to grind “relief” on the square steel shank. The

steel must be ground with the regular coarse grinding wheel and not the “Green Wheel”.

9. Although the angle is not critical, always grind the tooth so that there is enough “relief” under the

carbide edge (minimum 10 degrees). (Figure 15)

fig. 15

10. The tooth may continue to be ground until the carbide has approximately 1/4” remaining (Figure 16).

fig. 16

11. Before reinstalling the teeth, wire brush the inside of the cutter body and the cap screws. Spray with

light oil or WD40 and reassemble. Remember to reassemble teeth in the same order: 45 degree offset,

25 degree offset, and straight; repeated three times (Figure 13, pg. 13). Make sure to align the notch in

the teeth with the slot in the cutter head body so the cover plate can be assembled properly.

12. Torque cap screws on cover plate (item #24c, pg. 15) to 25 ft. lb. the first time around to insure even

pressure on the teeth. Alternate tightening screws in a crisscross pattern. Final tighten to 45 ft. lb.

13. The teeth can also be sharpened without removing them from the cutter head. Sharpen them free hand

by holding the entire head up to the grinding wheels.

14. To reassemble cutter head to drive shaft weldment:

15. Clean mating surfaces of cutter head and shaft. Spray both with light oil or WD40.

16. Reinstall cutter head using new 3/8” split lock washer and nuts

17. Pre-tighten nuts in crisscross pattern to 25 ft. lb. Final tighten to 45 ft. lb.

CAUTION: CHECK FOR LOOSE PARTS BEFORE USING YOUR STUMP GRINDER.

14

Page 15

Page 16

ITEM NO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

24a

24b

24c

24d

24e

24f

24g

24h

24j

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

CPSC92CHP PARTS LIST

. PART NO. QTY. DESCRIPTION

807-0101

807-0104

807-0121

807-0122

807-0137

807-0060

807-0154

807-0109

807-0110

807-0111

807-0118

807-0119

807-0025

807-0068

807-0140

807-0141

807-0124

807-0128

807-0129

807-0130

807-0131

807-0132

807-0133

807-0070

807-0007

807-0008

090-0513

807-0001

807-0002

807-0003

090-0113

090-0228

090-0207

030-0279

807-0006

807-0005

807-0013

030-0246

807-0059

807-0134

807-0135

807-0136

909-0012

030-0399

913-0044

807-0116

807-0153

807-0037

500-0041

030-0269

030-0268

807-0004

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

9

3

3

3

4

4

4

2

1

1

2

2

3

1

1

1

1

1

1

1

1

1

2

1

1

1

Machine Base Weldment

Cutter Head Support Weldment

Brake Plate

Brake Cable End Mount

Axle

Wheel Spacer

Kickstand Bracket

Kick Guard

Handle Mount Plate

Adjustment Plate

Idler Bracket

Cable End Support

Pivot Pin Weldment

Handle Weldment

Clutch Plate- Clutch

Clutch Plate- Engine

Belt Guard Weldment

Inner Guard

Guard Mount- Cutter End

Guard Mount- Engine End

Bumper Tube

Bumper Strap

Handle Support

Cutter Head Assembly

Cutter Head Body

Cutter Head Cover

3/8-24 x 1” Socket Head. Cap Screw GR8

Cutter Teeth - Straight

Cutter Teeth - 25 Degree LH

Cutter Teeth - 45 Degree LH

3/8-16 x 1 3/4 HHCS GR5 PLTD

3/8 Split Lock Washer PLTD

3/8-16 Hex Nut PLTD

1 3/16” 2 Bolt Bearing

Brake Caliper

Brake Rotor

Wheel 13/5.00-6 W/1” Dia. Hub

1” Drive Shaft Bearing

Axle Locking Collar

Drive Side Guard

Engine Side Guard

Open Side Guard

Idler Sheave

Engine- 9HP B & S Intek

Belt Tensioner

Clutch Control Cable

Throttle Control

Brake Handle

Black Handle Grip 7/8” x 5”

Clutch Brake CB62S

5H740 Belt

Pulley- 5 3/4” Dia.

16

Page 17

CPSC92CHP PARTS LIST

ITEM NO

. PART NO. QTY. DESCRIPTION

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

030-0118

030-0117

090-0013

090-0066

090-0072

090-0073

090-0088

090-0089

090-0110

090-0111

709-3408

090-0119

090-0153

090-0162

090-0226

090-0232

090-0233

090-0234

090-0394

090-0438

090-0460

090-0461

090-0470

090-0503

090-0617

703-0424

807-0036

807-0057

703-0425

080-0053

020-0001

709-3409

090-0497

807-0146

807-0056

100-0015

807-0035

090-0024-3

900-0074

090-0418

807-0009

500-0031

807-0156

090-0248

090-0400

706-1539

030-0286

1

2

1

9

12

4

3

3

4

4

1

1

1

2

1

2

27

4

3

4

31

12

2

35

1

2

1

1

1

3

2

1

1

1

2

2

1

7

4

2

1

1

1

2

2

2

1

Bushing 1 3/16”

Retaining Ring 1 3/16

1/4-20 x 1 3/4 HHCS GR5 PLTD

5/16-18 x 3/4 HHCS GR5 PLTD

5/16-18 x 2 HHCS GR5 PLTD

5/16-18 x 2 1/4 HHCS GR5 PLTD

5/16-18 x 1 HHCS GR5 PLTD

5/16-18 x 1 1/4 HHCS GR5 PLTD

3/8-16 X 1 HHCS GR5 PLTD

3/8-16 X 1 1/4 HHCS GR5 PLTD

Pin

3/8-16 X 2 1/4 HHCS GR5 PLTD

7/16-20 X 1 1/4 HHCS GR8 PLTD

#10-32 X 3/8 Slotted Self Tapping Screw

7/16 Internal Tooth Lock Washer PLTD

1/4 USS Flat Washer PLTD

5/16 USS Flat Washer PLTD

3/8 USS Flat Washer PLTD

5/16 Split Lock Washer

5/16-18 J-nut Plain

5/16-18 Nylon Insert Locknut PLTD

3/8-16 Nylon Insert Locknut PLTD

1/4-20 Nylon Insert Locknut PLTD

5/16-18 Self Tapping Screw

1/4-20 x 2 1/2 HHCS GR5 PLTD

1/4 SQ x 2” Key

Full Clevis

Clevis Pin 1/4 Dia. x 7/8 Long PLTD

Spring- Le-041D-7MW

5/16-18 x 5/16 Socket Set Screw w/patch

3/8-16 x 5/8 Socket Set Screw

Spring

3/8” E-Ring

Operator Presence Handle Weldment

Clevis Pin 5/16 Dia. x 2 Long PLTD

3/32 Hair Spring Cotter PLTD

Brake Cable Assembly

1.500 OD x 1.015 ID x 0.075 THK Shim

Cable Tie 1/8 x 5 1/2

5/16-18 Whiz Lock Nut PLTD

Drive Shaft Weldment

1/4 SQ x 1” Key

Leg Weldment

5/16-24 x 3/4 HHCS GR5 PLTD

#10-32 X 1 1/4 Slotted Head Machine Screw

#10-32 Kep Nut PLTD

Clutch Control Spring

17

Page 18

NOTES

18

Page 19

NOTES

19

Page 20

NOTES

COUNTRY HOME PRODUCTS

Meigs Road, P.O. Box 25, Vergennes, Vermont 05491

1(800)DR-OWNER (376-9637)

2001 CHP, Inc. 157721 CODE #31045X

03/26/04

20

Loading...

Loading...