Page 1

`

DR

SAFETY & OPERATING INSTRUCTIONS

®

CHIPPER/SHREDDER

DR Power Equipment

Serial No.

Order No.

Read and understand this manual and all instructions before operating the DR CHIPPER/SHREDDER.

Original Language

Toll-free phone: 1-800-DR-OWNER (376-9637)

Fax: 1-802-877-1213

Website: www.DRpower.com

Page 2

Table of Contents

Chapter 1: General Safety Rules ............................................................................................................................................................ 3

Chapter 2: Setting Up The DR CHIPPER/SHREDDER ......................................................................................................................... 8

Chapter 3: Operating The DR CHIPPER/SHREDDER ......................................................................................................................... 13

Chapter 4: Maintaining The DR CHIPPER/SHREDDER ...................................................................................................................... 17

Chapter 5: Troubleshooting .................................................................................................................................................................. 24

Chapter 6: Parts Lists and Schematic Diagrams .................................................................................................................................. 26

Conventions used in this manual

This indicates a hazardous situation, which, if not followed, will result in death or serious injury.

This indicates a hazardous situation, which, if not avoided, could result in death or serious injury.

This indicates a hazardous situation, which, if not avoided, could result in minor or moderate injury.

This information is important in the proper use of your machine. Failure to follow this instruction could result in damage to

your machine or property.

Serial Number and Order Number

A Serial Number is used to identify your machine and is located on the Serial Number Label on your machine. An Order Number

is used to check and maintain your order history and is located on the upper left portion of your packing slip. For your

convenience and ready reference, enter the Serial Number and Order Number in the space provided on the front cover of this

manual.

Additional Information and Potential Changes

DR Power Equipment reserves the right to discontinue, change, and improve its products at any time without notice or obligation

to the purchaser. The descriptions and specifications contained in this manual were in effect at printing. Equipment described

within this manual may be optional. Some illustrations may not be applicable to your machine.

2 DR

®

CHIPPER/SHREDDER

Page 3

Chapter 1: General Safety Rules

#

#

Read this Safety & Operating Instructions Manual before you use the DR CHIPPER/SHREDDER. Become familiar with the

operation and service recommendations to ensure the best performance from your machine. If you have any questions or need

assistance, please contact us at www.DRpower.com or call Toll-Free 1-800-DR-OWNER (376-9637) and one of our Technical

Support Representatives will be happy to help you.

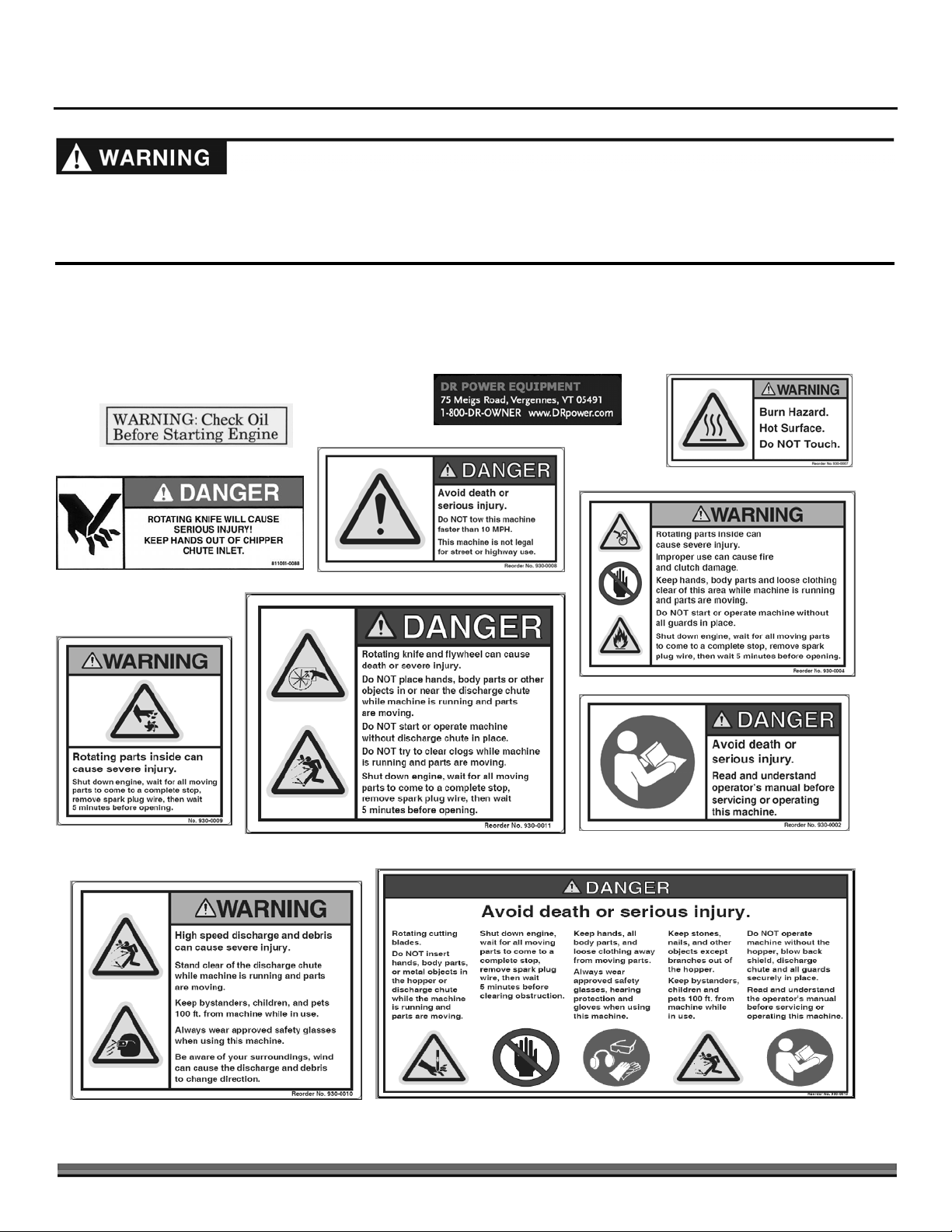

Labels

Your DR CHIPPER/SHREDDER carries prominent labels as reminders for its proper and safe use. Shown below are copies of all

the Safety and Information labels that appear on the equipment. Take a moment to study them and make a note of their location

on your CHIPPER/SHREDDER as you set up and before you operate the unit. Replace damaged or missing Safety and

Information labels immediately.

#235451

#137581

#241991

227141

#242041

#241821

247961

CONTACT US AT www.DRpower.com 3

Page 4

Protecting Yourself and Those Around You

This is a high-powered machine, with moving parts operating with high energy. You must operate the machine safely. Unsafe

operation can create a number of hazards for you, as well as anyone else in the nearby area. This machine can crush, grind, cut,

and sever parts of your body if they enter the inlet or discharge area of your CHIPPER/SHREDDER. Always take the following

precautions when using this machine:

Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people, their property, and

themselves.

Always wear protective goggles or safety glasses with side shields while using the CHIPPER/SHREDDER to protect your eyes

from possible thrown debris.

Avoid wearing loose clothing or jewelry, which can catch on moving parts or the material fed into the CHIPPER/SHREDDER.

We recommend wearing gloves while using the CHIPPER/SHREDDER. Be sure your gloves fit properly and do not have loose

cuffs or drawstrings.

Wear shoes with non-slip treads when using your CHIPPER/SHREDDER. If you have safety shoes, we recommend wearing

them. Do not use the machine while barefoot or wearing open sandals.

Wear long pants while operating the CHIPPER/SHREDDER.

Use ear protectors or earplugs rated for at least 20 dba to protect your hearing.

Keep bystanders at least 100 feet away from your work area. Stop the engine when another person or pet approaches.

Safety for Children and Pets

Tragic accidents can occur if the operator is not alert to the presence of children and pets. Children are often attracted to the

machine and the chipping/shredding activity.

these precautions:

Never

assume that children will remain where you last saw them. Always follow

Keep children and pets at least 100 feet from the working area and ensure they are under the watchful care of a responsible

adult.

Be alert and turn the machine off if children or pets enter the work area.

Never allow children to operate the CHIPPER/SHREDDER.

4 DR

®

CHIPPER/SHREDDER

Page 5

Safety with Gasoline - Powered Machines

Gasoline is a highly flammable liquid. Gasoline also gives off flammable vapor that can be easily ignited and cause a fire or

explosion. Never overlook the hazards of gasoline. Always follow these precautions:

Never run the Engine in an enclosed area or without proper ventilation as the exhaust from the Engine contains carbon

monoxide, which is an odorless, tasteless, and deadly poisonous gas.

Store all fuel and oil in containers specifically designed and approved for this purpose and keep away from heat and open

flame, and out of the reach of children.

Replace rubber Fuel Lines and Grommets when worn or damaged and after 5 years of use.

Fill the Gasoline Tank outdoors with the Engine off and allow the Engine to cool completely. Don't handle gasoline if you or

anyone nearby is smoking, or if you're near anything that could cause it to ignite or explode. Reinstall the Fuel Tank Cap and

Fuel Container Cap securely.

If you spill gasoline, do not attempt to start the Engine. Move the machine away from the area of the spill and avoid creating

any source of ignition until the gas vapors have dissipated. Wipe up any spilled fuel to prevent a fire hazard and properly

dispose of the waste.

Allow the Engine to cool completely before storing in any enclosure. Never store a machine that has gas in the tank, or a Fuel

Container, near an open flame or spark such as a water heater, space heater, clothes dryer or furnace.

Never make adjustments or repairs with the Engine running. Shut down the Engine, disconnect the Spark Plug wire, keeping

it away from the Spark Plug to prevent accidental starting, wait 5 minutes before making adjustments or repairs.

Never tamper with the Engine’s Governor setting. The Governor controls the maximum safe operation speed and protects

the Engine. Over-speeding the Engine is dangerous and will cause damage to the Engine and to the other moving parts of the

machine. If required, see your authorized dealer for Engine governor adjustments.

Keep combustible substances away from the Engine when it is hot.

Never cover the machine while the Muffler is still hot.

Do not operate the Engine with the Air Cleaner or the Carburetor Air Intake Cover removed. Removal of such parts could

create a fire hazard. Do not use flammable solutions to clean the Air Filter.

The Muffler and Engine become very hot and can cause a severe burn; do not touch.

CONTACT US AT www.DRpower.com 5

Page 6

General Safety

Operating this CHIPPER/SHREDDER safely is necessary to prevent or minimize the risk of death or serious injury. Unsafe

operation can create a number of hazards for you. Always take the following precautions when operating this machine:

Your CHIPPER/SHREDDER is a powerful tool, not a plaything. Exercise extreme caution at all times. The machine is

designed to chip wood and shred most organic materials. Do not use it for any other purpose.

Thoroughly inspect the area in which you will be working and remove all foreign objects. Look for rope, wire, etc., and remove

these objects before chipping/shredding. Inserting these objects into the CHIPPER/SHREDDER Hopper could damage the

machine and/or cause injury.

Know how to stop the CHIPPER/SHREDDER quickly; see “Stopping the Engine” in Chapter 3.

Never operate your unit on a slippery, wet, muddy, or icy surface. Exercise caution to avoid slipping or falling.

See manufacturer’s instructions for proper operation and installation of accessories. Only use accessories approved by DR

Power Equipment.

Never use the machine without ensuring that all guards and shields are in place.

Never, under any conditions, remove, bend, cut, fit, weld, or otherwise alter standard parts on the CHIPPER/SHREDDER.

This includes all shields and guards. Modifications to your machine could cause personal injuries and property damage and

will void your warranty.

Never use the machine with the Hopper(s) or Discharge Chute removed.

Never place any part of your body in the CHIPPER/SHREDDER Hopper(s), discharge opening, or near any moving part while

the machine is running. Keep the area of discharge clear of anything that will obstruct a clear discharge. Wind can also

change discharge direction, so be aware. If it becomes necessary to push material into the CHIPPER/SHREDDER Hopper(s),

use a small diameter stick, NOT WITH YOUR HANDS.

Keep your face and body back from the CHIPPER/SHREDDER Hopper(s) to avoid accidental bounce back of any material.

Do not allow an accumulation of processed material to build up in the discharge area as this will prevent proper discharge

and can result in kickback from the CHIPPER/SHREDDER Hopper(s).

Allow only one person to operate the CHIPPER/SHREDDER at any time.

Always operate the machine from the Operator Zone (see Figure 10

of the machine when the Engine is running or the Flywheel is turning.

If the machine should start making an unusual noise or vibration, shut down the Engine, disconnect the Spark Plug Wire,

keeping it away from the Spark Plug to prevent accidental starting, wait 5 minutes, then inspect for damage. Vibration is

generally a warning of trouble. Check for damaged parts and clean, repair, and/or replace as necessary.

Never tamper with safety devices. Check their proper operation regularly.

Never try to pick up, move, or transport the machine while the Engine is running or the Flywheel is turning.

Before performing any maintenance or inspection procedure on the CHIPPER/SHREDDER, shut the Engine OFF, remove the

Spark Plug Wire, and keep it away from the Spark Plug.

Never allow people who do not understand and/or have not read this Safety and Operating Instructions Manual to use the

CHIPPER/SHREDDER. Allow only responsible individuals who are familiar with these rules of safe operation to use your

machine.

Never overload or attempt to Chip or Shred material beyond the manufacturer’s recommendation. Personal injury or damage

to the machine could result.

While using the CHIPPER/SHREDDER, don't hurry or take things for granted. When in doubt about the equipment or your

surroundings, stop the machine and take the time to look things over.

Never operate the machine when under the influence of alcohol, drugs, or medication.

Use the machine only in daylight.

Stay alert for hidden hazards or traffic.

Keep all nuts and bolts tight and keep the equipment in good operating condition.

on page 13). Never pass or stand on the discharge side

6 DR

®

CHIPPER/SHREDDER

Page 7

A Note to All Users

Under California law, and the laws of some other states, you are not permitted to operate an internal combustion engine using

hydrocarbon fuels without an Engine Spark Arrester. This also applies to operation on US Forest Lands. All DR

CHIPPER/SHREDDERS shipped to California, New Mexico, and Washington State are provided with Spark Arresters. Failure of

the owner or operator to maintain this equipment in compliance with state regulations is a misdemeanor under California law and

may be in violation of other state and/or federal regulations. Contact your State Park Association or the appropriate state

organization for specific information in your area.

No list of warnings and cautions can be all-inclusive. If situations occur that are not covered by this manual, the operator must

apply common sense and operate this DR CHIPPER/SHREDDER in a safe manner. Contact us at www.DRpower.com or call Toll

Free: 1-800-DR-OWNER (376-9637) for assistance.

CONTACT US AT www.DRpower.com 7

Page 8

Chapter 2: Setting Up The DR CHIPPER/SHREDDER

It may be helpful to familiarize yourself with the controls and features of your DR CHIPPER/SHREDDER as shown in Figure 1

before beginning these procedures. If you have any questions at all, please feel free to contact us at www.DRpower.com.

DR CHIPPER/SHREDDER Controls and Features

Blowback Shield

8.00 FT-LBS Torque

Briggs & Stratton Engine

Chipper Hopper

Shredder Hopper

Blowback Shield

Pneumatic Tires

Fuel Shut-Off

Choke

8 DR

®

CHIPPER/SHREDDER

Oil Fill/Dipstick

Tow Beam

Fuel Fill

Throttle

Starter Handle

Figure 1

Page 9

Specifications

p

Engine

Tire Size 10 inch diameter

Clutch

Engagement speed

Frame

8.00 FT-LBS Torque Briggs & Stratton

Please refer to the Engine Owner’s Manual for Engine-

s

ecifications.

Centrifugal

1,000 RPM (the Rotor will turn at idle)

Welded 12 gauge steel construction

Belt

Size

Construction

Machine Dimensions

Operating Weight

Shipping Weight

Shipping Dimensions

V-Belt

44 inches

Wrapped for abrasion resistance

56" L x 41" W x 44" H

201 pounds

251 pounds

32" L x 34" W x 59" H

Unpacking the DR CHIPPER/SHREDDER

Tools and supplies needed:

Hammer or Pry Bar

Wire Cutters or Utility Knife

Gloves & Safety Glasses

1/2" Socket or Wrench

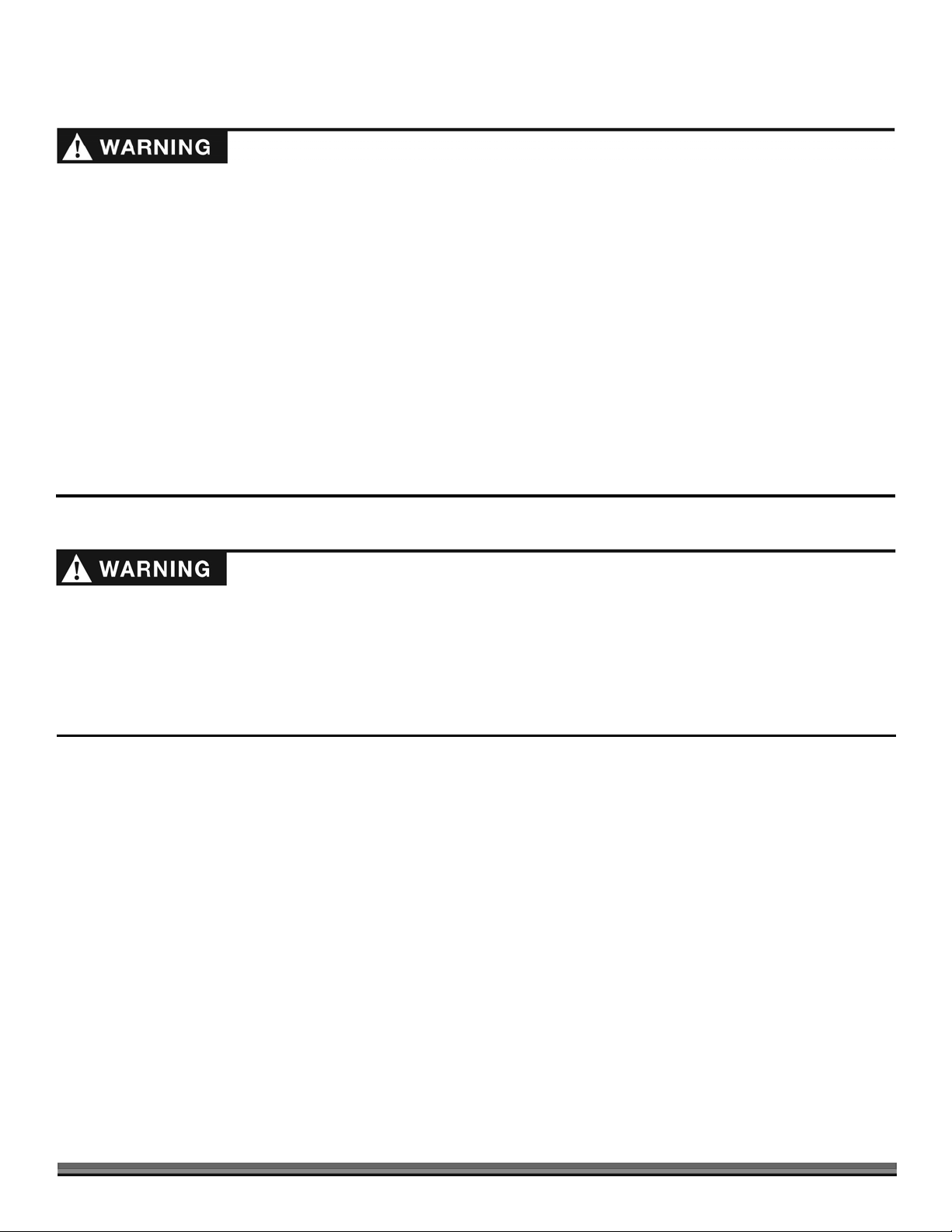

Parts supplied on shipping pallet (Figure 2) w/machine

Item Description Qty

1 Tow Beam 1

Parts supplied in Shredder Hopper

2 Chipper Hopper 1

3 Hardware Plastic Bag 1

4 Safety Glasses 1

Parts supplied in Plastic Bag (Figure 2)

5 5/16" - 18 x 3/4" Carriage Bolt 4

6 5/16" - 18 x 1" Bolt, HHCS 3

7 5/16" Flat Washer, USS 5

8 5/16" - 18 Nylon Lock Nut 7

9 1/4" - 20 Nylon Lock Nut 2

10 1/4" - 20 x 1-1/4" U-Bolt 1

11 Bent Hitch Plate 1

12 Knife Gauge 1

Engine Manual 1

Safety & Operating Instructions Manual 1

1

4

5 10

9

Figure 2

2

3

12

11

6

7

8

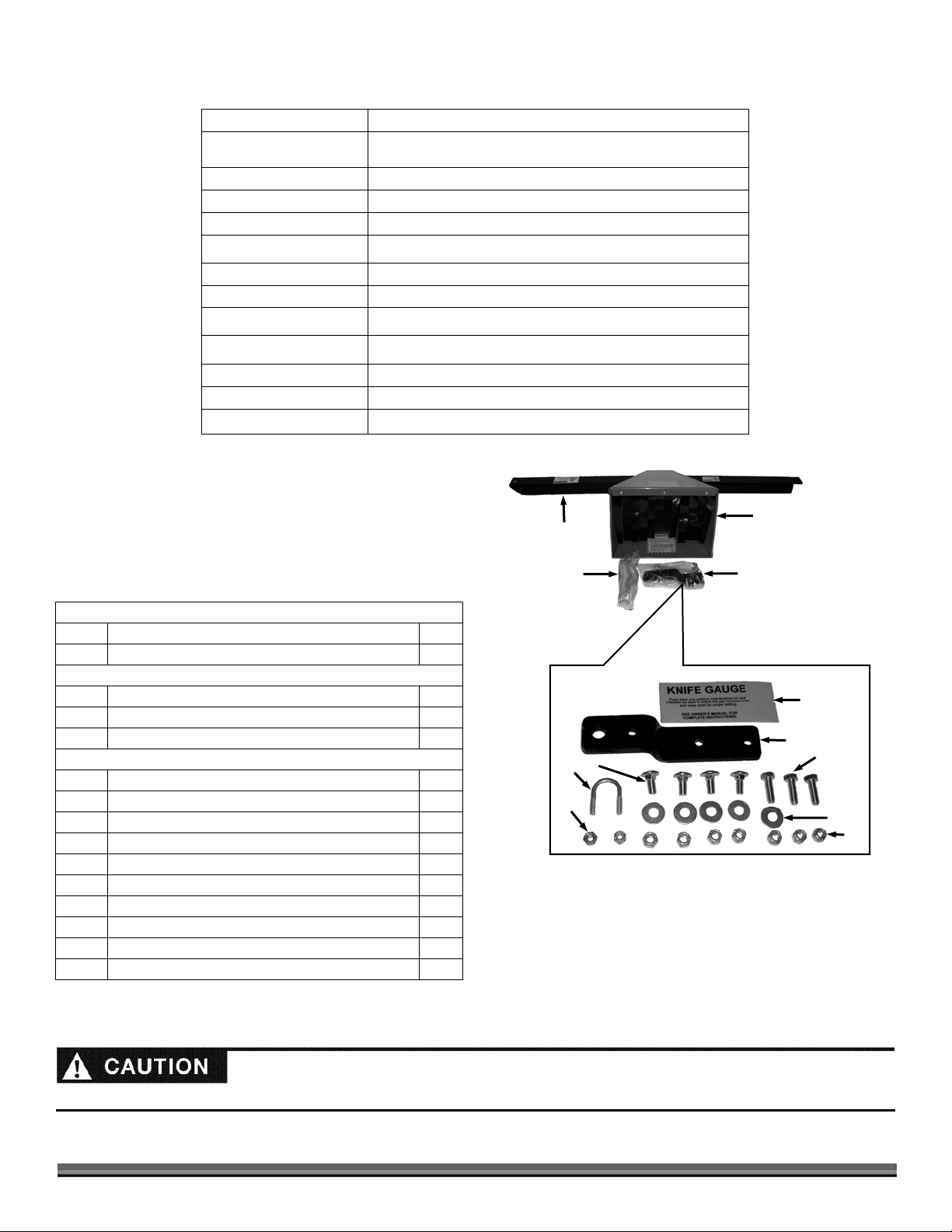

1. Pry off the four (4) Bottom Boards of the Crate from the shipping pallet (Figure 3 on page 10).

2. Cut the Ties securing the Tow Beam and the Chipper/Shredder to the Crate and Shipping Pallet (Figure 3 on page 10).

The Ties may be under tension. Wear Safety Glasses when cutting the Ties to protect your eyes.

CONTACT US AT www.DRpower.com 9

Page 10

A

Cable

Tie

Tow Beam

Figure 3

Cable

Tie

Bottom

Board

(4 places)

3. Remove the Tow Beam and lift the Crate off of the Shipping Pallet.

4. Remove the Hardware Plastic Bag, the Chipper Hopper, and the packing

material from inside the Shredder Hopper.

5. Using a 1/2" Wrench, remove the Lag Bolt and Washer securing the front

of the Chipper/Shredder frame to Shipping Pallet (Figure 4). This Bolt and

Washer may be discarded.

6. With the help of another person, carefully roll the DR

CHIPPER/SHREDDER from the Shipping Pallet, resting it on the front

frame support.

7. Compare the contents on the Shipping Pallet and in the Plastic Bag with

the parts supplied list on the previous page. If any of the parts are missing,

contact 1-800-DR-OWNER (376-9637). You will need packaging to return

the machine; do not discard your packaging material until you are fully

satisfied with your new DR CHIPPER/SHREDDER.

Figure 4

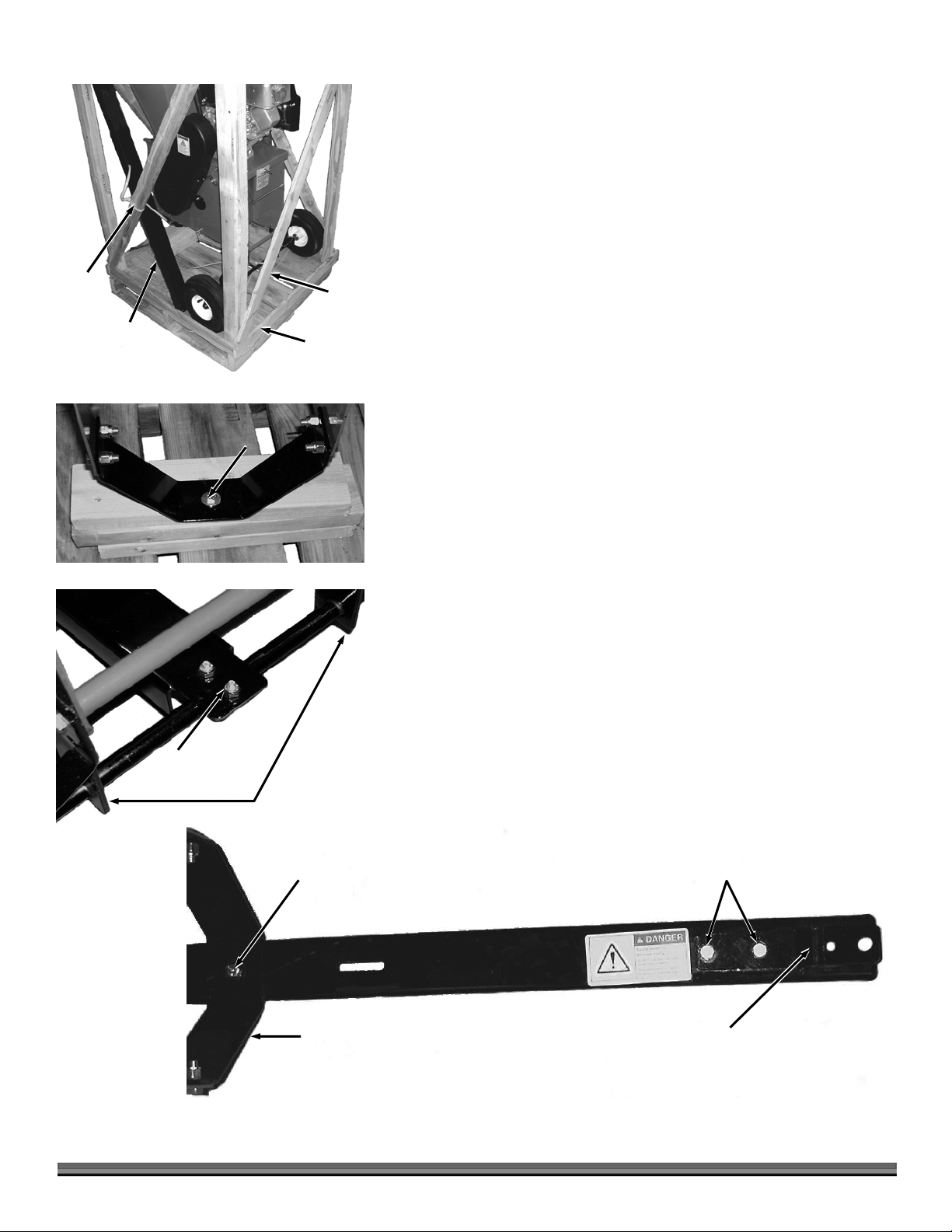

Tow Beam

Figure 5

U-Bolt

Securing

Bolt

Attaching the Tow Beam and Hitch Plate

Tools Needed:

7/16" Wrench

Two 1/2" Wrenches

1. Place the Tow Beam on top of and in the center of the Axle between the

Axle Supports. Put the U-Bolt around the Axle from underneath and up

through the two holes on the Tow Beam (Figure 5). Install two 1/4"- 20

Lock Nuts on the U-Bolt with a7/16" Wrench but do not tighten.

2. Lift the machine and align the Hole the Tow Beam with the Hole in the

Front Frame Support and insert a 5/16"- 18 x 1" Bolt down through the

Frame and through the Tow Beam (Figure 6).

3. With this Bolt in place, block up the Tow Beam so that you can easily install

a 5/16" Flat Washer and a 5/16" - 18 Lock Nut on the Bolt from under the

Tow Beam; but do not tighten.

4. Re-check the center of the Tow Beam on the Axle and tighten the two Lock

Nuts on the U-Bolt.

5. Now tighten the 5/16"-18 Lock Nut to secure the Front Frame Support to

the Tow Beam with two 1/2" Wrenches.

xle Supports

6. Attach the Hitch Plate to the Tow Beam with two 5/16"- 18 x 1" Bolts and

two 5/16"-18 Lock Nuts (Figure 6). Tighten with two 1/2" Wrenches.

5/16" Bolt 5/16" Bolts

Tow Beam

Frame Support

Figure 6

10 DR

®

CHIPPER/SHREDDER

Bent Hitch

Plate

Page 11

Attaching the Chipper Hopper

l

Tool Needed:

1/2" Wrench

Tip: Insert a towel or large rag into the opening to keep the Bolts from falling

into the Chipper. Position the Hopper as shown in Figure 7 with the Debris

Guard hanging down

1. Attach the Chipper Hopper to the machine using four 5/16"-18 x 3/4"

Carriage Bolts, four 5/16" Flat Washers and four 5/16"-18 Nylon Lock Nuts.

NOTE: Be sure to insert the Bolts, from the inside of the Chipper Hopper so that

the threads are sticking out (Figure 7) and the heads are flush against the Hopper.

Install the Bolts, Washers and Nuts one at a time.

2. Install a Flat Washer, then a Lock Nut on each Bolt. Initially install the

Bolts and Nuts finger tight and then tighten the Nuts one (1) turn using a

1/2" Socket or Wrench (Figure 7). Check to see that the Hopper is

centered on the Inlet Chute and then tighten the Nuts securely.

3. If you used a towel or rag in the Chipper opening, remove it now.

Chipper

Hopper

Figure 7

Debris

Guard

5/16" Carriage

Bolt, Washer,

and Lock Nut 4places

Adding Oil and Gasoline

You must add oil before starting the Engine. This machine is shipped

Fuel Fill

Dipstick

without oil. Traces of oil may be in the reservoir from factory testing, but

you must add oil before starting the Engine

. Fill the reservoir slowly,

checking the level frequently to avoid overfilling.

To get an accurate reading when checking the oil level:

- The Engine must be level.

- The Dipstick must

level reading on Briggs & Stratton Engines.

Engine Oil

SAE 30: above 50 degrees F; 10w-30: 10-90 degrees F; 5w-30:

30 degrees F or below

Fuel

Unleaded gasoline

NOTE: Use only the recommended high detergent Engine oil. Other types of oil

could cause problems operating your machine. Please refer to your Engine Owner’s

Manual for more detailed oil information.

1. Block the machine so the Engine is level. Remove the Oil Fill/Dipstick

(Figure 8) and clean the end of it with a rag.

2. Initially add 16 oz. of the oil recommended by the Engine Manufacturer. Wait one minute for the oil to settle.

3. Screw the Dipstick in and then remove it to check the oil level (clean the Dipstick with the rag after checking).

4. Continue adding a few ounces of oil at a time, rechecking the Dipstick until the oil reaches the fill mark. Be careful not to

overfill.

5. Replace the Dipstick and screw all the way in when full.

be screwed all the way in to ensure an accurate oil

Oil Drain

Figure 8

Fuel Fil

Oil Fill/

6. Remove the Fuel Fill Cap and fill the Fuel Tank with fresh, unleaded gas (with a minimum of 85 Octane) to approximately 1" to

1-1/2" below the top of the Fill Neck to allow for Fuel expansion (Figure 8). Be careful not to overfill and reinstall the Fuel Fill

Cap before starting the Engine. See your Engine Owner’s Manual for more detailed information.

NOTE: To refill the Fuel Tank, turn the Engine OFF, and let the Engine cool at least five minutes before removing the Fuel Fill Cap.

CONTACT US AT www.DRpower.com 11

Page 12

Check the Tire Pressure

Tools Needed:

Tire Pressure Gauge

Air Compressor or Hand Pump

1. Remove the Valve Stem Protective Cap (Figure 9) and check the Tire

pressure with a Tire Pressure Gauge.

2. Check the manufacturers recommended pressure that is stamped on the

side of the Tire.

Do not over inflate the Tires. Inflate to the manufacturers recommended

pressure.

Valve Stem

Protective Cap

Figure 9

3. If the pressure is too low, add air through the Valve Stem with an Air

Compressor or Hand Pump.

4. Replace the Valve Stem Protective Cap when finished.

12 DR

®

CHIPPER/SHREDDER

Page 13

Chapter 3: Operating The DR CHIPPER/SHREDDER

This chapter covers the procedures for starting and stopping your new DR CHIPPER/SHREDDER and discusses basic operation

features. It may be helpful to better familiarize yourself with the features of your CHIPPER/SHREDDER by reviewing Figure 1 in

Chapter 2 before beginning the steps outlined in this chapter.

Read and understand the warnings listed in “Chapter 1 General Safety Rules” before operating this CHIPPER/SHREDDER.

Starting the Engine

1. Check the Oil and Fuel level every time you use the DR CHIPPER/SHREDDER.

2. Turn the Fuel Shut-Off Valve to the OPEN position (Figure 1 on page 8).

3. Check Inlet Hoppers and Discharge Chute and remove any debris buildup from the machine by first unplugging the Spark Plug

Wire and following the instructions on page 16.

4. Move the Choke Control Lever (Figure 1 on page 8) to the right to the Choke position (leave in the Run position to the left if

the Engine is already warm).

5. Move the Throttle to the right, FAST (Rabbit) position, (Figure 1 on page 8).

6. Grasp the Recoil Starter Handle (Figure 1 on page 8)

then pull the cord rapidly to start the Engine. One or two (2) pulls will usually start the DR CHIPPER/SHREDDER.

6. As the Engine warms up, slowly adjust the Choke to the left towards the Run position. Wait until the Engine runs smoothly

before each Choke adjustment.

7. When the Engine is warmed up and running smoothly, ensure that the Choke is fully in the Run position to the left.

NOTE: The Throttle should always be fully to the right when Chipping/Shredding.

and slowly pull until you feel resistance. Let the cord retract a little bit,

Stopping the Engine

Move the Throttle Control Lever all the way to the left past the SLOW (Turtle) position to the “STOP” position.

NOTE: Close the Fuel Shut-Off Valve (Figure 1 on page 8)

when transporting or storing the DR CHIPPER/SHREDDER.

Before You Begin

Visually check the Chipper Knife for damage each time you use the machine.

NOTE:

Check for shaft movement while starting the Engine. If the shaft does not turn, clean out the Chipper/Shredder Hopper(s) as

instructed on page 16.

When viewed from the Chipper Hopper side (Operator Zone, Figure 10), the Flywheel turns in a clockwise direction.

NEVER assume you know where the Chipper Knife is. You do not know where it is.

ALWAYS operate the DR CHIPPER/SHREDDER from the Operator Zone shown in Figure 10.

ALWAYS stop the Engine when leaving the Operating Zone (Figure 10) or when moving the machine.

Figure 10

CONTACT US AT www.DRpower.com 13

Page 14

Processing Material

Read and understand the warnings listed in “Chapter 1 General Safety Rules” before operating this CHIPPER/SHREDDER.

Your DR CHIPPER/SHREDDER can process dry or green material.

Green material will process quicker and easier than dry material.

Soft wood processes easier than hard wood.

Your operator experience will teach you how different materials chip/shred and how fast you can process different materials.

Most materials process well with the standard screen provided with the DR CHIPPER/SHREDDER.

It is best to trim off any side twigs from the main branch that you are chipping.

When chipping branches, sometimes a tail will remain at the end of a branch. To avoid this, rotate the branch while feeding it

into the Chipper Hopper. Rotating the branch as you feed it into the machine will improve chipping performance.

Use caution with small diameter green saplings and branches less than 1" in diameter. Chip these grouped or bundled together

to provide support for each other. If the material is 1" or larger, feed only one at a time into the Chipper Hopper.

Make sure the DR CHIPPER/SHREDDER finishes processing material in the Hopper(s) before shutting the Engine off.

Using the Chipper Hopper

The Chipper Hopper is mounted on the side of the machine and is designed to chip the larger, heavier materials that the Shredder

Hopper isn’t designed to handle. The revolving Chipper Knife mounted on a flywheel turns branches fed into the Hopper into

“chips”. The Chipper can chip twigs and branches ranging in size from 1" to 3" in diameter. Cut your materials into manageable

lengths of no more than five or six feet long

before feeding them into the Chipper Hopper.

The Chipper Hopper must be securely bolted to the side of your DR CHIPPER/SHREDDER before using the machine!

Feed the branch into Chipper Hopper keeping the branch at the same angle as the Chipper Hopper.

As the branch becomes short and is at the outside edge of the Chipper Hopper, finish processing it by pushing it in with the

next branch.

Do not force material into the Chipper. If the machine does not chip well, the Chipper Knife may need sharpening or replaced,

or the gap between the Knife and the Wear Plate needs adjusting. See page 21.

Extremely hard knots will not process very well. Push any short stubs that have not self-fed through the Chipper, with the next

branch to be chipped.

Never throw remaining stubs or knots into the Shredder Hopper; damage will result.

Overloading the Chipper Hopper will cause the rotor speed to decrease. If you hear the Engine RPM decreasing, stop feeding

material into the Chipper Hopper until the Engine has returned to full speed.

NEVER allow processed material to build up within 3" of the Discharge opening. Move the DR CHIPPER/SHREDDER or the

pile as needed. Failure to do so could result in unnecessary jamming of the machine.

To move a pile of processed material, first shut off the Engine, and use a spade, rake, or long handle tool; NEVER

hands or feet!

If you jam the machine and do not stop the Engine, it can damage the machine. This damage can be costly and not covered

under warranty. See “To Free a Jammed Flywheel” on page 16.

use your

14 DR

®

CHIPPER/SHREDDER

Page 15

Using the Shredder Hopper

The Shredder Hopper is located on the top of the DR CHIPPER/SHREDDER and is the opening into which all materials to be

shredded should be fed. You can shred most organic materials. A flex guard, or blowback shield is attached to the Hopper. You

must push material past this flap using a wooden stick in order to enter the main Shredding Chamber where revolving steel

Hammers do the shredding.

The Blowback Shield is an important feature; it prevents kickback of materials! Do not use your machine unless the Blowback

Shield is securely fastened in place.

Due to the wide variety of materials that you can shred, and their very different physical characteristics, only feed limited

quantities of any material into the Shredder Hopper at first. Increase the amount and length of material if you find that the

material is processing without any difficulty. Your judgment and operator experience is very important. Be sure not to overload

the machine by feeding too much material into the Hopper at one time. If you hear the speed of the Engine decreasing, stop

feeding material into the machine at once. Do not resume feeding the machine until the Engine has returned to full speed.

The maximum diameter of material that you can shred is 3/8". Feed any larger material through the Chipper Hopper. Material

larger than 3/8" can cause serious damage to any of the internal parts of the Shredding Chamber. Inspect the DR

CHIPPER/SHREDDER after every use for bent Hammers, missing Spacers, clogging, or damage to the Screen or any other

obvious problems. If damage occurs, the Rotor Assembly can become unbalanced causing excessive vibration. If used in this

condition, damage can occur. Do not use the machine if vibration is present. Vibration is generally a warning sign of trouble.

You can feed several small branches into the Shredder Hopper at once providing their combined diameter is less than 3/8".

Cut branches longer than three (3) feet to make them more manageable. Allow green materials to dry, or process in small

batches with dry materials to avoid winding around the Rotor Assembly.

Wet materials will clog the machine easily. If clogging occurs, stop the Engine; remove the screen and process material without

it. Processing in this way will reduce the amount of reduction, but will reduce clogging.

MATERIALS BEST SUITED FOR SHREDDING

Leaves Flowers Corn Stalks Roots

Soil Palm frond tops Grass clippings Garden debris

Potato vines Straw and Hay Hedge clippings Tomato vines

Manure Kitchen Waste Small branches

The Hammers within the Shredding Chamber can tug suddenly at material fed into the Shredder Hopper. Do not hold on tightly

to branches and vines, and do not feed material straight down into the Hopper with your arm pointing downward toward the

opening. Instead, keep your arms parallel to the ground and several inches above the top edge of the Hopper.

CONTACT US AT www.DRpower.com 15

Page 16

Baffle Pivot Rod

Clip

To Free a Jammed Flywheel

Before performing any maintenance procedure or inspection, stop the Engine,

wait five (5) minutes to allow all moving parts to come to a complete stop

and cool. Disconnect the Spark Plug Wire, keeping it away from the Spark

Plug.

Figure 11

Figure 12

Screen Lower

Retaining Rod

Clip

Hammers &

Rotor Assy

Baffle Adjusting Rod

Clip

Screen Top

Retaining Rod

Snap Fastener Tab

Snap Fastener

Screen

1. Remove any material left in the Chipper/Shredder Hopper.

2. Check the Discharge Opening for clogs. If it is clogged, clear it with a

wooden stick.

3. Also, with a wooden stick, loosen and remove any material left in the

Chipping/Shredding Chamber(s).

4. Start the machine and allow any remaining material in the

Chipping/Shredding Chamber(s) to discharge.

5. If the Chipping/Shredding Chamber(s) does not clear and the Flywheel is

still jammed, repeat the above process.

6. Be certain the Chipping/Shredding Chamber(s) is clear before trying to

process more material into the Hopper(s), clogging could result in Belt or

Clutch failure.

To Clean Out a Clogged Shredder

1. Remove the Baffle Plate by removing the Hair Spring Clip on the Adjusting

Rod and the Pivot Rod and then removing the two (2) Rods (Figure 11).

2. Remove the Screen Top Retaining Rod (Figure 12) by first releasing the Snap

Fastener by bending the Tab down.

3. Remove the Screen Lower Hair Spring Clip from the Retaining Rod and

remove the Rod (Figure 11).

4. Now you can remove the Screen exposing the Shredder Hammers Assembly

(Figure 13).

5. Remove any debris wrapped around the Shredder Hammers Drive Shaft or

collected in the Hammers Assembly or Screen.

6. Reposition the Shredder Screen and reinstall the Top and Lower Screen

Retaining Rods, Snap Fastener, and Hair Spring Clip.

7. Reposition the Baffle Plate and reinsert the Baffle Pivot Rod, Adjusting Rod,

and the Hair Spring Clips.

8. Reconnect the Spark Plug wire, start the machine, and allow any remaining

material in the Shredding Chamber to discharge.

9. If the Shredding Chamber does not clear, repeat the above process.

Be certain the Shredding Chamber is clear before trying to process more

material into the Hopper, clogging could result in Belt or Clutch failure.

Figure 13

16 DR

®

CHIPPER/SHREDDER

Page 17

Chapter 4: Maintaining The DR CHIPPER/SHREDDER

g

Regular maintenance is the way to ensure the best performance and long life of your machine. Please refer to this manual and the

Engine Manufacturer's Owner's Manual for maintenance procedures. Service intervals listed in the checklist below supersede

those listed in the Engine Manufacturer's Owner's Manual.

Before performing any maintenance procedure or inspection, stop the Engine, wait five (5) minutes to allow all parts to cool.

Disconnect the Spark Plug Wire, keeping it away from the Spark Plug.

Regular Maintenance Checklist

PROCEDURE BEFORE

EACH USE

Check Engine Oil Level

Check General Equipment Condition

Check that the Shaft turns freely

Clean Engine Exterior & Cooling Fins

Inspect Knife for damage

Check Knife and Wear Plate for Sharpness

Check Knife and Wear Plate Attachment Screws

Check Knife to Wear Plate Gap

Check Rotor Hammers/Spacers for Wear

Check Side Bearing Collar Set Screws

Lubricate Side Bearings

Check Belt Tension and Condition

Clean Air Filter

Replace Air Filter

Check Tire Pressure

Change Engine Oil

Replace Drive Belt and Spark Plu

Reverse Rotor Hammers

st

1

st

1

Removing and Replacing the Engine Oil

VERY 8-10

E

HOURS

time 1hr

time 5 hrs

VERY 40

E

HOURS

VERY 100

E

HOURS

Tools and Supplies Needed:

5/8" Wrench

Rags and approved Container (for waste oil)

Small funnel

Engine Oil (see your Engine Manual for Oil specifications)

NOTE: Drain the oil when the Engine is warm; warm oil drains quickly and completely.

1. Level the Tow Beam, remove the Oil Fill/Dipstick, (Figure 1 on page 8) and using a 5/8" Wrench, remove the Oil Drain Cap

(Figure 8 on page 11) allowing the used oil to drain completely into a Waste Oil Container.

NOTE: An optional method is to use an Oil Extraction Pump.

2. Replace the Oil Drain Plug, and refill with new oil (see “Adding Oil and Gasoline” on page 11).

NOTE: If you are not reusing the oil, be sure to use environmentally safe disposal procedures in the disposing of the used oil.

CONTACT US AT www.DRpower.com 17

Page 18

Set Screws

Chipper Side

Bearing

Grease Fittings

Your DR CHIPPER/SHREDDER was greased at the Factory. The operator needs

to lubricate the Chipper Side and Drive Side Bearings periodically.

Tools and Supplies Needed:

Grease

Fitting

Figure 14

Straight

Edge

Figure 15

3/8"

Drive

Pulley

Shim(s)

Snap Ring

Flexible hose grease gun

Lithium grease

Clean cloth

5/32" Allen Wrench

Loctite

1. Wipe all dirt, etc., from the Grease Fitting(s) with a clean cloth (Figure 14).

2. Apply no more than three pumps of quality general-purpose lithium grease

Over lubrication can damage Bearings.

3. After greasing, check the Side Bearing Collar Set Screws (Figure 14) for

®

243 (if needed)

with a hand-pumped grease gun to each Grease Fitting, one on the Chipper

Side Bearing, and one on the Drive Side Bearing (not shown). To access the

Drive Side Bearing, you will have to remove the Belt Guard (see below).

tightness with a 5/32" Allen Wrench. There are two Set Screws per Bearing.

If they are loose, reset them with Loctite

®

243, obtainable at most hardware

stores.

Adjusting or Removing and Replacing the Drive Belt

Use only a DR Belt on your machine. The Belt has been thoroughly tested and proven for many hours of use.

Tools and Supplies Needed:

(2) 1/2" Wrench

5/32" Allen Wrench and Snap Ring Pliers (if needed)

Loctite

Straight Edge

1. Remove the Belt Guard by removing the retaining Nuts, Washers, and Bolts using two 1/2" Wrenches. Note the placement of

2. The Belt should deflect 3/8" under approximately three pounds of pressure as shown in Figure 15, if it doesn’t, adjust per the

3. Remove the Baffle Plate (see Figure 11 on page 16).

4. Loosen the four Engine Bolts (2 in the Front and 2 in the Rear) using two 1/2" Wrenches (Figure 16 on page 19).

5. Using two 1/2" Wrenches, hold the Belt Adjust Nut while turning out the Jam Nut (Figure 17 on page 19).

NOTE: If you are replacing the Belt, turn the Adjust Nut out to allow slack in the Belt.

6. Turn the Adjust Nut in to tighten or out to loosen for the correct Belt deflection (Figure 15).

®

243 (if needed)

Flat Washers for re-assembly.

following directions.

18 DR

®

CHIPPER/SHREDDER

Page 19

7. While holding the Adjust Nut, retighten the Jam Nut.

A

J

8. Retighten the Engine Bolts.

9. Check the alignment of the Clutch with the Drive Pulley by placing a

Straight Edge across the face of the Drive Pulley (Figure 18). The Straight

Edge should be parallel with the Belt. If adjustment is necessary, correct

the alignment as follows:

a) Remove the two Set Screws in the Drive Pulley Hub with a 5/32" Allen

Wrench and set them aside.

b) Using a Straight Edge, align the Drive Pulley (Figure 18) to be parallel with

the Belt, by moving the Drive Pulley in or out on the Rotor Shaft (Figure 15

on page 18).

NOTE: If the Drive Pulley cannot be moved in or out enough to obtain parallelism,

you will have to swap the shims behind or in front of the Drive Pulley. This will

necessitate removing the Belt and the Snap Ring on the Rotor Shaft (Figure 15 on

page 18), swapping the shims and reinstalling the Drive Pulley, Snap Ring and

Belt. Once you have obtained parallelism, continue with step c).

c) Apply Loctite

®

243 to the threads of the Set Screws and reinsert them into

the Drive Pulley Hub.

d) Tighten the Set Screws while maintaining the parallelism between the

Drive Pulley face and the Belt.

Rear

Engine

Bolts

Figure 16

djust Nut

am Nut

e) Recheck the alignment after tightening the Set Screws.

10. Reinstall the Belt Guard.

NOTE: Check and re-tighten the Drive Belt, if necessary, after an initial break-in

period of one (1) hour.

Figure 17

Belt and

Straight Edge

Parallel

Drive

Pulley

Figure 18

CONTACT US AT www.DRpower.com 19

Page 20

Knife Sharpening

A

A

You should never attempt to sharpen the Chipper Knife freehand; take the Knife to a machine shop for proper sharpening.

It is extremely important to consistently maintain the 45-degree angle for proper performance.

Excessive heat generated during the sharpening process will damage Knives and weaken the metal.

How many times a Knife can be sharpened is determined by how much material needs to be taken off to sharpen or to

compensate for dents or gouges.

A new Chipper Knife has a 5/16" measurement between the short side bevel edge and the Knife mounting holes (Figure 19).

The knife should never be sharpened to the extent that more than 3/32" is taken off this measurement.

Once this measurement is below 7/32" (Figure 20), or if you are unable to remove dents or gouges with these guidelines,

replace the Knife.

Knife Mounting Hole

Short Side Beveled Edge

Knife Mounting Hole

Short Side Beveled Edge

New Knife

Figure 19

Sharpened Knife

5/16" 5/16"

7/32" 7/32"

Removing and Replacing the Chipper Knife

ccess Cover removed

llen Screw, 3 places

Figure 21

20 DR

®

CHIPPER/SHREDDER

Knife

Figure 20

Tools and Supplies needed:

5/16" Wrench

3/16" Allen Wrench

Awl

Propane Torch

Gloves

Loctite

1. Using a 5/16" Wrench, remove the Access Cover (Figure 21) on the Chipper

2. Rotate the Chipper Disk using a stick until the three countersunk Allen

3. Clean out the heads of the Allen Screws with an awl or sharp tool.

4. Insert a 3/16” Allen wrench into the head of a screw.

®

243

Side.

Screws attaching the Knife to the Flywheel are visible through the Access

Opening (Figure 21).

Page 21

5. While applying a counterclockwise force with the Allen Wrench, apply heat

from a propane torch to the Screw to break loose the Loctite

®

securing the

screw.

NOTE: Remove the heat once the Screw has loosened and remove the Screw.

Tip: You may have to block the Flywheel in place while loosening the Screws

(Figure 22).

6. Repeat Steps 4 and 5 for the remaining two Allen Screws.

7. Remove the dull or damaged Knife and visually inspect the Chipper Disk Slot

and Knife mounting area and be sure they are clean. Metal burrs may need

filing so that the replacement Knife will be able to mount flush against the

Chipper Disk.

8. Apply Loctite

®

243 to the three new Allen Screws supplied with a new Knife or

to the original screws if replacing with a sharpened Knife.

9. Install a new or sharpened Knife and finger tighten the Allen Screws to hold

the Knife to the Chipper Disk.

10. Using a 3/16" Allen Wrench, tighten the center Screw, then tighten the outer

Screw, and finally tighten the inner Screw.

11. Double-check all three Screws for tightness one more time.

12. Reinstall the Access Cover.

13. Check the gap between the Knife and Wear Plate and adjust if required.

Knife

Block

Figure 22

Knife

Flywheel

Check and Adjusting the Knife to Wear Plate Gap

When you replace the Knife, check and set the clearance between the Knife and

Wear Plate. Set this clearance or gap to 1/16" (Figure 23). If the gap between

the Wear Plate and the Knife is not set correctly, you will have excessive vibration

when chipping and the Knife will seem to be dull. The Wear Plate should have a

square edge and be free of dents or gouges. The Wear Plate can be hand

sharpened. Be careful not to overheat it during the sharpening process. This will

change the characteristics of the steel and you will then have to replace the Wear

Plate.

Tools Needed:

1/2" Wrench

7/16" Wrench

Gap Gauge (provided with machine)

1. Remove the Chipper Hopper by performing the steps on page 11 in the

reverse order.

2. Using a stick, rotate the Chipper Disk until the Knife is opposite the Wear

Plate (Figure 24).

3. Slide the Gap Gauge between the Knife and Wear Plate (Figure 24). If the gap

is set correctly, the Gap Gauge will lightly touch both the Knife and Wear

Plate. If the gap is too small, you will not be able to get the Gauge between

the Knife and Wear Plate. If the gap is too large, there will be excess room

between Gap Gauge, Knife, and Wear Plate.

Wear Plate

Figure 23

Knife

Wear Plate

1/16"

Gap Gauge

Figure 24

CONTACT US AT www.DRpower.com 21

Page 22

Wear Plate Nuts

A

3 places

4. To adjust the Wear Plate Gap, loosen the three 1/4" Nuts using a 7/16"

Wrench (Figure 25). Now slide the Wear Plate up or down (in or out) to

achieve the correct gap setting.

5. Tighten the Nuts when the Wear Plate is in the correct position (Figure 23 on

page 21).

6. Replace the Chipper Hopper.

NOTE: After any Knife or Wear Plate maintenance or adjustment, rotate the

Chipper Disk watch and listen carefully for any unusual noises, clicking or vibration.

If you detect any of these, inspect the machine for damage, or any loose parts.

Repair or replace any damaged parts and tighten any loose parts before starting the

DR Chipper/Shredder.

Figure 25

Adjusting the Shredder Hammers

When the hard steel Hammers of the Rotor Assembly become dull or round on the cutting edge, they may be rotated or reversed.

NOTE: The Hammers have four cutting edges that may be used before replacement is necessary. To reverse the Hammers, proceed as

follows:

Tools and Part Required

Belt

ccess Cover

Figure 26

Shredder Hopper

Vibration Dampers

2 each side

Figure 27

(2) 1/2" Wrench

Hammer and Punch

(4) Grooved Pin, P/N 186180

Vise Grips

1. Remove the Belt Guard (page 18) and the Baffle Plate (page 16).

2. Loosen the 5/16" Nut and rotate the round Access Cover Plate to expose the

Access Hole (Figure 26).

3. Using two 1/2" Wrenches, remove the Shredder Hopper (Figure 27) by

removing the four (4) Bolts (hold the Nuts on top while backing out the

Bolts) from the Vibration Dampers. Note that the Rear Bolts are 1-1/2" and

the Front Bolts are 1-1/4" long. Lift the Hopper off with the Vibration

Dampers in place (Figure 27).

4. Rotate the Hammer(s) Rod until the Deep Grooved end of the Groove Pin at

the end of the Rod is pointing down (Figure 28 on page 23).

5. While holding the Hammer(s) Rod in place with Vise Grips, drive out the

Groove Pin with a punch (Figure 28 on page 23).

6. Rotate the Hammer assembly until the Rod is lined up with the Access Hole.

7. Carefully remove the Rod through the Access Hole and at the same time

remove the Hammers and spacers from the Rod leaving them in the same

order as you removed them.

8. Now reverse each Hammer (end to end) by using the lower hole in the

Hammer.

22 DR

®

CHIPPER/SHREDDER

Page 23

9. Slide the Rod back through the Access Hole and reinstall the Hammers and

Spacers in the same order as removed.

NOTE: Be sure you reinstall the Hammers and Spacers in exactly the same order

that they were removed. Refer to the Rotor Assembly Schematic on page 29 for the

correct order.

10. Replace the old Groove Pin with a new one (deep grooves pointing up to

install).

Vise Grips

11. Repeat steps 4 through 10 for the remaining three (3) Hammer(s) Rods.

Tip: To remember which Hammer(s) Rod you have reworked, it may be helpful

Rod

Punch Hammer(s)

to mark the end of the Rods with a marker or tape.

12. Reinstall the Shredder Hopper, Access Cover Plate, Belt Guard, and the Baffle

Plate.

NOTE: When reinstalling the Shredder Hopper Bolts in the Vibration Dampers,

remember that the shorter Bolts are in the Front and the Longer Bolts are in the Rear.

Deep

Grooves

pointing

down

Thread the Bolts up into the Dampers until one (1) or two (2) threads appear.

Thread a Lock Nut onto each of the Bolts coming up through the Vibration Dampers.

Figure 28

Hold the Nut and tighten the Bolt until one (1) thread is completely through the

front Nuts and about (3) threads showing through the Nuts in the rear. DO NOT over tighten the Bolts, as this will damage the

Vibration Dampers and possibly lead to damage to your machine.

Removing and Replacing the Clutch

The design of the Clutch on your machine is for rugged, dependable service, however, it is important to understand the limitations

of a Clutch. The Clutch design is to provide load free starting of the Engine, and slippage under excessive overloading of the

driven application. These features help protect the Engine from damages such as broken crankshafts and starters. The Clutch on

this machine is permanently lubricated and does not require oil or grease. The Drum, Shoes, and Springs in the Clutch are

normal wear items. If, after long periods of use, the Drum wobbles excessively, or if you notice decreased performance of the

Clutch, replace the Clutch.

The Clutch obtains its power from the Engine RPM. The lower the engagement speed, and the higher the maintained Engine

speed, the more torque the Clutch can transfer to the driven unit. NEVER operate the DR CHIPPER/SHREDDER Engine at less

than full RPM.

Tools and Supplies Needed:

(2) 1/2" Wrench

9/16" Wrench

Anti-seize compound

1. Remove the Baffle Plate (page 16), the Belt Guard (page 18), loosen the

Engine Bolts (page 18), and remove the Belt (page 18) and set it aside.

2. Remove the Clutch from the Engine Crankshaft by removing the Clutch Bolt

and Washer and then slide the Clutch Assembly from the Crankshaft (any

Spacer(s) remain on the Crankshaft).

Tip: Hold the Hub with Vise Grips while loosening the Clutch Bolt (Figure 29).

3. Remove the Key from the Keyway in the Engine Crankshaft and set it aside.

4. Clean the Engine Crankshaft and remove any burrs, then apply anti-seize

compound to the Crankshaft.

5. Install the Key in the Keyway of the Engine Crankshaft, align the Key with the slot in the new Clutch Hub, and then slide the

new Clutch Assembly onto the Crankshaft followed by the Washer and Clutch Bolt. Tighten the Bolt securely.

6. Reinstall the Drive Belt and set the Belt tension and alignment (page 18).

7. Reinstall the Belt Guard and Baffle Plate.

Figure 29

CONTACT US AT www.DRpower.com 23

Page 24

Chapter 5: Troubleshooting

Most problems are easy to fix. Consult the Troubleshooting Table below for common problems and their solutions. If you

continue to experience problems, contact us at www.DRpower.com or call toll-free 1-800-DR-OWNER (376-9637) for support.

Shut down the Engine, remove the Spark Plug Wire, and wait 5 minutes before performing any maintenance procedure or

inspection on the Chipper/Shredder.

Troubleshooting Table

SYMPTOM POSSIBLE CAUSE

Recoil will not pull out

or is difficult to pull.

The Engine will not

start.

(Please refer to the

Engine Owner’s Manual

for Engine-specific

procedures.)

The Engine lacks power

or is not running

smoothly.

(Please refer to the

Engine Owner’s Manual

for engine-specific

procedures.)

Engine smokes.

(Please refer to the

Engine Owner’s Manual

for engine-specific

procedures.)

Remove any built-up debris from the Chipper/Shredder Hopper Inlet(s) and Discharge Chute.

There may be an oil compression lock in the cylinder. Take out the Spark Plug; hold a rag

over the Spark Plug hole and pull the Recoil Cord several times to blow out any oil in the

Cylinder. Wipe off the Spark Plug and reinstall it.

Check the Engine oil level; the Engine may be seized.

The Recoil may be broken or jammed. Visit our website at www.DRpower.com.

Check the oil and gas level.

Make sure that the Fuel Shut-Off is in the ON position.

Check that the Spark Plug Wire is attached.

The Air Filter may be dirty; change it following the procedure in the Engine Owner’s Manual.

The gas may be old; change it if necessary. Use a fuel stabilizer if you keep gas longer than

one month.

Check the Throttle and Choke settings, adjustment and travel.

The Spark Plug may be dirty or cracked; change it if necessary. If it’s oily, leave it out, hold a

rag over the Plug Hole and pull the Recoil Cord several times to blow out any oil in the

Cylinder, then wipe off the Plug and reinsert it.

If your Engine still won’t start, visit our website at www.DRpower.com.

Make sure the Choke Lever is all the way to the RUN position (left).

Make sure that the Throttle Lever is all the way to the right (FAST- Rabbit).

The Air Filter may be dirty; change it following the procedure in the Engine Owner’s Manual.

The Spark Plug may be dirty or cracked; change it if necessary. If it’s oily, leave it out, hold a

rag over the Plug Hole and pull the Recoil Cord several times to blow out any oil in the

Cylinder, then wipe off the Plug and reinsert it.

The gas may be old; change it if necessary. Use a fuel stabilizer if you keep gas longer than

one month.

The Engine oil may be dirty. Change it if necessary.

Check that the Cooling Fins are clean and free of debris. Clean as needed.

If your Engine still lacks power, visit our website at www.DRpower.com.

Check the oil level and adjust as needed.

You may be operating the machine on too great an incline. The machine should be level.

The Air Filter may be dirty; change it following the procedure in the Engine Owner’s Manual.

You may be using the wrong oil - too light for the temperature. Refer to your Engine Owner’s

Manual for detailed information.

Check that the Cooling Fins are clean and free of debris. Clean as needed.

If your Engine still smokes, visit our website at www.DRpower.com.

24 DR

®

CHIPPER/SHREDDER

Page 25

Troubleshooting Table (Continued)

Shut down the Engine, remove the Spark Plug Wire, and wait 5 minutes before performing any maintenance procedure or

inspection on the Chipper/Shredder.

SYMPTOM POSSIBLE CAUSE

The Engine runs but the

Flywheel doesn’t rotate.

Shredding and chipping

action seems too slow or

flywheel stalling.

Belt frays or falls off

frequently.

- Clutch overheats.

- Belt burns.

- Flywheel won’t turn.

The machine has

excessive vibration.

When chipping, the log

seems to vibrate

excessively and

“hammers” my hands.

The Throttle Lever should be in the FAST (Rabbit) position to engage the Clutch.

The Drive Belt is loose, off or broken. Reinstall, re-tension, or change Belt (refer to “Chapter

4: Maintaining the DR Chipper/Shredder”).

Remove any built-up debris from the Chipper/Shredder Hopper Inlet(s) and Discharge Chute.

The inner Shoes of the Clutch are worn and/or the Clutch Shoe Retaining Springs are weak or

broken.

The Engine speed is too slow causing the Belt to slip. Run the Engine at full throttle (Rabbit).

Check for loose or damaged Drive Belt; tighten or replace.

Check for a dull or damaged Knife; sharpen or replace the Knife. Check for a clogged

Shredder Screen, clean if necessary.

The Drive Pulley or Clutch groove may be nicked. Check the Drive Belt for wear and hard

spots. File off any nicks on the Drive Pulley or Clutch.

The Drive Belt may be stretched; readjust or replace it.

Immediately stop the Engine and remove the Spark Plug Wire.

Turn the Flywheel with a wooden stick to be sure it turns freely.

Check the Drive Belt tension.

Remove any built-up debris from the Chipper/Shredder Hopper Inlet(s) and Discharge Chute.

Check for a dull or damaged Knife; sharpen or replace the Knife.

The Rotor is out of balance. Check the Rotor Assembly for any missing or broken Hammers

or Spacers; replace if necessary.

The Knife may not be seated properly on the Flywheel. Loosen the Knife mounting screws,

reset the Knife, and tighten the screws. Also, check the Knife to Wear Plate Gap.

If your machine still exhibits excessive vibration, visit our website at www.DRpower.com.

The Knife is dull; sharpen or replace it.

The gap between the Knife and Wear Plate is too great; adjust the Gap.

Change the Clutch (refer to “Chapter 4: Maintaining the DR Chipper/Shredder”).

Chipper Knife is hitting

the Wear Plate.

The machine’s wheels

track left or right while

being towed.

The gap between the Knife and the Wear Plate is set incorrectly; adjust the Knife to Wear Plate

Gap.

Check the tire pressure and set to the recommended pressure stamped on the side of the tire.

Check that the Tow Bar is centered on the axle; adjust as required.

CONTACT US AT www.DRpower.com 25

Page 26

Chapter 6: Parts Lists and Schematic Diagrams

Parts List – DR CHIPPER/SHREDDER ASSEMBLY – CHIPPER SIDE and DRIVE SIDE

NOTE: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

01 292541 Weldment, Shredder Hopper

02 157301 Bolt, HHCS, 1/4"-20 x 3/4"

03 293430 Guard, Flex

04 292561 Engine, B&S 825 Series

05 145170 Bolt, HHCS, 5/16"-18 x 2"

06 154181 Tensioner, Belt

07 145151 Washer, Flat, 5/16", USS

08 143131 Nut, Nylon Lock, 5/16"-18

09 288721 Screen, 1" Diameter Holes

10 292571 Plate, Baffle

11 185861 Bracket, Axle

12 167791 Bolt, HHCS, 5/16"-18 x 3/4"

13 143401 Nut, Nylon Lock, 1/4"-20

14 149340 U-Bolt, 1/4"-20 x 1-1/4"

15 169731 Axle, 28-1/4"

16 154651 Tire/Wheel, 4.10/3.50 x 4

17 154881 Cap, Push

18 292581 Cap Screw, HHCS, 5/16"-18 x 10"

19 291291 Rod, Screen and Baffle

20 292591 Fastener, Snap

21 292601 Bolt, HHCS, 5/16"-18 x 1-1/2", GR5

22 186001 Damper, Vibration

23 143121 Bolt, HHCS, 5/16"-18 x 1-1/4", GR5

24 149261 Beam, Tow

25 142920 Plate, Bent, Tow Beam Hitch

26 208331 Shield, Blowback

27 202131 Screw, PHMS, 10-24 x 3/4", ZP

28 292611 Mount Strip, Blowback Shield,

29 202121 Nut, Nylon Lock, 10-24, ZP

30 202111 Hopper Kit, includes #26, 27, 28 & 29

31 145290 Bolt, Carriage, 5/16"-18 x 3/4"

Ref# Part# Description

32 N/A CHIPPER/SHREDDER BASIC ASSY

33 154481 Nut, Nylon Lock, 3/8"-16

34 292621 Brace, Front Support

35 146051 Bolt, HHCS, 5/16"-18 x 1", GR5

36 292631 Bolt, HHCS, 3/8"-16 x 1", GR5

37 148551 Key, Shaft, 1/4" Square x 1-1/2"

38 142311 Pulley, Flywheel Shaft, 6"

39 292641 Spacer, 1-3/4"

40 158531 Spacer, Wheel, 5/8"

41 186131 Nut, Gripco, 5/16"-18

42 293391 Belt, 5H440

43 185941 Plate, Cover

44 292651 Guard, Belt, Assembly – Black

45 144451 Bolt, HHCS, 3/8"-24 x 1-1/4", GR 8

46 216511 Washer, Lock, Split, 3/8"

47 162081 Washer

48 140751 Clutch

49 183221 Spacer/Shim, Clutch

50 294061 Pipe, Oil Drain, 1/4" NPT x 6" Galv.

51 294071 Cap, Pipe, Oil Drain, 1/4" NPT, ZP

52 154801 Washer, Flat, 1/4", USS

53 152951 Ring, Retaining

54 202800 Shim, 1.562" OD x 1.192" ID x .025" Thk

155260 Shim, 1.562" OD x 1.192" ID x .050" Thk

202820 Shim, 1.562" OD x 1.192" ID x .075" Thk

202810 Shim, 1.562" OD x 1.192" ID x .125" Thk

Not Illustrated

292821 Standard Warranty

292221 Safety & Operating Instructions Manual

Available Accessories

288731 Screen, 1/4" Hole Diameter

288741 Screen, 1/2" Hole Diameter

288751 Screen, 3/4" Hole Diameter

288761 Screen, Oblong Stamped

288771 Screen, Rectangular Stamped

292661 Bagging Kit

140051 Stand, Tow Beam

140061 Pull Handle Kit

26 DR

®

CHIPPER/SHREDDER

Page 27

Schematic – DR CHIPPER/SHREDDER ASSEMBLY – CHIPPER SIDE

110401

CONTACT US AT www.DRpower.com 27

Page 28

Schematic – DR CHIPPER/SHREDDER ASSEMBLY – DRIVE SIDE

110403

28 DR

®

CHIPPER/SHREDDER

Page 29

Parts List and Schematic– DR CHIPPER/SHREDDER ROTOR ASSEMBLY

NOTE: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

01 292801 Weldment, Rotor

02 292811 Rod, Hammer

03 185790 Hammer

04 186160 Spacer, 5/16"

Ref# Part# Description

05 158531 Spacer, 5/8"

06 186171 Spacer, 7/8"

07 186171 Pin, Groove

110328

CONTACT US AT www.DRpower.com 29

Page 30

Parts List – DR CHIPPER/SHREDDER BASIC ASSEMBLY

NOTE: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

01 167791 Bolt, HHCS, 5/16"-18 x 3/4"

02 292681 Plate, Top

03 216391 Nut, Lock, Gripco, 3/8"-16

04 186050 Bearing, Drive Side, 1-3/16"

05 292701 Plate, Drive Side

06 154490 Bolt, HHCS, 3/8"-16 x 1-1/4"

07 186131 Nut, Gripco, 5/16"-18

08 292711 Assembly, Rotor

09 292721 Spacer

10 143121 Bolt, HHCS, 5/16"-18 x 1-1/4"

11 292261 Bolt, HHCS, 5/16"-18 x 10"

12 292731 Bolt, HHCS, 5/16"-18 x 9-1/2"

13 202821 Shim

14 185911 Screw, Set, 3/8"-16 x 5/8"

15 140741 Bushing, Taper Lock

16 195661 Bolt, Carriage, 1/4"-20 x 1"

17 186041 Plate, Wear

18 155121 Screw, Self Tapping, 10-32 x 3/8"

19 292791 Door, Inspection

20 152951 Ring, Retaining

21 186051 Bearing, Chipper Side, 1-3/16"

22 143401 Nut, Nylon Lock, 1/4"-20

Ref# Part# Description

23 143390 Washer, Flat, 1/4", SAE

24 292741 Weldment, Chipper Plate & Chute

25 140681 Screw, FHSCS, 5/16-18 x 3/4"

26 292751 Knife

27 292761 Disk, Chipper – includes Knife

28 183011 Ring, Retaining, SHR-118

29 292771 Weldment, Plate, Chipper Side

30 292781 Weldment, Scroll

31 292281 Bolt, HHCS, 5/16"-18 x 1-1/2"

30 DR

®

CHIPPER/SHREDDER

Page 31

Schematic – DR CHIPPER/SHREDDER BASIC ASSEMBLY

110404

CONTACT US AT www.DRpower.com 31

Page 32

Daily Checklist for the DR CHIPPER/SHREDDER

To help maintain your DR CHIPPER/SHREDDER for optimum performance, we recommend you follow this checklist each

time you use your Chipper/Shredder.

Before performing any maintenance procedure or inspection, stop the Engine, wait five (5) minutes to allow all parts to cool.

Disconnect the Spark Plug Wire, keeping it away from the Spark Plug.

[ ] Check the Engine oil and Fuel Tank level.

[ ] Check that Engine is clean of debris.

[ ] Inspect the Chipper/Hopper(s) for accumulated debris.

[ ] Check the general condition of the Chipper/Shredder, e.g.; nuts, bolts, welds, etc.

[ ] Check Belt for wear and/or stretching.

[ ] Check Tire Pressure and wear.

[ ] Check the Chipper Knife for tightness, nicks and wear.

[ ] Check the Wear Plate for tightness and nicks; the edge should be square.

[ ] check the Debris Guard for wear and damage.

[ ] Remove any debris wrapped around the Hammer(s) Rotor.

End of Season and Storage

Before performing any maintenance procedure or inspection, stop the Engine, wait five (5) minutes to allow all parts to cool.

Disconnect the Spark Plug Wire, keeping it away from the Spark Plug.

Change the Engine oil.

Clean or replace the Air Filter.

Check the Chipper Knife, Hammers, and Wear Plate for nicks and wear.

Remove any debris wrapped around the Hammer(s) Rotor.

If your DR CHIPPER/SHREDDER will be idle for more than 30 days, we recommend using a gas stabilizer. This will prevent

sediment from gumming up the Carburetor. If there is dirt or moisture in the gas or tank, remove it by draining the tank.

Completely fill the tank with fresh, unleaded gas and add the appropriate amount of stabilizer or gasoline additive. Run the

Engine for a short time to allow the additive to circulate. Close the Fuel Shut-Off Valve to prevent carburetor overflow and

leakage.

Clean the exterior of the unit to remove all dirt, grease, and any other foreign material. To prevent rust, touch up painted

surfaces that have been scratched or chipped.

Be sure all nuts, bolts, and screws are securely fastened.

Inspect moving parts and the Drive Belt for damage and wear; replace if necessary.

Remove the Spark Plug and pour about 1 ounce of motor oil into the Cylinder hole. Replace the Plug and crank the Engine

over a couple of times using the Pull Cord. This will coat the piston and seat the valves to prevent moisture buildup.

If possible, store the Chipper/Shredder in a dry, protected place. If it is necessary to store the machine outside, after the

DR CHIPPER/SHREDDER has cooled, cover the machine with a suitable protective cover that does not retain moisture. Do

not use plastic as this material cannot breathe; it also allows condensation to form, which will cause your machine to rust.

75 MEIGS ROAD, P.O. BOX 25, VERGENNES, VERMONT 05491

©2011 Country Home Products, Inc. All rights reserved 292221A

Loading...

Loading...