Page 1

DR

DR

SAFETY & OPERATING INSTRUCTIONS

®

GENERATOR ATTACHMENT for the

®

FIELD and BRUSH MOWER

READ AND UNDERSTAND THIS MANUAL AND ALL INSTRUCTIONS

BEFORE OPERATING THIS GENERATOR.

Page 2

And congratulations on your purchase of a new DR GENERATOR ATTACHMENT!

We have done our utmost to ensure that your DR GENERATOR ATTACHMENT will be one of the most

trouble-free and satisfying pieces of equipment you have ever owned. Please let us know of any questions you

may have. We want to answer them as quickly as possible. When you do call, please have your order number

handy. For technical assistance, please call Toll-Free 1-800-DR-OWNER (376-9637) and one of our Technical

Support Representatives will be happy to help you. We also hope to hear from you on how much you like your

new helper.

And, please tell your friends about your new DR GENERATOR ATTACHMENT! Having DR Owners spread the

word about our products and our way of doing business is the best advertising we can have, and the best way

to help us provide even better service in the years to come.

Thanks once again!

for all of us at

Country Home Products, Inc.

®

ALES MANAGER

S

COPYRIGHT

©2006 Country Home Products, Inc. All rights reserved.

®

DR

Power Equipment

A division of Country Home Products®

127 Meigs Road

Vergennes, VT 05491

Toll-free phone

Fax

: 1-802-877-1213

Web site:

ii DR® GENERATOR ATTACHMENT

: 1-800-DR-OWNER (376-9637)

www.dr-owner.com

Page 3

Table of Contents

CHAPTER 1.......................................................................................................................................... 1

INTRODUCING THE DR GENERATOR

Conventions used in this manual ................................................................................................ 1

CHAPTER 2.......................................................................................................................................... 3

GENERAL SAFETY RULES............................................................................................................3

Labels .......................................................................................................................................... 3

Operating the Generator Safely.................................................................................................... 5

Safety with Gasoline-Powered Machines..................................................................................... 6

A Note to All Users ....................................................................................................................... 7

Additional Information and Potential Changes........................................................................... 7

CHAPTER 3.......................................................................................................................................... 9

SETTING UP YOUR DR GENERATOR ATTACHMENT .............................................................. 9

Unpacking and Attaching the Skids............................................................................................. 9

Removing the ATM Brush Deck................................................................................................. 11

Installing the DR GENERATOR ATTACHMENT ....................................................................... 12

Installing the Interface Relay Harness ....................................................................................... 13

Installing the Maintenance Meter (if you don’t have one)........................................................ 15

Installing the Interface Relay Harness on the AT3 model......................................................... 17

ATTACHMENT............................................................ 1

CHAPTER 4........................................................................................................................................ 19

OPERATING YOUR DR GENERATOR ATTACHMENT ............................................................ 19

Specifications.............................................................................................................................. 20

Receptacles ................................................................................................................................. 20

Grounding the Generator........................................................................................................... 21

Operating Safety ......................................................................................................................... 22

Generator Loading Guidelines ................................................................................................... 23

Operating the DR GENERATOR ATTACHMENT ...................................................................... 24

Cold Weather Operation............................................................................................................. 25

CHAPTER 5........................................................................................................................................ 27

MAINTAINING THE DR GENERATOR ATTACHMENT........................................................... 27

Regular Maintenance Check List before each use..................................................................... 27

End of Season and Storage ........................................................................................................ 27

CHAPTER 6........................................................................................................................................ 29

TROUBLESHOOTING................................................................................................................ 29

CHAPTER 7........................................................................................................................................ 30

PARTS LIST AND SCHEMATIC DIAGRAMS ............................................................................. 30

Parts List - DR GENERATOR ATTACHMENT ........................................................................... 30

Schematic - DR GENERATOR ATTACHMENT.......................................................................... 31

Electrical Schematics - DR GENERATOR ATTACHMENT ........................................................ 32

Warranty...................................................................................................................................... 35

CALL TOLL FREE 1-800-DR-OWNER iii

Page 4

iv DR® GENERATOR ATTACHMENT

Page 5

CHAPTER 1

INTRODUCING THE DR GENERATOR ATTACHMENT

This manual will help you set up and safely operate your new DR GENERATOR ATTACHMENT. Careful

adherence to the safety and operating instructions in this manual will ensure many years of productive use.

Please let us know of any questions you may have. We want to answer them as quickly as possible. When you

do call, please have your order number handy. For technical assistance, please call Toll-Free:

1-800-DR-OWNER (376-9637) and one of our Technical Support Representatives will be happy to help you.

Conventions used in this manual

THIS INDICATES A HAZARDOUS SITUATION, WHICH, IF NOT FOLLOWED,

SERIOUS INJURY.

THIS INDICATES A HAZARDOUS SITUATION, WHICH, IF NOT AVOIDED,

SERIOUS INJURY

THIS INDICATES A HAZARDOUS SITUATION, WHICH, IF NOT AVOIDED,

MODERATE INJURY.

THIS INFORMATION IS IMPORTANT IN THE PROPER USE OF YOUR MACHINE. FAILURE TO FOLLOW

THIS INSTRUCTION COULD RESULT IN DAMAGE TO YOUR MACHINE OR PROPERTY.

.

WILL RESULT

COULD RESULT

COULD RESULT

IN

DEATH OR

IN

DEATH OR

IN

MINOR OR

Tip:

This is a helpful hint to guide you in getting the most out of your DR GENERATOR ATTACHMENT.

Tools Needed:

NOTE:

This information may be helpful to you.

This indicates you will need a special tool to perform a maintenance function on your

Generator.

If you are ever unsure about an action you are about to take, don’t do it. Contact Country Home Products’ tollfree support at 1-800-DR-OWNER (376-9637) for help or information.

CALL TOLL FREE 1-800-DR-OWNER 1

Page 6

2 DR® GENERATOR ATTACHMENT

Page 7

g

CHAPTER 2

GENERAL SAFETY RULES

THIS GENERATOR IS CAPABLE OF CAUSING AN ELECTRIC SHOCK. FAILURE TO OBSERVE THE

FOLLOWING SAFETY INSTRUCTIONS WILL RESULT IN DEATH OR SERIOUS INJURY.

READ THIS SAFETY AND OPERATING MANUAL BEFORE YOU USE THE DR GENERATOR ATTACHMENT.

BECOME FAMILIAR WITH THE SERVICE RECOMMENDATIONS TO ENSURE THE BEST PERFORMANCE

FROM YOUR GENERATOR. ALSO, REVIEW THE

ALL-TERRAIN

FIELD AND BRUSH MOWER BEFORE THE SET-UP AND OPERATION OF THE GENERATOR.

SAFETY AND OPERATING INSTRUCTIONS

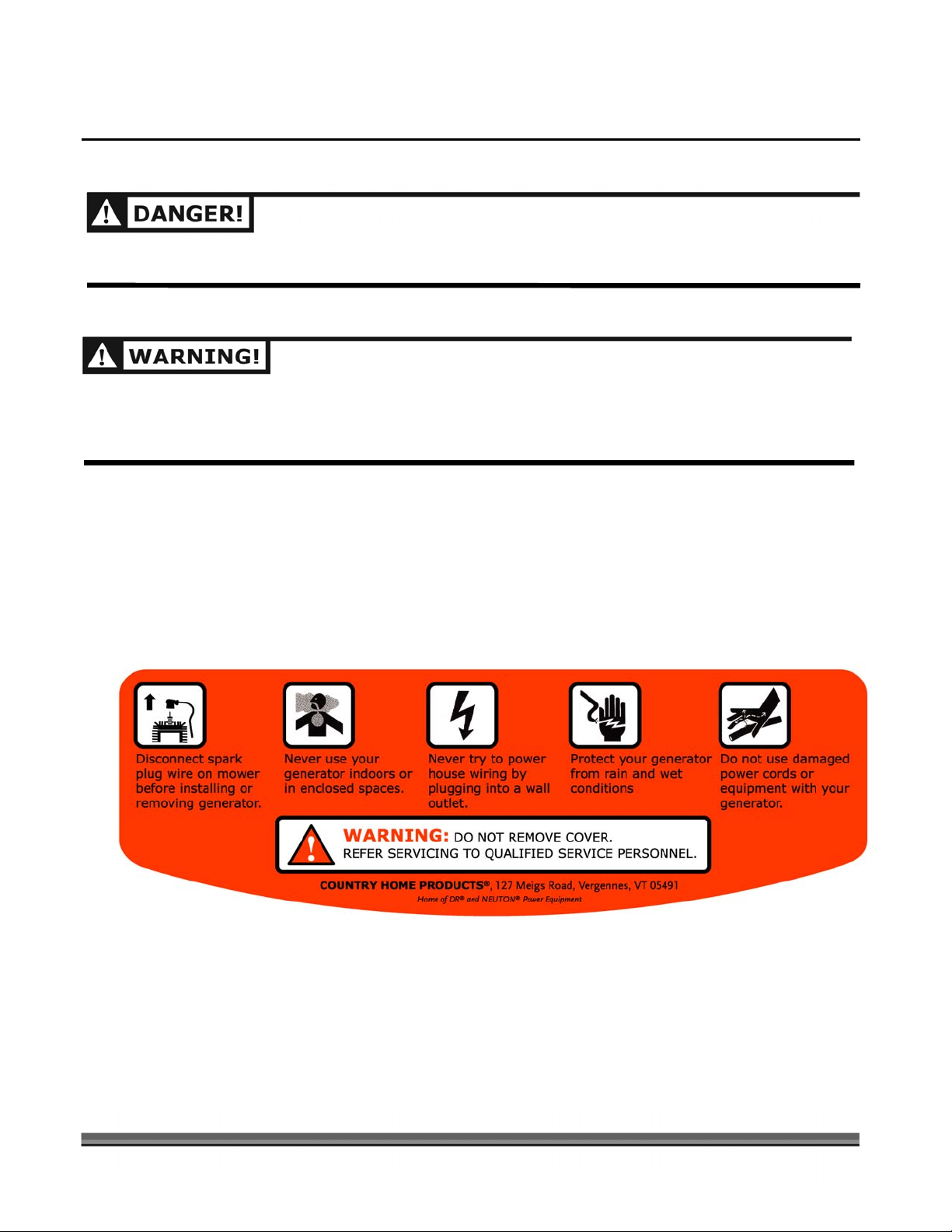

Labels

Your DR GENERATOR ATTACHMENT carries prominent labels as reminders for its proper and safe use.

Shown below are copies of all the labels that appear on the equipment. Take a moment to study them and

make a note of their location on your DR GENERATOR ATTACHMENT as you assemble and

operate the unit. Replace damaged or missing safety and information labels immediately.

FOR YOUR DR

before

you

This label reminds you about the importance of reading and understanding the Safety and Operatin

Instructions and notifies you of key hazards. (#192421)

CALL TOLL FREE 1-800-DR-OWNER 3

Page 8

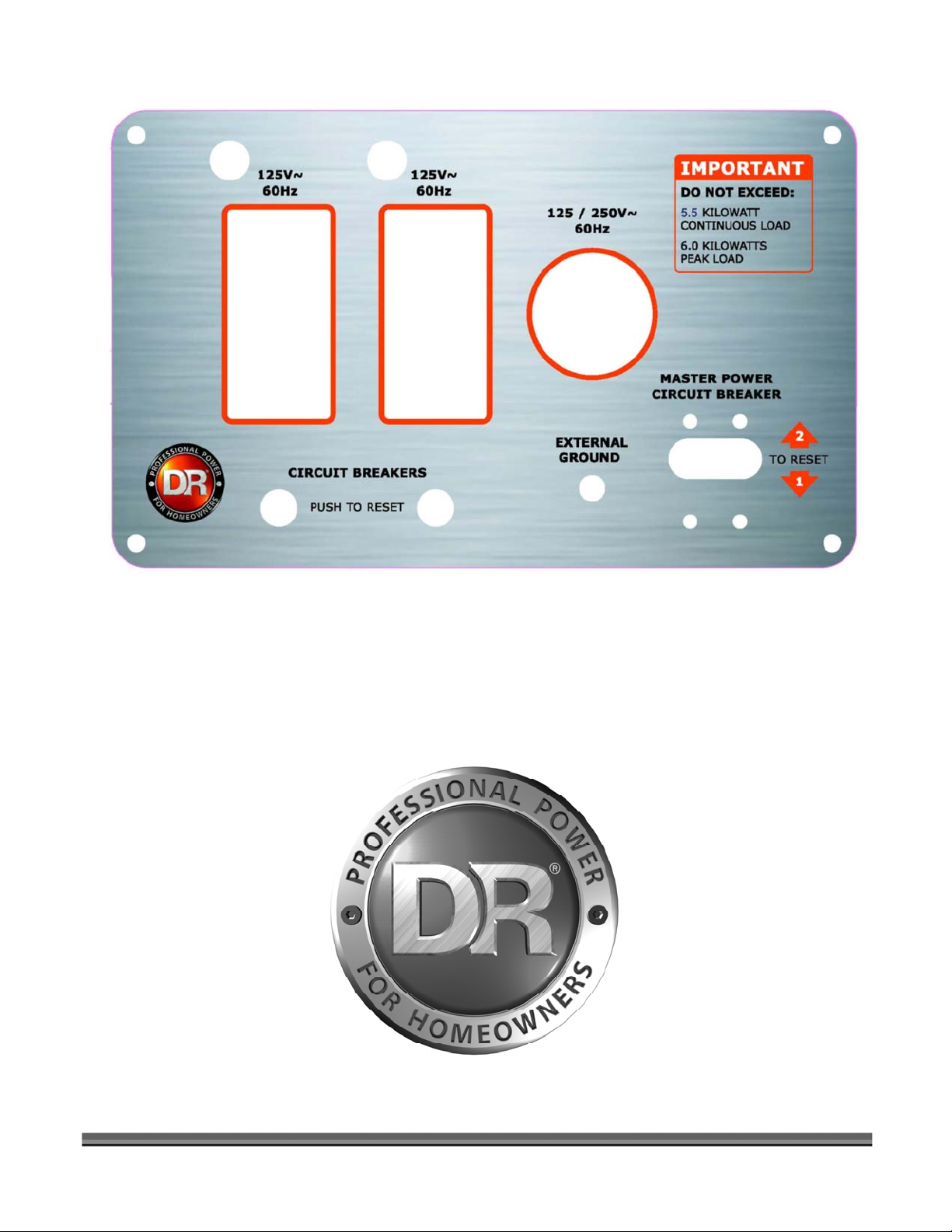

This panel label identifies the Outlet Voltages, Circuit Breakers, External Ground connection, and the

Max Load for your DR GENERATOR ATTACHMENT. #191971

4 DR® GENERATOR ATTACHMENT

#192391

Page 9

Operating the Generator Safely

THIS GENERATOR IS CAPABLE OF CAUSING AN ELECTRIC SHOCK. FAILURE TO OBSERVE THE

FOLLOWING SAFETY INSTRUCTIONS WILL RESULT IN DEATH OR SERIOUS INJURY.

• NEVER USE THE GENERATOR WHEN YOUR HANDS ARE WET. THE GENERATOR PRODUCES ENOUGH

ELECTRICAL POWER TO CAUSE A SERIOUS SHOCK OR ELECTROCUTION.

• ALWAYS KEEP THE GENERATOR DRY. PROTECT THE GENERATOR IN WET CONDITIONS SUCH AS

RAIN OR SNOW, OR NEAR A POOL OR SPRINKLER SYSTEM.

• NEVER OPERATE THE GENERATOR IN AN ENCLOSED AREA, OR EVEN PARTIALLY ENCLOSED, AS YOU

COULD BREATHE IN DANGEROUS CARBON MONOXIDE GAS FROM THE ATM ENGINE EXHAUST.

ALWAYS PROVIDE ADEQUATE VENTILATION WHEN OPERATING THE GENERATOR.

• ALWAYS MAKE CERTAIN THE GENERATOR IS PROPERLY GROUNDED PRIOR TO USE. SEE PAGE 19.

• NEVER CONNECT THE GENERATOR TO A BUILDING’S ELECTRICAL SYSTEM. TO DO THIS; AN

ISOLATION SWITCH (TRANSFORMER) MUST BE INSTALLED BY A LICENSED ELECTRICIAN.

THIS IS A HIGH-POWERED GENERATOR, WITH MOVING PARTS OPERATING AT HIGH SPEEDS. THE

MACHINE MUST BE OPERATED SAFELY TO PREVENT OR MINIMIZE THE RISK OF SEVERE INJURY. UNSAFE

OPERATION CAN CREATE A NUMBER OF HAZARDS FOR YOU. ALWAYS TAKE THE FOLLOWING

PRECAUTIONS WHEN OPERATING THIS GENERATOR:

• NEVER ALLOW PEOPLE WHO ARE UNFAMILIAR WITH THESE INSTRUCTIONS TO USE THE

GENERATOR.

• NEVER ALLOW CHILDREN TO OPERATE THE GENERATOR.

• KEEP YOUR HANDS AND FEET AWAY FROM THE BELTS, CHAINS, PULLEYS, AND CONCEALED AREAS

WHILE THE ENGINE IS RUNNING. NEVER REACH UNDER THE GENERATOR WHEN THE ENGINE IS

RUNNING.

• NEVER OPERATE THE GENERATOR IN AN AREA OF NATURAL GAS, FLAMMABLE LIQUIDS, VAPORS OR

EXPLOSIVE DUST.

• ALWAYS TURN OFF THE ATM ENGINE, REMOVE THE SPARK PLUG WIRE(S) AND DISENGAGE THE

GENERATOR BELT DRIVE BEFORE ADJUSTING OR SERVICING THE GENERATOR.

• NEVER OPEN THE OUTLET BOX OR GENERATOR COVER. DO NOT ATTEMPT ANY ELECTRICAL

REPAIRS YOURSELF. IF IN DOUBT, CONSULT A QUALIFIED ELECTRICIAN OR CONTACT COUNTRY

HOME PRODUCTS’ TOLL-FREE SUPPORT AT 1-800-DR-OWNER (376-9637) FOR HELP OR

INFORMATION.

• KNOW HOW TO STOP THE GENERATOR QUICKLY IN CASE OF EMERGENCY (STEP 9 ON PAGE 22).

CALL TOLL FREE 1-800-DR-OWNER 5

Page 10

• NEVER MOVE OR REPOSITION THE GENERATOR WITH ITS DRIVE BELT ENGAGED AND OPERATING.

• ALWAYS CHECK POWER CORDS AND EXTENSION CORDS FOR DAMAGE PRIOR TO EVERY USE AND

KEEP THEM AWAY FROM EXCESSIVE HEAT, OIL AND SHARP OBJECTS WHILE OPERATING THE

GENERATOR.

• NEVER OPERATE THE GENERATOR WHEN UNDER THE INFLUENCE OF ALCOHOL OR MEDICATION.

• ALWAYS SET THE PARKING BRAKE AND BE SURE THE GENERATOR (BLADE) AND WHEEL CONTROLS

ARE DISENGAGED BEFORE ATTEMPTING TO START THE ENGINE ON YOUR DR

AND BRUSH MOWER.

ALL-TERRAIN

FIELD

• NEVER, UNDER ANY CONDITIONS, REMOVE, BEND, CUT, FIT, WELD, OR OTHERWISE ALTER

STANDARD PARTS ON THE DR GENERATOR ATTACHMENT. MODIFICATIONS TO YOUR GENERATOR

COULD CAUSE AN INJURY AND WILL VOID YOUR WARRANTY.

• UNDERSTAND THE OUTPUT RECEPTACLES AND CONNECTIONS.

• ALWAYS MAKE CERTAIN NUTS AND BOLTS ARE TIGHT TO ASSURE A SAFE WORKING CONDITION.

Safety with Gasoline-Powered Machines

GASOLINE IS A HIGHLY FLAMMABLE LIQUID. GASOLINE ALSO GIVES OFF FLAMMABLE VAPOR THAT CAN

BE EASILY IGNITED AND CAUSE A FIRE OR EXPLOSION. DO NOT OVERLOOK THE HAZARDS OF

GASOLINE. ALWAYS FOLLOW THESE PRECAUTIONS:

• NEVER RUN THE ATM ENGINE IN AN ENCLOSED AREA OR WITHOUT PROPER VENTILATION.

• STORE ALL FUEL IN CONTAINERS SPECIFICALLY DESIGNED FOR THIS PURPOSE.

• FILL THE GASOLINE TANK OUTDOORS WITH THE ENGINE OFF. DON'T HANDLE GASOLINE IF YOU

OR ANYONE NEARBY IS SMOKING, OR IF YOU'RE NEAR ANYTHING THAT COULD CAUSE IT TO

IGNITE OR EXPLODE.

• IF YOU SPILL GASOLINE, DO NOT ATTEMPT TO START THE ENGINE. MOVE THE MACHINE AWAY

FROM THE AREA OF THE SPILL AND AVOID CREATING ANY SOURCE OF IGNITION UNTIL THE GAS

VAPORS HAVE DISSIPATED. WIPE UP ANY SPILLED FUEL TO PREVENT A FIRE HAZARD AND PROPERLY

DISPOSE OF THE WASTE.

• ALLOW THE ENGINE TO COOL COMPLETELY BEFORE STORING IN ANY ENCLOSURE. NEVER STORE

THE MACHINE NEAR AN OPEN FLAME OR SPARK WITH GAS IN THE TANK.

• NEVER CHANGE THE ENGINE GOVERNOR SETTINGS OR MODIFY THE ENGINE SPEED.

6 DR® GENERATOR ATTACHMENT

Page 11

THE GENERATOR MUST BE OPERATED SAFELY TO PREVENT OR MINIMIZE THE RISK OF MINOR OR

MODERATE INJURY. UNSAFE OPERATION CAN CREATE A NUMBER OF HAZARDS FOR YOU. ALWAYS TAKE

THE FOLLOWING PRECAUTIONS WHEN OPERATING THIS GENERATOR:

• USE EARMUFFS OR EARPLUGS RATED FOR AT LEAST 20 DBA TO PROTECT YOUR HEARING WHEN

YOU ARE WORKING CLOSE TO THE GENERATOR.

• ALWAYS GRASP A POWER CORD PLUG WHEN UNPLUGGING THE CORD FROM THE GENERATOR

OUTLET BOX; DO NOT PULL THE PLUG OUT BY THE CORD.

• NO LIST OF WARNINGS AND CAUTIONS CAN BE ALL-INCLUSIVE. IF SITUATIONS OCCUR THAT ARE

NOT COVERED BY THIS MANUAL, THE OPERATOR MUST APPLY COMMON SENSE AND OPERATE

THIS GENERATOR IN A SAFE MANNER.

CALL 1(800) DR-OWNER (376-9637) FOR ASSISTANCE.

A Note to All Users

Under California law, and the laws of some other states, you are not permitted to operate an internal

combustion engine using hydrocarbon fuels without an engine spark arrester. This also applies to

operation on US Forest Lands. All DR

State are provided with spark arresters. Failure of the owner or operator to maintain this equipment in

compliance with state regulations is a misdemeanor under California law and may be in violation of other

state and/or federal regulations. Contact your local fire marshal or forest service for specific information in

your area.

®

FIELD and BRUSH MOWERS shipped to California and Washington

Additional Information and Potential Changes

Country Home Products, Inc. reserves the right to discontinue, change, and improve its products at any

time without notice or obligation to the purchaser. The descriptions and specifications contained in this

manual were in effect at printing. Equipment described within this manual may be optional. Some

illustrations may not be applicable to your machine.

CALL TOLL FREE 1-800-DR-OWNER 7

Page 12

8 DR® GENERATOR ATTACHMENT

Page 13

CHAPTER 3

SETTING UP YOUR DR GENERATOR ATTACHMENT

This chapter covers the unpacking, attaching the Skids and the procedures necessary for connecting the DR

GENERATOR ATTACHMENT to your DR

at all, please feel free to contact our Customer Service Representatives at our toll free number:

1-800-DR-OWNER (376-9637).

Unpacking and Attaching the Skids

NOTE: We recommend two people for unpacking, as the unit weighs 90 pounds.

Parts Supplied:

• Generator Attachment

• Interface Relay Harness

• Drive Belt (same as Brush Deck)

• (2) Skids

• Crosspiece

• 5/16-18 x 2-1/2" Bolt

• 1-1/2" Spacer

• 5/16" Lock Washer

• (10) 5/16" Bolts, Washers & Lock Nuts

• #10 Screw x 5/8" & #10 Lock Nut

• Cable Ties

ALL-TERRAIN

Field and Brush Mower. If you have any questions

Tools Needed:

• (2) 1/2" Open End Wrench

• Phillips Screwdriver or optional wrench

1. Open the shipping container and remove the top packing piece and place it near the shipping

container (Figure 1 on page 10).

2. Remove the Crosspiece and the Parts Bag containing the Interface Relay Harness, Cable Ties, and

Hardware from the shipping container.

3. Carefully lift the DR GENERATOR ATTACHMENT out of the shipping container and rest it upside

down on the packing material from Step 1 (Figure 1 on page 10).

NOTE: One person should steady the Generator during assembly.

4. Remove the two (2) Skids from the bottom of the shipping container (Figure 1 on page 10).

5. Assemble the Belt Guide (Figure 2 on page 10) and install it on the Frame as shown. Tighten

securely.

6. Route the Generator Wire Harness through the Frame and out the rear of the Generator as shown

in Figures 2 and 3 on page 10.

7. Locate the Holes in the Frame Sides as shown in (Figure 3 on page 10). There are two (2) Holes at

the front of the Frame and one (1) at the rear on either side. Orient the Skids to match the Hole

patterns.

8. Place the Skids in the U-section Channel of the Frame and bolt them in place with six (6) Bolts,

Washers, and Lock Nuts (Figure 3 on page 10). Do not tighten completely at this time.

NOTE: The Bolt heads and Washers are on the outside and Lock Nuts are on the inside (Figure 3 on page

10).

CALL TOLL FREE 1-800-DR-OWNER 9

Page 14

A

9. Bolt the Crosspiece to the front of the Skids (Figure 4) using four (4) Bolts, Washers, and Lock

Nuts. Now tighten all of the hardware.

10. Tip the unit up right onto the Skids. The assembly is now complete.

NOTE: Do not discard your packaging material until you are fully satisfied with your new DR GENERATOR

ATTACHMENT.

Top Packing Material

Skids

1. 2. 3. 4.

Figure 1

Belt Guide Bolt

ssembly

Skid Inside Frame U-Channel

Frame

Channel

Figure 2

Spacer

Lock Washer

Bolt

Generator Wire

Harness

Packing Material

Crosspiece

Skid

Rear

Frame

Bolt Heads and

Washers (1 place

each side)

Generator Wire

Harness

Figure 3

10 DR® GENERATOR ATTACHMENT

Front

Bolt Heads

and Washers

(2 places

each side)

Crosspiece

Bolt Heads and

Washers (4 places)

Figure 4

Page 15

Removing the ATM Brush Deck

ALWAYS STOP THE ENGINE AND DISCONNECT THE SPARK PLUG WIRE(S) BEFORE PERFORMING ANY

MAINTENANCE OR SERVICING PROCEDURE ON YOUR MACHINE.

1. Remove the black belt guard by unscrewing

the black knob, lifting the cover and pulling

up and back to remove it.

2. Release the Belt Tension Lever (Figure 5).

Figure 5

3. Remove the Belt from the Deck Pulley and

the ATM Engine Pulley (Figure 6).

Belt Removed

Figure 6

4. Remove the pin and collar (Figure 7), and

then pull the power unit away from the

deck.

DO NOT PULL THE DECK AWAY FROM THE

POWER UNIT UNLESS YOU HAVE SOMEONE

HOLDING THE HANDLEBARS TO PREVENT IT

FROM FALLING BACKWARD.

Figure 7

CALL TOLL FREE 1-800-DR-OWNER 11

Page 16

A

A

r

A

Generator

TM

Installing the DR GENERATOR ATTACHMENT

1. With the help of another person to steady the

ATM power unit; line up the GENERATOR

ATTACHMENT with the ATM Attachment Pin

and slide the Generator onto the Pin (Figure 8).

2. Reattach the Collar and Retaining Pin to secure

the Generator (Figure 9).

3. Pull and release the Belt Tension Lever from the

Stow Clip beneath the Generator (Figure 10).

ttachment Pin

Figure 8

Retaining Pin

Collar

Figure 9

4. Install the supplied Drive Belt on the Engine

Pulley below the ATM (Figure 10).

5. Route the Drive Belt around the Generator Belt

Tension Pulley and the Generator Drive Pulley

(Figure 9).

6. Push the Belt Tension Lever back into its locked

position on the Generator (Figure 11).

Generator

Belt Tension Lever

Stow Clip

Drive

Pulley

Stow Clip

Drive

Belt

TM

12 DR® GENERATOR ATTACHMENT

Belt Tension

Pulley

Engine

Pulley

Belt Tension Leve

Figure 11 Figure 10

Page 17

Installing the Interface Relay Harness

NOTE: See page 17 for the AT-3 Lock-In/Out model ATM.

Tools Needed:

• 3/8" Open End Wrench

• Phillips Screw Driver

• Electric Drill

• 3/16" Drill Bit

• Tape Measure

To original Wire Harness PTO Connector

PTO Switch (Blade Engagement) B

Interface Relay

To Generator

A

C

D

UPPER

END

LOWER

END

1. Examine the Wire Harness and identify the

connections as shown in Figure 12.

2. Locate the Blade Engagement connection

beneath the Handlebar Control Panel

(Figure 13) and remove the existing

connector from the Blade Engagement

Switch.

3. Insert Connector B into the Blade

Engagement Switch (Figure 14).

4. Plug the Original Wire Harness Connector

into the A Connector of the new harness.

5. Locate and drill a 3/16" hole in the Right

Side Gas Tank Support, if not already there

(Figure 15).

3/16" Hole

1"

Relay Mounted

Vertical

1"

Wire Harness Connections

Figure 12

Existing Blade

Engagement

Connection

Original Upper Connection

Figure 13

Right Side Gas

Tank Support

Mounting

Screw

Figure 14

Figure 15

CALL TOLL FREE 1-800-DR-OWNER 13

New

Connector

New

Connector

B

Original

Connector

A

Page 18

A

f

Figure 16

Interface Relay

behind Support

6. Refer to Figure 16 for the proper relay

color code connections in the event your

relay should become disconnected.

7. Run the lower end of the new Interface

Relay Harness, with the Relay attached,

down along the handlebar and in back of

the Right Tank Support (Figure 17).

8. Mount the Interface Relay vertically

against the inside of the Tank Support

(Figure 15 on page 13) using the Screw

and Locking Nut supplied.

9. Plug the Connector D (Figure 12 on page

13), from the Relay, into the Generator

Harness (Figure 18).

10. Secure the new wire harness to the

existing ATM harness as shown using a

Cable Tie provided (Figure 18).

11. Secure the upper portion of the Wire

Harness to the handlebar frame using the

plastic Cable Ties provided (Figure 19).

Right Tank Support

12. Cut off excess Cable Ties. Your

installation is now complete.

Figure 17

Right Tank

Support

Cable Tie

Connector

rom Relay

Figure 18 Figure 19

14 DR® GENERATOR ATTACHMENT

D

Interface Relay Harness

TM Harness

Cable Tie

Generator

Harness

Cable Tie

Page 19

A

g

Adapter

Installing the Maintenance Meter (if you don’t have one)

Tools and Parts Needed:

• Screwdriver

• Cutting Pliers

• Meter Assembly #184271 Includes:

• Meter

• 66" Wire

• Control Panel Plug w/cutout

• Mounting Bracket

• Cable Ties

NOTE: Do not place the Mounting Bracket on the Meter before the Meter is inserted into the Control Panel.

1. Gently pry the black factory Panel Insert from the

Control Panel (Figure 20).

2. Insert the Control Panel Plug from the new Meter Kit

into the open hole in the Control Panel (Figure 21).

3. Insert the Meter firmly into the Panel Plug. The Meter

Flange should be flat against the face of the Panel

Plug.

4. Thread the Sensor Wire Adapter through the Meter

Mounting Bracket as shown (Figure 22) leaving

sufficient wire length to form a loop when the

connector is placed on the Meter.

5. Place the Mounting Bracket with Sensor wire

attached, on the Meter from the backside of the Panel.

Press the Mounting Bracket as far as possible toward

the Control Panel while holding the Meter in place

from the front. The Bracket should click into place.

6. Slide the Connector onto the male fitting on the back

of the Meter. When finished, the assembly should

appear as in Figure 23.

Figure 29

Control Panel

Flange

Front Panel

Insert

Control

Panel

Plu

Mounting

Bracket

Meter

To Meter

Figure 21

Figure 22 Figure 23

CALL TOLL FREE 1-800-DR-OWNER 15

To Engine

Spark Plug

Sensor

Wire

Connector

Sensor Wire

dapter

Page 20

r

g

Cable Ties

Figure 24

Wire routed down

existing harness to

spark plug wire.

Figure 25

7. Run the Sensor Wire from the Meter to the Handleba

(Figure 24) and secure in two (2) places as shown

with Cable Ties. Do not over tighten the Cable Ties.

DO NOT BIND THE WIRE TOO TIGHTLY WITH THE CABLE

TIES AND AVOID PLACING THE WIRE ON OR NEAR HOT

SURFACES.

8. Route the remaining Meter wire forward, following

down the existing wiring harness toward the engine

spark plug wire (Figure 25).

9. Attach the Sensor Wire to the Spark Plug Wire by

wrapping it around the plug wire as shown in Figure

25. Secure the Sensor Wire back on itself with a Cable

Tie (Figure 26). The Meter installation is now

complete.

NOTE 1: The Maintenance Meter is fully automatic with a

display that may be read at all times, whether the

engine is ON or OFF.

NOTE 2: During engine ON, the engine RPM is displayed,

when the engine is OFF, accumulated Run Time

hours is displayed.

NOTE 3: After 25 Hours of engine ON time, the meter will

automatically flash a “Change Oil” display. The

flashing will continue for several hours of operation

even after you change the oil.

Spark Plug Wire

16 DR® GENERATOR ATTACHMENT

Cable Tie

NOTE 4: If the engine RPM display is not responding to

changes in engine speed, check the connections at

the Meter and Spark Plug.

Figure 26

Wrapped Sensor Wire

Spark Plu

Page 21

Installing the Interface Relay Harness on the AT3 model

1. Remove the two (2) Extensions (Figure 27)

from the Upper End of the Generator Wire

Harness.

2. Locate the Operator Presence connection

beneath the Control Panel (Figure 28) and

separate the connectors by grasping the wires

on each side of the connector and pulling in

opposite directions as shown.

Extensions

Male Female

NOTE: The Generator Connectors are male and

female and will only connect to the ATM

Harness one way.

3. Connect the Generator Wire Harness to the

ATM Harness as shown in Figure 29.

4. Locate and drill a 3/16" hole in the Right Side

Gas Tank Support, if not already there. Refer to

page 13, step 5 for instructions and a list of

required tools.

5. Run the lower end of the new Interface Relay

Harness, with the Relay attached, down along

the Right Handlebar and in back of the Right

Tank Support, and mount the Relay. Refer to

steps 6 through 12 on page 14 for the routing,

mounting of the Relay and connection of the

Harness to the Generator.

6. The Harness installation is now complete. If

you are installing a Maintenance Meter, refer to

page 15.

Extensions

Removed

Upper End of Generator Wire Harness

Figure 27

Operator Presence

Connection

Figure 28

Figure 29

CALL TOLL FREE 1-800-DR-OWNER 17

Page 22

18 DR® GENERATOR ATTACHMENT

Page 23

CHAPTER 4

OPERATING YOUR DR GENERATOR ATTACHME NT

This chapter discusses the basic operation of your new DR GENERATOR ATTACHMENT. It may be helpful

to familiarize yourself with the features on your Generator by reviewing the picture below before beginning

the steps outlined in this chapter.

(4) 125VAC GFCI Outlets 125/250VAC Outlet

GFCI

Reset*

(2) 125VAC

Circuit Breakers*

(20-AMP)

* Push Button In To Reset

125/250VAC Circuit Breaker

(25-AMP)

Ground Connection

Skids

Figure 30

CALL TOLL FREE 1-800-DR-OWNER 19

Page 24

Specifications

Length 26-1/2"

Width 16-1/2"

Height 31"

Weight 90 lbs.

AC Output:

Rated Voltage 125/250 VAC

Rated Frequency 60 Hz

Rated Current 40/25 Amps

Rated Output (continuous) 4.8 – 5.5 Kilowatts

Maximum Output 6.0 Kilowatts

Receptacles

USE ONLY EXTENSION CORD SETS THAT ARE RATED FOR 125 VAC LOADS AT 20 AMPS OR GREATER.

• The DR GENERATOR ATTACHMENT is equipped with two (2) 125VAC, 20 AMP, Duplex, Ground Fault

Circuit Interrupter (GFCI) Receptacles. Use each receptacle to operate 125VAC, single-phase, 60 Hz electrical

loads requiring up to 2,400 Watts (2.4 KW). Each duplex outlet is protected against overload with a push-toreset circuit breaker (Figure 30).

• The DR GENERATOR ATTACHMENT is also equipped with a 125/250VAC, 25 AMP, Locking Receptacle. Use

this receptacle to operate 125/250VAC, single-phase, 60 Hz electrical loads requiring up to 6,000 Watts (6.0

KW) at 25 AMPS for 125 or 250VAC. Use only a NEMA L14-30 plug (Figure 31) with a 4-wire cord set rated for

250VAC loads at 30 AMPS or greater (Figure 31). The same 4-four wire cord can also be used to operate a

125VAC appliance having this type of connector. This outlet is also protected against overload with a circuit

breaker (Figure 30).

Figure 31

20 DR® GENERATOR ATTACHMENT

Page 25

Grounding the Generator

The National Electrical Code requires that the frame and external electrically conductive parts of this

Generator be properly connected to an approved earth ground. Local electrical codes may also require

proper grounding of the Generator. For that purpose, an EXTERNAL GROUND fastener is provided on the

Generator (Figure 32).

Generally, connecting a #12 AWG copper wire to the EXTERNAL GROUND fastener and then to an earthdriven copper or brass grounding-rod provides adequate protection against electrical shock. However, local

codes may vary; consult with a local electrician for grounding requirements in your area.

Figure 32

Properly grounding the Generator helps prevent electrical shock if a ground fault condition exists in the

Generator or in connected appliances. Proper grounding also helps dissipate static electricity, which often

builds up in ungrounded devices. A Ground Fault Circuit Interrupter (GFCI) is provided in the 125VAC

receptacles on the Generator front panel (Figure 30).

CALL TOLL FREE 1-800-DR-OWNER 21

Page 26

r

Operating Safety

• TO PREVENT ELECTRICAL SHOCK, MAKE SURE ALL APPLIANCES ARE IN GOOD WORKING ORDER

BEFORE YOU CONNECT THEM TO YOUR DR GENERATOR ATTACHMENT.

• MAKE SURE THE GENERATOR IS PROPERLY GROUNDED.

• DO NOT CONNECT 250VAC APPLIANCES TO THE 125VAC DUPLEX OUTLETS.

• DO NOT CONNECT 3-PHASE LOADS TO THE GENERATOR.

• DO NOT CONNECT 50 HZ APPLIANCES TO THE GENERATOR.

• ANY CONNECTION FOR AUXILIARY POWER TO A BUILDING MUST BE MADE BY A LICENSED

ELECTRICIAN (USING AN ISOLATION TRANSFORMER/SWITCH) AND MUST COMPLY WITH ALL

APPLICABLE LAWS AND ELECTRICAL CODES. IMPROPER CONNECTIONS CAN ALLOW ELECTRICAL

CURRENT FROM THE GENERATOR TO FEED BACK INTO THE UTILITY LINES AND MAY

ELECTROCUTE A UTILITY WORKER THAT CONTACTS THE LINES DURING A POWER OUTAGE.

ALSO, WHEN THE UTILITY POWER IS RESTORED FROM AN OUTAGE, THE GENERATOR MAY

EXPLODE, BURN, OR CAUSE FIRES IN THE BUILDING ELECTRICAL WIRING.

• THE TOTAL WATTAGE OF THE APPLIANCES CONNECTED TO THE DR GENERATOR ATTACHMENT

MUST NOT EXCEED 6.0 KILOWATTS.

• FOR CONTINUOUS OPERATION, DO NOT EXCEED 5.5 KILOWATTS FOR MORE THAN 30

MINUTES.

• MOST MOTORIZED APPLIANCES REQUIRE MORE THAN THEIR RATED WATTAGE FOR START-UP.

DO NOT EXCEED THE CURRENT LIMIT SPECIFIED FOR ANY GENERATOR OUTPUT (FIGURE 30).

• A CIRCUIT BREAKER ON THE FRONT PANEL OF THE DR GENERATOR ATTACHMENT (FIGURE 30)

WILL AUTOMATICALLY TRIP (BUTTON POPS OUT) IF THAT INDIVIDUAL CIRCUIT IS OVERLOADED

OR IF A DEFECTIVE APPLIANCE IS PLUGGED INTO THE CIRCUIT. IF A CIRCUIT BREAKER TRIPS

AUTOMATICALLY, CHECK THAT THE APPLIANCE CONNECTED DOES NOT EXCEED THE RATED

LOAD CAPACITY FOR THAT CIRCUIT AND/OR THE APPLIANCE IS WORKING PROPERLY BEFORE

RESETTING THE CIRCUIT BREAKER (FIGURE 30).

NOTE: You can determine an appliance’s wattage rating by multiplying its required voltage (125VAC o

250VAC) by the amount of current (Amps) it draws. Also see Generator Loading Guidelines on the next

page.

22 DR® GENERATOR ATTACHMENT

Page 27

Generator Loading Guidelines

Capacity

• Make sure the Generator can supply

enough rated (running) and surge

(starting) watts for the items you will power

at the same time. Follow these simple

steps:

• Select the items to be powered at the same

time.

• Total the rated (running) watts of these

items. This is the amount of power the

Generator must produce to keep the items

running (

Chart

).

• Estimate how many surge (starting) watts

that will be required. Surge wattage is the

short burst of power needed to start electric

motor-driven tools or appliances such as a

circular saw or refrigerator. Since all motors

do not start at the same time, total surge

watts can be estimated by adding only the

item(s) with the highest additional surge

watts to the total rated watts from Step 2.

Example:

Tool

or

Appliance

Sprayer 600 1200

Light – 75W 75 Refrigerator 800 1600

Freezer 500 Television 500 -

2475 Total 1600 Highest

Running Watts Surge Watts

Total Rated (Running) Watts = 2475

Highest Additional Surge Watts = 1600

Total Generator

Output Required = 4075

Table 1 – Wattage Reference

Rated

(Running)

Watts

Additional

Surge

(Starting)

Watts

Table 1-Wattage Reference Chart

Additional

Surge

(Starting

Tool or Appliance Rated*

(Running

Watts)

Watts)

Job Site

Circular Saw 1500 1500

Electric Drill-1/2HP 1000 1000

Table Saw - 10" 2000 2000

Air Compressor 2500 2500

Airless Sprayer-1/3 HP 600 1200

Reciprocating Saw 960 960

Miter Saw - 10" 1800 1800

Table Planer - 6" 1800 1800

Work Light-Quartz

1000 -

Halogen

Essentials

Light Bulb – 75Watt 75 Deep Freezer 500 500

Refrigerator/Freezer 18

800 1600

Cu. Ft.

Water Well Pump-

1000 2000

1/3 HP

Sump Pump 800 1200

Water Heater-40 Gal. 4000 --

Kitchen

Coffee Maker 1500 Microwave Oven 1000 Hot Plate 2500 Electric Stove-

1500 Single Element

Heating/Cooling

Furnace Fan-1/2 HP 800 1300

Window Fan 300 600

AC - 10,000 BTU 1200 1800

Family Room

Color TV-27" 500 PC w/17" Monitor 800 VCR 100 -

Other

Garage Door Opener 480 520

AM/FM Clock Radio 300 Security System 180 -

* Wattages listed are approximate only. Check tool or

appliance for actual wattage.

CALL TOLL FREE 1-800-DR-OWNER 23

Page 28

Operating the DR GENERATOR ATTACHMENT

NEVER START OR STOP THE GENERATOR WITH AN APPLIANCE OR TOOL PLUGGED IN.

1. Set the Parking Brake on your DR

2. Make certain that the Shift Lever is in the Neutral position and the PTO is in the Disengaged

position.

3. Plug the Generator Wire Harness into the Relay Wire Harness at the fuel tank mount. Be sure the

Main Power Switch on the Generator is OFF.

4. Start the engine in accordance with Chapter 4 of the

All-Terrain

5. After the engine has warmed up, set the Throttle to Run. Verify the engine RPM is at least 3300

RPM as indicated on the Maintenance Meter.

6. To start the Generator, hold the Operator Presence Lever down with your left hand and slowly

engage the PTO (Generator Belt Drive). When the generator is up to speed, release the Operator

Presence Lever.

7. Plug the appliance(s) that you wish to use into the corresponding outlet(s) (125VAC or 250VAC 60

Hz only) required by appliance(s).

NOTE:

To prolong the life of your Generator and the attached tools or appliances, it is important to take

Field and Brush Mower.

care when adding electrical loads to the Generator. The correct and safe way to manage Generator

power is to sequentially add loads a follows:

All-Terrain

Field and Brush Mower.

Safety & Operating Instructions

for your DR

• Plug-in and turn-on the first appliance or tool, preferably the largest rated load.

• Permit the Generator output to stabilize (ATM engine runs smoothly and attached load

operates properly).

• Plug-in the next appliance or tool in the other outlet and again, permit the Generator to

stabilize. Repeat this Step for each additional load. Keeping the load balanced between

the two (2) 125 V outlets will prolong the life of your Generator by reducing the vibration

loads.

• NEVER add more tools or appliances than the Generator capacity. Take care to consider

surge as explained on the previous page.

8. Upon completion of your work, turn-off and unplug the appliance(s) from the Generator and allow

the ATM and Generator to run under a “no-load” condition for approximately 2 minutes before

disengaging the PTO drive. This will allow the ATM and Generator to cool down.

9. Turn OFF the Master Power Circuit Breaker on the Generator Control Panel, disengage the PTO

drive on the ATM control panel, return the Throttle to Idle and turn off the ATM engine. Be sure to

remove the Key from the ATM for safety.

10. When removing the Generator from the ATM, be sure to disconnect the Generator harness from

Connector D at the Interface Relay. See Figure 18 on page 14.

24 DR® GENERATOR ATTACHMENT

Page 29

Cold Weather Operation

Under certain weather conditions (temperatures below 40°F [4°C] and a high dew point), your ATM engine

may experience icing of the carburetor and/or the crankcase breather system. Country Home Products, Inc.

offers an optional engine cover to prevent icing in these weather conditions. The cover can be purchased

through Country Home Products, Inc. by calling 1(800) DR-OWNER (376-9637). Please have your ATM

Model# and Serial# at hand when the call is placed.

CALL TOLL FREE 1-800-DR-OWNER 25

Page 30

26 DR® GENERATOR ATTACHMENT

Page 31

CHAPTER 5

MAINTAINING THE DR GENERATOR ATTACHMENT

Regular maintenance is the way to ensure the best performance and long life of your DR GENERATOR

ATTACHMENT. Please refer to this manual for maintenance procedures.

• WHEN PERFORMING ANY MAINTENANCE ON THE DR GENERATOR ATTACHMENT WHEN THE

UNIT IS STILL ATTACHED TO THE ATM, YOU MUST FIRST DISCONNECT THE SPARK PLUG WIRE(S)

ON THE ATM.

• ONLY A LICENSED ELECTRICIAN SHOULD REMOVE THE COVER OR FRONT PANEL OF THE

GENERATOR.

Regular Maintenance Check List before each use

• Check the engine oil level in your DR A

ll-Terrain

Field and Brush Mower.

• Check the general condition of the ATM and Generator, e.g.; nuts, bolts, welds etc.

• Make sure that the Generator is dry and there is no foreign material in the outlets.

• Check the condition of the Drive Belt for nicks and fraying, replace if necessary. See page 12.

End of Season and Storage

• WHEN PERFORMING ANY MAINTENANCE ON THE DR GENERATOR ATTACHMENT WHEN THE

UNIT IS STILL ATTACHED TO THE ATM, YOU MUST FIRST DISCONNECT THE SPARK PLUG WIRE(S)

ON THE ATM.

• ONLY A LICENSED ELECTRICIAN SHOULD REMOVE THE COVER OR FRONT PANEL OF THE

GENERATOR.

• Wipe down the Generator to remove any moisture and dirt that may have accumulated, especially

in and around the outlets.

• Vacuum out any accumulated debris from the Generator vents.

• Store the DR GENERATOR ATTACHMENT in a dry area to prevent moisture from damaging the

electrical components.

CALL TOLL FREE 1-800-DR-OWNER 27

Page 32

28 DR® GENERATOR ATTACHMENT

Page 33

CHAPTER 6

TROUBLESHOOTING

Most problems are easy to fix. Consult the Troubleshooting Table below for common problems and their

solutions. If you continue to experience problems, call Country Home Products, Inc. for support.

Troubleshooting Table

• WHEN PERFORMING ANY MAINTENANCE ON THE DR GENERATOR ATTACHMENT WHEN THE

UNIT IS STILL ATTACHED TO THE ATM, YOU MUST FIRST DISCONNECT THE SPARK PLUG WIRE(S)

ON THE ATM.

• ONLY A LICENSED ELECTRICIAN SHOULD REMOVE THE COVER OR FRONT PANEL OF THE

GENERATOR.

SYMPTOM POSSIBLE CAUSE

No output voltage at any

outlet.

No output voltage at one or

more outlet.

A circuit breaker trips when

an appliance or tool is

plugged in.

A circuit breaker trips when

an appliance or tool is turned

on.

ATM stalls when PTO is

engaged to start the

Generator.

⇒ The PTO (Blade Drive) is not engaged.

⇒ The Generator Drive Belt is broken or fell off the pulleys. Replace the

Drive Belt and be sure the Belt Tension Lever is secured. See page 12.

⇒ The circuit breaker has tripped for the outlet in question. Reset the

breaker by pushing the breaker button in until it clicks in the closed

position. See page 19.

⇒ Defective (shorted or wet) power cord on the appliance or tool, or in

the extension cord, if one is being used. Replace the power cord per

the appliance or tool instruction manual or replace the extension cord.

⇒ If the problem persists, call:

1(800) DR-OWNER (376-9637) for assistance.

⇒ Check that the rated power and surge power required by the appliance

or tool is within the Generator output specification. See page 23.

⇒ If the problem persists, call:

1(800) DR-OWNER (376-9637) for assistance.

⇒ Be sure the Generator power switch is OFF.

⇒ Be sure the Generator Wire Harness is plugged into the Relay Wire

Harness. See page 14, Figure 18.

⇒ Hold down the Operator Presence Lever while engaging the PTO. When

the Generator is up to speed, release the Operator Presence Lever.

NOTE: Country Home Products, Inc. has provided parts lists and schematic diagrams as reference tools only.

CHP makes no representation or warranty of any kind to the buyer that he/she is qualified to make

any repairs to the product or that he/she is qualified to replace any parts of the product. In fact, CHP

expressly states that all repairs and parts replacement should be undertaken by certified and licensed

technicians and not by the buyer. The buyer assumes all risk and liability arising out of his/her repairs

to the original product or replacement parts thereto, or arising out of his/her installation of

replacement parts thereto.

CALL TOLL FREE 1-800-DR-OWNER 29

Page 34

CHAPTER 7

PARTS LIST AND SCHEMATIC DIAGRAMS

Parts List - DR GENERATOR ATTACHMENT

NOTE: Part numbers listed are available through Country Home Products.

Ref# Part# Description

01 110691 Nut, 5/16"-18

02 110731 Nut, Nylon Lock, 1/4"-20

03 110761 Nut, Nylon Lock, 5/16"-18

04 112311 Spacer, .327" ID x .500" OD

05 112381 Washer, Flat, 1/4", USS

06 112391 Washer, 3/8", USS

07 112431 Washer, Split Lock, 5/16"

08 112501 Washer, Lock, 5/16"

11 123211 Bolt, 5/16"-18 x 3/4", HCS

12 123601 Bolt, 5/16"-18 x 2-1/4", HCS

14 192671 Bolt, M8 x 1"

15 150451 Bolt, 5/16"-18 x 1-3/4", HCS

16 150611 Idler Arm, Traction Drive

18 150941 Spring, .750" OD x .112"

19 151111 Bushing, .390" ID x .620" OD

20 151271 Pulley, Flat, Idler, 4"

21 164131 Nut, Nylon Lock, 3/8"

22 164401 Lever, Belt Tension Release

23 164841 Bolt, 3/8"-16 x 2-1/2", HCS

25 188401 Frame, Generator

26 188411 Plate, Generator, Mounting

27 189501 Generator, 6KW (includes 189541)

28 189511 Skid, Generator

29 189521 Cover w/Control Box Cover

30 189531 Pulley, V-Belt, Generator

31 189541 Wire & Electrical Assy. w/Plate

32 189731 Support, Skid, Generator

36 192411 Bolt, M8 x 1-1/4"

38 192641 Screw, Pan Head, 8-32 x 3/8"

Not Illustrated

114781 Screw, Pan Head, 10-24 x 5/8"

118731 Nut, Nylon Lock, 10-24

131661 Parts Shipped Separate Form

150681 Belt, B63K, 5/8" x 66"

184271 Meter, Hour/RPM/Maintenance

189741 Wire Harness, OP Override

192401 Key, M8 x 1"

189561 Safety & Operating Manual

Safety & Information Labels

192421 Warnings Label

191971 Control Panel

192391 DR Logo, 5-3/4"

30 DR® GENERATOR ATTACHMENT

Page 35

Schematic - DR GENERATOR ATTACHMENT

CALL TOLL FREE 1-800-DR-OWNER 31

Page 36

Electrical Schematics - DR GENERATOR ATTACHMENT

32 DR® GENERATOR ATTACHMENT

Page 37

Notes:

CALL TOLL FREE 1-800-DR-OWNER 33

Page 38

Notes:

34 DR® GENERATOR ATTACHMENT

Page 39

r

f

R

D

GENERATOR ATTACHMENT

2-Year Limited Warranty

Terms and Conditions

The DR® GENERATOR ATTACHMENT is warranted for two (2) years against defects in materials or workmanship when

put to ordinary and normal consumer use; ninety (90) days for any other use.

For the purposes of all the above warranties, “ordinary and normal consumer use” refers to non-commercial residential

use and does not include misuse, accidents or damage due to inadequate maintenance.

®

®

Country Home Products, Inc. (home of DR

fit for ordinary purposes for which a product of this type is used. Country Home Products, Inc. however, limits the

implied warranties of merchantability and fitness in duration to a period of two (2) years in consumer use, ninety (90)

days for any other use.

The 2-Year Limited Warranty on the DR® GENERATOR ATTACHMENT starts on the date the machine ships from ou

factory. The 2-Year Limited Warranty is applicable only to the original owner.

The warranty holder is responsible for the performance of the required maintenance as defined by the manufacturer's owner's

manuals. The warranty holder is responsible for replacement of normally wearing parts such as the drive belt. Attachments

and accessories to the machine are not covered by this warranty.

During the warranty period, the warranty holder is responsible for the machine transportation charges, if required. During the

warranty period, warranty parts will be shipped by standard method at no charge to the warranty holder. Expedited shipping o

warranty parts is the responsibility of the warranty holder.

SOME STATES DO NOT ALLOW LIMITATIONS ON THE LENGTH OF IMPLIED WARRANTIES, SO THE ABOVE

LIMITATIONS MAY NOT APPLY TO YOU.

Power Equipment) certifies that the DR

®

GENERATOR ATTACHMENT is

Country Home Products, Inc. shall not be liable under any circumstances for any incidental or consequential damages

or expenses of any kind, including, but not limited to, cost of equipment rentals, loss of profit, or cost of hiring services

to perform tasks normally performed by the DR

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES,

SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

®

GENERATOR ATTACHMENT.

Customer Service Hotline

Country Home Products, Inc.’s objective is to have 100% satisfied customers. For that reason, we operate a 6-day-aweek Technical Service Department for our Owners. You can access a Representative by dialing our TOLL-FREE Hotline

at 1-800-DR-OWNER (376-9637). The sole job of our well-trained and friendly folks is to ensure that you get any help

you need in a timely fashion. They are there to answer all your questions including: (1) inquiries on any of the above

warranties, (2) inquiries about replacement parts, or (3) your questions regarding service, maintenance and operation.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU ALSO HAVE OTHER RIGHTS, WHICH VARY FROM

COUNTRY HOME PRODUCTS, Inc.

STATE TO STATE.

MEIGS ROAD, P.O. BOX 25, VERGENNES, VERMONT 05491

1-800-DR-OWNER (376-9637) • www.dr-owner.com ©2003 CHP, Inc. 187131

Warranty

Page 40

Daily Checklist for the DR GENERATOR ATTACHMENT

To help maintain your DR GENERATOR ATTACHMENT for optimum performance, we recommend you

follow this checklist each time you use your Generator.

[ ] Check the engine oil level in your DR

Field and Brush Mower.

[ ] Check the general condition of the ATM and Generator, e.g.; nuts, bolts, welds etc.

[ ] Make sure that the Generator is dry and there is no foreign material in the outlets.

[ ] Check the condition of the Drive Belt for nicks and fraying.

COUNTRY HOME PRODUCTS, Inc.

MEIGS ROAD, P.O. BOX 25, VERGENNES, VERMONT 05491

1-800-DR-OWNER (376-9637) • www.dr-owner.com ©2006 CHP, Inc. 189561A

Loading...

Loading...