Page 1

CO

2

V

ol

%

O

2

Vol

%

CH

4

%UEG

CO

ppm

H

2

S

ppm

NH

3

ppm

Dräger X-am® 5600

approved as type MQG 01**

Multi-Gas Monitor

Technical Handbook

Page 2

Content

Content

For Your Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Tests and Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Intended operating area and operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

What is What . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Rear panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Special symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Standard gas configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Standard instrument configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Switching on the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Switching off the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Before entering the workplace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

During operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Calling the Info Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Calling the Info-Off Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Calling the Quick Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Possible functions of the quick menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Quick menu "Delete peak values" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Calling the Calibration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Calibration menu functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Identifying Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Concentration pre-alarm A1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Concentration main alarm A2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

STEL / TWA exposure alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Battery pre-alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Battery main alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Instrument alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Operation with pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Configuring the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Read Database and Display Graphically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Faults, Cause and Remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Warning messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Fault messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

2

Page 3

Content

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

H

added signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2

Carry out manual bump test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Manual implementation without the documentation of results in the instrument mem-

ory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Menu implementation with the documentation of results in the instrument memory

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Automatic implementation with the Bump Test Station . . . . . . . . . . . . . . . . . . . . 45

Calibrating/adjusting the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Carrying out the fresh air calibration/zero-point calibration . . . . . . . . . . . . . . . . . 48

Carrying out 1-button calibration/adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Calibrating/adjusting the sensitivity for an individual measuring channel . . . . . . 53

Example 1: Span calibration for Dräger Sensor IR Ex. . . . . . . . . . . . . . . . . . . . . 54

Example 2: Calibration routine for Dräger Sensor DUAL IR CO

IR CO

Replacing the batteries / rechargeable batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

and Dräger Sensor

2

Charging the rechargeable batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Charging with the multiple charging station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Charging with charging module and plug-in power pack or vehicle charging adapter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Replacing the Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Order List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3

Page 4

For Your Safety

General safety statements

Before using this product, carefully read the associated Instructions for Use. This

document does not replace the Instructions for Use.

Definitions of alert icons

The following alert icons are used in this document to provide and highlight areas of the

associated text that require a greater awareness by the user. A definition of the

meaning of each icon is as follows:

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death

or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, could result in

physical injury, or damage to the product or environment. It may also be used to alert

against unsafe practices.

NOTICE

Indicates additional information on how to use the product.

Intended Use

Portable gas detection instrument for the continuous monitoring of the concentration of

several gases in the ambient air within the working area and in explosion-hazard areas.

X-am 5600, depending on the instrument type and configuration of DrägerSensors:

independent measurement of one up to six gases.

4

Page 5

Tests and Approvals

Copies of the name plate and the declaration of conformity are provided in the

enclosed supplementary documentation (order no. 90 33 890).

The BVS 10 ATEX E 080 X technical suitability test is based on the adjustment with the

target gas.

Do not stick anything on the name plate on the gas detector.

The technical suitability tests are valid for the X-am 5600 gas detector and the

calibration cradle. The explosion-protection approvals are only valid for the X-am 5600

gas detector; the calibration cradle must not be used in the Ex zone.

Intended operating area and operating conditions

Areas subject to explosion hazards, classified by zones (MQG 01**)

The instrument is intended for the use in explosion-hazard areas of Zone 0, Zone 1 or

Zone 2 or in mines at risk due to fire damp. It is intended for use within a temperature

range of –20 °C to +50 °C, and for areas in which gases of explosion groups IIA, IIB or

IIC and temperature class T3 or T4 (depending on the batteries and rechargeable

battery) may be present. If used in mines, the instrument is only to be used in areas

known to have a low risk of mechanical impact.

Areas subject to explosion hazards, classified by divisions

The instrument is intended for use in explosion-hazard areas according to Class I&II,

Div. 1 or Div. 2 within a temperature range of –20 °C to +50 °C, and for areas where

gases or dusts of groups A, B, C, D, E, F, G and temperature class T3 or T4 may be

present (depending on the rechargeable battery and batteries).

It is intended for use in a temperature range

when using power pack ABT 0100:

of –20 °C to +50 °C or –20 °C to +40 °C depending on the batteries used

when using power pack HBT 0000/HBT 0100:

from –20 °C to +50 °C

and for gases of temperature class T3 or T4 (depending on the batteries and

rechargeable battery).

For applications in accordance with CSA (Canadian Standards Association), the

following should be observed:

Only the performance of the detector part of this instrument for flammable gases has

been tested. The instrument has not been approved for use in mines by the CSA.

WARNING

Only applicable to Class II certification. CSA Std. C22.2 No 152 does not have any

requirement for Class II hazardous locations and therefore this device has not been

performance tested by CSA for Class II. The sensor may become clogged and not

detect gas properly or warn the user of its inability to detect gas.

5

Page 6

Safety instructions

WARNING

To reduce the danger of explosion, do not mix new batteries with old batteries and do

not mix batteries made by different manufacturers.

WARNING

Always disconnect the instrument from the power pack before carrying out any

maintenance operations.

WARNING

Substitution of components may impair intrinsic safety.

CAUTION

Not tested in an oxygen-enriched atmosphere (>21 % O

CAUTION

Only the combustible gas detection portion of this instrument has been assessed by

CSA for performance. The instrument is not classified by CSA for use in mines.

WARNING

CSA requirement: A sensitivity test should be conducted before each use at a

concentration between 25 and 50 % of the maximum concentration of the measured

gas. The accuracy here must be between 0 and +20 % of the actual value. The

accuracy can be corrected via calibration.

).

2

WARNING

High off-scale readings may indicate an explosive concentration.

WARNING

Only use power packs ABT 0100 (83 22 237), HBT 0000 (83 18 704) or HBT 0100

(83 22 244). See marking on power pack for approved batteries and related

temperature class.

WARNING

Increased hydrogen concentrations within the measuring range of the Dräger Sensor

XXS H2 HC may result in false alarms due to the additive effect on the Dräger

sensors XXS H2S, and XXS CO, XXS H2S (LC) and XXS CO (LC) as well as due to

the negative effect on the Dräger Sensor XXS O2.

6

Page 7

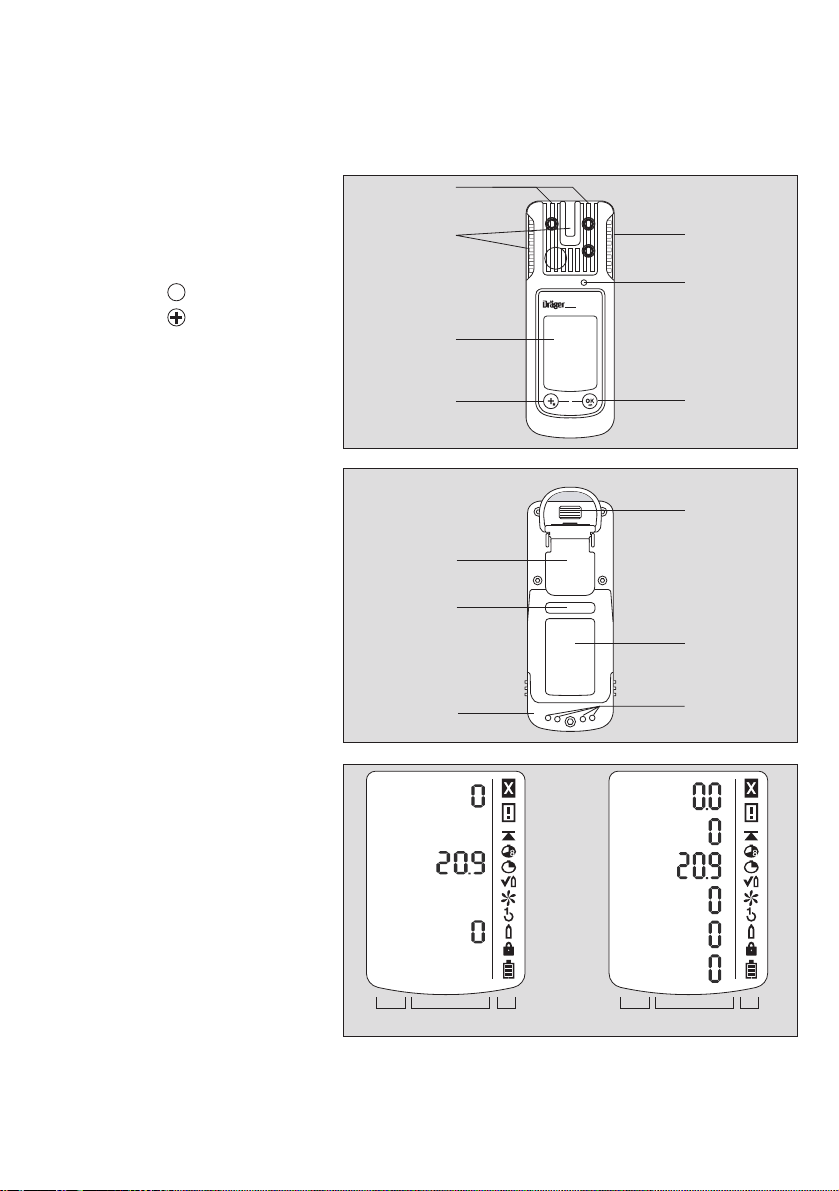

What is What

00233072_01.eps

0

1

2

6

5

4

3

2

X-am 5600

00333072_01.eps

2

1

4

6

3

5

456

ch4

O2

CO

%LEL

Vol %

ppm

123

CO2

Vol %

O

2

Vol %

ch4

%LEL

CO

ppm

H

2S

ppm

NH

3

ppm

Front panel

1 Gas entry

2 Alarm LED

3 Buzzer

OK

4 key

5 key

6 Display

Rear panel

1 IR interface

2 Fastening clip

3 Type plate

4 Charging contacts

5 Power pack

6 Serial no.

Display

for 1 to 4 measuring

channels:

1 Measured gas

display

2 Measured gas

display with unit

3 Special symbols

for 5 and 6 measuring

channels:

4 Measured gas

display with unit

5 Measured gas

display

6 Special symbols

The following only shows the instrument version with 6 measuring channels.

7

Page 8

Special symbols

Fault message, refer to page 15

Warning message, refer to page 15

The peak value display for all measuring gases, refer to page 15

The exposure evaluation display (TWA) for measuring gases, e.g., H

refer to page 15

The exposure evaluation display (STEL) for measuring gases, e.g., H

refer to page 15

The instrument is set to function test with gas (bump test),

refer to page 41

The instrument is set to the fresh air calibration function,

refer to page 48

The instrument is set to the 1-button calibration/adjustment function,

refer to page 50

The instrument is set to the single gas calibration function,

refer to page 53

The function for password entry is active, refer to page 18

Battery / rechargeable battery 100 % full

Battery / rechargeable battery 2/3 full

Battery / rechargeable battery 1/3 full

Battery / rechargeable battery empty

Marking offset channels:

Feature Reading on the display

ToxicTwins HCN+

CO H

compensation CO+

2

H

offsetting ch4+

2

S and CO,

2

S and CO,

2

8

Page 9

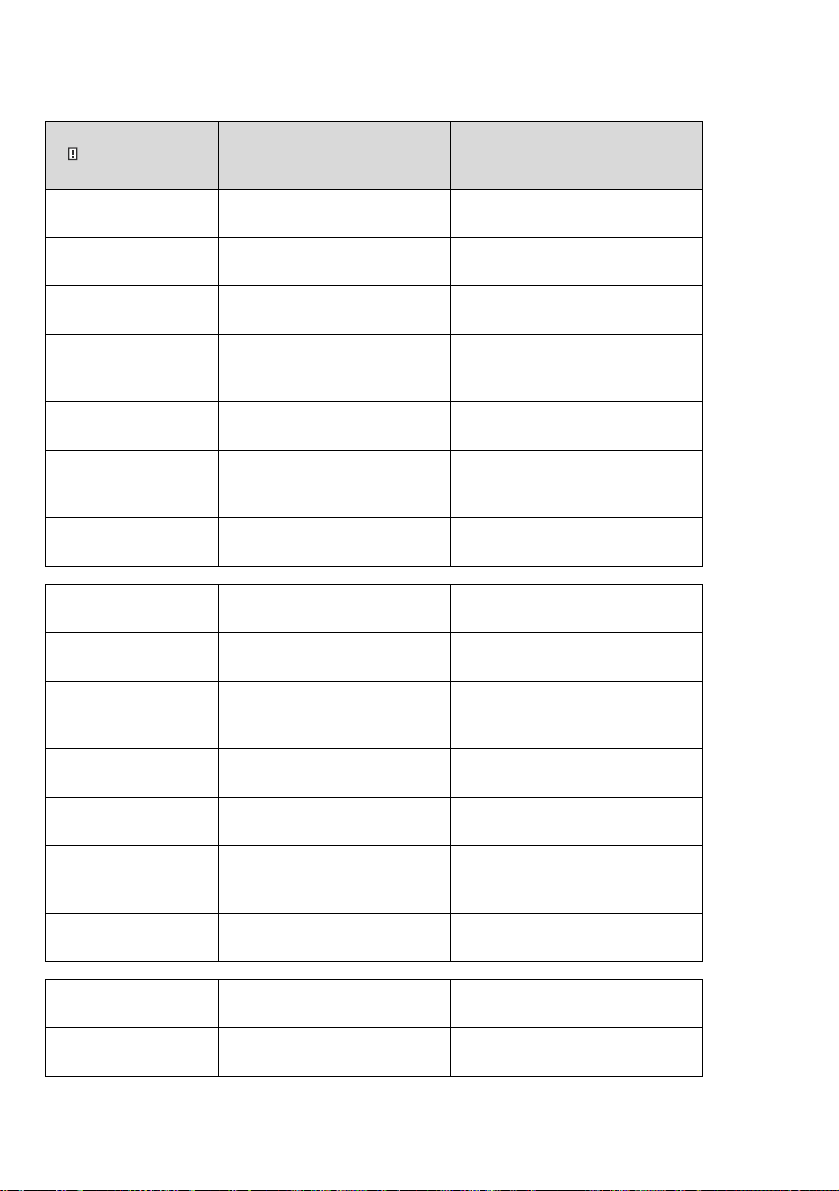

Configuration

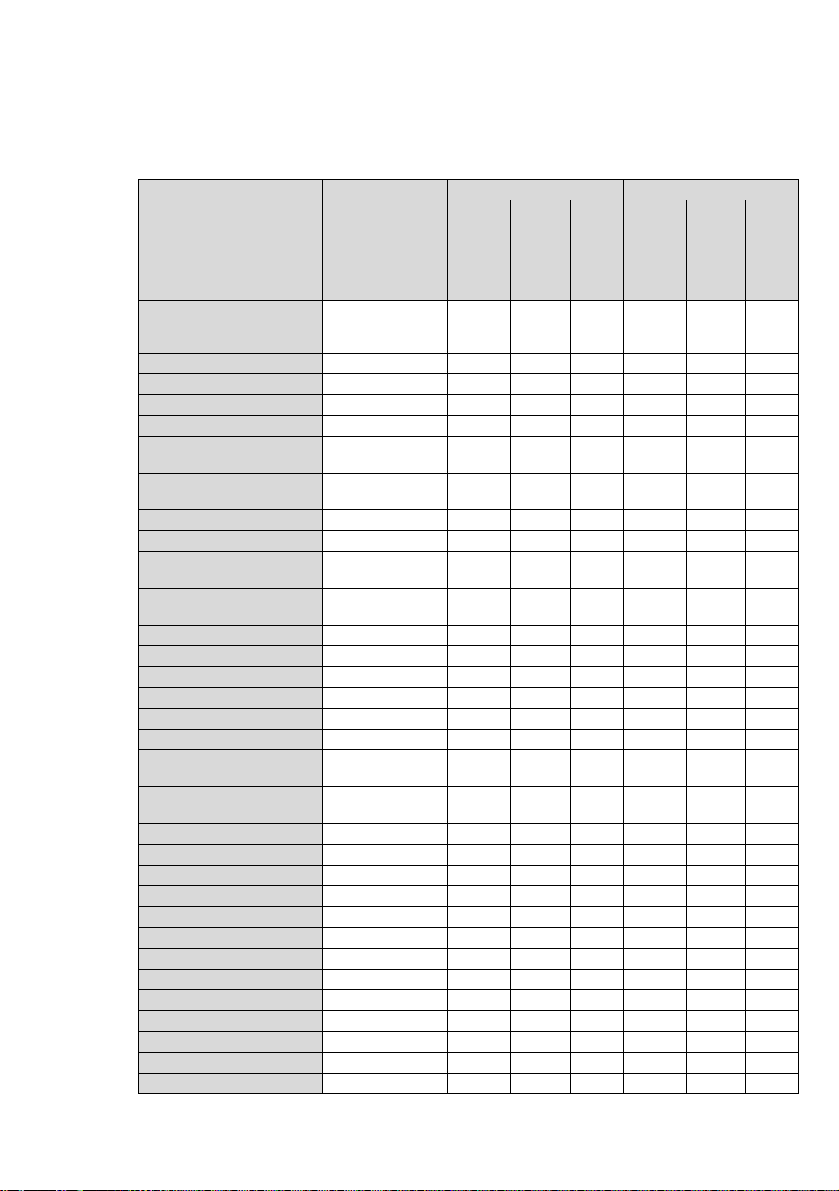

Standard gas configuration

DrägerSensor

Measuring

1)

range

Alarm A1

1)

Alarm A2

1)

DUAL IR Ex/CO2:

DUAL IR-Ex [%LEL]

DUAL IR-CO

[vol. %]

2

0 to 100

0 to 5

threshold

20

0.5

can be

acknowledged

self-latching

threshold

Yes

YesNoNo401.0NoNo

can be

acknowledged

Ye s

Ye s

IR-Ex [%LEL] 0 to 100 20 Yes No 40 No Ye s

IR-CO2 [vol. %] 0 to 5 0.5 Ye s No 1.0 No Ye s

XXS O2 [vol. %] 0 to 25 19

XXS O2 100 [vol. %] 0 to 100 18

XXS O2 LS/CO-LC

[vol.-%], [ppm]

XXS O2 / H2S-LC

[vol%], [ppm]

0 to 25 O

0 to 2000 CO

0 to 25 O

0 to 100 H2S

2

2

2)

No Ye s 23 No Ye s

2)

No Ye s 24 No Ye s

19 O

30 CO

19 O

5 H2SNoYes

No

2

Yes

2

YesNo23 O

60 CO

YesNo23 O

10 H2SNoNo

2

2

NoNoYe s

Ye s

Ye s

Ye s

XXS CO [ppm] 0 to 2000 30 Yes No 60 No Ye s

XXS CO LC [ppm] 0 to 2000 30 Ye s No 60 No Yes

XXS CO-LC/H2S-LC

[ppm]

XXS CO-LC/O2 [ppm],

[vol.-%]

0 to 2000 CO

0 to 100 H

0 to 2000 CO

0 to 25 O

2

2

30 CO

5 H

S

30 CO

19 O

S

2

2

Yes

YesNoNo

YesNoNo

Yes

60 CO

10 H

60 CO

23 O

S

2

2

NoNoYe s

Ye s

NoNoYe s

Ye s

XXS CO HC [ppm] 0 to 10,000 600 Ye s No 1.200 No Ye s

XXS CO H2-CP [ppm] 0 to 2,000 30 Ye s No 60 No Ye s

XXS H2 [ppm] 0 to 2,000 200 Ye s No 400 No Ye s

XXS H2S [ppm] 0 to 200 5 Ye s No 10 No Ye s

XXS H2S LC [ppm] 0 to 100 5 Ye s No 10 No Ye s

XXS H2S HC [ppm] 0 to 1,000 10 Ye s No 20 No Ye s

XXS H2S/CO [ppm]

XXS H2S-LC/CO-LC

[ppm]

0 to 200 H2S

0 to 2,000 CO

0 to 100 H2S

0 to 2000 CO

5 H2S

30 CO

5 H2S

30 CO

Yes No

Yes

YesNoNo

10 H2S

60 CO

10 H2S

60 CONoNo

No Ye s

Ye s

Ye s

XXS NO [ppm] 0 to 200 25 Yes No 50 No Ye s

XXS NO2 [ppm] 0 to 50 5 Ye s No 10 No Ye s

XXS SO2 [ppm] 0 to 100 0,5 Ye s No 1 No Ye s

XXS PH3 [ppm] 0 to 20 0.1 Ye s No 0.2 No Ye s

XXS PH3 HC [ppm] 0 to 1,000 5 Yes No 10 No Ye s

XXS HCN [ppm] 0 to 50 1,9 Ye s No 3,8 No Ye s

XXS HCN PC [ppm] 0 to 50 5 Ye s No 10 Ye s No

XXS NH3 [ppm] 0 to 300 20 Ye s No 40 No Ye s

XXS CO2 [vol. %] 0 to 5 0.5 Ye s No 1 No Ye s

XXS Cl2 [ppm] 0 to 20 0.5 Ye s No 1 No Ye s

XXS H2 HC [vol. %] 0 to 4 0.8 Ye s No 1.6 No Ye s

XXS OV [ppm] 0 to 50 10 Ye s No 20 No Ye s

XXS OV A [ppm] 0 to 50 10 Ye s No 20 No Ye s

self-latching

9

Page 10

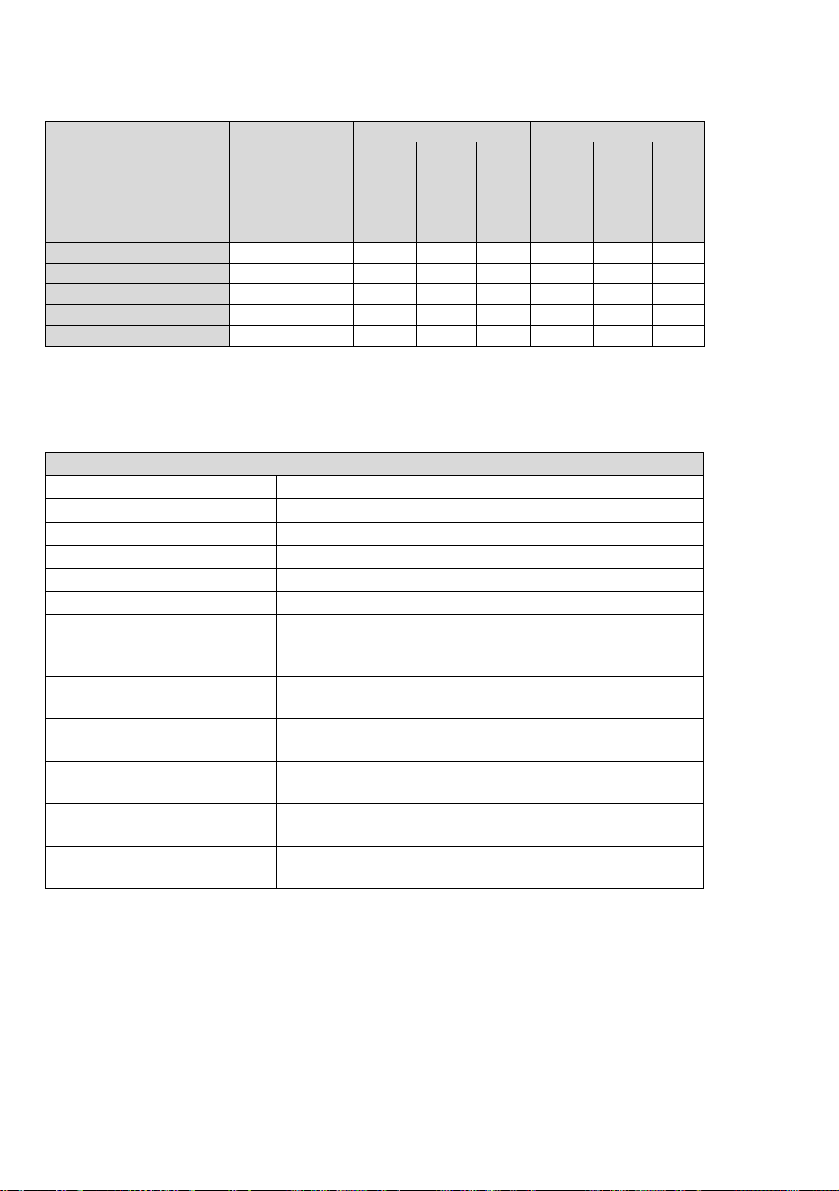

DrägerSensor

Measuring

1)

range

Alarm A1

1)

Alarm A2

1)

threshold

can be

acknowledged

self-latching

threshold

can be

acknowledged

self-latching

XXS Odorant [ppm] 0 to 40 10 Yes No 20 No Ye s

XXS Amine [ppm] 0 to 100 10 Yes No 20 No Ye s

XXS COCI2 [ppm] 0 to 10 0,1 Ye s No 0,2 No Yes

XXS O3 [ppm] 0 to 10 0,1 Ye s No 0,2 Ye s No

XXS NO2 LC [ppm] 0 to 50 0,5 Ye s No 1,0 Ye s No

1) Different settings can be selected to meet customer requirements on delivery. The current setting can

be checked and changed with the Dräger CC Vision software. A version of Dräger CC Vision which can

be used for Dräger X-am 5600 is supplied with the instrument on CD.

2) In the case of O2 A1 is the lower alarm threshold: an alarm is triggered if the value is too low.

Standard instrument configuration

Dräger X-am 5600

Bump test mode

Fresh air calibration 2)

Hydrogen offset

Operating signal

Capture range On

Switch off

LEL factor

ch

4

H

2

STEL

2)

2)

2) 6) 7)

(short-term average)

2) 7) 8)

TWA

(shift average)

Alarm A1

9)

Alarm A1 at O

Alarm A2

1) X-am® is a registered trademark of Dräger.

2) Different settings can be selected by the customer on delivery. The current setting can be

3) The fresh air calibration/zero-point calibration is not supported by the DrägerSensor DUAL IR

4) With activated DrägerSensor XXS H2 HC (68 12 025) and activated Ex-channel of the

5) A periodic short flashing indicates the operating capacity of the instrument. If there is no

6) STEL: average value of an exposure over a short period, generally 15 minutes.

7) Interpretation only if the sensor is designed for this.

8) TWA: shift averages are workplace limit values for generally eight hours per day of exposure for

9) Latching and acknowledgement of alarms A1 and A2 can be configured with the Dräger CC

9)

checked and changed with the Dräger CC Vision software.

CO

, DrägerSensor IR CO2 or the DrägerSensor XXS O3.

2

DrägerSensor DUAL IR Ex/CO2 (68 11 960) or DrägerSensor IR Ex (68 12 180).

operating signal, correct operation cannot be guaranteed.

five days a week during a working life.

Vision PC software.

2)

4)

2) 5)

sensor

2

1)

Extended bump test

3)

On

On

On

blocked at A2

4.4 vol. % (4.4 vol. % corresponds to 100 %LEL)

4.0 vol. % (4.0 vol. % corresponds to 100 %LEL)

STEL function - disabled

Average value duration = 15 minutes

TWA function - disabled

Average value duration = 8 hours

can be acknowledged, non-latching, pre-alarm,

rising flank

9)

cannot be acknowledged, latching, like main alarm,

falling flank

cannot be acknowledged, latching, main alarm,

rising flank

10

Page 11

By activating the H

DrägerSensor XXS H

activated DrägerSensor DUAL IR Ex/CO

IR Ex (6812180) and shown on the display at the position of the IR Ex display.

added signal, the LEL gas concentration of the activated

2

HC (6812025) is added to the LEL gas concentration of the

2

(6811960) or of the activated DrägerSensor

2

NOTICE

Previously set alarm thresholds are preserved so that in the presence of hydrogen

(H2) the alarm of the IR Ex channel could be triggered earlier.

Changing the configuration: see “Configuring the Instrument” on page 24.

WARNING

After a basic initialization has been carried out with the PC software Dräger

CC Vision, individual alarm settings may have been changed.

Selecting or disabling the capture ranges (only applies for the measuring mode):

The capture range is selected in the measuring mode (factory setting) and permanently

disabled in calibration mode.

The CC-Vision PC software can be used to select or disable the capture ranges for the

measuring mode.

11

Page 12

Operation

OK

OK

Before using the instrument for the first time, insert a charged NiMH T4 power pack

or batteries approved by Dräger, see "Changing the batteries" on page 58.

The instrument is now ready for operation.

WARNING:

To reduce the risk of ignition of a flammable or explosive atmosphere, strictly adhere

to the following warning statements:

Only use power pack types ABT 01xx, HBT 00xx or HBT 01xx. See the marking on

the rechargeable battery for permitted rechargeable batteries and the corresponding

temperature class.

Substitution of components may impair intrinsic safety.

Switching on the instrument

Press and hold the key for approx. 3 seconds until the countdown »3.2.1«

shown in the display has elapsed.

— All the display segments, including the visual, audible and vibration alarms, are

activated for a short time.

— The software version is displayed.

— The instrument performs a self test.

— The next sensor which is next due for calibration is displayed with the days

remaining until the next calibration/adjustment, e.g., »ch

— The time until the bump test interval elapses is displayed in days, e.g., »bt2«.

— All A1 and A2 alarm thresholds and if applicable »« (TWA)

for all toxic gases (e. g. H

— During the sensor warm-up phase:

S or CO) are displayed consecutively.

2

— The display for the measured value flashes

— The special symbol »« is displayed.

— No alarms are issued during the warm-up phase.

— The red LEDs flash.

— The gas detector is ready to measure when the measured values no longer flash

and the red LEDs are no longer illuminated. The special symbol »« may continue

to be displayed if corresponding warnings (e.g. not yet ready for calibration) are

active (to view the warnings, see the technical manual).

Press the key to cancel the display of the activation sequence.

%LEL CAL 123 «.

4

1)

and »« (STEL)1)

1) Only when activated in the instrument configuration. Delivery condition: not activated.

12

Page 13

Switching off the instrument

Press and hold the key and key at the same time until the countdown

»3.2.1« shown in the display has elapsed.

— Before the instrument is switched off, the visual, audible and vibration alarms are

activated for a short time.

OK

Before entering the workplace

WARNING

Before any measurements relevant to safety are made, check the adjustment with a

bump test, adjust if necessary and check all alarm elements. If national regulations

apply, a bump test must be performed according to the national regulations. Faulty

adjustment may result in incorrect measuring results, with possible serious

consequences.

WARNING

In an oxygen enriched atmosphere (>21 vol. % O

be guaranteed; remove instrument from the Ex area.

NOTICE

If the gas detector is used for offshore applications, a distance of 5 m to a compass

must be complied with.

Switch on the instrument. The current measured values are shown in the display.

Observe any warning » « or fault messages » «.

The instrument can be operated normally. If the warning message does not go

out automatically during operation, the instrument must be maintained after the

end of use.

), the explosion protection cannot

2

The instrument is not ready to measure and requires maintenance.

— If one of these special symbols is displayed, appropriate measures, refer to page 28

to page 32, must be taken.

Check that the gas inlet opening on the instrument is not covered and/or dirty.

13

Page 14

During operation

— During operation, the measured values for every measured gas are displayed.

— In the event of an alarm, the corresponding displays, including the visual, audible

and vibration alarms, are activated. See section "Identifying Alarms"

— If a measuring range is exceeded or not reached, the following displays are shown

instead of the measured value display:

»« (measuring range exceeded) or

»« (measuring range not reached).

— After the measuring range of the TOX measuring channels has been exceeded

temporarily (up to one hour), checking the measuring channels is not necessary.

— Following an extreme impact load, the display for the Ex- and the CO

range of the IR Sensor must be checked and adjusted with zero gas and span gas

if necessary.

NOTICE

Special states in which there is no measuring operation (quick menu, calibration

menu, warm-up of sensors, password input) are indicated by a visual signal (slow

flashing of the alarm LED ).

WARNING

When using an IR Sensor in the Dräger X-am 5600, the zero point and sensitivity

must be adjusted after an impact load that causes a display other than zero for the

IR sensor when the instrument is at fresh air.

measuring

2

14

Page 15

Calling the Info Mode

OK

OK

OK

OK

OK

OK

OK

In measuring mode, press the key for approx. 3 seconds.

If any warning or fault messages exist, the corresponding information or error codes

are displayed (page 28 to page 35).

Press the key successively for the next display.

The peak values and the exposition values TWA

Warning messages are displayed. Numerical codes of warning messages:

see page 28.

key

Fault messages are displayed. Numerical codes of fault messages:

see page 32.

key

The peak values = the maximum measured values in the case of, e.g., CO,

H

S, ... or the minimum measured values in the case of O2 within the storage

2

interval are displayed

key

The average values of the exposures based on a shift of, e.g., 8 hours (TWA)

of all the active sensors for the exposure evaluation are displayed

key

The short-term values (STEL) = average values of the concentrations over

the average value duration of all the active sensors for the exposure

evaluation are displayed

key

The instrument is in measuring mode again

OK

1)

and STEL1) are displayed.

— If no key is pressed for 10 seconds, the instrument returns automatically to

measuring mode.

Calling the Info-Off Mode

When the instrument is in a deactivated state, press the key.

The name of the gas, measuring unit and measuring range limit value are displayed for

all channels.

Pressing the key again exits the Info Off mode (or via timeout).

1) Only when activated in the instrument configuration. Delivery status: not activated.

15

Page 16

Calling the Quick Menu

— Only the fresh air calibration/zero-point calibration is activated in the quick menu on

delivery. The PC software Dräger CC Vision can be used to activate the bump test

for the quick menu and/or the function for displaying and deleting peak values.

In measuring mode, press the key three times.

If no functions have been activated in the quick menu, the instrument remains in

measuring mode.

— You can select the activated functions of the quick menu by pressing the key.

Press the key to call the selected function.

Possible functions of the quick menu

Press the key to cancel the active function and to switch to measuring mode.

— If no key is pressed for 60 seconds, the instrument returns automatically to

measuring mode.

OK

Function test with gas (bump test), refer to page 41.

Fresh air calibration, refer to page 48.

1)

Delete peak values, refer to page 17.

Display pump information, refer to page 21.

Activate or deactivate pump, refer to page 21.

______________________________________________

1) Fresh air calibration / zero-point calibration is not supported by the DrägerSensor DUAL IR CO2,

the DrägerSensor IR CO2 or the DrägerSensor XXS O3. A zero-point calibration / adjustment of

these sensors can be conducted using the Dräger CC-Vision PC software. To do so, a suitable

zero gas that is free of carbondioxide and ozone (e.g. N

) should be used.

2

16

Page 17

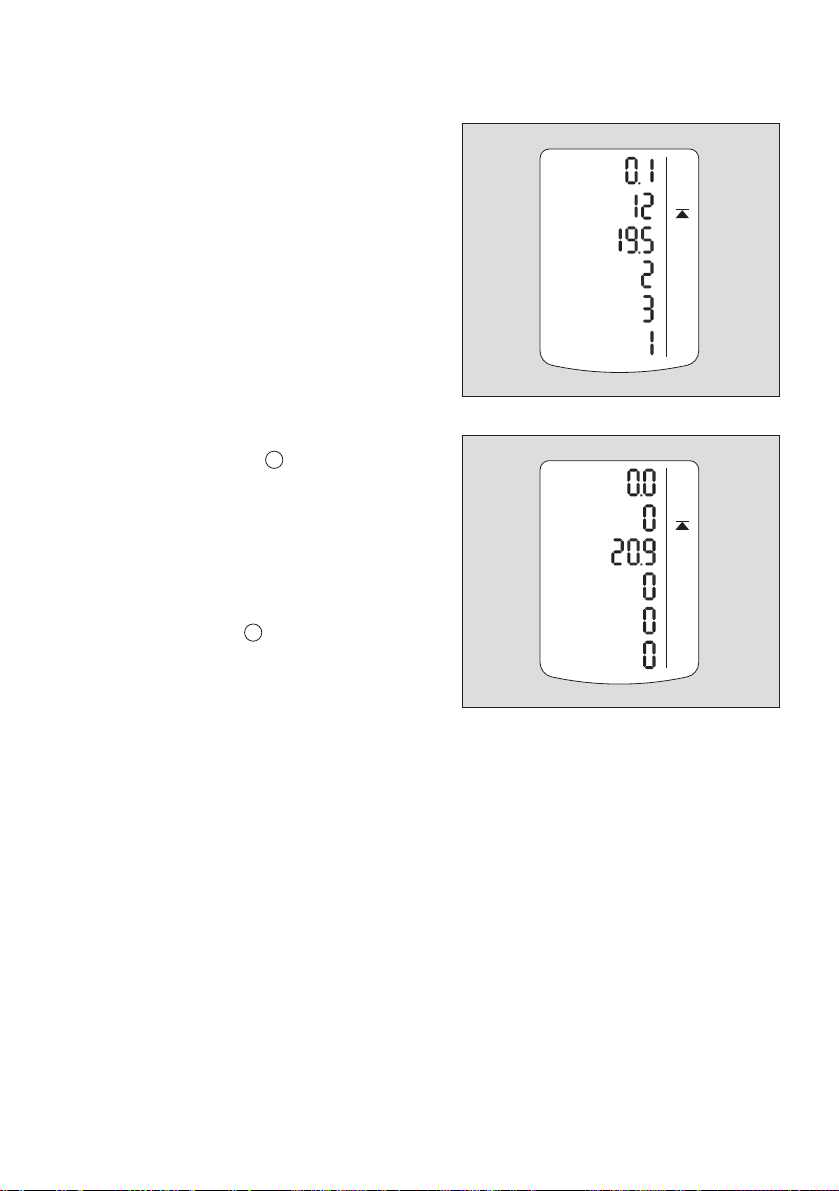

Quick menu "Delete peak

OK

OK

values"

After the function has been selected, the

current peak values are displayed; the

peak values special symbol appears in

the display at the same time.

The peak values can be deleted by

pressing the key for 5 sec. The

adjacent display appears.

Press the key to end the function.

CO

2

Vol %

ch

4

%LEL

2

O

Vol %

CO

ppm

2

S

H

ppm

3

NH

ppm

CO

Vol %

ch

4

%LEL

2

O

Vol %

CO

ppm

2

S

H

ppm

NH

3

ppm

04833072_01_en.eps

2

04933072_01_en.eps

17

Page 18

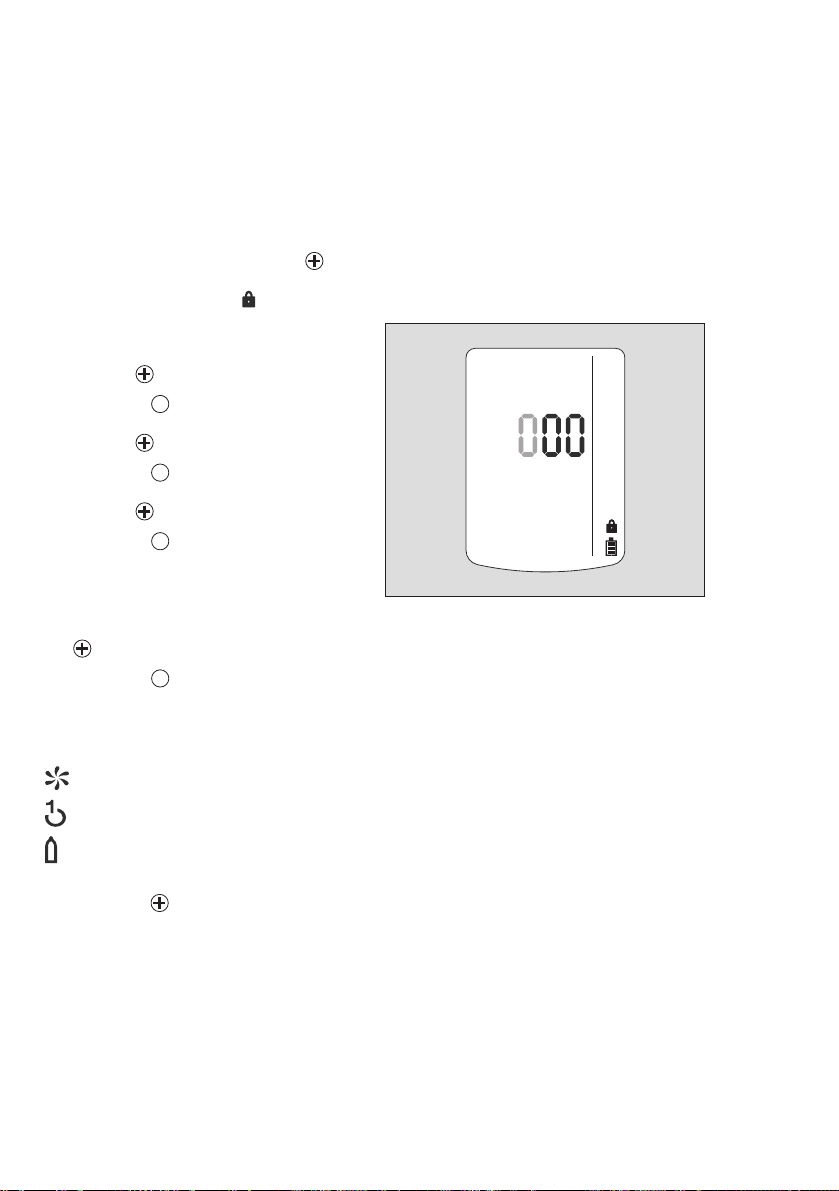

Calling the Calibration Menu

02333072_01.eps

— The calibration menu can only be accessed by entering a password.

Password on delivery: »001«

— The default password on delivery can be changed using the PC software Dräger

CCVision.

In measuring mode, press the key for at least 4 seconds.

— The function for entering the password is selected.

— The special symbol » « (for the "enter password" function) is displayed.

— The display shows »000«, with the

first digit flashing.

Use the key to set the flashing digit.

Press the key, the second digit

starts flashing.

Use the key to set the flashing digit.

Press the key, the third digit starts

flashing.

Use the key to set the flashing digit.

Press the key to confirm the

password once it has been set

completely.

— The calibration menu functions can

now be selected by pressing the

key.

Press the key to call the selected

function.

OK

OK

OK

OK

Calibration menu functions

Fresh air calibration, refer to page 48.

1)

1-button calibration/adjustment, refer to page 50.

Single gas calibration/adjustment, refer to page 53.

Press the key to cancel the active function.

— If no key is pressed for 10 minutes, the instrument automatically returns to

measuring mode.

______________________________________________

1) Fresh air calibration / zero-point calibration is not supported by the DrägerSensor DUAL IR CO2,

the DrägerSensor IR CO

these sensors can be conducted using the Dräger CC-Vision PC software. To do so, a suitable

zero gas that is free of carbondioxide and ozone (e.g. N2) should be used.

or the DrägerSensor XXS O3. A zero-point calibration / adjustment of

2

18

Page 19

Identifying Alarms

An alarm is displayed visually, audibly and through vibration in a specific pattern.

NOTICE

At low temperatures the legibility of the display can be improved by switching on the

backlight.

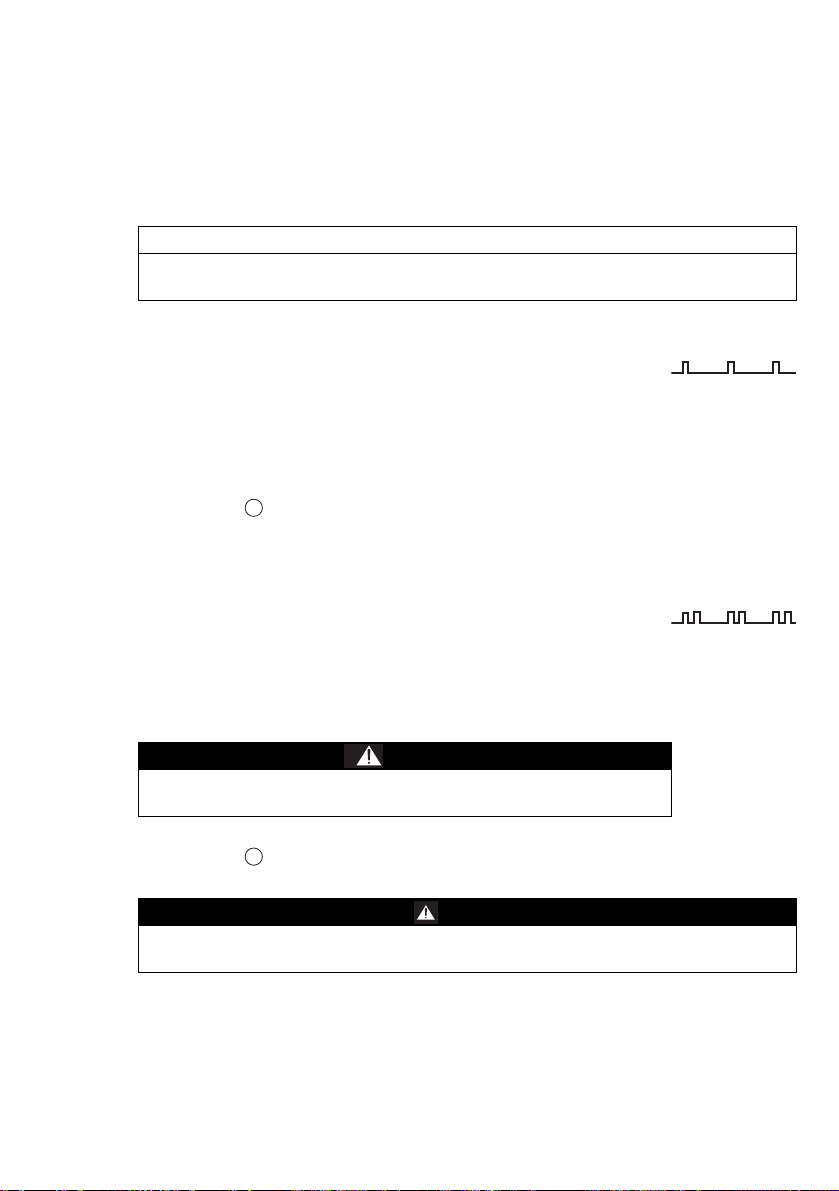

Concentration pre-alarm A1

The alarm is indicated by an intermittent alarm message:

Display »A1« and measured value alternating: not for O

— The pre-alarm A1 is not self-latching and stops when the concentration has dropped

below the alarm threshold A1.

— In the case of A1 a single tone is audible and the alarm LED flashes.

Acknowledging the pre-alarm:

Press the key. Only the audible alarm and the vibration alarm are switched off.

OK

Concentration main alarm A2

The alarm is indicated by an intermittent alarm message:

Display »A2« and measured value alternating:

In the case of A2 a double tone is audible and the alarm LED flashes

twice.

: »A1« and measured value alternating = oxygen deficiency

For O

2

» A2 « and measured value alternating = oxygen surplus

!

2

WARNING

Danger to life! Leave the area immediately. A main alarm is selflatching and cannot be acknowledged or cancelled.

After leaving the area, if the concentration is less than the alarm threshold A2:

Press the key. The alarm messages are switched off.

OK

WARNING

The measuring range 0 to 100 vol. % CH

mixtures in the measuring range of 0 to 100 %LEL.

is not suitable for monitoring explosive

4

19

Page 20

STEL / TWA exposure alarm

The alarm is indicated by an intermittent alarm message:

Display »A2« and »« (TWA) or » « (STEL) and measured

value alternating:

WARNING

Risk to health! Leave the area immediately.

After this alarm, the deployment of personnel is subject to the relevant national

regulations.

NOTICE

The STEL alarm can be triggered with a maximum delay of one minute.

— STEL and TWA alarms cannot be acknowledged or cancelled.

Switch off the instrument. The values for the exposure evaluation are deleted after

the instrument is switched on again.

Battery pre-alarm

The alarm is indicated by an intermittent alarm message:

Flashing special symbol »« on the right side of the display:

Acknowledging the pre-alarm:

Press the key. Only the audible alarm and the vibration alarm are switched off.

— The battery still lasts approx. 20 minutes after the first battery pre-alarm.

OK

Battery main alarm

The alarm is indicated by an intermittent alarm message:

Flashing special symbol »« on the right side of the display:

The battery main alarm cannot be acknowledged or cancelled:

— The instrument is automatically switched off again after 10 seconds.

— Before the instrument is switched off, the visual, audible and vibration alarms are

activated for a short time.

Instrument alarm

The alarm is indicated by an intermittent alarm message:

Special symbol » « on the right side of the display:

— The instrument or one or several sensor channels are not ready for operation.

— For remedies, refer to page 28 to page 35.

If necessary, commission the Dräger Safety Service Center to eliminate the error.

20

Page 21

Operation with pump

Observe the following when performing measurements using the pump

Perform visual inspection of the probe, if necessary.

Wait for the flushing time to end.

Flush the Dräger sampling hose or Dräger probes prior to each measurement with

the air sample to be measured.

The flushing phase is necessary to minimize or eliminate any effects associated with

the use of a sampling hose or a probe, e.g. memory effects, dead volume.

The duration of the flushing phase depends on factors such as type and concentration

of the gas or vapour to be measured, material, length, diameter and age of the

sampling hose or probe. As a rule of thumb, a typical flushing time of 3 seconds per

metre can be assumed for a sampling hose (factory-new, dry, clean). This flushing time

applies in addition to the sensor response time (see instructions for use of the gas

detector used).

Example:

The flushing time for a 10 m hose is approx. 30 seconds. The sensor response time is

approx. 60 seconds in addition. The overall time before reading the gas detector

therefore is approx. 90 seconds.

The flow alarm is delayed by 10 to 30 seconds, depending on the hose length.

Performing a measurement with Dräger Pump X-am 1/2/5000

Required accessories (see "Accessories" on page 67):

Dräger Pump X-am 1/2/5000

Sampling hose and probes

Commissioning and performing the measurement:

See instructions for use of Dräger Pump X-am 1/2/5000.

21

Page 22

Performing a measurement with the Dräger X-am Pump

OK

Required accessories (see "Accessories" on page 67):

Dräger X-am Pump

Sampling hose and probes

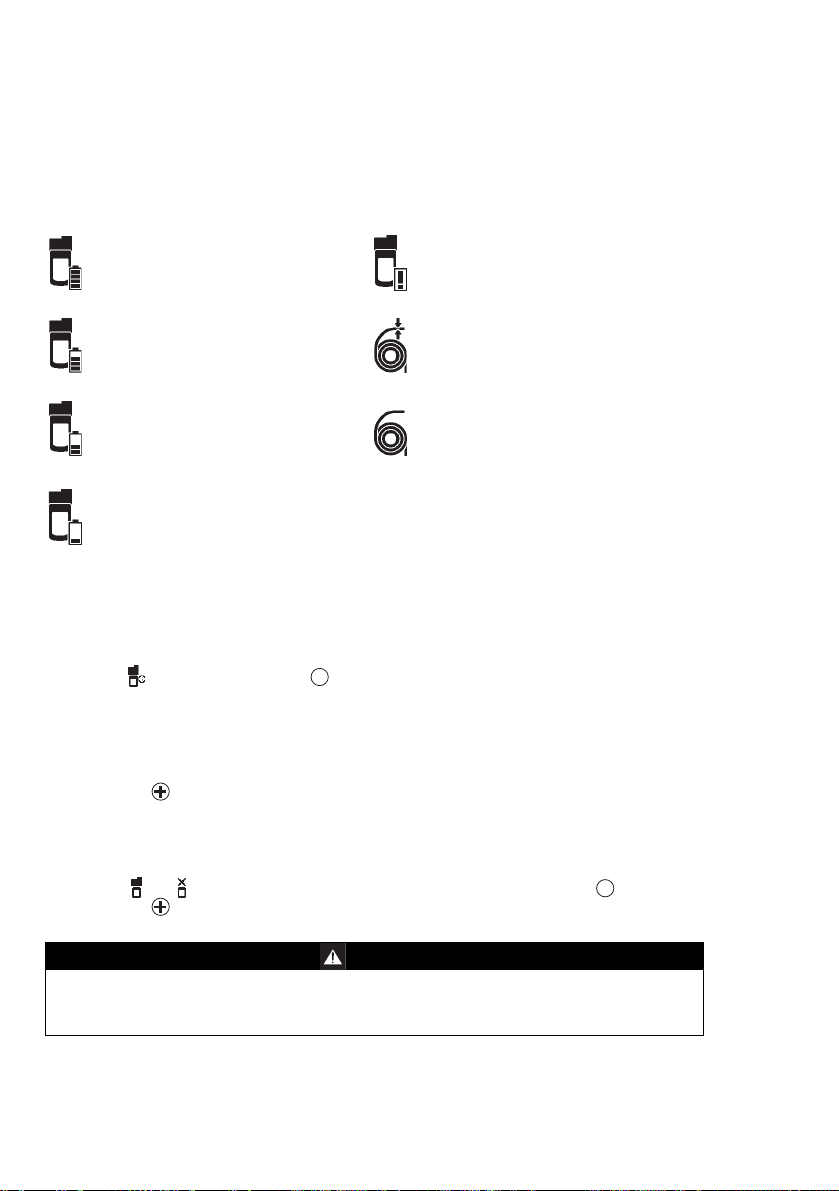

Pump symbols:

Pump battery 100 % charged Warning for pump

(Gas detector can no longer detect

pump.)

Remaining charge of pump

battery: 2/3

Remaining charge of pump

battery: 1/3

Leak test:

Block suction inlet

Leak test:

Release suction inlet

Pump battery discharged

Commissioning and performing the measurement:

See instructions for use of the Dräger X-am Pump.

Viewing pump information:

Open the quick menu (see "Calling the Quick Menu" on page 16).

Select and confirm with the button.

OK

The following pump information will be displayed:

— serial number

— pump runtime (current operation)

— pump battery charge

Press the button to return to measuring mode.

Activating or deactivating the pump:

Open the quick menu (see "Calling the Quick Menu" on page 16).

Select or and activate or deactivate the pump by pressing the button.

Press the button to return to measuring mode.

WARNING

No measurement!

If the pump is connected but deactivated, the gas detector is not ready to measure.

The red LEDs on the gas detector flash.

22

Page 23

WARNING

Impairment of accuracy!

After measuring high concentrations of nonane (>20 %LEL), the accuracy for

measuring nonane is impaired.

The pump is not suitable for long-term measurement of high concentrations of

nonane.

Performing a measurement with a manual pump adapter and rubber ball pump

Required accessories (see "Accessories" on page 67):

Manual pump adapter

Rubber ball pump

Sampling hose

Probes

Commissioning and performing the measurement:

See instructions for use of the accessories used.

23

Page 24

Configuring the Instrument

IR

Calibration cradle (order no. 83 18 752)

with inserted

USB DIRA with USB cable (order no. 83 17 409)

USB DIRA with USB cable

(order no. 83 17 409)

E-Cal module Dräger X-am 125

(order no. 83 18 754)

USB 2.0

USB 2.0

USB 2.0 / COM

01433072_01_en.eps

Dräger

CC-Vision

Dräger

CC-Vision

Dräger

CC-Vision

E-Cal

0

0

0

X-am 5600

To individually configure a instrument with standard configuration, the instrument must

be connected with a PC.

The installed PC software Dräger CC Vision is used for configuration.

Observe the documentation and online help of the software.

24

Page 25

Device settings

NOTICE

Only trained personnel are permitted to make changes to the device configuration.

The following changes can be made to the device parameters for a device:

Designation Field

Password Numeric field (3-figure)

Operating signal LED

Operating signal horn

1)

1)

Yes/ No

Yes/ No

Switch-off mode “Switch off permitted” or

“Switch off prohibited” or

“Switch off prohibited at A2”

Shift length (TWA)

2)

(in minutes) 60 - 14400

(setting for exposure alarm)

Short-term exposure limit (STEL)

minutes)

3) 4)

(in

0 - 15

(setting for exposure alarm)

User ID(12 characters) Alphanumeric field

Switch database on or off On/Off

Overwrite database Yes/No

Database mode Peak/Average

Database interval 1 s / 10 s / 30 s / 1 min / 2 min / 5 min /

10 min / 30 min

Date (date on the PC)

Time (time on the PC)

Warning after expiry of calibration interval Yes/No

Error after expiry of calibration interval Yes/No

Delay until error after expiry of calibration

0 - 10

interval (days)

Automatic detection of Bump Test Station Yes/No

Activate span calibration following

negative bump test

Yes/No (relates only to a device

connected to the Dräger Bump Test

Station)

Bump test mode “extended bump test” or “quick bump test”

or “bump test deactivated”

Warning after expiry of bump test interval Yes/No

Error after expiry of bump test interval

Yes/ No

(if warning activated)

Capture range Yes / No

Remote configuration Yes / No

Bump test interval (days) 1 - 732

25

Page 26

Delay until error after expiry of cal. interval

0-10

(days)

Activate user service life Yes/No

User service life (days)

0 - 999

(if activated)

Running in Yes/No

LEL category “---” or “PTB” or “IEC” or “NIOSH”

(if this is changed, the LEL factor will be

altered to match)

ToxicTwins (HCN) Yes/No

1) At least one of the two operating signals must be switched on.

2) Corresponds to the averaging time and is used to calculate the exposure value TWA.

3) Only evaluated if the sensor is provided for the purpose.

4) Corresponds to the averaging time and is used to calculate the exposure value STEL.

Sensor settings

The following changes can be made to the sensor parameters for the sensors:

Designation Field

Alarm threshold A1 (in measurement unit) 0 - A2

Alarm threshold A2 (in measurement unit) A1 – Measuring range limit value

Type of evaluation

Alarm threshold STEL

(in measurement unit)

Alarm threshold TWA

(in measurement unit)

1)

1)

1)

Inactive, TWA, STEL, TWA+STEL

0 – Measuring range limit value

0 – Measuring range limit value

Calibration interval (days) 0 - 180 (sensor-dependent)

Unit (sensor-dependent) Vol%, %UEG, %LEL, %LIE, ppm, mbar,

ppb, mg/m

3

Gas name: “Ex” (IR-Ex channel only) Yes/No

1) Only evaluated if the sensor is provided for the purpose.

Testing the parameters

In order to ensure that the values have been correctly transferred to the gas measuring

device:

Press the touch button Data from X-am 1/2/5x00

Check parameters.

26

Page 27

Read Database and Display Graphically

IR

Calibration cradle (order no. 83 18 752)

with inserted

USB DIRA with USB cable (order no. 83 17 409)

USB DIRA with USB cable

(order no. 83 17 409)

E-Cal module Dräger X-am 125

(order no. 83 18 754)

USB 2.0

USB 2.0

USB 2.0 / COM

01833072_01_en.eps

Dräger

GasVision

Dräger

GasVision

Dräger

GasVision

E-Cal

0

0

0

X-am 5600

To read the database of the instrument and display it graphically, the instrument must

be connected with a PC.

The installed PC software Dräger GasVision is used for reading and displaying the

database.

Observe the documentation and online help of the software.

27

Page 28

Faults, Cause and Remedy

Fault Cause Remedy

Not possible to switch on

the instrument

Not possible to switch off

the instrument

Display »––« Measuring range calibrated/

To display the numerical codes of the warning and fault messages in the info mode,

page 15.

Warning messages

Discharge the power pack Charge the power pack,

Discharge the alkaline

batteries

The instrument is not set to

measuring mode

The instrument is

configured to "Disable

prohibited"

adjusted incorrectly

Electronics or sensors

defective

page 59.

Insert new alkaline batteries,

page 58.

Select measuring mode.

Configure the instrument to

"Disable allowed" with Dräger

CC Vision.

Recalibrate/adjust the

measuring range, page 47.

Must be repaired by Service.

Special symbol

» « and displayed

numerical code:

152 Customersservicelifecounter

153 Database 90 % full Read the database soon and

154 Database full Read the database and clear

155 Interval for the function test

159 Calibration/adjustment not

28

Cause Remedy

abouttoelapse'

with gas (bump test) elapsed

possible. The menu function

cannot be carried out

because of a message which

is preventing the function

(e.g., sensors in warm-up

phase).

Reset the service life counter

using Dräger CC Vision.

clear memory afterwards.

memory.

Carry out the function test,

page 41.

Determine the message code

via the info menu and switch it

off, if necessary.

Page 29

Special symbol

» « and displayed

numerical code:

351 DrägerSensor XXS EC1 in

352 DrägerSensor XXS EC1 in

353 EC1 concentration has

354 The temperature is too high Operate the instrument within

355 The temperature is too low Operate the instrument within

356 The calibration interval for

357 Alarm setpoint A2 setting is

Cause Remedy

the warm-up phase

the warm-up phase

drifted into the negative

range

DrägerSensor XXS EC1 has

elapsed

greater than 60 %LEL

Wait until warm-up time is

complete.

Wait until warm-up time is

complete.

Carry out fresh air calibration/

zero-point calibration, page 48.

the allowed temperature range.

the allowed temperature range.

Carry out span calibration/

adjustment for DrägerSensor

XXS EC1, page 53.

Set alarm setpoint to less than

60 %LEL.

451 DrägerSensor XXS EC2 in

the warm-up phase

452 DrägerSensor XXS EC2 in

the warm-up phase

453 EC2 concentration has drifted

into the negative range

454 The temperature is too high Operate the instrument within

455 The temperature is too low Operate the instrument within

456 The calibration interval for

DrägerSensor XXS EC2 has

elapsed

457 Alarm setpoint A2 setting is

greater than 60 %LEL

551 DrägerSensor XXS EC3 in

the warm-up phase

552 DrägerSensor XXS EC3 in

the warm-up phase

Wait until warm-up time is

complete.

Wait until warm-up time is

complete.

Carry out fresh air calibration/

adjustment, page 48.

the allowed temperature range.

the allowed temperature range.

Carry out span calibration for

DrägerSensor XXS EC 3,

page 53.

Set alarm setpoint to less than

60 %LEL.

Wait until warm-up time is

complete.

Wait until warm-up time is

complete.

29

Page 30

Special symbol

Cause Remedy

» « and displayed

numerical code:

553 EC3 concentration has drifted

into the negative range

Carry out fresh air calibration/

zero-point calibration, page 48.

554 The temperature is too high Operate the instrument within

the allowed temperature range.

555 The temperature is too low Operate the instrument within

the allowed temperature range.

556 The calibration interval for

DrägerSensor XXS EC3 has

elapsed

557 Alarm setpoint A2 setting is

greater than 60 %LEL

575 Calibration interval for the

compensation channel has

Carry out span calibration for

DrägerSensor XXS EC 3,

page 53.

Set alarm setpoint to less than

60 %LEL.

Adjust the sensitivity of the

compensation channel.

elapsed

576 Calibration required because

of overgassing.

Adjust the sensitivity of the

compensation channel.

651 DrägerSensor XXS EC 4 in

the warm-up phase

652 DrägerSensor XXS EC 4 in

the warm-up phase

653 EC 4 concentration has

drifted into the negative

Wait until warm-up time is

complete.

Wait until warm-up time is

complete.

Carry out fresh air calibration/

zero-point calibration, page 48.

range

654 The temperature is too high Operate the instrument within

the allowed temperature range.

655 The temperature is too low Operate the instrument within

the allowed temperature range.

656 The calibration interval for

DrägerSensor XXS EC 4 has

elapsed

657 Alarm setpoint A2 setting is

greater than 60 %LEL

751 DrägerSensor IR CO

warm-up phase

752 DrägerSensor IR CO

warm-up phase

in the

2

in the

2

Carry out span calibration for

DrägerSensor XXS EC 4,

page 53.

Set alarm setpoint to less than

60 %LEL.

Wait until warm-up time is

complete.

Wait until warm-up time is

complete.

30

Page 31

Special symbol

Cause Remedy

» « and displayed

numerical code:

753 IR CO

concentration has

2

drifted into the negative

Carry out zero-point calibration,

page 48.

range

754 The temperature is too high Operate the instrument within

the allowed temperature range.

755 The temperature is too low Operate the instrument within

the allowed temperature range.

756 The calibration interval for

DrägerSensor IR CO

elapsed

has

2

781 Unstable signal from

DrägerSensor IR CO

2

Carry out span calibration/

adjustment for DrägerSensor IR

, page 53.

CO

2

The warning will reset itself

once the sensor has stabilised.

851 DrägerSensor IR Ex in the

warm-up phase

852 DrägerSensor IR Ex in the

warm-up phase

853 IR Ex concentration has

drifted into the negative range

Wait until warm-up time is

complete.

Wait until warm-up time is

complete.

Carry out fresh air calibration/

zero-point calibration, page 48.

854 The temperature is too high Operate the instrument within

the allowed temperature range.

855 The temperature is too low Operate the instrument within

the allowed temperature range.

856 The calibration interval for

DrägerSensor IR Ex has

elapsed

857 Alarm setpoint A2 setting is

greater than 60 %LEL

881 Unstable signal from

DrägerSensor IR Ex

Carry out span calibration/

adjustment for DrägerSensor IR

Ex, page 53.

Set alarm setpoint to less than

60 %LEL.

The warning will reset itself

once the sensor has stabilised.

31

Page 32

Fault messages

Special symbol

»« and displayed

numerical code:

102 The customers service

103 The instrument is defective The instrument must be

104 Check sum error program

105 The bump test interval has

106 The calibration interval has

107 Bump test error (at least 1

108 The instrument is defective The instrument must be

109 The menu function cannot be

111 Failed alarm element test:

112 Failed alarm element test:

113 Failed alarm element test:

114 Defective parameter check Correct parameters and repeat

115 Device is disabled by X-dock. Activate device with X-dock.

116 Failed software update. The device must be repaired by

117 User parameters not feasible Check configuration of user

118 Flow alarm of X-am Pump Check the gas circuit for

Cause Remedy

lifecounter has elapsed

code

elapsed

elapsed (at least 1 calibration

interval has elapsed)

channel has a bump test

error)

carried out because of an

error.

alarm light.

alarm horn.

Vibration motor.

Reset the service life counter

using Dräger CC Vision.

repaired by Service.

The instrument must be

repaired by Service.

Carry out bump test, page 45.

Carry out span calibration/

adjustment, page 50 or

page 53.

Carry out bump test, page 45 or

carry out span calibration/

adjustment, page 50 or page 53.

repaired by Service.

Determine the error code via the

info menu and switch it off, if

necessary.

Repeat alarm element test with

Dräger X-dock.

Repeat alarm element test with

X-dock.

Repeat alarm element test with

X-dock.

test using X-dock

DrägerService.

parameters and adjust

obstructions and replace filters if

necessary.

32

Page 33

Special symbol

»« and displayed

numerical code:

119 Battery pre-alarm of X-am

120 Battery alarm of X-am Pump Charge pump.

Cause Remedy

Charge pump.

Pump

301 The zero-point calibration/

adjustment of DrägerSensor

XXS EC1 is not valid

302 The span calibration/

adjustment of DrägerSensor

XXS EC1 is not valid

303 The measured value of

DrägerSensor XXS EC 1 is in

the negative range

304 DrägerSensor XXS EC1 is

not inserted or defective

305 Error during the function test

with gas (bump test) of the

DrägerSensor XXS EC1

307 Failed rise time test. Repeat rise time test with

308 User parameters not feasible Check configuration of user

326 Error during warm-up

acceleration DrägerSensor

XXS EC1

401 The zero-point calibration/

adjustment of DrägerSensor

XXS EC2 is not valid

402 The span calibration/

adjustment of DrägerSensor

XXS EC2 is not valid

403 The measured value of

DrägerSensor XXS EC 2 is in

the negative range

404 DrägerSensor XXS EC2 is

not inserted or defective

Carry out fresh air calibration/

zero-point calibration, page 48.

Carry out span calibration,

page 53 or carry out fresh air

calibration, page 48.

Carry out fresh air calibration/

zero-point calibration, page 48.

Check DrägerSensor XXS EC1,

page 62.

Repeat function test. Calibrate

or replace DrägerSensor XXS

EC1, if necessary page 62.

X-dock.

parameters and adjust

Disconnect and reconnect

power pack or replace the

sensor. Sensor must not be

loaded with gas within the first

5minutes.

Carry out fresh air calibration/

zero-point calibration, page 48.

Carry out span calibration/

adjustment, page 53.

Carry out fresh air calibration/

zero-point calibration, page 48.

Check DrägerSensor XXS EC2,

page 62.

33

Page 34

Special symbol

»« and displayed

numerical code:

405 Error during the function test

406 Failed filter test. Repeat filter test with X-dock.

407 Failed rise time test. Repeat rise time test with

408 User parameters not feasible Check configuration of user

426 Error during warm-up

Cause Remedy

with gas (bump test) of

DrägerSensor XXS EC2

acceleration DrägerSensor

XXS EC2

Repeat function test. Calibrate

or replace DrägerSensor XXS

EC2, if necessary page 62.

X-dock.

parameters and adjust

Disconnect and reconnect

power pack or replace the

sensor. Sensor must not be

loaded with gas within the first

5minutes.

501 The zero-point calibration/

adjustment of DrägerSensor

XXS EC3 is not valid

502 The span calibration/

adjustment of DrägerSensor

XXS EC3 is not valid

503 The measured value of

DrägerSensor XXS EC3 is in

the negative range

504 DrägerSensor XXS EC3 is

not inserted or defective

505 Error during the function test

with gas (bump test) of the

DrägerSensor XXS EC3

506 Failed filter test. Repeat filter test with X-dock.

507 Failed rise time test. Repeat rise time test with

508 User parameters not feasible Check configuration of user

525 The span calibration for the

compensation channel is not

valid

Carry out fresh air calibration/

zero-point calibration, page 48.

Carry out span calibration/

adjustment, page 53.

Carry out fresh air calibration/

zero-point calibration, page 48.

Check DrägerSensor XXS EC3,

page 62.

Repeat function test. Calibrate

or replace DrägerSensor XXS

EC3, if necessary page 62.

X-dock.

parameters and adjust

Adjust the sensitivity of the

compensation channel.

34

Page 35

Special symbol

Cause Remedy

»« and displayed

numerical code:

526 Error during warm-up

acceleration DrägerSensor

XXS EC3

Disconnect and reconnect

power pack or replace the

sensor. Sensor must not be

loaded with gas within the first

5minutes.

601 The zero-point calibration/

adjustment of DrägerSensor

Carry out fresh air calibration/

zero-point calibration, page 48.

XXS EC 4 is not valid

602 The span calibration/

adjustment of the

Carry out span calibration/

adjustment, page 53.

DrägerSensor XXS EC 4 is

not valid

603 The measured value of

DrägerSensor XXS EC 4 is in

Carry out fresh air calibration/

zero-point calibration, page 48.

the negative range

604 DrägerSensor XXS EC 4 is

not inserted or defective

605 Error during the function test

with gas (bump test) of

DrägerSensor XXS EC 4

Check DrägerSensor XXS EC

4, page 62.

Repeat function test. Calibrate

or replace DrägerSensor XXS

EC 4, if necessary page 62.

606 Failed filter test. Repeat filter test with X-dock.

607 Failed rise time test. Repeat rise time test with

X-dock.

608 User parameters not feasible Check configuration of user

parameters and adjust

626 Error during warm-up

acceleration DrägerSensor

XXS EC4

Disconnect and reconnect

power pack or replace the

sensor. Sensor must not be

loaded with gas within the first

5minutes.

701 The zero-point calibration/

adjustment of Dräger

Sensors IR CO

is not valid

2

702 The span calibration/

adjustment of Dräger

Sensors IR CO

is not valid

2

Carry out zero-point calibration,

page 48.

Carry out span calibration,

page 53 or carry out fresh air

calibration, page 48.

35

Page 36

Special symbol

Cause Remedy

»« and displayed

numerical code:

703 The measured value of

Dräger Sensors IR CO

the negative range

704 Dräger Sensor IR CO

inserted

2

is not

2

705 Error during the function test

with gas (bump test) of the

Dräger Sensors IR CO

2

Carry out zero-point calibration,

is in

page 48.

Check Dräger Sensor IR CO2,

page 62.

Repeat function test. Calibrate

or replace Dräger Sensor IR

, if necessary, page 62.

CO

2

706 Failed filter test. Repeat filter test with X-dock.

707 Failed rise time test. Repeat rise time test with X-

dock.

708 User parameters not feasible Check configuration of user

parameters and adjust

731 Error in Dräger Sensor IR

CO

2

732 Error in Dräger Sensor IR

CO

2

733 Unstable signal from

DrägerSensor IR CO

2

734 Zero-point calibration of

DrägerSensor IR CO

failed

2

735 Span calibration of

DrägerSensor IR CO

failed

2

Check Dräger Sensor IR CO2,

page 62.

Check Dräger Sensor IR CO2,

page 62.

The error will reset itself once

the sensor has stabilised.

Repeat zero-point calibration.

Repeat span calibration.

801 The zero-point calibration/

adjustment of Dräger Sensor

IR Ex is not valid

802 The zero-point calibration/

adjustment of Dräger Sensor

IR Ex is not valid

803 The measured value of

Dräger Sensors IR Ex is in

the negative range

804 Dräger Sensor IR Ex is not

inserted

805 Error during the function test

with gas (bump test) of the

Dräger Sensors IR Ex

36

Carry out fresh air calibration/

zero-point calibration, page 48.

Carry out span calibration,

page 53 or carry out fresh air

calibration, page 48.

Carry out fresh air calibration/

zero-point calibration, page 48.

Check Dräger Sensor IR Ex,

page 62.

Repeat function test. Calibrate

or replace Dräger Sensor IR Ex,

if necessary, page 62.

Page 37

Special symbol

»« and displayed

numerical code:

806 Failed filter test. Repeat filter test with X-dock.

807 Failed rise time test. Repeat rise time test with X-

808 User parameters not feasible Check configuration of user

831 Error in Dräger Sensor IR Ex Check Dräger Sensor IR Ex,

832 Error in Dräger Sensor IR Ex Check Dräger Sensor IR Ex,

833 Unstable signal from

834 Zero-point calibration of

835 Span calibration of

Cause Remedy

dock.

parameters and adjust

page 62.

page 62.

DrägerSensor IR Ex

DrägerSensor IR Ex failed

DrägerSensor IR Ex failed

The error will reset itself once

the sensor has stabilised.

Repeat zero-point calibration.

Repeat span calibration.

37

Page 38

Maintenance

Maintenance intervals

The instrument should be inspected and maintained by suitably qualified persons

annually. Comparisons:

EN 60079-29-2 – Gas detectors - Selection, installation, use and maintenance of

detectors for flammable gases and oxygen

EN 45544-4 – Electrical apparatus used for the direct detection and direct

concentration measurement of toxic gases and vapours - Part 4: Guide for selection,

installation, use and maintenance

National regulations

Recommended calibration interval for measuring channels O

CO: 6 months.

Recommended calibration interval for the measuring channel IR Ex/CO

, H2S, H2, SO2, NO2 and

2

: 12 months.

2

NOTICE

Calibration interval of other gases: see Instructions for Use for the respective

Dräger sensors.

Depending on instrument configuration:

Replace the alkaline batteries or charge the battery – refer to page 58 to page 59 –

after each use, at the latest after the battery alarm has been triggered or after

2weeks.

Calibrating/adjusting the instrument – page 47.

— In regular intervals, according to the sensors used and the operating conditions. For

sensor-specific calibration data, refer to the Instructions for Use/data sheets of the

Dräger sensors used

1)

.

— Before you carry out safety-related relevant measurements, the zero point and

sensitivity of the instruments should be tested in accordance with national

regulations.

Inspection by suitably qualified persons – every year.

— The inspection intervals must be established in each individual case and shortened

if necessary, depending on technical safety considerations, engineering conditions

and the technical requirements of the equipment.

— We recommend that a service agreement be concluded with Dräger Safety and that

repairs also be carried out by them.

Replace the sensors, page 62 – if necessary, when it is not possible to calibrate/

adjust the sensors anymore.

1) The Instructions for Use/data sheets of the sensors used are supplied with the instrument on CD.

See also attached Instructions for Use and Data Sheets of the sensors used.

The Instructions for Use/data sheets of the sensors used can also be downloaded from the

following Internet address: www.draeger.com

38

Page 39

H2 added signal

WARNING

After activating or deactivating the H

In the case of a manual function test the effect of the H

into account accordingly.

The functionality of the H2 added signal is only supported provided a Dräger

Sensor XXS H

or a Dräger Sensor IR Ex sensor in the Dräger X-am 5600. Both units must be set to

HC is operated in conjunction with a Dräger Sensor DUAL IR Ex/CO2

2

LEL.

An added signal can be activated and deactivated via the Dräger CC-Vision PC

software.

added signal check the set alarm thresholds.

2

WARNING

added signal must be taken

2

If the H

By activating the H

Sensor XXS H2 HC (68 12 025) is added to the LEL gas concentration of the activated

Dräger Sensor DUAL IR Ex/CO

(68 12 180) and shown on the display at the position of the IR Ex display.

added signal feature is activated, ch4+ appears in the measured value display.

2

added signal, the LEL gas concentration of the activated Dräger

2

(68 11 960) or of the activated Dräger Sensor IR Ex

2

NOTICE

Maintain the set alarm thresholds as they are to ensure that in the presence of

hydrogen (H

) the alarm of the IR Ex Channel is triggered earlier if required.

2

NOTICE

A potentially activated H

during a manual calibration, a PC calibration or an automatic Bump Test for the

added signal is automatically temporarily deactivated

2

relevant duration.

39

Page 40

ToxicTwins

When the ToxicTwins feature is activated, the measuring channels of the XXS CO

sensor and the XXS HCN sensor are offset against each other in such a manner that

the device issues an alarm before the respective A1 alarm threshold is reached if both

gases are detected at the same time.

Prerequisites:

— The XXS CO and XXS HCN sensors are installed.

— The ToxicTwins feature is activated (using the Dräger CC-Vision PC software).

If the ToxicTwins feature is activated, HCN+ appears in the measured value display.

CO H2 compensation

Carbon monoxide (CO) and hydrogen (H2) can occur simultaneously in workplaces in

the steel industry, refineries, sewage works, etc. Hydrogen affects the CO signal in

ordinary commercially available sensors, which leads to false alarms. The XXS CO

-CP sensor uses two sensing electrodes. One of these electrodes measures CO and

H

2

, the other one measures only H2. The difference between the two signals is

H

2

calculated, so that only the CO value will be displayed. For example, a hydrogen

concentration of 1000 ppm (2.5 %LEL) will only result in a maximum of 15 ppm CO

being displayed, but the CO alarm will not be triggered.

This feature is automatically available and activated if the XXS CO H

installed. Deactivation is not possible.

Prerequisites:

—XXS CO H

-CP sensor is installed.

2

If this feature is used, CO+ appears in the measured value display.

40

-CP sensor is

2

Page 41

Carry out manual bump test

WARNING

In the case of a manual function test the effect of the H

into account accordingly.

NOTICE

A potentially activated H

manual calibration, a PC calibration or an automatic Bump Test for the relevant duration.

added signal is automatically temporarily deactivated during a

2

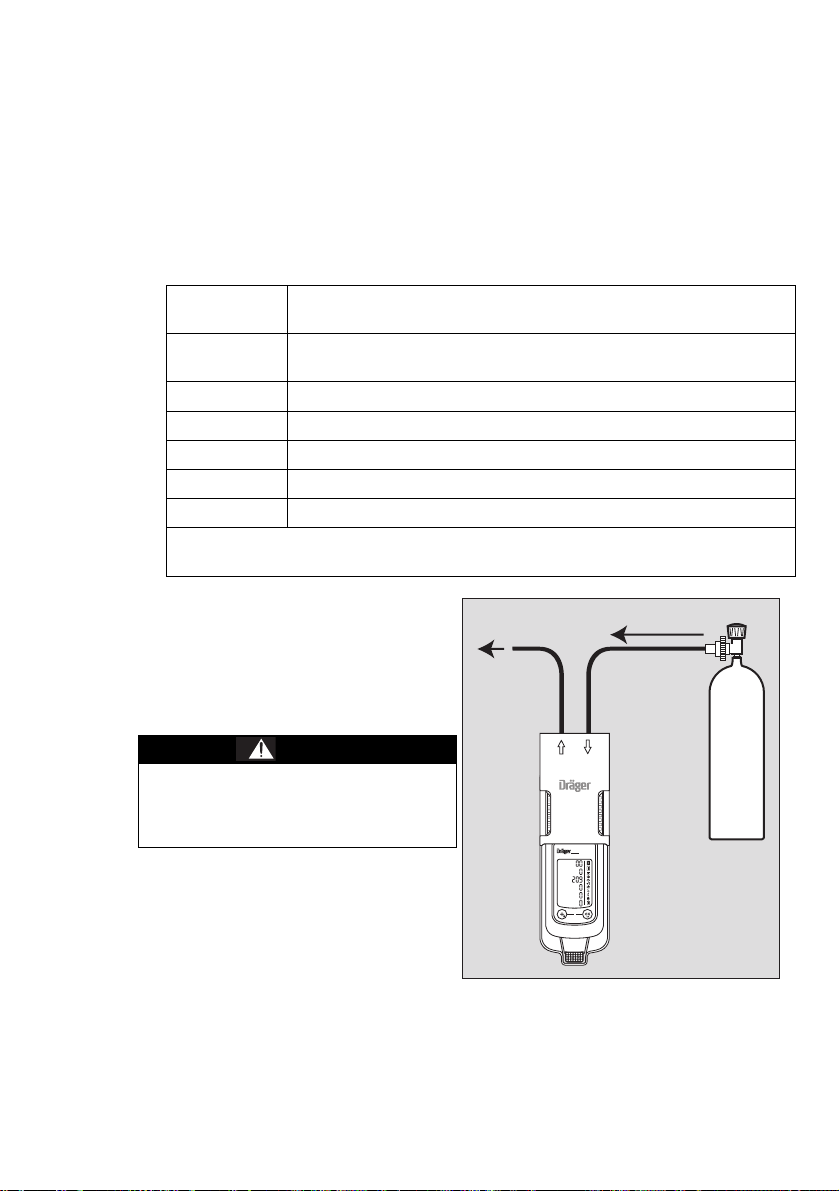

Manual implementation without the documentation of results in the instrument memory

Prepare a test gas cylinder, the

volume flow must be 0.5 l/min and the

gas concentration must be higher than

the alarm threshold concentration to

be tested.

Example:

test gas cylinder 68 11 132 = mixed gas

with 50 ppm CO, 15 ppm H

, 2.5 vol. % CH4, 18 vol. % O

%CO

2

S, 2 vol.

2

2

test gas cylinder 68 11 130 = mixed

gas with 50 ppm CO, 15 ppm H

2.5 vol. % CH

, 18 vol. % O

4

S,

2

2

Connect the test gas cylinder with the

calibration cradle (83 18 752).

Vent the test gas into a fume cupboard

or into the open air (with a hose

connected to the second connector of

the calibration cradle).

added signal must be taken

2

0.5 L/min

CO2

Vol%

ch4

%LEL

2

O

Vol%

CO

ppm

2S

H

ppm

3

NH

ppm

0

00533072_01_en.eps

CAUTION

Risk to health! Do not inhale the test gas.

Observe the hazard warnings of the relevant Safety Data Sheets.

Switch on the instrument and insert it into the calibration cradle – press downwards

until it engages.

Open the test gas cylinder valve to let test gas flow over the sensors.

41

Page 42

Wait until the instrument displays the test gas concentration with sufficient tolerance:

e. g.

IR Ex: ±20 %

IR CO2: ±20 %

: ±0.6 vol. %

O

2

TOX: ±20 % 1) of test gas concentration

1) Upon application of the Dräger mixed gas (order no. 68 11 130) the displays should be within

this range.

1)

of test gas concentration

1)

of test gas concentration

1)

If the alarm thresholds are exceeded, the instrument displays the gas concentration

in alternation with »A1« or »A2« depending on the test gas concentration.

Close the test gas cylinder valve and remove the instrument from the calibration

cradle.

— If the concentration has now fallen under the A1 alarm threshold:

Acknowledge the alarm.

If the displays are outside of the above-mentioned ranges:

Calibrating/adjusting the instrument, refer to page 47.

NOTICE

To check the measured value response times, apply t90 test gas to the X-am via the

calibration cradle. Check the results in accordance with the information in the table in

the enclosed supplementary documentation (order no. 90 33 890) until 90 % of the

end display is reached.

NOTICE

After the bump test, the display shows a printer icon even if there is no printer

connected to the bump test station.

42

Page 43

Menu implementation with the documentation of results in the instrument memory

The setting whether the bump test is to be carried out manually or automatically is

made using the PC software Dräger CC Vision.

The "Quick bump test" or the "Extended bump test" is selected using the Dräger CC

Vision PC software.

The "Quick bump test" checks whether the gas concentration has exceeded the Alarm

1 threshold (with oxygen, the check is whether the concentration has fallen below the

Alarm 1 threshold).

In the case of the “Extended bump test”, a check is made as to whether the gas

concentration has reached the set bump test concentration within a tolerance window.

Setting on delivery: Extended bump test.

Prepare a test gas cylinder, the

volume flow must be 0.5 l/min and the

0.5 L/min

gas concentration must be higher than

the alarm threshold concentration to

be tested.

Example:

test gas cylinder 68 11 132 = mixed

gas with 50 ppm CO, 15 ppm H

2vol. %CO

18 vol. % O

, 2.5 vol. % CH4,

2

2

test gas cylinder 68 11 130 = mixed

gas with 50 ppm CO, 15 ppm H

2.5 vol. % CH

, 18 vol. % O

4

Connect the test gas cylinder with the

S,

2

CO2

S,

2

2

Vol%

ch4

%LEL

2

O

Vol%

CO

ppm

2S

H

ppm

3

NH

ppm

0

calibration cradle (83 18 752).

Vent the test gas into a fume cupboard

or into the open air (with a hose

connected to the second connector of

the calibration cradle).

00533072_01_en.eps

WARNING

Risk to health! Do not inhale the test gas.

Observe the hazard warnings of the relevant Safety Data Sheets.

43

Page 44

Switch on the instrument and insert it into the calibration cradle – press downwards

02433072_01_en.eps

CO2

Vol %

O

2

Vol %

ch4

%LEL

CO

ppm

H

2S

ppm

NH

3

ppm

OK

until it engages.

Call the quick menu and select the function test with gas (bump test), page 16.

— The current gas concentration values

and the special symbol » «

(for bump test) flash.

Press the key to start the function

test with gas.

Open the test gas cylinder valve to let

test gas flow over the sensor.

— If gas concentration exceeds the

alarm thresholds A 1 or A 2 the

corresponding alarm will occur.

Exit the function test with gas:

After the preset bump test concentration

is reached or a gas alarm is triggered

(with the "Quick bump test"):

— The display containing the current

gas concentration changes with the

display »OK«.

— The bump test that was carried out is

documented with the result and date

in the instrument memory.

Close the test gas cylinder valve and

remove the instrument from the

CO2

Vol %

4

ch

%LEL

2

O

Vol %

CO

ppm

2S

H

ppm

3

NH

ppm

calibration cradle.

— If the concentration values have now

fallen under the A1 alarm thresholds,

the instrument returns to the

measuring mode.

02533072_01_en.eps

— If the set bump test concentration is not reached within the specified time, the alarm

mode is activated to indicate failure.

44

Page 45

— The fault message » « appears

02633072_01_en.eps

CO2

Vol %

O

2

Vol %

ch4

%LEL

CO

ppm

H

2S

ppm

NH

3

ppm

and » « is displayed instead of

the measured value on the faulty

measuring channel.

In this case, repeat the function test

with gas or calibrate/adjust the

instrument, page 47.

The function test with gas can also be

carried out automatically.

The "Bump Test Station" is required for

this function, refer to page 45.

Automatic implementation with the Bump Test Station