Page 1

Technical Documentation IPM

Savina 300

Intensive Care Ventilator

Warning

All servicing and/or test procedures on the

device require detailed knowledge of this documentation. Use of the device requires detailed

knowledge and observance of the relevant

Instructions for Use.

Page 2

– This page has been intentionally left blank –

2

No.1309-0000001227_Publication

Savina 300

Page 3

Table of contents

Table of contents

General

General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function descriptions

Block diagram and functional principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electronic assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control panel with TFT colour display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pneumatic assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance instructions

Disassembling/assembling the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the microfilter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the dust filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the O2 sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the diaphragm of the expiratory valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the internal batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the external batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the consumables in the O2 gas inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Annex

5

6

9

10

12

18

20

31

32

38

40

42

47

50

54

65

71

No.1309_0000001227_Publication

Savina 300

3

Page 4

– This page has been intentionally left blank –

4

No.1309-0000001227_Publication

Savina 300

Page 5

General

This chapter contains general notes and definitions that are important for the

use of this documentation.

General notes ....................................................................................................................................

6

No.1309_0000001227_Publication

Savina 300

5

Page 6

General

General notes

General notes

Notes on use Read through the following notes thoroughly before applying this documenta-

tion.

Dräger reserves the right to make changes to the device and/or to this documentation without prior notice. This documentation is intended solely as an

information resource for experts.

Copyright and other protected rights

Definitions

The content of this documentation, in particular its design, text, software,

technical drawings, configurations, graphics, images, data and their selection

and its composition and any amendments to it ("content") are protected by

copyright. The content must not (in whole or in part) be modified, copied, distributed, reproduced, republished, displayed, transmitted or sold without the

prior written consent of Dräger.

WARNING!

A WARNING statement provides important information about a potentially

hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION

A CAUTION statement provides important information about a potentially

hazardous situation which, if not avoided, may result in minor or moderate

injury to the user or patient or in damage to the medical device or other

property.

NOTE

A NOTE provides additional information intended to avoid inconvenience

during operation and/or servicing.

6

Inspection = Identification of actual condition

Maintenance = Measures to maintain the speci-

fied condition

Repair = Measures to restore specified

condition

Servicing = Inspection, maintenance, repair

No.1309_0000001227_Publication

Savina 300

Page 7

General

General notes

General safety precautions Read through each section thoroughly before beginning servicing. Always

use the correct tools and the specified test equipment. Otherwise the device

may not work correctly or may be damaged.

WARNING!

Improper servicing

If the medical product is not properly serviced, the safety of the patient

and/or the operator may be put at risk.

– Have the medical product checked and maintained on a regular basis

by appropriately qualified experts, otherwise the proper functioning of

the device may be compromised.

– Have repairs to the medical product carried out only by personnel who

have undergone product-specific Dräger training.

NOTE

Dräger recommends entering into a service contract with DrägerService

and having all repairs likewise carried out by DrägerService.

WARNING!

Replacement parts not certified by Dräger standards

Dräger cannot guarantee or confirm the operational safety of third-party

replacement parts used on the device.

– Use only replacement parts certified to Dräger standards for servicing

of the device, otherwise the proper functioning of the device may be

compromised.

– Pay attention to the „Servicing“ section of the Instructions for Use.

WARNING!

Non-conforming test values

If test values do not conform to specifications, the safety of the patient may

be put at risk.

– Do not put the device into operation if test values do not conform to

specifications.

– Contact your local service organization.

WARNING!

Impermissible modifications to the device

If impermissible modifications are made to the device, the safety of the

patient may be put at risk.

– Do not modify the device without Dräger's permission.

WARNING!

Risk of infection

The device may transmit pathogens following use on the patient.

– Before carrying out any servicing, ensure that the device and its com-

– Service only cleaned and disinfected devices and device components.

No.1309_0000001227_Publication

Savina 300

ponents have been handed over by the user cleaned and disinfected.

7

Page 8

General

General notes

WARNING!

Risk to patients

– Ensure that no patient is connected to the device before starting main-

tenance or repair work.

NOTE

Where reference is made to legislation, regulations and standards, in

respect of devices used and serviced in Germany they are based on the

laws of Germany. Users and technicians in other countries must comply

with their national laws and/or international standards.

8

No.1309_0000001227_Publication

Savina 300

Page 9

Function descriptions

This chapter contains descriptions of the device's technical functions.

Block diagram and functional principle ..............................................................................................

Electronic assembly ...........................................................................................................................

Control panel with TFT colour display................................................................................................

Pneumatic assembly..........................................................................................................................

10

12

18

20

No.1309_0000001227_Publication

Savina 300

9

Page 10

Function descriptions

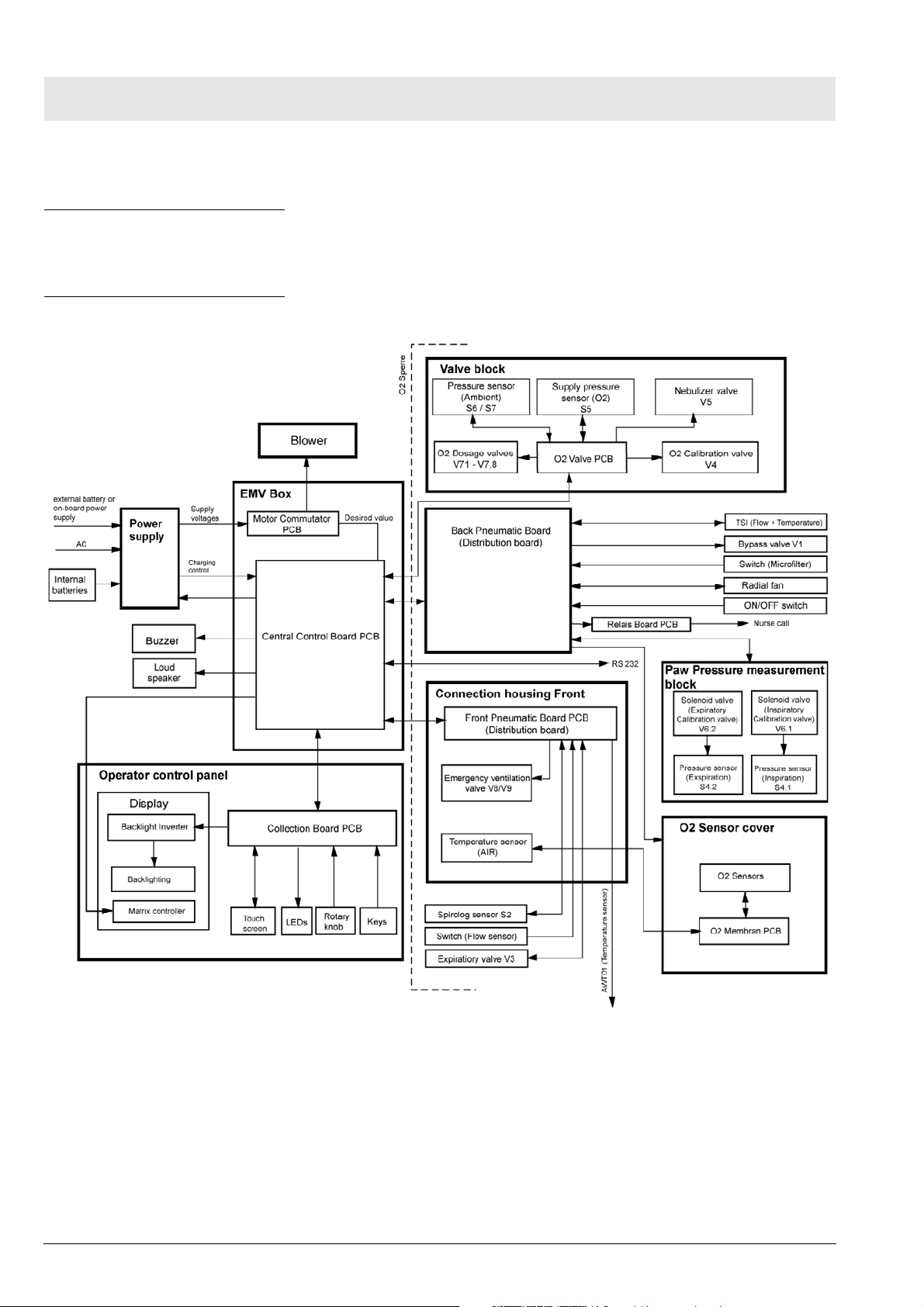

Block diagram and functional principle

Block diagram and functional principle

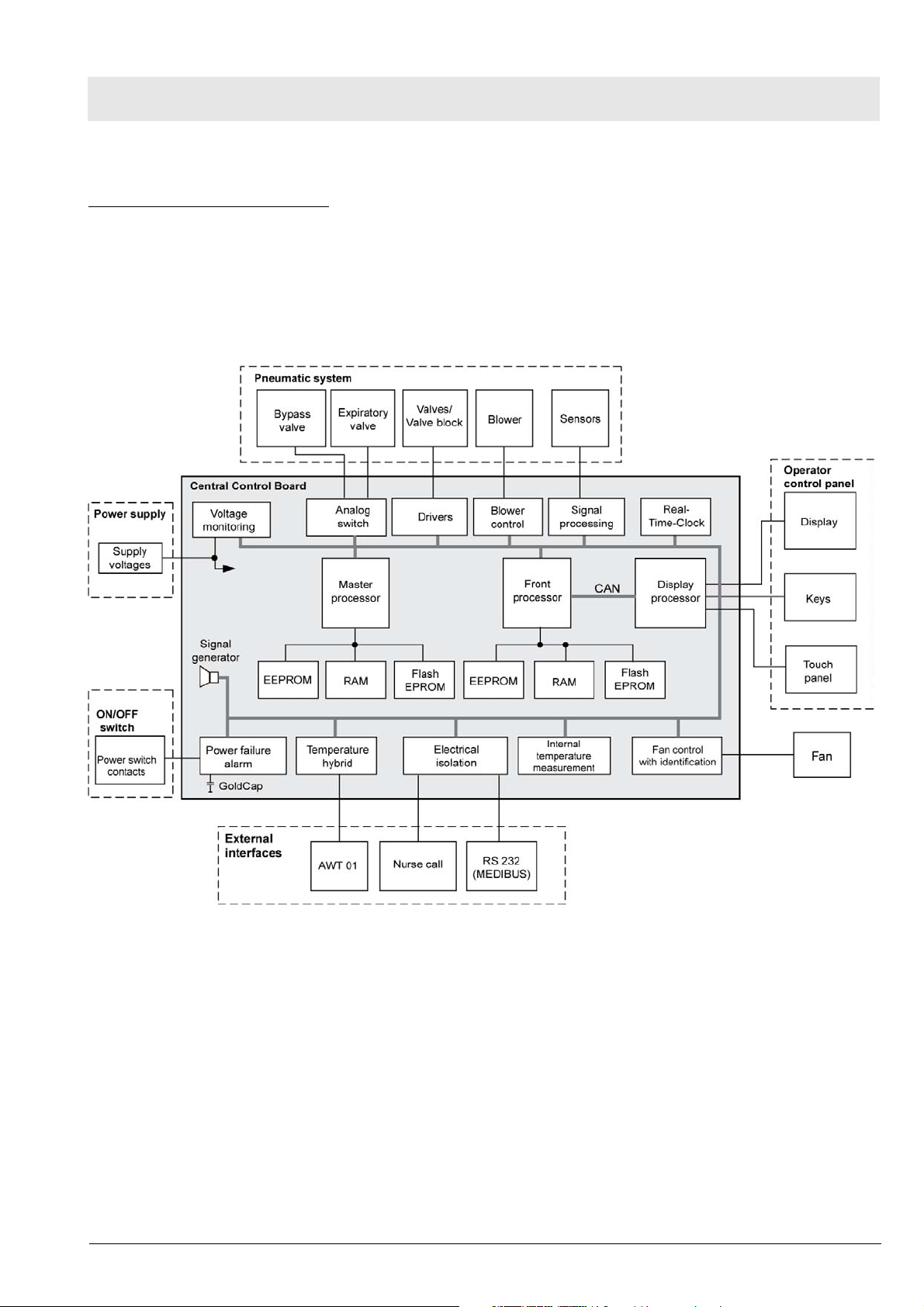

Introduction The following text sets out the block diagram and the functional principle of

the Savina 300.

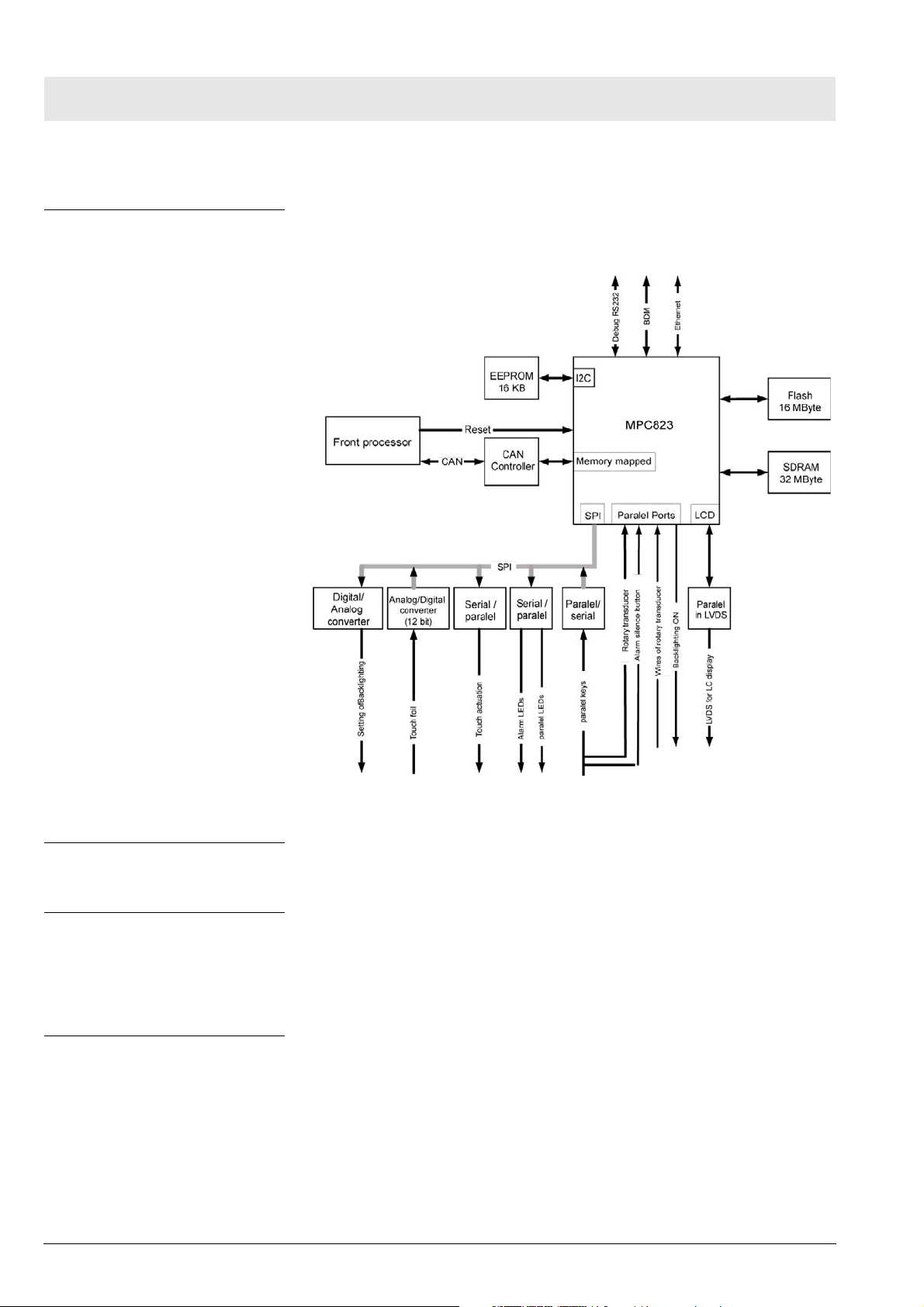

Block diagram

Fig. 1 Block diagram Savina 300

10

No.1309_0000001227_Publication

Savina 300

Page 11

Function descriptions

Block diagram and functional principle

Functional principle The blower generates the necessary compressed air for ventilation. A con-

trollable valve (non-return valve) is switched in parallel with the blower to regulate the pre-set ventilation parameter. The non-return valve opens or closes

according to the pre-set ventilation parameters.To increase the oxygen concentration in the ventilation gas, an external oxygen source can be connected

to the device. Sensors, the electronics and the valve block meter the oxygen

concentration.

Main components The device consists of the following main components:

– Elektronic assembly

– Control unit

– Pneumatic assembly

No.1309_0000001227_Publication

Savina 300

11

Page 12

Function descriptions

Electronic assembly

Electronic assembly

Introduction The electronic assembly contains the following subassemblies:

– Power supply unit

– Central Control Board

– Motor actuator

–O2 Valve PCB

– O2 Diaphragm PCB

– Fan

Power supply unit The power supply unit delivers the supply voltages for the device. The input

voltage range is 100 V to 240 V AC and 50 Hz to 60 Hz. The power supply

unit can also be operated with an external rechargeable battery (12 V or

24 V).

The connection to the alternating voltage is made by a power cable. The connection for the external rechargeable battery is made by an encoded connector.

The power supply unit actuates the „Mains power“, „External battery or onboard power supply“ and „Internal battery“ LEDs. The LEDs are mounted on

the membrane keypad of the control panel and indicate the respective operating status.

The device includes two internal rechargeable batteries (2 x 12 V) which

enable uninterrupted operation in the event of a mains power failure. The

internal rechargeable batteries supply the O2 sensors with power even when

the device is switched off. When the device is switched on the valid O2 values are present.

The power supply unit generates the following supply voltages:

–+5 V

–-15 V

–+15 V

–+24 V

–+48 V

The output voltages are short-circuit-proof and stable at no-load.

12

The output voltages are generated according to the following priority, dependent on the input voltages:

Input voltage Priority Action

AC voltage 1 Charge external and internal batteries, and maintain the

charge.

External battery/batteries 2 Charge internal batteries, and maintain the charge.

Internal batteries 3 -

No.1309_0000001227_Publication

Savina 300

Page 13

Function descriptions

Electronic assembly

The fan cools the power pack.

Central Control Board The Central Control Board is the device's central „control and monitoring

unit“. It has three separate processor systems (master processor, front processor and display processor).

Three processor systems save the changeable, non-volatile data to

EEPROMs.

Fig. 2 Block diagram of the Central Control Board

Master processor

The master processor has the following tasks:

– Activation of the actuators (valves, valve block, blower)

– Reading of the measured values from the sensors

– Control of the ventilation

– Monitoring of the front processor

The master processor data are cached in the RAM.

The EEPROM of the master processor system stores the calibration data of

the sensors and set values such as volume.

No.1309_0000001227_Publication

Savina 300

13

Page 14

Function descriptions

Electronic assembly

Front processor

The front processor has the following tasks:

– Interface with the display processor

– Monitoring of the master processor and display processor

– Monitoring of the input logic and the data e.g. the pixel sum

The RAM caches data from the front processor.

The EEPROM with socket of the front processor stores safety parameters,

set values such as volume, software options and the operating hours.

Display processor

The display processor has the following tasks:

– Presentation of curves and parameters on the display, LEDs

– Input and operator data (keyboard, rotary encoder, touchscreen)

– Collation of data such as the pixel sum.

The EEPROM of the display processor stores user-specific display settings,

such as measured value positions.

Flash EEPROMs

The device's operating system program (software) is stored in Flash

EEPROMs (rewritable memory modules).

Real-time clock

The real-time clock generates the time and date information. The real-time

clock has an internal battery.

The Central Control Board incorporates the following functions:

– Processing of the signals from the sensors (O2, flow, pressure, tempera-

ture)

– Control of the blower and valves

– Monitoring of the unit functions and the supply voltages

– Actuation of the displays

– Keypad interpretation

– Provision of the internal and external interfaces

– Set values such as the volume

14

Mains power failure alarm

If the mains power fails, the device switches to the internal batteries which

supply the device with power. If the internal batteries are discharged and the

device has no external batteries, an acoustic alarm is sounded with a GoldCap and a horn.

No.1309_0000001227_Publication

Savina 300

Page 15

Function descriptions

Electronic assembly

Temperature hybrid

The temperature hybrid reads the data of the AWT01 sensor and converts

these into digital signals. An electrical isolation occurs in this process.

Internal temperature measurement

The internal temperature measurement is a safety function. In the event of

overheating (if the internal temperature of the device is too high), an alarm is

sounded.

Fan actuation and fans

The fan rotates quickly after the device has been switched on to remove any

residual oxygen from the device. The rotation of the fan is detected and controlled in three stages (slow, medium and fast).

Three temperature sensors control the fan.

CAN

The CAN interface is a fast, serial interface. Via the CAN interface the control

unit can communicate with the electronic and pneumatic assemblies. The

transmission rate is 800 kbit/s.

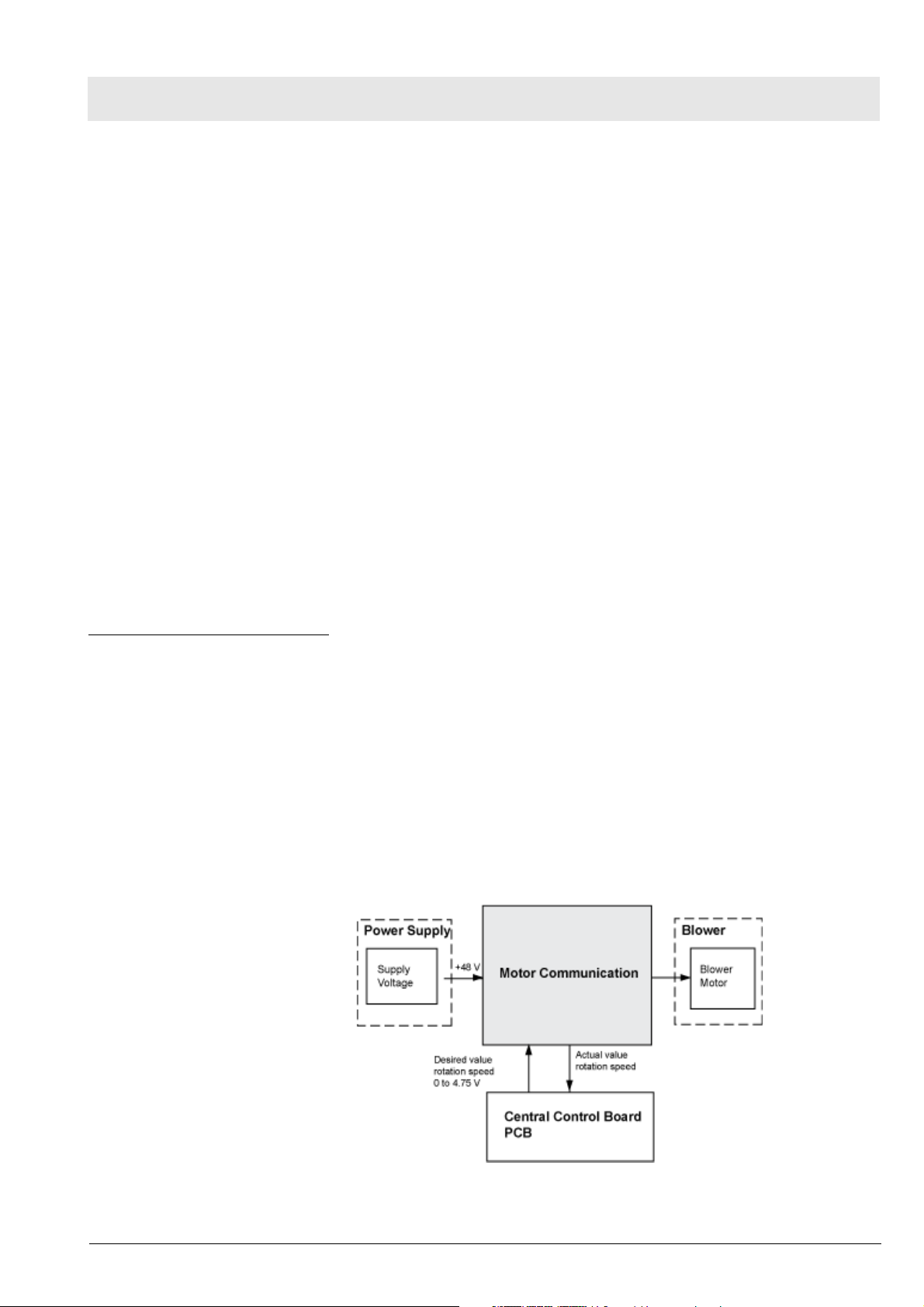

Motor actuator The motor actuator controls the blower motor. The motor actuator is located

in a self-contained housing. The supply voltage for the motor actuator is +48

V and is protected by a fuse (6.3AT).

The input voltage range of the motor actuator is 12 to 52.5 V. The rotation

speed is set by the Central Control Board. The control voltage for the rotation

speed is 0 V to +5.00 V, corresponding to a rotation speed of 0 to 12,000 rpm.

The rotation speed range is 4,000 to 12,000 rpm.

The motor actuator acquires the „actual speed signal“ and forwards it to the

Central Control Board. The „actual value signal“ is 6 pulses per rotation. In

the event of discrepancies in the rotation speed the Central Control Board

adjusts the speed according to the deviation.

Fig. 3 Block diagram of the motor actuator

No.1309_0000001227_Publication

Savina 300

15

Page 16

Function descriptions

Electronic assembly

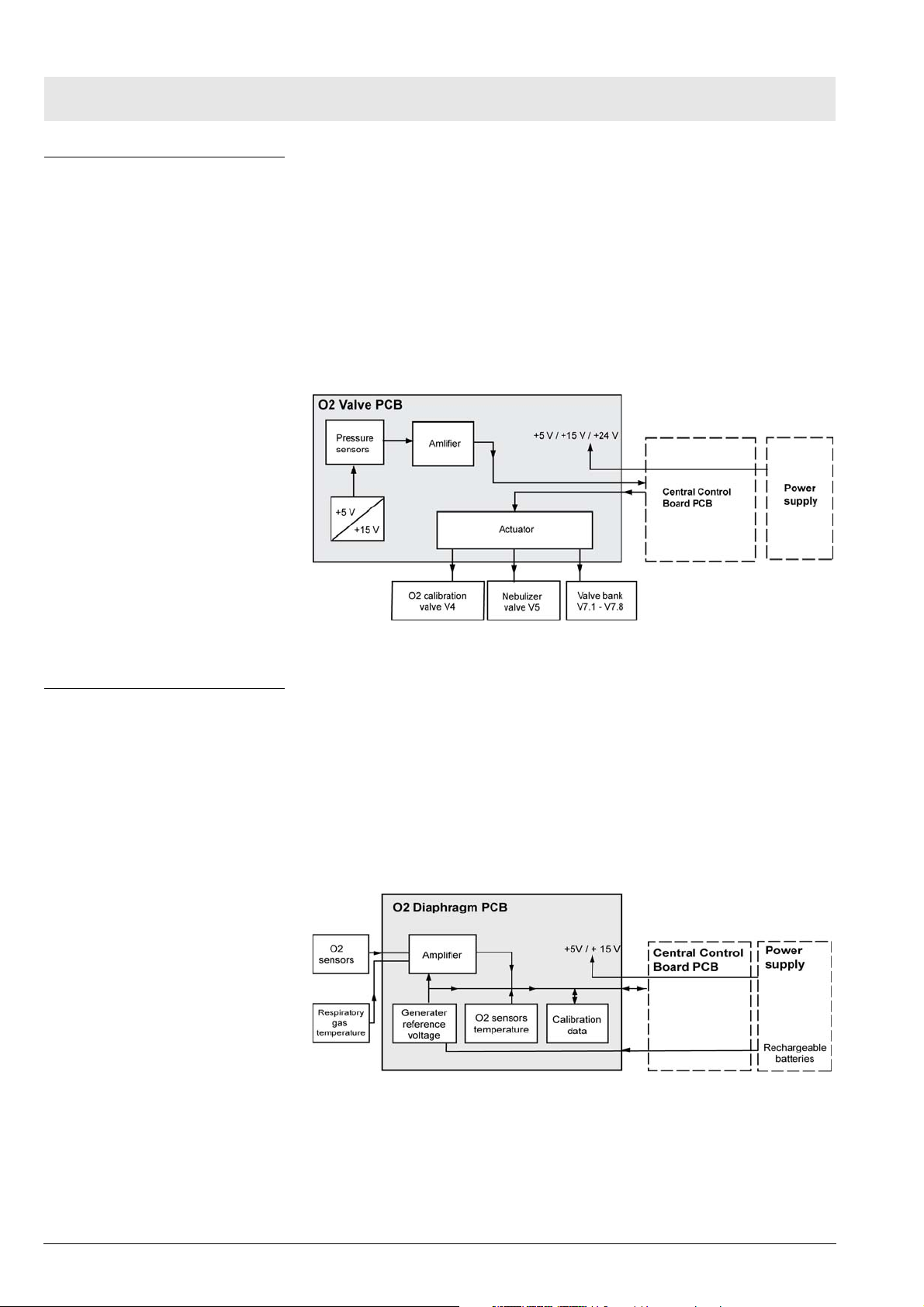

O2 Valve PCB The O2 Valve PCB holds the pressure sensors (absolute pressure S6 and S7

and O2 supply pressure S5), the actuator for the O2 calibrating valve and the

nebulizer valve and the actuator for the valve block.

The signals of the pressure sensors are amplified and routed to the Central

Control Board. The supply voltage (+5 V) for the pressure sensors is generated by the O2 Valve PCB.

The valve block valves, the O2 calibrating valve and the nebulizer valve can

be operated separately by an electronic switch. They are actuated by the

Central Control Board.

Fig. 4 Block diagram of the O2 Valve PCB

O2 Diaphragm PCB The O2 Diaphragm PCB amplifies the signals from the O2 sensors and mea-

sures the temperature of the O2 sensors and of the respiratory gas in the

inspiration block. The temperature of the O2 sensors is required to compensate for the temperature-sensitive O2 measurements. The EEPROM on the

Central Control Board stores the calibration data of the sensors. The reference voltage for the O2 sensors is generated from the voltage of the

rechargeable batteries.

The supply voltages for the O2 Diaphragm PCB are +5 V and +15 V.

16

Fig. 5 O2 Diaphragm PCB block diagram

No.1309_0000001227_Publication

Savina 300

Page 17

Function descriptions

Electronic assembly

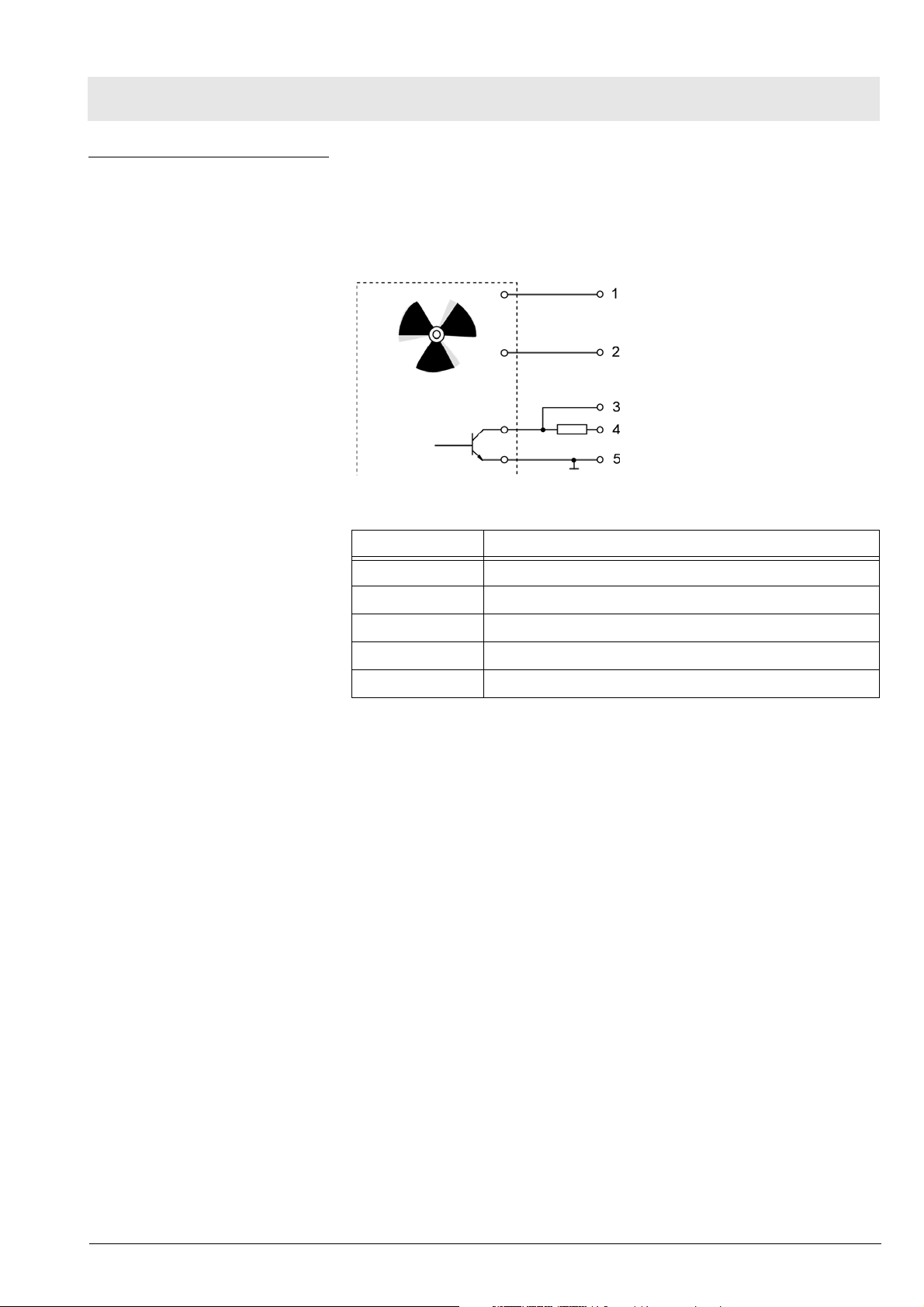

Fan The fan takes in ambient air through the cooler and cools the blower motor.

The air flow removes excess oxygen from the device.

The supply voltage for the fan is +24 V. The Central Control Board regulates

the speed of the fan.

Fig. 6 Fan control

Item Designation

1 Supply voltage

2 Target speed

3 Speed signal

4 Sensor supply voltage

5 Ground

No.1309_0000001227_Publication

Savina 300

17

Page 18

Function descriptions

Control panel with TFT colour display

Control panel with TFT colour display

Control unit The control panel is the interface between the unit and the user. The control

panel is used to enter and display the ventilation parameters.

Fig. 7 Block diagram of the control panel with TFT colour display

Membrane keypad The keypad features the control keys and the associated LEDs.

TFT colour display The 12.1” TFT colour display comprises the actual display and the backlight

converter. The TFT colour display has a resolution of 800 x 600 pixels.

The backlight converter generates a high voltage for the display backlighting.

Rotary encoder The rotary knob is used to set and acknowledge the ventilation parameters.

The shaft encoder transmits square signals to the processor system as it

rotates, and the signals are then evaluated by the Central Control Board. The

voltage supply is +5 V.

No.1309_0000001227_Publication

18

Savina 300

Page 19

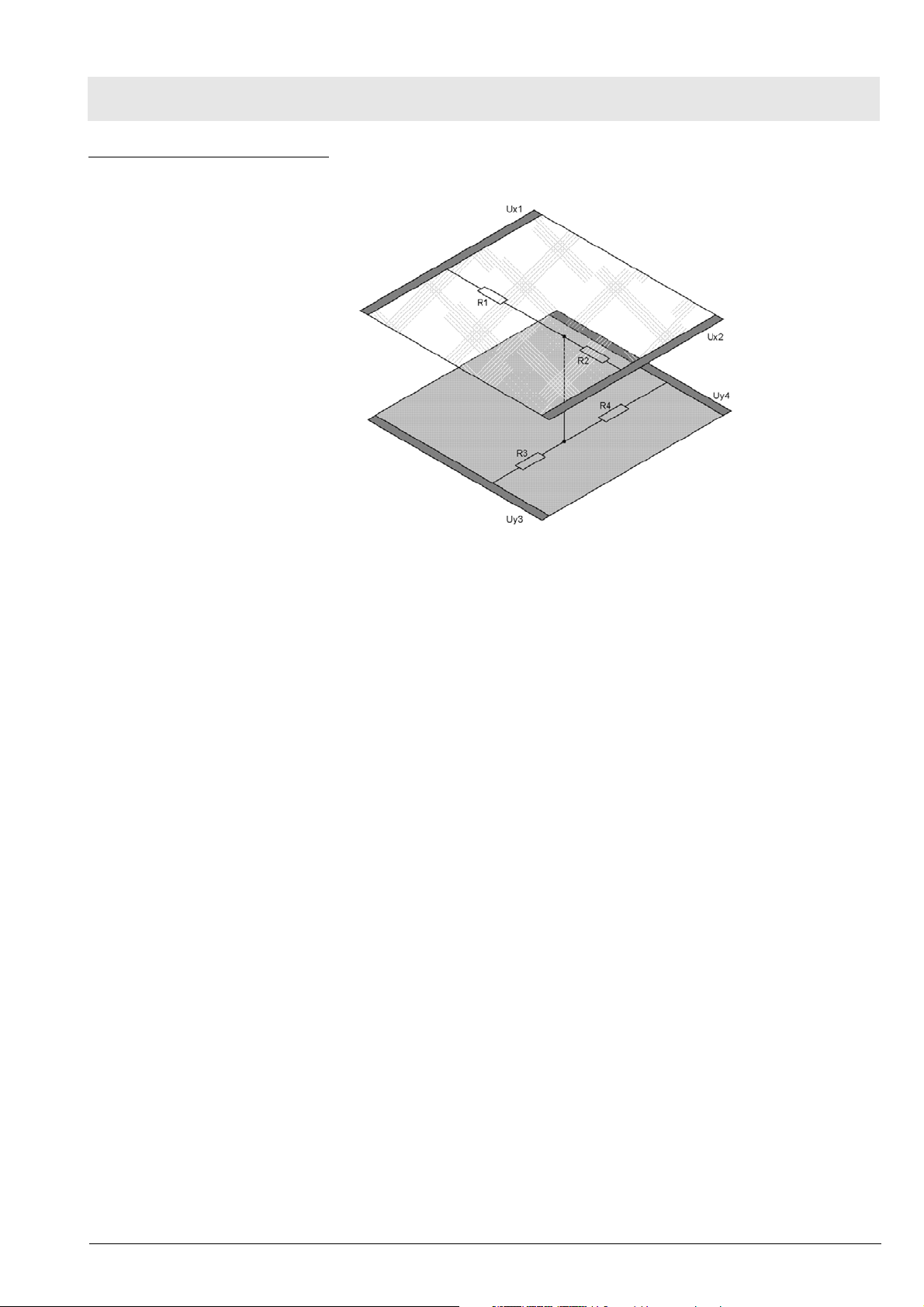

Touch-panel Analog-resistive touch-screen

Function descriptions

Control panel with TFT colour display

Fig. 8 Analog-resistive touch-screen

Analog systems consist of two opposing conductive indium tin oxide (ITO)

layers (x and y layer) which are actuated with a constant direct voltage.

Indium tin oxide is a transparent semiconducting material.

Between the two ITO layers there are a large number of small, barely visible

so-called spacer dots which ensure the two layers are kept separate.

In 8-wire systems the touch-screen has eight wires routed to the controller –

four for each axis.

When the touch-screen is touched at a certain point where the two ITO layers

are located an electrical contact is produced. The resistance of this contact

results in a different voltage at each point. The change in voltage is then used

to define the x and y coordinates.

The Central Control Board controls the communication between the processor system and the touch-screen. The correct position is determined with the

aid of the relevant software drivers. The analog touch-screen works very precisely, and provides a high resolution.

No.1309_0000001227_Publication

Savina 300

19

Page 20

Function descriptions

Pneumatic assembly

Pneumatic assembly

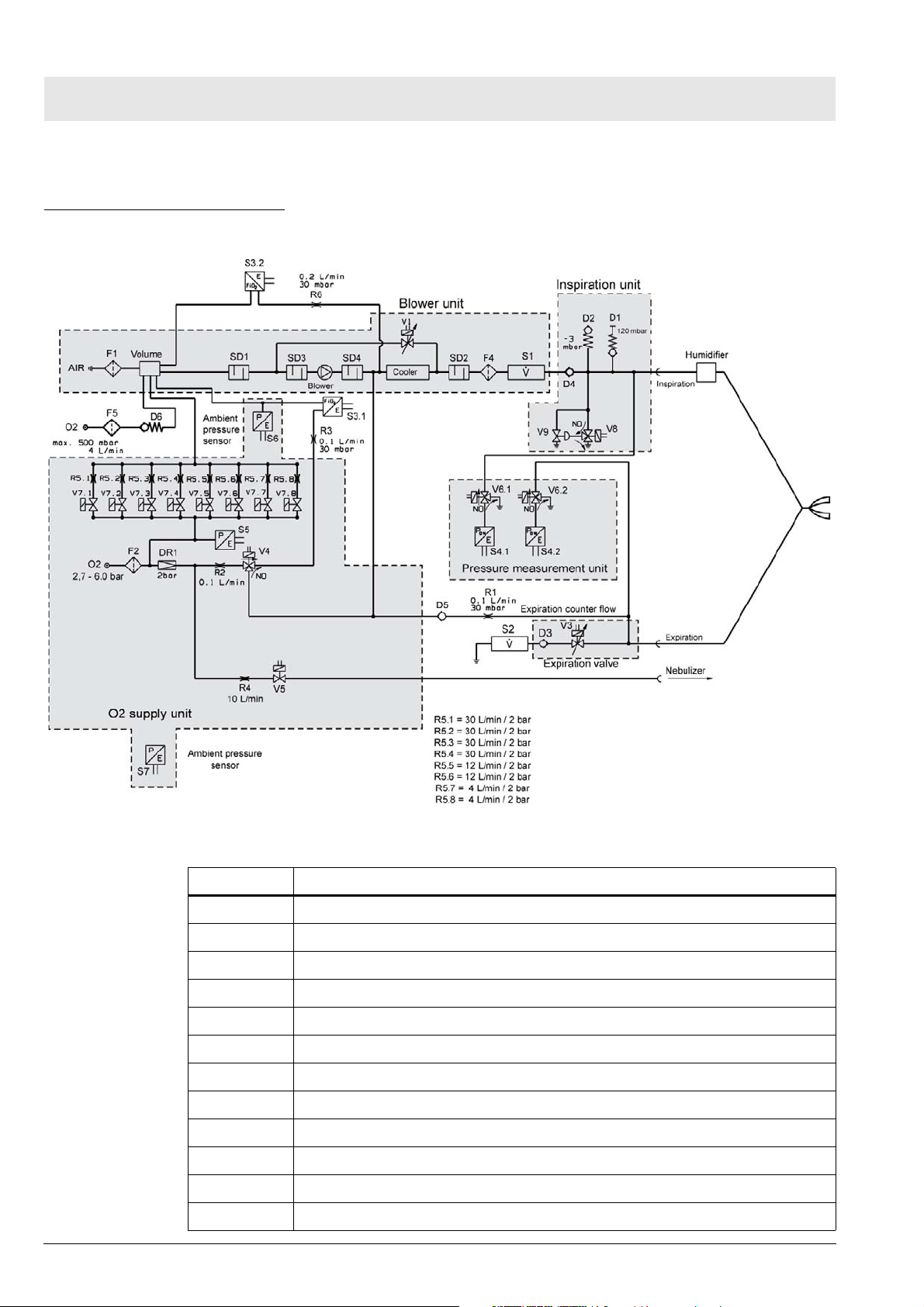

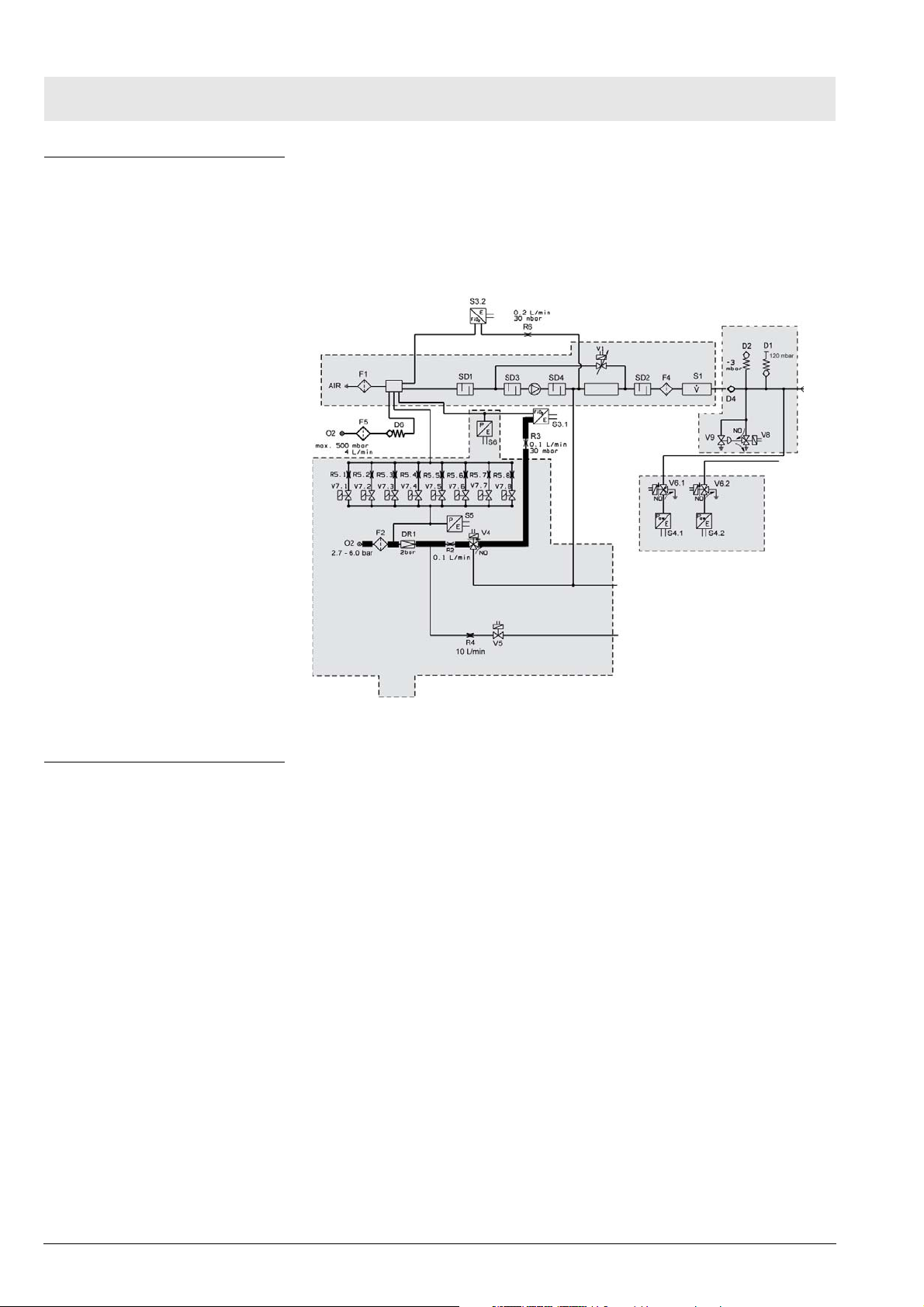

Functional diagram

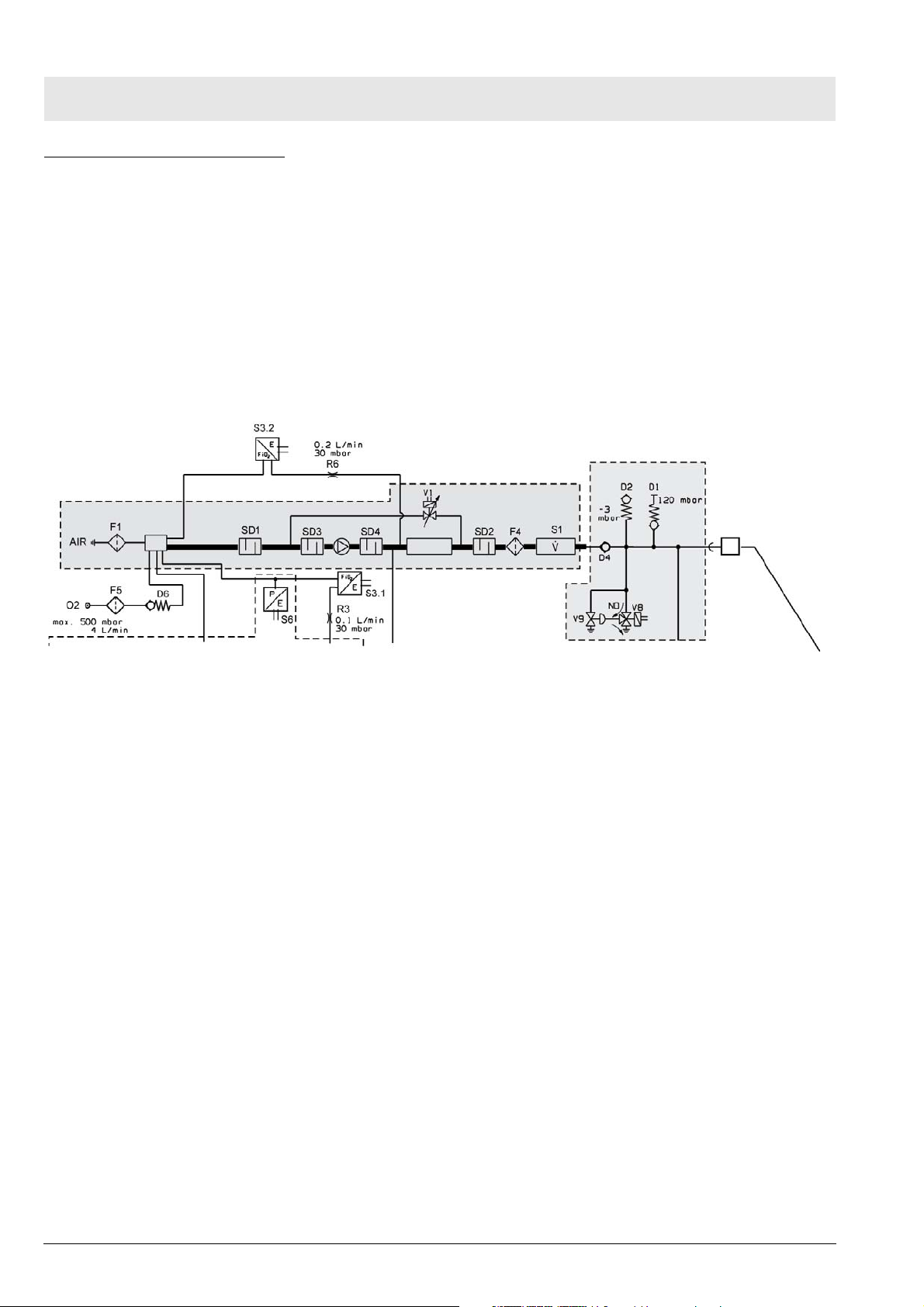

Fig. 9 Functional diagram

Item Designation

F1 Micro-filter (AIR)

F2 Filter (O2)

F4 Filter (inspiratory flow sensor)

F5 Filter (Filter element)

Volume Mixing chamber

SD1 Suction sound insulator

SD2 Sound insulator

DR1 Supply pressure regulator (Oxygen)

Gebläse Blower

Kühler Cooler

V1 Reduction valve

V3 Expiratory valve

20

No.1309_0000001227_Publication

Savina 300

Page 21

Function descriptions

Pneumatic assembly

Item Designation

V4 Switching valve (oxygen compensation)

V5 Switching valve (nebulizer)

V6.1 Calibration valve (inspiratory airway pressure sensor)

V6.2 Calibration valve (expiratory airway pressure sensor)

V7.1 - V7.8 Oxygen metering valves

V8 Pilot valve for emergency vent valve

V9 Emergency vent valve

S1 Inspiratory flow sensor

S2 Expiratory flow sensor

S3.1 O2 sensor 1 (measurement and control)

S3.2 O2 sensor 2 (Monitoring)

S4.1 Inspiratory airway pressure sensor (located in inspiratory branch)

S4.2 Expiratory airway pressure sensor (located in expiratory branch)

S5 Supply pressure sensor (oxygen)

S6 Pressure sensor 1 (absolute pressure)

S7 Pressure sensor 2 (absolute pressure)

D1 Safety pressure-limitting valve (passive, approx. 120 mbar)

D2 Emergency air valve (-3 mbar to -6 mbar)

D3 Expiratory non-return valve

D4 Inspiratory non-return valve

D5 Flush flow non-return valve

D6 Non-return valve (LPO)

R1 Flush flow metering unit (0,1 L/min at 30 mbar)

R2 O2 calibration metering unit for (0,1 L/min, integrated in valve block)

R3 Metering unit for O2 measurement (0,2 L/min at 30 mbar, Sensor 3.1)

R4 Metering unit for nebulizer (10 L/min, integrated in valve block)

R5.1 - R5.8 Metering units for the oxygen metering valves

R6 Metering unit for O2 measurement (0,2 L/min at 30 mbar, Sensor 3.2)

Main components The pneumatic assembly consists of the following components:

– Plug-in unit

– Valve block

– Inspiratory block

– Pressure measuring block

– Patient system

– Flow sensors

No.1309_0000001227_Publication

Savina 300

21

Page 22

Function descriptions

Pneumatic assembly

Device functions

Ventilation function When the device is switched on the power supply unit supplies the blower

motor with operating voltage. The blower motor draws in ambient air through

the microfilter F1, the volume and the sound insulators SD1 and SD3. The

blower motor compresses the gas intake to an overpressure up to max. 140

mbar at a delivery rate of up to 180 L/min. The air compressed by the blower

motor passes through the sound insulator SD4, the cooler, the sound insulator SD2, the filter F4 and the inspiratory flow sensor S1 to the inspiratory nonreturn valve D4. The controller operates the blower motor during a breath at a

constant speed. The bypass valve regulates the inspiratory pressure. The

combination of the blower motor and bypass valve V1 provides a pressure

source.

Fig. 10 Detail view of functional diagram; ventilation function

The sound insulators SD1 and SD2 on the inlet and outlet sides of the blower

motor reduce the sound level.

The bypass valve V1 is operated such that the desired respiratory pressure is

applied to the blower outlet, and thus to the patient. If the patient needs a high

flow during the inspiratory phase, the gas flows in part or in its entirety from

the blower motor outlet to the patient and the gas flow through the bypass

valve V1 is reduced. During the expiratory phase all the blower gas flows

through the bypass valve V1.

The cooler reduces the respiratory gas temperature down to a permissible

range.

22

No.1309_0000001227_Publication

Savina 300

Page 23

Function descriptions

Pneumatic assembly

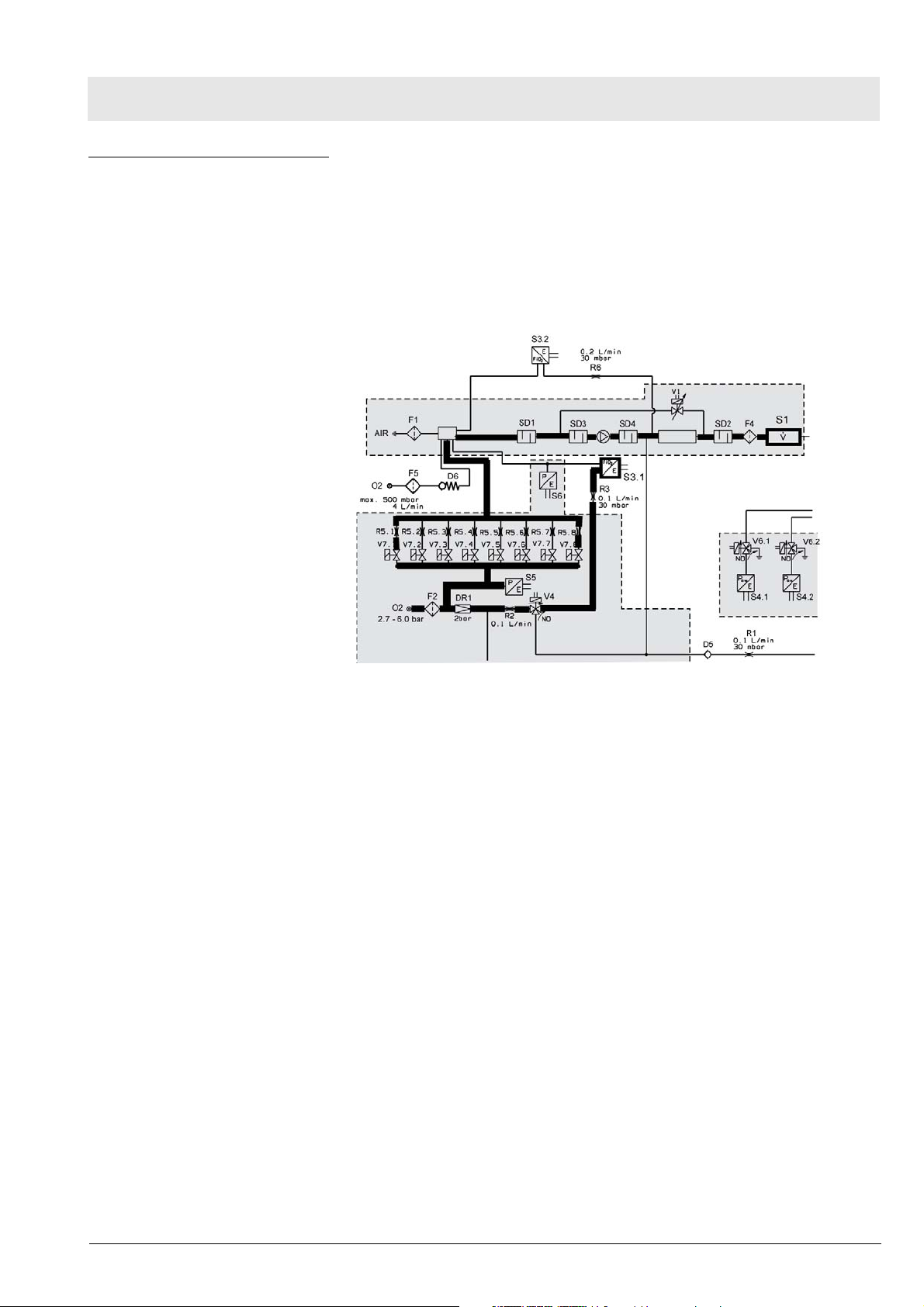

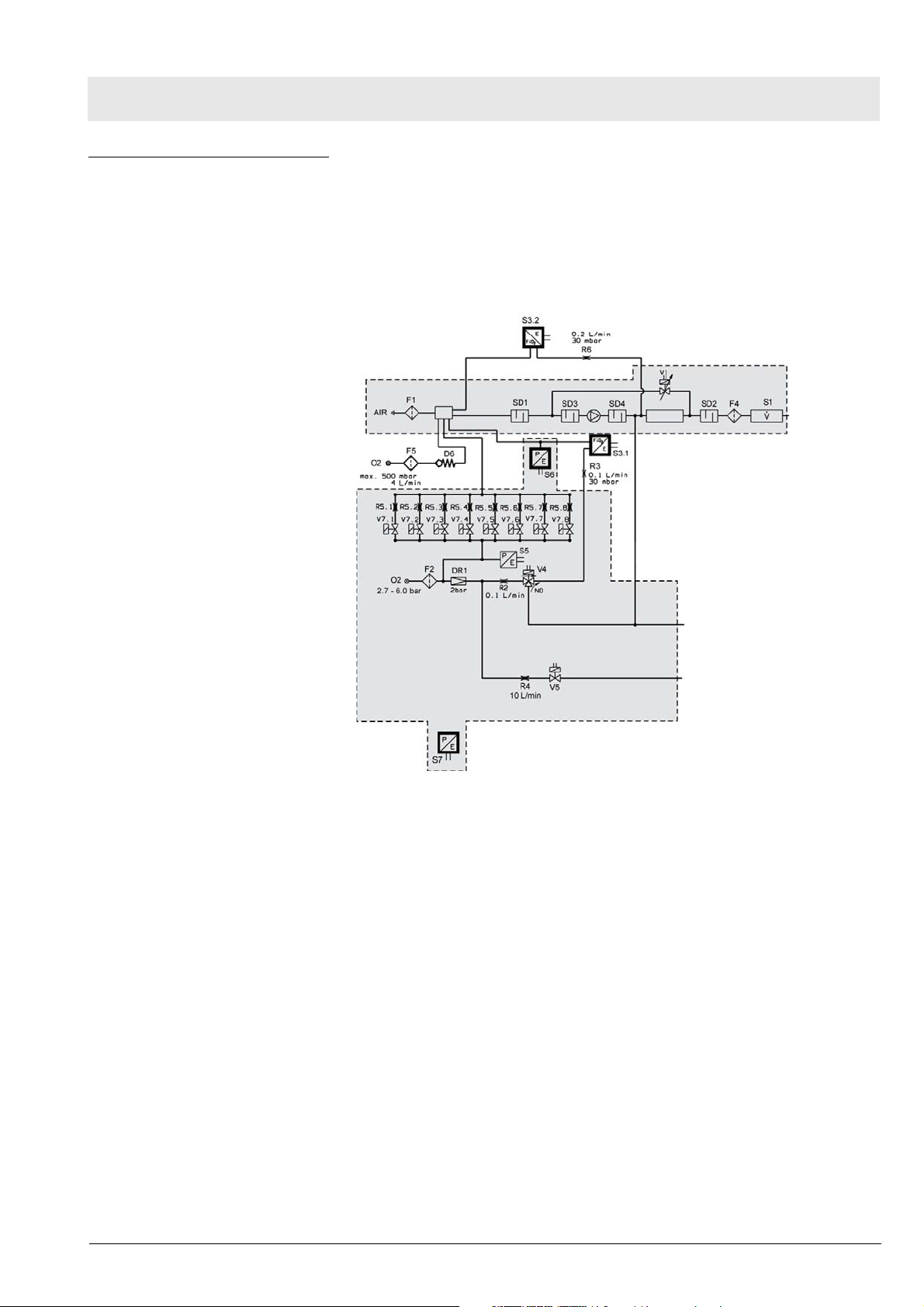

O2 mixture with O2 high

pressure

In order to be able to ventilate with an increased O2 concentration, the unit

must be supplied with 2.7 to 6.0 bar O2. The oxygen is filtered by the filter F2.

With the aid of the digital valve block consisting of 8 digital solenoid valves,

oxygen is metered into the volume (mixing chamber). The amount of metered

oxygen depends on the pre-set O2 concentration and on the inspiratory flow

rate measured by the flow sensor S1. The oxygen is metered in a closed control loop. In the process, the inspiratory O2 concentration is measured by the

O2 sensor S 3.1.

Fig. 11 Detail view of functional diagram; O2 mixture with O2 high pres-

sure

No.1309_0000001227_Publication

Savina 300

23

Page 24

Function descriptions

Pneumatic assembly

O2 mixture with O2 low

pressure („LPO“ option)

NOTE

Connect only O2 low pressure sources without humidifier to the device!

An O2 low pressure source without humidifier feeds the oxygen into the

“LPO” connection on the back of the unit. The filter (filter element) F5 protects

the non-return valve D6 from coarse particles. The oxygen flows from the

non-return valve D6 into the volume (mixing chamber). In the volume (mixing

chamber) it is mixed with the drawn-in and filtered fresh air.

Fig. 12 Detail view of functional diagram; O2 mixture with O2 low pressure

When no O2 low pressure source is connected to the unit, the non-return

valve D6 prevents gas from escaping during normal operation.

NOTE

In „LPO“ mode, the valve block in the O2 supply is not actuated.

24

No.1309_0000001227_Publication

Savina 300

Page 25

Function descriptions

Pneumatic assembly

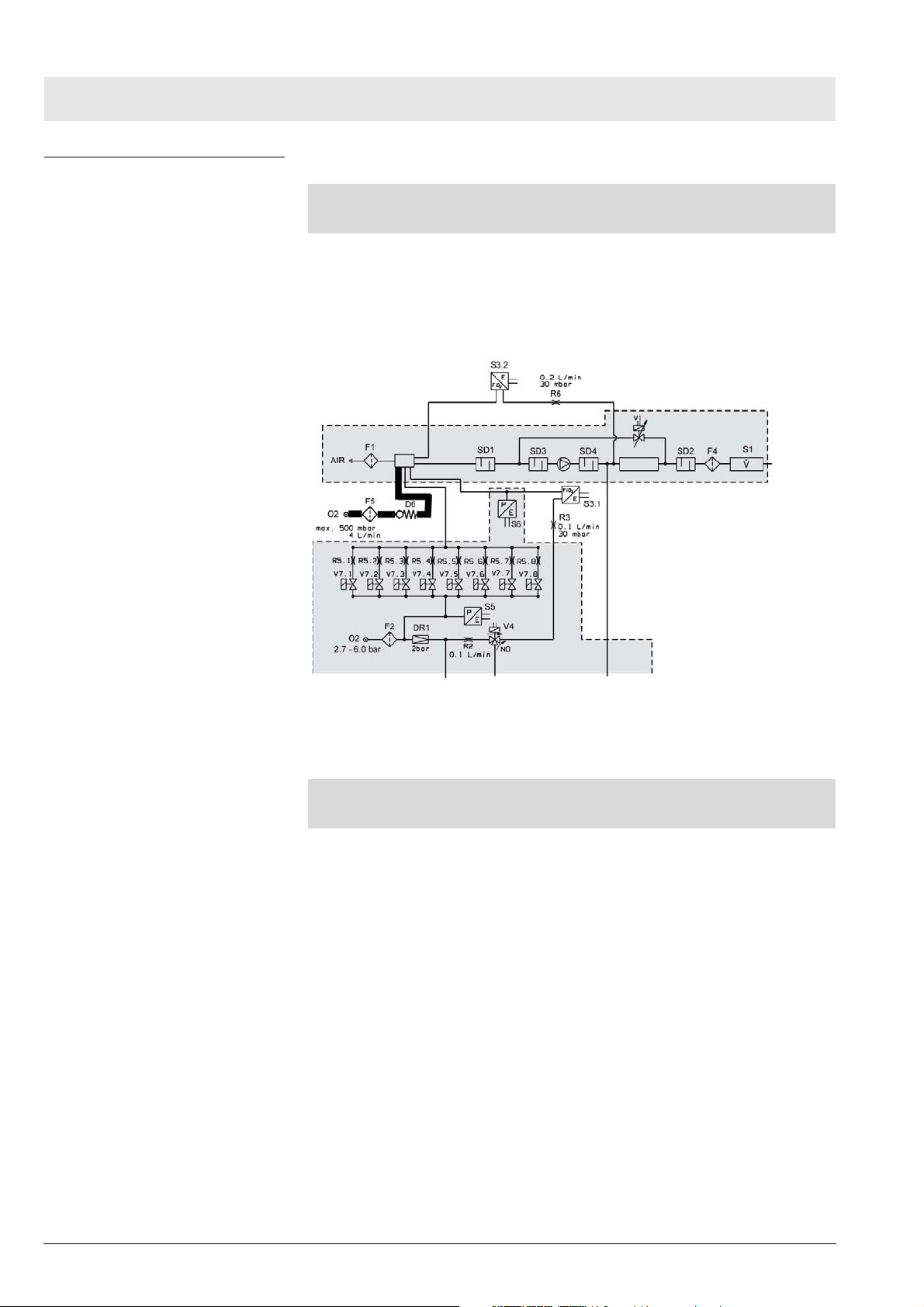

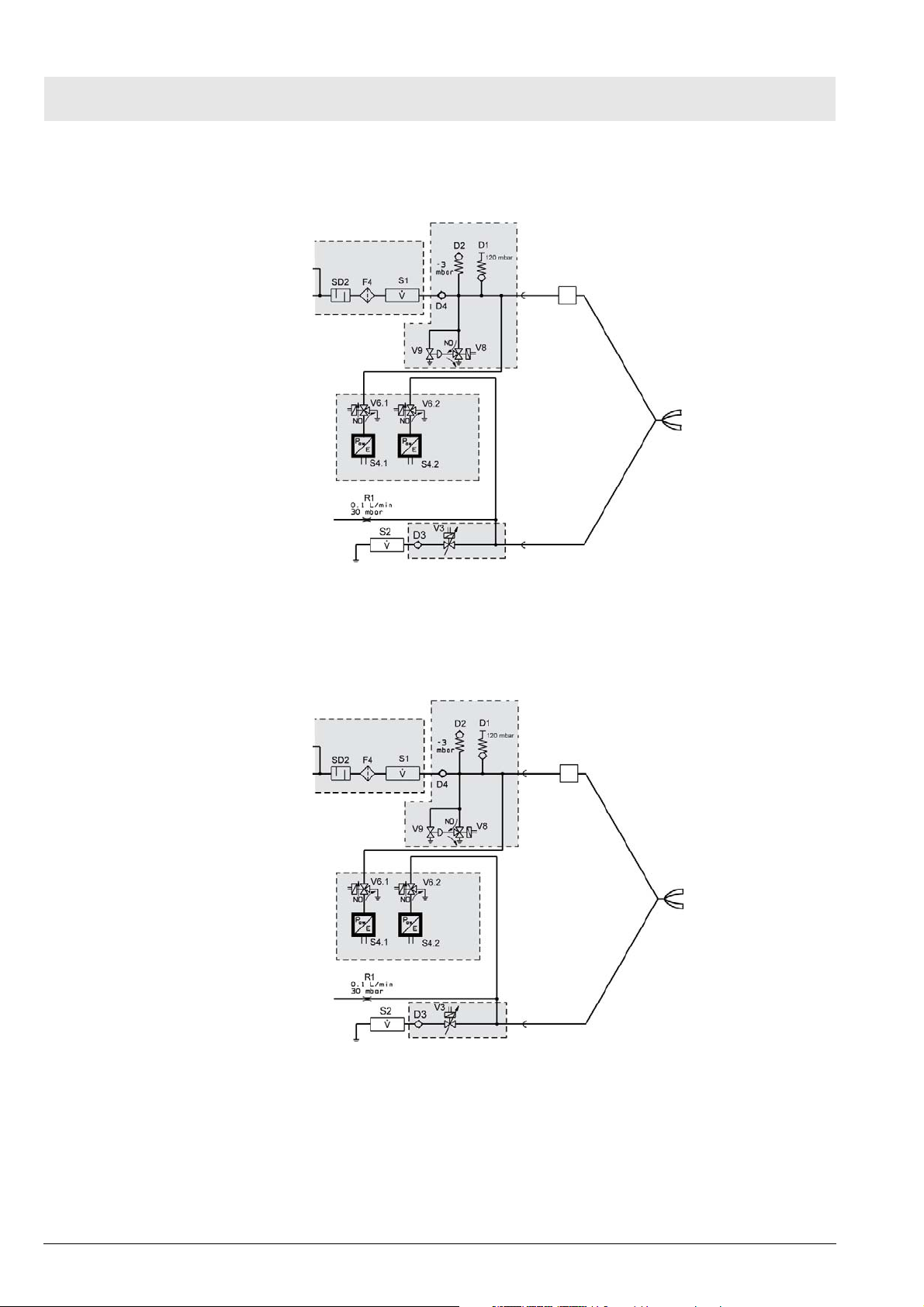

Pneumatic safety devices The pneumatic safety valve D1 ensures that the ventilation pressure cannot

rise above 120 mbar. In the event of inspiratory stenosis the pressure is limited by opening the expiratory valve. The mechanical vacuum valve D2

ensures (except in the case of inspiratory stenosis) that the patient can

breathe ambient air in case of a fault.

The pneumatic emergency vent valve V9 relieves the pressure in the breathing system in a case of expiratory stenosis if the pressure cannot be relieved

through the expiratory valve. To do so, the electric emergency vent valve

(pilot valve) V8 actuates the emergency vent valve V9 accordingly.

Fig. 13 Detail view of functional diagram; pneumatic safety devices

Drug nebulizer The drug nebulizer is operated with 100% oxygen. The pressure regulator

DR1 ensures in the case of widely varying supply pressure (2.7 to 6.0 bar)

that the pneumatic drug nebulizer receives a constant supply pressure of

2 bar.During the nebulizing phase the solenoid valve V5 operates in an “inspiration” (open position) and “expiration” (closed position) cycle. When the nebulizer function is inactive the nebulizer switching valve V5 is closed.

Fig. 14 Detail view of functional diagram; drug nebulier

No.1309_0000001227_Publication

Savina 300

25

Page 26

Function descriptions

Pneumatic assembly

O2 calibration function During operation, the switching valve (oxygen compensation) V4 is set to

“measurement” – that is, the connection between the inspiratory side and the

oxygen sensor is open. During oxygen sensor calibration oxygen passes to

the oxygen sensor. This layout permits “online” calibration of the oxygen sensor S3.1 during ventilation. The oxygen sensor S3.2 must be calibrated manually (patient disconnected).

Fig. 15 Detail view of functional diagram; O2 calibration function

O2 sensor detection The device has an oxygen sensor detector which is necessary for the „LPO“

option.

26

No.1309_0000001227_Publication

Savina 300

Page 27

Function descriptions

Pneumatic assembly

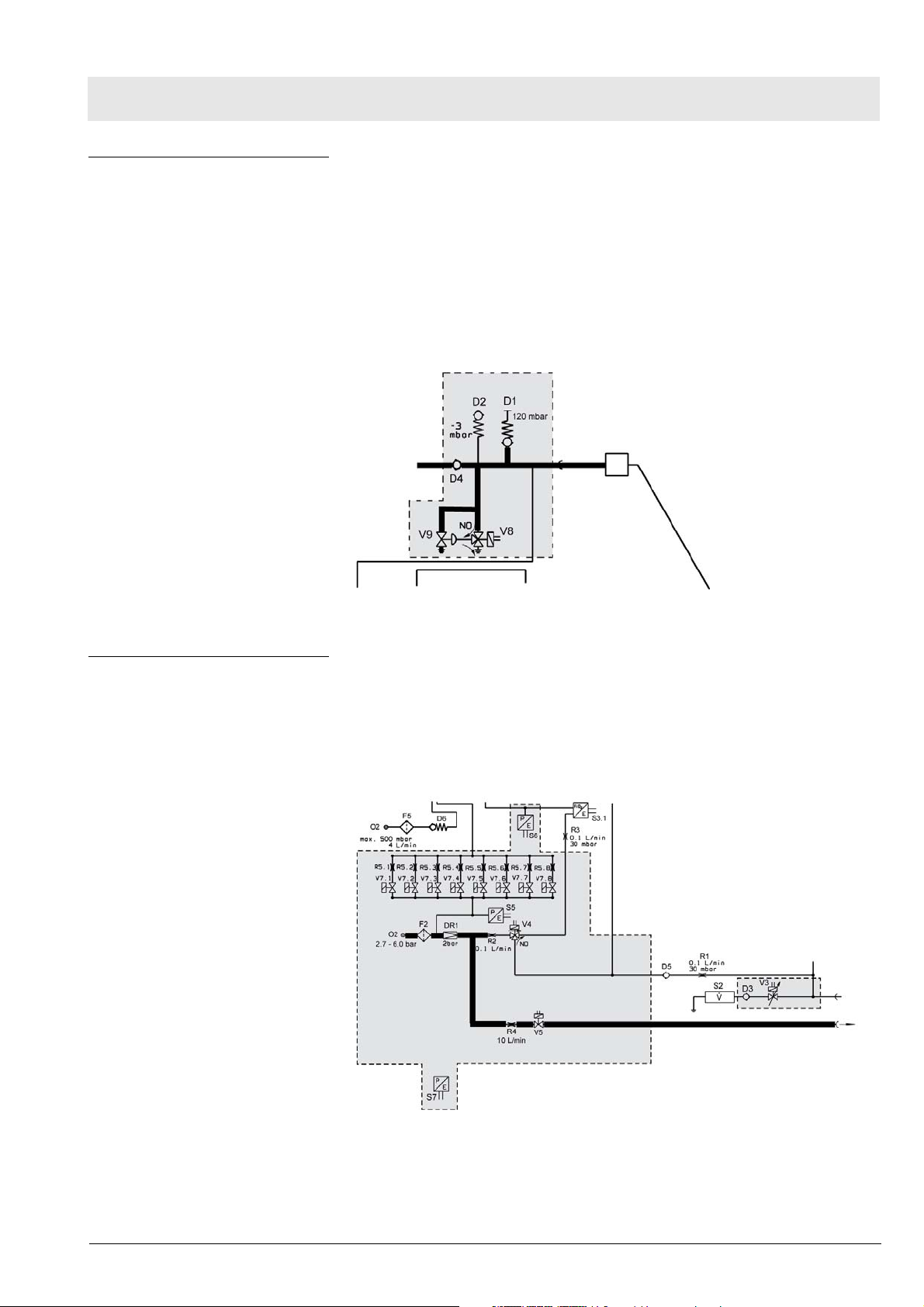

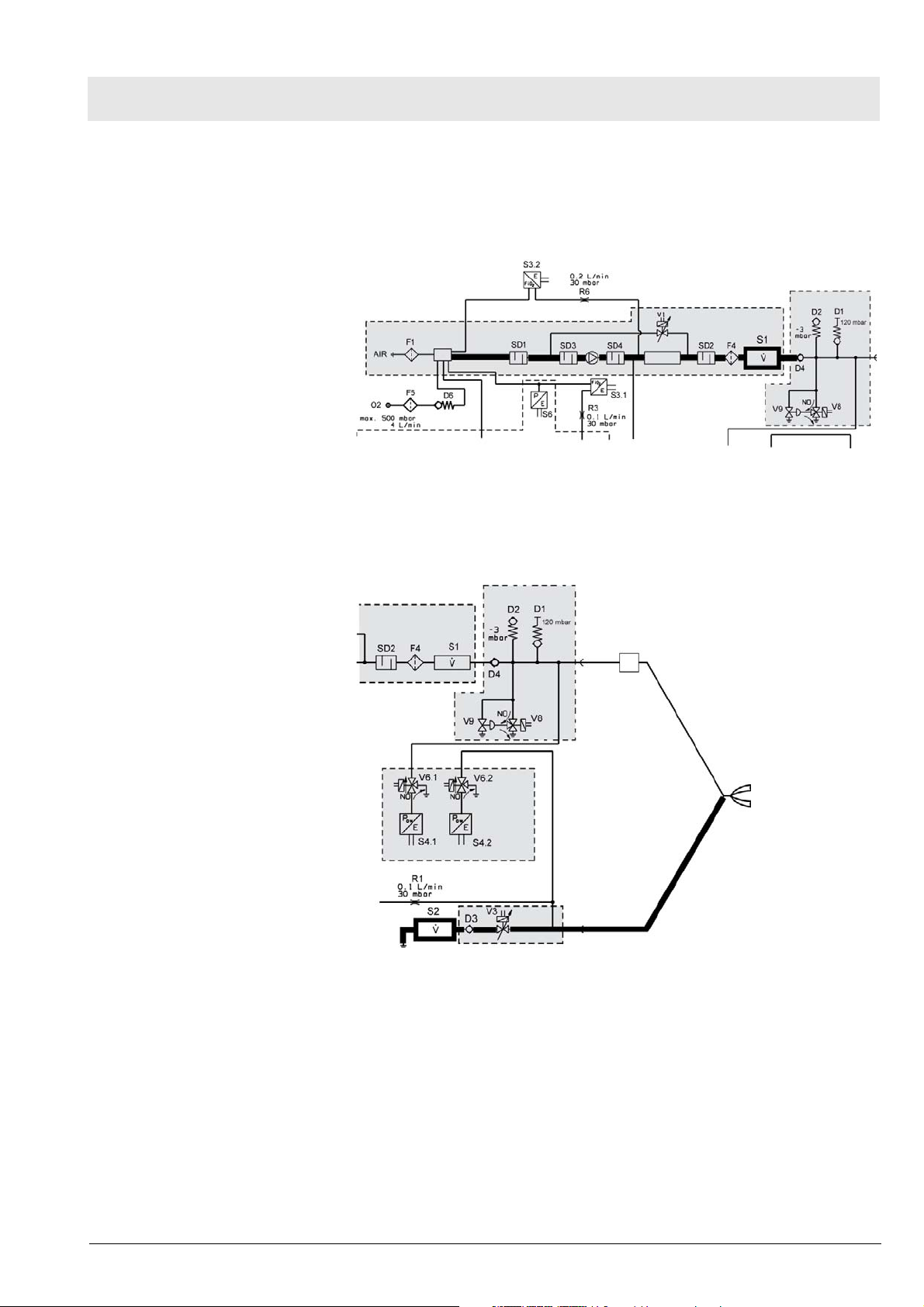

Sensors The pressure sensor (absolute pressure) S6 measures the atmospheric pres-

sure necessary for oxygen measurement and for volume application. The

pressure sensor (absolute pressure) S7 monitors the pressure sensor (absolute pressure) S6.The oxygen sensor S3.1 generates the signal for the displayed „FiO2“ measured value and the signal to control the inspiratory

oxygen concentration. The oxygen sensor S3.2 monitors the oxygen sensor

S3.1

Fig. 16 Detail view of functional diagram; pressure sensors and oxygen

sensor

The airway pressure sensor S4.1 measures the pressure in the inspiratory

branch. The airway pressure sensor S4.2 measures the pressure in the expiratory branch. The output signals of the airway pressure sensors are needed

No.1309_0000001227_Publication

Savina 300

27

Page 28

Function descriptions

Pneumatic assembly

to determine the airway pressure and for control and monitoring purposes.

The airway pressure is measured on the basis of the measured value from

the airway pressure sensor in the respective no-flow branch.

Fig. 17 Detail view of functional diagram; airway pressure sensors

The calibration valves V6.1 and V6.2 enable calibration of the inspiratory and

expiratory airway pressure sensors. During calibration, the corresponding

calibration valve interrupts the connection to the ventilation circuit and

switches the airway pressure sensor to ambient pressure.

28

Fig. 18 Detail view of functional diagram; calibration valves

No.1309_0000001227_Publication

Savina 300

Page 29

Function descriptions

Pneumatic assembly

Flow sensor S1 measures the inspiratory gas flow. The measurement variable is used to calculate the necessary oxygen flow and to actuate the oxygen metering valves V7.1 to V7.8 in order to control the breaths and monitor

the device functions. The flow sensor includes a temperature measurement

function to measure the inspiratory gas temperature.

Fig. 19 Detail view of functional diagram; flow sensor

The flow sensor S2 measures the gas flow through the expiratory valve. The

flow sensor is a temperature-compensated hot-wire anemometer with no flow

direction detector. With this signal the patient is monitored (e.g. the minute

volume).

Fig. 20 Detail view of functional diagram; flow sensor

Expiration is executed with the directly actuated expiratory valve V3.

The expiratory valve has the following functions:

– PEEP control during the expiratory phase

– Close the breathing system during the inspiratory phase.

No.1309_0000001227_Publication

Savina 300

29

Page 30

– This page has been intentionally left blank –

30

No.1309-0000001227_Publication

Savina 300

Page 31

Maintenance instructions

This chapter describes the measures required to maintain the specified con-

dition of the device.

Disassembling/assembling the device ...............................................................................................

Replacing the microfilter ....................................................................................................................

Replacing the dust filters....................................................................................................................

Replacing the O2 sensors..................................................................................................................

Replacing the diaphragm of the expiratory valve...............................................................................

Replacing the internal batteries .........................................................................................................

Replacing the external batteries ........................................................................................................

Replacing the consumables in the O2 gas inlet.................................................................................

32

38

40

42

47

50

54

65

No.1309_0000001227_Publication

Savina 300

31

Page 32

Maintenance instructions

Disassembling/assembling the device

Disassembling/assembling the device

Introduction This section describes how to disassemble and assemble the following

assemblies:

– Removing/fitting the Savina 300 from/into the trolley

– Filter cover

– Rear panel

Removing/fitting the

Savina 300 from/into the

trolley

Preconditions – The O2 and mains power supply to the Savina 300 have been cut.

– The tubing system and fitted units have been removed.

Removal 1. Loosen the nuts (Fig. 21/1) on the left and right sides of the trolley slightly

and push the two locking devices (Fig. 21/2) inwards towards A as far as

they will go.

2. Remove the screws (Fig. 21/3).

32

Fig. 21 View from below of trolley mount; screws

No.1309_0000001227_Publication

Savina 300

Page 33

Maintenance instructions

Disassembling/assembling the device

3. Lift the Savina 300 out of the trolley.

Installation 1. Place the Savina 300 in the trolley.

2. Use the screws (Fig. 22/3) to secure the Savina 300 to the trolley.

3. Push the locking devices (Fig. 22/2) on the left and right sides of the trol-

ley outwards towards B as far as they will go and tighten the nuts (Fig.

22/1).

Fig. 22 View from below of trolley mount; screws

No.1309_0000001227_Publication

Savina 300

33

Page 34

Maintenance instructions

Disassembling/assembling the device

Filter cover

Removal 1. Withdraw the power cable (Fig. 23/2) from filter cover guide.

2. Reach into the openings in the filter cover on both sides, press the

catches concealed behind them (Fig. 23/1) simultaneously towards A

slightly, move the filter cover back slightly and take the filter cover out of

the rear panel.

Fig. 23 View of device rear; filter cover

Removal of the filter cover is complete.

Installation 1. Slot the tabs (Fig. 24/1) of the filter cover into the recesses (Fig. 24/2) in

the rear panel, swivel the filter cover upwards and press the catches (Fig.

23/1) of the filter cover into the rear panel until they lock in place.

34

Fig. 24 Detail view of filter cover; tabs and recesses

2. Lay the power cable (Fig. 23/2) around the filter cover guide, as shown in

the illustration.

Fitting of the filter cover is complete.

No.1309_0000001227_Publication

Savina 300

Page 35

Rear panel

Preconditions – Savina 300 has been disconnected from the O2 supply and the mains

Removal 1. Pry the tab fuse (Fig. 25/2) from its holder using a small screwdriver or

Maintenance instructions

Disassembling/assembling the device

power supply.

– The tubing system and units mounted on the Savina 300 have been

removed.

– EGB conditions to protect against electrostatic discharge have been

established.

– The filter cover has been removed, see section headed „Filter cover“.

similar tool.

2. Remove the connectors and tubing listed below from the Savina 300, if

fitted:

Fig. 25 View of device rear; connections

Item Designation

1 Connection (external battery)

2 Tab fuse

3 Mains connection

4 Connection (nurse call)

5 Connection (RS232 port)

6 Connection for LPO (option)

7 Connection (O2 gas supply)

Connector for potential equalization

No.1309_0000001227_Publication

Savina 300

35

Page 36

Maintenance instructions

Disassembling/assembling the device

3. Holding the lever (Fig. 26/2) pushed back slightly, push the cable retainer

(Fig. 26/1) towards A and take it out of the rear panel.

Fig. 26 View of right rear of device; cable retainer

4. Remove the Savina 300 from the trolley, see section headed „Removing/fitting the Savina 300 from/into the trolley“.

5. Remove the screws (9x) (Fig. 27/1).

Fig. 27 View of device rear; screws

36

6. Remove the rear panel.

Removal of the rear panel is now complete.

No.1309_0000001227_Publication

Savina 300

Page 37

Maintenance instructions

Disassembling/assembling the device

Installation 1. Fit the rear panel to the Savina 300 using the screws (Fig. 27/1) tightened

with a torque of 1.8 Nm +/-0.2 Nm.

2. Fit the cable retainer (Fig. 26/1) in the rear panel.

3. Fit the Savina 300 into the trolley, see section headed „Removing/fitting

the Savina 300 from/into the trolley“.

4. Re-attach removed connectors and tubing to the Savina 300.

5. Fit the filter cover on the Savina 300, see section headed „Filter cover“.

6. Plug the tab fuse for the internal batteries into the holder on the power

supply unit.

7. Perform the „electrical safety test“ and „function tests“ as per the test

instructions.

Fitting of the rear panel is complete.

No.1309_0000001227_Publication

Savina 300

37

Page 38

Maintenance instructions

Replacing the microfilter

Replacing the microfilter

Introduction The following section provides a view of the microfilter and describes how to

remove and fit it.

View The microfilter (Fig. 28/1) is located on the rear of the device.

Removal

Preconditions – Savina 300 is switched off.

Procedure 1. Reach into the openings in the filter cover on both sides, press the

Fig. 28 Device rear; microfilter

catches concealed behind them (Fig. 29/1) simultaneously towards A

slightly, move the filter cover back slightly and take the filter cover out of

the rear panel.

2. Withdraw the power cable (Fig. 29/2) from filter cover guide.

38

Fig. 29 Savina 300 rear; filter cover

No.1309_0000001227_Publication

Savina 300

Page 39

Maintenance instructions

Replacing the microfilter

3. Withdraw the microfilter (Fig. 30/2) by the tab (Fig. 30/1) out of its mount

and dispose of it in the domestic waste bin.

Fig. 30 Savina 300 rear; microfilter

Removal of the microfilter is complete.

Fitting 1. Insert the new microfilter (Fig. 30/2) into its mount as far as it will go.

2. Close the tab (Fig. 30/1) against the microfilter.

3. Slot the pegs on the underside of the filter cover into the recesses in the

rear panel, swivel the filter cover upwards and with the catches (Fig. 29/1)

press the filter cover into the rear panel until it locks in place.

4. Lay the power cable (Fig. 29/2) around the filter cover guide, as shown in

the illustration.

Fitting of the microfilter is complete.

No.1309_0000001227_Publication

Savina 300

39

Page 40

Maintenance instructions

Replacing the dust filters

Replacing the dust filters

Introduction The following section provides a view of the dust filter set and describes how

to remove and fit it.

View The dust filters (Fig. 31/1) are located in the device's filter cover.

Fig. 31 Device rear; dust filters (3x)

Removal 1. Reach into the openings in the filter cover on both sides, press the

catches concealed behind them (Fig. 32/1) simultaneously towards A

slightly, move the filter cover back and take the filter cover out of the rear

panel.

2. Withdraw the power cable (Fig. 32/2) from filter cover guide.

Fig. 32 Savina 300 rear; filter cover

40

No.1309_0000001227_Publication

Savina 300

Page 41

Maintenance instructions

Replacing the dust filters

3. Withdraw the dust filters (Fig. 33/1) out of the filter cover and dispose of

them in the domestic waste bin.

Fig. 33 Filter cover; dust filters (3x)

Removal of the dust filters is complete.

Fitting 1. Insert the new dust filters (Fig. 33/1) in the recesses in the filter cover.

2. Slot the pegs (Fig. 34/1) on the underside of the filter cover into the

recesses (Fig. 34/2) in the rear panel, swivel the filter cover upwards and

with the catches (Fig. 32/1) press the filter cover into the rear panel until it

locks in place.

Fig. 34 Detail view of filter cover: Fitting

3. Lay the power cable (Fig. 32/2) around the filter cover guide, as shown in

Fitting of the dust filters is complete.

No.1309_0000001227_Publication

Savina 300

the illustration.

41

Page 42

Maintenance instructions

Replacing the O2 sensors

Replacing the O2 sensors

Introduction

NOTE

Replace the O2 sensors if calibration is no longer possible or if the alarm

message „FiO2 measurement failed“ is displayed.

The following section provides a view of the O2 sensors and describes how

to remove, fit and calibrate them.

View The O2 sensors (Fig. 35/1) are located behind the cover plate on the front of

the Savina 300.

Fig. 35 Device front; O2 sensors

No.1309_0000001227_Publication

42

Savina 300

Page 43

Removal

Preconditions – The Savina 300 is switched off and disconnected from the mains power

Maintenance instructions

Replacing the O2 sensors

supply.

Service equipment

– Screwdriver

required

Procedure 1. Swivel the inspiratory port (Fig. 36/1) down.

2. Loosen the screw (Fig. 36/2) using a screwdriver or similar and detach

the cover plate (Fig. 36/3).

Fig. 36 Device front; cover plate

3. Take the O2 sensors (Fig. 37/1) out of their mounts.

Fig. 37 Device front; removing the O2 sensors

NOTE

O2 sensors are special waste. When disposing of them, observe local

waste disposal regulations.

No.1309_0000001227_Publication

Savina 300

43

Page 44

Maintenance instructions

Replacing the O2 sensors

4. Dispose of the O2 sensors according to local waste disposal regulations.

Removal of the O2 sensors is complete.

Fitting 1. Push the O2 sensors (with the arrows on the oxygen cells pointing

upwards, as shown in the following illustration) into their mounts until you

feel a resistance.

Fig. 38 Device front; fitting the O2 sensors

2. Swivel the inspiratory port (Fig. 39/1) down.

3. Use the screw (Fig. 39/2) to secure the cover plate (Fig. 39/3) on the

Savina 300.

Fig. 39 Device front; cover plate

44

Fitting of the O2 sensors is complete.

No.1309_0000001227_Publication

Savina 300

Page 45

Calibrating the O2 sensors

Preconditions – The Savina 300 has been connected to the mains power supply.

Calibrating O2 sensor 2 in

„HPO“ mode

Maintenance instructions

Replacing the O2 sensors

– The blade fuse has been has been inserted into the slot on the power

supply unit.

– The Savina 300 has been connected to the O2 supply.

NOTE

To be able to calibrate the Savina 300 correctly, you must wait for the

device to warm up. If the blade fuse was removed, it may take as long as

20 minutes for the device to warm up.

CAUTION

If the quality of the oxygen from the central oxygen supply or the compressed gas oxygen cylinder is inadequate, calibrate the O2 sensor with

calibration gas (100% O2). Otherwise miscalibration may occur.

1. Switch on the Savina 300.

2. Set „VC-CMV/VC-AC“ mode.

3. Press the „Sensors/Parameters“ softkey.

4. Press the O2 calibration „Start“ softkey and confirm with the rotary knob.

The message „Disconnect patient“ is displayed.

5. Within the next 30 seconds detach the inspiratory tube from the inspiratory socket.

The message „O2 calibration in progress“ is displayed.

6. Detach the inspiratory tube from the inspiratory socket and, if necessary,

continue ventilation with an independent ventilator.

The Savina 300 calibrates O2 sensor 2. During calibration the alarms which

would normally occur due to the disconnection and the changed O2 concentration are disabled. After about 60 seconds the prompt „Reconnect patient“

is displayed.

NOTE

If the patient has not been reconnected after 30 seconds, Savina 300 starts

ventilating again in the preset ventilation mode and all alarms are enabled

again.

7. Immediately fit the inspiratory tube on the inspiratory socket.

NOTE

If the message „FiO2 measurement failed“ is displayed after calibrating, the

O2 sensors must be replaced – see „Replacing the O2 sensors“.

If the display indicates „O2 calibration OK“, calibration is complete.

No.1309_0000001227_Publication

Savina 300

45

Page 46

Maintenance instructions

Replacing the O2 sensors

Calibrating the O2 sensors

in „LPO“ mode

NOTE

In „LPO“ mode the O2 sensors are calibrated with ambient air. The O2

measurement accuracy is reduced as a result. If high O2 measurement

accuracy is required, the O2 sensors must be calibrated in „HPO“ mode.

1. In the situations listed below the O2 sensors cannot be calibrated in

„LPO“ mode:

a) During the 10-minute warm-up phase after switching on the

Savina 300

b) Up to one hour after the Savina 300 has been subjected to a major

temperature change, such as being transported from a cold room to a

heated room or due to extreme ventilation settings.

FiO2 measurement is possible during this time as long as no relevant alarm

is indicated.

2. Press the „Sensors/Parameters“ softkey.

3. Press the O2 calibration „Start“ softkey and confirm with the rotary knob.

4. When prompted by the Savina 300, disconnect the O2 concentrator and

confirm with the rotary knob.

The message „Disconnect patient“ is displayed.

5. Detach the inspiratory tube from the inspiratory socket and, if necessary,

continue ventilation with an independent ventilator.

The display indicates „O2 calibration in progress“. The Savina 300 calibrates

the O2 sensors. During calibration the alarms which would normally occur

due to the disconnection and the changed O2 concentration are disabled.

After about 60 seconds the prompt „Reconnect patient“ is displayed.

6. Immediately fit the inspiratory tube on the inspiratory socket.

NOTE

If the patient has not been reconnected after 30 seconds, Savina 300 starts

ventilating again in the preset ventilation mode and all alarms are enabled

again.

NOTE

If the message „FiO2 measurement failed“ is displayed after calibrating, the

O2 sensors must be replaced – see „Replacing the O2 sensors“.

If the display indicates „O2 calibration OK“, calibration is complete.

46

No.1309_0000001227_Publication

Savina 300

Page 47

Maintenance instructions

Replacing the diaphragm of the expiratory valve

Replacing the diaphragm of the expiratory valve

Introduction The following section provides a view of the expiratory valve diaphragm and

describes how to remove and fit it.

View The diaphragm (Fig. 40/1) is located on the expiratory valve.

Fig. 40 Detail view of expiratory valve; diaphragm

Removal 1. Push the flow sensor flap (Fig. 41/1) up to position A.

2. Push the flow sensor (Fig. 41/2) to the left as far as it will go.

3. Turn the locking ring (Fig. 41/3) of the expiratory valve to the left towards

B as far as it will go.

Fig. 41 Detail view of Savina 300; removing the expiratory valve

No.1309_0000001227_Publication

Savina 300

47

Page 48

Maintenance instructions

Replacing the diaphragm of the expiratory valve

4. Take the expiratory valve out of its mount.

5. Remove the diaphragm (Fig. 42/1) from the expiratory valve.

Fig. 42 Expiratory valve; diaphragm

NOTE

Diaphragms are classified as special waste. When disposing of them,

observe local waste disposal regulations.

6. Dispose of the old diaphragm according to local waste disposal regulations.

Removal of the expiratory valve diaphragm is complete.

Fitting 1. Clip the new diaphragm (Fig. 43/1) onto the rim of the expiratory valve

(Fig. 43/2) so that it engages on the expiratory valve rim all the way

round.

48

Fig. 43 Expiratory valve; fitting the diaphragm

No.1309_0000001227_Publication

Savina 300

Page 49

Maintenance instructions

Replacing the diaphragm of the expiratory valve

2. Push the expiratory valve into the mount on the Savina 300 until you feel

a resistance and turn the locking ring (Fig. 44/3) of the expiratory valve all

the way to the right towards B until you feel it lock in place.

Fig. 44 Detail view of Savina 300; fitting the expiratory valve

3. Check that the expiratory valve is securely locked in place by pulling on it

lightly.

4. Slide the flow sensor (Fig. 44/2) to the right into the flow sensor sleeve.

5. Push the flow sensor flap (Fig. 44/1) down towards A.

Fitting of the expiratory valve diaphragm is complete.

No.1309_0000001227_Publication

Savina 300

49

Page 50

Maintenance instructions

Replacing the internal batteries

Replacing the internal batteries

Introduction The following section provides a view of the internal batteries and describes

how to remove and fit them.

View The internal batteries are located on the rear of the device behind the rear

panel and the cover plate (Fig. 45/1).

Removal

Preconditions – The Savina 300 has been switched off and disconnected from the mains

Fig. 45 Rear of device; cover plate

power supply.

– The fuse link for the internal batteries has been removed from its holder

on the power supply unit.

– The Savina 300 has been removed from the trolley, see „Disassem-

bling/assembling the device“ section headed „Removing/fitting the

Savina 300 from/into the trolley“.

– The filter cover has been removed, see „Disassembling/assembling the

device“ section headed „Filter cover“.

– The rear panel has been removed, see „Disassembling/assembling the

device“ section headed „Rear panel“.

– ESD precautions have been taken.

50

No.1309_0000001227_Publication

Savina 300

Page 51

Maintenance instructions

Replacing the internal batteries

Procedure 1. Remove the screws (Fig. 46/1).

2. Remove the cover plate (Fig. 46/2).

Fig. 46 Rear of device; cover plate

3. Pull on the tab (Fig. 47/1) and withdraw the battery slightly out of the

device.

Fig. 47 Rear of device; tab

No.1309_0000001227_Publication

Savina 300

51

Page 52

Maintenance instructions

Replacing the internal batteries

4. Disconnect the cable connector (Fig. 48/1) from the battery lug.

Fig. 48 Rear of device; cable connector (1x)

5. Pull slightly on the cable link (Fig. 49/1) to bring the second battery out of

the compartment.

6. Push the cable connectors (Fig. 49/1) off of the battery lugs.

7. Disconnect the cable connector (Fig. 49/2) from the battery lug.

52

Fig. 49 Rear of device; cable connector (3x)

NOTE

Batteries are special waste. When disposing of them, observe local waste

disposal regulations.

8. Dispose of batteries according to local waste disposal regulations.

Removal of the batteries is now complete.

No.1309_0000001227_Publication

Savina 300

Page 53

Maintenance instructions

Replacing the internal batteries

Fitting 1. Place the new batteries in front of the Savina 300, paying attention to

their orientation (the lugs of the batteries point upwards towards the O2

supply).

2. Push the cable connectors (Fig. 49/1) firmly onto the lugs of the two batteries, as shown in Fig. 49.

3. Push the cable connector (Fig. 49/2) (--) firmly onto the battery lug.

4. Insert the first battery in the battery compartment.

5. Push the cable connector (Fig. 48/1) (+) firmly onto the battery lug.

6. Insert the second battery in the battery compartment.

7. Use the screws (Fig. 46/1) to secure the cover plate (Fig. 46/2).

8. Fit the rear panel on the Savina 300, see section headed „Disassembling/assembling the device“ section headed „Rear panel“.

9. Fit the filter cover on the Savina 300, see „Disassembling/assembling the

device“, section headed „Filter cover“.

10. Fit the Savina 300 on the trolley, see „Disassembling/assembling the

device“, section headed „Removing/fitting the Savina 300 from/into the

trolley“.

11. Insert the fuse link in the holder on the power supply unit.

12. Connect the Savina 300 to the mains power supply.

13. Perform the „electrical safety test“ and „function tests“ as per the test

instructions.

CAUTION

Batteries not fully charged! If the batteries are not fully charged, the running

time of the device in the event of a mains power failure may be reduced

considerably.

– Inform the user that the rechargeable batteries still need to be

recharged.

14. Leave the Savina 300 connected to the mains power supply until the

internal battery indicator lights up „green“.

Fitting of the batteries is now complete.

No.1309_0000001227_Publication

Savina 300

53

Page 54

Maintenance instructions

Replacing the external batteries

Replacing the external batteries

Introduction The following section provides a view of the external batteries and describes

how to remove and fit them.

View The external batteries are located behind the cover of the battery pack (Fig.

50/1).

Fig. 50 Trolley; cover (battery pack)

54

No.1309_0000001227_Publication

Savina 300

Page 55

Removal

Preconditions – The Savina 300 has been switched off and disconnected from the mains

Procedure 1. Actuate all locking brakes on the double-wheel castors.

Maintenance instructions

Replacing the external batteries

power supply.

– The connector of the DC battery cable has been disconnected from the

power supply unit of the Savina 300.

2. Remove the screw (Fig. 51/1), lift off the cover and place it aside.

Fig. 51 Detail view of trolley; screw

3. Remove the screws and split washers (Fig. 52/1) (2 of each) and disconnect the electrical cable with integrated tab fuse (25 A/32 V) (Fig. 52/3).

Fig. 52 View of external batteries; screws, split washers and electrical

4. Remove the screws and split washers (Fig. 52/2) (2 of each).

The batteries are fixed in the battery pack by a strap. The central screw holds

No.1309_0000001227_Publication

Savina 300

the strap in place.

cable

55

Page 56

Maintenance instructions

Replacing the external batteries

5. Loosen the screw (Fig. 53/1) initially just two turns.

Fig. 53 View of external batteries; screw (strap)

CAUTION

Danger of injury by falling battery!

When removing the batteries there is a risk that the upper battery might fall

out.

– Hold the top battery during removal.

56

No.1309_0000001227_Publication

Savina 300

Page 57

Maintenance instructions

Replacing the external batteries

6. Hold the top battery (Fig. 54/1) during removal and remove the screw with

bar (Fig. 54/2).

Fig. 54 View of external batteries; screw with bar

7. Take the strap out of the upper support (Fig. 55/1).

Fig. 55 View of external batteries; upper support

8. Remove used batteries and place them aside.

9. Remove the mounting brackets (Fig. 55/2) from the used batteries and fit

NOTE

Used batteries are special waste. Dispose of used batteries in accordance

with local waste disposal regulations.

No.1309_0000001227_Publication

Savina 300

them to the new batteries.

57

Page 58

Maintenance instructions

Replacing the external batteries

Fitting

10. Dispose of used batteries in accordance with local waste disposal regulations.

Removal of the batteries is complete.

CAUTION

Risk of device failure due to damaged insulating strip!

If the insulating strip is damaged, a short-circuit may occur in the battery

pack and result in device failure.

– Check the condition of the insulating strip before fitting the batteries.

1. Check that the insulating strip (Fig. 56/1) is not damaged; replace it as

necessary.

58

Fig. 56 Battery pack for external batteries; insulating strip

No.1309_0000001227_Publication

Savina 300

Page 59

Maintenance instructions

Replacing the external batteries

2. Check that the strap is not damaged; replace it as necessary.

3. Pay attention to the polarity of the battery (the „positive“ terminal is at the

top) and fit the bottom battery (Fig. 57/3) in the battery pack as shown in

Fig. 57.

Fig. 57 View of external batteries; batteries and cables

4. Place the electrical cables (Fig. 57/4), on the bottom battery so they are

not trapped, as shown in the illustration.

5. Pay attention to the polarity of the top battery (the „positive“ terminal is at

the top) (see Fig. 57) and insert the battery (Fig. 57/2) in the battery pack,

holding the battery firm while fitting it.

6. Insert the locating pin (Fig. 58/1) of the strap in the upper support as

shown in the illustration.

Fig. 58 View from above of battery pack; locating pin

No.1309_0000001227_Publication

Savina 300

59

Page 60

Maintenance instructions

Replacing the external batteries

7. During fitting, hold the upper battery (Fig. 59/1) and screw in the screw

with bar (Fig. 59/2) a few turns.

Fig. 59 View of external batteries; screw with bar

60

No.1309_0000001227_Publication

Savina 300

Page 61

Maintenance instructions

Replacing the external batteries

8. Make sure the strap (Fig. 60/2) is contacting flush on the batteries and

tighten the screw (Fig. 60/1) with a torque of 3 Nm.

Fig. 60 View of batteries; strap and screw

CAUTION

Risk of device failure due to electrical short-circuit!

If the electrical wires of the batteries contact the housing, an electrical

short-circuit may occur and cause a device failure.

– Screw the wires onto the batteries so that no contact with the housing

is possible.

No.1309_0000001227_Publication

Savina 300

61

Page 62

Maintenance instructions

Replacing the external batteries

9. Connect the cables by one screw and one spring washer each to the batteries as follows:

a) Cable with red marking on positive terminal (Fig. 61/2) (+) of top bat-

tery

b) Cable with no marking on negative terminal (Fig. 61/3) (--) of bottom

battery

Fig. 61 View of external batteries; electrical connections

62

No.1309_0000001227_Publication

Savina 300

Page 63

Maintenance instructions

Replacing the external batteries

10. Secure the electrical cable with integrated tab fuse (Fig. 61/1) by one

screw and one spring washer to the battery mounting brackets.

11. Check the fitting position of the end profile (Fig. 62/1) of the cover – see

following illustration. Correct the position of the end profile as necessary.

Fig. 62 Detail view of cover; end profile and groove

12. Place the cover on the battery pack so that the groove (Fig. 62/2) of the

cover and the tongue engage.

13. Make sure the end profile (Fig. 63/1) is sealed off from the column.

Fig. 63 View from above of battery pack; end profile

No.1309_0000001227_Publication

Savina 300

63

Page 64

Maintenance instructions

Replacing the external batteries

14. Secure the cover by the screw (Fig. 64/1).

Fig. 64 Detail view of trolley; screw

15. Insert the connection socket of the DS battery cable for the external batteries in the connector on the rear of the Savina 300.

Fitting of the external batteries is complete.

16. Perform the „function test“ and „electrical safety test“ as per the test

instructions.

CAUTION

Batteries not fully charged! If the batteries are not fully charged, the running

time of the device in the event of a mains power failure may be reduced

considerably.

– Inform the user that the rechargeable batteries still need to be

recharged.

17. Fully charge the external batteries (for time taken see instructions for

use).

64

No.1309_0000001227_Publication

Savina 300

Page 65

Maintenance instructions

Replacing the consumables in the O2 gas inlet

Replacing the consumables in the O2 gas inlet

Introduction The following section provides a view of the consumables in the O2 gas inlet

and describes how to remove and fit them.

View The consumables are located in the O2 gas inlet (Fig. 65/1).

Removal

Preconditions – Savina 300 has been disconnected from the mains power supply and the

Fig. 65 Rear of device; fitting location of consumables

O2 supply.

– ESD precautions have been taken.

– The Savina 300 has been removed from the trolley, see „Disassem-

bling/assembling the device“ section headed „Removing/fitting the

Savina 300 from/into the trolley“.

– The filter cover has been removed, see „Disassembling/assembling the

device“ section headed „Filter cover“.

– The attached connectors and tubing have been disconnected from the

Savina 300.

– The rear panel has been removed, see „Disassembling/assembling the

device“ section headed „Rear panel“.

No.1309_0000001227_Publication

Savina 300

65

Page 66

Maintenance instructions

Replacing the consumables in the O2 gas inlet

Procedure 1. Using a torque spanner and an insertion tool (size 22 mm), unscrew the

connection (Fig. 66/1) anti-clockwise.

Fig. 66 View of O2 gas inlet; screw connection

2. Push the seal (Fig. 67/1) off of the connector plate.

Fig. 67 View of O2 gas inlet; seal

66

No.1309_0000001227_Publication

Savina 300

Page 67

Maintenance instructions

Replacing the consumables in the O2 gas inlet

3. Take out the washer (Fig. 68/1) and dispose of it in accordance with local

waste disposal regulations.

Fig. 68 View of O2 gas inlet; washer

4. Remove the screws (Fig. 69/1) and detach the connector plate (Fig.

69/2).

Fig. 69 View of O2 gas inlet; screws

No.1309_0000001227_Publication

Savina 300

67

Page 68

Maintenance instructions

Replacing the consumables in the O2 gas inlet

5. Take out the sealing ring (Fig. 70/1) and dispose of it in accordance with

Fig. 70 View of O2 gas inlet; sealing ring

local waste disposal regulations.

6. Take out the gas inlet filter (Fig. 71/1) and dispose of it in accordance with

local waste disposal regulations.

Fig. 71 View of O2 gas inlet; gas inlet filter

Removal of the consumables is complete.

68

No.1309_0000001227_Publication

Savina 300

Page 69

Replacing the consumables in the O2 gas inlet

Fitting 1. Insert the filter (Fig. 71/1) in the O2 gas inlet.

2. Insert the sealing ring (Fig. 70/1) in the O2 gas inlet.

3. Use the screws (Fig. 69/1) to secure the connector plate (Fig. 69/2) to the

O2 gas inlet.

4. Insert the washer (Fig. 68/1) in the O2 gas inlet.

5. Push the seal (Fig. 67/1) onto the connector plate.

6. Screw the connection (Fig. 66/1) onto the O2 supply block with a tightening torque of 20 Nm +/-2 Nm using a torque spanner and insertion tool

(size 22 mm).

7. Fit the rear panel, see also „Disassembling/assembling the device“ section headed „Rear panel“.

8. Re-attach removed tubing and connectors to the appropriate connections

on the Savina 300.

9. Fit the filter cover, see also „Disassembling/assembling the device“ section headed „Filter cover“.

10. Perform the „electrical safety test“ and „function tests“ as per the test

instructions.

Maintenance instructions

Fitting of the consumables is complete.

No.1309_0000001227_Publication

Savina 300

69

Page 70

– This page has been intentionally left blank –

70

No.1309-0000001227_Publication

Savina 300

Page 71

Annex

Parts catalog

This chapter contains a list of the device's orderable parts.

Test Instructions

This chapter contains the measures required to determine the actual condi-

tion of the device.

No.1309_0000001227_Publication

Savina 300

71

Page 72

– This page has been intentionally left blank –

72

No.1309-0000001227_Publication

Savina 300

Page 73

Parts catalog

Savina 300

Revision: 01

2010-07-23

5664.920

Page 74

Parts catalog

Equipment affected

Item

Order No. Description Qty. Qty.unit

No.

8417800 Savina 300, System 1.000 St

Remark

Revision: 01

Items that are shown in the illustration but are not listed below the illustration are not available as spare parts

Savina 300

2/37

Page 75

Parts catalog

O2-sensor covering

Item

Order No. Description Qty. Qty.unit

No.

1 8417825 Sensor cover, compl. 1.000 St

2 8417828 Screw 1.000 St

3 MX01049 OxyTrace VE 1.000 St

4 R31296 O-RING SEAL 1.000 St

5 8410713 O-RING SEAL 1.000 St

6 8351201 PCB O2-DIAPHRAGM 1.000 St

7 8418922 Flat cable,O2-Measuring Module 1.000 St

8 D04766 PACKING RING 1.000 St

9 1340727 OVAL HEAD SCR.DIN7985-M3X6-A2 1.000 St

Remark

Items that are shown in the illustration but are not listed below the illustration are not available as spare parts

Savina 300

3/37

Revision: 01

Page 76

Parts catalog

Connector housing insp.

Item

Order No. Description Qty. Qty.unit

No.

1 8417840 Connector housing Insp., compl 1.000 St

2 8417936 Cable Harness Temp.Sensor 1.000 St

3 1338986 SCREW F. PLASTICS 3X12 DWN562 1.000 St

4 8412002 DIAPHRAGM 1.000 St

5 8413654 GASKET 1.000 St

6 8414519 Cable harness AWT01 1.000 St

7 8417838 Inspiration cap 1.000 St

8 M20622 O-RING SEAL 1.000 St

9 8416207 ID Color ring Exp. 1.000 St

10 8417077 Elbow fitting 22 Insp. 1.000 St

11 8417831 Plug 1.000 St

12 8410713 O-RING SEAL 1.000 St

13 8410181 DIAPHRAGM 1.000 St

14 M06763 VALVE SPRING 1.000 St

15 8412993 ELECTROVALVE 1.000 St

16 R22363 O-ring 1.000 St

17 8410307 SEALING WASHER 1.000 St

18 2M12034 SPRING 1.000 St

19 8412952 CREW 1.000 St

20 8419303 O-ring 16x1.25 1.000 St

21 8411147 Non-return valve 1.000 St

Remark

Revision: 01

Items that are shown in the illustration but are not listed below the illustration are not available as spare parts

Savina 300

4/37

Page 77

Parts catalog

Expiration valve

Item

Order No. Description Qty. Qty.unit

No.

0 1563572 SILICON FAT MOLYKOTE 111 COMP. 1.000 St

1 8417050 Expiration Valve, reuse., V 1.000 St

2 8416203 Flow sensor sleeve, compl. (gray) 1.000 St

3 8415864 Expiration valve, flutter seal 1.000 St

4 8416201 Lip seal (gray) 1.000 St

5 8413661 Membrane, complete 1.000 St

6 8416204 Pot (grey) 1.000 St

7 M20622 O-RING SEAL 1.000 St

Remark

Items that are shown in the illustration but are not listed below the illustration are not available as spare parts

Savina 300

5/37

Revision: 01

Page 78

Parts catalog

Connector housing exp.

Item

Order No. Description Qty. Qty.unit

No.

0 8403735 Spirolog Flow Sensor (5x) 1.000 St

1 8417848 Flow sensor cover 1.000 St

2 8417831 Plug 1.000 St

3 8417158 Connector mount-XL 1.000 St

4 8414028 Cable harness spirolog sensor 1.000 St

5 8417845 Connector housing Exp. 1.000 St

6 8416370 Cable harness flow switch 1.000 St

7 8413610 Valve actuator 1.000 St

8 8417921 Pba FrontPneuBoard 1.000 St

Remark

Revision: 01

Items that are shown in the illustration but are not listed below the illustration are not available as spare parts

Savina 300

6/37

Page 79

Parts catalog

Operating device

Item

Order No. Description Qty. Qty.unit

No.

0 8418754 Cable backlight 1.000 St

0 8418755 Cable collection board 1.000 St

1 8417806 Control unit, compl. 1.000 St

2 1874683 BACKLIGHT INVERTER 24V RoHS 1.000 St

3 8417931 Pba CollectionBoard 1.000 St

4 8418828 E-Set Display Sharp 1.000 St

5 8418829 E-Set Display AUO 1.000 St

6 8418830 E-Set Display LG 1.000 St

7 8417814 Housing cover, compl. 1.000 St

8 8417858 Insertion Strip DE 1.000 St

9 8417859 Insertion Strip EN GB + US 1.000 St

10 8417860 Insertion Strip FR 1.000 St

11 8417861 Insertion Strip CN 1.000 St

12 8417862 Insertion Strip RU 1.000 St

13 8417863 Insertion Strip JP 1.000 St

14 8417864 Insertion Strip IT 1.000 St

15 8417865 Insertion Strip ES 1.000 St

16 8417866 Insertion Strip PT 1.000 St

17 8417867 Insertion Strip RO 1.000 St

18 8417868 Insertion Strip GR 1.000 St

19 8417869 Insertion Strip PL 1.000 St

20 8417870 Insertion Strip TR 1.000 St

21 8417871 Insertion Strip NL 1.000 St

22 8417872 Insertion Strip BG 1.000 St

23 8417873 Insertion Strip SE 1.000 St

Remark

Items that are shown in the illustration but are not listed below the illustration are not available as spare parts

Savina 300

7/37

Revision: 01

Page 80

Parts catalog

Operating device

Item

Order No. Description Qty. Qty.unit

No.

24 8417874 Insertion Strip KO 1.000 St

25 8417875 Insertion Strip HU 1.000 St

26 8417876 Insertion Strip FI 1.000 St

27 8417877 Insertion Strip CZ 1.000 St

28 8417878 Insertion Strip SK 1.000 St

29 8607597 trim knob Cockpit 1.000 St

30 8607479 color ring MoBi Primus IE 1.000 St

31 8418700 Rotary encoder, complete 1.000 St

32 8417830 Pressing foot 1.000 St

33 8417852 Swivel axis 1.000 St

34 8417853 Spacer bolt 2.000 St

Remark

Revision: 01

Items that are shown in the illustration but are not listed below the illustration are not available as spare parts

Savina 300

8/37

Page 81

Parts catalog

Base group

Item

Order No. Description Qty. Qty.unit

No.

1 TSI-sensor 1.000 St

2 Plug-in unit 1.000 St

3 Filter holder 1.000 St

4 Valve unit 1.000 St

5 PAW-Pressure sensor unit 1.000 St

6 8418783 PCB Support hinge pivoting 1.000 St

7 8417911 Pba BackPneuBoard 1.000 St

8 8418817 EMC Gasket-D3 1.000 St

Remark

Items that are shown in the illustration but are not listed below the illustration are not available as spare parts

Savina 300

9/37

Revision: 01

Page 82

Parts catalog

TSI-sensor

Item

Order No. Description Qty. Qty.unit

No.

1 8413579 TSI-sensor 1.000 St

2 8418793 TSI tube 1.000 St

3 8413700 CABLE HARNESS 1.000 St

Remark

Revision: 01

Items that are shown in the illustration but are not listed below the illustration are not available as spare parts

Savina 300

10/37

Page 83

Parts catalog

Plug-in unit

Item

Order No. Description Qty. Qty.unit

No.

0 1554123 GLASS OF OXYGENOEX S 4, 125GR 1.000 St

1 Blower unit 1.000 St

2 1841416 Lead-acid battery 12V/3.5AH 1.000 St

3 8416370 Cable harness flow switch 1.000 St

4 8408197 SOCKET 1.000 St

Remark

Items that are shown in the illustration but are not listed below the illustration are not available as spare parts

Savina 300

11/37

Revision: 01

Page 84

Parts catalog

Blower unit

Item

Order No. Description Qty. Qty.unit

No.

1 8413643 Spare Parts (Blow.Engine Unit) 1.000 St

2 8413625 RADIAL FAN 1.000 St

3 8413644 REP.SET RADIATOR 1.000 St

4 8408197 SOCKET 1.000 St

5 8413710 GASKET 1.000 St

6 8410181 DIAPHRAGM 1.000 St

7 8414081 REP.SET DIAPHRAGM 1.000 St

8 8413610 Valve actuator 1.000 St

9 1339958 COUNTER SUNK SCREW M4X8 DIN965 4.000 St

10 8413748 FILTER TSI 1.000 St

Remark

Revision: 01

Items that are shown in the illustration but are not listed below the illustration are not available as spare parts

Savina 300

12/37

Page 85

Parts catalog

Filter holder

Item

Order No. Description Qty. Qty.unit

No.

1 8417836 filter holder 1.000 St

2 6737545 MICROFILTER 1.000 St

3 8413609 MAINS SWITCH 1.000 St

4 8418932 Cover 184_206 1.000 St

5 8418931 Cover 150-175 1.000 St

Remark

Items that are shown in the illustration but are not listed below the illustration are not available as spare parts

Savina 300

13/37

Revision: 01

Page 86

Parts catalog

Valve unit

Item

Order No. Description Qty. Qty.unit

No.

0 1329472 WASHER B 5,3 DIN 9021-A4 1.000 St

0 8413621 Flat cable, Valve bench 1.000 St

1 8417820 valve unit compl. 1.000 St

2 8413603 Valve Unit 1.000 St

3 2M10633 O-RING SEAL 1.000 St

4 M11995 TOROIDAL SEALING RING 1.000 St

5 8413756 filtering plate 1.000 St

6 8413755 FILTER TUBE 1 1.000 St

7 8413754 FILTER TUBE 2 1.000 St

8 8413666 Pressure regulator 1.000 St

9 8418792 dosage insert 1.000 St

10 8416272 O-ring 2x1mm 1.000 St

11 8412993 ELECTROVALVE 1.000 St

12 M09257 PACKING RING 1.000 St

13 8417753 Ground cable -85 1.000 St

14 CH09932 RUBBER BUFFER 1.000 St

15 8418789 Grommet 9.5mm 1.000 St

Remark

Revision: 01

Items that are shown in the illustration but are not listed below the illustration are not available as spare parts

Savina 300

14/37

Page 87

A

Parts catalog

Valve unit

Item

Order No. Description Qty. Qty.unit

No.

0 1329472 WASHER B 5,3 DIN 9021-A4 1.000 St

0 8413621 Flat cable, Valve bench 1.000 St

1 8417820 valve unit compl. 1.000 St

16 8350841 PCB O2-VALVE 1.000 St

17 8305624

18 1865862 Pressure Sensor 7bar absolute 1.000 St

19 2M03646 slide washer 1.000 St

20 1340727 OVAL HEAD SCR.DIN7985-M3X6-A2 1.000 St

21 D04766 PACKING RING 1.000 St

22 8418787 Spout 1.000 St

23 8418788 O_Ring 2.8x1.8 1.000 St

24 M12701 O-RING 1.000 St

25 8410713 O-RING SEAL 1.000 St

DMISSION PRESSURE SENSOR 1.000 St

Remark

Items that are shown in the illustration but are not listed below the illustration are not available as spare parts

Savina 300

Revision: 01

15/37

Page 88

Parts catalog

PAW-Pressure sensor unit

Item

Order No. Description Qty. Qty.unit

No.

0 8712007 CABLE CLIP (2,4X92) 1.000 St

1 8415643 pressure sensor 140mbar Savina 1.000 St

2 1865889 Pres.Sensor 120mbar difference 1.000 St

3 8412993 ELECTROVALVE 1.000 St

4 8410713 O-RING SEAL 1.000 St

5 D04766 PACKING RING 1.000 St

6 6804141 Isolate socket 1.000 St

7 8400964 SOCKET 1.000 St

Remark

alternativ

alternativ

Revision: 01

Items that are shown in the illustration but are not listed below the illustration are not available as spare parts

Savina 300

16/37

Page 89

Parts catalog

EMV-box

Item

Order No. Description Qty. Qty.unit

No.

0 8418755 Cable collection board 1.000 St

0 8417939 Cable harness motor electronic 1.000 St

1 8417901 pba CentralControlBoard 1.000 St

2 1845586 EEPROM 256X8 DIP8 I2CLV02856 1.000 St

3 1845527 REAL TIME CLOCK DIL24 RoHS 1.000 St

4 8418799 Insulation holder 4.000 St

5 8413620 Enginedrive, compl. 1.000 St

6 8417822 Oxygen seal 1.000 St

7 8414518 HORN,CPL. 1.000 St

8 8418763 Loudspeaker, complete 1.000 St

9 8417857 Rebound strap 1.000 St

10 8417896 Rebound strap pin 2.000 St

11 8418783 PCB Support hinge pivoting 4.000 St

Remark