Page 1

Dräger SAM 3100 / 3200

Sampling system

Instructions for Use

Page 2

Page 3

Contents

1 For your safety . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.1 General safety notes . . . . . . . . . . . . . . . . . . . . . . . . .4

1.2 Definitions of alert icons . . . . . . . . . . . . . . . . . . . . . .4

2 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3 Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4.1 Air quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4.2 Standard system without delivery unit . . . . . . . . . . .5

4.3 System with ejector unit . . . . . . . . . . . . . . . . . . . . . .5

4.4 System with gas sampling pump . . . . . . . . . . . . . . .5

4.5 Circuit breaker (option) . . . . . . . . . . . . . . . . . . . . . . .5

4.6 Motor circuit protector (option) . . . . . . . . . . . . . . . . .6

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

5.1 Mechanical fastening . . . . . . . . . . . . . . . . . . . . . . . .6

5.2 Installing gas lines . . . . . . . . . . . . . . . . . . . . . . . . . . .6

5.3 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . .7

6 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

7 Wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . .8

7.1 Wiring diagram for PEX 3000 . . . . . . . . . . . . . . . . . .9

7.2 Wiring diagram for Polytron 3000 / Polytron 7000 . .10

7.3 Wiring diagram for PIR 7000 / PIR 7200 . . . . . . . . . 11

8 List of materials . . . . . . . . . . . . . . . . . . . . . . . . . .12

Contents

Dräger SAM 3100/3200 3

Page 4

For your safety

!

!

!

1 For your safety

1.1 General safety notes

Before using this product, carefully read the Instructions

for Use.

Strictly follow the Instructions for Use. The user must fully

understand and strictly observe the instructions. Use the

product only for the purposes specified in the Intended use

section of this document.

Do not dispose of the Instructions for Use. Ensure that they

are retained and appropriately used by the product user.

Only trained and competent users are permitted to use

this product.

Comply with all local and national rules and regulations

associated with this product.

Only trained and competent personnel are permitted to

inspect, repair and service the product as detailed in these

Instructions for Use (see section 6 on page 8). Further

maintenance work that is not detailed in these Instructions

for Use may only be carried out by Dräger or personnel

qualified by Dräger. Dräger recommends a Dräger service

contract for all maintenance activities.

Use only genuine Dräger spare parts and accessories,

or the proper functioning of the product may be impaired.

Do not use a faulty or incomplete product. Do not modify

the product.

Notify Dräger in the event of any component fault or failure.

Safe connection to electrical devices

Electrical connections to devices which are not listed in

these Instructions for Use should only be made following

consultation with the respective manufacturers or an expert.

Use in potentially explosive atmospheres

WARNING

The equipment is only approved for use in potentially

explosive atmospheres when using components

suitable for such areas, complete with test certificate.

Risk of explosion!

Devices or components for use in potentially explosive

atmospheres, which have been tested and approved

according to national, European or international Explosion

Protection Regulations, may only be used under the

conditions specified in the approval and with consideration

of the relevant legal regulations. The devices or

components may not be modified in any manner. The use

of faulty or incomplete parts is forbidden. The appropriate

regulations must be observed at all times when carrying

out repairs on these devices or components.

1.2 Definitions of alert icons

The following alert icons are used in this document to identify

and highlight areas of the associated text that require a greater

awareness by the user. A definition of the meaning of each

icon is as follows:

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

!

Indicates a potentially hazardous situation which, if not

avoided, could result in physical injury, or damage to

the product or environment. It may also be used to

alert against unsafe practices.

NOTICE

i

i

Indicates additional information on how to use

the product.

2 Intended use

The Dräger SAM 3100/SAM 3200 is an aspirator system for

continual intake of gas/air mixtures for a gas transmitter

(SAM 3100) or for two gas transmitters (SAM 3200), in order

to carry out measurements of toxic and/or explosive

substances in hard-to-access places.

In the event of insufficient process overpressure, a partial flow

of the process gas is siphoned off from the process using

a gas sampling pump with electric drive, or alternatively using

an ejector.

In order to separate solid particles from the gas flow,

the gas is passed across a filter.

The sample gas is passed to the flow meter with ring

initiator (for flow monitoring) via a 3/2-way spherical valve

(option for simplified feeding of test gas) and then flows into

the sample chamber of the sensor or sensors.

The air is either discharged to atmosphere or fed back

to the intake point by means of the air outlet on

the transmitter.

WARNING

During installation without return feed for the sample

gas back to the intake point, the sample gas should be

guided to a vent or outside. Risk of poisoning or

explosion! The return feed must not be pressurised.

4 Dräger SAM 3100/3200

Page 5

Specification

!

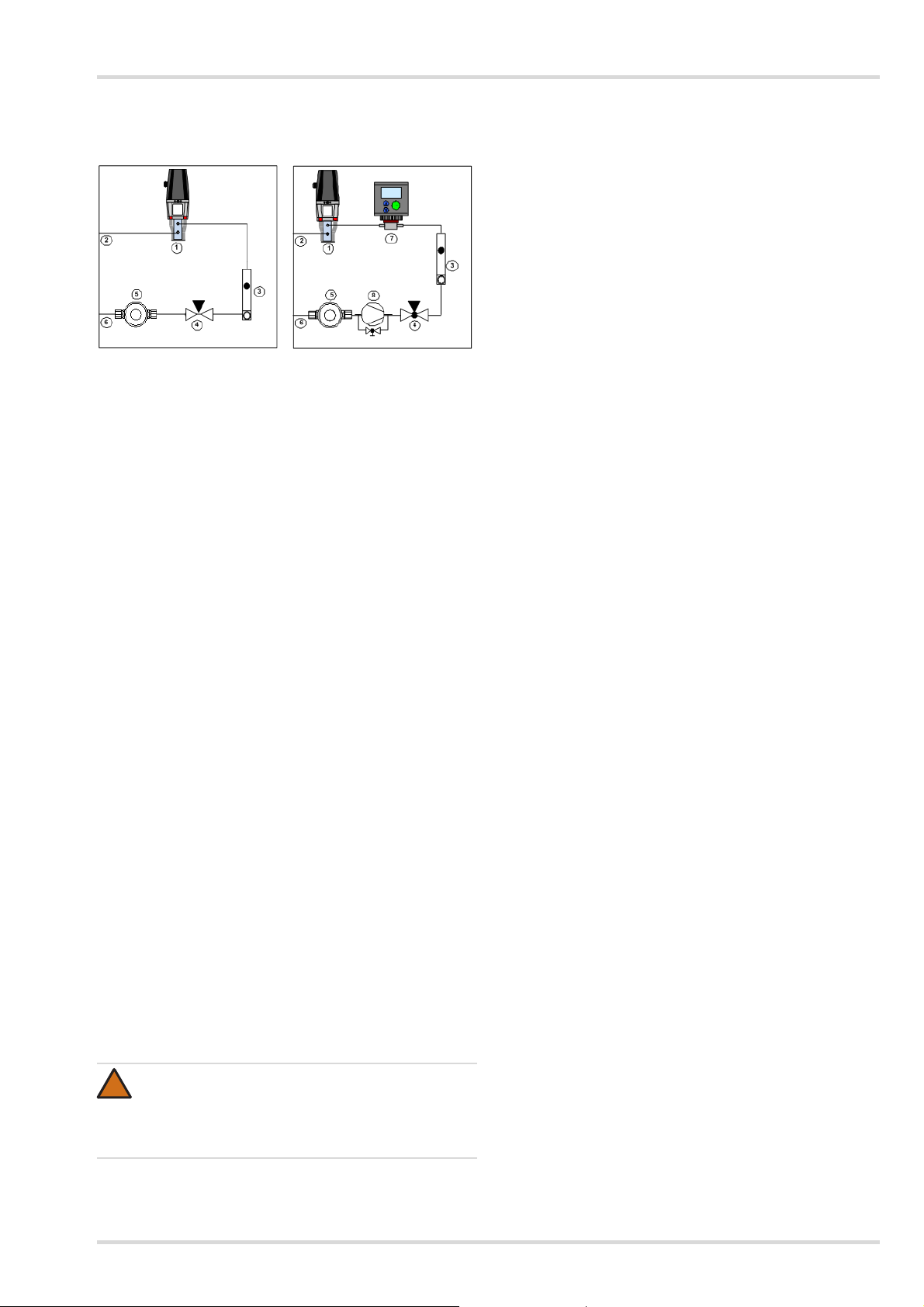

Example arrangements

Dräger SAM 3100 without

gas sampling pump:

1 Dräger PIR 7000 gas transmitter with process adapter

2 Sample gas outlet

3 Flow meter with ring initiator (flow monitoring at 25 to 250 l/h)

4 3/2-way calibrating gas valve

5 Analysis filter (filter element 1 µm PTFE)

6 Sample gas inlet

7 Dräger Polytron 7000 gas transmitter with adapter for

gas exposure

8 Gas sampling pump

Dräger SAM 3200 with gas

sampling pump:

3 Specification

Ambient temperature: +10 to +40 °C

Protection class: IP 20 (standard

Flow meter with ring initiator

Flow monitoring:

Standard: 10–100 l/h

Optional: 6–60 / 25–250 l/h

Material: PVDF

Sample gas lines

Material: Screw connections:

Gas sampling pump (option)

Power supply: 230 V / 50 Hz

Pumping rate: approx. 5.5 l/min.

Ejector (option)

Material: Stainless steel

Compressed air supply: 4 bar to 6 bar

configuration without

housing)

PVDF

Hose: PTFE

4 Settings

4.1 Air quantity

The flow should be set according to the sensor type:

Transmitter with electrochemical sensor ~60 l/h

Transmitter with electrochemical sensor + IR transmitter

in series ~80 l/h

IR transmitter ~180 l/h

The flow should be matched to the circumstances in the system

as a whole.

4.2 Standard system without delivery unit

The sample air leaves the process with excess pressure!

The sample gas flow should be set to 60 l/h at the fine

regulating valve on the flow meter. The top of the ball is the

read mark for the scale.

Notice on handling: see the Instructions for Use for the

flow meter.

4.3 System with ejector unit

To function correctly, the regulating valve needs an input

pressure of 1 bar to 10 bar. The control range of the

regulating valve is 0.2 bar to 10 bar.

Setting the sample gas flow:

Open the fine regulating valve on the flow meter (turn anti-

clockwise to the stop, then 1 turn back).

Set the flow approximately at the regulating valve, then carry

out the fine regulation using the regulating valve on the

flow meter . The top of the ball is the read mark for the scale.

Notice on handling: see the Instructions for Use for the

flow meter and for the regulating valve.

4.4 System with gas sampling pump

The sample gas flow should be set to 60 l/h at the fine

regulating valve on the flow meter. The top of the ball is the

read mark for the scale.

Setting the sample gas flow:

Open the fine regulating valve on the flow meter (turn anti-

clockwise to the stop, then 1 turn back), set the flow

approximately at the bypass valve on the gas sampling

pump, then carry out the fine regulation using the

regulating valve on the flow meter. The top of the ball is the

read mark for the scale.

Notice on handling: see the Instructions for Use for the

flow meter and for the gas sampling pump.

Regulating valve (option)

Input pressure: 1 bar to 10 bar

Control range: 0.2 bar to 10 bar

3/2-way spherical valve (option)

Material: Stainless steel

WARNING

The equipment is only approved for use in potentially

explosive atmospheres when using components

suitable for such areas, complete with test certificate.

Risk of explosion!

Test certificates are included in the equipment documentation.

4.5 Circuit breaker (option)

The circuit breaker is delivered together with the aspirator

system as a separate item. Installation is carried out on site

by the operator in accordance with the assembly

instructions. Information is included in the documentation.

The circuit breaker makes it possible to monitor line breaks

and short circuits. Furthermore, the action of the relay can

be reversed by means of a switch. Settings should be

adjusted in accordance with the operator's requirements

during commissioning. Information is included in

the documentation.

Standard: Auxiliary power 24 V DC

Optional: Auxiliary power 230 V, 50 Hz

Dräger SAM 3100/3200 5

Page 6

Installation

00423944_01.eps

123 4 5

00523944_01.eps

00623944_01.eps

00723944_01.eps

4.6 Motor circuit protector (option)

The motor circuit protector is delivered together with

the aspirator system as a separate item.

Adjustment range 0.25 to 0.4 A.

Using a screwdriver, set the value in accordance with

the rating plate on the motor of the gas sampling pump

(Ex pump 0.3 A, non-Ex pump 0.4 A).

Installation is carried out on site by the operator in

accordance with the assembly instructions. Information is

included in the documentation.

5 Installation

5.1 Mechanical fastening

The Dräger SAM 3100 / 3200 aspirator system is delivered

fully assembled.

The installation of the base plate or housing depends on

the local situation. Ensure that the installation is sufficiently

firm and free of vibration.

Connect the intake side to the hose laid by the customer,

using the compression fitting for a hose of 6 x 1 mm

(see section 5.2 on page 6).

The exhaust line is 6 x 1 mm as standard.

For exhaust lines more than 10 m in length, the cross-

sections should be expanded by the customer from the

outlet of the aspirator system in order to prevent pressure

build-up in the system.

Assembly instructions for PTFE hose connection

1 Screw-in piece 2 Nozzle

3 Clamping ring 4 Lock nut

5Hose

Slide the lock nut and clamping ring over the hose

as illustrated.

Slide the end of the hose over the nozzle to the stop.

5.2 Installing gas lines

The gas lines may only be connected by skilled personnel.

Local legislation and regulations must be observed.

When selecting gas lines (material, length), consider potential

adsorption effects.

When designing the length of the intake line, bear in mind

that a longer line will lengthen the alarm lag time.

Recommended hose material: PTFE (Teflon) or PE,

depending on the chemical resistance to the target gas.

When using other hose materials or diameters, a transition

to 6 x 1 mm PTFE hose must be created.

Cut off hose squarely!

Screw in the lock nut by hand until it is hand-tight.

To open the hose connection, unscrew the union nut and

remove the hose, together with the clamping ring, from the

aspirator system.

For air containing dust, an intake filter (order no. 68 06 743)

should be provided at the intake point to protect the aspirator

system and the line.

Avoid external influences such as splashing water, oil etc.

and the possibility of mechanical damage.

Pay attention to ventilation!

Always locate the intake point in the air flow between

a potential discharge or collection point and points of

potential hazard.

Pay attention to the density of gas!

For gases with a density lower than that of air, the intake

point must be located above any possible leak or at the

highest point at which large concentrations of gas may

occur. For gases and vapours with a density greater than

that of air, the intake point must be located below a possible

leak or at the lowest point at which such gases and vapours

may occur.

Pay attention to the seal of the gas connections, as leaks

can cause significant measuring errors to occur at the gas

transmitter.

When testing the seal, no overpressure or underpressure

should be generated at the sensor!

6 Dräger SAM 3100/3200

Page 7

5.3 Electrical connections

!

CAUTION

The electrics may be laid and connected only by

a specialist and whilst observing the relevant directives.

soldered connection

ring initiator

Installation

– +

– 1 +

5.3.1 Pump

For electrical installation works, the appropriate safety

regulations must be followed.

Before connecting the pump, ensure the electricity supply

is switched off.

The supply voltage should be checked against

the specifications on the rating plate on the gas

sampling pump. The supply voltage may deviate by

a maximum of +/– 10 % from the specifications on the

rating plate.

The earth wire should be connected to the gas

sampling pump. Install the gas sampling pump in such

a way that it is not possible to touch the live parts

(electrical connection).

A device for isolating the gas sampling pump from the

mains supply should be included in the electrical

installation. The electricity supply to the pump motor should

be protected with a fuse. The current consumption can be

found on the rating plate.

For systems with a gas sampling pump, a motor circuit

protector should be provided in the supply voltage cable,

without exception. The protection switch is installed in the

control cabinet. The motor circuit protector should be set to

the nominal motor current for the gas sampling pump

(see rating plate). Please note the manufacturer's technical

information (Instructions for Use are included in

the documentation).

limit value transmitter connection

00823944_en.eps

5.3.5 Connection cable:

The connection cables for the intrinsically safe circuit should

be selected according to the relevant installation standard.

In so doing, the formation of a summation current between

different intrinsically safe circuits of the float-type flow meter

should be prevented. When laying the cables, ensure sufficient

distance between the surfaces of the measuring component

and the connection cable.

5.3.6 Earth connection:

With float-type flow meters, when the flow impacts nonconductive components during operation this can cause

charge separation in the measuring tube. In the case of glass

equipment, it is, in principle, possible for the electrostatic field

generated within the measuring tube to penetrate through to

the outside of the equipment.

earthing

connection

5.3.2 Gas transmitter

Gas transmitters from Dräger are connected to a central

controller, e.g. Dräger REGARD, in accordance with

the specifications in the associated Instructions for Use

(see section 7 on page 8).

5.3.3 Flow meter with ring initiator

The flow meter is supplied provided with a connection

housing.

The cable is connected directly to the circuit breaker in

the control cabinet.

Please note the manufacturer's technical information

(see Instructions for Use for the flow meter).

5.3.4 Wiring diagram:

The electrical connection of the installed, intrinsically safe,

equipment to the + and – terminals is carried out in accordance

with the following illustration and table. A limit sensor is

connected to each terminal block. Pay attention to the

specified polarity.

01823944_en.eps

The float-type flow meter is connected to the installation plate

via the earth connection for the purpose of diverting

electrostatic charge. The earthing should be connected to the

local earth potential by the individual assembling the system as

a whole.

The operator is responsible fo r the uninterrupted earthin g

of the process line.

The connection merely ensures electrostatic earthing of the

equipment and does not meet the requirements for

equipotential bonding. When measuring dust-free gases

or liquids, the flow rate may not exceed 20 times the nominal

flow rate. Note the max. permissible operating pressure PS

printed on the rating plate.

Dräger SAM 3100/3200 7

Page 8

Maintenance

!

6 Maintenance

Dräger SAM 3100/3200 aspirator system:

The aspirator system is designed so as to minimise the need

for servicing.

Directions for maintenance and servicing can be found in

the Instructions for Use for the components used.

Depending on the dust load in the sample gas, the filter

inserts should be replaced when visibly soiled. Spare parts:

see the Instructions for Use for the filter.

In the case of systems with gas sampling pump, it is

recommended that the diaphragm and valve plates of the

pump are replaced at least once a year.

Spare parts: refer to the Instructions for Use for the gas

sampling pump.

The ejectors for delivering sample gas have no mechanical

parts subject to wear, and are therefore maintenance-free.

Gas transmitter

Maintenance and servicing of the gas transmitter should be

carried out according to the enclosed Instructions for Use.

The calibration interval and calibration i nstructions can be

found in the Instructions for Use for the gas transmitter and

for the DrägerSensor.

For aspirator systems with gas sampling pump, the pump

should be switched off during test gas feeding (calibrating).

For models with ejector, the air feed should likewise

be interrupted.

7 Wiring diagrams

CAUTION

Electrical wiring is only to be laid and connected by an

expert, paying attention to the relevant regulations and

laws concerning electrical equipment in potentially

explosive atmospheres as well as the approval

conditions.

Consult the Instructions for Use for installation!

8 Dräger SAM 3100/3200

Page 9

7.1 Wiring diagram for PEX 3000

02023944_en.eps

+24 Volts

0 Volt

Cable screen

contacted within

the cable gland

PEX 3000

Type XTR 0000,

XTR 0001,

XTR 0010

and XTR 0011

Cable screen

contacted within

the cable gland

PEX 3000

Type XTR 0090,

XTR 0091

Sensing head

Polytron SE Ex PR ... DD

Power supply

24 V 20 %,

0.15 A

4 to 20 mA

0 mA

Controller Unit

max. cable length

50 m

100 m

150 m

core cross-section

0.5 mm

2

1.0 mm

2

1.5 mm

2

12

3

12

3

Wiring diagrams

PEX 3000, all types PEX 3000, types XTR 0090 and XTR 0091

Connection to central controller: Connection to sampling head

Connect terminal +24 V to +24 volts Connect terminal br/br to terminal 1

Connect terminal SIG to 4 bis 20 mA input Connect terminal ge/yw to terminal 2

Connect terminal 0 V to 0 volts Connect terminal sw/bk to terminal 3

Dräger SAM 3100/3200 9

Page 10

Wiring diagrams

02423944_en.eps

Non-explosion-hazard areaExplosion-hazard area, zone 0, 1 or Div. 1

Safety barrier

Control unit

Ex i

PA

Earth point

4 ... 20 mA

0 V

+

–

+

4 to 20 mA

+24 V

!

!

02323944_en.eps

Non-explosion-hazard area

without a safety barrier

Control unit

4 ... 20 mA

0 V

+

–

+

4 to 20 mA

+24 V

Explosion-hazard area, zone 2 or non-explosion hazard

7.2 Wiring diagram for Polytron 3000 / Polytron 7000

Installing the transmitter in potentially explosive atmospheres of zone 0 or zone 1

Installing the transmitter in potentially explosive atmospheres of zone 2 or in areas not at risk of explosion.

WARNING

The category 1 classification must be cut out of the rating plate hanger at the location provided. Once the equipment has

been operated in accordance with this installation, it may n o longer be installed in mines in which firedamp may occur,

nor in potentially explosive atmospheres of zone 0 or zone 1 (equipment category 1 or 2). Risk of explosion!

Installing the transmitter in areas not at risk of explosion:

WARNING

The Ex protection classification must be removed from the transmitter. Once the transmitter has been operated in

accordance with this installation, it may no longer be installed in potentially explosive atmospheres.

10 Dräger SAM 3100/3200

Page 11

7.3 Wiring diagram for PIR 7000 / PIR 7200

2123944_en.eps

+

+

–

–

R

S

123456

power supply

red

black

brown

white

green/yellow

central device, e.g.

Dräger REGARD

02223944_en.eps

+

+

–

–

R

S

123456

power supply

red

black

brown

white

green/yellow

central device

Wiring diagram for operation as a 4 to 20 mA current source

(source operation):

Wiring diagram for operation as a 4 to 20 mA current sink

(sink operation):

Wiring diagrams

Dräger SAM 3100/3200 11

Page 12

List of materials

8 List of materials

Name Order no. Manufacturer

Gas transmitter and sensor type According to customer requirements Dräger

Aspirator system SAM 3100 / 3200

– Dräger

for a gas transmitter, comprising:

Base plate, 500 mm x 500 mm, stainless steel – Dräger

Filter, fine filter 1 µm 38.PC1410PVDF-ISW ISW

Flow meter with ring initiator,

monostable, flow monitoring

15. DK 800 PV K 1-MO

6–60 l/h

Krohne

10–100 l/h

25–250 l/h

All system hoses are PTFE, screw connections are PVDF, system is installed on the base plate.

Additional equipment:

Gas sampling pump, not for Ex areas PM21772-87 (N87 TTE) ISW (KNF)

Gas sampling pump, for Ex areas PM21773 -87 (N87 TTE Ex) ISW (KNF)

Protective housing, 500 x 500 x 300 mm,

plastic, filter mounted externally

Protective housing, 500 x 500 x 300 mm,

sheet steel, filter mounted externally

Protective housing, 500 x 500 x 300 mm,

stainless steel, for Ex areas, filter mounted externally

3/2-way spherical valve, stainless steel 02.SS-42 GXS 6 mm Swagelok

Ejector 01.710200.00VA ISW

Regulating valve 70.159.625 Festo

Isolation amplifier 24 V DC 03.160312 Steel

Isolation amplifier 230 V AC 03.160321 Steel

Motor circuit protector 0 to 0.4 A 115.072732 Eaton

KS 1453.600 Rittal

AE 1013.600 Rittal

AE 1013.600 Rittal

12 Dräger SAM 3100/3200

Page 13

Page 14

Page 15

Page 16

Dräger Safety AG & Co. KGaA

Revalstraße 1

23560 Lübeck, Germany

Tel +49 451 882 0

Fax +49 451 882 20 80

www.draeger.com

90 23 944 - GA 4675.790 de

© Dräger Safety AG & Co. KGaA

Edition 02 - September 2013 (Edition 01 - October 2006)

Subject to alteration

Loading...

Loading...