Page 1

Dräger Polytron 7000

00123758_4.eps

(approved as type P3U and P3FB)

Transmitter for electrochemical Sensors

Instructions for Use

Page 2

Contents

Contents

For Your Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installing the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Preparing for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing the docking station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-wire connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3-wire connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connections between several transmitters and a control unit with

HART multidrop connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4-wire connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installing the measuring unit Dräger Polytron 7000 . . . . . . . . . . . . . . . . . . . 25

Fitting the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Installing accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Daisy chain kit – Cable Entry Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Remote sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Duct adapter for remote sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Dräger Polytron 7000 software dongles . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Relay module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Pump module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Activating info mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Calibrating the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Setting up the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Replacing the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Fault – Cause – Remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Menu functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Basic operating procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Switching to quick-menu mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Switching to menu mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Entering the password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Navigation in the menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

The menu » Information « . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Submenu » Instrument « . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Submenu » Sensor « . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Submenu » Datalogger « . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

2

Page 3

The menu » Calibration « . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Submenu » Zero calibration « . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Submenu » Span cal. « . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Autocalibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

The menu » Settings « . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Submenu » Instrument « . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Submenu » Communication « . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Submenu » Sensor « . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Submenu » Datalogger « . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Polytron 7000 Operation via LON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Polytron 7000 Operation via PROFIBUS PA . . . . . . . . . . . . . . . . . . . . . 83

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Relay module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Pump module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Contents

Order List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Calibration accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

ATEX approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Metrological certificate of approval . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Section 5 of the Suitability Test Report . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Overview of the adjustment ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Information on DrägerSensor O

Information on DrägerSensor O

(6809720) . . . . . . . . . . . . . . . . . . . . . . .119

2

-LS (6809630) . . . . . . . . . . . . . . . . . . . . .121

2

IECEx approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

UL approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

CSA approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Drilling templates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Dräger docking station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

Remote sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

Duct adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

3

Page 4

For Your Safety

For Your Safety

Strictly follow the Instructions for Use

Any use of the apparatus requires full understanding and strict observation of these instructions.

The apparatus is only to be used for purposes specified here.

Maintenance

The unit must be inspected and serviced regularly by suitably qualified persons.

Repair and general overhaul of the apparatus may only be carried out by trained service personnel.

We recommend that a service contract be obtained with DrägerService and that all repairs also be carried out by them.

Only authentic Dräger spare parts may be used for maintenance.

Observe chapter "Maintenance Intervals".

Use in areas subject to explosion hazards

Equipment and components which are used in explosion-hazard areas and which have been inspected and approved

in accordance with international or European explosion-protection regulations may be used only under the specified

conditions. The equipment or components may not be modified in any manner. The use of faulty or incomplete parts is

forbidden. The appropriate regulations must be observed at all times when carrying out repairs on the equipment or

components. If the transmitter has been installed with a suitable safety barrier, its case may be opened or the sensor

may be changed while the transmitter is operating.

CAUTION

When the transmitter is installed in Ex areas Class II, Div. 1 & 2, Group E, F, G the opening of the housing (inclusive

sensor replacement) must not be done when connected to power (power must be turned off or the area has to be

declassified). Explosion hazard!

If the transmitter is equipped, either when delivered or subsequently, with the relay module and/or the pump module,

the complete unit is no longer approved for use in explosion-hazard areas. The use of the Dräger Polytron 7000

equipped with a pump module and/or relay module in explosion-hazard areas is forbidden! Explosion hazard!

Not suitable for use in oxygen-enriched atmospheres, i.e. oxygen content exceeds 21 vol. %. Explosion hazard!

When used in transmitters with pump module, the O2 LS sensor (68 09 630) must always be installed at vibrationfree locations. If used in this combination, vibrations may cause the measured value to deviate outside of the permissible range.

In applications where category 1G (Zone 0) or EPL Ga devices are required, intense electrostatic charging processes

must be avoided.

Accessories

Use only accessories shown in the Ordering List.

4

Page 5

Intended Use

Intended Use

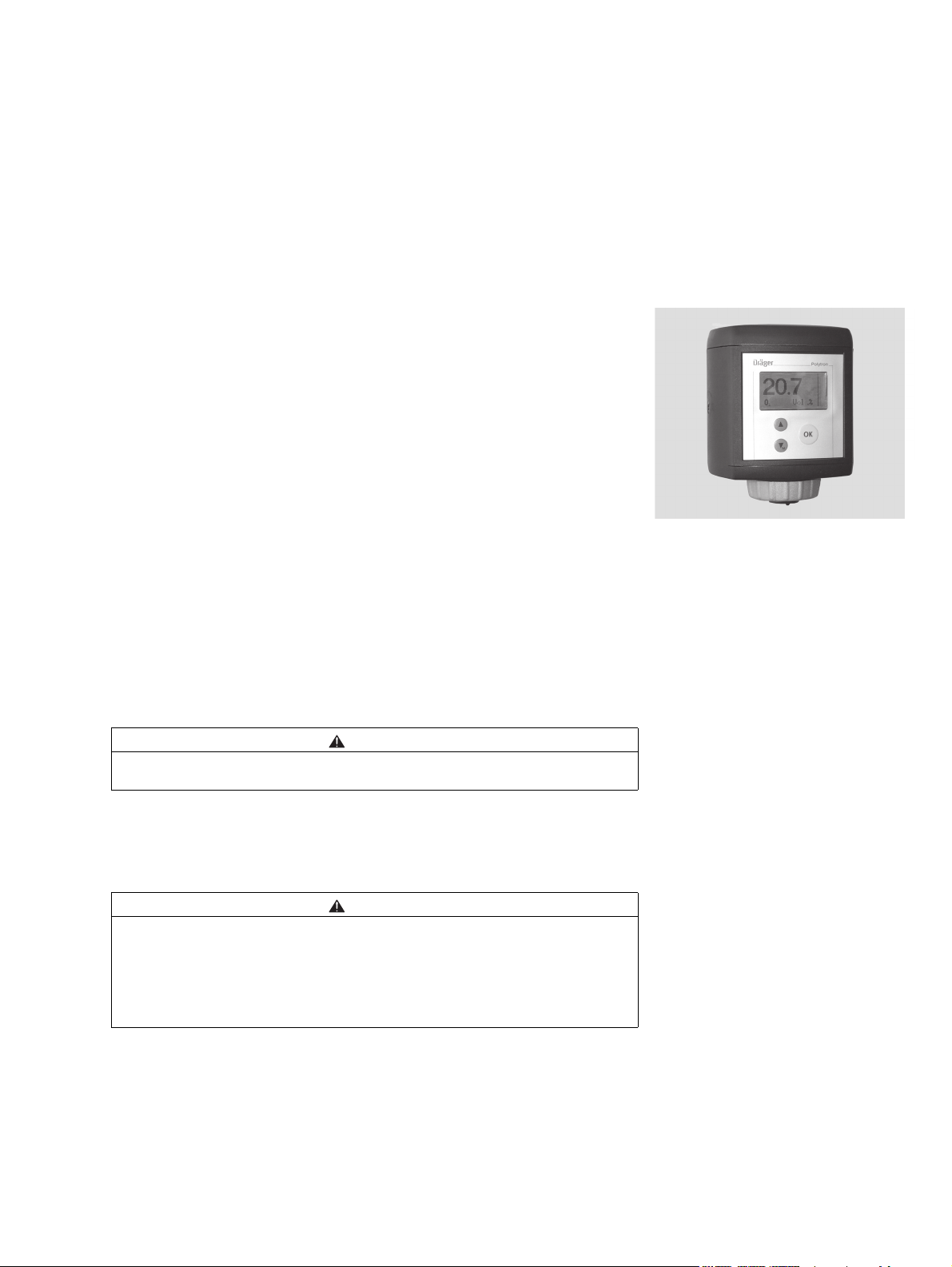

Dräger Polytron® 7000 Transmitter for electrochemical sensors

— For stationary, continuous monitoring of gas concentrations in ambient air, with built-in DrägerSensor®.

— Automatic configuration of transmitter to suit the built-in DrägerSensor.

— The measuring range may be selected, but it is dependent on the sensor installed.

— With 4 to 20 mA interface, LON communication, Foundation Fieldbus or PROFIBUS PA.

— For installation alternatively in Ex areas zone 0, 1, 2 corresponding to device category 1G, 2G, 3G or Class I,

Class II, Div. 1 & 2 hazardous area.

For further details, see the installation notes.

— Optionally compatible with HART® for connection to a suitable control unit.

— Optionally available with pump module for the continuous supply of the gas/air mixture to be tested to the transmitter.

CAUTION

No explosion protection. Explosion hazard!

_______________

® Polytron is a registered trademark of Dräger.

DrägerSensor is a registered trademark of Dräger.

HART is a registered trademark of HCF, Austin, Texas, USA

5

Page 6

Intended Use

If used together with a control unit (e. g. Regard without a safety barrier) or equipped with a relay module:

CAUTION

No explosion protection. Explosion hazard!

— Warning before any hazardous gas concentrations are reached.

— Automatic implementation of counter measures (for example, connection of an additional ventilation).

— Warning for device errors; display of necessary maintenance work.

— Special calibration mode (blocking of alarm triggering, display of calibration mode, one-man calibration).

Detection of oxygen in accordance with EN 50104

CAUTION

If the Dräger Polytron 7000 transmitter is used for the detection of oxygen, at least one alarm relay must be configured as latching.

Measuring function for the explosion protection

BVS 03 ATEX E 406 X

Dräger Polytron 7000 4 to 20 mA

Measuring range Testing standard

with/without display and keypad

with/without relay and pump module

in connection with DrägerSensor

LS (6809630)

O

2

0 to 25 Vol.-% O

O2 (6809720)

Measurement of oxygen

PFG No. 41300504

Dräger Polytron 7000 4 to 20 mA

Measuring range Testing standard

with/without display and keypad

with/without relay and pump module

in connection with DrägerSensor

O2 LS (6809630)

0 to 25 Vol.-% O

O2 (6809720)

2

EN 50104 (neutralization measurement)

2

EN 50104 (oxygen deficiency and

excess of oxygen)

6

Page 7

Design

00223758_1_1.eps

The Dräger Polytron 7000 was developed specifically as a modular system

which permits the user to select one of many different configurations.

Dräger Polytron 7000 transmitter with display and keypad and optional

for operation with a Palm Pilot 515 and infrared interface or a hand-held

HART-compatible operating device or an HART-compatible operating

station connected at any point to the 2-wire cable.

This version is suitable for installations where a display of measured value is

required on site and where access is easy for the operator.

The transmitter is operated directly via a built-in keypad and display.

Design

Optional extras:

Pump module

This module draws in the gas to be measured from a remote location and

pumps it into the Dräger Polytron 7000 transmitter.

CAUTION

This option is only possible without explosion protection approval. Explosion

hazard!

Relay module

This module permits the local switching of actuators, alarm generators, etc.

on the basis of the measured gas concentration.

CAUTION

This option is only possible without explosion protection approval. Explosion

hazard!

If the Dräger Polytron 7000 transmitter is used in connection with the relay

module for detecting oxygen according to EN 50104, the transmitter has to

be equipped with software version 8.0 or higher.

7

Page 8

Design

Daisy-chain kit

For the connection of several Dräger Polytron 7000 transmitters to one bus

line (multidrop installation). This option does not affect the explosion-protection approval of the transmitter.

Duct extension

For mounting the Polytron 7000 transmitters on a duct.

Used to measure the gas concentration in the duct. This option does not affect

the explosion-protection approval of the transmitter.

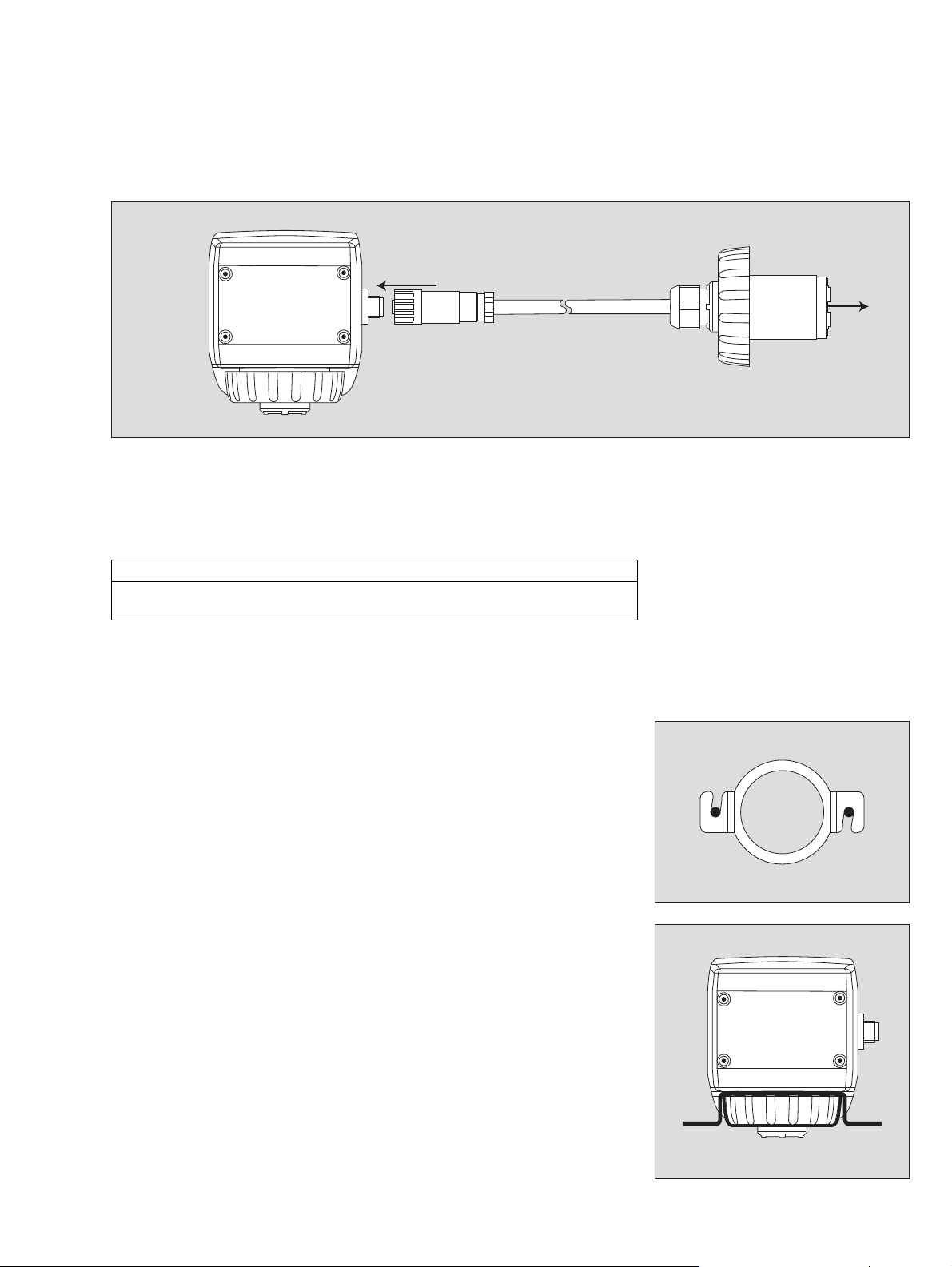

Remote sensor

For installation of the sensor at a distance of up to 30 m away from the Dräger

Polytron 7000 transmitter. This option does not affect the explosion-protection

approval of the transmitter.

Duct adapter for remote sensor

For mounting a remote sensor on a duct for measuring the gas concentration

in the duct. This option does not affect the explosion-protection approval of

the transmitter.

Dräger Polytron 7000 software dongles

For activation of additional functions of the Dräger Polytron 7000. This option

does not affect the explosion-protection approval of the transmitter.

8

Page 9

Installing the transmitter

Preparing for installation

The performance and effectiveness of the entire system depends essentially

on the position chosen for installing the transmitter.

The following should be noted during installation:

— Local requirements and regulations governing the installation of gas meas-

uring systems.

— Relevant regulations concerning the connection and routing of electric pow-

er supply and signal lines.

— The full scope of environmental factors to which the transmitter may be ex-

posed (ambient conditions: see Technical data, page 87).

— Physical properties of the gas to be measured:

For gases with a density lower than that of air, the transmitter must be located above any possible leak or at the highest point at which large concentrations of gas may occur.

For gases and vapours with a density greater than that of air, the transmitter

must be located below a possible leak or at the lowest point at which such

gases and vapours may occur.

Installing the transmitter

— The specific uses (e.g. possible leaks, ventilation conditions, etc.).

— Accessibility for the necessary maintenance work (see Installation instruc-

tions for the Polytron docking station).

— All other factors and conditions which could have a negative effect on the

installation and operation of the system (such as vibrations or varying temperatures).

— We recommend installing a reflective shield if the unit is exposed to strong

sunlight.

— The transmitter must be installed vertically (sensor facing downwards).

— The transmitter has been tested with regard to its weather-resistance and

may be installed out of doors. Use of a splash guard is recommended to

protect the sensor from splashing water, dust and wind.

NOTE

In explosion-hazard areas:

Observe the national regulations concerning electrical equipment in explosion-hazard areas.

The Dräger Polytron 7000 transmitter consists of several components:

— Dräger docking station

This can be pre-installed anywhere and contains the electrical installation

components.

— The measuring unit Dräger Polytron 7000

contains the electronics of the transmitter.

If the measuring unit is not fitted immediately after installing the docking station, the latter should be covered with the raincover provided (dust and water

protection) to protect against dust and splashing water.

9

Page 10

Installing the transmitter

00423758_1.eps

1

00523758_1.eps

2

00623758_1.eps

3

Installing the docking station

— If the transmitter is to be installed in a Zone 2 explosion-hazard area, select

a location with low exposure to mechanical risk.

— Docking station is installed vertically (transmitter with sensor facing down)

in an area with low vibrations and stable temperatures – near the possible

leak.

— A space of at least 15 cm (6") must be maintained above the transmitter for

installation of the measuring unit.

— A space of at least 10 cm (4") – preferably 30 cm (12") – must be maintained

below the docking station to permit access for maintenance.

Unpack the docking station.

1 Remove raincover (protection against dust and splashing water).

2 Remove the 4-pole terminal block (Part No. 83 16 268), keep it in a safe

place and insert it again after completion of the installation work.

A drilling template is provided on page 139. The mounting holes are

66 ±4mm (2.6 ± 0.16") apart.

CAUTION

Spacers (e.g. mounting bracket 68 09 951) must be used to prevent any

twisting of the housing when installed on uneven surfaces.

If the measuring unit is not to be mounted at this time:

Refit the raincover (protection against dust and splashing water).

For Multidrop installation only:

(see page 18)

Installing the Daisy Chain kit

Part No. 83 17 282

3 Break or drill out the prepared breakthrough for the second cable gland

from the inside of the docking station.

The hole should have a diameter of 20.5 mm.

Check that the docking station has no loose parts, and clean it if necessary.

Insert the nut of the cable gland into the docking station.

Screw in the cable gland from the outside of the docking station and tighten

it.

10

Page 11

Electrical connections

— The electrical wiring may be laid and connected only by a qualified electri-

cian, who must also comply with the appropriate regulations – a screened

or unscreened cable (such as LiY, LiYCY) may be used.

2-wire connection

Electrical connections

— Connection to central device with at least 2-wire cable, 0.5 (AWG 20) to

2.5 mm

2

(AWG 13).

Installing the 4 to 20 mA current loop on the transmitter

— For currents of 3 to 22 mA, a DC voltage between 16.5 V DC (3 mA),

or 8.0 V DC (22 mA) and 30 V DC must be present at the transmitter.

Fit 2-wire connecting cable in cable gland, cut to length and strip ends

(approx. 80 mm / 3.15").

Shorten the shield (if installed) to prevent short-circuiting:

Connect cable

1 Use a 4-pole terminal block (X8), Part No. 83 16 268, for the

Dräger Polytron 7000 – Observe the polarity of the connections.

Cut excess wires short or

2 secure them in centre terminals (Part No. 83 16 422).

1 Slide connecting terminal back into holder.

Secure cable in holder.

Fold up the installation notes and place them in the Dräger docking station

for future use during commissioning.

Refit raincover (protection against dust and splashing water).

Connecting to the central unit

Connect shield to earth of central unit (e.g. housing, earth bar, etc.).

X8

+24 V

0 V

0 V

Signal

1

2

00723758_1.eps

Connecting the Dräger Polytron 7000 transmitter to a Dräger control unit

(such as Regard, QuadGard, Unigard or Polytron):

— Further information about the connection can be found in the instructions

for the Dräger control unit.

Connecting the Dräger Polytron 7000 transmitter to control units with

a 4 to 20 mA interfaced made by other manufacturers:

— For operation together with control units made by other manufacturers, care

must be taken that the voltage at the transmitter does not drop below 16.5 V

at a current of 3 mA and 8.0 V at a current of 22 mA. The supply voltage,

the resistance of the cable and the load and the resistance of any installed

safety barrier must be taken into account.

— Further information about the connection can be found in the instructions

for the control unit being used.

11

Page 12

Electrical connections

Installing transmitter in mines where firedamp may occur

— Install a safety barrier with the appropriate explosion protection approval

(device category M1) between the transmitter and the control unit.

— Only safety barriers or power supply units with the following characteristics

may be used: UO (VOC) = 30 V, IO (ISC) = 0.3 A, PO = 700 mW.

— Make sure the maximum permissible capacitance and inductance connect-

ed to the safety barrier or power supply are not exceeded (taking into account the line as well). The safety-related input parameters of the

transmitter are as follows: Ci = 0 nF, Li = 50 µH.

Installing the transmitter in areas subject to explosion hazards of zone

0, 1 or Div. 1

Install a safety barrier with the appropriate explosion protection approval

(category 1, 2 or Div. 1) between the transmitter and the control unit.

— Only safety barriers with the following characteristics may be used: Uo (Voc)

≤30 V, Io (Isc) ≤0.3 A, Po ≤700 mW.

— Take care that the maximum permissible capacitance and inductance of

connections to the safety barrier are not exceeded, also taking the cable

into account. The safety-related input parameters of the transmitter are: Ci

= 5 nF, Li = 50 µH.

Transmitter supply units

(without HART-communication between Ex/Non-Ex area)

The following safety barriers are provided as examples only. Selected barriers

must be acceptable to the authority having jurisdiction and comply with the

assigned P3U entity parameters also taking the cable into account.

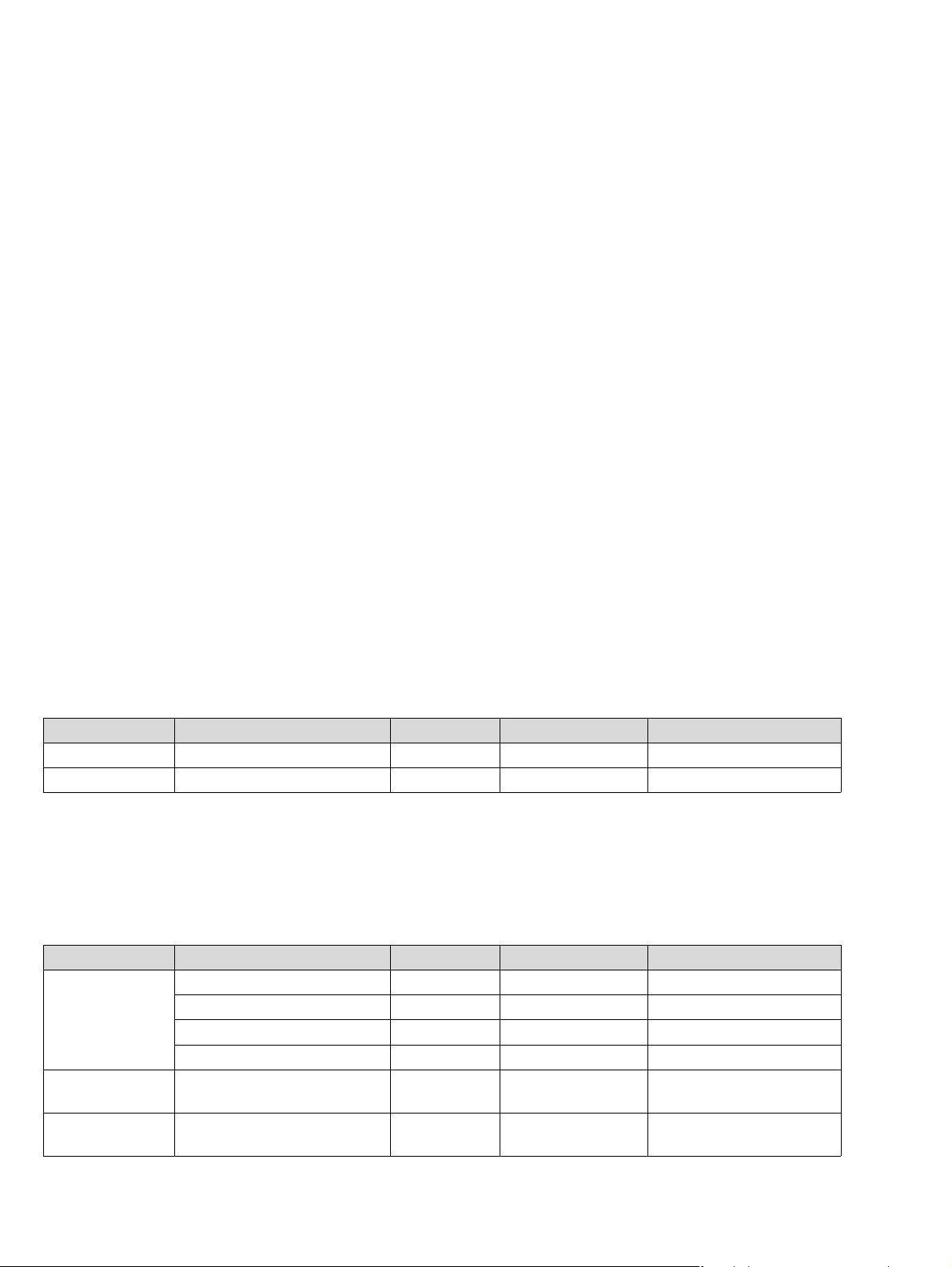

Manufacturer Type suitable for R

(Loop) Note

Cable

MTL MTL 5541 Zone 0, Div. 1 ≤ 350 Ω Suitable only for 2-wire

Pepperl & Fuchs KFD2–CR–Ex1.30 200 Zone 0, Div. 1 ≤ 400 Ω Suitable only for 2-wire

SMART transmitter supply units

(with HART-communication between Ex/Non-Ex area)

The following safety barriers are provided as examples only. Selected barriers

must be acceptable to the authority having jurisdiction and comply with the

assigned P3U entity parameters also taking the cable into account.

Manufacturer Type suitable for R

Endress +

Hauser

RN 221 N–B1 (ATEX) Zone 0 ≤ 380 Ω Suitable only for 2-wire

RN 221 N–C1 (FM) Div. 1 ≤ 380 Ω Suitable only for 2-wire

(Loop) Note

Cable

RN 221 N–D1 (CSA) Div. 1 ≤ 380 Ω Suitable only for 2-wire

RN 221 N–E1 (TIIS) ≤ 380 Ω Suitable only for 2-wire

MTL MTL 5541 Zone 0, Div. 1 ≤ 400 Ω Suitable for 2-wire

and 3-wire

Pepperl & Fuchs KFD2–STC4–Ex1 Zone 0, Div. 1 ≤ 300 Ω Suitable for 2-wire

and 3-wire

12

Page 13

— The cable resistances given apply for a load resistance of 250 Ω. Higher

00923758_1_en .eps

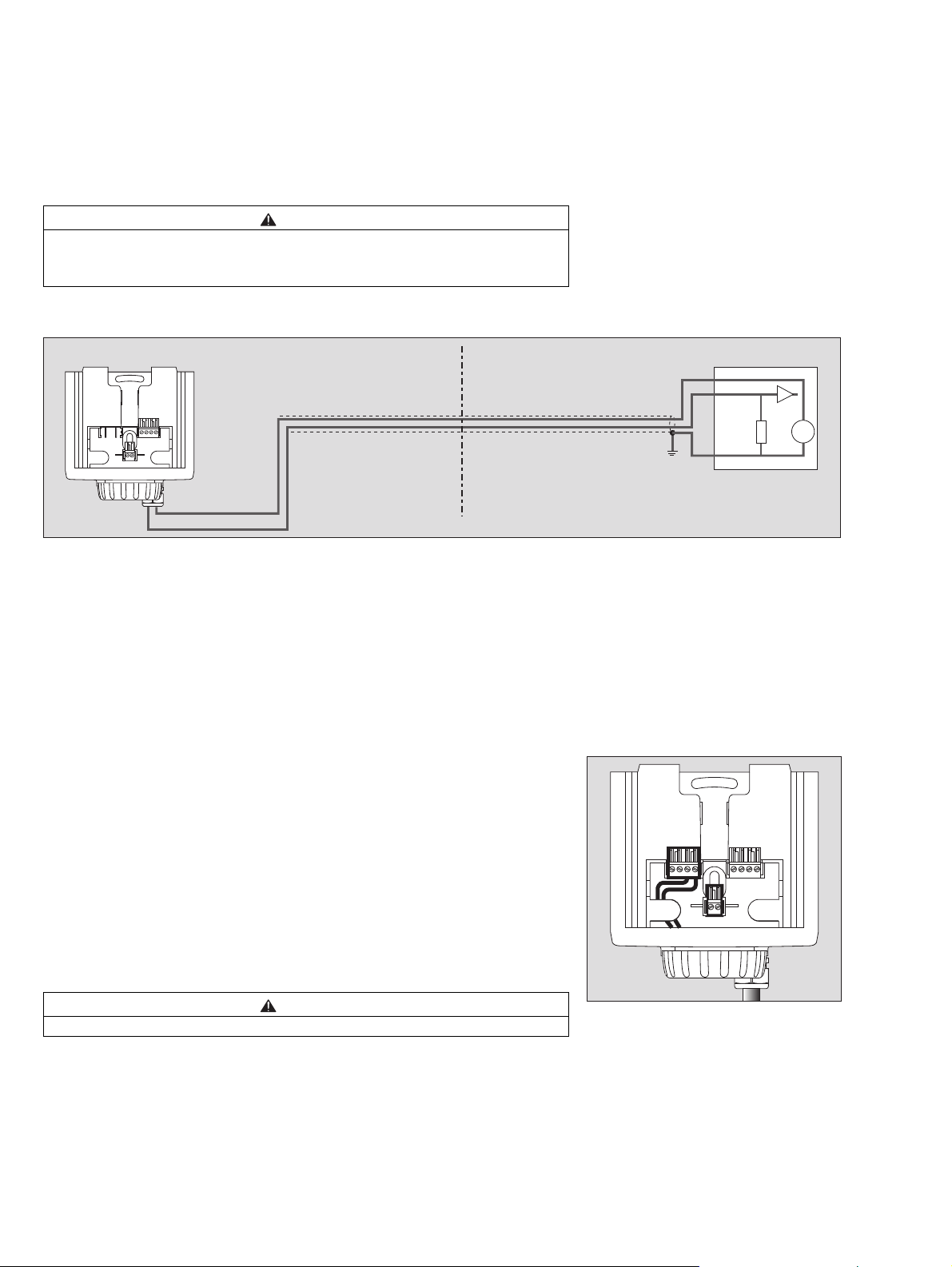

Non-explosion-hazard areaExplosion-hazard area, zone 0, 1 or Div. 1

Safety barrier

Control unit

Ex i

PA

Earth point

4 ... 20 mA

0 V

+

–

+

4 to 20 mA

+24 V

load resistances can drastically reduce the permissible cable resistance!

When other barriers have been selected, care must be taken that the volt-

ages on the transmitter do not fall below the following values when barrier

parameters and cable resistance are taken into account:

16.5 V for a current of 3 mA and 8.0 V for a current of 22 mA.

If HART communication is to be used, the HART specifications must also

be observed.

The maximum possible cable lengths can be found in the table on page 19.

In each case, use the line marked "Number of transmitters = 1".

— Connect shielding to earth point and/or 0 V (Ex i).

Electrical connections

Installing the transmitters in explosion-hazard areas of zone 2

— Use only supply units or a safety barrier of the device category 3.

— Only supply units or safety barriers with the following characteristics may

be used: UO (VOC) ≤ 30 V, IO (ISC) ≤ 0.3 A, PO ≤ 700 mW.

— Take care that the maximum permissible capacitance and inductance of

connections to the supply unit are not exceeded, also taking the cable into

account.

The safety-related input parameters of the transmitter are:

Ci = 5 nF, Li = 50 µH.

CAUTION

The category 1 marking has to be cut out from the rating-plate label. Once

the unit has been used after installation in the above manner, it may never

be installed in explosion-hazard areas of zone 0 or zone 1 (device category 1

or 2). Explosion hazard!

The maximum possible cable lengths can be found in the table on page 21.

In this table, select the line, " Number of transmitters = 1".

13

Page 14

Electrical connections

Installing the transmitters in non-explosion-hazard areas:

CAUTION

The explosion-protection markings has to be removed from the transmitter.

Once the transmitter has been used after installation in this manner, it may

never be installed in explosion-hazard areas.

The maximum possible cable lengths can be found in the table on page 21.

In this table, select the line, " Number of transmitters = 1".

Explosion-hazard area, zone 2 or non-explosion hazard

Non-explosion-hazard area

without a safety barrier

+24 V

4 to 20 mA

Installing fieldbus communication on the transmitter

— The transmitter can be connected to a certified intrinsically safe fieldbus

system, which supports FISCO (Fieldbus intrinsically safe concept).

— The PROFIBUS PA transmission technology for intrinsically safe applica-

tions is MBP. MBP stands for:

– Manchester Coding (M)

– Bus Powered (BP)

— 5 transmitters can be connected to a segment with a typical segment cur-

rent of 100 mA.

Install the 2-wire connection cable in the cable gland, cut it to length and

strip off the insulation (approx. 80 mm).

Shorten the shield (if installed) to prevent short-circuiting.

Connect cable:

1 Use a 4-pole terminal block (X7), Part No. 83 16 268, for the

Dräger Polytron 7000 – Observe the polarity of the connections. Cut excess

wires short or

2 secure them in center terminals (Part No. 83 16 422).

1 Slide connecting terminal back into holder.

Secure cable in holder.

Fold up the installation notes and place them in the Dräger docking station

for future use during commissioning.

Refit raincover (protection against dust and splashing water).

CAUTION

Insert 4-pole (X7) terminal block into left holder.

X7 X8

FB –

FB +

1

+

4 ... 20 mA

0 V

Control unit

2

+

–

00823758_1_en.eps

01023758_4.eps

14

Page 15

Installing the transmitter in areas subject to explosion hazards of

Zone 0 or Zone 1:

Only safety barriers with the following characteristics may be used:

U

max

≤24 V, I

≤0.38 A, P

max

≤5.32 W or those which correspond to the

max

FISCO model ia or ib.

— The safety-related input parameters of the transmitter are as follows:

Ci = 5 nF, Li = 10 µH.

— The transmitter may only be connected in 2-wire connection to the left

4-fold terminal block (X7) of the docking station. No electrical connections

may be made to the right 4-fold terminal block (X8).

Installing the transmitter in areas subject to explosion hazards of

Zone 2:

— Make sure that the supply unit corresponds with the FISCO model ic and

that the maximum permissible capacitance and inductance of connections

to the supply unit are not exceeded, (also take the cable into account).

— The safety-related input parameters of the transmitter are:

Ci = 5 nF, Li = 10 µH.

— The transmitter may only be connected in 2-wire connection to the left

4-fold terminal block (X7) of the docking station. No electrical connections

may be made to the right 4-fold terminal block (X8).

CAUTION

The category 1 marking has to be cut out from the rating-plate label. Once

the unit has been used after installation in the above manner, it may never

be installed in explosion-hazard areas of Zone 0 or Zone 1 (device

category 1 or 2). Explosion hazard!

Electrical connections

Connection to the control unit

Connect shield to earth of central unit (e.g. housing, earth bar, etc.).

CAUTION

In the case of PROFIBUS devices, the shield must only be connected on one

side of the cable to earth.

15

Page 16

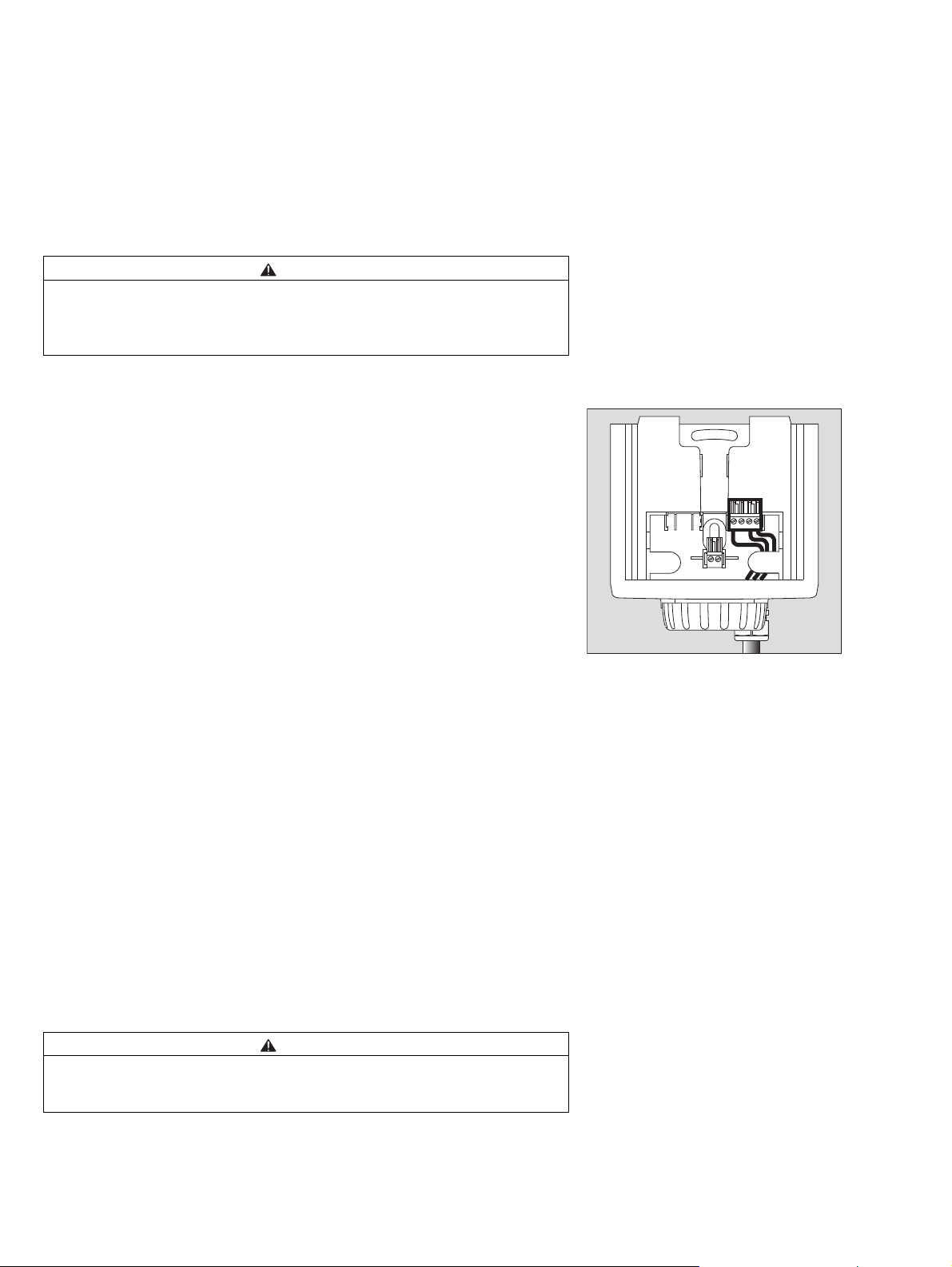

Electrical connections

01123758_1.eps

1

X8

+24 V

0 V

0 V

Signal

3-wire connection

— Connection to central device with at least 3-wire cable, 0.5 (AWG 20) to

2.5 mm2 (AWG 13).

CAUTION

The supplied ferrite sleeves are to be used when installing the transmitter in

three-wire technology.

A ferrite sleeve must be pushed onto each core prior to connecting the cable

to the four-pole terminal in the docking station.

Installing the 4 to 20 mA current loop on the transmitter

Install the 3-wire connection cable in the cable gland, cut it to length and

strip off the insulation (about 80 mm).

Shorten the shield (if installed) to prevent short-circuiting:

Connect cable

1 4-pin terminal for Dräger Polytron 7000 – observe polarity.

Slide connecting terminal back into holder.

Secure cable in holder.

Fold up the installation notes and place them in the Dräger docking station

for future use during commissioning.

Refit raincover (protection against dust and splashing water).

Connection to the control unit

Connect shield to earth of central unit (e.g. housing, earth bar, etc.).

Connecting the Dräger Polytron 7000 transmitter to a Dräger control unit

(such as Regard, QuadGard, Unigard or Polytron):

— Further information about the connection can be found in the instructions

for the Dräger control unit.

— When operated from the mains supply, the Polytron control unit provides a

supply voltage of at least 20 V. This must be taken into account when determining the maximum cable length (see the table on page 21).

— Unigard is not suitable for the connection of a Polytron 7000 transmitter

equipped with a relay or pump module.

Connecting the Dräger Polytron 7000 transmitter to control units with

a 4 to 20 mA interfaced made by other manufacturers:

— Further information about the connection can be found in the instructions

for the control unit being used.

Installing the transmitter in non-explosion-hazard areas:

CAUTION

Remove the explosion-protection markings from the transmitter. Once the

transmitter has been used after installation in this manner, it may never be

installed in explosion-hazard areas. Explosion hazard!

— When installing a transmitter in a non-explosion-hazard area, connect the

cable shield and the negative pole of the supply voltage to earth at the

switch cabinet or distribution panel.

16

Page 17

— Ensure that the supply voltage provided by the control unit (ignoring the

01223758_1_en.eps

Non-explosion-hazard area

Control unit

4 ... 20 mA

0 V

+

–

+

load resistance) is at least as high as specified in the tables of page 21 to

page 22.

— If digital communication in accordance with HART is to be used, the load

resistance of the supply unit must lie between 230 and 500 Ω.

— The permissible cable lengths are shown in the tables on page 21 to

page 22. In each case, use the line marked "Number of transmitters = 1".

Electrical connections

17

Page 18

Electrical connections

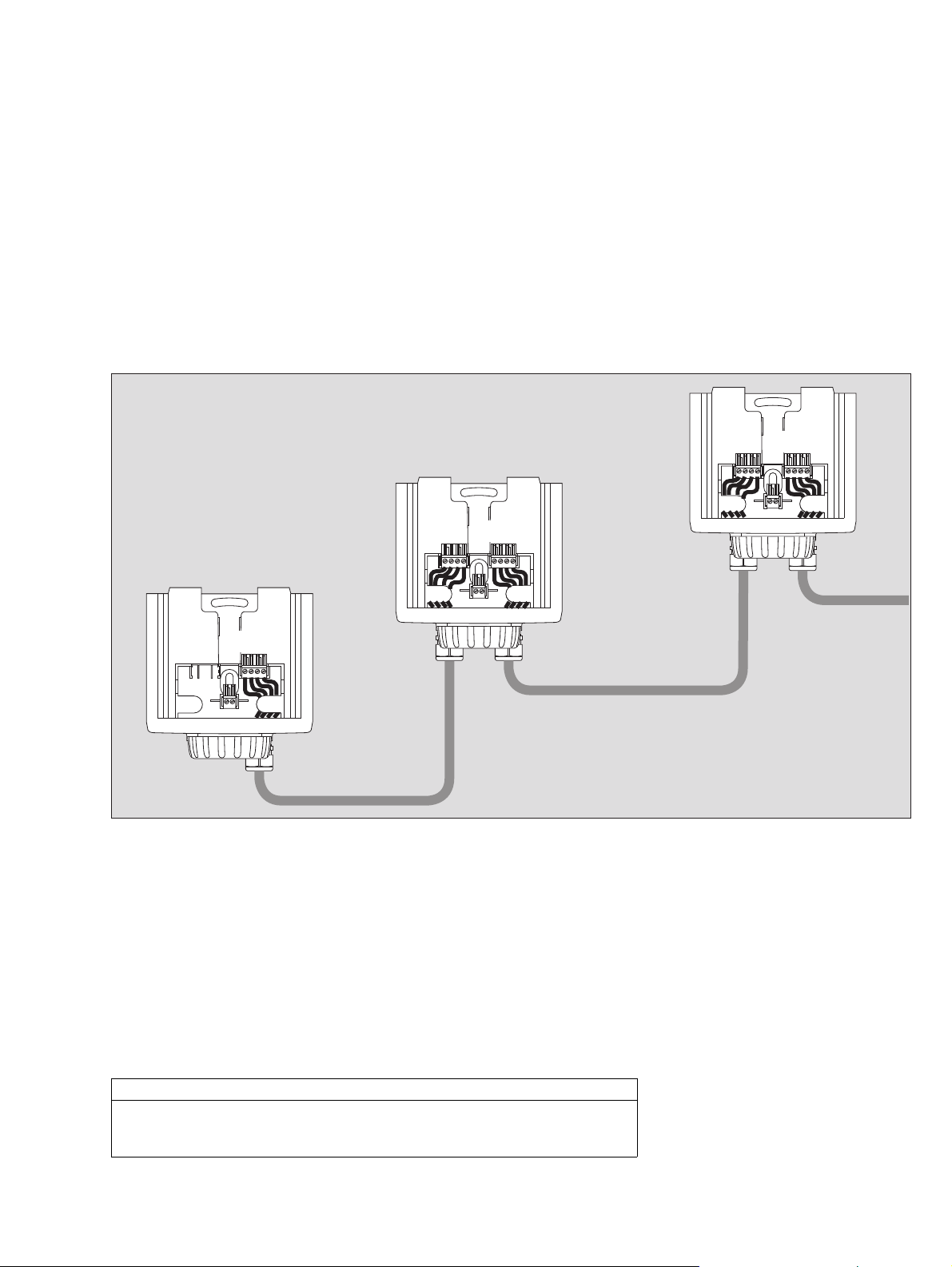

Connections between several transmitters and a control unit with HART multidrop connections

Each transmitter must first be put into service separately. Use the menu

item "Polling Address" to assign a different polling address in the range "1"

to "15" to each transmitter which is to be connected to the multidrop cable

(see page 70). It is best to assign sequential polling addresses, starting with

"1".

Installing the transmitters in areas subject to explosion hazards of zone

0 or zone 1

Depending on the supply unit, up to 7 transmitters can be connected to a 2-

wire or 3-wire cable.

The second cable gland is used for the cable to the next transmitter.

Install a safety barrier with the appropriate explosion protection approval

(category 1, 2 or Div. 1) between the transmitter and the control unit.

— Only safety barriers with the following characteristics may be used: Uo (Voc)

≤30 V, Io (Isc) ≤0.3 A, Po ≤700 mW.

— Take care that the maximum permissible capacitance and inductance of

connections to the safety barrier are not exceeded, also taking the cable

into account. The safety-related input parameters of the transmitter are: Ci

= 5 nF, Li = 50 µH.

— The safety barrier must be capable of transmitting the communications sig-

nals in both directions between the explosion-hazard area and the non-explosion-hazard area. Several manufacturers offer special SMART

transmitter supply units for this purpose.

SMART transmitter supply units

(with HART-communication between Ex/Non-Ex area)

The following safety barriers are provided as examples only and have not

been certified for use in combination with the P3U. Selected barriers must be

acceptable to the authority having jurisdiction and comply with the assigned

P3U entity parameters also taking the cable into account.

Manufacturer Type suitable for

RN 221 N–B1

(ATEX)

Endress +

Hauser

MTL MTL 5042 Zone 0, Div.

Pepperl & Fuchs KFD2–STC4–Ex1 Zone 0, Div.

— If a HART hand-held terminal is used, the permissible values may be lower.

Observe the safety-related parameters of the hand-held terminal.

RN 221 N–C1 (FM)

RN 221 N–D1 (CSA)

RN 221 N–E1 (TIIS)

Zone 0

Div. 1

1

1

for up to

5 transmitters

≤ 120 Ω ≤ 50 Ω –––

≤ 33 Ω ≤ 27 Ω ≤ 20 Ω

≤ 90 Ω ≤ 10 Ω –––

R

(Total)

Cable

for up to

6 transmitters

for up to

7 transmitters

18

Page 19

— The cable resistances given apply for the maximum possible number of

transmitters as well as a load resistance of 250 Ω. Higher load resistances

can drastically reduce the maximum possible cable resistance!

The following tables show permissible combinations of transmitters, supply

voltages and maximum possible cable lengths.

— The capacitance values are typical values for commercially available

shielded cables with PVC insulation. The use of cables with different capacity values will result in other cable lengths.

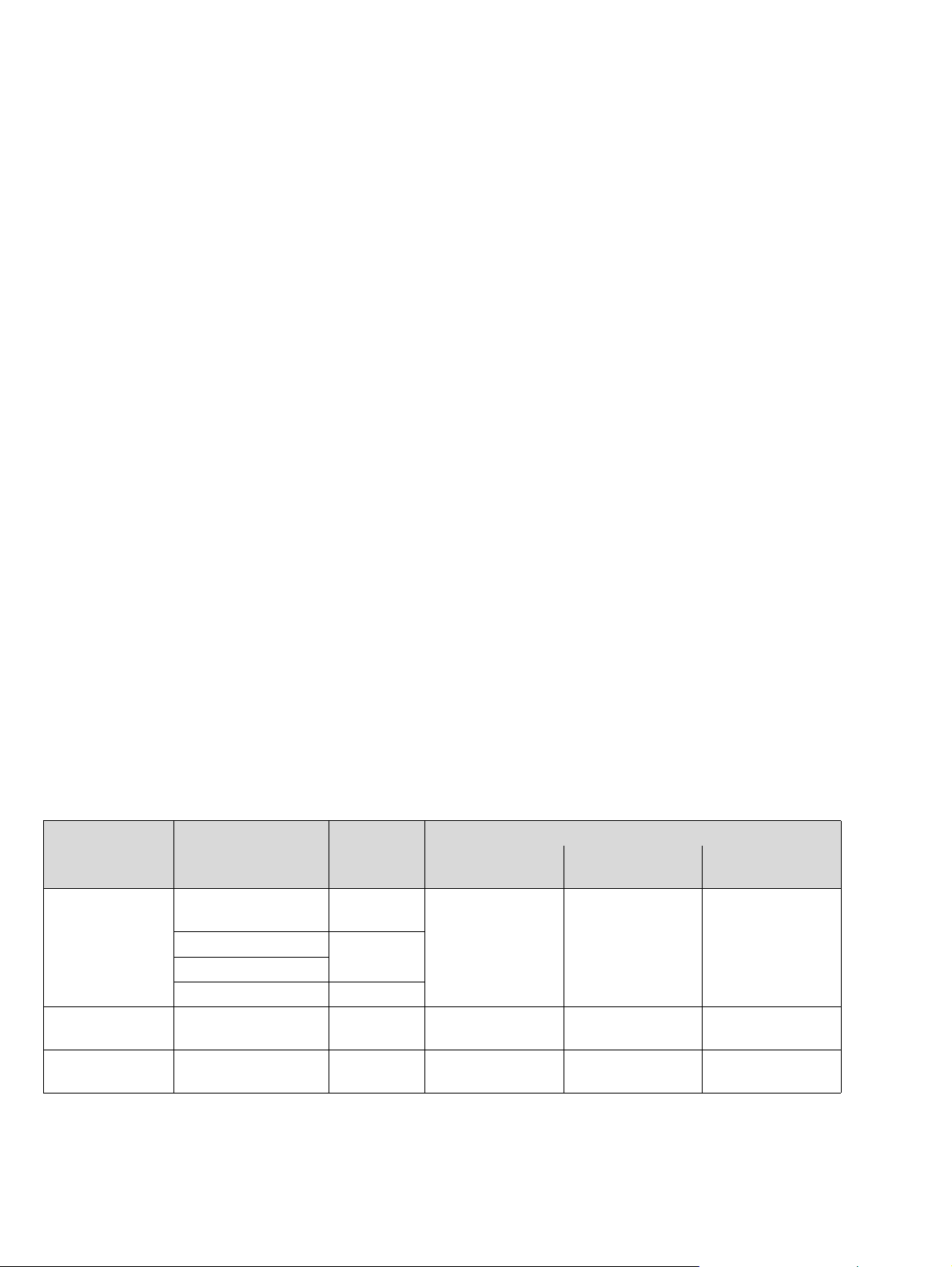

Maximum possible cable length

Transmitter

supply unit

Number of trans-

mitters

0.5 mm

265 pF/m

2

0.75 mm

320 pF/m

2

1 1042 m 921 m 828 m 792 m

2 1007 m 890 m 801 m 766 m

Endress +

Hauser:

RN 221 N

3 972 m 860 m 774 m 740 m

4 936 m 829 m 747 m 714 m

5 901 m 799 m 720 m 689 m

6 702 m 768 m 693 m 663 m

1 463 m 695 m 828 m 792 m

2 463 m 695 m 801 m 766 m

3 463 m 695 m 774 m 740 m

MTL:

MTL 5042

4 463 m 695 m 747 m 714 m

5 463 m 695 m 720 m 689 m

6 379 m 569 m 693 m 663 m

7 281 m 421 m 666 m 637 m

1 1042 m 921 m 828 m 792 m

2 1007 m 890 m 801 m 766 m

Pepperl & Fuchs:

KFD2–STC4–Ex1

3 972 m 860 m 774 m 740 m

4 936 m 829 m 747 m 714 m

5 901 m 799 m 720 m 689 m

6 140 m 211 m 421 m 663 m

1 1042 m 921 m 828 m 792 m

2 1007 m 890 m 801 m 766 m

3 972 m 860 m 774 m 740 m

Stahl:

9160/13–11–11

4 936 m 829 m 747 m 714 m

5 901 m 799 m 720 m 689 m

6 865 m 768 m 693 m 663 m

7 281 m 421 m 666 m 637 m

1.5 mm

375 pF/m

Electrical connections

2

2.5 mm

400 pF/m

2

19

Page 20

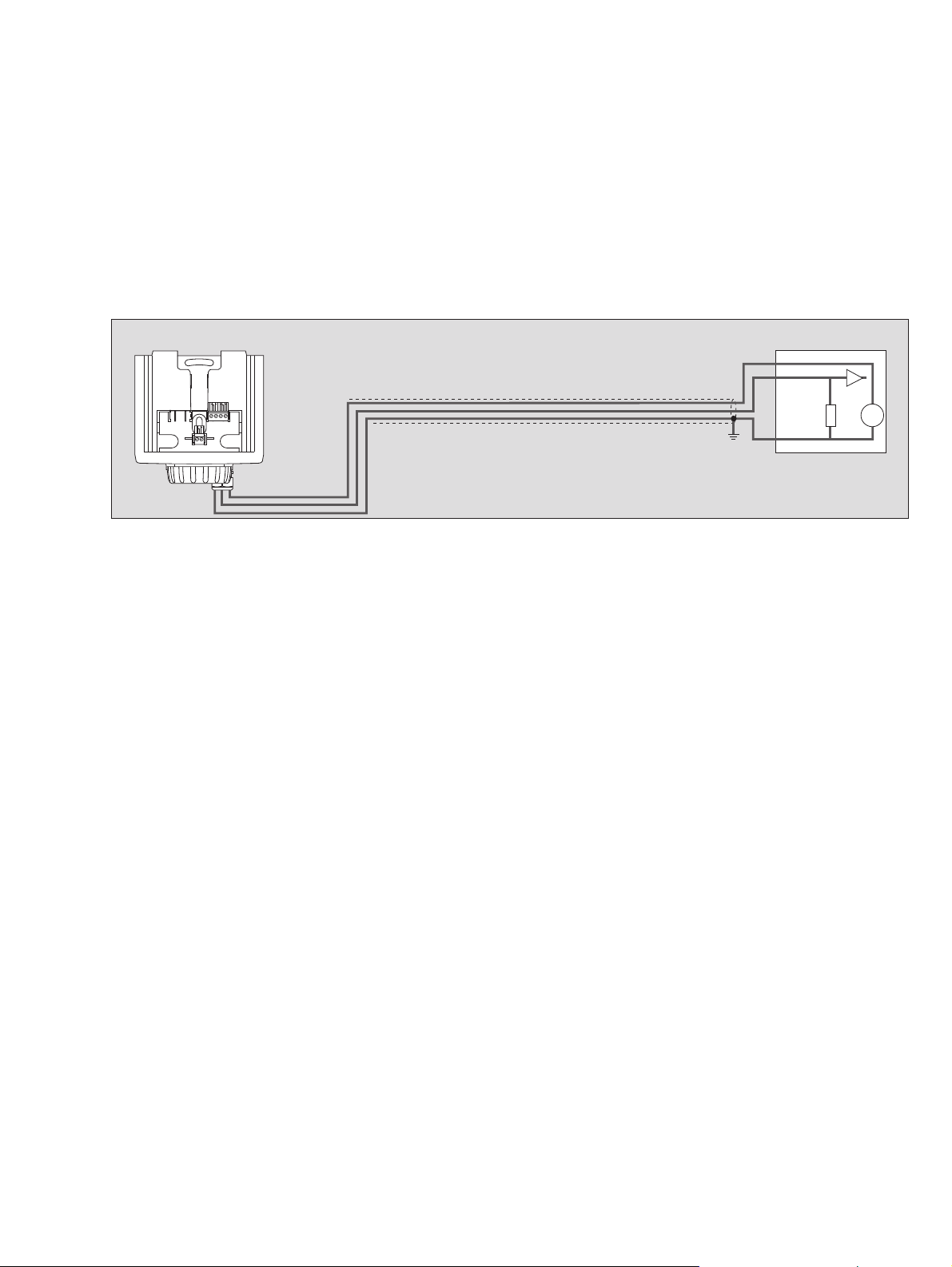

Electrical connections

01523758_1.eps

0 V

0 V

Signal

24 V

0 V

0 V

Signal

24 V

0 V

0 V

Signal

24 V

0 V

0 V

Signal

24 V

0 V

0 V

Signal

24 V

X7 X7 X8X8 X8

Installing the transmitters in explosion-hazard areas of zone 2 without a

safety barrier

— Use only supply units of the device category 3.

For safety reasons, we recommend that not more than 8 transmitters be

connected to a 2-wire or 3-wire cable.

— Take care that the maximum permissible capacitance and inductance of

connections to the supply unit are not exceeded, also taking the cable into

account.

The safety-related input parameters of the transmitter are:

Ci = 5 nF, Li = 50 µH.

CAUTION

The category 1 marking has to be cut out from the rating-plate label. Once

the unit has been used after installation in the above manner, it may never

be installed in explosion-hazard areas of zone 0 or zone 1 (device category 1

or 2). Explosion hazard!

Installing the transmitter in non-explosion-hazard areas:

For safety reasons, we recommend that not more than 8 transmitters be

connected to a 2-wire or 3-wire cable.

If the transmitters are equipped with relay or pump modules, not more than

4 transmitters should be connected to one cable.

The second cable gland is used for the cable to the next transmitter.

CAUTION

The explosion-protection marking has to be removed from the transmitter.

Once the transmitter has been used after installation in this manner, it may

never be installed in explosion-hazard areas. Explosion hazard!

The following tables show permissible combinations of transmitters, supply

voltages and maximum possible cable lengths.

— The capacitance values are typical values for commercially available

shielded cables with PVC insulation. The use of cables with different capacity values will result in other cable lengths.

20

Page 21

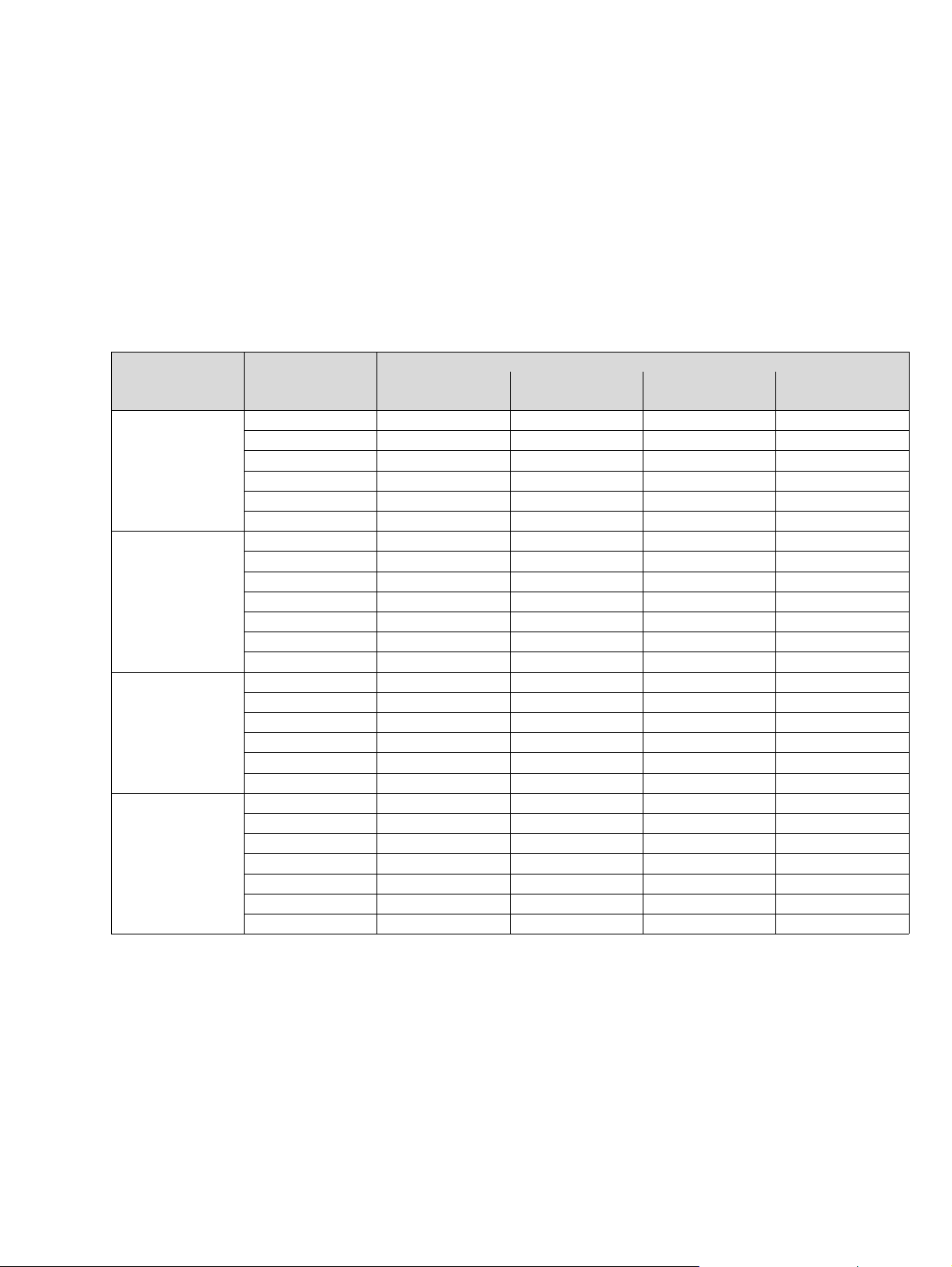

Transmitter without relay or pump module (2-wire):

Maximum cable length with a load resistance of 250 Ω

Minimum

supply voltage

Number of trans-

mitters

0.5 mm

265 pF/m

2

1 1042 m 921 m 828 m 792 m

2 1007 m 890 m 801 m 766 m

20 V

3 972 m 860 m 774 m 740 m

4 585 m 829 m 747 m 714 m

4 936 m 829 m 747 m 714 m

5 901 m 799 m 720 m 689 m

24 V

6 865 m 768 m 693 m 663 m

7 830 m 737 m 666 m 637 m

8 794 m 707 m 639 m 611 m

9 390 m 585 m 612 m 586 m

9 758 m 676 m 612 m 586 m

10 722 m 645 m 584 m 560 m

11 687 m 614 m 557 m 534 m

28 V

12 651 m 584 m 530 m 508 m

13 616 m 553 m 503 m 482 m

14 334 m 502 m 476 m 456 m

15 78 m 117 m 234 m 390 m

0.75 mm

320 pF/m

Electrical connections

2

1.5 mm

375 pF/m

2

2.5 mm

2

400 pF/m

Transmitter with relay module (3-wire):

Minimum

supply voltage

Number of trans-

mitters

1 287 m 431 m 828 m 792 m

2 144 m 216 m 431 m 718 m

20 V

3 96 m 144 m 287 m 479 m

4 72 m 108 m 216 m 359 m

1 386 m 579 m 828 m 792 m

2 193 m 289 m 579 m 766 m

24 V

3 129 m 193 m 386 m 643 m

4 96 m 145 m 289 m 482 m

1 429 m 644 m 828 m 792 m

2 215 m 322 m 644 m 766 m

28 V

3 143 m 215 m 429 m 715 m

4 107 m 161 m 322 m 537 m

Maximum cable length with a load resistance of not more than 500 Ω

0.5 mm

265 pF/m

2

0.75 mm

320 pF/m

2

1.5 mm

375 pF/m

2

2.5 mm

400 pF/m

2

21

Page 22

Electrical connections

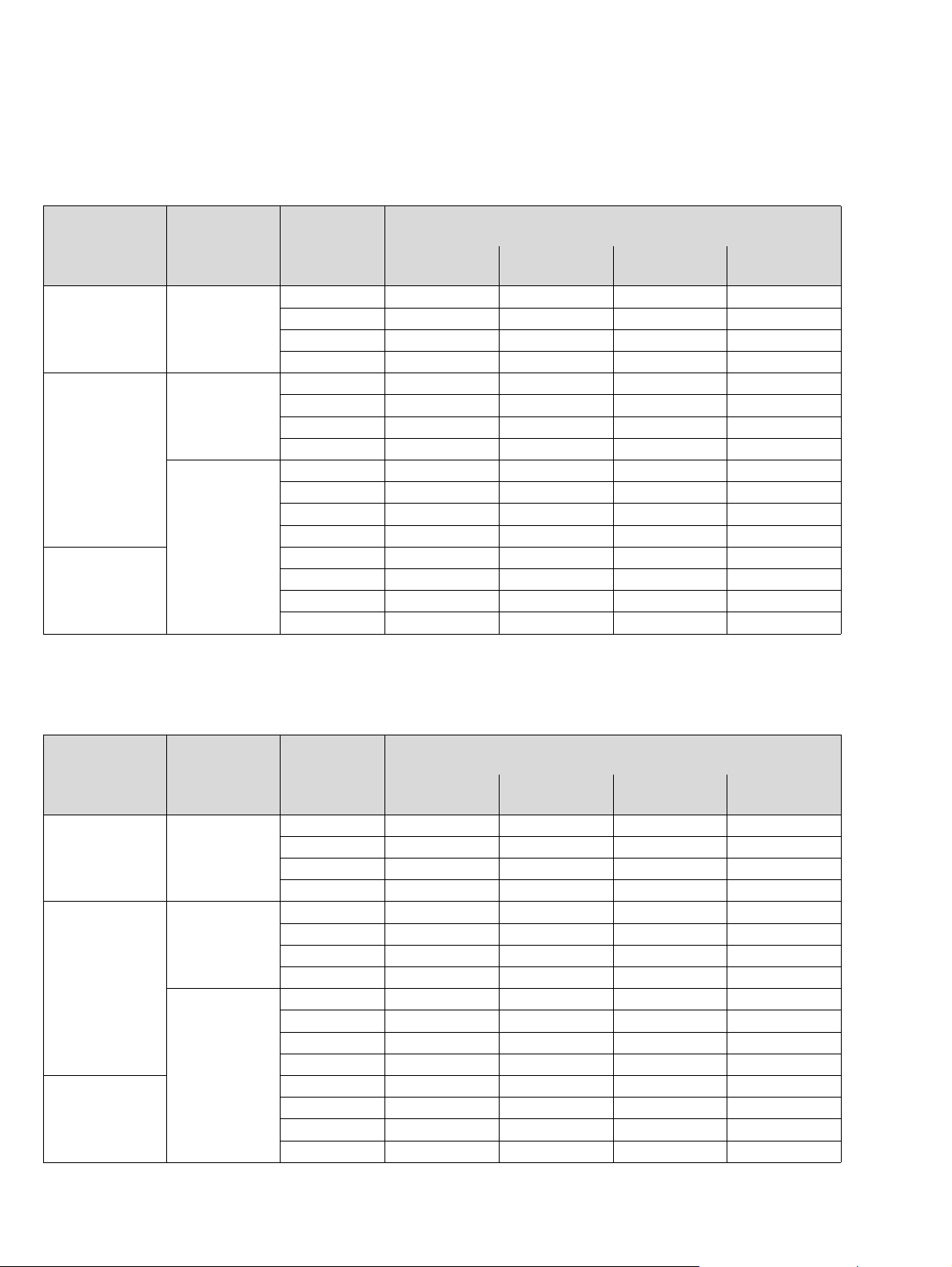

Transmitter with pump module (3-wire):

Minimum

supply voltage

Maximum pos-

sible

Number of

transmitters

flow-rate

20 V 0.5 L/min

1.0 L/min

24 V

1.5 L/min

28 V

Maximum cable length with a load resistance of not more than

500 Ω

0.5 mm

265 pF/m

2

0.75 mm

320 pF/m

2

1.5 mm

375 pF/m

2

2.5 mm

400 pF/m

1 161 m 241 m 482 m 792 m

2 80 m 120 m 241 m 401 m

3 54 m 80 m 161 m 268 m

4 40 m 60 m 120 m 201 m

1 233 m 349 m 699 m 792 m

2 116 m 175 m 349 m 582 m

3 78 m 116 m 233 m 388 m

4 58 m 87 m 175 m 291 m

1 135 m 203 m 406 m 586 m

2 68 m 102 m 203 m 338 m

3 45 m 68 m 135 m 226 m

4 34 m 51 m 102 m 169 m

1 271 m 406 m 812 m 792 m

2 135 m 203 m 406 m 677 m

3 90 m 135 m 271 m 451 m

4 68 m 102 m 203 m 338 m

2

Transmitter with relay and pump modules (3-wire):

Minimum

supply voltage

Maximum pos-

sible

Number of

transmitters

flow-rate

1 110 m 164 m 329 m 548 m

2 55 m 82 m 164 m 274 m

20 V 0.5 L/min

3 37 m 55 m 110 m 183 m

4 27 m 41 m 82 m 137 m

1 161 m 241 m 482 m 792 m

2 80 m 120 m 241 m 401 m

1.0 L/min

24 V

3 54 m 80 m 161 m 268 m

4 40 m 60 m 120 m 201 m

1 90 m 134 m 269 m 448 m

2 45 m 67 m 134 m 224 m

3 30 m 45 m 90 m 149 m

1.5 L/min

4 22 m 34 m 67 m 112 m

1 179 m 269 m 537 m 792 m

2 90 m 134 m 269 m 448 m

28 V

3 60 m 90 m 179 m 298 m

4 45 m 67 m 134 m 224 m

Maximum cable length with a load resistance of not more than

500 Ω

0.5 mm

265 pF/m

2

0.75 mm

320 pF/m

2

1.5 mm

375 pF/m

2

2.5 mm

2

400 pF/m

22

Page 23

4-wire connection

— Connection to central device with at least 4-wire cable, 0.5 (AWG 20) to

2.5 mm2 (AWG 13).

Installing the LON Communication on the transmitter

— For installation using LON communication up to 63 Polytron 7000 can be

connected to a four wire cable in any configuration including bus, star, loop

and mixed.

Electrical connections

X8X7

0 V

Signal

Signal

24 V

0 V

Signal

Signal

24 V

X7 X8

0 V

Signal

Signal

24 V

0 V

Signal

Signal

24 V

X8

0 V

Signal

Signal

24 V

Insert the 4-wire connecting cable in the cable gland, cut it to length and

strip the insulation (approx. 80 mm).

Shorten the shield (if installed) to prevent short-circuiting:

Connect cable

1 4-pin terminal for Dräger Polytron 7000 – observe polarity.

Slide connecting terminal back into holder.

Secure cable in holder.

Fold up the installation notes and place them in the Dräger docking station

for future use during commissioning.

Refit raincover (protection against dust and splashing water).

05723758_1.eps

Installing the transmitter in non-explosion-hazard areas:

CAUTION

With 4-core connection the transmitter has no Ex protection. Once the transmitter has been used after installation in this manner, it may never be

installed in explosion-hazard areas. Explosion hazard!

23

Page 24

Electrical connections

Installing fieldbus communication on the transmitter

— The PROFIBUS PA transmission technology for intrinsically safe applica-

tions is MBP. MBP stands for:

– Manchester Coding (M)

– Bus Powered (BP)

— 5 transmitters can be connected to a segment with a typical segment cur-

rent of 100 mA.

Install the 4-wire connection cable in the cable gland, cut it to length and

strip off the insulation (approx. 80 mm).

Shorten the shield (if installed) to prevent short-circuiting.

Connect cable:

1 4-pin terminal block for Dräger Polytron 7000, observing the polarity.

2 4-pin terminal block for Dräger Polytron 7000, observing the polarity.

Slide connecting terminal back into holder.

Secure cable in holder.

Fold up the installation notes and place them in the Dräger docking station

for future use during commissioning.

Refit raincover (protection against dust and splashing water).

X7 X8

FB –

FB +

1

+24 V

0 V

2

Installing the transmitter in 4-wire connection:

CAUTION

With 4-core connection the transmitter has no Ex protection. Once the transmitter has been used after installation in this manner, it may never be

installed in explosion-hazard areas. Explosion hazard!

01323758_4.eps

24

Page 25

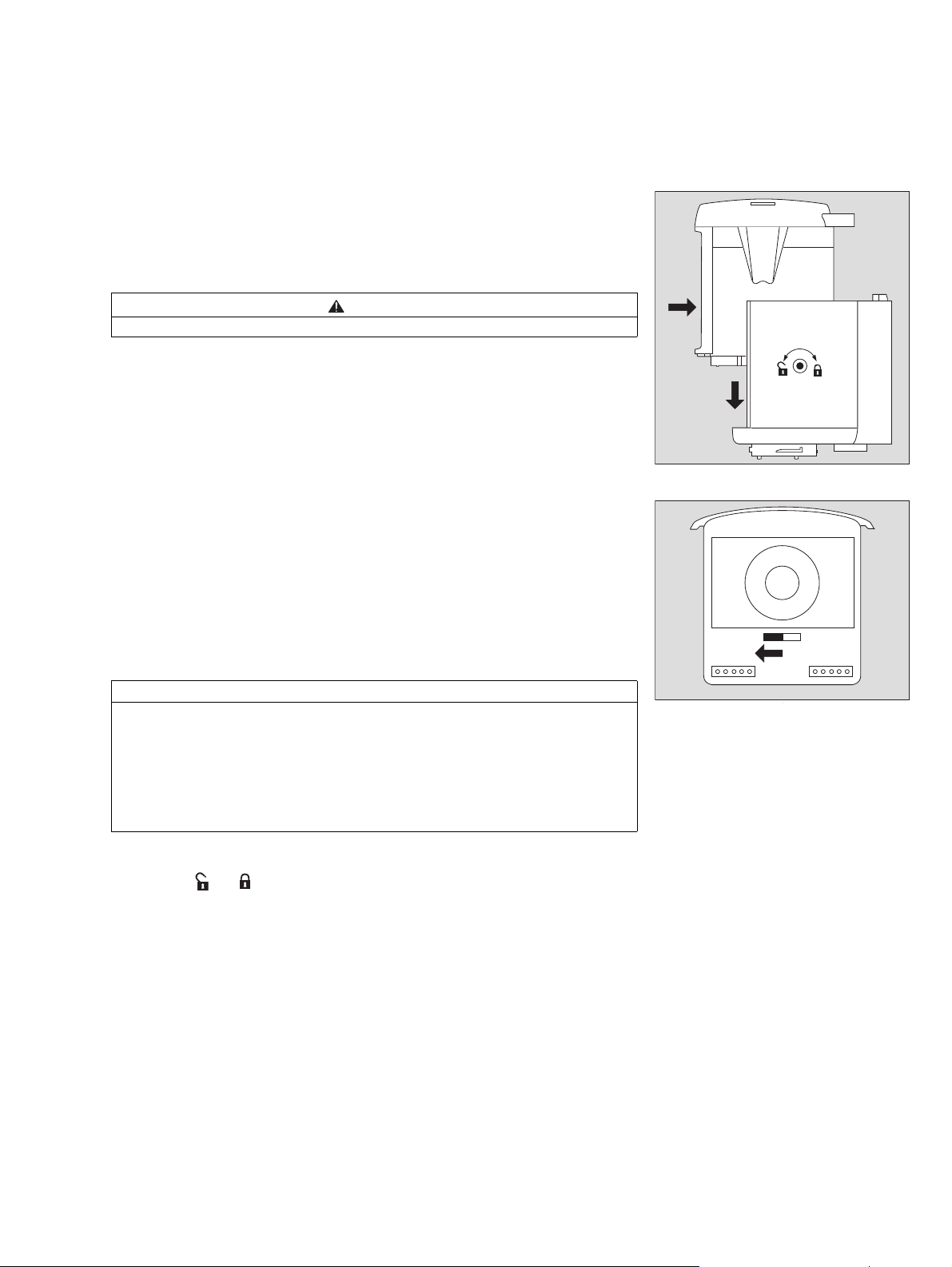

Installing the measuring unit Dräger Polytron 7000

Remove the rain cover from the previously installed docking station.

Examine seal for signs of dirt and clean if necessary.

1 Check position of eccentric catches and correct if necessary.

The eccentric opening must point upwards, engaged position.

CAUTION

Use only a 5 mm Allen key without a ball head.

Check the polarity and cable routing and check that the connector is se-

curely seated; rectify as necessary (see the installation notes for the Polytron docking station).

Unpack the Dräger Polytron 7000 measuring unit.

Electrical connections

2

3

1

Setting the switch for the backup battery

Check the position of the switch on the bottom of the unit.

This switch must be set to "on"; otherwise, the time, date and data saved in

the Datalogger and the Event Logger will be lost in the case of a power failure.

2 Insert the measuring unit about halfway up the docking station and slide it

in as far as it will go.

3 Lower the unit along the front edge of the docking station. About 5 mm be-

fore its hits the stop, the resistance will increase as the connector engages

with the socket on the printed circuit board.

NOTE

Check that the terminals in the docking station are correctly aligned if the

connector does not engage correctly!

Ensure that the front bottom of the measuring unit is flush with the bottom of

the Docking Station. Apply pressure to the measuring unit until it "clicks" into

place. If the fronts are not flush, the measuring unit is not completely sealed

and could get water inside the transmitter!

1 Turn the eccentric catches clockwise with an Allen key to lock the measur-

ing unit (

= approx. 180

o

).

01623758_1.eps

on off

05423758_1_en.eps

25

Page 26

Electrical connections

01723758_1.eps

1

Polytron

OK

Fitting the sensor

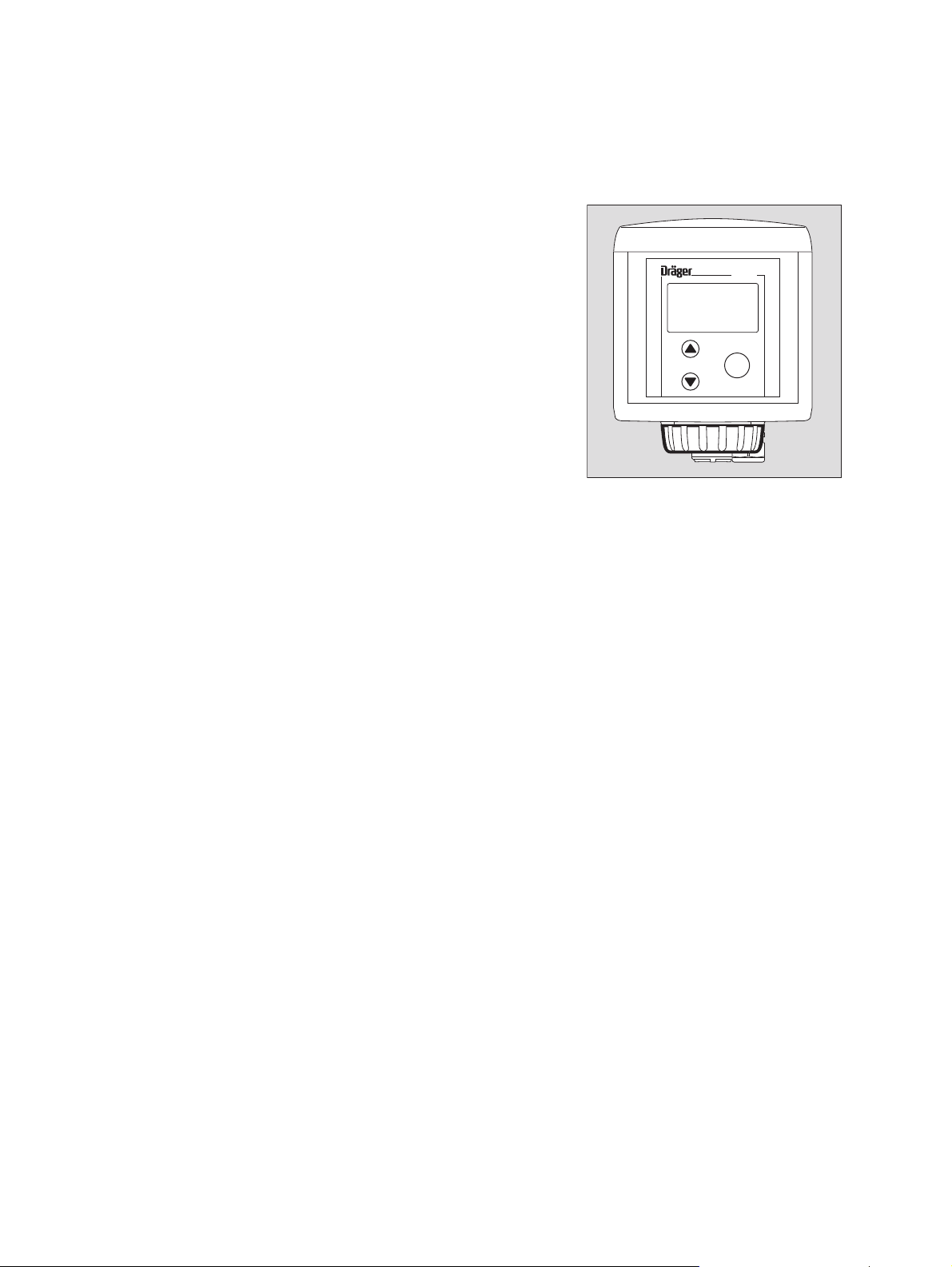

1 Remove bayonet ring from transmitter, remove dummy plate.

Remove sensor from packaging.

Remove the short-circuit strap from the sensor (if it is fitted).

There is a coded connector on the back of the sensor. Place the sensor in

the opening with the connector at the back and the Dräger logo at the front.

Before plugging the connector in the socket, ensure that they are identically

coded. Incorrect connection can damage the sensor!

Secure sensor in transmitter with bayonet ring.

If necessary, calibrate the sensor as described on page 44.

If pre-calibrated sensors are used, the alarm chain must be tested with, for

example, the bump test.

26

Page 27

Installing accessories

Various accessories are available for the Dräger Polytron 7000 transmitter

and may also be installed later.

Daisy chain kit – Cable Entry Kit

Intended use

Daisy chain kit – 83 17 282:

— For the connection of several transmitters to one bus cable (daisy chain or

multidrop connection)

Contents of the kit

— Cable gland with nut, 4-pole orange terminal block

Installing accessories

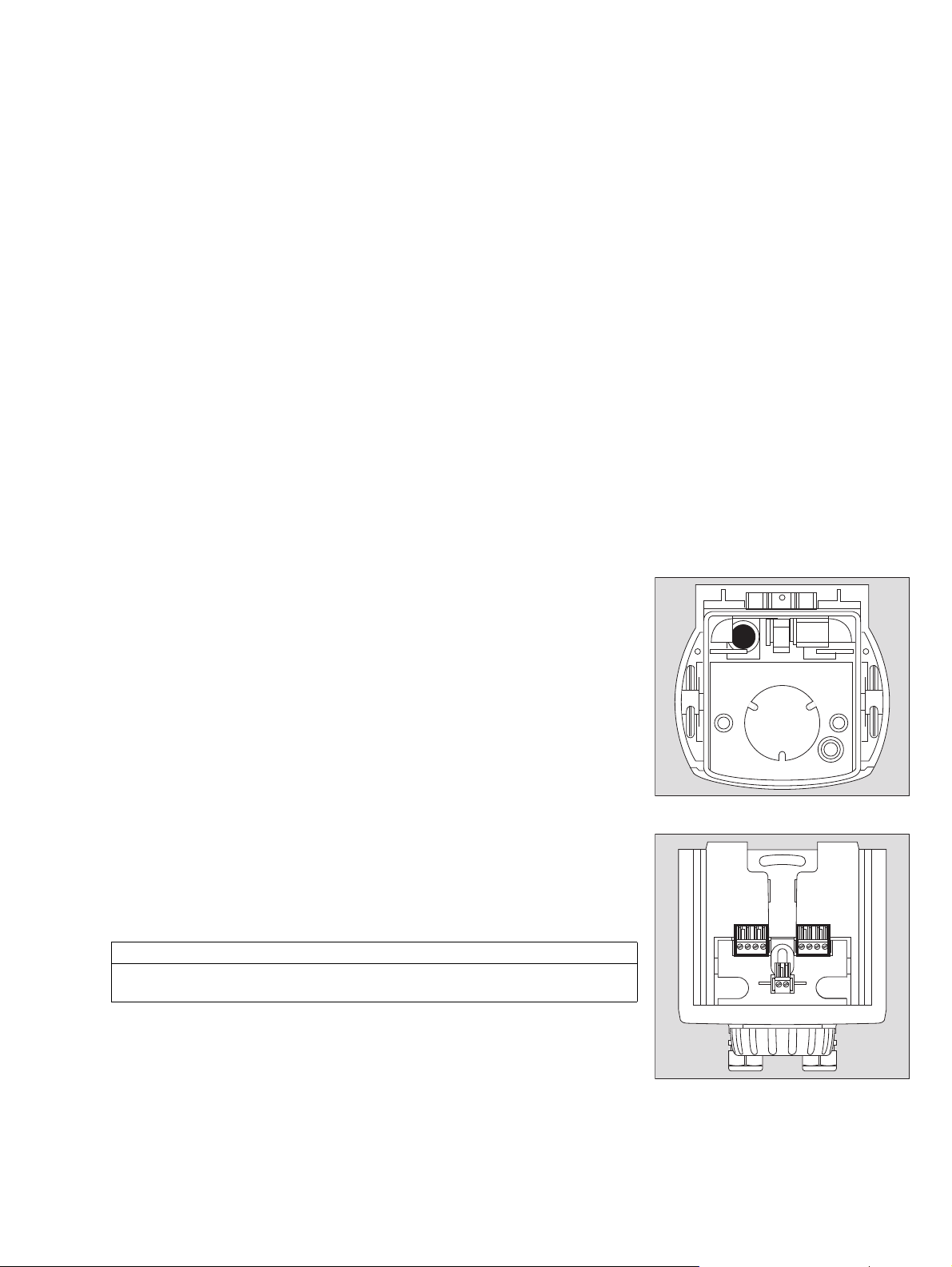

Preparing the docking station

Install the docking station as described in the installation notes 90 23 760.

1 Break or drill out the prepared breakthrough for the second cable gland

from the inside of the docking station.

The hole should have a diameter of 20.5 mm.

Check that the docking station has no loose parts, and clean it if necessary.

Insert the nut of the cable gland into the docking station.

Screw in the cable gland from the outside of the docking station and tighten

it.

Electrical connections

Connect the wiring as described in the installation notes for the docking

station (90 23 760).

2 Insert the 4-pole terminal block into the holder on the mounting plate.

If necessary:

refit the raincover (protection against dust and splashing water).

NOTE

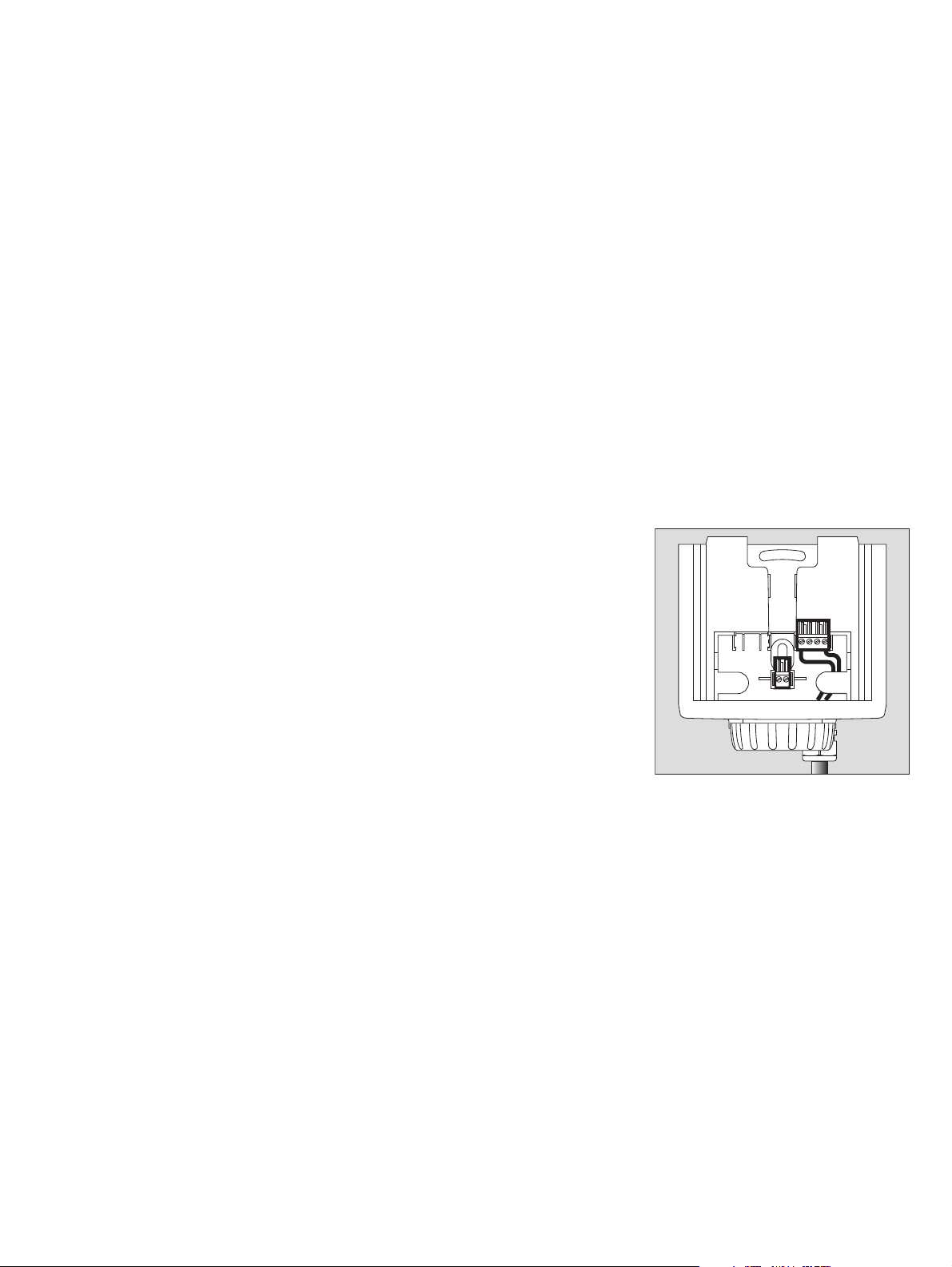

The two 4-pole terminal blocks for input (3) and output (2) are electrically

connected 1:1 to each other inside the transmitter.

1

01823758_1.eps

X7 X8

23

Installing the measuring unit

Install the measuring unit as described in the installation notes 90 23 759.

— Due to the second terminal block, the resistance when installing the meas-

uring unit is slightly higher.

Make sure that the measuring unit is fully lowered and hits the stop.

01923758_2.eps

27

Page 28

Installing accessories

02123758_1.eps

2

3

Remote sensor

Intended use

Remote Sensor Adapter Polytron 7000 - 83 17 275:

— For installation of the sensor at a distance of up to 30 m from the

Polytron 7000 transmitter.

Remote Cable + Sensor plug 5 m Polytron 7000 – 83 17 270Remote Cable +

Sensor adapter, 15 m Polytron 7000 – 83 17 998,

Remote Cable + Sensor plug 30 m Polytron 7000 – 83 17 999:

CAUTION

The cable of the remote adapter may be shortened at the end with the connector. The cable may not be extended. The use of a different cable is not

permitted!

If a Remote Sensor Adapter with sensor is used on a transmitter installed in

accordance with device category 3:

CAUTION

Remove the Category 1 marking from the transmitter. After being installed in

the manner described here, the accessory may never be used in explosionhazard areas of zone 0 or zone 1 (device category 1 or 2)! Explosion hazard!

1

1

02023758_1.eps

If a Remote Sensor Adapter with sensor is used on a transmitter installed in a

non-explosion-hazard area:

CAUTION

Remove the explosion-protection marking from the transmitter. After being

installed in the manner described here, the accessory may never be used in

explosion-hazard areas! Explosion hazard!

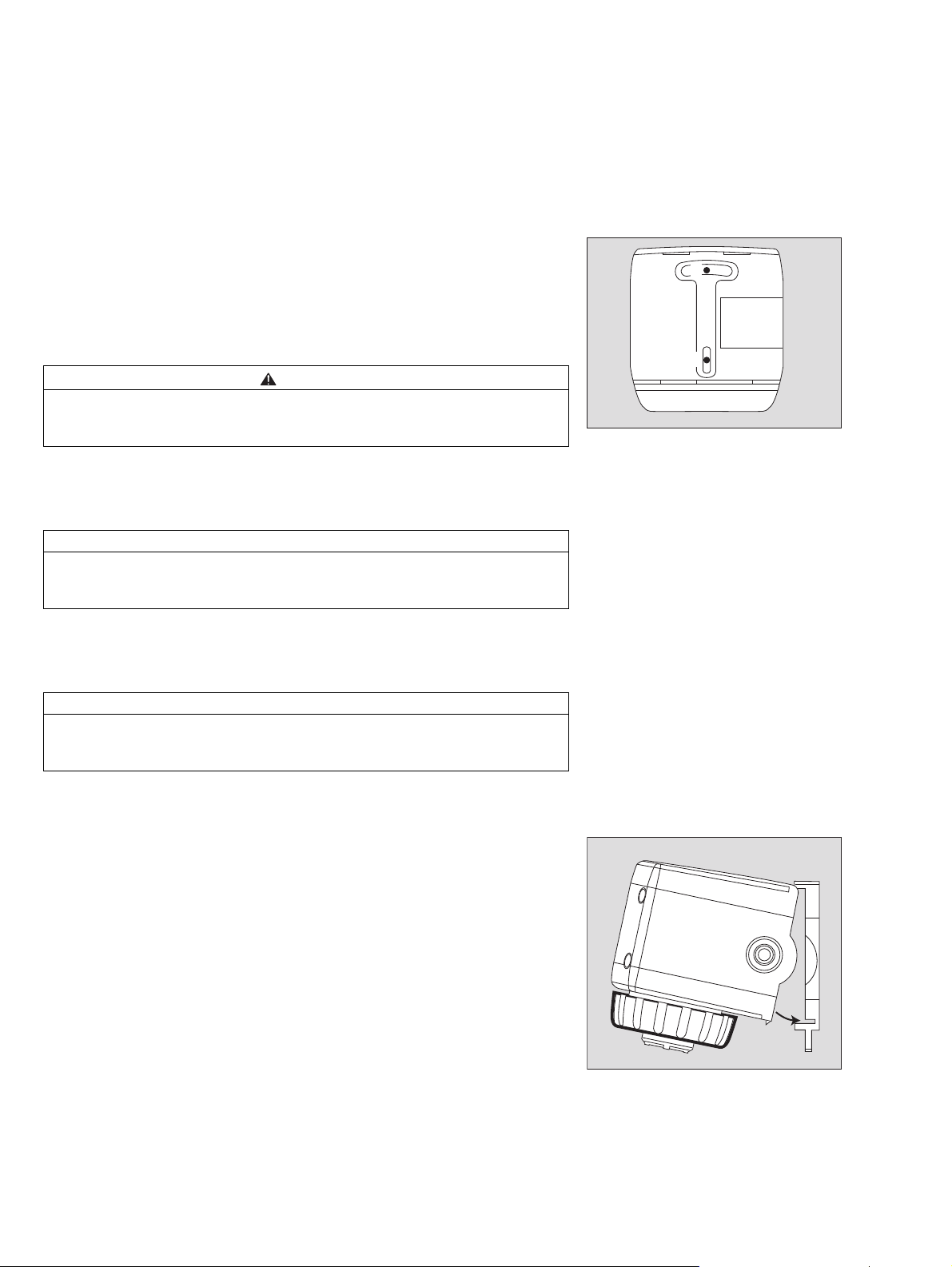

Wall mounting

1 Drill the holes for the mounting plate. (A drilling template is provided for this

on page 141). The mounting holes are 50 ±4 mm apart.

Screw the mounting plate of the remote sensor adapter to the wall at the

desired position.

2 Slide the case of the remote sensor on to the mounting plate until it snaps

into position.

Installing the sensor

3 Unscrew the bayonet ring from the transmitter and remove the blanking

disc.

Remove sensor from packaging.

Insert the sensor in the opening with the "Dräger" logo pointing to the front.

Secure the sensor with the bayonet ring.

28

Page 29

Connecting to the Polytron 7000

Remote sensor adapter

Installing accessories

4

Remote Cable

5 m / 15 m / 30 m

Connector

4 Connect the plug of the Remote Cable (cable length 5, 15 or 30 m) to the

remote sensor adapter and secure it by turning the ring clockwise.

5 Insert the sensor plug in the opening on the Dräger Polytron 7000 transmit-

ter with the "Dräger" logo pointing to the front.

Secure the sensor plug with the bayonet ring.

NOTE

The remote sensor is recognised automatically by the transmitter. No further

installation steps are required.

Duct adapter for remote sensor

5

Sensor plug

02223758_1_en.eps

Purpose

Duct adapter for remote sensor – 83 17 617:

— For mounting a remote sensor on a pipe or duct,

— For measuring the gas concentration in the pipe or duct.

Mounting

Drill a hole for the sensor opening (diameter 35+1 mm) at the desired meas-

uring point on the pipe.

Button the sealing sleeve into the hole.

Align the retaining clip so that it is centred on the hole.

1 Drill the holes for the securing screws. A drilling template is provided on

page 141.

2 Loosen the bayonet ring of the remote sensor.

3 Place the retaining clip on the pipe of the case and install the bayonet ring

again.

Insert the sensor opening into the sealing sleeve.

Turn the retaining clip to the correct position and screw it down.

1

1

02323758_1.eps

3

2

02423758_1.eps

29

Page 30

Installing accessories

02523758_1.eps

2

1

NOTE

To avoid faulty measurements, pay close attention to the fitting of the sensor

in the sealing sleeve!

Removal/changing the sensor

Loosen the securing screws.

Swing the retaining clip to one side.

Pull the remote sensor out of the sealing sleeve.

Change the sensor.

Install the remote sensor again.

Dräger Polytron 7000 software dongles

Intended use

Dräger Polytron 7000 software dongle – 83 17 618, 83 17 619 or 83 17 860:

— For activating additional functions in the Dräger Polytron 7000:

Data Dongle

83 17 618

Colour-code blue

Sensor Dongle

83 17 619

Colour-code silver

Sensor Diagnostic Dongle

83 17 860

Colour-code green

Installing the software dongles

1 Release the measuring unit with an Allen key by turning the eccentric catch-

es counter-clockwise ( = approx. 180o).

Use only a 5 mm Allen key without a ball head.

2 Push the measuring unit up to about half height and then pull it forwards out

of the docking station.

— The unit must be disconnected from the mains!

— Activates the Event Logger, the Datalogger

and the graphical concentration display.

— Activates the sensor self-test.

— Activates the sensor self-test, the display of

the remaining sensor lifetime and the sensor

diagnostic function.

NOTE

30

Page 31

3 Bend the snap-hooks on the cover of the measuring unit slightly outwards

to release them.

4 Remove the cover.

Installing accessories

4

Polytron

5 Hold the dongle with the "Dräger" logo pointing towards the measuring unit.

Then insert the dongle into any of the three slots.

Up to three dongles may be installed simultaneously.

Place the cover on the measuring unit and press it down until it snaps into

position.

CAUTION

6 Take care that pressure is applied only to the sleeve (6) of measuring unit.

Pressure on the inner structure can damage the unit.

7 Slide the measuring unit into the docking station and lower it into position,

see page 25.

8 Turn the eccentric catches clockwise with an Allen key to lock the measur-

ing unit ( = approx. 180o)

.

NOTE

Correct operation of the software dongle can be checked by switching

the measuring unit on and selecting the menu items » Information «,

» Instrument «, » Module « from the unit menu, see page 55.

3

OK

3

02623758_1.eps

5655

02723758_1.eps

7

8

31

02823758_1.eps

Page 32

Installing accessories

02923758_1.eps

2

1

03023758_1.eps

Polytron

OK

33

Relay module

Intended use

Relay module – to order:

— For switching of actuators, alarm generators, etc. on the basis of the meas-

ured gas concentration.

— The unit must be disconnected from the mains!

CAUTION

If a Polytron 7000 is subsequently equipped with the relay module and/or

the pump module, the complete unit loses its explosion-protection approval.

The user must ensure that no related approval markings are left on the Polytron 7000. The explosion-protection markings has to be removed from the

transmitter.

The use of the Polytron 7000 with a pump module and/or relay module

installed is not permitted in explosion-hazard areas! Explosion hazard!

NOTE

For operation with the relay module, the transmitter must have a 3-wire connection to the control unit.

Preparing the docking station

Remove any existing explosion-protection label from the docking station.

1 Release the measuring unit with an Allen key by turning the eccentric catch-

es counter-clockwise ( = approx. 180o).

CAUTION

Use only a 5 mm Allen key without a ball head.

2 Slide the measuring unit halfway upwards and then pull it forward out of the

docking station.

Converting the measuring unit

3 Bend the snap-hooks on the cover of the measuring unit slightly outwards

to release them.

Remove the cover.

32

Page 33

4 Plug the connection cable into the male connector behind the display, en-

03323758_1.eps

7

8

suring that the cable is not twisted.

Place the relay module on the measuring unit and snap it into position on

both sides.

In order to make this step easier, the relay cover may be removed.

CAUTION

5 Take care that pressure is applied only to the sleeve of measuring unit.

Pressure on the inner structure can damage the unit.

After connecting the relay module to the measuring unit:

6 Fit the cover again.

Installing accessories

5

4

03123758_1.eps

6

Mounting the measuring unit with relay module

7 Slide the measuring unit with relay module into the docking station and low-

er it into position, see page 25.

8 Turn the eccentric catches clockwise with an Allen key to lock the measur-

ing unit ( = approx. 180o).

Connecting the devices to be switched

The relay module has three 3 potential-free outputs, each capable of switching 250 V / 5 A:

— A1 relay (switches when the A1 gas alarm is active)

— A2 relay (switches when the A2 gas alarm is active)

— Fault relay (switches in the case of a device fault)

Setting the alarm thresholds: see page 64.

Connect the devices to be switched to the cable sockets.

Cable sockets of the following types may be used:

— Binder Type 692 Part No. 99–0210–00–04

— Amphenol Type C16-1 Part No. T 3109–001

— Hirschmann Type CA3 LD Part No. 934–125–100

— Dräger Safety Part No. 18 90 086

Polytron

OK

03223758_1.eps

33

Page 34

Installing accessories

03423758_1.eps

2

1

03523758_1.eps

33

Pin assignments of the built-in plug on the relay module:

(see also the inside of the relay cover)

1 normally closed

2 common

3 normally open

4 not connected

Note the assignments of the relay outputs on the relay cover.

Insert and lock the plug.

Close the relay cover.

Pump module

Intended use

Pump module – to order:

1 For drawing measuring gas from a remote site into the Dräger Polytron

7000 transmitter.

CAUTION

If a Polytron 7000 is subsequently equipped with the relay module and/or

the pump module, the complete unit loses its explosion-protection approval.

The user must ensure that no related approval markings are left on the Polytron 7000. Remove or cut away any existing approval label.

The use of the Polytron 7000 with a pump module and/or relay module

installed is not permitted in explosion-hazard areas! Explosion hazard!

Suitable explosion protection measures such as flame traps are required

when drawing measuring gas from potentially explosive atmospheres!

2

1

3

4

04423758_1.eps

NOTE

For operation with the pump module the electrical connection must be done

in 3-wire connection.

CAUTION

The Polytron 7000 must be disconnected from the supply voltage before the

pump module is installed. Explosion hazard!

Preparing the docking station

Remove any existing approval label/explosion-protection label from the

docking station.

1 Release the measuring unit with an Allen key by turning the eccentric catch-

es counter-clockwise ( = approx. 180o).

CAUTION

Use only a 5 mm Allen key without a ball head.

2 Slide the measuring unit halfway upwards and then pull it forward out of the

docking station.

3 Special gush holes are provided on the left and right-hand sides of the sen-

sor recess.

The glass tubes of the pump can be inserted in these holes.

Punch or drill the holes all the way through the docking station from inside.

Each hole should have a 6 mm channel.

Then deburr the holes from the outside.

34

Page 35

4 Check, from the bottom side of the docking station, that the holes go all the

way through.

Check that the docking station has no loose parts, and clean it if necessary.

3 Remove the O-rings from the glass tube and insert them into the grooves

on the bottom of the docking station.

Installing the pump in the transmitter

1 Bend the snap-hooks on the cover of the measuring unit slightly outwards

to release them.

Remove the cover.

Installing accessories

44

03623758_1.eps

Polytron

2 Plug the pump connecting cable to the terminal strip.

3 Slide the glass tube into the holes on the sides of the case and insert the

pump module into its holder. Lay the hoses so that they lie inside the case.

Place the cover on the measuring unit and press it down until it snaps into

position.

CAUTION

4 Take care that pressure is applied only to the sleeve of measuring unit.

Pressure on the inner structure can damage the unit.

11

OK

03723758_1.eps

2

03823758_1.eps

4

3

3

Insert the measuring unit about halfway up the docking station and slide it

in as far as it will go.

Lower the unit along the front edge of the docking station. About 5 mm be-

fore its hits the stop, the resistance will increase as the connector engages

with the socket on the printed circuit board.

03923758_1.eps

35

Page 36

Installing accessories

04023758_1.eps

5

6

06023758.eps

OK

1

2

++

––

5 Slide the measuring unit with pump module into the docking station and

lower it into position, see page 25.

6 Turn the eccentric catches clockwise with an Allen key to lock the measur-

ing unit ( = approx. 180o).

Installing the sensor and pump adapter

Unscrew the bayonet ring from the transmitter and remove the blanking

disc.

Place the sensor in the opening with the Dräger logo facing the front, and

push upwards gently until the connector engages.

1 Place the fastening ring over the sensor opening.

2 Secure the sensor with the bayonet ring.

The assembly direction of the pump adapter is determined by the gas flow

direction between pump and sensor:

— Connectors for intake and exhaust air point to the left, the symbol is vis-

ible from the front; the pump is positioned in front of the sensor in gas flow

direction; the sensor is positioned on the positive pressure side of the

pump. This is the preferred operating mode for all sensors.

— Connectors for intake and exhaust air point to the right, the symbol is

visible from the front; the pump is positioned behind the sensor in gas flow

direction; the sensor is positioned on the negative pressure side of the

pump. This operating mode should only be selected for special reasons.

CAUTION

This operating mode is not permissible for DrägerSensor O2 LS (6809630)

and DrägerSensor O

Insert the pump adapter sleeves into the holes on the underside of the

(6809720)!

2

docking station. The seal slides over the sensor.

1 Turn the securing ring clockwise until the pump adapter is secure.

Notes on installation of the inlet line

The material selected for the inlet hose or inlet pipe and the length of the inlet

line will affect the reaction time of the measured signal. In the worst cases,

reactions with the selected material, or absorption in this material, will prevent

a measurable gas concentration from reaching the sensor.

— Please contact your Dräger sales partner for choice on suitable selection of

tubing/hose.

— Maximum permissible pressure difference between flow inlet and the envi-

ronment of the transmitter: 50 mbar

36

Page 37

— The pressure difference between the flow inlet and the environment of the

transmitter can cause an additional measurement error.

CAUTION

In order to check for leaks, we recommend that you measure the flow at the

inlet point and behind the transmitter before using the pump module for the

first time and every six months thereafter.

Do not block the lower gas line of the pump adapter. This can damage the

gas sensor.

Installing accessories

37

Page 38

Start-up

Pioneering Solutions

Polytron 7000

A001_en.eps

Start-up

Switch on power supply.

The transmitter begins its warm-up routine:

— The software version, the date and the time are displayed.

NOTE

For the correct operation and functionality it is important to set the date

and time.

— The sensor is now warming up. The remaining warming-up time for the

sensor is displayed.

NOTE

Note on the operation with relay module:

During the warm-up period, the relay module indicates a fault. Alarms A1

and A2 are not indicated during the warm-up period.

— The sensor is ready for use.

SWversion: 8.0

29.10.11 11:47

Sensor ready

in 00

H2S

: 01 :

30

ppm

A003_en.eps

A004_de.eps

— Depending on the type of sensor installed, the warming-up period time may

last between 5 minutes and 12 hours. See the related information in the operating instructions for the sensor. The warm-up phase may take longer in

extremely high or low temperatures.

When the sensor has warmed up:

Calibrate sensor, page 44, when a pre-calibrated sensor is not used.

— Transmitter is ready for use.

Check the transmission of the signals between to the control unit and the

initiation of alarms, see the function group » Analogue interface « on

page 71.

0.0

H2S

ppm

A005_en.eps

38

Page 39

Analogue signal

A006_en.eps

O

2

Vol.%

20.9

A013_en.eps

O

2

A1

19.0

A007_en.eps

O

2

Vol.%

Y Y Y Y

A008_en.eps

O

2

Vol.%

X X X X

— A current between 4 and 20 mA flows through the transmitter during normal

operation. This current is proportional to the gas concentration.

— The Dräger Polytron 7000 transmitter uses various current values to indi-

cate the operational status of the transmitter:

Current Meaning

1)

4 mA

1)

20 mA

<3.2 mA

3.8 mA ... 4 mA

20 mA ... 20.5 mA

>23 mA Fault in analogue output

static signal: 3.4 mA

dynamic AC signal: 5 mA 1)for

0.4 seconds

and 3 mA1) for 0.7 seconds

Every 10 seconds

1 second2) <3.2 mA

1) Output current on delivery. The values may deviate by ±0.5 mA depending on the set

offset current.

2) Factory setting. Can be configured as desired, page 71.

Exceeding or falling below the transmitter supply voltage specified in the

technical data can lead to an incorrect display of the analogue signal!

Display

— In measuring mode, the display shows the actual gas concentration, e.g.:

1)

1)

1)

1)

2)

for

1)2)

Zero point

Full-scale value

Transmitter fault

Sensor drift below zero point

Full-scale value exceeded

Maintenance signal and signal during

the warm-up period

(configured on delivery: static)

Warning signal

(factory setting: off)

CAUTION

Start-up

An alarm is triggered:

— when rising above - for O

concentration alarm,

— When the full scale deflection is exceeded:

The special symbol » « is displayed instead of the measurement

value.

— The measured value drops below the measuring range:

The special symbol » « is displayed instead of the measurement

value.

also when falling below - the alarm levels for the

2

39

Page 40

Start-up

The following icons may be displayed on the right side of the display in

measuring mode in order to indicate the operating status of the unit:

A warning exists – see page 55 for information on how warnings are displayed.

The information can be retrieved in info mode, see page 40.

A fault exists – see page 55 for information on how faults are displayed.

Maintenance signal to the control unit, see page 75

A pump is installed.

There is a pump flow fault, see page 63

The measured value exceeds the full-scale value of the analogue interface

The measured value is less than the zero-point of the analogue interface

The analogue interface is set to a fixed value (e.g. for multidrop) and is not

transmitting measured values

"Predictive" maintenance: the sensor is ready for use

"Predictive" maintenance: the sensor is ready for use but nearing the end

of its operating lifetime

"Predictive" maintenance: the sensor is still ready for use but should be

replaced as soon as possible

The Datalogger is active in roll mode. For details on activating and deactivating the Datalogger, see page 79

The Datalogger is active in stack mode. For details of activating and deactivating the Datalogger, see page 81

Activating info mode

The info mode is used to display information on general unit settings and on

the unit status.

Press and hold the » « key (longer than 3 seconds) – information about

the units is displayed on several screens.

— Briefly press the » « key to move to the next screen.

— Briefly press the » « to move back to the previous screen.

— The info mode can be terminated at any time by pressing the » « key.

— If no key is pressed for 30 seconds, the unit automatically returns to its

previous state.

M

OK

0.0

H2S

Polytron

ppm

40

OK

M

04323758_1.eps

Page 41

Example of info mode:

A010_en.eps

2/4

Sensorname: O2

Part No. : 6809630

Serial No.

: XXXXXXX

EEPROM Typ

: 1

EEPROM Vers.: 1

Sensor Info

Screen 1

Instrument information

Line 1 – Date and time

Line 2 – Software version

Line 3 – Unit Part No.

Line 4 – Unit Serial No.

Line 5 – Unit code

Screen 2

Sensor information:

Line 1 – Sensor name

Line 2 – Sensor Part No.

Line 3 – Sensor Serial No.

Line 4 – EEPROM type

Line 5 – EEPROM version

Screen 3

Sensor configuration:

Line 1 – Gas name

Line 2 – Measuring range (can not be change) and unit of measurement

Line 3 – Measuring range for the analogue interface.

Displayed only, if the analogue interface card is installed

Line 4 – A1 alarm threshold and unit of measurement

Line 5 – A2 alarm threshold and unit of measurement

Screen 4

2)

1)

1)

Pump Infos:

Line 1 – Pump flow

Line 2 – Threshold error

Line 3 – Threshold warning

Line 4 – Pump run time

07.11.2011 12:34

SW Version

Part No.

Serial No.

DeviceCode: 00006317

Instrument Info

Gasname : O

Range : 25.00 Vo

4–20 SP

Alarm A1

Alarm A2

Sensor Config.

Power : XXX %

Fault : X.X l/min

Warning : X.X l/min

Op.time : XXXX h

: 8.0

: 8317778

: ARUA0001

2

: 25.00 Vo

: 19.00 Vo

: 23.00 Vo

Pump info

Start-up

1/4

A009_en.eps

3/4

A011_en.eps

4/4

A014_en.eps

1) Displayed only if a relay module is fitted!

2) Displayed only if a pump module is fitted!

41

Page 42

Start-up

If "xx.xx.xx xx:xx" is displayed instead of the date and time, or if an

incorrect date and time are displayed:

(only after the cock has been reset due to a power failure)

Set the date and time, see page 67.

CAUTION

If the date and time are not set correctly, some functions (such as calibration)

cannot be executed!

42

Page 43

Maintenance

Maintenance intervals

Before starting operation:

Check the calibration, see page 44.

Check the transmission of signals to the control unit and the triggering of

alarms, page 74.

At regular intervals,

to be defined by the person responsible for the gas warning installation:

Check the transmission of signals to the control unit and the triggering of

alarms, page 74.

If a selective filter specific to the sensor is being used:

Replace the selective filter –

See the related operating instructions for the sensor for details of the capacity of the selective filter being used.

Maintenance

At regular intervals defined in accordance with the sensor being used

by the person responsible for the gas warning system:

Calibrate the sensor, see page 44.

The interval for regular calibration depends on the sensor being used and

on the operating conditions.