DPMS XPQ User Manual

POWER INSTRUMENTS

DPMS XPQ Multi-Function Power Meter

User Manual 1087-332

I

POWER INSTRUMENTS

Copyright 2008© V1.0

This manual may not be reproduced in whole or in part by any means,

without the expressed written consent of AMETEK.

The information contained in this document is believed to be accurate at

the time of publication, however, AMETEK assumes no responsibility for any

errors which may appear here and reserves the right to make changes without

notice. Please ask your local representative for the latest product specications

before ordering.

II

DPMS XPQ User Manual

Please read this manual carefully before installation, operation and

maintenance of the DPMS XPQ meter.

The following symbols are used in this user’s manual and on the DPMS

XPQ meter to alert the danger or to prompt in the operating or setting process.

Danger symbol, Failure to observe the information may result in

injury or death.

Alert symbol, Alert to potential danger. Observe the information

after the symbol to avoid possible injury or death.

Installation and maintenance of the DPMS XPQ meter should only be

performed by qualied, competent personnel that have appropriate training and

experience with high voltage and current devices.

AMETEK is not liable for any problems that occur under proper operation.

III

POWER INSTRUMENTS

content

Chapter 1 Introduction……………………………………………………………………………6

Purpose..................................………………………………………………………7

Application Area..............................………………………………………………………9

Function......................................………………………..……………………………9

Comparison......................................………………………………………….………10

Chapter 2 Installation……………………………………………………………………………12

Appearance and Dimensions……………………..……………………………………13

Installation Method…………………………………………………….……….….……14

Wiring.......................………………………………………………...……………………17

Chapter 3 Meter Operation and Parameter Setting…………….…………………………36

Display Panel and Key………………………………….………………………………37

Metering Data Reading…………………………………...……………….……………39

Statistics Display……………………...…………………………………………………43

Meter Parameter Setting…………….………………….…....…………………………44

Energy Parameter Setting……………………………….………………………..……51

Voltage Eligibility Parameter Setting…………….……….……………………………53

Chapter 4 Function and Software…………………………….………………………..……56

Basic Analog Measurements……………………………....…………………….………57

Event Alarming…………………………………………………………..………………74

Chapter 5 Communication……………………………………………………..…….…………86

Introducing Modbus Protocol…………………….….….………………..………………87

Format of the communication………………………………….….……………………..90

Data Address Table and Application Details........................…..………………………96

Appendix……………………………………………………..……………………..……………122

Appendix A Technical Data and Specication………………………………………123

Appendix B Ordering Information………………………………………………..……127

IV

DPMS XPQ User Manual

Getting Started!

Congratulations!

You have received an advanced, versatile, multifunction power meter, also

known as a Remote terminal unit (RTU), which will greatly benet your power

system.

When you open the package, you will nd the following items.

1. DPMS XPQ meter 1

2. 14-Pin terminal 2

3. Installation clips 4

4. User’s operation manual 1

5. Maintenance guarantee card 1

Please read this manual carefully before operating or setting the meter to

avoid unnecessary results. You can read only part of this manual depending on

how you use the meter.

Chapter 1 helps you to understand the fundamental function, specication

and application area.

Chapter 2 describes detailed installation and wiring.

Chapter 3 describes the data display and parameter setting method.

Chapter 4 outlines the functions of the meter and the way to use them.

Chapter 5 gives the address table.

Appendix lists the technical data and specifications and ordering

information.

Chapter 1 Introduction

Purpose

Application Area

Functions

DPMS XPQ Series

5

6

DPMS XPQ User Manual

Purpose

Powerful Multifunction Power Meter

The DPMS XPQ series multifunction power meter is the new generation of

the very popular DPMS. It has more functions and higher accuracy. It not only

integrates three-phase energy measuring and displaying, energy accumulating,

harmonic measuring, malfunction alarm, statistics and records, digital input /

output and network communication, but also contains the following functions:

four quadrant energy measuring, time-of-use (TOU), auto-freezing, waveform

and over range waveform capture, programmable over range alarming,

schedule of events, trending records etc. Graceful and high-lighted back light

makes it easy to check the measuring data. Simple HMI interface makes it easy

to master. The multi-row display lets you observe various data without touching

any keys.

Ideal Choice for Electric Automation SCADA System

The DPMS XPQ can be used to replace all traditional electric meters.

It also can be used as a Remote Terminal Unit (RTU) for monitoring and

controlling in a SCADA system. All the measured data is available via digital

RS485 communication ports running the ModbusTM protocol.

Energy Management

The DPMS XPQ can measure double direction four quadrant kWh and

kVARh with accuracy up to class 0.5S of IEC60253-22. It can provide maximum/

minimum energy data and energy demand data. With the help of software, you

can easily know how the load and energy are running. It also gives you all kinds

of measurement tables.

7

POWER INSTRUMENTS

Remote Power Control

The main function of the DPMS XPQ is measurement, but it also has some

exible I/O functions. This makes the meter very useful as a distributed RTU

(metering, monitoring, remote controlling in one unit).

Power Quality Analysis

With the powerful digital signal processing ability, the DPMS XPQ intelligent

power meter can be used as an online power quality analysis instrument. It can

simultaneously and continuously give out the analysis results such as THD of

voltage and current, harmonics up to the 31st order and an unbalance factor of

voltage and current, etc. Main functions of the DPMS XPQ are listed in table 1.1.

Metering Energy

VLN, VLN average, VLL, VLL average.

I, I average, IN.

Power, Reactive Power, Apparent Power and Power

factor of each phase and total.

Frequency.

Bidirectional, four quadrants and system Energy,

Reactive Energy, Apparent Energy

Programmable energy freezing.

Period Energy, Reactive Energy, Apparent Energy

Four time zone schedules.

Statistics and Records Energy and Demand

Max/Min value of statistics with time stamp

Maximum of Demand

SOE, Waveform capture and records

kWh, kVARh of 4 quadrants:

Import, Export, Total, Net

Demand of Power and Reactive Power

Power Quality Analysis Over range Alarming

THD, Even THD and Odd THD of Voltage, Current

Harmonics and Crest factor of Voltage

Telephone Harmonic waveform Factor (THFF).

Harmonics and K Factor.

Unbalance Factor of Voltage and Current.

Statistics of Voltage Eligibility.

Monitor up to 240 parameters.

Programmable parameter limitations.

Programmable alarming logic.

Alarming outputs combined with DO or Relays.

Auto-recording of alarming events.

Alarming-trigger waveform recording.

Communication I/O port and Control

RS485 Communication port.

Modbus RTU Protocol

4 Digital Input (DI) (Wet or Dry)

2 Relay Output and 2 Digital Output (DO)

Table 1.1 Main functions of the DPMS XPQ series

8

DPMS XPQ User Manual

Application Area

Power Distribution Automation Intelligent Electric Switch Gear

Industry Automation Building Automation

Energy Management System Large UPS System

Function

Multifunction, High Accuracy

The DPMS XPQ sSeries multifunction Intelligent power meter is powerful

in data collecting and processing. Electric power parameters; metering,

energy accumulating ,harmonic measuring, malfunction alarming, statistics

and records, digital input /output and network communication, four quadrant

energy measuring, time-of-use(TOU), auto-freezing, waveform and over range

waveform capture, programmable over range alarming, schedule of events,

trending records etc.

Accuracy of Voltage and Current is 0.2%, True-RMS

Accuracy of Power and Energy is 0.5%, four quadrants metering.

Small Size and Easy Installation

With the size of DIN96 ×96 and 55mm depth after mounting, the DPMS

XPQ can be installed in a small cabin. The fixing clips are used for easy

installation and removal.

Easy to Use

With a large high density LCD screen, the display of the DPMS XPQ is

easy to read and use. All the setting parameters can be accessed by using

panel keys or a communication port. The setting parameters are protected in

9

POWER INSTRUMENTS

EEprom, which will maintain its content after the meter is powered off. With the

backlight of the LCD, the display can be easily read in a dim environment. The

back light “on” time is selectable.

Multiple Wiring Modes

The DPMS XPQ can easily be used in either: high voltage, low voltage,

three phase three wires, three phase four wires or a single phase system.

High safety, high stability, the DPMS XPQ was designed according to industrial

standards. It can run stably under high power disturbance conditions as it has

passed IEC and CE.

Comparison

To meet different demands of customers, the DPMS XPQ series consists

of four types: DPMS XPQ-D (time-of-use pattern), DPMS XPQ-E (power quality

pattern), DPMS XPQ-F (waveform and alarming pattern) and DPMS XPQ-G

(general function pattern). In order to introduce them all, this manual is based

on the DPMS XPQ-G. Other patterns may not contain some functions so please

refer to the following table carefully.

Table 1.2 Comparison of the DPMS XPQ series

Function

D E F G

Basic parameters ● ● ● ●

Digital I/O ● ● ● ●

Demand ● ● ● ●

Basic settings ● ● ● ●

Device property ● ● ● ●

10

DPMS XPQ User Manual

Harmonics THD Phases and all ● ● ●

phase ● ●

Voltage harmonic analysis ● ●

current harmonic analysis ● ●

Function

D E F G

Sequence ● ● ●

phase angle ● ● ●

Energy Real time ● ● ● ●

Current month TOU ● ●

Previous month TOU ● ●

Accumulative TOU ● ●

Frozen Real time ● ●

Current month TOU ● ●

Accumulative TOU ● ●

MAX/MIN Current ● ●

Previous ● ●

Voltage eligibility Daily, Monthly, Yearly, Frozen,

Accumulative

● ●

SOE log ● ●

Alarm log ● ● ●

Waveform log

● ●

Trending log ● ●

System status Alarming record ● ● ●

SOE, waveform, trending ● ●

Schedule of TOU ● ●

Run time

● ● ● ●

Alarm Alarming ● ● ●

Waveform triggering ● ●

Others Max and Min recording mode ● ● ●

Trending settings ● ●

Chapter 2 Installation

Appearance and Dimensions

Installation Method

Wiring

11

12

DPMS XPQ User Manual

Note: Before trying to operate the meter, note the functions according to its

pattern. The installation method is introduced in this chapter. Please read this

chapter carefully before beginning installation work.

Appearance and Dimensions

Fig 2.1 Appearance of the DPMS XPQ

PART NAME DESCRIPTION

1. Enclosure

The DPMS XPQ enclosures are made of high strength anticombustible engineered plastic

2. Front

Casing After the installation, this part is before the panel. The color of

the front casing is optional

3. LCD Display Large bright blue backlight LCD Display

4. Key

Four keys are used to select display and to set parameters of the

meter

5. Input Wiring Terminals Used for Voltage and Current input

6. Auxiliary Wiring Terminals Used for auxiliary power, communication and DI

7. Extend Wiring Terminals Auxiliary I/O wiring terminals

8. Installation Clip The clips are used for xing the meter to the panel

Table2.1 Part Names of the DPMS XPQ

3

1

2

4

8

5

7

6

13

POWER INSTRUMENTS

Dimensions

Fig 2.2 Dimensions

Installation Method

Environmental

Before installation, please check the environment temperature and humidity

to ensure the DPMS XPQ meter is being placed where optimum performance

will occur.

Temperature

Operation: -25 - 70 deg.

Storage: -40 - 85 deg.

Humidity

5% - 95% non-condensing

96.00

96.00

55.00

96.00

43.00

38.50

Front

Side

14

DPMS XPQ User Manual

The meter should be installed in a dry and dust free environment and avoid

heat, radiation and high electrical noise sources.

Maximum Altitude: 2,000m

Site Requirement: Indoor Use

Installation Steps

Normally, meters are installed on the panel of switch gear.

1. First, cut a square hole on the panel of the switch gear. The cutting size

is in g 2.3 Unit (mm)

Fig 2.3 Panel Cutting

2. Second, remove the clips from the meter and insert the meter into the

square hole from the front side.

Fig 2.4 Put the meter into the square hole

Cut

panel

90±

0.5

0.0

90±

0.5

0.0

15

POWER INSTRUMENTS

3. Finally, install clips back on the meter from the backside and push the

clip tightly so that the meter is afxed on the panel.

Fig 2.5 Use the clips to afx the meter on the panel

Space required for Installation

The space around the meter should be large enough so that the meter

removal, terminal strip wiring and wire arrangement could be done easily. The

recommended minimum space around the meter is shown in Table 2.2 and Fig

2.6.

Fig 2.6 Space around the meter

panel

Paneld

c

e

b

a

f

g

panel

16

DPMS XPQ User Manual

Environment Temperature Minimum Distance(mm)

a b c d e f g

<50< 25 25 38 38 64 25 25

≥50< 38 38 51 51 76 38 38

Table 2.2 Minimum Space

Wiring

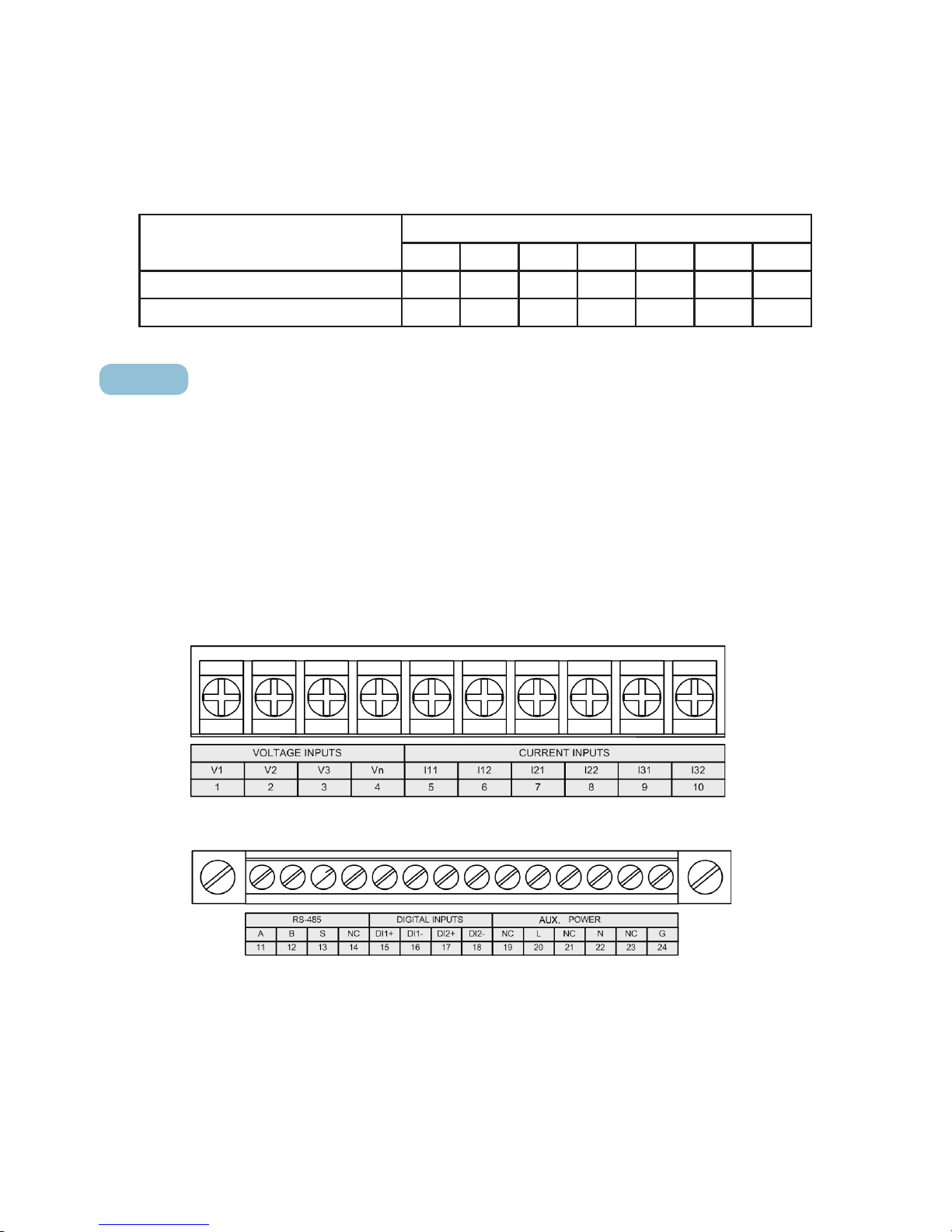

Terminal Strips

There are three terminal strips on the back: Voltage & Current input,

Auxiliary and Extend. Only the DPMS XPQ with the PRIO option has the Extend

Terminal Strip. The 1, 2 and 3 are used to represent each phase of a three

phase system. They have the same meaning with A, B and C or R, S and T in a

three phase system.

Voltage & Current Input Terminal Strip

Auxiliary Terminal Strip

Note: NC means No Connection

17

POWER INSTRUMENTS

Extend Terminal Strip

Fig 2.7 Terminal Strips

Safety Earth Connection

Before doing the meter wiring connection, please

make sure that the switch gear has a safety Earth

system. Connect the meter safety earth terminal to the

switch gear safety earth system. The following safety

earth symbol is used in this user’s manual.

Auxiliary Power

The auxiliary power supply of the meter is 100-

240Vac (50/60Hz) or 100-300Vdc. The meter’s typical

power consumption is less than 2W. A regulator or a

UPS should be used when the power supply undulates

too much. The terminals for the auxiliary power supply

are 20, 22 and 24 (L, N, G). A switch or circuit-breaker should be included in the

building installation, and it should be in close proximity to the equipment and

within easy reach of the operator, and it should be marked as the disconnecting

device for the equipment.

DANEROUS

Only qualied personnel

s h o u l d d o th e w i r e

connection work. Make

sure the power supply

is off and all the wires

are powerless. Failure to

observe this may result

in severe injury or death.

Note

Make sure the auxiliary

power terminal of the

meter, G, is connected

to th e safety Ea r t h of

switchgear.

18

DPMS XPQ User Manual

Fig 2.8 Wiring of Power Supply

A fuse (typical 1A/250Vac) should be used in the auxiliary power supply

loop. No.24 terminal must be connected to the safety earth system of

switchgear. An isolated transformer or EMI lter should be used in the auxiliary

power supply loop if there is a power quality problem in the power supply.

Fig 2.9 Wiring of Aux. Power Supply with power line lter

Choice of wire should be AWG22~16 or 0.6~1.3mm2.

Note: A lter should be used if there is an EMI problem.

Voltage Input

Meter input voltage should be 40~230Vac L-N,

60~400Vac. L-L. The voltage input could be directly

connected to the meter terminal without the use of PT if

the voltage system is less than 400Vac (L-L). If the input

Voltage is higher than 400Vac, a PT or VT should be

Note

The secondary of PT

c a n n o t be sh o r t ed ,

otherwise it may cause

the severe damage of

the instrument.

Note

Mak e sure th e po we r

supply voltage is the

same as what the meter

needs fo r its auxiliary

power.

L

N Acuvim-X

G

20

22

24

Power Supply

1A FUSE

Ground

L

N Acuvim-X

G

20

22

24

L L

N N

G G

Power Supply

1A FUSE

Ground

Power

lter

19

POWER INSTRUMENTS

used. A fuse (typical 1A/250Vac) should be used in the voltage input loop. A PT

should be used to transform the high voltage into the measurement range of the

meter if it is used in a high voltage system. The wire gauge of the input voltage

should be AWG16~12 or 1.3~2.0mm

2

.

Note: In no circumstances should the PT secondary be shorted. The PT

secondary should be well grounded at one end.

Current Input

In a practical engineering application, CTs should be installed in the

measuring loop. Normally the CT secondary is 5A. 1A is possible as an option.

A CT accuracy over 0.5% (rating over 3VA) is recommended and it will inuence

the measuring accuracy. The wire between the CT and meter should be as short

as possible. The length of the wire may increase the error of the measurement.

CTs must be required for rated current over 5A.

The wire guage of the input current should be AWG15~10 or 1.5~2.5mm2.

Note: The CT loop should not be open in any circumstances when the power

is on. There should not be any fuse or switch in the CT loop and one end of the

CT loop should be connected to the ground.

Vn Connection

Vn is the reference point of meter input voltage. The lower the wire

resistance the lower the error.

Three phase wiring diagram

The DPMS XPQ can satisfy most kinds of three phase wiring diagrams.

Please read this part carefully before you begin to do the wiring so that you may

chose a wiring diagram suitable for your power system.

20

DPMS XPQ User Manual

The voltage and current input wiring mode can be set separately in the meter

parameter setting process. The voltage wiring mode could be 3-phase 4-line

Wye (3LN), 3-phase 4-line 2PT Wye mode (2LN) and 3-phase 3-line open delta

(2LL). The current input wiring mode could be 3CT, 2CT and 1CT. Any voltage

mode could be grouped with one of the current modes.

Voltage Input Wiring

3-Phase 4-Line Wye mode (3LN)

The 3-Phase 4-Line Wye mode is commonly used in low voltage electric

distribution power systems. The power line can be connected to the meter

voltage input directly as in g 2.10a. In the high voltage input system, 3PT Wye

mode is often used as in g 2.10b. The voltage input mode of the DPMS XPQ

should be set to 3LN for both voltage input wiring modes.

Fig 2.10a 3LN direct connection

Acuvim-X

21

POWER INSTRUMENTS

Fig 2.10b 3LN with 3PT

3-Phase 3-Line direct connection mode (3LN)

In a 3-Phase 3-Line system, power line A, B and C are connected to V1, V2

and V3 directly. Vn is oated. The voltage input mode of the DPMS XPQ should

be set to 3LN.

Fig 2.11 3LN 3-Phase 3-Line direct connection

Acuvim-X

22

DPMS XPQ User Manual

3-Phase 4-Line 2PT mode (2LN)

In some 3-Phase 4-Line Wye systems, 2PT Wye mode is often used as in

g 2.12. It is supposed that the 3 phases of the power system are balanced. The

voltage of V2 is calculated according to V1 and V3. The voltage input mode of

the DPMS XPQ should be set to 2LN for 2PT voltage input wiring mode.

Fig 2.12 2LN with 2PTs

3-Phase 3-Line open Delta Mode (2LL)

Open delta wiring mode is often used in high voltage systems. V2 and

Vn connect together in this mode. The voltage input mode of the DPMS XPQ

should be set to 2LL for voltage input wiring mode.

Fig 2.13 2LL with 2PTs

23

POWER INSTRUMENTS

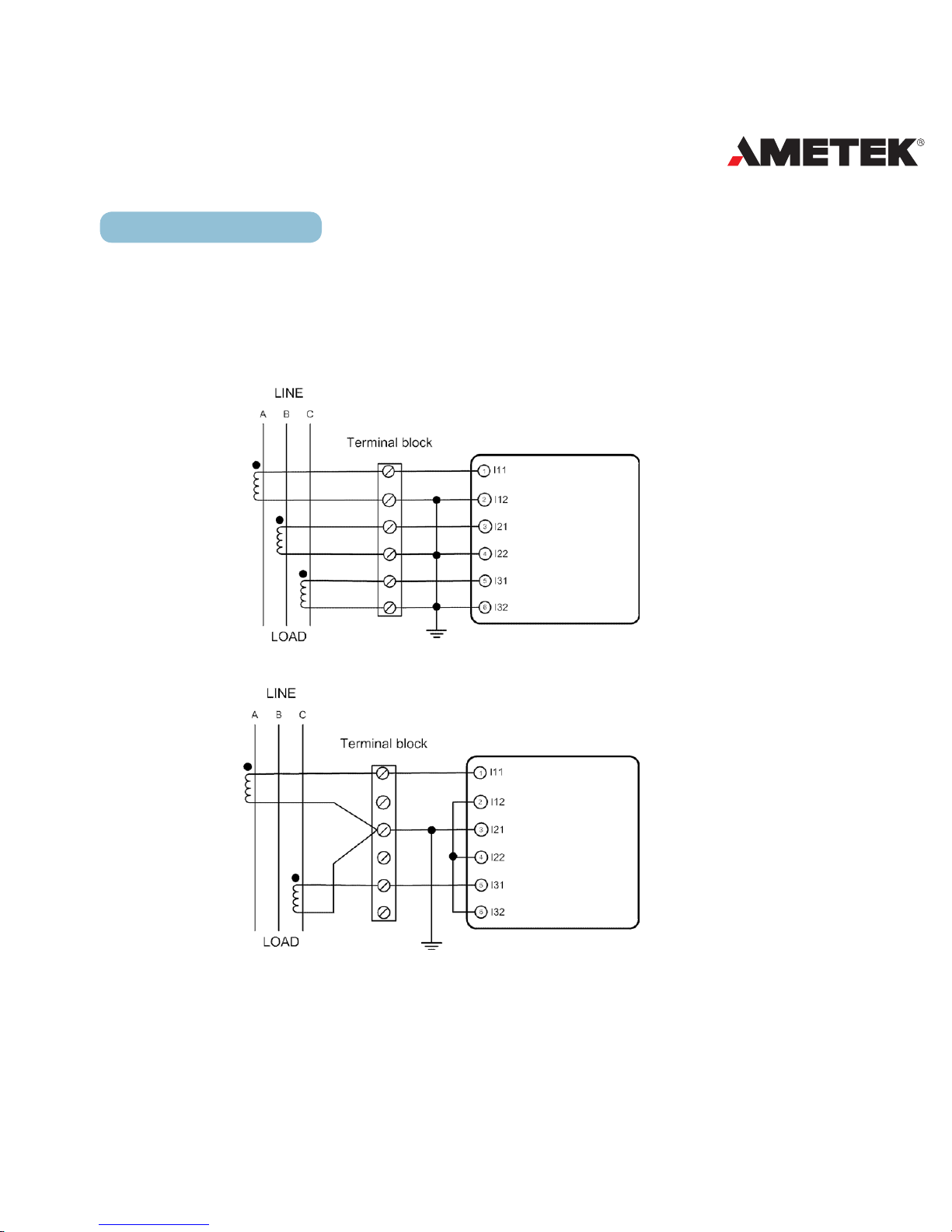

Current Input Wiring

3CT

All current input of a three phase system can be viewed as 3CT, whether

there are 2 CTs or 3 CTs on the input side. The current input mode of the DPMS

XPQ should be set to 3CT for this current input wiring mode.

Fig 2.14 3CT-a

Fig 2.15 3CT-b

24

DPMS XPQ User Manual

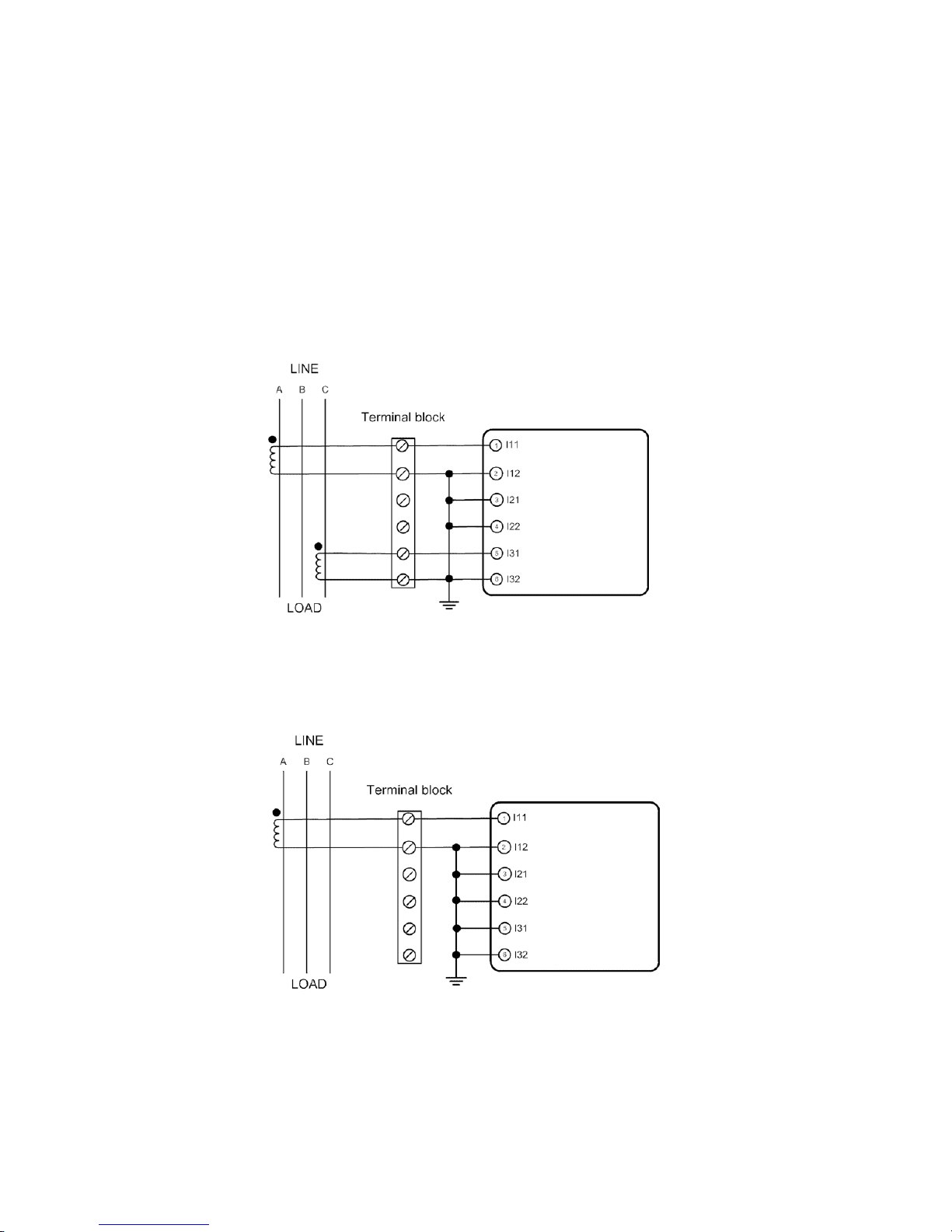

2CT

The difference in g. 2.16 and g. 2.15 is that there is not current input in

the I21 and I22 terminals. The I2 value is calculated from formula i1+i2+i3=0.

The current input mode of the DPMS XPQ should be set to 2CT for this current

input wiring mode.

Fig 2.16 2CT

1CT

If it is a three phase balanced system, a 1 CT connection method can be

used. The other two currents are calculated according to the balance supposing.

Fig 2.17 1CT

25

POWER INSTRUMENTS

Frequently used wiring method

The voltage and current wiring method are put together in one drawing.

The DPMS XPQ meter will display normally only if the setting of the meter is

associated with the wiring of the voltage and current input.

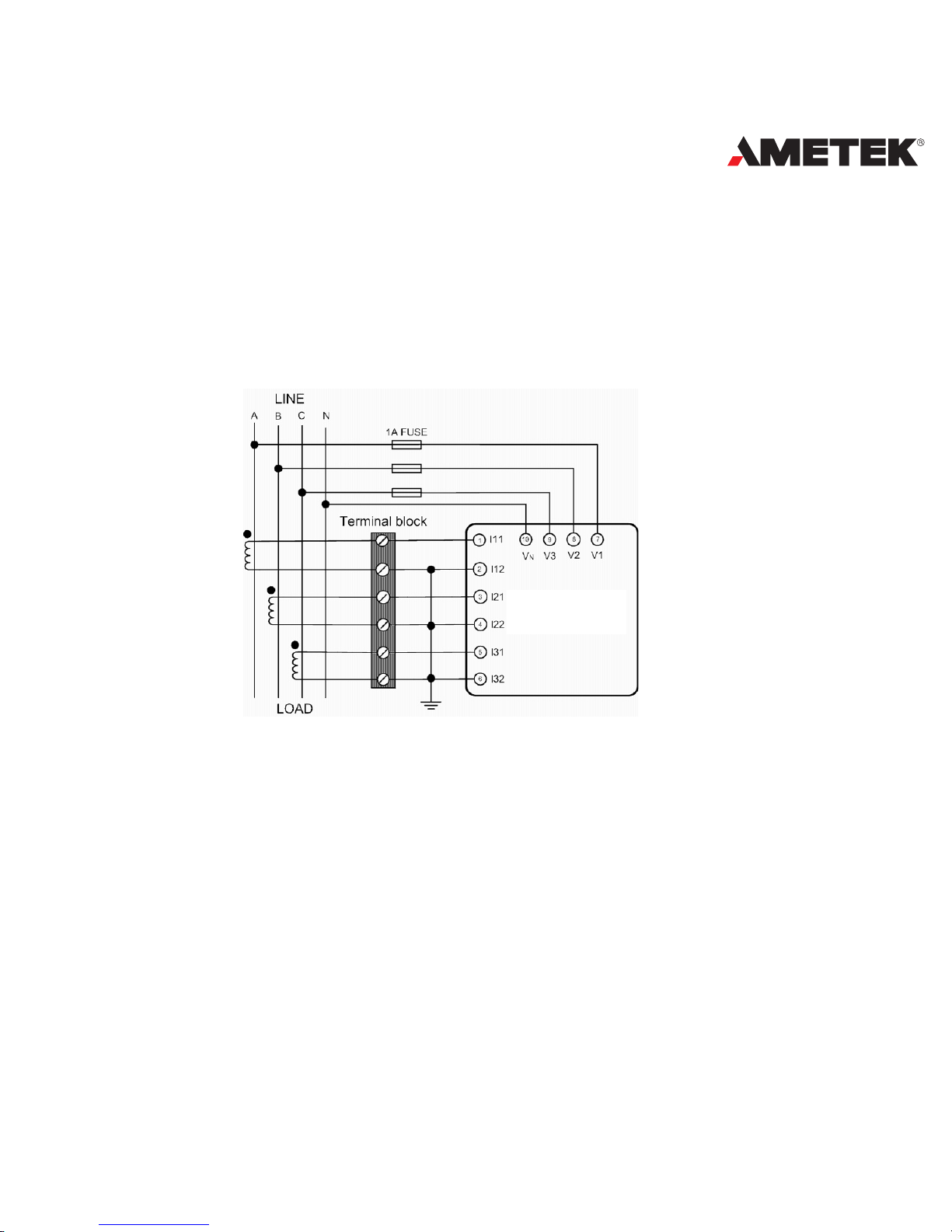

1. 3LN, 3CT with 3 CTs

Fig 2.18 3LN, 3CT with 3CTs

26

DPMS XPQ User Manual

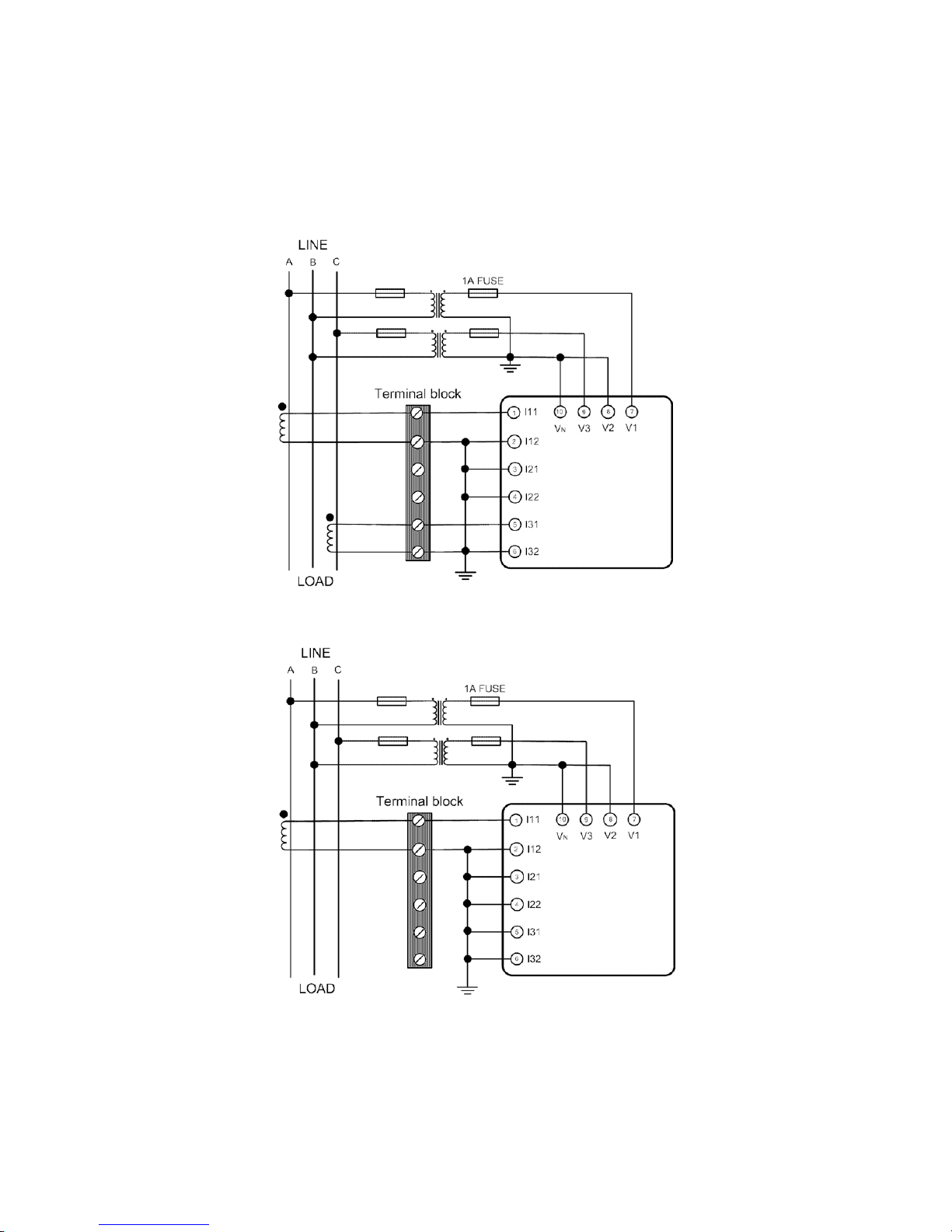

2. 3LN, 3CT with 2 CTs

Fig 2.19 3LN, 3CT with 2 CTs

3. 2LN, 2CT

Fig 2.20 2LN, 2CT

27

POWER INSTRUMENTS

4. 2LN, 1CT

Fig 2.21 2LN, 1CT

5. 2LL, 3CT

Fig 2.22 2LN, 3CT

Acuvim-X

Fig 2.21 2LN, 1CT

28

DPMS XPQ User Manual

6. 2LL, 2CT

Fig 2.23 2LL, 2CT

7. 2LL, 1CT

Fig 2.24 2LL, 1CT

Loading...

Loading...