DOUGHXPRESS DXA, DXA-SS Owner's Manual

DXA

DXA-SS

33018 RV E 102414

DXA/DXA-SS

Air Driven Automatic Dough Press

OWNER’S MANUAL

For Customer Service, Call 1-800-835-0606 ext. 205

or Visit www.doughXpress.com

Receiving & Setup ............................................................................................ 2

Operation .......................................................................................................... 3

Setting Temperature & Time ............................................................................. 4

Preference Settings .......................................................................................... 5

Machine Presets ............................................................................................6-7

Cycle Count ...................................................................................................... 8

Temperature & Time Modes .............................................................................9

Pressing Dough ......................................................................................... 10-11

Dough Weights & Shrinkage ..........................................................................12

FAQs...............................................................................................................13

Troubleshooting ..............................................................................................14

Cleaning & Maintenance ................................................................................15

Warranty .........................................................................................................16

CONTENTS

BEFORE warranty repair you MUST get Prior Authorization:

2

RECEIVING & SETUP

PLEASE READ THIS MANUAL IN ITS ENTIRETY

BEFORE OPERATING YOUR PIZZA PRESS.

INSPECTION

Inspect your box and machine for hidden shipping damage. Contact the delivery

company immediately, should you nd damage.

PLATEN SURFACE

Slight surface imperfections are a normal part of the aluminum casting process for

the platens on your press. These are not considered a defect and do not affect the

functionality of the machine in any way.

SHIPPING OR RETURNS

NOTE: Save all of your shipping/packing materials.

DO NOT RISK COSTLY SHIPPING DAMAGE!

SHIP ONLY IN ORIGINAL BOX.

1. Fasten machine to plywood shipping base with bolts provided.

2. Make sure handle is pressed down so that the heat platen will not swing around

during shipment.

3. Place in original box, and put side liner and top liner in place. Fold in aps and

seal the box.

*Additional bottom boards, box and liners may be obtained from your supplier

for a nominal cost.

INSTALLATION

1. Lift press from skid and place on cart, if you purchased one with the press.

Align legs with holes in top of cart and bolts (supplied) fasten to cart. You will

need a 9/16 wrench.

2. Remove plywood shipping base from press.

CAUTION: Heavy lifting can cause injury. We recommend two person lifting

or use of a mechanical aid when handling this press. Remember

to always maintain natural curves of back and bend knees to lift.

3. Plug the cord of the press into a correctly grounded electrical outlet. The correct

voltage is indicated on the identication tag of the press.

WARNING: When using an extension cord, use 12 or 14 ga.-3 conductor.

Maximum length, 25’ (7.62 m).

4. Remove wrap from handle and platens.

5. Supply a clean (void of oils) and dry (void of water) air source of 110-130 P.S.I.

(7-8 bar) to the 1/4” NPT air inlet located on the back panel of the machine.

Requires 1 CFM (30 L/min). It is strongly recommended that an external air lter

and water trap be installed at the machine’s air inlet connection. This equipment

has small valves and ports that can become blocked from moisture and residue

in compressed air causing it to malfunction. Damages to the equipment’s

internal air operated components resulting from unltered air are not covered

under warranty. Combination air lter/water traps are available at any major

hardware store or may be purchased directly from doughXpress (part #71145).

3

OPERATION

PREPARATION

1. Turn on the machine by pushing the on/off switch.

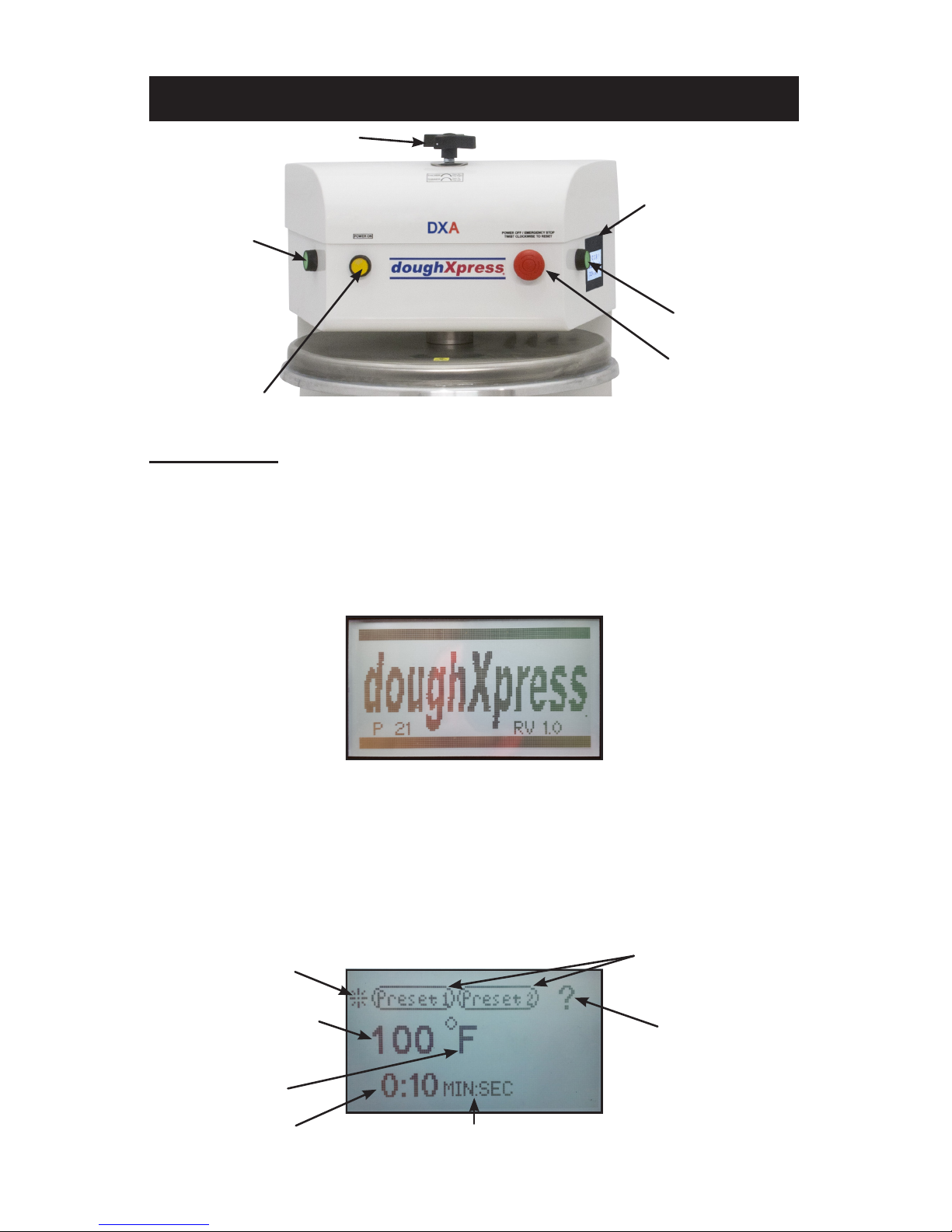

Startup/Splash screen is displayed as the controller boots up.

NOTE: The current program number and the software revision of the control-

ler are displayed at startup. (The default settings are program number

P 21 for °F, P 22 for °C and software revision RV 1.0)

After boot up, the home screen is displayed showing the current heat platen tempera-

ture and set cycle time. The heat indicating lamp is represented by the snowake

in the upper left corner of the display. The heat indicating lamp will display anytime

the heating element is heating and will cycle on and off after the set temperature is

reached to maintain set temperature.

Startup/Splash Screen

MACHINE PRESET

BUTTONS

ACCESS

SETTINGS MENU

TEMPERATURE

READOUT/SETTING

HEAT INDICATING

LAMP

TEMPERATURE

MODE

TIME

READOUT/SETTING

TIME SCALE

HOME MENU SCREEN

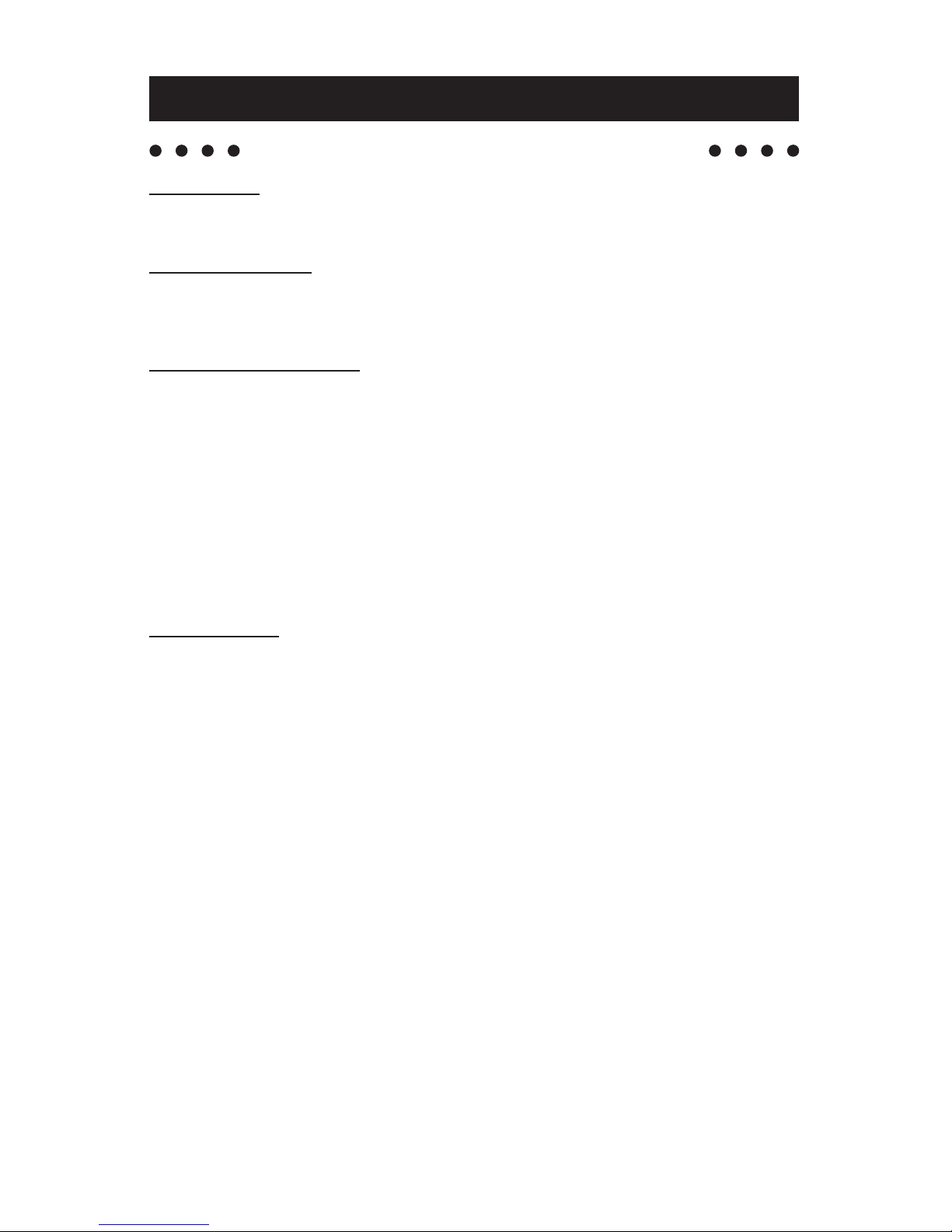

Thickness Control Knob

Start Cycle

Button

Start Cycle

Button

Power On/Off Button

Emergency Stop

Button

Digital Time and

Temperature

Control

4

SETTING TEMPERATURE & TIME

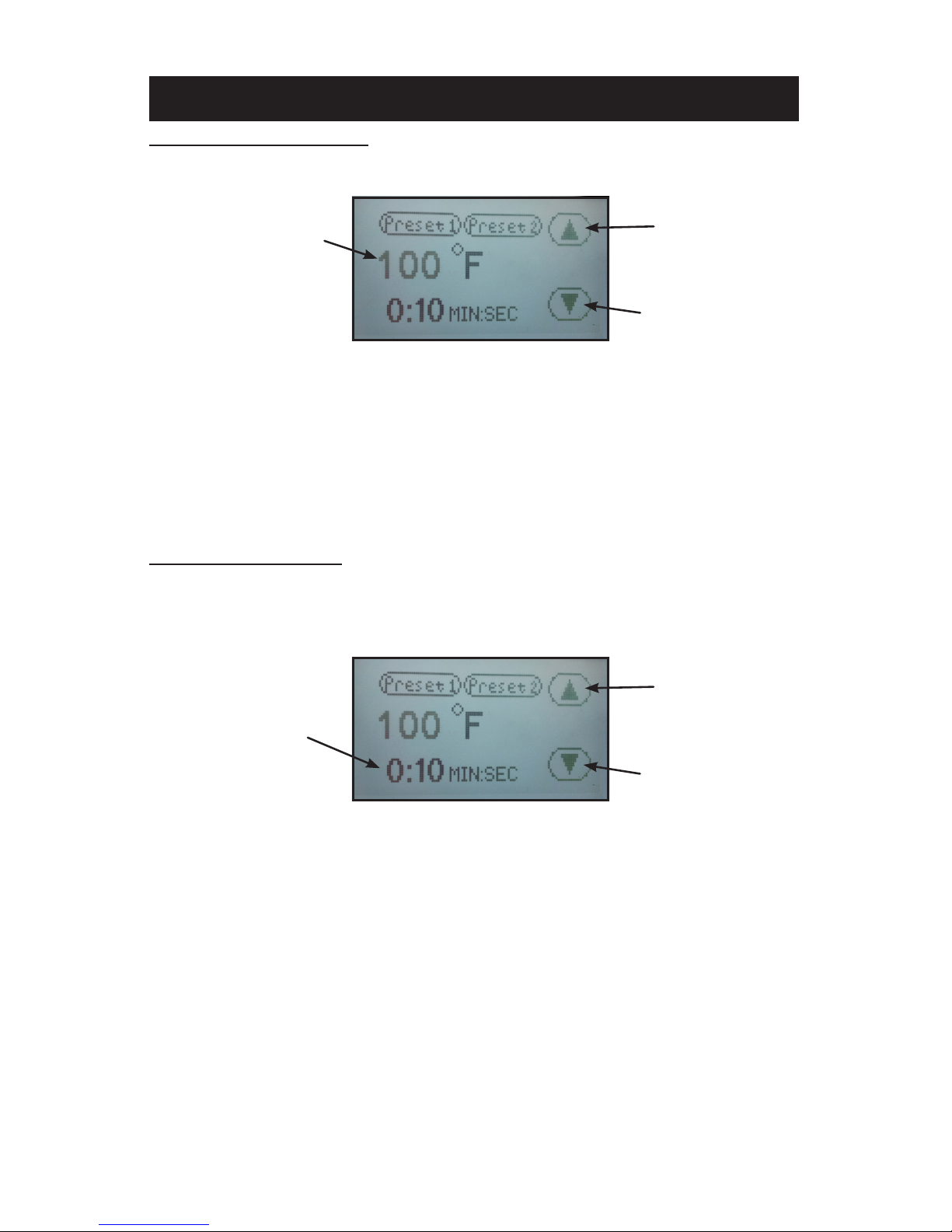

ADJUST TEMPERATURE:

1. Touch the temperature readout on the display. “UP” ▲ and “DOWN” ▼ arrows

will appear on the right side of the display and the temperature value will start

ashing and to indicate it is in set mode.

2. Press the “UP” ▲ or “DOWN” ▼ arrow to change the temperature value. Hold-

ing down on an arrow will change the temperature in 1 degree increments for

10 values; then change to 10 degrees incremental changes.

3. Once the desired temperature value is set, either press the temperature value

to lock the set temperature or simply wait for 2 seconds and it will lock in the

new value automatically.

ADJUST CYCLE TIME:

1. Touch the time readout on the display. “UP” ▲ and “DOWN” ▼ arrows will appear on the right side of the display and the cycle time value will start ashing

and to indicate it is in set mode.

2. Press the “UP” ▲ or “DOWN” ▼ arrow to change the cycle time value. Holding

down on an arrow will change the time in 1 second increments for 5 values;

then change to 10 seconds incremental changes.

3. Once the desired cycle time value is set, either press the time readout to lock

the cycle time or simply wait for 2 seconds and it will lock in the new value

automatically.

TEMPERATURE ADJUSTMENT SCREEN

TEMPERATURE

READOUT/SETTING

UP ARROW

DOWN ARROW

TEMPERATURE ADJUSTMENT SCREEN

UP ARROW

DOWN ARROW

TIME

READOUT/SETTING

5

PREFERENCE SETTINGS

SETTINGS:

1. Press the “?” on the upper right corner of the display on the Home Menu Screen

to access the settings menu.

2. Press the settings sub menu title to be adjusted.

SHUTDOWN TIMEOUT

The shutdown feature shuts off the heat to the press after a period of inactivity.

NOTE: The factory default is set at 3.0 hours.

1. From the settings menu press the “Shutdown Timeout” sub menu title.

2. Press the “UP” ▲ and/or “DOWN” ▼ arrows to set the desired shutdown time.

NOTE: Shutdown time adjusts in 1/2 hour intervals. Press the “Down” ▼ button

until “Disable” is displayed will deactivate this setting.

3. Press “Save” to save the setting.

4. Press “Back” to return to the previous screen.

NOTE: After the shutdown time has elapsed with the press idle, the heating ele-

ment will stop cycling to maintain the set temperature and the home screen

will display “SHUTDOWN.” Touching the display or closing the press will

take the machine out of shutdown mode.

SETTINGS MENU SCREEN

RETURN TO

PREVIOUS

SCREEN

ADJUST SHUTDOWN TIMEOUT

SETTING

SET QUANTITY OF PRESETS

DISPLAYED

VIEW/RESET CYCLE COUNT

SET TEMPERATURE SCALE

PREFERENCE

SET TIME SCALE PREFERENCE

SHUTDOWN TIMEOUT ADJUSTMENT SCREEN

UP ARROW

DOWN ARROW

SHUTDOWN TIMEOUT

SETTING

SAVE SETTINGS RETURN TO PREVIOUS SCREEN

Loading...

Loading...