Congratulations!

2/10

Perris,

Your selection of the Doughpro DP2300

is a sound business decision. Doughpro

equipment is a result of the highest

quality engineering and time-tested

design. Your machine, combined with

Doughpro’s reputation of innovation in

dough press equipment manufacturing,

insures the continuing capability of

delivering the best-decorated product

possible.

This manual describes installation,

operation, and maintenance procedures

for your new model DP2300.

Your model DP2300 machine will have

a long trouble-free life. Read this

manual carefully and keep it with your

machine; it’s your key to proper

operation and lasting service.

Installation

DOMESTIC

Use a separate 30 amp AC

circuit. Only industrial extension

cords with proper wire size

should be used; size 16/3 wire for

distance up to 25 feet, and size

14/3 for distance up to 50 feet.

INTERNATIONAL

Use a designated 30amp AC

circuit. Only industrial extension

cords with proper wire size (2.5

sq. mm) shall be used.

Make sure there is a proper electrical

wall outlet located within reach of the

cord and plug attached to the press.

Then place the press in an area which

allows for “swing clearance” of the

lower platen plus vertical and horizontal

clearance of the press itself.

Limited Machine Warranty

conditions, to be free from

manufacturing defects in material and

workmanship for a period of one year on

parts and labor from the invoice date.

This warranty will be effective only

when Doughpro authorizes the original

purchaser to return the product to the

factory in South Gate, California freight

prepaid and only when the product, upon

examination, has proven to be defective.

This warranty does not apply to any

machine that has been subjected to

misuse, negligence or accident.

Doughpro shall not be liable for the

injury, loss or damage, direct or

consequential, arising out of the use or

the inability to use the product.

No claim of any kind shall be greater in

amount than the sale price of the product

or part to which claim is made.

This is the sole warranty given by the company, it is in

lieu of any other warranties, expressed or implied, in

law or in fact, including the warranties of

merchantability and fitness for a particular use, and is

accepted such by the purchaser in taking delivery of

this product.

Specifications

Electrical:

208V/50-60Hz/4600W/22.11Amps

Includes 72” cord and NEMA

approved plug.

Shipping Weight:

200lbs. (91kg.) – DP2300

Safety Summary

WARNING

In case of power cord damage,

do not attempt to repair or

replace the power cord. Contact

the manufacturer or the local

distributor.

Doughpro warrants this dough press

machine, when operated under normal

-1- DP2300 2/04

2/10

WARNING

Avoid touching hot surfaces

while operating the machine.

CAUTION

During normal operation, the

base of the machine must be

installed or placed above the wall

socket.

CAUTION

When servicing or cleaning the

machine, make sure that the

power cord is removed from the

wall socket.

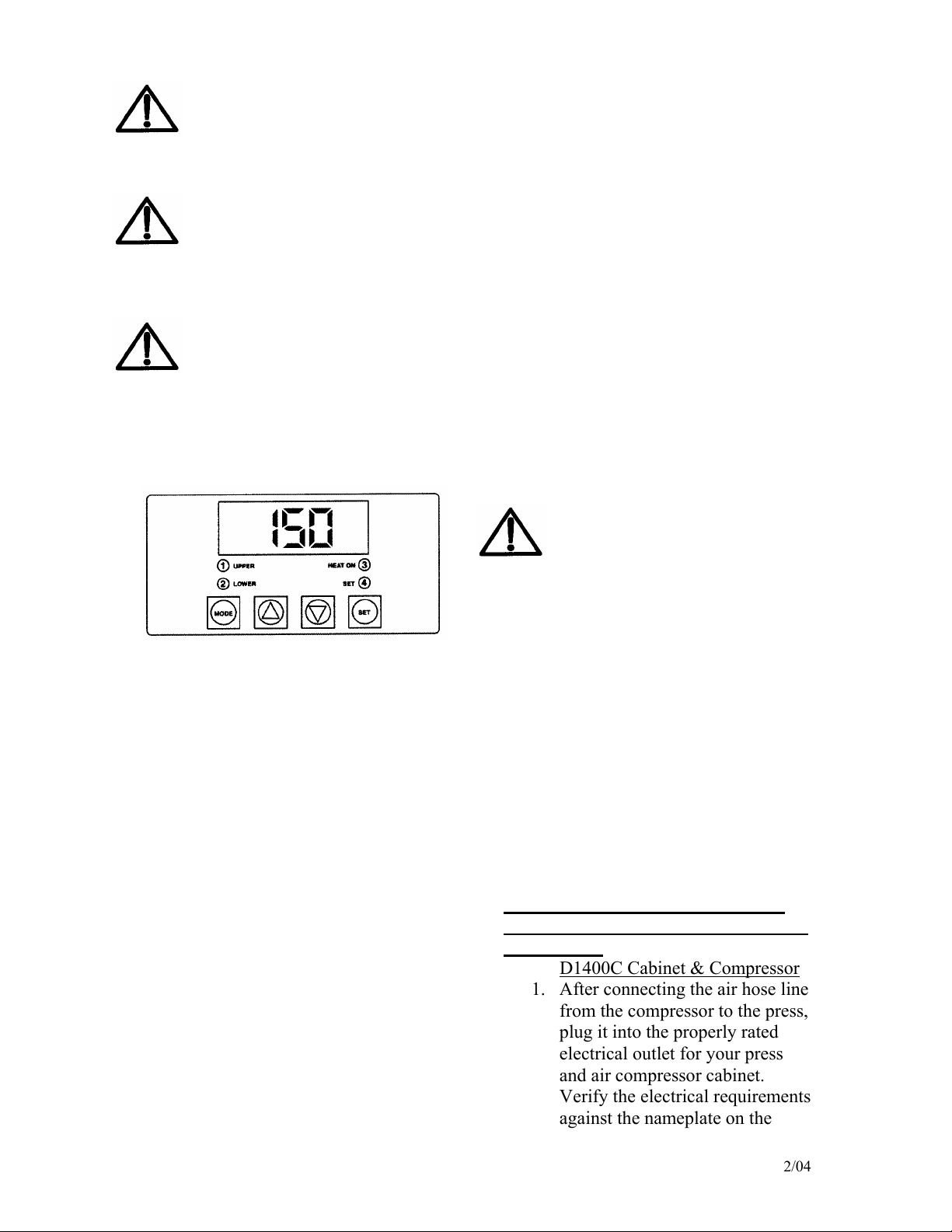

Operation Timer/Temperature

Control

Fig. A

Solid State Controller

This controller has three (3) control

features:

1. Temperature – May be set from

100°-425°F (38°-163°C)

2. Time – Time may be set from 1

second to 10 minutes.

3. Counter – Cycle counter counts

the number of applications from

1 to 9999 (see additional Notes –

Counter).

4. “2Lower” (Fig. A) Refers to

models using upper and lower

heated surfaces.

Controller Operation

1. Viewing the Modes of Operation:

-2- DP1300 2/04

4. Resetting the Counter

PRESSING DOUGH:

For best results, your dough should be

proofed before pressing, but it will also

press directly out of your refrigerator.

Flour is not required to press a crust

and should not be dusted on any part of

the machine.

D1400C Cabinet & Compressor

• To view the set points of

temperature, timer and counter,

press MODE button to view the

desired mode of operation.

2. Changing Temperature:

• Press MODE button until

temperature is displayed.

• Press and hold SET button

while pressing the UP (↑) and

DOWN (↓) arrow buttons to

desired temperature setting.

3. Changing Time:

• Press MODE button until time

is displayed.

• Press and hold SET button

while pressing the UP (↑) and

DOWN (↓) arrow buttons to

desired timer setting.

The DISENGAGE switch may

be pressed anytime during a

cycle, and the cycle will stop

immediately, and the timer will

reset.

• Press MODE button until the

counter is displayed.

• To Reset the Counter (# of

Cycles), simultaneously push

UP (↑) or DOWN (↓) arrow

buttons (approx. 5 seconds).

1. After connecting the air hose line

from the compressor to the press,

plug it into the properly rated

electrical outlet for your press

and air compressor cabinet.

Verify the electrical requirements

against the nameplate on the

back of the press and air

Incoming air to machine shall not

exceed 90 psi as this will damage

internal parts and void the machine

warranty!

2/10

compressor cabinet.

Note: The compressor portion of the

machine has a separate on/off switch

located on the rear of the lower cabinet.

2. Switch the DP2300 to the ON

position.

Note: Initial temperature setting of

150°F has been shown to be acceptable

for most dough formulations; however,

you may have to determine the best

temperature for your own dough by trial

and error testing of your product at

different temperature settings.

3. Set the timer in accordance with

the following information:

2-4 seconds –For warm dough

with moderate yeast content.

2-6 seconds – For room

temperature dough with

moderate yeast content.

6-8 seconds – For cold dough

right out of the refrigerator with

low yeast content.

Remember that the timer does not

actuate until the upper platen mates

with the lower platen and resistance

is felt.

4. Set the thickness control lever to

“thick” or “thin” or anywhere in

between these settings as your

product requires.

Note: Diameter and thickness is

determined through experimenting with

your own dough and is a product of

dough weight, temperature, pressing

time, and thickness setting.

5. Swing open the lower platen and

apply a quick spray of a good

water based food release on the

-3- DP2300 2/04

lower platen. Doughpro offers

its own food release spray

NATURALLY CLEAR Model

No. DPPC1. (See our catalog

and price list for information.)

Note: This spray will not

the taste of your crust in any

way.

6. Place your pre-portioned ball of

dough in the approximate center

of the lower platen. Add another

dash of spray to the top of the

dough ball.

7. Close the platen and, with both

hands, press the two green

buttons on each side of the

machine simultaneously.

8. Hold the buttons in until

resistance is felt then release at

once. The timer will actuate and,

when the time cycle is

completed, the upper platen will

rise automatically (timer is preset

at factory for six (6) seconds, but

this is easily changed by

following the upcoming

instructions.)

9. Remove the crust, place on a

disc, screen, pan or peel, add

toppings and bake.

:$51,1*

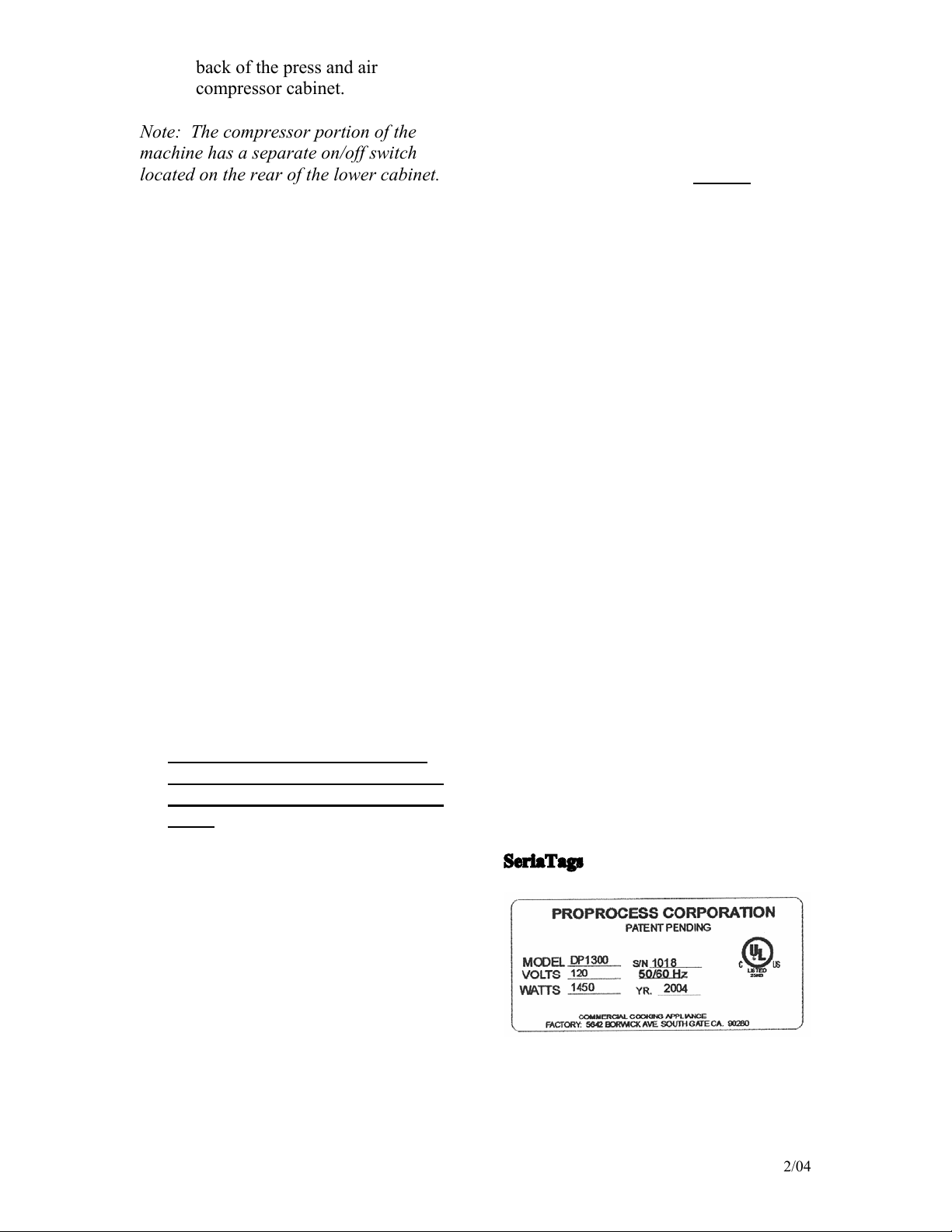

SeriaTags

affect

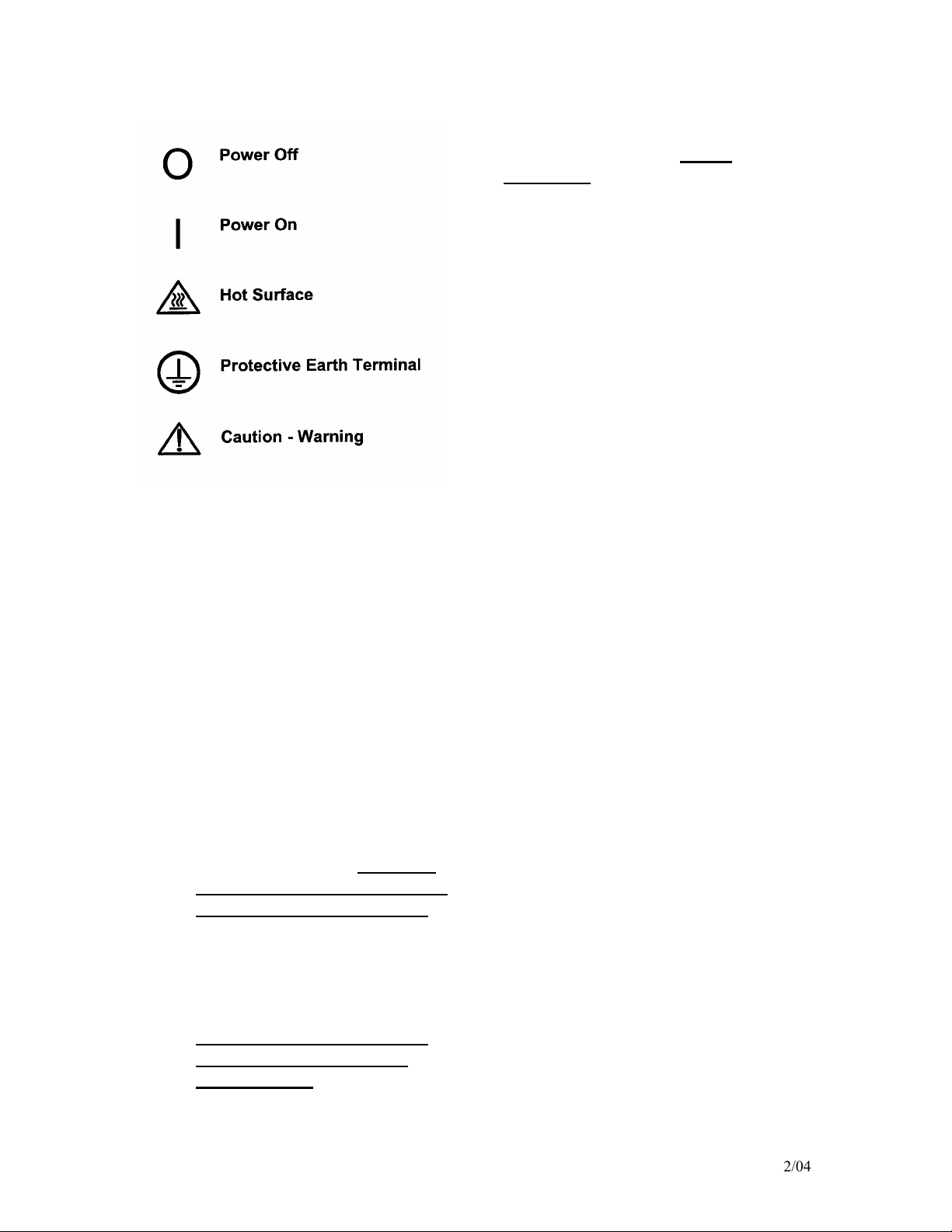

International Symbols

2/10

Preventative Maintenance Suggestions

The Doughpro DP2300 machines are

relatively maintenance free. For a long

and trouble-free life, the following

preventative maintenance should be

followed:

Daily Care:

1. Platens: Turn your machine off

and allow to cool down before

attempting to clean. These

platens should only be cleaned

with mild soap and warm water

then wiped off with a clean, soft

cloth or soft sponge. Never use

steel wool or harsh abrasives or

you will cause costly damage.

2. All other exterior surfaces:

Here again a daily wipe down

with mild soap and warm water

will do the job quite nicely.

Never use steel wool or harsh

abrasives or you will cause

costly damage.

Service Problems:

-4- DP2300 2/04

Contact our factory or approved service

agency (800) 624-6717 (U.S. only).

Note: When contacting factory for

information, parts or service

instructions, it is of the utmost

importance that the serial number of the

machine be provided. This number can

be found on the serial plate located on

the rear of the machine.

Piston Maintenance:

In order to ensure proper and trouble

free operation of the press piston, it is

important that the machine be lubricated

once every three (3) months, under

normal operation. High volume users

may require more frequent lubrication.

The lubricant used must be USDA H-1

authorized for food machinery. This

lubricant can be ordered through

Proluxe as part number # 110-002.

Please follow these simple instructions:

1. Locate the grease port on the

machine. Machines with pull

down arms have a single grease

port located below the upper

head on the right side of the

vertical post. Machines with

swing-away upper heads have

two grease ports; one on the right

side of the vertical post and one

on the back of the vertical post.

All other machines have a single

port. (refer to illustration)

2. Place grease gun head against

grease port and apply enough

pressure to allow gun head to

engage the grease port.

3. Squeeze handle of grease gun

which forces the grease into the

piston. One squeeze is all it

takes.

Service Problems:

Contact our factory or approved service

agency (U.S. only). Note: When

contacting factory for information, parts

or service instructions, it is of the utmost

importance that the serial number of the

machine be provided. This number can

be found on the serial plate located on

the rear of the machine.

-5-

DP2300BZ

AUTOMATIC

PIZZA PRESS

71

77

4X

84

81

82

78

79

76

4X

4X

4X

83

81

83

87

1

75

73

104

4X

9

4X

78

4X

79

4X

34

25

90

96

106

2X

95

2X

94

2X

107

99

2X

97

18

14

35

35

55

2

3X

11

4X

39

41

2

40

7

3X

83

81

82

18

35

59

36

100

8

48

3X

57

13

58

56

2X

66

72

12

125

124

3

44

42

43

22

10

4X

A6

A2

114

98

110

26

20

115

32

116

123

113

108

15

113

111

111

110

10/31/18

112

A1

EXPDP2300BZ RM 103118

CUSTOMER MANUAL

PAGE 1 OF 3

20

112

32

A4

63

24

26

115

31

113

117

126

46

111

98

A3

110

118

116

109

47

70

4X

33

32

69

4X

68

4X

2X

37

2X

23

9

28

32

33

32

27

32

29

A7

32

33

16

93

17

38

91

52

54

6X

53

33

80

52

59

2X

36

2X

53

53

53

86

2X

A9

18

35

121

86

85

118

2X

119

A5

100

120

2X

2X

2X

53

53

122

21

65

61

64

62

A10

38

5

35

59

60

67

EXPDP2300BZ RM 103118

CUSTOMER MANUAL

PAGE 2 OF 3

12X

36

35

59

36

14

74

57

2X

89

4X

49

30

50

51

45

12X

4

6

35

57

19

92

PROLUXE PARTS LIST FOR MODEL

DP2300BZ

ITEM

No.

DESCRIPTION

DP2300BZ

208 ~ AC

DP2300BZCEC

220 ~ AC

QTY.

1 HOUSING, INSTRUMENTAL 11010252201 11010252201 1

2 HEX BOLT STAINLESS STEEL, 1/4-20 X 1/2 BH142012S BH142012S 3

3 NUT, LOCKING JAM (MACHINED) 11070 11070 1

4 CLAMP, CABLE 1/2 CC12 CC12 2

5 FITTING, AIR 1/4" FEMALE PIPE X, 1/4 TUBE 90 DEG. AQ70P4X4 AQ70P4X4 1

6 CLAMP, CABLE 3/8 CC38 CC38 1

7 DECAL LABEL FUSE 2 MIL MYLAR 1 COLOR BLACK DLFUSE DLFUSE 1

8 ARM, MACHINED DP2300 11023002101 11023002101 1

9 BOLT, SHOULDER 3/8 x 2 11023003 11023003 5

10 SPRING, DIE RED MEDIUM HEAVY DUTY 11020106 11020106 4

11 BOLT, HEX 1/4-20 x 5/8 BH142058 BH142058 4

12 POWER DISTRIBUTION CABLE 110230068 110230068 1

13 TERMINAL BLOCK STAGE #5 DOUBLE 6015 6015 1

14 SCREW, SET 8-32 x 1 SST8321 SST8321 2

15 COVER, LEVELING SPRING 11023002 11023002 1

16 O-RING #2-243 N-70 MPSS062 MPSS062 1

17 POST COLLAR 1101751162301 1101751162301 1

18 SCREW, PAN HEAD PHILLIPS 8-32 x 3/8 SP83238 SP83238 6

19 TERMINAL BLOCK #7 6017 6017 1

20 WASHER, SAE #6 WSAE6 WSAE6 2

21 NUT, HEX 3/8-16 NH3816 NH3816 1

22 SCREW, SET 1/4-20 x 1/2 SST142012 SST142012 1

23 O-RING, SOFT BUNA-N 110230077 110230077 1

24 ALIGNMENT SWITCH ASSEMBLY 1101169341 1101169341 1

25 HANDLE, SWING AWAY 11023004501 11023004501 1

26 SCREW, PAN HEAD PHILLIPS 6-32 x 1/4 SP63214 SP63214 2

27 PISTON RAM MACHINED DP2300 11023003001 11023003001 1

28 COLLAR, STOP PIN DP12504 DP12504 2

29 BASE ASSEMBLY 1102300BZ1102 1102300BZ1102 1

30 COVER PLATE, BASE 11054 11054 1

31 POST GUIDE DP2300 11023004 11023004 1

32 SCREW, SET 3/8-16 X 1/2" SST381612 SST381612 7

33 SCREW,SET 3/8"-16 X 1/2", CONE POINT SST381612CP SST381612CP 5

34 KNOB SWING 110017 110017 1

35 WASHER, SAE #8 WSAE8 WSAE8 11

36 NUT, HEX 8-32 NH832 NH832 6

37 NUT, HEX JAM 5/16-18 NHJ51618 NHJ51618 2

38 2" BLK/BRS AIR GAUGE 110130007 110130007 1

39 FUSE BUSS 1 AMP MPPF701R MPPF701R 1

40 FUSE HOLDER MPPF708 MPPF708 1

41 SCREW, PAN HEAD PHILLIPS 2-56 x 1/4 SP25614 SP25614 1

42 THRUST WASHER 11059 11059 1

43 ADJUSTMENT SCREW 110230042 110230042 1

44 THRUST PLATE DP15404 DP15404 1

45 SCREW, SOCKET HEAD CAP, 1/4-20 x 1 SSH14201D SSH14201D 12

46 O-RING MPSR138 MPSR138 2

47 O-RING PISTON ROD 62308 62308 1

48 SCREW, SOCKET HEAD 1/4-20 X 3/4 SSH142034 SSH142034 3

49 PISTON ASSEMBLY 110230039 110230039 1

50 GASKET, PISTON 8" MPSG140 MPSG140 1

51 PISTON, COVER 11013 11013 1

52 FITTING, AIR 1/8" PIPE x 1/4" TUBE, 90 DEGREE AQ69P4X2 AQ69P4X2 2

53 FITTING, AIR 1/4" PIPE x 1/4" TUBE 90° AQ69P4X4 AQ69P4X4 7

54 TUBING, BLACK AIR LINE 1/4 TPE4014 TPE4014 5.125 FT

55 RELAY, SOLID STATE MPR90217 MPR90217 2

56 SCREW, PAN HEAD PHILLIPS 8-32 x 1/4 SP83214 SP83214 2

57 SCREW, PAN HEAD PHILLIPS 8-32 x 1/2 SP83212 SP83212 5

58 MARKER STRIP #5 MS6015 MS6015 1

59 WASHER, INTERNAL TOOTH LOCK #8 WLIT8 WLIT8 6

PLDP2300BZ RM 103118 CUSTOMER MANUAL

PROLUXE PARTS LIST FOR MODEL

DP2300BZ

ITEM

No.

DESCRIPTION

DP2300BZ

208 ~ AC

DP2300BZCEC

220 ~ AC

QTY.

60 POWER CORD 110573175 MPPW202 1

61 GUIDE PISTON POST 11072 11072 1

62 BUSHING, GUIDE POST MPSB070 MPSB070 1

63 ROD, THREADED 110230016 110230016 1

64 NUT, COUPLING 3/8-16 x 1-3/4 NC3816134 NC3816134 1

65 SCREW, SOCKET HEAD 3/8-16 x 4 SSH38164 SSH38164 1

66 TRANSFORMER 11096975 MPPT700R 1

67 STRAIN RELIEF 3231 3231 1

68 BOLT, HEX 5/16-18 x 1-1/2 PARTIALLY TREADED BH51618112G5 BH51618112G5 4

69 WASHER SPLIT LOCK 5/16 WL516 WL516 4

70 WASHER, SAE 5/16 WSAE516 WSAE516 4

71 WASHER, STEEL .311 O.D. x .150 I.D. x .020 THICK 311150019 311150019 4

72 WIRE HARNESS DP15450 DP15450 1

73 CONTROL PANEL OVERLAY ODP1300BZ ODP1300BZ 1

74 MARKER STRIP #7 MS6017 MS6017 1

75 FACIA CONTROL PLATE 11086027 11086027 1

76 CONTROL, DIGITAL 110175116052 110175116052 1

77 SPACER, NYLON 110969111 110969111 4

78 NUT, HEX 6-32 NH632 NH632 8

79 WASHER, INTERNAL TOOTH LOCK #6 WLIT6 WLIT6 8

80

SCREW, PAN HD 8-32 X 5/8" SP83258 SST381612 2

81 SWITCH, MOM P/S OP SCREW ON GE P9XPLOSO P9XPLOSO 3

82 GREEN MUSHROOM BUTTON SCREW ON P9ARB3V P9ARB3V 2

83 CONTACT N/O SCREW TYPE, GE #P9B10VN 110101751 110101751 3

84 BUTTON BLACK MUSHROOM SCREW ON GE P9ARB3N P9ARB3N 1

85 VALVE, QUICK EXHAUST 110559033 110559033 1

86 MUFFLER, 1/4 SUPER QUITE FLOW 110559029 110559029 3

87 PLUG, BUTTON 7/8, PLASTIC (BLACK) PB78P PB78P 1

89 LEG, APPLIANCE, 4", SATIN NICKEL FINISH AE601653 AE601653 4

90 SCREW, BUTTON HEAD 1/4-20 X 5/8 SB142058 SB142058 1

91 NIPPLE, BRASS 1/4 x 2 N142 N142 1

92 BOLT HEX SLOTTED 8-32 x 1/4 BH83214 BH83214 12

93 SCREW, SOCKET HEAD 5/16-18 X 1 DOMESTIC SSH516181D SSH516181D 1

94 WASHER, LOCK SPLIT 1/2" WL12 WL12 2

95 WASHER, SAE 1/2" WSAE12 WSAE12 2

96 GUARD, LEFT SIDE BURN 11017452306 11017452306 1

97 GUARD, RIGHT SIDE BURN 11017452307 11017452307 1

98 RTD SENSOR ASSEMBLY 110949110 110949110 2

99 NUT, HEX 1/2-13 NH1213 NH1213 2

100 CLAMP, CABLE 5/16 CC516 CC516 2

104 U.P. ADJUSTMENT BOLT DP15467 DP15467 4

105 MANUAL DP2300 (BLAZE) MDP2300BZ MDP2300BZCEC 1

106 SHAFT, WELDMENT 11017452309 11017452309 2

107 KNOB KN113 KN113 1

108 UPPER HEAT SHROUD WELDING 110230061 110230061 1

109 SHROUD, LOWER PLATEN 110230037 110230037 1

110 WIRE, TGGT, 14 GA 110069 110069 13.25 FT

111 TFE, SHRINK TUBING 7 AWG 110131 110131 .66 FT

112 TERMINAL, RING #6 14-16 GA (HI-TEMP) 1601HT 1601HT 2

113 TERMINAL, RING #8 14-16 GA (BLUE) 1604 1604 4

114 TERMINAL, QD 3/16 x 18-22 GA (PINK) 2280 2280 2

115 WIRE, TFE 14 GA GREEN WTFE14G WTFE14G 5.45 FT

116 SLEEVING, PVC WIRE OPVC1050 OPVC1050 1.91 FT

117 TFE NON SHRINK TUBING 110133 110133 .50 FT

118 TERMINAL, RING #6 x 18-22 GA, RED MOLEX 2202 2202 4

119 VALVE SOLENOID 11017511604 11017511604 1

120 SCREW, PAN HEAD 8-32 x 1-1/2 STAINLESS STEEL SP832112S SP832112S 2

121 AIR REGULATOR, DP2300 110130004 110130004 1

122 MOUNTING BRACKET REGULATOR AND PANEL NUT PLASTIC 110130005 110130005 1

PLDP2300BZ RM 103118 CUSTOMER MANUAL

PROLUXE PARTS LIST FOR MODEL

DP2300BZ

ITEM

No.

DESCRIPTION

DP2300BZ

208 ~ AC

DP2300BZCEC

220 ~ AC

QTY.

123 14-16 GA #10 FORK TERMINAL ISUL. 1626 1626 2

124 SCREW, SET 1/4-20 X 3/8 CONE POINT SST142038CP SST142038CP 1

125 SCREW, SET 1/4-20 X 1/4 SST142014 SST142014 1

126 O-RING GASKET DP18302 DP18302 1

A1 KITTED, UPPER PLATEN WITH WIRING ONLY 11017452374208K 11017452374220K 1

A2 KITTED, UPPER PLATEN COMPLETE ASSEMBLY 11017452374208AK 11017452374220AK 1

A3 KITTED, LOWER PLATEN WITH WIRING ONLY 11017452332208K 11017452332220K 1

A4 KITTED, LOWER PLATEN COMPLETE ASSEMBLY 11017452332208AK 11017452332220AK 1

A5 KITTED, SOLENOID VALVE ASSEMBLY 11017511604K 11017511604K 1

A6 AIR LINE EXTERNAL SYSTEM 110230010 110230010 1

A7 ALIGNMENT SWITCH ASSY KIT 1101169341K 1101169341K 1

A8 KITTED, MOUNTING TEMPLATE DP127K DP127K 1

A9 REGULATOR, GAUGE AND FITTING KIT DP15405K DP15405K 1

A10 KITTED, PISTON ASSY 110230039K 110230039K 1

PLDP2300BZ RM 103118 CUSTOMER MANUAL

DOUGHPRO

DP2300 Automatic Air Press Trouble Shooting Guide

Symptom Probable Cause Action to be Taken

Ref. #'s on

Explosion

Drawing

Power Button on Digital Controller

face is depressed but doesn’t turn

on.

Power Cord is not plugged in.

Plug power cord into wall 's

receptacle and depress power

button on controller

60

Circuit Breaker is tripped off in the

site's breaker box

Reset circuit breaker that the Grill is

plugged into. Depress Power Button

to turn on.

___

Transformer has taken a electrical

surge and is damaged

Replace Transformer after you check

secondary side of transformer. If

working properly, you should

receive 12vdc.

66

Check voltage on the secondary side

of the Transformer. If you read

12VDC then you are receiving voltage

to the Controller.

Replace Controller. Controller

should be on once the power button

is depressed.

76

Possibly blown Fuse Replace fuse.

39

Digital Controller's LED's are

scrambled or randomly irratic. If

when turning on, the display will

first go to segment check

Possibly a componet on the Digital

Controller is damaged

Replace Digital Controller

76

Possibly control needs to reset

While unit is on (controller lit up)

Unplug unit, wait for 1 min. then

plug machine on and depress power

button.

___

Digital Controller on startup goes

through LED segment check (8888)

then to version # and then loops

back to to the above reboot.

The relay driver on the digital control

may be blown.

Replace Digital Controller.

76

Digital display shows PROB. No

heat on Upper Platen.

Sensor lost it's continuity as shown

on a muti-meter.

Disconnect prob that is open (no

continuity as shown on a multimeter. Must replace Sensor (RTD).

Do not cut and splice new sensor.

Install new 2000 ohm RTD sensor to

under side of Heat Platen and

reconnect to Controller.

A1.10

When depressing the tactile button

on Digital Controller, nothing

happens.

The tactile buttons under the overlay

may be not close enough to activate.

Same goes if the buttons are already

pressed by overlay without

depressing button.

Carefully (no too much at one time

to avoid fracturing the traces on the

Controller) tighten the nuts on the

back of the Controller until button

activate. Same goes in reverse if

buttons are held down by the

overlay.

___

Digital display shows Rela and

Particular zone is over heating or

outer zone).

The Relay on the switched side is not

opening to regulate temperture.

Replace the Relay.

55

Beeper not functioning or

intermitten beeper sound.

Beeper on Digital Control board

failed.

Replace Digital Controller board

76

1

DOUGHPRO

DP2300 Automatic Air Press Trouble Shooting Guide

Symptom Probable Cause Action to be Taken

Ref. #'s on

Explosion

Drawing

If setpoint is reached but slighty off

in temperature.

Offset may need to be calibrated and

adjusted.

Must call (800) 624-6717 ext. 129

for confidential instructions.

___

Press does not close when pressing

the two, green, start buttons

Did not simultaneously press the start

buttons exactly at the same time

Try pressing both buttons eactly at

the same time. This is a anti-tiedown safety feature.

82

The Lower Platen switch mounted on

the base is not in contact to complete

circuit

Make sure the roller plunger comes

into contact (clicking noise). This is

also a safety feature that both

platens are aligned before

Heater Platen overheating

If the Relay (depending the year of

the model) on the coil side are

receiving 12vdc indicates the

Controller is functioning properly. On

the switching side of the relay, is

there 120 vac going to the heater in

question . If there is no voltage on

the to the switching side of the relay

to the heaters, the Relay is not

working properly

Replace Relay If the Controller's

heat-on LED is not lit indicating the

controller is working properly.

55

Power is on but hear a leaking of air

under the lower platen / Ram

casting while Press is idle.

The O'rings are warn allowing the air

to pass through the cylinder. This

occurs when the cylinder walls looses

it's lubrication due to excessive water

generated by poorly maintained

compressor or undersized

compressor generating heat thus

generating water. Be sure to drain

captured water from compressor

tank on a regular basis.

The cylinder needs orings, gasket

and new cylinder grease. Request

instruction sheet and need to order

P/N 110033 for the kit.

___

After activation Lower Platen and

when cycle is complete, the Lower

Platen either is very slow coming

down or doesn’t go up or down at

all.

The Mufflers on the Solenoid Valve

maybe dirty and now allowing alr

from passing though. This occurs

when excess water is passing from

the compressor to the press. If this

doesn't correct the problem. You

may need to replace the solenoid

valve.

Replace both Solenoid Valve

mufflers.

A5.2

Both Upper and Lower Platen not

aligned when activating. You may

experience a shifting of the platens

when coming into contact, or

striking noise.

Upper and Lower Platen misaligned.

On the left side of the Post Collar

(#35) are back- to-back set screws.

Remove the first locking set screw.

Adjust stopping set screw to align

platen (*IMPORTANT* must reduce

air pressure to a minimum as not to

damaging closing platens). After

alignment is complete, re-install

locking set screw as not to move the

alignment set screw.

17

2

Rev 12916

Warranty & Return Policy

Proluxe warrants all products manufactured by it against defects in workmanship or materials from the date of purchase for a period of

(1) year on parts and labor. This warranty applies to only equipment purchased and used in the United States. Warranty period

shall begin when equipment ships. Warranty travel shall only be covered for 60 miles. Limited lifetime warranty on heating

elements.

ALL WARRANTY SERVICE CALLS MUST BE APPROVED BY PROLUXE. IF THIS PROCEDURE IS NOT FOLLOWED,

WARRANTY SERVICE WILL NOT BE COVERED. WARRANTY SERVICE WILL BE PAID ON STRAIGHT TIME, OVERTIME WILL

NOT BE COVERED.

Exclusions:

1. WOOD / GAS FIRED OVENS: PROLUXE warranty applies to the main body of the oven being steel / refractory and insulation shall

be free from defects in materials and workmanship for a period of four years from the date of purchase. The gas equipment shall be

free from defects in materials and workmanship for a period of one (1) year

from the date of purchase. Lifetime warranty against cracks on oven floor.

2. Air compressors are excluded from this warranty, but PROLUXE may act as a warranty expeditor in certain instances regarding

these compressors. The air compressor manufacturer provides a limited warranty

and a copy of this warranty is furnished with all compressors sold by PROLUXE. For prompt handling of compressor warranty claims

the instructions of the compressor manufacturer must be adhered to.

3. Equipment built to special order as well as accessories cannot be canceled and are not returnable unless defective within the

terms of this warranty.

4. In no event shall PROLUXE be liable for consequential damages arising out of the failure of any of its products if operated

improperly, altered or caused by normal wear or damage by operator abuse.

5. BC2325 pedestal warranty disclaimer: Pedestals shall only be covered under warranty if they have been cleaned using the factory

approved cleaning method. Cracked or damaged pedestals must be inspected by the factory before warranty is authorized.

6. Limited lifetime warranty on heating elements: If replacement is needed, Proluxe will send the new part at no charge but labor will

not be covered unless the unit is still under the 1 year manufacture warranty.

Returned Merchandise Policy:

Should it become necessary to return any of the company’s products, the following instructions must be adhered to: First,

contact our customer service department for approval and a return authorization number. Please have the serial number

of your item available at that time. All merchandise must be shipped freight prepaid by customer or service agency.

Subject to the inspection of the product by the company, a restocking charge of 20% of the Net purchased price paid to

PROLUXE will be assessed. Merchandise may not be returned for credit without prior written approval of PROLUXE. Collect shipments

will not be accepted. No returns after 60 days of original shipment date on machines. Purchased parts may not be returned after 30

days.

If upon inspection by PROLUXE or its authorized agent it is determined the equipment has not been used in an appropriate manner,

has been modified, or has not been properly maintained, or has been subject to misuse,

misapplication, neglect, abuse, accident, unauthorized modification, damage during transit, delivery, fire, flood, act or war,

riot or act of God, then this warranty shall be deemed null and void.

Terms & Conditions:

1. Prices indicated in the PRICE LIST are suggested retail prices and are shown in U.S. DOLLARS.

2. Terms of Payment: 1% 10 days, NET 30 days.

3. NEW ACCOUNTS: Satisfactory credit information must be provided before open account status can be extended.

Unless agreed otherwise, all shipments will be made C.O.D., CASH IN ADVANCE.

4. PRICING: Prices, specifications, model numbers, capacities and accessories are subject to change without notice.

5. FREIGHT / ROUTING: Method of shipment will be determined by PROLUXE unless otherwise

advised by PURCHASER.

6. DAMAGED CLAIMS: All merchandise shipped at purchaser’s risk. Inspection must be made by purchaser at time

goods are received. If goods are damaged, the PURCHASER shall request that the agent of the transportation

company make a written notation on the proper shipping documents immediately and then file a claim for damage.

GOODS DAMAGED IN SHIPMENT ARE NOT RETURNABLE.

7. RETURNS: Machines may not be returned after 60 days. Purchased parts may not be returned after 30 days. A

restocking fee of 20% will be assessed on non-warranty returns.

8. TAXES: Prices indicated herein DO NOT include State, Federal, Local or foreign taxes or duties, nor do they include

fees, permits, insurance or other levies, all of which are the responsibility of the purchaser.

9. All orders are subject to acceptance by PROLUXE.

10. Possession of this price list shall not be considered an offer to sell.

Loading...

Loading...