Operations Manual

Model: DP2000PRE

Pizza Rev Manual Press

formerly DOUGHPRO. New Name. Same Quality. Superior Service.

proluxe.com

Congratulations!

Factory in Perris, California

Your selection of the Proluxe DP2000

is a sound business decision. Whether

your intended use is to press or par bake

dough for pizzas, tortillas, mushi skins

or other appropriate dough products, rest

assured that you have made a wise

choice.

Proluxe equipment is a result of the

highest quality engineering and timetested design. Your machine, combined

with Proluxe’s reputation of

innovation in dough press equipment

manufacturing, insures the continuing

capability of delivering the bestdecorated product possible.

This manual describes installation,

operation, and maintenance procedures

for your new model DP2000.

Your model DP2000 machine will have

a long trouble-free life. Read this

manual carefully and keep it with your

machine; it’s your key to proper

operation and lasting service.

Included with your shipment:

• 5 Rubber Feet

• Platen Saver **If your unit has

polished platens**

Installation

DOMESTIC

Use a separate 30 amp AC

circuit. Only industrial extension

cords with proper wire size

should be used; size 16/3 wire for

distance up to 25 feet, and size

14/3 for distance up to 50 feet.

INTERNATIONAL

Use a designated 30 amp AC

circuit. Only industrial extension

cords with proper wire size (2.5

sq. mm) shall be used.

Make sure there is a proper electrical

wall outlet located within reach of the

cord and plug attached to the press.

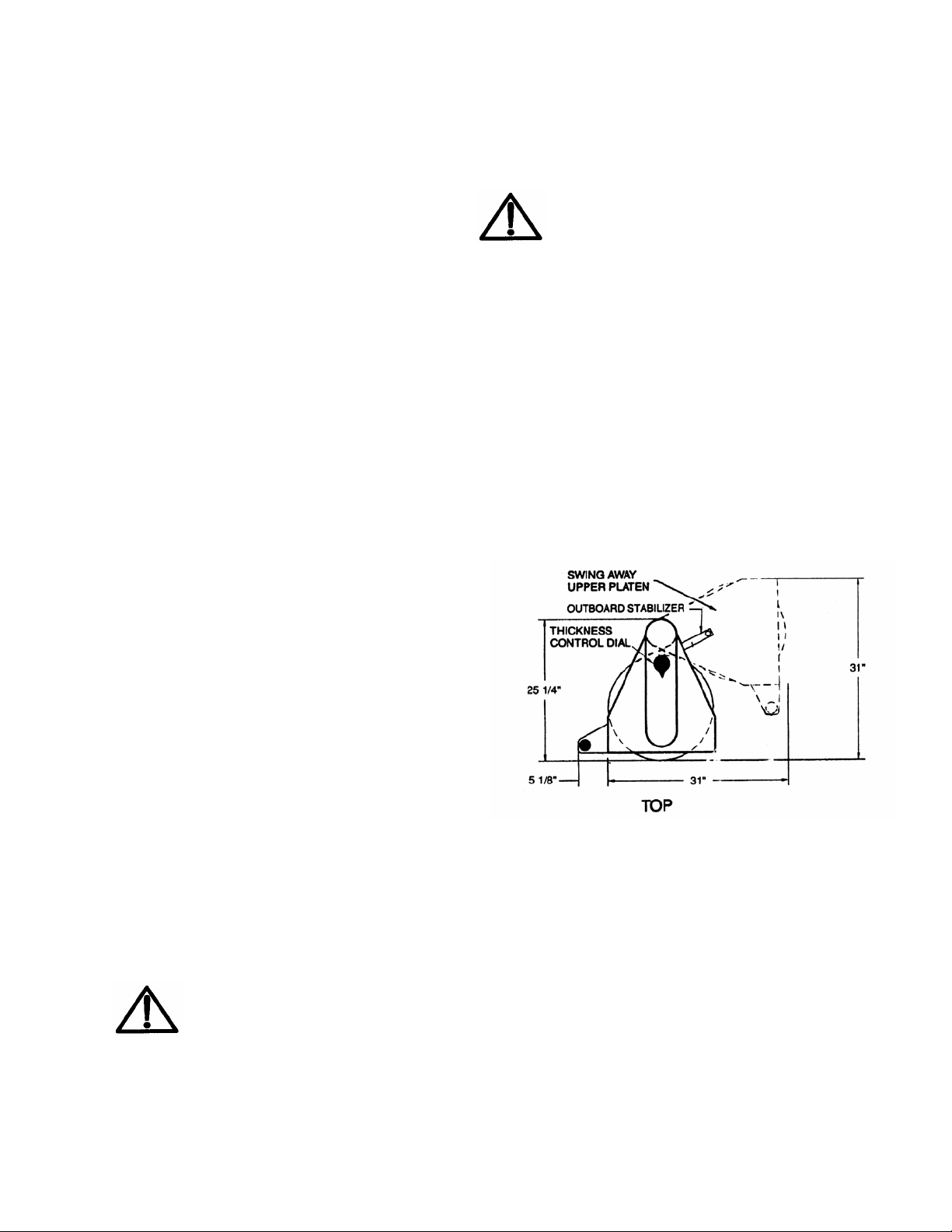

Then place the press in an area that

allows for “swing clearance”. Note that

the upper platen rotates up to 90°, in a

backward rotation, to facilitate removal

of the dough product after the press

cycle has been completed. Also note

that the machine requires a vertical, clear

space of 33” from the bottom of the

machine to the top of the pull handle.

Limited Machine Warranty

Proluxe warrants this dough press

machine, when operated under normal

conditions, to be free from

manufacturing defects in material and

workmanship for a period of one year on

parts and labor from the invoice date.

This warranty will be effective only

when Proluxe authorizes the original

purchaser to return the product to the

-1- DP2000-1725-7/04

prepaid and only when the product, upon

examination, has proven to be defective.

This warranty does not apply to any

machine that has been subjected to

misuse, negligence or accident.

Proluxe shall not be liable for the

injury, loss or damage, direct or

consequential, arising out of the use or

the inability to use the product.

No claim of any kind shall be greater in

amount than the sale price of the product

or part to which claim is made.

This is the sole warranty given by the company, it is in

lieu of any other warranties, expressed or implied, in

law or in fact, including the warranties of

merchantability and fitness for a particular use, and is

accepted such by the purchaser in taking delivery of

this product.

Specifications

Electrical:

208V/50-60Hz/4600W/22.11Amps

Requires 30 AMP outlet

Includes 72” NEMA 6-30P approved

cord and plug.

Shipping Weight:

180lbs. (82kg)

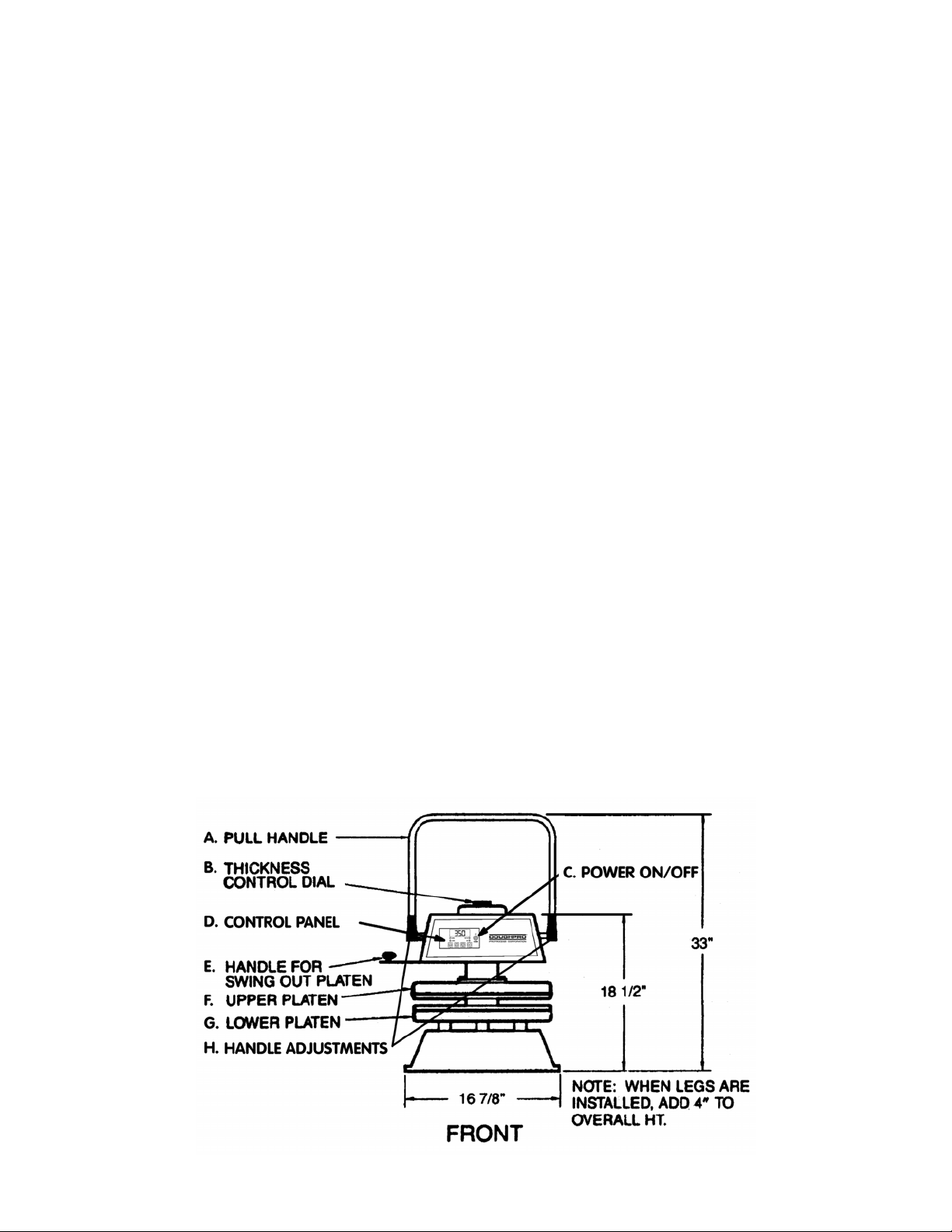

Familiarize yourself with controls and

operating mechanisms before attempting

to use the DP2000. These are as

follows:

(A) Pull Pressing Handle for raising

and lowering the upper platen.

This action forces the mating of

the platens.

(B) Thickness Control Dial.

(C) On/Off Button. The green light

above the button will illuminate

when turned on to indicate

power is in the press.

(D) Control Panel (see Control

Board Operations)

(E) Handle for swing-out platen.

(F) Upper platen

(G) Lower platen

(H) Handle adjustments (see

Tightening the Pull-Down

Handle)

Safety Summary

-2- DP2000-1725-7/04

WARNING

In case of power cord damage,

do not attempt to repair or

replace the power cord. Contact

the manufacturer or the local

distributor.

WARNING

Avoid touching hot surfaces

while operating the machine.

CAUTION

During normal operation, the

base of the machine must be

installed or placed above the wall

socket.

CAUTION

When servicing or cleaning the

machine, make sure that the

power cord is removed from the

wall socket.

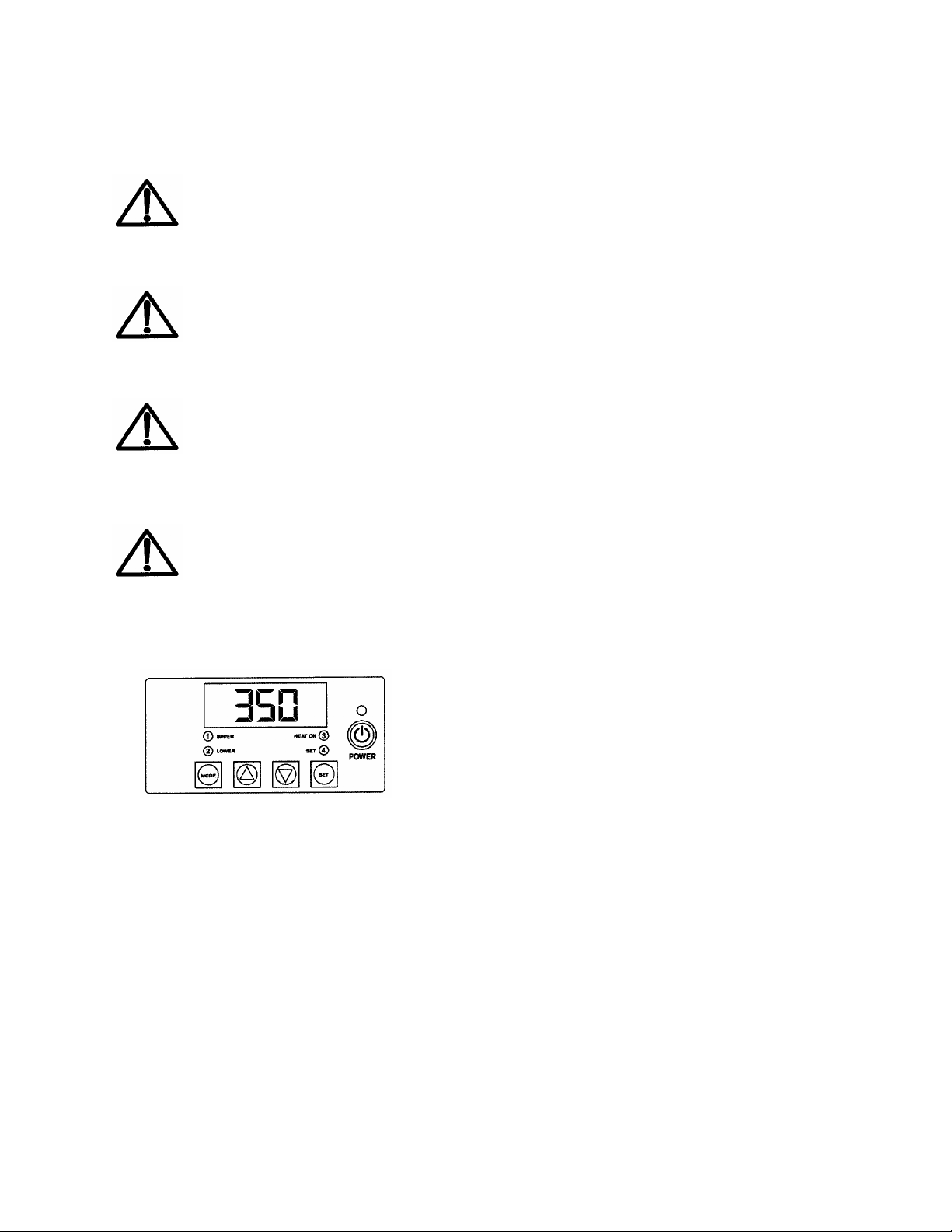

Control Board Operations

Solid State Controller

This controller has three (3) control

features:

1. Temperature – Temperature may

be set from 0°-450°F (0°232°C). The factory default

setting is 2°. If you would like

to change this setting, simply

follow the Controller Operation

directions.

2. Counter – Cycle counter counts

the number of applications from

1 to 9999 (see additional Notes –

Counter).

3. Timer – A timer mode is

available upon special request. If

you would like to have the timer

function installed, please call

1-800-624-6717

Controller Operation

Temperature Control

1. Press the MODE button until

temperature is displayed.

2. Push and hold SET button and

simultaneously push UP (V) or

DOWN (W) arrow buttons to the

desired temperature setting.

For the DP2000, both the upper

and lower platens may be set to

different temperatures.

• Upper Platen: Simply

push the MODE button

until the “upper” light is

illuminated. Adjust the

temperature as noted

above.

• Lower platen: Simply

push the MODE button

until the “lower” light is

illuminated. Adjust the

temperature as noted

above.

-3- DP2000-1725-7/04

Dough Pressing Operations

SETTING CRUST THICKNESS

CONTROL:

*The thickness is determined by dough

weight and temperature setting on each

platen.

PRESSI

NG DOUGH:

1. First make sure you have the

correct type electrical current or

serious damage could occur!

2. Press the Power Button in order

to turn the machine on. A green

light will illuminate above the

power button indicating that

power is in the machine.

3. Both the upper and lower platens

will heat up once you have

adjusted your digital control to

your desired setting. Note:

Different products require

different temperature settings. In

order to determine the right

temperature setting for your

product, refer to the following

table simply as a guide

-4- DP2000-1725-7/04

No. DPPC1. (See our catalog

and price list for information.)

Note: This spray will not affect

the taste of your crust in any

way.

6. Place your pre-portioned ball of

dough in the approximate center

of the lower platen. Add another

dash of spray to the top of the

dough ball.

7. Close the platen and pull the “U”

shaped handle down to

commence the pressing

operation.

8. Hold the handle down for as long

as you have determined to be the

appropriate amount of time for

your particular product and then

simply pull the handle back up

when you have completed.

9. Inspect your dough. If it is too

thick, rotate the thickness control

dial, located on the top of the

machine, to the line marked

“THIN”. Reverse this procedure

if your product presses too thin.

Experiment with temperature,

dough weight, time, and pressure

until you arrive at the desired

result.

10. Remove the finished product by

rotating the upper platen out of

the way until you have sufficient

space to do so. Place the dough

on a screen or in a pan. Since the

shape of the dough may be

altered slightly in the transfer

process, some hand fitting may

be required. Add toppings, if

desired, and now you are ready

to bake.

ADDITIONAL NOTES:

Temperature

Note

Fahrenheit/Centigrade (Celsius)

Conversion

The temperature controller can

be programmed to display either

°F or °C. To change: Press the

MODE button until the

temperature is displayed, then

push and hold the SET button for

10 seconds.

Counter

The controller has a built in cycle

counter.

• Press MODE button until the

counter is displayed.

• Counter display range is 0000 to

9999.

• To reset the cycle counter,

display the counter reading, then

push and hold both UP (V) and

DOWN (W) arrow buttons for 3

seconds until the counter resets

to zero (0000) on the display.

Tightening the Pull-Down Handle

The pull-down pressing handle requires

adjustment periodically to prevent it

from free falling. Whenever the handle

seems too loose or is falling by itself, the

problem can be corrected easily and

quickly as follows:

1. Using a 3/16” hex shaped Allen

wrench, insert in key slot located

on the right beneath the upper

shroud.

2. Tighten until the press action of

the handle becomes firm but not

too tight.

-5- DP2000-1725-7/04

International Symbols

Serial Tags

Preventative Maintenance Suggestions

The Proluxe DP2000 machines are

relatively maintenance free. For a long

and trouble-free life, the following

preventative maintenance should be

followed:

Daily Care:

1. Platens: These platens should

only be cleaned with mild soap

and warm water then wiped off

with a clean, soft cloth or soft

sponge. Never use steel wool or

harsh abrasives or you will

cause costly damage.

2. All other exterior surfaces:

Here again a daily wipe down

with mild soap and warm water

will do the job quite nicely.

Never use steel wool or harsh

abrasives or you will cause

costly damage.

-6- DP2000-1725-7/04

Piston Maintenance:

In order to ensure proper and trouble

free operation of the press piston, it is

important that the machine be lubricated

once every three (3) months, under

normal operation. High volume users

may require more frequent lubrication.

The lubricant used must be USDA H-1

authorized for food machinery. This

lubricant can be ordered through

Proluxe as part number # 110-002.

Please follow these simple instructions:

1. Locate the grease port on the

machine. Machines with pull

down arms have a single grease

port located below the upper

head on the right side of the

vertical post. Machines with

swing-away upper heads have

two grease ports; one on the right

side of the vertical post and one

on the back of the vertical post.

All other machines have a single

port. (refer to illustration)

2. Place grease gun head against

grease port and apply enough

pressure to allow gun head to

engage the grease port.

3. Squeeze handle of grease gun

which forces the grease into the

piston. One squeeze is all it

takes.

Service Problems:

Contact our factory or approved service

agency (U.S. only). Note: When

contacting factory for information, parts

or service instructions, it is of the utmost

importance that the serial number of the

machine be provided. This number can

be found on the serial plate located on

the rear of the machine.

-7- DP2000-1725-7/04

DOUGHPRO

DP2000 Trouble Shooting Guide

Symptom Probable Cause Action to be Taken

Power Button on Digital Controller

face is depressed but doesn’t turn

on.

Power Cord is not plugged in.

Plug power cord into wall 's receptacle

and depress power button on

controller

Circuit Breaker is tripped off in the

site's breaker box

Reset circuit breaker that the Grill is

plugged into. Depress Power Button to

turn on.

Transformer has taken a electrical

surge and is damaged

Replace Transformer after you check

secondary side of transformer. If

working properly, you should receive

12vdc.

Check voltage on the secondary side

of the Transformer. If you read

12VDC then you are receiving voltage

to the Controller.

Replace Controller. Controller should

be on once the power button is

depressed.

Possibly blown Fuse Replace fuse.

Digital Controller's LED's are

scrambled or randomly irratic. If

when turning on, the display will

first go to segment check

Possibly a componet on the Digital

Controller is damaged

Replace Digital Controller

Possibly control needs to reset

While unit is on (controller lit up)

Unplug unit, wait for 1 min. then plug

machine on and depress power button.

Digital Controller on startup goes

through LED segment check (8888)

then to version # and then loops

back to to the above reboot.

The relay driver on the digital control

may be blown.

Replace Digital Controller.

Digital display shows PROB. No

heat on Upper Platen or Lower

Platen.

Sensor lost it's continuity as shown

on a muti-meter.

Disconnect prob that is open (no

continuity as shown on a multi-meter.

Must replace Sensor (RTD). Do not cut

and splice new sensor. Install new

2000 ohm RTD sensor to under side of

Heat Platen and reconnect to

Controller.

When depressing the tactile button

on Digital Controller, nothing

happens.

The tactile buttons under the overlay

may be not close enough to activate.

Same goes if the buttons are already

pressed by overlay without

depressing button.

Carefully (no too much at one time to

avoid fracturing the traces on the

Controller) tighten the nuts on the

back of the Controller until button

activate. Same goes in reverse if

buttons are held down by the overlay.

Digital display shows Relay and

Particular zone is over heating or

outer zone).

The Relay on the switched side is not

opening to regulate temperture.

Replace the Relay.

Beeper not functioning or

intermitten beeper sound.

Beeper on Digital Control board

failed.

Replace Digital Controller board

If setpoint is reached but slighty off

in temperature.

Offset may need to be calibrated and

adjusted.

confidential instructions.

Must call (800) 624-6717 for

DOUGHPRO

DP2000 Trouble Shooting Guide

Symptom Probable Cause Action to be Taken

Heater Platen overheating

If the Relay (depending the year of

the model) on the coil side are

receiving 12vdc indicates the

Controller is functioning properly. On

the switching side of the relay, is

there 120 vac going to the heater in

question . If there is no voltage on

the to the switching side of the relay

to the heaters, the Relay is not

working properly. It has been seen

on remote cases, the Sensor (2M

ohm) can give a false reading as well.

Replace Relay If the Controller's heaton LED is not lit indicating the

controller is working properly. If this is

not the issue, replace sensor.

Dough not having same thickness

across the press dough.

To adjust upper platen for level press

Underneath the arm resting on the

Upper Platen Shroud you will find 4,

stacked hex bolts sitting over the upper

platen attach to the arm. The top bolts

are called locking bolts. The 4 larger

Hex Bolts below are Adjustment Bolts.

Break free the 4 Locking blts. With a

open end wrench adjust the A. bolts

(1/8 turn at a time where needed and

test with dough. After satisfied,

tighten the Locking bolts making sure

not to move the larger Adustment

Bolts.

PARTLISTFORTHE

DP2000PR

ITEM # DESCRIPTION

1 PLUG, METAL PUSH-IN NICKEL PLATED 110200013

2 HOUSING, INSTRUMENT 11011812204

3 CABLE STRAIN RELIEF 3231

4 SCREW, SOCKET FLAT HEAD 1/4-20 X 3/4 SF142034

5 HANDLE SOCKET 11016650

6 BRACKET, HOUSING ASSEMBLY 110144130

7 CAM RAMP ASSEMBLY 1109312

8 SCREW, BUTTON SOCKET HD STAINLESS 1/2-20X2 SB12202S

9 SCREW, SET 1/4-20X3/8 SST142038

10 GEAR RACK 1109380

11 PISTON ASSEMBLY 11018974

12 BOLT, HEX 5/16-18 X 1 3/4 BH51618134G5

13 BOLT, LEVEL ADJUSTMENT 1109367

14 KNOB, SWING AWAY 110017

15 HANDLE SWING 11023003503

16 CAP, VINYL (ADJUSTMENT SCREWS) SC0687

17 SPRING DIE YELLOW 11023006

18 BASE ASSEMBLY WITH POST 1106191103

19 SHIM, GEAR RACK 110144120

20 COVER PLATE, BASE 11010954

21 BUSHING, INSULATING 1/2 110966022

22 WIRE SUPPORT TUBE 110200020

23 SHOULDER BOLT 3/8 X 1-3/4 X 5/16-18 11020003

24 CORD, POWER 110573175

25 BUSHING, SPACER 11024369

26 NUT, HEX 1/4-20 NH1420

27 ORING #2-238 N-70, PISTON 238N70

28 WASHER, STEEL 311150019

29 MARKER STRIP #2 MS6992

30 SCREW, SET 8-32X1 SST8321

31 TENSION STRAP ASSEMBLY 11041663

32 HANDLE, PRESSURE 1109390

33 ARM 1109842103

34 SCREW, PHILLIPS PAN HEAD 8-32 X 1/4 SP83214

35 GEAR BAR 1109361

36 COLLAR, GEAR BAR 11013183

37 CLAMP, CABLE 1/2 CC12

38 SCREW, PAN HEAD 8-32X3/8 PHILLIPS SP83238

39 SCREW, SOCKET HEAD 1/4-20X3 1/4 SSH1420314

40 SCREW, PAN HEAD 8-32X1 SP8321

41 TRANSFORMER 11096975

42 WASHER, SAE #8 WSAE8

43 SCREW, BUTTON HEAD 1/4-20X3/4 SB142034

44 SCREW, SOCKET HEAD 1/4-20X1/2 SSH142012

45 TERMINAL BLOCK 11098414

46 SCREW, PAN HEAD 8-32X1/2 PHILLIPS SP83212

47 SOLID STATE RELAY MPR90217

DP2000PRE

208 ~ AC

QTY

1

1

1

1

2

1

1

1

7

1

1

4

4

1

1

4

4

1

1

1

1

1

4

1

1

2

1

4

1

1

1

1

1

10

1

2

2

6

1

1

1

10

4

1

1

4

2

PLDP2000PRRA30000

PARTLISTFORTHE

DP2000PR

ITEM # DESCRIPTION

48 SWITCH, MICRO V15G31C25K

49 SCREW, ROUND HEAD 4-40 X 5/8 SR44058

50 WIRE HARNESS 110589050

51 SCREW, SOCKET HEAD 3/8-16X3/4 SSH381634

52 CONTROL PANEL OVERLAY ODP1300

53 CONTROL, FACIA PLATE ASSEMBLY 11086027

54 DIGITAL CONTROL 11096905220

55 SPACER, NYLON 1/4 110969111

56 NUT, HEX 6-32 NH632

57 WASHER, #6 INTERNAL TOOTH LOCK WLIT6

58 POWER DISTRIBUTION CABLE DP2000 110589067

59 WASHER, #8 INTERNAL TOOTH LOCK WLIT8

60 NUT, HEX 8-32 NH832

61 TERMINAL BLOCK #6 6016

62 SCREW, SOCKET HEAD 1/4-20X5/8 SSH142058

63 SCREW, SOCKET HEAD 5/16-18X1 SSH516181D

64 ORING, POST/COLLAR MPSS062

65 SCREW, SOCKET SET, 5/16"-18 X 3/4 SST5161834

66 COLLAR POST ARM 1104132303

67 BUSHING, BRASS (TENSION STRAP) 11018966

68 MICROSWITCH BRACKET 1101021213

69 FITTING, ZERK 1/4-28 B792

70 ARM RETAINING PLATE 11056858

71 PIN, ROLL 1/8 X 5/16 PR18516

72 SCREW, SOCKET HEAD 1/2-13X1 1/2 SSH1213112

73 NUT, LOCK NUT 1/2-20 NHSL1220

74 FITTING, ZERK 1/8 B610

75 SET SCREW SOCKET 1/4-20X7/8 SST142078

76 MARKER STRIP #6 MS6016

77 WASHER, SAE 1/2 WSAE12

78 FUSE HOLDER 1 AMP MPPF708

79 FUSE BUSS 1 AMP MPPF701R

80 SCREW PHILLIPS PAN 2-56 x 1/4 SP25614

81 FEET, RUBBER RF209

82 MANUAL, DP2000, PIZZA REV MDP2000PR

DP2000PRE

208 ~ AC

QTY

1

2

1

2

1

1

1

4

8

8

1

4

4

1

2

2

1

1

1

1

1

1

1

1

1

1

1

2

1

2

1

1

1

5

1

A1 UPPER PLATEN WIRE ONLY 1102000PR74208K

A1.1 UPPER PLATEN MACHINED 1102000PR74208

A1.2 WIRE, TGGT, 14 GA. (HEATER) 110069

A1.3 TFE, SHRINK TUBING 7AWG 110131

A1.4 TERMINAL, RING #6 14-16 GA HIGH TEMP 1601HT

A1.5 TERMINAL, RING #8 14-16 GA 1604

A1.6 TERMINAL, QD 3/16 X 18-22 GA 2280

A1.7 WASHER, SAE #6 WSAE6

A1.8 SCREW, PAN HEAD PHILLIPS 6-32X1/4 SP63214

A1.9 WIRE, TFE 14 GA. GREEN WTFE14G

A1.10 RTD, SENSOR ASSEMBLY 110949110

1

1

7.00ft.

.33ft.

1

2

2

1

1

3.08ft.

1

PLDP2000PRRA30000

PARTLISTFORTHE

DP2000PR

ITEM # DESCRIPTION

A1.11 SCREW, SET 3/8-16X1/2 SST381612

A1.12 SLEEVING, PVC WIRE OPVC1050

A1.13 TERMINAL, FEMALE MOLEX MPSQ100

A1.14 WASHER, SAE 5/16 WSAE516

A2 UPPER PLATEN COMPLETE ASSEMBLY 1102000PR74208AK

A1 UPPER PLATEN WIRE ONLY 1102000PR74208K

A2.1 FIBER GLASS INSULATION 1101171251

A2.2 SHROUD, UPPER PLATEN 1109336

A3 LOWER PLATEN WIRE ONLY 1102000PR32208K

A3.1 LOWER PLATEN MACHINED 1102000PR32208

A3.2 WIRE, TGGT, 14GA 110069

A3.3 TFE, SHRINK TUBING 7AWG 110131

A3.4 TFE, NON SHRINK TUBING 110133

A3.5 TERMINAL, RING#6 14-16 GA 1601HT

A3.6 TERMINAL, RING#8 14-16 GA 1604

A3.7 TERMINAL, #6 RING x 18-22 GA., RED MOLEX 2202

A3.8 WASHER, SAE #6 WSAE6

A3.9 SCREW, PAN HEAD PHILLIPS 6-32X1/4 SP63214

A3.10 WIRE, TFE 14 GA. GREEN WTFE14G

A3.11 RTD, SENSOR ASSEMBLY 110949110

A3.12 SCREW, SET 3/8-16X1/2 SST381612

DP2000PRE

208 ~ AC

QTY

1

1.33ft.

1

4

1

1

1

1

1

1

3.50ft.

.33ft.

.33ft.

1

3

2

1

1

1.5ft.

1

1

A4 LOWER PLATEN COMPLETE ASSEMBLY 1102000PR32208AK

A3 LOWER PLATEN WIRE ONLY 1102000PR32208K

A4.1 FIBER GLASS INSULATION 1101171251

A4.2 SHROUD, UPPER PLATEN 110230036

A5 KITTED, PINION GEAR ASSEMBLY 1109360K

A5.1 GEAR, PINION 1109360

A5.2 PLAIN STEEL WOODRUFF KEY, 3/16" X 3/4 KW931634

A5.3 SCREW, SET 1/4-20X3/8" SST142038

A6 KIT, MICRO SWITCH BRACKET ASSEMBLY 110200019K

A6.1 BRACKET, MICRO SWITCH

A6.2 WASHER, SPLIT LOCK , 1/4 WL14

A6.3 NUT, HEX 1/4-20 NH1420

A6.4 SKREW, SET 1/4-20X3/4 CONE POINT SST142034CP

110200019 1

1

1

1

1

1

1

4

1

1

1

1

1

PLDP2000PRRA30000

Rev 12916

Warranty & Return Policy

Proluxe warrants all products manufactured by it against defects in workmanship or materials from the date of purchase for a period of

(1) year on parts and labor. This warranty applies to only equipment purchased and used in the United States. Warranty period

shall begin when equipment ships. Warranty travel shall only be covered for 60 miles. Limited lifetime warranty on heating

elements.

ALL WARRANTY SERVICE CALLS MUST BE APPROVED BY PROLUXE. IF THIS PROCEDURE IS NOT FOLLOWED,

WARRANTY SERVICE WILL NOT BE COVERED. WARRANTY SERVICE WILL BE PAID ON STRAIGHT TIME, OVERTIME WILL

NOT BE COVERED.

Exclusions:

1. WOOD / GAS FIRED OVENS: PROLUXE warranty applies to the main body of the oven being steel / refractory and insulation shall

be free from defects in materials and workmanship for a period of four years from the date of purchase. The gas equipment shall be

free from defects in materials and workmanship for a period of one (1) year

from the date of purchase. Lifetime warranty against cracks on oven floor.

2. Air compressors are excluded from this warranty, but PROLUXE may act as a warranty expeditor in certain instances regarding

these compressors. The air compressor manufacturer provides a limited warranty

and a copy of this warranty is furnished with all compressors sold by PROLUXE. For prompt handling of compressor warranty claims

the instructions of the compressor manufacturer must be adhered to.

3. Equipment built to special order as well as accessories cannot be canceled and are not returnable unless defective within the

terms of this warranty.

4. In no event shall PROLUXE be liable for consequential damages arising out of the failure of any of its products if operated

improperly or caused by normal wear or damage by operator abuse.

5. BC2325 pedestal warranty disclaimer: Pedestals shall only be covered under warranty if they have been cleaned using the factory

approved cleaning method. cracked or damaged pedestals must be inspected by the factory before warranty is authorized.

6. Limited lifetime warranty on heating elements: If replacement is needed, Proluxe will send the new part at no charge but labor will

not be covered unless the unit is still under the 1 year manufacture warranty.

Returned Merchandise Policy:

Should it become necessary to return any of the company’s products, the following instructions must be adhered to: First,

contact our customer service department for approval and a return authorization number. Please have the serial number

of your item available at that time. All merchandise must be shipped freight prepaid by customer or service agency.

Subject to the inspection of the product by the company, a restocking charge of 20% of the Net purchased price paid to

PROLUXE will be assessed. Merchandise may not be returned for credit without prior written approval of PROLUXE. Collect shipments

will not be accepted. No returns after 60 days of original shipment date on machines. Purchased parts may not be returned after 30

days.

If upon inspection by PROLUXE or its authorized agent it is determined the equipment has not been used in an appropriate manner,

has been modified, or has not been properly maintained, or has been subject to misuse,

misapplication, neglect, abuse, accident, unauthorized modification, damage during transit, delivery, fire, flood, act or war,

riot or act of God, then this warranty shall be deemed null and void.

Terms & Conditions:

1. Prices indicated in the PRICE LIST are suggested retail prices and are shown in U.S. DOLLARS.

2. Terms of Payment: 1% 10 days, NET 30 days.

3. NEW ACCOUNTS: Satisfactory credit information must be provided before open account status can be extended.

Unless agreed otherwise, all shipments will be made C.O.D., CASH IN ADVANCE.

4. PRICING: Prices, specifications, model numbers, capacities and accessories are subject to change without notice.

5. FREIGHT / ROUTING: Method of shipment will be determined by PROLUXE unless otherwise

advised by PURCHASER.

6. DAMAGED CLAIMS: All merchandise shipped at purchaser’s risk. Inspection must be made by purchaser at time

goods are received. If goods are damaged, the PURCHASER shall request that the agent of the transportation

company make a written notation on the proper shipping documents immediately and then file a claim for damage.

GOODS DAMAGED IN SHIPMENT ARE NOT RETURNABLE.

7. RETURNS: Machines may not be returned after 60 days. Purchased parts may not be returned after 30 days. A

restocking fee of 20% will be assessed on non-warranty returns.

8. TAXES: Prices indicated herein DO NOT include State, Federal, Local or foreign taxes or duties, nor do they include

fees, permits, insurance or other levies, all of which are the responsibility of the purchaser.

9. All orders are subject to acceptance by PROLUXE.

10. Possession of this price list shall not be considered an offer to sell.

Loading...

Loading...