OPERATION MANUAL

Mini - Dough Presses

Models:

DP1806, DP1807, DP1808 & DP1809

PROPROCESS CORPORATIONO7328 Madison St. OParamount, CA 90723

(562) 531-0305 O(800) 624-6717 OFax (562) 869-7715

Website: www.doughpro.com

Doughpro - 20281 Harvill Ave - Perris, CA 92570

(951) 657-0379 - (800) 624-6717 - Fax (951) 657-4594

OPERATION MANUAL

DDUDHPRD

Mini - Dough Presses

Models:

DPI 806, DP1807, DP1808 & DPI 809

NSF

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Doughpro - 20281 Harvill Ave - Ferris, CA 92570

(951) 657-0379 - (800) 624-6717 - Fax (951) 657-4594

Website: www.doughpro.com

GETTING STARTED

GETTING STARTED

Mini-Dough Presses

First make sure the press is placed in an area with sufficient room for cleaning and

unobstructed operation. Start by plugging the press into a properly rated outlet

depending on the electrical rating of the press selected - 120V or 240V. Start by setting

the temperature as follows dependent on the desired product: Fresh dough pizza crusts:

150

o

F (65.5oC), Tortillas or other par baked products: 225oF (107oC). Vary the

temperature setting to suit the desired result. ALLOW 15-20 MINUTES FOR WARM-UP.

Now proceed as follows:

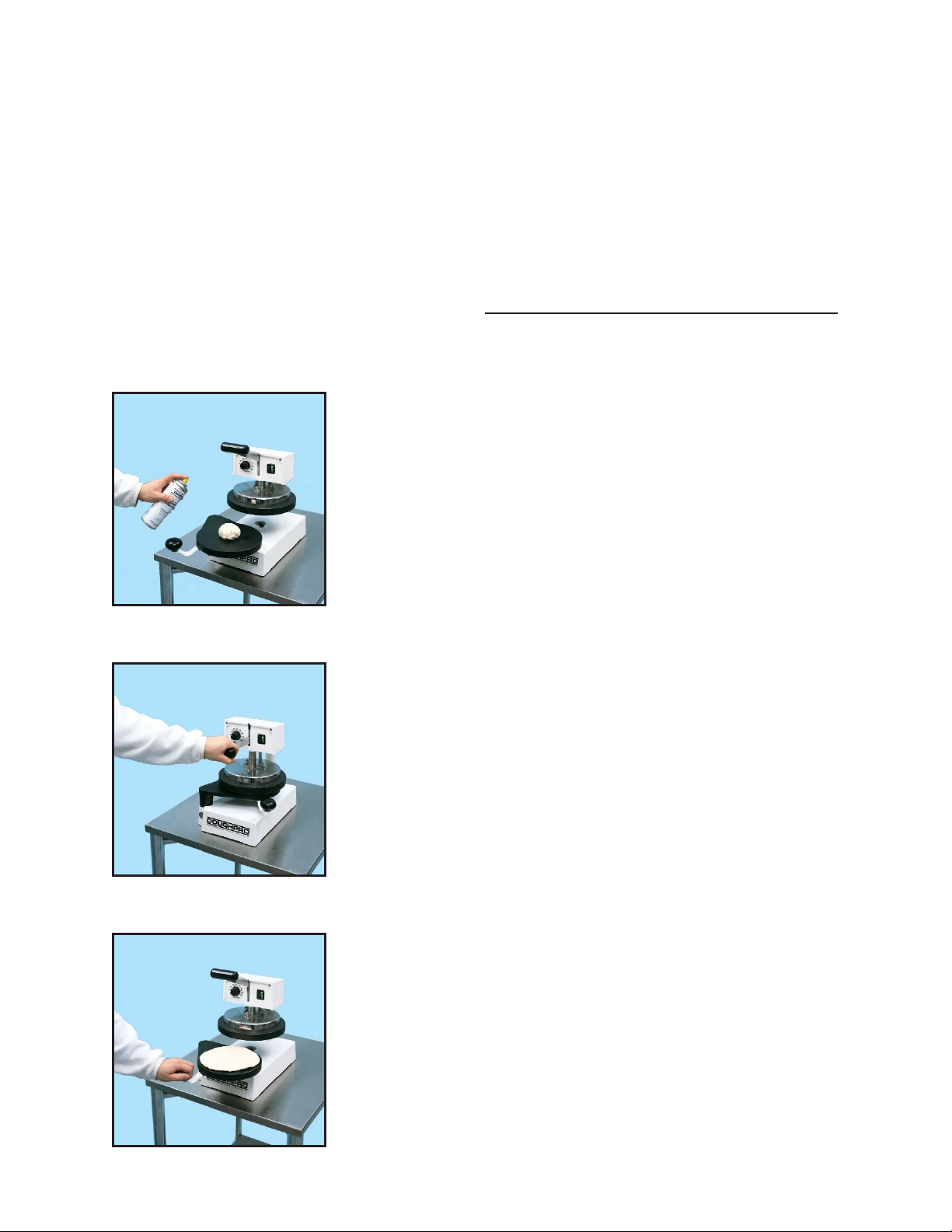

STEP 1 - After allowing upper platen to reach desired

temperature, swing out lower platen and place pre-portioned ball of dough in approximate center and swing

closed. An approved lubricant/release agent such as

olive oil or DOUGHPRO’s Cookware Food Release

Spray # DPPC1 applied to the top of the dough ball will

greatly improve the pressing operation.

STEP 2 -

Pull down on handle and hold for

about 3-7 seconds.

STEP 3 - Lift up handle, open platen and place

flattened crust on screen, disc or pan. Now you’re ready

for make-up and baking.

Mini-Dough Presses

First make sure the press is placed in an area with sufficient room for cleaning and

unobstructed operation. Start by plugging the press into a properly rated outlet

depending on the electrical rating of the press selected - 120V or 240V. Start by setting

the temperature as follows dependent on the desired product: Fresh dough pizza crusts:

150°F (65.5°C), Tortillas or other par baked products: 225°F (107°C). Vary the

temperature setting to suit the desired result. ALLOW 15-20 MINUTES FOR WARM-UP.

Now proceed as follows:

STEP I - After allowing upper platen to reach desired

temperature, swing out lower platen and place pre-por-

tioned ball of dough in approximate center and swing

closed. An approved lubricant/release agent such as

olive oil or DOUGHPRO's Cookware Food Release

Spray # DPPCI applied to the top of the dough ball will

greatly improve the pressing operation.

STEP 2 - Pull down on handle and hold for

about 3-7 seconds.

STEP 3 -

flattened crust on screen, disc or pan. Now you're ready

for make-up and baking.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Lift up handle, open platen and place

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

Mini-Dough Presses

Introduction

General Specifications

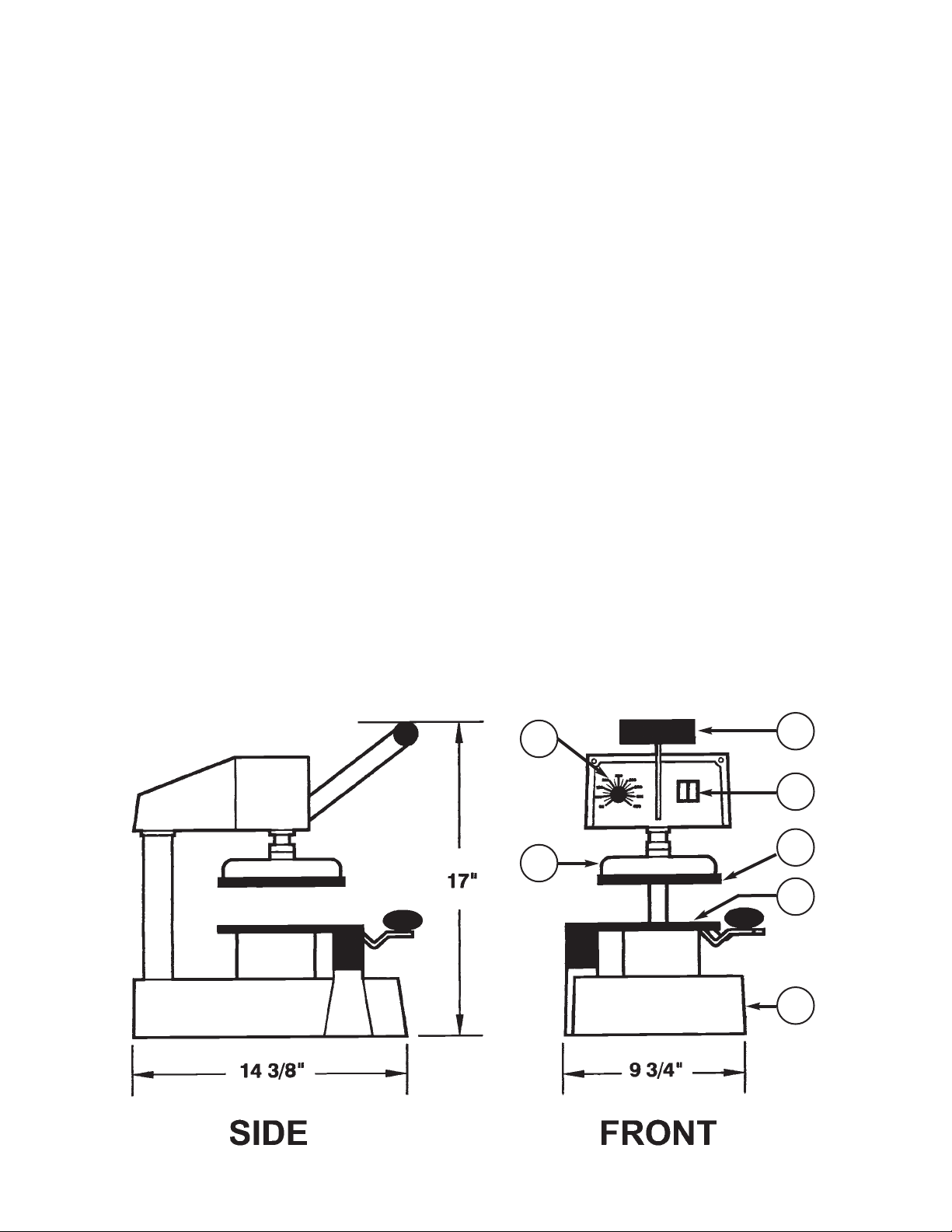

1. Pull Handle - Forces the upper platen down.

2. On / Off Switch - Red light tells you that power is on then goes out when

temperature setting has been attained.

3. Upper Platen - Heated to help the dough flow faster and more evenly.

4. Lower Platen - Dough is placed here; swings out for easy removal of flattened

dough.

5. Cast Aluminum Base

6. Temperature Control - 0

o

- 425oF (218oC)

7. Chrome Plated Shroud

Exterior finish: Highly resistant power coat white gloss, approved for use with food

products. Molds are probrite coated anti-stick surfaces.

Electrical: 120V / 60hz / 1ph / 750W / 6.25amps

240V / 50-60hz / 1ph / 1000W / 4.1amps

Provided with approved cord and plugs.

Shipping Weight: 35lbs. (16kg)

1

2

3

4

5

6

7

Mini-Dough Presses

Introduction

General Specifications

Pull Handle - Forces the upper platen down.

On I Off Switch - Red light tells you that power is on then goes out when

temperature setting has been attained.

Upper Platen - Heated to help the dough flow faster and more evenly.

Lower Platen - Dough is placed here; swings out for easy removal of flattened

dough.

Cast Aluminum Base

Temperature Control - 0° - 425°F (218°C)

Chrome Plated Shroud

Exterior finish: Highly resistant power coat white gloss, approved for use with food

products. Molds are probrite coated anti-stick surfaces.

Electrical: 120V ¡60hz! Iph ¡750W! 6.25amps

240V ¡50-60hz! Iph ¡1000W! 4.lamps

Provided with approved cord and plugs.

Shipping Weight: 351bs. (16kg)

1

17"

143/8"

93/4"

SIDE FRONT

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Parts List for DP180X

X

REF # DESCRIPTION

DP180

120 ~ AC

1 BASE ASSEMBLY 11038411

2 ARM 11038421

3 COVER PLATE, BASE 120V 11025454

9 TERMINAL BLOCK 6014

10 SCREW, TERMINAL BLOCK SP83212

11 SCREW, COVER PLATE SP83238

12 RUBBER FEET 2093W

13 TERMINAL BLOCK 6015

14 FUSE HOLDER 345601

15 FUSES 5/PACK MPPF008

17 LOWER PLATEN SHIM 110486323 0030

18 MOUNTING RACK 11041271

19 TEMPERATURE CONTROL T16A0318

21 6" LOWER PLATEN 110638326

21 7" LOWER PLATEN 110638327

21 8" LOWER PLATEN 110638328

21 9" LOWER PLATEN 110638329

22 LIMITER, TEMPERATURE 3455RC6025

23 SENSOR 110144110

24 KNOB, SWING AWAY (MUSHROOM) 110017

25 HANDLE, LOWER PLATEN (Bracket for 1808 & 1809) 11030963

25 HANDLE, LOWER PLATEN (Bracket for 1806 & 1807) 11065763

26 SCREW, PAN SP632716S

27 SCREW, BUTTON HEAD SB142012

28 SCREW, BUTTON HEAD SB142058

31 PIN, ROLL PR31658

32 UPPER PLATEN W/WIRE 120V 11063831102

32 UPPER PLATEN W/WIRE 240V 11063831103

33 SHROUD, UPPER PLATEN 110254368

34 HEX BOLT BH10241

35 HEX BOLT (MACHINE) 11025467

36 PISTON ROD ASSEMBLY 11048674

37 CORD, POWER 120V 110174

37 CORD, POWER 240V 110175

38 STRAIN RELIEF (CORD) MPPSS167

39 PIN, REAR HANDLE 110254262

40 PIN, FRONT HANDLE 110254261

41 CABLE, POWER DISTRIBUTION 110391067

43 SCREW, SET SST832516

44 SCREW, SET SST381612

45 SCREW, FLAT HEAD SF102412P

46 HANDLE, PRESSURE ASSY. 11025490

47 TEMPERATURE CONTROL KNOB 1920C

50 HOUSING 11024622

51 POWER SWITCH 120V 11025452120

51 POWER SWITCH 240V 11025452240

52 HEX NUT NH3816

53 DETENT, PLUNGER SWING MPSP134

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

INSTRUCTIONS FOR CLEANING

Use only mild soap and water on painted or non-stick coated surfaces. Never use harsh

abrasive cleaners, wire mesh pads, etc. These will inflict costly damage. Cleaning

should be performed whenever required, but at least once a day. Before cleaning turn

machine off and allow to cool down. NEVER SUBMERGE MACHINE OR ANY PART

THEREOF IN WATER OR OTHER LIQUIDS.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

DDUDHPRD

PLEASE READ CAREFULLY BEFORE ATTEMPTING TO USE THIS APPLIANCE.

LIMITED MACHINE WARRANTY

WHAT IS COVERED

Proprocess/Doughpro warrants the equipment, from manufacturing defects in workmanship and

material sold within the domestic United States.

HOW LONG DOES THE COVERAGE LAST

One-year warranty for parts and labor. The heating elements on the upper and lower platens have a

limited lifetime warranty on the elements.

WHA

T WE WILL DO

We will repair or replace the defective equipment on normal warranty one-year parts and labor. The

heating elements on the upper and lower platen only; will be replaced by next day air service; under

the normal one-year warranty. Such repair or replacement will be at the expense of Proprocess

Corporation under the normal one-year parts and labor warranty.

HOW T

O GET SERVICE

Contact our Factory to obtain warranty service. Proprocess must issue a return authorization

number, and call tag, or find the name and location of a Factory Authorized Service Center nearest

you. When calling for service, please furnish the model number, serial number, and a description of

the problem.

WHA

T THIS WARRANTY DOES NOT COVER

THE WARRANTIES PROVIDED BY PROPROCESS/DOUGHPRO DO NOT APPLY IN THE

FOLLOWING INSTANCES:

O Damage due to misuse, abuse, alteration, or accident.

O Improper or unauthorized repairs.

O Submerged in water.

(Excess water or chemical within the electrical panel)

O Dropped.

O Damage in shipment.

O Equipment exported to foreign countries.

Website: www.doughpro.comOE-Mail: info@doughpro.com

PROPROCESS CORPORA TION

P.O. Box 869O7328 Madison St.OParamount, CA 90723

(562) 531-0305

O

(800) 624-6717OFax (562) 869-7715

FOR SERVICE CALL: (800) 624-6717

PLEASE READ CAREFULLY BEFORE ATTEMPTING TO USE THIS APPLIANCE.

LIMITED MACHINE WARRANTY

WHAT IS COVERED

material sold within the domestic United States.

One-year warranty for parts and labor. The heating elements on the upper and lower platens have a

limited lifetime warranty on the elements.

We will repair or replace the defective equipment on normal warranty one-year parts and labor. The

heating elements on the upper and lower platen only; will be replaced by next day air service; under

the normal one-year warranty. Such repair or replacement will be at the expense of Proprocess

Corporation under the normal one-year parts and labor warranty.

Contact our Factory to obtain warranty service. Proprocess must issue a return authorization

number, and call tag, or find the name and location of a Factory Authorized Service Center nearest

you. When calling for service, please furnish the model number, serial number, and a description of

the problem.

/Doughpro warrants the equipment, from manufacturing defects in workmanship and

HOW LONG DOES THE COVERAGE LAST

WHAT WE WILL DO

HOW TO GET SERVICE

WHAT THIS WARRANTY DOES NOT COVER

THE WARRANTIES PROVIDED BY (DOUGHPRO DO NOT APPLY IN THE

FOLLOWING INSTANCES:

FOR SERVICE CALL: (800) 624-6717

Damage due to misuse, abuse, alteration, or accident.

Improper or unauthorized repairs.

Submerged in water.

(Excess water or chemical within the electrical panel)

Dropped.

Damage in shipment.

Equipment exported to foreign countries.

DDUGHPRD

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Website: www.doughpro.com

E-Mail: info@doughpro.com

DDUGHPRD

STEARNS PRODUCT DEVELO PMENT CORPORATION

20281 Harvill Ave, Perris, CA 92570 Tel: (800) 6246717 - Fax: (951) 657-4594

Warranty & Return Policy

STEARNS PRODUCT DEVELOPMENT CORPORATION

materidis from the

Jate of pLrchase far a period of (1) year on parts and obor, This warranty app'ies to only equipment purchased and used in

the United States.

Exclusions:

i . WOOD i GAS FIRED OVENS: STEARNS PRODUCT DEVELOPMENT CORPORATION warranty applies to the main be-dy of the

oven being steel

I refractory and insulaUcn shall be free from defects in materials and workmanship fcr a period of four (4) years from the

date of purchase. The gas equipment shal be free from defects in materials and workmanship for a period of one (1) year

from the date of purchase. This warranty excludes the ardDori and borne over

2. TAN000RI & HOME OVENS: STEARNS PRODUCT DEVELOPMENT CORPORATION varrants theTandoori & Home Oven

including gas

equipment shall be free from defects iii materials and workmanship for a period cf one (1) year from the date of purchase.

3_ Air compressors are excluded frani this warranty, but STEARNS PRODUCT DEVELOPMENT CORPORATION may act as a

warranty

expedior n certain Instances regarding these compressors. The air compressor manufacturer provides a limited warranty

and a copy ofthis warranty is furnshed wilh aH compressors sold by STEARNS PRODUCT DEVELOPMENT CORPORATION For

prompt

handling of compressor warranty claims the instructiors of the coirpressor manufacturer must be adhered to.

4 Equipment built to special order as well as accessories are not returnable unless defective withn the terms of this

warranty.

5_ In no event shall STEARNS PRODUCT DEVELOPMENT CORPORATION be liable for consequential damagesarising out of

the failure of

any of its products if operated improperly or caused by normal wear or damage by operator abuse.

Returned Merchandise Policy:

Should it become necessary to return any ofibe company's products, the following instructions must be adhered to: First.

contactour customer service departmeritfcr approval and a return authorization number. Please finve the seria! number

ofyouritem available atThattime All merchandise must be shipped freightprepaid by customer or servioe agency.

Subject to the inspedion of the product by the conipany. a restocking charge of 20% of the Net purchased price paid to

STEARNS PRODUCT DEVELOPMENT CORPORATION will be assessed. Merchandise may not be returned for credit without prier

written

approval of STFARWS PRODUCT UEVELOPMENT CORPORATION. Collect shipments wil! not be accepted. No reums after 60

days of original

shipment date on machines. Purchased parts may not be returned after 30 days.

If upon inspection by STEARNS PRODUCT DEVELOPMENT CORPORATION or its authorized agent it is determined the equipment

has not been

used in arr appropriate manner, has been modified, or has not been properly maintained, or has been subject to misuse,

misapplïcation, neglect, abuse, accident, unauthorized modïuication, damage during transit, delïvery, fire, flood, act or war,

riot or act of God, Ihen this warranty shall be deemed null and void.

Terms & Conditions:

Prices indicated ìn the PRICE LIST are suggested retaìl prices and are shown in U.S. DOLLARS.

Ternis of Payment: 2% 10 days, NET 30 days.

3 NEW ACCOUNTS: Satisfactory credit information must be provided before open account status can be extended,

Unless agreed otherwise, all shipments will be made COD., CASH IN ADVANCE,

4. PRICING: Prices, specifications, model numbers, capacities and accessories are subject to change without notice.

5 FREIGHT I ROUTING: Method of shipment will be determined by STEARNS PRODUCT DEVELOPMENT CORPORATION unless

otherwise

advised by PURCHASER.

DAMAGED CLAIMS: All merchandise shipped at purchaser's risk. Inspection must be made by purchaser at time

goods are received. If goods are damaged, the PURCHASER shall request that the agent of the transportation

company make a written notation on the proper shipping documents immediately and then file a claim for damage.

GOODS DAMAGED IN SHIPMENT ARE NOT RETURNABLE,

RETURNS: Machines may not be returned after 60 days. Purchased parts may not be returned after 30 days. A

restocking fee of 20% will be assessed ori non-warranty returns.

TAXES: Prices indicated herein DO NOI include State, Federal. Local or foreign taxes or duties. nor do they include

fees, permits, insurance or other levies, all of which are the responsibilily öl the purchaser.

AIl orders are subject to acceptance by STEARNS PRODUCT DEVELOPMENT CORPORATION.

Possession of this price list shall not be considered an offer to sell.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

warrants ai products nanufactured by it ainst defects in workmanship or

Loading...

Loading...