DoorKing 9411 Single Channel with Aux Relay, 9410 Single Channel, 9409 Dual Channel Information Manual

Information Manual

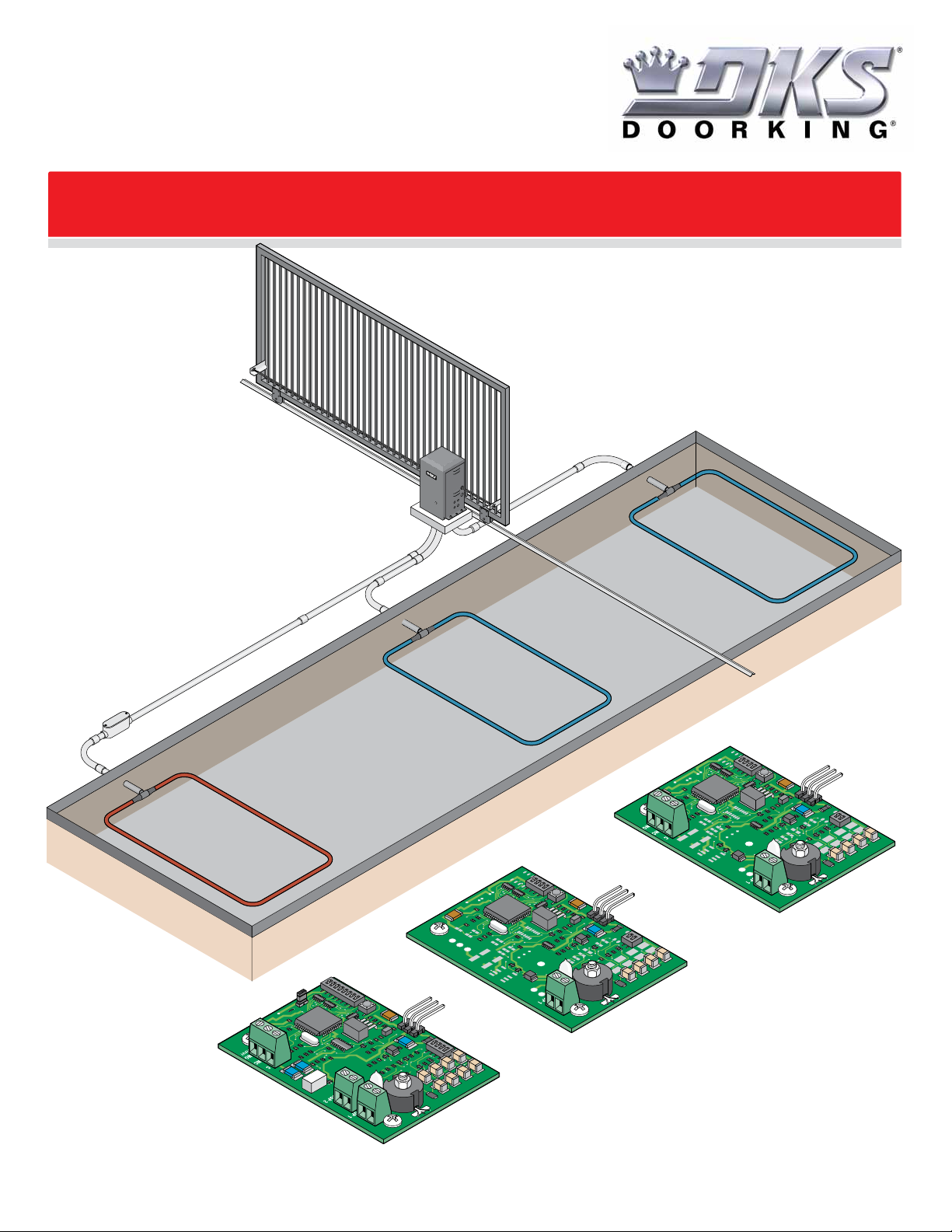

Underground Loops and Loop Detectors

Underground Loops and Loop Detectors

DoorKing Plug-In Loop Detectors and Loop Accessories

9409 Dual Channel

9411 Single Channel

with Aux Relay

9410 Single Channel

Copyright 2016 DoorKing, Inc. All rights reserved.

INTRODUCTION 2

Underground Loop

Lead-In Wire or Cable

Loop Detector

Design Facts

2

2

2

2-3

SECTION 1 - HOW THE LOOP SYSTEM WORKS 4

Field of Sensitivity

Height of Detection

Field Cancellation Effect

Field Enhancement Effect

Loop Phasing

Electrically Reverse the Phase of a Loop

Loop Detection Field Interference and Loop Placement

4

4

5

5

6

6

7

SECTION 2 - LOOP INSTALLATION GUIDELINES 8

Saw Cut Loop Guidelines

DoorKing Preformed Loop Guidelines

8-9

10

SECTION 3 - TYPICAL LOOP LAYOUT EXAMPLES 11

Slide Gates

Swing Gates

11

12

SECTION 4 - TROUBLESHOOTING LOOP SYSTEMS 13

Loop Diagnostics

Poor Connections

Shorted Loop Wire

Detector Adjustments

13

13

13

13

SECTION 5 - DOORKING LOOP DETECTORS AND ACCESSORIES 14

Loop Info-Q-2-16

1

INTRODUCTION

A loop detection system is a method of sensing vehicles and is typically used in automated gate applications to prevent a

gate from automatically closing on a vehicle or to automatically open the gate when a vehicle is exiting a property. Vehicle

loops can also be used to activate card readers, ticket spitters, etc. When properly installed, loops are an extremely

reliable form of vehicle detection. The loop detection system operates by creating an electrical field of sensitivity that

tunes to the surrounding environment. When a metallic object enters this electrical field, the loop detector senses a

change in the field and generates an output, usually activating a relay in a gate operator or other access control device that

controls the operation of the gate.

There are three basic components in a loop detection system:

• Underground loop

• Loop lead-in wire or cable

• Loop detector

Operator Chassis Ground

grounding restrictions).

Short Leg Length

Loop with

3 Wire Turns

(See page 6 for

Long Leg Length

PVC Conduit

in Watertight J-Box

Underground Loop

The loop is made from a continuous

piece of wire (NO SPLICES) that is

coiled around for a number of turns

in a square or rectangular pattern.

The wire is embedded into pavement

either as a preformed loop placed

prior to paving, or into a saw cut that

is cut into existing pavement. Both

ends of this wire are then extended

to the edge of the pavement.

Design Facts

Proper installation of the loops is essential for reliable functioning of the detector system. Most detector problems are caused

by improper loop installation! The geometry (size and shape) of the loop defines the detection zone characteristics.

Loop Lead-In Wire or Cable

The lead-in wire or cable extends the two

ends of the loop wire back to the loop

detector. On short runs (Loop is within ten

feet from the loop detector), the two wires

exiting the loop can be twisted together,

run in conduit to the operator and

connected directly to the loop detector.

The lead-in wire: DoorKing recommends

that lead-in wire be twisted a minimum of six turns per foot.

The lead-in cable: If additional lead-in wire is required, DoorKing recommends that you

use a shielded twisted pair (Insulated (floated) at one end and grounded at gate operator) with a direct burial rated jacket or be placed in PVC conduit. All splices must be

soldered and placed in a watertight J-box.

Soldered Spliced Connections

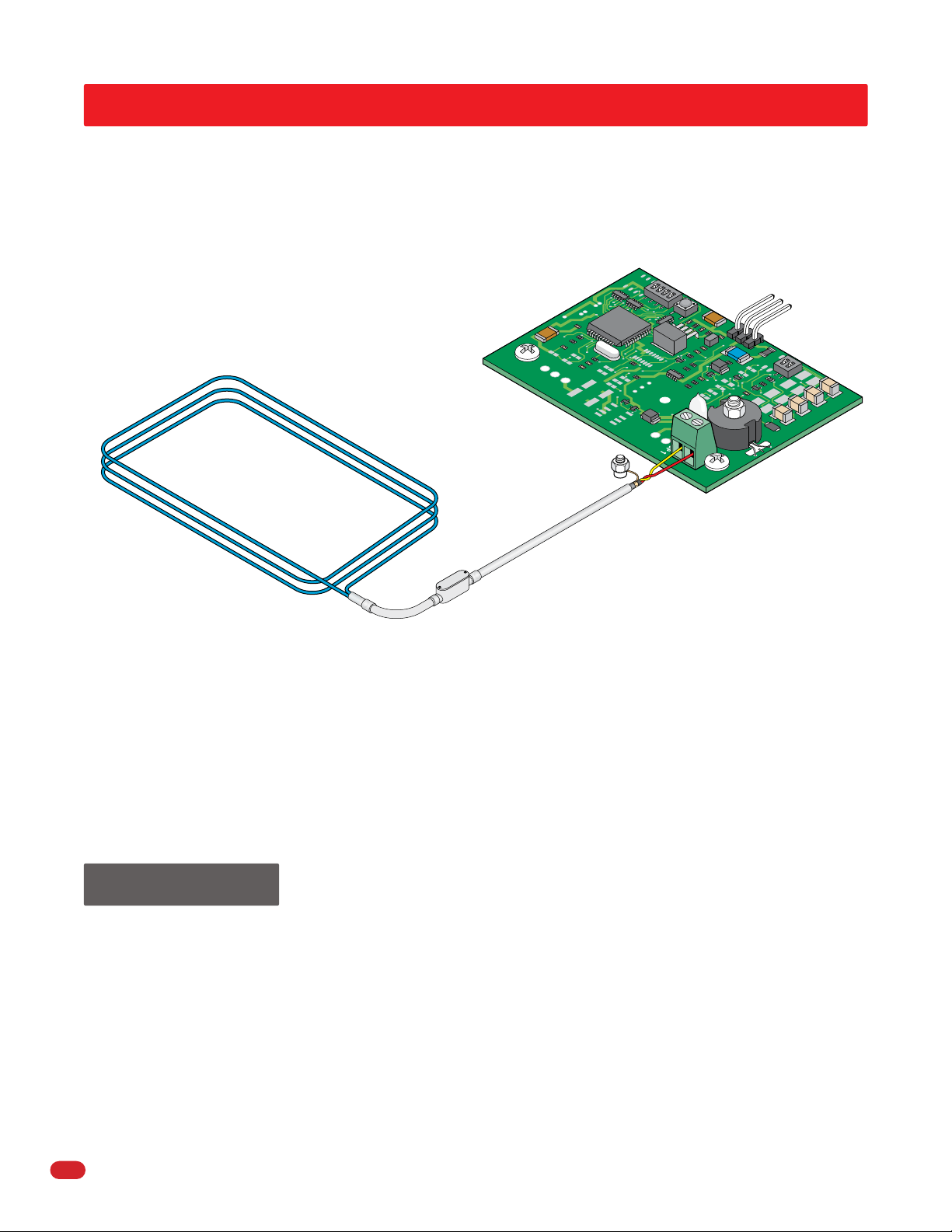

Loop Detector

The loop detector is the electronic

component that controls the loop

system. DoorKing offers loop detectors

(Models 9409, 9410 and 9411) that plug

directly into the gate operator control

board, eliminating the wire harness and

wiring connections other than the loop

lead-in wires. These detector boards have

a terminal strip where the loop lead-in

wire connects. There are also various

other types of standalone detectors

available on the market that can be hard

wired into the gate operator control

board.

• Loop size may vary and will depend on lane width, traffic patterns, and types of vehicles to be detected.

• The short leg of any loop used for vehicle detection should never be less than 18 in. The height of detection is directly

related to the length of the short leg of the loop. A general rule of thumb to follow is that the height of detection is

1/2 to 2/3 the length of the short leg of the loop.

• Normal loops (4 ft x 8 ft) are used to detect motorcycles and automobiles. Minimum size for loops to detect typical

vehicular traffic is 18 in x 48 in. It is always recommended to use a larger loop whenever possible.

• Maximum “detection height” of a loop is 3 to 4', which may be achieved with a loop measuring 6' on the short leg.

• Loops can be saw cut into concrete or asphalt. They can be placed under brick pavers and asphalt or be imbedded in a

poured concrete road surface.

2

Loop Info-Q-2-16

Loops that are physically adjacent to each other and operating on separate loop detectors may interfere (cross-talk) with each

other if they are operating on the same frequencies. Changing the operating frequency on one of the loop detectors can

eliminate this interference. (See page 7 for more information)

When connecting two loops to a single loop detector terminal, always connect the loops in series. If the loops are close

together, the direction of the windings should be considered. Loops physically near each other and wound in the same direction

electrically (i.e. both Clockwise or Counter-Clockwise) will cause field cancellation effects (a dead zone) between the loops. This

may be desirable when two loops (reverse loops) are placed on each side of a sliding gate. Wiring the loops in this manner will

allow the gate to slide between the two loops without causing the loops to detect the gate. If the loops are wound in electrically

opposite directions (i.e. one Clockwise and one Counter-Clockwise), field enhancement will occur between the loops, effectively

extending the field of sensitivity for the loop system. (See pages 5 and 6 for more information)

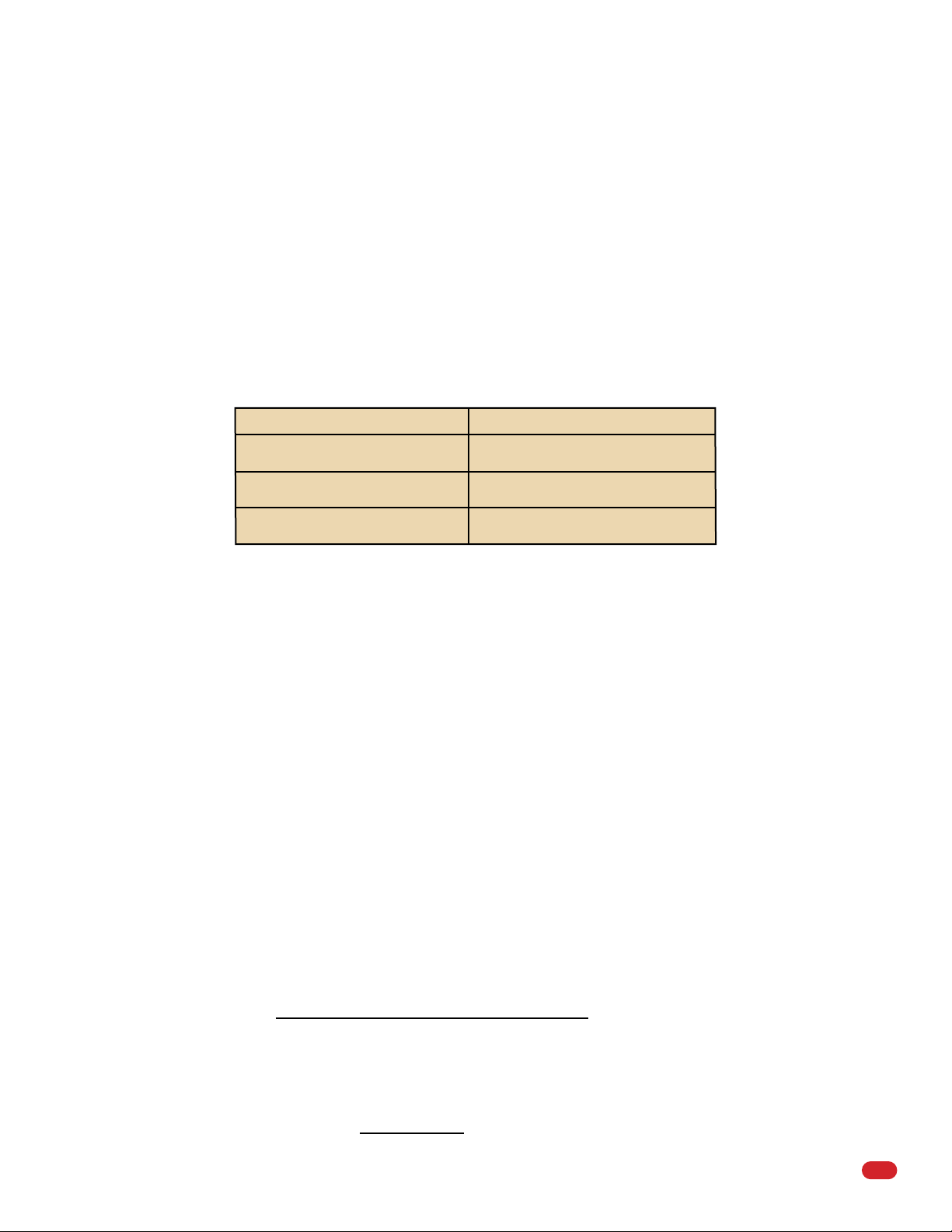

Determine the Number of Wire Turns Required for Each Loop

Loop area (Sq. Ft.) - Multiply loop width by loop length.

Loop Area in Square Feet Number of Turns Required

6 - 12

12 - 60

60 - 240

Note: The number of turns should be increased by 1 turn if lead-in wire or cable length is 500 ft or greater.

• During the construction of new installations (i.e. concrete or asphalt), a pre-formed loop may be used as an alternate to

the saw cut type. Pre-formed loops are typically encased in PVC or other durable materials to provide high reliability and

long life. Sizes may vary depending on the source of the pre-formed loop. DoorKing offers a variety of pre-formed loops

that come with 25 feet of lead-in wire. (See page 10 for more information)

6

4

3

• The loop will tune to its environment. Stationary or static metal objects, such as conduits, pipes, metal grates, etc., will

not affect the loop field. High voltage electrical power lines, either underground or overhead, can affect the loop field.

In addition, fluctuating electrical fields, such as heating coils, can cause loop lock-ups and false detection.

• A heavy grid of reinforcing bars (re-bar) may affect the loop field. To minimize this, DO NOT place a loop directly on the

rebar. Support the loop 1 - 2 inches above the rebar. If possible, make cuts or bends in the rebar grid directly below the

loop. Bars and electrical wires running at angles to the loop have less effect on the loop than those running parallel to the

loop wires. (See page 10 for more information)

• If a single loop is used with a long lead-in cable (500 feet or greater), it is advisable to add an additional turn in the loop.

This increases the ratio of the loop inductance to the total inductance, thereby improving loop sensitivity and overall loop

system stability.

• The inductance of the loop (in micro henries) must fall within the tuning range of the loop detector for the loop system to

operate properly. This is typically not a problem since most loop detectors have a very wide tuning range (20 - 2500

micro henries) and can accommodate most size loops.

To calculate the inductance of a loop use this formula:

Side 1 + Side 2 + Side 3 + Side 4 ) Number of Turns2 = Inductance

(

2

Example: To calculate the inductance of a typical 6 x 8 foot loop with four turns of wire:

6 + 8 + 6 + 8 ) 42 = 224 Micro Henries

(

2

Loop Info-Q-2-16

3

SECTION 1 - HOW THE LOOP SYSTEM WORKS

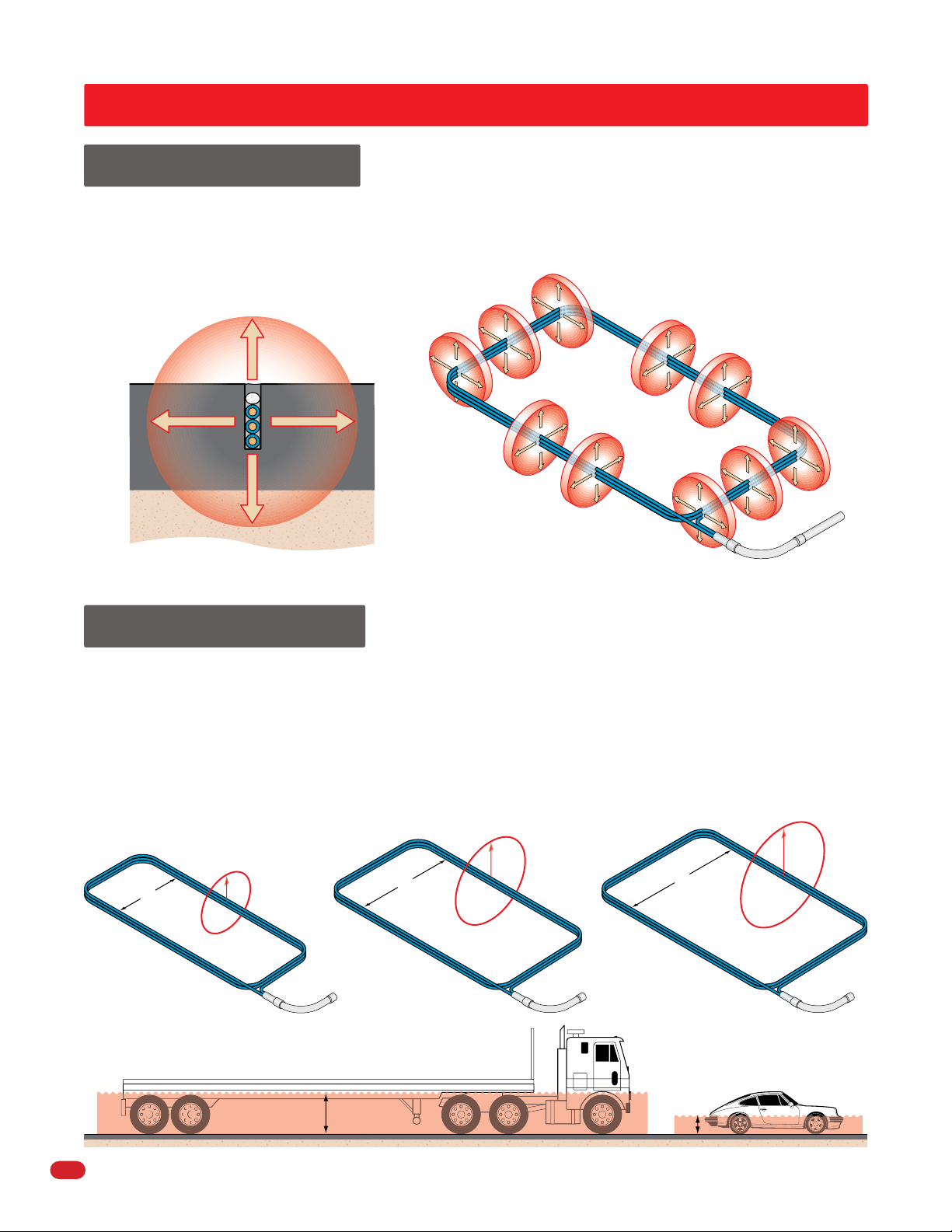

Field of Sensitivity

A loop sets up an inductive field, called a field of sensitivity. This field of sensitivity completely surrounds the loop wires

extending above, below, and on all sides of the loop. When a vehicle (or any metallic object) enters this field of sensitivity, the

inductance of the loop changes as more of the inductive field is disrupted by the vehicle. Once the disruption of the inductive

field is high enough, the loop detector senses this change and outputs a signal, usually in the form of a dry contact relay switch

activation.

Sensitivity Field

Roadway

3 Turn

Saw Cut Loop

Cutaway of Underground Loop

Inductive Field of Sensitivity

Height of Detection

The height of the field of sensitivity, and therefore the height of detection, is determined by the size of the loop. The height

of detection is especially important when you need to detect a high bed truck, which requires more height than a passenger car.

The height of detection above (and below) the loop is determined by the shortest leg of the loop. The height of detection is

equal to 1/2 to 2/3 the length of the SHORT LEG. For example, a four-foot by eight-foot loop will give you approximately 2-1/2

feet of detection height, whereas a six-foot by eight-foot loop will give you approximately 4-feet of detection height. The short

leg of a loop used for vehicle detection should never be shorter than 18 in. The maximum “detection height” of a loop is

6-feet on the short leg. If larger loops are used, the “detectable height” of the loop will NOT increase.

Maximum Detection Height

Approx. 4 ft.

6’

o

ng

L

eg

18”

Short Leg

L

Detection Height

Approx. 1 ft.

M

in.

ong

L

eg

5’

Short Leg

L

o

ng

Detection Height

Approx. 3 ft.

L

eg

Short Leg

L

Larger short leg needed to detect trailer height vs. car height.

4

Loop Info-Q-2-16

Loading...

Loading...