Page 1

El

DOI

USA

SERVICE OFFICE

The Dometic Corp.

509 So. Poplar St.

La Grange, IN 46761

Phone: 219 463 4858

CANADA

Dometic Dist.

866 Langs Dr.

Cambridge, Ontario

Canada N3H 2N7

Phone: 519 653 4390

FOR SERVICE CENTER

ASSISTANCE

.

CALL: 800 544 4881

~ ‘APPROVED

IN

<

OPERA;

Electrolux Siegen GmbH

In der Steinwiese 16

D- 67074 Siegen

821 2669-03 08198

r

netic

RECORD THIS INFORMATION FOR FUTURE REFERENCE

BEFORE INSTALLING THE UNIT:

Model No.

__ Serial No. _

Product No.

Date Purchased Place of Purchase

REFRIGERATOR MODEL

RM 2202

For Mobile Home or Recreational Vehicle

Installation

Operation by LP Gas, 12V DC or 120V AC

FOR CHILD SAFETY

DANGER: Risk of child entrapment. Before you throw away your old

refrigerator: Take off the doors, leave the shelves in place, so that

children may not easily climb inside.

FOR YOUR SAFETY

If you smell gas:

1. Shut off gas supply at

main valve.

2. Open windows.

3. Don’t touch electrical

switches.

4. Extinguish any open

flame.

5. Immediately call your

gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline

or other flammable vapors

and liquids in the vicinity of

this or any other appliance.

ITALLATION &

NG INSTRUCTIONS

INDEX

Page

I

Installation 2Operating Instructions

7

Maim. 8 Service 10

WARNING

Improper installation, adjustment,

alteration, service or maintenance

can cause injury or property

damage. Refer to this manual. For

assistance or additional information consult a qualified installer,

service agency or the gas supplier

AVIS

Cet appareil doit Qtre repare

seulement par un reparateur

autorise. Modification de I’appareil

pourrait Qtre extremement

dangeruse, et pourrait causer mal

ou mort.

r

REFRIGERATOR-

MODEL

RM2202

IMPORTANT INSTRUCTIONS

READ CARFULLY

Page 2

SECTION A. INSTALLATION

1. GENERAL INSTRUCTIONS

This appliance is designed for storage of food and

storage of frozen food and making ice.

The refrigerators outlined herein have been design certified by A.G.A. under ANSI 221 .I 9 Refrigerator Standard

for installation in a mobile home or recreational vehicle

and are approved by the Canadian Gas Association. The

certifications are, however, contingent on the installation

being made in accordance with the following instructions

as applicable.

In the U.S.A., the installation must conform with:

1. National Fuel Gas Code ANSI Z223.1-(latest edition)

2. Manufactured Home Construction and Safety

Standard, Title 24 CFR, Part 3280

3. Recreational Vehicles ANSI A119.2-(latest edition).

The unit must be electrically grounded in accordance

with the National Electric Code ANSI/NFPA 70-(latest

edition) when installed if an,external alternating current

electrical source js utilized.

4. Any applicable local code.

In Canada, the installation must conform with:

1. Current CGA B 149 Gas Installation Codes

2. Current CSA Standard Z 240.4 GAS-EQUIPPED

RECREATIONAL VEHICLES AND MOBILE

HQUSING

3. Any applicable local code

The unit must be electrically grounded in accordance

with the CANADIAN ELECTRICAL CODE C 22 Parts 1

and 2.

2. VENTILATION

The installation shall be made in such a manner as to

separate the combustion system from the living space of

the mobile home or recreational vehicle. Louver openings must have a minimum dimension of 114 inch for air

supply or venting of combustion products.

Proper installation requires one fresh air intake and one

upper exhaust vent. The ventilation kits shown in this

instruction manual have been certified for use with the

refrigerator model listed in the Table. For “Certified Vent

System Kits” see Section B. The ventilation kits must be

installed and used without modification. An opening

toward the outside at floor level in the refrigerator com-

partment must be provided for ventilation of heavier-

than-air fuel gases. The lower vent of the recommended

kits is provided with properly sized openings. The flow of

combustion and ventilation air must not be obstructed.

The lower side vent is fitted with a panel which provides

an adequate access opening for ready serviceability of

the burner and control manifold of the refrigerator. This

should be centered on the back of the refrigerator.

3. CERTIFIED INSTALLATION

Certified installations require one upper side vent and

one lower side vent.

For certified vent system kits, see Section B.

For further information, contact your dealer or distributor.

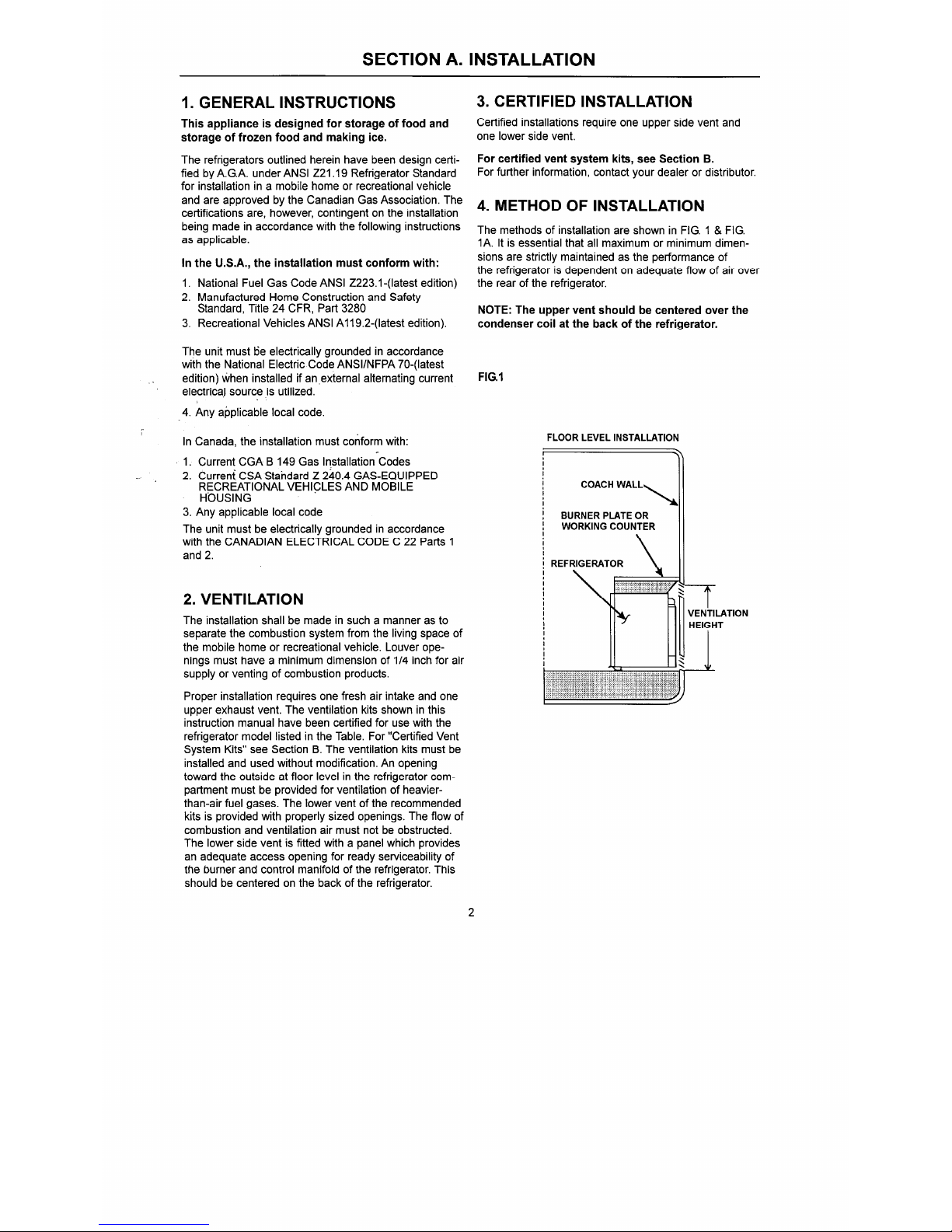

4. METHOD OF INSTALLATION

The methods of installation are shown in FIG. 1 & FIG.

IA. It is essential that all maximum or minimum dimensions are strictly maintained as the performance of

the refrigerator is dependent on adequate flow of air over

the rear of the refrigerator.

NOTE: The upper vent should be centered over the

condenser coil at the back of the refrigerator.

FIG.1

FLOOR LEVEL INSTALLATION

COACH WALL

BURNER PLATE OR

WORKING COUNTER

I

I

I

! REFRIGERATOR

2

Page 3

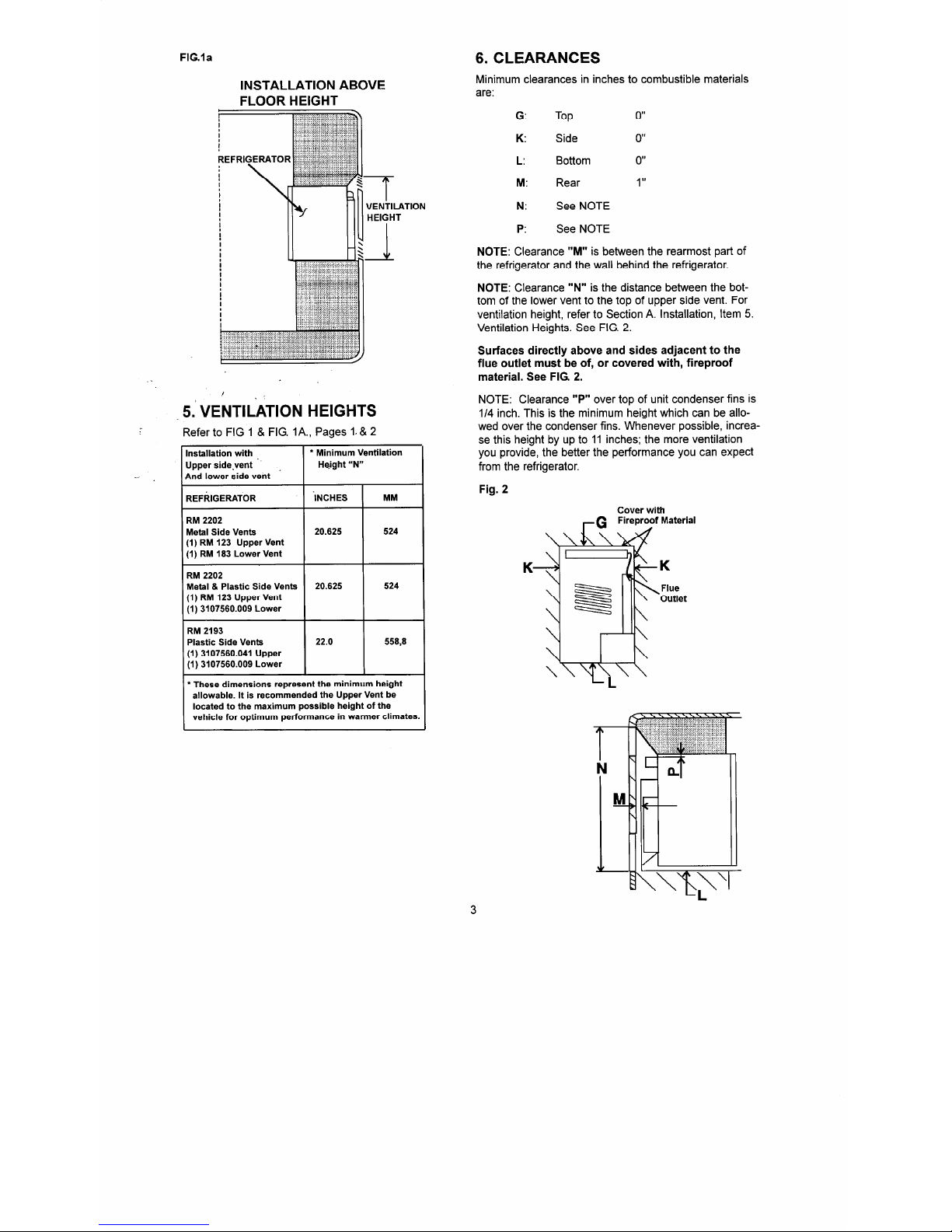

FIG.la

6. CLEARANCES

Minimum clearances in inches to combustible materials

are:

G:

Top

0”

K:

Side

0”

L:

Bottom

0”

M:

Rear

1

II

N: See NOTE

P: See

NOTE

NOTE:

Clearance

“M”

is between the rearmost part of

the refrigerator and the wall behind the refrigerator.

NOTE: Clearance “N” is the distance between the bot-

tom of the lower vent to the top of upper side vent. For

ventilation height, refer to Section A. Installation, Item 5.

Ventilation Heights. See FIG. 2.

Surfaces directly above and sides adjacent to the

flue outlet must be of, or covered with, fireproof

material. See FIG 2.

NOTE: Clearance

“PI’

over top of unit condenser fins is

l/4 inch. This is the minimum height which can be allowed over the condenser fins. Whenever possible, increase this height by up to 11 inches; the more ventilation

you provide, the better the performance you can expect

from the refrigerator.

Fig. 2

Cover with

G Fireproof Material

INSTALLATION ABOVE

.

. .

5.’ “E;JTILATION HEIGHTS

Refer to FIG 1 & FIG. IA., Pages 1. & 2

Installation with

l

Minimum Ventilation

Upper side.vent Height “N”

And lower side vent

REFRIGERATOR ‘INCHES

MM

RM 2202

Metal Side Vents 20.625 524

(1) RM 123 Upper Vent

(1) RM 183 Lower Vent

RM 2202

Metal & Plastic Side Vents 20.625 524

(1) RM 123 Upper Vent

(1) 3107560.009 Lower

RM 2193

Plastic Side Vents

(1) 3107560.041 Upper

(1) 3107560.009 Lower

22.0 558,8

l

These dimensions represent the minimum height

allowable. It is recommended the Upper Vent be

located to the maximum possible height of the

vehicle for optimum performance in warmer climates.

Page 4

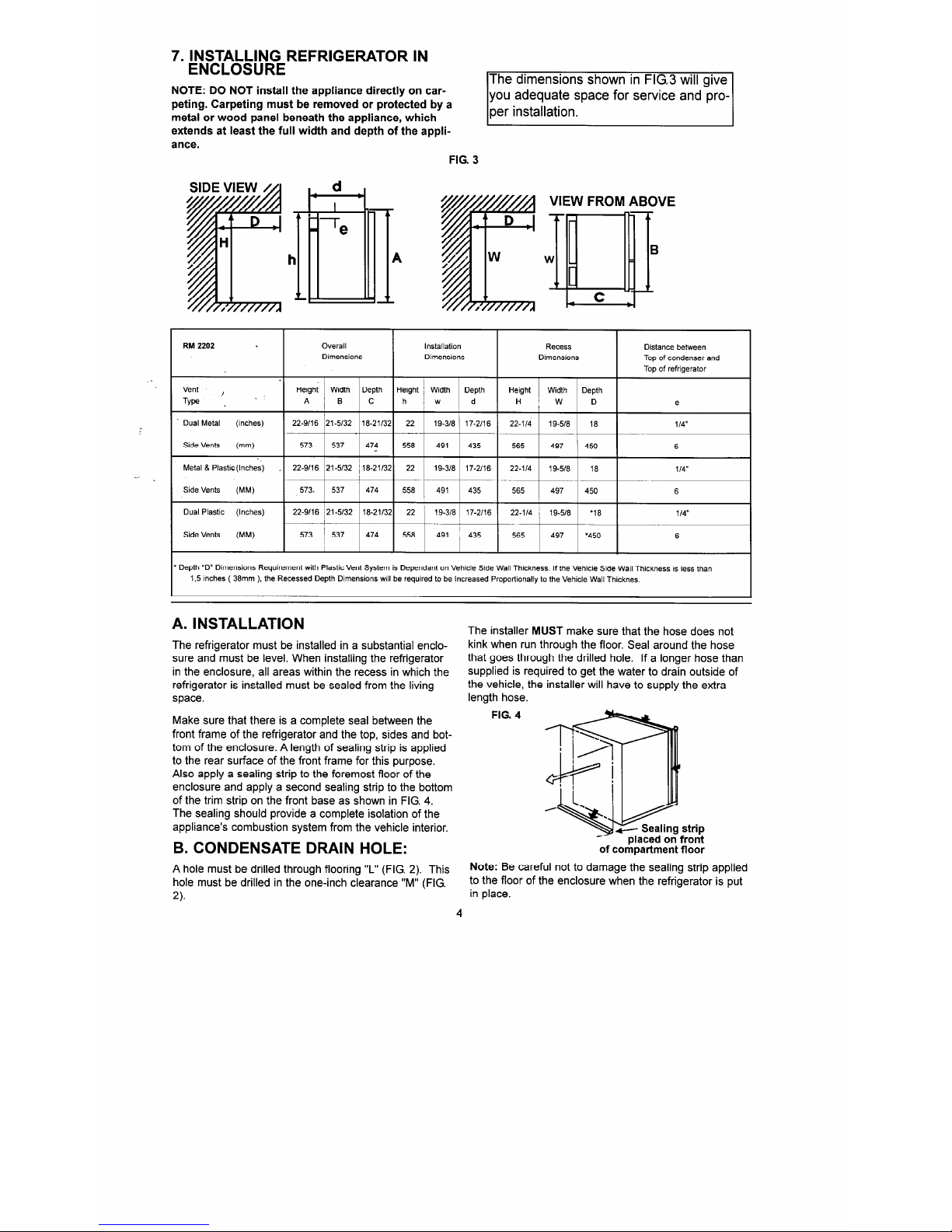

7. INSTALLING REFRIGERATOR IN

ENCLOSURE

NOTE: DO NOT install the appliance directly on car-

The dimensions shown in FIG.3 will give

peting. Carpeting must be removed or protected by a

you adequate space for service and pro-

metal or wood panel beneath the appliance, which

extends at least the full width and depth of the appliance.

FIG. 3

VIEW FROM ABOVE

RM 2202

Overall Installation

Recess Distance between

Dimensions Dimensions Dimensions

Top of condenser and

Top of refrigerator

.

Heigh;

I

Vent ,,

Width

Depth

Height / Width

Depth

Height Width

h ‘w

Depth

Type

A

B

c d

H

w

D e

Dual Metal (inches)

22-g/16 21-5/32 l&21/32 22

1 g-318

17-2/l 6 22-114

19-518 18

l/4

Side Vents

(mm)

573 537

474 558

491

435

565 497 450 6

Metal 8 Plastic(lnches) 22-9116 21-5/32 118-21/32 22 19-3/8 17-2/16 19-5/8 18 l/4

. .

Side Vents

(MM)

573. 537

474

558 491 435 450 6

Dual Plastic (Inches)

22-g/16 21-5/32 18-21132 22 ’ 19-3/8 17-2/16 22-114 / 19-5/8

*18

114”

_

Side Vents

(MM)

573

/

537

474 558

491 ) 435 565 497 v50 6

*

Depth “D” Dimensions Requirement with PlasticVent System is Dependant on Vehicle Side Wall Thickness. If the Vehicle Side Wall Thickness is less than

1,5 Inches ( 38mm ), the Recessed Depth Dimensions will be required to be Increased Proportionally to the Vehicle Wall Thicknes.

A. INSTALLATION

The refrigerator must be installed in a substantial enclosure and must be level. When installing the refrigerator

in the enclosure, all areas within the recess in which the

refrigerator is installed must be sealed from the living

space.

The installer MUST make sure that the hose does not

kink when run through the floor. Seal around the hose

that goes through the drilled hole. If a longer hose than

supplied is required to get the water to drain outside of

the vehicle, the installer will have to supply the extra

length hose.

Make sure that there is a complete seal between the

front frame of the refrigerator and the top, sides and bottom of the enclosure. A length of sealing strip is applied

to the rear surface of the front frame for this purpose.

Also apply a sealing strip to the foremost floor of the

enclosure and apply a second sealing strip to the bottom

of the trim strip on the front base as shown in FIG. 4.

The sealing should provide a complete isolation of the

appliance’s combustion system from the vehicle interior.

FIG. 4

B. CONDENSATE DRAIN HOLE:

placed on front

of compartment floor

A hole must be drilled through flooring “L” (FIG. 2). This

Note:

Be careful not to damage the sealing strip applied

hole must be drilled in the one-inch clearance “M” (FIG.

to the floor of the enclosure when the refrigerator is put

2).

in place.

Page 5

C. SECURING REFRIGERATOR IN

ENCLOSURE

The refrigerator is installed in the enclosure with eight

screws. Six screws are in the front frame and two are in

the plate on the rear. See FIG. 5.

FIG. 5

(3) Screws on

each

ide of frame

(2) Screws-

.

NOTE:

Push refrigerator into enclosure until front frame

is tight against the cabinet. First, secure the frame to

cabinet with six screws. Second, install the two screws

to the floor at the rear of the refrigerator.

. .

Failure to follow the sequence in securing the refrigerator

in the enclosure can cause leakage between the frame

and cabinet. Any space between the counter, storage

area or ceiling and top of the refrigerator should be

blocked. The heat produced at the rear of the refrigerator

will become trapped in this space, making the top of the

refrigerator hot and reducing the efficiency.

The dimensions shown in FIG. 3 will give you adequate

space for service and proper installation.

8. GAS CONNECTION

Hook-up to the gas supply line is accomplished at the

manual gas shutoff valve, which is furnished with a 318”

SAE (UNF 98” - 18) male flare connection. Always use

a backup wrench when connecting the gas supply line to

the gas inlet fitting. All completed connections should be

checked for leaks with a noncorrosive leak detector.

(See FIG. 6 - Gas inlet fitting may have a different orientation than shown).

DO NOT

USE A FLAME

I

TO

CHECK FOR GAS LEAKS

FIG. 6

GAS

INLET

FITTING

‘b GAS SAFETY VALUE

The gas supply system must incorporate a pressure

regulator to maintain a supply pressure of not more than

13.5 inches water column, static (no load).

LP GAS

CYLINDER

PRESSURE

REGULATOR

TO

REFRIGERATOR

When testing the gas supply system at test pressures in

excess of l/2 psig, the refrigerator and its individual

shutoff valve must be disconnected from the gas supply

piping system.

When testing the gas supply system at pressures less

than or equal to l/2 psig, the appliance must be isolated

from the gas supply piping by closing its individual

manual shutoff valve.

In case detailed instructions on the installation and

connection to the gas supply are required, contact your

dealer or distributor.

Page 6

9. TESTING LP GAS SAFETY

SHUTOFF

The gas safety shutoff must be tested after the refrigerator is connected to LP gas supply.

To test the gas safety shutoff, proceed as follows:

A. Start the refrigerator according to the instructions for

LP Gas Operation. See “Section C. Operation

Instructions. ”

B. Check that the gas flame is lit. Allow it to burn a few

minutes to ensure a full, stable flame.

C. Turn the gas safety valve (D, FIG. 6) to the “OFF”

position. Within l-2 minutes the gas safety device

within the valve should automatically close. An

audible “click” from the valve may be heard.

D. Turn the gas safety valve to the “ON” position

(D, FIG. 6).

E. Without pushing in the knob (D, FIG. 6) of the gas

safety device, apply a commercial leak detection

solution to the burner jet. No bubbles should appear.

Bubbles indicate a gas leak and the safety valve must

be replaced by a qualified serviceman.

F. Rinse the burner jet with water. Light the burner and

allow it to burn for five minutes.

.

10.120 VOLT’A~ ELECTRICAL

CONNECTION

. .

The refrigerator is equipped with a three-prong (grounded) plug for protection against shock hazards, and

should be plugged directly into a properly grounded

three-prong receptacle. DO NOT cut or remove the gro&ding prong from this plug. The power cord should be

routed to avoid direct contact with the burner cover, fuel

cover or manual gas shutoff valve knob.

11.12 VOLT DC CONNECTION

The 125 watt heating element operates the cooling unit

when the refrigerator is connected to the battery of the

vehicle. It has a current rating of about 10.5 amps; therefore, the wiring from the battery to the refrigerator must

be of heavy enough gauge to carry this load satisfactorily without undue voltage drop. To ensure this, the minimum size of wire to be used is 14 A.W.G The terminal

block for connecting the 12V supply cable to the battery

is positioned at the lower lefthand corner of the rear side

(G, FIG. 8). From this terminal, the connection to the

battery should be made using ring-type clamps with

tightening bolts to ensure good contact with the battery

terminals. Polarity is not important, therefore it does not

matter which wire leads to which battery terminal.

DO NOT connect lights or any other electrical com-

ponents to the same circuit that is used by the refri-

gerator.

’ IMPORTANT:

To prevent the refrigerator from being

left on and

draining the battery when the vehicle’s engine is

not running and charging the battery, it is recommended that an automatic cutout relay be installed

between the battery and the refrigerator toggle

switch so that the refrigerator will not draw current

when the vehicle ignition is switched off.

Alternatively, a suitable plug and receptacle should

be installed in the 12V supply line so that the refrigerator can be disconnected from the supply, as

necessary.

I I

FUSE

A 12 amp (continuous rating) fuse should be incorporated in the wiring of the DC supply, as near to the battery

as possible. The fuse must be in the side of the wiring

which is not connected to the chassis. For example, if

the vehicle has a negative ground, the fuse must be in

the positive side of the wiring.

12. CHANGING DOOR HINGES

FROM ONE SIDE TO THE OTHER

If required, the door hinges can be moved to the opposite side. Reverse the door hang in the following way:

A. Unscrew the upper hinge pin,, taking care not to lose

the set of washers and bushrngs.

B. Lift the door from the lower hinge pin. If decorative

door panel is to be installed, proceed to Step 13.

C. Unscrew the pin and mount it on the opposite side

hinge.

D. Unscrew the travel catch and mount it on the

opposite side.

E. Change the cover plate and travel lock plate in top of

door frame to opposite side. Use a screwdriver to

press down on one edge of the cover plate. The

opposite edge will rise above the frame. Use a knife

blade under the raised edge to pop it out. See FIG. 7.

Use needle-nosed pliers to carefully lift lock plate out

of door frame. See FIG. 7.

F. Replace door on lower hinge pin. Replace upper

hinge pin and bushings removed in Step A.

G. C&$hat the door closes properly and seals all

FIG. 7

6

Page 7

-

. .

13.

INSTALLATION OF DECORATIVE

A. Remove the door. See Section 12.

DOOR PANEL

The door panel can easily be mounted. The dimensions

of the panel must be:

Height

20-I 5/l 6”

Width

17-27132”

Thickness

up to 118”

Weight

49 Ibs.

B. Remove the lower trim molding. (NOTE: Trim molding

is not installed on new units in cartons)

C. Fit the new panel in place and slide it up as far as

possible.

D. Fit the trim molding back in place.

SECTION B. CERTIFIED VENT SYSTEMS

VENT KIT OPTIONS

DUAL METAL

SIDE

VENTS

UPPER METAL SIDE VENT

LOWER PLASTIC SIDE VENT

* Vent System Requires One Each.

**Alternative instructions forwarded with ventilator kit. Used in conjunction with

upper and lower side vents at minimum vent heights for optimum performance.

DUAL PLASTIC SIDE

VENTS

COMPONENTS 1 PART NO.

* RM 123 Upper Metal Side Vent

3100451.024

* Lower Plastic Side Vent

-!-

3107560.009

-“PowerVentilator, Optional 31087Om-

* Upper Plastic Side Vent _ 3107560.041

* Lower Plastic Side Vent 3107560.009

~__ -

** Power Ventilator

3108705.751

SECTION C. OPERATING INSTRUCTIONS

1 JMPORTANCE OF LEVELING A

REFRIGERATOR

In an absorption refrigerator system, ammonia is lique-

fied in the finned condenser coil at the top of the refrige-

rator. The liquid ammonia then flows into the evaporator

(inside the freezer section) and is exposed to a circulating flow of hydrogen gas, which causes the ammonia to

evaporate, creating a cold condition in the freezer.

The tubing in the evaporator section is specifically

sloped to provide a continuous movement of liquid

ammonia downward by gravity through this section. If

the refrigerator is operated when it is not level and the

vehicle is not moving, liquid ammonia will accumulate in

sections of the evaporator tubing. This will slow the

circulation of hydrogen and ammonia gas, or in severe

cases, completely block it, resulting in a loss of cooling.

Remember to level the vehicle when stopping for more

than an hour, otherwise the cooling unit could be perma-

nently damaged due to overheating if it is left “ON”.

When the vehicle is moving, the leveling is not critical as

the rolling and pitching motion of the vehicle will pass to

either side of level, keeping the liquid ammonia from

accumulating in the evaporator tubing.

Page 8

2. CONTROLS

FIG.

8

The gas and electric controls are located at the rear of

the refrigerator and are accessible through the lower

vent in the outside wall of the vehicle. See FIG. 8.

A = DC ON/OFF SWITCH

B = AC ON/OFF SWITCH

c =

AC THERMOSTAT

D =

DAS SAFETY VALUE

E =

PIEZO IGNITOR BUTTON

F

=

GAS THERMOSTAT

G =

GAS INLET FITTING

H = DC TERMINAL BLOCK

3.,OPERATING INSTRUCTIONS

-A. LP GAS OPERATION

After initial installation, servicing, or changing gas cylin-

ders, etc., the gas line may contain some air which

should be allowed to escape by briefly turning on the

refrigerator or other gas appliances. This will ensure that

the flame lights immediately. See FIG. 8 for control

location and identification.

1)

2)

3)

4)

8)

8)

7)

Open the shutoff valve of the gas bottle. Check that

there is enough gas.Open any on-board shutoff valve

which is in the gas line to the refrigerator.

Open the lower vent at the rear of the refrigerator on

the outside of the vehicle, and switch the electrical

toggle switch/es (A and B) to the “OFF” position.

Turn the gas thermostat control (F) to the highest

setting.

Depress the knob (D) of the flame failure device, turn

it to position “ON”, and hold it down while depres

sing the piezo igniter button (E) several times in quick

succession (a click should be heard each time it is

depressed).

Keep the knob depressed for a further 1 O-l 5

seconds.

Release the knob and check for flame by looking

through the opening in the metal burner cover.

If the burner has not lit, repeat the lighting procedure.

If the burner fails to light within a couple of attempts,

contact a qualified technician or your dealer.

8)

9)

In normal ambient conditions, the thermostat should

be set between 3-5. If you wrsh a colder temperature

inside the compartment, set the thermostat to a

higher position.

If the ambient temperature is higher than about 7O”F,

the thermostat should be set to its highest position.

To terminate gas operation, turn knob (D) to the

“OFF” position.

DO

NOT attempt to operate the refrigerator by

both gas and electricity at the same time. Always

c

ensure that one method of operation IS turned off

before using the alternate energy source.

NOTE: The refrigerator has a flame failure device

which will automatically shut off the gas to the bur-

ner if the flame is blown out. While the knob (D) is

being held in, this device is temporarily inoperative.

8

Page 9

Most LP gas appliances used in recreational

vehicles are vented to the outside of the vehicle.

When parked close to a gasoline pump, it is possible that the gasoline fumes could enter this type of

appliance and ignite from the burner flame,

CAUSING A FIRE OR AN EXPLOSION.

FOR YOUR SAFETY, it is recommended that all LP

gas appliances which are vented to the outside

should be shut off when refueling.

The refrigerator must be shut off during refueling.

B. ELECTRIC OPERATION

120V AC OPERATION

To start 120V AC operation:

1.) Terminate gas operation by turning the knob of the

gas control device (D in FIG.8) to the “OFF” position.

2.) If the refrigerator is in 12V DC mode, switch the 12C

DC switch (A in FIG.8) to the “OFF” position.

3.) Check that the 120VAC’supply cord is connected

,and that AC- is available.

4.) Switch the 120V AC toggle switch (B in FIG8) to the

“ON” position.

5.) On 120V AC operation, the temrjerature is controlled

by a thermostat. The thermostat knob (C in FIG.8)

should be set to position 35 in normal working

conditions. If the,ambient temperature is high and/or

fresh food is put into the refrigerator, you may set the

refrigerator to a higher positions.

6.) To terminate 120V AC operation, switch the AC

toggle switch (B in FIG.8) to the “OFF” position.

DC ELECTRIC OPERATION

The DC operation is mainly designed to let the cooling

unit of the refrigerator work while being on the road.

To start 12V DC operation, proceed as follows:

1.) Terminate Gas operation by turning the knob of the

gas control device (D in Fig. 8) to the “OFF” position.

2.) Start 12V DC operation by switching the 12V toggle

switch (A in Fig.8) to the “ON” position.

Whenever possible, the cabinet should be precooled,

together with its contents, by starting up and running the

refrigerator on gas or AC for several hours, or overnight,

before switching to 12V DC and starting on a journey.

The 12V heating element is rated at 125 watts and has a

current consumption of about 10.5 Amps. The refrigerator should not therefore be left operating on 12V when

the engine is not running and charging the battery.

If an automatic cut-out relay, as recommended in Section

A, item 11, has not been installed, the refrigerator should

be switched off at the 12V toggle switch (A in Fig. 8)

soon after the engine is switched off, otherwise the

battery may become discharged.

3.TO TERMINATE DC OPERATION

To terminate DC operation, turn the DC switch to the

“OFF” position (A in FIG. 8).

4.HOW TO USE THE REFRIGERATOR

A. FOOD STORAGE COMPARTMENT

The storage compartment is completely closed and

unventilated, which is necessary to maintain the required

low temperature for food storage. Consequently, foods

having a strong odor or those that absorb odors easily

should be covered. Vegetables, salads, etc. should be

covered to retain their crispness. The coldest positions in

the refrigerator are under the cooling fins and at the

bottom of the refrigerator. The warmer areas are on the

upper door shelves. This should be considered when

placing different types of food in the refrigerator.

The refrigerator is designed for the storage of fresh

foods, milk, etc. It is not intended for the storage of fro-

zen food. The internal volume of the refrigerator is 1.7

cubic feet, net.

NEVER PUT HOT FOOD INTO THE REFRIGERATOR.

Avoid using large dishes and do not stack food or food

containers too closely as this interferes with the circulation of cold air within the cabinet.

If possible, start the refrigerator on gas or AC the day

before it is to be used, to allow time for the interior to be

cooled. It is then preferable to load the refrigerator with

food which has been precooled in your household

refrigerator, or in the market.

Before moving the vehicle, make sure that all containers

are tightly covered to avoid spills. If required, crumpled

paper may be packed between bottles and other items to

prevent shifting while traveling.

Engage the travel catch at the top of the front corner of

the door before moving the vehicle.

B. DEFROSTING

To defrost, take out any food, etc. then turn off the gas

valve or switch of the DC/AC supply to the refrigerator.

Leave the refrigerator door open and place a suitable

dish or other receptacle under the evaporator to catch

the defrost water.

When all the frost has melted, any remaining drops of

water in the refrigerator should be wiped up with a clean

cloth.

DO NOT use a hot air blower. Permanent damage

could result from warping the metal or plastic parts.

DO NOT use a knife or an ice pick, or other sharp

tools to remove frost from the freezer shelf.

9

Page 10

E. CLEANING

Cleaning the refrigerator is usually done after it is defro-

sted or put into storage. To clean the interior of the refrigerator, use lukewarm water and a mild dishwashing

detergent. Use only warm water to clean the finned evaporator, gaskets, ice trays and shelves. NEVER use

strong chemicals or abrasives to clean these parts as the

protective surfaces will be damaged. It is important to

always keep the refrigerator clean.

F. SHUTOFF (STORAGE PROCEDURE)

Place the toggle switch(es) for DC and AC operation to

the “OFF” position or turn the gas valve to position

“OFF”, as applicable. See FIG. 8.

When not in use, the refrigerator should be emptied,

cleaned and dried and the door left open so that fresh air

can circulate inside.

The travel latch placed in the second hole will hold the

door ajar and allow air to circulate.

Most LP gas

appliances

used in recreational

vehicles are vented to the outside of the vehicle.

When parked close to a gasoline pump, it is possible that the gasoline fumes could enter this type of

appliance and ignite from the burner flame,

CAUSING A FIRE OR AN EXPLOSION.

FOR

YOUR SAFETY, when refueling, shut off all LP

gas appliances which are vented to the outside.

SECTION D. MAINTENANCE & SERVICE

,f

TIPS FOR THE SERVICE TECHNICIAN

The user should be aware of service that must be done

on a regular schedule to keep the refrigerator operating

properly.

The service should only be performed by a

qualified technician who is familiar with LP gas

systems and refrigerators.

1 .REFRIGERATOR REMOVAL

Before working on, or removing the refrigerator, make

sure the electrical supply (AC and DC) is turned OFF

before leads are disconnected. Shut off the gas supply.

Disconnect and cap the gas supply line. Loosen the

screws anchoring the refrigerator to the enclosure and

slide the refrigerator out of the compartment.

Replacement is the reverse of removal. Check all

connections for gas leaksRefer to Section A, Item 1

through 13 of Installation Instructions.

2. PERIODIC MAINTENANCE

To keep a Dometic refrigerator operating efficiently and

safely, periodic inspection and cleaning of several com-

ponents once or twice a year is recommended.

A. It is important to keep the area at the back of the refri

gerator clean. Check the lower vent, upper vent and

area between these openings for any obstructions

such as bird/insect nests, spider webs, etc. Clean the

coils on the back of the refrigerator. Use a soft brist

led brush to dust off the coils..

NOTE: AVOID SPRAYING WATER THROUGH THE

REFRIGERATOR VENTS WHEN WASHING THE RV.

It is important to keep the refrigerator vent area free

from combustible material, gasoline and other

flammable vapors or liquids.

B. Check all connections in the LP gas system (at the

back of the refrigerator) for gas leaks. The LP gas

supply must be turned on. Apply a noncorrosive

bubble solution to all LP gas connections. The appea

rance of bubbles indicates a leak and should be

repaired immediately by a qualified serviceman who is

familiar with LP gas systems and refrigerators.

DO NOT USE A FLAME TO CHECK FOR GAS LEAKS.

10

Page 11

C. Examination and Cleaning of Flue, Burner and Jet

Once or twice a year, look through the opening (see FIG.

9) in the burner box and examine the appearance of the

burner flame which should be predominantly blue in

color when the gas thermostat knob is set to its highest

position. (Refer to FIG. 10).

If this is not the case, clean the flue, burner, jet, etc. (see

section D and E).

7) Reassemble the components in the reverse order to

that described above.

FIG. 11

FIG. 9

OPENING IN

BURNER BO

FIG. 10

CLEAR BLUE COLOR OF FLAME

D. Cleaning of Burner, Burner Jet (Refer to FIG. 11)

Proceed as follows:

1) Turn off the gas at the gas bottle.

2) By using a phillips screwdriver, remove the screw (6)

and carefully withdraw the burner cover box. Clean

the inside of the box of soot and other deposits.

3) To clean the burner, unscrew the screw (C) that fixes

the burner on the boiler tube and be careful in order

not to lose the washer.

4) Clean the inside of the burner.

5) To examine and eventually clean the burner jet,

unscrew the gas pipe union (K) and pull out the

burner jet (L).

6) Clean the jet by washing it in alcohol and blowing it

through with air.

NOTE: The jet fitted to this refrigerator is a size

“43” which is suitable for use on propane gas at

11 inches water column. The orifice in the jet is

very small and must never be cleaned by means

of a pin or similar instrument as this would

damage the orifice. It must only be cleaned as

described above.

DO NOT use a wire or pin when cleaning the

burner jet as damage can occur to the precision

opening. This can cause damage to the

refrigerator or create a fire hazard.

E. CLEANING OF FLUE TUBE, FLUE BAFFLE

Proceed as follows:

1) To clean the flue tube and the flue baffle, it is neces

sary to withdraw the refrigerator out of the recess.

See Section D, Item 7.

2)

By using a phillips screwdriver, remove the screw (B,

in FIG 11) and carefully withdraw the burner cover

box.

3) Place a piece of paper or cloth between the boiler

tube (E, in FIG 11) and the burner assembly, to catch

falling deposits.

4) Remove the “T-piece” (A, in FIG. 12) at the top of the

flue by unscrewing the screw (B, in FIG. 12) that fixes

it to the flue pipe.

5) Carefully takeout the flue baffle (C, FIG. 12) and

clean.

6) Clean the flue tube of soot, etc. with the aid of a spe

cial flue brush, available from your supplier.

FIG. 12

A

11

Page 12

7) Reassemble the components in the reverse order to

that described for removal, taking care to remake the

To replace the 12V DC heater or the IIOV AC heater,

gas connections soundly, and not forgetting to refit

proceed as described below:

the flue baffle.

1. Remove the refrigerator out of the recess as

described in item “2E”.

8) Reinstall the refrigerator in its recess. Connect the

gas and electrical supplies, and check for gas leaks.

Light the burner and check the appearance of the

flame to ensure that it is predominantly blue (when

the thermostat is at “MAX”), then leave the

refrigerator on “test” for at least an hour.

2. Remove the boiler insulation cover (D in FIG. 12) and

remove the boiler insulation (E in FIG. 12).

3. Disconnect the faulty heater (F in FIG. 12) from the

terminals and remove it from the metal pocket on the

boiler.

4. Check that the new heater is of the correct type and

voltage and fit it in the boiler tube pocket in the same

way as the original was fitted.

5. Fit the boiler insulation round the boiler tube and replace the boiler insulation cover.

F. Replacing of ignition system

If the flame cannot be lit because no sparks are

produced bv oushina the olunaer. olease check:

I .

Y I “II

If the connection cable between the piezo igniter (E in

6. Connect the heater leads to the terminal block and

FIG. 8) and the electrode (I in FIG. 11) is not defective

switch as before and re- install the refrigerator. Check

or loose. If it is broken or if the insulation of the wire is

for gas leaks and test the fridge for satisfactory

defective, replace the connection cable.

operation.

If the piezo igniter has to be replaced, remove the

ignition cable and pull out the defective igniter (E in

3. TROUBLESHOOTING

FIG. 8) by unscrewing the nut under the metal- plate

that holds the controls. Put in the new piezo igniter, fix

If the refrigerator fails to work, check the following points

it by screwing on the nut. Re- connect the ignition

before calling a service technician:

I I

caore.

.

If the electrode (I in FIG. 11) is defective, screw out

the burner as described in item 22b. Carefully loosen

the metal plate (G in FIG 11) by loosing srew (F) and

take qut the defective electrode. Put the ignition cable

on the new electrode and fix the metal plate (G).

Check, that the thermocouple (H) and the electrode

are in the original position

!

G Replacing of thermocouple

. .

The tip of the thermbcouple senses the flame. To replace

the thermocouple proceed ,as follows:

1. Disconnect the thermocouple connection at the flame

safety failure device (D in FIG. 8).

2. Remove the faulty thermocouple out of the burner and

put in a new one usig the description above for

changing the spark- electrode, step “F”.

3. Carefully tighten the thermocouple connection to the

falme safety failure device. Tighten it “finger- tight”

plus 114 turn. The plug must be properly tightened to

the safety device to ensure good contact.

Do not overtighten!

H. Lubrication

No lubrication is required to any part of the refrigerator or

gas controls.

I. Electric equipment

Before eventually replacing one of the electric heaters,

please check all the items of “3. TROUBLESHOOTING”.

If the fridge does not operate in one of the possible elec-

trical modes because a fuse is blown, examine the

supply wiring, cut- out relay (if installed) and repair any

faulty components or wires before fitting a new fuse and

reconnecting.

If current is available to the fridge (evt. measured with an

electricaltest- meter at the input- clamps) and the coolingunit at the back does not heat up after being “on” for at

least half an hour, this indicates that the heater has an

open circuit and needs replaced by a new one. (If an

electrical test- meter is available, the two heater leads

can be disconnected and the heater tested for

continuity).

A. Instructions for STARTING THE REFRIGERATOR,

Section C, have been followed.

B. The refrigerator is level.

C. If it is possible to start the refrigerator on any of the

connected sources of energy.

D. If the refrigerator fails to work on GAS, check:

1)

That the gas bottle is not empty.

2) That all LP Gas valves in the supply line to the

refrigerator are open.

NOTE: The following checks should be performed

only by a qualified technician.

3) That sparks are generated by the piezo ignitor.

4)

That the flame continues to burn after releasing

the knob of the flame failure device (D, in FIG.8).

If not, the thermocouple may be loose or

defective.

E. If the refrigerator fails to work DC, check:

1) That the DC supply is connected to the

refrigerator.

2) That the fuse on the DC supply is intact.

3) That the DC switch is set to the “ON” position

(A, in FIG. 8).

F. If the refrigerator fails to work on AC, check:

1)

That the AC supply is connected to the

refrigerator.

2) That the fuse on the AC supply is intact.

3) That the AC switch is set to the “ON” position.

4) That the AC thermostat is not set to the “0”

position.

G. If the refrigerator is not cold enough it may be

because:

1) The ventilation is inadequate because of

reduced area of the ventilation passages

(partial blockage of grilles from wire mesh, etc.).

2)

The evaporator is frosted up.

3) The temperature control setting is incorrect.

4) The gas pressure is incorrect. Check the

pressure regulator.

5) The ambient temperature is too high.

6) Too much warm food is loaded at one time.

7)

The door is not properly closed or the magnetic

sealing strip is defective.

12

Loading...

Loading...