Page 1

SERVICE INSTRUCTION

COOLING

3120

3130

miniBar

miniCool

Previous models

Greenline

Face-lifting

HiPro

599 5152 -85

Publication-No.:

04.02.25

EN/SERVICE/MB/KV/RS

DES

Dometic GmbH

In der Steinwiese 16

D-57074 Siegen

Tel. 0049 / 271/692-0

Fax. 0049 / 271/692-300

replaces 599 4720-12/5

599 4708-82/3

ENGLISH

Page 2

2

1.0 Summery of Models 3

2.0 Electronics 3

2.1 Fuzzy Logic 3

2.2 Fuzzy Logic with 2 Sensors 3

3.0 Automatic Defrost Function 4

4.0 Cooling Unit 5

5.0 Heating Shell 5

5.1 Resistances at Heating Elements 5

6.0 Lighting 6

7.0 Installation 8

8.0 Securing 9

9.0 Changing the Sliding Hinge 10

10.0 Changing the Decorative Panel 11

11.0 Automatic Door Control (ADC) 11

11.1 Mechanical ADC 11

11.2 Automatic Door Control (electrical) 13

12.0 Mounting a miniSafe 18

13.0 Storing Goods 19

14.0 Troubleshooting 20

15.0 Energy Saving Tips 20

16.0 Technical Data 21

17.0 Wiring Diagrams 24

17.1 Refrigerators without Lighting 24

17.2 Refrigerators with Lighting 25

17.3 Refrigerators with 55l/56l Capacity 26

18.0 HiPro Generation 27

19.0 HiPro Electronic 27

19.1 Temperature in the HiPro 27

compartment

19.2 Self-test of the electronics 28

19.3 Automatic fault analysis 28

19.4 Automatic Defrost Function 29

19.5 Cooling unit check 29

19.6 Heating Shell 29

20.0 Lighting 30

21.0 Automatic Door Control 30

22.0 Operation intervention 30

23.0 Installation 31

24.0 Securing 31

25.0 Changing the Sliding Hinge 31

26.0 Energy Saving Tips 31

27.0 Manual fault analysis 32

28.0 Technical Data 32

29.0 Wiring Diagram/ Occupancy electronics 33

TABLE OF CONTENTS

Page 3

Summery of Models

Face lifting models and Greenline models are the latest generation of

miniBars/miniCools and consumes approximately 40% less energy than its

predecessors.

RH 430LD RH 330LD RH 236LD

RH 440LD RH 340LD RH 237LD

RH 441LD RH 341LD RH 238LD

RH 460LD RH 360LD RH 252LD

RH 461LD RH 361LD RH 255LD

RH 456LD/LDE RH 356LD/LDE RH 300LD

RH 455LD RH 355LD RH 226LD

RH 436D RH 136D RH 447D RH 137D -

- EA 330/L -

- EA 355/L -

- EAW 3220 -

Changes Face-lifting models to Greenline models:

Automatic defrost -cycle and design

Changes Greenline models to Previous models: cooling unit, the heating

cartridge, lighting, insulation and electronic controls (Fuzzy Logic).

Electronics

Fuzzy Logic

All Greenline models and Facelifting models maintain a constant temperature level which has been set at the beginning

of operation. This temperature level is controlled by

electronic intelligence in an energy-saving way.

Unlike conventional appliances, the electronic control

component does not switch on and off but controls (clocks)

the cooling units heating power in a way which does not

require system circulation to be interrupted.

The electronic controls sensor (A) is an air sensor. This means that the

sensor can react directly to the temperature inside the cooling appliance.

Fuzzy Logic with 2 sensors

By means of the second sensor the electronics carries out a leak detection

test. If leaks or blockages in the cooling unit are recognised the miniBar is

shut off by the electronics. The test is done after every defrost cycle

(every 24 hours).

After a Power-On-Reset, the controllers software runs a self test routine to

check the function of the sensors. The result of the test is shown with the

length of the first duty-cycle of the heating element (jumper X4).

There are four different states which are shown in the following table:

3

2.0

1.0

Face lifting Greenline Models Previous Models

A

2.1

2.2

Page 4

Status Duty-Cycle

both sensors o.k. 7 sec. ON

air-sensor missing/defective 9 sec. ON

evaporator-sensor missing/defective 12 sec. ON

both sensors missing/defective 15 sec. ON

If the air-sensor fails during normal operation, the software shuts down the

cooling unit in steps to 0.

In refrigerators without evaporator-sensor or if the evaporator-sensor is

defective the leakage test is not carried out.Then the new electronics works

like the previous one without leakage detection.

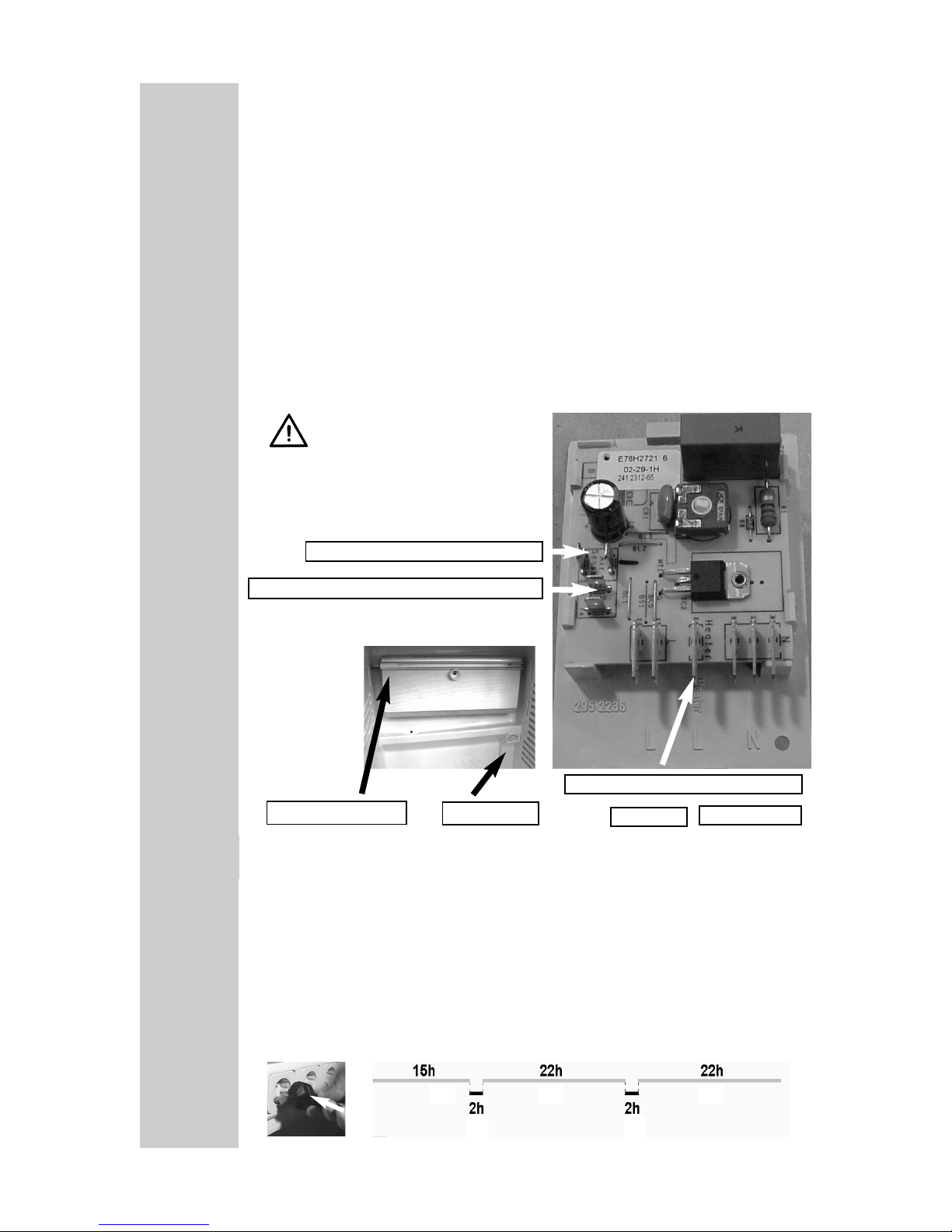

Automatic Defrost Function

The electronic also regulates the automatic defrosting of the refrigerator.

When the plug has been stuck to the socket the running time of the

refrigerator up to the first defrosting is 15 hours for greenline models

and 39 hours for the new face lift models (RH4XX). For all models the

defrosting takes 2 hours. Then the refrigerator works 22 hours and

afterwards defrosts 2 hours. Therfore the starting of the refrigerators

determines the time of defrosting.

For example: Starting at 7.00h = first defrosting 22.00h - 24.00h (for facelift

models 22.00h next day)

4

3.0

S

TT

TT TT

S

(39h)

X4, connection heating element

Connections evaporator-sensor = Y3, Y4

Connections air-sensor = Y1, Y2

Do not change the

connections of the

evaporator-sensor and

the air-sensor !

Air-sensor

Evaporator-sensor

N

X1,X2,X3 = N

X5,X6 = L

In service case please pull sensor off

electrics and check by means of

measurement.

(ch. 15.0 Troubleshooting)

Ambient temperature°C Resistance (kW)

0° 32,51 +/-2%

10° 19,86 +/-2%

15° 15,68 +/-2%

20° 12,48 +/-2%

Page 5

5

Cooling Unit

The cooling unit has been optimised for the Greenline models and FaceLifting models. Unlike the cooling units of its predecessors, the Greenline

models and Face Lifting models cooling units can be replaced.

When replacing the cooling unit, however, the heating element

(heating shell) must be replaced as well.

Ammonia is used as a coolant. This is a natural compound also used in house

hold cleaning agents (1 litre of Salmiak cleaner contains up to 200g of

ammonia - about twice as much as is used in the refrigerator). For the safety of

hotel guests and personnel, it has been established by inspectors that the

coolant poses no threat to health.

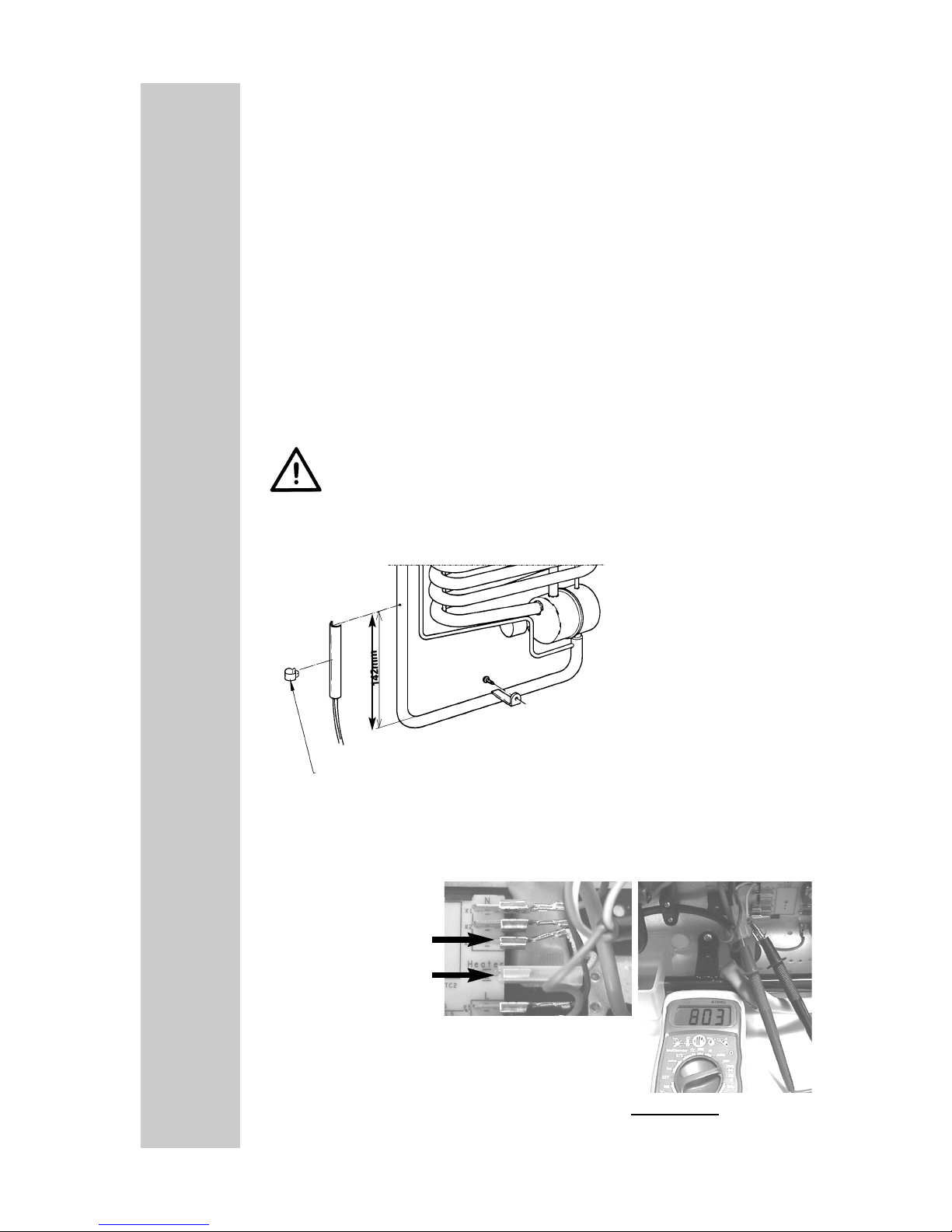

Heating Shell

The conventional heating element (previous models) is replaced by a heating shell. The heating shell is situated directly to the cooker tube. An optimal

efficiency ratio is achieved by means of a direct and enlarged contact area.

Measuring of resistances at heating elements

4.0

In case service is required:

5.0

Attention please! The heating bowls upper

edge must be placed at the shown position

(142 mm).

Install the mounting clip at the centre of

the heating shell.

142 mm

Resist

ances :

ch. 15.0 Troubleshooting

5.1

Connections N

and X4

Measure resistance...

...replace heating shell if required.

230V / 65 W heating shell ~ 800

WW

230V / 80 W heating shell ~ 650

WW

110V / 65 W heating shell ~ 186

WW

110V / 80 W heating shell ~ 150

WW

Page 6

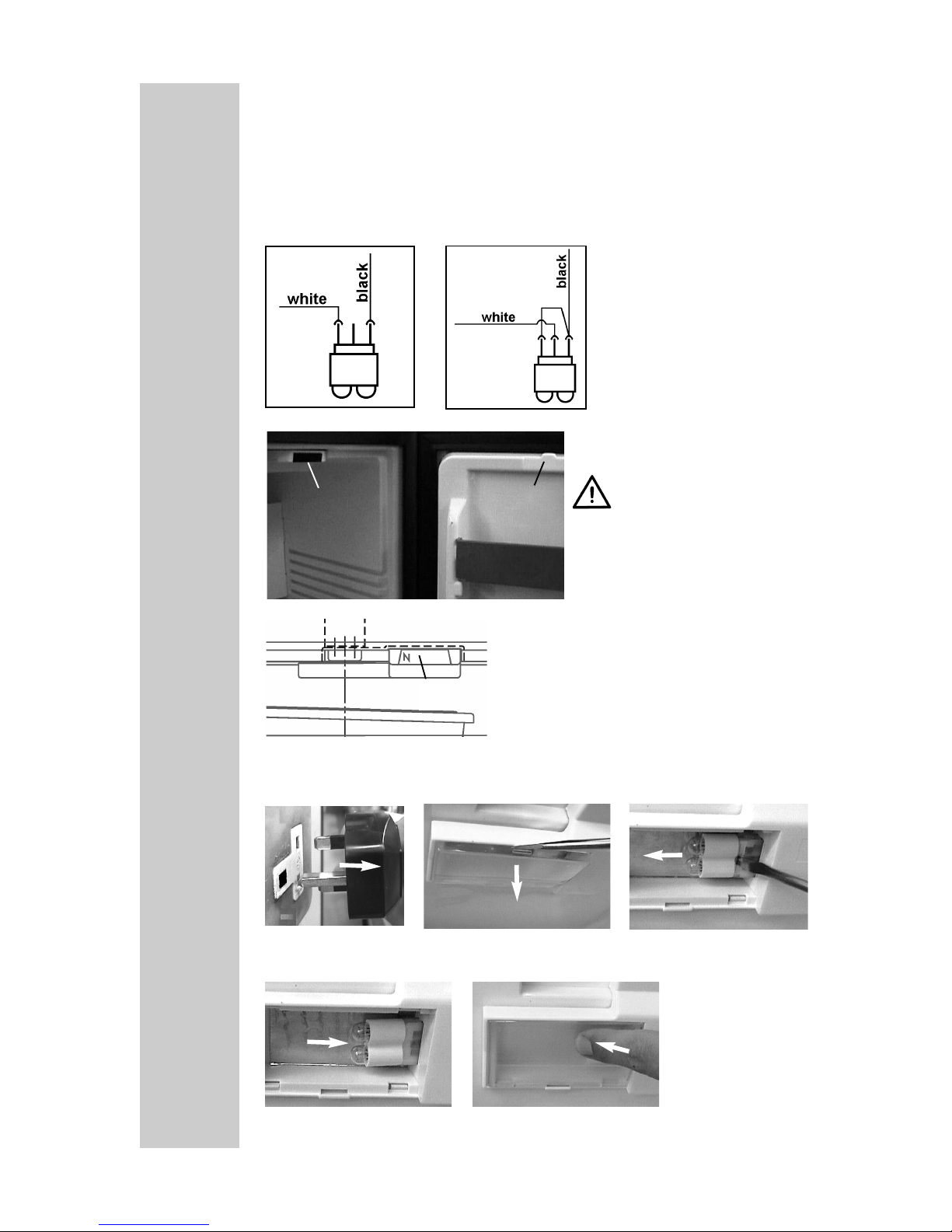

Lighting (except for RH 356LD/E, RH 456LD/E)

All Greenline and face lifting cooling appliances are equipped with sensorcontrolled lighting. The lightings sensor (proximity switch, A) is activated by

means of a magnet (B) which has been foam-installed into the door.

The lighting mechanism consists of two lamps for 180-250V operation

switched in series. For voltages of 100-140V, the lamps are switched in

parallel by means of a bridge.

A = Proximity switch

Take care when

replacing- pay

attention to correct

polarity

B = Magnet

Changing bulbs:

6

6.0

A

B

180-250V

100-140V

The proximity switch (A) is mark with a N

on the left side in front (correct polarity) .

If you chance the proximity switch please

eighth of the polarity.

A

1. Pull out the

mains plug.

2. Remove the

reflector disk.

3. Remove defective

bulb.

4. Insert new bulb.

5. Clip reflector disk

back in.

Page 7

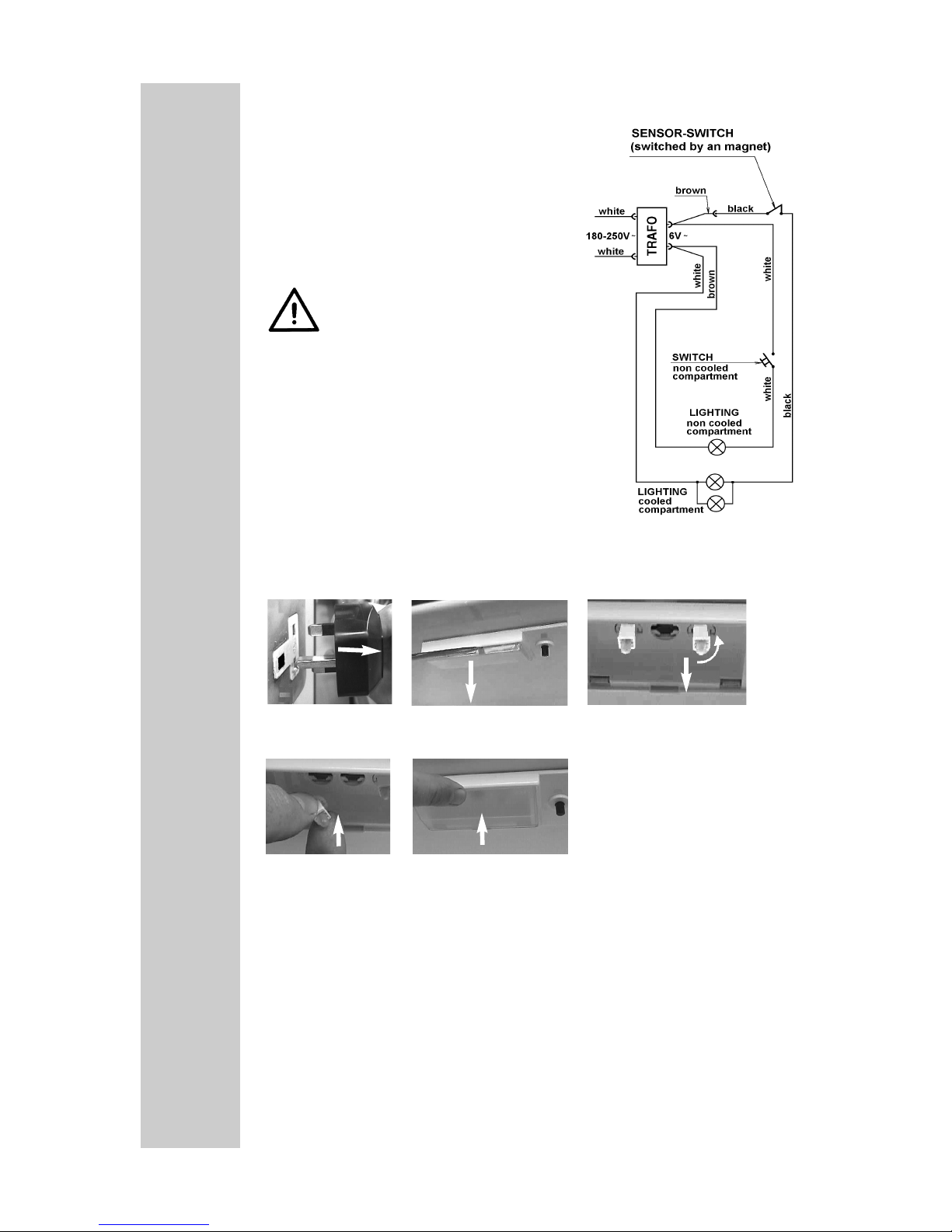

Lighting for RH 356LD/LDE and RH 456LD/LDE

The above models are equipped with

separate warm shelf and cooling section

lighting. This lighting mechanism consists

of:

- sensor - switch

- 1 light bulb for warm shelf

- 2 light bulb for cooling section

- Transformer (output voltage 6V)

Pay attention to country-specific voltages for the transformer!

Changing bulbs:

7

1. Pull out the

mains plug.

2. Remove the

reflector disk.

3. Remove the

defective bulb.

4. Insert new bulb.

5.Clip reflector disk back in.

90°

1.

2.

Page 8

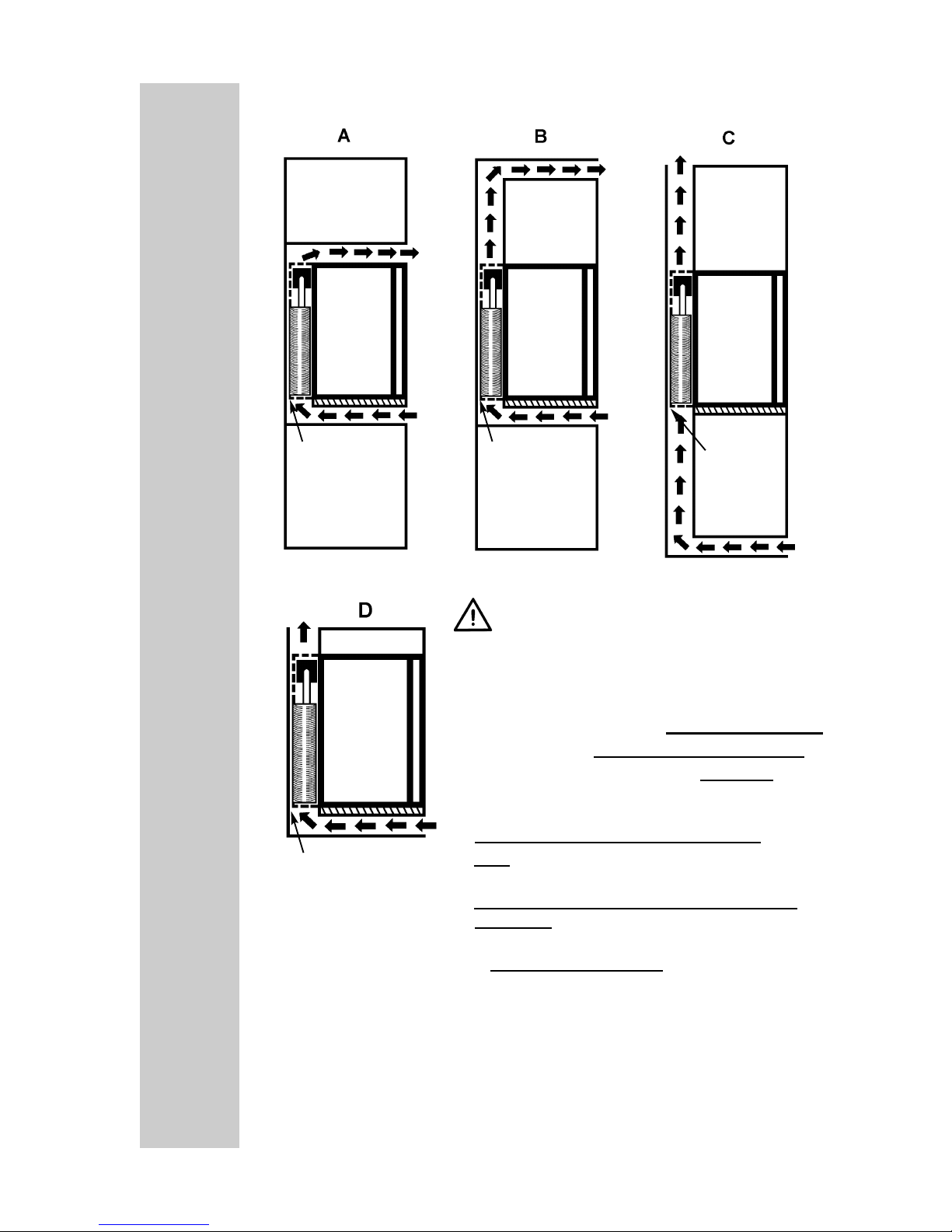

Installation

8

7.0

1. The refrigerator must be level both directions

2. There sould be 20mm clearance to the wall

3. Ventilation must be provided as shown in

alternatives A,B,C or D

4. The ventilation duct must at least measure

105mm x the wt

dth of the refrigerator

5. Only the entire cooling unit must project into

the duct as shown

6 Air p

assing through the duct must not be

preheated by any source of heat

7. Ventilation grills, if used, must have openings

of at least 200cm² each

Please follow the installation details below

carefully. Guarantee is valid for products

installed as described only.

IMPORTANT:

20mm20mm

20mm

20mm

200cm²

200cm²

200cm²

200cm²

200cm²

200cm²

200cm²

200cm²

Page 9

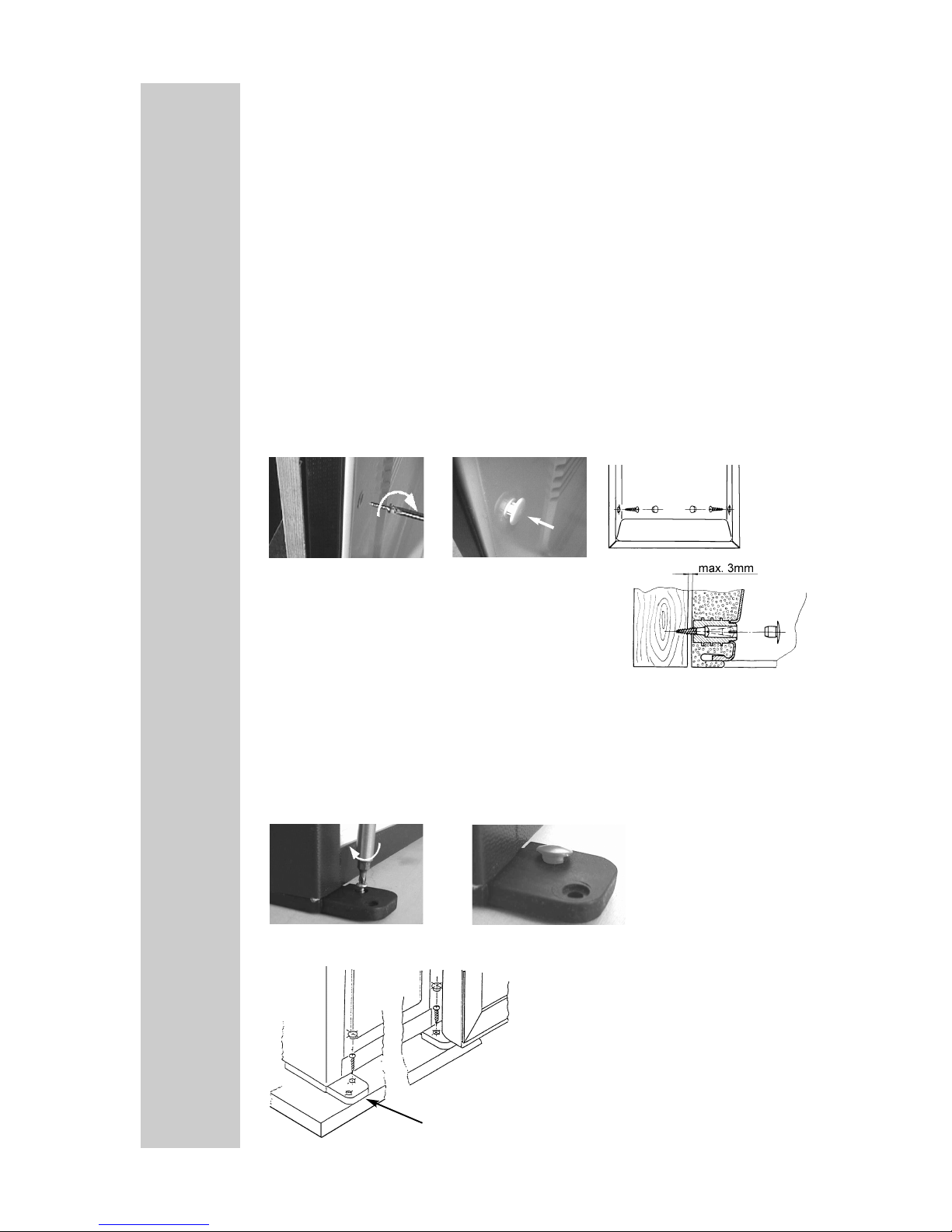

Securing

RH 356LD/E, RH 456LD/E

RH136, RH137, RH330, EA330, RH340, RH341, RH360,

RH361, RH437, RH447, RH430, RH440, RH41, RH460,

RH461, EAW 3220

The miniBar must be screwed onto the cupboard using the lower hinges.

9

Recess dimensions in mm:

Model Hight Width Depth

RH 430LD, RH 330LD 526 388 432

RH 436D, RH 136D 526 388 432

EA 330L 526 388 432

RH 440LD, RH 340LD 558 405 466

RH 447D, RH 137D 558 405 466

RH 441LD, RH 341LD 558 405 469

RH 456LD/E, RH 356LD/E 662 454 523

RH 460LD, RH 360LD 567 490 494

RH 461LD, RH 361LD 567 490 494

EAW 3220 567 490 494

1. Tighten screw.

2. Put on cap.

8.0

1. Tighten screw.

2. Put on cap.

on level with furniture

Page 10

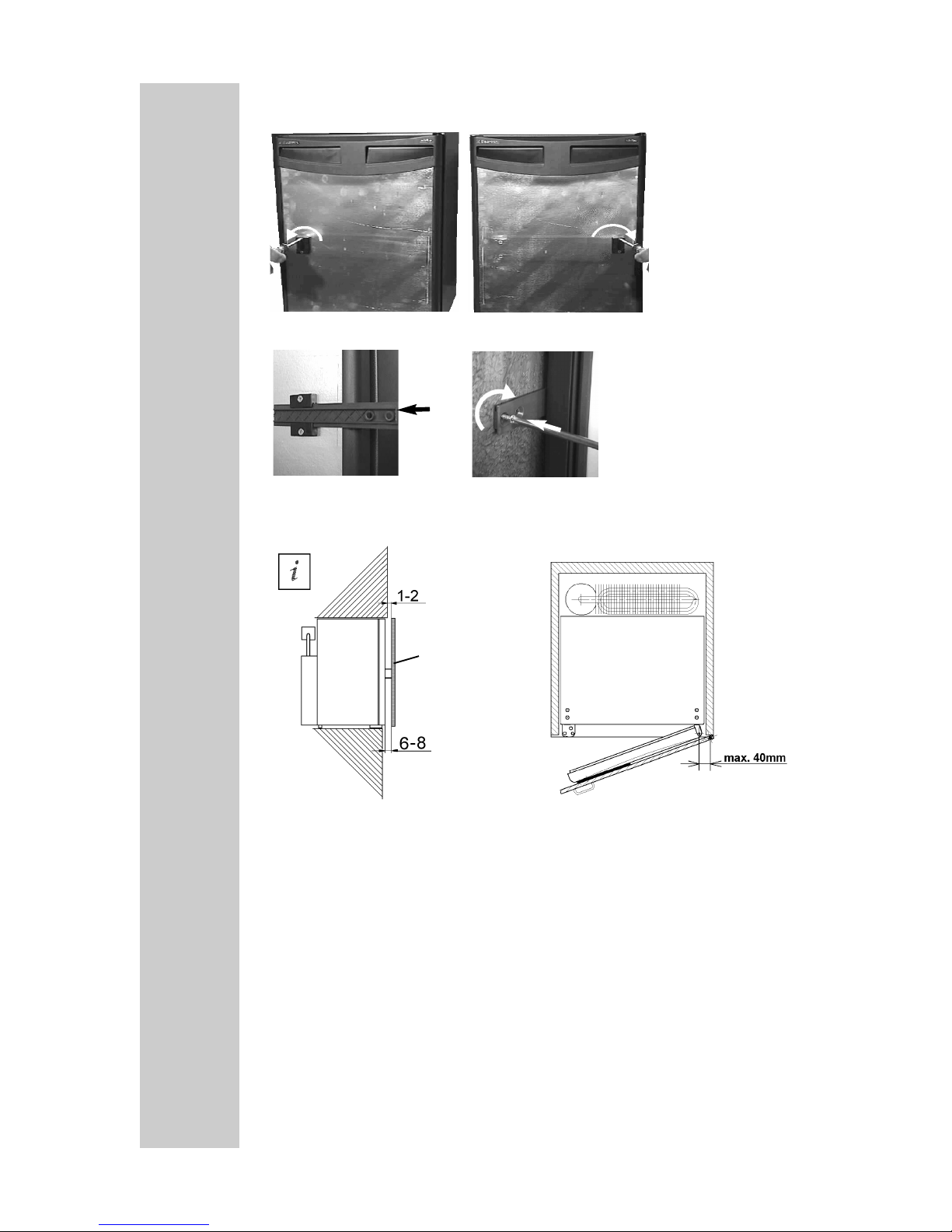

Changing the Sliding Hinge

10

9.0

1.

2.

3.

4.

Distance to cupboard door (A)

A

1. When closed, the cupboard door (A)

must not lie against the rest of the

surrounding cupboard area

(distance 1-2mm).

1.

2.

1.

2.

mm

mm

2. There must be a distance of

6-8mm between the cupboard

door and the miniBar.

Page 11

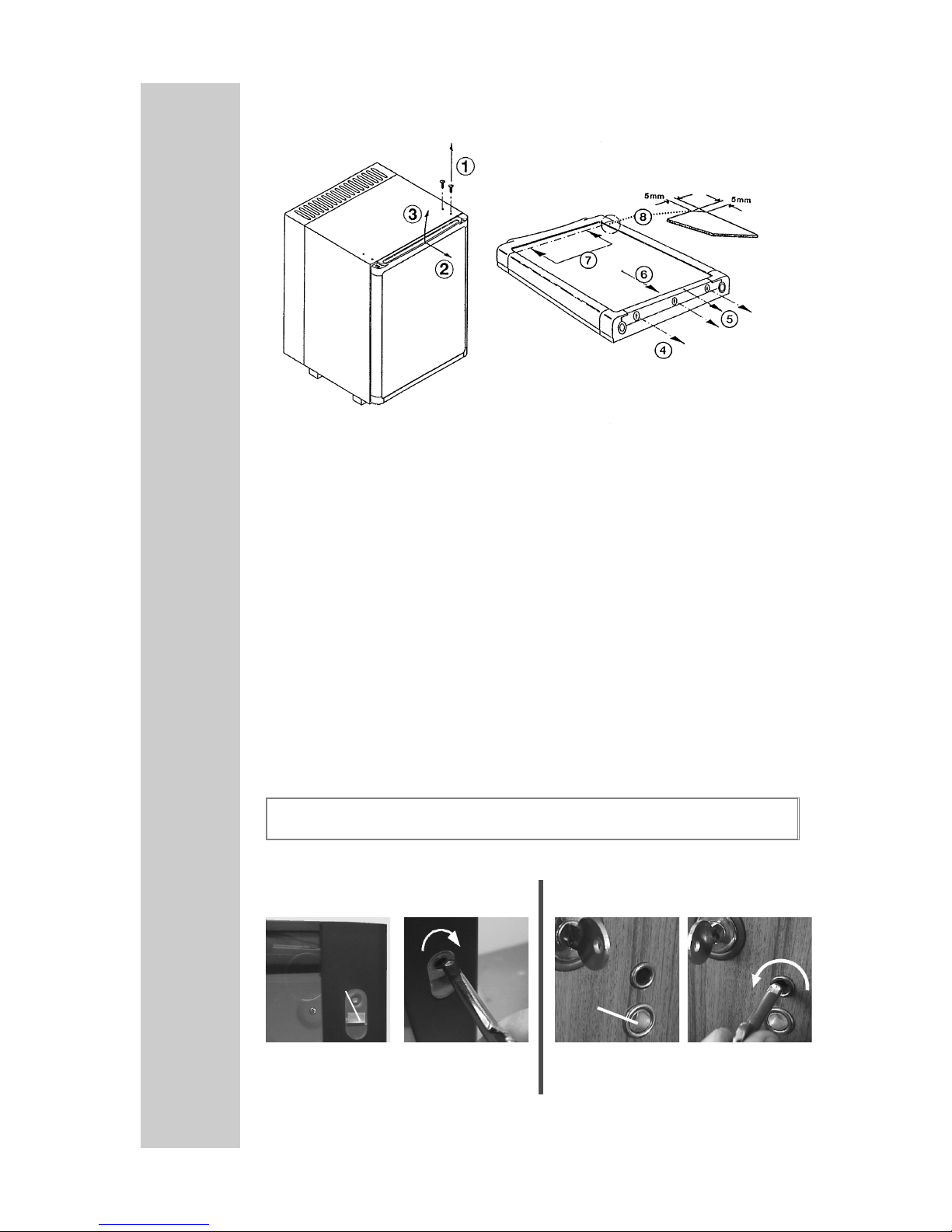

Changing the Decorative Panel

Automatic Door Control (ADC)

Mechanical ADC

Reset of automatic door control:

11

10.0

- Unscrew the 2 screws of the upper door hinge.

- Pull the door and the hinge off, away from the housing and in an upward

direction from the lower hinge pin (2-3).

- Unscrew the screws (4) and pull off the frame section (5).

- Pull the decorative panel (6) out of the door frame and push in the new

decorative panel (7) in such a way that the upper edge runs exactly

parallel to the upper section of the frame.

Put on upper section of frame (5) and re-fasten with screws (4).

- Set the door on the lower hinge, put the upper hinge in the door, guide

the door with the hinge into the hinge hole opening and screw together.

11.0

1.

The red dot has disappeared now.

Using a red dot in the display window (A, point 3), the ADC shows that

the miniBar´s door has been opened.

1.

2.

RH456LD/E

All other models

A

A

2.

3. Insert ADC key and turn to the

right.

3. Insert ADC key and turn to the

left.

11.1

Page 12

Change of the Mechanical ADC

( for RH356 / RH456 LD E)

12

11.1.1

Pin

(triggers a weight when opening the door )

ADC - component, complete

The complete component is not screwed in the doorframe but inserted. So without

removal of the door or loosing of screwings the ADC-component can be exchanged.

Press in the mounting

pins and pull out the

component a little bit.

Press in the mounting pins on

the other side as well by

means of a screw driver.....

......and pull out the complete ADC.

Page 13

Automatic Door Control (electrical)

(for RH356 / RH456 LD E)

When the miniBar is opened, a magnetically operated approximation switch

located underneath on the fridge is activated (FIG 1.)

Depending on the connection (opening/closing mechanism), an electric

circuit is closed or opened. Accordingly, this is registered and processed at

the hotel reception. Note: Electrical rating!

The miniBar´s wiring connection is situated at the rear of the appliance and consists of a 3-pin terminal strip (1).

Installation of the Electrical Door Control

The following miniBars could be retrofitted with an electrical

door control :

RH 330, RH 340, RH 341, RH 360, RH 361, RH 430, RH 440,

RH 441, RH 460, RH 461 with the

Service-Kit

Spare part number: 210 6821-20

Instruction 599 4722-46/9

RH355, RH356 with the

Service-Kit

Spare part number: 210 6821-30

Instruction

599 4722-59/2

The instructions are on the following pages.

13

11.2

11.2.1

1= Terminal strip

2= Approximination switch

A= blue (opening mechanism)

B= black (closing mechanism)

C= white

FIG. 1

Page 14

INSTRUCTION

Retrofit Electrical Automatic Door Control

RH 330, RH340, RH 341, RH 360, RH 361

In order to retrofit the electrical automatic door control, the following service-kit with spare

part number 210 6821-20 will be required.

You can order the service-kit at:

Dometic GmbH

Export Department

In der Steinwiese 16

D-57074 Siegen

Tel.: 0049 271/ 692-0

Fax.: 0049 271/ 629-303

Mounting the Electrical Automatic Door Control

14

Service-kit

Spare part number: 210 6821-20

B

C

D

E

F

A

three pieces

1. Pull out the mains

plug.

2. Unscrew the door

hinge.

3. Remove the door. 4. Unscrew the middle screw

from the lower doorstrip.

5. Mount the magnet

(B) at the lower doorstrip.The magnet

should be directed

towards the inside of

the miniBar.

6. Unscrew the two

lower hinges.

7. Take the distanceplates (A) and put

the plates under the

hinges .

8. Mount the hinges

with the distanceplates back on place.

A

A

599 4722-38/6 RS 04.03.1999

Page 15

15

9. Unscrew the two

feet.

10. Take two plain

washers (F) und put

the washers under

the feet.

Mount the feet

back on place.

11. Drill a hole for the

sensor, ø3mm,

depth 5mm.

12. Fix the sensor (E) with

clip (C), leveled with the

housing.

13. Mount the terminal strip (D) on the rear side

of the miniBar (Prick two holes in the rear wall

for mounting the terminal strip).

F

C

E

D

centred

10 mm

Ø 3 mm

13,5 mm

14. Lead the sensor-cable to the terminal strip and

fix the cable with scotch tape.

1= terminal strip

2= approximation switch

A= blue (opening mechanism)

B= black (closing mechanism)

C= white

15. Connect the Sensor-cable to the terminal strip.

16. Take the last plain-

washer and put it

on the lower hinge

pin.

17. Mount the door

back on place

(follow point 2 and

3 backwards).

Page 16

INSTRUCTION

Retrofit Elelectrical Door Control

RH 355, RH 356

In order to retrofit the electrical door control for the above model, the following service-kit

with spare part number 210 6821-30 will be required.

You can order the service-kit at:

Electrolux GmbH

Export department

In der Steinwiese 16

D- 57074 Siegen

Tel.: 0049 271/ 692-0

Fax.: 0049 271/ 629-300

Mounting the Electrical Door Control

16

Service-Kit

Spare part number:

210 6821-30

A

B

C

D

If the minibar is wellappointed with 4 feet (8mm high), replace the 4 feet with new

feet (11mm high). Spare part number 295 1182-02.

Attention! The feet are not contain in the service-kit. Order the 4 feet separately.

If the miniBar is wellappointed with feet 11mm or higher, the high for the door

control is ok.

1. Pull out the mains plug.

599 4722-62/6 RS 31.03.1999

2. Mount the sensor and the magnet.

miniBar-underside

The magnet should be

directed towards the

inside of the miniBar.

Scotch tape

Position for mouning the sensor (D) with the clamp (B).

Position for mounting the magnet.

Page 17

17

6. Dismantle the 8 mm high feed and mount the

feet 11 mm high.

5. Connect the sensor-cables to the terminal strip.

C

4. Mount the

terminal strip (C).

miniBar - sidewall (inside)

2 x Ø2,2 drillings for mounting the terminal strip.

Only for miniBar with feed 8 mm high!

1= Terminal strip

2= Approximination switch

A= blue (opening mechanism)

B= black (closing mechanism)

C= white

Page 18

Mounting a miniSafe in RH355LD/ RH455LD

SKE160

SKE 180

18

Drawing picture for right

hand hinge (1).

By left hand hinge, 10mm

drilling on the opposite

(2).

3 cap nuts M8

3 mushroom head square neck bolt

12.0

Fixing underside

Fixing rear side

Page 19

Storing Goods

19

13.0

The statics of the miniBars is aligned

with the original condition of the

appliance. Changes, e.g. bigger door

étagères lead to static changes .

The door could be overloaded.

Any damage due to improper use is not covered by the warranty. The

warranty does not cover any modifications to the appliance or the use of

non-original Dometic parts; the warranty does not apply if the installation

and operating instructions are not adhered to and no liability shall be

entertained.

No original door étagère

used. The overloaded door

hangs crookedly and doesn't

close.

Example :

Page 20

Troubleshooting

Energy Saving Tips

At an average room temperature of approx. 22°C, it is sufficient to

operate the miniBar with an average thermostat setting.

If possible, always store pre-cooled goods.

Do not expose the miniBar to direct sunlight and do not place it close

to a source of heat.

An unobstructed air circulation in the fridge aggregate must be

ensured (ref. chapter 7.0 Installation).

When removing goods, only open the miniBar briefly.

Switch on the miniBar approx. 12 hours prior to stocking.

20

14.0

Failure : No cooling (the cooling unit at the back of the appliance is cold)

Possible Cause Fault Elimination (authorised service provider)

a.) Defective heating shell ?

b.) Defective Air and / or

Evaporator-Sensor?

c.) Defective electronic ?

d.) The appliance is in defrost

mode.

a.) Measure resistance, replace heating shell if

required.

230V / 65 W ~ 800W

230V / 80 W ~ 650W

110V / 65 W ~ 186W

110V / 80 W ~ 150W

b.) Pull sensor off electrics and check by means

of measurement.

Ambient Temperature (°C) Resistance (kOhm)

0° 32,51 +/-2%

10° 19,86 +/-2%

15° 15,68 +/-2%

20° 12,48 +/-2%

c.) Plug in and measure voltage applied at

heating shell output!

After a maximum of 15 seconds, the heating

shell will be driven by mains voltage.

d.) Pull out plug and put back in again.

Failure : No cooling (the cooling unit is warm)

a.) Is the appliance level?

b.) Has sufficient ventilation been

provided ?

c.) Running time to short ?

d.) Defective cooling unit ?

e.) Light permanently on when

door closed.

a.) Level the appliance using a spirit level.

b.) See section "Installation 7.0".

c.) Leave system running for a few hours.

d.) Replace cooling unit and - if required-

refrigerator.

e.) Replace lighting sensor. Install new door, if

required.

Possible Cause Fault Elimination (authorised service provider)

15.0

Page 21

21

Technical Data

Built-in Built-in Freestanding / Freestanding

Built-in

Casing Metal Metal Metal Wood

Gross Contents

(litres) 30 40 40 55

Cooled / uncooled 30 / - 40 / - 40 / - 35 / 20

Dimensions (mm)

(H x W xD) 522x384x412 554x401x446 554x401x449 780x420x445

Electrical Rating (W) 65 65 65 65

Power Consumption

kWh / 24h* 0,7 0,8 0,8 0,8

Net Weight (kg) 11 14 15 26

Built-in Freestanding Freestanding / Freestanding /

Built-in Built-in

Casing Metal Metal Metal Metal

Gross Contents

(litres) 56 56 60 60

Cooled / uncooled 40 / 16 40 / 16 60 / - 60 / -

Dimensions (mm)

(H x W x D) 658x450x503 730x450x505 563x486x474 563x486x474

Electrical Rating (W) 65 65 80 80

Power Consuption

kWh / 24h* 0,9 0,9 1,0 1,45

Net Weight (kg) 21 21 20 23

Freestanding / Freestanding /

Built-in Built-in

Casing Metal Metal

Gross Contents

(litres) 30 40

Cooled / uncooled 30 / - 40 / -

Dimensions (mm)

(H x W x D) 522x384x411 554x401x446

Electrical Rating (W) 65 65

Power Consuption

kWh/ 24h* 0,7 0,8

Net Weight (kg) 11 14

* Power consumption measured at an average ambient tempertature of 25°C as an average

annual value and at a cooling compartment tempertature of 7°C in line with DIN/EN153.

We reserve the right to make technical modifications to our products without notice!

Model RH330LD / EA330L RH340LD RH341LD RH355LD / EA355L

Model RH356LDE RH356LD RH360LD RH361LD

Model RH136D RH137D

16.0

Page 22

Built-in Built-in Freestanding / Freestanding

Built-in

Casing Metal Metal Metal Wood

Gross Contents

(litres) 30 40 40 55

Cooled / uncooled 30 / - 40 / - 40 / - 35 / 20

Dimensions (mm)

(H x W xD) 522x384x412 554x401x446 554x401x449 780x420x445

Electrical Rating (W) 65 65 65 65

Power Consumption

kWh / 24h* 0,7 0,8 0,8 0,8

Net Weight (kg) 11 14 15 26

Built-in Freestanding Freestanding / Freestanding /

Built-in Built-in

Casing Metal Metal Metal Metal

Gross Contents

(litres) 56 56 60 60

Cooled / uncooled 40 / 16 40 / 16 60 / - 60 / -

Dimensions (mm)

(H x W x D) 658x450x503 730x450x505 563x486x474 563x486x474

Electrical Rating (W) 65 65 80 80

Power Consuption

kWh / 24h* 0,9 0,9 1,0 1,45

Net Weight (kg) 21 21 20 23

Freestanding / Freestanding / Built-in Built-in

Built-in Built-in

Casing Metal Metal Metal Metal

Gross Contents

(litres) 30 40 30 40

Cooled / uncooled 30 / - 40 / - 30 / - 40 / -

Dimensions (mm)

(H x W x D) 522x384x411 554x401x446 522x384x412 554x401x446

Electrical Rating (W) 65 65 65 65

Power Consuption

kWh/ 24h* 0,7 0,8 0,7 0,8

Net Weight (kg) 11 14 11

111144

44

22

Model RH 430LD RH 440LD RH 441LD RH 455LD

Model RH 456LDE RH 456LD RH 460LD RH 461LD

EAW3220

Model RH 436D RH 447D RH 438D RH 448D

* Power consumption measured at an average ambient tempertature of 25°C as an average

annual value and at a cooling compartment tempertature of 7°C in line with DIN/EN153.

We reserve the right to make technical modifications to our products without notice!

Page 23

Technical Data miniSafe

23

miniSafe SK 160 SKE 160 *SKE 180 *SKE190

Built-in Built-in Built-in Built-in

Schließsystem Mechanical, Electronical, Electronical, Electronical,

key keycode keycode keycode

Gehäuse Steel 2 mm Steel 2 mm Steel 2 mm Steel 2 mm

Tür Steel 2 mm Steel 2,5 mm Steel 5 mm Steel 5 mm

Volumen (Liter) 6,8 7,0 19 28

Abmessungen (mm)

(H x B xT) 167x250x236 160x250x218 210x300x355 240x375x370

Nettogewicht (kg) ca.7 5,5 10,5 13,3

Notöffnung Masterkey Masterkey and Masterkey and Masterkey and

electronical electronical electronical

Mastercode Mastercode Mastercode

* socket for charging electronical devices as option.

Subject to change without notice !

Page 24

Wiring diagrams

24

17.0

17.1 Refrigerators without Lighting

RH136D, RH137D, RH330D, EA330, RH340D, RH341D, RH 455D,

EA 355, RH360D, RH361D, RH437D, RH447D, RH430D, RH440D,

RH441D, RH 455D, RH460D, RH461D, EAW3220

Page 25

25

17.2 Refrigerators with Lighting

RH330LD, EA330L, RH340LD, RH341LD, RH 355LD, EA355L,

RH360LD, RH361LD, RH430LD, RH440LD, RH441LD, RH 455LD,

RH460LD, RH461LD, EAW3220

Page 26

26

17.3 Refrigerators with 55l/56l Capacity

RH356LD, RH356LDE, RH456LD, RH456LDE

Page 27

HiPro Generation

HiPro models are the latest generation of miniBars and consume

approximately 15% less energy than the RH4XX models.

Technology and design defined with a new name :

HiPro Technoloy!

HiPro means High-Professional, High-Protection and High-Profitable

Technology.

HiPro 3000

HiPro 4000

HiPro 6000

Changes HiPro compared to Face-lifting models:

- absolutely new design with modular shelf and

drawer system

- different outer measures

- error detecting via flashing signals

- fixed indoor temperature

- modified cooling unit

- better isolation

- all plugs connected to the electronic are encoded

- door sealing replaceable

- less energy consumption

HiPro Electronic

After connecting the electronic with the main supply (hard ware reset)

following actions take place:

- initialization of the hardware

- values of resistance are read in

- self-test

- initialization of RedDot and function test of cooling unit

Error status is signalised by flashing of the indoor lighting and,

if available, the REDDOT_LED.

Temperature in the HiPro compartment

Set up of the desired cold-storage area temperature.

The cold-storage area temperature is set as follows:

- for Europe 5°C

- for USA 3°C

Cold-storage area temperature can be readjusted with the help of the

remote control by via the sensors.

27

18.0

HiPro models:

19.0

19.1

yellow 5°C

blue 3°C

black

Reset

Coolingsystem

red

RedDot

Reset

Remote control only

for Service and Hotels

Page 28

When operated, the electronic measures the temperature of the indoor air

sensor (NTC) and controls depending on this, the heating efficiency of the

absorber with the help of the HiPro-Electronic .

Self-test of the electronics

After switching on the supply voltage (Hardware- Reset) the software

carries out a selftest, in which the value of resistance of the NTC-sensors

(air-sensor, evaporator sensor) are measured.

In case the value of the resistance measuring is not corresponding

to the values of resistance fixed by the software, an error is

signalized.

Automatic fault analysis

The type of error is signalised through n flashing impulses of the inner

lighting (P_LIGHT) as well as REDDOT_LED with a frequency of 0.5 Hz, as

shown in the following table:

Type of error Number of flashing impulses

general error electronic, power supply n = 0

everything OK / no poti connected n = 1

everything OK / poti connected n = 2

error NTC- Air-Sensor n = 3

error NTC- Evaporator-Sensor n = 4

error NTC- Air-Sensor + Evaporator Sensor n = 5

With the help of a reset you can see the fault signal (n) again.

In case an error is recognised (n>2), the temperature adjustment will not be

started, and the heating element will not be switched on.

The inner lighting and the Red-Dot will flash with ca. 4 Hz.

28

19.2

Air-Sensor

Evaporator-Sensor

The air-senosr is mark with

a red point!

19.3

Page 29

Automatic Defrost Function

The HiPro electronic also regulates the automatic defrosting of the

refrigerator. When the plug has been stuck to the socket the running time of

the refrigerator up to the first defrosting is 39 hours For all

models the defrosting takes 2 hours. Then the refrigerator works 22

hours and afterwards defrosts 2 hours.

Therefor the starting of the refrigerators determines the time of defrosting.

For example: Starting at 7.00h = first defrosting 22.00h (next day).

Cooling unit check

In order to carry out the check of the cooling unit, e.g. a leak within the

cooling circle, the temperature difference at the evaporator sensor is

determined every 40 minutes. If, after finishing the defrost phase the fridge

does not reach a cool-down of 4K within 40 min, a system error exists,

and the fridge is switched off.

The system error is saved in the EEPROM and indicated by permanent

flashing of the indoor lighting as well as the REDDOT_LED with 8 Hz.

System errors are:

- Leak / clogging of the cooling unit

- the HiPro is not balanced

- heating element defective

In service-case the cooling unit is not changeable. You have to

install a complete new HiPro miniBar!

Heating Shell

After max. 5 seconds, the heating element is driven with supply voltage and

works for 20 seconds. This cycle is repeated for 45 minutes. After this the

electronic controls the prefixed temperature.

Please see also point 5.0, page 5

29

19.4

S

TT

TT

TT

S

39h

19.5

19.6

Page 30

Lighting (ca. 7,6V) and Infrared sensors

Two LEDs (A) light the

cooling compartment whilst

the door is opened.

Two sensors (B) control the

LEDs as well as the

(optional) door control.

Change of lighting / Infrared sensors

The complete lighting is fastened into the

inner housing with a clip and can be pulled off

very easily. Detach the plug connections and

change the lighting. Same is applicable for the

infrared sensors. All plugs are encoded.

Automatic Door Control

The electronic contains an infra-red reflecting light barrier for recognition

fridge door was opened.

For resetting the REDDOT-indicator

use the remote control.

The reflecting light barrier is checked

every 200 ms.

Operation intervention

The electronic uses the infra-red reflecting light barrier also for changing the

fixed temperature and for resetting the check-Cooling unit.

Action Reaction

reset Red- Dot Red- Dot switches off

fixed temperature 3°C 3 x flashing

fixed temperature 5°C 5 x flashing

reset leak leak-flash stops

30

20.0

B

A

21.0

A

Infrarot - Sensor

The LED (A) placed at the bottom edge of the minibar

indicates whether the miniBar door has been opened.

22.0

Page 31

Installation

refer to point 7.0, page 8

Securing

Changing the Sliding Hinge

refer to point 9.0, page 10

Energy Saving Tips

If possible, always store pre-cooled goods.

Do not expose the miniBar to direct sunlight and do not place it close

to a source of heat.

An unobstructed air circulation in the cooling unit must be

ensured (ref. chapter 7.0 Installation).

When removing goods, only open the miniBar briefly.

Switch on the miniBar approx. 12 hours before stocking.

31

23.0

24.0

Drive in the screws and put the caps back on.

The Hipro can be screwed to

the furniture using the fittings

at the bottom.

25.0

26.0

Page 32

Manual fault analysis

Technical Data

32

27.0

Failure : No cooling (the cooling unit at the back of the appliance is cold)

Possible Cause Fault Elimination (authorised service provider)

a.) Defective heating shell ?

b.) Defective Air and / or

Evaporator-Sensor?

c.) Defective electronic ?

d.) The appliance is in defrost

mode.

a.) Measure resistance, replace heating shell if

required.

230V / 65 W ~ 800W

230V / 80 W ~ 650W

b.) Pull sensor off electrics (air-sensor X9,

evaporator-sensor X8) and check by means of

measurement.

Ambient Temperature (°C) Resistance (kOhm)

0° 27,70

10° 18,07

15° 14,74

20° 12,11

25° 10,00

c.) Plug in and measure voltage at

heating shell output (X3)!

After max. 5 seconds, the heating

shell will be driven by mains voltage (230V) for

20 seconds.

d.) Pull out plug and put back in again.

28.0

Model HiPro 3000

Model HiPro 4000 with cooling unit cover + feet

Casing Plastic

Gross Volume ( litres) 28

cooled / uncooled 28 / -

Dimensions (mm)

(H x W xD) 527 x 388 x 418

Electrical Rating (W) 65

Power Consumption

kWh / 24h* 0,6

Net Weight (kg) 12

Assembly x

freestanding x

Casing Plastic

Gross Volume ( litres) 37

cooled / uncooled 37 / -

Dimensions (mm)

(H x W xD) 559 x 405 x 452 601 x 405 x 472

Electrical Rating (W) 65

Power Consumption

kWh / 24h* 0,7

Net Weight (kg) 13.5 14.5

Assembly x

freestanding xx

Page 33

Wiring Diagram/ Occupancy electronics

33

Model HiPro 6000 with cooling unit cover + feet

Casing Plastic

Gross Volume ( litres) 51

cooled / uncooled 51 / -

Dimensions (mm)

(H x W xD) 568 x 490 x 474,5 610 x 490 x 494,6

Electrical Rating (W) 80

Power Consumption

kWh / 24h* 0,9

Net Weight (kg) 17 18

Assembly x

freestanding xx

* Power consumption measured at an average ambient temperature of 25°C as an average

annual value and at a cooling compartment temperature of 7°C according to EN 153.

We reserve the right to make technical changes and modifications without notice!

29.0

Connections electronics:

X1 Main Voltage (110V oder 230V

X2 X3 Heating shell

X4 Interior light

X5 Infrared senors (reflecting light barrier)

X6 RedDot LED

X7 Potentiometer (not used in HiPro)

X8 Evaporator Sensor

X9 Air Sensor

X10 Serial interface

X11 X12 Automatic Door Control

Page 34

Notes

34

Page 35

35

Page 36

Dometic GmbH

In der Steinwiese 16

D-57074 Siegen

Tel.: +49-(0) 271 / 692 0

Fax: +49-(0) 271 / 692 300

www.dometic.de/minibar

www.dometic.com

© Dometic GmbH - 2002 - Subject to change without notice - Printed in Germany

Loading...

Loading...