Dometic Horizon 920****.000 series, Horizon 920****.020 series Installation & Operating Instructions Manual

Page 1

USA

SERVICE OFFICE

Dometic Corporation

2320 Industrial Parkway

Elkhart, In 46516

574-294-2511

CANADA

Dometic Corporation

46 Zatonski, Unit 3

Brantford, ON N3T 5L8

CANADA

519-720-9578

For Service Center

Assistance Call:

800-544-4881

This manual must be read and

understood before installation,

adjustment, service, or maintenance is performed. This unit must

be installed by a qualied service

technician. Modification of this

product can be extremely hazardous and could result in personal

injury or property damage.

INSTALLATION &

OPERATING INSTRUCTIONS

Lire et comprendre ce manuel avant

de procéder à l'installation, à des réglages, de l'entretien ou des réparations. L'installation de cet appareil doit

être effectuée par un réparateur quali-

é. Toute modication de cet appareil

peut être extrêmement dangereuse et

entraîner des blessures ou dommages

matériels.

MODEL

920(XX)(XX).000(#)

920(XX)(XX).020(#)

REVISION:

Form No. 3310426.022 7/07

(Replaces 3310426.014)

(French 3310427.020)

©2007 Dometic Corporation

LaGrange, IN 46761 U.S.A.

Important:

These instructions must stay with

unit. Owner read carefully.

Page 2

920(XX)(XX).000(#) & 920(XX)(XX).020(#) HORIZON AWNING INSTALLATION and OPERATING INSTRUCTIONS

SAFETY INSTRUCTIONS

This manual has safety information and instructions to help users eliminate or reduce the risk

of accidents and injuries.

RECOGNIZE SAFETY INFORMATION

This is the safety-alert symbol. When you see this

symbol in this manual, be alert to the potential

for personal injury.

Follow recommended precautions and safe operating instructions.

UNDERSTAND SIGNAL WORDS

A signal word , WARNING OR CAUTION is used

with the safety-alert symbol. They give the level

of risk for potential injury.

indicates a potentially hazard-

ous situation which, if not avoided, could result

in death or serious injury.

indicates a potentially hazard-

ous situation which, if not avoided may result in

minor or moderate injury.

used without the safety alert

symbol indicates, a potentially hazardous situation which, if not avoided may result in property

damage.

GENERAL INFORMATION

A. Application

The Horizon Case Awning is designed for use on

vehicles that cannot accept a full sized awning. It is

especially well suited for vehicles with an over cab

extension where there is not sufcient surface for a

bottom mounting bracket.

B. Position Of The Awning

1. Before beginning installation of the case, be sure

the door will open when the awning is completely

extended. Allow for at least a 15-degree pitch of

the fabric of the awning.

2. Check for a solid backing or under-structure

where screws and adapters are to be used. For

installations with mounting brackets, be sure that

all mounting brackets are secured in a very solid

manner.

3. Before drilling, be sure that there are no obstacles

inside the wall (cables, wires, gas pipes, etc.). Having evaluated the construction of the vehicle, pick

the mounting style which best ts the application.

See Figures 3 & 4.

4. Minimum clearance from bottom of case to door

is 3.00 inches.

Important: Read all of the following steps before

beginning installation.

Dometic Corporation reserves the right to modify ap-

pearances and specications without notice.

LIST OF HARDWARE:

8'-13' Models Only:

(2) - Bottom Rafter Mounting Bracket

(8) - 10-12 X 1.00"L Sheet Metal Screw

(3) - Mounting Bracket 6"

(6) - 1/4-20 X 2.00"L Carriage Bolt

(6) - 1/4 Split Lock Washer

(6) - 1/4 Flat Washer

(6) - 1/4-20 Locknut With Nylon Insert

(3) - 8-18 X .38 Self Drilling Pan Head Cross Screw

Additional Quantities (HARDWARE): 15' Model only

(1) - Mounting Bracket 6"

(2) - 1/4-20 X 2.00"L Carriage Bolt

(2) - 1/4 Split Lock Washer

(2) - 1/4 Flat Washer

(1) - 8-18 X .38 Self Drilling Pan Head Cross Screw

Read and follow all safety information and instructions.

16' Model Only:

(2) - Bottom Rafter Mounting Bracket

(8) - 10-12 X 1.00"L Sheet Metal Screw

(2) - Mounting Bracket 6"

(2) - Mounting Bracket 18"

(8) - 1/4-20 X 2.00"L Carriage Bolt

(8) - 1/4 Split Lock Washer

(8) - 1/4 Flat Washer

(8) - 1/4-20 Locknut With Nylon Insert

(4) - 8-18 X .38 Self Drilling Pan Head Cross Screw

2

Page 3

920(XX)(XX).000(#) & 920(XX)(XX).020(#) HORIZON AWNING INSTALLATION and OPERATING INSTRUCTIONS

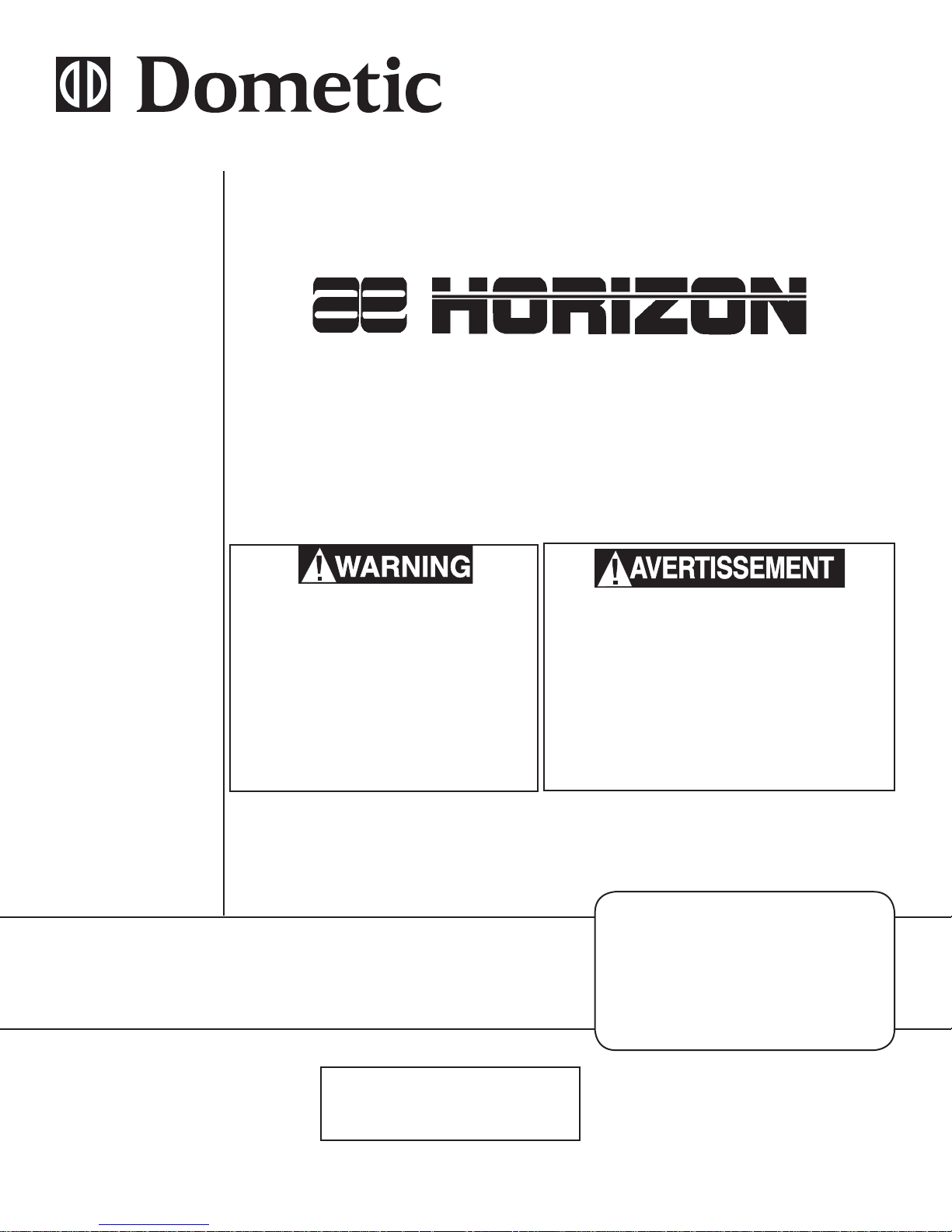

FIG. 1A: 8'-13' MODEL BRACKET SPACING

A

B

From End of

Back Rail

C

8' 10' 12' 13'

A 1" 1-1/2" 1-1/2" 1-1/2"

B 44" 53-1/4" 63-1/8" 73"

C 93-7/8" 112-1/2" 132-1/4" 151-7/8"

FIG. 1B: 15' MODEL BRACKET SPACING

C

A

From End of

Back Rail

B

B

15'

A 1-1/2"

B 55-1/8"

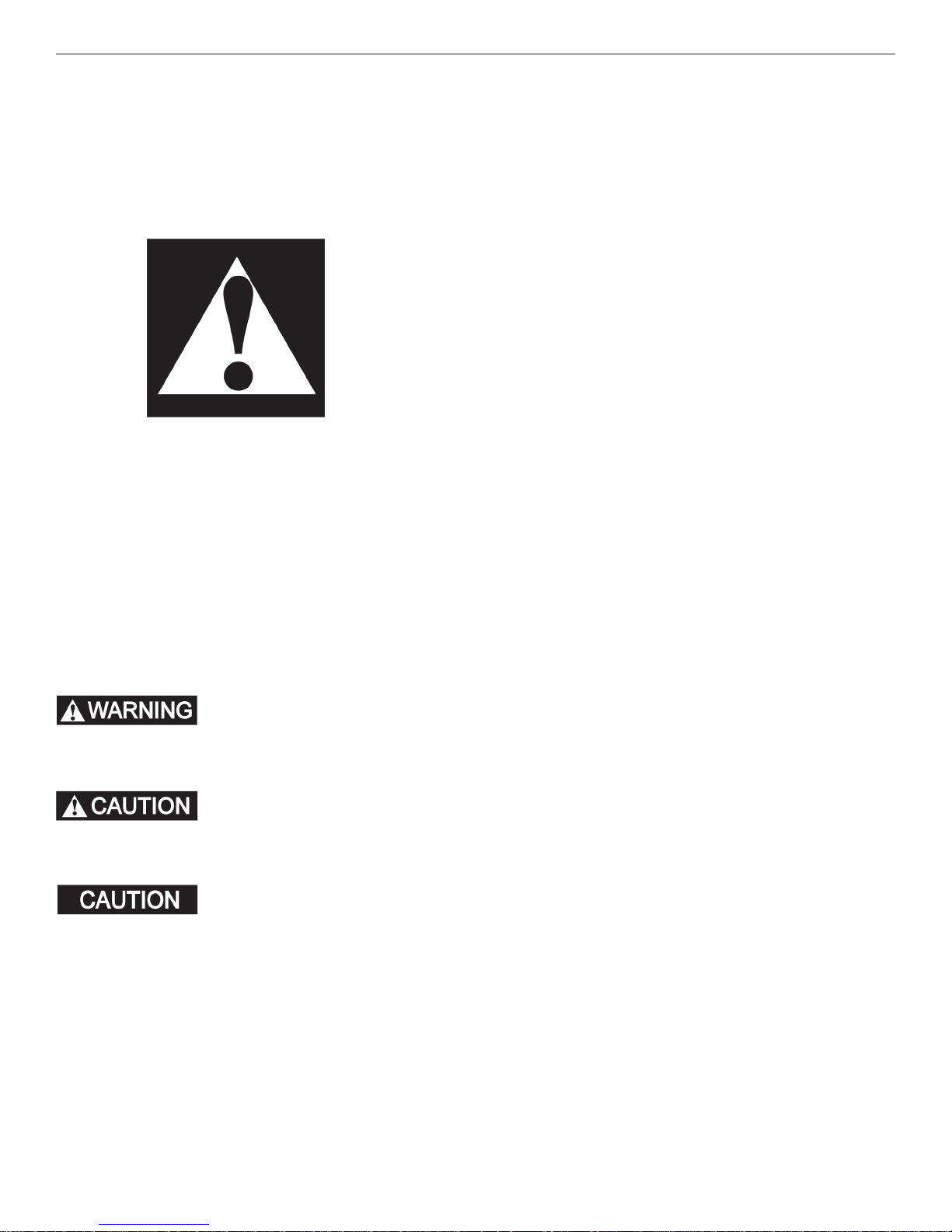

FIG. 1D

Behind Arm Attachment

8'-13' MODEL SHOWN

INSTALLATION INSTRUCTIONS

A. Installation Using Standard Brackets

1. Determine locations of mounting brackets on side

of vehicle. See FIG. 1A , FIG 1B, and FIG 1C.

2. The left and right brackets must be mounted behind where the arms are attached. (See FIG. 1D)

The outside edge of the bracket must be aligned

with, but not protruding beyond, the edge of back

of the aluminum case. See FIG. 1A for the 8'-13'

models. See FIG. 1B for the 15' models, and FIG.

1C for the 16' models, which use 4 brackets evenly

spaced.

3. Mark the wall bracket position. Using a bracket as

a template, mark the hole locations. Pre-drill holes

using a 5/16" drill bit (use 7/32" drill bit if drilling

through steel). Install top brackets with 1/4-20 X

2"L carriage bolts, nuts and washers provided.

C 171-1/2"

FIG. 1C: 16' MODEL BRACKET SPACING

B

B

A

From End of

Back Rail

16'

A 1-1/2"

B 57-3/4"

C 191-1/4"

To prevent water leakage, always use silicon

sealant where each fastener enters the vehicle

side wall or roof.

4. If mounting area sub-structure is not solid, we

recommend using a backing plate (not provided)

C

inside the vehicle. See FIG. 2.

5. After the wall brackets are installed, using a

pencil, mark location of edges of brackets on the

wall. Draw the marks approximately 2" below the

bracket. These marks will later help you identify

the location of the brackets for installation of the

8-18 X .38" self-drilling screws.

3

Page 4

920(XX)(XX).000(#) & 920(XX)(XX).020(#) HORIZON AWNING INSTALLATION and OPERATING INSTRUCTIONS

FIG. 2

Flat

Washer

Front

View

(Outside)

6. Set the awning on mounting brackets. Open aw-

Wall

Wall

Split Lock

Washer

Bracket

ning 18". Using the pencil marks as a guide, drive

supplied 8-18 X .38" self-drilling screws into case

back cover and through wall bracket as shown in

Figure 5.

Rear Plate

(not supplied)

Locknut

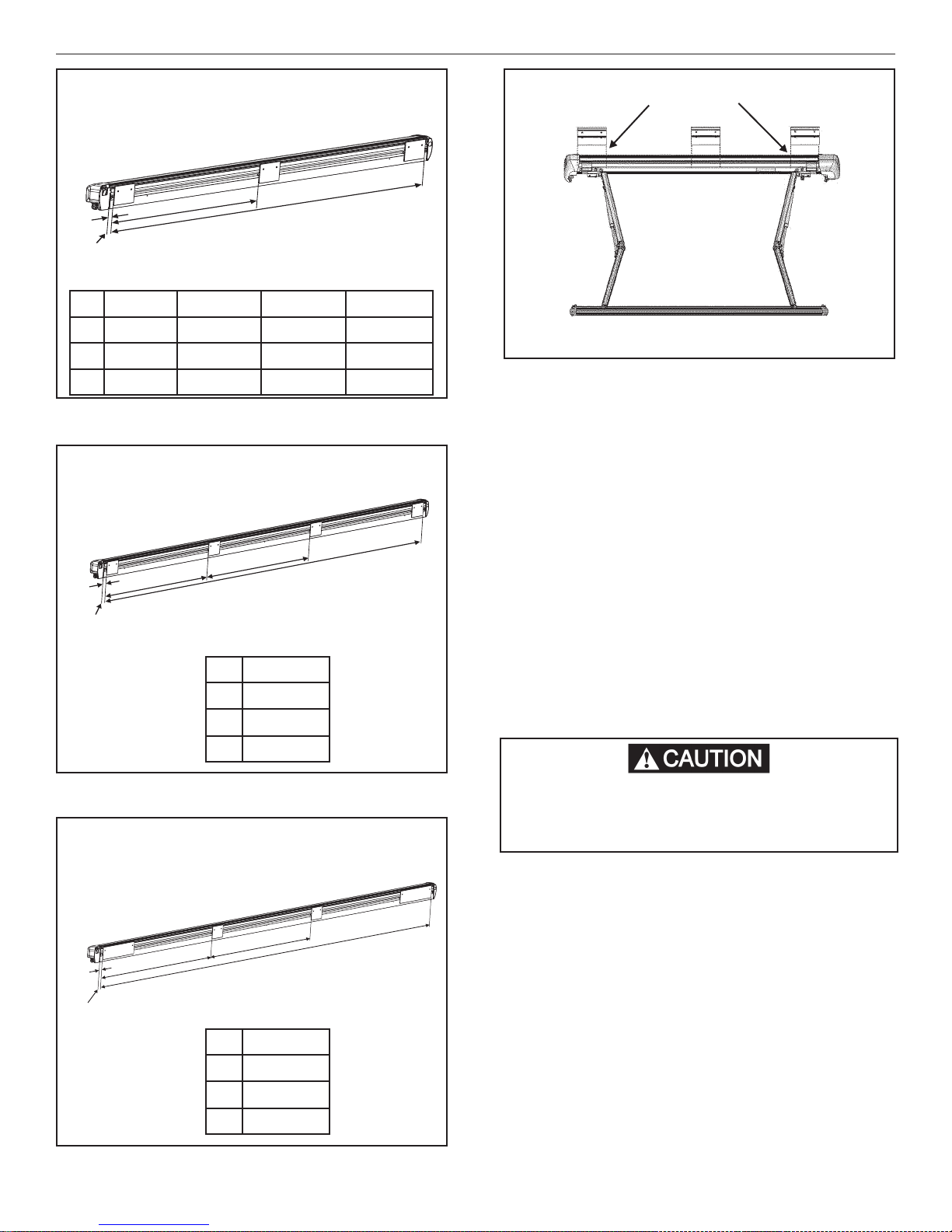

DO NOT over-tighten fasteners. This will cause

them to "strip out" and severely weaken their

holding ability.

FIG. 4

90°

FIG. 5

90°

Left

Shoulder

DO NOT over-tighten fasteners. This will cause

them to "strip out" and severely weaken their

holding ability.

FIG. 3

Coach Wall with Optional Rear Plate

Step 1

Step 3

8-18 X .38" Self

Drilling Screw

Step 2

A

B

8-18 X .380 Pan Head

Recess self Drilling Screw

Right

Right Arm

Table 1: Screw Location

Awning Length / A and B Indicate Mounting

8' 10' 12' 13' 15' 16'

A 2 1/4" 2 1/4" 2 1/4" 2 1/4" 2 3/4" 2 3/4"

B 1 3/4" 2 1/4" 2 1/4" 2 1/4" 2 1/4" 14 1/4"

Shoulder

Screw Location

Left Arm

B

A

To prevent water leakage, always use silicon

sealant where each fastener enters the side

wall or roof of the vehicle.

4

Page 5

920(XX)(XX).000(#) & 920(XX)(XX).020(#) HORIZON AWNING INSTALLATION and OPERATING INSTRUCTIONS

B.Secure Back Cover To Mounting Brackets

1. Position and drive a 8-18 X .38" pan head self

drilling screw into location indicated by Table 1:

Screw Location. See FIG. 5

C. Installation Of Bottom Mounting Brackets

Important: Always mount into solid under-struc-

ture.

1. Location of bottom mounting brackets must be

set so that upright legs are vertical when retracted

from case. See FIG. 4. To determine the location

of bottom mounting bracket, fully extend awning

per Operating Instructions below. Unfold legs from

lead rail. (See FIG. 8) Pull adjustment knob and

extend leg until the fabric is at approximately a

10-degree pitch.

2. Swing one leg toward vehicle sidewall. Extend leg

until foot reaches intended wall bracket mounting

location and 10-degree fabric slope is maintained.

Mark location on side of vehicle to maintain this

height. See FIG. 6. Repeat for other leg.

IMPORTANT: Foot wall bracket must be installed

in a location with adequate reinforcement in and

behind the wall.

4. Using the holes in the brackets as a guide, mark

and drill using a 5/32" drill bit. Secure each bracket

to vehicle using the 10-12 X 1"L pan head sheet

metal screws provided.

5. If mounting area sub-structure is not solid, use

oscar rivets(not supplied). (FIG. 6)

OPERATING INSTRUCTIONS

A. To Open

1. Place the hook of the crank into the eye of the gear

and unroll the awning approximately 3 feet.

2. Next, per FIG. 8, remove the legs. Legs can be

extended by pulling the spring loaded adjustment

knob and allowing the leg to telescope.

IMPORTANT: Remember to extend the legs to

the ground after approximately 3 feet of the canopy

is extended. This reduces any strain on the walls/

brackets of the vehicle. See FIG. 7.

3. Then fully extend the awning. The awning will be

fully extended when fabric starts to sag. After this

occurs, roll awning back 1/4 turn to reach maximum

tension.

4. Stake the legs to the ground directly under the

leadrail (carport position) or place feet in wall

brackets (patio position). See FIG. 9.

FIG. 6

Coach

Wall

(4) 10-12 X 1"

screw or oscar rivet

LEADRAIL

DESIRED

HEIGHT

CARPORT

POSITION

PATIO

POSITION

FIG. 7

3 FT

5

Page 6

920(XX)(XX).000(#) & 920(XX)(XX).020(#) HORIZON AWNING INSTALLATION and OPERATING INSTRUCTIONS

FIG. 8

RAFTER ARM

IN STOWED

POSITION

PULL RAFTER

AWAY FROM CEN-

TER IN A HORI-

ZONTAL POSITION

PULL OUT

THEN TWIST

CLOCKWISE

SWING RAFTER

TOWARD GROUND

ADJUSTMENT KNOB

NOW FACES COACH

(PULL KNOB TO TELE-

SCOPE LEGS)

FIG. 8A

View 1 When stowing

Right Hand Rafter Arm

View 2 When stowing

Right Hand Rafter Arm

Foot Must Be Placed

Under Hook

View 1 When stowing

Right Hand Rafter Arm

View 2 When stowing

Right Hand Rafter Arm

Foot Must Be Placed

Under Hook

FIG. 9

Wall BracketFIG. 10

Rafter Arm

PIN IN UP

POSITION

PIN ENGAGED TO LOCK

5. For patio position, engage the support arm foot

into the bottom mounting bracket. See FIG. 10.

6. Roll up the awning a little - until the fabric is taut.

6

Page 7

920(XX)(XX).000(#) & 920(XX)(XX).020(#) HORIZON AWNING INSTALLATION and OPERATING INSTRUCTIONS

B. To Close

1. Remove stakes if in the carport position, or from

wall bracket if in patio position.

2. Place the hook of the crank into the eye of the gear

and roll awning up, to within 3-feet of being closed.

Lower the lead rail as required if the awning is in

the carport position.

2. Pull the adjustment knob, and retract the support

arms until knob is in top most hole.

3. Using FIG. 8 as reference, reverse the steps to

properly stow the support arms into the leadrail.

Support arm foot must be between the leadrail and

stow clip. See gure 8A.

4. Finish rolling up awning.

Fabric must roll around roller tube from bottom of roller tube.

C. Other Operation Notes

Important: We remind you that the awning is to

shelter you from the sun, not from rain, wind or

snow.

1. To resist unexpected gusts of wind, it is always

best to set awning legs into the patio position. If

carport position is to be used, be sure that the awning feet are properly staked into the ground. For

further protection we recommend the ends of the

awning leadrail be tied with straps (not provided)

and staked to the ground.

2. If heavy wind and/or rain conditions exist, retract

awning and place in storage position!

FIG. 11

Lower Arm Away

From Door 5-6

Additional Holes.

Note: The awning is designed with a water dump feature

that will lower one side of the awning to allow water to run

off. Before the water dump feature will operate as designed,

lower both arms 5 to 6 holes (fabric slope approximately

10 degrees) below the coach awning rail. See FIG. 11.The

water dump feature will not work if awning slope is zero

degrees or near zero degrees.

4. The 13 ft -16 ft awnings come with a tension rafter

assembly. FIG. 12

a. Position the square nut inside the small tension

rafter. Align the threaded hole on the square

nut to the hole on the small tension rafter as

shown in gure 13.

b. Guide the knob's threaded stud through the

FIG. 12

Important: Never leave the awning in a position that

causes the fabric to have no slope. Adjust both arms of

the awning 5 to 6 adjustable arm holes below awning

rail (fabric slope approximately 10 degrees).

Water Pooling Hazard:

Whenever rain is expected the awning must

be placed in the storage position. Pooling

of water on top of the awning fabric, will

make the awning unstable causing the arms

and roller tube to bend or collapse. Never

release adjustment knob with water pooled

on canopy. This will result in personal injury,

death and damages to the awning and/or recreational vehicle.

3. If light rains are expected, place the awning in the

water shed position. See FIG. 11

Tension Rafter

hole and turn until it engages the nut.

c. Slide the small tension rafter inside the large

tension rafter as shown in gure 14.

5. Tension rafter application.

a. Lower the Front Bar to an accessible shoulder

level by lowering the rafter arm.

b. Place large end against the center of the back

cover of the case as shown. See Figure 15.

c. Extend tension rafter, placing small end in front

bar as shown approximately 6” off the center

of the front bar.

d. Tighten knob.

e. Pull small end of tension rafter to the center

of the front bar. This will tension the fabric.

f. If front bar was lowered, raise to the desired

height.

7

Page 8

6"

920(XX)(XX).000(#) & 920(XX)(XX).020(#) HORIZON AWNING INSTALLATION and OPERATING INSTRUCTIONS

Front BarFront Bar

Center Line

Knob

Knob

FIG. 15

FIG. 13

Kob

Thread

Square Nut

FIG. 15

Outer Cap

Tabs

Pull or Push Tension Rafter

Towards Center line

Knob

Knob

Holes

Back Cover

Back Cover

Failure to properly use the tension rafter could

result water pooling in a manner that will prevent

the rain shed device from functioning properly.

OWNER MAINTENANCE ITEMS

1. Lubricate the rafter arms and support arms using paraf-

n wax or silicone spray.

2. Periodically clean the awning fabric with 1/4 cup of dish

soap and 1/4 cup of bleach mixed with 5 gallons of warm

water. Allow to dry before rolling awning back up.

3. Mildew cannot form on the fabric, but rather will form on

dirt or dust on the fabric. The key is to keep the fabric

clean.

4. To remove grease spots from vinyl fabrics, use only a

soap and water solution. Avoid use of caustic household

cleaners, mildew removers or hard bristle brushes.

5. Occasionally the awning may develop a pinhole, actu-

ally a spot of paint akes off from the top layer of vinyl.

This may be quickly remedied with a very small dab

of VLP (Vinyl Liquid Patch) on the tip of a Q-tip®. By

gently rolling the Q-tip® around the pinhole, the VLP

will melt the paint (in the stripe) and that will quickly ll

in the pinhole with a perfect match. Be sure to wait until

the VLP (Dometic P/N 143498) sets before rolling up

the awning.

6. Always make sure the awning is extended high enough

before opening entry door.

7. Lower one end of awning for proper water run-off and

to avoid water pooling.

Outer Cap Installed

8

Loading...

Loading...