Page 1

RECORD THIS INFORMATION FOR FUTURE

REFERENCE:

Model Number

Serial Number

Date Purchased

Retailer / Qualied Installer

DMH1072

HYBRID REFRIGERATOR

ABSORPTION COOLING SYSTEM

UPPER FOOD STORAGE COMPARTMENT

COMPRESSOR COOLING SYSTEM

LOWER FOOD STORAGE COMPARTMENT

(LOWER DRAWER)

FIRE OR EXPLOSION HAZARD.

If you smell gas:

1. Open windows.

2. Do not attempt to light appliance.

3. Do not touch electrical switches.

4. Extinguish any open ame.

5. Shut off fuel supply.

6. Evacuate immediately and call emergency services.

Failure to follow these instructions could result in re or explosion, which could cause

property damage, personal injury, or death.

OPERATING

INSTRUCTIONS

REVISION C

Form No. 3315255.000 09/16

(French 3315256.000_C)

©2016 Dometic Corporation

LaGrange, IN 46761

Improper installation, adjustment, alteration, service or maintenance can cause injury or

property damage. Refer to this manual. For assistance or additional information consult

a qualied installer, service agency or the gas supplier.

SUFFOCATION AND ENTRAPMENT HAZARD.

Prior to disposal of refrigerator:

1. Remove fresh food and freezer doors.

2. Leave shelves and baskets in place to prevent children from easily climbing inside

refrigerator.

FIRE OR EXPLOSION HAZARD.

Do not store or use gasoline or other ammable vapors and liquids in the vicinity of this

or any other appliance.

Read these instructions carefully. These

instructions MUST stay with this product.

USA

SERVICE OFFICE

Dometic Corporation

1120 North Main Street

Elkhart, IN 46514

CANADA

Dometic Corporation

46 Zatonski, Unit 3

Brantford, ON N3T 5L8

CANADA

SERVICE CENTER &

DEALER LOCATIONS

Please Visit:

www.eDometic.com

Page 2

INTRODUCTION

Thank you for purchasing your new Dometic refrigerator. This refrigerator (hereinafter referred to as “refrigerator,” or “product”) is designed and intended for use in recreational vehicles (hereinafter referred to as “RV,” or “RVs”). This refrigerator is

designed for the storage of fresh and frozen foods, as well as making ice.

Use these instructions to operate your refrigerator safely and correctly. Keep these instructions with your refrigerator for

future reference.

Dometic Corporation reserves the right to modify appearances and specications without notice.

TABLE OF CONTENTS

INTRODUCTION .................................................................................................................................................................... 2

DOCUMENT SYMBOLS ........................................................................................................................................................3

IMPORTANT SAFETY INSTRUCTIONS ................................................................................................................................ 3

A. Recognize Safety Information ...................................................................................................................................3

B. Understand Signal Words ..........................................................................................................................................3

C. Supplemental Directives ............................................................................................................................................3

D. General Safety Messages .........................................................................................................................................4

REFRIGERATOR OVERVIEW ...............................................................................................................................................5

A. Refrigerator Volume ...................................................................................................................................................5

B. Refrigerator Illustration ..............................................................................................................................................5

C. Absorption Cooling System .......................................................................................................................................6

D. Compressor Cooling System .....................................................................................................................................6

E. Keep Refrigerator Level .............................................................................................................................................6

F. Operating Refrigerator At High Altitude ..................................................................................................................... 6

G. Operating Refrigerator During Extreme Cold Weather .............................................................................................. 6

H. When Refrigerator Is Not In Use ............................................................................................................................... 6

CONTROLS ............................................................................................................................................................................7

A. Control Panel Buttons ................................................................................................................................................7

B. Modes Of Operation ..................................................................................................................................................9

C. Temperature (Thermostat) Control ............................................................................................................................9

START / STOP REFRIGERATOR ........................................................................................................................................10

A. Purge LP Gas Lines ................................................................................................................................................10

B. Turn Refrigerator On................................................................................................................................................10

C. Turn Refrigerator Off ................................................................................................................................................ 11

FOOD COMPARTMENTS .................................................................................................................................................... 11

A. Food Compartment Guidelines ................................................................................................................................ 11

B. Shelving ................................................................................................................................................................... 12

C. Baskets .................................................................................................................................................................... 12

D. Lower Food Compartment Drawer .......................................................................................................................... 13

PRODUCT CARE .................................................................................................................................................................13

A. Defrost Food Compartment(s) ................................................................................................................................. 13

B. Clean Food Compartment(s) ................................................................................................................................... 14

C. Airing Position (Store Refrigerator) .......................................................................................................................... 14

PRODUCT MAINTENANCE .................................................................................................................................................15

A. Replace Fuses ......................................................................................................................................................... 15

B. Clean Burner Assembly ........................................................................................................................................... 16

C. Clean Service Area Enclosure ................................................................................................................................. 17

D. Inspect LP Gas Connections ................................................................................................................................... 17

E. Test Control System ................................................................................................................................................17

F. Product Removal / Disposal ....................................................................................................................................17

2

Page 3

TABLE OF CONTENTS

APPENDIX A: TROUBLESHOOTING .................................................................................................................................. 18

A. General Symptoms .................................................................................................................................................. 18

B. Cooling Performance Symptoms ............................................................................................................................. 19

C. Absorption System Ignition Error ............................................................................................................................. 20

D. Compressor System Error Codes ............................................................................................................................ 20

APPENDIX B: SPARE PARTS .............................................................................................................................................21

A. Model DMH1072 Spare Parts ..................................................................................................................................21

APPENDIX C: EQUIPMENT REAR VIEW ...........................................................................................................................22

A. Model DMH1072 Rear View ....................................................................................................................................22

APPENDIX D: SCHEMATIC ................................................................................................................................................. 23

A. Model DMH1072 Schematic .................................................................................................................................... 23

APPENDIX E: CONSUMER SUPPORT ...............................................................................................................................24

APPENDIX F: DOMETIC WARRANTY ................................................................................................................................25

APPENDIX G: MAINTENANCE SCHEDULE ....................................................................................................................... 26

REGISTRATION CARD ........................................................................................................................................................ 27

A. Protect Your New Investment .................................................................................................................................. 27

DOCUMENT SYMBOLS

Indicates additional information that is NOT related

to physical injury.

IMPORTANT SAFETY INSTRUCTIONS

This manual has safety information and instructions to help

you eliminate or reduce the risk of accidents and injuries.

A. Recognize Safety Information

This is the safety alert symbol. It is used to

alert you to potential physical injury hazards.

Obey all safety messages that follow this

symbol to avoid possible injury or death.

B. Understand Signal Words

A signal word will identify safety messages and

property damage messages, and will indicate the

degree or level of hazard seriousness.

indicates a hazardous situation that,

if NOT avoided, could result in death or serious injury.

indicates a hazardous situation that,

if NOT avoided, could result in minor or moderate

injury.

is used to address practices NOT

related to physical injury.

C. Supplemental Directives

Read and follow all safety information and

instructions to avoid possible injury or death.

Read and understand these instructions before [installing / using / servicing / performing

maintenance on] this product.

3

Indicates step-by-step instructions.

Incorrect [installation / operation / servicing /

maintaining] of this product can lead to serious injury. Follow all instructions.

The installation MUST comply with all applicable local and national codes, including

the latest edition of the following standards:

U.S.A.

● ANSI/NFPA70, National Electrical Code

(NEC)

● ANSI/NFPA 1192, Recreational Vehicles

Code

● Title 24 CFR, Part 3280, Manufactured

Home Construction and Safety Standard

● National Fuel Gas Code, ANSI Z223.1/

NFPA 54

CANADA

● CSA C22.1, Parts l & ll, Canadian Electri-

cal Code

● CSA Z240 RV Series, Recreational

Vehicles

● CSA Z240.4, Gas-Equipped Recreational

Vehicles and Mobile Housing

● CSA B149.1, Natural Gas and Propane

Installation Code

Page 4

IMPORTANT SAFETY INSTRUCTIONS

D. General Safety Messages

Failure to obey the following warnings could result in death or serious injury:

● This product MUST be [installed / serviced] by a

qualied service technician.

● Do NOT modify this product in any way. Modica-

tion can be extremely hazardous.

● Disconnect product from power supply (if ap-

plicable), and do NOT operate product when

cleaning or maintaining product.

● Do NOT allow anyone (including children) with

reduced physical, sensory or mental capabilities,

or lack of experience and knowledge to use this

product, unless they have been given supervision

or instruction (concerning use of this product) by

a person responsible for their safety.

● Do NOT allow children to play with product or with

xed controls (if applicable).

● ABSORPTION-COOLING-SYSTEMS. FIRE,

BURN, OR INHALATION HAZARD. Do NOT

fracture or puncture cooling unit. The cooling unit

is under pressure and contains ammonia, sodium

chromate, and other chemicals. Repeated or

prolonged exposure to sodium chromate could

cause organ damage or cancer. Exposure to a

high concentration of ammonia refrigerant could

cause pulmonary edema (uid in lungs); chemical

burns to eyes, lungs, and skin; and could cause

a re (when exposed to open ame).

● COMPRESSOR-COOLING-SYSTEMS. FIRE,

FROSTBITE, OR INHALATION HAZARD. Do

NOT fracture or puncture cooling unit. The cooling

unit is under pressure and contains tetrauoroethane refrigerant, and may contain other chemicals. Contact with liquid refrigerant could cause

irritation or frostbite to eyes and skin. Exposure

to a high concentration of refrigerant could cause

cardiac arrhythmia (irregular heartbeat). A high

concentration of refrigerant could cause a re

(when exposed to open ame).

● FIRE OR INHALATION HAZARD. If refrigerator

stops working and/or it emits an ammonia smell,

immediately turn refrigerator OFF (if it is safe to

do so), leave the vicinity, and contact a qualied

Service Center.

● CARBON MONOXIDE HAZARD. This product

can produce carbon monoxide. Carbon Monoxide

has no odor and can kill you. The burner and ue

system MUST be kept clean.

See “Product Maintenance” on

page (15).

● FIRE OR EXPLOSION HAZARD. Do NOT store

or use gasoline, oil or gasoline soaked rags, or

other ammable vapors and liquids in the service

area behind the refrigerator or in the vicinity of

this or any other gas appliance.

● FIRE OR EXPLOSION HAZARD. BEFORE refu-

eling or parking near a gasoline pump, make sure

ALL LP gas appliances (vented to the outside of

RV) are shut OFF . Otherwise, fumes from gaso-

line pumps could come into contact with an LP

gas appliance burner ame and ignite.

● PRESSURE HAZARD. Do NOT place carbonated

liquids, glass containers, or sealed bottles or cans

in freezer. Liquids expand when frozen and could

cause container to explode.

Failure to obey the following caution

could result in injury:

● FROSTBITE OR FROSTNIP HAZARD. Do NOT

touch cold surfaces (or stored items) in freezer

compartment with damp or wet skin. Skin could

stick to cold surfaces and freeze.

4

Page 5

REFRIGERATOR OVERVIEW

A. Refrigerator Volume

Total refrigerator volume: 9.0 cu. ft.

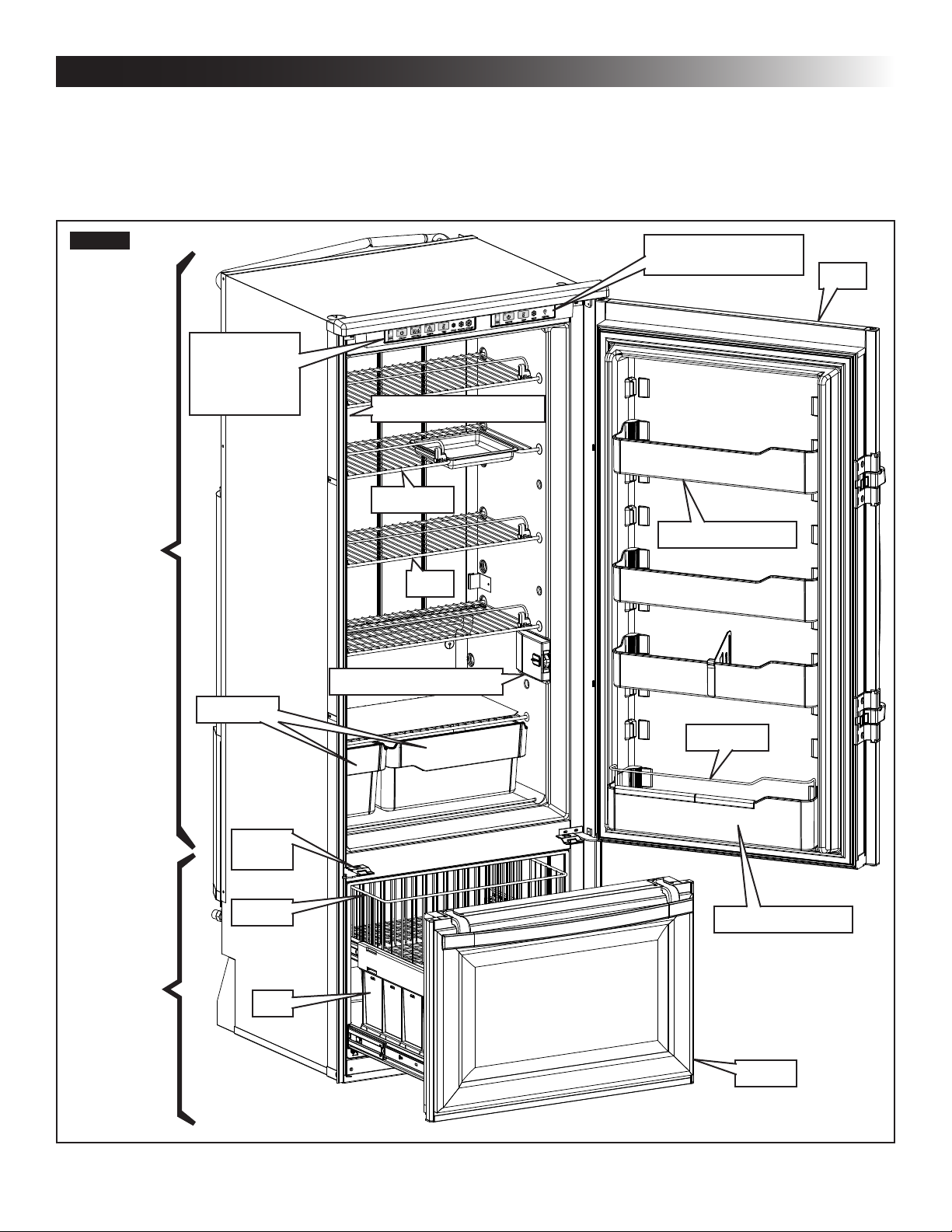

B. Refrigerator Illustration

Appearance and features may vary depending on model. Quantity and position of items may also vary. See (FIG. 1).

FIG. 1

Upper

Food Storage

Compartment

Upper

Compartment

Control

Panel

LH Light / Airing Slide

Milk Shelf

Shelf

RH Light / Airing Slide

Lower Compartment

Control Panel

Upper Door Shelf

Door

Lower

Food Storage

Compartment

Crispers

Drawer

Catch

Basket

Door Rail

Lower Door Shelf

Bin

Drawer

5

Page 6

REFRIGERATOR OVERVIEW

C. Absorption Cooling System

See “General Safety Messages” for information on absorption cooling systems, and

consequences of exposure to refrigerant.

The upper food compartment is used for fresh food

storage only. This compartment is cooled by vaporabsorption refrigeration.

The absorption system will function on BOTH LP

Gas and electric (120 Vac) power.

D. Compressor Cooling System

See “General Safety Messages” for information on compressor cooling systems, and

consequences of exposure to refrigerant.

The lower food compartment (drawer) may be used

for fresh food storage, or frozen food storage (depending on temperature setting). This compartment

is cooled by vapor-compression refrigeration.

The compressor cooling system will function on

electric (120 Vac and 12 Vdc) power ONLY.

E. Keep Refrigerator Level

(ABSORPTION COOLING SYSTEM ONLY)

For optimal cooling performance, an absorption refrigerator must be level. If the refrigerator operates

in a noticeable out-of-level condition for several

hours, loss of cooling performance will occur.

When RV is parked and absorption system is operating, the RV must be level enough to live in and

feel comfortable.

The RV does NOT need to be PERFECTLY

level, but there should be no noticeable slop-

ing of RV oor or walls.

It is NOT critical for refrigerator to be level

while RV is traveling. The rolling and pitching motion of travel helps keep the absorption

system balanced.

F. Operating Refrigerator At High Altitude

All gas appliances experience lowered efciency

(or rating) at high altitude. This is a direct result of

lower atmospheric pressure and oxygen levels, and

is not a defect of the refrigerator.

Reduced cooling performance and burner outage

may occur at altitudes higher than 5500 feet above

sea level (while operating on LP gas). Always operate refrigerator on electric power at altitudes above

5500 feet.

G. Operating Refrigerator During Extreme

Cold Weather

Upper food compartment performance may be reduced in extremely cold (subzero) temperatures.

This temporary condition is normal for absorption

refrigerators and does not indicate product failure.

If performance is reduced during cold weather, turn

upper food compartment OFF.

See “Start / Stop Refrigerator” on page (10).

When ambient temperature rises, please

restart upper food compartment before requesting service.

H. When Refrigerator Is Not In Use

Always turn refrigerator OFF when not in use.

Do NOT allow refrigerator to run idle or unattended for more than a day. See “C. Airing

Position (Store Refrigerator)” on page (14).

6

Page 7

CONTROLS

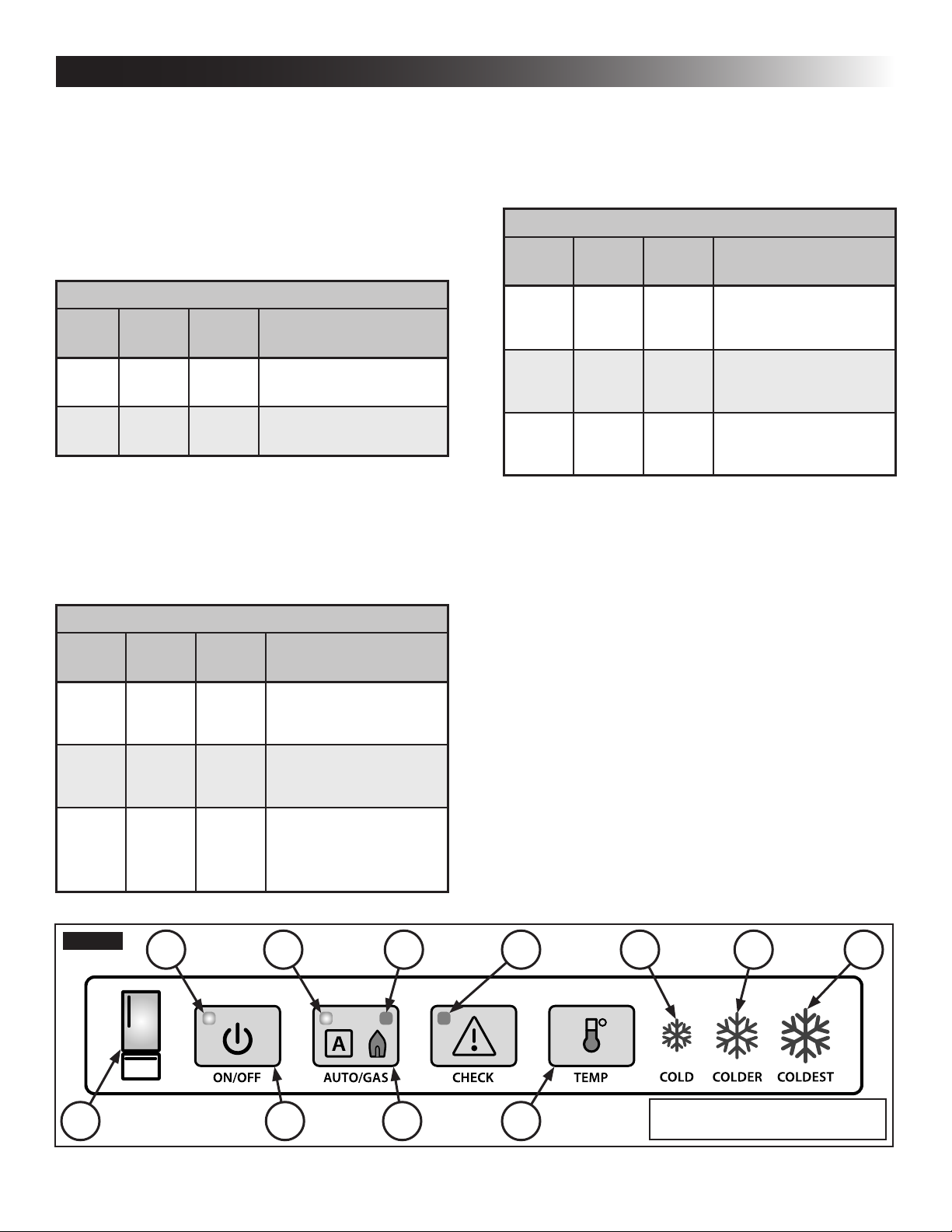

A. Control Panel Buttons

1. UPPER FOOD COMPARTMENT

See (FIG. 2).

a. (1) ON/OFF (power) button

Press this button to turn power ON or OFF.

Steady blue LED (H) indicates absorption

cooling system is ON. LED (A) indicates

power status. See (Table 1).

Table 1

(1)

Button

ON

OFF

(A)

LED

GREEN

(Steady)

OFF

(Dark)

b. (2) AUTO/GAS (mode selector) button

Press this button to select operation mode of

automatic detect or LP gas only.

LEDs (B) and (C) indicate modes of operation. LED (D) indicates LP gas ignition status. See (Table 2).

(H)

LED

BLUE

(Steady)

OFF

(Dark)

Power to absorption

cooling system is ON.

Power to absorption

cooling system is OFF.

Description

(E)

LED

BLUE

(Steady)

OFF

(Dark)

OFF

(Dark)

c. (3) TEMP (temperature) button

Press this button to cycle through temperature settings.

LEDs (E), (F), and (G) indicate temperature /

cooling levels. See (Table 3).

Table 3

(F)

LED

OFF

(Dark)

BLUE

(Steady)

OFF

(Dark)

(G)

LED

OFF

(Dark)

OFF

(Dark)

BLUE

(Steady)

Description

COLD

(Minimum cooling level.)

COLDER

(Intermediate cooling

level.)

COLDEST

(Maximum cooling level.)

(B)

LED

GREEN

(Steady)

OFF

(Dark)

N/A N/A

FIG. 2

Table 2

(C)

LED

OFF

(Dark)

GREEN

(Steady)

A B C D E F G

(D)

LED

OFF

(Dark)

OFF

(Dark)

AMBER

(Steady)

Description

Absorption cooling

system is in AUTOMATIC

detect mode.

Absorption cooling system

is in LP GAS only mode.

Ignition ERROR.

See “C. Absorption

System Ignition Error” on

page (20).

H

1 2 3

7

Upper Compartment Controls

(Absorption System)

Page 8

CONTROLS

2. LOWER FOOD COMPARTMENT

See (FIG. 3).

a. (4) ON/OFF (power) button

Press this button to turn power ON or OFF.

Steady blue LED (M) indicates compressor cooling system is ON. LED (J) indicates

power / error status. See (Table 4).

Table 4

(4)

Button

ON

OFF

ON

FIG. 3

(J)

LED

GREEN

(Steady)

OFF

(Dark)

GREEN

(Flashing)

(M)

LED

BLUE

(Steady)

OFF

(Dark)

N/A

b. (5) TEMP (temperature) button

Press this button to select storage temperature setting of “fresh food” or “frozen food.”

LEDs (K) and (L) indicate modes of operation. See (Table 5).

(K)

LED

Description

Power to compressor

cooling system is ON.

Power to compressor

cooling system is OFF.

ERROR code.

See “D. Compressor

System Error Codes”

on page (20).

J K L

OFF

(Dark)

BLUE

(Steady)

BLUE

(Flashing)

(L)

LED

BLUE

(Steady)

OFF

(Dark)

BLUE

(Flashing)

Table 5

Description

DEFAULT setting.

Lower food compartment is set

for FROZEN food storage.

Lower food compartment is set

for FRESH food storage.

Temperature ERROR.

See “D. Compressor System

Error Codes” on page (20).

M

4 5

Lower Compartment Controls

(Compressor System)

8

Page 9

CONTROLS

B. Modes Of Operation

See “A. Control Panel Buttons” on page

(7) for details on control settings and LED

indicators.

1. STANDBY MODE

If refrigerator controls cannot read food com-

partment temperature, or if temperature is outside normal operating range, the affected system switches to standby mode. The refrigerator

continues to operate using any available energy

source.

Standby mode for upper food compartment runs

the absorption system continuously. This could

cause fresh food items to freeze.

Standby mode for lower food compartment runs

the compressor system on an intermittent cycle.

This could cause frozen food items to thaw, or

fresh food items to freeze.

For either incident, the affected cooling system

remains in standby mode until sensor failure is

repaired and system is reset.

2. UPPER FOOD COMPARTMENT

The upper food compartment operates on (2)

power modes:

a. Auto mode - [default].

In this mode, the power source is automatically selected in the following order:

I. 120 Vac - [default].

Electric power takes priority in this mode.

The upper compartment attempts to op-

erate on electric power rst.

Electric power is ALWAYS the pri-

mary source of power. The upper

compartment reverts back to electric power (from other power sources) whenever it becomes available.

II. LP Gas - [secondary].

The upper compartment automatically

switches to LP gas if electric power is unavailable.

If electric power becomes available

during LP gas operation, the upper

compartment automatically switches back to electric power.

b. LP gas mode.

In this mode, the upper compartment only

operates on LP gas. The ignition cycle proceeds to light the LP gas burner in the following order:

I. The lighter sparks for approximately 45

seconds.

II. If rst attempt fails, the lighter repeats up

to 3 times.

There is a 2 minute rest period between each attempt.

III. If ignition cycle fails, upper compartment

remains OFF, and will not cool.

To attempt a new ignition cycle for

LP gas operation, see “A. Purge LP

Gas Lines” on page (10).

3. LOWER FOOD COMPARTMENT

The lower food compartment (drawer) operates

on electric power only. The power source is automatically selected in the following order:

a. 120 Vac - [default].

The lower compartment attempts to operate

on 120 Vac power rst.

120 Vac is ALWAYS the primary

source of power. The lower compartment reverts back to 120 Vac (from 12

Vdc) whenever it becomes available.

b. 12 Vdc - [secondary].

The lower compartment automatically

switches to 12 Vdc power if 120 Vac is unavailable.

If 120 Vac becomes available during

12 Vdc operation, the lower compartment automatically switches back to

120 Vac power.

C. Temperature (Thermostat) Control

See “A. Control Panel Buttons” on page

(7) for details on control settings and LED

indicators.

1. UPPER FOOD COMPARTMENT

The upper food compartment has (3) tempera-

ture modes (settings):

a. Cold (minimum cooling level).

b. Colder (intermediate cooling level).

c. Coldest (maximum cooling level).

2. LOWER FOOD COMPARTMENT

The lower food compartment has (2) tempera-

ture modes (settings):

a. Frozen food (freezer) mode - [default].

b. Fresh food (refrigerator) mode.

Before changing temperature

setting from fresh food to freezer, make sure

interior surfaces are completely dry. Otherwise, drawer slides may freeze up, making

drawer operation difcult.

9

Page 10

START / STOP REFRIGERATOR

Failure to obey the following warnings could

result in death or serious injury:

● FIRE OR EXPLOSION HAZARD. BEFORE refu-

eling or parking near a gasoline pump, make sure

ALL LP gas appliances (vented to the outside of

RV) are shut OFF . Otherwise, fumes from gaso-

line pumps could come into contact with an LP

gas appliance burner ame and ignite.

● FIRE HAZARD. Make sure there are NO obstruc-

tions (blockage) between burner jet and burner

tube BEFORE lighting LP gas burner.

FIG. 4

Solenoid Valve

Inlet Fitting

Manual Shutoff Valve

(In Open Position)

Pressure Test Port

Burner Jet

Lighter (Electrode)

LP Gas Burner

Mounting

Screws

Burner Tube

A. Purge LP Gas Lines

If air is trapped in LP gas (supply) lines, the refrigerator will not operate in LP gas mode.

Common causes for air in LP gas lines:

● Refrigerator has not operated in LP gas mode

for a long time.

● LP gas tanks have been replaced or relled.

To purge trapped air from LP gas lines, perform the

following procedure:

1. Press “ON/OFF” button twice (upper storage

controls) to cycle power OFF and ON. See

(FIG. 2).

Door MUST be open to access control

panel.

2. Press “Auto/Gas” button to select LP gas mode,

and start ignition cycle. See (FIG. 2).

a. The lighter sparks for approximately 45 sec-

onds. See (FIG. 4).

b. If rst attempt fails, the lighter repeats up to

3 times.

There is a 2 minute rest period between each attempt.

3. Repeat steps (1) through (2) if ignition cycle fails.

If ignition cycle fails after 4 attempts,

see “Appendix A: Troubleshooting” on

page (18).

B. Turn Refrigerator On

This refrigerator is intended for continuous use. Do NOT allow it to run unattended

when there is a risk for loss of electricity or fuel.

Food spoilage could occur.

The lower and upper food compartments operate

independently. Each food compartment has a dedicated set of controls.

Door MUST be open to access control panel.

See “A. Control Panel Buttons” on page

(7) for details on control settings and LED

indicators.

1. UPPER FOOD COMPARTMENT

For an absorption system to function correctly, it MUST be level. See “E. Keep Refrigerator Level” on page (6).

For LP gas operation, manual gas valves

MUST be open, and 12 Vdc power supply

(for controls) MUST be available.

a. Press “ON/OFF” button (upper storage con-

trols) to turn power ON. See (FIG. 2).

b. Select mode of operation.

See “B. Modes Of Operation” on page

(9) for more details.

I. Auto mode - [default].

This mode is automatically selected when

power is turned ON.

II. LP gas (only) mode.

Press “Auto/Gas” button to select LP gas

mode.

If ignition cycle fails, see “A. Purge

LP Gas Lines” on page (10).

2. LOWER FOOD COMPARTMENT

a. Press “ON/OFF” button (lower storage con-

trols) to turn power ON. See (FIG. 3).

b. The mode of operation (ac/dc) is selected

automatically.

See “B. Modes Of Operation” on page

(9) for more details.

10

Page 11

START / STOP REFRIGERATOR

C. Turn Refrigerator Off

The lower and upper food compartments operate

independently. Each food compartment has a dedicated set of controls.

Door MUST be open to access control panel.

See “A. Control Panel Buttons” on page

(7) for details on control settings and LED

indicators.

1. UPPER FOOD COMPARTMENT

a. Press “ON/OFF” button (upper storage con-

trols) to turn power OFF. See (FIG. 2).

The control system still consumes a

small amount of power when turned

off.

b. Clean out upper food compartment, and per-

form appropriate storage procedure.

See “Product Care” on page (13) for

full cleaning and storage instructions.

2. LOWER FOOD COMPARTMENT

a. Press “ON/OFF” button (lower storage con-

trols) to turn power OFF. See (FIG. 3).

The control system still consumes a

small amount of power when turned

off.

b. Clean out lower food compartment, and per-

form appropriate storage procedure.

See “Product Care” on page (13) for

full cleaning and storage instructions.

FOOD COMPARTMENTS

A. Food Compartment Guidelines

FIRE OR EXPLOSION HAZARD.

Do NOT store gasoline, oil or gasoline soaked rags,

or other ammable vapors and liquids inside storage compartment(s). Failure to obey this warning

could result in death or serious injury.

1. ALL FOOD COMPARTMENTS

The following points apply to both lower and up-

per food compartments:

● Cool food compartment before placing food

inside.

● Never put hot food (or drinks) into food com-

partment. (Allow items to cool rst.)

● Foods that have a strong odor or absorb

odors easily should be covered.

● Vegetables, salads, etc. should be covered to

maintain crispness.

● Do NOT leave food compartment door/draw-

er open longer than necessary. Otherwise,

frost formation and reduced efciency will occur.

● The food compartment is closed and unven-

tilated to maintain low temperature requirements for food storage.

2. UPPER FOOD COMPARTMENT

The upper food compartment is used for fresh

food storage only. The following points apply:

● Arrange items to allow free air circulation.

Do not overpack. A stuffed refrigerator works

harder to cool, and has higher cabinet (enclosure) temperatures.

● Position items according to item (food) tem-

perature requirements:

● The coldest areas of the refrigerator are

near the evaporator (cooling ns), and at

bottom of refrigerator.

● The warmest areas of the refrigerator are

on upper door shelves.

11

Page 12

FOOD COMPARTMENTS

3. LOWER FOOD COMPARTMENT

The lower food compartment may be used for

fresh food storage, or frozen food storage (depending on temperature setting). Ice may also

be made (with ice tray) in frozen food (freezer)

mode.

See “C. Temperature (Thermostat) Control” on page (9).

The following points apply to storage of frozen

food:

● To help prevent food from drying out, keep

food in covered dishes, containers, plastic

bags, or wrap in aluminum foil.

● Meat or sh (raw or prepared) can be stored

approximately 3 times longer when frozen

(compared to fresh food storage).

● Wipe excess moisture off items to be frozen.

Otherwise, frost buildup and reduced efciency could occur.

B. Shelving

1. REMOVE SHELF

a. Remove shelf lock from shelf. See (FIG. 5).

I. Insert tip of at bladed screwdriver into

slot of shelf lock.

II. Turn screwdriver (counter-clockwise),

and remove shelf lock from shelf.

III. Repeat steps (I) through (II) for each shelf

lock (on shelf to be removed).

FIG. 5

Shelf Bushing

FIG. 6

Wall Indent

c. Repeat steps (a) through (b) for each shelf

to be removed.

2. REPLACE SHELF

a. Replace shelf in refrigerator. See (FIG. 6).

I. Choose desired shelf height position.

II. Tilt right side of shelf at an angle (up or

down) and align shelf bushings (left side)

to refrigerator wall indents.

III. Slide shelf to the left until shelf bushings

(left side) fully engage refrigerator wall indents.

IV. Tilt right side of shelf at an angle (up or

down) until shelf bushings (right side)

align with refrigerator wall indents.

V. Slide shelf to the right until shelf bushings

(right side) fully engage refrigerator wall

indents.

b. Replace shelf lock on shelf. See (FIG. 5).

I. Place open end of shelf lock onto left side

of shelf (next to shelf bushing).

II. Push down until shelf lock snaps in place.

III. Repeat steps (I) through (II) for each shelf

lock (to be replaced on shelf).

Shelf

Shelf

Bushing

Shelf

Shelf Lock

b. Remove shelf from refrigerator. See (FIG. 6).

I. Slide shelf to the left until shelf bushings

(right side) disengage from refrigerator

wall indents.

II. Tilt right side of shelf at an angle (up or

down).

III. Slide shelf to the right until shelf bushings

(left side) disengage from refrigerator wall

indents. Then remove shelf.

Twist To

Remove

C. Baskets

1. REMOVE BASKET

a. Pull drawer open. See (FIG. 1).

b. Locate tabs at front edge of basket and press

tabs outward. See (FIG. 7).

c. Pull basket forward.

d. Lift basket to remove.

Rear basket is NOT removable.

12

Page 13

FOOD COMPARTMENTS

FIG. 7

2. REPLACE BASKET

a. With drawer open, align rods on side of bas-

ket with groove in tabs. See (FIG. 7).

b. Push basket rearward until rods clear the

tabs and tabs snap into place, securing basket.

Front basket can be placed in bottom

of drawer for usage.

FIG. 8

Tab

Slide Lever,

Left Side

2. REPLACE DRAWER

a. Push drawer slides all the way back in refrig-

erator lower food compartment.

b. Set drawer on oor in front of refrigerator

with gears on back of drawer aligned with,

and setting on, gear tracks. See (FIG. 9).

FIG. 9

D. Lower Food Compartment Drawer

1. REMOVE DRAWER

a. Pull drawer all the way forward.

b. Locate lever on left side drawer slide and

push lever upward. See (FIG. 8).

c. Locate lever on right side drawer slide and

push lever downward.

d. Pull drawer forward, removing from refrig-

erator.

PRODUCT CARE

A. Defrost Food Compartment(s)

Food compartments require regular defrosting to

maintain cooling efciency. Do NOT allow heavy

frost buildup on evaporator.

Frequency depends on user habits (how often and how long doors are opened). Defrosting once a month is a good general rule.

FIRE, BURN, OR INHALATION

HAZARD. Do NOT fracture or puncture cooling

unit. This could cause a leak in the cooling system.

Gear

Gear Track

c. Lift drawer front off oor and push straight

back into refrigerator.

See “General Safety Messages” for information on

cooling systems, and consequences of exposure to

refrigerant.

Do NOT use a hot air blower to remove frost from storage compartment(s). Permanent damage could occur, including warped metal

or plastic parts.

Do NOT use a knife, ice pick, or any other sharp

tool to remove frost from food compartments.

1. Turn refrigerator off.

13

Page 14

PRODUCT CARE

See “C. Turn Refrigerator Off” on

page (11) for full instructions.

2. Empty refrigerator of all contents.

3. Verify drip tray is in place (under evaporator) inside upper food compartment. See (FIG. 10).

FIG. 10

Drip Tray

Evaporator Fins

Evaporator Cover

4. Place both drawer and door in airing position until frost is melted.

To reduce defrost time, ll ice trays with

warm water and place in lower food compartment.

See “C. Airing Position (Store Refrigerator)” on page (14) for full instructions.

5. When all frost has melted, continue with “B.

Clean Food Compartment(s)” on page (14).

B. Clean Food Compartment(s)

ELECTRICAL SHOCK HAZARD.

Do NOT spray liquids near electrical components,

outlets, or connections. Failure to obey this warning

could result in death or serious injury.

Do NOT use strong chemicals or

abrasives to clean parts, as their protective surfaces will be damaged.

Always keep refrigerator clean. A clean refrigerator

reduces odors and helps prevent stains from developing. Follow the recommended cleaning schedule:

● Clean spills immediately.

● Thoroughly clean immediately after defrosting.

● Clean before storing refrigerator, or when taking

out of storage (before use).

● Thoroughly clean lower and upper food com-

partments once every 3 months (during continuous use).

Discard expired items. Clean shelves,

door shelves, baskets, and bins.

1. To clean door liner and interior liner of refrigerator:

a. Mix 4 tablespoons of baking soda to 1 quart

of warm water.

b. Wipe down surfaces with baking soda solu-

tion.

c. Wipe down surfaces with warm water to re-

move baking soda solution.

d. Dry surfaces with clean cloth.

To clean lower food compartment,

drawer MUST be removed. See “D.

Lower Food Compartment Drawer” on

page (13).

2. To clean nned evaporator, gasket, and shelves:

a. Wipe down surfaces with warm water only.

b. Dry surfaces with clean cloth.

Make sure interior surfaces are completely dry before turning unit back on.

Otherwise, drawer slides may freeze

up, making drawer operation difcult.

3. To remove cover from light(s) for cleaning, maintenance, etc:

a. Spread rear of cover slightly, releasing tabs

(top and bottom).

b. Remove cover.

C. Airing Position (Store Refrigerator)

ALWAYS place refrigerator in airing

position before storage. Otherwise, moisture will be

trapped inside refrigerator, and could result in mold

/ mildew, stains, and lingering odors.

When refrigerator is not in use, perform the following procedures to place drawer and door in airing

position:

1. PREPARE FOR AIRING POSITION

a. Turn refrigerator off.

See “C. Turn Refrigerator Off” on

page (11) for full instructions.

b. Defrost refrigerator (if applicable).

See “A. Defrost Food Compartment(s)”

on page (13) for full instructions.

c. Clean refrigerator.

See “B. Clean Food Compartment(s)”

on page (14) for full instructions.

2. DOOR AIRING (UPPER COMPARTMENT)

a. Pull door open. See (FIG. 1).

b. Push airing slide tab in (toward refrigerator

wall), then pull slide forward (toward user)

until it clicks into airing position. See (FIG. 1)

& (FIG. 11).

If door hinge is on RH side, use LH airing slide. If door hinge is on LH side,

use RH airing slide.

c. Close door against airing slide (to keep door

14

ajar) until latch clicks once.

Page 15

PRODUCT CARE

FIG. 11

Airing Slide

Tab

PRODUCT MAINTENANCE

For refrigerator to function correctly, periodic maintenance MUST be performed. All procedures within

this section MUST be performed by a qualied

service technician.

For more maintenance instructions, see Diagnostic Service

Manual.

See “Appendix G: Maintenance Schedule” on

page (26).

A. Replace Fuses

Replace fuses if blown. See (Table 6).

Table 6

Fuse Location Description

5 A Power Module Absorption Heaters

3 A* Power Module Absorption Control System

3 A In-Line Absorption Cooling Fan

15A In-Line Compressor dc Power

4 A In-Line Compressor ac Power

1 A In-Line Compressor Cooling Fan

*On products built after June 2016, the 3 amp fuse

for the absorption control system is a resettable

fuse and can NOT be replaced. If the resettable

fuse has been tripped, determine and remedy the

cause and address as necessary. Once the condition causing the fuse to trip has been addressed,

reset the control system fuse by pressing the ON

/ OFF button on the absorption control interface to

power OFF the system, wait 5 seconds, and then

press again to restore power mode to ON.

3. DRAWER AIRING (LOWER COMPARTMENT)

a. Pull drawer open. See (FIG. 1).

b. Allow drawer to rest against drawer catch (to

keep drawer ajar). See (FIG. 1).

The drawer cannot be locked in airing position, so the drawer could open

freely.

4. DISCONNECT 12 VDC POWER

The refrigerator control system still consumes

a small amount of power when refrigerator is

turned off.

To prevent battery from discharging (while RV is

in storage), disconnect (switch off) 12 Vdc power to refrigerator.

Alternatively, connect 12 Vdc battery to a

(trickle) charger that is approved for your

RV (house) battery.

1. POWER MODULE FUSES

The power module has (2) fuses. To replace

fuse(s), perform procedure below. See (FIG. 15)

& (Table 6).

a. Turn refrigerator off.

See “C. Turn Refrigerator Off” on

page (11) for full instructions.

b. ELECTRICAL SHOCK HAZ-

ARD. Disconnect 120 Vac power from product. Failure to obey this warning could result

in death or serious injury.

Unplug 120 Vac power cord from receptacle

at rear of refrigerator enclosure.

c. Disconnect the positive (+) 12

Vdc terminal from supply battery. Otherwise,

damage to unit could occur.

d. With refrigerator disconnected from 120 Vac

power, remove power module cover.

e. Remove old fuse(s) from fuse holder(s), and

discard.

f. Insert new fuse(s) into fuse holder(s).

g. Replace power module cover.

h. Reconnect 12 Vdc power.

i. Reconnect 120 Vac power.

2. IN-LINE FUSES

To replace in-line fuse(s), perform procedure be-

low. See (Table 6).

a. Turn refrigerator off.

See “C. Turn Refrigerator Off” on

page (11) for full instructions.

15

Page 16

PRODUCT MAINTENANCE

b. Disconnect the positive (+) 12

Vdc terminal from supply battery. Otherwise,

damage to unit could occur.

c. Open in-line fuse holder (at back of refrigera-

tor), remove old fuse, and discard.

d. Insert new fuse into in-line fuse holder, and

close fuse holder.

e. Reconnect 12 Vdc power.

B. Clean Burner Assembly

Failure to obey the following warnings could result in death or serious injury:

● CARBON MONOXIDE HAZARD. This product

can produce carbon monoxide. Carbon Monoxide

has no odor and can kill you. The burner and ue

system MUST be kept clean.

● FIRE OR EXPLOSION HAZARD. NEVER use a

wire or pin to clear obstructions from burner jet

(damage will occur).

● FIRE OR EXPLOSION HAZARD. Do NOT use

compressed air to clean burner jet (orice could

dislodge).

● FIRE OR EXPLOSION HAZARD. Do NOT at-

tempt to adjust burner jet.

FIG. 12

6. Clean burner tube with a dry brush. See (FIG. 4).

7. Verify burner tube slots are centered under ue

tube. See (FIG. 13).

FIG. 13

Translucent

Blue Flame

Burner Tube

8. Verify electrode is in correct location over burner

tube slots, and has a 1/8″ - 3/16″ gap from burner tube. See (FIG. 14).

Temporarily loosen (electrode mounting)

screw and make adjustments with needle

nose pliers if necessary.

FIG. 14

Flue

Tube

Flue

Tube

Flue Tube

Burner Tube Slots

Burner Jet

1. Turn refrigerator off.

See “C. Turn Refrigerator Off” on

page (11) for full instructions.

2. Unplug 120 Vac power cord from receptacle at

rear of refrigerator enclosure.

3. Disconnect the positive (+) 12 Vdc terminal from

supply battery.

4. Turn manual shutoff valve OFF (to closed posi-

tion). See (FIG. 4).

The slot on manual shutoff valve is vertical

when valve is off (closed).

5. Remove burner cover (with screw) from burner

assembly, and save for reinstallation later. See

(FIG. 15).

Electrode GapScrew

Burner TubeBurner Tube Electrode

9. Reconnect 12 Vdc power.

10. Reconnect 120 Vac power.

11. Turn manual shutoff valve ON (to open position).

See (FIG. 4).

12. Verify burner ame has correct appearance

(translucent blue color). See (FIG. 13).

Under ideal conditions, ame should NOT

have any yellow coloring.

13. Verify LP gas safety shutoff (solenoid valve)

functions correctly. See (FIG. 4).

See Diagnostic Service Manual for full instructions.

16

Page 17

PRODUCT MAINTENANCE

C. Clean Service Area Enclosure

FIRE OR EXPLOSION HAZARD. Do

NOT store or use gasoline, oil or gasoline soaked

rags, or other ammable vapors and liquids in the

service area behind the refrigerator or in the vicinity

of this or any other gas appliance. Failure to obey

this warning could result in death or serious injury.

Check lower vent, upper vent, and area between

these openings for obstructions.

Obstructions may include bird / insect nests,

spider webs, etc.

D. Inspect LP Gas Connections

All connections in the LP gas system (at back of

refrigerator) must be checked for leaks.

1. Verify LP gas (supply) bottle is NOT empty, and

supply line is turned ON.

2. FIRE OR EXPLOSION HAZ-

ARD. NEVER use an open ame to check for

gas leaks. Failure to obey this warning could result in death or serious injury.

Apply an approved non-corrosive leak detection

solution to all LP gas connections.

If bubbles appear, proceed to step (3).

3. FIRE OR EXPLOSION HAZ-

ARD. Turn OFF LP gas supply at tank. Failure

to obey this warning could result in death or serious injury.

Turn LP gas supply line OFF immediately!

4. ALWAYS use a backup wrench

when loosening or tightening LP gas connections.

Tighten all loose connections, and repair all

leaks as necessary.

E. Test Control System

Check control system by connecting/disconnecting

120 Vac power, starting/stopping engine, etc.

F. Product Removal / Disposal

See Installation Instructions for refrigerator removal / replacement procedure, and for recycling

information.

17

Page 18

APPENDIX A: TROUBLESHOOTING

A. General Symptoms

These symptoms apply to general refrigerator operation. See (Table 7).

Table 7

Symptom Possible Cause Action

● Do NOT open refrigerator doors.

● Open RV windows and doors (to air out RV), and evacuate RV.

Refrigerator emits an ammonia smell.

Absorption system is leaking.

● Turn manual LP gas valve OFF at rear of refrigerator.

● Disconnect 120 Vac and 12 Vdc power at rear of refrigerator.

● Contact a Dometic dealer or Service Center for repair.

Do NOT use refrigerator until it has been repaired.

Refrigerator emits an odor

from fumes.

Heavy frost buildup.

Refrigerator does not function in electric mode.

Refrigerator (upper food

compartment) does not

function in LP gas mode.

Dislocated or damaged

burner.

Dirty ue tube.

User habits, including frequent or prolonged opening

of food compartment(s).

Drawer / door is not sealing

correctly.

Electric power source issue.

LP gas power source issue.

● Turn refrigerator OFF at control panel.

● Contact a Dometic dealer or Service Center for repair.

● Do not open drawer / door longer than necessary.

● Regular defrosting is required. See “A. Defrost Food

Compartment(s)” on page (13).

● Make sure drawer / door is fully closed and gasket is sealing.

● Make sure power is turned ON at control panel.

● Make sure 120 Vac or 12 Vdc power is available and con-

nected (plugged in).

● Make sure receptacle is energized by plugging in another

appliance.

● Fuse may be blown. See “A. Replace Fuses” on page (15),

or contact a Dometic dealer or Service Center.

● LP gas (supply) bottle may be empty. Replace (supply) bottle.

● Air may be trapped in gas line. See “A. Purge LP Gas Lines”

on page (10).

18

Page 19

APPENDIX A: TROUBLESHOOTING

B. Cooling Performance Symptoms

These symptoms apply to cooling performance of food storage compartments. See (Table 8).

Table 8

Symptom Possible Cause Action

● Make sure temperature (cooling level) setting is correct.

Cooling performance issues common to BOTH

lower and upper food compartments.

(Too cold, or not cold

enough.)

Cooling performance issues for upper food compartment.

(Too cold, or not cold

enough.)

Improper use or settings.

Standby mode:

Compartment temperature

sensing error.

Refrigerator is out of level. ● See “E. Keep Refrigerator Level” on page (6).

Over-packed food storage. ● Arrange food to allow free air circulation.

Extremely cold (subzero)

weather conditions.

● Make sure drawer / door is closed and sealing properly.

Refrigerator requires time to cool down when power has

been off for a long while.

● See “1. Standby Mode” on page (9) for more information.

● Contact a Dometic dealer or Service Center for repair.

● Turn upper food compartment OFF.

When ambient temperature rises, please restart upper food

compartment before requesting service

Upper food compartment

stops cooling.

(Electric and gas modes.)

Lower food compartment

stops cooling.

Absorption system is not

functioning.

Control module is not operating.

Compressor issue.

● Immediately turn refrigerator OFF.

● Contact a Dometic dealer or Service Center for repair.

Do NOT use refrigerator until it has been repaired. Do

NOT attempt to solve problem by repeatedly restarting

refrigerator.

● Make sure power is turned ON at control panel.

● Make sure 12 Vdc power is available and connected.

● If LED error code is ashing, see “D. Compressor System

Error Codes” on page (20).

● If no LED error code is ashing:

● Make sure power is turned ON at control panel.

● Make sure 120 Vac or 12 Vdc power is available and

connected.

19

Page 20

APPENDIX A: TROUBLESHOOTING

C. Absorption System Ignition Error

This error applies to the upper food compartment. The control panel LED illuminates when an ignition error occurs.

See (FIG. 2) & (Table 9).

See “Controls” on page (7) for more information.

Table 9

(D)

LED

AMBER

(Steady)

● Check LP gas (LP gas did NOT ignite). See “B. Modes Of Operation” on page (9).

● LP gas (supply) bottle may be empty. Replace (supply) bottle.

● Air may be trapped in gas line. See “A. Purge LP Gas Lines” on page (10).

Description

D. Compressor System Error Codes

These error codes apply to the lower food compartment. The control panel LED ashes when certain errors occur.

See (FIG. 3) & (Table 10).

See “Controls” on page (7) for more information.

Table 10

(J)

LED

(K)

LED

(L)

LED

Number Of

Flashes

1

2

Description

● Battery voltage is outside normal operating range. Check battery.

Lower compartment shuts down under this condition if 120 Vac

power is also NOT available.

● Compressor fan overload. Foreign object(s) may be obstructing fan

blades from spinning.

AMBER

(Flashing)

N/A

N/A N/A

BLUE

(Flashing)

BLUE

(Flashing)

3

4

5

Continuous

● Compressor system (motor start error).

● Contact a Dometic dealer or Service Center for repair.

● Compressor system (motor speed error).

● Contact a Dometic dealer or Service Center for repair.

● Thermal shutoff (Compressor controller is too hot). Compressor

system restarts automatically when temperature is within normal

operating range.

● If problem persists, contact a Dometic dealer or Service Center for

repair.

● Temperature in lower food compartment is outside normal operating

range. Compressor system continues to operate in standby mode

until temperature returns to normal operating range.

● If problem persists, contact a Dometic dealer or Service Center for

repair.

20

Page 21

APPENDIX B: SPARE PARTS

A. Model DMH1072 Spare Parts

To order spare parts, see contact information in “Appendix E: Consumer Support” on page (24).

Table 11

Part Number Description

3850992011 Crisper (Narrow)

3850993019 Crisper (Wide)

3850974019 Door Shelf, Upper

3850975016 Door Shelf, Lower

3850324025 Shelf (Wire)

3313470.211 Shelf, Milk (Wire)

2931117234 Shelf, Plastic (Bottom)

2932102011 Lock (Clip), Shelf

3313470.153 Basket, Freezer (Wire)

3313470.154 Drawer Catch (Lock)

3313470.152 Handle Assembly, Door

3313470.151 Handle Assembly, Drawer

3313470.078 Door Assembly

3313470.079 Drawer Front Assembly

3313470.150 LED Light / Airing Slide Assembly (LH / RH)

2932781012 Electrode

3850644422 Heater 325W, 120V

2930697079 Burner (with Conductor)

2932667039 Bafe

2007337120 Shelf Rail (Short)

2007337211 Shelf Rail (Long)

2930693045 Shelf Holder

2932658012 Bottle Holder (Long)

3106753.001 Bottle Holder (Short)

3850959010 Switch

21

Page 22

APPENDIX C: EQUIPMENT REAR VIEW

A. Model DMH1072 Rear View

FIG. 15

Heaters

Power

Module

Cover

12V DC

Burner

Cover Screw

Thermofuse

Flue

Bafe

Flexible

Power Cord

Compressor

Module

12 Vdc

Terminal Block

Inlet Fitting

Compressor

Assembly

Burner

Jet

Manual Gas Shutoff ValveWater Drain Hose

Burner

Cover

22

Page 23

APPENDIX D: SCHEMATIC

A. Model DMH1072 Schematic

FIG. 16

$

&

'

)

+

-

.

0

2

3

5

6

&21752/02'8/(3&%

$%62537,21&21752/

%

,17(5)$&(',63/$<

(/(&752'(

'

7+(50$/6:,7&+

7+(50$/6:,7&+

(

/,*+702'8/(6

+($7(59$&

*

)5$0(+($7(5

7(50,1$/%/2&.

12786('

,

7+(50,6725

7+(50,6725

-

62/(12,'9$/9(

/

$&6$)(7<*1'

3527(&7,9(($57+

1

&2035(6625

&21752//(5

&+$66,6*1'

3

)$1

)$1

4

&2035(6625

&21752/,17(5)$&(

',63/$<

6$)(7<)86(/,1.

6$)(7<)86(/,1.

5

/,*+76:,7&+

%/$&.

%52:1

5('

<(//2:

*5((1

*5((1<(//2:

%/8(

*5(<

:+,7(

25$1*(

,1/,1(48,&.

&211(&7,21

)8//<,168/$7('

)86(

12132/$5,7<6(16,7,9(

&211(&7,21

:,5(&2/25,55(/(9$17

-

*

%

(

$

3

3

3

3

3

3

3

3

6

(

2

-

$

$

$

-

-

-

-

-

-

$

5

5

'

/

1

*

9$&

9

+

-

'&

3

3

3

3

'

0

2

3

12786('

.

&

3

)

/

1

/

1

)

$

&

'

&

3

7

',63/$<%2$5'

4

23

Page 24

APPENDIX E: CONSUMER SUPPORT

Dometic website www.DometicUSA.com

Please visit our website for information and news about Dometic products. Our website provides information on product

care and warranties. You can also download product literature, including manuals and brochures.

Service and spare parts www.eDometic.com

For service and spare parts, please contact Service Center Assistance. Please see the front page of this manual - or -

visit our Dometic website to nd a Dometic Service Center near you.

Contact us www.DometicUSA.com

For contact information, please see the front page of this manual - or - visit our Dometic website.

Register product www.eDometic.com

Timely registration allows for enhanced communication and service under the terms of your warranty. Please see

“Appendix F: Dometic Warranty” on page (25).

To register your product, ll in the pre-printed registration card on the last page of this manual, or register on-line at

www.eDometic.com.

TO REGISTER ON-LINE:

1. Access www.eDometic.com then click “CONSUMER CENTER.”

2. Click “Register My Product.”

3. Complete the on-line form, then click “Submit.”

DOMETIC CORPORAT ION ELKHART, IN U SA

MF G NO

S ER NO

MOD NO

Equipped for LP (Propane) Gas

Manifold pressure of 11" W.C. (2 .74 kPa)

I NSTALL ONLY WI TH VENT KI T ACCORD ING TO

IN STALLEZ UNI QUEMENT AVEC LA TROUSSE

CONFORME'MENT FORMULAI RE NO. 32 1 32 38 . - - -

The model number (e.g. DMH1072) and serial number

(e.g. 012 34567) are printed on the data label inside the

refrigerator compartment.

REFRIGERANT

Na

CrO

4

2

FORM NO 32 1 32 3 8. - - -

D' AI R DE COMBUST ION

YEAR OF M ANUFACT URE:

2014

ANS Z 21 . 1 9 - 20 0 9

CSA 1 . 4 - 2 00 9 REF RI GERAT OR

FOR M ANUFACT URED HOME (MO BI L E H OME)

OR REC REAT I ONAL VEH I CLE I NSTA LL AT I ON

PO UR I NSTA L LAT I ON DANS UNE M AI SO N

PREFA BRI QUEE (MOB I L E) O U UN

VEH I CULE DE CAMPI NG

TEST ED T O 85 0 I BF / I N ( 5 , 86 MPA)

1 546 2 4

MADE IN USA

331 32 87. 009

24

Page 25

APPENDIX F: DOMETIC WARRANTY

Congratulations, and Thank You for purchasing the industry’s best built and best backed RV refrigerator. Dometic’s exclusive

two (2) year warranty is included along with important maintenance information. Please take a few moments to familiarize

yourself with our warranty and maintenance program. We truly appreciate your business, and we are condent you will enjoy

many years of trouble-free RV use.

LIMITED TWO-YEAR WARRANTY DOMETIC REFRIGERATORS

THE SELLER NAMED BELOW MAKES THE FOLLOWING WARRANTY

WITH RESPECT TO THE DOMETIC PRODUCT:

1. This warranty is made only to the rst purchaser (herein after referred to as the “Original Purchaser”) who acquires the product for his own

use and is installed and operated within the continental United States and Canada.

2. This warranty will be in effect for two years on parts and freight and two years on labor from the date of purchase by the Original Purchaser.

It is suggested that the original purchaser retain a copy of the dated bill of sale as evidence of the date of purchase.

3. This warranty covers only specied parts, which shall be free from defects in material and workmanship under normal use. This warranty

does not cover conditions unrelated to the material and workmanship of the product. Such unrelated conditions include, but are not limited

to: (a) damage not reported within the rst 7 days of ownership; (b) faulty installation or installation that does not comply with R.V.I.A. standards, and any damage resulting from such; (c) the need for normal maintenance and any damage resulting from the failure to provide such

maintenance; (d) failure to follow Sellers instructions for use of product; (e) any accident to or misuse of any part of this product and any

alteration by anyone other than the Seller or its authorized representative; (f) any non-Dometic parts that are installed as replacement parts

will void any warranty (implied or written); (g) ame outage due to blow out or high altitude; (h) reduced performance due to high altitude;

(i) radio frequency interference and electromagnetic interference; (j) 12V system chassis ground decay and corrosion; (k) puncture of foam

cabinet or vacuum insulated panels after acknowledged receipt; (l) animal or insect inltration which damages unit or inhibits performance;

(m) abuse or misuse of electrical components.

4. The specied parts covered by this warranty are as follows: Major components (cooling unit, LP gas valve, burner, burner housing, electronic display, electronic module, evaporator ns, foam integrity, frame, thermistor, spark probe, ignition wire, ice maker compressor, second absorption loop, display escutcheon, lower toe plate, humidity switch, frame heater mullion, ice maker mullion) are covered for parts

and freight for two years and labor for two years from date of purchase. All other components that fail must be reported within the rst 90

days of ownership in order to receive coverage of parts, freight and labor under warranty.

5. This warranty requires the Original Purchaser to provide preventative maintenance on a yearly basis, starting at the anniversary

of his date of purchase. The Original Purchaser must keep a record of the preventative maintenance to keep the warranty in effect. Failure

of the Original Purchaser in providing this annual maintenance may void the warranty. The preventative maintenance must be performed

at a Dometic Authorized Service Center/Dealer. The preventative maintenance required is an inspection, cleaning and full diagnostics performed on the entire electronic system, burner assembly, wiring and cooling unit. A copy of the receipt covering the maintenance checks

must accompany the warranty claim during the second year of ownership. The cost of this preventative maintenance is the Original Purchaser’s responsibility and should take about one hour.

6. In order to obtain the benets of this warranty, the original purchaser must return the product which is found defective to the Seller named

below or to a Dometic Authorized Service Center during the period that this warranty is in effect. The original purchaser is responsible for

all charges incurred in delivery of the product to the Seller or Dometic Authorized Service Center, and in pick up after the warranty service

has been completed. To obtain the location of the nearest Authorized Service Center, please call 1-800-544-4881.

7. Any item returned in the manner described in paragraph 6 will be examined by the Seller or the Authorized Dometic Service Center. If it

is found that the returned item was defective in material and workmanship, the Seller or the Authorized Dometic Service Center will repair

the product per the terms outlined in paragraph 4. Conrm the service agency is an Authorized Dometic Service Center. DO NOT pay the

service agency for Warranty repairs. Such payments will not be reimbursed.

8. The Seller does not authorize any person or company to create any warranty obligations or liability on their behalf. This warranty is not

extended by the length of time which you are deprived of the use of the product. Repairs and replacement parts provided under the terms

of this warranty shall carry only the non-expired portion of this warranty.

9. In no event shall either seller be liable for incidental or consequential damages. This includes any damage to another product or products

resulting from such a defect. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitations may not apply.

10. Any implied warranty, including the implied warranty of merchantability and tness for any purpose, is limited to the duration of this limited

warranty. Some states do not allow limitations on how long an implied warranty can last, so the above limitation may not apply.

11. This warranty give specic legal rights, you may also have other rights which vary from state to state. No action to enforce this warranty

shall be commenced later than ninety (90) days after the expiration of the warranty period. Claims must be submitted in writing to the Dometic Warranty Department for arbitration.

12. All products (except those specically built for commercial use) are warranted only when installed in vehicles built to current edition R.V.I.A.

A119.2 and C.R.V.A. Z-240 Standards.

13. The Seller reserves the right to change the design of any product without notice and with no obligation to make corresponding changes in

products previously manufactured.

DOMETIC CORPORATION

Warranty Department

1120 North Main Street

Elkhart, IN 46514

25

Page 26

APPENDIX G: MAINTENANCE SCHEDULE

REFRIGERATOR OWNER MAINTENANCE YEARLY RECORD

Customer Name: Model No.: Date of Purchase:

Address: Serial No.:

City: State: Zip Code:

Phone:

FIRST YEAR

Date:

Dealership:

Address:

City:

State: Zip:

Phone:

Technician:

Cleaned Burner Assembly: Yes / No

Cleaned/Check All Terminals Connections: Yes / No

Cleaned/Inspect All Ground Connections: Yes / No

Inspect and Test Door Seals: Yes / No

Inspect and Tighten LP Lines: Yes / No

Power Ventilator Installed: Yes / No

Gas Safety Shutdown in 45 seconds: Yes / No

SECOND YEAR

Date:

Dealership:

Address:

City:

State: Zip:

Phone:

Technician:

Cleaned Burner Assembly: Yes / No

Cleaned/Check All Terminals Connections: Yes / No

Cleaned/Inspect All Ground Connections: Yes / No

Inspect and Test Door Seals: Yes / No

Inspect and Tighten LP Lines: Yes / No

Power Ventilator Installed: Yes / No

Gas Safety Shutdown in 45 seconds: Yes / No

ACTUAL SPEC. RANGE

Electrode Gap 3/16"

Thermistor Reading 7-10,000 ohms @ 32°

D/C Voltage 9.5 to 15 volts D/C

A/C Voltage 120 Volts ± 10%

Thermocouple Reading 25-35 Millivolts

Delay Between Modes Approx. 5 seconds

ICE MAKER MODELS

Inspect Water Valve and All Connections: Yes / No

Inspect Heat Tape Switch for Proper

Operation: Yes / No

ACTUAL SPEC. RANGE

Electrode Gap 3/16"

Thermistor Reading 7-10,000 ohms @ 32°

D/C Voltage 9.5 to 15 volts D/C

A/C Voltage 120 Volts ± 10%

Thermocouple Reading 25-35 Millivolts

Delay Between Modes Approx. 5 seconds

ICE MAKER MODELS

Inspect Water Valve and All Connections: Yes / No

Inspect Heat Tape Switch for Proper

Operation: Yes / No

26

Page 27

REGISTRATION CARD

A. Protect Your New Investment

We truly appreciate your decision to purchase a new Dometic product, and we want to help you protect this wise

investment.

We back our Dometic products with one of the most comprehensive warranties in the industry. Please complete and

mail this registration card, or register your product on-line at www.eDometic.com.

Here

TIME-DATED

MATERIAL

Please Process

Promptly!

Tape

FIRST

CLASS

POSTAGE

REQUIRED

Dometic Processing Center

1120 North Main Street

Elkhart, IN 46514

Tape

Here

Page 28

■ WARRANTY VERIFICATION

Your prompt registration records your right to protection

under the terms and conditions of your warranty.

■ OWNER CONFIRMATION

Your completed registration serves as conrmation

of ownership in the event of product damage or theft.

■ FACTORY COMMUNICATION

Returning the attached card or registering on-line guarantees you will receive product information and specials.

Including your email address will allow us to communi-

cate with you quickly and efciently.

Return this card within 10 days to ensure your:

■ WARRANTY VERIFICATION

■ FACTORY COMMUNICATION

■ OWNER CONFIRMATION

■ 2 PLUS 3 SERVICE CONTRACT INVITATION

■ 2 PLUS 3 SERVICE CONTRACT

Returning the attached card or registering on-line ensures an invitation to upgrade to an optional 2 Plus 3

Full Service Contract. This service contract allows you

to add up to 3 years of additional warranty coverage.

PLEASE RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

TO THE CONSUMER

PLEASE AFFIX THESE INSTRUCTIONS

TO THE REFRIGERATOR

TO THE INSTALLER

IMPORTANT:

10 Days

Return Within

Name

Address

City

Email Address

Email me exclusive offers and information on new products from Dometic.

Email me offers and information from Dometic partners.

Fold here. Close with tape.

Owner’s Registration Card

Registering your product is an essential step to ensure you receive all the

benets you are entitled to as a DOMETIC customer. Complete the information below

and mail to us, or register on-line at www.eDometic.com.

Be sure to include your email address, so we can communicate with you

quickly and efciently. Your address will remain condential and will not be

distributed to third parties.

State/Prov.

Zip/Postal CodeDate of Purchase

MO DAY YEAR

—

REFRIGERATOR MODEL NUMBER

SERIAL NUMBER

Loading...

Loading...