Page 1

OPERATING

INSTRUCTIONS

RM2351

RM2354

RM2451

RM2454

RM2551

RM2554

DM2652

DM2662

DM2663

DM2852

DM2862

NDM1062

FIRE OR EXPLOSION HAZARD

If you smell gas:

1. Open windows.

2. Do not attempt to light appliance.

3. Do not touch electrical switches.

Failure to follow these instructions could result in re or explosion, which

could cause property damage, personal injury, or death.

4. Extinguish any open ame.

5. Shut off fuel supply.

6. Evacuate immediately and call

emergency services.

FOR YOUR SAFETY

Do not store or use gasoline or other ammable vapors and liquids in the vicinity of

this or any other appliance.

REVISION D

Form No. 3313240.016 12/17

(French 3313241.013_D)

©2017 Dometic Corporation

LaGrange, IN 46761

Improper installation, adjustment,

alteration, service or maintenance can cause

injury or property damage. Refer to this manual. For assistance or additional information

consult a qualied installer, service agency

or the gas supplier.

If the refrigerator stops cooling - or - if

it emits an ammonia smell, immediately

turn the refrigerator off and contact a

Service Center.

USA & CANADA

SERVICE OFFICE

Dometic Corporation

1120 North Main Street

Elkhart, IN 46514

SERVICE CENTER &

DEALER LOCATIONS

Please Visit:

www.dometic.com

Page 2

INTRODUCTION

Thank you for purchasing a new Dometic refrigerator. This product is a recreational vehicle refrigerator intended for the storage of fresh and frozen foods, as well as making ice.

Appearance of your product may vary from illustrations shown in this document.

Please read and be aware of possible safety hazards identied in this manual, and become familiar with the alert symbols

on the refrigerator. Read this manual carefully so that you know how to operate the refrigerator safely and correctly. Keep

this manual with the refrigerator for future reference.

CONTENTS

REFRIGERATOR OVERVIEW ........................................................................... 3

INSTRUCTIONS FOR USE .............................................................................. 6

STORAGE COMPARTMENTS ........................................................................... 9

PRODUCT CARE .................................................................................... 10

MAINTENANCE & SERVICE ........................................................................... 12

TROUBLESHOOTING ................................................................................ 14

APPENDIX A - SPARE PARTS .......................................................................... 15

APPENDIX B - REARVIEW EQUIPMENT ................................................................. 17

APPENDIX C - WIRING DIAGRAM ...................................................................... 19

APPENDIX D - CONSUMER SUPPORT .................................................................. 24

APPENDIX E - DOMETIC WARRANTY ................................................................... 25

APPENDIX F - MAINTENANCE SCHEDULE ............................................................... 26

SYMBOLS

The following symbols are used throughout this manual:

This is the safety alert symbol. It is used to alert you to personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury or death.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE is used to address practices not related to personal injury.

Information

Step-by-step instructions

2

Page 3

REFRIGERATOR OVERVIEW

ABSORPTION COOLING SYSTEM

When turning on the refrigerator, you should adjust the thermostat (excludes RM2351, RM2451,

RM2551, DM2652 & DM2852 - not adjustable) to

the coldest temperature setting. The cooling cycle

may require an extended running time before cooling effect is observed.

LEVELING THE REFRIGERATOR

Leveling is one of the requirements for proper operation

with absorption refrigerators. To ensure proper leveling the

vehicle needs to be leveled so it is comfortable to live in

(no noticeable sloping of oor or walls).

Any time the vehicle is parked for several hours with the

refrigerator operating, the vehicle should be leveled to allow proper cooling.

When the vehicle is moving, the leveling is not critical, as

the rolling and pitching movement of the vehicle will pass

to either side of level, keeping the liquid ammonia from

accumulating in the evaporator tubing.

OPERATING REFRIGERATOR AT HIGH

ALTITUDE

All gas appliances experience lowered efciency (or rating) at high altitude This is a direct result of lower atmospheric pressure and oxygen levels, and is not a defect of

the refrigerator.

Reduced cooling performance and burner outage may

occur at altitudes higher than 5500 feet above sea level

(while operating on LP gas). Always operate refrigerator

on electric power at altitudes higher than 5500 feet.

WHEN THE REFRIGERATOR IS NOT

IN USE

Any absorption refrigerator that is to be taken out of service for an extended period of time should be turned off.

It is important that you do not leave the refrigerator

to run idle and/or unattended for days or weeks.

AUTOMATIC ENERGY SELECTOR

SYSTEM

The refrigerator is equipped with an automatic energy selector system. The user turns the refrigerator on and then,

the refrigerator automatically selects the most suitable energy source available, either 120 VAC or LP gas operation.

The system can be set by the user to be fully automatic

(AUTO mode is selected) or to operate on LP gas only

(AUTO mode is off).

On 3-way models, the control system can manually be set

to DC mode (DC operation). The DC mode overrides all

other operating modes.

The refrigerator controls will work down to 9.6 VDC.

PURGING AIR FROM THE LINES

If the refrigerator has not been used for a long time - or -

the LP tanks have just been relled, air may be trapped in

the supply lines. To purge the air from the lines, turn the

refrigerator off and on by pressing the ON/OFF button. If

the ame is not lit within 45 seconds, turn the refrigerator

off and back on again. This procedure can be repeated 3 to

4 times. If repeated attempts fail to start the LP gas operation, check to make sure that the LP gas supply tanks are

not empty and that all manual shutoff valves in the lines

are open. If the problem persists, turn the refrigerator off

and take it to a Service Center.

3

Page 4

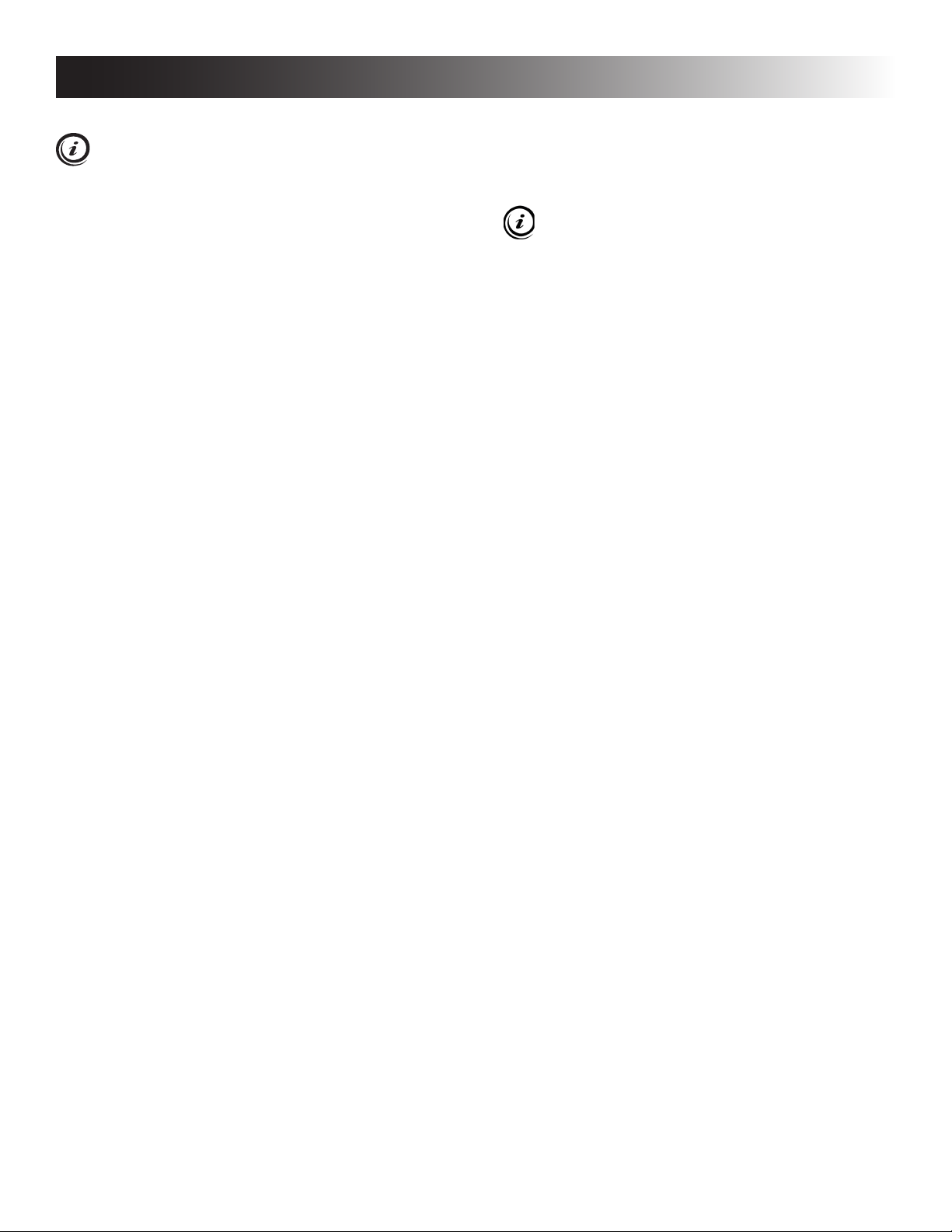

B

C F

A C GE F

REFRIGERATOR OVERVIEW

CONTROL PANEL

RM2351, RM2451, RM2551, DM2652 & DM2852

A B

1. ON/OFF button (main power)

2. AUTO/GAS mode selector

button

AUTO

ON

1 2

OFF

GAS

CHECK

AUTOMATIC REFRIGERATOR TEMPERATURE CONTROL

RM2354, RM2454, RM2554 & DM2663

A D E

COLD

ON

DC

AUTO

1 2

1 2 3 4

OFF

AC

GAS

CHECK

DM2662, DM2862 & NDM1062

A D

A. AUTO mode indicator lamp

B. CHECK indicator lamp

(GAS mode only)

1. ON/OFF button (main power)

2. DC mode selector button

3. AUTO/GAS mode selector

button

4

COLDEST

5

3

4. Temperature selector button

A. DC mode indicator lamp

B. AC mode indicator lamp

C. GAS mode indicator lamp

D. AUTO mode indicator lamp

E. CHECK indicator lamp

(GAS mode only)

F. Temperature indicator lamps

1. ON/OFF button (main power)

2. AUTO/GAS mode selector

button

3. Temperature selector button

ON

AUTO

COLD

1 2

3

4

5

21

OFF

B C

AC

GAS

CHECK

E

NDM1062

B

AES

ON

1 2 3 4 5

OFF

AUTO

AC

GAS

CHECK

D

COLD

1

2

345

COLDEST CLC

4

COLDEST

3

LAC

A. AUTO mode indicator lamp

B. AC mode indicator lamp

C. GAS mode indicator lamp

D. CHECK indicator lamp

E. Temperature indicator lamps

1. ON/OFF button (main power)

2. AES/AUTO/GAS mode

selector button

3. Temperature selector button

4. Climate control button

5. Low ambient control button

A. AC mode indicator lamp

B. AES/AUTO mode indicator lamp

C. GAS mode indicator lamp

D. CHECK indicator lamp

E. Temperature indicator lamps

F. Climate control indicator lamp

G. Low ambient control indicator

lamp

Page 5

REFRIGERATOR OVERVIEW

MODES OF OPERATION

AUTO MODE - AES/AUTO MODE

When operating in AUTO - AES/AUTO mode, the AUTO

- AES/AUTO mode indicator lamp is illuminated. The control system will automatically select between AC and GAS

operation. AC has priority over GAS. Should AC become

unavailable, the system automatically switches to GAS.

As soon as AC becomes available again, the control will

switch back to AC regardless of the status of the GAS

operation.

If the CHECK indicator lamp is illuminated the controls

have failed to ignite the burner in the GAS mode. To restart an ignition attempt with the CHECK lamp illuminated

(or to turn off the CHECK lamp), press the ON/OFF button

OFF and back ON again. The control system activates

the ignition system and makes three attempts to light the

burner for a period of approximately 45 seconds at two

minutes interval. Should 120 VAC become available while

the CHECK indicator lamp is on, the CHECK lamp will not

turn off until the ON/OFF button is pressed OFF and then

ON again.

GAS MODE

RM2351, RM2451, RM2551, DM2652 & DM2852:

When operating in GAS mode, the AUTO mode indicator

lamp will be off.

RM2354, RM2454, RM2554, DM2662, DM2663, DM2862 &

NDM1062: When operating in GAS mode, the GAS Mode

indictor lamp is illuminated.

This mode provides LP gas only. The control system acti-

vates the ignition system and attempts to light the burner

for a period of approximately 45 seconds at two minutes

interval. If unsuccessful, the CHECK indicator lamp will

illuminate.

To restart GAS operation, press the ON/OFF button to

OFF and then back ON. The control system attempts a

new ignition sequence.

LIMP MODE OF OPERATION

In the event of a failure of a major operating component,

the control system will continue to operate the cooling

system.

RM2351, RM2451, RM2551, DM2652 & DM2852

If the control can not read the temperature sensor and

control the preset temperature, the control will run the

cooling unit continuously at the energy source available.

The refrigerator will continue to operate in this mode indenitely - or - until a new sensor is installed and the system reset.

RM2354, RM2454, RM2554, DM2662, DM2663, DM2862 &

NDM1062

Two modes of operation can occur:

1) The rst limp mode of operation will execute if the

display module becomes non functional. The control

system reverts to full automatic operation selecting

the best energy source available with AC, DC (3way only) and GAS priority. The temperature setting

is maintained at the mid position. The power module

will continually attempt to reestablish operation of the

display module.

2) The second limp mode of operation will execute when

a failure of the temperature sensing device or associated electronic circuitry occurs. If this should happen,

the control system operates on the energy source selected via the control panel. The cooling unit runs continuously on the selected energy source. The refrig-

erator continues to operate in this mode indenitely or

until a new sensor is installed and the system is reset.

DC MODE

RM2354, RM2454, RM2554 & DM2663

When operating in DC mode (3-way models only), the DC

mode indicator lamp is illuminated and all other lamps

are off. To select another operating mode, turn off the DC

mode by pressing the DC selector button. The DC lamp

is turned off.

When there is no charging of the house battery, switch to

AUTO mode or GAS mode since running the refrigerator on

12 VDC will quickly drain the battery.

5

Page 6

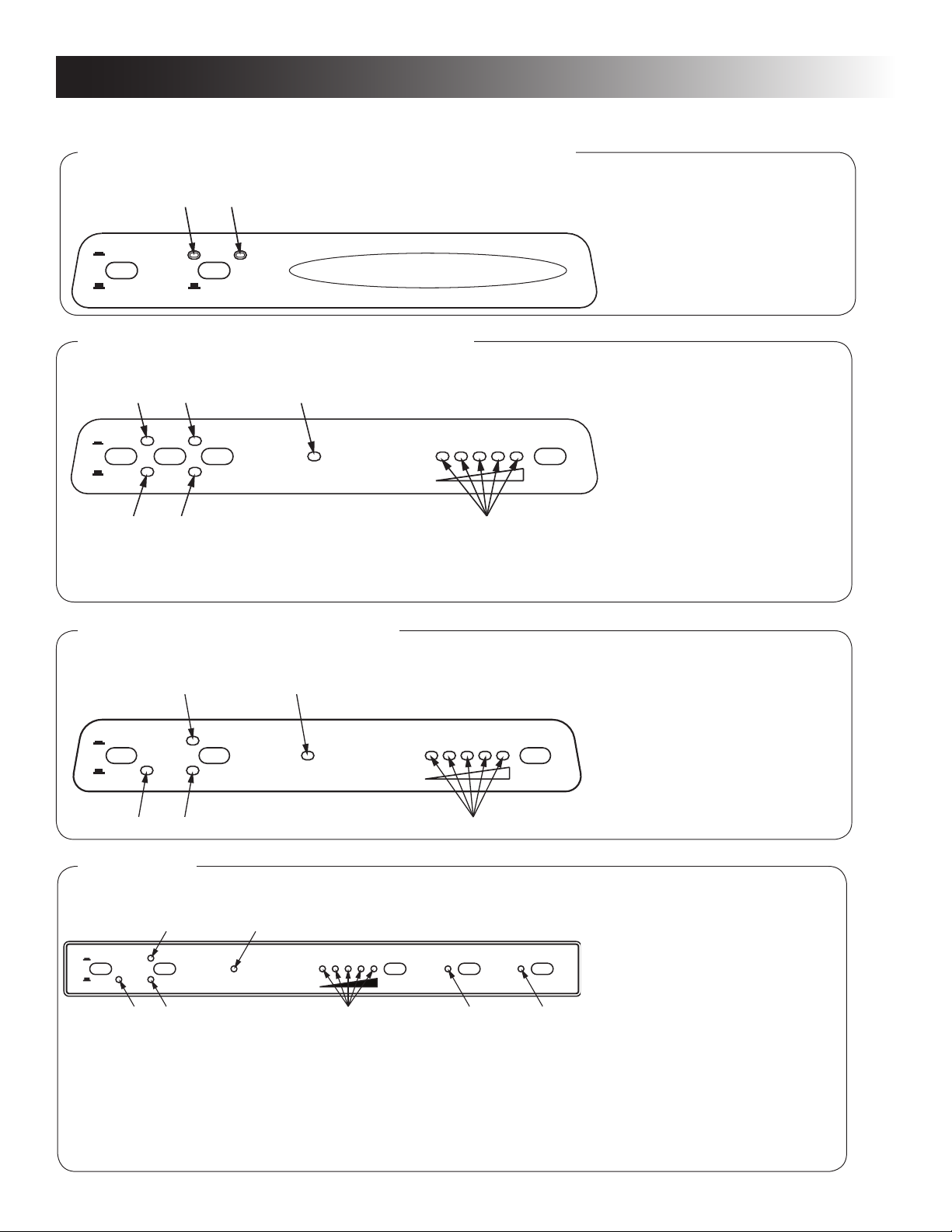

INSTRUCTIONS FOR USE

STARTING THE REFRIGERATOR

FIRE HAZARD. When the RV has not been

used for some time, make sure that the path

between the burner jet and the burner tube

has not been obstructed before lighting the

LP gas burner. Failure to obey this warning

could cause a re resulting in death or serious injury.

FIRE OR EXPLOSION HAZARD. When refueling or parked near gasoline pumps shut off all

LP gas appliances. Failure to obey this warning could cause a re or explosion resulting

in death or serious injury

LP GAS EQUIPMENT ASSEMBLY

SOLENOID VALVE

BURNER MOUNTING SCREWS

INLET FITTING

MANUAL SHUTOFF VALVE

Shown in open position

PRESSURE TEST PORT

BURNER JET

BURNER TUBE

SPARK ELECTRODE

- DC mode (3-way models only)

Press the DC mode indicator button. The DC

lamp will be turned on. To select AUTO or GAS

mode, turn off the DC mode by pressing the

DC mode selector button. The DC lamp will

then be turned off.

ADJUSTING THE THERMOSTAT

RM2354, RM2454, RM2554, DM2662, DM2663, DM2862

& NDM1062

The thermostat controls both the gas and electric operation, thereby eliminating the necessity of resetting each

time a different energy source is employed. After the initial

start-up, the thermostat should be adjusted to the desired

temperature setting.

1. Press the temperature selector button until the

lamp at the desired setting is illuminated.

RM2351, RM2451, RM2551, DM2652 & DM2852

The temperature is controlled by a factory preset temperature setting.

COLD WEATHER LOW AMBIENT

CONTROL

NDM1062

The refrigerator is equipped with an exclusive feature that

allows for trouble-free operation in low ambient temperature (like below 50°F) for extended periods of time. Once

the outdoor temperature is above 50°F, the low ambient

switch should be turned off.

1. Turn the Low ambient control switch to I (ON).

1. Check that all the manual gas valves are in the

ON position.

2. Make sure that a continuous 12 VDC supply is

available for the electronic control to function.

3. Press the ON/OFF button.

4. Select operation mode:

- AUTO - AES/AUTO mode (AC and Gas)

Press the AUTO/GAS - AES/AUTO/Gas mode

selector button (if not already on). The illuminated lamp indicates the selected mode.

(If the CHECK indicator lamp is illuminated,

see REFRIGERATOR OVERVIEW > MODES

OF OPERATION > AUTO MODE - AES/AUTO

MODE for further information.)

- GAS mode (LP gas operation only)

Press the AUTO/GAS - AES/AUTO/Gas mode

selector button to turn off the AUTO mode (if

not already off).

(Within 45 seconds the burner should be ignited and operating normally. If not, see REFRIGERATOR OVERVIEW > MODES OF

OPERATION > GAS MODE for further information.)

The Low ambient control

switch is located beneath

the top decoration panel

that houses the control

panel.

2. Press the LAC button. The indicator lamp will

illuminate.

AES

ON

OFF

6

AUTO

AC

GAS

CHECK

COLD

1

2

COLDEST CLC

345

LAC

Page 7

INSTRUCTIONS FOR USE

EXTREME COLD WEATHER

OPERATION

Refrigerator performance may be reduced in extremely

cold (subzero) temperatures. This temporary condition is

normal for absorption refrigerators and does not indicate

product failure. In the event that performance is reduced

in such conditions, turn the refrigerator off. As ambient

temperatures rise, please restart your refrigerator according to instructions before requesting service.

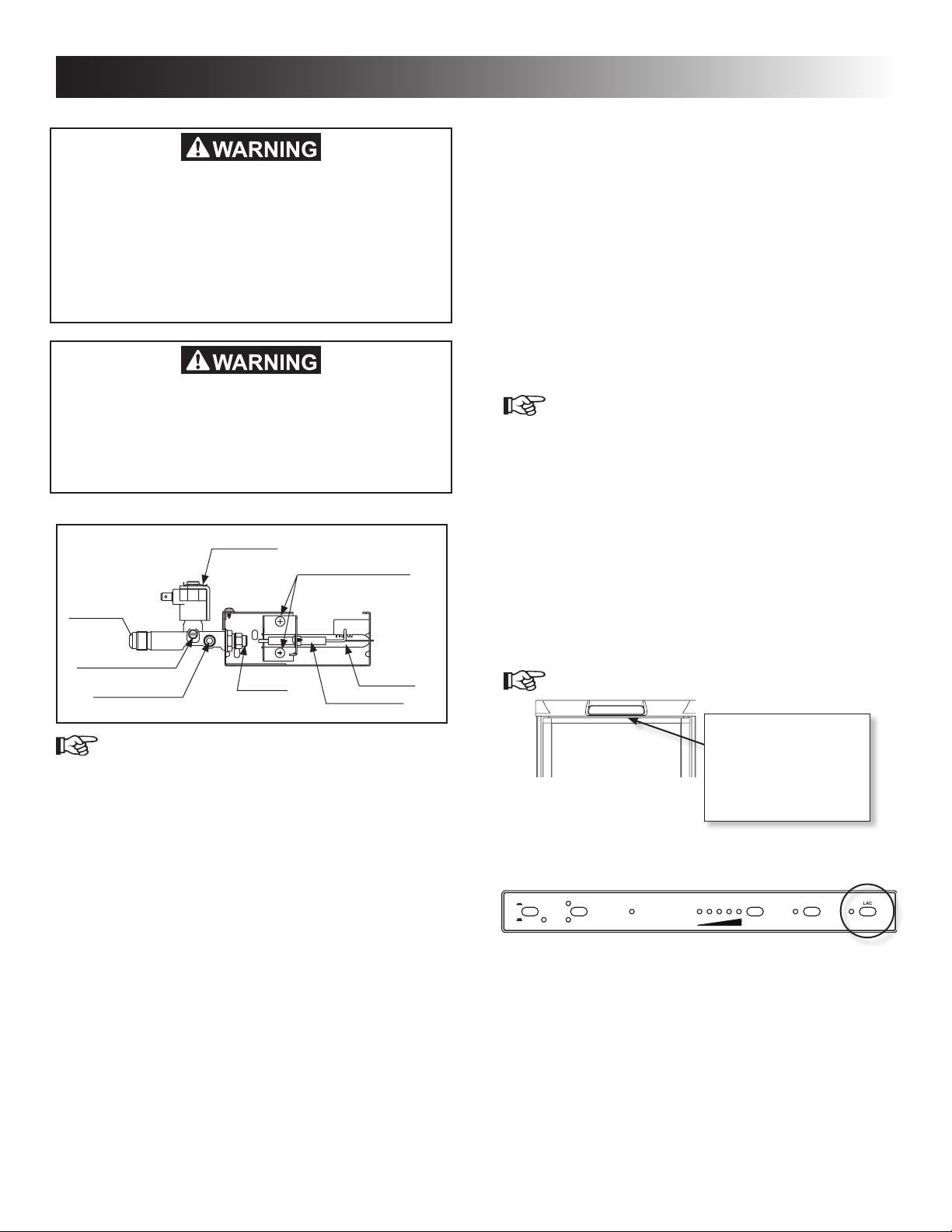

CLIMATE CONTROL SYSTEM

NDM1062

During the summer months of high temperature and

humidity, the metal frame between the freezer and fresh

food compartments may have water droplets forming. The

number of water droplets will increase if the vehicle is not air

conditioned during these months. The refrigerator comes

standard with a 12 VDC climate control that will evaporate

the water droplets when they form. The climate control can

be left on continuously or used only when temperatures

require it. Note that when turned on, the climate control

will draw 12 VDC power continuously. Turn it off when a

charging source is not available.

1. Turn the climate control switch to I (ON).

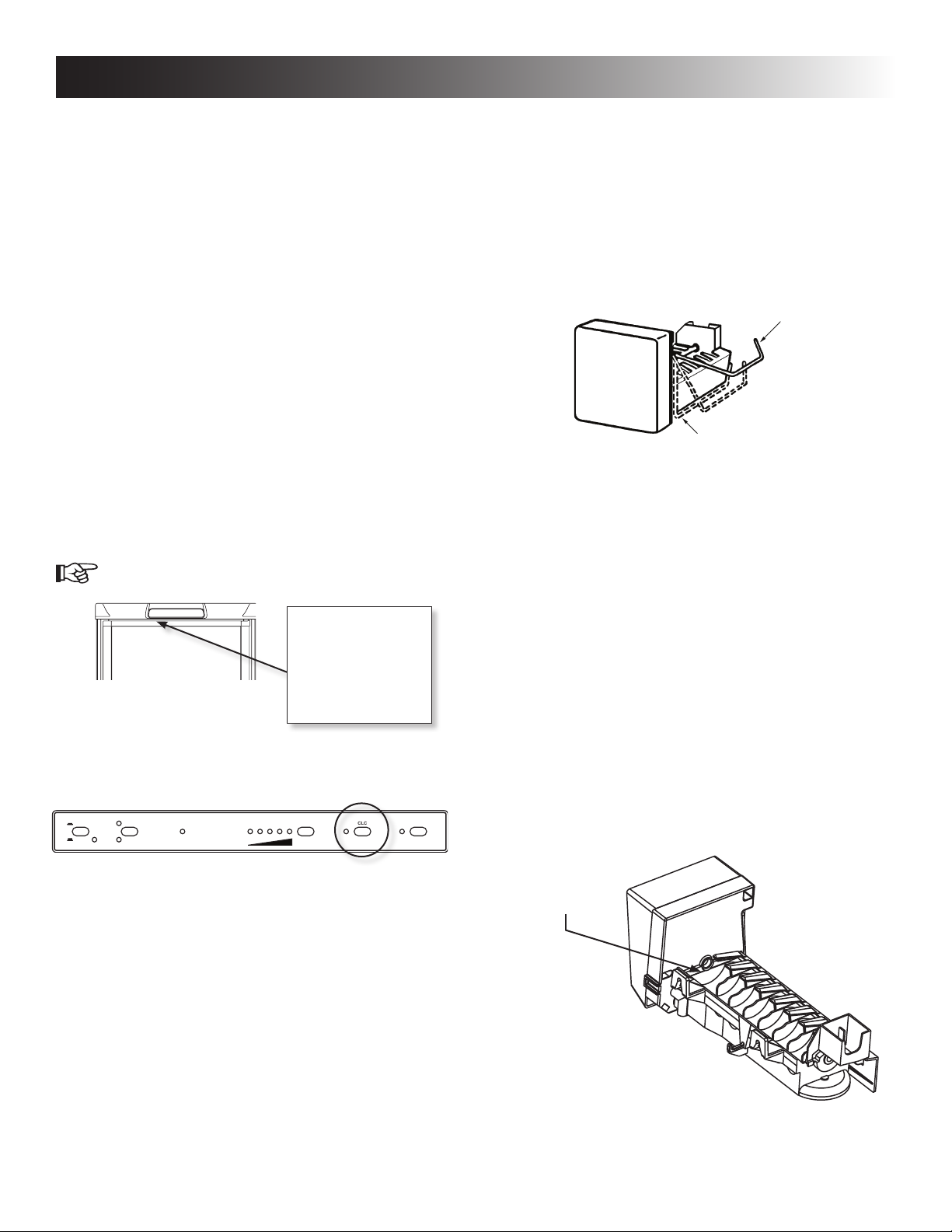

OPERATING THE ICE MAKER

(ICE MAKER MODELS ONLY)

Before the ice maker can operate, make sure that:

• The refrigerator is connected to 120 VAC .

• The water valve supplying the refrigerator is turned on.

• The ice level bail arm is in its fully down position.

Keep bail arm in the up (OFF) position until water is present at the ice maker.

Ice level

bail arm

Down

position

When the ice maker thermostat senses the preset tempera-

ture for the ejection of the ice cubes, the ngers will start to

rotate, dumping any ice cubes and lling the mold with water.

When the storage container is full, the bail arm will come

in contact with the ice cubes. The bail arm cannot return

to the full down position and the ice production is stopped

until the bin is emptied, or ice cubes are removed.

The Climate control

switch is located beneath the top decoration panel that houses

the control panel.

2. Press the CLC button. The indicator lamp will

illuminate.

AES

ON

OFF

AUTO

AC

GAS

CHECK

COLD

1

345

2

COLDEST CLC

To prevent water from splashing out of the mold assembly

while travelling in your recreational vehicle, raise the bail

arm to the full UP/OFF position about 1-1/2 hours before

departing. This will allow the water in the mold to freeze.

WATER SUPPLY

The water supply system must have a minimum pressure

of 15 pounds per square inch gauge (psig). A 1/4” diameter water line to the water valve should be used at the rear

of the refrigerator. The water line must have a manual

shutoff valve placed where it is easily accessible.

LAC

The maximum water level is represented by a thin line. It

is essential that the water level does not exceed this line!

Maximum

water level

If necessary,change the water ow by adjusting the water

supply. For instructions, see ADJUSTING THE SIZE OF

CUBES.

7

Page 8

INSTRUCTIONS FOR USE

ADJUSTING THE SIZE OF CUBES

If the ice maker was cleaned and drained, no ice

cubes will be dumped into the bin during the rst

cycle.

The rst few cycles may have small cubes due to air

trapped in the water lines. The rst container of ice cubes

should be dumped if the water system has been winterized or not used for several weeks. Once the ice maker has run through several cycles and if cubes are too

small or sticking together, adjustment is necessary on the

amount of water entering the mold.

TO ADJUST THE SIZE OF CUBES, FOLLOW THESE

STEPS:

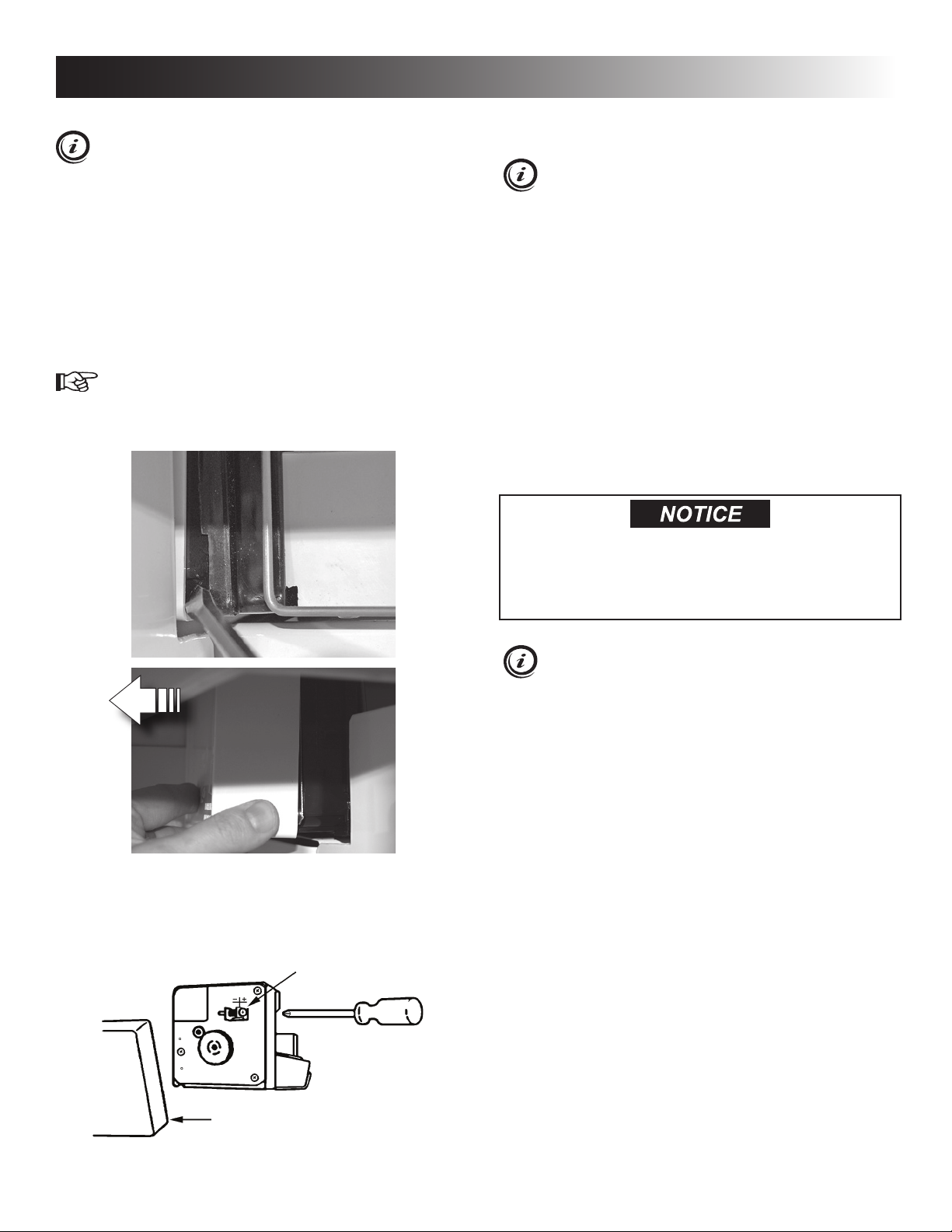

1. Remove the protective cover from the ice mak-

er mechanism. Using a at-head screwdriver,

place the tip of the screwdriver in the slot. Twist

the screwdriver blade gently to loosen the cover.

3. Turn the screw clockwise to decrease the cube

size or if the mold is overlling, and the cubes

are stuck together.

To prevent overlling, do not turn the adjustment

screw more than one revolution at a time. Allow

the ice maker to cycle several times before another

adjustment is made. Be sure to replace the protective cover on the cycle after the adjustments are

complete.

TURNING OFF THE REFRIGERATOR, AND

WHEN NOT IN USE

You can turn off your refrigerator by pressing the main

power ON/OFF button found on the control panel to the

OFF position. This will shut off all power to the refrigerator,

including DC power to the refrigerator.

If the refrigerator will not be in operation for an extended

period of time or put into winter storage it should be emp-

tied, defrosted, cleaned, and the doors placed in the airing

position. If ice cube trays are in use, they should also be

dried and kept outside the cabinet.

This refrigerator is intended for continuous

use. Do not allow it to run unattended when

there is a risk for loss of electricity or fuel.

Food spoilage could occur.

2. Locate the adjusting screw under the protective cover. Turn the screw counterclockwise to

increase the size of cubes.

Adjusting screw

The refrigerator’s control system still consumes a

few milliamps even if it is turned off. If your RV is

being put into winter storage, it is recommended to

either put your RV batteries on a battery charger or

turn off the vehicle’s main 12 VDC switch. This will

prevent the RV battery from discharging.

Cover

8

Page 9

STORAGE COMPARTMENTS

FIRE OR EXPLOSION HAZARD. Do not store

or use gasoline, oil or gasoline soaked rags,

or other ammable vapors and liquids in the

service area behind the refrigerator or in the

vicinity of this or any other gas appliance.

Failure to obey this warning could cause a

re or an explosion resulting in death or serious injury.

REFRIGERATOR VOLUME

MODEL TOTAL REFRIGERATED

VOLUME (CU. FT.)

RM2351& RM2354 3

RM2451& RM2454 4

RM2551 & RM2554 5

DM2652, DM2662 & DM2663 6

DM2852 & DM2862 8

NDM1062 9.2

FOOD STORAGE COMPARTMENT

• Cool the refrigerator before placing any food inside.

Never put hot food or drinks into the refrigerator - cool

them rst.

• The food storage compartment is completely closed and

unventilated, which is necessary to maintain the required

low temperature for food storage. Consequently, foods

having a strong odor or those that absorb odors easily

should be covered.

• Vegetables, salads, etc. should be covered to retain

their crispness.

• The coldest positions in the refrigerator are under the

cooling ns and at the bottom of the refrigerator. The

warmer areas are on the upper door shelves. This

should be considered when placing different types of

food in the refrigerator.

• Arrange all food in the unit to allow for free air circulation. Do not overpack because a stuffed refrigerator

must work harder and will have higher cabinet temperatures.

• Do not leave the unit’s door open any longer than necessary. This will reduce frost formation and increase the

efciency of the refrigerator.

FROZEN FOOD STORAGE

COMPARTMENT

This compartment is not designed for deep or quick freezing of food.

• To prevent food from drying out, keep it in covered

dishes, containers, plastic bags or wrapped in aluminum foil.

• Meat or sh, whether raw or prepared, can be stored in

the frozen food storage compartment provided they are

precooled rst in the refrigerator. They can be stored

about three times longer in the frozen food compartment as compared to the fresh food compartment.

• Quick frozen soft fruits and ice cream should be placed

in the coldest part of the compartment, which is at the

bottom of the aluminum liner.

• Frozen vegetables, may be stored in any part of the

compartment.

• To prevent frost buildup, which can reduce the efcien-

cy, wipe excess moisture off items being placed in the

compartment.

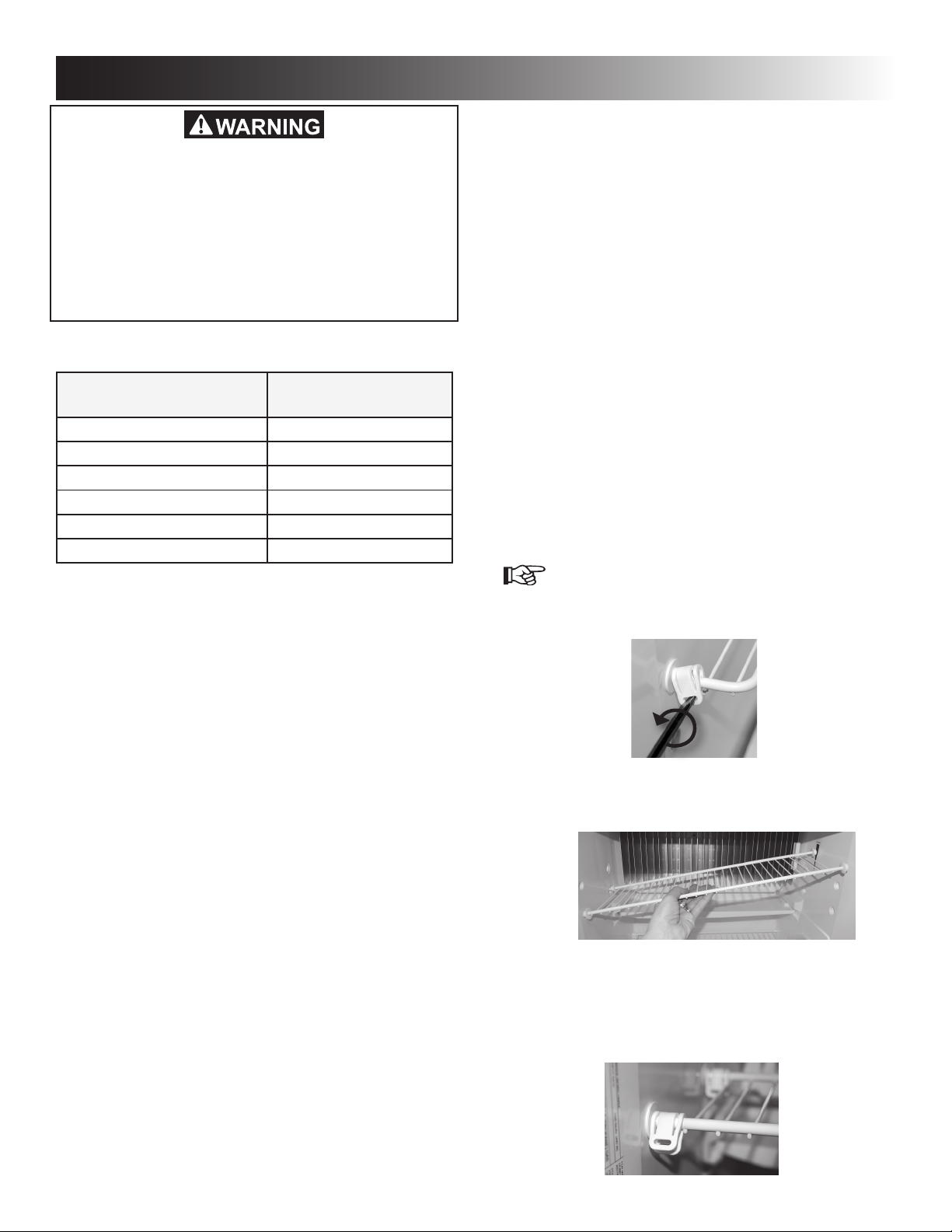

REMOVING AND REPLACING THE

SHELVES

1. Remove the shelf locks by inserting the tip of a

at bladed screwdriver into the slot of the locks.

Turn the screwdriver counterclockwise and then

remove the shelf locks from the wire shelf.

2. Slide the shelf to the left until bushings disengage, then tilt the shelf to one side at an angle

while pulling forward.

3. Reposition the shelf in the desired location. Insert the ends of the wire shelf on the left-hand

side and slide the shelf into the holes on the

right-hand side.

4. Slide the plastic plugs into the holes of the wall.

5. Snap the shelf locks back onto the wire shelf.

9

Page 10

STORAGE COMPARTMENTS

ICE CUBES

Ice cubes can be made in the freezer compartment. For

faster freezing, place trays in direct contact with the bottom

of the freezer compartment.

PRODUCT CARE

DEFROSTING

1. Shut off the refrigerator by pressing the main

power ON/OFF button (OFF position).

2. Empty the refrigerator.

3. Leave the cabinet and freezer doors open and

make sure the drip tray is in place under the

nned evaporator.

Defrosting time can be reduced by lling ice trays

with hot water and placing them in the freezer compartment.

RM2351, RM2454, RM2554, DM2662, DM2663, DM2862

& NDM1062

Ice will be made more rapidly if the thermostat is set at its

highest position, but be sure to move the thermostat back

to normal setting when ice is formed; the refrigerator might

otherwise become too cold.

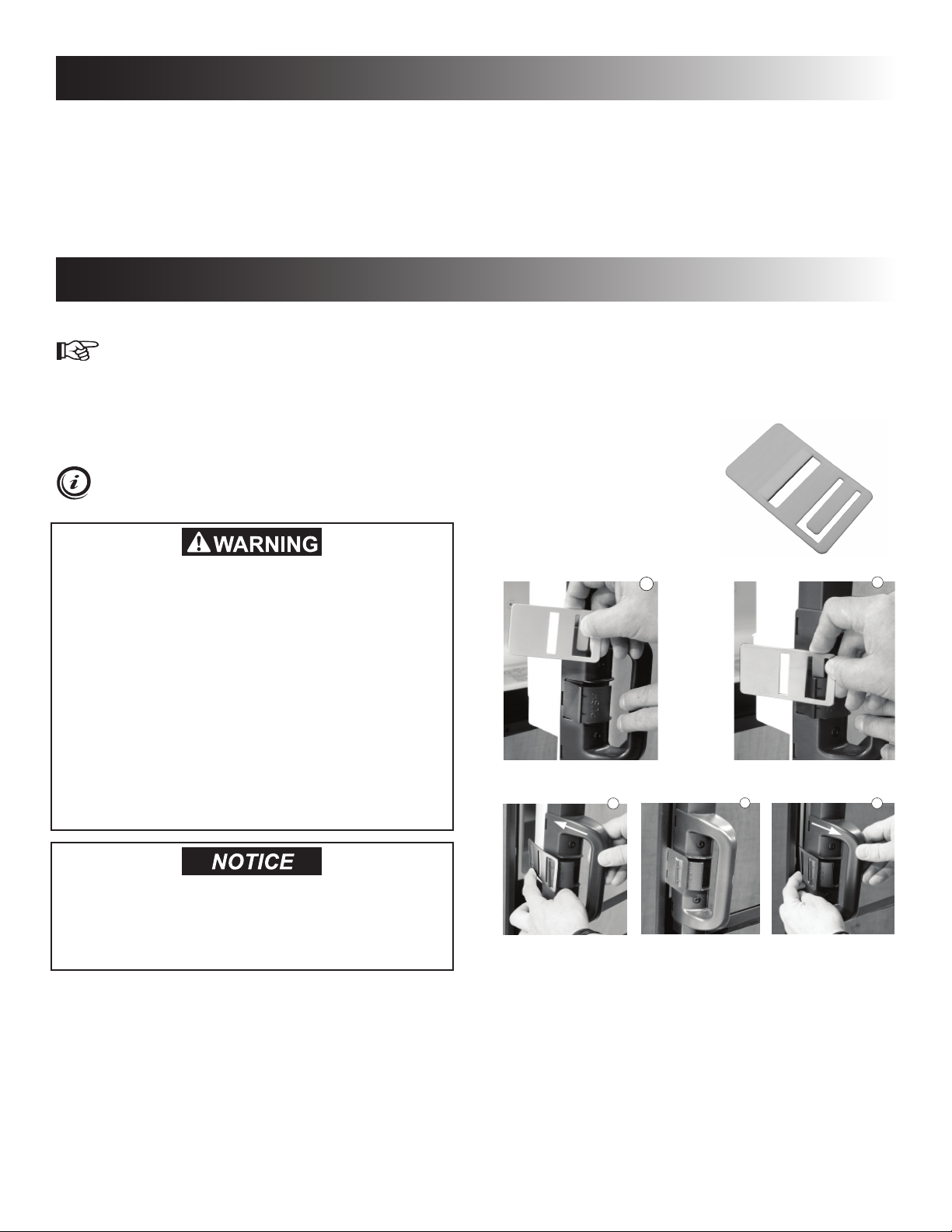

AIRING POSITION

DM2652, DM2662, DM2663, DM2852 &

DM2862

Use the airing position card

to keep the doors ajar if the

refrigerator is put in storage

or will not be used for an extended period of time.

FIRE AND INHALATION HAZARD. Do not use

a knife, ice pick, or any other sharp tool to

remove frost from the freezer compartment.

Failure to obey this warning could cause a

leak in the ammonia cooling system which

could lead to a re hazard resulting in death

or serious injury.

An ammonia leak also poses an inhalation

hazard, and could cause chemical burns to

the skin and eyes. Exposure to a high concentration of ammonia could result in death

or serious injury.

Do not use a hot air blower to remove frost

from the freezer compartment. Permanent

damage could result from warping the metal

or plastic parts.

4. When all the frost has melted, dry the interior

with a clean cloth and turn the refrigerator back

on.

RM2354, RM2454, RM2554, DM2662, DM2663, DM2862

& NDM1062

5. Set the thermostat to the coldest setting for a

few hours. Then, reset the thermostat to the

desired setting, usually at mid setting. Replace

food after refrigerator has reached appropriate

cool temperature.

1

3

4

2

5

10

Page 11

PRODUCT CARE

CLEANING

Always keep the refrigerator clean. Cleaning the refrigerator is usually done after it is defrosted or put into storage.

Use a lukewarm, weak soda solution to clean the interior

liner of the refrigerator. Use warm water only to clean the

nned evaporator, gasket, and shelves. Do not spray liquids near electrical outlets, connections, or the refrigerator

components.

After cleaning the interior liner/evaporator ns, make sure

thermistor bulb and thermistor bracket are properly positioned. See “Troubleshooting” on page 14.

Do not use strong chemicals or abrasives to

clean these parts, as the protective surfaces

will be damaged.

To keep the refrigerator operating efciently, periodic inspection and cleaning of several components once a year

is recommended:

• Check the lower vent, upper vent and area between

these openings for any obstructions such as bird/insect

nests, spider webs, etc.

• Make sure the refrigerator area is free from combusti-

ble material, gasoline and other ammable vapors or

liquids.

STORAGE PROCEDURE/ WINTERIZING THE REFRIGERATOR

(ICE MAKER MODELS ONLY)

The refrigerator is equipped with a heater tape wrapped

around the water solenoid valve and outlet water tube.

During cold weather operation below 32°F/0°C the automatic temperature switch will turn the heater tape on

automatically.

If the RV will not be in use for an extended period of time

or put into storage:

• Drain the RV water system.

• Disconnect the water lines from the inlet and outlet

sides of the water valve. Drain the lines into a cup and

allow the lines to dry.

• The ice maker should be drained and dried. Note that

this procedure must be performed by a qualied service technician.

• Using a lukewarm soda solution, clean the interior

liner of the refrigerator. Clean the nned evaporator

and shelves. Use warm water only and never strong

chemicals or abrasives since these can damage the

protective surfaces.

• Place doors in the airing position.

FIRE OR EXPLOSION HAZARD. Do not store

or use gasoline, oil or gasoline soaked rags,

or other ammable vapors and liquids in the

service area behind the refrigerator or in the

vicinity of this or any other gas appliance.

Failure to obey this warning could cause a

re or an explosion resulting in death or serious injury.

• If accessible, clean the coils on the back of the refrigerator. Use a soft bristled brush to dust off the coils.

11

Page 12

MAINTENANCE & SERVICE

To keep the refrigerator working properly, a qualied service technician should, at least once a year,

inspect the connections, the control system, the LP

gas pressure and ue bafe.

FIRE AND INHALATION HAZARD. If the refrigerator stops working -or- if it emits an ammonia smell, immediately turn the refrigerator

off, leave the vicinity, and contact a Service

Center.

A high concentration of ammonia refrigerant could cause an inhalation hazard, could

cause chemical burns to the skin and eyes,

and could cause a re resulting in death or

serious injury.

REPLACING THE FUSES

2-way models are equipped with 2 fuses - one for the

refrigerator control system and one for the AC heater.

3-way models are equipped with 3 fuses - two fuses in

the power module and one in-line blade fuse.

Control system 3 A

AC heater 5 A

12 VDC heater 30 A

REPLACING THE FUSES

POWER MODULE

To replace the fuses, follow these steps:

1. Turn off the refrigerator and unplug the power

cord and disconnect the 12V wires.

2. Remove the power module cover.

3. Snap the fuse out of the fuse holder and t the

new fuse in to the fuse holder.

4. Put back the power module cover.

3. Replace the fuse.

4. Put the holder back together.

PERIODIC MAINTENANCE

To be performed by a qualied service technician

only.

CHECKING THE LP GAS CONNECTIONS

1. Check all connections in the LP gas system (at

the back of the refrigerator) for gas leaks. The

LP gas supply must be turned on.

2. Apply an approved leak detection solution to all

LP gas connections. The appearance of bubbles indicates a leak and should be repaired immediately!

FIRE OR EXPLOSION HAZARD. Never use an

open ame to check for gas leaks. Failure to

obey this warning could cause a re or explosion resulting in death or serious injury.

CHECKING THE CONTROL SYSTEM

Check the control system by connecting/disconnecting the

120 VAC power, starting/stopping the engine, etc.

DM2652 (OPTIONAL FAN), DM2852 (OPTIONAL FAN),

DM2862 (OPTIONAL FAN) & NDM1062

INLINE FUSE

The inline fuse for the power vent fans is connected to

the 12V DC socket.

To replace the inline fuse, follow these steps:

1. Disconnect 12V DC power.

2. Open the fuse holder.

12

Page 13

MAINTENANCE & SERVICE

CLEANING THE BURNER

1. Turn off the refrigerator

2. Unplug the power cord from the 120 VAC outlet. Disconnect the wires or shut off the 12 VDC

power supply to the refrigerator.

3. Turn off the manual shut off valve.

4. Remove cover from burner housing.

5. Clean the burner tube with a brush. Blow out the

burner with compressed air.

FIRE HAZARD. Never use a wire or pin to clear

obstructions from the burner jet as damage

will occur. Do not attempt to adjust the burner

jet. Failure to obey this warning could cause

a re resulting in death or serious injury.

REFRIGERATOR REMOVAL / DISPOSAL

To be performed by a qualied service technician

only.

See Installation Instructions for refrigerator removal /

replacement procedure, and for recycle information.

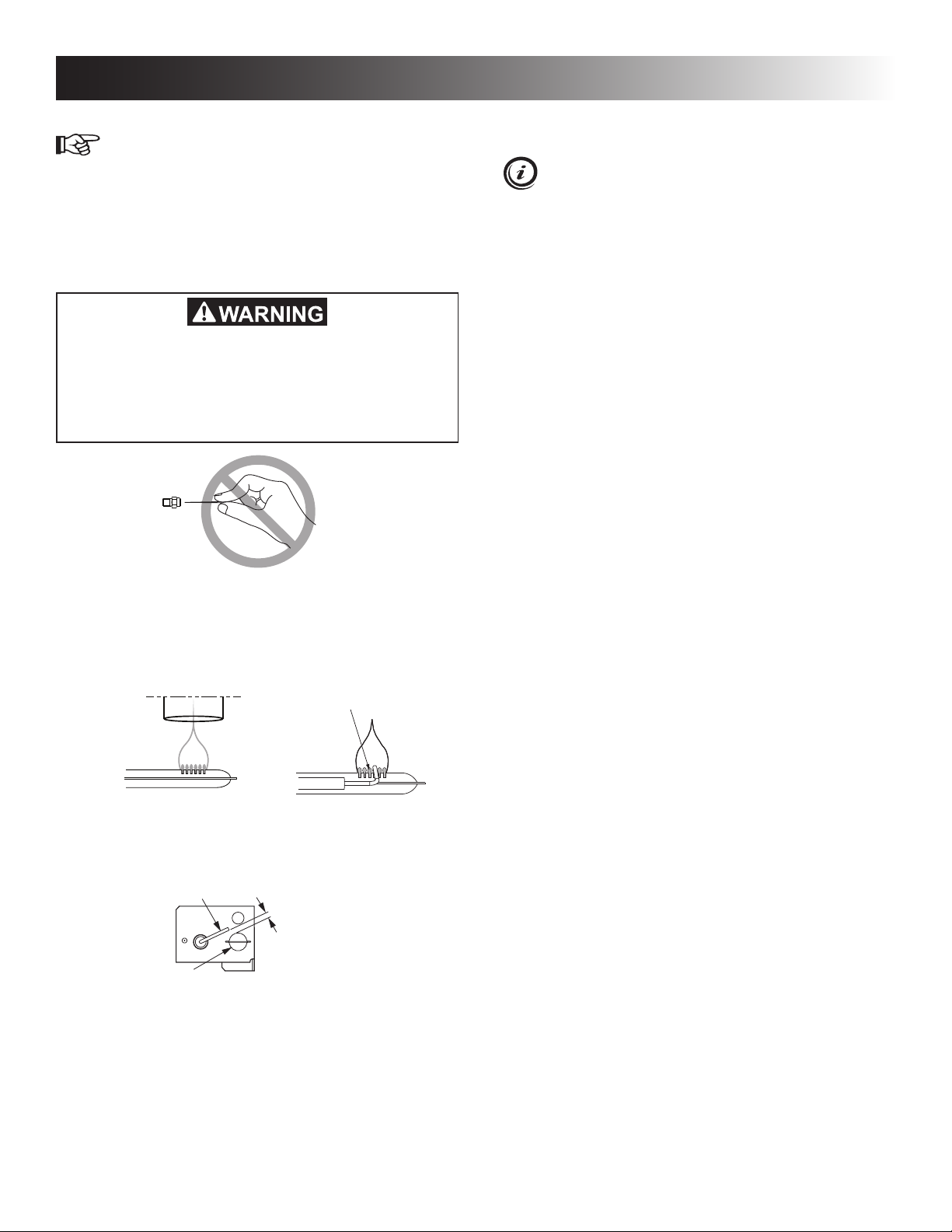

6. Verify that the burner jet slots are centered un-

der the ue tube.

7. Be sure to check the burner ame for proper appearance. The ame should be clear blue over

the slots of the burner.

Clear Blue Color

Of Flame

Slots Centered

Under Flue Tube

8. Check the electrode for proper location and gap.

Adjustments may be made with needle nose pliers if necessary.

Electrode

Burner Tube

9. Turn on the manual gas shut off valve.

10. Examine all ttings for leaks. Use a commercial

non-corrosive bubble solution.

11. Connect the 120 VAC power cord.

12. Reconnect/Turn on the 12 VDC power.

13. Check LP gas safety shutoff.

1/8" to 3/16"

(3-5 mm)

13

Page 14

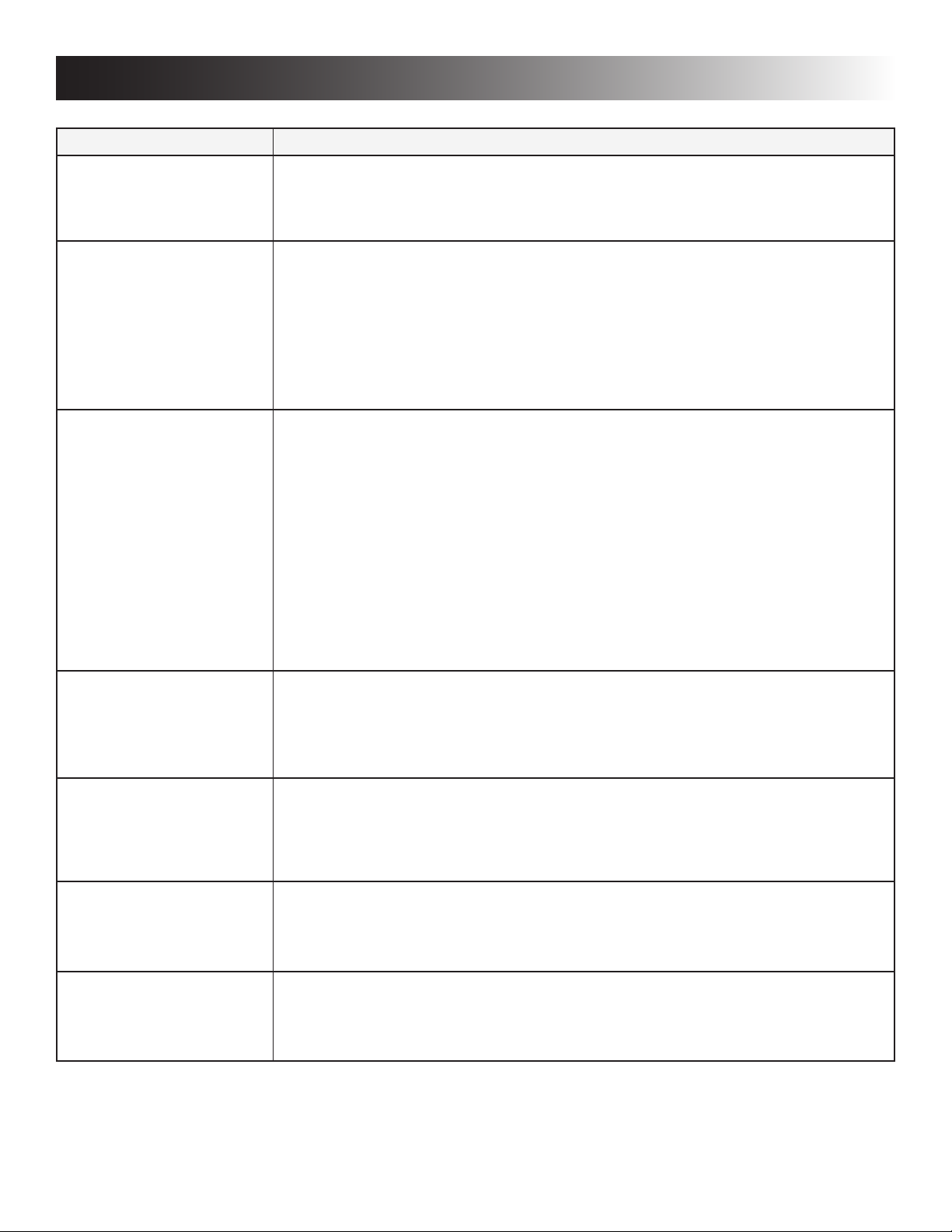

TROUBLESHOOTING

If you run into a problem, refer to the troubleshooting table below.

Symptom Check/Remedial action

Refrigerator stops cooling. • Immediately turn the refrigerator off and contact a Dometic dealer or Service Center.

NOTE! Do not leave it running for an extended period of time, and never try to solve the

problem by repeatedly restarting the refrigerator.

• Do not use the refrigerator until it has been repaired

Refrigerator emits an ammonia smell

• Immediately turn the refrigerator off at the front control panel.

• Do NOT open refrigerator doors.

• Open coach windows and doors (to air out the coach) and evacuate.

• Turn off manual LP gas valve at rear of refrigerator.

• Disconnect the 120 VAC power at rear of refrigerator.

• Contact a Dometic dealer or Service Center for repair.

• Do not use the refrigerator until it has been repaired.

Refrigerator or freezer is not

cold enough

Refrigerator does not work

on electric

The refrigerator does not

work in gas operation mode

• For refrigerators equipped with a thermostat, check the thermostat and adjust if

necessary.

• Is the plug rmly connected to the socket? Is the socket switched on?

Check the socket by plugging in another appliance.

• Is the refrigerator level? (Due to the nature of its operation it is important to keep an

absorption refrigerator level.)

• Door closing properly? Check the door gasket.

• Heavy frost build-up on evaporator ns? To prevent frost build-up do not leave the unit’s

door open longer than necessary.

• Over packed refrigerator? The unit will have to work harder if the refrigerator is stuffed,

and results in higher cabinet temperatures. Arrange the food in the unit to allow for free

air circulation.

• Is the plug rmly connected to the receptacle? Is the receptacle energized? Check the

receptacle by plugging in another appliance.

• Is there a power failure?

• Blown fuse. Turn refrigerator off and contact a Dometic dealer or Service Center for

repair.

• LP gas bottle empty? Change the gas bottle.

• Air in the gas line? Remove the air by repeating the ignition sequence.

• If problem resists, turn refrigerator off and contact a Dometic dealer or Service Center

for repair.

Refrigerator emits an odor

from fumes:

Refrigerator too cold • Dislocated thermistor bracket. Clip thermistor bracket to last n on right side of cooling

If the problem persists and the refrigerator is still not working properly, turn refrigerator off and contact your nearest Service Center. State the problem, model, product, and serial number. These details are stated on the data label inside the

refrigerator compartment.

• Dislocated or damaged burner. Turn refrigerator off and contact a Dometic dealer or

Service Center for repair.

• Dirty ue tube. Turn refrigerator off and contact a Dometic dealer or Service Center for

repair.

ange and center vertically on n.

• Dislocated thermistor bulb. Position thermistor bulb inside thermistor bracket groove

and center vertically in bracket.

14

Page 15

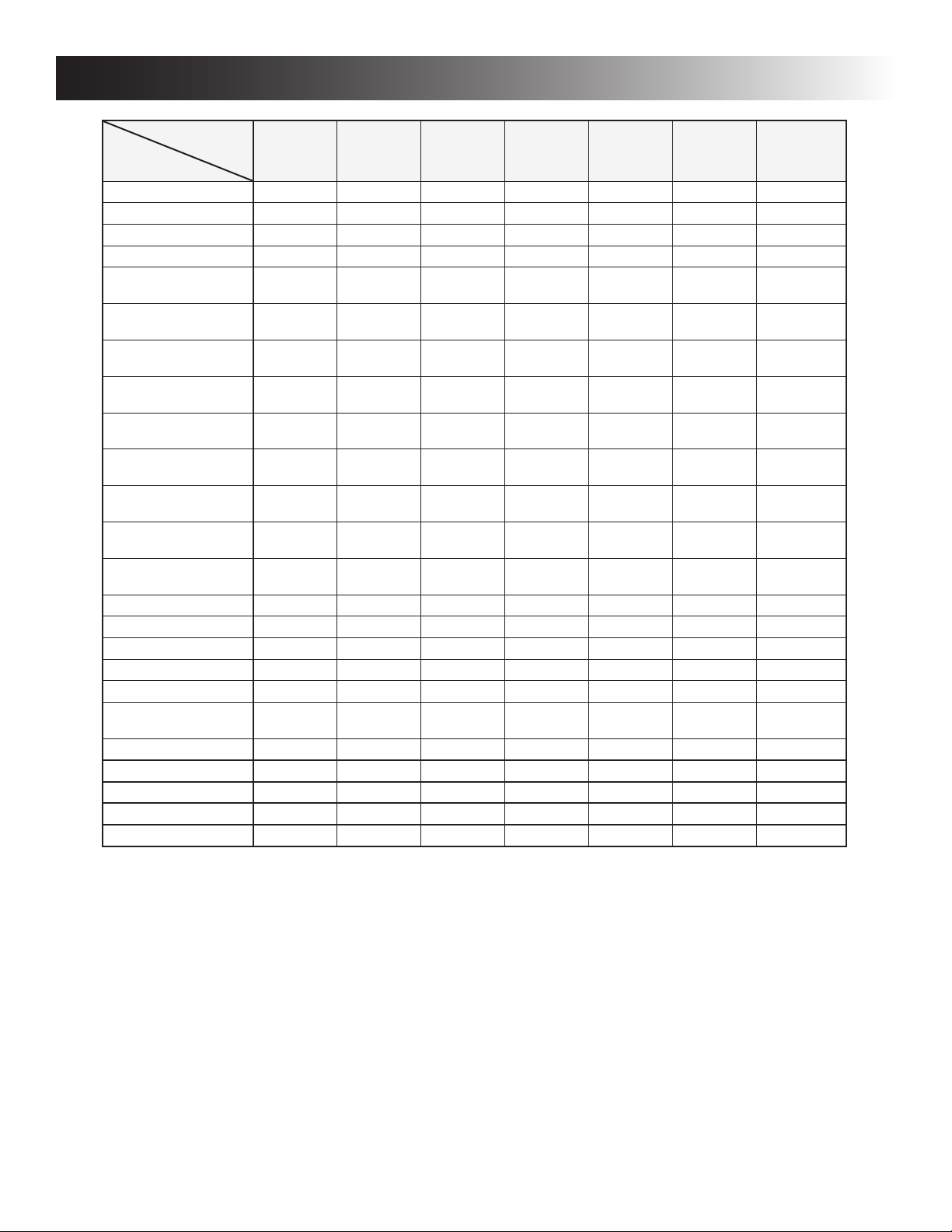

APPENDIX A - SPARE PARTS

MODEL

SPARE PARTS

Airing position card N/A N/A N/A N/A N/A N/A 3312986.403

Bafe 2007172022 2007172022 2932667013 2932667013 2932667021 2932667021 2932667039

Box 2932636018 2932636018 N/A N/A N/A N/A N/A

Box, vegetable N/A N/A N/A N/A 2932621010 2932621010 2932621010

Box, vegetable

(crisper), 2 pieces

Box, vegetable

(meat locker)

Burner

(with conductor)

Door reversing kit,

(light brown)

Door reversing kit,

(black)

Door reversing kit,

right-left (light brown)

Door reversing kit,

left-right (light brown)

Door reversing kit,

right-left (black)

Door reversing kit,

left-right (black)

Door shelf, lower N/A N/A 2932575018 2932575018 2932575018 2932575018 2932575018

Door shelf, (2 pieces) N/A N/A 2932576016 2932576016 N/A N/A 2932576016

Door shelf, (3 pieces) 2002261242 2002261242 N/A N/A 2932576016 2932576016 N/A

Door shelf, freezer N/A N/A N/A N/A N/A N/A 2932577014

Electrode 2932781012 2932781012 2932781012 2932781012 2932781012 2932781012 2932781012

Halogen lamp

(12V, 10W base G4)

Handle (black) N/A N/A 2932670025 2932670025 2932670025 2932670025 3851174023

Heater 175W, 12V N/A 3850646104 N/A 3850646104 N/A 3850646104 N/A

Heater 175W, 120V 3850644455 3850644455 3850644455 3850644455 3850644455 3850644455 N/A

Heater 275W, 12V N/A N/A N/A N/A N/A N/A N/A

Heater 325W, 120V N/A N/A N/A N/A N/A N/A 3850644422

RM2351 RM2354 RM2451 RM2454 RM2551 RM2554 DM2652

N/A N/A N/A N/A N/A N/A N/A

N/A N/A N/A N/A N/A N/A N/A

2930697079 2930697079 2930697079 2930697079 2930697079 2930697079 2930697079

385030401 385030401 N/A N/A N/A N/A N/A

385030402 385030402 N/A N/A N/A N/A N/A

N/A N/A 293275002 293275002 293275002 293275002 293275008

N/A N/A 293275003 293275003 293275003 293275003 293275009

N/A N/A 293275013 293275013 293275013 293275013 293275011

N/A N/A 293275014 293275014 293275014 293275014 293275012

N/A N/A N/A N/A N/A N/A N/A

15

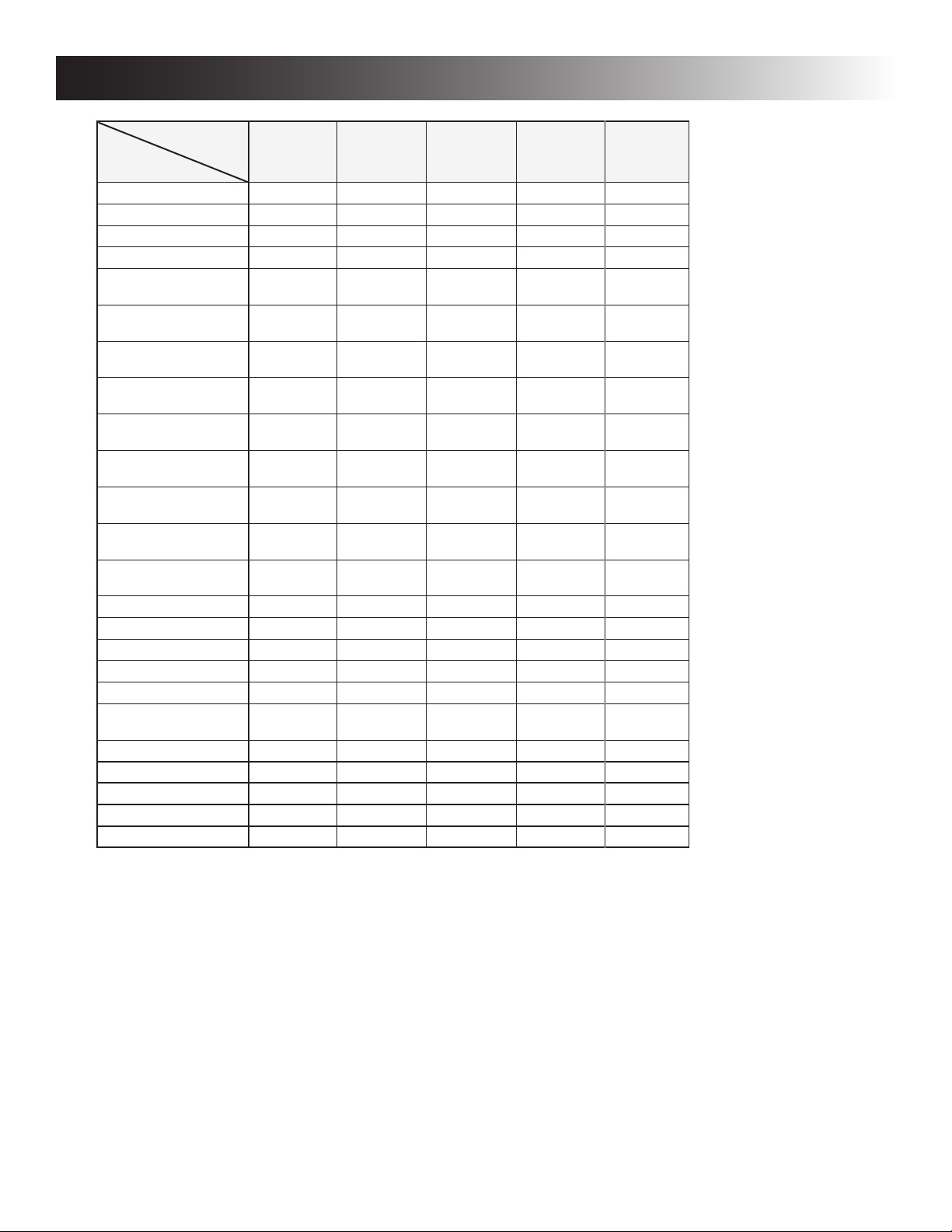

Page 16

APPENDIX A - SPARE PARTS

MODEL

SPARE PARTS

Airing position card 3312986.403 3312986.403 3312986.403 3312986.403 N/A

Bafe 2932667039 2932667039 2932667047 2932667047 2932667047

Box N/A N/A N/A N/A N/A

Box, vegetable 2932621077 2932621077 2932621010 2932621077 N/A

Box, vegetable

(crisper), 2 pieces

Box, vegetable

(meat locker)

Burner

(with conductor)

Door reversing kit,

(light brown)

Door reversing kit,

(black)

Door reversing kit,

right-left (light brown)

Door reversing kit,

left-right (light brown)

Door reversing kit,

right-left (black)

Door reversing kit,

left-right (black)

Door shelf, lower 2932575059 2932575059 2932575018 2932575059 2932575075

Door shelf, (2 pieces) 2932576065 2932576065 N/A N/A N/A

Door shelf, (3 pieces) N/A N/A 2932576016 2932576065 2932576081

Door shelf, freezer N/A N/A 2932577014 N/A N/A

Electrode 2932781012 2932781012 2932781012 2932781012 2932781012

Halogen lamp

(12V, 10W base G4)

Handle (black) 3851174023 3851174023 3851174023 3851174023 2932094044

Heater 175W, 12V N/A N/A N/A N/A N/A

Heater 175W, 120V N/A N/A N/A N/A N/A

Heater 275W, 12V N/A 3850646096 N/A N/A N/A

Heater 325W, 120V 3850644422 3850644422 3850644422 3850644422 3850644422

DM2662 DM2663 DM2852 DM2862 NDM1062

N/A N/A N/A N/A 2002726178

N/A N/A N/A N/A 2932621085

2930697079 2930697079 2930697079 2930697079 2930697079

N/A N/A N/A N/A N/A

N/A N/A N/A N/A N/A

N/A N/A 293275008 N/A N/A

N/A N/A 293275009 N/A N/A

293275011 293275011 293275011 293275011 293275011

293275012 293275012 293275012 293275012 293275012

N/A N/A N/A N/A 3850455019

16

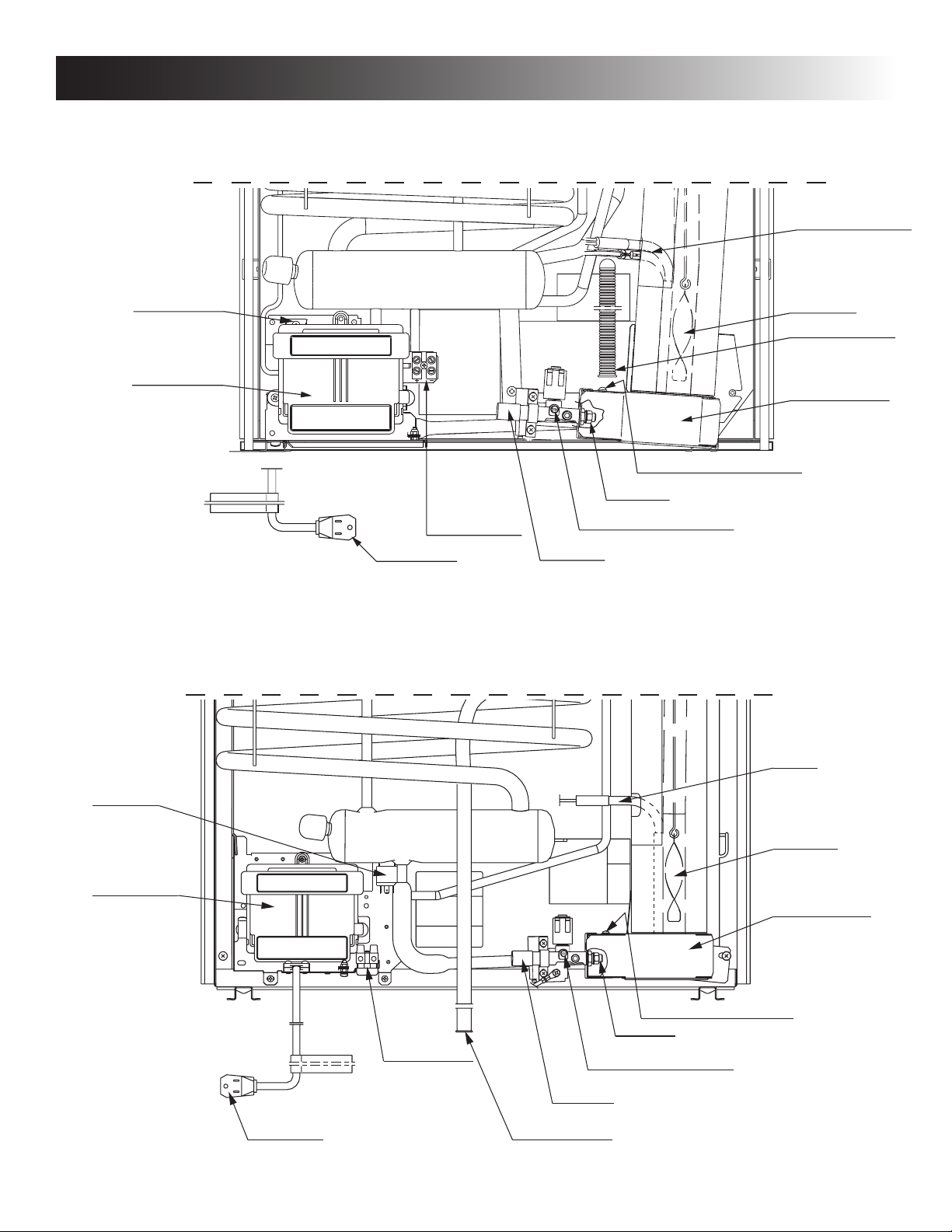

Page 17

APPENDIX B - REARVIEW EQUIPMENT

RM2351 & RM2354

1 heater - RM2351

2 heaters - RM2354

Relay

Power module

cover

Burner jet

12 V DC

Terminal block

Flexible cord

Manual gas shutoff valve

Inlet fitting

RM2451, RM2454, RM2551 & RM2554

Flue baffle

Drain water hose

Protection cover

Screw for protection cover

Relay,

3-way only

Power module

cover

Flexible cord

12V DC

12 volt

Terminal block

Heater

Flue baffle

Protection cover

Screw for protection cover

Burner jet

Manual gas shutoff valve

Inlet fitting

Drain water hose

17

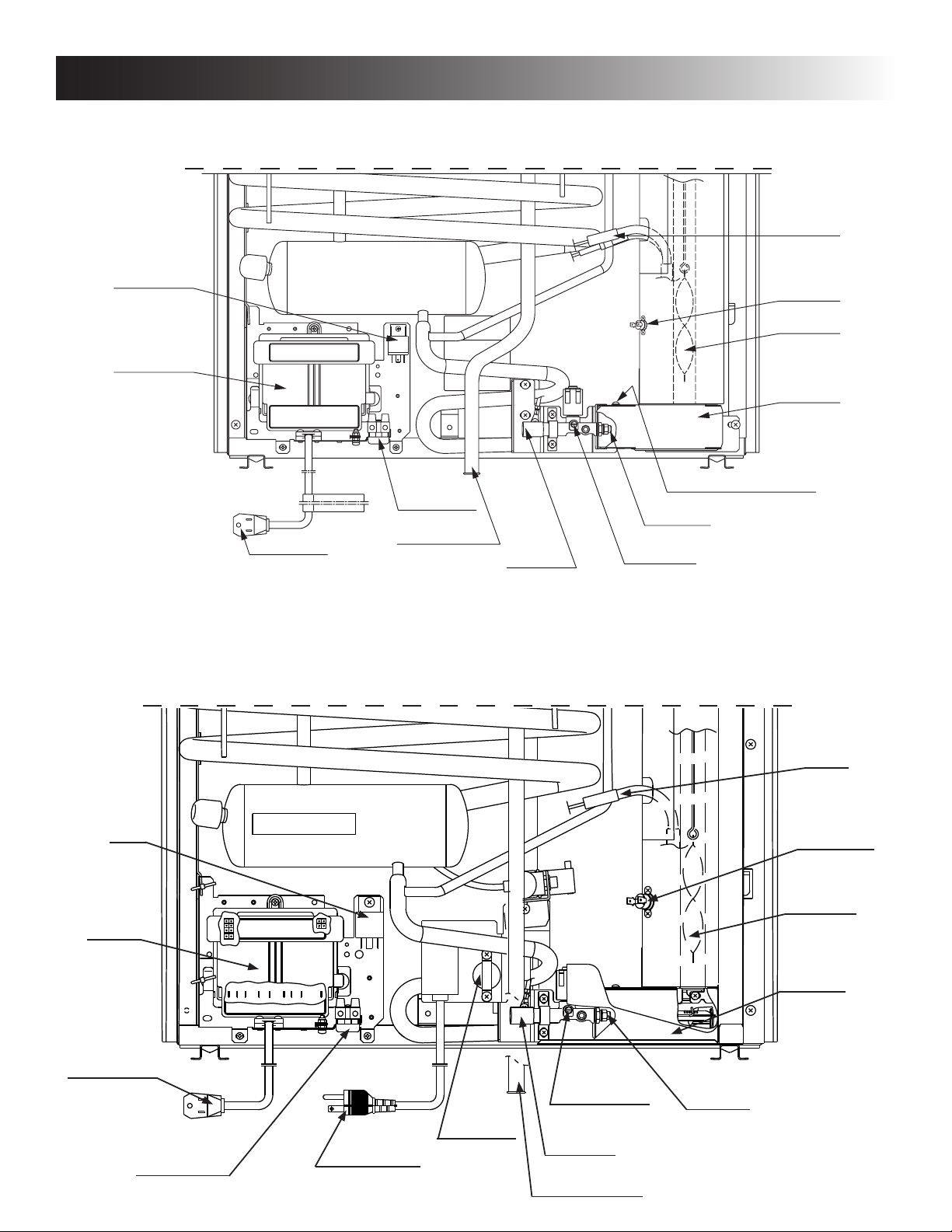

Page 18

APPENDIX B - REARVIEW EQUIPMENT

DM2652, DM2662, DM2663, DM2852, DM2862 & NDM1062

Relay,

3-Way only

Power module

cover

12V DC

Heater(s)

Thermofuse

Flue baffle

Protection

cover

Relay

Power

Module

Cover

Flexible cord

12 volt DC

Terminal block

Drain water hose

Inlet fitting

Shown without Secondary Burner Housing for illustrative purposes only.

NDM1062 (WITH ICE MAKER)

Screw for protection cover

Burner jet

Manual gas

shutoff valve

Heater

Thermofuse

Flue Bafe

Flexible Cord

12V DC

Terminal Block

12V DC

Flexible Cord

(Icemaker)

Manual Gas

Shutoff Valve

Burner Jet

Thermostat

Inlet Fitting

18

Shown without Secondary Burner Housing for illustrative purposes only.

Drain Water Hose

Protection

Cover

Page 19

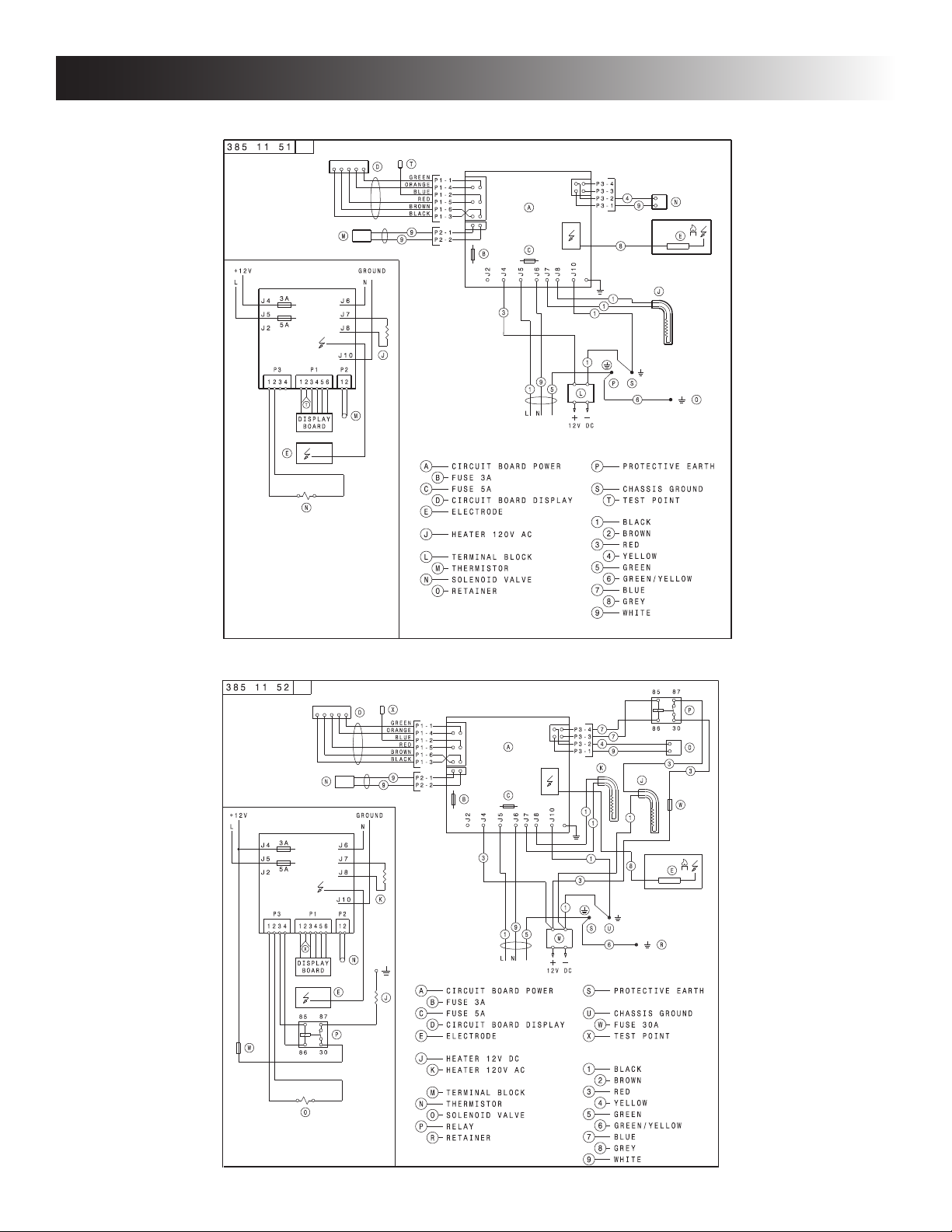

APPENDIX C - WIRING DIAGRAM

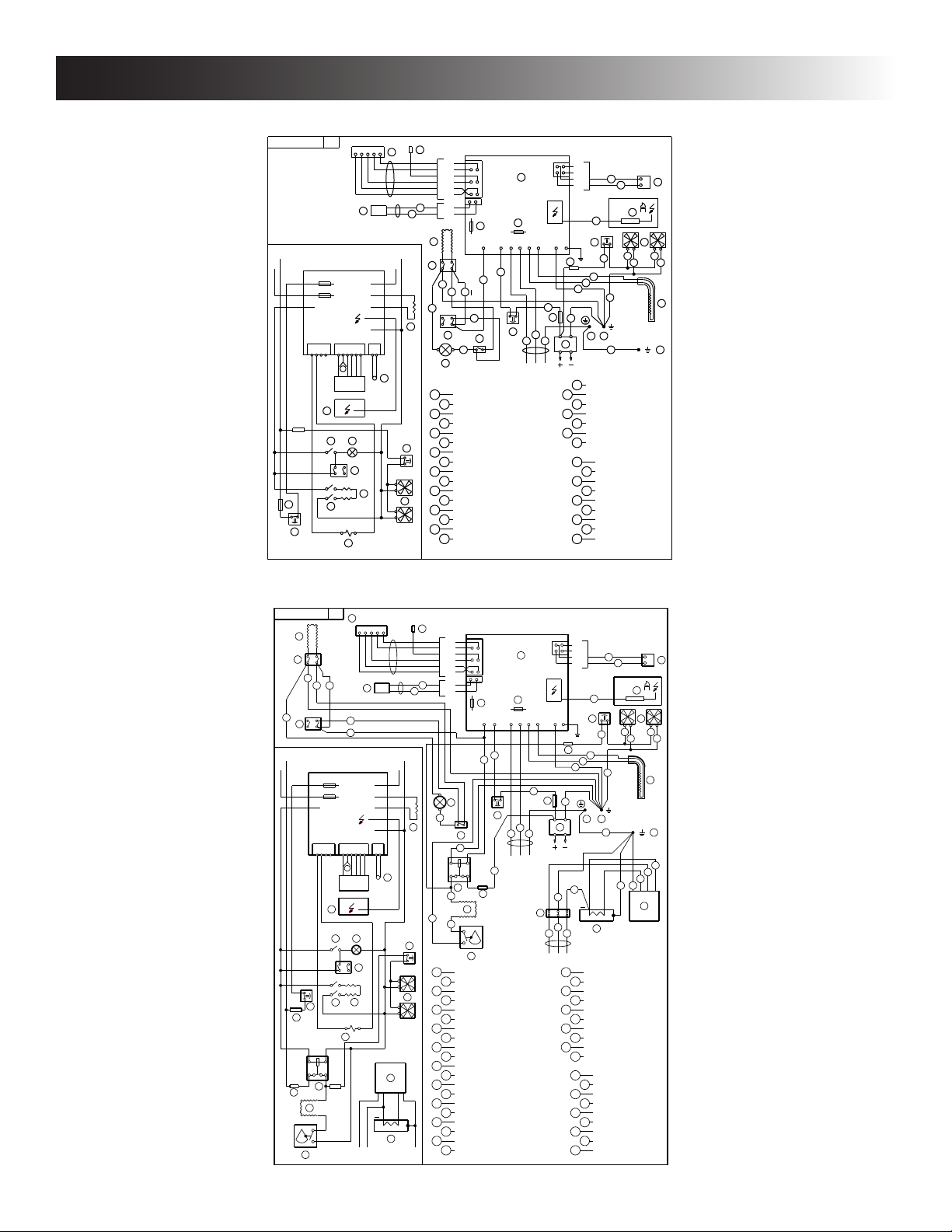

RM2351, RM2451 & RM2551

RM2354, RM2454 & RM2554

19

Page 20

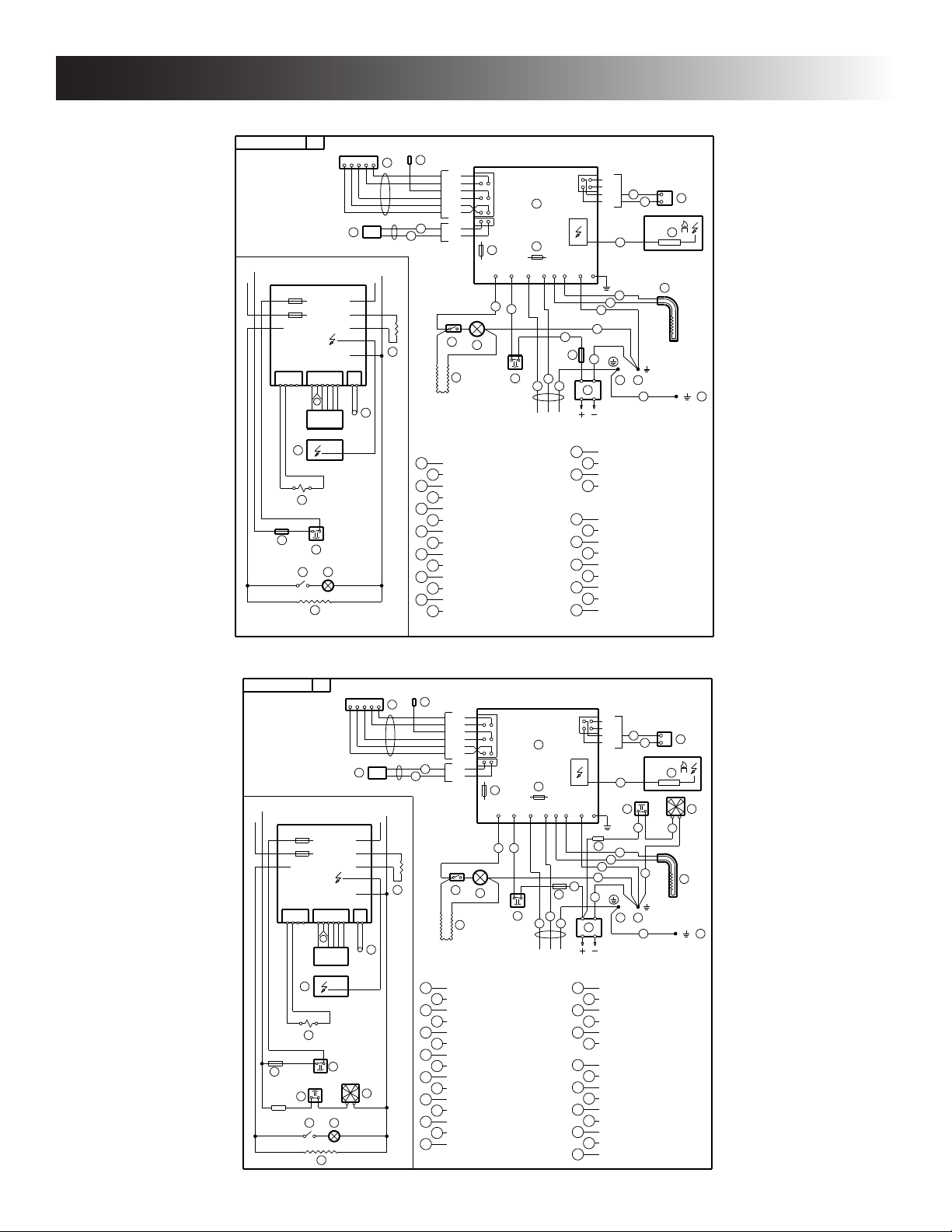

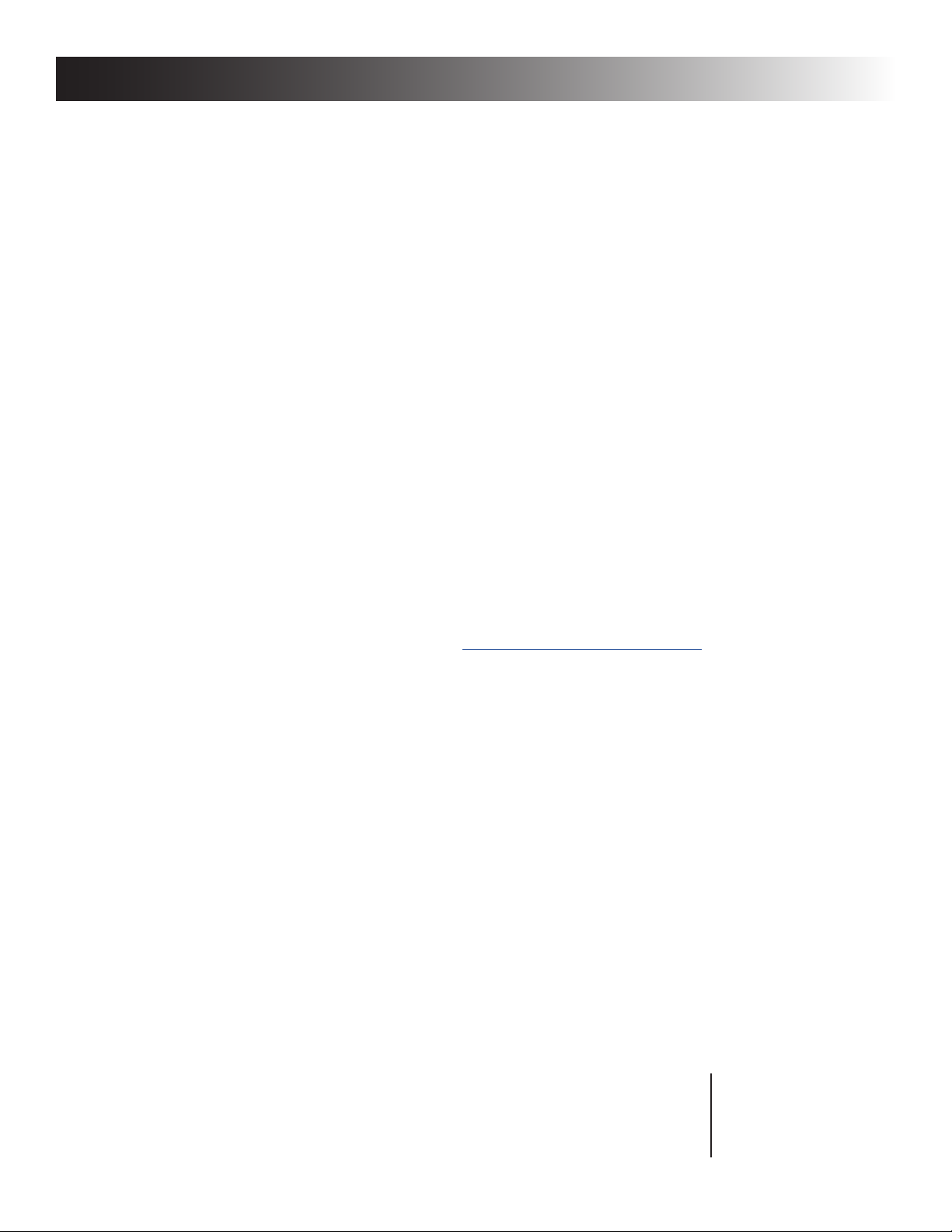

APPENDIX C - WIRING DIAGRAM

DM2652, DM2662, DM2852 & DM2862 (NO FAN) WITH AND WITHOUT ICE MAKER

385 14 82

T

D

GREEN

P1−1

ORANGE

P1−4

BLUE

P1−2

RED

P1−5

L

J 4

J 5

J 2

1 2 3 4 1 2 3 4 5 6 1 2

BROWN

P1−6

BLACK

P1−3

P2−1

M

GROUND+12V

N

3 A

5 A

P3

P1 P2

T

DISPLAY

BOARD

J 6

J 7

J 8

J10

M

9

P2−2

9

H

J

G

K

A

C

B

J 4

J 5

J 2

3

J 6

3

F

195

L N

P3−4

P3−3

P3−2

4

P3−1

8

J 8

J 7

J10

1

1

1

1

3

U

1

P S

L

12V D C

N

9

E

J

6 O

E

N

U

F

GH

K

A

CIRCUIT BOARD POWER S

B

FUSE 3A

C

FUSE 5A

D

CIRCUIT BOARD DISPLAY

E

ELECTRODE

THERMOFUSE

F

LAMP

G

SWITCH LAMP

H

J HEATER 120V AC

K

HEATING CABLE

L

TERMINAL BLOCK

M

THERMISTOR

N

SOLENOID VALVE

RETAINER

O

PROTECTIVE EARTH

P

CHASSIS GROUND

TEST POINT

T

U

THERMAL FUSE

BLACK1

BROWN

2

RED

3

4

YELLOW

5

GREEN

6

GREEN/YELLOW

BLUE

7

GREY

98WHITE

DM2652, DM2662, DM2852 & DM2862 (ONE FAN) WITH AND WITHOUT ICE MAKER

385 14 84

T

D

GREEN

L

J 4

J 5

J 2

1 2 3 4 1 2 3 4 5 6 1 2

P1−1

ORANGE

P1−4

BLUE

P1−2

RED

P1−5

BROWN

P1−6

BLACK

P1−3

P2−1

M

GROUND+12V

3 A

5 A

P3

P1 P2

T

DISPLAY

BOARD

J 6

J 7

J 8

J10

M

9

P2−2

9

N

J

H

G

K

A

C

B

J 4

J 5

J 2

3

J 6

3

F

195

L N

P3−4

P3−3

P3−2

4

P3−1

8

J 8

J 7

3

Y

12V D C

U

J10

X

1

1

1

1

1

P S

L

N

9

E

3

3

1

6 O

V

J

E

N

Y

3 A

F

U

V

GH

K

A

CIRCUIT BOARD POWER

B

FUSE 3A

C

FUSE 5A

D

CIRCUIT BOARD DISPLAY

E

ELECTRODE

THERMOFUSE

F

LAMP

G

SWITCH LAMP

H

J HEATER 120V AC

K

HEATING CABLE

L

TERMINAL BLOCK

M

THERMISTOR

N

SOLENOID VALVE

RETAINER

O

PROTECTIVE EARTHP

CHASSIS GROUND

S

TEST POINT

T

U THERMOFUSE

V

FAN

X

FUSE 3A

Y THERMAL FUSE

BLACK1

BROWN

2

RED

3

YELLOW

4

5

GREEN

6

GREEN/YELLOW

BLUE

7

GREY

98WHITE

20

Page 21

U

3

12V D C

H

A

B

C

D

E

F

G

CIRCUIT BOARD DISPLAY

FUSE 5A

SWITCH LAMP

L

K

HEATER 120V AC

LAMP

MNTHERMOFUSE

PROTECTIVE EARTH

R

TEST POINT

FANS

CIRCUIT BOARD POWER

S

TERMINAL BLOCK

CHASSIS GROUND

T

H

FUSE 3A

ELECTRODE

THERMISTOR

J HEATING CABLE

N

GROUND+12V

L

1 2 3 4 1 2 3 4 5 6 1 2

DISPLAY

BOARD

3 A

J 4

J 5

J 2

J 6

J 7

J 8

L

P3

J10

P1 P 2

T

5 A

D

J

CLC

J2

J10

P1−1

P1−4

P3−4

P3−3

P3−1

A

C

B

J5J8J7

J6

P3−2

T

P1−5

P1−2

P1−6

P1−3

L

P2−1

P2−2

9

9

GREEN

ORANGE

BLUE

RED

BROWN

BLACK

3

L N

H

195

K

1

O

6 P

R S

4

9

GND

LAC

+12V

F

G

1

8

3

3

1

8

LAC

+12V

GND

CLC

G

O

J

E

F

U THERMOFUSE

E

8

J4

M

3

3

N

1

1

1

1

OPSOLENOID VALVE

RETAINER

M

N

3

1 1

3 A

V

FUSE 3AV

U

GREEN/YELLOW

GREEN

7

6

5

4

3

2

1 BLACK

BROWN

RED

BLUE

GREY

WHITE

8

9

YELLOW

THERMAL FUSEY

Y

Y

385 14 04

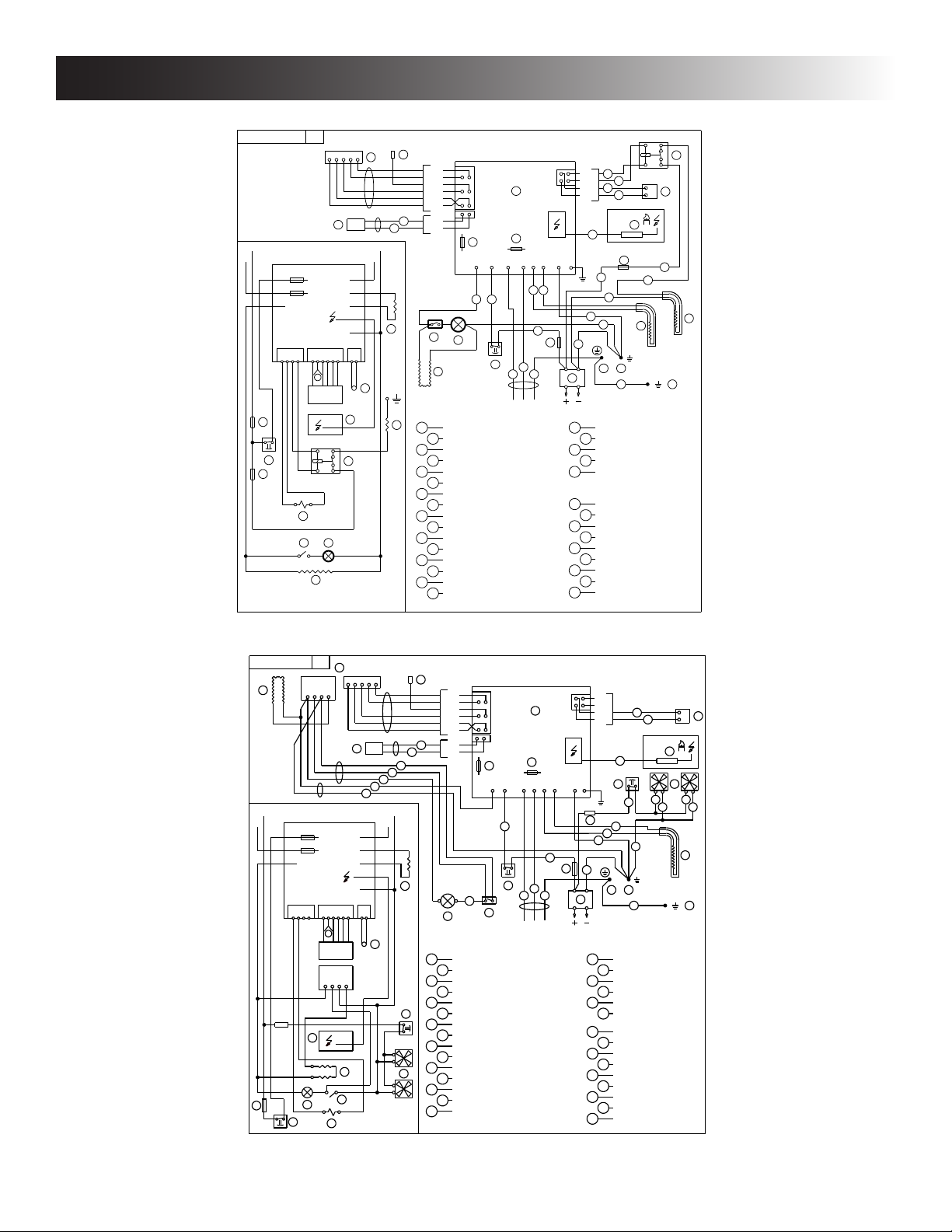

APPENDIX C - WIRING DIAGRAM

DM2663 (NO FAN) WITHOUT ICE MAKER

385 14 83

X

D

GREEN

P1−1

ORANGE

P1−4

BLUE

P1−2

+12V

L

Y

F

W

3 A

J 4

J 5

5 A

J 2

P1 P 2

P3

1 2 3 4 1 2 3 4 5 6 1 2

X

DISPLAY

BOARD

8 7

8 5

3 0

8 6

O

GH

L

RED

P1−5

BROWN

P1−6

BLACK

P1−3

P2−1

GROUND

N

N

9

P2−2

9

K

H

G

L

J

A

CIRCUIT BOARD POWER

FUSE 3A

B

C

FUSE 5A

D

CIRCUIT BOARD DISPLAY

ELECTRODE

E

THERMOFUSE

F

LAMP

G

H

SWITCH LAMP

HEATER 12V DC

J

K

HEATER 120V AC

HEATING CABLE

L

M

TERMINAL BLOCK

N

THERMISTOR

O

SOLENOID VALVE

RELAY

P

R

RETAINER

N

J 6

J 7

J 8

J10

E

P

A

C

B

J 4

J 5

J 2

3

J 7

J 6

J 8

1

1

3

3

Y

F

195

L N

J10

1

M

12 V D C

S

W

Y

3

5

7

98WHITE

P3−4

7

P3−3

7

P3−2

4

P3−1

9

E

8

W

3

1

1

1

S U

6 R

PROTECTIVE EARTH

CHASSIS GROUND

U

FUSE 30A

TEST POINT

X

THERMAL FUSE

BLACK1

BROWN

2

RED

YELLOW

4

GREEN

6

GREEN/YELLOW

BLUE

GREY

8 7

8 5

P

3 0

8 6

O

3

3

K

J

NDM1062 (STAINLESS STEEL DOORS)

21

Page 22

APPENDIX C - WIRING DIAGRAM

NDM1062 (STAINLESS STEEL DOORS & ICE MAKER)

385 14 44

J

L

J4

J5

J2

U

Y

8 6

3 0

AG

AE

°

C

AF

D

+12V

CLC

GND

LAC

L

3 A

5 A

P1 P2

P3

1 2 3 4 1 2 3 4 5 6 1 2

T

DISPLAY

BOARD

LAC

+12V

GND

CLC

E

J

G

F

O

8 5

8 7

AD

3 A

N

L

3

1

J6

J7

J8

J10

L

M B 4

3

GROUND+12V

AA

AB

8

N

GROUND

T

GREEN

ORANGE

BROWN

BLACK

9

9

1

H

M

N

P1−1

P1−4

BLUE

P1−2

RED

P1−5

P1−6

P1−3

P2−1

P2−2

B

J2

3

F

8

G

1

8 6

8 5

8 7

3 0

AD

AG

3

AE

1

1

°

C

AF

A

CIRCUIT BOARD POWER

B

FUSE 3A

C

FUSE 5A

D

CIRCUIT BOARD DISPLAY

E

ELECTRODE

LAMP

F

SWITCH LAMP

G

HEATER 120V AC

H

J HEATING CABLE

K

TERMINAL BLOCK

L

THERMISTOR

MNTHERMOFUSE

FANS

OPSOLENOID VALVE

RETAINER

RSPROTECTIVE EARTH

CHASSIS GROUND

TUTEST POINT

THERMOFUSE

A

C

J4

J5J8J7

J6

3

3

U

195

L N

3

AC

J10

Y

K

12V D C

6

159

L N

120 V AC

P3−4

P3−3

P3−2

P3−1

8

M

V

1

1

1

1

R S

9

M B 4

PROTECTIVE EARTH

V

Y

CHASSIS GROUND

AA

ICEMAKER

AB

WATER VALVE

TERMINAL BLOCK

AC

AD

RELAY

AE

HEATING CABLE

THERMOSTAT

AF

AG

FUSE 4A

BLACK1

BROWN

2

RED

3

YELLOW

4

5

GREEN

6

GREEN/YELLOW

BLUE

7

GREY

98WHITE

4

9

3

1

6 P

6

AB

E

3

1 1

6

O

N

3

H

9

1

2

AA

22

Page 23

W

3

12V D C

H

A

B

C

D

E

F

G

CIRCUIT BOARD DISPLAY

FUSE 5A

SWITCH LAMP

L

K

HEATER 120V AC

LAMP

MNTHERMOFUSE

FANS

CIRCUIT BOARD POWER

TERMINAL BLOCK

H

FUSE 3A

ELECTRODE

THERMISTOR YELLOW

98WHITE

GREY

BLUE

RED

BROWN

BLACK1

2

3

4

5

6

7

J HEATING CABLE

GREEN

GREEN/YELLOW

N

GROUND+12V

L

1 2 3 4 1 2 3 4 5 6 1 2

DISPLAY

BOARD

3 A

J4

J5

J2

J6

J7

J8

L

P3

J10

P1 P2

Z

5 A

D

J2

P1−1

P1−4

P3−4

P3−3

P3−1

A

C

B

J5J8J7

J6

P3−2

Z

P1−5

P1−2

P1−6

P1−3

L

P2−1

P2−2

9

9

GREEN

ORANGE

BLUE

RED

BROWN

BLACK

3

L N

H

195

K

1

O

6 P

S X

4

9

F

G

8

O

E

J

T

3

U

3

8

O SOLENOID VALVE

31

1

J

U

FG

T

J10

E

8

J4

333

1 1

M N

1

1

1

1

M

N

P RETAINER

3 A

Y

THERMAL FUSER

S PROTECTIVE EARTH

TEST POINTZ

FUSE 3AY

CHASSIS GROUNDX

W

SWITCH L.A.CU

THERMOFUSE

T SWITCH

R

W

R

385 14 05

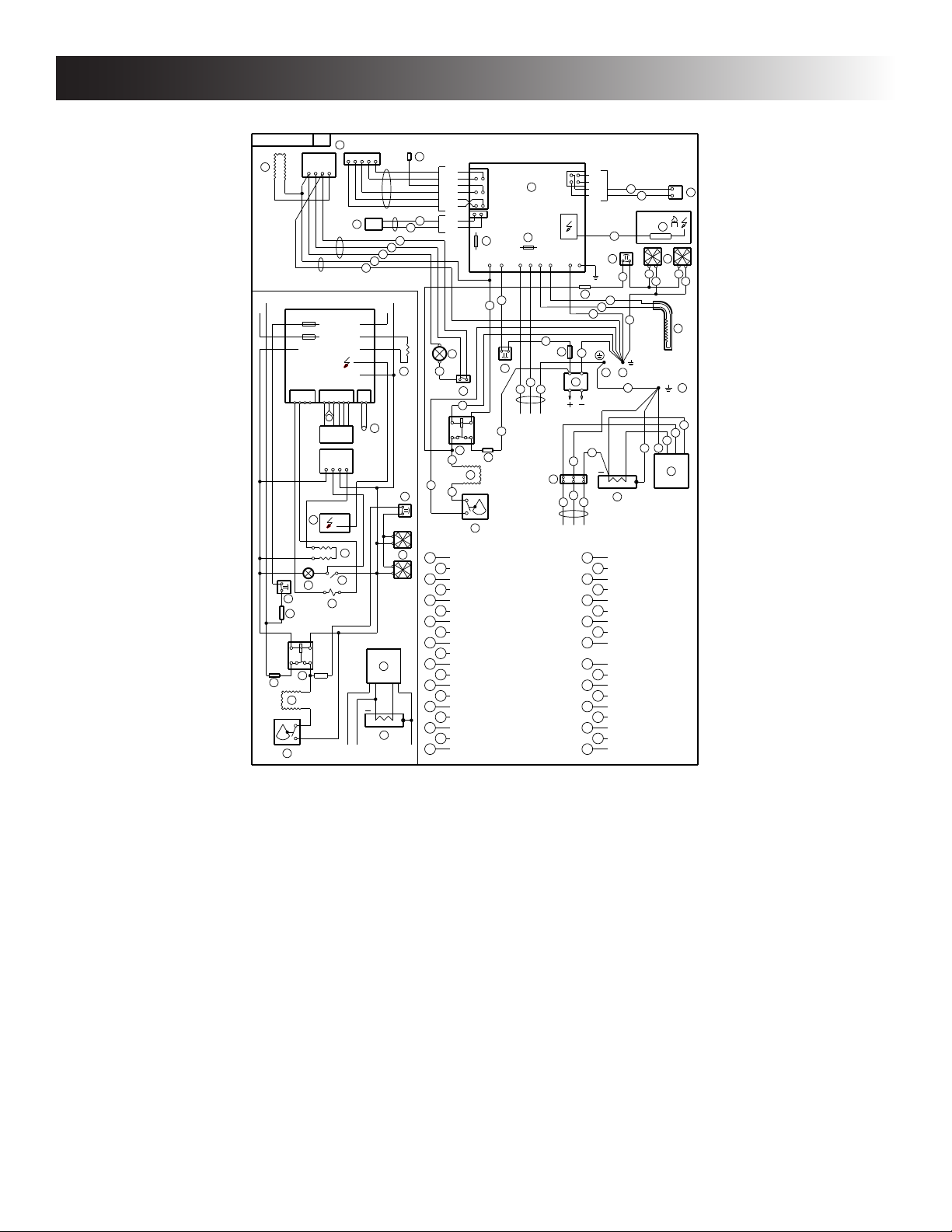

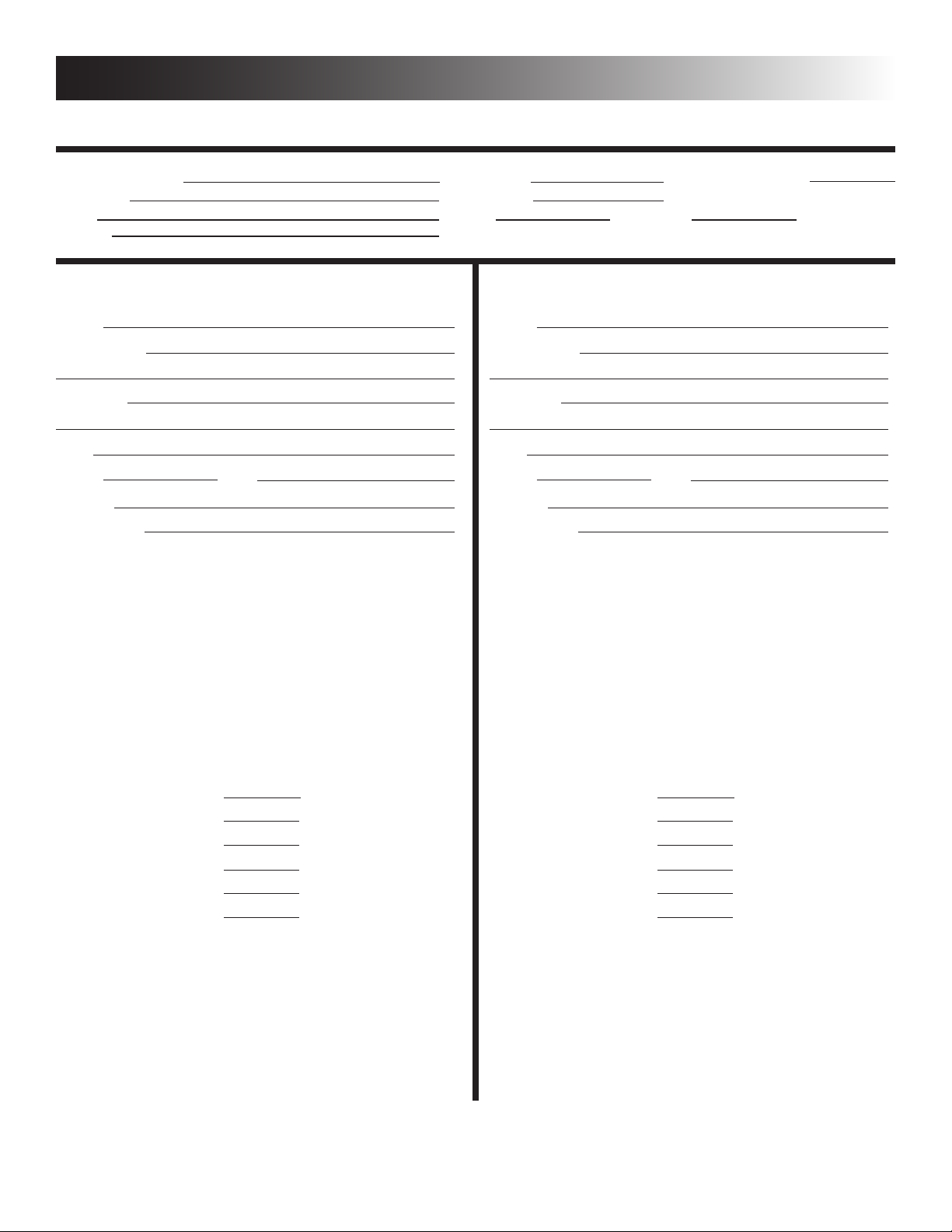

APPENDIX C - WIRING DIAGRAM

NDM1062 (DOOR INSERT PANELS)

NDM1062 (DOOR INSERT PANELS & ICE MAKER)

385 14 52

J

T

3

U

L

R

86

30

AG

°

C

AF

D

1

31

L

8

3

3 A

J4

J5

5 A

J2

P3

1 2 3 4 1 2 3 4 5 6 1 2

W

AD

AE

P1 P 2

Z

DISPLAY

BOARD

E

FG

U

J

T

O

85

87

3 A

N

L

J6

J7

J8

J10

M B 4

Z

GREEN

P1−1

ORANGE

P1−4

BLUE

P1−2

RED

P1−5

BROWN

P1−6

BLACK

P1−3

P2−1

9

P2−2

9

GROUND+12V

N

F

8

H

L

M

N

AA

AB

GROUND

G

1

86

85

87

30

AD

3

AE

1

1

°

AF

CIRCUIT BOARD POWER

A

FUSE 3A

B

C

FUSE 5A

D

CIRCUIT BOARD DISPLAY

ELECTRODE

E

F

LAMP

SWITCH LAMP

G

H

HEATER 120V AC

J HEATING CABLE

TERMINAL BLOCK

K

THERMISTOR

L

MSTHERMOFUSE

N FANS

O SOLENOID VALVE

P RETAINER

R THERMAL FUSE

PROTECTIVE EARTH

T SWITCH

U SWITCH L.A.C

W THERMOFUSE

A

C

B

J2

J5J8J7

J6

J4

3

3

W

195

L N

3

AG

C

J10

Y

3

R

1

K

12V D C

6

AC

159

L N

120 V AC

X CHASSIS GROUND

Z

AB

AD

AF

P3−4

P3−3

P3−2

4

P3−1

8

M

3

1

1

1

1

S X

6 P

9

M B 4

AB

FUSE 3AY

TEST POINT

AA

ICEMAKER

WATER VALVE

AC

TERMINAL BLOCK

RELAY

AE

HEATING CABLE

THERMOSTAT

AG

FUSE 4A

BLACK1

BROWN

2

RED

3

YELLOW

4

5

GREEN

6

GREEN/YELLOW

BLUE

7

GREY

98WHITE

9

6

3

1 1

6

O

E

N

3

H

9

1

2

AA

23

Page 24

APPENDIX D - CONSUMER SUPPORT

Dometic website www.DometicUSA.com

Please visit our website for information and news about Dometic products. Our website provides information on product

care and warranties. You can also download product literature, including manuals and brochures.

Service and spare parts www.eDometic.com

For service and spare parts, please contact Service Center Assistance. Please see the front page of this manual - or -

visit our Dometic website to nd a Dometic Service Center near you.

Contact us www.DometicUSA.com

For contact information, please see the front page of this manual - or - visit our Dometic website.

Register product www.eDometic.com

Timely registration allows for enhanced communication and service under the terms of your warranty. Please see

“Appendix E - Dometic Warranty” on page (25).

To register your product, ll in the pre-printed registration card on the last page of this manual, or register on-line at

www.eDometic.com.

TO REGISTER ON-LINE:

1. Access www.eDometic.com then click “Register your Dometic PRODUCT.”

2. Complete the on-line form, then click “SUBMIT”.

24

Page 25

APPENDIX E - DOMETIC WARRANTY

LIMITED TWO-YEAR WARRANTY (DOMETIC REFRIGERATORS)

THE SELLER NAMED BELOW MAKES THE FOLLOWING WARRANTY WITH RESPECT TO THE DOMETIC PRODUCT:

1. This Warranty is made only to the rst purchaser (hereinafter referred to as the “Original Purchaser”), who acquires the Dometic Product for his or her own use

and when the Dometic Product is installed and operated within the continental United States and Canada.

2. WARRANTY PERIOD: This Warranty will be in effect for two (2) years from the date of purchase by the Original Purchaser. The Original Purchaser should

retain a copy of the dated bill of sale as evidence of the date of purchase.

3. WARRANTY: This Warranty covers labor, specied parts, and freight. The Dometic Product shall be free from defects in material and workmanship at the

time of sale and under normal use. All Dometic Products (except those specically built for commercial use) are warranted only when installed per the Seller’s

installation instructions on vehicles built to R.V.I.A. A119-2 and C.R.V.A. Z-240 Standards. This Warranty does NOT cover conditions unrelated to the material

and workmanship of the Dometic Product. Such unrelated conditions include, but are not limited to: (a) damage not reported within 10 days of ownership; (b)

faulty installation or installation that does not comply with the Seller’s instructions or R.V.I.A. and C.R.V.A. standards, and any damage resulting from such; (c)

damage or failure caused by installation of accessories not manufactured and marketed by the Seller or any non-Dometic parts that are installed as replacement

parts; (d) the need for normal maintenance and any damage resulting from the failure to provide such maintenance; (e) failure to follow Seller’s instructions for

use of this Dometic Product; (f) ame outage due to blow out or high altitude; (g) reduced performance due to high altitude; (h) radio frequency interference

(RFI) or electromagnetic interference (EMI); (i) 12 VDC system chassis ground decay and corrosion; (j) puncture of foam cabinet or vacuum insulated panels

after acknowledged receipt; (k) animal or insect inltration which damages unit or inhibits performance; (l) any accident to, or misuse of, any part of the

Dometic Product and any alteration by anyone other than the Seller or its authorized representative; and (m) normal wear.

4. WARRANTY COVERS DOMETIC COMPONENT PARTS: Major components (cooling unit, LP gas valve, burner, burner housing, electronic display,

electronic module, evaporator ns, foam integrity, frame, thermistor, spark probe, ignition wire, ice maker compressor, second absorption loop, display

escutcheon, lower toe plate, humidity switch, frame heater mullion, ice maker mullion) are covered for labor, parts and freight for two (2) years from date

of purchase. All other components that fail must be reported within the rst 90 days of ownership in order to receive warranty coverage for labor, parts and

freight.

5. The Original Purchaser must provide preventative maintenance on a yearly basis, beginning at the rst anniversary of the date of purchase. The Original

Purchaser must keep a record of the preventative maintenance to keep the warranty in effect. Failure of the Original Purchaser in providing this annual

maintenance may void the warranty. The preventative maintenance must be performed at a Dometic Authorized Service Center/Dealer. The required

preventative maintenance is an inspection, cleaning and full diagnostics performed on the entire electronic system, burner assembly, wiring and cooling unit. A

copy of the receipt covering the maintenance checks must accompany the warranty claim during the second year of ownership. The cost of this preventative

maintenance is the Original Purchaser’s responsibility and the preventative maintenance should take about one hour.

6. WARRANTY REMEDY: In order to obtain the benets of this Warranty, the Original Purchaser has the following two options during the WARRANTY

PERIOD:

a. Preferred option: Deliver the Dometic Product for inspection to the nearest Authorized Dometic Service Center during the Warranty Period. To obtain the

location of the nearest Authorized Dometic Service Center, refer to https://www.dometic.com/en-us/us/nd-a-dealer. The Authorized Dometic Service

Center will work with the Seller to obtain Warranty coverage if a Seller defect is identied. CONFIRM THE SERVICE CENTER IS AN AUTHORIZED

DOMETIC SERVICE CENTER. DO NOT PAY THE SERVICE CENTER FOR WARRANTY REPAIRS.

b. Second option: If it is not feasible under the circumstances to deliver the Dometic Product to an Authorized Dometic Service Center, please call 1-800-

544-4881 for additional Warranty assistance. Seller prefers option a. rst and only option b. if option a. is determined not to be feasible under the

circumstances.

7. Any item returned in the manner described in paragraph 6 will be examined by the Authorized Dometic Service Center. If it is found that the returned item was

defective in material and workmanship at the time of sale, the Authorized Dometic Service Center will contact the Seller for Warranty coverage. The Seller

shall, at Dometic’s sole option, repair or replace the Dometic Product, or refund Original Purchaser’s purchase price. If the Seller determines that repairs to the

Dometic Product are to be made, then only authorized Dometic parts will be used.

8. The Seller does not authorize any person or company to create any Warranty obligations or liability on its behalf. This Warranty is not extended by the length of

time which you are deprived of the use of the Dometic Product.

9. IN NO EVENT SHALL SELLER BE LIABLE FOR EITHER INCIDENTAL OR CONSEQUENTIAL DAMAGES. THIS INCLUDES ANY DAMAGE

TO ANOTHER PRODUCT OR PRODUCTS RESULTING FROM SUCH A DEFECT. SOME STATES DO NOT ALLOW THE EXCLUSION OR

LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

10. ANY IMPLIED WARRANTY, INCLUDING THE IMPLIED WARRANTY OF MERCHANTABILITY AND FITNESS FOR ANY PURPOSE, IS

LIMITED TO THE DURATION OF THIS LIMITED WARRANTY. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

11. THIS WARRANTY GIVES SPECIFIC LEGAL RIGHTS, YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

No action to enforce this Warranty shall be commenced later than ninety (90) days after the expiration of the Warranty Period. Claims must be submitted in

writing to the Dometic Warranty Department.

12. The Seller reserves the right to change the design of any Dometic product without notice and with no obligation to make corresponding changes in Dometic

products previously manufactured.

PROTECTION FOR YOUR NEW INVESTMENT

We appreciate that you have chosen to purchase a

Dometic product for your recreational vehicle and we want to help

you protect this wise investment. We at Dometic, back our products with one of the most comprehensive warranties in the industry.

Register your product online at: www.eDometic.com.

25

Dometic Corporation

Warranty Department

1120 North Main Street

Elkhart, Indiana 46514

1-574-294-2511

Register Your Product @

www.eDometic.com

Form No. 3316980.000 (10/17)

(French 3316985.000)

©2017 Dometic Corporation

LaGrange, IN 46761

Page 26

APPENDIX F - MAINTENANCE SCHEDULE

REFRIGERATOR OWNER MAINTENANCE YEARLY RECORD

Customer Name: Model No.: Date of Purchase:

Address: Serial No.:

City: State: Zip Code:

Phone:

FIRST YEAR

Date:

Dealership:

Address:

City:

State: Zip:

Phone:

Technician:

Cleaned Burner Assembly: Yes / No

Cleaned/Check All Terminals Connections: Yes / No

Cleaned/Inspect All Ground Connections: Yes / No

Inspect and Test Door Seals: Yes / No

Inspect and Tighten LP Lines: Yes / No

Power Ventilator Installed: Yes / No

Gas Safety Shutdown in 45 seconds: Yes / No

SECOND YEAR

Date:

Dealership:

Address:

City:

State: Zip:

Phone:

Technician:

Cleaned Burner Assembly: Yes / No

Cleaned/Check All Terminals Connections: Yes / No

Cleaned/Inspect All Ground Connections: Yes / No

Inspect and Test Door Seals: Yes / No

Inspect and Tighten LP Lines: Yes / No

Power Ventilator Installed: Yes / No

Gas Safety Shutdown in 45 seconds: Yes / No

ACTUAL SPEC. RANGE

Electrode Gap 3/16”

Thermistor Reading 7-10,000 ohms @ 32°

D/C Voltage 9.5 to 15 volts D/C

A/C Voltage 120 Volts ± 10%

Thermocouple Reading 25-35 Millivolts

Delay Between Modes Approx. 5 seconds

ICE MAKER MODELS

Inspect Water Valve and All Connections: Yes / No

Inspect Heat Tape Switch for Proper

Operation: Yes / No

ACTUAL SPEC. RANGE

Electrode Gap 3/16”

Thermistor Reading 7-10,000 ohms @ 32°

D/C Voltage 9.5 to 15 volts D/C

A/C Voltage 120 Volts ± 10%

Thermocouple Reading 25-35 Millivolts

Delay Between Modes Approx. 5 seconds

ICE MAKER MODELS

Inspect Water Valve and All Connections: Yes / No

Inspect Heat Tape Switch for Proper

Operation: Yes / No

26

Loading...

Loading...