Page 1

REFRIGERATION

REFRIGERATOR

RM2351, DM2652, DM2662, DM2663, DM2682, DM2852, DM2862 DM2882, RM2354, RM2551, DM2683,

RM3962, RM2554, RM3762, RM2451, RM1350, RM2454, DM2672, DM2872, RM1350SL

DM & RM Refrigerators

EN

Installation Manual

WARNING: Improper installation, adjustment,

alteration, service or maintenance can

cause injury or property damage. Refer to

this manual. For assistance or additional

information consult a qualified installer,

service agency or the gas supplier.

FIRE OR EXPLOSION HAZARD

If you smell gas:

1. Open windows.

2. Do not attempt to light appliance.

3. Do not touch electrical switches.

4. Extinguish any open flame.

5. Shut off fuel supply.

6. Evacuate immediately and call emergency

services.

Failure to follow these instructions could result

in fire or explosion, which could cause property

damage, personal injury, or death.

Page 2

Refrigerator

NORTH AMERICAN ADDRESS INFORMATION

USA & CANADA

Service Office

Dometic Corporation

1120 North Main Street

Elkhart, IN 46514

REVISION F | Form No. 3313238.036 7/18 | ©2018 Dometic Corporation

Read these instructions carefully. These instructions MUST stay with this product.

Service Center & Dealer Locations

Visit: www.dometic.com

CONTENTS

1 Explanation of symbols and safety instructions ................................................ 3

2 General information ..................................................................... 4

3 Intended use ........................................................................... 4

4 Specifications .......................................................................... 5

5 Prepare for installation .................................................................. 14

6 Installation ............................................................................ 24

7 Disposal .............................................................................. 43

EN

2

Page 3

Refrigerator

1 EXPLANATION OF SYMBOLS AND SAFETY INSTRUCTIONS

This manual has safety information and instructions to help you eliminate or reduce the risk of accidents

and injuries.

1.1 Recognize safety information

This is the safety alert symbol. It is used to alert you to potential physical injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury or death.

1.2 Understand signal words

A signal word will identify safety messages and property damage messages, and will indicate the degree or level

of hazard seriousness.

indicates a hazardous situation that, if not avoided, could result in death or serious injury.

indicates a hazardous situation that, if not avoided, could result in minor or moderate injury.

is used to address practices not related to physical injury.

indicates additional information that is not related to physical injury.

I

1.3 Supplemental directives

Read and follow all safety information and instructions to avoid possible injury or death.

Read and understand these instructions before installation of this product.

Incorrect installation of this product can lead to serious injury.

The installation must comply with all applicable local or national codes, including the latest edition of the

following standards:

This appliance is certified under the latest edition of ANSI Z21.19, CSA 1.4 Refrigerators using gas fuel. The

installation must conform with local codes, or in absence of local codes, the following standards as applicable:

U.S.A.

• ANSI/NFPA70, National Electrical Code (NEC)

• ANSI/NFPA 1192, Recreational Vehicles Code

• Title 24 CFR, Part 3280, Manufactured Home

Construction and Safety Standard

• National Fuel Gas Code, ANSI Z223.1/NFPA 54

Canada

• CSA C22.1, Parts l & ll, Canadian Electrical Code

• CSA Z240 RV Series, Recreational Vehicles

• CSA Z240.4, Gas-Equipped Recreational Vehicles

and Mobile Housing

• CSA B149.1, Natural Gas and Propane Installation

Code CERTIFICATION

1.4 General safety messages

Failure to obey the following warnings could result in death or serious injury:

• This product must be installed by a qualified service technician.

• Any modifications or deviations:

– Can lead to carbon monoxide leaking into the living area.

– Can reduce cooling performance and/or result in damage to the refrigerator.

– Will void agency certifications.

– Will void refrigerator warranty.

• ELECTRICAL SHOCK HAZARD. This product is equipped with a three-prong (grounding) plug for protection

against shock hazards. This product should be plugged directly into a three-prong receptacle that provides

grounding in compliance with all applicable electrical codes. Do not cut or remove grounding prong from

plug.

3

EN

Page 4

Refrigerator

• FIRE OR EXPLOSION HAZARD:

– Before refueling or parking near a gasoline pump, make sure all LP gas appliances (vented to the outside of

RV) are shut off . Otherwise, fumes from gasoline pumps could come into contact with an LP gas appliance

burner flame and ignite.

– Do not store or use gasoline, oil- or gasoline-soaked rags, or other flammable vapors and liquids in the

service area behind the refrigerator or in the vicinity of this or any other gas appliance.

• ABSORPTION-COOLING SYSTEMS: FIRE, BURN, OR INHALATION HAZARD. Do not fracture or puncture

cooling unit. The cooling unit is under pressure and contains ammonia, sodium chromate, and other

chemicals. Repeated or prolonged exposure to sodium chromate could cause organ damage or cancer.

Exposure to a high concentration of ammonia refrigerant could cause pulmonary edema (fluid in lungs);

chemical burns to eyes, lungs, and skin; and could cause a fire (when exposed to open flame).

• COMPRESSOR-COOLING SYSTEMS: FIRE, FROSTBITE, OR INHALATION HAZARD. Do not fracture or

puncture cooling unit. The cooling unit is under pressure and contains tetrafluoro ethane refrigerant, and may

contain other chemi cals. Contact with liquid refrigerant could cause irritation or frostbite to eyes and skin.

Exposure to a high concentration of refrigerant could cause cardiac arrhythmia (irregular heartbeat). A high

concentration of refrigerant could cause a fire (when exposed to open flame).

• FIRE OR INHALATION HAZARD. If the refrigerator stops working and/or it emits an ammonia smell,

immediately turn refrigerator off (if it is safe to do so), leave the vicinity, and contact a qualified Service Center.

• LIFTING HAZARD. Use proper liing technique and control when liing the product.

2 GENERAL INFORMATION

Optional Parts* Reference Number

Innovator Refrigerator Ventilation

System

Z-bracket 3103812.xxx

*Available as accessory (not included)

3108705.751, 3108705.744

3 INTENDED USE

The DM and RM refrigerators are designed and intended for use only inside a recreational vehicle (hereinafter

referred to as “RV”) for which it is supplied. Use the instructions to ensure correct installation of the refrigerator.

Dometic Corporation accepts no liability for damage in the following cases:

• Faulty assembly or connection.

• Damage to the product resulting from mechanical influences and excess voltage.

• Alterations to the product without expressed permission from Dometic Corporation.

• Use for purposes other than those described in the operating manual.

Dometic Corporation reserves the right to modify appearances and specifications without notice.

EN

4

Page 5

Refrigerator

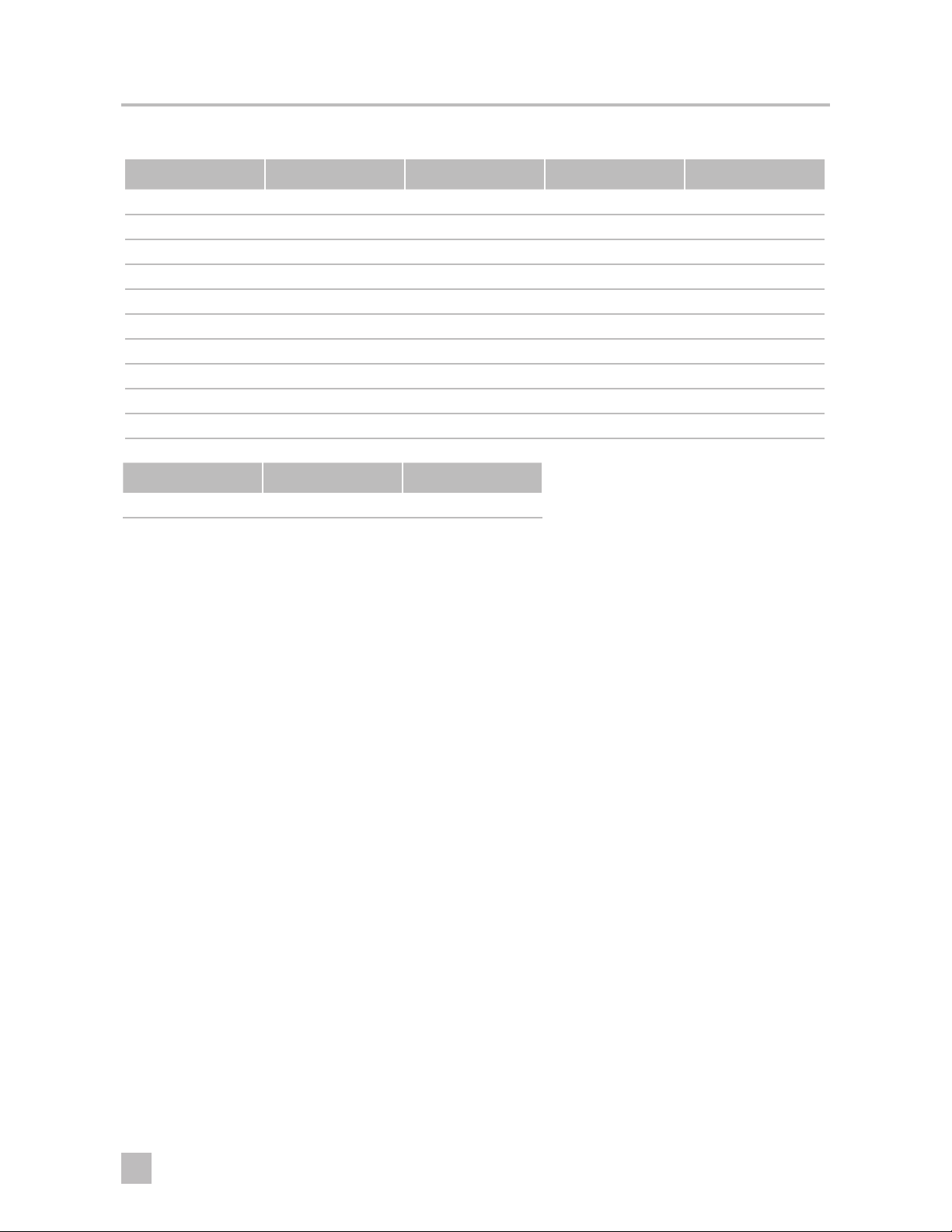

4 SPECIFICATIONS

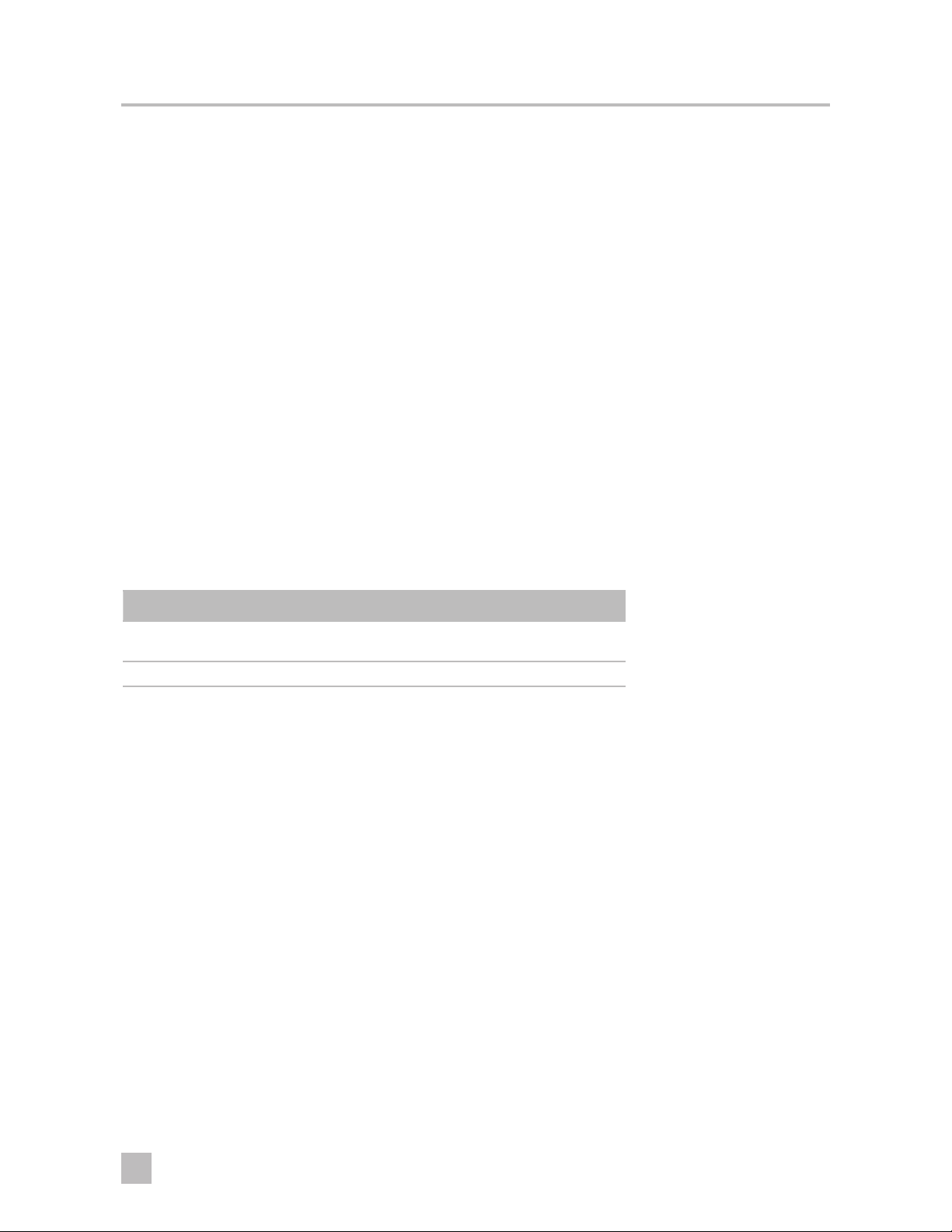

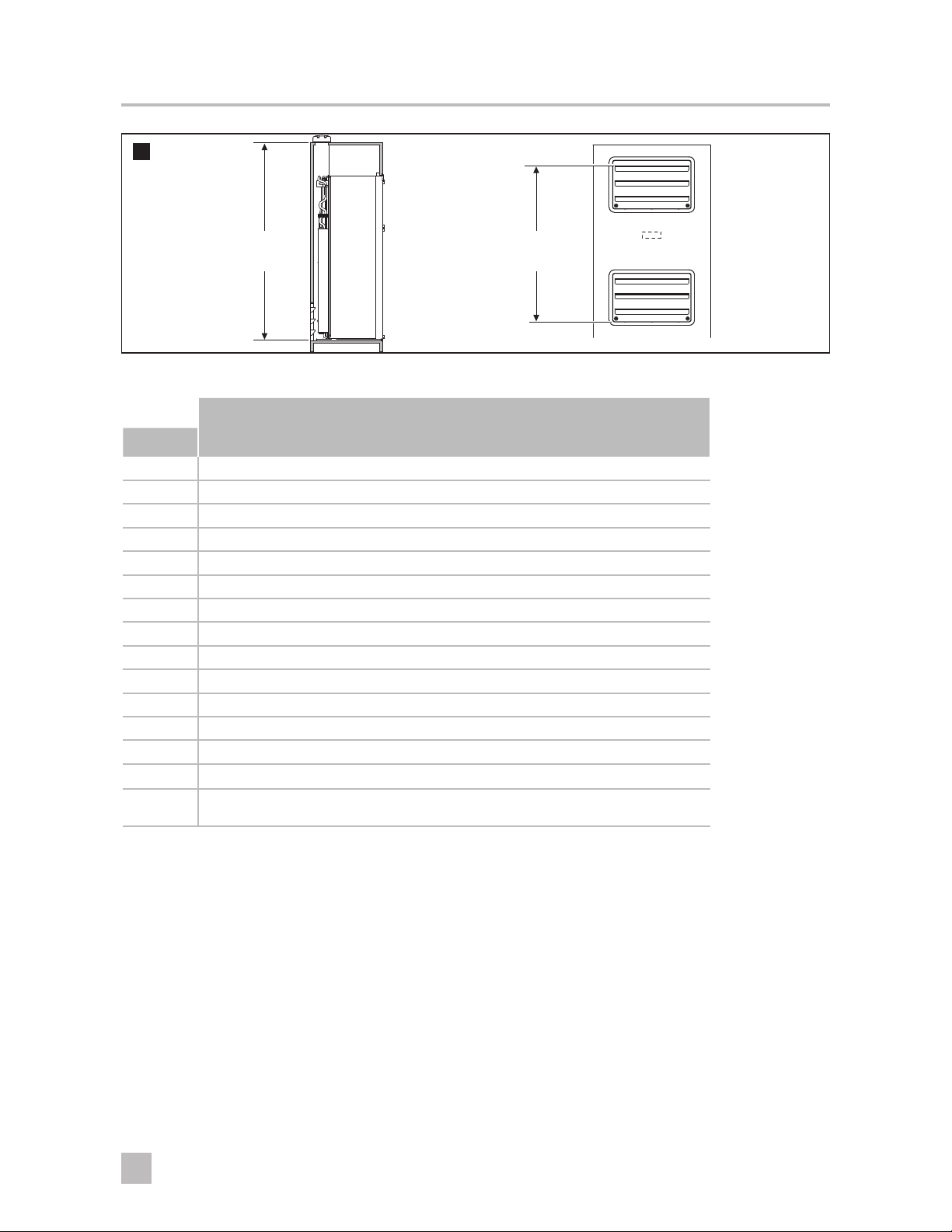

4.1 Overall and rough in dimensions for enclosure

1

C

D

A

H

B

D

W

OVERALL DIMENSIONS ENCLOSURE DIMENSIONS

MODEL Height (A) Width (B) Depth (C) Height (H) Width (W) Depth (D)

RM2351 30-3/16" 21-7/8" 22-11/16" 29-3/4" 20-1/2" 21-1/2"

RM2354 30-3/16" 21-7/8" 22-11/16" 29-3/4" 20-1/2" 21-1/2"

RM2451 37-3/8" 24-7/8" 24-11/16" 36-1/2" 23-11/16" 24"

RM2454 37-3/8" 24-7/8" 24-11/16" 36-1/2" 23-11/16" 24"

RM2551 43-1/2" 24-7/8" 24-11/16" 42-5/8" 23-11/16" 24"

RM2554 43-1/2" 24-7/8" 24-11/16" 42-5/8" 23-11/16" 24"

DM2652 54-11/16" 24-7/8" 26-1/16" 53-3/4" 23-11/16" 24"

DM2662 54-11/16" 24-7/8" 26-1/16" 53-3/4" 23-11/16" 24"

DM2663 54-11/16" 24-7/8" 26-1/16" 53-3/4" 23-11/16" 24"

DM2672 55" 24-7/8" 26-3/16" 53-3/4" 23-11/16" 24"

DM2682 55" 24-7/8" 26-3/16" 53-3/4" 23-11/16" 24"

DM2683 55" 24-7/8" 26-3/16" 53-3/4" 23-11/16" 24"

RM3762 54-3/4" 25-5/64" 26-1/16" 53-3/4" 23-11/16" 24"

DM2852 60-13/16" 24-7/8" 26-1/16" 59-15/16" 23-11/16" 24"

DM2862 60-13/16" 24-7/8" 26-1/16" 59-15/16" 23-11/16" 24"

DM2872 61-1/8" 24-7/8" 26-3/16" 59-15/16" 23-11/16" 24"

DM2882 61-1/8" 24-7/8" 26-3/16" 59-15/16" 23-11/16" 24"

RM3962 63-15/16" 25-5/64" 26-1/16" 62-15/16" 23-11/16" 24"

RM1350 64-5/16" 33-11/16" 28-1/16"1

29-1/2"

RM1350SL 64-5/16" 33-11/16" 26-1/16"1

27-1/2"

1

Steel Doors

2

Door Insert Panels

3

Add 1" depth for units with one or two optional ventilator fans.

2

2

63-3/16" 32-3/4" 26-1/16"

63-3/16" 32-3/4" 24-1/16"

3

3

3

3

3

3

3

3

3

3

3

3

5

EN

Page 6

Refrigerator

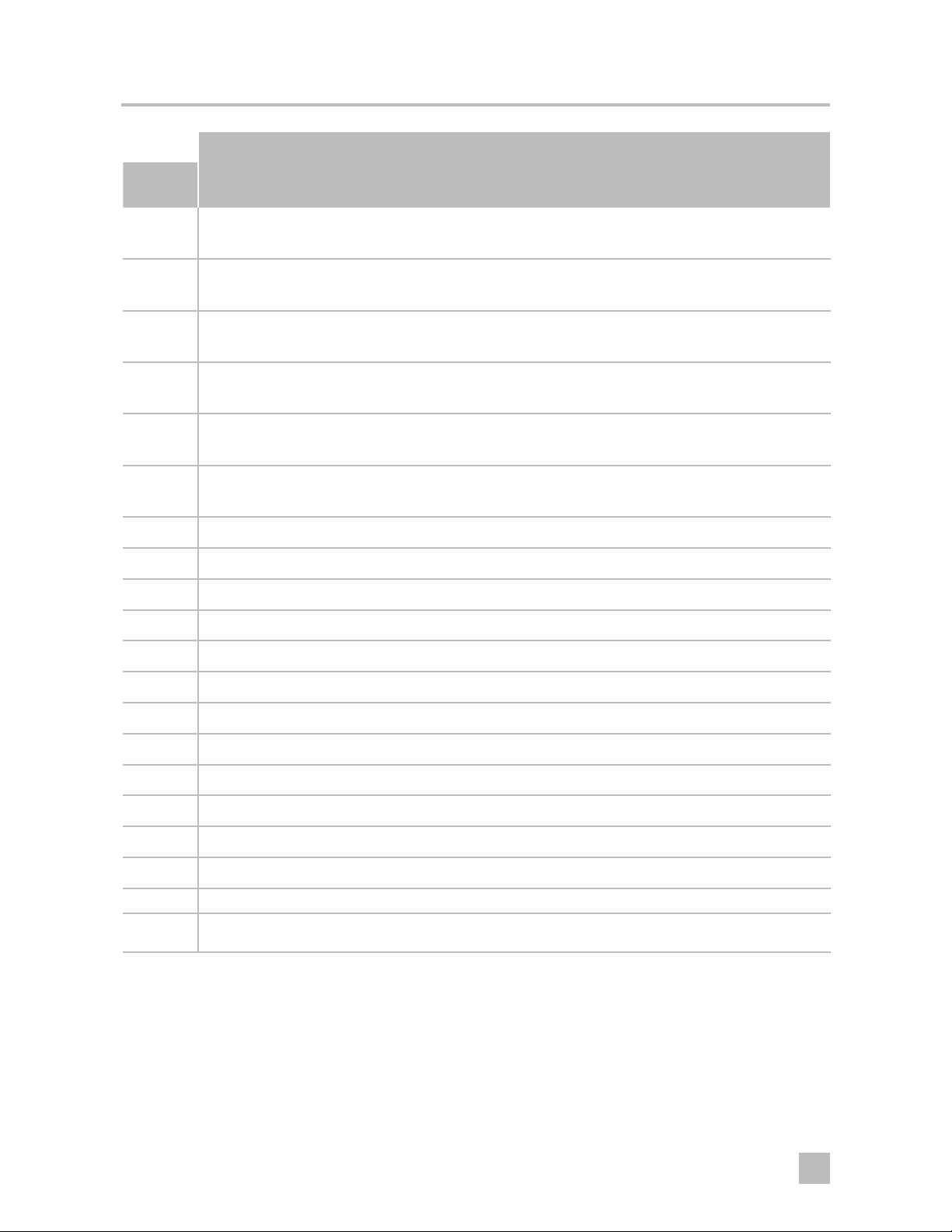

4.2 Door panel dimensions

RM2351, RM2354, RM2451, RM2454, DM2652, DM2662, DM2663, DM2672, DM2682,

DM2683, RM2551, RM2554, RM3762, DM2852, DM2862, DM2872, DM2882, RM3962

PANEL DIMENSIONS (MAX. THICKNESS 5/32")

Model Height Max. Height Min. Width Max. Width Min.

UPPER DOOR

DM2652

DM2662

DM2663

DM2852

DM2862

DM2672

DM2682

DM2683

DM2872

DM2882

RM3762

RM3962

15-27/32" 15-25/32" 20-3/4" 20-5/8"

17-25/32" 17-23/32" 22-1/4" 22-1/8"

17-3/64" 16-31/32" 23-25/32" 23-11/16"

LOWER DOOR/SINGLE DOOR

RM2351

RM2354

RM2451

RM2454

DM2652

DM2662

DM2663

RM2551

RM2554

DM2852

DM2862

DM2672

DM2682

DM2683

DM2872

DM2882

RM3762 32-7/16" 32-23/64" 23-25/32" 23-11/16"

RM3962 41-39/64" 41-9/16" 23-25/32" 23-11/16"

26-17/64" 26-3/16" 19-5/8" 19-17/32"

32-9/16" 32-1/2" 20-3/4" 20-5/8"

38-11/16" 38-5/8" 20-3/4" 20-5/8"

32-29/32" 32-27/32" 22-1/4" 22-1/8"

39-1/16" 39" 22-1/4" 22-1/8"

EN

6

Page 7

Refrigerator

RM1350

PANEL DIMENSIONS (MAX. THICKNESS 5/32")

Model Height Max. Height Min. Width Max. Width Min.

UPPER DOOR

RM1350M

RM1350SLM

RM1350MIM

19-7/32" 19-9/64" 15-43/64" 15-19/32"

RM1350WIM

RM1350WID (le)

RM1350WID (right) 9-9/32" 9-13/64" 15-43/64" 15-19/32"

LOWER DOOR

RM1350M

RM1350SLM

RM1350MIM

40-1/32" 39-31/32" 15-43/64" 15-19/32"

RM1350WIM (right)

RM1350WID

RM1350WIM (le)

A: 5-63/64"

C: 11-55/64"

E: 15-43/64"

A: 5-29/32"

C: 11-49/64"

E: 15-9/32"

B: 9-49/64"

D: 28-17/64"

F: 40-1/32"

B: 9-11/16"

D: 28-3/16"

F: 39-31/32"

+.197 +5

59.842

.295 (7.5)

(1520)

.394 - .098 (10-2.5)

11.181

(284)

45°

15.237

(387)

27.224 (691.5)

(31.279 (794.5))

2

C

D

A

B

F

E

3

0.197(2x)

Max. 1.00

(Max. 25)

in. (mm)

(5)(2x)

7

EN

Page 8

Refrigerator

4

.197(2x)

(5)(2x)

Max. 1.00

(Max. 25)

in. (mm)

6

.197(2x)

(5)(2x)

(32.106 (815.5))

28.051 (712.5)

+.197 +5

.394 - .098 (10-2.5)

16.811

(427)

45°

12.756

(324)

.295 (7.5)

+.197 +5

.394 - .098 (10-2.5)

59.842

(1520)

5

Max. 1.00

(Max. 25)

.197(2x)

(5)(2x)

Max. 1.00

(Max. 25)

in. (mm)

.197(2x)

(5)(2x)

.295 (7.5)

+.197 +5

.394 - .098 (10-2.5)

29.921

(23.2)

(760)

.913

11.181

(284)

9.370

(238)

15.237

(387)

14.960

(380)

+.197 +5

.394 - .098 (10-2.5)

.295 (7.5)

45°

27.224

(691.5)

in. (mm)

Max. 1.00

(Max. 25)

(32.106 (815.5))

28.051 (712.5)

45°

16.811

(427)

12.756

(324)

.295 (7.5)

59.842

(1520)

EN

8

Page 9

Refrigerator

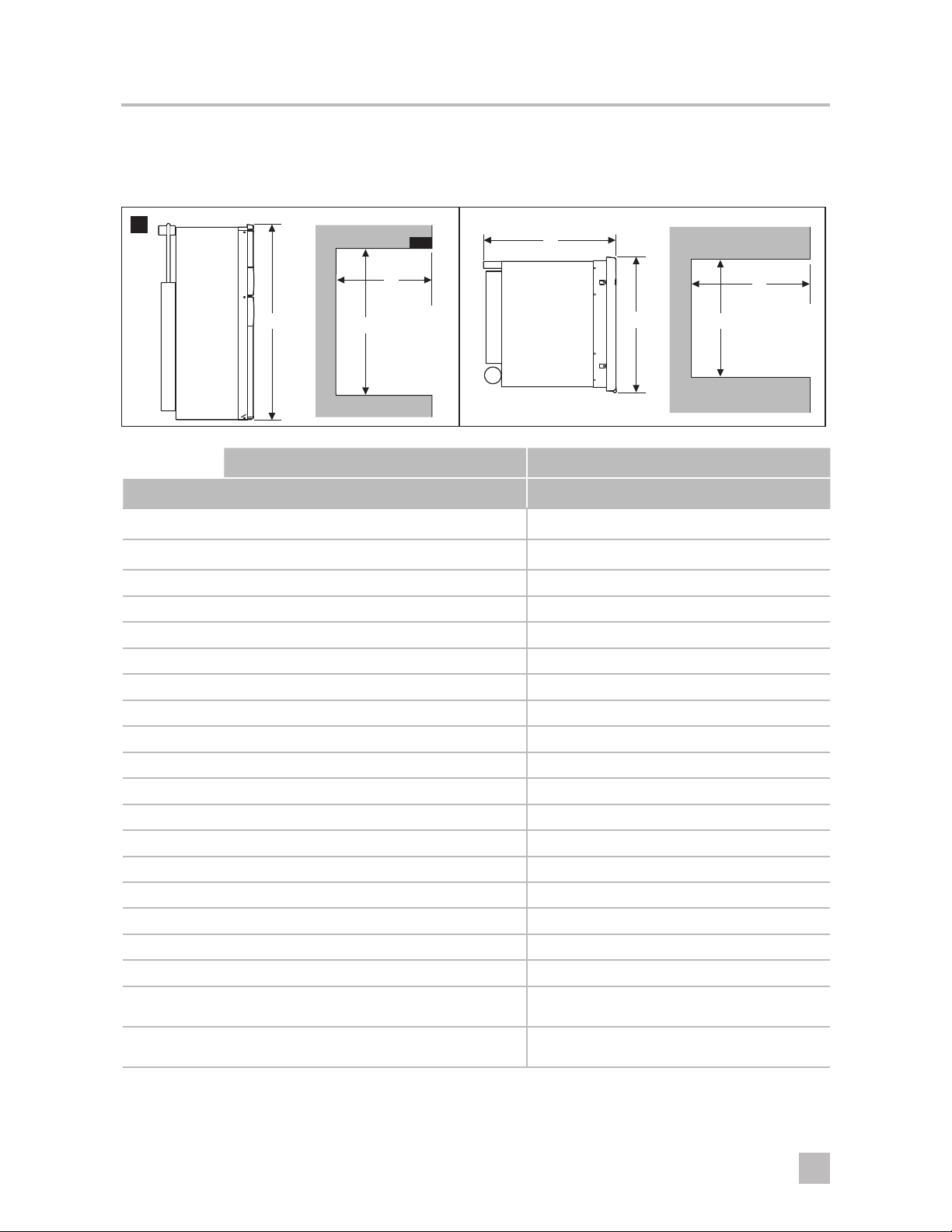

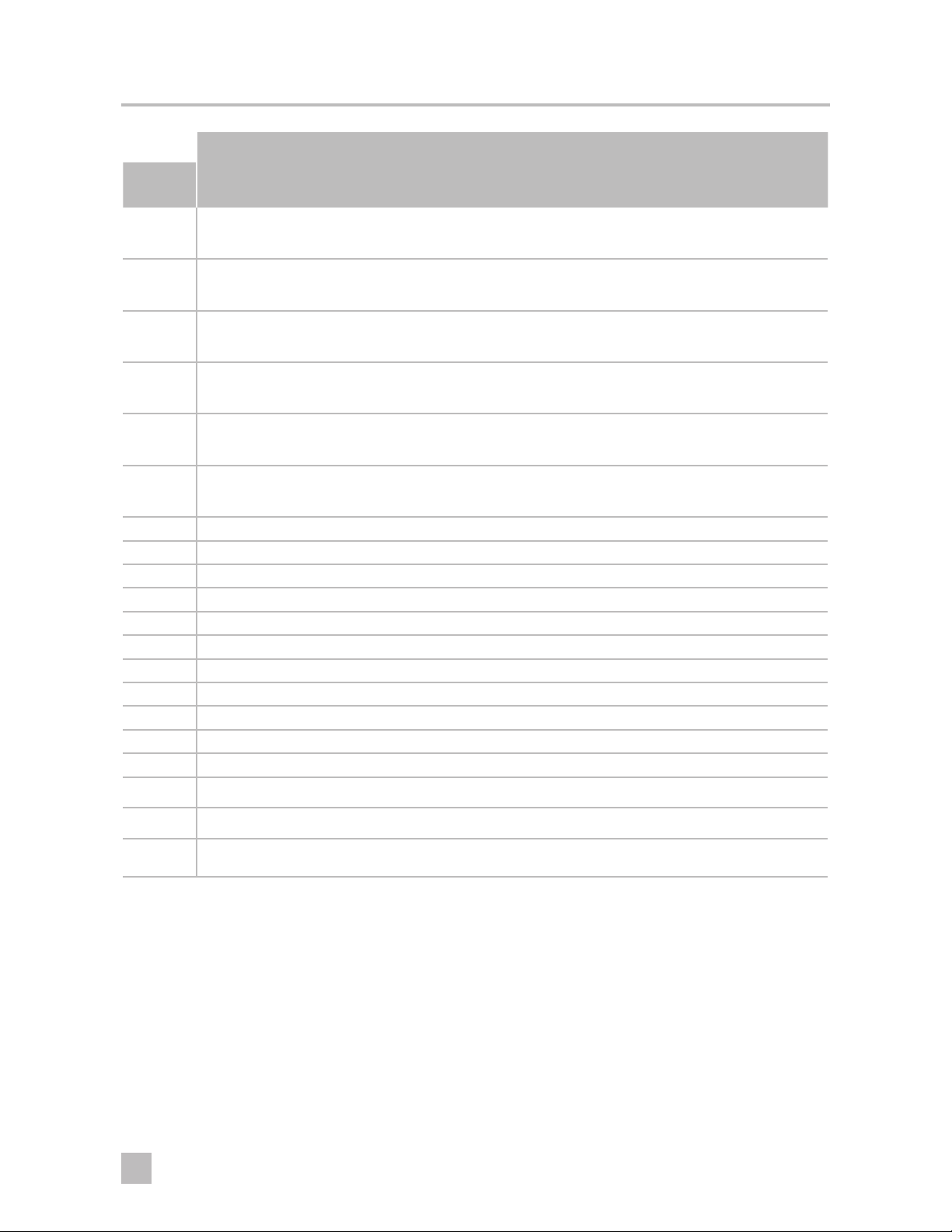

4.3 Clearances

The maximum clearances specified are necessary for correct refrigerator performance. CSA International

I

certification allows the refrigerator to have zero inch minimum clearance at the sides, rear, top, and

bottom.

Clearances

7

G

Top (G) 0" Min. to 1/4" Max.

Side (K) 0" Min. to 1/4" Max.

K

K

Bottom (L) 0" Min. to 0" Max.

M

Rear (M1) 0" Min. to 1" Max.

1

The distance between the refrigerator cooling unit and the wall or

baffle behind it

L

4.4 Minimum ventilation heights

Model B1 B2 Model B1 B2

RM2351 31" 28" DM2682 57-3/4" 56"

RM2354 31" 28" DM2683 57-3/4" 56"

RM2451 37-3/4" 36" RM3762 57-3/4" 56"

RM2454 37-3/4" 36" DM2852 63-3/4" 61"

RM2551 44-1/2" 42" DM2862 63-3/4" 61"

RM2554 44-1/2" 42" DM2872 63-3/4" 61"

DM2652 57-3/4" 56" DM2882 63-3/4" 61"

DM2662 57-3/4" 56" RM3962 66-13/16" 63"

DM2663 57-3/4" 56" RM1350 69-1/8" 63"

DM2672 57-3/4" 56" RM1350SL 69-1/8" 63"

B1 = Roof vent and lower side vent / B2 = Upper and lower side vent

➤ Measure the ventilation height from the seam between the frame and the door of the lower side wall vent,

to the top of the roof opening (B1), or to the top of the uppermost row of louvers on the upper side wall vent

(B2).

9

EN

Page 10

Refrigerator

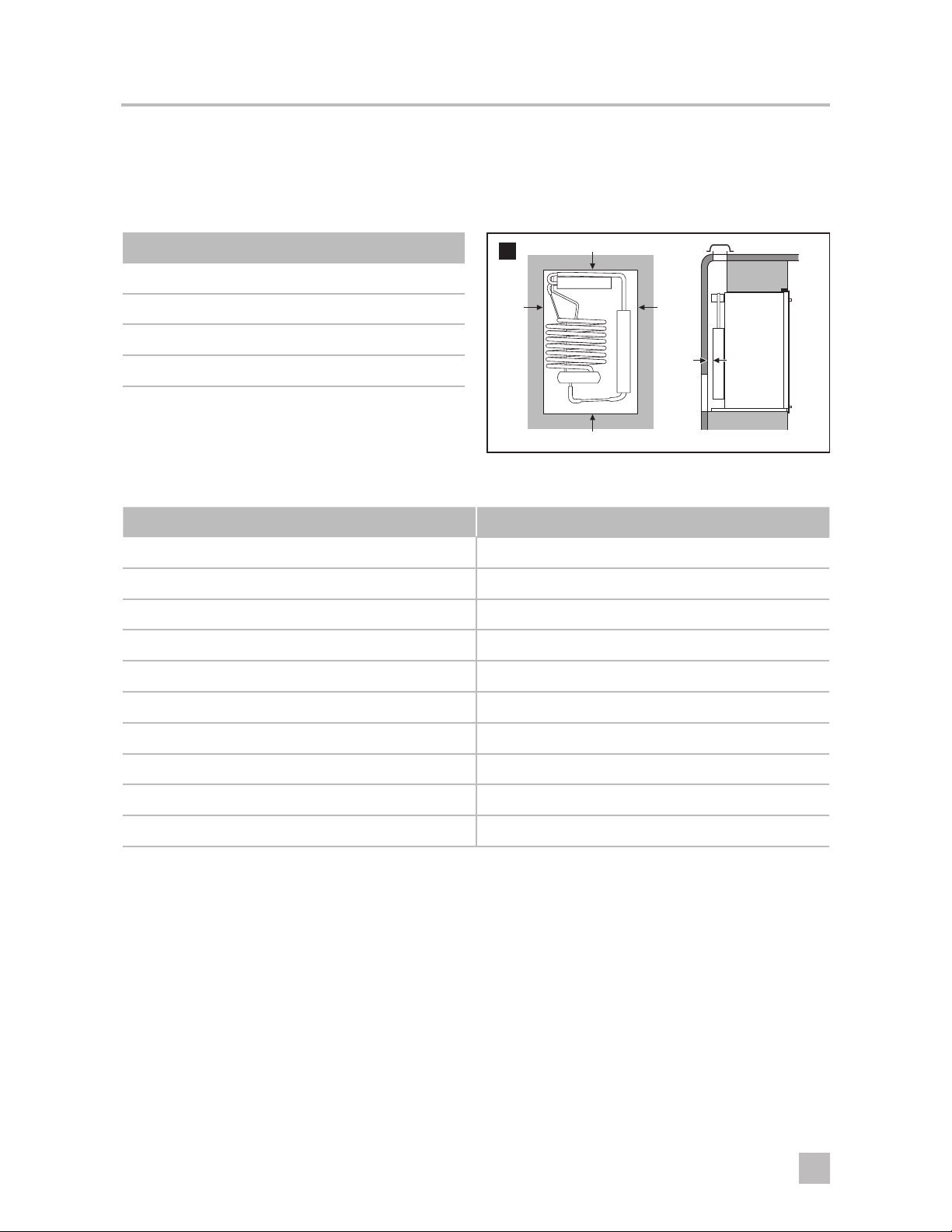

8

Roof Vent and

Lower Side Vent

Minimum

Ventilation

Height

Upper and

Lower Side Vent

Minimum

Ventilation

Height

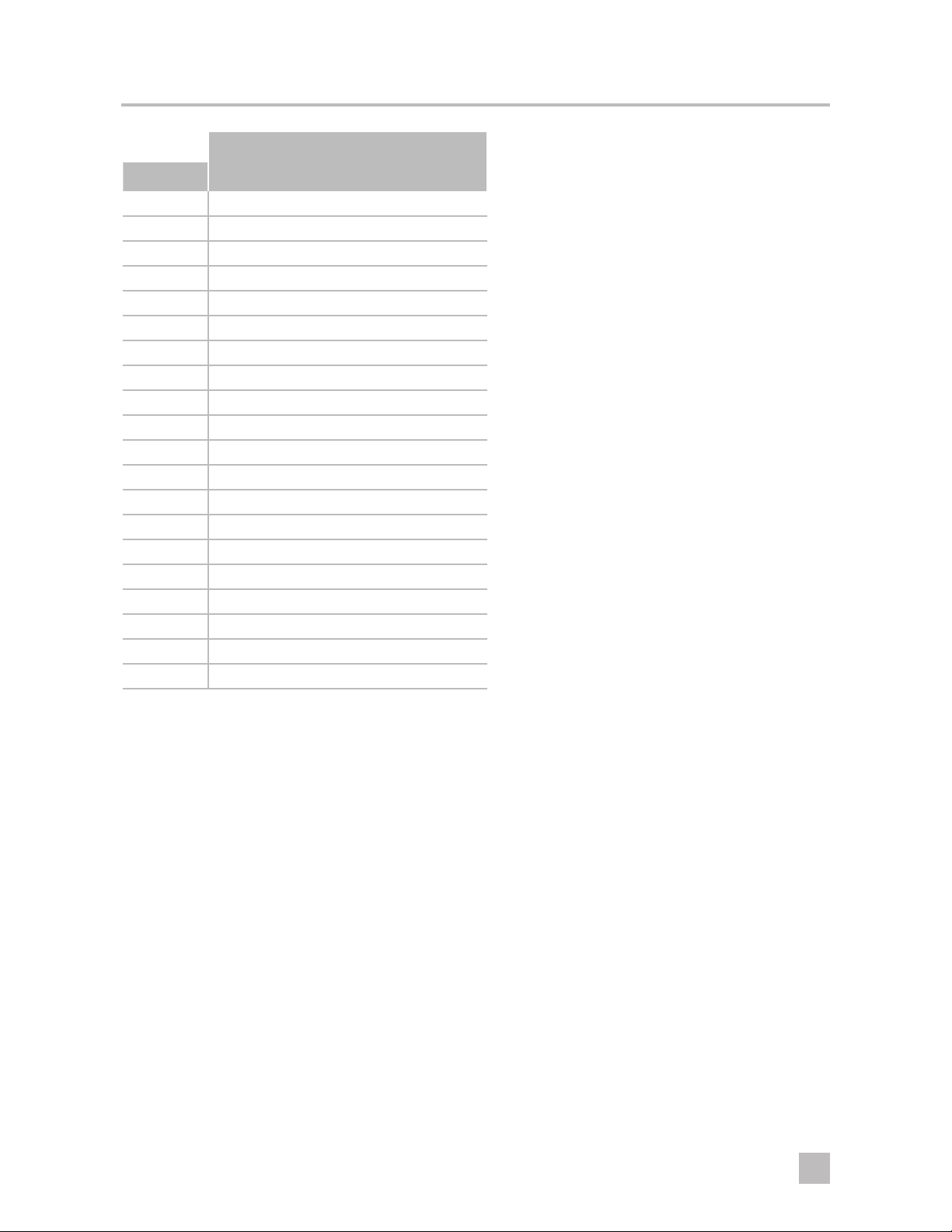

4.5 Approved vents

Roof Vent Application

Model Roof Vent Lower Side Vent Fan

RM2351 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.751

RM2354 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.751

RM2451 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.751

RM2454 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.751

RM2551 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.751

RM2554 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.751

DM2672 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2682 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2683 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

RM3762 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2872 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2882 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

RM3962 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

RM1350 3311236.xxx^ 3109349.xxx^, 3317027.xxx^

RM1350SL 3311236.xxx^

3109349.xxx^, 3109350.xxx^, 3316941.xxx^,

3317027.xxx^

•

•

*Fan(s)

*Position may

vary by model

†

†

†

†

†

†

†

†

†

†

†

†

†

* Optional vents may be used in applications where the preferred vent cannot be used

†

Optional fan. Note that some models can be purchased with factory installed fan(s)

• Fan(s) are factory installed on these models

^ Suffix "xxx" should be replaced by a color code. See "Vent Color Codes" on page 14.

EN

10

Page 11

Refrigerator

Upper & Lower Side Vent Application

Model

RM2351

RM2354

RM2451

RM2454

RM2551

RM2554

Upper

Side Vent

3109492.xxx^, 3100451.xxx^*,

80301223XX^*, 3317024.xxx^

3109492.xxx^, 3100451.xxx^*,

80301223XX^*, 3317024.xxx^

3109350.xxx^, 3109492.xxx^*,

80301223XX^*, 3316941.xxx^,

3317024.xxx^

3109350.xxx^, 3109492.xxx^*,

80301223XX^*, 3316941.xxx^,

3317024.xxx^

3109350.xxx^, 3109492.xxx^*,

80301223XX^*, 3316941.xxx^,

3317024.xxx^

3109350.xxx^, 3109492.xxx^*,

80301223XX^*, 3316941.xxx^,

3317024.xxx^

3102364.xxx/80302113XX^*,

3102364.xxx/80302113XX^*,

3109350.xxx^, 3109492.xxx^*,

3102364.xxx/80302113XX^*,

3316941.xxx^, 3317024.xxx^

3109350.xxx^, 3109492.xxx^*,

3102364.xxx/80302113XX^*,

3316941.xxx^, 3317024.xxx^

3109350.xxx^, 3109492.xxx^*,

3102364.xxx/80302113XX^*,

3316941.xxx^, 3317024.xxx^

3109350.xxx^, 3109492.xxx^*,

3102364.xxx/80302113XX^*,

3316941.xxx^, 3317024.xxx^

Lower

Side Vent

3109492.xxx^,

3317024.xxx^

3109492.xxx^,

3317024.xxx^

Fan

3108705.751

3108705.751

3108705.751

3108705.751

3108705.751

3108705.751

DM2652 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2662 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2663 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2672 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2682 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2683 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

RM3762 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2852 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2862 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2872 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2882 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

RM3962 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

†

†

†

†

†

†

†

†

†

†

†

†

†

†

†

†

†

†

RM1350 3109349.xxx^, 3317027.xxx^ 3109349.xxx^, 3317027.xxx^ •

RM1350SL

3109349.xxx^, 3109350.xxx^,

3316941.xxx^, 3317027.xxx^

3109349.xxx^, 3109350.xxx^,

3316941.xxx^, 3317027.xxx^

* Optional vents may be used in applications where the preferred vent cannot be used

†

Optional fan. Note that some models can be purchased with factory installed fan(s)

• Fan(s) are factory installed on these models

^ Suffix "xxx" should be replaced by a color code. See "Vent Color Codes" on page 14.

11

•

EN

Page 12

Refrigerator

Corner Application

Model Roof Vent

RM2351 3311236.xxx^

RM2354 3311236.xxx^

RM2451 3311236.xxx^

RM2454 3311236.xxx^

RM2551 3311236.xxx^

RM2554 3311236.xxx^

Upper

Side Vent

3109492.xxx^, 80301223xx^†,

3317024.xxx^

3109492.xxx^, 80301223xx^†,

3317024.xxx^

3109350.xxx^, 3109492.xxx^*,

80301223xx^*, 3316941.xxx^,

3317024.xxx^

3109350.xxx^, 3109492.xxx^*,

80301223xx^*, 3316941.xxx^,

3317024.xxx^

3109350.xxx^, 3109492.xxx^*,

80301223xx^*, 3316941.xxx^,

3317024.xxx^

3109350.xxx^, 3109492.xxx^*,

80301223xx^*, 3316941.xxx^,

3317024.xxx^

3102364.xxx/80302113xx^†,

3102364.xxx/80302113xx^†,

3109350.xxx^, 3109492.xxx^*,

3102364.xxx/80302113xx^*,

3316941.xxx^, 3317024.xxx^

3109350.xxx^, 3109492.xxx^*,

3102364.xxx/80302113xx^*,

3316941.xxx^, 3317024.xxx^

3109350.xxx^, 3109492.xxx^*,

3102364.xxx/80302113xx^*,

3316941.xxx^, 3317024.xxx^

3109350.xxx^, 3109492.xxx^*,

3102364.xxx/80302113xx^*,

3316941.xxx^, 3317024.xxx^

Lower

Side Vent

3109492.xxx^,

3317024.xxx^

3109492.xxx^,

3317024.xxx^

Fan

3108705.751

3108705.751

3108705.751

3108705.751

3108705.751

3108705.751

DM2652 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2662 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2663 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2672 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2682 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2683 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

RM3762 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2852 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2862 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2872 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

DM2882 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

RM3962 3311236.xxx^ 3109350.xxx^, 3316941.xxx^ 3109350.xxx^, 3316941.xxx^ 3108705.744

†

†

†

†

†

†

†

†

†

†

†

†

RM1350 3311236.xxx^ 3109349.xxx^, 3317027.xxx^ 3109349.xxx^, 3317027.xxx^ •

RM1350SL 3311236.xxx^

3109349.xxx^, 3109350.xxx^,

3316941.xxx^, 3317027.xxx^

3109349.xxx^, 3109350.xxx^,

3316941.xxx^, 3317027.xxx^

* Optional vents may be used in applications where the preferred vent cannot be used

†

Optional fan. Note that some models can be purchased with factory installed fan(s)

• Fan(s) are factory installed on these models

^ Suffix "xxx" should be replaced by a color code. See "Vent Color Codes" on page 14.

EN

•

12

Page 13

Refrigerator

Island Application

Model Roof Vent Fan

RM2351 3311236.xxx^ 3108705.751

RM2354 3311236.xxx^ 3108705.751

RM2451 3311236.xxx^ 3108705.751

RM2454 3311236.xxx^ 3108705.751

RM2551 3311236.xxx^ 3108705.751

RM2554 3311236.xxx^ 3108705.751

DM2652 3311236.xxx^ 3108705.744

DM2662 3311236.xxx^ 3108705.744

DM2663 3311236.xxx^ 3108705.744

DM2672 3311236.xxx^ 3108705.744

DM2682 3311236.xxx^ 3108705.744

DM2683 3311236.xxx^ 3108705.744

RM3762 3311236.xxx^ 3108705.744

DM2852 3311236.xxx^ 3108705.744

DM2862 3311236.xxx^ 3108705.744

DM2872 3311236.xxx^ 3108705.744

DM2882 3311236.xxx^ 3108705.744

RM3962 3311236.xxx^ 3108705.744

†

†

†

†

†

†

†

†

†

†

†

†

RM1350 3311236.xxx^ •

RM1350SL 3311236.xxx^ •

* Optional vents may be used in applications where the preferred vent cannot be used

†

Optional fan. Note that some models can be purchased with factory installed fan(s)

• Fan(s) are factory installed on these models

^ Suffix "xxx" should be replaced by a color code. See "Vent Color Codes" on page 14.

13

EN

Page 14

Refrigerator

Vent Color Codes

Side Vents Black White Tan Ivory

3109350.XXX 3109350.065 3109350.011 3109350.102 3109350.110

3109429.XXX 3109492.004 3109492.003 N/A N/A

3109349.XXX 3109349.065 3109349.005 N/A N/A

3316941.XXX 3316941.000 3316941.010 3316941.020 3316941.030

3317024.XXX 3317024.000 3317024.010 3317024.020 3317024.030

3317027.XXX 3317027.000 3317027.010 3317027.020 3317027.030

3102364.XXX N/A 3102364.019 N/A N/A

80302113XX N/A 8030211322 N/A N/A

80301223XX N/A 8030122320 N/A N/A

3100451.XXX N/A 3100451.024 N/A N/A

Roof Vents Black White

3311236.XXX 3311236.024 3311236.000

Other colors may be available for replacement upon request.

I

EN

14

Page 15

Refrigerator

5 PREPARE FOR INSTALLATION

FIRE OR EXPLOSION HAZARD. Failure to obey the following warnings could result in serious

injury or death:

• Turn off LP gas supply at the tank.

• Never use an open flame to check for gas leaks.

5.1 Removing the existing refrigerator

Proceed to "5.2 Preparing the refrigerator

I

enclosure" if a refrigerator is not already

present.

9

➤ Unplug the 120 VAC power cord from the

receptacle at the rear of the refrigerator enclosure.

➤ Disconnect the 12 VDC leads from the refrigerator

and cap the lead ends.

➤ Turn off the LP gas supply to the refrigerator.

➤ Disconnect the LP gas line from the refrigerator.

Cap the line and verify there are no LP gas leaks

➤ Remove the screws anchoring the refrigerator to

the enclosure.

➤ Slide the refrigerator out of the enclosure and

remove it from the RV.

5.2 Preparing the refrigerator

enclosure

Inspecting the refrigerator enclosure

➤ Verify the following to inspect the refrigerator

enclosure:

• There are no holes, other than ventilation holes,

inside the enclosure.

• The surface for sealing strips is clean and flat to

allow a complete seal.

• No objects are protruding into the enclosure,

except utility connections for the refrigerator.

• The enclosure seams are sealed to prevent flue

gases from leaking into the living area.

• Utility hookups are present and comply with all

applicable codes.

Assembling the refrigerator enclosure

➤ Ensure the following when assembling the

refrigerator enclosure:

• The refrigerator must be level and installed in a

sturdy enclosure.

• The floor must be level and able to support the

weight of the refrigerator and its contents.

• Adjacent heat sources must not affect the

ventilation of the refrigerator.

• All joints in the enclosure must be sealed to

prevent flue gases from leaking into the living area.

• The enclosure must be free of materials that may

damage the refrigerator.

• A wood strip must be placed above the upper

opening of the enclosure. The top frame of the

refrigerator is anchored to the wood strip with

screws.

• The refrigerator must not be installed directly on

carpeting.

15

EN

Page 16

Refrigerator

5.3 Choosing the type of vent application

Read before proceeding:

I

• Certified installation requires one lower fresh air intake vent and one upper exhaust vent.

• Center the vents to the back of the refrigerator. Refer to "Offset vent application" if it is not possible to center

the vent.

• Use only the Dometic vents specified for the installation.

• Ensure that vent openings are clear of obstructions.

• Ensure that the lower vent opening is even with, or below, floor level to allow any raw LP gas to escape.

• Do not allow the floor to block or interfere with the vent openings.

• Additional holes are required for vents installed above floor level to vent raw LP gas outdoors. The holes must

be a diameter of 1-3/4", clear of any obstruction, and covered with a screen (minimum 14 X 14 per inch).

Roof vent application

• This application is recommended for typical installations.

• This application can be used if the vents are inboard or offset due to a radius roof or interference with

building materials.

➤ Check the enclosure depth and add a baffle, if required.

Upper and lower side vent application

• Choose this type of installation when a roof vent installation is not possible.

• A baffle should be added.

• The refrigerator must be equipped with fan(s).

Island application

• This application is intended for refrigerators installed on an inside wall and must be vented through the floor

to the ceiling.

Corner application

• This application is intended for refrigerators installed in the rear corner of the vehicle or in an angled cabinet.

• The refrigerator must be equipped with fan(s).

Offset vent application

• The vents must always be offset toward the flue side of the cooling unit.

• For offset vent applications, prior written approval and safety certification must be obtained from Dometic

Corporation.

EN

16

Page 17

Refrigerator

5.4 Installing the vent application

FIRE OR EXPLOSION HAZARD. Make sure vent allows raw (unburned) LP Gas to escape to the

outside. LP Gas is heavier than air, and will collect at floor level if not vented correctly. Failure to obey this warning

could result in death or serious injury.

Read before proceeding:

I

• Use the inboard installation option when the radius of the roof, or the presence of building materials,

interferes with the placement of the roof vent.

• All fasteners are to be provided by the installer.

• Select the appropriate screw types for the application for which they are being used.

• Minimize screw lengths to fit applications appropriately, unless otherwise noted.

• Rivets are acceptable only where noted.

➤ Apply sealant around the thread or rivet body of all fasteners.

➤ Apply dry sealant around the surface mounting face of all vent frames or vent bases before installation.

➤ Apply wet sealant around the perimeter of all vent frames or vent bases aer installation. Do not allow the

sealant to block the molded weep tracks in the vent frame.

Roof vent application

10

Side

View

Roof Vent

Box Baffle

Recess Depth

11

Side

View

Roof Vent

Box Baffle

Recess Depth

17

EN

Page 18

Refrigerator

Plastic roof vent (No. 3311236.xxx)

12

Cutout

23-3/4"

6-1/2"

➤ Confirm ventilation height. Refer to "4.4 Minimum ventilation heights" on page 9.

➤ Confirm the recess depth. Refer to "5.5 Recess depth" on page 22.

➤ Install a box baffle, if required.

➤ Install the lower side vent. Refer to "Side vents" on page 19.

➤ Center the roof vent base over the cutout.

➤ Secure the roof vent base using sixteen #10 screws (not provided).

➤ Place the cap on top of the base.

➤ Secure the cap to base using four #10 screws (not provided). The screws must be a minimum of 1-1/4".

➤ Apply sealant over all the screws.

Upper and lower side application

➤ Confirm ventilation height. Refer to "4.4 Minimum ventilation heights" on page 9.

➤ Confirm the recess depth. Refer to "5.5 Recess depth" on page 22.

➤ Install a box baffle above the lower access vent, if required.

➤ Install the lower side vent.

➤ Install the upper side vent.

Refer to "Side vents" on page 19 for specific instructions on installing the side vents.

I

EN

18

Page 19

Refrigerator

Side vents

Upper and Lower Plastic Side Vent

(No. 3109350.xxx)

Upper Metal Side Vent (No. 3100451.xxx)

13

13-3/4"

➤ Place the frame into the cutout.

➤ Secure the frame using seven #10 screws (not

provided) through the inside flange of the frame.

Seven Z-brackets could be used if the wall is

I

of laminate construction. Use #10 screws (not

provided) to secure the frame with Z-brackets.

➤ Install the vent door into the frame using the upper

tabs as a guide.

➤ Lock the vent door into place by fully seating and

twisting the black latches in the bottom corners of

the vent door.

21-9/16"

Cutout

14

19-1/4"

Cutout

7-3/4"

➤ Place the vent over the cutout.

➤ Secure the frame using fourteen #10 screws Not

provided).

Rivets could be used for this vent.

I

Upper Metal Side Vent (No. 80301223xx)

15

21"

10-1/4"

➤ Place the vent over the cutout.

➤ Secure the frame using sixteen #10 screws (not

provided).

Rivets could be used for this vent.

I

Cutout

Lower Metal Side Vent (No. 3102364.xxx,

80302113xx)

16

19-1/4"

Cutout

9-11/16"

➤ Place the vent over the cutout.

➤ Secure the frame using sixteen #10 screws (not

provided).

Rivets could be used for this vent.

I

19

EN

Page 20

Refrigerator

Upper and Lower Plastic Side-By-Side Vent

(No. 3109349.xxx)

17

28-5/8"

Cutout

13-5/8"

➤ Place the frame into the cutout.

➤ Secure the frame with five Z-brackets.

➤ Install six #10 screws (three on each end, not

provided) to completely secure the frame.

➤ Remove the screw cap plugs from the vent frame

and install them over the six screws in the front

frame.

➤ Install the vent door into the frame using the upper

tabs as a guide.

➤ Lock the vent door into place by fully seating and

twisting the black latches in the bottom corners of

the vent door.

Upper and Lower Plastic Side Vent

(No. 3109492.xxx)

18

19-1/4"

Cutout

9-11/16"

➤ Place the frame into the cutout.

➤ Secure the frame with seven Z-brackets using #10

screws (not provided).

➤ Install the vent door into the frame using the upper

tabs as a guide.

➤ Lock the vent door into place by fully seating and

twisting the black latches in the bottom corners of

the vent door.

Upper and Lower Plastic Side Vent

(No. 3316941.xxx)

19

21-9/16"

Cutout

13-3/4"

➤ Place the frame into the cutout.

➤ Secure the frame using sixteen #8 screws (not

provided) through the inside flange of the frame.

➤ Install the vent door into the frame using the lower

tabs as a guide.

➤ Lock the vent door into place by fully seating and

twisting the latches in the top corners of the vent

door.

Upper and Lower Plastic Side Vent

(No. 3317027.xxx)

20

28-5/8"

Cutout

13-3/4"

➤ Place the frame into the cutout.

➤ Secure the frame using sixteen #8 screws (not

provided) through the inside flange of the frame.

➤ Install the vent door into the frame using the lower

tabs as a guide.

➤ Lock the vent door into place by fully seating and

twisting the latches in the top corners of the vent

door.

EN

20

Page 21

Refrigerator

Upper and Lower Plastic Side Vent

(No. 3317024.xxx)

21

19-1/4"

Cutout

9-11/16"

➤ Place the frame into the cutout.

➤ Secure the frame using twelve #8 screws (not

provided) through the inside flange of the frame.

➤ Install the vent door into the frame using the lower

tabs as a guide.

➤ Lock the vent door into place by fully seating and

twisting the latches in the top corners of the vent

door.

Fan (Innovator Refrigerator Ventilation

System*) (No. 3108705.751, 3108705.744)

22

*Patent #5,355,693

Z-Bracket (No. 3103812.xxx)

23

Side

View

Wall or Frame

Vent Frame Vent Frame

Wall or Frame

D

Z-Bracket

D

Z-Bracket

Use appropriate D:

xxx = 016 = .62"

xxx = 024 = .81"

xxx = 040 = .19"

21

EN

Page 22

Refrigerator

5.5 Recess depth

Side

24

View

Max. 1"

(without baffle)

Island application

26

25

27

Side

View

1/2"

Below

Fins

Box Baffle

Box Baffle

Access Panel

Minimum

Ventilation

Height

Access

Panel

Duct

and Fan

Access

Panel

Duct

and Fan

Box Baffle

Recess Depth

➤ Confirm the ventilation height. Refer to "4.4

Minimum ventilation heights" on page 9.

➤ Confirm the recess depth. Refer to"5.5 Recess

depth" above.

➤ Install a box baffle above the lower access panel, if

required.

14"

22"

➤ Install the access panel.

28

Fan

(Centered

Horizontally)

1/4" x 0.025"

Metal Mesh

L

Min. 3"

Max. 8"

➤ Install the air duct.

➤ Install the roof vent. Refer to "Roof vent

application" on page 17.

D

W

EN

22

Page 23

Refrigerator

Corner application with roof vent

29

Side

View

Minimum

Ventilation

Vent Cutout

Height

➤ Confirm the ventilation height. Refer to "4.4

Minimum ventilation heights" on page 9.

Corner application with upper and lower side vents

31

30

Top

View

Baffle

Vent Cutout

Recess

Depth

Roof Vent

➤ Confirm the recess depth. Refer to "5.5 Recess

depth" on page 22.

➤ Install the lower side vent. Refer to "Side vents" on

page 19.

➤ Install the roof vent. Refer to "Roof vent

application" on page 17.

32

Baffle

Upper

Side Vent

Minimum

Ventilation

Height

*Fan

*Position may

vary by model

➤ Confirm the ventilation height. Refer to "4.4

Minimum ventilation heights" on page 9.

Baffle

Recess

Depth

Lower

Side Vent

➤ Confirm the recess depth. Refer to "5.5 Recess

depth" on page 22.

➤ Install the lower side vent. Refer to "Side vents" on

page 19.

➤ Install the upper side vent. Refer to "Side vents" on

page 19.

23

EN

Page 24

Refrigerator

Offset vent - upper and lower side vent

33

Center of

Refrigerator

Prior written approval and safety certification must be obtained from Dometic Corporation for this

I

application.

➤ Confirm the ventilation height. Refer to "4.4 Minimum ventilation heights" on page 9.

➤ Confirm the recess depth. Refer to "5.5 Recess depth" on page 22.

➤ Install the lower side vent. Refer to "Side vents" on page 19.

➤ Install the upper side vent or roof vent. Refer to "Side vents" on page 19, or "Roof vent application" on

page 17.

Offset vent - side and roof vent

34

Center of

Refrigerator

5.6 Placing the insulation

Read before proceeding:

I

• Dimensions will vary by model.

• If there is more than 1/4" between the side or top of the refrigerator and the inside of the enclosure, fill the

space with insulation, baffles, or other non-flammable fabricated seals.

• Do not allow insulation to come into contact with the cooling unit.

➤ Cut the insulation two to three inches shorter than the depth of the enclosure.

➤ Secure the insulation to the enclosure walls and ceiling. This will prevent it from shiing when the refrigerator

is installed.

35

Insulation

Refrigerator

Rear Side To p

2" – 3"

Insulation

Refrigerator

2" – 3"

Insulation

EN

24

Page 25

Refrigerator

5.7 Connecting the water supply

For refrigerator models equipped with ice maker, ice and water dispensers:

➤ Ensure that the water supply system has a minimum pressure of 15 pounds per square-inch (psig).

➤ Use a 1/4" diameter water line to the water valve at the rear of the refrigerator.

➤ Ensure that the water line is equipped with a manual shut-off valve that is easily accessible.

6 INSTALLATION

6.1 Installing the refrigerator

Refrigerator model RM1350SL is equipped with vacuum-insulated panel technology. The insulating

I

panels are located on the top, back, sides, and doors. If the surface is punctured, the effectiveness of the

insulation will be reduced, resulting in poor refrigerator performance.

36

Do NOT remove factory

installed sealing strip

*RM2351, RM2354

Apply sealing strip to floor

➤ Carefully place the refrigerator in the enclosure.

➤ Verify that there is a complete seal between the front frame of the refrigerator and the top, sides and bottom

of the enclosure.

A length of sealing strip is applied to the rear surface of the front frame of the refrigerator. The sealing strip

I

provides complete isolation of the combustion system from the vehicle interior.

➤ RM2351, RM2354: Apply a sealing strip to the front edge of the enclosure floor. Do not damage the

sealing strip when the refrigerator is put in place.

RM2351 & RM2354: Do not remove the factory-installed sealing strip at the top rear corner of the

I

cabinet. It is not part of the shipping materials and must be le intact.

Seal

Seal

25

EN

Page 26

Refrigerator

6.2 Securing the refrigerator

The following steps must be completed in order to prevent leakage between the refrigerator and the

I

enclosure.

RM2351, RM23514

37

Plug

Screw

Front

Frame

Seal

Do NOT

remove

factoryinstalled

sealing

strip

Rear

Base

➤ Install four screws (not provided) through the front

frame.

➤ Install one screw (not provided) in the rear base.

➤ Cover the screw heads using the plugs provided

RM2451, RM2454, RM2551, RM2554, DM2652,DM2662, DM2663, DM2852, DM2862

38

Rear

Base

Screw

Front

Base

Lower

Front

Strip

39

Hinge

Top Panel

➤ Install the lower front strip by sliding it under the

bottom hinge plate. Refer to "6.3 Installing the

hinge plate" on page 29.

➤ Secure the refrigerator and the lower front strip

using two screws (not provided).

EN

➤ Gently remove the tabs from the hole in the

hinge plate, on both sides, using a flat-bladed

screwdriver.

➤ Tilt the top decoration panel and li to remove it

from the top frame. Do not damage the circuit

board and wires.

➤ Install two screws (not provided) in the top frame.

➤ Seal the opening for the screws with aluminum

tape (not provided).

➤ Replace the top decoration panel. Do not pinch

the wires behind the panel.

26

Page 27

Refrigerator

40

Optional Screw

➤ Install one screw (not provided) in the rear base.

An optional screw may be added on the opposite

side.

DM2672, DM2682, DM2683, DM2872 & DM2882

41

Bottom Frame

➤ Secure the refrigerator using two screws (not

provided) through the bottom frame of the

refrigerator.

43

Screw

Top Frame

Screw

42

Adhesive Backing

Lower Front Strip

➤ Remove the three pieces of adhesive backing tape

from the lower front strip.

➤ Align the lower front strip to the bottom frame and

install it by firmly pressing the trim piece to the

frame.

44

Top Panel

➤ Install two screws (not provided) through the holes

underneath the top frame.

➤ Seal the opening for the screws using the black

labels provided.

27

Adhesive Backing

➤ Remove the three pieces of adhesive backing tape

from the top decoration panel.

➤ Align the top decoration panel to the top frame

and install by firmly pressing the trim piece onto

the frame.

EN

Page 28

Refrigerator

45

Optional Screw

➤ Install one screw (not provided) in the rear base.

An optional screw may be added on the opposite

side.

RM3762, RM3962

46

Screw

Top Decoration

Panel

➤ Secure the refrigerator using two screws (not

provided) through the holes underneath the top

decoration panel.

➤ Seal the openings for the screws on the metal

frame using tape or sealant.

➤ Install the lower front strip by sliding it under the

bottom hinge plate. Refer to "6.3 Installing the

hinge plate" on page 29.

➤ Secure the refrigerator and the lower front strip

using two screws (not provided).

47

Optional Screw

➤ Install one screw in the rear base. An optional

screw may be added on the opposite side.

EN

28

Page 29

Refrigerator

RM1350, RM1350SL

48

Screw

Top Panel

➤ Secure the refrigerator using two screws (not

provided) through the holes underneath the top

decoration panel.

➤ Seal the openings for the screws on the metal

frame using tape or sealant.

➤ Install the lower front strip by sliding it under the

bottom hinge plate. Refer to "6.3 Installing the

hinge plate" on page 29.

➤ Secure the refrigerator and the lower front strip

using two screws (not provided).

49

Ice Maker Cord

(optional)

Screw

➤ Install one screw (not provided) in the rear base.

An optional screw may be added on the opposite

side.

6.3 Installing the hinge plate

The refrigerator is provided with a lower front strip that is shipped as a loose part.

I

➤ Attach the front strip aer the refrigerator is set into the cutout opening.

50

Screw

Hinge

Plate

Front Strip

➤ Slide the lower front strip under the bottom hinge plate(s).

➤ Secure the hinge plate(s) and the lower front strip using two screws (not provided).

51

Screw

Hinge Plate

Front Strip

29

EN

Page 30

Refrigerator

6.4 Installing the drain water hose

FIRE HAZARD. Do not allow the drain tube to contact the burner assembly or boiler casing.

Failure to obey this warning could cause a fire resulting in death or serious injury.

Read before proceeding:

I

• The perforated plug must be present at the end of the drain water hose.

• The drain water hose must not be kinked or routed uphill.

52

Hose

Option 1 - through the floor

➤ Drill a hole through the flooring.

➤ Place sealant around the hole.

➤ Confirm that the supplied hose is long enough.

➤ Supply an extra length of hose, if needed.

Option 2 - through vent frame (plastic vents only)

➤ Pull the end of the hose through the louvers in the vent door.

➤ Cut the hose to length.

➤ Reinstall the perforated plug.

Option 3 - hanging clip (plastic vents only)

➤ Install the clip (not provided, part number 3106559.xxx) during vent installation.

➤ Insert the hose into the “j” portion of clip.

➤ Cut the hose to length.

➤ Reinstall the perforated plug.

➤ Ensure that the hose is positioned to drain into the uppermost row of louvers in the vent door.

Option 4 - through vent door (side-by side plastic vent only)

➤ Drill a 5/8" hole in the vent frame directly above the floor line.

➤ Route the drain hose through the hole and cut it to length.

➤ Reinstall the perforated plug on the outside of the vent frame.

➤ Apply sealant around the plug to ensure water does not seep into the enclosure.

Option 5 – attached to vent frame (3316941.xxx, 3317027.xxx, and 3317024.xxx only)

➤ Remove the perforated plug.

➤ Cut the hose to length.

➤ Push the end of the hose through the attachment feature located on the vent frame.

EN

30

Page 31

Refrigerator

6.5 Connecting the gas

FIRE OR EXPLOSION HAZARD. Failure to obey the following warnings could result in property

damage, serious injury, or death:

• Install gas connections in compliance with the applicable supplemental directives listed in this manual. Refer

to"1.3 Supplemental directives" on page 3.

• Never use an open flame to check for gas leaks. Use a commercial leak detection solution to check all

connections, as specified in these instructions.

• Should the gas supply fail to shut off or if overheating occurs, shut off the gas valve to the refrigerator before

shutting off the electrical supply.

• Do not put sealing compound on flair fittings.

• Never use a wire or pin to clear obstructions from burner jet (damage will occur).

• Do not attempt to adjust burner jet.

Read before proceeding:

I

• Connection to the gas supply line is accomplished at the manual gas valve. The manual gas valve is furnished

with a 3/8" SAE (UNF 5/8" -18) male flare connection.

• The gas supply system must incorporate a pressure regulator to maintain a supply pressure of not more than

11" water column.

• When testing the gas supply system at test pressures:

– greater than 1/2 psi, the refrigerator and its individual shutoff valve must be disconnected from the gas

supply piping system.

– 1/2 psi, or less, the refrigerator must be isolated from the gas supply piping system by closing the

individual manual shutoff valve.

• If local codes allow for the use of a flexible gas appliance connector, do not use a connector that has

previously serviced another gas appliance.

• If detailed instructions on the installation and connection to the gas supply are required, contact the nearest

dealer or distributor.

➤ Always use two wrenches to hold the valve and flair nut when loosening and tightening gas connections.

➤ Route all connections to avoid contact with the boiler casing, burner cover, or any other refrigerator

components.

➤ Perform an air pressure test on the piping system.

➤ Examine all completed connections for leaks using a commercially available soap solution made for the

detection of leaks.

RM2351, RM2354

53

Flexible Cord

31

Relay

Power

Module

Cover

12 VDC

Terminal

Block

Inlet

Fitting

Manual Gas

Shutoff Valve

Burner Jet

1 Heater

(RM2351)

2 Heaters

(RM2354)

Flue Baffle

Drain Water

Hose

Protection

Cover

Cover Screw

EN

Page 32

Refrigerator

RM2451, RM2454, RM2551, RM2554

54

Flexible Cord

Power

Module

Cover

Relay

(3-way ONLY)

12 VDC

Terminal

Block

Inlet Fitting

Drain

Water

Hose

Cover Screw

Burner Jet

Manual Gas Shutoff Valve

Heater

Flue Baffle

Protection

Cover

DM2672, DM2682, DM2683, DM2872, DM2882, DM2652, DM2662, DM2663, DM2852,

DM2862

55

Power Module Cover

Relay

(3-way ONLY)

Drain

Water

Hose

Thermofuse

Cover

Screw

Heater(s)

Flue Baffle

Protection Cover

Flexible Cord

RM3762, RM3962

56

Power Module

Flexible Cord

12 VDC

Terminal

Block

D+

12 VDC

Terminal

Block

Drain

Water

Hose

Inlet

Fitting

Inlet

Fitting

Burner Jet

Manual Gas Shutoff Valve

Heater

Thermofuse

Flue Baffle

Cover

Screw

Protection Cover

Burner Jet

Manual Gas Shutoff Valve

EN

32

Page 33

Refrigerator

RM1350M, RM1350SLM

57

Heaters

Drain Water Hose

Protection Plate

Power

Module

LP Gas Connection

12 VDC Terminal Block

RM1350IM, RM1350MIM, RM1350WIM

58

Water Hose

Ice maker

Heaters

Protection

Plate

LP Gas Connection

Heating Cable

Drain

Water

Hose

Power Module

Thermostat

Water Valve

12 VDC Terminal Block

*Valid for refrigerators equipped with the automatic door locking system

Flexible Cord

Water Hose - Door

(RM1350WIM ONLY)

Heating Cable

(RM1350WIM ONLY)

Flexible Cord

(Ice maker)

Flexible Cord

(Refrigerator)

*Alternator Signal Wire

RM1350WID

59

33

Water Hose

Ice maker

Protection

Plate

Heaters

LP Gas Connection

Heating Cable

Control Unit

Power Module

Thermostat

Water Valve

Drain

Water

Hose

Alternator Signal Wire

12 VDC Terminal Block

Water Hose

Water Dispenser (Door)

Flexible Cord

(Ice Dispenser)

Flexible Cord

(Refrigerator)

Heating Cable

EN

Page 34

Refrigerator

6.6 Connecting the electrical

120 VAC connection

120 VAC

60

Connection

3" – 6"

The free length of the cord is 2'.

I

➤ Install the electrical receptacle on the opposite

side of the burner assembly, and 3–6" above the

refrigerator, to allow easy access through the vent

door.

12 VDC connection

Read before proceeding:

I

• RM2451, RM2551, DM2652, DM2672,

DM2872, DM2852, RM3762, RM3962,

RM1350, & RM1350SL refrigerator models are

not designed for 12 VDC operation of the cooling

system. However, 12 VDC must be supplied to

operate the controls.

• RM2354, RM2454, RM2554, DM2662,

DM2663, DM2682, DM2683, DM2862,

& DM2882 refrigerator models require a

continuous 12 VDC supply to maintain the

automatic energy system.

MAXIMUM WIRE LENGTH

Model

RM2351, RM2451, RM2551,

DM2652, DM2662,

DM2672, DM2682,

DM2852, DM2862,

DM2872, DM2882,

RM3762, RM3962, RM1350,

RM1350SL,

RM2354, RM2454,

RM2554, DM2663, DM2683

Wire

Size

(AWG)

14

12

10

8

Wire

Length

(Feet)

17

27

17

27

Alternator (D+) connection

RM3762, RM3962, RM1350 & RM1350SL

I

(with the automatic door locking system)

• The refrigerator requires a signal wire connection

from the vehicle's alternator (D+) to maintain

temporary gas lock-out function, and the

automatic travel door-latch for RM1350 and

RM1350SL.

• The gas operation will automatically lock out for

15 minutes when the engine is switched off, to

prevent gas operation when stopping at a fuel

station.

EN

61

Alternator Signal Wire

to the Refrigerator

D+–+

➤ Connect the vehicle's alternator (D+) to the D+ on

the terminal block

Ignition Switch

Charge Light

D+

B+

Alternator

Battery

34

Page 35

Refrigerator

RM2351, RM2451, RM2551

62

+12V

L

3A

J4

5A

J5 J7

J2

P3

1 1 12 2 23 3 54 4 6

E

P1 P2

T

Display

Board

N

N

J6

J8

J10

M

RM2354, RM2454, RM2554

63

+12V

L

W

3A

J4

J5

5A

J2

P3

P1 P2

1

2

3 544 6

1

2

3

X

Display

Board

E

85

87

86 30

O

Ground

N

J6

J7

J8

J10

K

1

2

N

J

P

Ground

J

A Circuit Board Power S Chassis Ground

B Fuse 3A T Test Point

C Fuse 5A 1 Black

D Circuit Board Display 2 Brown

E Electrode 3 Red

J Heater 120 VAC 4 Yellow

L Terminal Block 5 Green

M Thermistor 6 Green/Yellow

N Solenoid Valve 7 Blue

O Retainer 8 Gray

P Protective Earth 9 White

A Circuit Board Power U Chassis Ground

B Fuse 3A W Fuse 30A

C Fuse 5A X Test Point

D Circuit Board Display 1 Black

E Electrode 2 Brown

J Heater 120 VDC 3 Re d

K Heater 120 VAC 4 Yellow

M Terminal Block 5 Green

N Thermistor 6 Green/Yellow

O Solenoid Valve 7 Blue

P Relay 8 Gray

R Retainer 9 White

S Protective Earth

D

D

Orange

M

Orange

N

5

3

2

1

X

3

2

1

T

P1–1

P1–4

7

P1–2

P1–5

P1–6

P1–3

9

P2–1

P2–2

9

5

P1–1

P1–4

7

P1–2

P1–5

P1–6

P1–3

9

P2–1

9

P2–2

B

B

J2 J4 J5 J6 J7J8 J10

A

C

J2 J4 J5 J6 J7 J8 J10

3

1

9

5

LLN

A

C

3

1

9

5

M

+

LSN

12VDC

1

–

+

12VDC

P3–4

P3–3

P3–2

P3–1

1

1

3

P3–4

P3–3

4

P3–2

P3–1

8

1

1

1

1

P

–

7

K

1

1

8

U

6

N

9

E

J

S

6

7

4

9

3

J

O

P

O

3

W

E

R

DM2672, DM2682, DM2872, DM2882, DM2652, DM2662, DM2852, DM2862 (no fan) with &

without ice maker

35

64

+12V

L

J4

3A

J5

5A

J2

P3 P1 P2

1234 12123456

T

Display

Board

E

N

U

F

G

H

K

J10

Ground

N

J6

J7

J8

J

M

A Circuit Board Power P Protective Earth

B Fuse 3A S Chassis Ground

C Fuse 5A T Test Point

D Circuit Board Display U Thermal Fuse

E Electrode 1 Black

F Thermofuse 2 Brown

G Lamp 3 Red

H Switch Lamp 4 Yellow

J Heater 120 VAC 5 Green

K Heating Cable 6 Green/Yellow

L Terminal Block 7 Blue

M Thermistor 8 Gray

N Solenoid Valve 9 White

O Retainer

M

D

Orng

T

P1–1

5

P1–4

7

P1–2

2

P1–5

2

P1–6

1

P1–3

9

P2–1

P2–2

9

H

G

K

A

C

B

3

3

F

1 9 5

LLN

3

U

+ –

12VDC

P3–4

P3–3

P3–2

P3–1

1

1

1

4

9

8

1

1

S

P

6

N

E

J

O

EN

Page 36

Refrigerator

DM2672, DM2682, DM2872, DM2882, DM2652, DM2662, DM2852, DM2862 (one fan) with and

without ice maker

65

+12V

L

3A

J4

3A

J5

5A

J2

P3 P1 P2

1234 12123456

T

Display

Board

E

N

F

Y

U

G

H

K

J10

Ground

N

J6

J7

J8

J

A Circuit Board Power S Chassis Ground

M

V

B Fuse 3A T Test Point

C Fuse 5A U Thermal Fuse

D Circuit Board Display V Thermofuse

E Electrode Y Thermal Fuse

F Thermofuse 1 Black

G Lamp 2 Brown

H Switch Lamp 3 Red

J Heater 120 VAC 4 Yellow

K Heating Cable 5 Green

L Terminal Block 6 Green/Yellow

M Thermistor 7 Blue

N Solenoid Valve 8 Gray

O Retainer 9 White

P Protective Earth

M

D

Orng

T

P1–1

5

P1–4

7

P1–2

2

P1–5

2

P1–6

1

P1–3

9

P2–1

P2–2

9

H

G

K

A

C

B

3

3

3

F

1 9 5

LLN

Y

+ –

12VDC

P3–4

P3–3

P3–2

P3–1

B

1

1

1

4

9

8

1

1

P

E

U

3 3

J

S

6

DM2872, DM2882, DM2852, DM2862 (one or two fans) with and without ice maker

66

A Circuit Board Power S Chassis Ground

B Fuse 3A T Test Point

C Fuse 5A U Thermal Fuse

D Circuit Board Display V Thermofuse

E Electrode Y Thermal Fuse

F Thermofuse 1 Black

G Lamp 2 Brown

H Switch Lamp 3 Red

J Heater 120 VAC 4 Yellow

K Heating Cable 5 Green

L Terminal Block 6 Green/Yellow

M Thermistor 7 Blue

N Solenoid Valve 8 Gray

O Retainer 9 White

P Protective Earth

D

T

P1–1

5

Orng

M

P1–4

7

P1–2

2

P1–5

2

P1–6

1

P1–3

9

P2–1

9

P2–2

B

H

G

K

A

C

3

3

3

Y

F

1 9 5

L N

L

+ –

12VDC

P3–4

P3–3

P3–2

P3–1

1

1

1

4

N

9

8

1

1

P

E

3

J

S

6

O

1 and 2 Fan Options

U

3

B

1

V

N

V

O

DM2663, DM2683 (no fan) without ice maker

67

L

+12V

Y

F

W

J4

3A

J5

5A

J2

P3 P1 P2

1234 12123456

X

Display

Board

85

86

O

H

L

Ground

N

J6

J7

J8

K

J10

A Circuit Board Power R Retainer

N

E

87

P

30

G

B Fuse 3A S Protective Earth

C Fuse 5A U Chassis Ground

J

D Circuit Board Display W Fuse 30A

E Electrode X Test Point

F Thermofuse Y Thermal Fuse

G Lamp 1 Black

H Switch Lamp 2 Brown

J Heater 12 VDC 3 Red

K Heater 120 VAC 4 Yellow

L Heating Cable 5 Green

M Terminal Block 6 Green/Yellow

N Thermistor 7 Blue

O Solenoid Valve 8 Gray

P Relay 9 White

EN

858687

1

E

S U

6

7

7

4

9

1

X

D

Orng

N

P1–1

5

P1–4

7

P1–2

3

P1–5

2

P1–6

P1–3

1

9

P2–1

9

P2–2

H

G

L

A

C

B

J2 J4 J5 J6 J7J8 J10

3

3

3

F

1 9 5

L N

Y

11 1

M

+ –

12VDC

1

8

P3–4

P3–3

P3–2

P3–1

P

30

O

W

33

J

K

R

36

Page 37

Refrigerator

RM3762, RM3962 (no fan) without ice maker

68

J

F

P2

P4

P3

E

P1

J1J3

P7

P6

P5

D

F3

J2

H

C

G

S

Ground

N

L

K

A Control Board O Chassis Ground

B Circuit Board Display P Terminal Block

C Thermistor 1 Black

D Fuse 5A Mini Auto 2 Brown

E Fuse 5A Glass 3 Red

F Solenoid Valve 4 Yellow

G Electrode 5 Green

T

H Thermal Fuse 6 Green/Yellow

J Thermo Fuse 7 Blue

K Heater 120 VAC 8 Gray

L Protective Earth 9 White

M Retainer 10 Light Blue

N Burner Housing

A B

P1–1

2

P1–2

1

3

P1–3

C

RM3762, RM3962 (one or two fans) with and without ice maker

69

A B

A Control Board O Chassis Ground

B Circuit Board Display P Terminal Block

C Thermistor 1 Black

D Fuse 5A Mini Auto 2 Brown

E Fuse 5A Glass 3 Red

F Solenoid Valve 4 Yellow

G Electrode 5 Green

H Thermal Fuse 6 Green/Yellow

J Thermo Fuse 7 Blue

K Heater 120 VAC 8 Gray

L Protective Earth 9 White

M Retainer 10 Light Blue

N Burner Housing

P1–1

2

P1–2

1

3

P1–3

C

P2–1

P2–2

3

10

T

S

Circuit Board Power

J2 J3 J1

D

F3

10

8

R

1

12VDC

3

+ –

E

1 1

9

1

P

O

D+

P2–1

P2–2

S

9

3

4

1 9 5

L N

3

10

T

1

N

G

H

7

7

L

6

Circuit Board Power

J2 J3 J1

D

F3

10

3

P

8

+ –

R

12VDC

J

F

K

M

9

3

4

E

1 1

9

1

O

1 9 5

D+

L N

1 and 2 Fan Options

(Not used on some models)

U

3

X

1

N

G

H

7

J

F

7

K

L

6

M

V

37

EN

Page 38

Refrigerator

RM1350M (manual door lock & door insert panels or steel doors)

RM1350MIM (manual door lock, ice maker & door insert panels)

70

2

K

Fan

Fan

1

3

1

C°

M

3

Relay

86 85

30

Water Valve

9

9 5

1

Z

LLN

120VAC

During operation, the ice maker will add 1.4A to the refrigerator's total draw.

I

A B

D

L

10

3

10

1

3

1

87

Y

3

3

X

5

2

1

9

C

1

1

1

O

C°

Maker

Ice

P1–1

1

P1–2

3

P1–3

9

P2–1

9

P2–2

3

N

3

P

4A

Circuit Board Power

J1

J2

J3

F

P5 P1P3P4P2P6P7

33

1

3

+ D+

12VDC

A Control Board M Thermostat 1 Black

B Circuit Board Display N Lamp 2 Brown

C Thermistor O Heating Cable 3 Red

D Heating Cable P Switch Lamp 4 Yellow

E Solenoid Valve R Thermo Fuse 5 Green

F Fuse 5A Mini Auto Fuse S Terminal Block 6 Green/Yellow

G Fuse 5A Glass U Heater 120 VAC 7 Blue

H Electrode V Retainer 8 Gray

J Burner Housing X Thermostat 9 White

K Heating Cable Girder Y Chassis Ground 10 Light Green

L Door Contact Z Protective Earth

H

9

J

3

4

1

9 5

N

120VAC

7

7

1

1

1

ZUV

G

1

1

Y

S

–

R

E

RM1350SLM (manual door lock & door insert panels or steel doors)

71

Fan

1

3

M

Fan

1

C°

86 85

30

Fan

Fan

3

1

1

3

3

Relay

Water Valve

9

9 5

1

LLN

120VAC

2

K

A B

D

L

10

3

10

11

3

1

87

Z

Y

3

3

X

5

2

1

9

C

1

1

1

O

C°

Maker

Ice

P1–1

1

P1–2

3

P1–3

9

P2–1

9

P2–2

3

N

3

P

4A

Circuit Board Power

J2

J3

F

P5 P1 P3P4 P2P6P7

3

A Control Board M Thermostat 1 Black

B Circuit Board Display N Lamp 2 Brown

C Thermistor O Heating Cable 3 Red

D Heating Cable P Switch Lamp 4 Yellow

E Solenoid Valve R Thermo Fuse 5 Green

F Fuse 5A Mini Auto Fuse S Terminal Block 6 Green/Yellow

G Fuse 5A Glass U Heater 120 VAC 7 Blue

H Electrode V Retainer 8 Gray

J Burner Housing X Thermostat 9 White

K Heating Cable Girder Y Chassis Ground 10 Light Green

L Door Contact Z Protective Earth

J1

33

1

+

12VDC

H

9

J

3

4

1

9 5

N

120VAC

7

7

1

1

1

ZUV

G

1

1

Y

S

–

D+

R

E

During operation, the ice maker will add 1.4A to the refrigerator's total draw.

I

EN

38

Page 39

Refrigerator

RM1350IM (automatic door lock, ice maker & steel doors)

72

P1–1

K

Fan

Fan

1

3

1

C°

M

3

Relay

86 85

30

Water Valve

9

9 5

1

Z

LLN

120VAC

During operation, the ice maker will add 1.4A to the refrigerator's total draw.

I

A B

D

L

10

3

10

1

3

1

87

Y

3

3

3

1

C°

X

Maker

5

Ice

2

1

9

2

P1–2

1

P1–3

3

9

C

1

P

1

O

P2–1

9

P2–2

3

N

3

4A

Circuit Board Power

J1

J2

J3

F

P5 P1P3P4P2P6P7

33

1

3

+ D+

12VDC

A Control Board M Thermostat Z Protective Earth

B Circuit Board Display N Lamp 1 Black

C Thermistor O Heating Cable 2 Brown

D Heating Cable P Switch Lamp 3 Re d

E Solenoid Valve R Thermo Fuse 4 Yellow

F Fuse 5A Mini Auto Fuse S Terminal Block 5 Green

G Fuse 5A Glass T Door Ignition Lock 6 Green/Yellow

H Electrode U Heater 120 VAC 7 Blue

J Burner Housing V Retainer 8 Gray

K Heating Cable Girder X Thermostat 9 White

L Door Contact Y Chassis Ground 10 Light Green

H

9

J

3

4

1

9 5

N

120VAC

7

7

1

1

1

ZUV

G

1

1

Y

S

–

R

E

RM1350WIM (automatic door lock, ice maker, water dispenser & door insert panels or steel doors)

73

Fan

3

Water Valve

W1

12VDC

3

1

K

Fan

1

C°

M

3

Relay

86 85

30

W2

120VAC

9

9

9 5

1

Z

LLN

120VAC

P1–1

A B

D

L

10

3

10

1

3

1

87

Y

1 2 3

V

1

C°

X

Maker

5

Ice

2

1

9

3

3

2

P1–2

1

P1–3

3

9

C

1

P

1

O

P2–1

9

P2–2

3

N

3

4A

Circuit Board Power

J1

33

1

+

12VDC

G

1

1

Y

S

–

D+

120VAC

J2

J3

F

P5 P1P3P4P2P6P7

3

A Control Board M Thermostat Z Protective Earth

B Circuit Board Display N Lamp 1 Black

C Thermistor O Heating Cable 2 Brown

D Heating Cable P Switch Lamp 3 Re d

E Solenoid Valve R Thermo Fuse 4 Yellow

F Fuse 5A Mini Auto Fuse S Terminal Block 5 Green

G Fuse 5A Glass T Door Ignition Lock 6 Green/Yellow

H Electrode U Heater 120 VAC 7 Blue

J Burner Housing V Retainer 8 Gray

K Heating Cable Girder X Thermostat 9 White

L Door Contact Y Chassis Ground 10 Light Green

H

9

J

3

4

7

7

1

1

1

1

9 5

ZUV

N

R

E

39

During operation, the ice maker will add 1.4A to the refrigerator's total draw.

I

EN

Page 40

Refrigerator

RM1350WID (automatic door lock, ice maker, water and ice dispensers & door insert panels or steel

doors)

74

Fan

1

3

3

Ice

Maker

K

Fan

1

C°

M

Relay

86 85

30

Water Valve

W1

12VDC

5219

P1–1

C

O

3

1

5A

120VAC

2

P1–2

1

P1–3

3

9

P2–1

9

P2–2

3

N

1

3

P

1

4A

I

9

9

U1–1

U1–2

J1J4J2J5J3

9 55

1

Z

N

A B

D

L

10

1

3

1

87

3

3

W2

120VAC

9 923

J8–1

J8–3

J8–2

J8–4

9

10

1

Y

Control Module

Water & Ice

J6

9

Q

3

3

1

C°

X

J7–1

J7–2

4

Circuit Board Power

J1

33

1

+

12VDC

G

1

1

Y

S

–

D+

120VAC

J2

J3

F

P5 P1P3P4P2P6P7

3

A Control Board M Thermostat Z Protective Earth

B Circuit Board Display N Lamp 1 Black

C Thermistor O Heating Cable 2 Brown

D Heating Cable P Switch Lamp 3 Red

E Solenoid Valve Q Auger 4 Yellow

F Fuse 5A Mini Auto Fuse R Thermo Fuse 5 Green

G Fuse 5A Glass S Terminal Block 6 Green/Yellow

H Electrode T Door Ignition Lock 7 Blue

I Heating Cable Door U Heater 120 VAC 8 Gray

J Retainer V Water & Ice Dispenser 9 White

K Heating Cable Girder X Thermostat 10 Light Green

L Door Contact Y Chassis Ground

9

1

LLN

9 5

1

1

3

4

7

1

H

J

R

E

7

ZUV

During operation, the ice maker will add 1.4A to the refrigerator's total draw.

I

EN

40

Page 41

Refrigerator

6.7 Reversing the door swing

RM2351, RM2354, RM2451, RM2454, RM2551, RM2554, RM3762, RM3962, DM2652,

I

DM2662, DM2663, DM2852, DM2862: A hinge kit must be used in order to change the door

swing. For the conversion kit number, visit www.eDometic.com.

DM2672, DM2682, DM2683, DM2872, DM2882

75

Hinge-Pin

Door

Hinge-Pin

Top Decoration

Door

Hinge-Pin

➤ Open the door and remove the three screws holding the upper hinge to the frame.

➤ Li the freezer-door off the middle hinge and set it aside.

➤ Remove the screws holding the middle hinge and li the fresh-food door off the lower hinge.

➤ Remove the screws holding the lower hinge.

➤ Remove the top and bottom caps on each door.

➤ Unscrew the inserts and blanks and move them to the opposite side of the doors.

➤ Unscrew the handle and slide it off the frame.

➤ Install the door handle on the opposite side of the door by sliding onto the frame and securing it using the

screws.

➤ Install the top and bottom caps to the door.

➤ Swap the upper and lower hinges.

➤ Flip the middle hinge over.

➤ Secure the hinges to the frame, starting at the bottom.

➤ Re-attach each door in the reverse order of their removal.

Handle

41

EN

Page 42

Refrigerator

6.8 Installing the door panels

RM2351, RM2354, DM2652, DM2662, DM2663, DM2672, DM2682, DM2683, DM2852,

DM2862, DM2872, DM2882, RM2451, RM2454, RM2551, RM2554

76

Door

Frame

Panel

Decoration

Strip

Screws

Door Door

Decoration

Strip

➤ Open the door 90 degrees.

➤ Locate the decoration strips taped to one of the shelves or to the inside of the door.

➤ Insert the vertical edges of the door panel into the grooves of the door frame.

➤ Push the panel downwards so that the lower horizontal edge of the panel is fitted into the bottom groove.

➤ Secure the decoration strips by using three screws, or by snapping them in, depending on the model.

RM3762, RM3962

77

Decoration

Strip

Handle

Door Panel

➤ Remove the handle using a flat-bladed screwdriver to push the tabs away.

➤ Insert a finger into the plastic profile and pull to remove the decoration strip.

➤ Open the door 90 degrees.

➤ Insert the door panel edges into the grooves of the door frame.

➤ Push the panel sideways until the edge of the panel is fitted into the opposite side groove.

➤ Snap on the decoration strip.

➤ Install the door handle.

EN

42

Page 43

Refrigerator

78

Handle

Handle

➤ Snap on the door handle by inserting the two tabs into the door handle slot and sliding it into place.

➤ Secure the handle using two screws.

RM1350, RM1350SL

79

Decoration Strip

Handle

Door

Decoration Strip

➤ Open the door and remove the screw securing the handle to the door.

➤ Slide off the door handle.

RM1350WID: It is not necessary to remove the right freezer-door handle in order to install the door

I

panel.

➤ Slide off the decoration strip.

➤ Insert the door panel edges into the grooves of the door frame.

➤ Push the panel sideways until the edge of the panel is fitted into the opposite side groove.