Dometic Coldmachine 86, Coldmachine 96, CS-NC15, Coldmachine 85, Coldmachine 94 User Manual

...Page 1

ENDEFR

ES

PT

IT

NL

DA

SVNOFI

RU

PL

SK

CS

HU

REFRIGERATION

COOLING UNITS

ColdMachine 50, 54, 55, 84, 85, 86, 94, 95, 96, CS-NC15

Cooling unit

Installation and Operating Manual. . . . . . . 13

Kühlaggregat

Montage- und Bedienungsanleitung . . . . .38

Groupe frigorifique

Instructions de montage

et de service . . . . . . . . . . . . . . . . . . . . . . . . .63

Unidad frigorífica

Instrucciones de montaje y de uso. . . . . . .89

Unidade de refrigeração

Instruções de montagem e manual de

instruções . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Gruppo refrigerante

Istruzioni di montaggio e d’uso . . . . . . . . 141

Koelaggregaat

Montagehandleiding en

gebruiksaanwijzing . . . . . . . . . . . . . . . . . .167

Køleaggregat

Monterings- og betjeningsvejledning . . . 191

Kylaggregat

Monterings- och bruksanvisning . . . . . . . 213

Kjøleaggregat

Monterings- og bruksanvisning. . . . . . . . 235

Jäähdytysaggregaatti

Asennus- ja käyttöohje . . . . . . . . . . . . . . . 257

Холодильный агрегат

Инструкция по монтажу и эксплуатации 280

Agregat chłodzący

Instrukcja montażu i obsługi. . . . . . . . . . .306

Chladiaci agregát

Návod na montáž a uvedenie

do prevádzky. . . . . . . . . . . . . . . . . . . . . . . 331

Chladicí agregát

Návod k montáži a obsluze . . . . . . . . . . .355

Hűtőkészülék

Szerelési és használati útmutató . . . . . . . 379

Page 2

Page 3

Coldmachine

A

1

2

B

2

3

4

5

6

7

0

1

1

2

1

2

Kompressor ein

Compressor on

Compresseur en fonction

Fremdversorgung

External Voltage

Alimentation Extérieure

Speicherabruf

Discharge of Cold Accum.

Décharge de la Plaque

1

2

3

4

min max

Hauptschalter

Main Switch

Commutateur

principal

Temperature

Electronic

Control

5

6

3

Page 4

VD-01, VD-04, VD-08

3

VD-03

min. 30 mm

4

VD-02, VD-05, VD-18, VD-21

10 mm

10 mm

10 mm

5

Coldmachine

10 mm

10 mm

10 mm

10 mm

10 mm

4

Page 5

Coldmachine

6

7

8

VD-06

VD-07, VD-09

1/3

10 mm

2/3

VD-14N, VD-15

1

2

3

4

1/32/3

5

5

Page 6

VD-16

9

VD-14N, VD-15

1

F

T

D

C

P

gn/ge

gr

bl

br

sw

0

b

a

Coldmachine

gn/ge

gr

bl

br

1

sw

F

D

C

P

T

6

Page 7

Coldmachine

c

d

1

3

2

AB

CD

7

Page 8

1. 2.

e

g

SW21

f

h

Coldmachine

SW19

SW21

SW16

8

2 – 3 mm

2 – 3 mm

Page 9

Coldmachine

Ø

/mm²

l/m

12 V

24 V

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28

0

2

6

10

14

i

VD-01, VD-02, VD-03, VD-04, VD-05,

VD-07, VD-08, VD-09, VD-18, VD-21

rt

swblgn/ge

sw/bl

2

3

4

5

6

7

0

1

br

12 3

4

j

9

Page 10

12 3

4

br gn ws

rt

T

P

C

sw/bl

VD-06

k

bl br ge gn gr rt sw ws ∨

EN Blue Brown Yellow Green Grey Red Black White or

DE Blau Braun Gelb Grün Grau Rot Schwarz Weiss oder

FR Bl eu Marron Jaune Vert Gris Rouge Noir Blanc ou

ES Azul Marrón Amarillo Verde Gris Rojo Negro Blanco o bien

PT Azul Castanho Amarelo Verde Cinzento Vermelho Preto Branco ou

IT Blu Marrone Giallo Verde Grigio Rosso Nero Bianco oppure

NL Blauw Bruin Geel Groen Grijs Rood Zwart Wit of

DA Blå Brun Gul Grøn Grå Rød Sort Hvid eller

SV Blå Brun Gul Grön Grå Röd Svart Vit eller

NO Blå Brun Gul Grønn Grå Rød Svart Hvit eller

FI Sininen Ruskea Keltainen Vihreä Harmaa Punainen Musta Valkoinen tai

RU Синий Коричневый Желтый Зеленый Серый Красный Черный Белый или

PL Niebieski Brązowy Żółty Zielony Szary Czerwony Czarny Biały lub

SK Modrá Hnedá Žltá Zelená Sivá Červená Čierna Biela alebo

CS Modrá Hněda Žlutá Zelená Šedá Červená Černá Bílá nebo

HU Kék Barna Sárga Zöld Szürke Piros Fekete Fehér vagy

Coldmachine

10

Page 11

Coldmachine

l

257 mm

281 mm

360 mm

81 mm

128,50 mm

9,50 mm

9,50 mm

11

Page 12

~ 215 mm

m

Coldmachine

~ 310 mm

12

Page 13

EN

Coldmachine

Please read this instruction manual carefully before installation and first

use, and store it in a safe place. If you pass on the product to another

person, hand over this instruction manual along with it.

Contents

1 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

6 Technical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

7 Installing the cooling unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

8 Using the cooling unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9 Use coolant accumulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

10 Guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

11 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

12 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

13 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

13

Page 14

EN

Explanation of symbols Coldmachine

1 Explanation of symbols

DANGER!

D

!

!

A

I

Safety instruction: Failure to observe this instruction will cause fatal or

serious injury.

WARNING!

Safety instruction: Failure to observe this instruction can cause fatal or

serious injury.

CAUTION!

Safety instruction: Failure to observe this instruction can lead to injury.

NOTICE!

Failure to observe this instruction can cause material damage and impair

the function of the product.

NOTE

Supplementary information for operating the product.

2 Safety instructions

The manufacturer accepts no liability for damage in the following cases:

• Faulty assembly or connection

• Damage to the product resulting from mechanical influences and incorrect

connection voltage

• Alterations to the product without express permission from the manufacturer

• Use for purposes other than those described in the operating manual

2.1 General safety

DANGER!

D

14

• Danger of fatalinjuries!

When using the device on boats: if the device is powered by the

mains, ensure that the power supply has a residual current circuit

breaker!

Page 15

EN

Coldmachine Safety instructions

WARNING!

!

• This device may only be installed and repaired by a qualified

technician. Inadequate repairs can lead to considerable hazards.

Should your device need to be repaired, please contact customer

services.

• Do not operate the device if it is visibly damaged.

• Do not open the refrigerant circuit under any circumstances. An

exception to this is when the device has to be disconnected for return

shipping (chapter “Installing the external temperature regulator” on

page 22).

• Set up the device in a dry location where it is protected against splashing water.

• Do not place the device near naked flames or other heat sources

(heaters, direct sunlight, gas ovens etc.).

• Make sure that the compressor is sufficiently ventilated.

• Electronic devices are not toys!

Always keep and use the device out of the reach of children.

• People (including children) whose physical, sensory or mental

capacities or whose lack of experience or knowledge prevent them

from using this product safely should not use it without the supervision

or instruction of a responsible person.

• Before you start up the device for the first time, check that the

operatingvoltage matches the battery voltage (see type plate).

• If the connection cable is damaged, it must be replaced to prevent

possible electrical hazards. Only replace a damaged connection

cable with a connection cable of the same type and specifications.

• Do not store any explosive substances, such as spray cans with

propellants in the device.

15

Page 16

EN

Scope of delivery Coldmachine

2.2 Operating the device safely

DANGER! Danger of fatal injuries!

D

A

I

2.3 Safety precautions when handling batteries

!

• Do not touch exposed cables with your bare hands. This especially

applies when operating the device from the AC mains.

NOTICE!

• Never use cleaners that contain sand, acids or solvents to clean the

vaporiser.

• Protect the device against rain and moisture.

• Disconnect the cooling device and other consumer units from the

battery before you connect the quick charging device.

NOTE

• Disconnect the device if you are not going to use it for a prolonged

period.

CAUTION! Danger of injury!

• Batteries contain aggressive and caustic acids. Avoid battery fluid

coming into contact with your body. If your skin does come into

contact with battery fluid, wash the part of your body in question

thoroughly with water.

• If you connect the device to a battery, make sure that no food comes

into contact with the battery acid.

3Scope of delivery

Quantity Description

1 Cooling unit or vaporiser

1 Operating manual

16

Page 17

EN

Coldmachine Accessories

4Accessories

If you wish to operate the cooling unit from the 230 V AC mains, please use one of

the following rectifiers.

Available as accessory (not included in scope of delivery):

Description Item number

CoolPower EPS100 rectifier

For devices with BD35F compressor (50/80/CS/CS series)

CoolPower MPS35 rectifier

For devices with BD35F compressor (50/80/CS/CS series)

CoolPower MPS50 rectifier

For devices with BD50F compressor (90 series)

9600000440

9600000445

9600000441

5 Intended use

The cooling unit is suited for building your own refrigerator or cooler.

The cooler unit is suitable for cooling and freezing food. The device is also suitable

for use on boats.

CAUTION! Health hazard!

!

Please check if the cooling capacity of the device is suitable for storing

the food or medicine you wish to cool.

6 Technical description

The cooling units are suitable for use with 12 V or 24 V DC voltage and can therefore

be used for camping or on boats. Furthermore, you can connect them to a 230 V

mains supply via the rectifiers (see chapter “Accessories” on page 17).

When used on boats, the cooling unit can withstand a constant heeling of 30°.

The cooling unit must be used together with a vaporiser. In addition, you can use an

accumulator with or without TEC control. The CS-NC15 comprises a cooling unit

and a vaporiser.

Use the continuously variable thermostat on the vaporiser to set the desired

temperature.

17

Page 18

EN

Technical description Coldmachine

The accumulator and TEC program control ensure a high cooling capacity

and improve the unit’s efficiency. The accumulator is charged when there is

a sufficient supply of power (for example when powered by a mains adapter). In the

event of accumulator usage or under-voltage, the coolant is drawn from the

accumulator until it is empty. Thus, no power is taken from the battery during this

time.

The TEC program control always ensures that

• Cold energy is stored if there is excess electrical energy (external supply of power

by a generator).

• The coolant accumulator can be used at any time to ensure that the complete

battery power is used for other consumers.

• Stored cold energy is automatically retrieved to preserve the interior cooling

temperature of the cooling area, once the battery capacity is exhausted.

NOTE

I

Further information on the coolant accumulator can be found in chapter

“Use coolant accumulator” on page 27.

6.1 Battery monitor

The cooling device is equipped with an electronic device to protect against reversing the polarity when connecting to a battery. To protect the battery, the cooling

device switches off automatically if the voltage is insufficient (see following table).

Devices without TEC control

Connection voltage Switch-off voltage Restart voltage

12 V

24 V

Devices with TEC control

Connection voltage Switch-off voltage Restart voltage

12 V

24 V

10.4 V 11.7 V

22.8 V 24.2 V

10.7 V 13.0 V

22.0 V 26.0 V

18

Page 19

EN

Coldmachine Installing the cooling unit

7 Installing the cooling unit

WARNING!

!

7.1 Tools required

For installation and assembly, you will need the following tools:

•Drill

• Screwdriver

• Open-ended spanner: 16 mm, 19 mm and 21 mm

• Sealant and PUR foam

• Cable, cable lugs and cable clips

•Ester oil

7.2 Notes on the cooling container

Permitted cooling area contents

Make sure that maximum cooling area contents specified are not exceeded for the

respective vaporiser type (see chapter “Technical data” on page 32).

The installation may only be performed by a qualified technician.

Minimum insulation

The maximum cooling area contents are based on a minimum insulation thickness of

35 mm of foam polyurethane with a density of 40 kg/m³. If other insulating materials

are used such as styrofoam, double the wall thickness to attain the same level of heat

insulation.

Installing the vaporiser

The vaporiser must be installed in the cooling container (except CS-NC15, the

vaporiser is premounted).

Observe the following in the process:

• Correct installation position (fig. 3, page 4 up to fig. 9, page 6)

• Arrangement in the cooling container as far to the top as possible

• Install a least 10 mm from the wall (not VD-14N and VD-15).

19

Page 20

EN

Installing the cooling unit Coldmachine

NOTICE!

A

Connecting the vaporiser

➤ Connect the vaporisers VD-14N and VD-15 in accordance with fig. 0, page 6.

➤ Connect vaporiser VD-16 according to fig. 9, page 6.

➤ Connect other vaporisers according to fig. j, page 9.

Keys for the illustrations

For cooling units without valve couplings (ready-to install units): Do not

open the refrigerant circuit during installation. You may have to make the

wall openings larger to be able to slide the vaporiser through them

(fig. a, page 6). Or alternatively, you create an opening that allows you

to install the cooling lines at the top (fig. b, page 6).

No. in fig. 8,

page 5

1 DC fan

2 Thermostat button

3

4

5 Connection cable

No. in fig. 9,

page 6

1 Connection cable

No. in fig. 0,

page 6

1 Connection cable

Explanation

Connection plug for DC fan

Thermostat

Explanation

Explanation

20

Page 21

EN

Coldmachine Installing the cooling unit

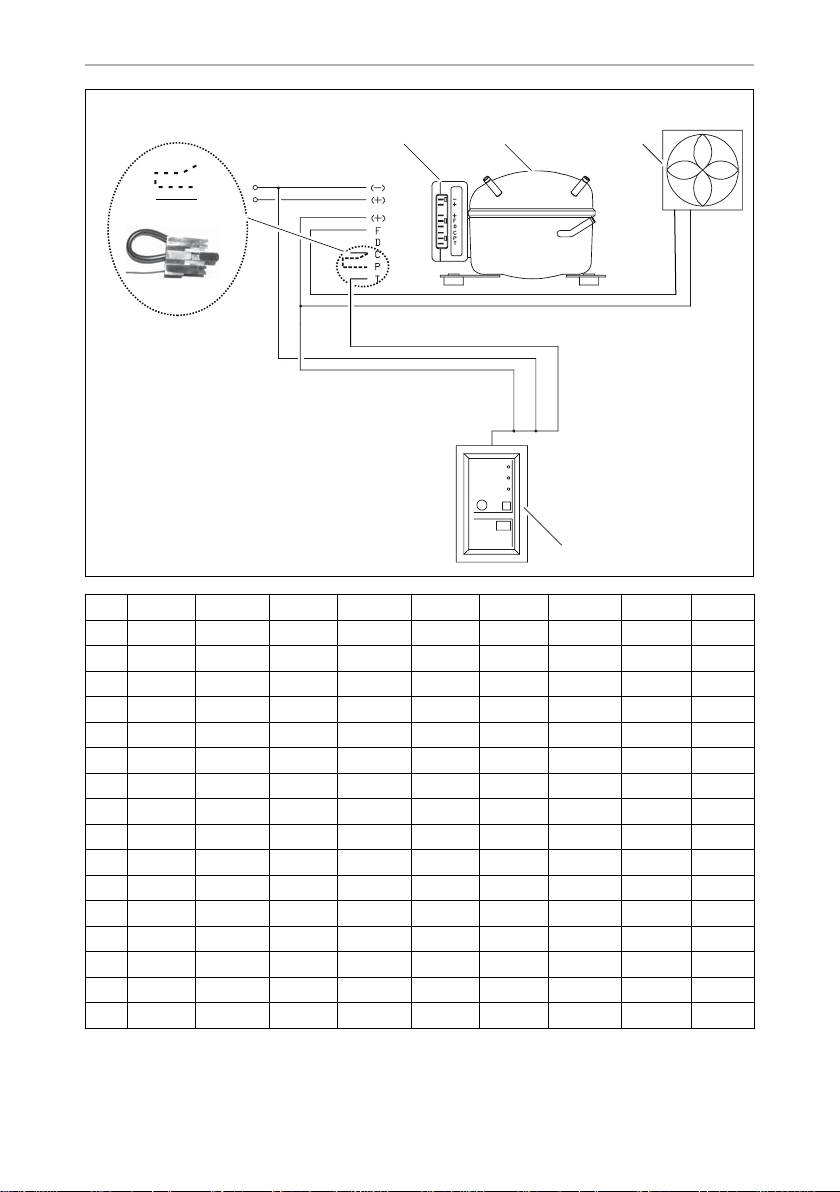

No. in

fig. j, page 9 and

fig. k, page 10

1 Connection block

2 Compressor

3Fan

4 Switch fig. j or TEC controller fig. k

NOTICE!

A

For cooling units with valve couplings

➤ Cut out a hole with a diameter of at least 30 mm (fig. c, page 7) for the cooling

lines. To do this, use a circular cutter.

A

Carefully insulate and seal off the wall openings after installation to

prevent moisture penetration.

NOTICE!

Never bend the connecting line between the vaporiser and the unit. The

minimum bending radius is 25 mm.

Explanation

7.3 Installing the cooling unit

It is important to select the proper location for setting up the unit. To ensure troublefree operation, please note the following points:

• Set up the cooling unit in a dry, sheltered place. Avoid placing it near heat

sources such as radiators, gas ovens or hot water pipes. Do not place in direct

sunlight.

• On a boat, install the cooling unit, if possible, below the waterline.

• The refrigeration unit functions at a tilt angle of up to 30°. Install the unit on a flat

base so that it will still operate, even at the strongest possible inclination.

• The heated air must dissipate unhindered (fig. d, page 7).

• When installing the cooling unit in a closed room such as a wardrobe, pantry or

aft compartment, openings must have a cross section of at least 200 cm²

(25cmx8cm) for cooling and exhaust air.

• Make sure that the air flow on the condenser (fig. d C, page 7) is not restricted.

• Maintain a minimum distance between the condenser and adjoining wall of

50 mm.

21

Page 22

EN

Installing the cooling unit Coldmachine

• CS-NC15: Observe the drilling template (fig. l, page 11) and the installation

drawing (fig. m, page 12).

7.4 Installing the external temperature regulator

Mechanical thermostat

The temperature regulator can be mounted either on the outside or inside of the

cooling container. The interior temperature is regulated depending on the surface

temperature of the vaporiser, or for VD-14N and VD-15, depending on the room

temperature.

➤ Connect the coiled end of the sensor cable to the vaporiser (fig. e, page 8, not

VD-14N, VD-15) using the clamping plate. This is premounted on VD-14N,

VD-15.

➤ Make sure that the sensor line does not make contact anywhere else with the

vaporiser or with the suction line.

TEC control

The TEC control must be attached outside of the cooling container. The internal

temperature is regulated according to the vaporiser surface temperature.

The temperature sensor has been factory-mounted to the accumulator.

➤ Connect the temperature sensor with the TEC control via the plug-in coupling.

Mount the one-way couplings (not CS-NC15)

NOTICE!

A

The cooling unit is delivered in a disconnected state (the vaporiser and compressor

are separated); however, it has been filled at the factory with the proper amount of

coolant.

➤ Install the machine part and the vaporiser.

➤ Remove the screwed-on caps from the coupling halves that protect the rubber

seal from dirt.

The fig. f, page 8, shows the condition of the coupling halves after removing the

caps when uncoupled.

Coolant leakage will lead to system failure. In such cases, the complete

cooling unit must be disassembled, returned, the one-way couplings

replaced and the device refilled at the factory.

22

Page 23

EN

Coldmachine Installing the cooling unit

NOTICE! Risk of coolant leakage

A

➤ Apply some ester oil on the O-ring and thread of both coupling halves (fig. f,

page 8).

➤ Place the coupling halves by hand on top without tension and tighten them by

hand (fig. g, page 8).

➤ Tighten the union nuts SW21 to the end of the thread: use the width 21 open-

ended spanner for tightening and the second open-ended spanner (width 19 or

16) for counter-tightening.

The gap between the coupling halves will be 2–3 mm (fig. h, page 8).

A

➤ Tighten the union nuts to a torque of 30 Nm by approx. a further 90°, to connect

both couplings firmly with each other.

The cutting ring of the male coupling half must cut itself into the female coupling

half.

Always use two open-ended spanners to prevent the couplings from

turning in the coupling holder.

NOTICE! Risk of coolant leakage

The coupling is not permanently sealed.

If the device must be decoupled for return shipping:

WARNING!

!

➤ Screw the caps back onto the coupling halves to prevent dirt and moisture from

entering the refrigerant circuit.

The coolant in the system is under pressure.

Wear safety goggles and gloves when disconnecting.

23

Page 24

EN

Installing the cooling unit Coldmachine

7.5 Connecting the cooling unit

Connecting to a battery

The cooling unit can be operated from a 12 V or a 24 V DC voltage supply.

NOTICE!

A

➤ Determine the required cross section of the cable in relation to the cable length

according to fig. i, page 9.

Key for fig. i, page 9

A

➤ Before you start up the unit for the first time, check that the operating voltage

matches the battery voltage (see type plate).

To avoid voltage loss and therefore a drop in performance, the cable

should be kept as short as possible and should not be interrupted.

For this reason avoid additional switches, plugs or power strips.

Co-ordinate axis Meaning Unit

l Cable length m

∅ Cable cross section mm²

NOTICE!

Make sure that the polarity is correct.

➤ Connect your cooling unit

– as directly as possible to the pole of the battery or

– to a plug socket which is fuse protected with at least 15 A (at 12 V) or 7.5 A (at

24 V).

NOTICE!

A

For safety reasons the cooling unit is equipped with an electronic system to prevent

polarity reversal. This protects the cooling unit when it is connected to a battery.

24

Disconnect the cooling device and other power consuming devices

from the battery before you connect the battery to a quick charging

device. Overvoltage can damage the electronics of the device.

Page 25

EN

Coldmachine Using the cooling unit

Connecting to a 230 V mains supply

WARNING!

!

➤ To operate the cooling unit from the 230 V mains, use the rectifier

– CoolPower EPS100 for devices with BD35F compressor

– CoolPower MPS35 for devices with BD35F compressor

– CoolPower MPS50 for devices with BD50F compressor (90 series).

I

• Never handle plugs and switches with wet hands or if you are

standing on a wet surface.

• If you are operating your cooling device on board a boat with

a mains connection of 230 V from the land, you must install a residual

current circuit breaker between the 230 V mains supply and the

cooling device.

Seek advice from a trained technician.

(50/80/CS/CS series),

(50/80/CS/CS series),

NOTE

The output voltage of the described rectifier is 24 V. Please remember

this when connecting other consumers at a later time.

8 Using the cooling unit

8.1 Energy saving tips

• Choose a well ventilated installation location which is protected from direct

sunlight.

• Allow hot food to cool down first before placing it in the device.

• Do not open the refrigerated container more often than necessary.

• Do not leave the door open for longer than necessary.

• Defrost the refrigerated container once a layer of ice forms.

• Avoid unnecessary low temperatures.

• Clean the condenser of dust and dirt at regular intervals.

• Clean the lid seal regularly.

25

Page 26

EN

Using the cooling unit Coldmachine

8.2 Start the cooling unit

Devices without TEC control

➤ Switch in the cooling unit by turning the control button clockwise

(fig. 1 A1 or B1, page 3).

If you turn the control button further, you can regulate the temperature. Devices with

energy storage function offer a storage activation button (fig. 1 A2, page 3).

NOTE

I

Devices with TEC control

Devices with TEC control are started by actuating the main switch

(fig. 2 6, page 3). You can then regulate the temperature (fig. 2 5, page 3)

with the temperature selector.

If the red LED flashed or glows, a fault has occurred and the system

cannot be operated (see error table in Chapter chapter “LED on the

thermal element (fig. 1 2, page 3)” on page 29).

8.3 Shutting down the cooling unit

If you do not intend to use the cooling device for a prolonged period, proceed as

follows:

➤ Devices without TEC control: Turn the control to 0.

➤ Devices with TEC control: Switch off the device with the main switch

(fig. 2 6, page 3).

➤ Disconnect the power cable from the battery or pull the DC cable plug out of the

rectifier.

➤ Clean the cooling device.

➤ Leave the door slightly open over the cover.

This prevents odour build-up.

26

Page 27

EN

Coldmachine Use coolant accumulator

9 Use coolant accumulator

9.1 Display and control elements of devices with

TEC program control

No. in

fig. 2,

page 3

1 Green LED: Indicates that the compressor is working.

2 Yellow LED: indicates that the external power supply is present (voltage is

3 Red LED: indicates that the accumulator is being discharged because

4 Accumulator discharge button: interrupts compressor operation until

5 Temperature selector: allows the temperature in the cooling area to be set

6 Main switch: for switching the cooling device on and off.

Explanation

higher than 13.5 V or 27.0 V).

The LED flashes if the external power supply is too low (voltage ≤ 10.7 V or

21.7 V. Version E: ≤ 10.7 V or 22.0 V).

• the discharge button has been pressed

• Low voltage shutdown (voltage ≤ 10.7 V or 21.4 V. Version E: ≤ 10.7 V or

22.0 V).

• the stored cold energy is exhausted

• The external supply voltage level is restored after low voltage.

as required

Min. (left limit) = warmest setting

Max. (right limit) = coldest setting

Position 0 = OFF

Position – = ON

27

Page 28

EN

Guarantee Coldmachine

9.2 Accumulator function

The accumulator function ensures that cold energy is stored automatically (up to

8 hours) if enough electrical power is available, for example when supplied by a

mains adapter.

Stored cooling power is discharged

• automatically when the switch-off voltage is reached (see the table on page 18)

• or manually by pressing the discharge button (fig. 1 A2 or fig. 2 4, page 3).

NOTE

I

The accumulator is automatically charged if,

• the restart voltage is exceeded

• or the accumulator is empty and you switch the device off and on again using the

control button(fig. 2 6, page 3, does only function on VD-06).

A

The cold accumulator can only be discharged manually if it was fully

charged beforehand.

NOTICE!

When you are discharging the accumulator, although there is an

external supply of power – for example to avoid operating noise from

the compressor – use the main switch to switch the unit off (fig. 1 B1 or

fig. 2 6, page 3).

NOTE

I

Please remember: Low internal temperature = high current

consumption!

10 Guarantee

The statutory warranty period applies. If the product is defective, please contact the

manufacturer's branch in your country (see the back of the instruction manual for the

addresses) or your retailer.

For repair and guarantee processing, please include the following documents when

you send in the device:

• A copy of the receipt with purchasing date

• A reason for the claim or description of the fault

28

Page 29

EN

Coldmachine Disposal

11 Disposal

➤ Place the packaging material in the appropriate recycling waste bins wherever

possible.

If you wish to finally dispose of the product, ask your local recycling centre

or specialist dealer for details about how to do this in accordance with the

M

applicable disposal regulations.

12 Troubleshooting

LED on the thermal element (fig. 1 2, page 3)

Number of

flashes

1 Battery protection shutdown Check battery voltage, fuse and cable

2 Fan overvoltage shutdown Check condenser and vaporiser fan

3 Compressor start-up fault Reduce load on cooling system:

4 Compressor overload shutdown Reduce load on cooling system:

5 Electronic fuse shutdown Reduce load on cooling system:

Error type Remedy

cross section

current:

total target value < 0.5 A

• Ensure good ventilation around the

cooling unit

• Store pre-cooled goods

• Ensure good ventilation around the

cooling unit

• Store pre-cooled goods

• Ensure good ventilation around the

cooling unit

29

Page 30

EN

Troubleshooting Coldmachine

Compressor does not run

Fault Possible cause Remedy

UT = 0 V The connection between the battery and

the – electronics is interrupted

Main switch defective (if installed) Replace the main switch

Additional supply line fuse has blown (if

installed)

U

≤ U

T

ON

Start attempt with

U

≤ U

T

OFF

Start attempt with

U

≥ U

T

ON

U

Voltage between the positive and negative electronic terminals

T

U

Switch-on voltage of the electronics

ON

Switch-off voltage of the electronics

U

OFF

Battery voltage is too low Charge the battery

Loose cables

Poor contact (corrosion)

Battery capacity too low Replace the battery

Cable cross section too low Replace the cable (fig. i,

Ambient temperature too high –

Insufficient ventilation and/or cooling Provide improved ventila-

Condenser is dirty Clean the condenser

Fan defective (if installed) Replace the fan

Establish a connection

Replace the fuse

Establish a connection

page 9)

tion for the cooling unit

Interior temperature too low in control setting 1

Fault Possible cause Remedy

Compressor runs

constantly

Compressor runs for a long

time

Thermostat sensor has no contact on the

vaporiser

Thermostat defective Change the thermostat

Large quantities have been frozen in the

freezer compartment

Secure the sensor

–

30

Page 31

EN

Coldmachine Troubleshooting

Cooling capacity drops, interior temperature rises

Fault Possible cause Remedy

Compressor runs for a long

time/continuously

Compressor runs

infrequently

Vaporiser is iced over Defrost the vaporiser

Ambient temperature too high –

Insufficient ventilation and/or cooling Provide improved ventilation

for the cooling unit

Condenser is dirty Clean the condenser

Fan defective (if installed) Replace the fan

Battery capacity exhausted Charge the battery

Unusual noises

Fault Possible cause Remedy

Loud humming A component of the refrigerant circuit can-

not move freely (lies against the wall)

Foreign body jammed between the

cooling device and the wall

Fan noise (if installed) Clean the fan blades

Bend the component

carefully away from the

obstruction

Remove the foreign body

31

Page 32

EN

Technical data Coldmachine

13 Technical data

50 54 55

Max. cooling area

contents:

Connection voltage: 12 Vg or 24 Vg

Power consumption: 35 – 40 W, depending on the vaporiser type

Coolant quantity: 28 g 35 g

CO2 equivalent: 0.040 t 0.050 t

Global warming

potential (GWP):

Dimensions

(WxHxD) inmm:

Weight: 3.74 kg 6.0 kg 6.5 kg

80 litres 130 litres

1430

315 x 140 x 170 386x155x130 220x160x220

84 85 86

Max. cooling area

contents:

Connection voltage: 12 Vg or 24 Vg

Coolant quantity: 45 g

CO2 equivalent: 0.064 t

Global warming

potential (GWP):

Dimensions

(WxHxD) inmm:

Weight: 6.0 kg 6.0 kg 6.5 kg

386x155x130 220x155x220 220x230x177

250 litres

1430

32

Page 33

EN

Coldmachine Technical data

94 95 96

Max. cooling area

contents:

Connection voltage: 12 Vg or 24 Vg

Coolant quantity: 60 g

CO2 equivalent: 0.086 t

Global warming

potential (GWP):

Dimensions

(WxHxD) inmm:

Weight: 6.0 kg 6.0 kg 6.5 kg

386x155x130 220x155x220 220x230x177

400 litres

1430

CS-NC15

Max. cooling area

contents:

Connection voltage: 12 Vg or 24 Vg

Coolant quantity: 60 g

CO2 equivalent: 0.086 t

Global warming

potential (GWP):

Dimensions

(WxHxD) inmm:

Weight: 8.5 kg

250 litres

1430

360x255x275

33

Page 34

EN

Technical data Coldmachine

VD-01 VD-02 VD-03 VD-04

Max. cooling area

content at 35 mm PU

insulation:

Max. cooling area

content at 50 mm PU

insulation:

Power consumption: 35 W 35 W 50 W 45 W

Voltage 12 Vg or 24 Vg

Coolant quantity: 17 g 20 g 30 g

CO2 equivalent: 0.024 t 0.029 t 0.043 t

Global warming

potential (GWP):

Dimensions

(WxHxD) in mm:

Weight: 1.5 kg 1.0 kg 2.0 kg 1.5 kg

Max. cooling area

content at 35 mm PU

insulation:

Max. cooling area

content at 50 mm PU

insulation:

Power consumption: 30 W

Temperature: ambient: 32 °C, internal: 5 °C

80 litres 30 litres 170 litres 130 litres

100 litres 50 litres 200 litres 170 litres

1430

300x245x110 275x215x25 380x230x82 375x255x100

CU-50 +

VD-01

50 litres 30 litres 60 litres

75 litres 50 litres 80 litres

CU-50 +

VD-02

CU-50 +

VD-07

34

Page 35

EN

Coldmachine Technical data

VD-05 VD-07 VD-08 VD-09

Max. cooling area

content at 35 mm PU

insulation:

Max. cooling area

content at 50 mm PU

insulation:

Power consumption: 45 W 35 W 60 W 60 W

Voltage 12 Vg or 24 Vg

Coolant quantity: 30 g 45 g 15 g 65 g

CO2 equivalent: 0.043 t 0.064 t 0.021 t 0.093 t

Global warming

potential (GWP):

Dimensions

(WxHxD) in mm:

Weight: 1.5 kg 1.5 kg 2.0 kg 2.0 kg

130 litres 100 litres 160 litres 160 litres

170 litres 130 litres 180 litres 180 litres

1430

375x350x25 255x210x90 450x270x340 365x140x270

VD-14N VD-15 VD-18

Max. cooling area

content at 35 mm PU

insulation:

Max. cooling area

content at 50 mm PU

insulation:

Power consumption: 80 W 60 W 45 W

Voltage 12 Vg or 24 Vg

Coolant quantity: 15 g

CO2 equivalent: 0.021 t

Global warming

potential (GWP):

Dimensions

(WxHxD) in mm:

Weight: 2.5 kg 1.5 kg 1.5 kg

300 litres 200 litres 100 litres

400 litres 250 litres 150 litres

1430

220x275x65 220x275x65 350x250x25

35

Page 36

EN

Technical data Coldmachine

VD-16 VD-21

Max. cooling area

content at 60 mm PU

insulation:

Max. cooling area

content at 100 mm PU

insulation:

Power consumption: 60 W 60 W

Voltage 12 Vg or 24 Vg

Coolant quantity: 40 g 10 g

CO2 equivalent: 0.057 t 0.014 t

Global warming

potential (GWP):

Dimensions

(WxHxD) in mm:

Weight: 2.5 kg 4.0 kg

130 litres 250 litres

200 litres 300 litres

1430

330x260x130 1370x305x10

VD-16 for series 80 VD-16 for series 90

Max. cooling area

content at 35 mm PU

insulation:

Max. cooling area

content at 50 mm PU

insulation:

Power consumption: 65 W 80 W

Voltage 12 Vg or 24 Vg

Coolant quantity: 40 g

CO2 equivalent: 0.057 t

Global warming

potential (GWP):

Dimensions

(WxHxD) in mm:

Weight: 5.0 kg

120 litres 200 litres

200 litres 250 litres

1430

380x300x62

36

Page 37

EN

Coldmachine Technical data

Test/certificates:

The coolant circuit contains R-134a.

Contains fluorinated greenhouse gases

37

Page 38

DE

Coldmachine

Bitte lesen Sie diese Anleitung vor Einbau und Inbetriebnahme sorgfältig

durch und bewahren Sie sie auf. Geben Sie sie im Falle einer Weitergabe

des Produktes an den Nutzer weiter.

Inhaltsverzeichnis

1 Erklärung der Symbole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2 Sicherheitshinweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3 Lieferumfang . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4 Zubehör. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5 Bestimmungsgemäßer Gebrauch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6 Technische Beschreibung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7 Kühlaggregat einbauen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8 Kühlaggregat benutzen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9 Kältespeicher benutzen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

10 Gewährleistung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

11 Entsorgung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

12 Störungen beseitigen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

13 Technische Daten . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

38

Page 39

DE

Coldmachine Erklärung der Symbole

1 Erklärung der Symbole

GEFAHR!

D

!

!

A

I

Sicherheitshinweis: Nichtbeachtung führt zu Tod oder schwerer

Verletzung.

WARNUNG!

Sicherheitshinweis: Nichtbeachtung kann zu Tod oder schwerer

Verletzung führen.

VORSICHT!

Sicherheitshinweis: Nichtbeachtung kann zu Verletzungen führen.

ACHTUNG!

Nichtbeachtung kann zu Materialschäden führen und die Funktion des

Produktes beeinträchtigen.

HINWEIS

Ergänzende Informationen zur Bedienung des Produktes.

2 Sicherheitshinweise

Der Hersteller übernimmt in folgenden Fällen keine Haftung für Schäden:

• Montage- oder Anschlussfehler

• Beschädigungen am Produkt durch mechanische Einflüsse und falsche

Anschlussspannung

• Veränderungen am Produkt ohne ausdrückliche Genehmigung vom Hersteller

• Verwendung für andere als die in der Anleitung beschriebenen Zwecke

39

Page 40

DE

Sicherheitshinweise Coldmachine

2.1 Allgemeine Sicherheit

GEFAHR!

D

!

• Lebensgefahr!

Beim Einsatz auf Booten: Sorgen Sie bei Netzbetrieb unbedingt

dafür, dass Ihre Stromversorgung über einen FI-Schutzschalter abgesichert ist!

WARNUNG!

• Die Installation und Reparatur an diesem Produkt darf nur von Fachkräften durchgeführt werden. Durch unsachgemäße Reparaturen

können erhebliche Gefahren entstehen.

Wenden Sie sich im Reparaturfall an den Kundendienst.

• Wenn das Produkt sichtbare Beschädigungen aufweist, dürfen Sie es

nicht in Betrieb nehmen.

• Öffnen Sie auf keinen Fall den Kühlkreislauf. Eine Ausnahme besteht,

wenn Sie das Produkt für den Rückversand entkoppeln müssen

(Kapitel „Externen Temperaturregler montieren“ auf Seite 48).

• Stellen Sie das Produkt an einem trockenen und gegen Spritzwasser

geschützten Platz auf.

• Stellen Sie das Produkt nicht in der Nähe von offenen Flammen oder

anderen Wärmequellen (Heizung, starke Sonneneinstrahlung, Gasöfen usw.) ab.

• Achten Sie darauf, dass der Kompressor ausreichend belüftet wird.

• Elektrogeräte sind kein Kinderspielzeug!

Verwahren und benutzen Sie das Gerät außerhalb der Reichweite von

Kindern.

• Personen (einschließlich Kinder), die aufgrund ihrer physischen, sensorischen oder geistigen Fähigkeiten oder ihrer Unerfahrenheit oder

Unkenntnis nicht in der Lage sind, das Produkt sicher zu benutzen,

sollten dieses Produkt nicht ohne Aufsicht oder Anweisung durch eine

verantwortliche Person nutzen.

• Kontrollieren Sie vor Inbetriebnahme des Produktes, ob die Betriebsspannung und die Batteriespannung übereinstimmen (siehe Typenschild).

• Wenn das Anschlusskabel beschädigt ist, müssen Sie es ersetzen, um

Gefährdungen zu vermeiden. Tauschen Sie ein beschädigtes

Anschlusskabel nur gegen ein Anschlusskabel gleicher Art und

Spezifikation aus.

40

Page 41

DE

Coldmachine Sicherheitshinweise

• Lagern Sie keine explosionsfähigen Substanzen wie z. B. Sprühdosen

mit Treibgas im Produkt.

2.2 Sicherheit beim Betrieb des Produktes

GEFAHR!

D

A

I

2.3 Sicherheit beim Umgang mit Batterien

• Lebensgefahr!

Fassen Sie nie mit bloßen Händen an blanke Leitungen. Dies gilt vor

allem beim Betrieb am Wechselstromnetz.

ACHTUNG!

• Verwenden Sie nie sand-, säure- oder lösungsmittelhaltige Putzmittel

zur Reinigung des Verdampfers.

• Schützen Sie das Produkt vor Regen und Feuchtigkeit.

• Klemmen Sie das Kühlaggregat und andere Verbraucher von der Batterie ab, bevor Sie ein Schnellladegerät anschließen.

HINWEIS

• Klemmen Sie das Produkt ab, wenn Sie es lange nicht brauchen.

!

VORSICHT! Verletzungsgefahr!

• Batterien können aggressive und ätzende Säuren enthalten. Verhindern Sie jeden Körperkontakt mit der Batterieflüssigkeit. Sollte es

doch zur Berührung mit Batterieflüssigkeit kommen, so spülen Sie das

entsprechende Körperteil gründlich mit Wasser ab.

• Wenn Sie das Produkt an eine Batterie anschließen, stellen Sie sicher,

dass Lebensmittel nicht mit Batteriesäure in Berührung kommen.

41

Page 42

DE

Lieferumfang Coldmachine

3 Lieferumfang

Menge Bezeichnung

1 Kühlaggregat oder Verdampfer

1 Bedienungsanleitung

4Zubehör

Falls Sie das Kühlaggregat am 230-V-Wechselstromnetz betreiben wollen,

verwenden Sie bitte einen der folgenden Gleichrichter.

Als Zubehör erhältlich (nicht im Lieferumfang enthalten):

Bezeichnung Artikel-Nr.

CoolPower EPS100 Gleichrichter

für Geräte mit Kompressor BD35F (Serie 50/80/CS/CS)

CoolPower MPS35 gleichrichter

für Geräte mit Kompressor BD35F (Serie 50/80/CS/CS)

CoolPower MPS50 Gleichrichter

für Geräte mit Kompressor BD50F (Serie 90)

9600000440

9600000445

9600000441

5 Bestimmungsgemäßer Gebrauch

Das Kühlaggregat eignet sich zum Selbstbau eines Kühlschrankes oder einer

Kühlbox.

Das Kühlaggregat eignet sich zum Kühlen und Tiefkühlen von Lebensmitteln. Das

Gerät ist auch für den Betrieb auf Booten geeignet.

VORSICHT! Gesundheitsgefahr!

!

Prüfen Sie bitte, ob die Kühlleistung des Gerätes den Anforderungen

der Lebensmittel oder Medikamente entspricht, die Sie kühlen wollen.

42

Page 43

DE

Coldmachine Technische Beschreibung

6 Technische Beschreibung

Die Kühlaggregate sind geeignet für den Einsatz an einer Gleichspannung von 12 V

oder 24 V und können somit z. B. auch beim Camping oder auf Booten eingesetzt

werden. Außerdem können sie über Gleichrichter an ein 230-V-Netz angeschlossen

werden (siehe Kapitel „Zubehör“ auf Seite 42).

Beim Einsatz auf Booten kann das Kühlaggregat einer Dauer-Krängung von 30° ausgesetzt werden.

Das Kühlaggregat muss mit einem Verdampfer komplettiert werden. Zusätzlich

können Sie einen Kältespeicher mit oder ohne TEC-Steuerung einsetzen. Bei

CS-NC15 bilden das Kühlaggregat und der Verdampfer eine Einheit.

Über den Thermostat am Verdampfer kann die gewünschte Temperatur stufenlos

eingestellt werden.

Kältespeicher und TEC-Programmsteuerung ermöglichen hohe Kühlleistungen und

verbessern den Wirkungsgrad. Der Kältespeicher wird bei ausreichender Stromversorgung (z. B. bei Versorgung durch ein Netzgerät) aufgeladen. Bei Speicherabruf oder Unterspannung wird die Kälte dem Kältespeicher entnommen, bis er leer

ist. So wird in dieser Zeit die Batterie nicht belastet.

Die TEC-Programmsteuerung sorgt dafür, dass

• Kälteenergie gespeichert wird, wenn überschüssige elektrische Energie vorhanden ist (Fremdversorgung durch Lichtmaschine, Ladegerät, Netzgerät usw.)

• der Kältespeicher jederzeit abgerufen werden kann, um die komplette Batterieenergie für andere Verbraucher zur Verfügung zu stellen

• gespeicherte Kälteenergie automatisch zur Erhaltung der Kühlrauminnentemperatur abgerufen wird, wenn die Batteriekapazität erschöpft ist.

I

HINWEIS

Weitere Informationen zum Kältespeicher finden Sie im Kapitel „Kältespeicher benutzen“ auf Seite 53.

43

Page 44

DE

Kühlaggregat einbauen Coldmachine

6.1 Batteriewächter

Ein elektronischer Verpolungsschutz schützt das Produkt gegen Verpolung beim

Batterieanschluss. Zum Schutz der Batterie schaltet sich das Produkt automatisch ab,

wenn die Spannung nicht mehr ausreicht (siehe folgende Tabellen).

Geräte ohne TEC-Steuerung

Anschlussspannung Ausschaltspannung

12 V

24 V

Geräte mit TEC-Steuerung

Anschlussspannung Ausschaltspannung

12 V

24 V

10,4 V 11,7 V

22,8 V 24,2 V

10,7 V 13,0 V

22,0 V 26,0 V

Wiedereinschaltspannung

Wiedereinschaltspannung

7 Kühlaggregat einbauen

WARNUNG!

!

7.1 Benötigtes Werkzeug

Für Einbau und Montage benötigen Sie folgende Werkzeuge:

•Bohrmaschine

• Schraubendreher

• Maulschlüssel: 16 mm, 19 mm und 21 mm

• Dichtungsmasse und Montageschaum

• Kabel, Kabelschuhe und Kabelschellen

•Esteröl

Der Einbau darf nur von fachkundigem Personal durchgeführt werden.

44

Page 45

DE

Coldmachine Kühlaggregat einbauen

7.2 Hinweise zum Kühlbehälter

Zulässige Kühlrauminhalte

Achten Sie darauf, dass der angegebene maximale Kühlrauminhalt für den jeweiligen Verdampfer-Typ nicht überschritten wird (siehe Kapitel „Technische Daten“ auf

Seite 57).

Mindestisolierung

Der maximale Kühlrauminhalt basiert auf einer Mindestisolierung von 35 mm

geschäumtem Polyurethan mit einem Raumgewicht von 40 kg/m³. Bei Verwendung

anderer Isolierstoffe wie z. B. Styropor sind die Wandstärken zu verdoppeln, um die

gleiche Wärmedämmung zu erreichen.

Verdampfer montieren

Der Verdampfer muss in den Kühlbehälter installiert werden (außer CS-NC15, der

Verdampfer ist vormontiert).

Beachten Sie dabei Folgendes:

• richtige Einbaulage (Abb. 3, Seite 4 bis Abb. 9, Seite 6)

• Anordnung im Kühlbehälter möglichst weit oben

• Mindestabstand zur Wand von 10 mm einhalten (nicht VD-14N und VD-15)

ACHTUNG!

A

Verdampfer anschließen

➤ Schließen Sie den Verdampfer VD-14N und VD-15 gemäß Abb. 0, Seite 6 an.

➤ Schließen Sie den Verdampfer VD-16 gemäß Abb. 9, Seite 6 an.

➤ Schließen Sie die anderen Verdampfer gemäß Abb. j, Seite 9 an.

Bei Kühlaggregaten ohne Ventilkupplungen (einbaufertige Einheiten):

Öffnen Sie bei der Montage den Kühlkreislauf nicht. Gegebenenfalls

müssen Sie die Wanddurchbrüche so groß vorsehen, dass Sie den

Verdampfer durchschieben können (Abb. a, Seite 6). Oder Sie

fertigen den Durchbruch so an, dass Sie die Kühlleitungen von oben

einbauen können (Abb. b, Seite 6).

45

Page 46

DE

Kühlaggregat einbauen Coldmachine

Legenden zu den Abbildungen

Nr. in

Abb. 8, Seite 5

1 DC-Lüfter

2 Thermostatknopf

3

4

5Anschlusskabel

Nr. in

Abb. 9, Seite 6

1Anschlusskabel

Nr. in

Abb. 0, Seite 6

1Anschlusskabel

Nr. in

Abb. j, Seite 9

und Abb. k,

Seite 10

Erklärung

Anschlussstecker DC-Lüfter

Thermostat

Erklärung

Erklärung

Erklärung

A

46

1 Anschlussblock

2Kompressor

3Lüfter

4 Schalter Abb. j bzw. TEC-Steuerung Abb. k

ACHTUNG!

Isolieren und dichten Sie die Wanddurchbrüche nach erfolgter

Montage wieder sorgfältig gegen Eindringen von Feuchtigkeit ab.

Page 47

DE

Coldmachine Kühlaggregat einbauen

Bei Kühlaggregaten mit Ventilkupplungen

➤ Fertigen Sie zur Durchführung der Kühlleitungen einen Ausschnitt mit einem

Durchmesser von mindestens 30 mm (Abb. c, Seite 7). Verwenden Sie dazu

einen Kreisschneider.

ACHTUNG!

A

Knicken Sie niemals die Verbindungsleitung zwischen Verdampfer und

Aggregat. Biegeradius mindestens 25 mm.

7.3 Kühlaggregat montieren

Die richtige Platzwahl für die Aufstellung des Aggregates ist besonders wichtig. Um

ein einwandfreies Funktionieren des Gerätes sicherzustellen, beachten Sie folgende

Punkte:

• Stellen Sie das Kühlaggregat an einem trockenen, geschützten Platz auf.

Vermeiden Sie das Aufstellen neben Wärmequellen wie Heizungen, Gasöfen,

Warmwasserleitungen etc. Lassen Sie das Kühlaggregat nicht in der prallen

Sonne stehen.

• Installieren Sie das Kühlaggregat auf Booten möglichst unterhalb der

Wasserlinie.

• Das Kühlaggregat funktioniert bei einem Neigungswinkel von bis zu 30°.

Installieren Sie es auf einer geraden Ebene, damit es auch bei möglichst starker

Krängung noch arbeitet.

• Die erwärmte Luft muss ungehindert abziehen können (Abb. d, Seite 7).

• Bei Einbau des Kühlaggregates in einen geschlossenen Raum wie Kleiderschrank, Pantry oder Backkiste müssen Öffnungen mit einem freien Querschnitt

von je mindestens 200 cm² (25 cm x 8 cm) für Be- und Entlüftung vorgesehen

werden.

• Achten Sie darauf, dass der Luftstrom am Kondensator (Abb. d C, Seite 7) nicht

beeinträchtigt wird.

• Halten Sie einen Mindestabstand zwischen Kondensator und angrenzender

Wand ein (50 mm).

• CS-NC15: Beachten Sie zur Montage die Abbildung der Bohrschablone

(Abb. l, Seite 11) und die Einbauzeichnung (Abb. m, Seite 12).

47

Page 48

DE

Kühlaggregat einbauen Coldmachine

7.4 Externen Temperaturregler montieren

Mechanischer Thermostat

Der Temperaturregler kann innerhalb oder außerhalb des Kühlbehälters angebracht

werden. Die Regelung der Innentemperatur erfolgt in Abhängigkeit von der

Verdampfer-Oberflächentemperatur bzw. für VD-14N und VD-15 in Abhängigkeit

von der Raumtemperatur.

➤ Verbinden Sie das schneckenförmig aufgewickelte Ende der Fühlerleitung

mittels der Klemmplatte fest mit dem Verdampfer (Abb. e, Seite 8, nicht

VD-14N, VD-15). Dies ist bei VD-14N, VD-15 vormontiert.

➤ Achten Sie darauf, dass die Fühlerleitung nicht an anderer Stelle mit dem Ver-

dampfer oder mit der Saugleitung in Berührung kommt.

TEC-Steuerung

Der TEC-Regler (Steuerung) muss außerhalb des Kühlbehälters angebracht werden.

Die Regelung der Innentemperatur erfolgt in Abhängigkeit von der VerdampferOberflächentemperatur.

Der Temperaturfühler ist werkseitig fest am Energiespeicher angebracht.

➤ Verbinden Sie den Temperaturfühler mit der TEC-Steuerung über die Steck-

kupplung.

Einweg-Kupplungen montieren (nicht CS-NC15)

ACHTUNG!

A

Das Kühlaggregat wird entkuppelt geliefert (Verdampfer und Kompressor sind

getrennt), hat aber werkseitig die richtige Kältemittelbetriebsfüllung.

➤ Bauen Sie das Maschinenteil und den Verdampfer ein.

➤ Entfernen Sie die aufgeschraubten Schutzkappen von den Kupplungshälften,

die die Gummidichtung vor eventuellen Verunreinigungen schützen.

Abb. f, Seite 8, zeigt den Zustand der Kupplungshälften nach Entfernen der

Schraubkappen im entkuppelten Zustand.

Kältemittelverluste führen zum zum Ausfall der Kühlanlage. In solchen

Fällen muss das komplette Kühlaggregat ausgebaut, eingeschickt, die

Einwegkupplungen gewechselt und das Produkt im Werk neu befüllt

werden.

48

Page 49

DE

Coldmachine Kühlaggregat einbauen

ACHTUNG! Gefahr von Kältemittelverlusten

A

➤ Tragen Sie etwas Esteröl auf den Dichtungsring und die Gewinde der beiden

Kupplungshälften auf (Abb. f, Seite 8).

➤ Setzen Sie die Kupplungshälften mit der Hand spannungsfrei auf und ziehen Sie

diese handfest an (Abb. g, Seite 8).

➤ Ziehen Sie die Überwurfmuttern SW21 bis zum Ende des Gewindes an:

verwenden Sie den Maulschlüssel mit der Schlüsselweite 21 zum Anziehen und

den zweiten Maulschlüssel (SW19 oder SW16) zum Kontern.

Der Abstand zwischen den Kupplungshälften beträgt 2–3 mm (Abb. h,

Seite 8).

A

➤ Ziehen Sie die Überwurfmuttern SW21 mit einem Drehmoment von 30 Nm um

ca. 90° weiter an, um die beiden Kupplungen fest miteinander zu verbinden.

Der Schneidring der männlichen Kupplungshälfte muss sich in die weibliche

Kupplungshälfte schneiden.

Verwenden Sie immer zwei Maulschlüssel, um ein Verdrehen der

Kupplungen im Kupplungshalter zu verhindern.

ACHTUNG! Gefahr von Kältemittelverlusten

Die Kupplung ist noch nicht dauerhaft abgedichtet.

Falls das Gerät für den Rückversand entkuppelt werden muss:

WARNUNG!

!

➤ Schrauben Sie die Schutzkappen wieder auf die entsprechenden Kupplungs-

hälften auf, um das Eindringen von Schmutz und Feuchtigkeit in den geöffneten

Kältemittelkreislauf zu verhindern.

Kältemittel befindet sich unter Druck im System.

Beim Entkuppeln Schutzbrille und Schutzhandschuhe tragen.

49

Page 50

DE

Kühlaggregat einbauen Coldmachine

7.5 Kühlaggregat anschließen

An eine Batterie anschließen

Das Kühlaggregat kann mit 12 V oder mit 24 V Gleichspannung betrieben werden.

ACHTUNG!

A

➤ Bestimmen Sie den notwendigen Querschnitt der Leitung in Abhängigkeit von

der Leitungslänge gemäß Abb. i, Seite 9.

Legende zu Abb. i, Seite 9

A

➤ Kontrollieren Sie vor Inbetriebnahme des Aggregates, ob die Betriebsspannung

und die Batteriespannung übereinstimmen (siehe Typenschild).

Um Spannungs- und Leistungsverluste zu vermeiden, muss die Leitung

möglichst kurz und nicht unterbrochen sein.

Vermeiden Sie deshalb zusätzliche Schalter, Stecker oder Verteilerdosen.

Koordinatenachse Bedeutung Einheit

l Leitungslänge m

∅ Leitungsquerschnitt mm²

ACHTUNG!

Beachten Sie die richtige Polarität.

➤ Schließen Sie Ihr Kühlaggregat

– möglichst direkt an die Pole der Batterie an oder

– an einen Steckplatz an, der mit mindestens 15 A (bei 12 V) bzw. 7,5 A (bei

24 V) abgesichert ist.

ACHTUNG!

A

Zur Sicherheit ist das Kühlaggregat mit einem elektronischen Verpolungsschutz ausgestattet, der das Kühlaggregat gegen Verpolung beim Batterieanschluss schützt.

50

Klemmen Sie das Gerät und andere Verbraucher von der Batterie ab,

bevor Sie die Batterie mit einem Schnellladegerät aufladen. Überspannungen können die Elektronik der Geräte beschädigen.

Page 51

DE

Coldmachine Kühlaggregat benutzen

An ein 230-V-Netz anschließen

WARNUNG!

!

➤ Um das Kühlaggregat am 230-V-Netz zu betreiben, verwenden Sie den Gleich-

richter

– CoolPower EPS100 bei Geräten mit Kompressor BD35F (Serie

– CoolPower MPS35 bei Geräten mit Kompressor BD35F (Serie

– CoolPower MPS50 bei Geräten mit Kompressor BD50F (Serie 90).

I

• Hantieren Sie nie mit Steckern und Schaltern, wenn Sie nasse Hände

haben oder mit den Füßen in der Nässe stehen.

• Wenn Sie Ihr Produkt an Bord eines Bootes per Landanschluss am

230-V-Netz betreiben, müssen Sie auf jeden Fall einen FI-Schutzschalter zwischen 230-V-Netz und Produkt schalten.

Lassen Sie sich von einem Fachmann beraten.

50/80/CS/CS),

50/80/CS/CS),

HINWEIS

Die Ausgangsspannung der beschriebenen Gleichrichter beträgt 24 V.

Bitte beachten Sie dies beim eventuellen Anschluss weiterer Verbraucher.

8 Kühlaggregat benutzen

8.1 Tipps zum Energiesparen

• Wählen Sie einen gut belüfteten und vor Sonnenstrahlen geschützten Einsatzort.

• Lassen Sie warme Speisen erst abkühlen, bevor Sie sie einlagern.

• Öffnen Sie den Kühlbehälter nicht häufiger als nötig.

• Lassen Sie die Tür nicht länger offen stehen als nötig.

• Tauen Sie den Kühlbehälter ab, sobald sich eine Eisschicht gebildet hat.

• Vermeiden Sie eine unnötig tiefe Innentemperatur.

• Befreien Sie den Kondensator in regelmäßigen Abständen von Staub und Verunreinigungen.

• Reinigen Sie regelmäßig die Deckeldichtung.

51

Page 52

DE

Kühlaggregat benutzen Coldmachine

8.2 Kühlaggregat in Betrieb nehmen

Geräte ohne TEC-Steuerung

➤ Schalten Sie das Kühlaggregat mit einer Rechtsdrehung des Schaltknopfes

(Abb. 1 A1 oder B1, Seite 3) ein.

Wenn Sie den Knopf weiter drehen, können Sie die Temperatur regeln. Geräte mit

Energiespeicherfunktion besitzen zusätzlich einen Speicherabrufknopf

(Abb. 1 A2, Seite 3).

HINWEIS

I

Geräte mit TEC-Steuerung

Geräte mit TEC-Steuerung werden über den Hauptschalter (Abb. 2 6, Seite 3) in

Betrieb genommen. Mit dem Temperaturwähler (Abb. 2 5, Seite 3) können Sie

dann die Temperatur regeln.

Wenn die rote LED blinkt oder leuchtet, liegt ein Fehler vor und das

System ist nicht betriebsbereit (siehe Fehlertabelle im Kapitel „LED am

Thermoelement (Abb. 1 2, Seite 3)“ auf Seite 55).

8.3 Kühlaggregat außer Betrieb nehmen

Wenn Sie das Kühlaggregat für längere Zeit stilllegen wollen, gehen Sie wie folgt

vor:

➤ Geräte ohne TEC-Steuerung: Drehen Sie den Regler auf Stufe „0“.

➤ Geräte mit TEC-Steuerung: Schalten Sie das Gerät mit dem Hauptschalter

(Abb. 2 6, Seite 3) aus.

➤ Klemmen Sie die Anschlusskabel von der Batterie ab oder ziehen Sie den Stecker

der Gleichstromleitung aus dem Gleichrichter.

➤ Reinigen Sie das Produkt.

➤ Lassen Sie die Tür oder den Deckel leicht geöffnet.

So verhindern Sie, dass sich Gerüche bilden.

52

Page 53

DE

Coldmachine Kältespeicher benutzen

9 Kältespeicher benutzen

9.1 Anzeige- und Bedienelemente von Geräten mit

TEC-Programmsteuerung

Nr. in

Abb. 2,

Seite 3

1 Leuchtdiode grün: zeigt an, dass der Kompressor arbeitet.

2 Leuchtdiode gelb: zeigt an, dass Fremdversorgung vorhanden ist

3 Leuchtdiode rot: zeigt an, dass der Kältespeicher abgerufen wird aufgrund

4 Kältespeicherabruftaste: unterbricht Kompressorbetrieb bis

5 Temperaturwähler: ermöglicht eine stufenlos einstellbare Kühlraum-

6 Hauptschalter: erlaubt Ein- und Ausschalten des Kühlgerätes.

Erklärung

(Klemmspannung über 13,5 V bzw. 27,0 V).

Leuchtdiode blinkt, wenn Versorgungsspannung zu niedrig ist (Klemmspan-

nung ≤ 10,7 V bzw. 21,7 V. Version E: ≤ 10,7 V bzw. 22,0 V).

• manueller Betätigung der Speicherabruftaste

• Unterspannungsabschaltung (Klemmspannung ≤ 10,7 V bzw. 21,4 V.

Version E: ≤ 10,7 V bzw. 22,0 V).

• gespeicherte Kälteenergie aufgebraucht ist

• Fremdversorgungsspannung nach Unterspannung wieder erreicht wird.

Temperatur

min. (Linksanschlag) = wärmste Einstellung

max. (Rechtsanschlag) = kälteste Einstellung

Stellung 0 = AUS

Stellung – = EIN

53

Page 54

DE

Gewährleistung Coldmachine

9.2 Kältespeicherfunktion

Die Kältespeicherfunktion sorgt dafür, dass automatisch Kälteenergie gespeichert

wird (bis zu 8 Stunden), wenn ausreichend Strom verfügbar ist, z. B. bei Versorgung

durch ein Netzgerät.

Der Abruf der gespeicherten Kälte geschieht

• automatisch bei Erreichen der Ausschaltspannung (siehe Tabelle Seite 44)

• oder manuell durch Drücken der Speicherabruftaste (Abb. 1 A2 oder

Abb. 2 4, Seite 3).

HINWEIS

I

Der Kältespeicher wird automatisch wieder aufgeladen,

• wenn die Wiedereinschaltspannung überschritten wird

• wenn der Kältespeicher entladen ist und Sie das Gerät einmal mittels des Hauptschalter (Abb. 2 6, Seite 3) aus- und wieder einschalten (funktioniert nur bei

VD-06).

A

Der Kältespeicher kann manuell nur abgerufen werden, nachdem er

zuvor vollständig geladen wurde.

ACHTUNG!

Wenn Sie den Kältespeicher abrufen, obwohl Fremdversorgung vorliegt – z. B. um Betriebsgeräusche des Kompressors zu vermeiden –

schalten Sie das Aggregat über den Hauptschalter (Abb. 1 B1 oder

Abb. 2 6, Seite 3) aus.

HINWEIS

I

Beachten Sie: Niedrige Innentemperatur = Höherer Stromverbrauch!

10 Gewährleistung

Es gilt die gesetzliche Gewährleistungsfrist. Sollte das Produkt defekt sein, wenden

Sie sich bitte an die Niederlassung des Herstellers in Ihrem Land (Adressen siehe

Rückseite der Anleitung) oder an Ihren Fachhändler.

Zur Reparatur- bzw. Gewährleistungsbearbeitung müssen Sie folgende Unterlagen

mitschicken:

• eine Kopie der Rechnung mit Kaufdatum,

• einen Reklamationsgrund oder eine Fehlerbeschreibung.

54

Page 55

DE

Coldmachine Entsorgung

11 Entsorgung

➤ Geben Sie das Verpackungsmaterial möglichst in den entsprechenden

Recycling-Müll.

Wenn Sie das Produkt endgültig außer Betrieb nehmen, informieren Sie

sich bitte beim nächsten Recyclingcenter oder bei Ihrem Fachhändler

M

über die zutreffenden Entsorgungsvorschriften.

12 Störungen beseitigen

LED am Thermoelement (Abb. 1 2, Seite 3)

Anzahl des

Blinkens

1 Batterieschutzabschaltung Batteriespannung, Stecker-

2 Lüfterüberstromabschaltung Verflüssiger- und Verdampferlüfterstrom

3 Verdichteranlauffehler Kühlsystem entlasten:

4 Verdichterüberlastabschaltung Kühlsystem entlasten:

5 Elektronikschutzabschaltung Kühlsystem entlasten:

Fehlertyp Lösung

verbindungen, Sicherung und

verwendeten Kabelquerschnitt prüfen

prüfen:

gesamter Sollwert < 0,5 A

• Be- und Entlüftung des

Kühlaggregates gewährleisten

• Lagerung vorgekühlter Waren

• Be- und Entlüftung des

Kühlaggregates gewährleisten

• Lagerung vorgekühlter Waren

• Be- und Entlüftung des

Kühlaggregates gewährleisten

55

Page 56

DE

Störungen beseitigen Coldmachine

Kompressor läuft nicht

Störung Mögliche Ursache Lösung

UKL = 0 V Unterbrechung in der Anschlussleitung

Batterie – Elektronik

Hauptschalter defekt (falls vorhanden) Hauptschalter wechseln

Zusätzliche Leitungsabsicherung durchgebrannt (falls vorhanden)

U

≤ U

KL

EIN

Startversuch mit

U

≤ U

KL

AUS

Startversuch mit U

U

Spannung zwischen Plus- und Minusklemme der Elektronik

KL

U

Einschaltspannung Elektronik

EIN

U

Ausschaltspannung Elektronik

AUS

KL

Batteriespannung zu niedrig Batterie laden

Lose Kabelverbindung

Schlechter Kontakt (Korrosion)

Batteriekapazität zu gering Batterie wechseln

Kabelquerschnitt zu gering Kabel wechseln (Abb. i,

≥ U

Umgebungstemperatur zu hoch –

EIN

Be- und Entlüftung nicht ausreichend für bessere Be- und

Kondensator verschmutzt Kondensator reinigen

Lüfter defekt (falls vorhanden) Lüfter wechseln

Verbindung herste llen

Leitungsabsicherung wechseln

Verbindung herste llen

Seite 9)

Entlüftung des Kühlaggregats sorgen

Innentemperatur zu kalt in Regler-Stufe „1“

Störung Mögliche Ursache Lösung

Kompressor läuft dauernd Thermostat-Fühler hat keinen Kontakt am

Ver dam pfe r

Thermostat defekt Thermostat wechseln

Kompressor läuft lange Im Gefrierfach wurde größere Menge ein-

gefroren

Fühler befestigen

–

56

Page 57

DE

Coldmachine Technische Daten

Kühlleistung lässt nach, Innentemperatur steigt

Störung Mögliche Ursache Lösung

Kompressor läuft

lange/dauernd

Kompressor läuft selten Batteriekapazität erschöpft Batterie laden

Verdampfer vereist Verdampfer abtauen

Umgebungstemperatur zu hoch –

Be- und Entlüftung nicht ausreichend für bessere Be- und

Entlüftung des Kühlaggregats sorgen

Kondensator verschmutzt Kondensator reinigen

Lüfter defekt (falls vorhanden) Lüfter wechseln

Ungewöhnliche Geräusche

Störung Mögliche Ursache Lösung

Lautes Brummen Bauteil des Kältekreislaufes kann nicht frei

schwingen (liegt an Wandung an)

Fremdkörper zwischen Kühlmaschine und

Wand eingeklemmt

Lüftergeräusch (falls vorhanden) Lüfterflügel reinigen

Bauteil vorsichtig abbiegen

Fremdkörper entfernen

13 Technische Daten

50 54 55

max. Kühlrauminhalt: 80 Liter 130 Liter

Anschlussspannung 12 Vg oder 24 Vg

Leistungsaufnahme: 35 – 40 W, je nach Verdampfertyp

Kühlmittelmenge: 28 g 35 g

CO2-Äquivalent: 0,040 t 0,050 t

Treibhauspotential

(GWP):

Abmessungen

(B x H x T) in mm:

Gewicht: 3.74 kg 6,0 kg 6,5 kg

315 x 140 x 170 386 x 155 x 130 220 x 160 x 220

1430

57

Page 58

DE

Technische Daten Coldmachine

84 85 86

max. Kühlrauminhalt: 250 Liter

Anschlussspannung: 12 Vg oder 24 Vg

Kühlmittelmenge: 45 g

CO2-Äquivalent: 0,064 t

Treibhauspotential

(GWP):

Abmessungen

(B x H x T) in mm:

Gewicht: 6,0 kg 6,0 kg 6,5 kg

386 x 155 x 130 220 x 155 x 220 220 x 230 x 177

94 95 96

max. Kühlrauminhalt: 400 Liter

Anschlussspannung: 12 Vg oder 24 Vg

Kühlmittelmenge: 60 g

CO2-Äquivalent: 0,086 t

Treibhauspotential

(GWP):

Abmessungen

(B x H x T) in mm:

Gewicht: 6,0 kg 6,0 kg 6,5 kg

386 x 155 x 130 220 x 155 x 220 220 x 230 x 177

1430

1430

CS-NC15

max. Kühlrauminhalt: 250 Liter

Anschlussspannung: 12 Vg oder

24 Vg

Kühlmittelmenge: 60 g

CO2-Äquivalent: 0,086 t

Treibhauspotential

(GWP):

Abmessungen

(B x H x T) in mm:

Gewicht: 8,5 kg

1430

360 x 255 x 275

58

Page 59

DE

Coldmachine Technische Daten

VD-01 VD-02 VD-03 VD-04

max. Kühlrauminhalt

bei 35 mm

PU-Isolierung:

max. Kühlrauminhalt

bei 50 mm

PU-Isolierung:

Leistungsaufnahme: 35 W 35 W 50 W 45 W

Anschlussspannung: 12 Vg oder 24 Vg

Kühlmittelmenge: 17 g 20 g 30 g

CO2-Äquivalent: 0,024 t 0,029 t 0,043 t

Treibhauspotential

(GWP):

Abmessungen

(B x H x T) in mm:

Gewicht: 1,5 kg 1,0 kg 2,0 kg 1,5 kg

max. Kühlrauminhalt

bei 35 mm

PU-Isolierung:

max. Kühlrauminhalt

bei 50 mm

PU-Isolierung:

Leistungsaufnahme: 30 W

Temperatur: Umgebung: 32 °C, Innen: 5 °C

80 Liter 30 Liter 170 Liter 130 Liter

100 Liter 50 Liter 200 Liter 170 Liter

1430

300 x 245 x 110 275 x 215 x 25 380 x 230 x 82 375 x 255 x 100

CU-50 +

VD-01

50 Liter 30 Liter 60 Liter

75 Liter 50 Liter 80 Liter

CU-50 +

VD-02

CU-50 +

VD-07

59

Page 60

DE

Technische Daten Coldmachine

VD-05 VD-07 VD-08 VD-09

max. Kühlrauminhalt

bei 35 mm

PU-Isolierung:

max. Kühlrauminhalt

bei 50 mm

PU-Isolierung:

Leistungsaufnahme: 45 W 35 W 60 W 60 W

Anschlussspannung: 12 Vg oder 24 Vg

Kühlmittelmenge: 30 g 45 g 15 g 65 g

CO2-Äquivalent: 0,043 t 0,064 t 0,021 t 0,093 t

Treibhauspotential

(GWP):

Abmessungen

(B x H x T) in mm:

Gewicht: 1,5 kg 1,5 kg 2,0 kg 2,0 kg

130 Liter 100 Liter 160 Liter 160 Liter

170 Liter 130 Liter 180 Liter 180 Liter

1430

375 x 350 x 25 255 x 210 x 90 450 x 270 x 340 365 x 140 x 270

VD-14N VD-15 VD-18

max. Kühlrauminhalt

bei 35 mm

PU-Isolierung:

max. Kühlrauminhalt

bei 50 mm

PU-Isolierung:

Leistungsaufnahme: 80 W 60 W 45 W

Anschlussspannung: 12 Vg oder 24 Vg

Kühlmittelmenge: 15 g

CO2-Äquivalent: 0,021 t

Treibhauspotential

(GWP):

Abmessungen

(B x H x T) in mm:

Gewicht: 2,5 kg 1,5 kg 1,5 kg

300 Liter 200 Liter 100 Liter

400 Liter 250 Liter 150 Liter

1430

220 x 275 x65 220 x 275 x 65 350 x 250 x 25

60

Page 61

DE

Coldmachine Technische Daten

VD-16 VD-21

max. Kühlrauminhalt

bei 60 mm

PU-Isolierung:

max. Kühlrauminhalt

bei 100 mm

PU-Isolierung:

Leistungsaufnahme: 60 W 60 W

Anschlussspannung: 12 Vg oder 24 Vg

Kühlmittelmenge: 40 g 10 g

CO2-Äquivalent: 0,057 t 0,014 t

Treibhauspotential

(GWP):

Abmessungen

(B x H x T) in mm:

Gewicht: 2,5 kg 4,0 kg

130 Liter 250 Liter

200 Liter 300 Liter

1430

330 x 260 x 130 1370 x 305 x 10

VD-16 für Serie 80 VD-16 für Serie 90

max. Kühlrauminhalt

bei 35 mm PU-Isolierung:

max. Kühlrauminhalt

bei 50 mm

PU-Isolierung:

Leistungsaufnahme: 65 W 80 W

Anschlussspannung: 12 Vg oder 24 Vg

Kühlmittelmenge: 40 g

CO2-Äquivalent: 0,057 t

Treibhauspotential

(GWP):

Abmessungen

(B x H x T) in mm:

Gewicht: 5,0 kg

120 Liter 200 Liter

200 Liter 250 Liter

1430

380 x 300 x 62

61

Page 62

DE

Technische Daten Coldmachine

Prüfung/Zertifikate:

Der Kühlkreis enthält R-134a.

Enthält fluorierte Treibhausgase

62

Page 63

FR

Coldmachine Explication des symboles

Veuillez lire attentivement cette notice avant le montage et la mise en

service. Veuillez ensuite la conserver. En cas de passer le produit, veuillez

le transmettre au nouvel acquéreur.

Table des matières

1 Explication des symboles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

2 Consignes de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

3 Pièces fournies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4 Accessoires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5 Usage conforme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6 Description technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7 Montage du groupe frigorifique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8 Utilisation du groupe frigorifique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

9 Utiliser la plaque réfrigérante . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

10 Garantie. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

11 Retraitement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

12 Guide de dépannage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

13 Caractéristiques techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

1 Explication des symboles

DANGER !

D

!

Consigne de sécurité : le non-respect de ces consignes entraîne la

mort ou de graves blessures.

AVERTISSEMENT !

Consigne de sécurité : le non-respect de ces consignes peut entraîner

la mort ou de graves blessures.

63

Page 64

FR

Consignes de sécurité Coldmachine

ATTENTION !

!

A

I

Consigne de sécurité : le non-respect de ces consignes peut entraîner

des blessures.

AVIS !

Le non-respect de ces consignes peut entraîner des dommages

matériels et des dysfonctionnements du produit.

REMARQUE

Informations complémentaires sur l'utilisation du produit.

2 Consignes de sécurité

Le fabricant décline toute responsabilité pour des dommages dans les cas suivants :

• des défauts de montage ou de raccordement

• des sollicitations mécaniques et une tension de raccordement incorrecte ayant

endommagé le matériel

• des modifications apportées au produit sans autorisation explicite de la part du

fabricant

• une utilisation différente de celle décrite dans la notice

2.1 Sécurité générale

DANGER !

D

!

64

• Danger de mort !

En cas d’utilisation sur des bateaux : veillez à ce que

votre alimentation électrique soit sécurisée par un disjoncteur différentiel si l’appareil est branché sur le secteur !

AVERTISSEMENT !

• L'installation et la réparation de ce produit ne doivent être effectuées

que par du personnel qualifié. Toute réparation mal effectuée risquerait d'entraîner de graves dangers.

Si des réparations sont nécessaires, adressez-vous au service aprèsvente.

• Si l’appareil est visiblement endommagé, il est interdit de le mettre en

service.

Page 65

FR

Coldmachine Consignes de sécurité

• N'ouvrez jamais le circuit frigorifique. Vous ne pouvez déroger à cette

règle que si vous devez désaccoupler l'appareil pour le réexpédier

(chapitre « Montage des régulateurs de température externes »,

page 72).

• Installez l’appareil dans un endroit sec et à l’abri des éclaboussures

d’eau.

• Ne placez pas l’appareil près de flammes ou d’autres sources de chaleur (chauffage, rayons solaires, fours à gaz, etc.).

• Veillez à ce que le compresseur soit suffisamment aéré.

• Les appareils électriques ne sont pas des jouets pour enfants !

Placez et utilisez l’appareil hors de la portée des enfants.

• Ne laissez pas des personnes (enfants compris) incapables d’utiliser le

produit de manière sûre, en raison de déficiences physiques, sensorielles ou mentales ou de leur manque d’expérience ou de connaissances, utiliser ce produit sans surveillance.

• Avant de mettre l’appareil en service, vérifiez que la tension de service

et la tension de la batterie sont identiques (voir plaque signalétique).

• Si le câble de raccordement est endommagé, vous devez le remplacer afin d’éviter tout danger. Ne remplacez un câble de raccordement

endommagé que par un câble de raccordement de même type et de

même spécification.

• Ne stockez aucune substance explosive comme p. ex. des aérosols

contenant des agents propulseurs dans l’appareil.

2.2 Consignes de sécurité concernant l’utilisation

de l’appareil

DANGER !

D

A

• Danger de mort !

Ne touchez jamais les lignes électriques dénudées sans avoir protégé