Page 1

RECORD THIS INFORMATION FOR FUTURE

REFERENCE:

Model Number

Serial Number

ADB Model Number

ADB Serial Number

Date Purchased

DuraSea Roof Top Air Conditioner

Roof Top Unit

Description Model Type Use With Air Distribution Box (not included)

Model Control

Air Conditioner B3300 3341P 3309278.004 Integral Mechanical

INSTALLATION & OPERATING

INSTRUCTIONS

Form No. 3314452.000 7/12

©2012 Dometic, LLC

LaGrange, IN 46761

TYPE

3341P701

Read these instructions carefully. These

instructions MUST stay with this product.

Page 2

INTRODUCTION

This air conditioner (hereinafter referred to as “unit,” or “product”) is designed and intended for installation on the roof of a

boat during or after the time the vessel is manufactured.

This unit can be installed by one person with brief help from additional personnel. Use the following procedure to ensure a

properly installed, and properly functioning product.

Dometic, LLC reserves the right to modify appearances and specications without notice.

TABLE OF CONTENTS

INTRODUCTION .................................................................................................................................................................... 2

DOCUMENT SYMBOLS ........................................................................................................................................................3

IMPORTANT SAFETY INSTRUCTIONS ................................................................................................................................ 3

A. Recognize Safety Information ...................................................................................................................................3

B. Understand Signal Words ..........................................................................................................................................3

C. Supplemental Directives ............................................................................................................................................3

D. General Safety Messages .........................................................................................................................................3

SPECIFICATIONS .................................................................................................................................................................. 4

A. Table - Unit Data ....................................................................................................................................................... 4

B. Power Requirements ................................................................................................................................................. 4

C. Roof Requirements ....................................................................................................................................................4

INSTALLATION INSTRUCTIONS ..........................................................................................................................................5

A. Choosing Proper Location For Unit ...........................................................................................................................5

B. Roof Preparation .......................................................................................................................................................5

C. Wiring Requirements .................................................................................................................................................6

D. Placing Unit On Roof .................................................................................................................................................6

E. Installing Unit ............................................................................................................................................................. 6

F. Wiring System ...........................................................................................................................................................8

G. Air Distribution Box Installation .................................................................................................................................. 9

OPERATING INSTRUCTIONS ............................................................................................................................................. 10

A. Controls ...................................................................................................................................................................10

B. “OFF” Position .........................................................................................................................................................10

C. Cooling Operation .................................................................................................................................................... 10

D. Heating Operation (With Optional Electric Heater Installed) ................................................................................... 10

E. Fan Operation .......................................................................................................................................................... 10

MAINTENANCE ................................................................................................................................................................... 11

A. Air Filter ................................................................................................................................................................... 11

B. Air Distribution Box Housing .................................................................................................................................... 11

C. Fan Motor ................................................................................................................................................................ 11

D. Frost Formation On Cooling Coil ............................................................................................................................. 11

E. Heat Gain ................................................................................................................................................................ 11

F. Condensation .......................................................................................................................................................... 11

SERVICE - UNIT DOES NOT OPERATE .............................................................................................................................12

WIRING DIAGRAMS ............................................................................................................................................................ 12

A. Unit Wiring Diagram ................................................................................................................................................12

B. Air Distribution Box Wiring Diagram ........................................................................................................................12

OWNER'S LIMITED WARRANTY ........................................................................................................................................13

A. What's Covered .......................................................................................................................................................13

B. What's Not Covered ................................................................................................................................................13

C. Coverage Period ...................................................................................................................................................... 14

D. Getting Service ........................................................................................................................................................ 14

E. Table Of Warranty Periods.......................................................................................................................................15

2

Page 3

DOCUMENT SYMBOLS

Indicates additional information that is NOT related

to physical injury.

IMPORTANT SAFETY INSTRUCTIONS

This manual has safety information and instructions to help

users eliminate or reduce the risk of accidents and injuries.

A. Recognize Safety Information

This is the safety alert symbol. It is used to

alert you to potential physical injury hazards.

Obey all safety messages that follow this

symbol to avoid possible injury or death.

B. Understand Signal Words

A signal word will identify safety messages and

property damage messages, and will indicate the

degree or level of hazard seriousness.

indicates a hazardous situation that,

if NOT avoided, could result in death or serious injury.

indicates a hazardous situation that,

if NOT avoided, could result in minor or moderate

injury.

is used to address practices NOT

related to physical injury.

C. Supplemental Directives

Indicates step-by-step instructions.

Read and follow all safety information and

instructions to avoid possible injury or death.

Read and understand these instructions before [installing / using / servicing / performing

maintenance] on this product.

Incorrect [installation / operation / servicing /

maintaining] of this product can lead to serious injury. Follow all instructions.

The installation MUST comply with all applicable ABYC, local or national codes,

including the latest edition of the following

standards:

U.S.A.

● ANSI/NFPA70, National Electrical Code

(NEC)

CANADA

● CSA C22.1, Parts l & ll, Canadian Electri-

cal Code

D. General Safety Messages

Failure to obey the following warnings could result in death or serious injury:

● This product MUST be [installed / serviced] by a

qualied service technician.

● Do NOT modify this product in any way. Modica-

tion can be extremely hazardous.

● Do NOT add any devices or accessories to this

product except those specically authorized in

writing by Dometic, LLC.

3

Page 4

SPECIFICATIONS

A. Table - Unit Data

Type 3341P

A/C OR HP A/C

Nominal Cooling

Capacity (kW)

Electric Heat

Capacity (kW)

Electrical Rating 220 - 240 Vac 50 Hz, 1 ph

Full Load Amps

(Compressor / Motor)

Locked Rotor Amps

(Comp / Motor)

Power (kW)

Compressor + Motor

Power (kW)

Heater

Refrigerant R410A

Gram / Ounce

Minimum Wire Size Up to 8 meters use 1.5 mm2, Copper.

AC Circuit Protection

(Installer Supplied)

* Generator Size 1 Unit - 3.5 kW

Rating Plate 3313169.000

Height 333 mm

Width 759 mm

Depth 886 mm

Weight 46.7 kg

Consult Regulatory Codes.

10 Amp Time Delay Fuse,

3.4

1.6

5.56 / 1.4

25 / 2.6

1.38

1.6

822 / 29

or Circuit Breaker

2 Unit - 5.0 kW

B. Power Requirements

● 220 - 240 Vac, 50 Hz, 10 Amp.

● Power when the unit starts must be above 198

Vac and the frequency must be 50 Hz at all

times.

C. Roof Requirements

● A 362 mm x 362 mm (±3 mm) square opening

(hereinafter referred to as “roof opening”) is required for installing this unit.

● If applicable: Roof construction with rafters/

joists support frames on minimum of 406 mm

centers.

● Minimum of 25 mm and maximum of 102 mm

distance between roof to ceiling.

* Dometic Marine gives GENERAL guidelines for generator requirements. To reduce start-up power draw by up to

65%, consider installing a Dometic SmartStart.

4

Page 5

INSTALLATION INSTRUCTIONS

A. Choosing Proper Location For Unit

This unit is specically designed for installation on the roof

of a boat. Mount only with front of unit facing the bow (the

vented end should face aft). See (FIG. 4).

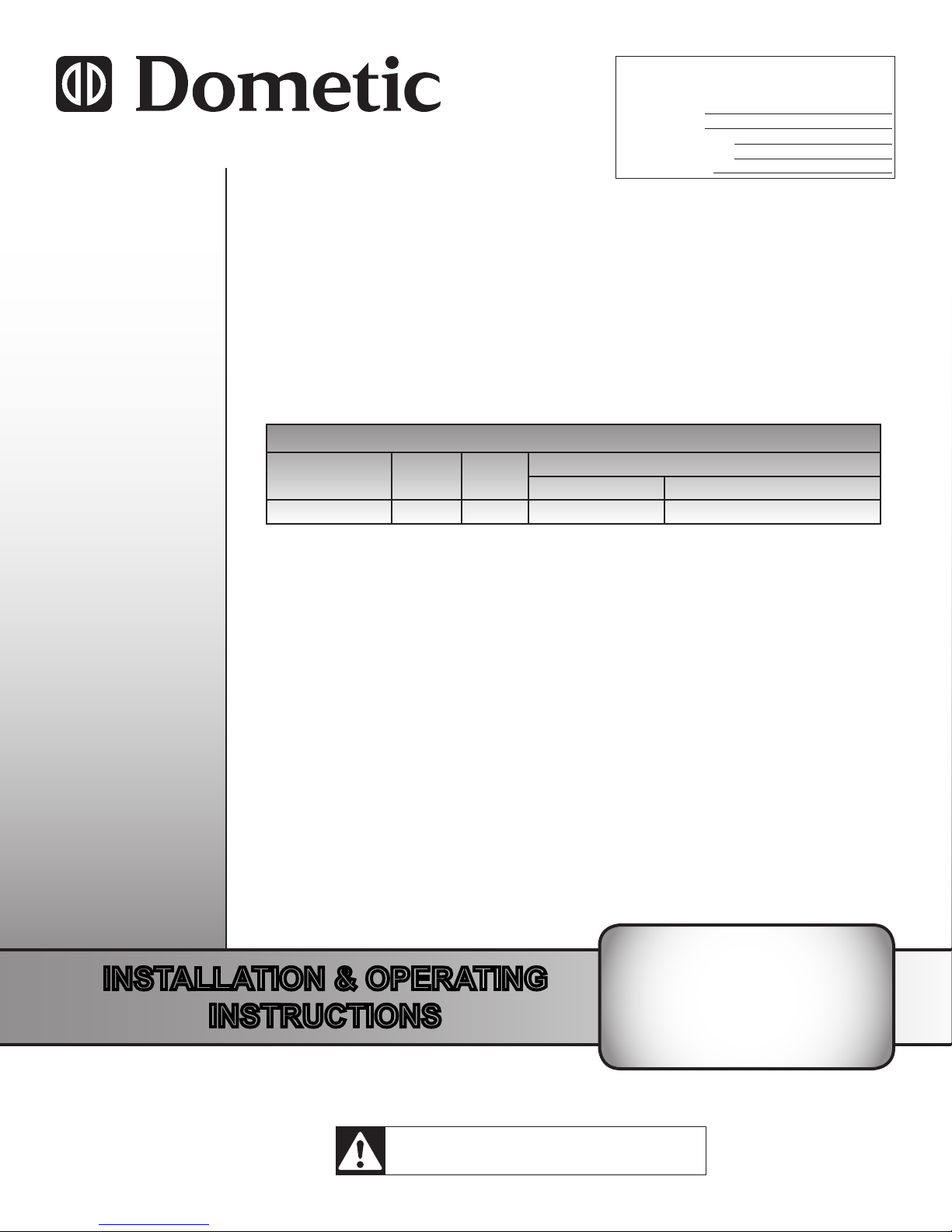

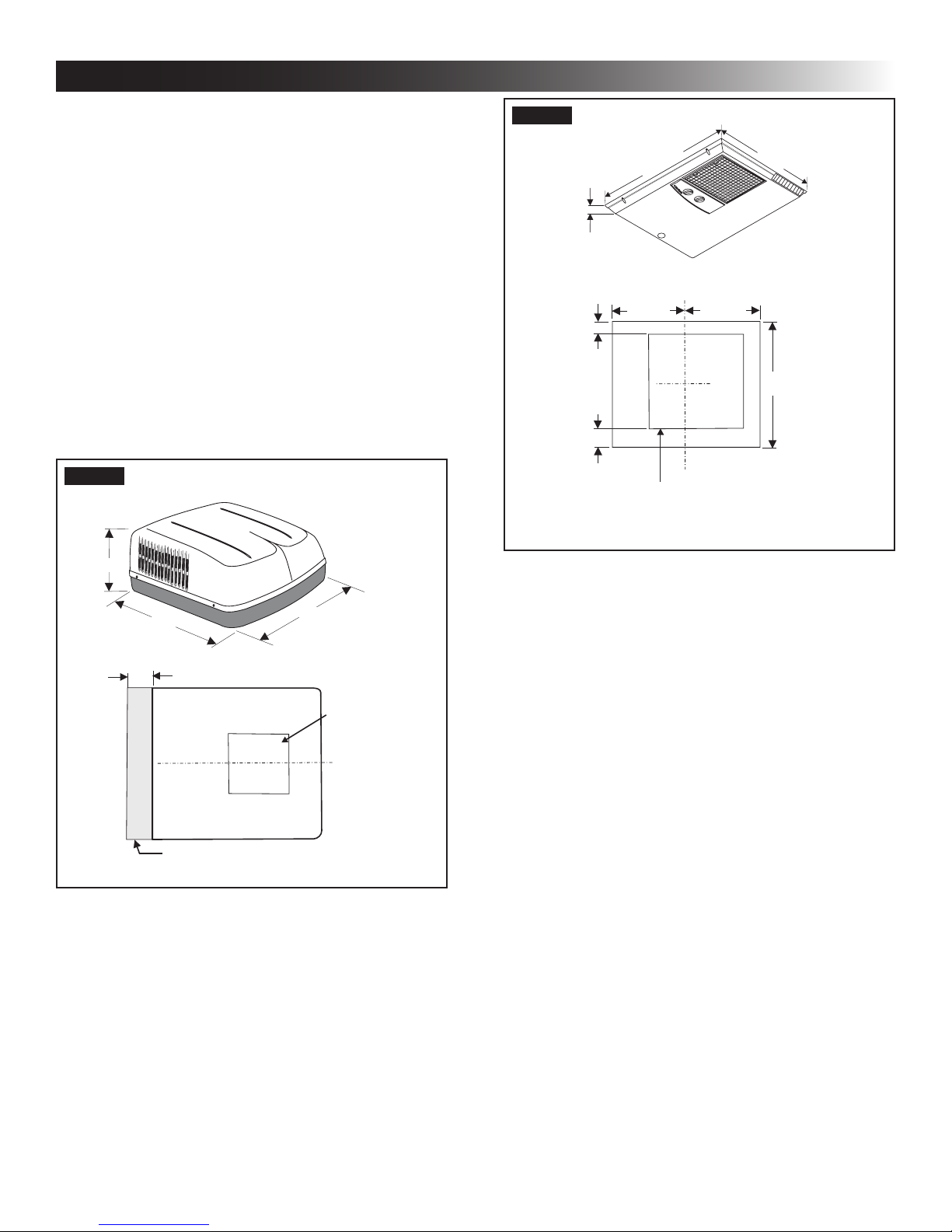

FIG. 2

572 mm

508 mm

When determining your cooling requirements, the following

should be considered:

● Size of boat;

● Window area (increases heat gain);

● Amount of insulation in walls and roof;

● Geographical location where boat will be used;

● Personal comfort level required.

It is preferred that the unit be installed on a relatively at

and level roof section, but up to a 15° tilt is acceptable.

1. After location has been selected:

a. Check for obstructions in the area where unit

will be installed. See (FIG. 1).

FIG. 1

333 mm

886 mm

Dimensions Are Nominal

457 mm

Center Line

Of Unit

759 mm

Roof Opening

Front

64 mm

Dimensions Are Nominal

286 mm

70 mm

76 mm

Roof Opening

Dimensions Are Nominal

286 mm

508 mm

B. Roof Preparation

1. FIRE OR ELECTRICAL SHOCK

HAZARD. Verify there are no obstacles inside

boat’s roof and/or walls (wires, pipes, etc.). Shut

OFF gas supply, disconnect 120 Vac power

from boat, and disconnect positive (+) 12 Vdc

terminal from supply battery BEFORE drilling or

cutting into boat. Failure to obey these warnings

could result in death or serious injury.

Front

286 mm

Keep This Area Free Of Obstructions

Dimensions Are Nominal

b. Maintain structural integrity.

Otherwise damage to product and/or boat

could occur.

The roof must be designed to support 60

kg when the boat is in motion. Normally

a 91 kg static load design will meet this

requirement.

c. Check inside the boat’s cabin for air distri-

bution box obstructions (i.e. space for doors

to open, room dividers, curtains, ceiling xtures, etc.). See (FIG. 2).

2. Carefully mark and cut the required roof opening. See section, "C. Roof Requirements" on

page (4).

3. Using the roof opening as a guide, cut the matching hole in the ceiling.

4. Maintain structural integrity. Otherwise damage to product and/or boat could

occur.

NEVER create a low spot on boat

roof. Otherwise, water will pool and could cause

a leak.

The opening created must be framed to provide adequate support and prevent air from being drawn from the roof cavity. Framing stock

19 mm or more in thickness must be used.

Remember to provide an entrance hole for

power supplies at the front of the opening. See

(FIG. 3).

5

Page 6

INSTALLATION INSTRUCTIONS

FIG. 3

Do Not Cut Roof

Structure Or

Rafters

19 mm Min.

Leave Access For Power

Supply Wiring

Good-Rafters

Supported By

Cross Beams

Good LocationBetween Roof

Rafters

Frame Opening So It

Won't Collapse When

Bolting Down Unit

381 mm Min. At

Front Of Opening

C. Wiring Requirements

1. Route a copper, with ground, 220 - 240 Vac supply wire from the time delay fuse or circuit breaker box to the roof opening. The proper size wire

can be determined from chart on page 4.

a. This supply wire must be located in the front

portion of the roof opening.

b. The power MUST be on an appropriately

sized separate time delay fuse or circuit

breaker. The proper protection can be determined from chart on page 4.

c. Make sure that at least 381 mm of supply

wire extends into the roof opening. This ensures an easy connection at the junction box.

d. Protect the wire where it passes into the

opening with approved method.

FIG. 4

Rear

Front

4. Place the air distribution box kit (ordered separately) inside the boat. This box contains mounting hardware for the unit and will be used inside

the boat.

This completes the outside work. Minor

adjustments can be done from inside the

boat if required.

Lift And Place

Front Towards Bow

Do Not Slide

E. Installing Unit

1. Remove air distribution box and mounting hardware from carton. The upper duct is shipped inside the lower duct which is part of the ceiling

template.

2. Check for correct alignment and adjust the unit

as necessary (roof gasket centers over the roof

opening). See (FIG. 5).

FIG. 5

Center Unit From Below

D. Placing Unit On Roof

1. Remove the unit from the carton and discard

carton.

2. LIFTING HAZARD. Use proper

lifting technique and control when lifting product.

Failure to obey this caution could result in injury.

Place the unit on the roof.

3. Do NOT slide unit. Otherwise,

damage to gasket (on bottom of unit) may occur,

and could cause a leak.

Lift and place the unit over the prepared opening using the gasket on the unit as a guide. See

(FIG. 4).

Roof Gasket

3. All models listed in this manual will use a four

(4) bolt pattern for installing the air distribution

box kit.

6

Page 7

INSTALLATION INSTRUCTIONS

4. Remove upper duct from ceiling template and

locate it over blower discharge.

Edges WITHOUT anges install toward

REAR and SIDE of opening. See (FIG. 6).

FIG. 6

Upper

Screw

5. Use two (2) #10 x 10 mm screws to hold duct to

base pan. Screw holes are provided in bottom of

base pan for these screws.

6. Reach up into return air opening of the unit and

pull the unit electrical cord down for later connection. See (FIG. 7).

7. If your installation includes the optional electric

heat kit, install it at this time. Follow the instructions with the heat package for its installation

procedure.

Sides Without Tab

To Rear And Side

Of Unit

Lower

Front

FIG. 8

Upper Discharge

Air Duct

Step a

Remove At

Perforation

Step a & b

Remove At

Step c

Use As

Packaged

b. If distance is 51 mm - 76 mm, remove per-

forated tabs from bottom duct only. See

(FIG. 8).

c. If distance is 76 mm - 102 mm, install ducts

as received. See (FIG. 8).

9. Install ceiling template by sliding lower duct over

upper duct.

10. Hold the ceiling template up to the roof opening.

a. Start each mounting bolt through the ceiling

template and up into the base pan by hand.

See (FIG. 9).

FIG. 9

Junction

Box

Perforation

Lower Discharge

Air Duct

Mounting

Bolts

FIG. 7

Measure Ceiling Thickness

8. Measure the ceiling to roof thickness:

a. If distance is 25 mm - 51 mm, remove perfo-

rated tabs from both upper and lower ducts.

See (FIG. 7) & (FIG. 8).

Pull Down

Electric Cord

Mounting

Bolts

b. Tighten all four (4) bolts until they touch the

template but are not tight.

c. With the ceiling template at against the ceil-

ing install the 6 wood screws (installed sup-

plied) at an angle, so as to stretch and atten

the template. Three (3) across the front and

three (3) across the back of the template.

See (FIG. 10).

7

Discharge

Air Duct

Page 8

INSTALLATION INSTRUCTIONS

FIG. 10

Knobs

Wood

Screws

d. Tighten mounting bolts to

correct torque specications. Overtightening could damage unit’s base pan or ceiling

template. Not enough torque will allow an inadequate roof seal, and could cause a leak.

Tighten all four (4) mounting bolts EVENLY

within 4.5 to 5.6 N·m. See (FIG. 11).

This will compress the roof gasket to

approximately 13 mm.

c. Install Romex connector in junction box. See

(FIG. 13).

d. Route the previously run 120 Vac power sup-

ply wire through Romex connector and into

the junction box. 152 mm leads are sufcient for connection to unit wires and ground

screw. See (FIG. 12) & (FIG. 13).

FIG. 12

Corner

Reinforcement

Heater Connection

Junction

Box

Mounting

Bolts

Wood Screw

Mounting

Bolts

Corner

Nut Retainer

Thermostat Sensor

Tube Clip

Unit Electrical

Connection

Discharge Air

Duct

FIG. 11

F. Wiring System

1. 220 - 240 Vac Power Supply Connection

a. ELECTRICAL SHOCK HAZ-

ARD. Verify 220-240 Vac power is disconnected from boat. Failure to obey this warning could result in death or serious injury.

b. ELECTRICAL SHOCK HAZ-

ARD. Provide grounding in compliance with

all applicable electrical codes. Failure to

obey this warning could result in death or serious injury.

Evenly Tighten

The 4 Mounting

Bolts To 4.5 - 5.6

N·M

8

FIG. 13

Romex Connector

Identied

Earth Screw

Junction Box

Cover

e. Connect RED (Active) wire in junction box to

f. Connect BLACK (Neutral) wire in junction

g. Connect EARTH wire to identied EARTH

h. Tighten the strain relief onto the power sup-

i. Carefully push all excess wire back into the

j. Plug heater cord (if applicable) into mating

AC Power Supply

Screw

Heater Connection

(if applicable)

Unit Electrical

Cord

Thermostat

Knob

Wood Screw

RED wire from supply wire.

box to BLACK wire from supply wire.

screw in junction box.

ply wire to hold it rmly in place. Be careful

not to damage the wires.

junction box and install junction box cover

with two (2) #10 x 10 mm blunt point screws.

See (FIG. 13).

connector in the control box.

Page 9

INSTALLATION INSTRUCTIONS

k. Plug the unit electrical cord into the mating

connector in the control box. See (FIG. 12).

l. Insure the thermostat sensor tube remains in

the retainer clip. See (FIG. 12).

G. Air Distribution Box Installation

1. Remove return air grille from air distribution box

by pulling in on half-round nger catches. See

(FIG. 14).

FIG. 14

Half Round

Catches

Return Air Grille

FIG. 16

Wood

Screw

Hole Plug

Wood

Screw

4. Install four (4) #8 x 16 mm wood screws that

hold air distribution box tight to ceiling. Hand

tighten to prevent stripping of the screw in the

ceiling. Do NOT use a power screw driver. See

(FIG. 16) & (FIG. 17).

FIG. 17

2. Hold air distribution box up to ceiling template

and install three (3) #10 x 10 mm screws at air

distribution box mounting point. See (FIG. 15).

FIG. 15

Install 3 Screws In To

Metal Template

3. Snap hole plug into place at rear of air distribution box. See (FIG. 16).

Do Not Use Power Screw Driver To

Tighten Wood Screws

5. Reinstall return air grille and lter into air distribution box.

6. The unit installation is now complete and is

ready for operation. The power supply to the unit

may now be turned on.

7. Verify that all features of the installed system

work. Please read the following operating instructions before attempting to run the unit.

9

Page 10

OPERATING INSTRUCTIONS

A. Controls

1. The Selector Switch has 10 positions including

“OFF”. This controls fan speed, optional heating

mode, and cooling modes. See (FIG. 18).

FIG. 18

2. The thermostat controls the temperature range

at the lter between approximately 18 °C and

32 °C.

B. “OFF” Position

1. This is to turn unit off.

C. Cooling Operation

1. Set the thermostat at the desired temperature

level.

2. Select the fan speed that best satises your

needs:

a. HIGH COOL: Selected when maximum cool-

ing and dehumidication required.

b. MED. COOL: Selected when normal or aver-

age cooling required.

c. LOW COOL: Selected when room is at de-

sired comfort level and needs to be maintained. Normally this speed used for night time

operation.

The blower runs continuously to circulate air and maintain an even temperature. The compressor will come on

as cooling is required to maintain the

selected temperature level.

D. Heating Operation (With Optional

Electric Heater Installed)

This electric heater will NOT replace a fur-

nace for heating your boat in cold weather.

The intent is to remove the chill on cool days

or mornings using a 1.6 kW heater.

1. Turn the selector switch to “HEAT”. There are

three positions: HIGH FAN, MED FAN or LOW

FAN to select from, depending upon personal

choice. See (FIG. 18).

2. Use low fan speed with the electric heat strips

(use of higher speeds will make the outlet air

feel cool, but all heating speeds deliver the same

watts of electric heat to the boat).

3. The heat strip will come on and begin heating.

4. The element will “cycle off” when the thermostat

is satised. The fan will continue to run helping keep the temperature throughout the boat

uniform.

E. Fan Operation

1. This will circulate the air in your boat without

cooling or heating. There are three positions:

HIGH FAN, MED. FAN or LOW FAN to select

from, depending upon personal choice.

10

Page 11

MAINTENANCE

A. Air Filter

1. Periodically (a minimum of every 2 weeks of operation) remove the return air lter located behind the return air grille and wash it with soap

and warm water, let dry and then reinstall.

NEVER run the unit without return air l-

ter in place. This will plug the unit evaporator coil with dirt and may substantially

degrade the performance of the unit over

time.

B. Air Distribution Box Housing

1. Clean air distribution box housing and control

panel with a soft cloth dampened with a mild detergent. Never use furniture polish or scouring

powders.

C. Fan Motor

1. The blower motor is factory lubricated and requires no service.

D. Frost Formation On Cooling Coil

1. Frost on a small portion of the coil is not unusual. Under certain conditions, ice may form

on the evaporator coil. This is indicated by very

cold output at very low air speed and the icing

can be seen through the air inlet hole with the

lter removed. If this should occur, inspect the

lter and clean if dirty. Make sure air vents are

open and not obstructed. Units have a greater

tendency to frost when the outside temperature

is relatively low. This may be prevented by adjusting the thermostat control knob to a warmer

setting (counter clockwise). Should frosting continue, operate on any FAN ONLY setting until

the cooling coil is free of frost; then resume normal operation. If frost condition persist, contact

your local service center for assistance.

E. Heat Gain

The ability of the air conditioner to maintain the desired

inside temperature depends on the heat gain of the boat.

Some preventative measures taken by the occupants of

the boat can reduce the heat gain and improve the performance of the air conditioner. During extremely high outdoor

temperatures, the heat gain of the boat may be reduced by:

● Mooring the boat in a shaded area

● Using window shades (blinds and/or curtains)

● Keeping windows and doors shut or minimizing

usage

● Avoiding the use of heat producing appliances

● Adding heat-rejection lm to windows

Operation on High Fan/Cooling mode will give optimum

or maximum efciency in high humidity or high outside

temperature.

Starting the air conditioner early in the morning and giving it a “head start” on the expected high outdoor ambient

temperature will greatly improve its ability to maintain the

desired indoor temperature.

F. Condensation

The manufacturer of this unit will not be responsible for

damage caused by condensation forming on ceilings,

windows, or other surfaces. Air contains water vapor which

condenses when temperature of a surface is below Dew

point. During normal operation this unit is designed to

remove a certain amount of moisture from the air, depending on the size of the space being conditioned. Keeping

doors and windows closed when this air conditioner is in

operation will greatly reduce the chance of condensation

forming on interior surfaces.

11

Page 12

SERVICE - UNIT DOES NOT OPERATE

:+7

02725

&20

:+7%/.

%/8

<(/

%/.

67$57

*51<(/

*5<%/.

*51<(/

%51

&

6

5

2/

:+7%/8

&2035(6625

31.%/8

31.255(' 37&5

&20

+(50

)$1

&$3

:+731.25:+7

:+7*5<

%/.

:+7%51

&211(&72572&21752/6

*51<(/

5('

(/(&75,&+($7

12721620(

02'(/6

&211(&725

72&21752/6

02725

&20

:+7%/.

%/8

<(/

%/.

67$57

',(/(&75,&

*51<(/

%51

&

6

5

2/

:+7%/8

3$66('

&2035(6625

&203

&20

+(50

&$3

)$1&$3

)$1

&$3

:+7*5<

*51<(/

5('

67$57$66,67

12786('21620(

02'(/6

If your unit fails to operate or operates improperly, check

the following before calling your service center.

● Check your fuse or circuit breaker to see if it is

open. Insure fuse is not burnt, or circuit breaker

is “ON” and not activated.

● After the above checks, call your local service

center for further help. This unit must be ser-

viced by qualied service personnel only.

● If any wiring or supply cord is damaged and

needs to be replaced, it must be replaced by

the manufacturer or its service agent or a simi-

larly qualied person.

WIRING DIAGRAMS

A. Unit Wiring Diagram

To locate a service technician near you:

● Go to WWW.dometic.com/marinedealers or

● Call Dometic Marine at 1-800-542-2477 8:00

AM to 5:00 PM Eastern Time, or 1-888-440-

4494 after hours and weekends.

When calling for service, always give the following:

● Unit type and serial number found on the iden-

tication label located on base pan of unit bottom. Return air grille must be removed from air

distribution box to view.

● Air distribution box model and serial number

found on rating plate located on ceiling tem-

plate. Observe this rating plate through the lter

opening.

B. Air Distribution Box Wiring Diagram

12

Page 13

OWNER'S LIMITED WARRANTY

As hereinafter described, Dometic limits the duration of any implied warranty to the duration of the underlying express

warranty and also disclaims any liability for consequential or incidental damages arising from any application, installation, use or malfunction of any warranted product.

A. WHAT'S COVERED

What does the Limited Warranty cover?

Products manufactured by Dometic Corporation (Dometic) are under limited warranty to be free from defects in workmanship or

materials. This being under normal use and service, with the obligation of Dometic under this limited warranty, being limited to re-

placing or repairing any component(s) which shall disclose defects within the limits dened in Section C. Which upon examination

by Dometic, shall appear to the satisfaction of Dometic to be defective or not up to specications.

This Limited Warranty is made in lieu of all other express warranties, obligations, or liabilities on the part of Dometic.

In addition, Dometic shall not be responsible for any incidental or consequential damages. In those instances in which a

cash refund is made, such refund shall effect the cancellation of the contract of sale without reservation of rights on the part of

the purchaser. Such refund shall constitute full and nal satisfaction of all claims which the purchaser has or may have

against Dometic due to any actual or alleged breach of warranty, either express or implied, including, without limitation,

any implied warranty or merchantability or tness for a particular purpose. Some states do not allow the exclusion or limitation of incidental or consequential damages so the above limitation may not apply to you.

The Dealer is not an agent for Dometic, except for the purpose of administering the above warranty to the extent herein

provided. Dometic does not authorize the dealer or any other person to assume for Dometic any liability in connection

with such warranty, or any liability or expense incurred in the replacement or repair of its products other than those

expressly authorized herein. Dometic shall not be responsible for any liability or expense except as is specically authorized and provided in this section.

Dometic reserves the right to improve its products, through changes in design or material without being obligated to incorporate

such changes in products of prior manufacture. Dometic can make changes at any time in design, materials, or part of units of any

one, model year, without obligation or liability to owners of units of the same year's model of prior manufacture.

This warranty gives you; the purchaser, specic legal rights, and you may also have other rights which vary from state to state. You

also have implied warranty rights, including an implied warranty of merchantability, which means that your product must be t for

the ordinary purpose for which such goods are used. The duration of any implied warranty rights is limited to the duration of

the express warranty as found in Section C. Some states do not allow limitations on how long an implied warranty lasts, so the

above limitation may not apply to you.

B. WHAT'S NOT COVERED

What does this Limited Warranty not cover?

This Warranty Shall Not Apply to:

1. Failures resulting from improper installation or use contrary to instructions.

2. Failures resulting from abuse, misuse, accident, re, or submergence.

3. Any part manufactured by Dometic, which shall have been altered so as to impair its original characteristics.

4. Any parts which fail as a result of misuse, improper application or improper installation.

5. Items not manufactured by Dometic, i.e., items, which are purchased from another manufacturer and supplied as received

by Dometic without alteration or modication except as any part of a Dometic manufactured unit or component.

6. Components or parts used by or applied by the purchaser, as an integral part of products not manufactured by Dometic.

7. Labor resulting from difcult access to a Dometic product. The original installer or OEM is responsible for accessibility of

unit.

8. Leaks due to improper installation of split systems and refrigeration systems, for example; packing glands, are nuts, quick

disconnects. The adjustment of the refrigerant charge on a split system should be charged to the original installer or OEM.

9. Freight Damage (see page 10 for instructions for handling freight damage).

10. Pumps that have been run dry, are water damaged or have blown freeze plugs.

11. Pumps with cracked heads.

12. Pump seals are not covered.

13. UV light bulbs are not covered.

14. Liquid line lter dryers are not covered.

15. Blowers with water damage.

16. Logic boards with water damage.

13

Page 14

OWNER'S LIMITED WARRANTY

17. Logic boards with blown MOV's (Power Surge).

18. Mis-programmed displays.

19. Display heads with water damage.

20. Dirty Condensers and/or Evaporators.

21. Failures due to improper winterization.

22. Unit damage as a result of improper return packaging.

23. Replacement of freon with substitute without authorization from factory.

24. Environmental and/or Recovery Fees.

25. Welding and Nitrogen Fees.

26. Travel costs are included in the hourly labor allowances and should not be billed as a separate item without preapproval

from the factory.

Installation and application of Dometic components is not warranted by Dometic, because Dometic has no control or

authority over the selection, location, application, or installation of these components.

C. COVERAGE PERIOD

What is the period of coverage?

(See Limited Warranty Periods at the end of this book).

All Dometic components bear a data plate on which there are model and serial numbers. The serial number is date coded. To

determine whether or not any Dometic component is in warranty, proceed as follows:

1. Determine the manufacture date of the component from the serial number on the data plate. If you are not familiar with the

date code, write or call the Dometic Customer Service Department to obtain the manufacture date. The hours of the Customer Service Department are 8:00 a.m. - 5:00 p.m. (USA, Eastern Standard Time Zone) Monday through Friday excluding

holidays.

2. It is possible that there might exist a considerable time lag between the date a component is manufactured and the date it

is put in service. In such instances, the date of manufacture could indicate that the item is out of warranty. However, based

on the date the equipment is rst put in service, the item may still be covered by the Dometic warranty as described in

Section A. For proof of date put in service, Dometic will require a copy of the bill of sale of the Dometic equipment from the

installer or new boat dealer to the original owner.

D. GETTING SERVICE

How do you get service?

Please read the following Warranty Procedure:

If the failure of a Dometic component is determined to be covered under the Dometic warranty and the time in service is determined

to be within the warranty time limit, the owner has the following three options:

1. Preferred option: Have a Dometic authorized Servicing Dealer, perform the work needed. The customer needs to call

Dometic Customer Service Department for a recommendation as to the closest dealer. If the customer already knows an

authorized servicing dealer, the dealer should be contacted directly.

2. Second option: If the customer contacts Dometic Service Department for a Servicing Dealer and Dometic has no one in that

particular area, Dometic will authorize the use of a local service company and Dometic will work with the local company to

assist in any way possible.

3. Third option: The customer may send his equipment back to the factory to have the repair work done. Dometic will make

every effort to return the equipment to the customer within a three week time period. If the claim represents a legitimate

warranty problem, Dometic will pay the freight both ways. Dometic prefers option one rst, option two second, and option

three only if one and two are not available.

The customer may contact the Dometic Service Department at 954-973-2477 Monday through Friday, 8:00 a.m. - 5:00 p.m. Eastern Time. After hours (evening and weekends) technical support is offered through Dometic's 24/7 Hotline at 888-440-4494.

14

Page 15

OWNER'S LIMITED WARRANTY

E. TABLE OF WARRANTY PERIODS

DOMETIC DURASEA ROOFTOP AIR CONDITIONING

Important Notes:

1. Warranty periods begin from the date of possession of the boat by the rst owner if OEM installed or date

of installation if dealer installed, but not to exceed three (3) years from date of production. The warranty is

transferable and will carry the remainder of the original owner's warranty based on the original date of purchase or date of installation.

2. Proof of purchase or installation may be required to verify warranty coverage.

3. Any unit or replacement part installed due to a warranty failure carries the remainder of the original warranty.

Warranty coverage does not start over from the repair/replacement date.

4. Warranty coverage shall not exceed three (3) years from date of production.

5. These warranty periods are effective March 1, 2010.

Product Sale Type Warranty Coverage

DuraSea Rooftop

OEM or Dealer Installed 1-Year Warranty, parts and labor.

Not to exceed three (3) years from date

of manufacture.

15

Loading...

Loading...