Page 1

ORIGINAL INSTRUCTION MANUAL

ОРИГІНАЛЬНИЙ ПОСІБНИК З ЕКСПЛУАТАЦІЇ

ORYGINALNA INSTRUKCJA OBSŁUGI

MANUAL DE INSTRUCŢIUNI ORIGINAL

ORIGINAL-BEDIENUNGSANLEITUNG

EREDETI KEZELŐI KÉZIKÖNYV

PÔVODNÝ NÁVOD NA OBSLUHU

PŮVODNÍ NÁVOD K POUŽITÍ

WARNING:

Read this instruction manual carefully before putting the petrol mist blower into operation and strictly observe

the safety regulations!

Save instruction manual for future reference.

ПОПЕРЕДЖЕННЯ:

Уважно прочитайте ці інструкції з експлуатації перед тим, як використовувати бензиновий обприскувач, та строго дотримуйтесь

правил з техніки безпеки!

Збережіть інструкцію з експлуатації для подальшого використання.

OSTRZEŻENIE:

Przeczytać uważnie niniejszą instrukcję obsługi przed uruchomieniem spalinowego opryskiwacza mgławiącego i ściśle przestrzegać

przepisów dotyczących bezpieczeństwa!

Instrukcję obsługi zachować do wglądu na przyszłość.

AVERTISMENT:

Citiţi cu atenţie acest manual înainte de a pune în funcţiune atomizorul cu motor pe benzină şi respectaţi cu stricteţe reglementările de

siguranţă!

Păstraţi manualul de instrucţiuni pentru a-l putea consulta pe viitor.

WARNUNG:

Lesen Sie diese Bedienungsanleitung aufmerksam durch, bevor Sie das Benzin-Sprühgerät in Betrieb nehmen, und halten Sie sich strikt

an die Sicherheitsbestimmungen!

Bewahren Sie diese Bedienungsanleitung für spätere Bezugnahme auf.

VIGYÁZAT!

Mielőtt a benzines párafúvót használni kezdené, olvassa el gyelmesen a kezelési kézikönyvet, és szigorúan tartsa be a biztonsági

szabályokat.

A kezelési kézikönyvet őrizze meg, később még szükség lehet rá.

VÝSTRAHA:

Pred uvedením benzínového rozprašovacieho dúchadla do činnosti si dôkladne prečítajte tento návod na obsluhu a prísne dodržiavajte

bezpečnostné predpisy!

Návod na obsluhu uchovajte pre použitie v budúcnosti.

VAROVÁNÍ:

Před uvedením benzínového postřikovače do provozu si důkladně prostudujte tento návod k obsluze a pečlivě dodržujte bezpečnostní

směrnice!

Návod k použití si uložte k pozdějšímu nahlédnutí.

SP-7650.4 R

Page 2

2

3

Thank you very much for selecting the DOLMAR petrol mist blower.

We are pleased to be able to offer you the DOLMAR petrol mist

blower, which is the result of a long development program and many

years of knowledge and experience.

The mist blower combines the advantages of state-of-the-art

technology with ergonomic design. They are of handy, compact and

represent professional equipment for a great variety of applications.

Please read, understand and follow this booklet, which refers in

detail to the various points that will demonstrate its outstanding

performance. This will assist you to safety obtain the best

possible results from your DOLMAR mist blower.

English

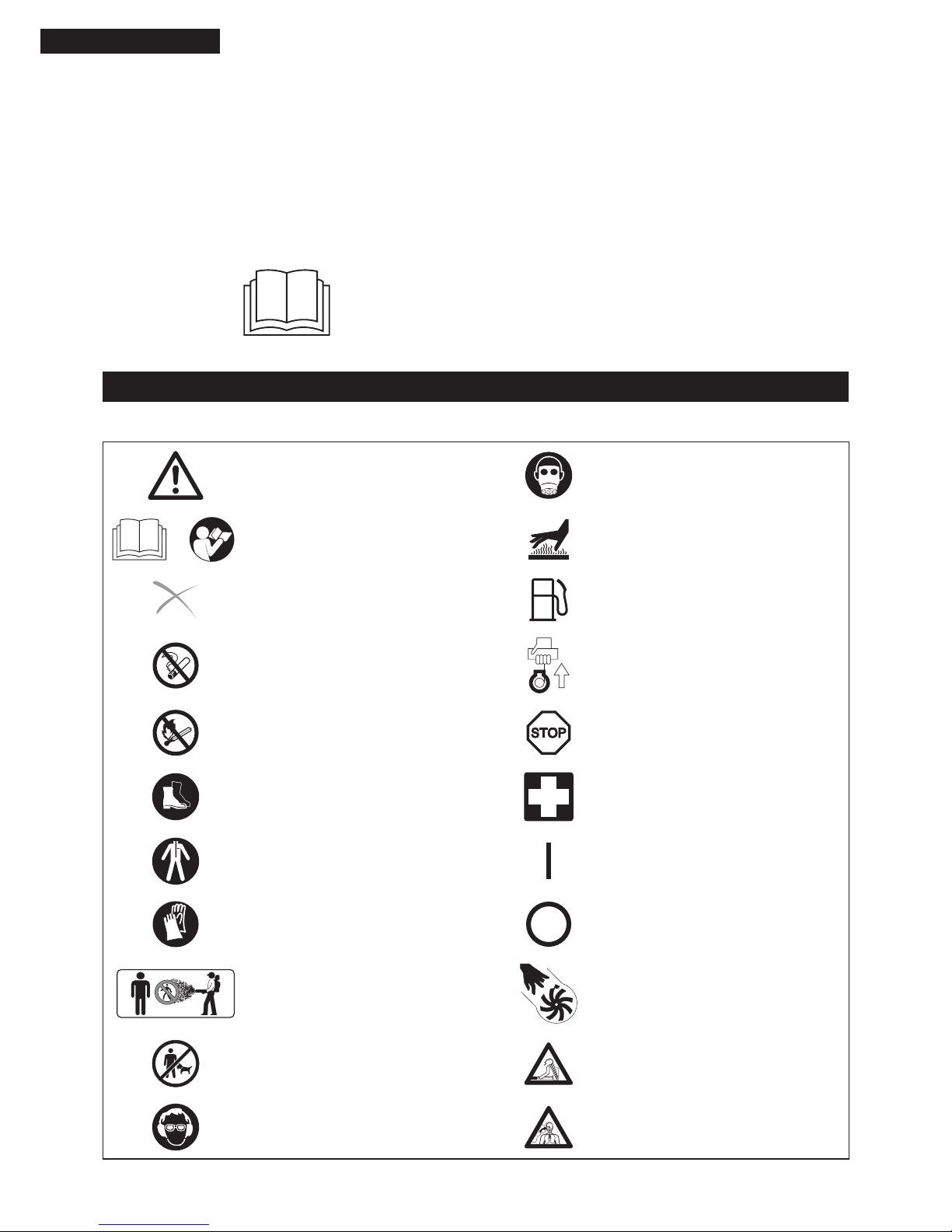

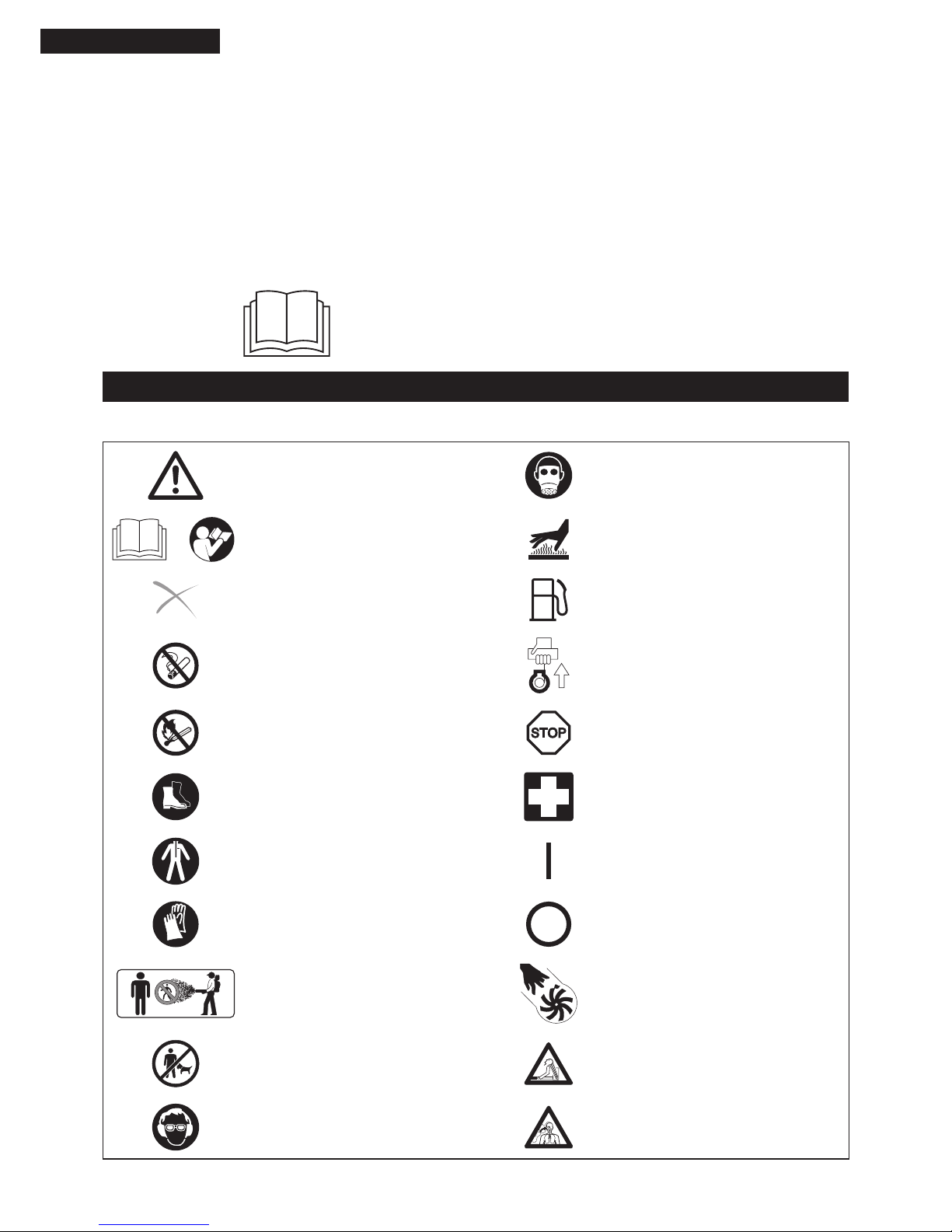

SYMBOLS

It is very important to understand the following symbols when reading this instructions manual.

WARNING/DANGER Wear respiratory protection

Read, understand and follow instruction

manual

Hot surfaces – Burns to ngers or hands

Forbidden Fuel (Gasoline)

No smoking Engine-manual start

No open ame Emergency stop

Wear sturdy boots with nonslip soles. First aid

Wear suitable protective clothing ON/START

Protective gloves must be worn OFF/STOP

Keep bystanders away when spraying

Severing of ngers or hand, impeller

blade

Keep the area of operation clear of all

persons and pets

Long hair may cause entanglement

accident

Wear eye and ear protection

Poisonous fumes or toxic gases.

Do not operate in an unventilated area.

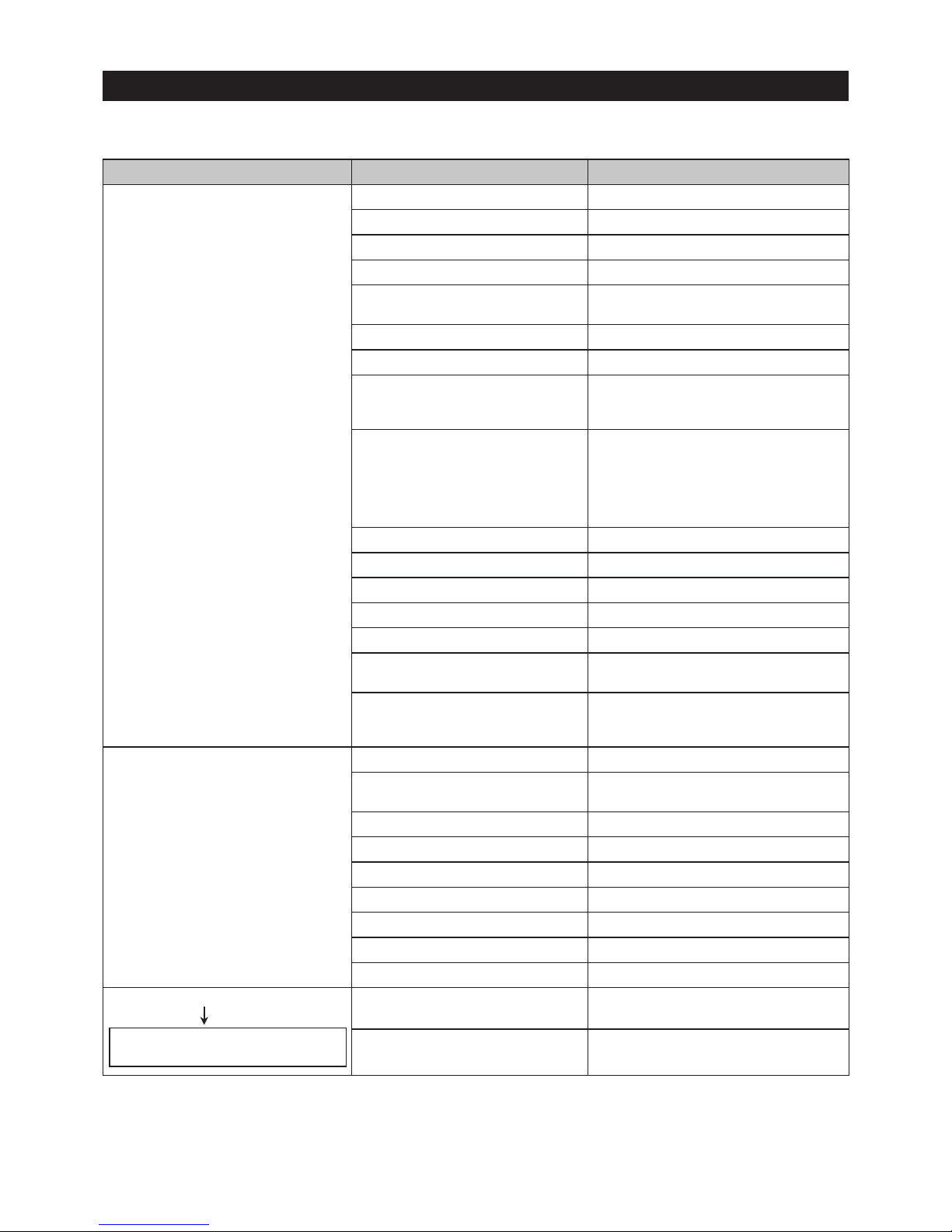

Table of Contents

Page

Symbols ............................................................................................2

Important safety instructions.............................................................3

Technical data...................................................................................9

Designation of parts........................................................................10

Assembly instructions ..................................................................... 11

Before starting the engine ..............................................................13

Starting and stopping engine ..........................................................15

Adjusting idle speed .......................................................................16

Operation method ...........................................................................17

Inspection and maintenance...........................................................23

Storage ........................................................................................... 26

Troubleshooting ..............................................................................28

Page 3

3

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

● Read all safety warnings and all instructions. Failure to follow the warnings and

instructions may result in electric shock, re and/or serious injury.

Save all warnings and instructions for future reference.

General instructions

● To ensure correct and safe operation, the user must read, understand and follow

this instruction manual to assure familiarity with the handling of the mist blower (1).

Users insufciently informed will risk danger to themselves as well as others due

to improper handling.

● It is recommended only to loan the mist blower to people who have proven to be

experienced with mist blowers.

● Always hand over the instruction manual.

● First-time users should ask the dealer for basic instructions to familiarize oneself

with the handling of a mist blower.

● Children and young persons aged under 18 years must not be allowed to operate

the mist blower. Persons over the age of 16 years may however use the machine

for the purpose of being trained only while under the direct supervision of a

qualied trainer.

● Use mist blowers with the utmost care and attention.

● Operate the mist blower only if you are in good physical condition.

● Perform all work conscientiously and carefully. The user has to accept responsibility

for others.

● Never use the mist blower while under the inuence of alcohol or drugs (2).

● Do not use the unit when you are tired.

● Save these instructions for future referral.

Intended use of the machine

● Use right machine. The mist blower is only intended for spraying liquid chemicals

and other liquids to control pests and weeds in fruit, ower and vegetable gardens,

on trees and bushes and on other plants, such as coffee, tobacco and cotton. It is

also useful in the maintenance of young trees for, e.g., controlling the bark beetle

and other pests and plant diseases.

Never use for any other purpose.

If the machine is equipped with proper pipe for blower operation, the machine can

be used for blower operation.

● Only use plant protection products that are specically approved for use with mist

blowers by their manufacturer and that meet all applicable safety regulations,

standards and ordinances.

Get information from your dealer on how to operate your mist blower. Observe all

applicable local safety regulations, standards and ordinances.

All operating and servicing people should be trained and familiarized with the proper

handling procedures for the chemical products being used, as well as with rst aid/

emergency care, and liquid chemical disposal regulations.

WARNING:

● Your mist blower is only for professional use. Do not lend or rent your mist blower

without the instruction manual. Make sure that anyone using it understands the

information contained in this instruction manual.

Personal protective equipment

● To reduce the risk of injury when using chemical products, wear proper protective

apparel when lling, using and cleaning the mist blower. Always follow all of

the chemical manufacturer’s instructions with respect to proper eye, skin and

respiratory protection. They may differ from and exceed the following precautions.

● When using toxic chemicals, the operator and any bystanders may need to wear

a properly tted respirator approved for the chemical being used. Refer to the

chemical product label. Breathing toxic chemicals can cause serious or fatal injury.

● The clothing worn should be functional and appropriate, i.e. it should be tight tting

but not cause a hindrance. Do not wear jewelry, clothing or long hair which could

be drawn into the air intake. (3)

● In order to avoid head-, eye-, hand- or foot injuries as well as to protect your

hearing the following protective equipment and protective clothing must be used

during operation of the mist blower.

(2)

(1)

(3)

Page 4

4

5

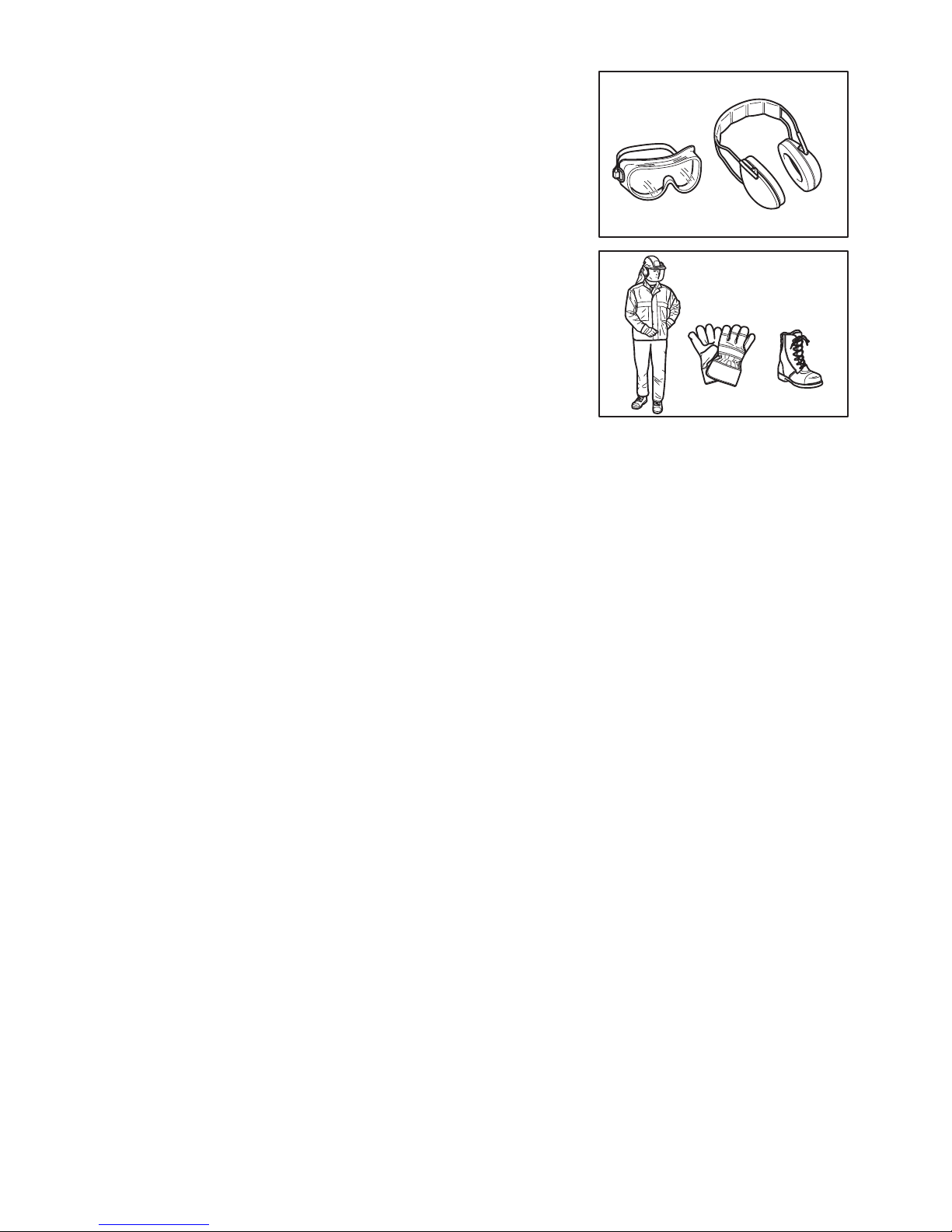

Pay particular attention to the following regulations

● Clothing must be sturdy and snug-tting, but allow complete freedom of movement.

Avoid loose-tting jackets, ared or cuffed pants, scarves, unconned long hair or

anything that could be drawn into the air intake.

Wear long pants to protect your legs.

Do not wear shorts. (5)

● Mist blower noise may damage your hearing. Wear sound barriers (ear plugs or

ear mufers) to protect your hearing. Continual and regular users should have their

hearing checked regularly. (4)

● Always use rubber/chemical-resistant gloves when working with the mist blower.

Good footing is most important. Wear rubber/chemical boot. (5)

● Proper eye protection is a must. Even though the discharge is directed away from

the operator, ricochets and bounce-backs can occur during mist blower operation.

(4)

● Never operate a mist blower unless wearing goggles or properly tted safety

glasses with adequate top and side protection which comply with ANSI Z 87.1 (or

your applicable national standard).

HANDLING OF CHEMICALS

● Some chemicals used with your mist blower may contain toxic and/or caustic

substances. Such chemicals can be dangerous and cause serious or fatal injury to

persons and animals and/or severe damage to plants and the environment.

Avoid direct contact with chemicals.

Follow the chemical manufacturer’s instructions with respect to any contact with

its product.

● Read the manufacturer’s label and instruction manual each time before mixing or

using the chemical and before storing or disposing of it.

Do not rely on your memory.

Careless or improper use may cause serious or fatal injury.

● Carefully read the labels on chemical containers before use.

Chemicals are classied into categories of toxicity.

Each category will have unique handling characteristics.

Familiarize yourself with the characteristics for the category of the chemical you

are using.

Chemicals may be used only by persons trained in their handling and the

appropriate rst-aid measures.

● Chemicals may be harmful to persons, animals and the environment if improperly

used. In addition, it is advisable not to use some chemicals that are caustic,

corrosive or poisonous in your mist blower.

● Mix only compatible pesticides. Wrong mixtures can produce toxic fumes.

When handling and spraying chemicals, make sure you are operating in accordance

with local, state, and federal environmental protection rules and guidelines. Do not

spray when it is windy. To help protect the environment, use only the recommended

dosage – do not overuse.

Pay special attention when using near watersheds, waterway, etc.

● Avoid opening mouth such as eating, drinking, or smoking while handling chemicals

or while you are spraying. Never blow through nozzles, tubes, pipes or any other

component by mouth. Always handle chemicals in a well-ventilated area while

wearing appropriate protective clothing and safety equipment.

Do not store or transport chemicals together with food, drink, or medicines, and

never reuse a chemical container for any other purpose.

Do not transfer liquid chemicals to other containers, especially food and/or drink

containers.

● In case of accidental contact or ingestion of chemicals or in case of contamination

of clothing, stop working and immediately rinse them out with clear water and

consult the chemical manufacturer’s instructions.

If doubtful about what to do, ask a poison control center or doctor for advice without

delay.

Keep the product’s label ready to read to or show the persons you consult.

Clean all chemical spills immediately.

Dispose of any residue observing state, federal or your nation’s laws and

regulations.

● Keep chemicals out of reach of children, other unauthorized people and animals.

When not in use, store chemicals in a safe and locked place. Follow the

manufacturer’s recommendations for proper storage.

(4)

(5)

Page 5

5

Preparing chemicals

● Prepare chemical solutions according to the chemical manufacturer’s instructions.

● Prepare solution only enough for the job at hand so that no solution is left over.

● Mix chemicals only by following instructions – wrong mixtures can produce toxic

fumes or explosive mixtures.

● Never spray undiluted chemicals.

● Prepare solution and ll the container outdoors only in a well-ventilated place.

● The operator should clarify the name of the chemical currently in use.

Storage

● Do not store spray solution in the container for more than one day.

● Always store and transport spray solution only in approved containers.

● Never store or transport the spray solution in containers intended for foods, drinks

or animal feed.

● Do not store or transport spray solution with foods, drinks or animal feed.

● Keep spray solution out of the reach of children, other unauthorized people and

animals.

● Store the spray solution in a locked place secured against unauthorized use.

Disposal

Never dispose of residual chemicals or contaminated rinsing solutions in waterways,

drains, sewers, street gutters, manholes or the like.

When disposing of contaminated rinse, observe all applicable laws, regulations and

ordinances.

Strictly observe the precautionary instructions of the chemical manufacturer.

Filling the container

● Tighten all connections and check to be sure the pipes as well as a tube are

securely attached and in good condition. Keep the solution discharge lever closed.

● Before using the mist blower with chemicals, ll it with fresh water to assure that

you have assembled it properly and practice spraying. Also, check for any leaks at

this time. When thoroughly familiar with the mist blower operation, follow normal

operating procedures.

● Fill your mist blower in well-ventilated areas, outdoors.

● Do not use:

– ammables in the mist blower, which may cause explosion resulting in serious

or fatal injury;

– caustic or corrosive materials in the mist blower, which could result in damage

to the unit;

– liquids with a temperature above 50°C to reduce the risk of scalding and damage

to the unit.

To ll the solution tank, place the mist blower on a level surface, ll the solution

only in good light and visibility. To reduce the risk of contaminating the surrounding

environment, be careful not to overll the solution tank with chemical solution.

To reduce the risk of injury, do not ll the mist blower while wearing it on your back.

If you ll the solution tank with a hose attached to a central water supply, be sure the

end of the hose is out of the solution to reduce the risk of backow, i.e. the chemicals

being sucked into the water supply in the case of a sudden vacuum.

Calculate the correct amount of chemical solution so that it is used up at one time,

with no extra solution left over in the tank.

After lling, t the solution tank cap and tighten it down rmly.

● Check for leakage while relling and during operation. A leak from the solution tank

or a loose tting could soak your clothing and come into contact with your skin.

Page 6

6

7

Starting up the mist blower

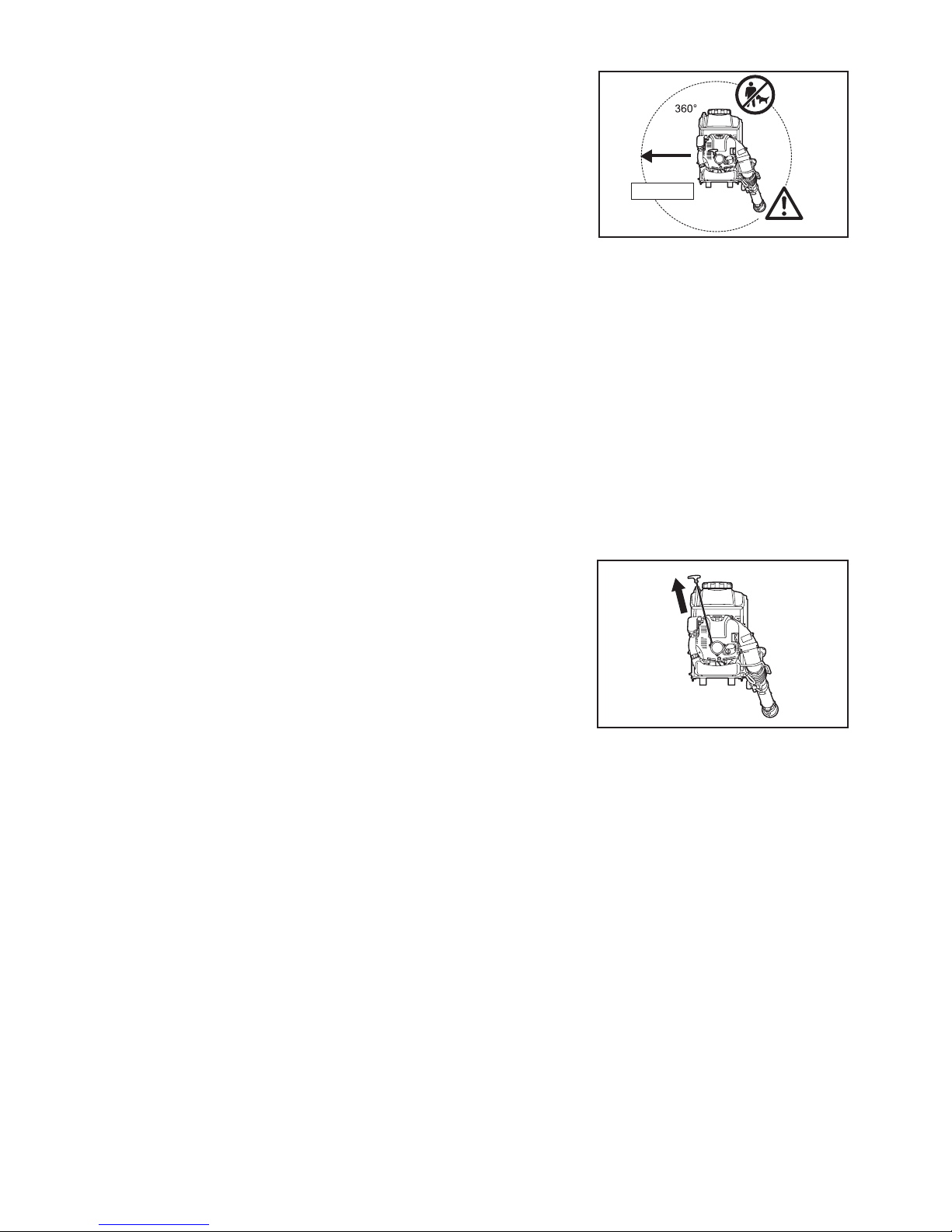

● Please make sure that there are no children or other people within a working range

of 20 meters (66 feet) (6), also pay attention to any animals in the working vicinity.

Never use the mist blower in urban areas.

● Before operating, always check that the mist blower is safe for operation:

Check the security of the throttle trigger. The throttle trigger should be checked for

smooth and easy action. Check for proper functioning of the throttle trigger lock.

Check for clean and dry handles and test the function of the l-O switch. Keep

handles free of oil and fuel.

● To reduce the risk of leakage and skin contact with chemicals, check that the

container cap and all connections in the path of the spray are tight, and be sure

the hose is securely attached and in good condition. Keep the solution discharge

lever closed.

● Make sure that the solution discharge lever is closed before starting the machine.

● Check that the spark plug cap is securely mounted on the spark plug – a loose

plug cap may cause arcing that could ignite combustible fumes and cause a re.

● Check condition of harness straps and replace damaged or worn straps.

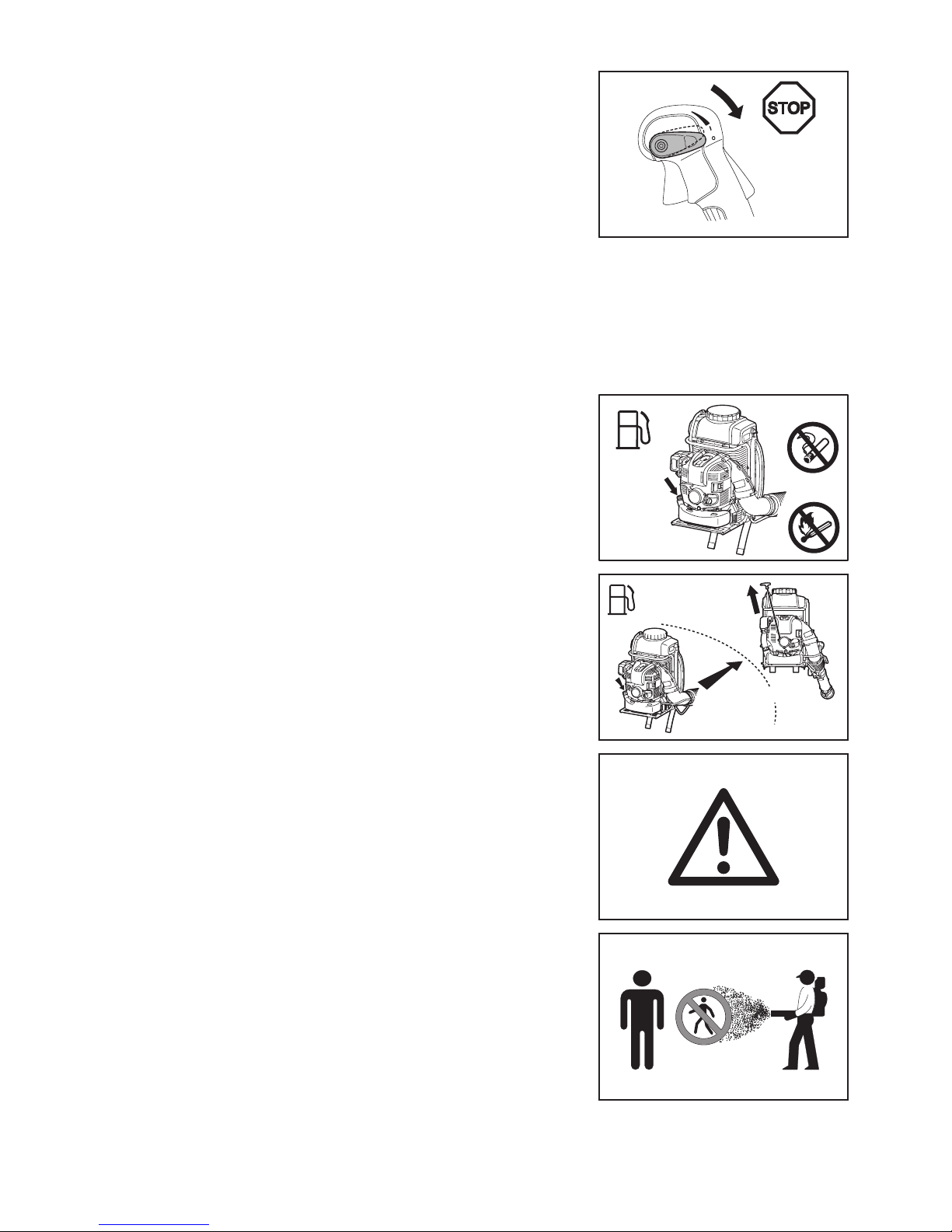

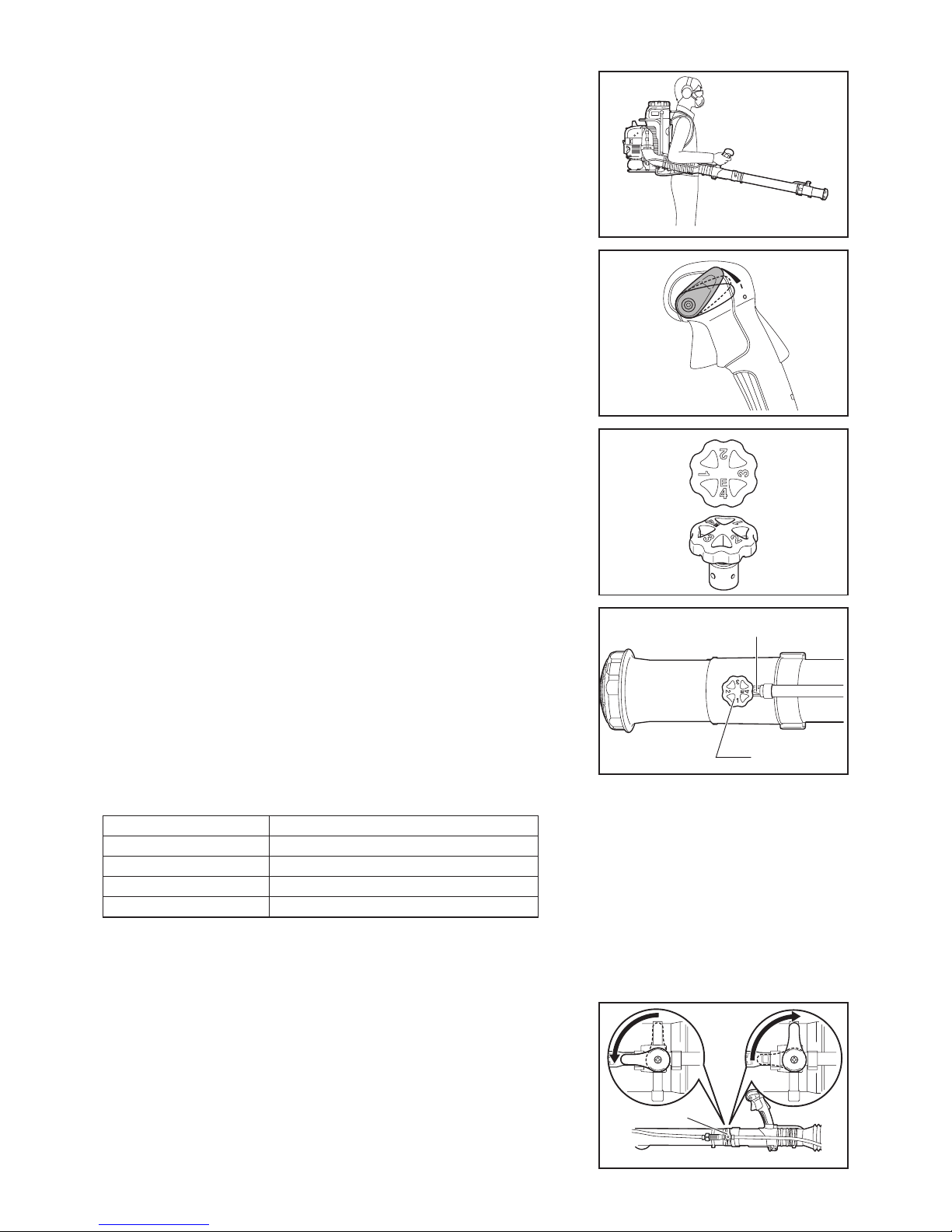

● Adjust shoulder strap to suit your size before starting work.

In an emergency, you may slip out of the shoulder strap and throw off the machine

quickly. Practice slipping out of the harness a number of times before using the

machine in order to become accustomed to it. Do not throw off the machine while

practicing as it could damage the machine.

● When you pull the starter handle, do not wrap the starter rope around your hand.

Do not let the starter handle snap back, but guide the starter rope to rewind it

properly.

Failure to follow this procedure may result in injury to your hand or ngers and may

damage the starter mechanism.

● The assistance of another person may be needed in placing the mist blower on

your back after starting. In order to reduce the risk of injury to the assistant from

thrown objects, chemical spray/liquid or from contact with hot exhaust fumes, keep

the engine at idle speed during this brief period, and do not let your assistant stand

in the area of the outlet nozzle or exhaust. Otherwise, the mist blower should be

started and operated without assistance.

● Start the mist blower only in accordance with the instructions.

● Do not use any other methods for starting the engine (7)!

● Use the mist blower and the accessories supplied only for applications specied.

● Start the mist blower engine only after the entire machine has been assembled.

Operation of the machine is permitted only after all the appropriate accessories

are attached.

● The engine is to be switched off immediately if there are any engine problems.

● Use the mist blower for single-handed operation with the right hand on the control

handle. Carry as a backpack with the shoulder straps over both shoulders.

To reduce the risk of loss of control, never carry the mist blower with the strap(s)

over one shoulder.

● When working with the mist blower, always wrap your ngers tightly around the

handle, keeping the control handle cradled between your thumb and forenger.

Keep your hand in this position to have your machine under control at all times.

Make sure your control handle is in good condition and free of moisture, pitch, oil

or grease.

● Always ensure a safe, well-balanced footing.

● In order to keep the solution tank upright and reduce the risk of spillage, do not

bend at the waist. Bend only at the knees and support yourself as required to

ensure proper balance.

Remember that a mist blower lled with liquid has a signicant amount of weight.

Use extra caution when bending, leaning or walking.

● Operate the mist blower in such a manner as to avoid inhalation of the exhaust

gases. Never run the engine in enclosed rooms (risk of suffocation and gas

poisoning). Carbon monoxide is an odorless gas.

Always ensure there is adequate ventilation.

● Your mist blower is not insulated against electric shock. To reduce the risk of

electrocution, never operate this mist blower in the vicinity of any wires or cables

(power, etc.) which may be carrying electric current. Do not spray on or near

electrical installations.

20 m (66 ft)

(6)

(7)

Page 7

7

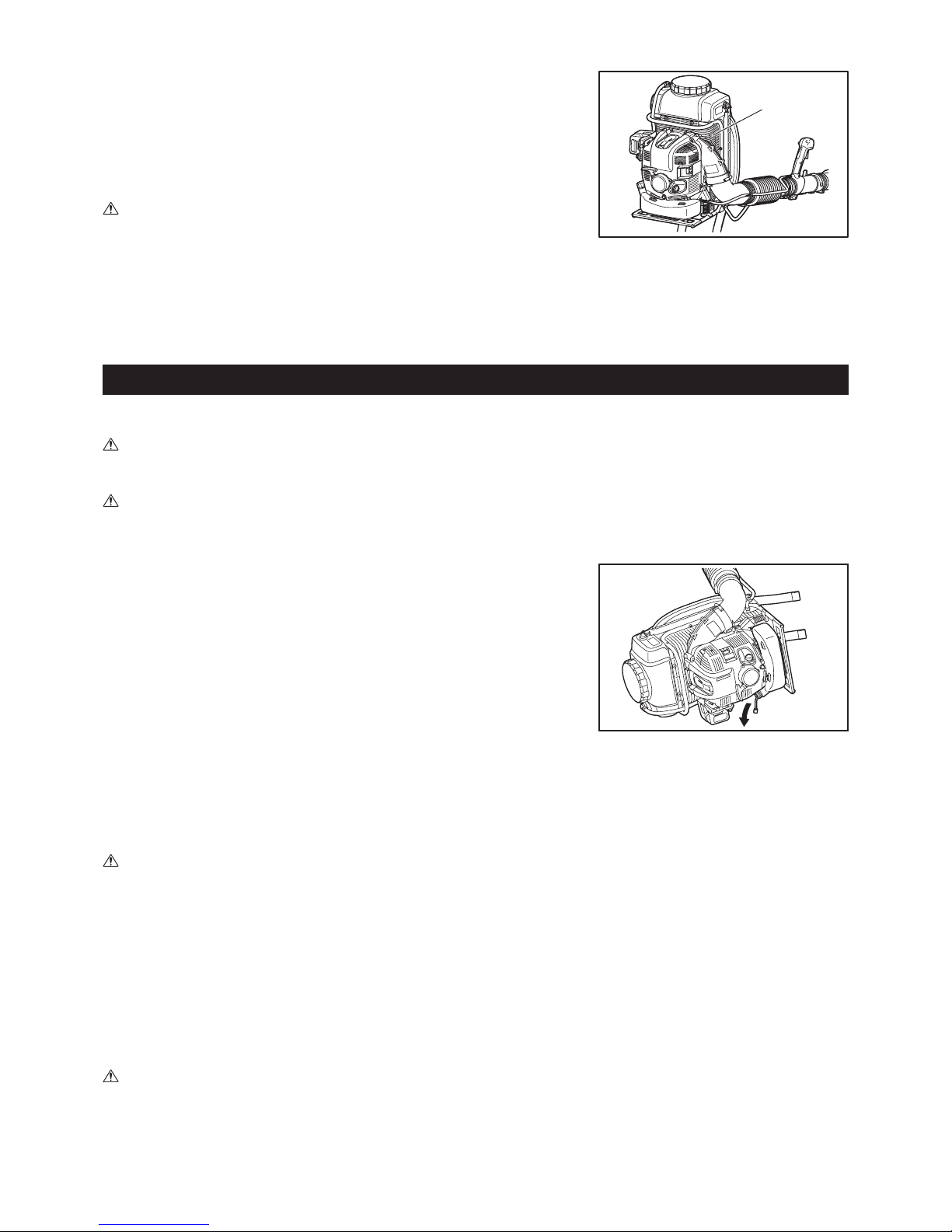

● Switch off the engine when resting and when leaving the mist blower unattended.

Place it in a safe location to prevent danger to others, setting re to combustible

materials, or damage to the machine (8).

● Never lay the hot mist blower onto dry grass or onto any combustible materials.

● Do not place the mist blower on the ground when operating at high speed, because

small objects such as sand, grass, dust, etc. may be pulled into the air intake and

damage the fan wheel.

● During work breaks, do not leave the mist blower in the hot direct sunlight or near

any heat source.

● All protective parts and guards supplied with the machine must be used during

operation.

● Never operate the engine with a faulty exhaust mufer.

● Do not put your hand into exhaust vent. The mufer become very hot during

operation, and may cause burns.

● Do not touch engine cover for long time. It may become hot during operation and

may cause burns.

● Shut off the engine during transport (8).

● Position the mist blower safely during car or truck transportation to avoid fuel

leakage.

● When transporting the mist blower, ensure that the fuel tank and liquid/chemical

container are completely empty.

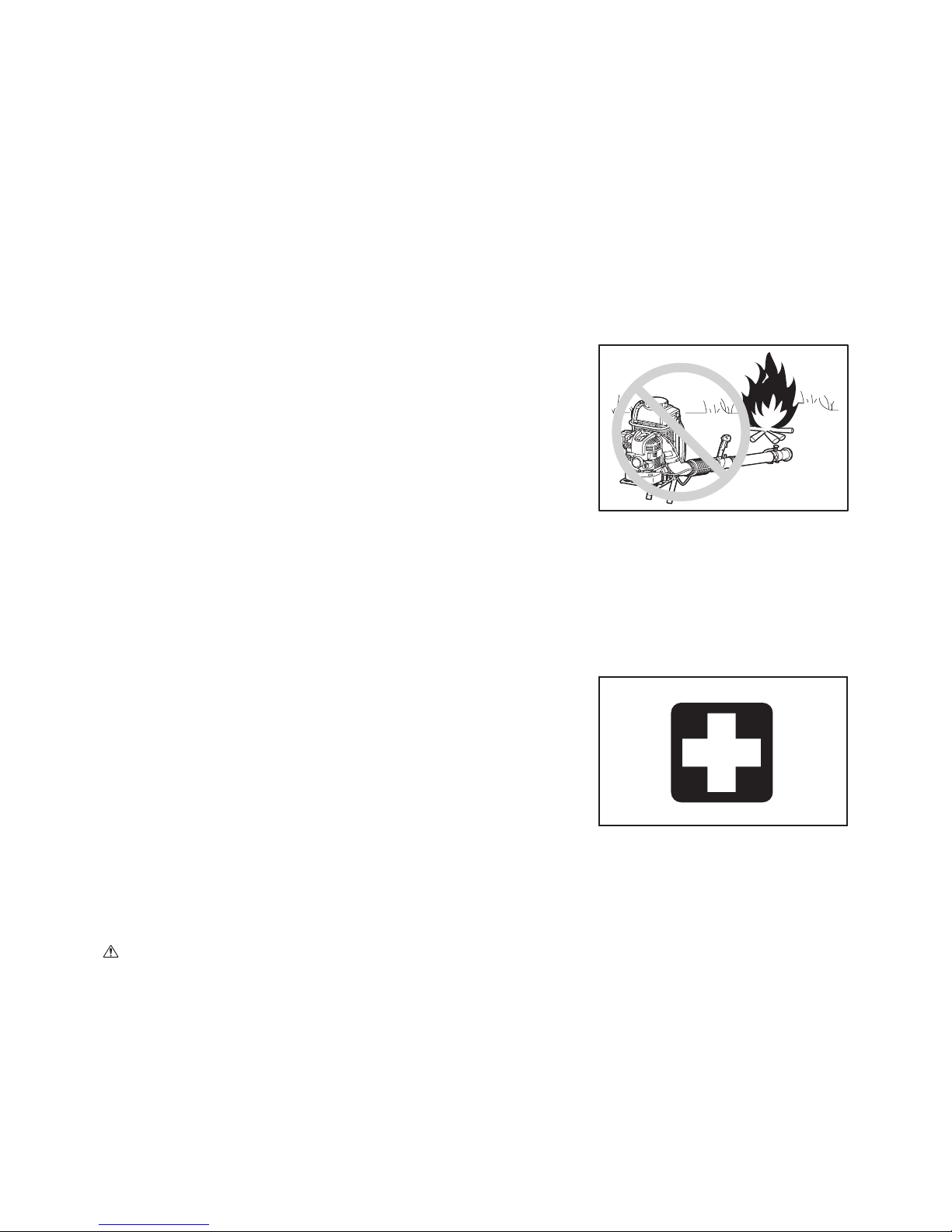

Refueling

● Shut off the engine (8) during refueling, keep well away from open ame (9) and

do not smoke.

● Avoid skin contact with petroleum products. Do not inhale fuel vapor.

Always wear protective gloves during refueling. Change and clean protective

clothing at regular intervals.

● Take care not to spill either fuel or oil in order to prevent soil contamination

(environmental protection). Clean the mist blower immediately after fuel has been

spilled. Allow wet cloths to dry before disposing in properly, covered container to

prevent spontaneous combustion.

● Avoid any fuel contact with your clothing. Change your clothing immediately if fuel

has been spilled on it (re hazard).

● Inspect the fuel tank cap at regular intervals making sure that it stays securely

fastened.

● Carefully tighten the locking screw of the fuel tank. Change locations to start the

engine (at least 3 meters (10 feet) away from the place of refueling) (10).

● Never refuel in closed rooms. Fuel vapors accumulate at ground level (risk of

explosions)

● Only transport and store fuel in approved containers. Make sure stored fuel is not

accessible to children.

● Do not attempt to refuel a hot or a running engine.

Method of operation

● Use the mist blower only in good light and visibility. During cold seasons beware of

slippery or wet areas, ice and snow (risk of slipping).

Always ensure a safe footing (11).

● Never work on unstable surfaces or steep terrain (11).

● If you are unfamiliar with the risks associated with the particular chemical you use,

review the product label and/or material safety data sheet for that substance and/

or consult the material manufacturer/supplier.

You may also ask your employer, governmental agencies and other sources for

information on hazardous materials.

Some other authorities have published lists of substances known to cause cancer,

reproductive toxicity, etc. (11).

● To reduce the risk of personal injury, do not direct air blast towards bystanders,

since the high pressure of the air ow could injure eyes and could blow small

objects at great speed (12).

● Never spray in the direction of humans, animals or property which might be injured

or damaged by spraying (12).

● Never insert any foreign object into the air intake of the machine or into the nozzle

of the mist blower. It will damage the fan wheel and may cause serious injury to

the operator or bystanders as a result of the object or broken parts being thrown

out at high speed.

● Pay attention to the direction of the wind, i.e., do not work against the wind.

● To reduce the risk of stumbling and loss of control, do not walk backward while

operating the machine.

● Always shut off the engine before cleaning or servicing the unit or replacing parts.

● Take a rest to prevent loss of control caused by fatigue. We recommend to take a

10 to 20-minute rest every hour.

(8)

(9)

(10)

3 m (10 ft)

(11)

(12)

Page 8

8

9

After nishing work

● Always wash yourself thoroughly with soap and water after spraying or handling

chemicals. Shower immediately, and wash all protective clothing separately from

other items.

Follow any additional recommendations of the chemical manufacturer.

Always clean dust and dirt off the mist blower.

● Empty, rinse and clean solution tank and assembly after each use. This helps

to prevent the solution from crystallizing, which could later cause clogging and

chemical damage to the unit. In addition, residual chemicals may have undesirable

effects during subsequent spraying with a different type of chemical (e.g., residual

herbicide may damage or kill plants being sprayed with a pesticide).

Do not store the mist blower with spray solution in the solution tank.

● Keep children, unconcerned people and pets away from areas that have just been

sprayed.

After the use of some chemicals, especially agricultural pesticides, a notice must

be posted on the treated area that a “Restricted Entry Interval” (REI) is in effect.

See the chemical product’s label and any applicable governmental regulations.

Maintenance instructions

● Perform cleaning and maintenance before storage.

● Be kind to the environment. Operate the mist blower with as little noise and pollution

as possible. In particular check the correct adjustment of the carburetor.

● Clean the mist blower at regular intervals and check that all screws and nuts are

securely tightened.

● Never service or store the mist blower in the vicinity of open ames, sparks, etc.

(13).

● Always store the mist blower in a well-ventilated locked room and with an emptied

fuel tank and the emptied solution tank.

(13)

Observe and follow all relevant accident prevention instructions issued by the trade associations and by insurance companies.

Do not perform any modications to the mist blower as this will risk your safety.

The performance of maintenance or repair work by the user is limited to those activities as described in this instruction manual. All other work is

to be done by Authorized Service Agents.

Use only genuine spare parts and accessories supplied by DOLMAR.

Use of non-approved accessories and machines means increased risk of accidents and injuries. DOLMAR will not accept any liability for accidents

or damage caused by the use of any non-approved attachment or accessories.

First Aid

In case of accident make sure that a well-stocked rst-aid kit is available in the vicinity

of the operations. Immediately replace any item taken from the rst aid kit.

When asking for help, please give the following information:

● Place of accident

● What happened

● Number of injured persons

● Extent of injuries

● Your name

Packaging

The DOLMAR mist blower is delivered in a protective cardboard box to prevent

shipping damage. Cardboard is a basic raw material and is therefore consequently

reusable or suitable for recycling (waste paper recycling).

SAVE THESE INSTRUCTIONS.

WARNING:

● DO NOT let comfort or familiarity with product (gained from repeated use) replace

strict adherence to safety rules for the subject product. MISUSE or failure to follow

the safety rules stated in this instruction manual may cause serious personal

injury.

Page 9

9

TECHNICAL DATA

Model SP-7650.4 R

Weight (with full fuel, full chemical, 220 ml of engine oil) (kg) 30.4

Weight (dry weight) (kg) 14.1

Dimension (without blower pipe L x W x H) (mm) 420 x 440 x 595

Engine type Air cooled, 4-stroke, single cylinder

Max. engine performance (kW) 2.7

Max. engine speed (min

–1

) 7,400

Idling speed (min

–1

) 2,800

Engine displacement (cm

3

) 75.6

Fuel Automobile gasoline

Fuel tank capacity (L) 1.8

Engine oil

API grade SF class or higher, SAE 10W-30 oil

(automobile 4-stroke engine oil)

Engine oil volume (L) 0.22

Carburetor (Diaphragm-carburetor) WALBRO WYK

Spark plug NGK CMR6A

Electrode gap (mm) 0.7 – 0.8

Chemical tank capacity (L) 15.0

Spray range (Horizontal / Vertical) (m) 16 / 13

Max air velocity (m/s) 85

Air ow rate (m

3

/min) 14.1

Vibration per ISO 22867

a

hv eq

(m/s2) 2.7

Uncertainty K (m/s

2

) 0.8

Sound pressure level average to ISO 22868

L

PA eq

dB (A) 95.4

Uncertainty K dB (A) 2.9

Sound power level average to ISO 22868

L

WA eq

dB (A) 110.1

Uncertainty K dB (A) 1.3

Note:

1. Use the oil and spark plug specied in the table.

2. This specication is subject to change without prior notice.

3. Use the level line 10 L as a guide line for the gross weight 25 kg of the mist blower including the solution.

4. Vibration and noise levels are measured with using the straight pipe (long).

For European countries only

EC Declaration of Conformity

Makita declares that the following Machine(s):

Designation of Machine: Petrol Mist Blower

Model No./ Type: SP-7650.4 R

Specications: see “TECHNICAL DATA” table

Conforms to the following European Directives:

2006/42/EC, 2000/14/EC

They are manufactured in accordance with the following standard or standardized documents:

EN ISO 28139, ISO 10988

The technical le in accordance with 2006/42/EC is available from:

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgium

The conformity assessment procedure required by Directive 2000/14/EC was in accordance with annex V.

Measured Sound Power Level: 110.1 dB

Guaranteed Sound Power Level: 111 dB

8.7.2014

Yasushi Fukaya

Director

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgium

Page 10

10

11

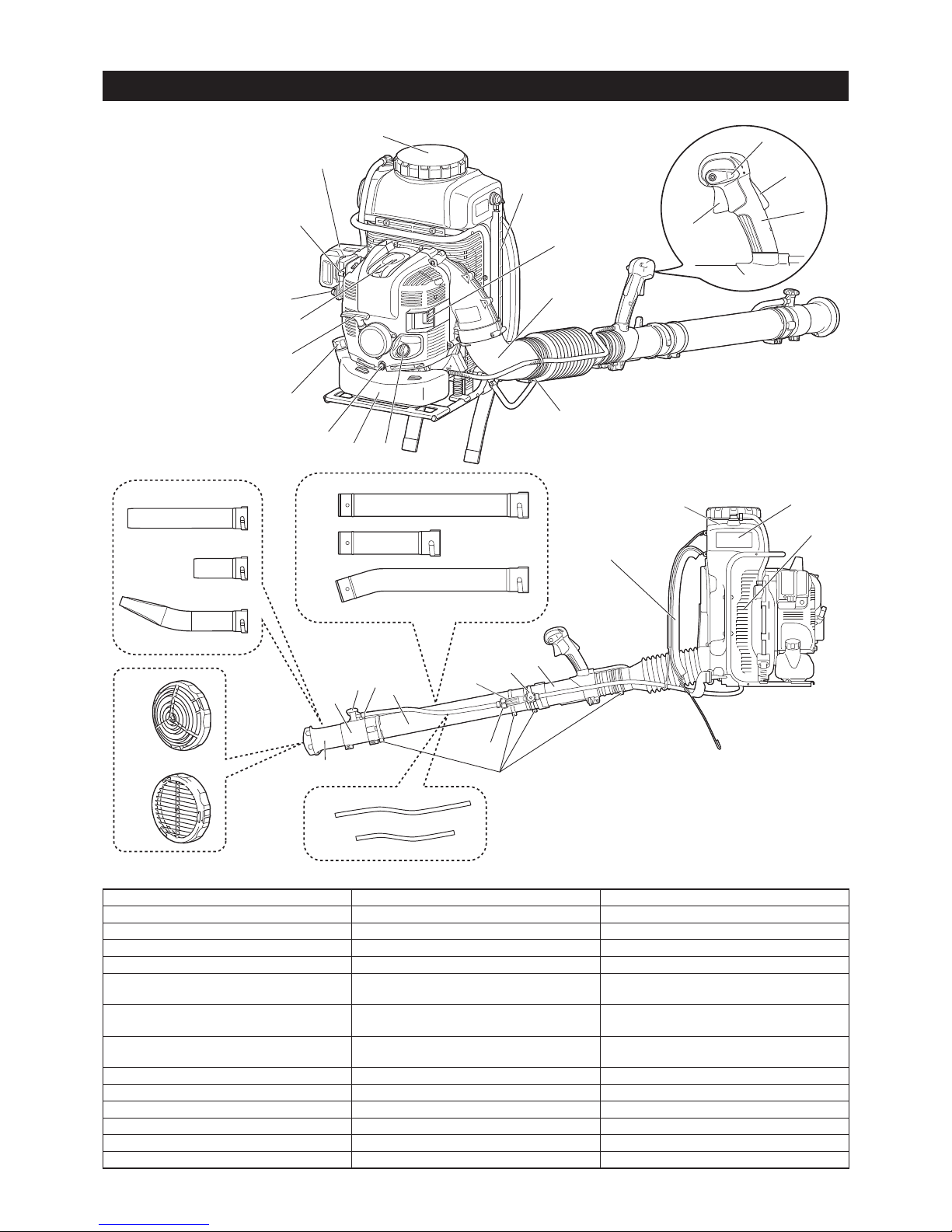

DESIGNATION OF PARTS

1

2

4

3

5

7

11

15

17

8

6

10

13

14

16

9

12

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

41

1. Stop control lever 15. Oil drain bolt 29. Straight pipe (long) (optional accessory)

2. Control handle 16. Fuel tank 30. Straight pipe (short) (optional accessory)

3. Throttle trigger 17. Oil cap 31. Bent pipe (optional accessory)

4. Lock-off lever 18. Hose band (diameter 100 mm) 32. Strainer of tube joint

5. Solution tank cap 19. Hose band (diameter 76 mm) 33. Strainer of solution tank (in solution tank)

6. Air cleaner cover 20. Top nozzle

34. End pipe (long) (optional accessory for

blower operation)

7. Tube for solution level check 21. Second nozzle

35. End pipe (short) (optional accessory for

blower operation)

8. Choke lever 22. Liquid adjustment knob

36. Flat pipe (optional accessory for blower

operation)

9. Mufer 23. Straight pipe 37. Tube (long) (optional accessory)

10. Primer pump 24. Solution discharge lever 38. Tube (short) (optional accessory)

11. Plug cover 25. Swivel pipe 39. Dispersion cover

12. Elbow 26. Shoulder strap 40. Deector

13. Starter handle 27. Air inlet net 41. Hose clamp

14. Fuel tank cap 28. Solution tank

Page 11

11

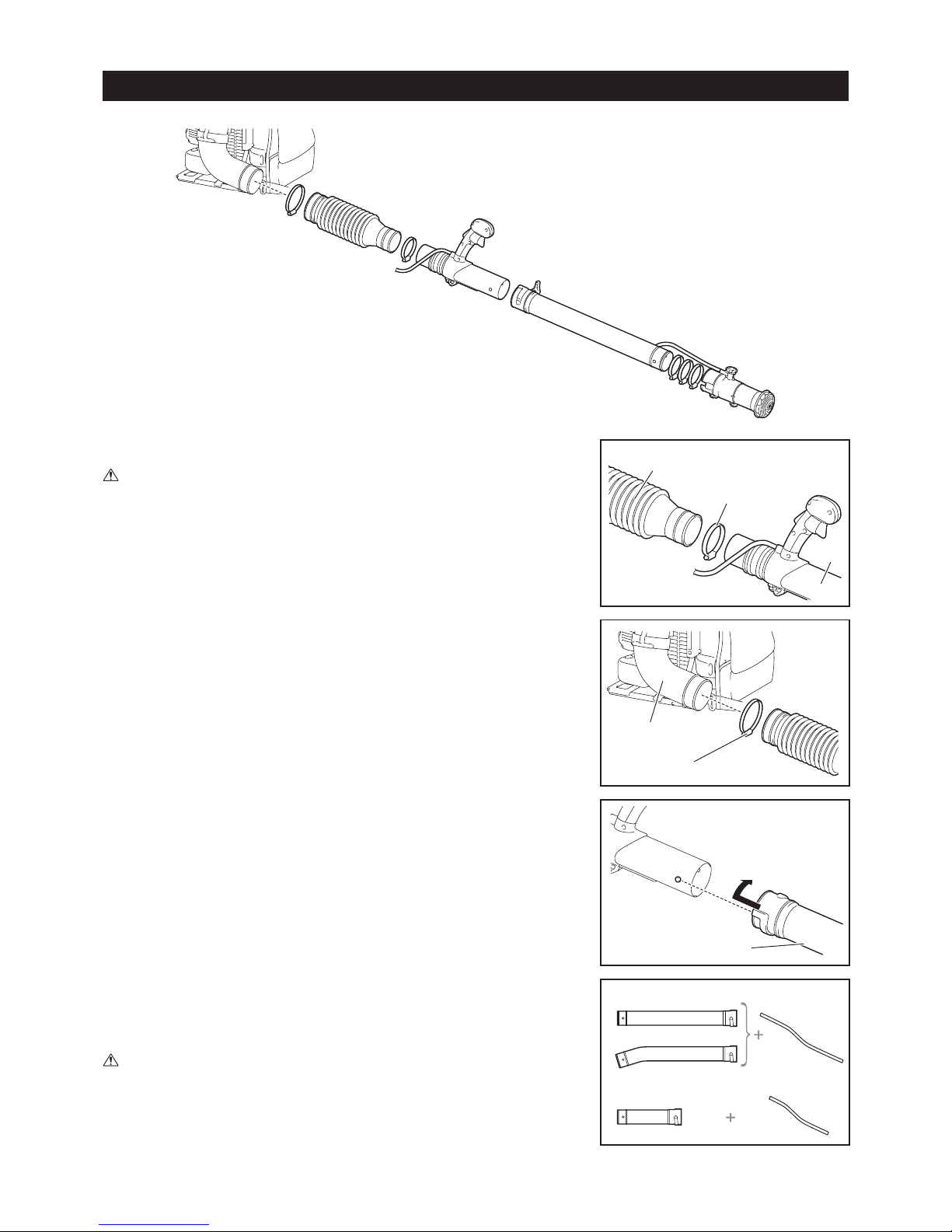

ASSEMBLY INSTRUCTIONS

Assembling mist blower pipes

CAUTION:

● Before performing any work on the mist blower, always stop the engine and pull

the spark plug connectors off the spark plug.

● Always wear protective gloves!

● Start the mist blower only after having assembled it completely.

● Make sure that all the hose bands are tight after assembly.

NOTE:

● Make the band’s bolt heads come outer side when you tighten them as illustrated.

1. Assemble the swivel pipe (1) with the exible pipe (2).

Tighten them with the 76 mm diameter band (3).

2. Assemble the exible pipe with the elbow (4) of the mist blower.

Tighten them with the 100 mm diameter band (5).

3. Assemble the straight pipe (6) with the swivel pipe (1).

Align the groove of the straight pipe with the projection on the swivel pipe, and

turn the straight pipe until it clicks, and then tighten them with the 76 mm diameter

band (3).

NOTE:

● The straight pipe stated above means the following three pipes and can be

substituted depending on your work need.

– Straight pipe (long) (6)

– Bent top pipe (7)

– Straight pipe (short) (8)

When using the straight pipe (long) (6) or the bent pipe (7), use with tube (long)

(9).

When using the straight pipe (short) (8), use with tube (short) (10).

To replace a tube, the hose clamps need to be removed and assembled. Use

pliers or a similar tool, if necessary.

CAUTION:

● When replacing the tube, be careful not to damage it.

Only one or combination of the above pipes is supplied as a standard equipment

with your mist blower, which may differ from country to country.

The remaining types of pipes may need to be obtained as optional accessories.

(2)

(3)

(1)

(4)

(5)

(6)

(6)

(7)

(8)

(9)

(10)

Page 12

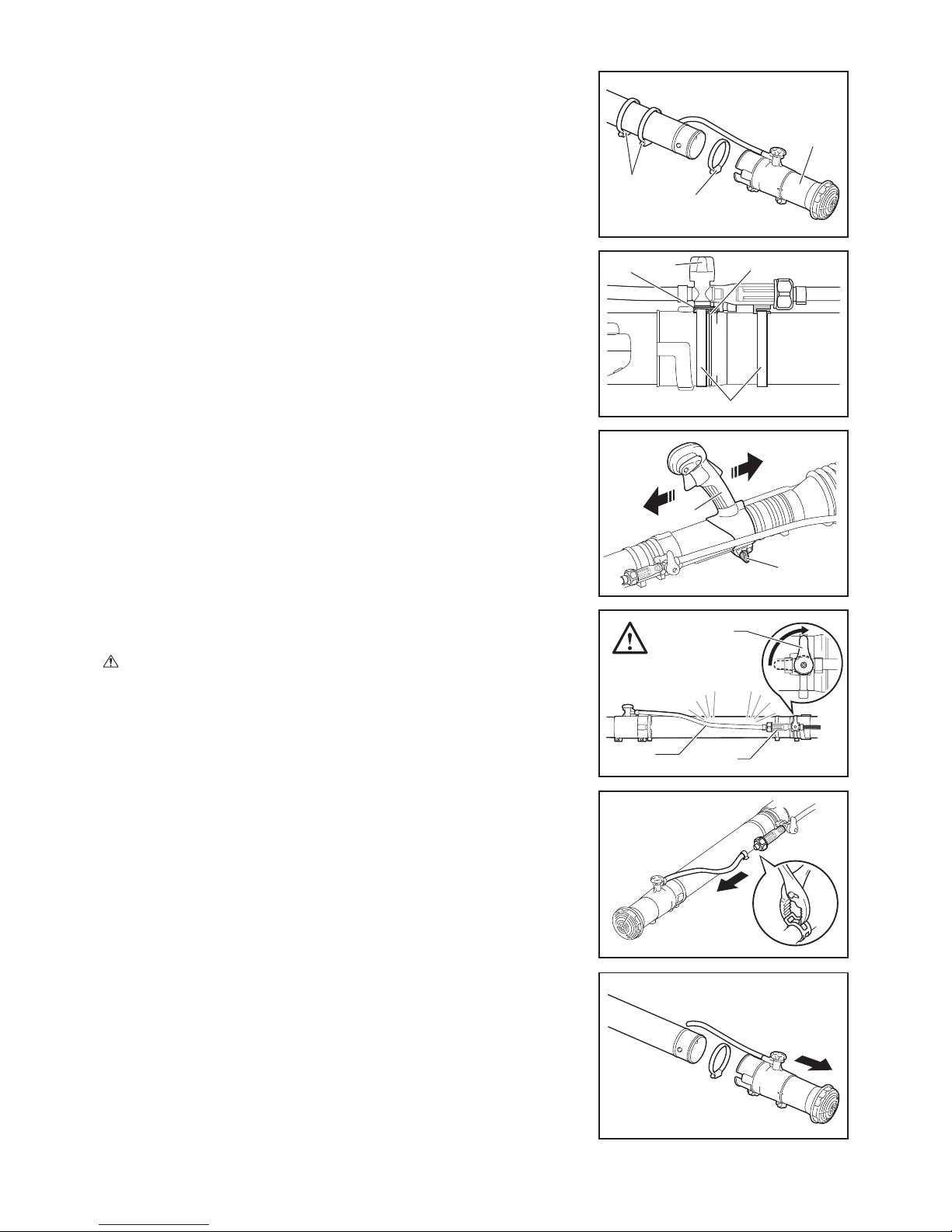

12

13

4. Set two of 76 mm diameter bands (3) on the pipe loosely (those bands are used for

tightening the solution discharge lever and tube joint later).

Assemble the second nozzle (11) with straight pipe.

Tighten them with another 76 mm diameter band (3).

(11)

(3)

(3)

(3)

(13)

(14)

(12)

(1)

(2)

5. Put the solution discharge lever (12) onto the pipe.

Make sure that the open side of the lever’s base (13) faces the swivel pipe.

Align the lever’s base with the gap of the projection on the straight pipe (14).

Then tighten them with the 76 mm diameter bands (3).

6. Make sure all clamps are tight.

Adjusting and securing the control handle

1. Put the machine on your back and adjust the shoulder strap (see “Adjusting the

shoulder strap”).

2. Slide the control handle (1) along the tube to the most comfortable position.

3. Secure the control handle by turning the knob (2).

Installing the end pipe (optional accessory for blower

operation)

WARNING:

● Drain all chemical solution from the solution hose (1) and tube joint (2), and make

sure the solution discharge lever (3) is closed before installing the end pipe.

Otherwise chemical solution may be spilled out.

1. Remove the solution hose from the tube joint by loosening the hose band.

2. Remove the 76 mm band, and remove the second nozzle from the straight pipe.

(1)

(2)

(3)

Page 13

13

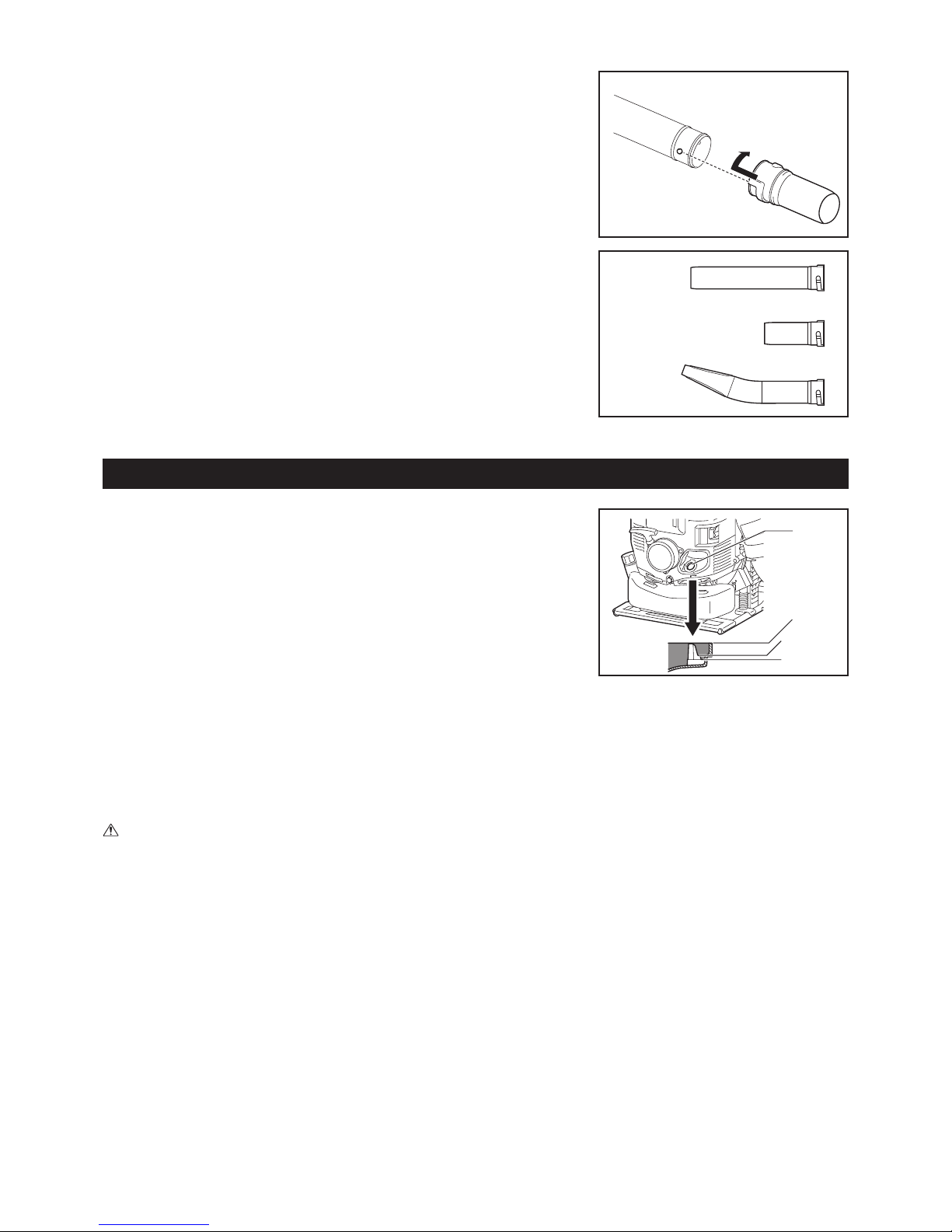

BEFORE STARTING THE ENGINE

1. Checking and relling engine oil

1) Follow the procedure below when the engine oil is cold i.e. the mist blower has

not been running.

● Inspection: Set the blower down on a level surface and remove the oil cap.

Verify that the oil level is within the upper (1) and lower (2) limit

marks on the oil level gauge (3). If the oil is not up to the 100 mL

level (4), ll up with new oil.

● Adding oil: Set the mist blower down on a level surface and remove the oil

cap. Fill the oil up to the upper limit of the oil level gauge.

2) On average, engine oil normally needs to be added after every 20 hours of

operation. This interval for every change in oil corresponds to refueling the mist

blower approximately 10 – 15 times.

3) Please change the oil whenever it becomes dirty or signicantly changes color.

(Refer to P. 23 for the oil change procedure and frequency.)

Recommended oil: DOLMAR genuine oil or SAE10W-30 oil of API type SF

grade or better (4-stroke motor oil for automobiles)

Oil capacity: Approximately 0.22 L (220 mL)

(3)

(1)

(4)

(2)

CAUTION:

● If the mist blower is not stored in an upright position, the oil may ow from the level gauge into the engine and give a false reading when

checking the oil level. This may result in inadvertently overlling whenever adding engine oil. Always store in an upright position.

● If the upper oil level limit is exceeded, this can result in the oil becoming dirty and white smoke from burning excess oil.

Check Point #1: Concerning the oil cap when adding oil

● Wipe off dirt and grime around the opening before removing the oil cap.

● Remove the oil cap and place it on a clean surface so that it does not accumulate any sand, dirt, or other foreign bodies. These may stick to

the cap and adulterate the engine oil if proper care is not taken. Dirty oil containing sand, dirt, or foreign bodies may cause excessive wear on

the engine due to improper lubrication and result in a breakdown.

Check Point #2: If oil is spilled when adding oil

● Oil spillage on the outside on the mist blower may result in the engine oil becoming dirty or adulterated. Therefore, please wipe off any oil

spillage before starting the engine.

3. Align the groove of the end pipe with the projection on the straight pipe, and turn

the end pipe until it clicks.

NOTE:

● The end pipe stated above means the following three end pipes and can be

substituted depending on your work need.

– End pipe (long) (4)

– End pipe (short) (5)

– Flat pipe (6)

(4)

(5)

(6)

Page 14

14

15

2. Fuel supply

WARNING:

● When supplying the fuel, be sure to observe the following instructions to prevent ignition or re:

– Fuel supply must be made in a place free of re. Never bring the re (smoking, etc.) near to the place of fuel supply.

– Stop the engine and allow the engine to cool down before fuel supply.

– Refuel on at surface. Do not refuel on unstable or bad ventilated place.

– Refuel in good light and visibility.

– Refuel at open clear place.

– Open the fuel tank cap full of fuel slowly. The fuel may sprout out under internal pressure.

– Take care not to spill the fuel. Any spilled fuel must be wiped clean.

– Do not fuel more than necessary.

– Carry out fuel supply in a well-ventilated place.

● Handle the fuel with care.

– Fuel sticking to the skin or entering an eye may cause allergies or irritation. When any physical abnormality is detected, consult the medical

specialist immediately.

Storage period of fuel

Fuel should be used up within a period of 4 weeks, even if it is kept in a special container in a well-ventilated shade.

If a special container is not used or if the container is not covered, fuel may deteriorate in one day.

Storage of machine and rell tank

● Keep the machine and tank at a cool place free from direct sunshine.

● Never keep the fuel in the cabin or trunk.

Fuel

The engine is a 4-stroke engine. Be sure to use an automobile gasoline (regular gasoline or premium gasoline).

Points for Fuel

● Never use a gasoline mixture which contains engine oil. Otherwise, it will cause excessive carbon accumulation or mechanical troubles.

● Use of deteriorated fuel will cause irregular startup.

When refueling the fuel, be sure to stop the engine and make sure that the engine cools down.

Refuelling method

● Loosen the tank cap a little so that there will be no difference in atmospheric pressure.

● Detach the tank cap, and refuel, discharging air by tilting the fuel tank so that the refuel port will be oriented upward. (Never rell fuel full to the

oil rell port.)

● After refueling, securely tighten the tank cap.

● If there is any aw or damage on the tank cap, replace it.

● The tank cap will wear. Replace the tank cap every two to three years.

Page 15

15

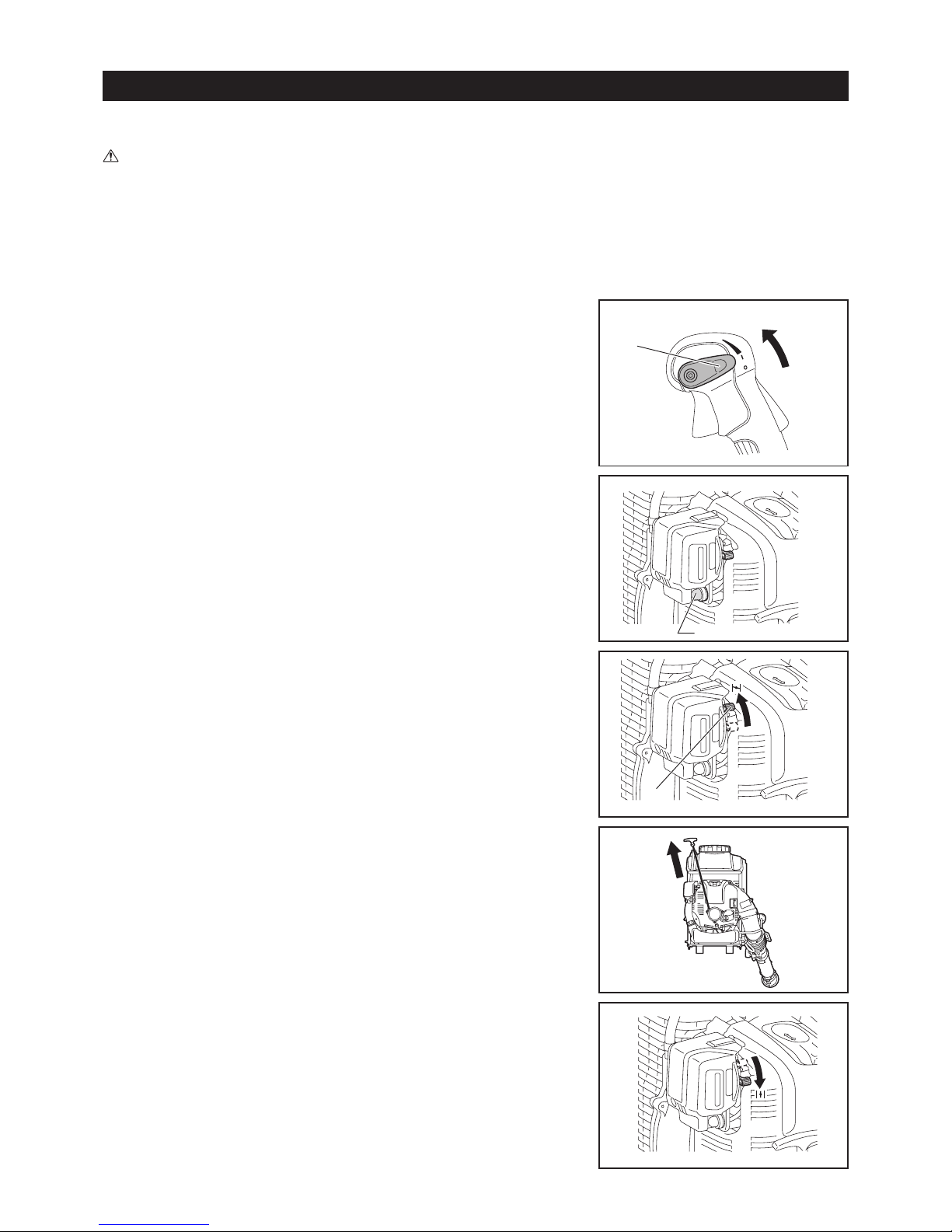

1) When the engine is cold, or after refuelled (cold start):

(1) Set this machine on a at space.

(2) Set the stop control lever (1) to “I” position.

(1)

(3)

(3) Push the primer pump (2) several times until fuel enters into the primer

pump.

● In general, fuel enters into the carburetor by 7 to 10 pushes.

● If the primer pump is pushed excessively, an excess of gasoline returns

to the fuel tank.

(4) Lift the choke lever (3).

(5) Hold the air cleaner cover with a left hand to prevent the engine from

moving, settle down to take the stable position.

(6) Pull the starter handle slowly until feeling compression. Then pull it

strongly. It may take two to four attempts until engine starts.

● Do not pull the rope to the full extension.

● Return the starter handle gently into the housing. Otherwise released

starter handle may hit your body or it may not rewind appropriately.

(7) When the engine starts, gradually lower the choke lever while checking

the engine operation. Be sure to lower the choke lever fully in the end.

● In cold or when the engine is cooled down, always lower the choke

lever slowly. Otherwise, the engine may stop.

(8) Grasp the control handle (the lock-off lever is released by the grasp)

and pull the throttle trigger for warm-up operation. Continue warm-up

operation for 2 to 3 minutes.

(9) When the rotation of the engine stabilizes and the engine accelerates

smoothly from low to high speed by throttle movement, it is completion of

warming-up.

(2)

STARTING AND STOPPING ENGINE

1. Starting

WARNING:

● Never attempt engine start in a place where the unit was refueled. When starting the engine, keep a distance of at least 3 m (10 feet).

– Otherwise, it may cause ignition or re.

● Exhaust gas from the engine is toxic. Do not operate the engine in a poorly-ventilated place, such as in a tunnel, building, etc.

– Operating the engine in the poorly-ventilated place may cause poisoning by exhaust gas.

● In case of detection of any abnormality in sound, odor, vibration after start, stop the engine immediately and carry out inspection.

– If the engine is operated without attending such abnormality, an accident may occur.

● Make sure that the engine stops when the stop control lever is set to “O” position.

● Make sure that the solution discharge lever is closed before starting the machine.

Page 16

16

17

NOTE:

● The engine may be damaged if the choke lever is moved further beyond the “CLOSE” position.

● If the engine stops with an explosion sound or if the engine started, but stopped before operation of the choke lever, return it to the “OPEN”

position and pull the starter handle several times to start the engine again.

● If the operator keeps pulling the starter handle several times with the choke lever left in the “CLOSE” position, the engine may be difcult to

start because of over-suction of the fuel.

● In case of over-suction of the fuel, remove the spark plug and pull the handle several times rapidly to discharge any excess fuel. Dry the spark

plug electrode.

● When the throttle valve does not return to a position in contact with the idling adjusting screw even if the throttle trigger is set to the low speed,

correct the control cable catching state to ensure proper return of the valve.

2) When the engine is warm (warm start)

(1) Place the engine on a at ground.

(2) Press the primer pump several times.

(3) Make sure that the choke lever is down.

(4) Hold the air cleaner cover with a left hand to prevent the engine from moving, settle down to take the stable position.

(5) Pull the starter handle slowly until feeling compression. Then pull it strongly.

(6) When the engine is difcult to start, open the throttle valve by 1/3.

2. Stopping

1) Release the throttle trigger to reduce the engine speed, and set the stop

control lever to the “O” position.

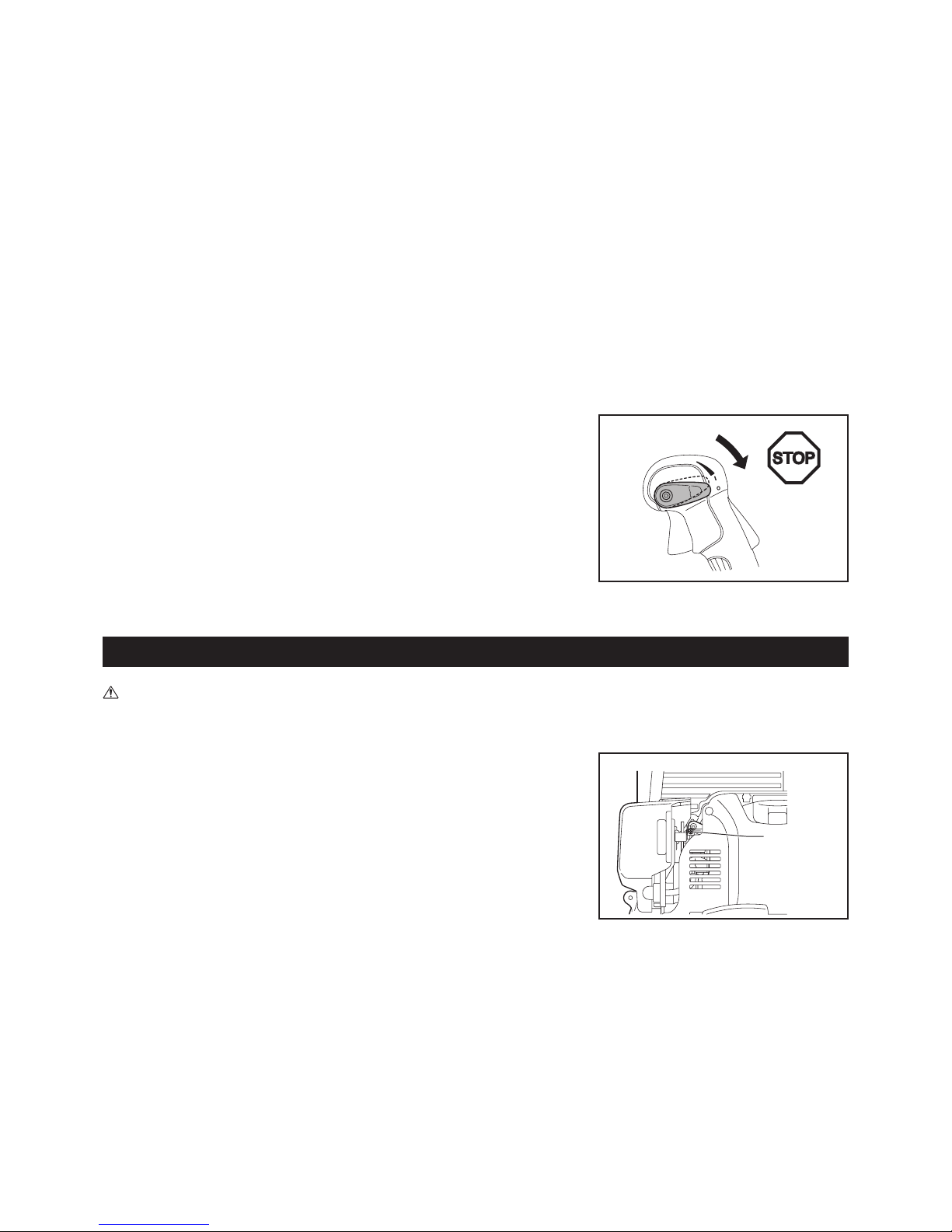

ADJUSTING IDLE SPEED

DANGER:

● The adjustment of the carburetor is completed at the time of factory shipment. Please do not adjust other than idling adjusting. When adjustment

becomes necessary, please consult your authorized service center.

Checkup of idle speed

Set the idle speed rotation to 2,800 min–1.

● If it is necessary to change the rotation speed, regulate the adjusting screw (1),

with Phillips screwdriver.

● Turn the adjusting screw to the right, and the engine rotation will increase. Turn the

adjusting screw to the left, and the engine rotation will drop.

(1)

Page 17

17

OPERATION METHOD

Installing the strainer

The mist blower is provided with the strainers at the solution tank opening and the

pipe inlet head.

Always make sure the strainer is installed in place.

To install the strainer, push it in place.

To remove the strainer, pry it out of place.

WARNING:

● Tighten the tank cap rmly. Failure to tighten the tank cap may cause solution

leakage, pressure reduction and the like.

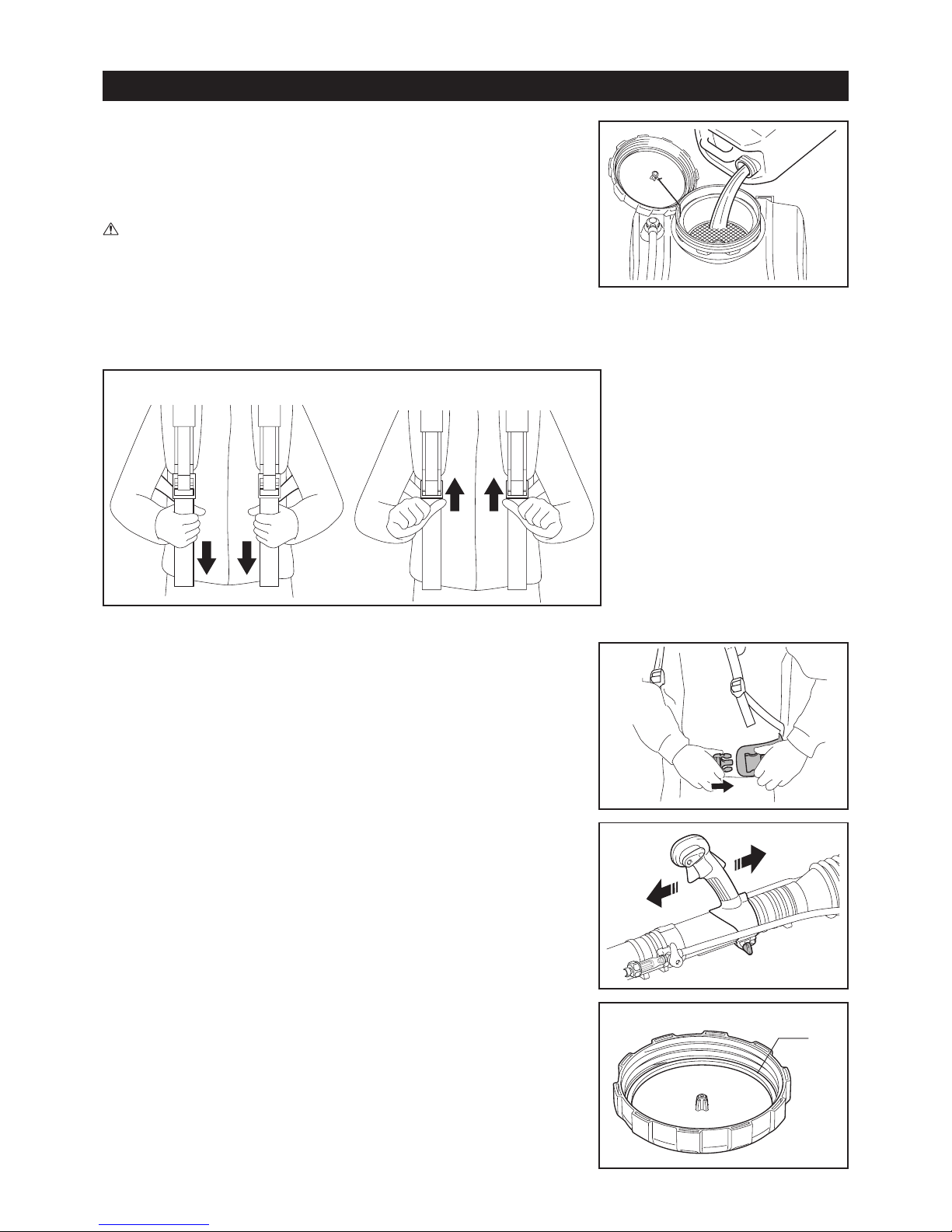

Adjusting the shoulder strap

Adjust the shoulder strap to a length that is comfortable to work while carrying the

mist blower.

Adjust as shown in the gure.

(1)

Hip belt (optional accessory)

The hip belt (optional accessory) enables the operator to carry the appliance more

stably.

Adjusting the control handle

Move the control handle along the swivel pipe to the most comfortable position.

Filling the solution tank

1. Keep the gasket (1) in good condition and lubricated with grease and clean.

2. Put the mist blower on a at surface.

To tighten strap To loosen strap

Page 18

18

19

3. Before lling the solution tank, be sure to close the solution discharge lever (2).

(2)

4. The solution tank is capable of 15 liters of solution.

When the tank is full, the total weight including solution is nearly 30 kg.

Adjust the solution pouring volume so that the mist blower with solution in tank is

not over-weighted and can be within an operator’s strength.

When 10 liters of solution is poured (that is, when the poured solution level points

10 liters marking on the side of the tank), the total product weight is nearly 25 kg.

It is recommended that the total weight of the machine does not excess 30 kg for

men, and 25 kg for women.

Use the solution level in the tube on the side of the mist blower as a guideline to check

the solution level in the solution tank.

Solution mixing function

The solution mixing device inside the solution tank allows solution to be mixed with

air bubbles coming out of it during spraying operation.

Page 19

19

Mist blower operation

To increase engine speed, grasp the control handle (the lock-off lever is released by

the grasp) and pull the throttle trigger.

Pressure on the throttle trigger controls engine speed.

Position of the stop control lever can restrict the angle of the throttle trigger.

There are four positions for the stop control lever. “O”(engine stop), “I”, and two

throttle trigger angle restriction positions.

“I” position does not restrict the engine speed (you can pull the throttle trigger fully).

The throttle trigger angle gets restricted from one step above the “I” position. The

throttle trigger is more restricted when you move the stop control lever one more step

above the “I” position.

Adjust engine speed appropriate for the work location and conditions during operation.

Liquid adjustment knob

Liquid adjustment knob allows a wide range of different discharge rates.

Adjusting the discharge rate

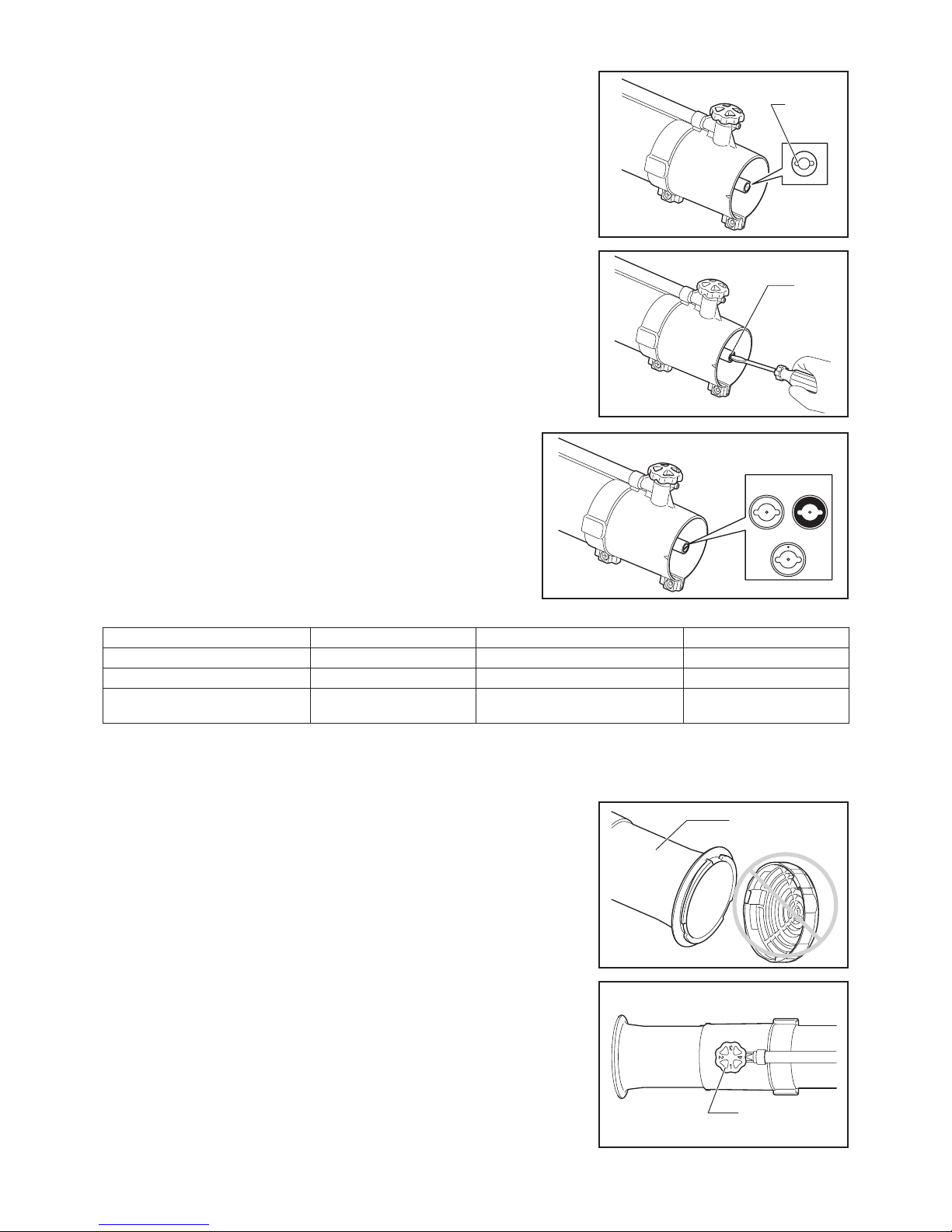

Turn the liquid adjustment knob (1) on the second nozzle to obtain the desired

discharge rate so that the number on the liquid adjustment knob is aligned with the

triangle marking (2).

Discharge rate

Spray holding the straight pipe with the angle of 0 degrees to minus degrees to the horizontal.

Knob position Discharge rate (L/min) (mean value)

1 0.36

2 1.0

3 1.6

4 2.5

NOTE:

● Use the gures shown in the above table as a guide line for operation and these may be changed according to the density of chemical solution

used in the solution tank.

Solution discharge lever

To start the solution feeding (A), turn the solution discharge lever (1) horizontally to

the pipe.

To stop the solution feeding (B), turn the solution discharge lever vertically to the pipe.

(2)

(1)

(1)

(A) (B)

Page 20

20

21

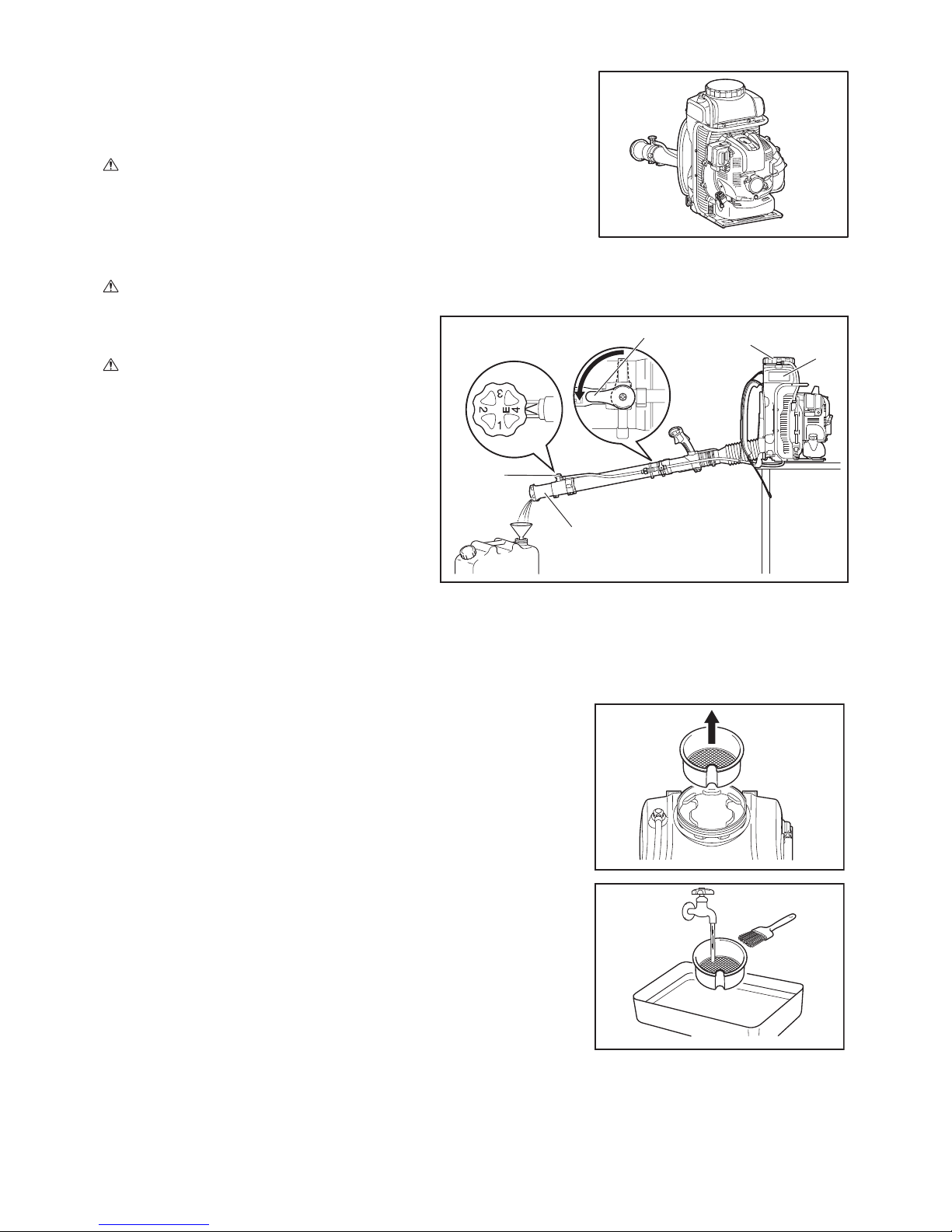

Installing and removing the dispersion cover

To install the dispersion cover (1), mount the dispersion cover on the top nozzle (2)

so that its protrusion (3) is aligned with the notch (4) in the top nozzle.

(2)

(4)

(1)

(3)

(2)

(3)

(4)

(1)

Secure the dispersion cover by turning it fully clockwise.

To remove the dispersion cover, follow the above procedure in reverse.

Changing the nozzle to a small-amount-solution-discharge

nozzle (optional accessory)

When a small amount of solution needs to be sprayed, replace the nozzle cap with

another type of supplied nozzle cap with a small discharge hole.

To replace the nozzle, follow the procedure below.

1. Remove the screw (1) from the second nozzle (2) and then remove the top nozzle

(3) and dispersion cover (4).

Installing and removing the deector (optional accessory)

The deector (1) allows chemicals to be sprayed upward. This helps treatment for

low-growing plants and the underside of leaves of plants.

To install the deector (1), mount the deector on the top nozzle so that the “I” mark

(3) on it is aligned with the “I” mark (4) of the top nozzle (2).

Secure the deector by turning it fully clockwise.

To remove the deector, follow the above procedure in reverse.

(1)

(2)

(3)

(4)

(1)

Page 21

21

3. Mount another supplied nozzle with a small discharge hole.

NOTE:

● Choose a right nozzle out of the following two according to the kind (viscosity)

of the chemical you use.

(7) (8)

(9)

(3)

(10)

Nozzle type Viscosity of chemical Example of chemical Discharge rate (L/min)*

1

Aluminum nozzle (silver color) (7) *

2

High MALATHION (Mix the oil.) 0.14

Brass nozzle (gold color) (8) *

2

Low Aqua K-Othrine (Mix the water.) 0.075

Brass nozzle with punch marking

(gold color) (9) *

2

Low Cipermetrinato (Mix the water.) 0.060

Note 1: The discharge rate shown in the table is that in case of water only used for a guide line. This varies by chemicals being used.

Note 2: The type of the nozzle(s) provided with the mist blower changes from country to country.

4. Mount the top nozzle (3) and secure it with the screw (1).

NOTE:

● When using an above small-amount-solution-discharge nozzle, do not mount the

dispersion cover (4) or deector (optional accessory) and put it aside so that it is

not lost.

5. Set the knob (10) to the position 4.

(5)

(6)

2. Fit a slotted bit screwdriver to the slit (5) in the nozzle top and remove the nozzle

cap (6) by turning it fully counterclockwise.

Page 22

22

23

Draining and cleaning the solution tank

WARNING:

● Always wear rubber/chemical-resistant gloves when cleaning and draining the solution tank.

Draining the solution tank

WARNING:

● Never dispose chemical or rinsed water by opening the cap

at the bottom of the solution tank.

● Before and after draining, make sure that the solution

discharge lever is closed.

● If chemical solution is still remained in the solution tank

after the method mentioned in the instruction manual, tilt

the machine towards pipe side to pour out all the remained

solution.

1. Put the mist blower onto a stable place. Position the nozzle

(1) lower than the bottom of solution tank (2), and place a

receiving container beneath it.

2. Set the knob (3) to the position E.

3. Open the solution tank cap (4) slightly to release pressure of the tank.

4. Open the solution discharge lever (5). Chemical solution is discharged from the nozzle.

5. Clean the tank inside with water.

Cleaning the strainer of solution tank

Remove the tank cap, take out the strainer from inside the tank and then clean it

after use.

(3)

(1)

(4)

(2)

(5)

TRANSPORTING THE MIST BLOWER

Please keep the mist blower in an upright position whenever transporting or storing.

Transporting or storing in a position that is not upright may cause oil to spill inside the

mist blower engine. This may result in oil leaks and white smoke from burning oil, and

the air cleaner may become dirty with oil.

DANGER:

● When transporting and storing the mist blower, be sure to stop the engine.

Page 23

23

1. Loosen and remove the cap (1) that comes out with the strainer (2).

2. Clear dust and particles away from strainer.

3. Put the strainer back to the original position. Be sure to tighten the cap rmly.

INSPECTION AND MAINTENANCE

DANGER:

● Before inspection and maintenance, stop the engine and allow it to cool. Remove also the spark plug and plug cap.

– If inspection or maintenance is attempted immediately after engine stop or with the plug cap left attached, the operator may suffer burn or an

accident due to careless startup.

● After inspection and maintenance, make sure that all parts are assembled. Then, proceed to operation.

● Always wear rubber/chemical-resistant gloves for inspection and maintenance.

NOTICE:

● Never use gasoline, benzine, thinner, alcohol or the like. Discoloration, deformation or cracks may result.

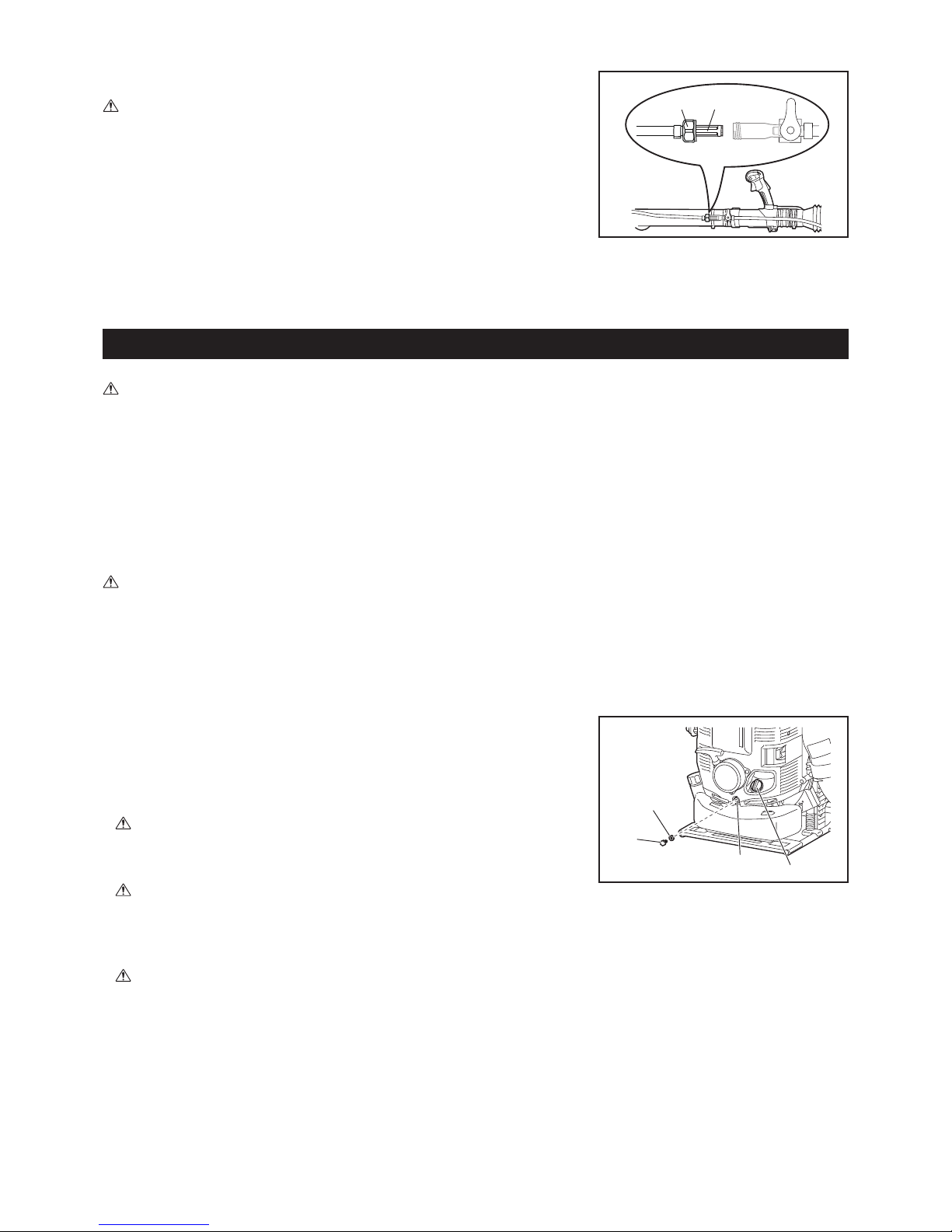

Replacement of engine oil

Deteriorated engine oil will shorten the life of the sliding and rotating parts to a great extent. Be sure to check the period and quantity of replacement.

DANGER:

● In general, the engine main unit and engine oil still remain hot just after the engine is stopped. In replacement of oil, make sure that the engine

main unit and engine oil are sufciently cooled down. Otherwise, there may remain a risk of burn. In addition just after of the engine stops all

the oil may not return to crank case. Do not check the oil level right after engine stops.

● If the oil lled above the limit, it may be contaminated or may catch re with white smoke.

Interval of replacement: Initially, every 20 operating hours, and subsequently every 50 operating hours

Recommended oil: SAE10W-30 oil of API Classication SF Class or higher (4-stroke engine oil for automobile)

Oil change procedure

1. Set the mist blower down on a level surface.

2. Place a waste oil container under the drainage hole (1) to catch the oil as it drains out.

The container should have a capacity of at least 220 mL to be able to catch all of the oil.

3. Loosen the oil drain bolt (2) to let the oil drain out. Be careful not to allow oil to get on the

fuel tank or other parts.

CAUTION:

● Be careful not to lose the gasket (aluminum washer) (3). Place the oil drain bolt (2) in a

location where it will not accumulate dirt.

4. Remove the oil cap (4). (Removing the oil cap (4) allows the oil to drain easily.)

CAUTION:

● Be sure to set the oil cap (4) down in a location where it will not accumulate dirt.

5. As the level of the oil being drained decreases, tilt the mist blower over on to the side with

the drain so that the oil will completely drain out.

6. After the oil has completely drained out, tighten the oil drain bolt (2) securely. If the bolt is not tightly fastened, this may result in an oil leak.

CAUTION:

● Do not forget to put the gasket (aluminum washer) (3) back on when reattaching the drain plug.

7. Adding oil during the oil change procedure is performed in the same manner as the separately explained procedure for adding oil whenever the

level is insufcient. Always add oil by lling from the opening under the oil cap.

(Specied oil level: Approximately 220 mL)

8. After lling with oil, tighten the oil cap (4) securely to prevent oil leaks.

(3)

(2)

(1)

(4)

(2)

(1)

Cleaning the tube joint

WARNING:

● Do not remove the hose band, tube, or cap, when the solution discharge lever is

open.

● Do not loosen the cap when the solution discharge lever is open.

Page 24

24

25

Points in replacement of engine oil

● Never discard replaced engine oil in garbage, earth or sewage ditch. Disposal of oil is regulated by law. In disposal, always follow the relevant

laws and regulations. For any points remaining unknown, contact Authorized Service Agent.

● Oil will deteriorate even when it is kept unused. Perform inspection and replacement at regular intervals (replace with new oil every 6 months).

(4)

(3)

(2)

(1)

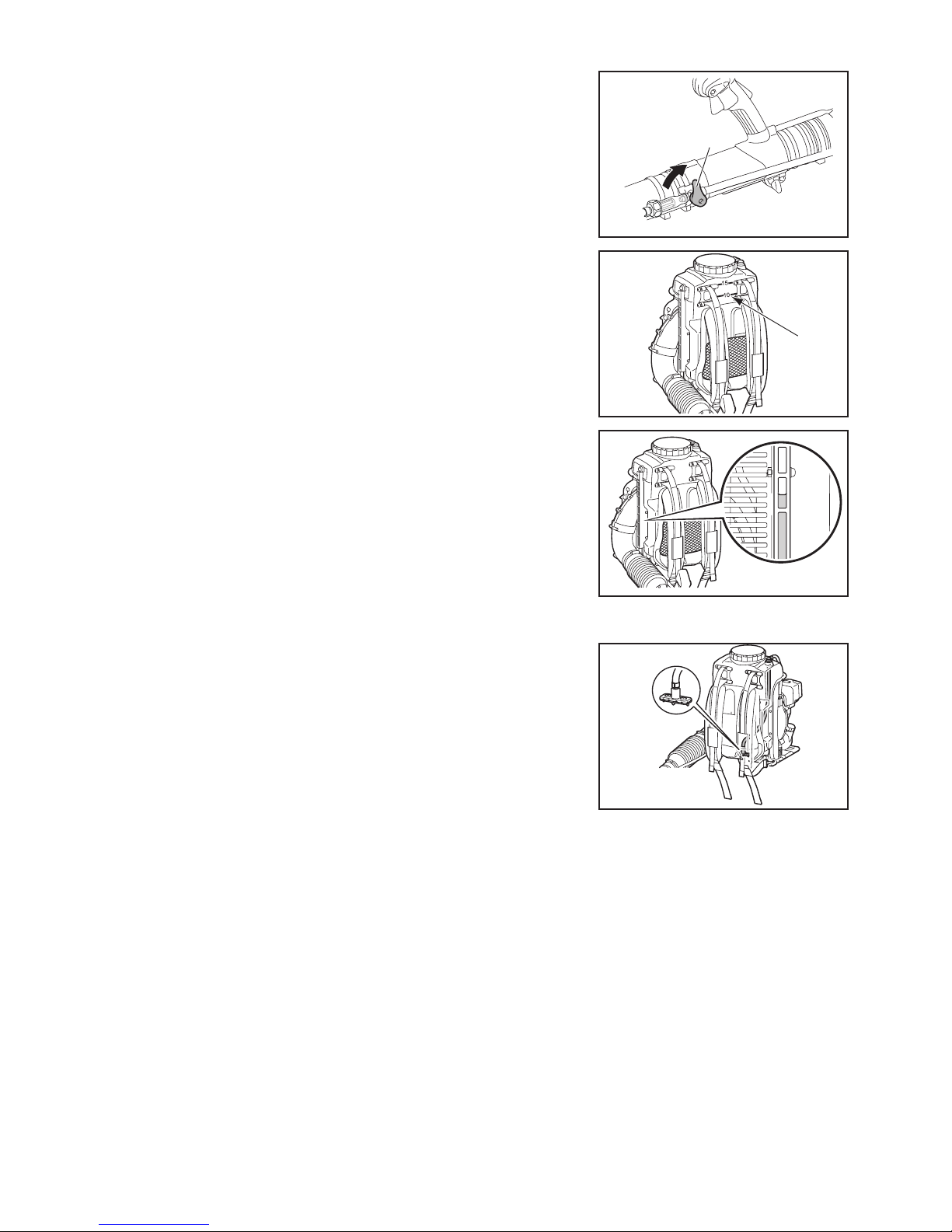

Cleaning of air cleaner

WARNING: INFLAMMABLES STRICTLY PROHIBITED

Interval of Cleaning and Inspection: Daily (every 10 operating hours)

1. Loosen the knob bolt (1).

2. Remove the air cleaner cover (2).

3. Take out the element (3) and remove any dirt with the brush.

NOTE:

● The element is a dry type and should not get wet. Never wash with water.

4. Replace the element with a new one if it is damaged or very dirty.

5. Wipe off any oil that has come into contact with the breather with a rag or cloth.

6. Install the element in the cleaner case (4).

7. Attach the air cleaner cover and tighten the knob bolt.

DANGER:

● Clean the element several times a day, if excessive dust adheres to it.

● If operation continues with the element remaining not cleared of oil, oil in the air cleaner may fall outside, resulting in oil contamination.

Checking the spark plug

CAUTION:

● When removing the spark plug, clean the spark plug and cylinder head rst, so that no dirt, sand, etc. will enter the cylinder.

● You must remove the spark plug after the engine has cooled down in order to avoid damaging the threaded hole in the cylinder.

● The spark plug must be installed properly into the threaded hole. If installed at an angle, the threaded hole in the cylinder will get damaged.

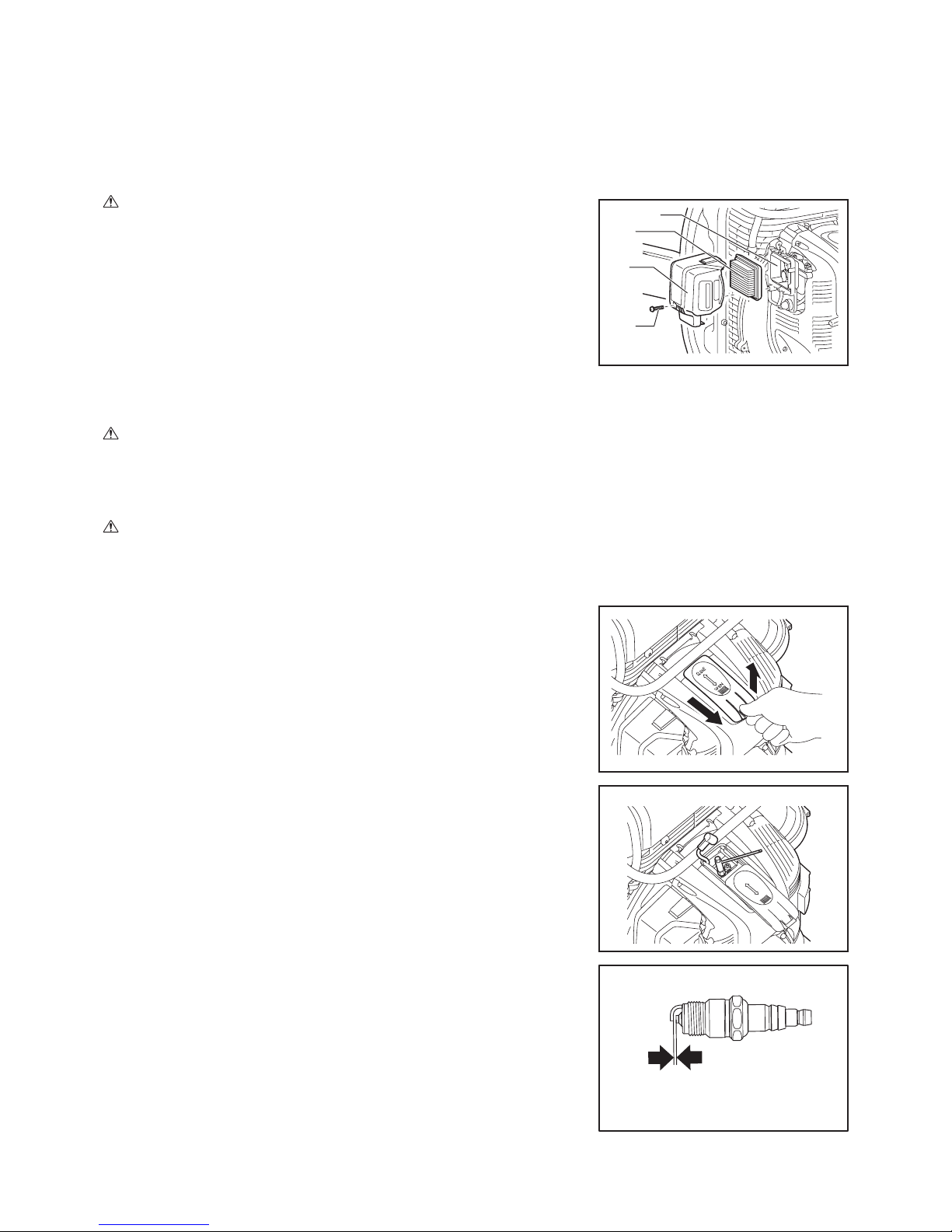

1. Opening/closing the plug cover

To open the plug cover, pull up on the seam of the plug cover projection and slide

in the direction of the “OPEN” indication as shown in the gure at right.

When closing the cover, slide the cover in the “CLOSE” direction till the click under

the plug cover projection rides over the engine cover. Finally, push in the projection.

2. Removing the spark plug

Use an attached box wrench to remove or install the spark plug.

3. Checking the spark plug

The clearance between two electrodes of spark plug (see the gure) is

0.7 to 0.8 mm. Adjust to the correct clearance when it is too wide or too narrow.

Clean thoroughly or replace the spark plug if it has accumulated carbon or

contaminated.

4. Replacing the spark plug

For replacement, use NGK-CMR6A.

0.7 – 0.8 mm

Page 25

25

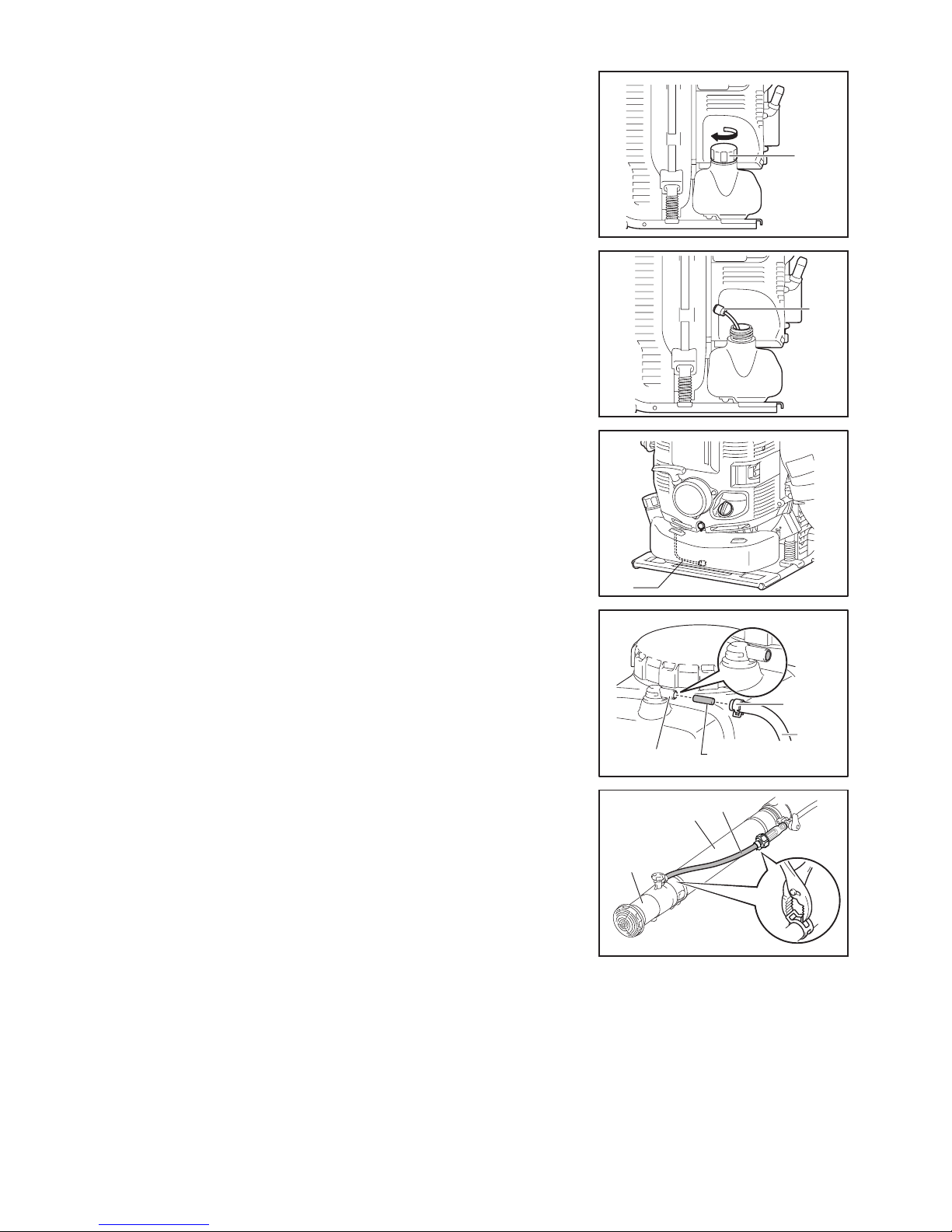

Cleaning the fuel lter

● Clogged fuel lter may cause difculty of start-up or failure of engine speed

increase.

● Check the fuel lter regularly as follows:

1. Remove the fuel tank cap (1), drain the fuel to empty the tank. Check the tank

inside for any foreign materials. If any, wipe clean such materials.

2. Pull out the fuel lter (2) with wire through the fuel lling port.

3. If the fuel lter surface is contaminated, clean it with gasoline. Foul gasoline must

be disposed of according to the method specied by each local authority.

Excessively foul lter must be replaced.

4. Reset the fuel lter in the fuel tank and tighten rmly the fuel tank cap.

NOTE:

● When resetting the fuel lter in the tank, return it to the position as shown in the

gure.

For replacement, contact your authorized service center.

(1)

(2)

(2)

(4)

(3)

(2)

(1)

Cleaning the joint pipe cleaner element

1. Remove the hose band (1) and the hose (2).

2. Pull out the element (3) and remove any dirt form it with a brush.

If it is difcult to pull out the element, use a slender stick to catch it out.

3. Replace the element with a new one if it is damaged or very dirty.

4. Press the element into the joint pipe (4) until the element tail is ush with its port

end.

5. Install the hose and secure it with a hose band.

Replacement of solution hose

● Check the solution hose (1) frequently. Damaged hose may result in leakage of

chemical solution. Replace the hose if necessary as follows.

1. Remove the nozzle (2) from the pipe (3).

2. Loosen the hose band, and then replace the old hose with new one.

Inspection of bolts, nuts and screws

● Retighten loose bolts, nuts, etc.

● Check for fuel and oil leakage.

● Replace damaged parts with new ones for safety operation.

Replacement of gaskets and packings

In reassembling after the engine is dismounted, be sure to replace the gaskets and

packings with new ones.

(3)

(2)

(1)

Page 26

26

27

Cleaning of parts

● Keep the engine always clean.

● Keep the cylinder ns free of dust or dirt. Dust or dirt adhering to the ns will cause

seizure.

● Blowing air is taken in from the air inlet net (1). When airow has dropped down

during operation, stop engine and inspect the air inlet net for blocking by obstacles.

● Note that failure to remove any such obstacles may result in the engine becoming

overheated and damaged.

WARNING:

● Never use the mist blower without the net of the mist blower. Before each use,

check that the net is attached in place and is free from any damage.

(1)

Any maintenance of adjustment work that is not included and described in this manual is only to be performed by Authorized Service Centers.

STORAGE

Draining the fuel

WARNING:

● When draining the fuel, be sure to stop the engine and conrm that the engine cools down.

– Just after stopping the engine, it may still hot with possibility of burns, inammability and re.

CAUTION:

● When the machine is kept out of operation for a long time, drain up all fuel from the fuel tank and carburetor, and keep it at a dry and clean

place.

Drain up fuel from the fuel tank and carburetor according to the following procedure:

1) Remove the fuel tank cap, and drain fuel completely.

If there is any foreign matter remaining in the fuel tank, remove it completely.

2) Pull out the fuel lter from the rell port using a wire.

3) Push the primer pump until fuel is drained from there, and drain fuel coming

into the fuel tank.

4) Reset the lter to the fuel tank, and securely tighten the fuel tank cap.

5) Then, continue to operate the engine until it stops.

6) Remove the spark plug, and drip several drops of engine oil through the spark

plug hole.

7) Gently pull the starter handle so that engine oil will spread over the engine, and

attach the spark plug.

8) During storage, please keep the machine upright.

9) Keep the drained fuel in a special container in a well-ventilated shade.

Draining the solution tank

WARNING:

● When draining the solution tank, be sure to stop the engine and conrm that the engine cools down.

– Just after stopping the engine, it may still hot with possibility of burns, inammability and re.

Before storing the mist blower, drain the solution tank by referring to the section titled “Draining and cleaning the solution tank”.

Cleaning the strainer at the top of the solution tank

When storing the mist blower, always clean the strainer at the top of solution tank.

To clean the strainer, refer to the section titled “Draining and cleaning the solution tank”.

Cleaning the strainer at the tube joint

When storing the mist blower, always clean the strainer at the tube joint.

To clean the strainer, refer to the section titled “Draining and cleaning the solution tank”.

CAUTION:

● When storing the mist blower, be sure to stop the engine.

Page 27

27

Retaining the straight pipe with a supplied hand strap

When storing the mist blower, retain the straight pipe with a supplied hand strap tied

to the frame.

Retaining the pipe in this position will be easy to transport the unit.

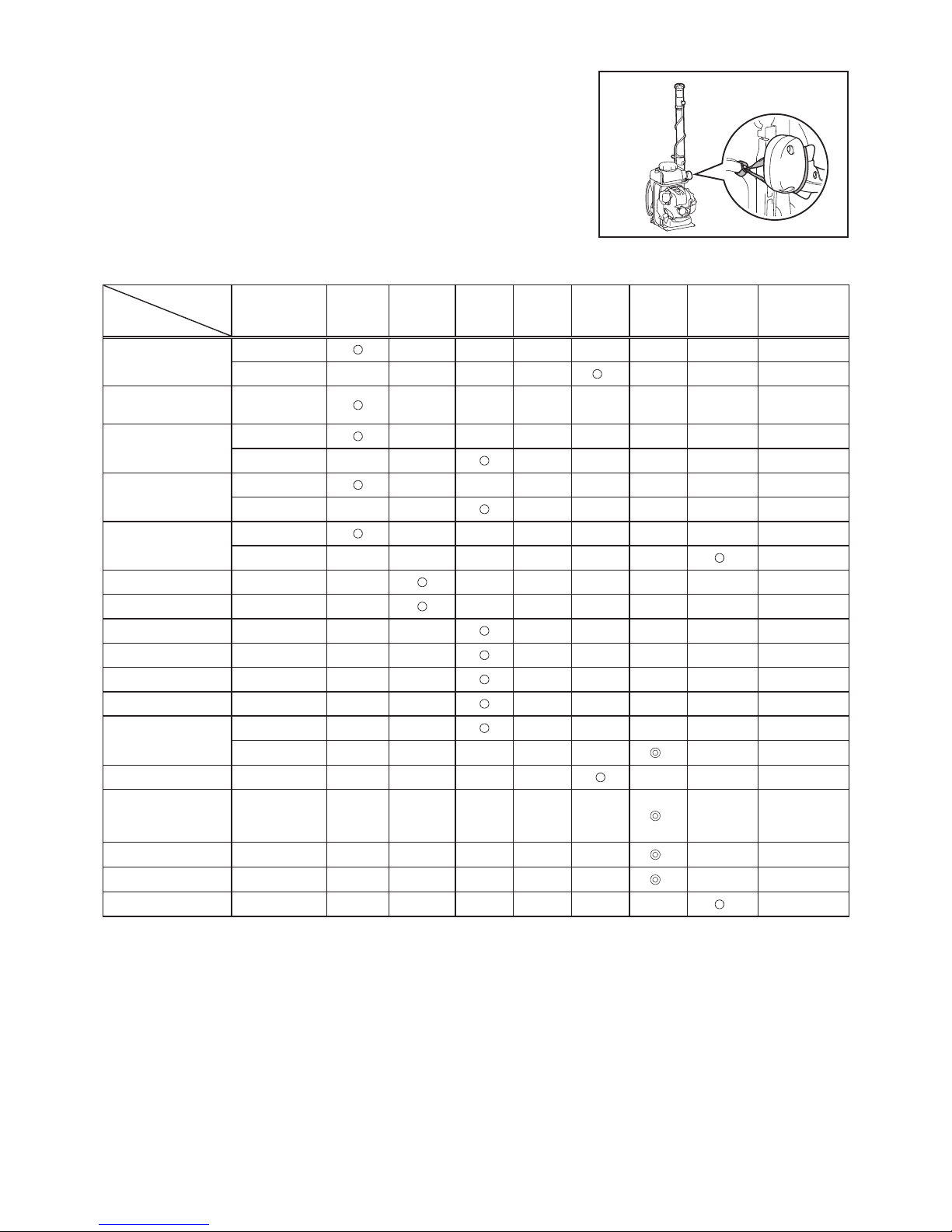

Maintenance interval

Operating time

Item

Before

operation

After

lubrication

Daily

(10h)

30h 50h 200h

Shutdown/

rest

Corresponding

Page

Engine oil Inspect

13

Replace

*1

23

Tightening parts (bolt,

nut)

Inspect

25

Strainer of solution

tank

Inspect

22

Clean

22

Strainer of tube joint Inspect

23

Clean

23

Fuel tank Clean/inspect

—

Drain fuel

*3

26

Throttle trigger Check function

—

Stop control lever Check function

16

Idle speed Inspect/adjust

16

Air cleaner Clean

24

Ignition plug Inspect

24

Cooling air duct Clean/inspect

26

Fuel pipe Inspect

25

Replace

*2

—

Fuel lter Clean/replace

25

Clearance between

air intake valve and air

discharge valve

Adjust

*2

—

Oil tube Inspect

*2

—

Engine overhaul

*2

—

Carburetor Drain fuel

*3

26

*1 Perform initial replacement after 20h operation.

*2 For the 200 operating hour inspection, request Authorized Service Center or a machine shop.

*3 After emptying the fuel tank, continue to run the engine and drain fuel in the carburetor.

Page 28

28

TROUBLESHOOTING

Before making a request for repairs, check a trouble for yourself. If any abnormality is found, control your machine according to the description

of this manual. Never tamper or dismount any part contrary to the description. For repairs, contact Authorized Service Agent or local dealership.

State of abnormality Probable cause (malfunction) Remedy

Engine does not start. I-O switch is set to STOP. Set the I-O switch to START.

Failure to operate primer pump. Push 7 to 10 times.

Low pulling speed of starter rope. Pull strongly.

Lack of fuel. Feed fuel.

Incorrect choke position.

Set to “CLOSE” (cold start).

Set to “OPEN” (warm start).

Clogged fuel lter. Clean.

Bent or blocked fuel tube. Straighten or replace fuel tube.

Deteriorated fuel.

Deteriorated fuel makes starting more difcult.

Replace with new one. (Recommended

replacement: 1 month)

Excessive suction of fuel.

Set throttle lever from medium speed to high

speed, and pull starter handle until engine

starts.

If engine will not start still, remove spark plug,

make electrode dry, and reassemble them as

they originally are. Then, start as specied.

Detached plug cap. Attach securely.

Contaminated spark plug. Clean.

Abnormal clearance of spark plug. Adjust clearance.

Abnormality of spark plug. Replace.

Abnormal carburetor. Make request for inspection and maintenance.

Starter rope cannot be pulled, or no

compression is felt.

Make request for inspection and maintenance.

Abnormal drive system/electric system.

(I-O switch fault, wiring fault, connector

fault, etc.).

Make request for inspection and maintenance.

Engine stops soon.

Engine speed does not increase.

Insufcient warm-up. Perform warm-up operation.

Choke lever is set to “CLOSE” although

engine is warmed up.

Set to “OPEN”.

Low idle speed. Adjust idle speed.

Clogged fuel lter. Clean.

Contaminated or clogged air cleaner. Clean.

Abnormal carburetor. Make request for inspection and maintenance.

Exhaust mufer fault (clogged etc.). Make request for inspection and maintenance.

Abnormal drive/electric system. Make request for inspection and maintenance.

Detached throttle wire. Attach securely.

Engine does not stop.

Run engine at idling, and set choke lever to

CLOSE.

Detached connector. Attach securely.

Abnormal electric system. Make request for inspection and maintenance.

When the engine does not start after warm-up operation:

If there is no abnormality found for the check items, open the throttle by about 1/3 and start the engine.

Page 29

29

Дуже дякуємо Вам за вибір бензинового обприскувача

DOLMAR. Ми раді запропонувати Вам бензиновий обприскувач

DOLMAR, що є результатом довготривалої програми розвитку та

багаторічного знання й досвіду.

Цей обприскувач втілює у собі переваги новітніх технологій та

ергономічного дизайну. Даний виріб є зручним та компактним

професійним інструментом, призначеним для широкого кола

робіт.

Будь ласка, прочитайте, зрозумійте та дотримуйтесь

інструкцій з цієї брошури, оскільки в ній наведені детальні

вказівки щодо роботи інструмента, які дозволять йому

продемонструвати відмінні робочі характеристики. Це

допоможе Вам безпечно досягти найкращих результатів

експлуатації Вашого обприскувача DOLMAR.

Українська

СИМВОЛИ

Під час читання цієї інструкції з експлуатації вкрай важливо розуміти такі символи.

ПОПЕРЕДЖЕННЯ/НЕБЕЗПЕКА

Використовуйте засоби захисту

органів дихання

Прочитайте, зрозумійте і

дотримуйтесь інструкції з експлуатації

Гарячі поверхні – можна обпекти

пальці або руки

Заборонено Пальне (бензин)

Не палити Ручний запуск двигуна

Уникайте контакту з відкритим

полум’ям

Аварійна зупинка

Надягайте міцне взуття із нековзною

підошвою.

Перша допомога

Надягайте відповідний захисний одяг УВІМКНЕННЯ/ЗАПУСК

Надягайте захисні рукавиці ВИМКНЕННЯ/STOP

Під час обприскування не дозволяйте

стороннім особам наближатися

Відрізання пальців або руки об лезо

крильчатки

Не допускайте до зони роботи

сторонніх осіб та домашніх тварин

Довге волосся може заплутатись і

призвести до нещасного випадку

Використовуйте засоби захисту зору

і слуху

Отруйні пари або токсичні гази.

Не використовуйте там, де відсутня

вентиляція.

Зміст

Сторінка

Символи .........................................................................................29

Важливі правила безпеки .............................................................30

Технічні дані ..................................................................................36

Найменування частин ...................................................................37

Інструкції з монтажу ......................................................................38

Перед запуском двигуна ...............................................................40

Запуск та зупинення двигуна .......................................................42

Регулювання холостого ходу ........................................................43

Спосіб використання ....................................................................44

Технічне обслуговування та догляд .............................................50

Зберігання .....................................................................................53

Усунення несправностей ..............................................................55

Page 30

30

31

ВАЖЛИВІ ПРАВИЛА БЕЗПЕКИ

ПОПЕРЕДЖЕННЯ:

● Прочитайте усі застереження та інструкції. Недотримання застережень та

інструкцій може призвести до ураження електричним струмом, займання та/

або тяжкої травми.

Збережіть усі застереження та інструкції для

подальшого використання.

Загальні інструкції

● Для належного і безпечного користування обприскувачем користувач повинен

прочитати, зрозуміти і дотримуватись цієї інструкції з експлуатації (1).

Недостатньо проінформовані користувачі піддають себе та оточуючих людей

небезпеці через невідповідне поводження з інструментом.

● Передавати обприскувач дозволяється виключно особам, які довели, що

мають досвід роботи із обприскувачами.

● Разом із інструментом слід завжди передавати й інструкцію з експлуатації.

● Особи, які користуються цим інструментом уперше, повинні попросити дилера

надати основні інструкції щодо належного поводження з обприскувачем.

● Заборонено користуватись обприскувачем дітям та особам, яким не

виповнилося 18 років. Разом з тим, особам, яким вже виповнилося 16 років,

дозволяється використовувати інструмент виключено з навчальною метою,

однак під безпосереднім наглядом кваліфікованого інструктора.

● Будьте надзвичайно уважними та обережними під час використання

обприскувачів.

● Користуйтесь обприскувачем лише за умови доброго фізичного стану.

● Усі роботи слід виконувати сумлінно та обережно. Користувач несе

відповідальність за інших людей.

● За жодних обставин не використовуйте обприскувач, перебуваючи під

впливом алкоголю або ліків (2).

● Не використовуйте інструмент, коли ви втомлені.

● Збережіть інструкцію для подальшого використання.

Використання інструмента за призначенням

● Використовуйте правильне обладнання. Обприскувач призначений лише для

розприскування рідких хімікатів та інших рідин для боротьби зі шкідниками та

бур’янами у плодових, декоративних садах та огородах, на деревах, кущах

та інших рослинах, як-от кава, тютюн і бавовна. Окрім того, даний інструмент

корисний для догляду за молодими деревами, як-от для боротьби із короїдами

й іншими шкідниками та захворюваннями рослин.

В жодному разі не використовуйте даний інструмент для інших цілей.

Якщо інструмент обладнано відповідною трубкою для функції обприскування,

його можна використовувати для обприскування.

● Використовуйте лише засоби захисту рослин, що спеціально призначені

виробником для використання із обприскувачами та відповідають усім

наявним правилам, стандартам і розпорядженням з техніки безпеки.

Інформацію щодо порядку використання обприскувача можна отримати у

дилера. Дотримуйтесь усіх наявних місцевих правил, стандартів і розпоряджень

з техніки безпеки.

Весь персонал, що відповідає за експлуатацію та обслуговування, має пройти

підготовку та ознайомитись із правилами належного поводження із хімікатами,

що використовуються, а також із правилами надання першої/екстреної допомоги

та утилізації рідких хімікатів.

ПОПЕРЕДЖЕННЯ:

● Ваш обприскувач призначений виключено для професійного використання. Не

передавайте та не здавайте в оренду обприскувач без інструкції з експлуатації.

Переконайтесь, що особи, які будуть користуватись інструментом, розуміють

інформацію, що міститься у даній інструкції з експлуатації.

Засоби індивідуального захисту

● Для зменшення ризику травмування під час використання хімікатів, надягайте