Dolmar 109, 110i, 111, 111i, 115i Service Manual

DOLMAR GmbH • Postfach 70 04 20 • D-2000 Hamburg 70 • Germany

Service Manual

2/93

DOLMAR 109

DOLMAR 110i

DOLMAR 111

DOLMAR 111i

DOLMAR 115i

2

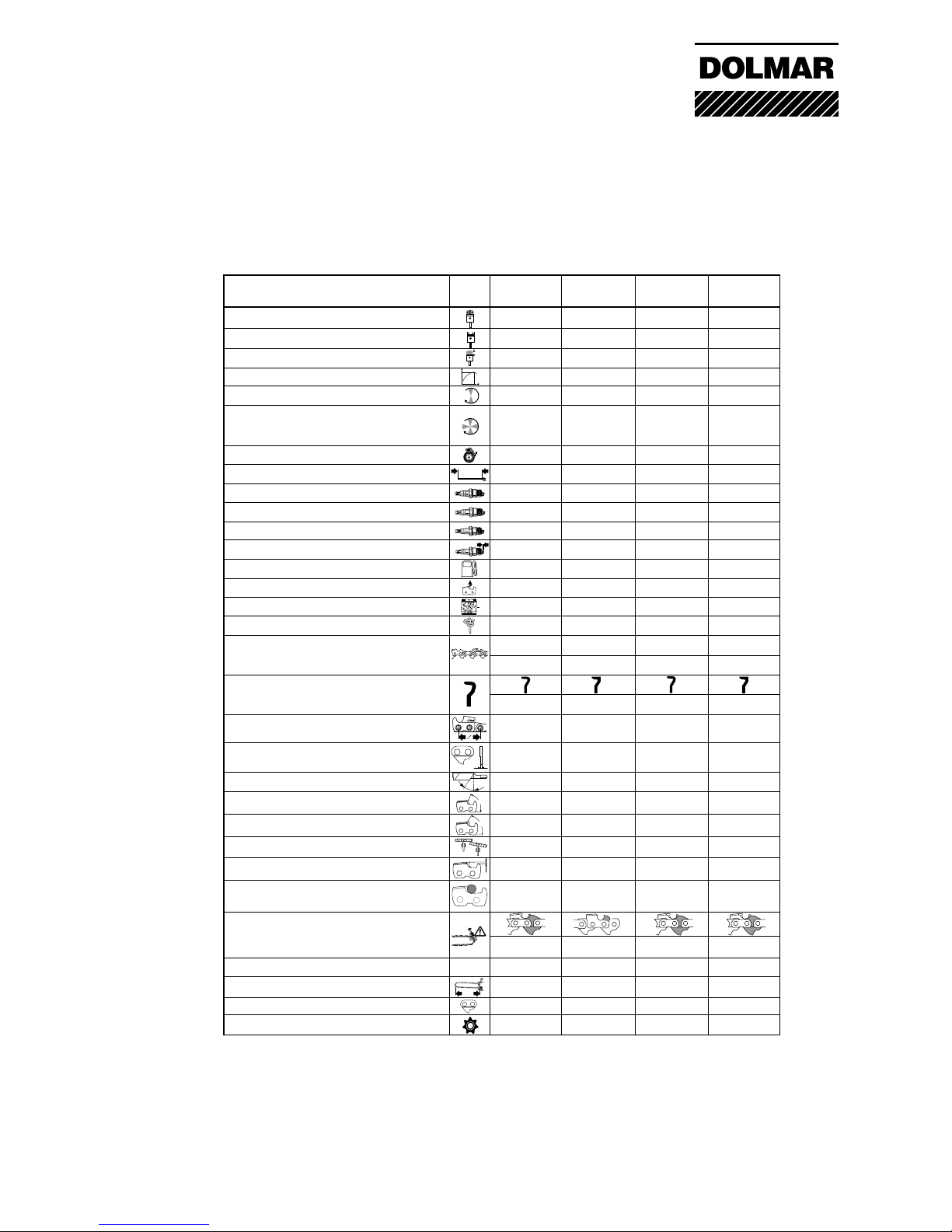

Table of contents

Index Technical data Page 3

Special tools 4

01 Chain brake 5

02 Clutch, clutch drum 6

03 Oil pump 7

04 Ignition system 8

05 Starter assembly 10

06 Carburettor, intake system 11

07 Cover system, air filter 13

08 Vibration dampers, handle 14

09 Fuel tank 15

10 Cylinder and piston 16

11 Crankcase, crankshaft 17

12 Checking operations 18

Torques 19

DOLMAR GmbH

- Bumper Depth Gauge Bumper Bumper

Drive Link Drive Link Drive Link

Type Spur (fixed) Rim (loose) Spur (fixed) Rim (loose)

Cutting length cm 38 33/38 38 45

Drive Link count 56 56/64 56 64

Sprocket Z 7877

Model

109 110i 115i

Displacement cm

3

43 43 52 52

Bore mm 40 40 44 44

Stroke mm 34 34 34 34

Rating kW 2,0 2,3 2,4 2,7

Idling 1/min 2500 2500 2500 2500

Allowed max. engine speed

with bar and chain 1/min 12500 13200 12500 13000

(* with speed limitation)

Gap Flywheel / Coil mm 0,2-0,3 0,2-0,3 0,2-0,3 0,2-0,3

High tension wire length mm 180 180 180 180

Spark plug NGK BPMR-7A BPMR-7A BPMR-7A BPMR-7A

BOSCH WSR-6F WSR-6F WSR-6F WSR-6F

CHAMPION

Elektrode gap mm 0,5 0,5 0,5 0,5

Fuel tank capacity Ltr. 0,56 0,56 0,56 0,56

Oil tank capacity Ltr. 0,28 0,28 0,28 0,28

Carb. adjustment L / H 1/1 1/ 1 1/8 1/1 1/ 1 1/8

Starter rope ø / length mm 3,5 / 980 3,5 / 980 3,5 / 980 3,5 / 980

Saw chain Model 093 084 093 099

Normal profil Low profil Normal profil Low profil

Cutter type

Semi chisel Chisel Semi chisel Chisel

Gauge inch 3/8 .325 3/8 3/8

mm (9,52) (8,2) (9,52) (9,52)

Drive link inch 0.58 0.58 0.58 0.58

mm (1,5) (1,5) (1,5) (1,5)

Filling Angle 35° 30° 35° 25°

Side Angle 85° 75° 85° 60°

Cutting Angle 60° 60° 60° 60°

File Guide Angle 90° 10° 90° 90°

Depth Gage Setting mm 0,65 0,65 0,65 0,65

File ø mm 5,5 4,5 5,5 5,5

Technical data

Kick back reduction

r.p.m.

H

Max.

L

H

S

1

2

90°

10°

r.p.m.

L

From 1/2 Cutter mm 4,8 4,0 4,8 4,8

3

DOLMAR GmbH

111/111i

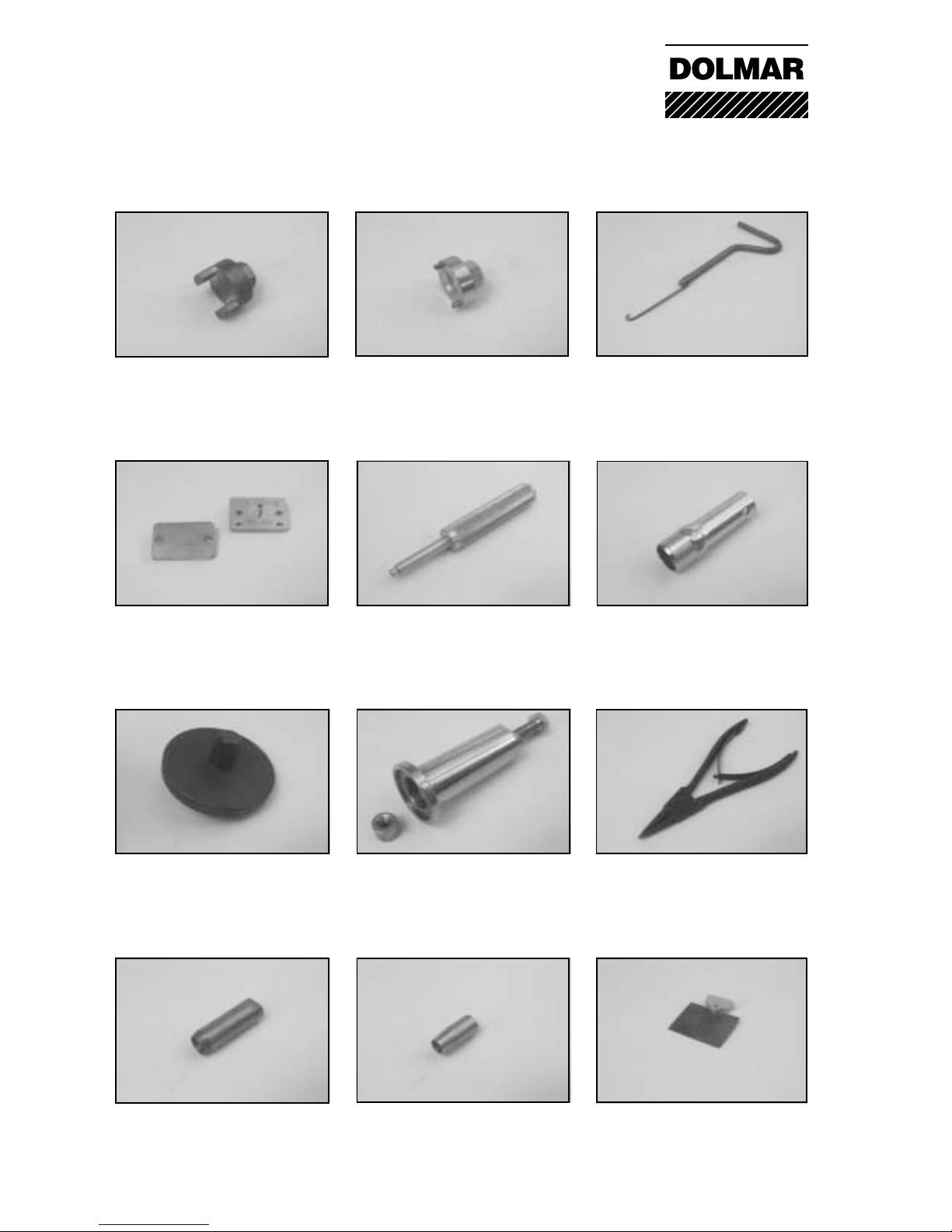

Special tools

Puller for tension spring

of chain brake

950 237 000

Mounting tool for

clutch hub

944 500 690

Mounting tool for

clutch hub

944 500 680

Special socket wrench

for rubber buffer

944 500 621

Drift for piston pin

944 603 260

Sealing plate for

leakage test of crankcase

944 603 020 / 944 603 030

Mounting for roler bearing

crankcase

950 500 050

Puller for drive worm

of oil pump

957 433 000

Snap ring pincer for external snap

rings of starting system

946 101 010

Radial ring extractor

944 500 900

Mounting sleeve

for radial rings

944 500 550

Setting gauge for

ignition armature

944 500 890

4

DOLMAR GmbH

DOLMAR GmbH

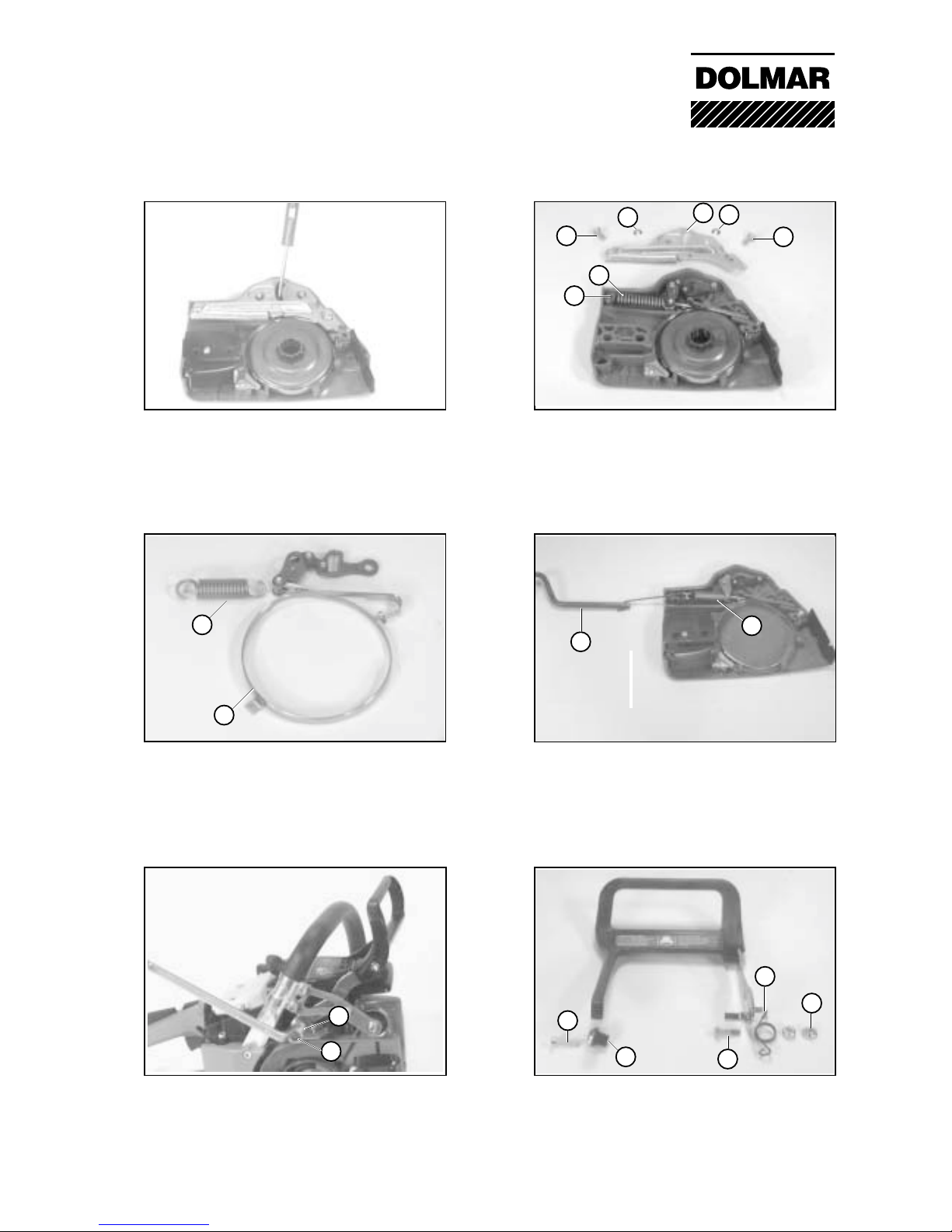

3

4

5

5

7

6

5

4

2

1

9

10

6

8

11

12

13

14

16

12

11

01-04 Removing the hand guard

Remove the nut (11) and push the screw (12)

in direction of the cylinder. Unscrew screw

(13) on the starter side and remove the insert

(14).

01-02 Relieving the tension spring

To remove the brake band it is necessary to

remove the cover plate (3). For this purpose

unscrew screws (4) and remove retaining

rings (5). Relieve the tension spring (6) by

levering it off the housing peg (7).

01-02 Replacing the brake band

A damaged or defective brake band (8) and a

damaged or defective tension spring must be

replaced without delay (6).

Caution: Safety components

01-04 Fitting the hand guard

When fitting the hand guard, ensure that the

compression spring (16) is installed correctly.

01-02 Pretensioning the tension spring and

the brake gate

Following the installation of the brake band,

engage the tension spring in the brake gate

(9) and using the pulling hook (10) no.

950.237.000 pass the spring over the peg (7).

01-02 Releasing the chain brake

Insert the clutch drum (1) and by levering

down the brake gate, using a screwdriver (2),

release the chain brake.

01 Chain brake

DOLMAR GmbH

6

4

2

6

3

5

6

7

8

1

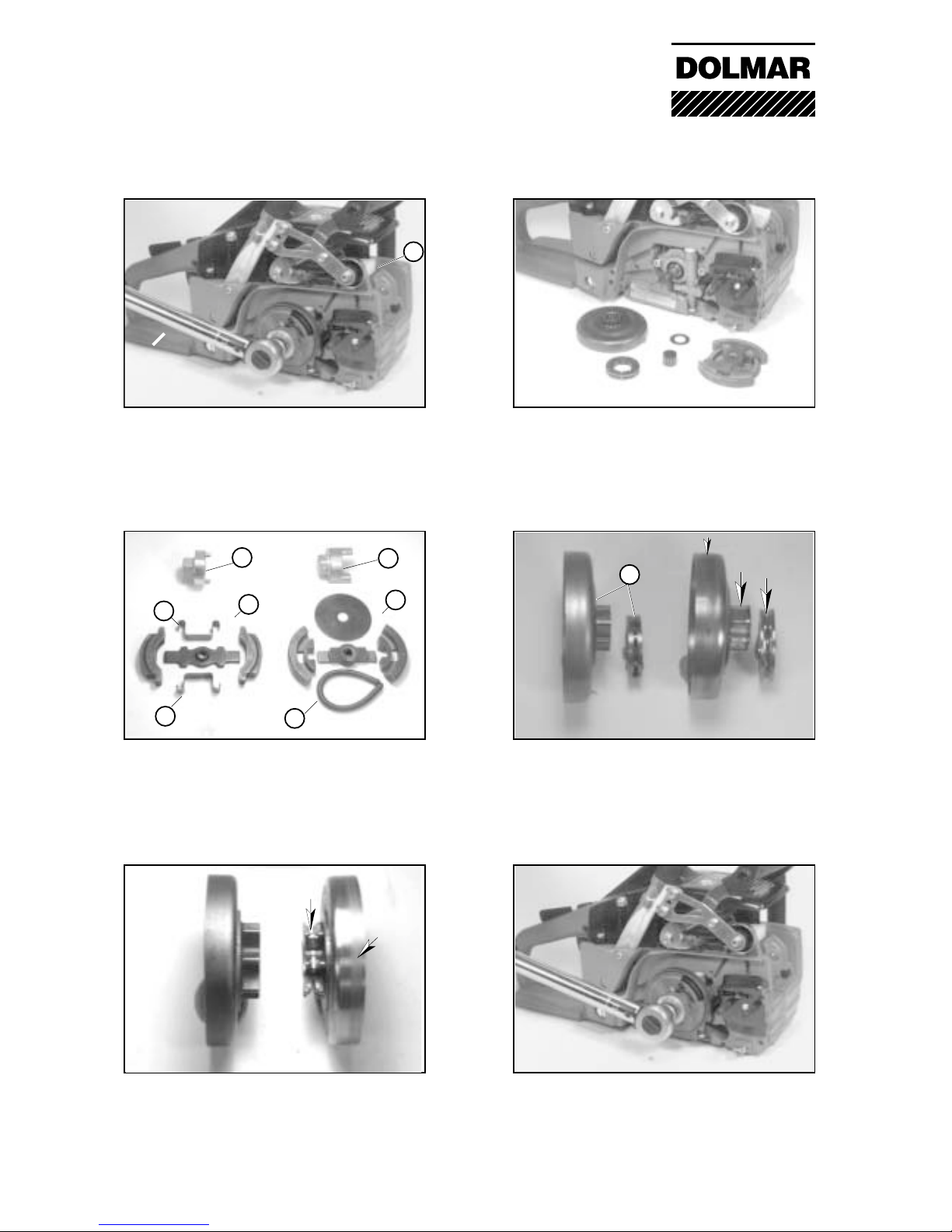

02-03 Checking the clutch drum /sprocket

of models 109 / 111

Worn sprockets or clutch drums (arrows)

must be replaced.

02-01 Removing the clutch drum

For the removal of the clutch/clutch drum it is

necessary to immobilize the cylinder unit.

For this purpose unscrew the silencer and

insert the piston stopper wedge (1) into the

exhaust duct of the cylinder.

02-01 Unscrewing the clutch

Use spanner (2), no. 944 500 680 for clutch

(3) and use spanner (4) no. 944 500 690

for clutch (5) .

Caution: Left-hand thread

02-01 Differing clutch designs

Clutch (5) for models 109, 110, 111.

Clutch (3) for model 115.

Clutch springs may be replaced as a

complete set (6) or individually (7).

02-03 Mounting the clutch drum and clutch

Prior to installation, lightly grease the clutch

drum bearing and tighten the clutch using a

torque of 35 Nm.

02-03 Checking the clutch drum /sprocket

Worn sprockets (arrows) or clutch drums must

be replaced.

Ring pinion system (8) is standard equipment

only for models 110/115. As replacement also

available for models 109/111.

02 Clutch drum

Loading...

Loading...