Dodge USAF 200 User Manual

INSTRUCTION MANUAL

for

DODGE® USAF 200 Series

Direct Mount Pillow Blocks

WARNING: Because of the possible danger to persons( s) or property from accidents which may result from the improper

use of products, it is important that correct procedures be followed. Products must be used in accordance with the

engineering information specified in the catalog. Proper installation, maintenance and operation procedures must be

observed. The instructions in the instruction manuals must be followed. In spections should b e made as necessary to a ssure

safe operation under prevailing conditions. Proper guards and other suitable safety devices or procedures as may be

desirable or as may be specified in safety codes should b e provided, and are neither provided by Baldor Electric Company

nor are the responsibility of Baldor Electric Company. This unit and its ass ociated equi pment must be installed, adj usted and

maintained by qualified personnel who are familiar with the construction and operation of all equipment in the system and the

potential hazards involved. When risk to persons or property may be involved, a fails afe device must be an integral part of

the driven equipment beyond the speed reducer output shaft.

1

GENERAL INFORMATION

DODGE USAF bearings conform with all appropriate

AFBMA standards. They are available in either adapter or

direct mounting styles for 17/16" through 8”, and up to 220

mm diameter shafts. A wide variety of seals is available

including metallic LER, TRIPLE-TECT non-metallic with vring, Drop-in TRIPLE-TECT with neoprene v-ring, Auxiliary

Taconite, or Split non-metallic. TRIPLE-TECT is provided

as standard on complete assemblies. DODGE USAF

housings provide you with maximum application flexibility.

Cast-in dimples allow for easy field modification for vents,

lube ports and sensors. Oversized drains and an oil

equalization hole make USAF ready for circulating oil

systems off the shelf. For hostile environments, USAF

offers optional cast-closed end housings, stainless

hardware kits, and nylon coating. Complete installation,

maintenance, and modification instructions for direct

mounted units are provided in this manual. Modification

instructions are shown on Table 7.

INSPECTION

Inspect shaft. Ensure that the shaft is smooth, straight,

clean, and within commercial tolerances.

Inspect bearing. Do not allow bearing to be exposed t o

any dirt or moisture. Do not remove slushing compound as

it acts as both a protectant and lubricant and is also

compatible with standard greases.

WARNING

To ensure that drive is not unexpectedly started, turn off

and lock out or tag power source before proceeding.

Failure to observe these precautions could result in bodily

injury.

INSTALLATION

NOTE: Housing caps and bases are not

interchangeable; they must be matched with mating

half. Install non-expansion bearing first.

DIRECT MOUNTED BEARINGS

1. Measure the internal clearance of the bearing

before mounting. Place the bearing in a upright position

as shown in Figure 1. Seat the inner ring and roller

elements by pressing down firmly on the inner ring bore

while rotating the inner ring a few times. Position the roller

assemblies so that a roller is at the top-most position on

both sides. For bore sizes above 6½” only, press these top

rollers inward ensuring contact with center guide flange.

Using a feeler gauge measure the cleara nce for both sides

by inserting as far as possible and sliding ove r top of roller

(Figure 1). Write down the measured clearance and

compare with specifications (Table A). NOTE: Do not

rotate bearing when moving feeler between roller and

outer ring.

NOTE: TRIPLE TECT™ seals are standard seals up to 10

(220 mm) bore. For assistance in installing seals use seal

instruction manual 499665 supplied with the seals.

2. Install the bearing parts in the following sequence:

(refer to the replacement parts drawing and table.)

a) V-ring Seal – Slide one of the V-ri ng seals onto the

shaft, making sure lip is toward the bearing. (NOTE:

Do not install V-ring seal on seal ring until housing cap

has been set in place and tightened.)

b) Seal Ring – Install a seal ring on shaft with largest

O.D. toward bearing.

c) Bearing – Make sure that the internal clearance has

been written down. Install bearing. Bearings with

cylindrical bore up to 2¾ (70 mm) may be cold

mounted on the shaft. Apply coat of light oil to the shaft

and bearing bore, then press the bearing o n by usi ng a

mechanical or hydraulic device or use the mounting

nut to drive the bearing onto the shaft.

Bearings with cylindrical bore above 2¾ (70 mm) are

heated for mounting on shaft. Bearings, heated in oil

between 200°F - 215°F, when still in a heated

condition, should have the bore wiped dry with a clean

cloth. The bearing should be rapidly pushed on the

shaft and positioned squarely against the shoulder. A

slight screwing motion during fitting facilitates the

mounting. It is advisable to use gloves. Large bearings

are generally handled with a hoist or crane.

For cylindrical bore direct mounted bearings, it is not

necessary to check internal clearance after mounting.

It is, however, important to verify the shaft diameters

(Tables 1 & 2) and to measure the unmounted internal

clearance to ensure conformance to specifications

(Table A).

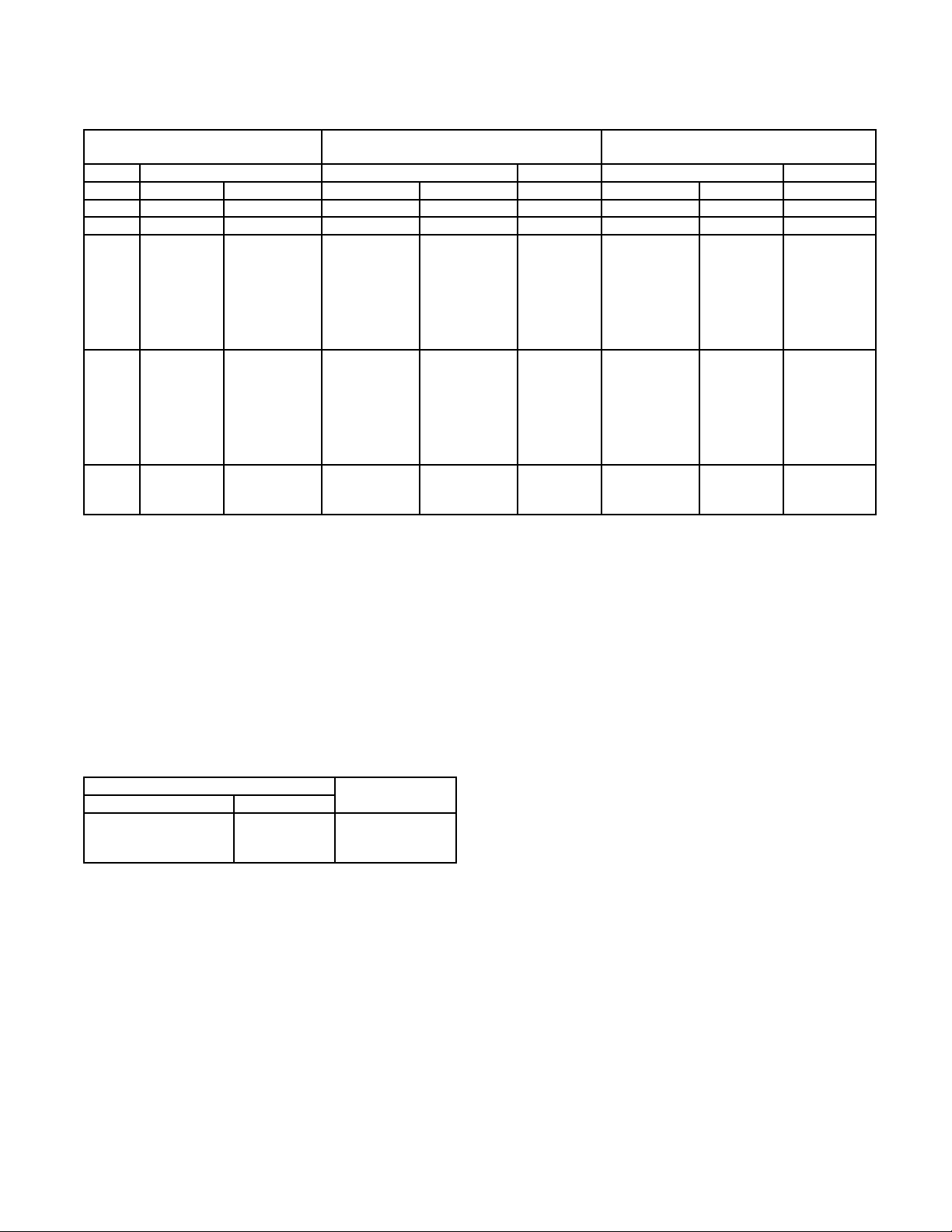

Table A.

Radial Internal Clearance in Self-Aligning Roller

Bearings (Values in .0000 inches)

Bore Diameter

MM

Over Incl. Low High

14 24 14 18

24 30 16 22

30 40 18 24

40 50 22 30

50 65 26 36

65 80 32 44

80 100 39 53

120 140 57 75

140 160 65 87

160 180 71 95

180 200 79 103

200 225 87 114

With Cylindrical Bore

2

TABLE 1 – SHAFT B

EARING SEAT DIAMETERS FOR

CYLINDRICAL BORE MOUNTED PILLOW BLOCKS

Bearing Bore

Diameter

MM Inches Shaft Diameter (S-1) MEAN Shaft Diameter (S-1) MEAN

Nom. Max. Min. Max. Min. FIT Max. Min. FIT

75 2.9528 2.9522 2.9540 2.9532 .0011T 2.9543 2.9536 .0014T

80 3.1496 3.1490 3.1508 3.1500 3.1511 3.1504 .0015T

85 3.3464 3.3457 3.3179 3.3470 3.3484 3.3475

90 3.5433 3.5425 3.5447 3.5438 3.5452 3.5443

95 3.7402 3.7394 3.7416 3.7407 .0014T 3.7421 3.7412 .0019T

100 3.9370 3.9362 3.9384 3.9375 3.9389 3.9380

105 4.1338 4.1331 4.1353 4.1344 4.1358 4.1349

110 4.3307 4.3299 4.3321 4.3312 4.3326 4.3317

120 4.7244 4.7236 4.7258 4.7249 4.7263 4.7254

125 4.9212 4.9203 4.9229 4.9219 4.9235 4.9225

130 5.1181 5.1171 5.1197 5.1187 5.1203 5.1193

140 5.5118 5.5108 5.5134 5.5124 5.5140 5.5130

150 5.9055 5.9045 5.9071 5.9061 .0016T 5.9077 5.9067 .0022T

160 6.2992 6.2982 6.3008 6.2998 6.3014 6.3004

170 6.6929 6.6919 6.6945 6.6935 6.6951 6.6941

180 7.0866 7.0856 7.0882 7.0872 7.0888 7.0878

190 7.4803 7.4791 7.4821 7.4809 7.4829 7.4817 .0026T

200 7.8740 7.8728 7.8758 7.8746 .0019T 7.8772 7.8760 .0032T

220 8.6614 8.6602 8.6632 8.6620 8.6646 8.6634

These fits apply to roller bearings with inner ring rotation under radial and thrust loads.

Bearing Bore Diameter Normal Load High Load

Up to 220 mm P/C = 0.10 to 0.15 P/C>0.15

Where

P = Equivalent Dynamic Load on the Bearing (lbs.)

C = Basic Dynamic Load Rating of Bearing (lbs.)

TABLE 2 – TOLERANCE

Shaft Diameter (S-2 & S3)

Over Including Tolerance

2" (50 mm) 4" (100 mm) +.000" to -.004"

4" (100 mm) 6" (150 mm) +.000" to -.005"

Over 6" (150 mm) +.000" to -.006"

d. Lockwasher and Lo cknut – Install the lock-washer

with inner prong located in the keyway of the shaft and

pointing towards the bearing. Install locknut,

chamfered face toward bearing. Tighten locknut using

a spanner wrench.

Locate a lockwasher tab that aligns with a locknut slot

and bend tab into slot. If slot is past tab, then tighten,

not loosen, locknut to meet a washer tab.

Normal Load High Load

e. Seal Ring – Install second seal ring with large O.D.

toward locknut.

f. V-ring Seal – Slide second V-ring seal onto the

shaft, again making certain lip is toward bearing.

NOTE: Do not install V–ring seal on seal ring until

housing cap has been set in place and tightened.

Steps e. and f. are not necessary if pillow block

housing is a "cast closed end" style.

3. Remove any paint, dirt or burrs from the mating

surfaces of the housing halves. Thoroughly clean seal

grooves on both sides. Set lower half of housing on base

and apply oil to the bearing seats.

4. Apply grease to the bearing and seal rings. The

lubricant should be smeared between the rolling elements.

(See Grease Lubrication Section below.) This step and th e

first sentence of Step 8 do not apply for oil lubricated

bearings.

3

Loading...

Loading...