Dodge TXT-HXT 305A, TXT 425A, TXT 509A, TXT-HXT 709, TXT-HXT 609 User Manual

...

PARTS REPLACEMENT MANUAL

FOR

DODGE® TORQUE-ARM ™

Speed Reducers

Straight Bore & Taper Bushed

TXT/HXT 309A - 315A - 325A

TXT/HXT 409A - 415A - 425A

TXT/HXT 509B - 515B - 525B

TXT/HXT 609 - 615 - 625

TXT/HXT 709 - 715 - 725

TXT/HXT 305A

TXT/HXT 405A

TXT/HXT 505A

TXT 605

TXT 705

WARNING: Because of the possible danger to per sons(s) or property from accidents which may result from the improper use

of products, it is important that correct procedures be f ollowed. Products must be used in accordance with the engineering

information specified in the catalog. Proper installation, maintenance and operation procedures must be observed. The

instructions in the instruction manuals must be followed. Inspections should be made as necessary to assure safe o peration

under prevailing conditions. Proper guards and other suitable safety devic es or procedures as may be desirable or as may be

specified in safety codes should be provided, and are neither provided by Baldor Electric Company nor are the responsibility of

Baldor Electric Company. This unit and its associated equipment must be installed, adjusted and maintained by qualified

personnel who are familiar with the construction and operation of all equipment in the system and the potential hazards

involved. When risk to persons or property may be involved, a holding de vice must be an integral part of the driven e quipment

beyond the speed reducer output shaft.

INSTALLATION

1. Use eyebolts or lifting lugs to lift reducer.

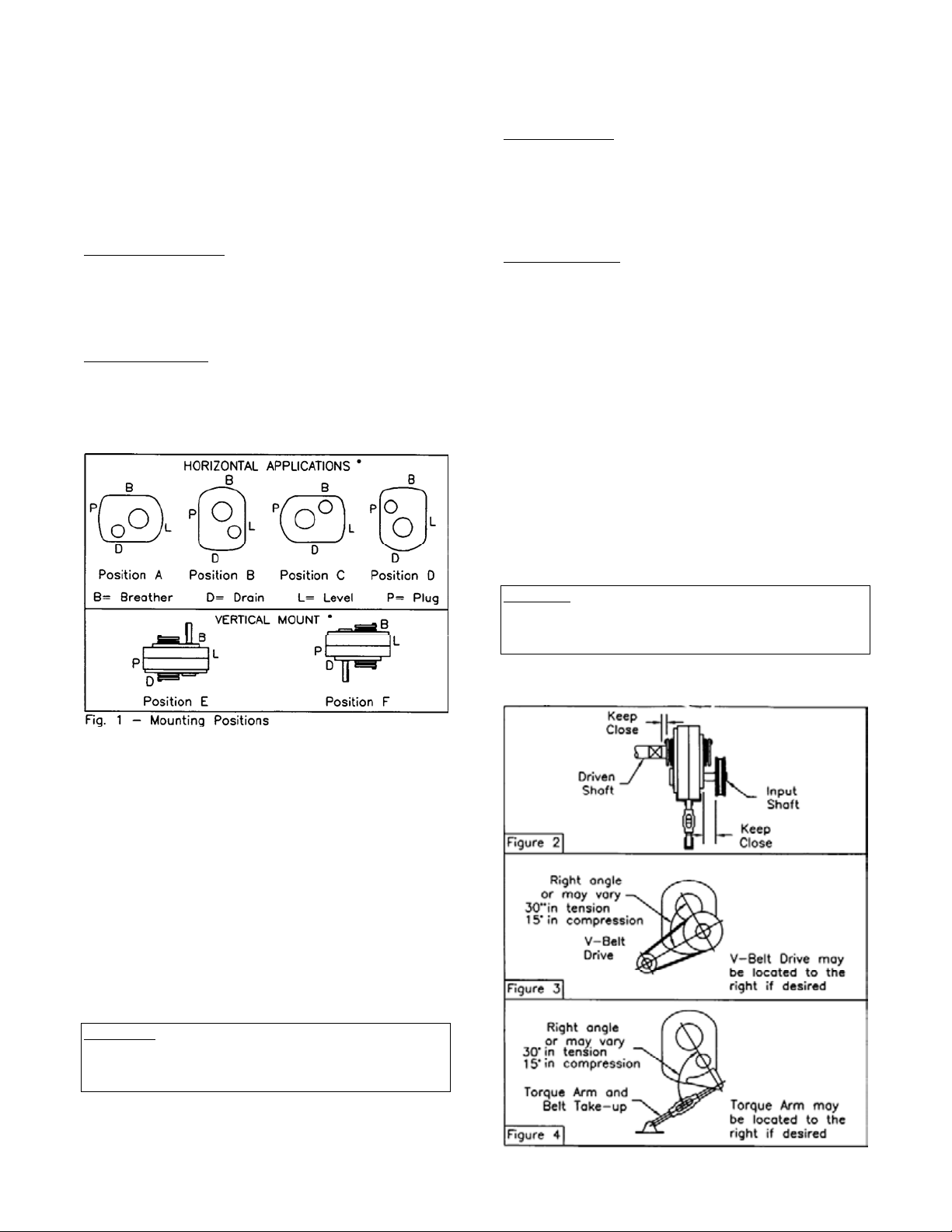

2. Determine the running positions of the reducer. (See

Fig. 1) Note that the reducer is supplied with either 4 or 7

plugs; 4 around the sides for horizontal installations and 1

on each face for vertical installations. These plugs must be

arranged relative to the running positions as follows:

Horizontal Installations - Install the magnetic drain plug in

the hole closest to the bottom of the reducer. Throw away

the tape that covers the filter/ventilation plug in shipment

and install plug in topmost hole. Of the 3 remaining plugs

on the sides of the reducer, the lowest one is the minimum

oil level plug.

Vertical Installations - Install the filter/ventilation plug in the

hole provided in the top face of the reducer housing. Use

the hole in the bottom face for the magnetic drain plug. Of

the 5 remaining holes on the sides of the reducer, use a

plug in the upper housing half for the minimum oil level

plug.

For Straight Bore: Mount reducer on driven shaft as close

to bearing as practical. If bushings are used, assemble

bushings in reducer first. A set of bushings for one reducer

consists of one keyseated bushing and one plain bushing.

Extra length setscrews are furnished with the reducer.

Driven shaft should extend through full length of speed

reducer. Tighten both setscrews in each collar.

For Taper Bushed: Mount reducer on driven shaft per

instruction sheet No. 499629 packed with tapered

bushings.

4. Install sheave on input shaft as close to reducer as

practical. (See Fig. 2)

5. Install motor and V-belt drive so belt will

approximately be at right angles to the center line between

driven and input shaft. (See Fig. 3) This will permit

tightening the V-belt with the torque arm.

6. Install torque arm and adapter plates using the long

reducer bolts. The bolts may be shifted to any of the holes

on the input end of the reducer.

7. Install torque arm fulcrum on a flat and rigid support

so that the torque arm will be approximately at right angles

to the center line through the driven shaft and the torque

arm anchor screw. (See Fig. 4) Make sure that there is

sufficient take-up in the turnbuckle for belt tension

adjustment when using V-belt drive.

• Below 15 RPM output speed, oil level must be adjusted

to reach the highest oil level plug (P.).

The running position of the reducer in a horizontal

application is not limited to the four positions shown in Fig.

1. However, if running position is over 20* in position "B" &

"D" or 5* in position "A" & "C", either way from sketches,

the oil level plug cannot be used safely to check the oil

level, unless during the checking, the torque arm is

disconnected and the reducer is swung to within 20* for

position "A" & "C" or 5* for position "B" & "D" of the

positions shown in Fig. 1. Because of the many possible

positions of the reducer, it may be necessary or desirable

to make special adaptations using the lubrication filling

holes furnished along with other standard pipe fittings,

stand pipes and oil level gauges as required.

3. Mount reducer on driven shaft as follows:

WARNING: To ensure that drive is not unexpectedly

started, turn off and lock out or tag power source before

proceeding. Failure to observe these precautions could

result in bodily injury.

CAUTION: Unit is shipped without oil. Add proper amount

of recommended lubricant before operating. Failure to

observe this precaution could result in damage to or

destruction of the equipment.

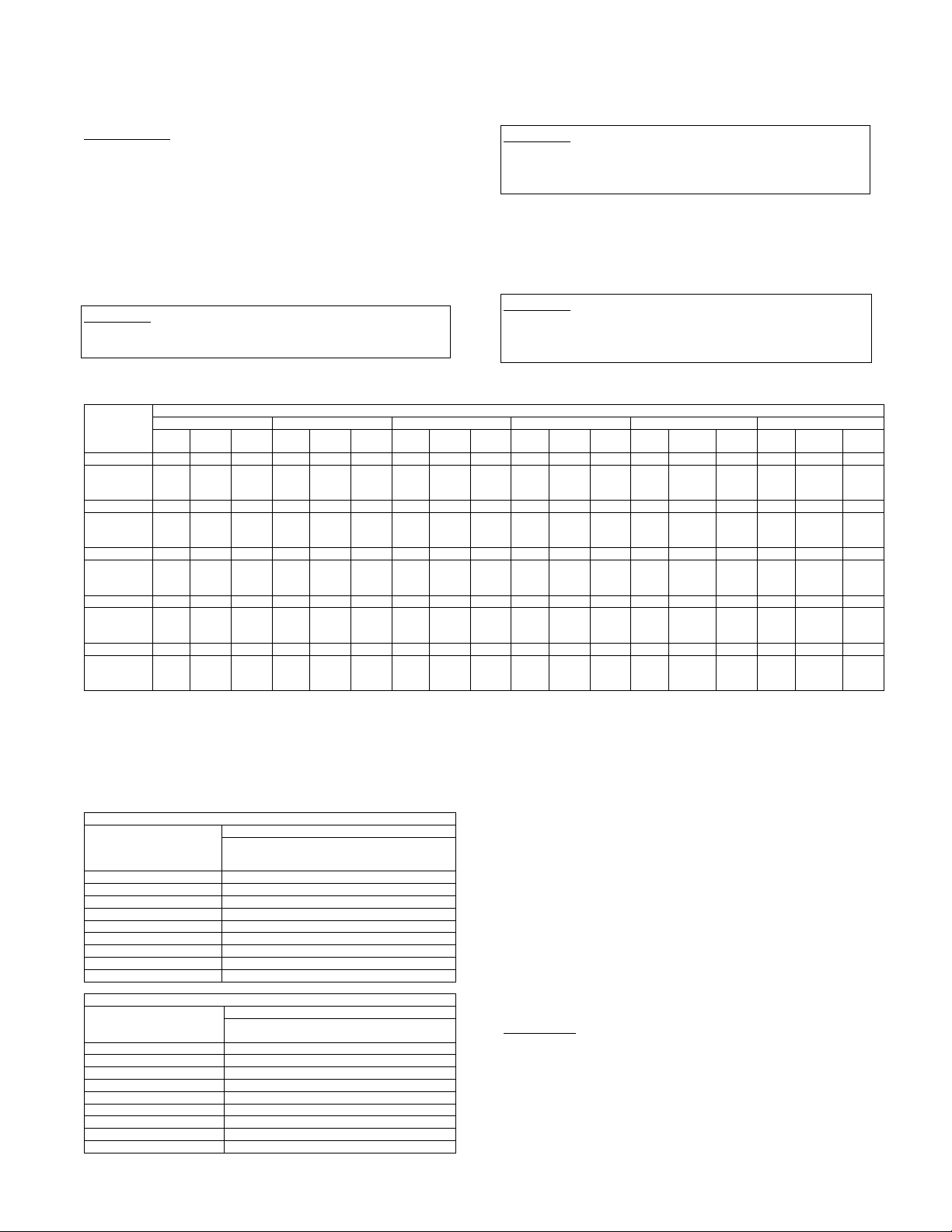

8. Fill gear reducer with recommended lubricant. See

page 3, table 1.

2

LUBRICATION

IMPORTANT: Because reducer is shipped without oil, it is

necessary to add the proper amount of oil before running.

Use a high-grade petroleum base rust and oxidation

inhibited (R&O) gear oil - see tables. Follow instructions

CAUTION: Too much oil will cause overheating and too

little will result in gear failure. Check oil level regularly.

Failure to observe this precaution could result in bodily

injury.

on reducer warning tags, and in the installation manual.

Under average industrial operating conditions, the

lubricant should be changed every 2500 hours of

operating or every 6 months, whichever occurs first. Drain

reducer and flush with kerosene, clean magnetic drain

plug and refill to proper level with new lubricant.

CAUTION: Extreme pressure (EP) lubricants are not

recommended for average operating conditions. Failure to

observe these precautions could result in bodily injury.

Under extreme operating conditions, such as rapid rise

and fall of temperature, dust, dirt, chemical particles,

chemical fumes, or oil sump temperatures above 200°F,

the oil should be changed every 1 to 3 months, depending

on severity of conditions.

CAUTION: Do not use EP oils containing slippery

additives such as graphite or molybdenum disulfide in the

reducer when backstop is used. These additives will

destroy sprag action.

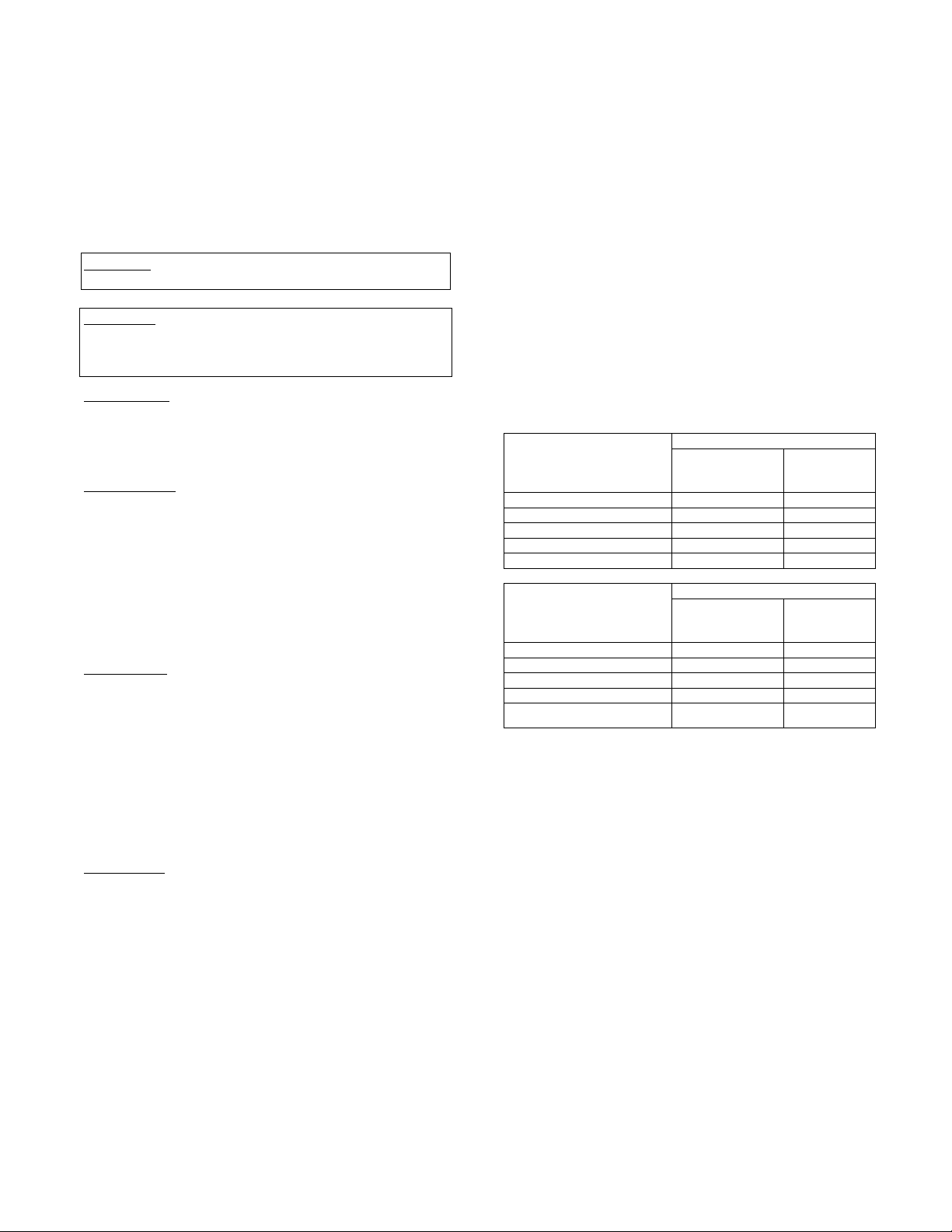

Table 1 - Oil Volumes •

Consult DODGE for proper oil level for reducers with backstops and which are mounted in C-position or D-position.

Reducer

Size

TXT/HXT

305A 28 .88 .83 48 1.50 1.42 44 1.38 1.30 44 1.38 1.30 80 2.50 2.37 100 3.13 2.96

309A

315A

325A

405A 48 1.50 1.42 72 2.25 2.13 68 2.13 2.01 60 1.88 1.77 128 4 3.79 166 4.88 4.62

409A

415A

425A

505A 108 3.38 3.19 136 4.25 4.02 124 3.88 3.67 120 3.75 3.54 248 7.75 7.33 288 9 8.52

509B

515B

525B

605 144 4.50 4.3 184 5.75 5.4 144 4.50 4.3 160 5 4.7 384 12 11.4 352 11 10.4

609

615

625

705 240 7.50 7.1 288 9 8.5 240 7.50 7.1 296 9.25 8.8 608 19 18 552 17.25 16.3

709

715

725

† Position A † Position B † Position C † Position D † Position E † Position F

c

Qt.

L Oz.

Oz.

48 1.50 1.42 48 1.50 1.42 24 .75 .71 72 2.25 2.13 84 2.63 2.48 96 3 2.84

60 1.88 1.77 72 2.25 2.13 40 1.25 1.18 56 1.75 1.66 108 3.38 3.19 136 4.25 4.02

104 3.25 3.08 128 4 3.79 104 3.25 3.08 128 4 3.79 224 7 6.62 272 8.50 8.04

136 4.25 4.0 160 5 4.7 136 4.25 4.0 160 5 4.7 276 8.63 8.2 292 9.13 8.6

208 6.50 6.1 256 8 7.6 232 7.25 6.9 296 9.25 8.7 492 15.38 14.6 524 16.38 15.5

Approximate Volume of Oil Required to Fill Reducer to Oil Level Plug

c

Qt.

L Oz.

c

Qt.

L Oz.

c

Qt.

L Oz.

Qt.

c

L Oz.

c

Qt.

† Refer to Figure 1 on page 2 for mounting positions.

c U.S. Measure: 1 quart = 32 fluid ounces = .94646 liters.

Table 2 – Oil Recommendations

ISO Grades for Average Operating Conditions

Ambient Temperatures of 15ºF thru 60ºF

Output

RPM

301–400 220

201–300 220

151–200 220

126–150 220

101–125 220

81–100 220

41–80 220

11–40 220

1–10 220

Ambient Temperatures of 50ºF thru 125ºF

Output

RPM

301–400 320

201–300 320

151–200 320

126–150 320

101–125 320

81–100 320

41–80 320

11–40 320

1–10 320

TXT3A–7

HXT3A–7

Reducer Size

Reducer Size

TXT3A–7

HXT3A–7

TXT305A–705

HXT305A–505A

TXT305A–705

HXT305A–505A

Note: If reducer position is to vary from those shown in figure 1,

either more or less oil may be required. Consult Dodge.

If output is less than 15 RPM, consult Dodge.

• Below 15 RPM output speed, oil level must be adjusted to reach the

highest oil level plug (P.).

Guidelines for TORQUE-ARM™ Reducer Long-Term

Storage

During periods of long storage, or when waiting for

delivery or installation of other equipment, special care

should be taken to protect a gear reducer to have it ready

to be in the best condition when placed into service.

By taking special precautions, problems such as seal

leakage and reducer failure due to lack of lubrication,

improper lubrication quantity, or contamination can be

avoided. The following precautions will protect gear

reducers during periods of extended storage:

Preparation

1. Drain the oil from the unit. Add a vapor phase corrosion

inhibiting oil (VCI-105 oil by Daubert Chemical Co.) in

accordance with Table 3.

2. Seal the unit airtight. Replace the vent plug with a

standard pipe plug and wire the vent to the unit.

3

L

3. Cover the shaft extension with a waxy rust

preventative compound that will keep oxygen away from

the bare metal. (Non-Rust X-110 By Daubert Chemical

Co.)

4. The instruction manuals and lubrication tags are

paper and must be kept dry. Either remove these

documents and store them inside or cover the unit with a

durable waterproof cover which can keep moisture away.

5. Protect reducer from dust moisture, and other

contaminants by storing the unit in a dry area.

6. In damp environments, the reducer should be packed

inside a moisture-proof container or an envelope of

polyethylene containing a desiccant material. If the

reducer is to be stored outdoors, cover the entire exterior

with a rust preventative.

When placing the reducer into service:

1. Assemble the vent plug into the proper hole.

2. Clean the shaft extensions with petroleum solvents.

3. Fill the unit to the proper oil level using a

recommended lubricant. The VCI oil will not affect the new

lubricant.

4. Follow the installation instructions provided in this

manual

Table 3 – Quantities of VCI #105 Oil

Size Quarts or Liters

TXT / HXT 3A – 305A .1

TXT / HXT 4A – 405A .2

TXT / HXT 5B – 505A .3

TXT / HXT6 – TXT605 .4

TXT / HXT7 – TXT705 .5

VCI #105 & #10 are interchangeable.

VCI #105 is more readily available.

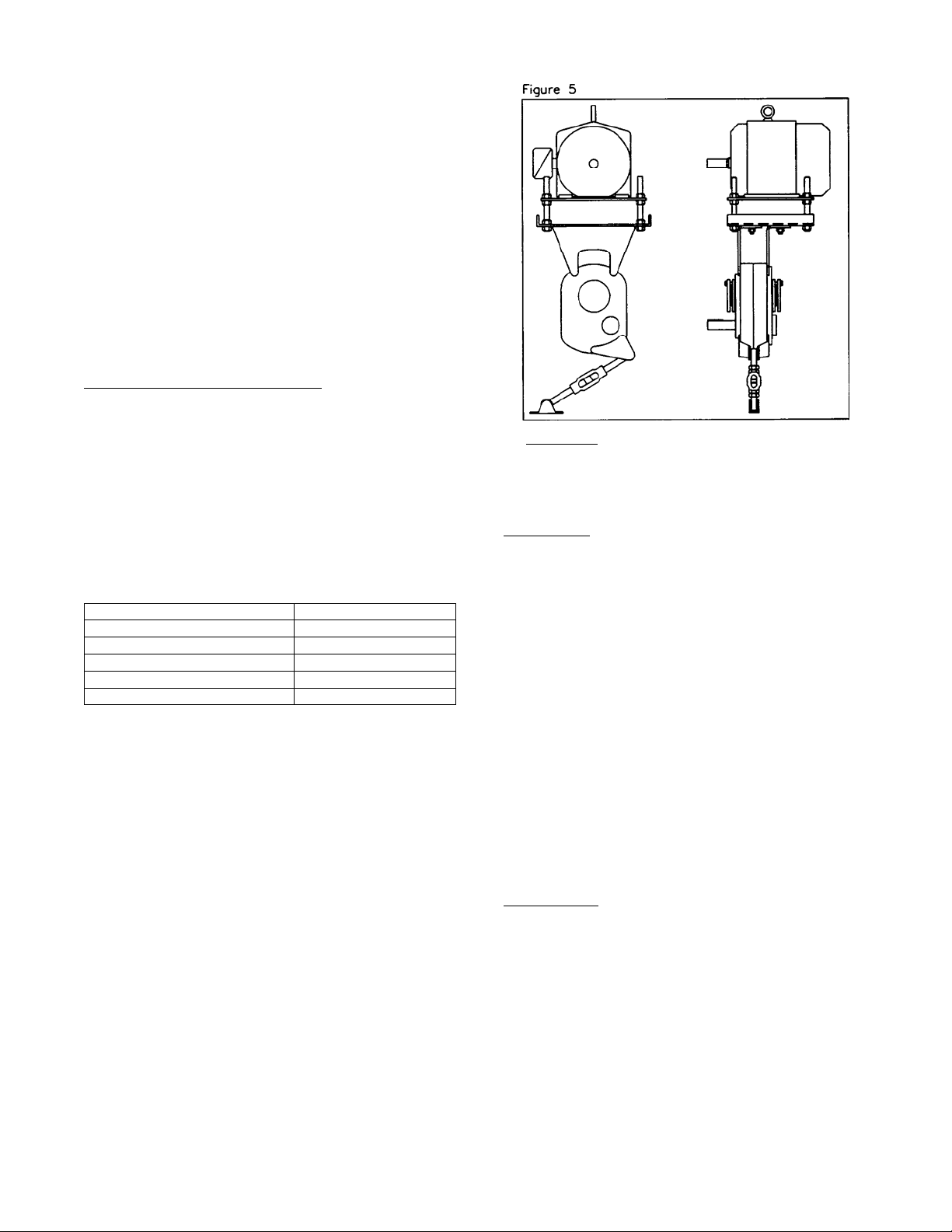

MOTOR MOUNTS

The motor mount must be installed on output end of

reducer as shown in Figure 5.

Remove two or three (as required) housing bolts on output

end of reducer. Place the motor mount in position and

install the longer housing bolts supplied with the motor

mount. Tighten bolts to torque specified in Table 4.

Install motor, drive sheave, and driven sheave so that the

driven sheave is as close to the reducer housing as

practical. Install V-belt and tension with the four adjusting

screws provided on the T-A M motor mount.

Check all bolts to see that they are securely tightened.

WARNING: Belt guard removed for illustration

purposes. Do not operate if belt guard is not in place.

REPLACEMENT OF PARTS

IMPORTANT: Using tools normally found in a

maintenance department, a DODGE TORQUE-ARM

speed reducer can be disassembled and reassembled by

careful attention to the instructions following.

Cleanliness is very important to prevent the introduction of

dirt into the bearings and other parts of the reducer. A tank

of clean solvent, an arbor press, and equipment for

heating bearings and gears (for shrinking these parts on

shafts) should be available.

Our factory is prepared to repair reducers for customers

who do not have proper facilities or who, for any reason,

desire factory service.

The oil seals are of the rubbing type and considerable

care should be used during disassembly and reassembly

to avoid damage to the surface which the seals rub on.

The keyseat in the input shaft, as well as any sharp edges

on the output hub should be covered with tape or paper

before disassembly or reassembly. Also, be careful to

remove any burrs or nicks on surfaces of the input shaft or

output hub before disassembly or reassembly.

Ordering Parts: When ordering parts for reducer, specify

reducer size number, reducer serial number, part name,

part number, and quantity.

It is strongly recommended that, when a pinion or gear is

replaced, the mating pinion or gear is replaced also.

If the large gear on the output hub must be replaced, it is

recommended that an output hub assembly of a gear

assembled on a hub be ordered to secure undamaged

surfaces on the output hub where the output seals rub.

However, if it is desired to use the old output hub, press

the gear and bearing off and examine the rubbing surface

under the oil seal carefully for possible scratching or other

damage resulting from the pressing operation. To prevent

oil leakage at the shaft oil seals, the smooth surface of the

output hub must not be damaged.

4

If any parts must be pressed from a shaft or from the

output hub, this should be done before ordering parts to

make sure that none of the bearings or other parts are

damaged in removal. Do not press against outer race of

any bearing.

Because old shaft oil seals may be damaged in

disassembly, it is advisable to order replacements for

these parts.

Removing Reducer from Shaft

CAUTION: Remove all external loads from drive before

removing or servicing drive or accessories.

WARNING: To ensure that drive is not unexpectedly

started, turn off and lock out or tag power source before

proceeding. Failure to observe these precautions could

result in bodily injury.

Straight Bore: Loosen screws in both output hub collars.

Remove the collar next to the end of the shaft. This

exposes three puller holes in the output hub to permit the

use of a wheel puller. In removing the reducer from the

shaft, be careful not to damage the ends of the hub.

Taper Bushed:

1. Remove bushing screws.

2. Place the screws in the threaded holes provided in

the bushing flanges. Tighten the screws alternately and

evenly until the bushings are free on the shaft. For ease of

tightening screws, make sure screw threads and threaded

holes in bushing flanges are clean.

3. Remove the outside bushing, the reducer, and then

the inboard bushing.

Disassembly:

1. Position the reducer on its side and remove all

housing bolts. Drive dowel pins from housing. Gently tap

the output hub and input shaft with a soft hammer

(rawhide, not a lead hammer) to separate the housing

halves. Open housing evenly to prevent damage to the

parts inside.

2. Lift shaft, gear, and bearing assemblies from

housing.

3. Remove seals from housing.

Reassembly:

1. Output Hub Assembly: Heat gear to 325°F to 350°F

to shrink onto hub. Heat bearings to 270°F to 290°F to

shrink onto hub. Any injury to the hub surfaces where the

oil seals rub will cause leakage, making it necessary to

use a new hub.

2. Countershaft Assembly: Shaft and pinion are integral.

Press gear and bearings on shaft. Press against inner (not

outer) race of bearings.

3. Input Shaft Assembly: Shaft and pinion are integral.

Press bearings on shaft. Press against inner (not outer)

race of bearings.

4. Drive the two dowel pins into place in the right-hand

housing half. Apply RTV732 sealant to carriers for R.H.

side(backstop side) of reducer. Install carriers and torque

bolts per table 4.

5. Place R.H. housing half on blocks to allow for

protruding end of output hub.

6. Install bearing cups in right-hand housing half,

making sure they are properly seated.

7. Mesh output hub gear and small countershaft gear

together and set in place in housing. Set input shaft

assembly in place in the housing. Make sure bearing

rollers (cones) are properly seated in their cups. set

bearing cups for left-hand housing half in place on their

rollers.

8. Clean housing flange surfaces on both halves,

making sure not to nick or scratch flange face. Place a

1/8 bead of RTV732 sealant on flange face. (make sure

RTV is placed between bolt holes and inside of flange

face) Place other housing half into position and tap with a

soft hammer (rawhide, not lead hammer) until housing

bolts can be used to draw housing halves together.

Torque housing bolts per torque values listed in table 4.

Table 4 – Recommended Torque Values

Reducer

Size

TXT / HXT 305A & 3A 50–45 17–15

TXT / HXT 405A & 4A 50–45 30–27

TXT / HXT 505A & 5B 75–68 30–27

TXT605 & TXT / HXT 6 75–68 30–27

TXT705 & TXT / HXT 7 150–135 50–45

Reducer

Size

TXT / HXT 305A & 3A 17–15 17–15

TXT / HXT 405A & 4A 30–27 30–27

TXT / HXT 505A & 5B 30–27 30–27

TXT605 & TXT / HXT 6 30–27 30–27

TXT705 & TXT / HXT 7

Dry Torque (lb.–ft.)

Housing

Bolts

Dry Torque (lb.–ft.)

C’shaft

Bearing Cover

Screws

50–45 50–45

9. Place output hub seal carrier in position without

shims and install two carrier screws diametrically opposed.

Torque each screw to 25 in.-lbs. Rotate the output hub to

roll in the bearings and then torque each screw to 50 in.lbs. Again turn output hub to roll in the bearings. With a

feeler or taper gage, measure the gap between the

housing and the carrier flange. To determine the required

shim thickness, take the average of the two feeler gage

readings. Remove carrier and install the required shims

plus .002. Install carrier with shims and torque bolts per

table 4. Rotate hub assy, tap lightly with rawhide mallet on

end of hub, while rotating, to ensure bearings are seated.

Using a dial indicator check end play of hub bearings,

endplay should be .001-.003. Repeat this process as

necessary to obtain proper end play. Place a 1/8 diameter

bead of RTV732 sealant inside the carrier at the shim I.D.

and install carrier on reducer housing. Torque carrier bolts

to value shown in Table 4.

10. Adjust the countershaft bearings using the same

method as in step 8 above. The axial end play should be

.001” to .003”.

11. Again, using the same procedure as in step 8,

adjust the input shaft bearings, except the axial end play

should be .002” to .004”.

5

Output Hub

Seal Carrier

Screws

Input Shaft

Seal Carrier

Screws

Loading...

Loading...