Page 1

INSTALLATION MANUAL

TA1M thru TA7M Motor Mounts

TA3ML thru TA7ML (Long Series) Motor Mounts

for DODGE® TORQUE-ARM Speed Reducers

(Sizes TXT1 thru TXT7)

INSTALLATION

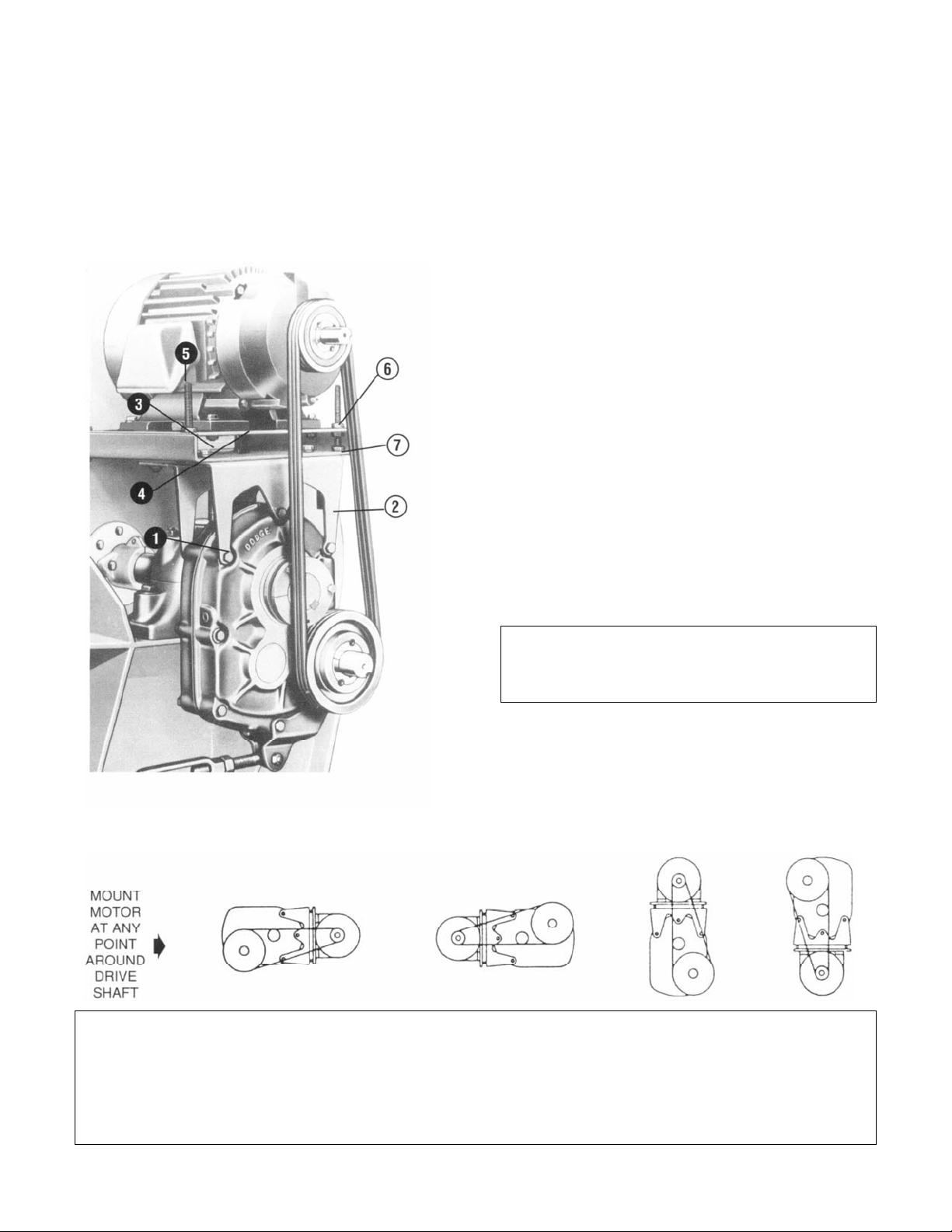

Note: Refer to photo for position of all parts before installation.

1. Remove the two or three bolts required for mounting the TAM

and TAML Motor Mounts from the reducer housing. Install

the front and rear supports (2) using the new reducer bolts

(1) supplied with the motor mount. Make sure support flanges

face output side of reducer. Tighten bolts securely.

2. Mount bottom plate (3) on supports with bolts supplied. Insert

bolts (7) from top through slotted holes. Add flatwasher,

lockwasher, and nut. Hand tighten.

3. Thread two nuts (6) on each threaded stud (5) leaving

approximately 1″ of stud protruding at one end. Insert

threaded stud with 1″ of threads through corner holes of

bottom plate, thread a hex nut (6) on the stud and tighten

securely.

4. Slide top plate (4) over the threaded stud, making sure

center handling hole is positioned opposite input side of

reducer. Thread a hex nut (6) on the studs and tighten

securely.

5. Locate the proper position for the motor and bolt it to the top

plate. Tighten bolts securely.

WARNING: To ensure that drive is not unexpectedly started, turn

off and lock out or tag power source before proceeding. Remove

all external loads from drive before removing or servicing drive or

accessories. Failure to observe these precautions could result in

bodily injury.

6. Install motor sheave and reducer sheave as close to motor

and reducer housings as possible. Accurately align the motor

and reducer sheave by sliding bottom plate in relation to

supports. Tighten bolts (7) securely.

7. Install V-belts and tension belts by alternately adjusting nuts

(6) on the threaded studs (jackscrews). Make certain that all

bolts are securely tightened, the V-belt drive is properly

aligned and an appropriate belt guard is installed before

operating the drive.

Note: Guards have been removed for photographic purposes.

WARNING: Because of the possible danger to persons(s) or property from accidents which may result from the improper use of products, it is

important that correct procedures be followed: Products must be used in accordance with the engineering information specified in t he catalog

Proper installation, maintenance and operation procedures must be observed. The instructions in the instruction manuals must be followed.

Inspections should be made as necessary to assure safe operation under prevailing conditions. Proper guards and other suitable safety

devices or procedures as may be desirable or as may be specified in safety codes should be provided, and are neither provided by Baldor

Electric Company nor are the responsibility of Baldor Electric Company. This unit and its associated equipment must be installed, adjusted

and maintained by qualified personnel who are familiar with the construction and operation of all equipment in the system and the potential

hazards involved. When risk to persons or property may be involved, a holding device must be an integral part of the driven equipment beyond

the speed reducer output shaft.

Page 2

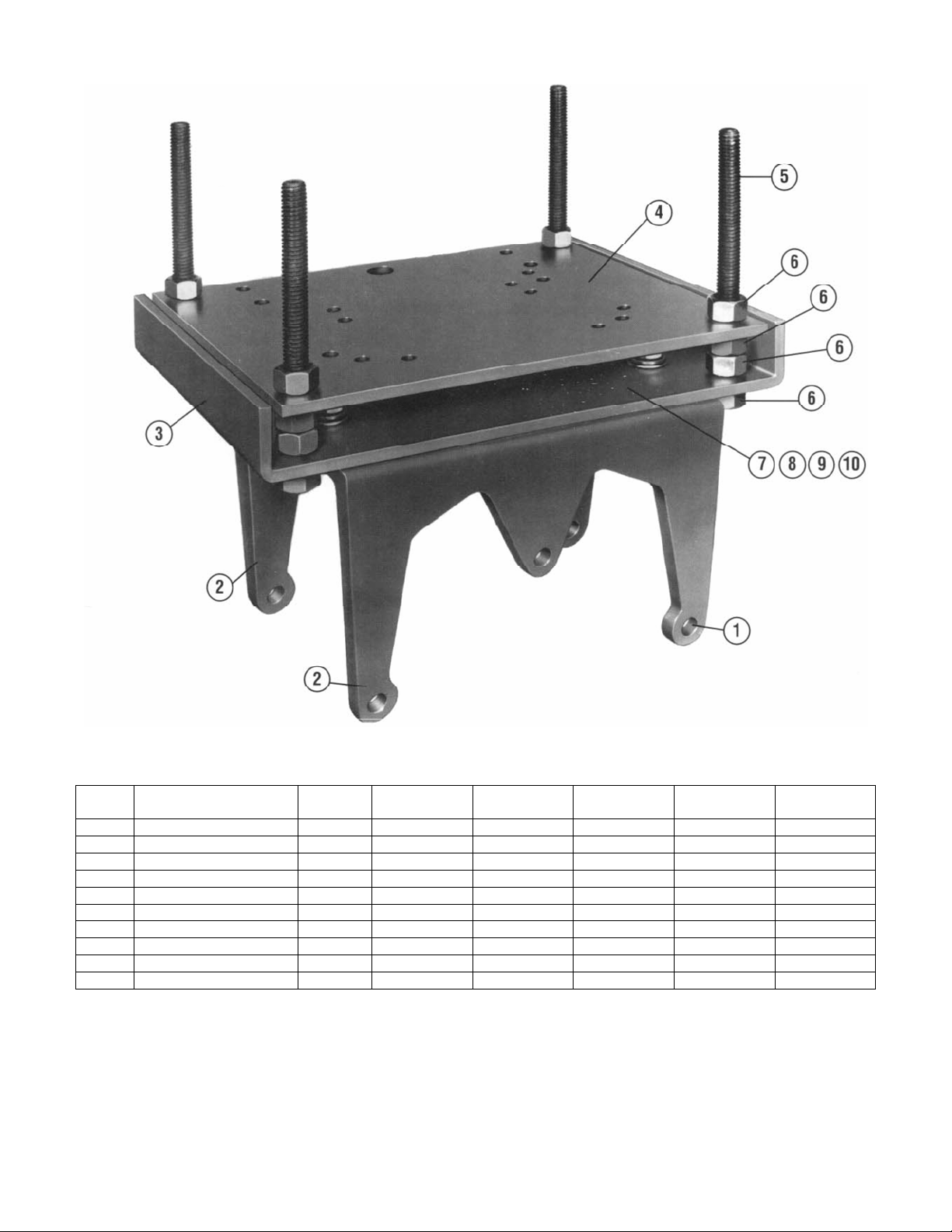

REPLACEMENT PARTS FOR TA3ML THRU TA7ML MOTOR MOUNTS

REF.

NO.

1 HOUSING BOLTS 3 411732 411733 411734 411735 411736

2 SUPPORT 2 243386 244354 245386 246386 247386

3 BOTTOM PLATE 1 351180 354183 354183 356213 356267

4 TOP PLATE 1 351181 354184 354184 356214 356268

5 THREADED STUD 4 408004 408003 408003 408003 408591

6 HEX NUT 16 407122 407279 407279 407279 407214

7 BOLT 4 411102 411102 411102 411102c 411102c

8 WASHER 4 419078 419078 419078 419078c 419078c

9 LOCKWASHER 4 419019 419019 419019 419019c 419019c

10 NUT 4 407282 407282 407282 407282 407282

NAME OF

PART

NO.

REQ’D

TA3ML

PART NO.

TA4ML

PART NO.

TA5ML

PART NO.

TA6ML

PART NO.

TA7ML

PART NO.

c 6 REQ'D. ON TA6ML & TA7ML

Page 3

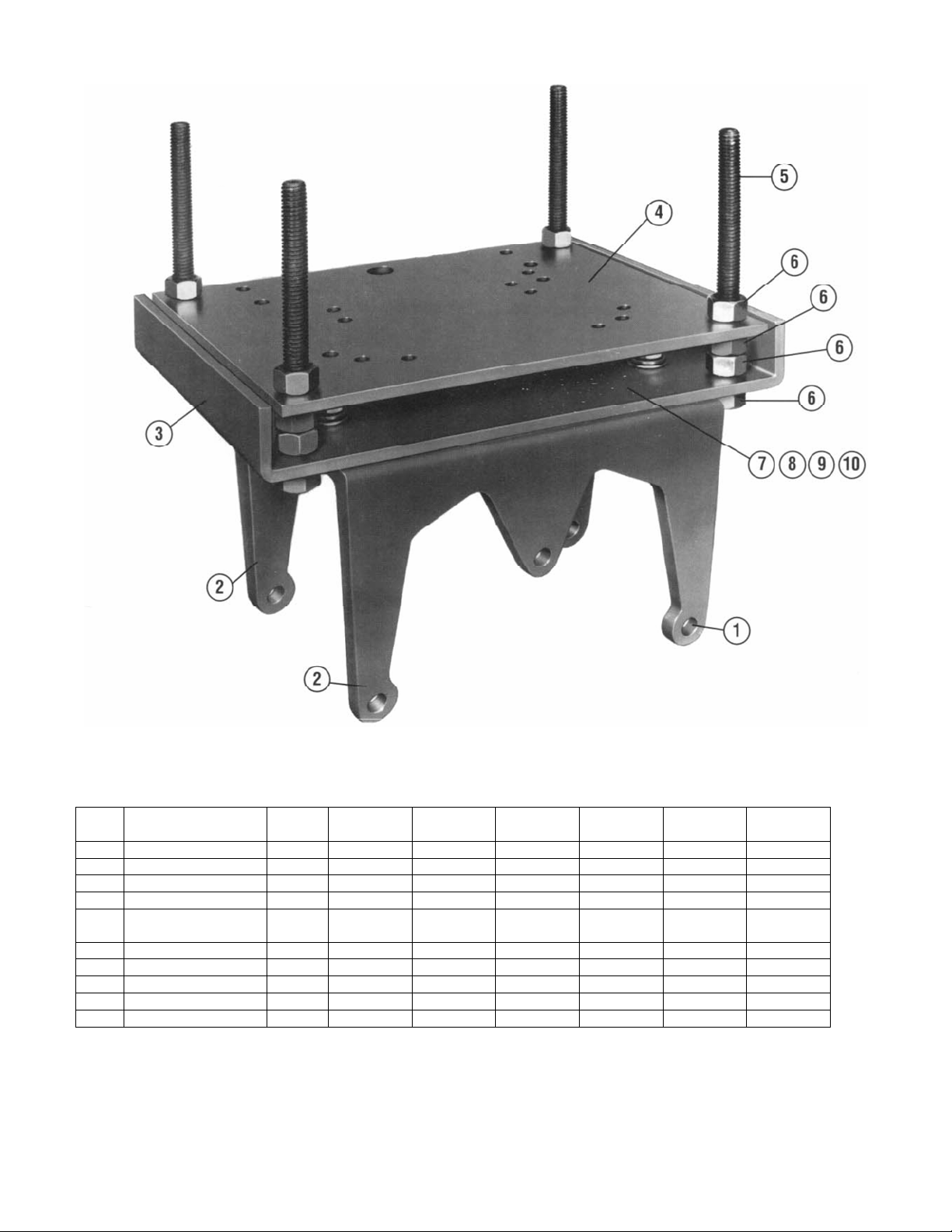

REPLACEMENT PARTS FOR TA1M THRU TA7M MOTOR MOUNTS

REF.

NO.

10 NUT 4 407282 407282 407282 407282 407282 407282

NAME OF

PART

1 HOUSING BOLTS *3 411731 411732 411733 411734 411735 411736

2 SUPPORT 2 241385 243385 244355 245385 246385 247385

3 BOTTOM PLATE 1 351180 351180 354183 354183 356213 356267

4 TOP PLATE 1 351181 35181 354184 354184 356214 356268

5 THREADED

STUD

6 HEX NUT 16 407122 407122 407279 407279 407279 407214

7 BOLT 4 411102 411102 411102 411102 411102c 411102c

8 WASHER 4 419078 419078 419078 419078 419078c 419078c

9 LOCKWASHER 4 419019 419019 419019 419019 419019c 419019c

NO.

REQ’D

4 408004 408004 408003 408003 408003 408591

TA1M

PART NO.

TA3M

PART NO.

TA4ML

PART NO.

TA5M

PART NO.

TA6M

PART NO.

TA7M

PART NO.

* 2 REQ’D. ON TA1M

c 6 REQ'D. ON TA6M & TA7M

Page 4

www.baldor.com www.ptplace.com www.dodge-pt.com www.reliance.com

Baldor Electric Company Headquarters

P.O. Box 2400, Fort Smith, AR 72902-2400 U.S.A., Ph: (1) 479.648.5792, Fax (1) 479.648.5792, International Fax (1) 479.648.5895

DODGE/Reliance Division

6040 Ponders Court, Greenville, SC 29615-4617 U.S.A., Ph: (1) 864.297.4800, FAX: (1) 864.281.2433

Copyright © 2007 Baldor Electric Company All Rights Reserved. Printed in USA.

04/07

3C-K

This material is not intended to provide operational instructions. Appropriate instruction

manuals and precautions should be studied prior to installation, operation or maintenance

of equipment.

Loading...

Loading...