Page 1

DR RESTRAINTS 8O - 1

RESTRAINTS

TABLE OF CONTENTS

page page

RESTRAINTS

DESCRIPTION ..........................2

OPERATION ............................4

WARNING

WARNINGS - RESTRAINT SYSTEM ........5

DIAGNOSIS AND TESTING - SUPPLEMENTAL

RESTRAINT SYSTEM ...................6

STANDARD PROCEDURE

STANDARD PROCEDURE - HANDLING

NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS .........................6

STANDARD PROCEDURE - SERVICE

AFTER A SUPPLEMENTAL RESTRAINT

DEPLOYMENT.........................7

STANDARD PROCEDURE - VERIFICATION

TEST ................................8

ACM COVER

REMOVAL .............................9

INSTALLATION ..........................9

AIRBAG CONTROL MODULE

DESCRIPTION .........................10

OPERATION ...........................10

REMOVAL .............................11

INSTALLATION .........................12

AUTOMATIC LOCKING RETRACTOR

DESCRIPTION .........................13

OPERATION ...........................14

CHILD RESTRAINT ANCHOR

DESCRIPTION .........................14

OPERATION ...........................16

REMOVAL .............................16

INSTALLATION .........................17

CLOCKSPRING

DESCRIPTION .........................18

OPERATION ...........................18

STANDARD PROCEDURE - CLOCKSPRING

CENTERING .........................19

REMOVAL .............................20

INSTALLATION .........................21

DRIVER AIRBAG

DESCRIPTION .........................22

OPERATION ...........................23

REMOVAL .............................23

INSTALLATION .........................24

FRONT CENTER SEAT BELT & RETRACTOR

REMOVAL .............................25

INSTALLATION .........................26

FRONT CENTER SEAT BELT

REMOVAL .............................26

INSTALLATION .........................27

FRONT OUTBOARD SEAT BELT &

RETRACTOR

REMOVAL

REMOVAL - STANDARD CAB ............28

REMOVAL - QUAD CAB ................29

INSTALLATION

INSTALLATION - STANDARD CAB .........31

INSTALLATION - QUAD CAB .............32

FRONT OUTBOARD SEAT BELT BUCKLE

REMOVAL .............................33

INSTALLATION .........................34

PASSENGER AIRBAG

DESCRIPTION .........................34

OPERATION ...........................35

REMOVAL .............................35

INSTALLATION .........................37

PASSENGER AIRBAG ON/OFF SWITCH

DESCRIPTION .........................38

OPERATION ...........................38

REMOVAL .............................39

INSTALLATION .........................39

REAR CENTER SEAT BELT & RETRACTOR

REMOVAL .............................39

INSTALLATION .........................40

REAR OUTBOARD SEAT BELT & RETRACTOR

REMOVAL .............................41

INSTALLATION .........................42

REAR SEAT BELT BUCKLE

REMOVAL

REMOVAL - CENTER & LEFT OUTBOARD . . 43

REMOVAL - CENTER ANCHOR & RIGHT

OUTBOARD..........................43

INSTALLATION

INSTALLATION - CENTER & LEFT

OUTBOARD..........................45

INSTALLATION - CENTER ANCHOR &

RIGHT OUTBOARD ....................45

SEAT BELT SWITCH

DESCRIPTION .........................46

OPERATION ...........................46

DIAGNOSIS AND TESTING - SEAT BELT

SWITCH ............................47

SEAT BELT TENSIONER

DESCRIPTION .........................47

OPERATION ...........................48

SEAT BELT TENSION REDUCER

DESCRIPTION .........................48

OPERATION ...........................49

Page 2

8O - 2 RESTRAINTS DR

DIAGNOSIS AND TESTING - SEAT BELT

TENSION REDUCER ...................49

SEAT BELT TURNING LOOP ADJUSTER

REMOVAL .............................50

INSTALLATION .........................50

SIDE CURTAIN AIRBAG

DESCRIPTION .........................51

OPERATION ...........................51

REMOVAL .............................52

INSTALLATION .........................53

RESTRAINTS

DESCRIPTION

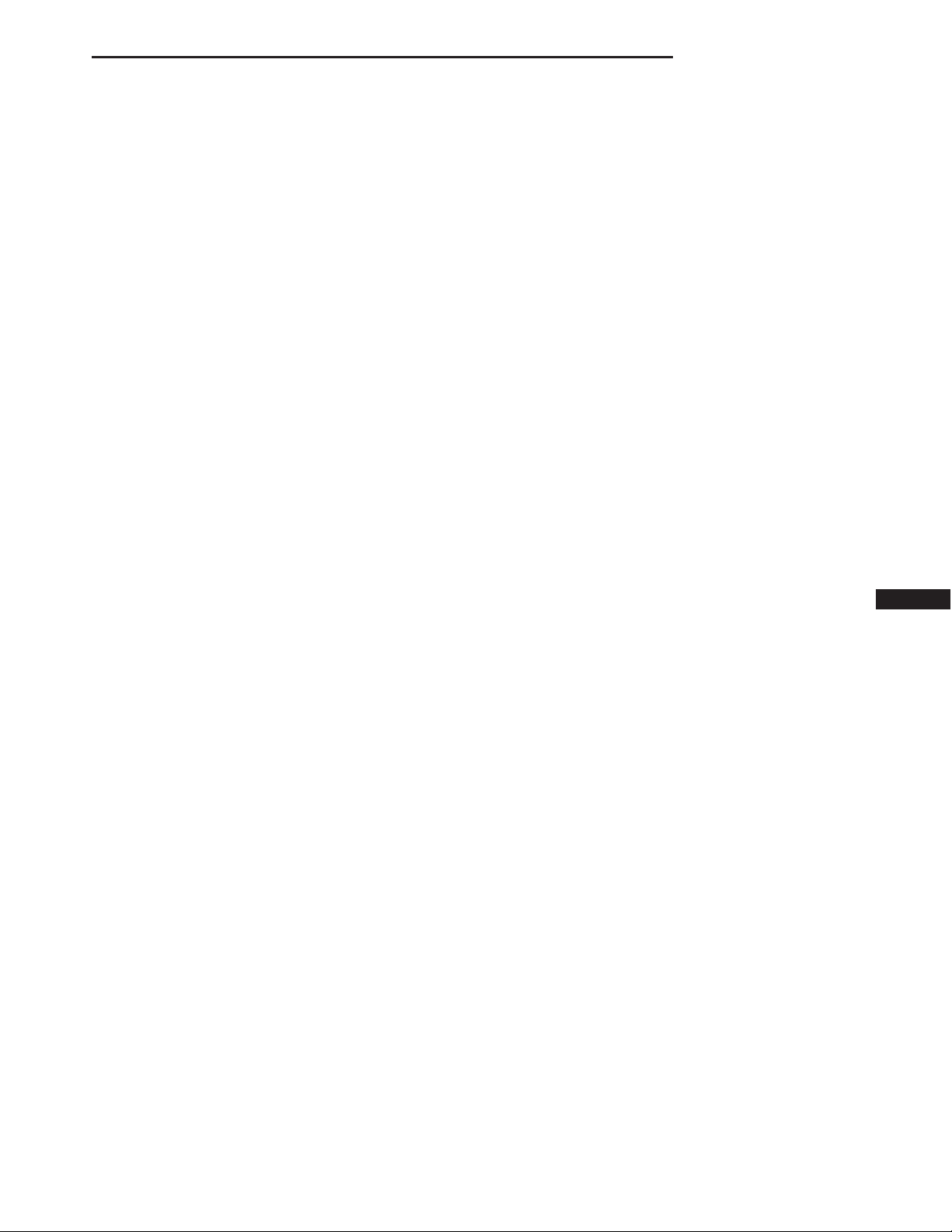

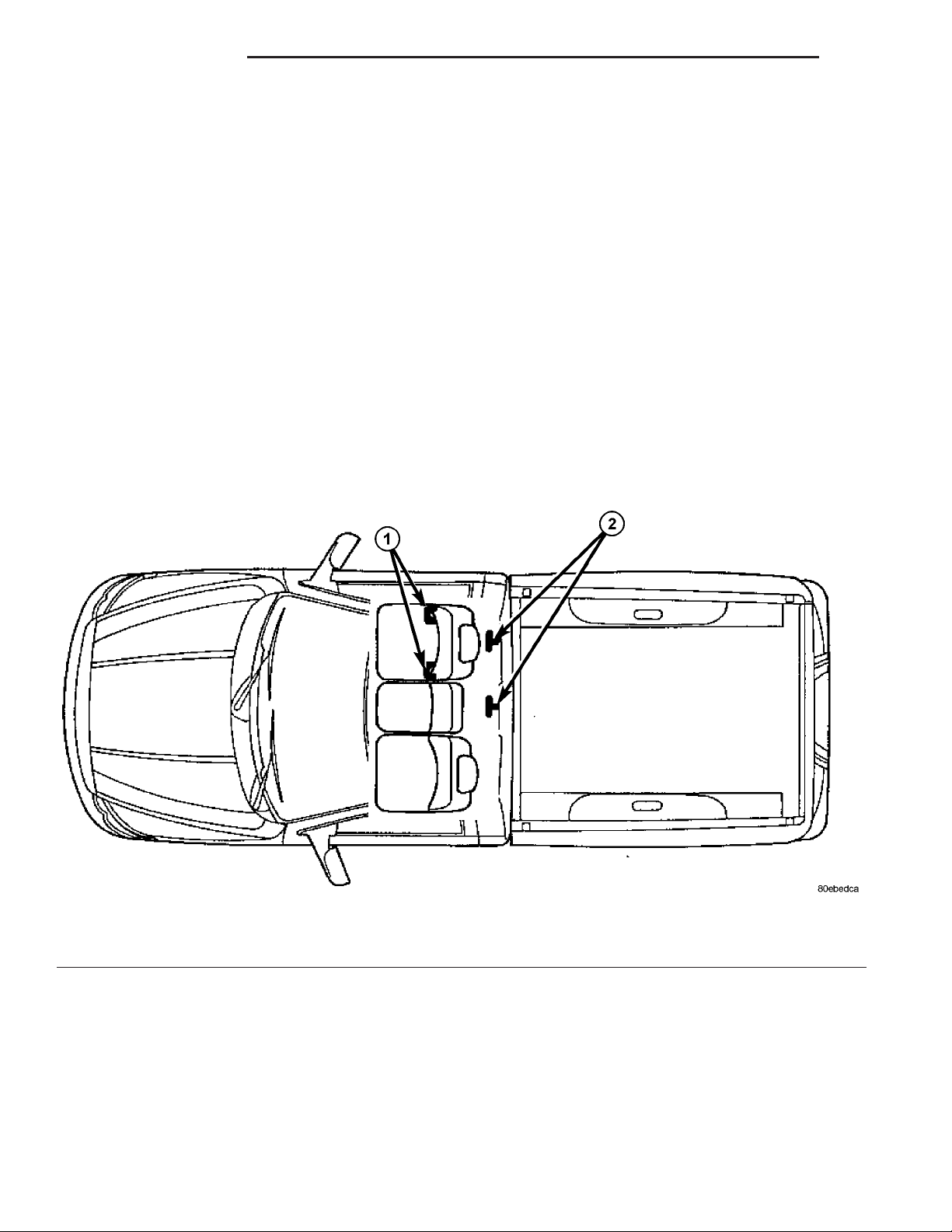

An occupant restraint system is standard factoryinstalled safety equipment on this model. Available

occupant restraints for this model include both active

and passive types. Active restraints are those which

require the vehicle occupants to take some action to

employ, such as fastening a seat belt; while passive

restraints require no action by the vehicle occupants

to be employed (Fig. 1).

ACTIVE RESTRAINTS

The active restraints for this model include:

• Front Seat Belts - Both outboard front seating

positions are equipped with three-point seat belt systems employing a lower B-pillar mounted inertia

latch-type emergency locking retractor, height-adjustable upper B-pillar mounted turning loops, a fixed

lower seat belt anchor secured to the lower B-pillar

(standard cab) or floor panel adjacent to the B-pillar

(quad cab), and a traveling end-release seat belt

buckle secured to the inboard seat track. The driver

side retractor for standard cab models includes an

electrically actuated seat belt tension reducer. The

passenger side front seat retractor for all models is

also switchable from an emergency locking retractor

to an automatic locking retractor. The front seat belt

buckle for the driver side of all models includes an

integral seat belt switch that detects whether its seat

belt has been fastened. The center front seating position for standard cab models is also equipped with a

three-point seat belt employing a floor panel

mounted inertia latch-type retractor, a routing

bracket and bezel near the top of the cab back panel,

and two fixed end-release buckles secured to the center seat cushion frame. The center front seating position for quad cab models is equipped with a fixed lap

belt and an end-release buckle secured to the center

seat cushion frame.

• Rear Seat Belts - All three rear seating posi-

tions are equipped with three-point seat belt systems. The outboard seating position belts employ a

lower C-pillar mounted inertia latch-type emergency

locking retractor, a fixed position upper C-pillar

mounted turning loop, and a fixed lower seat belt

SIDE IMPACT AIRBAG CONTROL MODULE

DESCRIPTION .........................53

OPERATION ...........................54

REMOVAL

REMOVAL ...........................55

REMOVAL ...........................55

INSTALLATION

INSTALLATION .......................56

INSTALLATION .......................57

anchor secured to the lower C-pillar. The rear seat

center seating position belt has a rear floor panel

mounted inertia latch-type emergency locking retractor and a routing bracket and bezel on the top of the

cab back panel. The end-release buckle units for the

right outboard seating position and the center seating position lower anchor are integral to the center

retractor mounting bracket on the rear floor panel.

The end-release buckle units for the center and left

outboard seating positions are individually secured to

the rear floor panel on models with the standard

equipment rear bench seat, or secured with the rear

seat mounting hardware on models with the optional

60/40 split rear bench seat.

• Child Restraint Anchors - All standard cab

models are equipped with two, fixed-position, child

seat upper tether anchors that are integral to the

upper cab back panel reinforcement and concealed

behind individual trim cover and bezel units that are

integral to the cab back trim panel. All quad cab

models are equipped with three child seat upper

tether anchor straps that are secured to the upper

cab back panel reinforcement, behind the upright

rear seat back. Two lower anchors are also provided

for the front outboard seating position of standard

cab models, and for each rear outboard seating position on quad cab models. These lower anchors are

accessed from the front of the seat where the seat

back meets the seat cushion. The child seat tether

and lower anchors for the front seat are deleted on

quad cab models.

PASSIVE RESTRAINTS

The passive restraints available for this model

include the following:

• Dual Front Airbags - Next Generation driver

and front passenger airbags are available for this

model. This airbag system is a passive, inflatable,

Supplemental Restraint System (SRS) and vehicles

with this equipment can be readily identified by the

“SRS - AIRBAG” logo molded into the driver airbag

trim cover in the center of the steering wheel and

also into the passenger airbag door on the instrument panel above the glove box (Fig. 2). Vehicles

with the airbag system can also be identified by the

airbag indicator, which will illuminate in the instru-

Page 3

DR RESTRAINTS 8O - 3

RESTRAINTS (Continued)

Fig. 1 Supplemental Restraint System

1 - AIRBAG CONTROL MODULE

2 - PASSENGER AIRBAG

3 - PASSENGER AIRBAG ON/OFF SWITCH (STD CAB ONLY)

4 - DRIVERAIRBAG

ment cluster for about six seconds as a bulb test each

time the ignition switch is turned to the On position.

A pyrotechnic-type seat belt tensioner is integral to

the front outboard seat belt retractors mounted on

each lower B-pillar of all models equipped with dual

front airbags.

• Side Curtain Airbags - Optional side curtain

airbags are available for this model when it is also

equipped with dual front airbags. This airbag system

is a passive, inflatable, Supplemental Restraint System (SRS) and vehicles with this equipment can be

readily identified by a molded identification trim but-

5 - SIDE CURTAIN AIRBAG

6 - SIDE IMPACT AIRBAG CONTROL MODULE

7 - SEAT BELT TENSIONER

ton with the “SRS - AIRBAG” logo located on the

headliner above each B-pillar (Fig. 2).

The supplemental restraint system includes the

following major components, which are described in

further detail elsewhere in this service information:

• Airbag Control Module - The Airbag Control

Module (ACM) is located on a mount on the floor

panel transmission tunnel, below the center of the

instrument panel.

• Airbag Indicator - The airbag indicator is inte-

gral to the ElectroMechanical Instrument Cluster

(EMIC), which is located on the instrument panel in

front of the driver.

Page 4

8O - 4 RESTRAINTS DR

RESTRAINTS (Continued)

the Programmable Communications Interface (PCI)

data bus network. This method of communication is

used by the ACM for control of the airbag indicator

on all models equipped with dual front airbags.

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES/COMMUNICATION - DESCRIPTION).

Hard wired circuitry connects the supplemental

restraint system components to each other through

the electrical system of the vehicle. These hard wired

circuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained by

many different methods. These circuits may be connected to each other, to the vehicle electrical system,

and to the supplemental restraint system components through the use of a combination of soldered

Fig. 2 SRS Logo

• Clockspring - The clockspring is located near

the top of the steering column, directly beneath the

steering wheel.

• Driver Airbag - The driver airbag is located in

the center of the steering wheel, beneath the driver

airbag trim cover.

• Driver Knee Blocker - The driver knee blocker

is a structural unit secured to the back side of and

integral to the instrument panel steering column

opening cover.

• Passenger Airbag - The passenger airbag is

located on the instrument panel, beneath the passenger airbag door on the instrument panel above the

glove box on the passenger side of the vehicle.

• Passenger Airbag On/Off Switch - Standard

cab models without a rear seat are equipped with a

passenger airbag on/off switch, which is located on

the right side of the instrument panel center bezel.

• Passenger Knee Blocker - The passenger knee

blocker is a structural reinforcement that is integral

to and concealed within the glove box door.

• Seat Belt Tensioner - The seat belt tensioner

is integral to the front outboard seat belt retractor

units on vehicles equipped with dual front airbags.

• Side Impact Airbag Control Module -Two

Side Impact Airbag Control Modules (SIACM) are

used on vehicles with the optional side curtain airbags, one left side and one right side. One SIACM is

located behind the B-pillar trim above the outboard

front seat belt retractor within each B-pillar.

• Side Curtain Airbag - In vehicles equipped

with this option, a side curtain airbag is located on

each inside roof side rail above the headliner, and

extends from the A-pillar to the B-pillar on standard

cab models, and from the A-pillar to the C-pillar on

quad cab models.

The ACM, both SIACMs, and the EMIC each contain a central processing unit and programming that

allow them to communicate with each other using

splices, splice block connectors, and many different

types of wire harness terminal connectors and insulators. Refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, further

details on wire harness routing and retention, as well

as pin-out and location views for the various wire

harness connectors, splices and grounds.

OPERATION

ACTIVE RESTRAINTS

The primary passenger restraints in this or any

other vehicle are the standard equipment factory-installed seat belts and child restraint anchors. Seat

belts and child restraint anchors are referred to as

an active restraint because the vehicle occupants are

required to physically fasten and properly adjust

these restraints in order to benefit from them. See

the owner’s manual in the vehicle glove box for more

information on the features, use and operation of all

of the factory-installed active restraints.

PASSIVE RESTRAINTS

The passive restraints are referred to as a supplemental restraint system because they were designed

and are intended to enhance the protection for the

occupants of the vehicle only when used in conjunction with the seat belts. They are referred to as passive restraints because the vehicle occupants are not

required to do anything to make them operate; however, the vehicle occupants must be wearing their

seat belts in order to obtain the maximum safety

benefit from the factory-installed supplemental

restraint system.

The supplemental restraint system electrical circuits are continuously monitored and controlled by a

microprocessor and software contained within the

Airbag Control Module (ACM) and, on vehicles

equipped with the side curtain airbags, both Side

Page 5

DR RESTRAINTS 8O - 5

RESTRAINTS (Continued)

Impact Airbag Control Modules (SIACM). An airbag

indicator in the ElectroMechanical Instrument Cluster (EMIC) illuminates for about six seconds as a

bulb test each time the ignition switch is turned to

the On or Start positions. Following the bulb test,

the airbag indicator is turned on or off by the ACM

to indicate the status of the supplemental restraint

system. If the airbag indicator comes on at any time

other than during the bulb test, it indicates that

there is a problem in the supplemental restraint system electrical circuits. Such a problem may cause airbags not to deploy when required, or to deploy when

not required.

Deployment of the supplemental restraints

depends upon the angle and severity of an impact.

Deployment is not based upon vehicle speed; rather,

deployment is based upon the rate of deceleration as

measured by the forces of gravity (G force) upon the

impact sensors. When an impact is severe enough,

the microprocessor in the ACM or the SIACM signals

the inflator of the appropriate airbag units to deploy

their airbag cushions. The outboard front seat belt

tensioners are provided with a deployment signal by

the ACM in conjunction with the driver and passenger airbags. During a frontal vehicle impact, the

knee blockers work in concert with properly fastened

and adjusted seat belts to restrain both the driver

and the front seat passenger in the proper position

for an airbag deployment. The knee blockers also

absorb and distribute the crash energy from the

driver and the front seat passenger to the structure

of the instrument panel. The seat belt tensioner

removes the slack from the outboard front seat belts

to provide further assurance that the driver and

front seat passenger are properly positioned and

restrained for an airbag deployment.

Typically, the vehicle occupants recall more about

the events preceding and following a collision than

they do of an airbag deployment itself. This is

because the airbag deployment and deflation occur so

rapidly. In a typical 48 kilometer-per-hour (30 mileper-hour) barrier impact, from the moment of impact

until the airbags are fully inflated takes about 40

milliseconds. Within one to two seconds from the

moment of impact, the airbags are almost entirely

deflated. The times cited for these events are approximations, which apply only to a barrier impact at the

given speed. Actual times will vary somewhat,

depending upon the vehicle speed, impact angle,

severity of the impact, and the type of collision.

When the ACM monitors a problem in any of the

dual front airbag system circuits or components,

including the seat belt tensioners, it stores a fault

code or Diagnostic Trouble Code (DTC) in its memory

circuit and sends an electronic message to the EMIC

to turn on the airbag indicator. When the SIACM

monitors a problem in any of the side curtain airbag

system circuits or component, it stores a fault code or

DTC in its memory circuit and sends an electronic

message to the ACM, and the ACM sends an electronic message to the EMIC to turn on the airbag

indicator. Proper testing of the supplemental

restraint system components, the Programmable

Communications Interface (PCI) data bus, the electronic message inputs to and outputs from the EMIC,

the SIACM, or the ACM, as well as the retrieval or

erasure of a DTC from the ACM, SIACM, or EMIC

requires the use of a DRBIIIt scan tool. Refer to the

appropriate diagnostic information.

See the owner’s manual in the vehicle glove box for

more information on the features, use and operation

of all of the factory-installed passive restraints.

WARNING

WARNINGS - RESTRAINT SYSTEM

WARNING: DURING AND FOLLOWING ANY SEAT

BELT OR CHILD RESTRAINT ANCHOR SERVICE,

CAREFULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLATION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

Page 6

8O - 6 RESTRAINTS DR

RESTRAINTS (Continued)

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

SIDE CURTAIN AIRBAG, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCONNECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

SUPPLEMENTAL RESTRAINT SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

WARNING: AN AIRBAG INFLATOR UNIT MAY CONTAIN SODIUM AZIDE AND POTASSIUM NITRATE.

THESE MATERIALS ARE POISONOUS AND

EXTREMELY FLAMMABLE. CONTACT WITH ACID,

WATER, OR HEAVY METALS MAY PRODUCE HARMFUL AND IRRITATING GASES (SODIUM HYDROXIDE

IS FORMED IN THE PRESENCE OF MOISTURE) OR

COMBUSTIBLE COMPOUNDS. AN AIRBAG INFLATOR UNIT MAY ALSO CONTAIN A GAS CANISTER

PRESSURIZED TO OVER 2500 PSI. DO NOT

ATTEMPT TO DISMANTLE AN AIRBAG UNIT OR

TAMPER WITH ITS INFLATOR. DO NOT PUNCTURE,

INCINERATE, OR BRING INTO CONTACT WITH

ELECTRICITY. DO NOT STORE AT TEMPERATURES

EXCEEDING 93° C (200° F).

WARNING: WHEN HANDLING A SEAT BELT TENSIONER RETRACTOR, PROPER CARE SHOULD BE

EXERCISED TO KEEP FINGERS OUT FROM UNDER

THE RETRACTOR COVER AND AWAY FROM THE

SEAT BELT WEBBING WHERE IT EXITS FROM THE

RETRACTOR COVER.

THE CORRECT FASTENERS PROVIDED IN THE

SERVICE PACKAGE OR SPECIFIED IN THE

DAIMLERCHRYSLER MOPAR PARTS CATALOG.

WARNING: WHEN A STEERING COLUMN HAS AN

AIRBAG UNIT ATTACHED, NEVER PLACE THE COLUMN ON THE FLOOR OR ANY OTHER SURFACE

WITH THE STEERING WHEEL OR AIRBAG UNIT

FACE DOWN.

DIAGNOSIS AND TESTING - SUPPLEMENTAL

RESTRAINT SYSTEM

Proper diagnosis and testing of the supplemental

restraint system components, the Programmable

Communications Interface (PCI) data bus, the data

bus electronic message inputs to and outputs from

the ElectroMechanical Instrument Cluster (EMIC),

the Airbag Control Module (ACM), or the Side

Impact Airbag Control Module (SIACM) as well as

the retrieval or erasure of a Diagnostic Trouble Code

(DTC) from the ACM or SIACM requires the use of a

DRBIIIt scan tool. Refer to the appropriate diagnostic information.

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

SIDE CURTAIN AIRBAG, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCONNECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

SUPPLEMENTAL RESTRAINT SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

WARNING: REPLACE ALL RESTRAINT SYSTEM

COMPONENTS ONLY WITH PARTS SPECIFIED IN

THE DAIMLERCHRYSLER MOPAR PARTS CATALOG. SUBSTITUTE PARTS MAY APPEAR INTERCHANGEABLE, BUT INTERNAL DIFFERENCES MAY

RESULT IN INFERIOR OCCUPANT PROTECTION.

WARNING: THE FASTENERS, SCREWS, AND

BOLTS ORIGINALLY USED FOR THE RESTRAINT

SYSTEM COMPONENTS HAVE SPECIAL COATINGS

AND ARE SPECIFICALLY DESIGNED FOR THE

RESTRAINT SYSTEM. THEY MUST NEVER BE

REPLACED WITH ANY SUBSTITUTES. ANY TIME A

NEW FASTENER IS NEEDED, REPLACE IT WITH

STANDARD PROCEDURE

STANDARD PROCEDURE - HANDLING

NON-DEPLOYED SUPPLEMENTAL RESTRAINTS

At no time should any source of electricity be permitted near the inflator on the back of a non-deployed airbag or seat belt tensioner. When carrying a

non-deployed airbag, the trim cover or airbag cushion

side of the unit should be pointed away from the

body to minimize injury in the event of an accidental

deployment. If the airbag unit is placed on a bench or

any other surface, the trim cover or airbag cushion

side of the unit should be face up to minimize move-

Page 7

DR RESTRAINTS 8O - 7

RESTRAINTS (Continued)

ment in the event of an accidental deployment. When

handling a non-deployed seat belt tensioner, take

proper care to keep fingers out from under the

retractor cover and away from the seat belt webbing

where it exits from the retractor cover. In addition,

the supplemental restraint system should be disarmed whenever any steering wheel, steering column, seat belt tensioner, driver airbag, passenger

airbag, side curtain airbag, or instrument panel components require diagnosis or service. Failure to

observe this warning could result in accidental airbag deployment and possible personal injury.

All damaged, faulty or non-deployed airbags and

seat belt tensioners which are replaced on vehicles

are to be handled and disposed of properly. If an airbag or seat belt tensioner unit is faulty or damaged

and non-deployed, refer to the Hazardous Substance

Control System for proper disposal. Dispose of all

non-deployed and deployed airbags and seat belt tensioners in a manner consistent with state, provincial,

local and federal regulations.

SUPPLEMENTAL RESTRAINT STORAGE

Airbags and seat belt tensioners must be stored in

their original, special container until they are used

for service. Also, they must be stored in a clean, dry

environment; away from sources of extreme heat,

sparks, and high electrical energy. Always place or

store any airbag on a surface with its trim cover or

airbag cushion side facing up, to minimize movement

in case of an accidental deployment.

age. Because the ACM and SIACM each contain

impact sensors that are used by the supplemental

restraint system to monitor or confirm the direction

and severity of a vehicle impact, improper orientation

or insecure fastening of these components may cause

airbags not to deploy when required, or to deploy

when not required. All other vehicle components

should be closely inspected following any supplemental restraint deployment, but are to be replaced only

as required by the extent of the visible damage

incurred.

CLEANUP PROCEDURE

Following a supplemental restraint deployment,

the vehicle interior will contain a powdery residue.

This residue consists primarily of harmless particulate by-products of the small pyrotechnic charge that

initiates the propellant used to deploy a supplemental restraint. However, this residue may also contain

traces of sodium hydroxide powder, a chemical

by-product of the propellant material that is used to

generate the inert gas that inflates the airbag. Since

sodium hydroxide powder can irritate the skin, eyes,

nose, or throat, be certain to wear safety glasses,

rubber gloves, and a long-sleeved shirt during

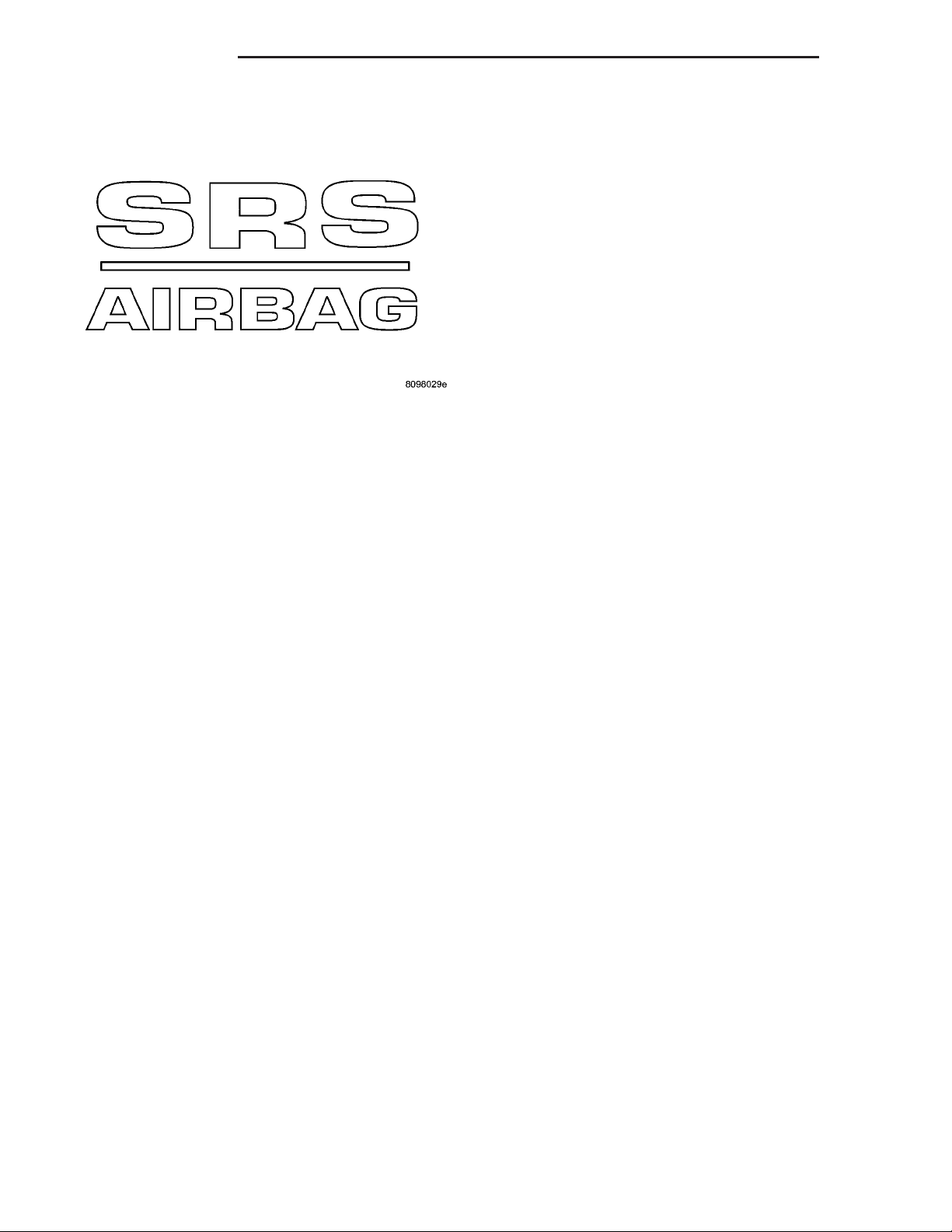

cleanup (Fig. 3).

STANDARD PROCEDURE - SERVICE AFTER A

SUPPLEMENTAL RESTRAINT DEPLOYMENT

Any vehicle which is to be returned to use following a supplemental restraint deployment, must have

the deployed restraints replaced. In addition, if the

driver airbag has been deployed, the clockspring

must be replaced. If the passenger airbag is

deployed, the passenger airbag door must be

replaced. The seat belt tensioners are deployed by

the same signal that deploys the driver and passenger airbags and must also be replaced if either front

airbag has been deployed. If a side curtain airbag

has been deployed, the complete airbag unit, the

headliner, as well as the upper A, B, and C-pillar

trim must be replaced. These components are not

intended for reuse and will be damaged or weakened

as a result of a supplemental restraint deployment,

which may or may not be obvious during a visual

inspection.

It is also critical that the mounting surfaces and/or

mounting brackets for the Airbag Control Module

(ACM) and Side Impact Airbag Control Module

(SIACM) be closely inspected and restored to their

original conditions following any vehicle impact dam-

Fig. 3 Wear Safety Glasses and Rubber Gloves -

Typical

WARNING: IF YOU EXPERIENCE SKIN IRRITATION

DURING CLEANUP, RUN COOL WATER OVER THE

AFFECTED AREA. ALSO, IF YOU EXPERIENCE

IRRITATION OF THE NOSE OR THROAT, EXIT THE

VEHICLE FOR FRESH AIR UNTIL THE IRRITATION

CEASES. IF IRRITATION CONTINUES, SEE A PHYSICIAN.

(1) Begin the cleanup by using a vacuum cleaner

to remove any residual powder from the vehicle interior. Clean from outside the vehicle and work your

Page 8

8O - 8 RESTRAINTS DR

RESTRAINTS (Continued)

way inside, so that you avoid kneeling or sitting on a

non-cleaned area.

(2) Be certain to vacuum the heater and air conditioning outlets as well (Fig. 4). Run the heater and

air conditioner blower on the lowest speed setting

and vacuum any powder expelled from the outlets.

Fig. 4 Vacuum Heater and A/C Outlets - Typical

CAUTION: All damaged, faulty, or non-deployed

supplemental restraints which are replaced on vehicles are to be handled and disposed of properly. If

an airbag unit or seat belt tensioner unit is faulty or

damaged and non-deployed, refer to the Hazardous

Substance Control System for proper disposal. Be

certain to dispose of all non-deployed and deployed

supplemental restraints in a manner consistent with

state, provincial, local and federal regulations.

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

SUPPLEMENTAL RESTRAINT SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

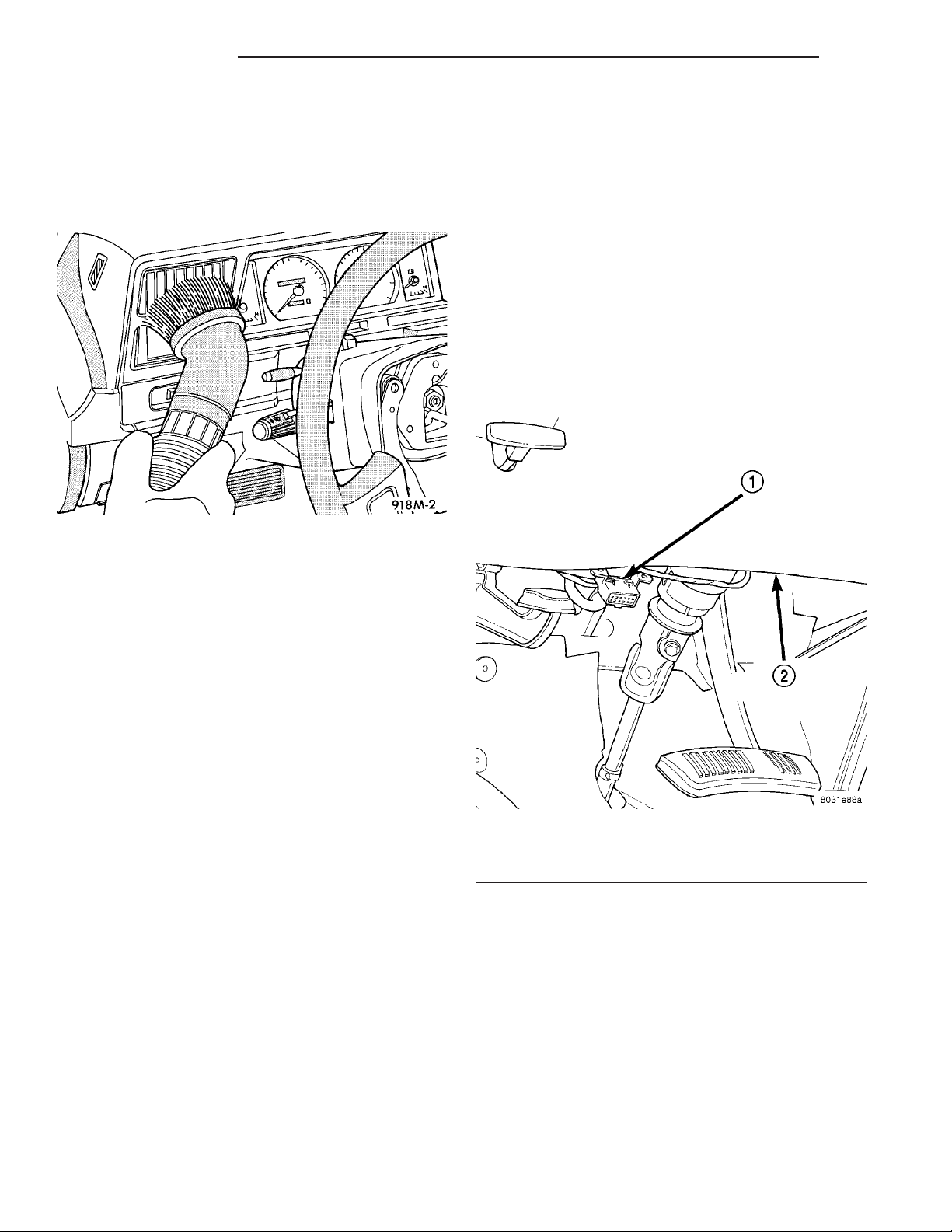

(1) During the following test, the battery negative

cable remains disconnected and isolated, as it was

during the supplemental restraint system component

removal and installation procedures.

(2) Be certain that the DRBIIIt scan tool contains

the latest version of the proper DRBIIIt software.

Connect the DRBIIIt to the 16-way Data Link Connector (DLC). The DLC is located on the driver side

lower edge of the instrument panel, outboard of the

steering column (Fig. 5).

(3) Next, remove the deployed supplemental

restraints from the vehicle. Refer to the appropriate

service removal procedures.

(4) You may need to vacuum the interior of the

vehicle a second time to recover all of the powder.

STANDARD PROCEDURE - VERIFICATION TEST

The following procedure should be performed using

a DRBIIIt scan tool to verify proper supplemental

restraint system operation following the service or

replacement of any supplemental restraint system

component.

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

SIDE CURTAIN AIRBAG, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCONNECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

Fig. 5 16-Way Data Link Connector - Typical

1 - 16–WAY DATA LINK CONNECTOR

2 - BOTTOM OF INSTRUMENT PANEL

(3) Turn the ignition switch to the On position and

exit the vehicle with the DRBIIIt scan tool.

(4) Check to be certain that nobody is in the vehi-

cle, then reconnect the battery negative cable.

(5) Using the DRBIIIt, read and record the active

(current) Diagnostic Trouble Code (DTC) data.

(6) Next, use the DRBIIIt to read and record any

stored (historical) DTC data.

(7) If any DTC is found in Step 5 or Step 6, refer

to the appropriate diagnostic information.

(8) Use the DRBIIIt to erase the stored DTC data.

If any problems remain, the stored DTC data will not

erase. Refer to the appropriate diagnostic information to diagnose any stored DTC that will not erase.

Page 9

DR RESTRAINTS 8O - 9

RESTRAINTS (Continued)

If the stored DTC information is successfully erased,

go to Step 9.

(9) Turn the ignition switch to the Off position for

about fifteen seconds, and then back to the On position. Observe the airbag indicator in the instrument

cluster. It should illuminate for six to eight seconds,

and then go out. This indicates that the supplemental restraint system is functioning normally and that

the repairs are complete. If the airbag indicator fails

to light, or lights and stays on, there is still an active

supplemental restraint system fault or malfunction.

Refer to the appropriate diagnostic information to

diagnose the problem.

ACM COVER

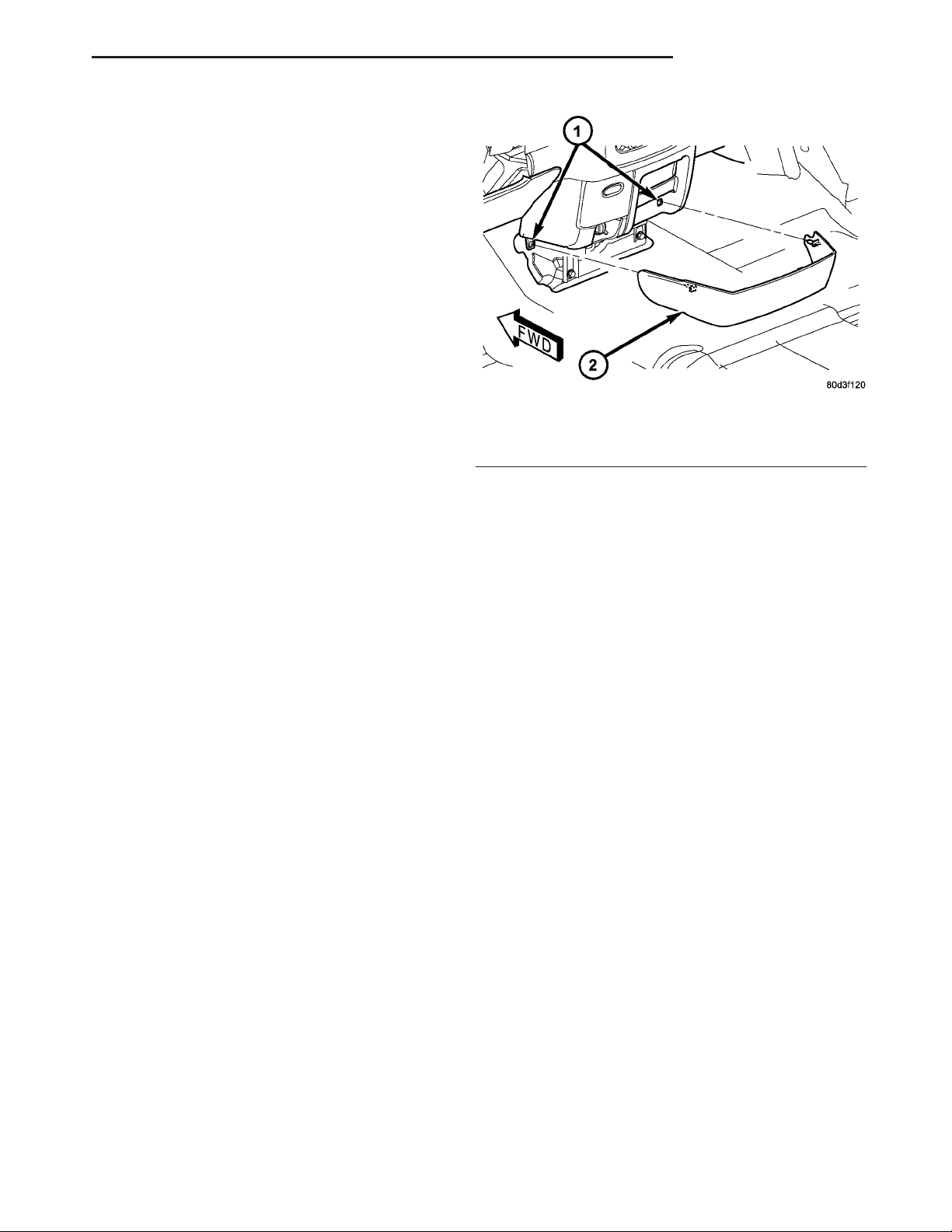

Fig. 6 ACM Cover Remove/Install

REMOVAL

The Airbag Control Module (ACM) cover is used

only on models with an automatic transmission. Models with a manual transmission require that the floor

console be removed to access the ACM for service.

(Refer to 23 - BODY/INTERIOR/FLOOR CONSOLE REMOVAL).

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

SIDE CURTAIN AIRBAG, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCONNECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

SUPPLEMENTAL RESTRAINT SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

(2) Using a trim stick or another suitable wide

flat-bladed tool, gently pry each side of the ACM

cover away from the instrument panel at each side of

the center bracket on the floor panel transmission

tunnel far enough to disengage the two snap clip

retainers from the instrument panel receptacles (Fig.

6).

(3) Remove the ACM cover from the instrument

panel.

1 - INSTRUMENT PANEL RECEPTACLE (2)

2 - ACM COVER

INSTALLATION

The Airbag Control Module (ACM) cover is used

only on models with an automatic transmission. Models with a manual transmission require that the floor

console be reinstalled following ACM service. (Refer

to 23 - BODY/INTERIOR/FLOOR CONSOLE INSTALLATION).

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

SIDE CURTAIN AIRBAG, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCONNECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

SUPPLEMENTAL RESTRAINT SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Position the ACM cover to the instrument

panel (Fig. 6).

(2) Align the snap clip retainer on each side of the

ACM cover with the instrument panel receptacle at

each side of the center bracket on the floor panel

transmission tunnel.

(3) Using hand pressure, press firmly and evenly

on the outside of the ACM cover over each snap clip

retainer location until each retainer is fully engaged

in its instrument panel receptacle.

(4) Reconnect the battery negative cable.

Page 10

8O - 10 RESTRAINTS DR

AIRBAG CONTROL MODULE

DESCRIPTION

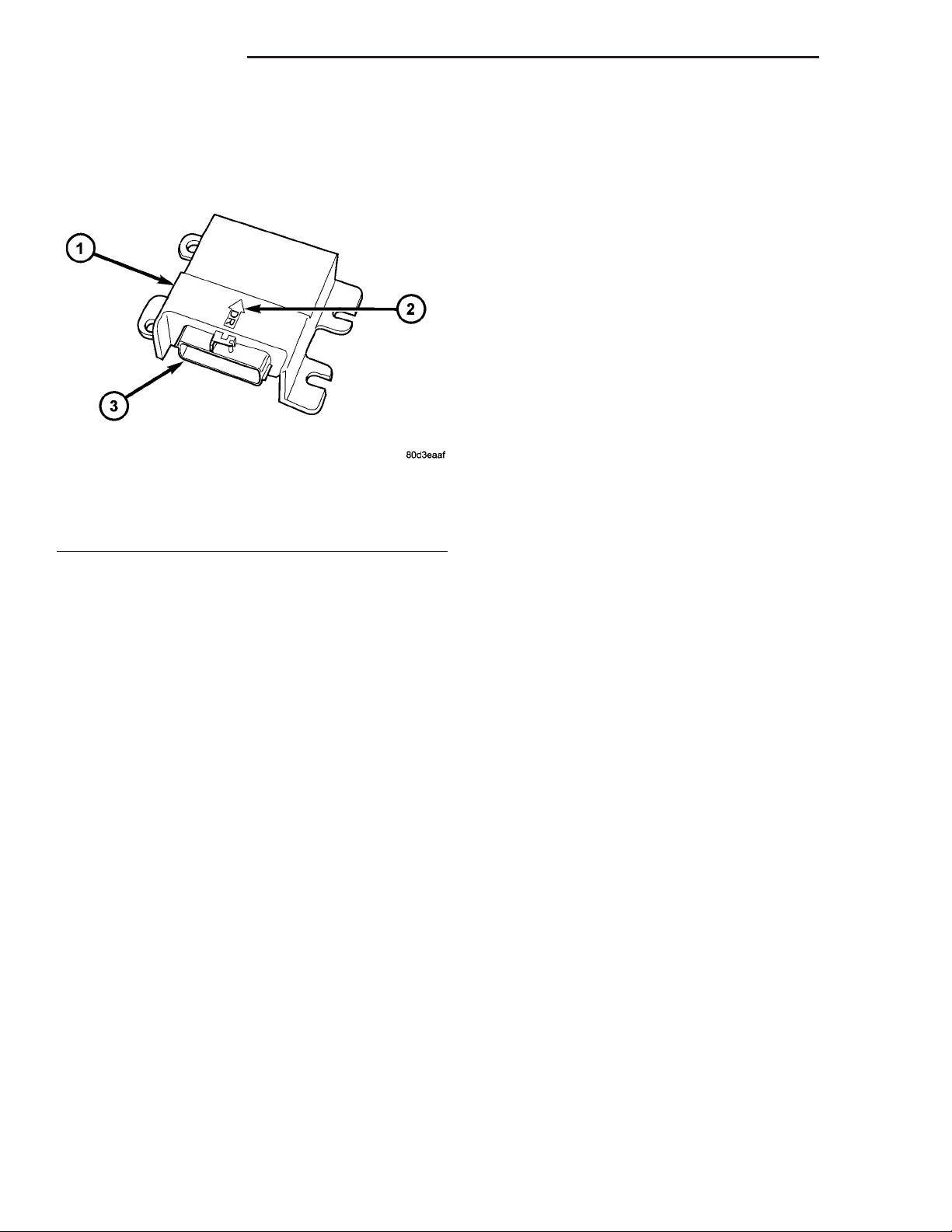

Fig. 7 Airbag Control Module

1 - AIRBAG CONTROL MODULE

2 - ORIENTATION ARROW

3 - CONNECTOR RECEPTACLE

The Airbag Control Module (ACM) is secured with

four screws to the top mounting surface of a stamped

steel bracket welded onto the top of the floor panel

transmission tunnel forward of the instrument panel

center support bracket and below the instrument

panel center stack in the passenger compartment of

the vehicle (Fig. 7). Concealed within a hollow in the

center of the die cast aluminum ACM housing is the

electronic circuitry of the ACM which includes a

microprocessor, an electronic impact sensor, an electromechanical safing sensor, and an energy storage

capacitor. A stamped metal cover plate is secured to

the bottom of the ACM housing with four screws to

enclose and protect the internal electronic circuitry

and components.

The ACM housing has integral mounting flanges

on each side. Two of the mounting flanges, one on

each side, have an integral locating pin on their

lower surface. The left flanges have round mounting

holes, while the flanges on the right side have slotted

mounting holes. An arrow cast into the top of the

ACM housing near the rear provides a visual verification of the proper orientation of the unit, and

should always be pointed toward the front of the

vehicle. A molded plastic electrical connector receptacle containing twenty-three terminal pins exits the

rearward facing side of the ACM housing. These terminal pins connect the ACM to the vehicle electrical

system through a dedicated take out and connector of

the instrument panel wire harness.

The impact sensor and safing sensor internal to

the ACM are calibrated for the specific vehicle, and

are only serviced as a unit with the ACM. The ACM

cannot be repaired or adjusted and, if damaged or

faulty, it must be replaced.

OPERATION

The microprocessor in the Airbag Control Module

(ACM) contains the front supplemental restraint system logic circuits and controls all of the front supplemental restraint system components. The ACM uses

On-Board Diagnostics (OBD) and can communicate

with other electronic modules in the vehicle as well

as with the DRBIIIt scan tool using the Programmable Communications Interface (PCI) data bus network. This method of communication is used for

control of the airbag indicator in the ElectroMechanical Instrument Cluster (EMIC) and for supplemental

restraint system diagnosis and testing through the

16-way data link connector located on the driver side

lower edge of the instrument panel. (Refer to 8 ELECTRICAL/INSTRUMENT CLUSTER/AIRBAG

INDICATOR - OPERATION).

The ACM microprocessor continuously monitors all

of the front supplemental restraint system electrical

circuits to determine the system readiness. If the

ACM detects a monitored system fault, it sets an

active and stored Diagnostic Trouble Code (DTC) and

sends electronic messages to the EMIC over the PCI

data bus to turn on the airbag indicator. An active

fault only remains for the duration of the fault, or in

some cases, the duration of the current ignition

switch cycle, while a stored fault causes a DTC to be

stored in memory by the ACM. For some DTCs, if a

fault does not recur for a number of ignition cycles,

the ACM will automatically erase the stored DTC.

For other internal faults, the stored DTC is latched

forever.

In standard cab models, the ACM also monitors a

resistor multiplexed input from the passenger airbag

on/off switch and provides a control output for the

Off indicator in the switch through a passenger airbag indicator driver circuit. If the passenger airbag

on/off switch is set to the Off position, the ACM turns

on the passenger airbag on/off switch Off indicator

and will internally disable the passenger airbag from

being deployed if an impact is detected that is sufficient for an airbag deployment. The ACM also turns

on the on/off switch Off indicator for about seven seconds each time the ignition switch is turned to the

On position as a bulb test. Following the bulb test,

the ACM controls the status of the Off indicator

based upon the resistance of the input from the on/off

switch. The ACM will also set and/or store a DTC for

faults it detects in the passenger airbag on/off switch

circuits, and will turn on the airbag indicator in the

EMIC if a fault has been detected.

Page 11

DR RESTRAINTS 8O - 11

AIRBAG CONTROL MODULE (Continued)

On models equipped with optional side curtain airbags, the ACM communicates with both the left and

right Side Impact Airbag Control Modules (SIACM)

over the PCI data bus. The SIACM notifies the ACM

when it has detected a monitored system fault and

stored a DTC in memory for its respective side curtain airbag system, and the ACM sets a DTC and

controls the airbag indicator operation accordingly.

The ACM receives battery current through two circuits; a fused ignition switch output (run) circuit

through a fuse in the Integrated Power Module

(IPM), and a fused ignition switch output (run-start)

circuit through a second fuse in the IPM. The ACM

receives ground through a ground circuit and take

out of the instrument panel wire harness. This take

out has a single eyelet terminal connector that is

secured by a ground screw to the instrument panel

support structure. These connections allow the ACM

to be operational whenever the ignition switch is in

the Start or On positions. The ACM also contains an

energy-storage capacitor. When the ignition switch is

in the Start or On positions, this capacitor is continually being charged with enough electrical energy to

deploy the front supplemental restraint components

for up to one second following a battery disconnect or

failure. The purpose of the capacitor is to provide

backup supplemental restraint system protection in

case there is a loss of battery current supply to the

ACM during an impact.

Two sensors are contained within the ACM; an

electronic impact sensor, and a safing sensor. The

electronic impact sensor is an accelerometer that

senses the rate of vehicle deceleration, which provides verification of the direction and severity of an

impact. The safing sensor is an electromechanical

sensor within the ACM that provides an additional

logic input to the ACM microprocessor. The safing

sensor is a normally open switch that is used to verify the need for a front supplemental restraint

deployment by detecting impact energy of a lesser

magnitude than that of the electronic impact sensor,

and must be closed in order for the front airbags or

seat belt tensioners to deploy. A pre-programmed

decision algorithm in the ACM microprocessor determines when the deceleration rate as signaled by the

impact sensor and the safing sensor indicate an

impact that is severe enough to require front supplemental restraint system protection and, based upon

the status of the passenger airbag on/off switch input

and the severity of the monitored impact, determines

what combination of seat belt tensioner and front airbag deployment is required for each front seating

position. When the programmed conditions are met,

the ACM sends the proper electrical signals to deploy

the seat belt tensioners and dual front airbags.

The hard wired inputs and outputs for the ACM

may be diagnosed and tested using conventional

diagnostic tools and procedures. However, conventional diagnostic methods will not prove conclusive in

the diagnosis of the ACM, the PCI data bus network,

or the electronic message inputs to and outputs from

the ACM. The most reliable, efficient, and accurate

means to diagnose the ACM, the PCI data bus network, and the electronic message inputs to and outputs from the ACM requires the use of a DRBIIIt

scan tool. Refer to the appropriate diagnostic information.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

SIDE CURTAIN AIRBAG, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCONNECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

SUPPLEMENTAL RESTRAINT SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

WARNING: THE AIRBAG CONTROL MODULE CONTAINS THE IMPACT SENSOR, WHICH ENABLES

THE SYSTEM TO DEPLOY THE FRONT SUPPLEMENTAL RESTRAINTS. NEVER STRIKE OR DROP

THE AIRBAG CONTROL MODULE, AS IT CAN DAMAGE THE IMPACT SENSOR OR AFFECT ITS CALIBRATION. IF AN AIRBAG CONTROL MODULE IS

ACCIDENTALLY DROPPED DURING SERVICE, THE

MODULE MUST BE SCRAPPED AND REPLACED

WITH A NEW UNIT. FAILURE TO OBSERVE THIS

WARNING COULD RESULT IN ACCIDENTAL,

INCOMPLETE, OR IMPROPER FRONT SUPPLEMENTAL RESTRAINT DEPLOYMENT AND POSSIBLE

OCCUPANT INJURIES.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

(2) On models with a manual transmission,

remove the floor console from the top of the floor

panel transmission tunnel. (Refer to 23 - BODY/INTERIOR/FLOOR CONSOLE - REMOVAL).

(3) On models with an automatic transmission,

remove the ACM cover from the instrument panel.

Page 12

8O - 12 RESTRAINTS DR

AIRBAG CONTROL MODULE (Continued)

(Refer to 8 - ELECTRICAL/RESTRAINTS/ACM

COVER - REMOVAL).

(4) Reach through the rearward facing opening

below the instrument panel center stack support

bracket on the top of the floor panel transmission

tunnel to access and disconnect the instrument panel

wire harness connector for the Airbag Control Module (ACM) from the ACM connector receptacle located

on the rearward facing side of the module (Fig. 8). To

disconnect the instrument panel wire harness connector from the ACM:

(a) Slide the red Connector Position Assurance

(CPA) lock on the top of the connector toward the

side of the connector.

(b) Depress the connector latch tab and pull the

connector straight away from the ACM connector

receptacle.

(7) Still working from the left side of the floor

panel transmission tunnel, lift the ACM upward far

enough to disengage the locating pins on the bottom

of the ACM mounting flanges from the locating holes

in the mounting bracket, then slide the ACM toward

the left far enough to disengage the slotted holes in

the right ACM mounting flanges from under the

heads of the two previously loosened right mounting

screws.

(8) Remove the ACM from the left side of the floor

panel transmission tunnel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

SIDE CURTAIN AIRBAG, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCONNECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

SUPPLEMENTAL RESTRAINT SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

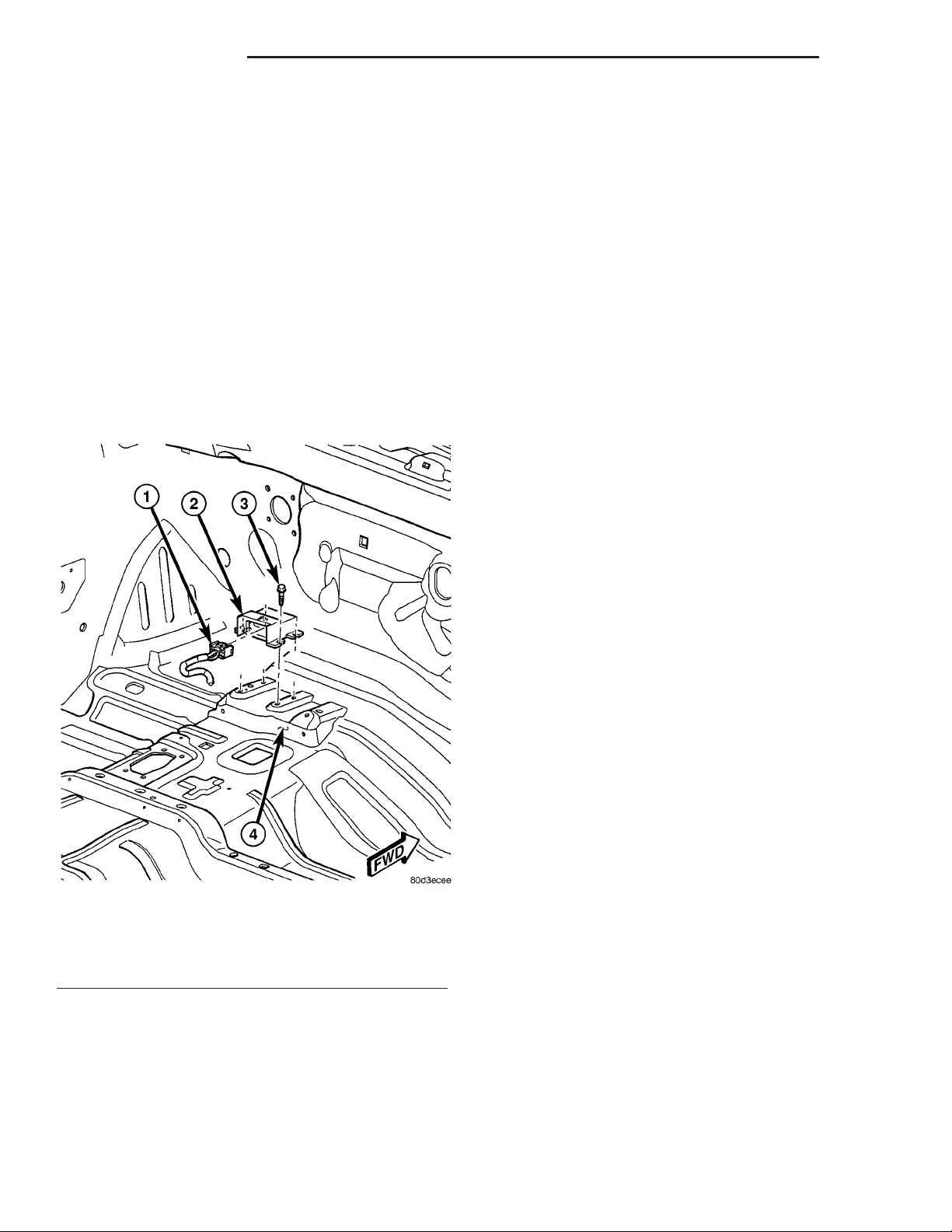

Fig. 8 Airbag Control Module Remove/Install

1 - WIRE HARNESS CONNECTOR

2 - AIRBAG CONTROL MODULE

3 - SCREW (4)

4 - FLOOR PANEL TRANSMISSION TUNNEL

(5) From the right side of the floor panel transmission tunnel, loosen each of the two screws that secure

the right side of the ACM to the bracket on the floor

panel transmission tunnel about 7 millimeters (0.25

inch).

(6) From the left side of the floor panel transmission tunnel, remove the two screws that secure the

left side of the ACM to the bracket on the floor panel

transmission tunnel.

WARNING: THE AIRBAG CONTROL MODULE CONTAINS THE IMPACT SENSOR, WHICH ENABLES

THE SYSTEM TO DEPLOY THE FRONT SUPPLEMENTAL RESTRAINTS. NEVER STRIKE OR DROP

THE AIRBAG CONTROL MODULE, AS IT CAN DAMAGE THE IMPACT SENSOR OR AFFECT ITS CALIBRATION. IF AN AIRBAG CONTROL MODULE IS

ACCIDENTALLY DROPPED DURING SERVICE, THE

MODULE MUST BE SCRAPPED AND REPLACED

WITH A NEW UNIT. FAILURE TO OBSERVE THIS

WARNING COULD RESULT IN ACCIDENTAL,

INCOMPLETE, OR IMPROPER FRONT SUPPLEMENTAL RESTRAINT DEPLOYMENT AND POSSIBLE

OCCUPANT INJURIES.

(1) Position the Airbag Control Module (ACM) to

the left side of the floor panel transmission tunnel

near the ACM bracket (Fig. 8). When the ACM is correctly positioned, the arrow on the ACM housing will

be pointed forward in the vehicle.

(2) From the left side of the floor panel transmission tunnel, slide the ACM toward the right far

enough to engage the slotted holes in the right ACM

mounting flanges under the heads of the two previously loosened right mounting screws, then engage

Page 13

DR RESTRAINTS 8O - 13

AIRBAG CONTROL MODULE (Continued)

the locating pins on the bottom of the ACM mounting

flanges into the locating holes in the bracket.

(3) Still working from the left side of the floor

panel transmission tunnel, install and tighten the

two screws that secure the left ACM mounting

flanges to the bracket that is welded onto the floor

panel transmission tunnel. Tighten the screws to 14

N·m (10 ft. lbs.).

(4) From the right side of the floor panel transmission tunnel, tighten each of the two screws that

secure the right side of the ACM to the bracket on

the floor panel transmission tunnel. Tighten the

screws to 14 N·m (10 ft. lbs.).

(5) Reach through the rearward facing opening

below the instrument panel center stack support

bracket on the top of the floor panel transmission

tunnel to access and reconnect the instrument panel

wire harness connector for the ACM to the ACM connector receptacle located on the rearward facing side

of the module. Be certain that the latch and the red

Connector Position Assurance (CPA) lock on the connector are each fully engaged.

(6) On models with an automatic transmission,

reinstall the ACM cover onto the instrument panel.

(Refer to 8 - ELECTRICAL/RESTRAINTS/ACM

COVER - INSTALLATION).

(7) On models with a manual transmission, reinstall the floor console onto the top of the floor panel

transmission tunnel. (Refer to 23 - BODY/INTERIOR/FLOOR CONSOLE - INSTALLATION).

(8) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verification test procedure should be performed following

service of any supplemental restraint system component. (Refer to 8 - ELECTRICAL/RESTRAINTS STANDARD PROCEDURE - VERIFICATION TEST).

AUTOMATIC LOCKING

RETRACTOR

DESCRIPTION

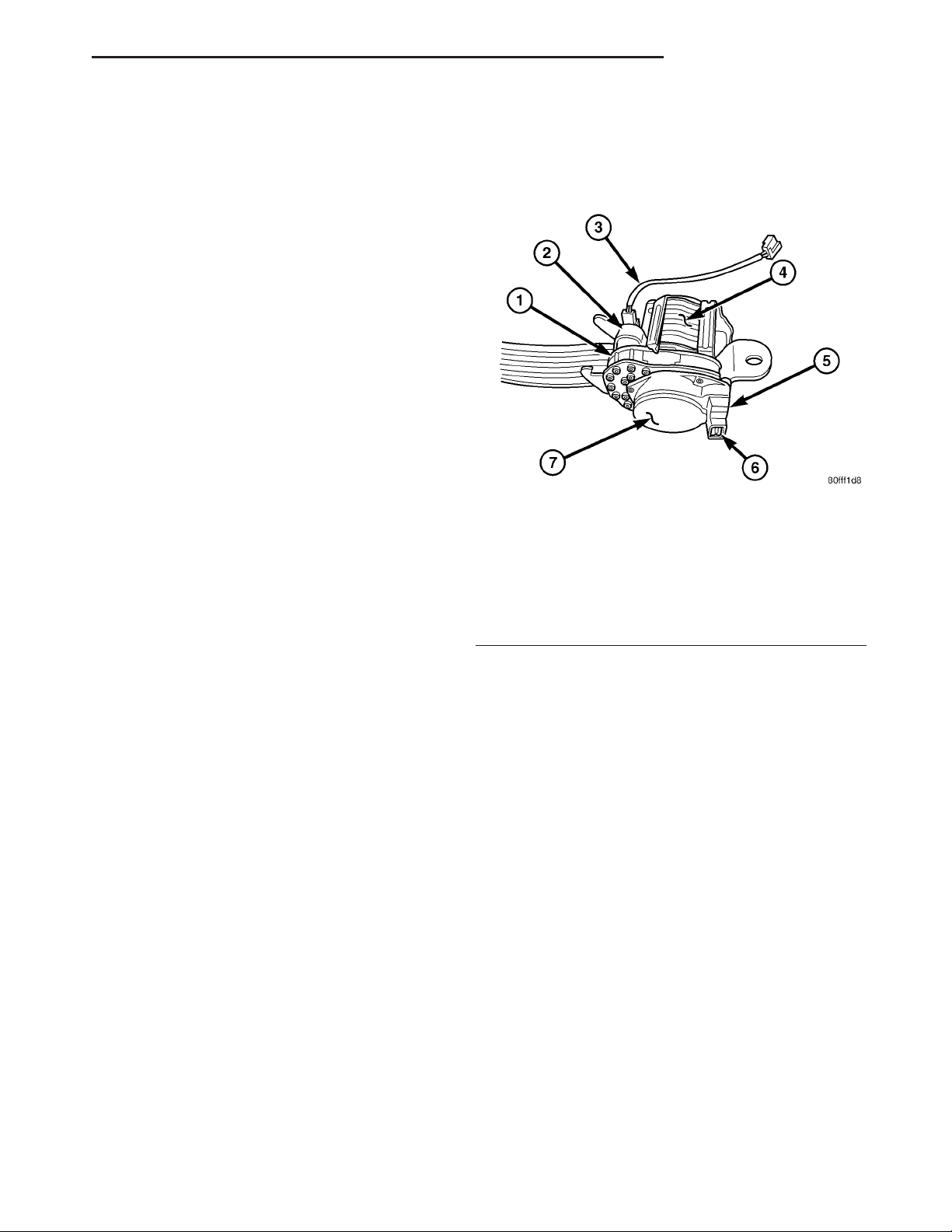

Fig. 9 Automatic Locking Retractor

1 - TENSIONER HOUSING OR CHAMBER

2 - GAS GENERATOR

3 - TENSIONER PIGTAIL WIRE

4 - SPOOL

5 - TENSION REDUCER (DRIVER SIDE ON STANDARD CAB

ONLY)

6 - REDUCER CONNECTOR RECEPTACLE

7 - RETRACTOR LOCKING MECHANISM COVER

The seat belt retractors used in all seating positions include an inertia-type, emergency locking

mechanism as standard equipment (Fig. 9). However,

the retractor locking mechanism for the passenger

side front seating position is mechanically switchable

from an emergency locking retractor to an automatic

locking retractor. The primary function of this feature is to securely accommodate a child seat in the

passenger side front seating position of the vehicle

without the need for a self-cinching seat belt tip half

latch plate unit or another supplemental device that

would be required to prevent the seat belt webbing

from unwinding freely from the retractor spool of an

inertia-type emergency locking retractor mechanism.

The automatic locking mechanism is integral to the

passenger side front seat belt and retractor unit and

is concealed beneath a molded plastic cover located

on the same side of the retractor spool as the seat

belt tensioner housing. The retractor is secured to

the inner B-pillar on the right side of the vehicle and

is concealed beneath the molded plastic inner B-pillar trim. The automatic locking mechanism cannot be

adjusted or repaired and, if faulty or damaged, the

entire passenger side front seat belt and retractor

unit must be replaced.

Page 14

8O - 14 RESTRAINTS DR

AUTOMATIC LOCKING RETRACTOR (Continued)

OPERATION

The automatic locking mode of the retractor is

engaged and the retractor is switched from operating

as a standard inertia-type emergency locking retractor by first buckling the combination lap and shoulder belt buckle. Then grasp the shoulder belt and

pull all of the webbing out of the retractor. Once all

of the belt webbing is extracted from the spool, the

retractor will automatically become engaged in the

pre-locked automatic locking mode and will make an

audible clicking or ratcheting sound as the shoulder

belt is allowed to retract to confirm that the automatic locking mode is now engaged. Once the automatic locking mode is engaged, the retractor will

remain locked and the belt will remain tight around

whatever it is restraining.

CHILD RESTRAINT ANCHOR

DESCRIPTION

The retractor is returned to standard emergency

locking mode by unbuckling the combination lap and

shoulder belt buckle and allowing the belt webbing to

be almost fully retracted onto the retractor spool. The

emergency locking mode is confirmed by the absence

of the audible clicking or ratcheting sound as the belt

webbing retracts. This mode will allow the belt to

unwind from and wind onto the retractor spool freely

unless and until a predetermined inertia load is

sensed, or until the retractor is again switched to the

automatic locking mode.

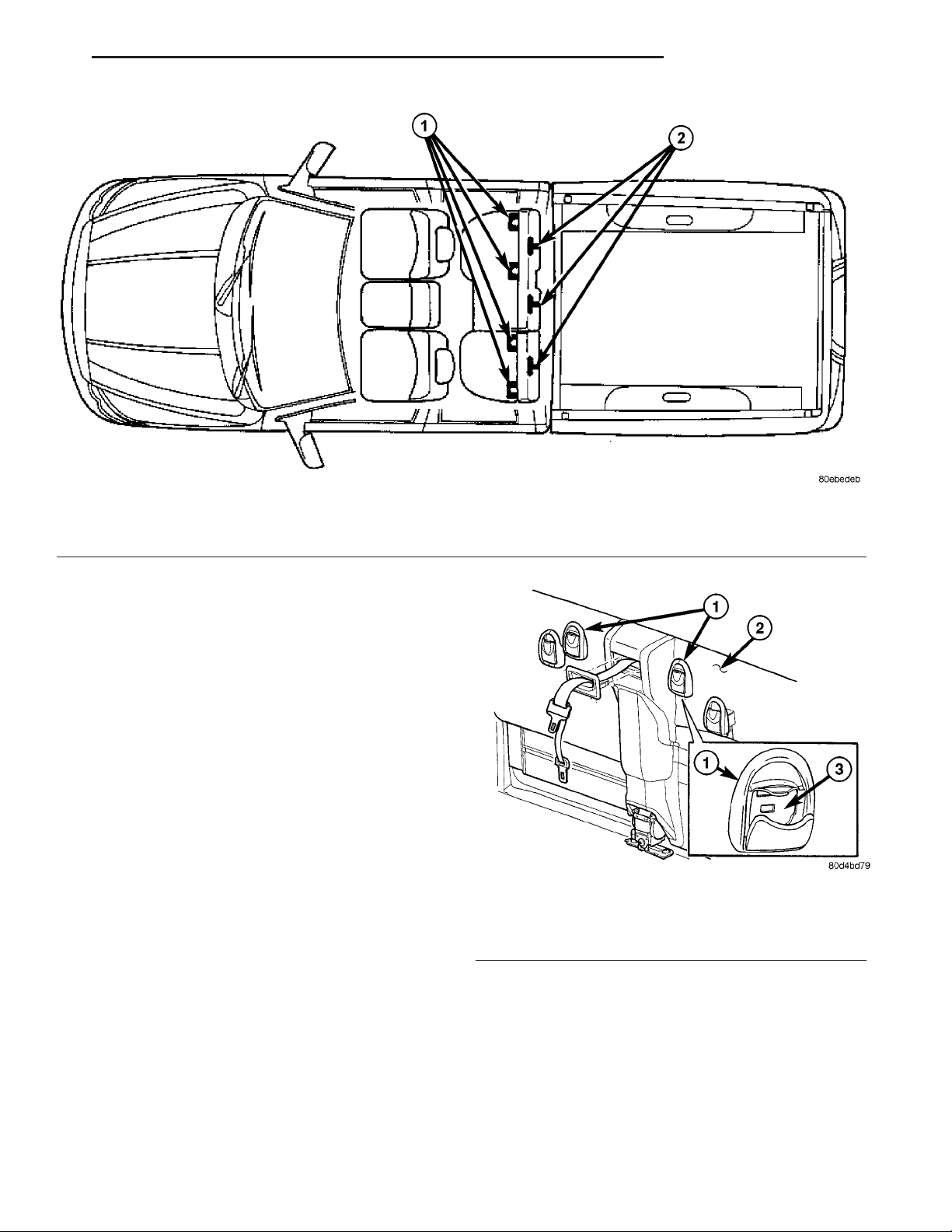

Fig. 10 Child Restraint Anchor Location - Standard Cab

1 - LOWERANCHOR (PROVIDED FOR OUTBOARD SEATING

POSITION ONLY)

2 - TETHER ANCHOR (PROVIDED FOR CENTER AND

OUTBOARD SEATING POSITIONS)

Page 15

DR RESTRAINTS 8O - 15

CHILD RESTRAINT ANCHOR (Continued)

Fig. 11 Child Restraint Anchor Location - Quad Cab

1 - LOWERANCHOR (PROVIDED FOR REAR OUTBOARD

SEATING POSITIONS ONLY)

This model is equipped with a Lower Anchors and

Tether for CHildren, or LATCH child restraint

anchorage system (Fig. 10) or (Fig. 11). The LATCH

system provides for the installation of suitable child

restraints in certain seating positions without using

the standard equipment seat belt provided for that

seating position. Standard cab models are equipped

with a fixed-position child restraint upper tether

anchor for the front center and outboard seating positions, and child restraint lower anchors for the front

outboard seating position. Quad cab models are

equipped with a fixed-position child restraint upper

tether anchor strap for the rear center and both rear

outboard seating positions, and child restraint lower

anchors for both rear outboard seating positions. All

front seat child restraint anchors are deleted on quad

cab models.

The two upper tether anchors for standard cab

models are integral to the upper cab back panel reinforcement and are concealed behind individual trim

cover and bezel units that are integral to the cab

back trim panel (Fig. 12). These upper tether anchors

cannot be adjusted or repaired and, if faulty or damaged, they must be replaced as a unit with the upper

cab back panel reinforcement. The upper tether

anchor trim covers and bezels are serviced as a unit

with the cab back trim panel.

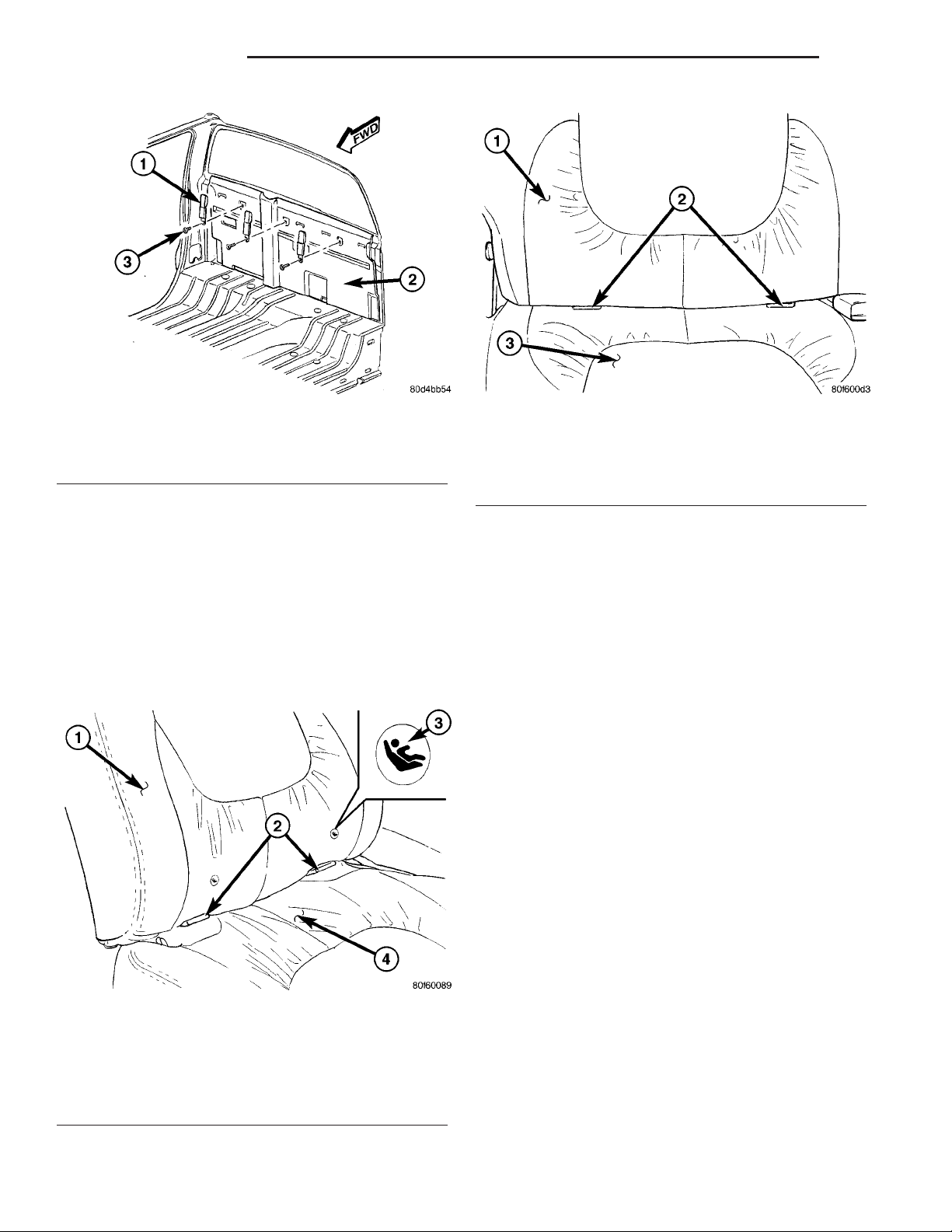

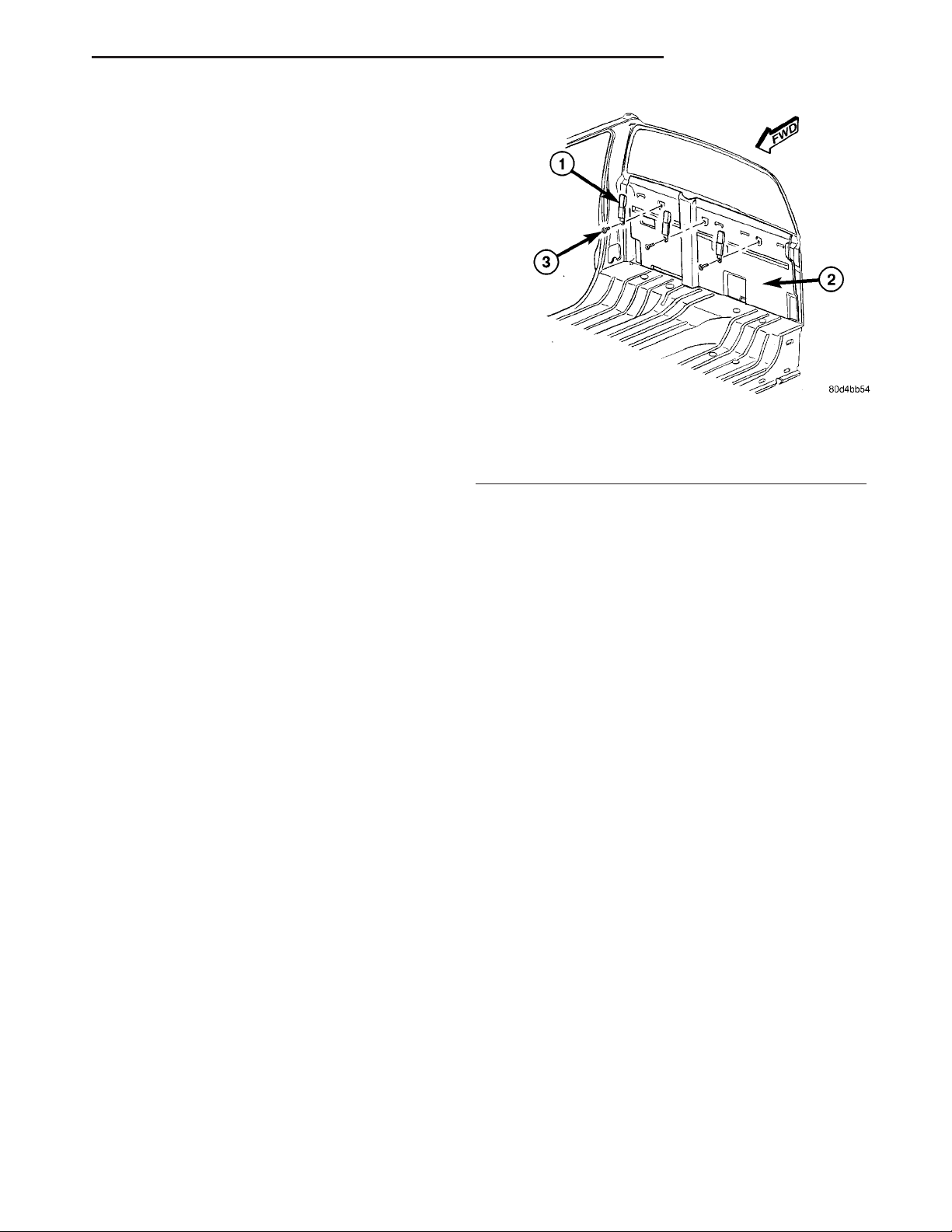

The three upper tether anchor straps for quad cab

models are secured to the upper cab back panel reinforcement with screws (Fig. 13). These anchor straps

are concealed behind the upright rear seat back. The

2 - TETHER ANCHOR (PROVIDED FOR REAR CENTER AND

OUTBOARD SEATING POSITIONS)

Fig. 12 Child Tether Anchor - Standard Cab

1 - COVER & BEZEL (2)

2 - CAB BACK TRIM PANEL

3 - ANCHOR (2)

upper tether anchor straps are available for individual service replacement.

The lower anchors for all models are integral to

their respective front or rear seat cushion frame (Fig.

14) or (Fig. 15). Round markers with an imprinted

child seat icon on the standard cab front seat back

trim cover helps identify the anchor locations for that

application because they may be otherwise difficult to

see with the seat back in the upright position. These

lower anchors are each constructed from round steel

Page 16

8O - 16 RESTRAINTS DR

CHILD RESTRAINT ANCHOR (Continued)

Fig. 13 Child Tether Strap - Quad Cab

1 - TETHER STRAP (3)

2 - CAB BACK PANEL

3 - SCREW (3)

bar stock that is formed into a U-shape, then

securely welded at each end to the seat cushion

frame. They are each accessed from the front of their

respective seats, at each side where the seat back

meets the seat cushion. These lower anchors cannot

be adjusted or repaired and, if faulty or damaged,

they must be replaced as a unit with the seat cushion frame. On quad cab models, if the lower anchors

have been bent or broken as a result of a vehicle collision, the latch for the affected rear seat cushion

frame unit must also be replaced.

Fig. 15 Child Restraint Lower Anchor - Quad Cab

Rear Seat

1 - REAR SEAT BACK

2 - LOWERANCHOR (2 PER OUTBOARD REAR SEATING

POSITION)

3 - REAR SEAT CUSHION

WARNING: DURING AND FOLLOWING ANY SEAT

BELT OR CHILD RESTRAINT ANCHOR SERVICE,

CAREFULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLATION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

Fig. 14 Child Restraint Lower Anchor - Standard

Cab Front Seat

1 - FRONT SEAT BACK

2 - LOWERANCHOR (2) - PASSENGER SIDE OUTBOARD

SEATING POSITION ONLY

3 - LOWERANCHOR MARKER (2)

4 - FRONT SEAT CUSHION

OPERATION

See the owner’s manual in the vehicle glove box for

more information on the proper use of all of the factory-installed child restraint anchors.

REMOVAL

The following procedure applies only to the rear

seat upper child tether straps used on quad cab models. The child restraint anchors used in other models

and locations are integral to other components and

cannot be serviced separately.

Page 17

DR RESTRAINTS 8O - 17

CHILD RESTRAINT ANCHOR (Continued)

WARNING: DURING AND FOLLOWING ANY SEAT

BELT OR CHILD RESTRAINT ANCHOR SERVICE,

CAREFULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLATION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

(1) Remove the rear seat from the vehicle. (Refer

to 23 - BODY/SEATS/SEAT - REAR - REMOVAL).

(2) Remove the screw that secures the child tether

strap to the upper cab back panel reinforcement (Fig.

16).

(3) Remove the child tether strap from the upper

cab back panel reinforcement.

INSTALLATION

The following procedure applies only to the rear

seat upper child tether straps used on quad cab models. The child restraint anchors used in other models

and locations are integral to other components and

cannot be serviced separately.

WARNING: DURING AND FOLLOWING ANY SEAT

BELT OR CHILD RESTRAINT ANCHOR SERVICE,

CAREFULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLATION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

1 - TETHER STRAP (3)

2 - CAB BACK PANEL

3 - SCREW (3)

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

cab back panel reinforcement (Fig. 16).

child tether strap to the upper cab back panel rein-

forcement. Tighten the screw to 14 N·m (10 ft. lbs.).

to 23 - BODY/SEATS/SEAT - REAR - INSTALLA-

TION).

Fig. 16 Child Tether Strap - Quad Cab

(1) Position the child tether strap onto the upper

(2) Install and tighten the screw that secures the

(3) Reinstall the rear seat into the vehicle. (Refer

Page 18

8O - 18 RESTRAINTS DR

CLOCKSPRING

DESCRIPTION

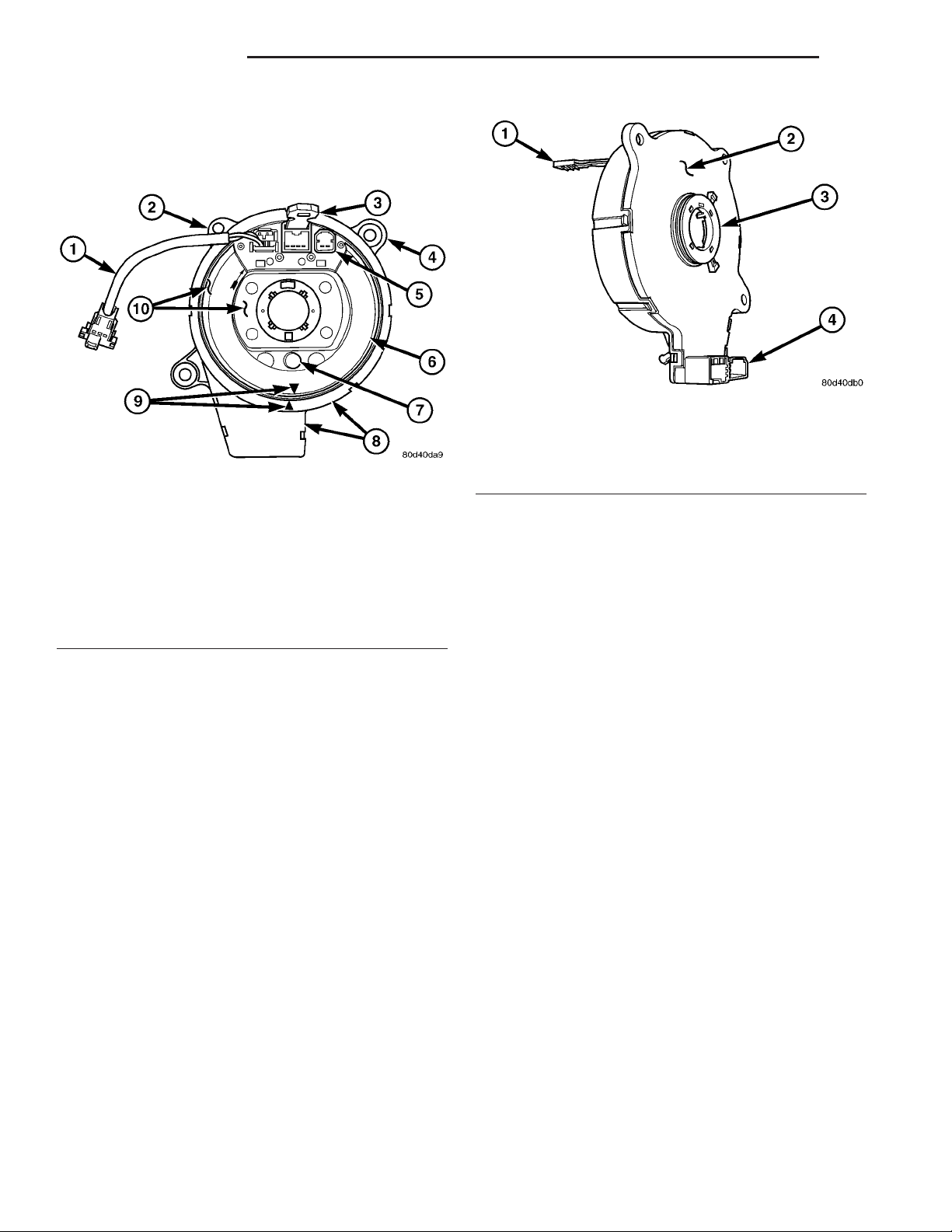

Fig. 18 Turn Signal Cancel Cam

1 - LOCKING PIN

2 - CLOCKSPRING CASE

3 - CANCEL CAM

Fig. 17 Clockspring

1 - PIGTAIL WIRE

2 - LOCATING TAB

3 - LOCKING PIN

4 - MOUNTING TAB (2)

5 - UPPER CONNECTOR RECEPTACLE (2)

6 - LABEL

7 - ENGAGEMENT DOWEL & BOOT

8 - CASE

9 - CENTERINGARROWS

10 - ROTOR

The clockspring assembly is secured with two

screws onto the multi-function switch mounting

housing near the top of the steering column behind

the steering wheel (Fig. 17). The clockspring consists

of a flat, round molded plastic case with a stubby tail

that hangs below the steering column (Fig. 18). The

tail contains two connector receptacles that face

toward the instrument panel. Within the plastic case

is a spool-like molded plastic rotor with a large

exposed hub. The upper surface of the rotor hub has

a large center hole, two large flats, an engagement

dowel with a yellow rubber boot, a short pigtail wire

with connector, and two connector receptacles that

face toward the steering wheel.

The lower surface of the rotor hub has a molded

plastic turn signal cancel cam with two lobes that is

keyed to the rotor and is secured there with four

integral snap features. Within the plastic case and

wound around the rotor spool is a long ribbon-like

tape that consists of several thin copper wire leads

sandwiched between two thin plastic membranes.

The outer end of the tape terminates at the connector

receptacles that face the instrument panel, while the

inner end of the tape terminates at the pigtail wire

and connector receptacles on the hub of the clockspring rotor that face the steering wheel.

4 - LOWER CONNECTOR RECEPTACLE (2)

Service replacement clocksprings are shipped precentered and with a molded plastic locking pin that

snaps into a receptacle on the rotor and is engaged

between two tabs on the upper surface of the rotor

case. The locking pin secures the centered clockspring rotor to the clockspring case during shipment,

but the locking pin must be removed from the clockspring after it is installed on the steering column.

(Refer to 8 - ELECTRICAL/RESTRAINTS/CLOCKSPRING - STANDARD PROCEDURE - CLOCKSPRING CENTERING).

The clockspring cannot be repaired. If the clockspring is faulty, damaged, or if the driver airbag has

been deployed, the clockspring must be replaced.

OPERATION

The clockspring is a mechanical electrical circuit

component that is used to provide continuous electrical continuity between the fixed instrument panel

wire harness and the electrical components mounted

on or in the rotating steering wheel. On this model

the rotating electrical components include the driver

airbag, the horn switch, the speed control switches,

and the remote radio switches, if the vehicle is so

equipped. The clockspring case is positioned and

secured to the multi-function switch mounting housing near the top of the steering column. The connector receptacles on the tail of the fixed clockspring

case connect the clockspring to the vehicle electrical

system through two take outs with connectors from

the instrument panel wire harness.

The clockspring rotor is movable and is keyed by

an engagement dowel that is molded onto the rotor

hub between two fins that are cast into the lower

surface of the steering wheel armature. A yellow rub-

Page 19

DR RESTRAINTS 8O - 19

CLOCKSPRING (Continued)

ber boot is installed over the engagement dowel to

eliminate contact noise between the dowel and the

steering wheel. The two lobes on the turn signal cancel cam on the lower surface of the clockspring rotor

hub contact a turn signal cancel actuator of the

multi-function switch to provide automatic turn signal cancellation. The yellow sleeved pigtail wires on

the upper surface of the clockspring rotor connect the

clockspring to the driver airbag, while a steering

wheel wire harness connects the two connector receptacles on the upper surface of the clockspring rotor to

the horn switch feed pigtail wire connector and, if

the vehicle is so equipped, to the optional speed control and remote radio switches on the steering wheel.

Like the clockspring in a timepiece, the clockspring

tape has travel limits and can be damaged by being

wound too tightly during full stop-to-stop steering

wheel rotation. To prevent this from occurring, the

clockspring is centered when it is installed on the

steering column. Centering the clockspring indexes

the clockspring tape to the movable steering components so that the tape can operate within its

designed travel limits. However, if the clockspring is

removed from the steering column or if the steering

shaft is disconnected from the steering gear, the

clockspring spool can change position relative to the

movable steering components. The clockspring must

be re-centered following completion of this service or

the tape may be damaged.

Service replacement clocksprings are shipped precentered and with a plastic locking pin installed.

This locking pin should not be disengaged until the

clockspring has been installed on the steering column. If the locking pin is removed or damaged before

the clockspring is installed on a steering column, the

clockspring centering procedure must be performed.

(Refer to 8 - ELECTRICAL/RESTRAINTS/CLOCKSPRING - STANDARD PROCEDURE - CLOCKSPRING CENTERING).

tion relative to the other steering components. The

clockspring must then be re-centered following completion of such service or the clockspring tape may be

damaged. Service replacement clocksprings are

shipped pre-centered, with a plastic locking pin

installed (Fig. 19). This locking pin should not be

removed until the clockspring has been installed on

the steering column. If the locking pin is removed

before the clockspring is installed on a steering column, the clockspring centering procedure must be

performed.

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

SIDE CURTAIN AIRBAG, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCONNECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

SUPPLEMENTAL RESTRAINT SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

STANDARD PROCEDURE - CLOCKSPRING

CENTERING

The clockspring is designed to wind and unwind

when the steering wheel is rotated, but is only

designed to rotate the same number of turns (about

five complete rotations) as the steering wheel can be

turned from stop to stop. Centering the clockspring

indexes the clockspring tape to other steering components so that it can operate within its designed

travel limits. The rotor of a centered clockspring can

be rotated two and one-half turns in either direction

from the centered position, without damaging the

clockspring tape.

However, if the clockspring is removed for service

or if the steering column is disconnected from the

steering gear, the clockspring tape can change posi-

Fig. 19 Clockspring and Multi-Function Switch

1 - CLOCKSPRING

2 - LOCATING PIN

3 - SCREW (2)

4 - LOCKING PIN

5 - ENGAGEMENT DOWEL BOOT

Page 20

8O - 20 RESTRAINTS DR

CLOCKSPRING (Continued)

NOTE: Before starting this procedure, be certain to

turn the steering wheel until the front wheels are in

the straight-ahead position.

(1) Place the front wheels in the straight-ahead

position.

(2) Remove the clockspring from the steering column. (Refer to 8 - ELECTRICAL/RESTRAINTS/

CLOCKSPRING - REMOVAL).

(3) Rotate the clockspring rotor clockwise to the

end of its travel. Do not apply excessive torque.

(4) From the end of the clockwise travel, rotate the

rotor about two and one-half turns counterclockwise.

The engagement dowel and yellow rubber boot

should end up at the bottom, and the arrows on the

clockspring rotor and case should be in alignment.

The clockspring is now centered.

(5) The front wheels should still be in the straightahead position. Reinstall the clockspring onto the

steering column. (Refer to 8 - ELECTRICAL/RESTRAINTS/CLOCKSPRING - INSTALLATION).

REMOVAL

The clockspring cannot be repaired. It must be

replaced if faulty or damaged, or if the driver airbag

has been deployed.

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

SIDE CURTAIN AIRBAG, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCONNECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

SUPPLEMENTAL RESTRAINT SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

NOTE: Before starting this procedure, be certain to

turn the steering wheel until the front wheels are in

the straight-ahead position.

(1) Place the front wheels in the straight ahead

position.

(2) Remove the driver airbag from the steering

wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL).

(3) Disconnect the steering wheel wire harness

connectors from the upper clockspring connector

receptacles.

CAUTION: Be certain that the screws that secure

the steering wheel puller to the steering wheel are

fully engaged in the steering wheel armature without passing through the steering wheel and damaging the clockspring.

(4) Remove the steering wheel from the steering

column. (Refer to 19 - STEERING/COLUMN/STEERING WHEEL - REMOVAL).

(5) Remove the steering column opening cover

from the instrument panel. (Refer to 23 - BODY/INSTRUMENT PANEL/STEERING COLUMN OPENING COVER - REMOVAL).

(6) If the vehicle is so equipped, grasp the steering

column tilt knob firmly and pull it straight rearward

to remove it from the tilt adjuster mechanism lever

located on the left side of the column just below the

multi-function switch control stalk.

(7) From below the steering column, remove the

two outboard screws that secure the upper shroud to

the lower shroud.

(8) Using hand pressure, push gently inward on

both sides of the upper shroud near the parting line

between the upper and lower shrouds to release the

snap features that secure it to the lower shroud.

(9) Remove the upper shroud from the lower

shroud.

(10) From below the steering column, remove the

one center screw that secures the lower shroud to the

steering column lock housing.

(11) Remove the lower shroud from the steering

column.

(12) Disconnect the two instrument panel wire

harness connectors for the clockspring from the two

connector receptacles below the steering column on

the back of the clockspring housing.

(13) Remove the two screws that secure the clockspring to the multi-function switch mounting housing

(Fig. 20).

(14) Remove the clockspring from the multi-function switch mounting housing. The clockspring cannot be repaired. It must be replaced if faulty or

damaged, or if the driver airbag has been deployed.

(15) If the removed clockspring is to be reused, be

certain to secure the clockspring rotor to the clockspring case to maintain clockspring centering until it

is reinstalled on the steering column. If clockspring

centering is not maintained, the clockspring must be

centered again before it is reinstalled. (Refer to 8 ELECTRICAL/RESTRAINTS/CLOCKSPRING STANDARD PROCEDURE - CLOCKSPRING CENTERING).

Page 21

DR RESTRAINTS 8O - 21

CLOCKSPRING (Continued)

THIS IS THE ONLY SURE WAY TO DISABLE THE

SUPPLEMENTAL RESTRAINT SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

NOTE: Before starting this procedure, be certain

that the front wheels are still in the straight-ahead

position.

(1) Carefully slide the centered clockspring down