VEHICLES SOLD IN CANADA

With respect to any Vehicles Sold in Canada, the name

Chrysler LLC shall be deemed to be deleted and the

name Chrysler Canada Inc. used in substitution therefor.

DRIVING AND ALCOHOL

Drunken driving is one of the most frequent causes of

accidents.

Your driving ability can be seriously impaired with blood

alcohol levels far below the legal minimum. If you are

drinking, don’t drive. Ride with a designated non-drinking

driver, call a cab, a friend, or use public transportation.

WARNING!

Driving after drinking can lead to an accident. Your

perceptions are less sharp, your reflexes are slower,

and your judgment is impaired when you have been

drinking. Never drink and then drive.

This manual illustrates and describes the operation of

features and equipment that are either standard or optional on this vehicle. This manual may also include a

description of features and equipment that are no longer

available or were not ordered on this vehicle. Please

disregard any features and equipment described in this

manual that are not on this vehicle.

Chrysler LLC reserves the right to make changes in

design and specifications, and/or make additions to or

improvements to its products without imposing any

obligation upon itself to install them on products previously manufactured.

Copyright © 2008 Chrysler LLC

SECTION PAGE

1

INTRODUCTION

2

THINGS TO KNOW BEFORE STARTING YOUR VEHICLE

3

UNDERSTANDING THE FEATURES OF YOUR VEHICLE

4

UNDERSTANDING YOUR INSTRUMENT PANEL

5

STARTING AND OPERATING

6

WHAT TO DO IN EMERGENCIES

7

MAINTAINING YOUR VEHICLE

8

MAINTENANCE SCHEDULES

9

INDEX

....................................................................147

TABLE OF CONTENTS

.............................................................3

...............................5

................................9

.................................... 21

.................................................. 37

................................................77

................................................ 83

..................................................121

INTRODUCTION

CONTENTS

䡵 A Message From Chrysler LLC ............. 4

1

4 INTRODUCTION

A MESSAGE FROM CHRYSLER LLC

Chrysler LLC and Cummins威 welcome you as a Cummins威 turbocharged diesel-powered truck owner.

Almost 100% of all heavy duty trucks are diesel-powered

because of the fuel economy, rugged durability, and high

torque which permits pulling heavy loads. Cummins威,

engines power well over half of these trucks. Now this

same technology and proven performance is yours in

your truck equipped with the Cummins威 turbocharged

diesel engine.

Your diesel truck will sound, feel, drive, and operate

differently from a gasoline-powered truck. It is important

that you read and understand this manual. You may find

that some of the starting, operating, and maintenance

procedures are different. However, they are simple to

follow and careful adherence to them will ensure that

you take full advantage of the features of this engine.

THINGS TO KNOW BEFORE STARTING YOUR VEHICLE

CONTENTS

䡵 Steering Wheel Lock — If Equipped ......... 6

▫ To Manually Lock The Steering Wheel ......6

2

▫ To Release The Steering Wheel Lock ........ 6

䡵 Engine Break-In Recommendations .......... 6

6 THINGS TO KNOW BEFORE STARTING YOUR VEHICLE

STEERING WHEEL LOCK — IF EQUIPPED

Your vehicle may be equipped with a passive steering

wheel lock. This lock prevents steering the vehicle without the ignition key. If the steering wheel is moved

approximately a half turn in either direction and the key

is not in the ignition switch, the steering wheel will lock.

To Manually Lock the Steering Wheel

With the engine running, turn the steering wheel upside

down, turn off the engine and remove the key. Turn the

steering wheel slightly in either direction until the lock

engages.

To Release the Steering Wheel Lock

Insert the key in the ignition switch and start the engine.

If the key is difficult to turn, move the wheel slightly to

the right or left to disengage the lock.

NOTE: If you turned the wheel to the right to engage

the lock, you must turn the wheel slightly to the right to

disengage it. If you turned the wheel to the left to engage

the lock, turn the wheel slightly to the left to disengage it.

ENGINE BREAK-IN RECOMMENDATIONS

The Cummins威 turbocharged diesel engine does not

require a break-in period due to its construction. Normal

operation is allowed, providing the following recommendations are followed:

NOTE: Light duty operation such as light trailer towing

or no load operation will extend the time before the

engine is at full efficiency. Reduced fuel economy and

power may be seen at this time.

THINGS TO KNOW BEFORE STARTING YOUR VEHICLE 7

For additional vehicle break-in requirements, refer to

“Trailer Towing” in Section 5 of the Owners Manual.

•

Warm up the engine before placing it under load.

•

Do not operate the engine at idle for prolonged

periods.

•

Use the appropriate transmission gear to prevent

engine lugging.

•

Observe vehicle oil pressure and temperature indicators.

•

Check the coolant and oil levels frequently.

•

Vary throttle position at highway speeds when carrying or towing significant weight.

Because of the construction of the Cummins威 turbocharged diesel engine, engine run-in is enhanced by

loaded operating conditions which allow the engine

parts to achieve final finish and fit during the first

6,000 miles (10 000 km).

2

UNDERSTANDING THE FEATURES OF YOUR VEHICLE

CONTENTS

䡵 Overhead Console With Electronic Vehicle

Information Center (EVIC)................. 10

▫ Electronic Vehicle Information Center (EVIC)

— If Equipped ....................... 11

3

▫ Dome/Reading Lights ................ 10

▫ Compass/Temperature Button ........... 18

10 UNDERSTANDING THE FEATURES OF YOUR VEHICLE

OVERHEAD CONSOLE WITH ELECTRONIC VEHICLE INFORMATION CENTER (EVIC)

The overhead console contains dome/reading lights, and

an Electronic Vehicle Information Center (EVIC).

Dome/Reading Lights

Located in the overhead console are two dome/reading

lights.

The dome/reading lights illuminate when a door is

opened or when the interior lights are turned on by

rotating the dimmer control located on the headlight

switch.

The reading lights are activated by pressing on the

recessed area of the corresponding lens.

NOTE: The dome/reading lights will remain on until

the switch is pressed a second time, so be sure they have

been turned off before leaving the vehicle.

Dome/Reading Lights

UNDERSTANDING THE FEATURES OF YOUR VEHICLE 11

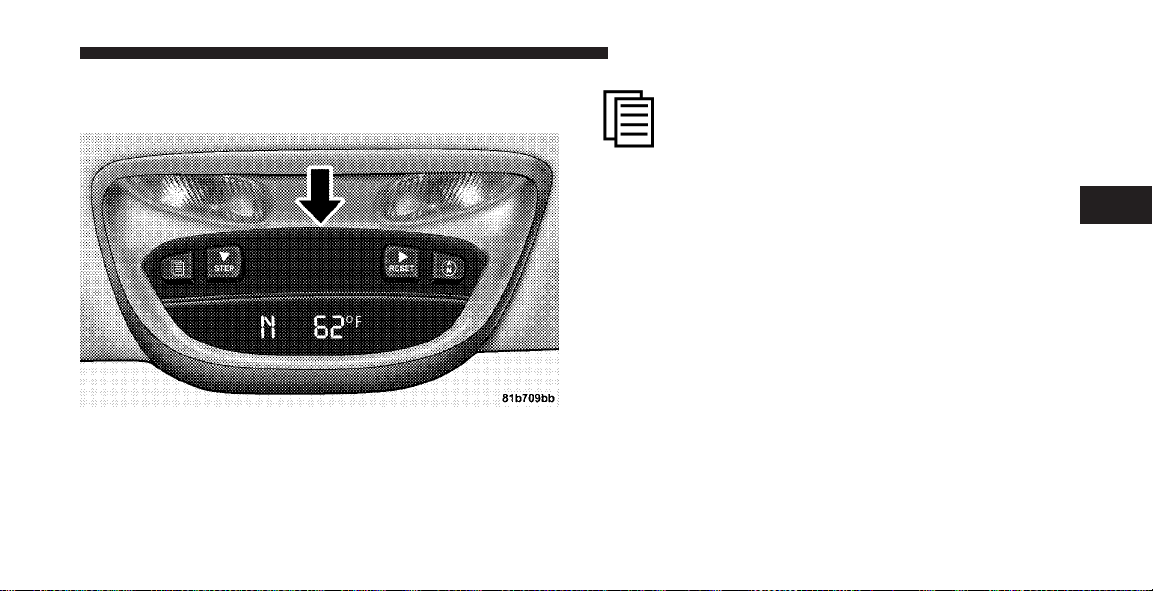

Electronic Vehicle Information Center (EVIC) — If

Equipped

Overhead Console With EVIC

Pressing the MENU button will change the

display to one of the following features:

Trip Functions

Pressing the STEP button allows you to scroll through

one of the following Trip Function features:

•

TRIP – Shows the total distance traveled since the last

reset. To reset the TRIP function, press and hold the

RESET button.

•

ELAPSED TIME – Shows the total elapsed time of

travel since the last reset. Elapsed time will increment

when the ignition switch is in the ON/RUN or START

positions.

•

UNIT IN US/METRIC – Press the RESET button to

toggle between US and METRIC.

3

12 UNDERSTANDING THE FEATURES OF YOUR VEHICLE

•

AVG. MPG – Shows the average fuel economy since

the last reset. When the fuel economy is reset, the

display will show dashes for two seconds. Then the

history information will be erased, and the averaging

will continue from the last fuel average reading before

the reset. (Example: If your EVIC displays 18 AVG.

MPG and the RESET button is pressed, the previous

averaging history will be erased and the display will

return to the 18 AVG. MPG, not to 0 AVG. MPG.) The

display may take several miles/kilometers for the

value to change, dependent upon driving habits.

•

MI TO EMPTY (Distance to Empty) – Shows the

estimated distance that can be traveled with the fuel

remaining in the tank. This estimated distance is

determined by a weighted average of fuel economy,

according to the current fuel tank level. MI TO EMPTY

cannot be reset through the RESET button.

NOTE: Significant changes in driving style or vehicle

loading will greatly affect the actual drivable distance of

the vehicle, regardless of the MI TO EMPTY displayed

value.

When the MI TO EMPTY value is less than 30 miles

(48 km) estimated driving distance, the MI TO EMPTY

display will change to a text display of ⬙LOW FUEL.⬙

This display will continue until the vehicle runs out of

fuel. Adding a significant amount of fuel to the vehicle

will turn off the ⬙LOW FUEL⬙ text and a new MI TO

EMPTY value will display.

System Status (EVIC Displays)

When the appropriate conditions exist, the EVIC displays

the following messages:

•

TURN SIGNALS ON (with a continuous warning

chime)

•

PERSONAL SETTINGS NOT AVAILABLE – Vehicle

not in PARK or Vehicle in Motion (Manual Transmission Only)

•

LEFT/RIGHT FRONT DOOR AJAR (one or more,

with a single chime if speed is above 1 mph (1.6 km/h)

•

LEFT/RIGHT REAR DOOR AJAR (one or more, with

a single chime if speed is above 1 mph (1.6 km/h)

•

DOOR(S) AJAR (with a single chime if vehicle is in

motion)

•

LOW WASHER FLUID (with a single chime)

•

OIL CHANGE REQUIRED (with a single chime)

•

SERVICE AIR FILTER

•

PERFORM SERVICE

•

EXHAUST FILTER XX% FULL

UNDERSTANDING THE FEATURES OF YOUR VEHICLE 13

•

EXHAUST FILTER FULL — POWER REDUCED SEE

DEALER

•

SERVICE REQUIRED — SEE DEALER NOW

•

EXHAUST SYSTEM — REGENERATION REQUIRED

NOW

•

EXHAUST SYSTEM — REGENERATION IN PROCESS

•

EXHAUST SYSTEM — REGENERATION COMPLETED

•

TIRE PRESSURE LT LOAD SET

•

TIRE PRESSURE MAX LOAD SET

Oil Change Required — If Equipped

Your vehicle is equipped with an engine oil change

indicator system. The “Oil Change Required” message

will flash in the EVIC display for approximately 10 seconds after a single chime has sounded to indicate the next

3

14 UNDERSTANDING THE FEATURES OF YOUR VEHICLE

scheduled oil change interval. The engine oil change

indicator system is duty cycle based, which means the

engine oil change interval may fluctuate, dependent

upon your personal driving style.

NOTE: When prompted by the Engine Oil Change

Indicator System, the engine oil and filter must be

changed. If not prompted by the Engine Oil Change

Indicator System within 7,500 miles (12 000 km) or

six months since the last oil and filter change, change the

engine oil and engine oil filter. Under no circumstances

should engine oil intervals exceed 7,500 miles

(12 000 km) or six months, whichever comes first.

Unless reset, this message will continue to display each

time you turn the ignition switch to the ON/RUN

position. To turn off the message temporarily, press and

release the MENU button. To reset the oil change indicator system (after performing the scheduled maintenance)

use the following procedure.

1. Turn the ignition switch to the ON position (do not

start the engine).

2. Fully depress the accelerator pedal slowly three times

within 10 seconds.

3. Turn the ignition switch to the OFF/LOCK position.

NOTE: If the indicator message illuminates when you

start the vehicle, the oil change indicator system did not

reset. If necessary, repeat this procedure.

Perform Service

This vehicle will require emissions maintenance at a set

interval. To help remind you when this maintenance is

due, the Electronic Vehicle Information Center (EVIC)

will display “Perform Service.” When the “Perform Service” message is displayed on the EVIC, it is necessary to

have the emissions maintenance performed. Emissions

maintenance includes replacing the Closed Crankcase

Ventilation (CCV) filter element, cleaning of the EGR

UNDERSTANDING THE FEATURES OF YOUR VEHICLE 15

Cooler, and cleaning of the EGR Valve. The procedure for

clearing and resetting the “Perform Service” indicator

message is located in the appropriate service information.

Refer to the “Maintenance Schedule” in Section 8 for the

proper emission maintenance intervals.

Personal Settings (Customer Programmable

Features)

Personal settings allows the driver to set and recall

features when the transmission is in PARK. If the transmission is not in PARK, the EVIC will display NOT

AVAILABLE and VEHICLE NOT IN PARK.

Press and release the MENU button until the

Personal Settings displays on the EVIC.

Use the STEP button to display one of the following:

•

“LANGUAGE” – When in this display you may select

one of three languages for all display nomenclature,

including the trip functions. Press the RESET button

while in this display to select English, Espanol, or

Francais. Then, as you continue, the information will

display in the selected language.

•

“AUTO DOOR LOCKS > ON” – When ON is selected,

all doors will lock automatically when the vehicle

reaches a speed of 15 mph (24 km/h). To make your

selection, press and release the RESET button until

“ON” or “OFF” appears.

•

“AUTO UNLOCK ON EXIT > ON” – When ON is

selected, all doors will unlock when the vehicle is

stopped and the transmission is in the PARK or

NEUTRAL position and the driver’s door is opened.

To make your selection, press and release the RESET

button until “ON” or “OFF” appears.

3

16 UNDERSTANDING THE FEATURES OF YOUR VEHICLE

•

“RKE UNLOCK DRV DR 1st” – When DRV DR 1st is

selected, only the driver’s door will unlock on the first

press of the remote keyless entry UNLOCK button.

When Driver Door 1st Press is selected, you must

press the remote keyless entry UNLOCK button twice

to unlock the passenger’s doors. To make your selection, press and release the RESET button until “DRV

DR 1st ” appears.

•

“RKE UNLOCK ALL DR 1ST” – When ALL DR 1ST is

selected, all of the doors will unlock on the first press

of the remote keyless entry unlock button. To make

your selection, press and release the RESET button

until “All DR 1st” appears.

•

“SOUND HORN W/LOCK > ON” – When ON is

selected, a short horn sound will occur when the

remote keyless entry LOCK button is pressed. This

feature may be selected with or without the flash lights

on lock/unlock feature. To make your selection, press

and release the RESET button until “ON” or “OFF”

appears.

•

“FLASH LIGHTS W/LOCK > ON” – When ON is

selected, the front and rear turn signals will flash when

the doors are locked or unlocked with the remote

keyless entry transmitter. This feature may be selected

with or without the sound horn on lock feature

selected. To make your selection, press and release the

RESET button until “ON” or “OFF” appears.

•

“HEAD LAMP OFF DELAY > 0 SEC” – When this

feature is selected, the driver can choose to have the

headlights remain on for 0, 30, 60, or 90 seconds when

exiting the vehicle. To make your selection, press and

release the RESET button until “0,” “30,” “60,” or “90”

appears.

UNDERSTANDING THE FEATURES OF YOUR VEHICLE 17

•

“KEY OFF POWER DELAY > OFF” – When this

feature is selected, the power window switches, radio,

hands–free system (if equipped), and power outlets

will remain active for up to 10 minutes after the

ignition switch is turned OFF. Opening a vehicle door

will cancel this feature. To make your selection, press

and release the RESET button until “Off,” “45 sec.,”

“5 min.,” “10 min.” appears.

•

“ILLUMINATED APRCH > OFF” – When this feature

is selected, the headlights will activate and remain on

for up to 90 seconds when the doors are unlocked with

the remote keyless entry transmitter. To make your

selection, press and release the RESET button until

“OFF,” “30 sec.,” “60 sec.,” or “90 sec.” appears.

NOTE: If this feature is enabled, the headlamps will be

on during the engine pre-heat and cold crank; therefore,

it is recommended that the feature be disabled when

overnight ambient temperature is at or below 20°F (-7°C)

to prevent excessive drain on batteries during cold cranking.

•

“UNIT IN > US/METRIC” – The EVIC and odometer

display can be changed between English and Metric

units of measure. To make your selection, press and

release the RESET button until “US” or “METRIC”

appears.

•

“COMPASS VARIANCE > 8” – Press the RESET

button to change the compass variance setting. For

additional information, refer to “Compass Variance”

in this section.

•

“COMPASS CALIBRATE > YES” – Press the RESET

button to calibrate the compass. For additional information, refer to “Compass Calibrate” in this section.

3

18 UNDERSTANDING THE FEATURES OF YOUR VEHICLE

Compass/Temperature Button

Pressing the Compass/Temperature button

will return the display to the normal compass/

temperature display.

NOTE: Temperature accuracy can be affected from heat

soak. For best accuracy, the vehicle should be driven at a

speed greater than 25 mph (40 km/h) for several minutes.

Automatic Compass Calibration

This compass is self-calibrating, which eliminates the

need to set the compass manually. When the vehicle is

new, the compass may appear erratic and the EVIC will

display “CAL” until the compass is calibrated. You may

also calibrate the compass by completing one or more

360° turns (in an area free from large metal or metallic

objects) until the “CAL” message displayed in the EVIC

turns off. The compass will now function normally.

Manual Compass Calibration

If the compass appears erratic and the “CAL” message

does not appear in the EVIC display, you must put the

compass into the Calibration Mode manually as follows:

1. Turn the ignition switch to the ON/RUN position.

2. Press the MENU button until “Personal Settings” is

displayed.

3. Press the STEP button until “Calibrate Compass YES”

is displayed.

4. Press and release the RESET button to start the calibration. The message “CAL” will display in the EVIC.

5. Slowly drive the vehicle 5 mph (8 km/h) in a complete

360° circle (in an area free from large metal or metallic

objects) until the “CAL” message turns off. The compass

will now function normally.

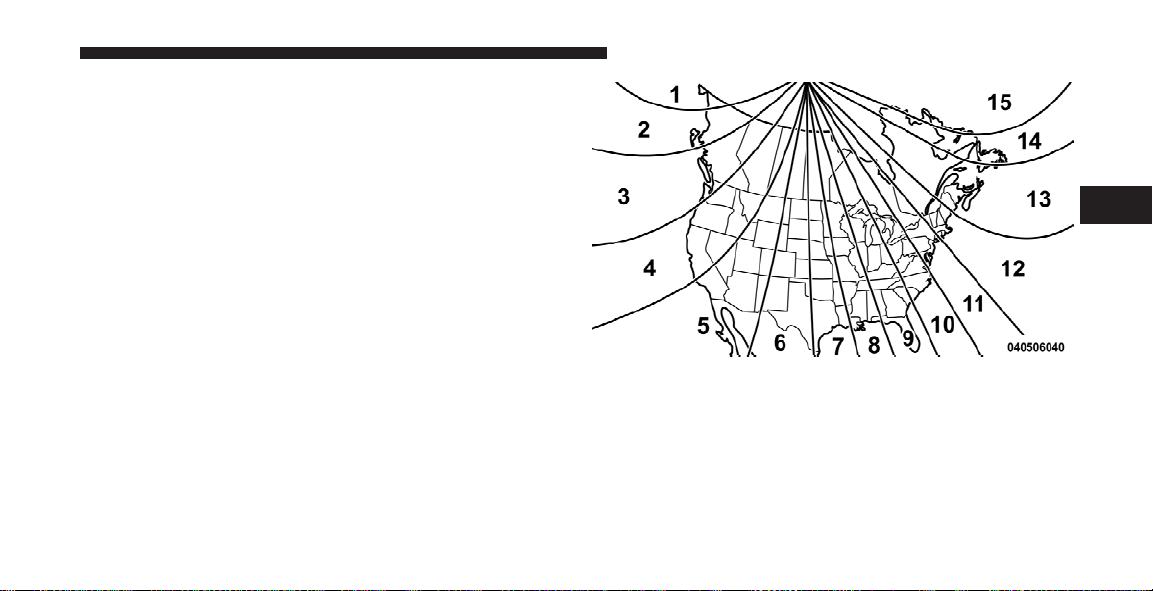

Compass Variance

Compass Variance is the difference between magnetic

North and Geographic North. In some areas of the

country, the difference between magnetic and geographic

North is great enough to cause the compass to give false

readings. If this occurs, the compass variance must be set

using the following procedure:

NOTE: Magnetic materials should be kept away from

the overhead console. This is where the compass sensor is

located.

UNDERSTANDING THE FEATURES OF YOUR VEHICLE 19

3

Compass Variance Map

20 UNDERSTANDING THE FEATURES OF YOUR VEHICLE

1. Turn the ignition switch to the ON/RUN position.

2. Press the MENU button until “Personal Settings” is

displayed.

3. Press the STEP button until “Compass Variance” is

displayed.

4. Press and release RESET button until the proper

variance zone is selected according to the map.

5. Press and release the Compass button to exit.

UNDERSTANDING YOUR INSTRUMENT PANEL

CONTENTS

䡵 Instrument Panel Features ................ 22

䡵 Instrument Cluster ..................... 23

▫ 6.7L Diesel Engine .................... 23

䡵 Instrument Cluster Description ............. 24

4

22 UNDERSTANDING YOUR INSTRUMENT PANEL

INSTRUMENT PANEL FEATURES

1 — Headlight Switch 6 — Passenger Airbag* 11 — TPMS “Light Load” Reset Switch* 16 — Transfer Case Control

2 — Air Outlets 7 — Glove Box 12 — Power Sliding Back Glass Switch* 17 — Parking Brake Release Lever

3 — Instrument Cluster 8 — Passenger Airbag On/

4 — Climate Controls 9 — Power Outlet 14 — Exhaust Brake Switch* * If Equipped

5 — Radio 10 — Heated Seat Switch 15 — Cigar Lighter

Off Switch*

13 — Cupholders 18 — Adjustable Pedal Control

Switch*

Switch*

INSTRUMENT CLUSTER

6.7L Diesel Engine

UNDERSTANDING YOUR INSTRUMENT PANEL 23

4

24 UNDERSTANDING YOUR INSTRUMENT PANEL

INSTRUMENT CLUSTER DESCRIPTION

1. Check Gages Warning Light

This light will illuminate when the voltmeter,

engine oil pressure, or engine coolant temperature

gauge indicates a reading either too high or too low.

Examine the gauges carefully, and follow the instructions

contained below for each indicated problem.

NOTE: When the ignition switch is turned to OFF, the

fuel gauge, voltmeter, oil pressure and engine coolant

temperature gauges may not show accurate readings.

When the engine is not running, turn the ignition switch

to ON to obtain accurate readings.

2. Voltmeter

When the engine is running, the gauge indicates

the electrical system voltage. The pointer should

stay within the normal range if the battery is charged. If

the pointer moves to either the extreme left or right, and

remains there during normal driving, the electrical system should be serviced.

NOTE:

•

If the gauge pointer moves to either extreme of the

gauge, the “Check Gages Warning Light” will illuminate and a single chime will sound.

•

The voltmeter may show a gauge fluctuation at various engine temperatures. This cycling operation is

caused by the post-heat cycle of the intake manifold

heater system. The number of cycles and the length of

the cycling operation is controlled by the engine

control module. Post-heat operation can run for several minutes, and then the electrical system and voltmeter needle will stabilize.

•

The cycling action will cause temporary dimming of

the headlights, interior lights, and also a noticeable

reduction in blower motor speed.

UNDERSTANDING YOUR INSTRUMENT PANEL 25

3. Turn Signal Indicator Light

The arrows will flash with the exterior turn signals

when the turn signal lever is operated.

4. Tachometer

The tachometer indicates engine speed in revolutions per

minute.

CAUTION!

Do not operate the engine with the tachometer

pointer at high RPM for extended periods. Engine

damage may occur.

5. Airbag Warning Light

The indicator lights and remains lit for six to

eight seconds when the ignition is first turned

on. If the light stays on, flickers or comes on

while driving, have the airbag system checked

by an authorized dealer.

6. High Beam Indicator Light

This indicator shows that headlights are on high

beam.

7. Seat Belt Reminder Light

When the ignition switch is first turned ON, this

light will turn on for five to eight seconds as a bulb

check. During the bulb check, if the driver’s seat

belt is unbuckled, a chime will sound. After the bulb

check or when driving, if the driver seat belt remains

unbuckled, the “Seat Belt Warning Light” will flash or

remain on continuously.

8. Speedometer

The speedometer shows the vehicle speed in miles per

hour (mph) and/or kilometers per hour (km/h).

4

26 UNDERSTANDING YOUR INSTRUMENT PANEL

9. Oil Pressure Gauge

The pointer should always indicate some oil pres-

sure when the engine is running. A continuous

high or low reading, under normal driving conditions,

may indicate a lubrication system malfunction. Immediate service should be obtained.

NOTE: If the gauge pointer moves to either extreme of

the gauge, the “Check Gages Warning Light” will illuminate and a single chime will sound.

10. Transfer Case Position Light

This display indicator shows the transfer case position

selection.

For additional information refer to “Four-Wheel Drive

Operation” in Section 5 of this manual.

11. TOW HAUL Indicator Light

The TOW HAUL button is located at the end of

the shift lever. This light will illuminate when

the TOW HAUL button is pushed once.

12. Temperature Gauge

The temperature gauge indicates engine coolant

temperature. Any reading within the normal

range indicates that the cooling system is operating satisfactorily. The gauge needle will likely indicate a

higher temperature when driving in hot weather, up

mountain grades, in heavy traffic, or when towing a

trailer. If the needle rises to the 245°F (118°C) mark, stop

the vehicle, shift into NEUTRAL, and increase the engine

idle speed for two to three minutes. If the temperature

reading does not return to normal, shut your engine OFF

and allow it to cool. Seek authorized service immediately.

Refer to “Cooling System” under “Maintaining Your

Vehicle” in Section 7.

UNDERSTANDING YOUR INSTRUMENT PANEL 27

CAUTION!

Do not leave your vehicle unattended with the engine running, as you would not be able to react to the

temperature indicator if the engine overheats.

NOTE:

•

Engine idle speed will automatically increase to 1,000

RPM at elevated coolant temperatures to improve

engine cooling.

•

If the gauge pointer moves to either extreme of the

gauge, the “Check Gages Warning Light” will illuminate and a single chime will sound.

13. Vehicle Security Light

The light will flash rapidly for approximately

16 seconds when the Vehicle Security Alarm is

arming. The light will flash at a slower rate

after the alarm is set. The “Vehicle Security Light” will

also come on for about two seconds when the ignition is

first turned ON.

14. Shift Lever Indicator (Automatic Transmissions

Only)

When the shift lever is moved (on vehicles with the

68RFE transmission), this indicator will show the selected

gear range (P R N D). Vehicles equipped with Auto-6/

Electronic Range Select (ERS) will display the selection of

the desired top gear, in the position next to the D (Drive).

15. Odometer/Trip Odometer

The odometer shows the total distance the vehicle has

been driven. U.S. federal regulations require that upon

transfer of vehicle ownership, the seller certify to the

purchaser the correct mileage that the vehicle has been

driven. Therefore, if the odometer reading is changed

during repair or replacement, be sure to keep a record of

the reading before and after the service so that the correct

mileage can be determined.

4

28 UNDERSTANDING YOUR INSTRUMENT PANEL

The two trip odometers show individual trip mileage. To

switch from odometer to trip odometers, press and

release the Trip Odometer button.

To reset a trip odometer, display the desired trip odometer to be reset then push and hold the button (approximately two seconds) until the display resets.

Vehicle Warning Messages

When the appropriate conditions exist, messages such as

“door” (indicates that a door(s) may be ajar), “gASCAP”

(which indicates that your gas cap is possibly loose or

damaged), and “noFUSE” (indicates that the IOD fuse is

removed from the Integrated Power Module), will display in the odometer.

NOTE: There is also an engine hour function. This

indicates the total number of hours the engine has been

running. To display the engine hours perform the following: Place the ignition in RUN, but do not start the

engine. With the odometer value displayed, hold the trip

button down for a period of six seconds. The odometer

will change to trip value first, then it will display the

engine hour value. The engine hours will be displayed

for a period of 30 seconds until the ignition is turned off

or the engine is started.

DPF Full

The messages “dPF” and “FULL” will alternately display

in the odometer when Diesel Particulate Filter (DPF)

service is required. Refer to “Overhead Console with

Electronic Vehicle Information Center (EVIC)” in Section 3 for more information.

16. Front Fog Light Indicator Light — If Equipped

This indicator will illuminate when the front fog

lights are on.

UNDERSTANDING YOUR INSTRUMENT PANEL 29

17. Malfunction Indicator Light (MIL)

The Malfunction Indicator Light (MIL) is part of

an onboard diagnostic system which monitors

the emissions and engine control system. If the

vehicle is ready for emissions testing the light will come

on when the ignition is first turned on and remain on, as

a bulb check, until the engine is started. If the vehicle is

not ready for emissions testing the light will come on

when the ignition is first turned on and remain on for

15 seconds, then blink for five seconds, and remain on

until the vehicle is started. If the bulb does not come on

during starting, have the condition investigated

promptly.

If this light comes on and remains on while driving, it

suggests a potential engine control problem and the need

for system service.

Although your vehicle will usually be drivable and not

need towing, see your authorized dealer for service as

soon as possible.

CAUTION!

•

Prolonged driving with the MIL on could cause

damage to the engine control system. It also could

affect fuel economy and drivability.

•

If the MIL is flashing, severe catalytic converter

damage and power loss will soon occur. Immediate service is required.

18. Brake Warning Light

This light monitors various brake functions,

including brake fluid level and parking brake

application. If the brake light turns on, it may

indicate that the parking brake is applied, that

the brake fluid level is low, or that there is a problem with

the anti-lock brake system reservoir.

If the light remains on when the parking brake has been

disengaged, and the fluid level is at the full mark on the

master cylinder reservoir, it indicates a possible brake

4

30 UNDERSTANDING YOUR INSTRUMENT PANEL

hydraulic system malfunction or a problem with the

Brake Booster has been detected by the Anti-Lock Brake

System (ABS) / Electronic Stability Program (ESP) system. In this case, the light will remain on until the

condition has been corrected. If the problem is related to

the brake booster, the ABS pump will run when applying

the brake and a brake pedal pulsation may be felt during

each stop.

The dual brake system provides a reserve braking capacity in the event of a failure to a portion of the hydraulic

system. A leak in either half of the dual brake system is

indicated by the “Brake Warning Light,” which will turn

on when the brake fluid level in the master cylinder has

dropped below a specified level.

The light will remain on until the cause is corrected.

NOTE: The light may flash momentarily during sharp

cornering maneuvers, which change fluid level conditions. The vehicle should have service performed, and

the brake fluid level checked.

If brake failure is indicated, immediate repair is necessary.

WARNING!

Driving a vehicle with the “Brake Warning Light” on

is dangerous. Part of the brake system may have

failed. It will take longer to stop the vehicle. You

could have an accident. Have the vehicle checked

immediately.

Vehicles equipped with the Anti-Lock Brake System

(ABS), are also equipped with Electronic Brake Force

Distribution (EBD). In the event of an EBD failure, the

UNDERSTANDING YOUR INSTRUMENT PANEL 31

“Brake Warning Light” will turn on along with the “ABS

Warning Light.” Immediate repair to the ABS system is

required.

Operation of the “Brake Warning Light” can be checked

by turning the ignition switch from the OFF position to

the ON position. The light should illuminate for approximately two seconds. The light should then turn off unless

the parking brake is applied or a brake fault is detected.

If the light does not illuminate, have the light inspected

by an authorized dealer.

The light also will turn on when the parking brake is

applied with the ignition switch in the ON position.

NOTE: This light shows only that the parking brake is

applied. It does not show the degree of brake application.

19. Anti-Lock Brake (ABS) Warning Light

This light monitors the Anti-Lock Brake System

(ABS). The light will turn on when the ignition

switch is turned to the ON position and may

stay on for as long as four seconds.

If the “ABS Warning Light” remains on or turns on while

driving, it indicates that the Anti-Lock portion of the

brake system is not functioning and that service is

required. However, the conventional brake system will

continue to operate normally if the “Brake Warning

Light” is not on.

If the “ABS Warning Light” is on, the brake system

should be serviced as soon as possible to restore the

benefits of Anti-Lock brakes. If the “ABS Warning Light”

does not turn on when the ignition switch is turned to the

ON position, have the light inspected by an authorized

dealer.

4

32 UNDERSTANDING YOUR INSTRUMENT PANEL

20. Cargo Light

The cargo light will illuminate when the cargo

lamp is activated by pressing the cargo light

button on the headlight switch.

21. Electronic Throttle Control (ETC) Warning Light

This light informs you of a problem with the

Electronic Throttle Control (ETC) system. If a

problem is detected, the light will come on

while the engine is running. If the light remains

lit with the engine running your vehicle will usually be

drivable, however, see your authorized dealer for service

as soon as possible. If the light is flashing when the

engine is running, immediate service is required and you

may experience reduced performance, an elevated/

rough idle or engine stall and your vehicle may require

towing. The light will come on when the ignition is first

turned on and remain on for 15 seconds as a bulb check.

If the light does not come on during starting, have the

system checked by an authorized dealer.

22. SERV 4WD Indicator Light

The “4WD” indicator will be illuminated

whenever the four-wheel drive mode is engaged on either the manual or electric shift

four-wheel drive systems. The “SERV 4WD

Indicator Light” monitors the electronic shift four-wheel

drive system. If the “SERV 4WD Indicator Light” stays on

or comes on while driving, it means that the four-wheel

drive system is not functioning properly and that service

is required.

23. Water In Fuel Indicator Light

Indicates there is water detected in the fuel

filter. If this light remains on, DO NOT start the

vehicle before you drain the water from the

fuel filter to prevent engine damage. Refer to

“Maintenance Procedures/ Draining Fuel/Water Separator Filter” in Section 7 for water drain procedure.

UNDERSTANDING YOUR INSTRUMENT PANEL 33

24. Tire Pressure Monitoring Telltale Light — If

Equipped

Each tire, including the spare (if provided),

should be checked monthly, when cold and

inflated to the inflation pressure recommended

by the vehicle manufacturer on the vehicle

placard or tire inflation pressure label. (If your vehicle

has tires of a different size than the size indicated on the

vehicle placard or tire inflation pressure label, you should

determine the proper tire inflation pressure for those

tires.)

As an added safety feature, your vehicle has been

equipped with a Tire Pressure Monitoring System

(TPMS) that illuminates a low tire pressure telltale when

one or more of your tires is significantly under-inflated.

Accordingly, when the low tire pressure telltale illuminates, you should stop and check your tires as soon as

possible, and inflate them to the proper pressure. Driving

on a significantly under-inflated tire causes the tire to

overheat and can lead to tire failure. Under-inflation also

reduces fuel efficiency and tire tread life, and may affect

the vehicle’s handling and stopping ability.

Please note that the TPMS is not a substitute for proper

tire maintenance, and it is the driver ’s responsibility to

maintain correct tire pressure, even if under-inflation has

not reached the level to trigger illumination of the TPMS

low tire pressure telltale.

4

34 UNDERSTANDING YOUR INSTRUMENT PANEL

Your vehicle has also been equipped with a TPMS

malfunction indicator to indicate when the system is not

operating properly. The TPMS malfunction indicator is

combined with the low tire pressure telltale. When the

system detects a malfunction, the telltale will flash for

approximately one minute and then remain continuously

illuminated. This sequence will continue upon subsequent vehicle start-ups as long as the malfunction exists.

When the malfunction indicator is illuminated, the system may not be able to detect or signal low tire pressure

as intended. TPMS malfunctions may occur for a variety

of reasons, including the installation of replacement or

alternate tires or wheels on the vehicle that prevent the

TPMS from functioning properly. Always check the

TPMS malfunction telltale after replacing one or more

tires or wheels on your vehicle, to ensure that the

replacement or alternate tires and wheels allow the TPMS

to continue to function properly.

CAUTION!

The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures and

warning have been established for the tire size

equipped on your vehicle. Undesirable system operation or sensor damage may result when using replacement equipment that is not of the same size,

type, and/or style. Aftermarket wheels can cause

sensor damage. Do not use tire sealant from a can, or

balance beads if your vehicle is equipped with a

TPMS, as damage to the sensors may result.

UNDERSTANDING YOUR INSTRUMENT PANEL 35

Tire Light Load Inflation Switch – If Equipped

The tire light load inflation switch allows you to choose

between “Light Load” vehicle conditions and “Max

Load” vehicle conditions, tire pressures, and related

TPMS warning levels. The switch is located on the

instrument panel, below the climate control panel. For

additional information, refer to “Tire Pressure Monitoring System (TPMS) — If Equipped” in Section 5 of this

manual.

25. Transmission Temperature Warning Light

(Automatic Transmissions Only)

This light indicates that there is excessive trans-

mission fluid temperature that might occur

with severe usage such as trailer towing. It may

also occur when operating the vehicle in a high

torque converter slip condition, such as four-wheel drive

operation (e.g., snow plowing, off-road operation). If this

light comes on, stop the vehicle and run the engine at idle

or faster, with the transmission in NEUTRAL until the

light goes off.

26. Wait To Start Light

The “Wait To Start Light” will illuminate when the

ignition is turned to the RUN position and the

intake manifold temperature is below 66°F (19°C). Follow

engine starting procedure for proper engine starting and

operating. Wait until the “Wait To Start Light” turns OFF,

then start the vehicle.

NOTE: The “Wait To Start Light” may not illuminate if

the intake manifold temperature is warm enough.

27. Odometer/Trip Odometer Button

Press this button to toggle between the odometer and the

trip odometer display. Holding the button in resets the

trip odometer reading when in trip mode.

4

36 UNDERSTANDING YOUR INSTRUMENT PANEL

28. Fuel Gauge

Shows level of fuel in tank when ignition switch is in the

ON position.

29. Low Fuel Warning Light

This light will illuminate when the pointer is between “E” and 1/8 indication mark (approximately

15% of tank volume) on the fuel gauge. When the

fuel gauge pointer is on “E” (equivalent to Distance To

Empty [DTE]=0ontheoverhead console, if so

equipped) there is reserve fuel capacity, which corresponds to approximately 8% of tank volume. This reserve

capacity was put in place to prevent the likelihood of

customers running out of fuel when operating at maximum load conditions in areas where there are not many

fuel stations.

30. CRUISE Indicator Light

This light will illuminate when the electronic

speed control system is turned on.

CONTENTS

STARTING AND OPERATING

䡵 Starting Procedures ..................... 39

▫ Manual Transmission – If Equipped ........ 39

▫ Automatic Transmission – If Equipped ...... 39

▫ Normal Starting Procedure –

Engine Manifold Air Temperature

Above 66°F (19°C) ..................... 40

▫ Starting Procedure – Engine Manifold Air

Temperature Below 66°F (19°C) ........... 41

▫ Starting Procedure – Engine Manifold Air

Temperature Below 0°F (-18°C) ............ 42

▫ Starting Fluids ....................... 44

䡵 Normal Operation – Diesel Engine .......... 44

▫ Cold Weather Precautions ............... 45

▫ Engine Idling ........................ 47

▫ Stopping The Engine ................... 48

▫ Engine Speed Control .................. 50

▫ Operating Precautions .................. 50

▫ Cooling System Tips – Automatic

Transmission ........................ 50

5

38 STARTING AND OPERATING

䡵 Engine Block Heater .................... 52

▫ Block Heater Usage .................... 52

䡵 Diesel Exhaust Brake (Engine Braking) –

If Equipped ........................... 53

䡵 Automatic Transmission — If Equipped ....... 54

▫ Automatic Transmission With Overdrive

(68RFE) — If Equipped (Ram Truck Only) .... 54

▫ Automatic Transmission With Overdrive

(AS68RC) – If Equipped (Chassis Cab Only)

... 60

䡵 Manual Transmission — If Equipped ......... 66

▫ Shifting ............................ 67

▫ Downshifting ........................ 68

▫ Reverse Shifting ...................... 69

䡵 Power Take Off Operation – If Equipped

(Chassis Cab Only) ...................... 70

▫ Stationary Mode ...................... 70

▫ Mobile Mode ........................ 71

▫ Power Take Off – Aftermarket Installation .... 72

䡵 Fuel Requirements ...................... 72

▫ Fuel Specifications .................... 73

䡵 Engine Runaway ....................... 74

䡵 Adding Fuel .......................... 74

▫ Fuel Filler Cap (Gas Cap) ............... 75

▫ Avoid Using Contaminated Fuel ........... 75

▫ Bulk Fuel Storage ..................... 76

STARTING AND OPERATING 39

STARTING PROCEDURES

Before starting your vehicle, adjust your seat, adjust both

inside and outside mirrors, and fasten your seat belts.

The starter should not be operated for more than 15second intervals. Waiting a few minutes between such

intervals will protect the starter from overheating.

WARNING!

Do not leave children or animals inside parked

vehicles in hot weather. Interior heat build up may

cause serious injury or death.

Manual Transmission – If Equipped

Apply the parking brake, place the shift lever in NEUTRAL and depress the clutch pedal to the floor before

starting the vehicle. This vehicle is equipped with a

clutch interlocking ignition system. It will not start unless

the clutch is fully depressed.

Automatic Transmission – If Equipped

Start the engine with the shift lever in NEUTRAL or

PARK position. Apply the brake before shifting to any

driving range.

The Cummins威 diesel engine is equipped with several

features designed to assist cold weather starting and

operation:

•

The engine block heater is a resistance heater installed

in the water jacket of the engine just above and behind

the oil filter. It requires a 110–115 Volt AC electrical

outlet with a grounded, three-wire extension cord.

NOTE: The engine block heater cord is a factory installed option. If your vehicle is not equipped, heater

cords are available from your authorized MOPAR威

dealer.

5

40 STARTING AND OPERATING

•

A 12–Volt heater built into the fuel filter housing aids

in preventing fuel gelling. It is controlled by a built-in

thermostat.

•

A heated intake air system both improves engine

starting and reduces the amount of white smoke

generated by a warming engine.

Normal Starting Procedure – Engine Manifold Air

Temperature Above 66°F (19°C)

Observe the instrument panel cluster lights when starting

the engine.

1. Always apply the parking brake.

2. Shift into PARK for an automatic transmission. For

vehicles equipped with a manual transmission, fully

depress and hold the clutch pedal and shift into NEUTRAL.

CAUTION!

If the “Water in Fuel Indicator Light” remains on, DO

NOT START the engine before you drain the water

from the fuel filter to avoid engine damage. Refer to

“Maintenance Procedures/Draining Fuel/Water Separator Filter” in Section 7 of this manual.

4. Turn the ignition key to START and crank the engine.

Do not press the accelerator during starting.

CAUTION!

Do not crank engine for more than 15 seconds at a

time or starter motor damage may result. Turn key to

OFF and wait at least two minutes for starter to cool

before repeating start procedure.

3. Turn the ignition key to the ON position and watch the

instrument panel cluster lights.

5. When the engine starts, release the key.

STARTING AND OPERATING 41

6. Check to see that there is oil pressure.

7. Release the parking brake.

Starting Procedure – Engine Manifold Air

Temperature Below 66°F (19°C)

NOTE: The temperature displayed on the overhead

console (if equipped) does not necessarily reflect the

engine manifold air temperature. When engine temperatures fall below 66°F (19°C) the “Wait To Start Light” will

remain on indicating the intake manifold heater system is

active.

Follow the steps in the “Normal Starting” procedure

except:

1. The “Wait To Start Light” will remain on for a period

of time (length of time depends on engine temperature).

CAUTION!

If the “Water in Fuel Indicator Light” remains on, DO

NOT START engine before you drain the water from

the fuel filter to avoid engine damage. Refer to

“Maintenance Procedures/Draining Fuel/Water Separator Filter” in Section 7 of this manual.

2. After the “Wait To Start Light” goes off, turn the

ignition key to START. Do not press the accelerator

during starting.

CAUTION!

Do not crank engine for more than 15 seconds at a

time or starter motor damage may result. Turn key to

OFF and wait at least two minutes for starter to cool

before repeating start procedure.

5

42 STARTING AND OPERATING

3. After engine start-up, check to see that there is oil

pressure.

4. Allow the engine to idle about three minutes until the

manifold heaters have completed the post-heat cycle.

5. Release the parking brake and drive.

NOTE:

•

Engine idle speed will automatically increase to 1,000

RPM at low coolant temperatures to improve engine

warm-up.

•

If the engine stalls, or if the ignition switch is left ON

for more than two minutes after the “Wait To Start

Light” goes out, reset the grid heaters by turning the

ignition switch to OFF for at least five seconds and

then back ON. Repeat steps 1 through 5 of “Starting

Procedure — Engine Manifold Air Temperature Below

66°F (19°C).”

Starting Procedure – Engine Manifold Air

Temperature Below 0°F (-18°C)

In extremely cold weather below 0°F (-18°C) it may be

beneficial to cycle the manifold heaters twice before

attempting to start the engine. This can be accomplished

by turning the ignition OFF for at least five seconds and

then back ON after the “Wait To Start Light” has turned

off, but before the engine is started. However, excessive

cycling of the manifold heaters will result in damage to

the heater elements or reduced battery voltage.

NOTE: If multiple pre-heat cycles are used before

starting, additional engine run time may be required to

maintain battery state of charge at a satisfactory level.

1. If the engine stalls after the initial start, the ignition

must be turned to the OFF position for at least five

seconds and then to the ON position to recycle the

manifold heaters.

STARTING AND OPERATING 43

NOTE: Excessive white smoke and poor engine performance will result if manifold heaters are not recycled.

2. Heat generated by the manifold heaters dissipates

rapidly in a cold engine. If more than two minutes pass

between the time the “Wait To Start Light” turns off and

the engine is started, recycle the manifold heaters by

turning the ignition OFF for at least five seconds and then

back ON.

3. If the vehicle is driven and vehicle speed exceeds

19 mph (31 km/h) before the manifold heater post-heat

(after start) cycle is complete, the manifold heaters will

shut off.

4. If the engine is started before the “Wait To Start Light”

turns off, the preheat cycle will turn off.

5. If the engine is cranked for more than 10 seconds, the

post-heat cycle will turn off.

NOTE:

•

Engine idle speed will automatically increase to 1, 000

RPM at low coolant temperatures to improve engine

warm-up.

•

When a diesel engine is allowed to run out of fuel or

the fuel gels at low temperatures, air is pulled into the

fuel system. If your engine has run out of fuel, refer to

“Adding Fuel/Priming If The Engine Has Run Out Of

Fuel” in this section.

5

44 STARTING AND OPERATING

Starting Fluids

WARNING!

Starting fluids or flammable liquids are never to be

used in the Cummins威 diesel engine (see Warning

label). Never pour diesel fuel, flammable liquid,

starting fluids (ether) into the air cleaner canister, air

intake piping, or turbocharger inlet in an attempt to

start the vehicle. This could result in a flash fire and

explosion causing serious personal injury and engine

damage.

The engine is equipped with an automatic electric air

preheating system. If the instructions in this manual are

followed, the engine should start in all conditions.

WARNING!

Do not leave children or animals inside parked

vehicles in hot weather. Interior heat build up may

cause serious injury or death.

NORMAL OPERATION – DIESEL ENGINE

Observe the following when the engine is operating.

•

All message center lights are off.

•

Malfunction Indicator Light (MIL) is off.

•

Engine oil pressure is above 10 psi (69 kPa) at idle.

•

Voltmeter operation:

•

The voltmeter may show a gauge fluctuation at

various engine temperatures. This cycling operation

is caused by the post-heat cycle of the intake manifold heater system. The number of cycles and the

length of the cycling operation is controlled by the

engine control module. Post-heat operation can run

for several minutes, and then the electrical system

and voltmeter needle will stabilize.

•

The cycling action will cause temporary dimming of

the headlamps, interior lamps, and also a noticeable

reduction in blower motor speed.

STARTING AND OPERATING 45

Cold Weather Precautions

Operation in ambient temperature below 32°F (0°C) may

require special considerations. The following charts suggest these options:

Fuel Operating Range

NOTE: Use “Ultra Low Sulfur Diesel Fuels” ONLY.

*No. 1 Ultra Low Sulfur Diesel Fuel should only be used

where extended arctic conditions (-10°F/-23°C) exist.

NOTE:

•

Use of Climatized Ultra Low Sulfur Diesel Fuel or

Number 1 Ultra Low Sulfur Diesel Fuel results in a

noticeable decrease in fuel economy.

•

Climatized Ultra Low Sulfur Diesel Fuel is a blend of

Number 2 Ultra Low Sulfur and Number 1 Ultra Low

Sulfur Diesel Fuels which reduces the temperature at

which wax crystals form in fuel.

5

46 STARTING AND OPERATING

•

The engine requires the use of “Ultra Low Sulfur

Diesel Fuel”. Use of incorrect fuel could result in

engine and exhaust system damage. Refer to” Fuel

Requirements” in Section 5.

Engine Oil Usage

Refer to “Maintenance Procedures” in Section 7 of this

manual for the correct engine oil viscosity.

Winter Front Usage

If a winter front or cold weather cover is to be used, a

percentage of the total grille opening area must be left

uncovered to provide sufficient air flow to the charge air

cooler and automatic transmission oil cooler. The percentage of opening must be increased with the increasing

ambient air temperature and/or engine load. If the

cooling fan can be heard cycling frequently, increase the

size of the opening in the winter front. A suitable cold

weather cover is available from your MOPAR威 dealer.

Battery Blanket Usage

A battery loses 60% of its cranking power as the battery

temperature decreases to 0°F (-18°C). For the same decrease in temperature, the engine requires twice as much

power to crank at the same RPM. The use of 120 VAC

powered battery blankets will greatly increase starting

capability at low temperatures. Suitable battery blankets

are available from your authorized MOPAR威 dealer.

Engine Warm-Up

Avoid full throttle operation when the engine is cold.

When starting a cold engine, bring the engine up to

operating speed slowly to allow the oil pressure to

stabilize as the engine warms up.

NOTE: High-speed, no-load running of a cold engine

can result in excessive white smoke and poor engine

performance. No-load engine speeds should be kept

under 1,200 RPM during the warm-up period, especially

in cold ambient temperature conditions.

STARTING AND OPERATING 47

Your vehicle is equipped with a turbo speed limiter, this

feature limits the engine speed to 1,200 RPM when

engine coolant temperatures are below 70°F (21°C). This

feature is designed to protect the turbo charger from

damage and will only operate in PARK or NEUTRAL.

If temperatures are below 32°F (0°C), operate the engine

at moderate speeds for five minutes before full loads are

applied.

NOTE:

•

If ambient temperatures are low and the coolant

temperature is below 180°F (82°C), the engine idle

speed will slowly increase to 1,000 RPM after two minutes of idle, if the following conditions are met:

•

foot is off brake pedal and throttle pedal

•

automatic transmission is in PARK

•

vehicle speed is zero

•

Applying the throttle will cancel fast idle

•

If the engine is equipped with an exhaust brake,

operating the exhaust brake at idle will greatly improve warm up rate and will help keep the engine

close to operating temperature during extended idle.

Engine Idling

Avoid prolonged idling, long periods of idling may be

harmful to your engine because combustion chamber

temperatures can drop so low that the fuel may not burn

completely. Incomplete combustion allows carbon and

varnish to form on piston rings, engine valves, and

injector nozzles. Also, the unburned fuel can enter the

crankcase, diluting the oil and causing rapid wear to the

engine.

If the engine is allowed to idle for extended periods, the

engine speed may increase for a period of time and then

return to normal idle speed.

5

48 STARTING AND OPERATING

CAUTION!

Extended periods of idle time may not allow the

vehicle’s exhaust aftertreatment system to properly

regenerate. This can lead to the illumination of the

Malfunction Indicator Light (MIL) or an Electronic

Vehicle Information Center (EVIC) warning message.

Operating the engine for extended periods with the

MIL illuminated or an EVIC warning message displayed can cause extensive engine and exhaust system damage.

NOTE: For EVIC messages related to the vehicle’s

exhaust system, refer to “Intervention Regeneration

Strategy — EVIC Message Process Flow” in Section 7 of

this manual.

An optional driver-controlled high idle speed is available

on automatic transmission equipped vehicles with speed

control. This feature allows the driver to select an elevated idle speed between 1,100 and 1,500 RPM. Your

dealer can enable this feature.

The optional driver-controlled high idle speed will help

increase cylinder temperatures and provide additional

cab heat, however, may still cause the exhaust aftertreatment system to not properly regenerate. Extended periods of idle time should be avoided.

Stopping The Engine

Idle the engine a few minutes before routine shutdown.

After full load operation, idle the engine three to five

minutes before shutting it down. This idle period will

allow the lubricating oil and coolant to carry excess heat

away from the combustion chamber, bearings, internal

components, and turbocharger. This is especially important for turbocharged, charge air-cooled engines.

STARTING AND OPERATING 49

NOTE:

•

During engine shut down on vehicles equipped with

manual transmissions, it is normal for the diesel

engine to resonate heavily for a moment during engine

shut off. When the engine is connected to a manual

transmission, this resonance causes load gear rattle

from the transmission. This is commonly referred to as

“shut down rattle.” The manufacturer recommends

performing engine shut down with the clutch pedal

pushed to the floor (clutch disengaged). When engine

shut down is performed in this manner the rattle is

reduced (not eliminated).

•

Refer to the following chart for proper engine

shutdown.

Driving

Condition

Stop and

Go

Stop and

Go

Highway

Speeds

City Traffic Maximum

Highway

Speeds

Uphill

Grade

Load

Empty Cool Less than

Medium One

Medium Warm Two

GCWR

Maximum

GCWR

Maximum

GCWR

Turbo-

charger

Temperature

Hot Five

Idle Time

(min.) Be-

fore Engine

Shutdown

One

5

Three

Four

50 STARTING AND OPERATING

Engine Speed Control

CAUTION!

Prevent overspeeding the engine going downhill.

When descending steep grades, use a combination of

gears and service brakes to control vehicle/engine

speed. Overspeed can cause severe engine damage.

Operating Precautions

Avoid Overheating The Engine

The temperature of the engine coolant (antifreeze) (a

mixture of 50% ethylene-glycol and 50% water) must not

exceed the normal range of the temperature gauge 240°F

(116°C) with a 16 psi (110 kPa) radiator cap.

Usually the engine coolant (antifreeze) temperature indicated during operation will be to the left of center in the

normal range of the gauge.

Avoid Low Coolant Temperature Operation

Continual operation at low engine coolant (antifreeze)

temperature below the normal range on the gauge 140°F

(60°C) can be harmful to the engine. Low engine coolant

(antifreeze) temperature can cause incomplete combustion which allows carbon and varnish to form on piston

rings and injector nozzles. Also, the unburned fuel can

enter the crankcase, diluting the lubricating oil and

causing rapid wear to the engine.

Cooling System Tips – Automatic Transmission

To reduce potential for engine and transmission overheating in high ambient temperature conditions, take the

following actions:

•

City Driving —

When stopped, put transmission in NEUTRAL and increase engine idle speed.

•

Highway Driving —

Reduce your speed.

•

Up Steep Hills —

Select a lower transmission gear, but try and keep the

torque converter clutch engaged.

•

Air Conditioning —

Turn it off temporarily.

Do Not Operate The Engine With Low Oil

Pressure

When the engine is at normal operating temperature, the

minimum oil pressures required are:

Idle 700 to 800 RPM ...............10psi(69kPa)

Full speed and load ..............30psi(207 kPa)

CAUTION!

If oil pressure falls to less than normal readings, shut

the engine off immediately. Failure to do so could

result in immediate and severe engine damage.

STARTING AND OPERATING 51

Do Not Operate The Engine With Failed Parts

Practically all failures give some warning before the parts

fail. Be on the alert for changes in performance, sounds,

and visual evidence that the engine requires service.

Some important clues are:

•

engine misfiring or vibrating severely

•

sudden loss of power

•

unusual engine noises

•

fuel, oil or coolant leaks

•

sudden change, outside the normal operating range, in

the engine operating temperature

•

excessive smoke

•

oil pressure drop

5

52 STARTING AND OPERATING

ENGINE BLOCK HEATER

The engine block heater warms engine coolant and

permits quicker starts in cold weather. Connect the heater

cord to a ground-fault interrupter protected 110–115 Volt

AC electrical outlet with a grounded, three-wire extension cord.

The engine block heater cord is routed under the hood to

the right side and can be located just behind the grille

near the headlamp.

NOTE: The engine block heater cord is a factory installed option. If your vehicle is not equipped, heater

cords are available from your authorized MOPAR威

dealer.

The block heater must be plugged in at least one hour to

have an adequate warming effect on the coolant.

WARNING!

Remember to disconnect the cord before driving.

Damage to the 110–115 Volt electrical cord could

cause electrocution.

NOTE: The block heater will require 110 Volts AC and

6.5 Amps to activate the heater element.

Block Heater Usage

For ambient temperatures below 0°F (-18°C), engine

block heater usage is recommended.

For ambient temperatures below –20°F (-29°C), engine

block heater usage is required.

STARTING AND OPERATING 53

DIESEL EXHAUST BRAKE (ENGINE BRAKING) –

IF EQUIPPED

The exhaust brake feature will only function when the

driver turns the exhaust brake switch to the ON position.

Exhaust Brake Switch

Once the switch is in the ON position and the vehicle is

moving faster than 5 mph (8 km/h); the exhaust brake

will automatically operate when the driver removes

pressure from the accelerator pedal. Exhaust braking is

most effective when the engine RPM is higher. The

automatic transmission has been programmed to downshift more aggressively when the exhaust brake is enabled to increase brake performance.

CAUTION!

Use of aftermarket exhaust brakes is not recommended and could lead to engine damage

WARNING!

Do not use the exhaust brake feature when driving in

icy or slippery conditions as the increased engine

braking can cause the rear wheels to slide and the

vehicle to swing around with the possible loss of

vehicle control, which may cause an accident possibly resulting in personal injury or death.

5

54 STARTING AND OPERATING

NOTE: For optimum braking power it is recommended

to use the exhaust brake while in TOW/HAUL Mode.

The purpose of the exhaust brake (engine braking) feature is to supply negative (braking) torque to the engine.

Typically, the engine braking is used for, but not limited

to, vehicle towing applications where vehicle braking can

be achieved by the internal engine power, thereby sparing the mechanical brakes of the vehicle.

Benefits of the exhaust brake are:

•

vehicle driving control

•

reduced brake fade

•

longer brake life

•

faster cab warm-up.

The exhaust brake feature can also be used to reduce the

engine warm up time. To use the exhaust brake as a

warm-up device, the vehicle must be stopped or moving

less than 5 mph (8 km/h), the exhaust brake switch must

be in the ON position, and the coolant temperature must

below 180°F (82°C) and ambient temperature below 60°F

(16°C).

AUTOMATIC TRANSMISSION — IF EQUIPPED

Automatic Transmission with Overdrive (68RFE)

— If Equipped (Ram Truck Only)

The shift lever display located in the instrument panel

cluster indicates the transmission gear range (the selector

is illuminated for night driving). The shift lever is

mounted on the right side of the steering column. You

must depress the brake pedal to pull the shift lever out of

PARK position (Brake Interlock System). To drive, move

the shift lever from PARK or NEUTRAL to the desired

DRIVE position. Pull the shift lever toward you when

shifting into REVERSE, SECOND, FIRST or PARK, or

when shifting out of PARK.

STARTING AND OPERATING 55

Gear Ranges

DO NOT race the engine when shifting from PARK or

NEUTRAL position into another gear range.

PARK

This gear position supplements the parking brake by

locking the transmission. The engine can be started in

this range. Never use PARK while the vehicle is in

motion. Apply the parking brake when leaving the

vehicle in this range. Always apply the parking brake

first, then place the shift lever into the PARK position. On

four-wheel drive vehicles be sure that the transfer case is

in a drive position.

WARNING!

•

Never use the PARK position as a substitute for

the parking brake. Always apply the parking

brake fully when parked to guard against vehicle

movement and possible injury or damage.

•

Your vehicle could move and injure you and others

if it is not completely in PARK. Check by trying to

move the shift lever back and forth without first

pulling it toward you after you have set it in

PARK. Make sure it is in PARK before leaving the

vehicle.

(Continued)

5

56 STARTING AND OPERATING

WARNING! (Continued)

•

It is dangerous to move the shift lever out of PARK

or NEUTRAL if the engine speed is higher than

idle speed. If your foot is not firmly on the brake

pedal, the vehicle could accelerate quickly forward

or in reverse. You could lose control of the vehicle

and hit someone or something. Only shift into

gear when the engine is idling normally and when

your foot is firmly on the brake pedal.

REVERSE

Use this range only after the vehicle has come to a

complete stop.

NEUTRAL

Shift into NEUTRAL when the vehicle is standing for

prolonged periods with the engine running. The engine

may be started in this range. Set the parking brake if you

must leave the vehicle.

DRIVE

Drive range provides underdrive 1st, 2nd and 3rd gears,

direct 4th gear and overdrive 5th and 6th gears. The shift

into overdrive 5th and 6th gear occurs only after the

transmission has completed the shift into 4th gear. No

other movement of the shift mechanism is required to

complete the 4–5 or 5–6 gear shifts.

The 4th and 5th gear upshifts occurs automatically unless

the TOW HAUL mode is enabled.

Upshifts into both overdrive gears, 5th and 6th, will be

delayed when the transmission fluid temperature is

below 40° F (4.5° C) or above 240° F (115.5° C).

NOTE: Use caution when operating a heavily loaded

vehicle in 2nd or 1st gear in high ambients as torque

converter slip can impose significant additional heat load

on the cooling system.

STARTING AND OPERATING 57

Overdrive Operation

The overdrive automatic transmission contains an electronically controlled 5th and 6th (Overdrive). The transmission will automatically shift from DRIVE to Overdrive if the following conditions are present:

•

the shift lever is in DRIVE;

•

the engine coolant has reached normal operating temperature;

•

vehicle speed is above approximately 30 mph

(48 km/h);

•

the “TOW HAUL O/D OFF” switch has not been

activated;

•

transmission has reached normal operating

temperature.

NOTE: If the vehicle is started in extremely cold temperatures, the transmission may not shift into Overdrive

and will automatically select the most desirable gear for

operation at this temperature. Normal operation will

resume when the transmission fluid temperature has

risen to a suitable level. Refer to the Note under “Torque

Converter Clutch” later in this section.

If the transmission temperature gets extremely hot, the

transmission will automatically select the most desirable

gear for operation at this temperature. If the transmission

temperature becomes hot enough the “Transmission

Temperature Warning Light” may illuminate and the

transmission may downshift out of Overdrive until the

transmission cools down. After cool down, the transmission will resume normal operation.

The transmission will downshift from Overdrive to

DRIVE if the accelerator pedal is fully depressed at

vehicle speeds above approximately 35 mph (56 km/h).

5

58 STARTING AND OPERATING

When To Use TOW HAUL

1 — Tow/Haul Switch

2 — AUTO-6 (ERS) Switch

When driving in hilly areas, towing a trailer, carrying a

heavy load, etc., and frequent transmission shifting occurs, press the TOW/HAUL switch once to select TOW

HAUL. In TOW HAUL mode, 4th to 5th gear upshifts are

delayed. Shifts into 5th and 6th gear are still allowed

under steady cruise conditions. Closed throttle downshifts (for improved engine braking) may occur during

steady braking maneuvers. Pressing the switch a second

time restores normal operation. Normal operation is

always the default at engine start-up.

The “TOW HAUL Indicator Light” will illuminate in the

instrument cluster to indicate when the switch has been

activated. If the TOW HAUL modes are desired, the

button must be pressed each time the engine is started.

Electronic Range Select (ERS) Operation

The Auto–6 Electronic Range Select (ERS) shift control

allows you to move the switch down (-) or up (+) when

the shifter is in the D (Drive) position, allowing the

selection of the desired top gear. For example, if the

driver shifts the transmission into 3rd gear, the transmission will never shift above 3rd gear, but can shift down to

2nd or 1st gear, when needed.

STARTING AND OPERATING 59

Switching from ERS to D-Mode can be done at any

vehicle speed. To switch from “Drive” mode to “ERS”

mode, press the switch down (-) once. The current gear

will be maintained as the top gear. To disable ERS, simply

press and hold the switch up (+) until “D” is displayed in

the instrument cluster odometer.

WARNING!

Do not downshift for additional engine braking on a

slippery surface. The drive wheels could lose their

grip and the vehicle could skid.

Screen Display 123456D

Actual Gear(s)

Allowed

NOTE: To select the proper gear position for maximum

deceleration (engine braking), simply press and hold the

switch down (-). The transmission will shift to the range

from which the vehicle can best be slowed down.

1 1-2 1-3 1-4 1-5 1-6 1-6

Torque Converter Clutch

A feature designed to improve fuel economy has been

included in the automatic transmission on your vehicle.

A clutch within the torque converter engages automatically at calibrated speeds. This may result in a slightly

different feeling or response during normal operation in

the upper gears. When the vehicle speed drops or during

acceleration when the transmission downshifts to second

gear, the clutch automatically disengages.

NOTE:

•

The torque converter clutch will not engage until the

transmission fluid and engine coolant are warm [usually after 1-3 miles (1.6 - 4.8 km) of driving]. Because

the engine speed is higher when the torque converter

clutch is not engaged, it may seem as if the transmission is not shifting into Overdrive when cold. This is

normal. Pressing the TOW HAUL O/D OFF button,

5

60 STARTING AND OPERATING

when the transmission is sufficiently warm, will demonstrate that the transmission is able to shift into and

out of Overdrive.

•

If the vehicle has not been driven in several days, the

first few seconds of operation after shifting the transmission into gear may seem sluggish. This is due to the

fluid partially draining from the torque converter into

the transmission. This condition is normal and will not

cause damage to the transmission. The torque converter will refill within five seconds of shifting from

PARK into any other gear position.

Automatic Transmission with Overdrive (AS68RC)

– If Equipped (Chassis Cab Only)

The shift lever display located in the instrument panel

cluster, indicates the transmission gear range (the selector

is illuminated for night driving). The shift lever is

mounted on the right side of the steering column. You

must depress the brake pedal, to pull the shift lever out of

PARK position (Brake Interlock System). To drive, move

the shift lever from PARK or NEUTRAL to the desired

drive position. Pull the shift lever toward you when

shifting into REVERSE, SECOND, FIRST or PARK, or

when shifting out of PARK.

Gear Ranges

DO NOT race the engine when shifting from PARK or

NEUTRAL position into another gear range.

PARK

This gear position supplements the parking brake by

locking the transmission. The engine can be started in

this range. Never use PARK while the vehicle is in

motion. Apply the parking brake when leaving the

vehicle in this range. Always apply parking brake first,

then place the shift lever in PARK position. On fourwheel drive vehicles be sure that the transfer case is in a

drive position.

STARTING AND OPERATING 61

WARNING!

•