Page 1

DR/DH POWER SYSTEMS 8N - 1

POWER SYSTEMS

TABLE OF CONTENTS

page page

POWER LOCKS - ELECTRICAL DIAGNOSTICS.... 1

POWER LOCKS - SERVICE INFORMATION ..... 73

POWER MIRRORS - SERVICE INFORMATION. .. 86

POWER SEATS - SERVICE INFORMATION...... 90

POWER LOCKS - ELECTRICAL DIAGNOSTICS

TABLE OF CONTENTS

page page

POWER LOCKS - ELECTRICAL DIAGNOSTICS

DIAGNOSIS AND TESTING

ALL DOOR LOCK OUTPUT CIRCUIT SHORT

TO GROUND OR VOLTAGE...............2

ALL DOOR UNLOCK OUTPUT CIRCUIT

SHORT TO GROUND OR VOLTAGE ........7

DRIVER DOOR UNLOCK OUTPUT CIRCUIT

SHORT TO GROUND OR VOLTAGE .......12

DRIVER CYLINDER LOCK SWITCH INPUT

CIRCUIT SHORTED (WITH VTSS ONLY) ....17

DRIVER CYLINDER LOCK SWITCH INPUT

STUCK (WITH VTSS ONLY)..............20

DRIVER DOOR LOCK SWITCH INPUT

CIRCUIT OPEN OR SHORT TO VOLTAGE . . . 23

DRIVER DOOR LOCK SWITCH INPUT

CIRCUIT SHORTED ....................27

DRIVER DOOR LOCK SWITCH INPUT

CIRCUIT STUCK ......................30

PASSENGER DOOR LOCK SWITCH INPUT

CIRCUIT OPEN OR SHORT TO VOLTAGE . . . 33

POWER TOP - SUNROOF - SERVICE

INFORMATION.......................... 96

POWER WINDOWS - SERVICE INFORMATION . 105

PASSENGER DOOR LOCK SWITCH INPUT

CIRCUIT SHORTED ....................37

PASSENGER DOOR LOCK SWITCH INPUT

CIRCUIT STUCK ......................40

RKE FOB BATTERY LOW ...............43

RKE MODULE COMMUNICATION LINK .....44

*ALL DOOR LOCKS INOPERATIVE ........46

*AUTO (ROLLING) DOOR LOCKS

INOPERATIVE ........................49

*CYLINDER LOCK SWITCH INOPERATIVE . . 51

*DOOR LOCK INHIBIT INOPERATIVE ......55

*LEFT REAR DOOR FAILS TO LOCK AND

UNLOCK ............................56

*DRIVER DOOR FAILS TO LOCK AND

UNLOCK ............................60

*ONE DOOR LOCK MOTOR INOPERATIVE . . 64

*RIGHT DOORS FAIL TO LOCK AND

UNLOCK – QUAD CAB .................65

*RKE INOPERATIVE ...................69

SCHEMATICS AND DIAGRAMS ............72

POWER LOCKS - ELECTRICAL DIAGNOSTICS

DIAGNOSIS AND TESTING

Page 2

8N - 2 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

ALL DOOR LOCK OUTPUT CIRCUIT SHORT TO GROUND OR VOLTAGE

Page 3

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 3

ALL DOOR LOCK OUTPUT CIRCUIT SHORT TO GROUND OR VOLTAGE (CONTINUED)

For the Power Door Lock circuit diagram (Refer to 8 - ELECTRICAL/POWER LOCKS - SCHEMATICS AND DIAGRAMS).

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Whenever the instrument cluster is awake.

• Set Condition:

The instrument cluster monitors the door lock output circuits and when one of them is shorted to ground or to

voltage, this code will set. This code will only set when the door locks are actuated.

Possible Causes

(P392) DOOR LOCK DRIVER RIGHT DOORS SHORTED TO (G778) DOOR UNLOCK DRIVER RIGHT DOORS

(P393) DOOR LOCK DRIVER LEFT DOORS SHORTED TO (P5) DOOR UNLOCK DRIVER LEFT REAR

(P393) DOOR LOCK DRIVER LEFT DOORS SHORT TO GROUND

(P392) DOOR LOCK DRIVER RIGHT DOORS SHORT TO GROUND

(P392) DOOR LOCK DRIVER RIGHT DOORS SHORT TO VOLTAGE

(P393) DOOR LOCK DRIVER LEFT DOORS SHORT TO VOLTAGE

DOOR LATCH

INSTRUMENT CLUSTER

Diagnostic Test

DTC PRESENT

1.

Turn the ignition on.

With the DRBIIIT, record and erase DTC’s.

With the DRBIIIT, read DTC’s.

Operate the door locks several times from a door

lock switch while monitoring the DRBIIIT.

Does the DRBIIIT display ALL DOOR LOCK

OUTPUT SHORT TO GROUND OR VOLTAGE?

Yes >>

No >>

Go To 2

Using the wiring diagram/schematic as

a guide, inspect the wiring and connectors. Check for any possible shorted

conditions between the instrument cluster and the door lock motors.

Perform BODY VERIFICATION TEST VER 1. (Refer to 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE DIAGNOSIS AND TESTING)

Page 4

8N - 4 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

ALL DOOR LOCK OUTPUT CIRCUIT SHORT TO GROUND OR VOLTAGE (CONTINUED)

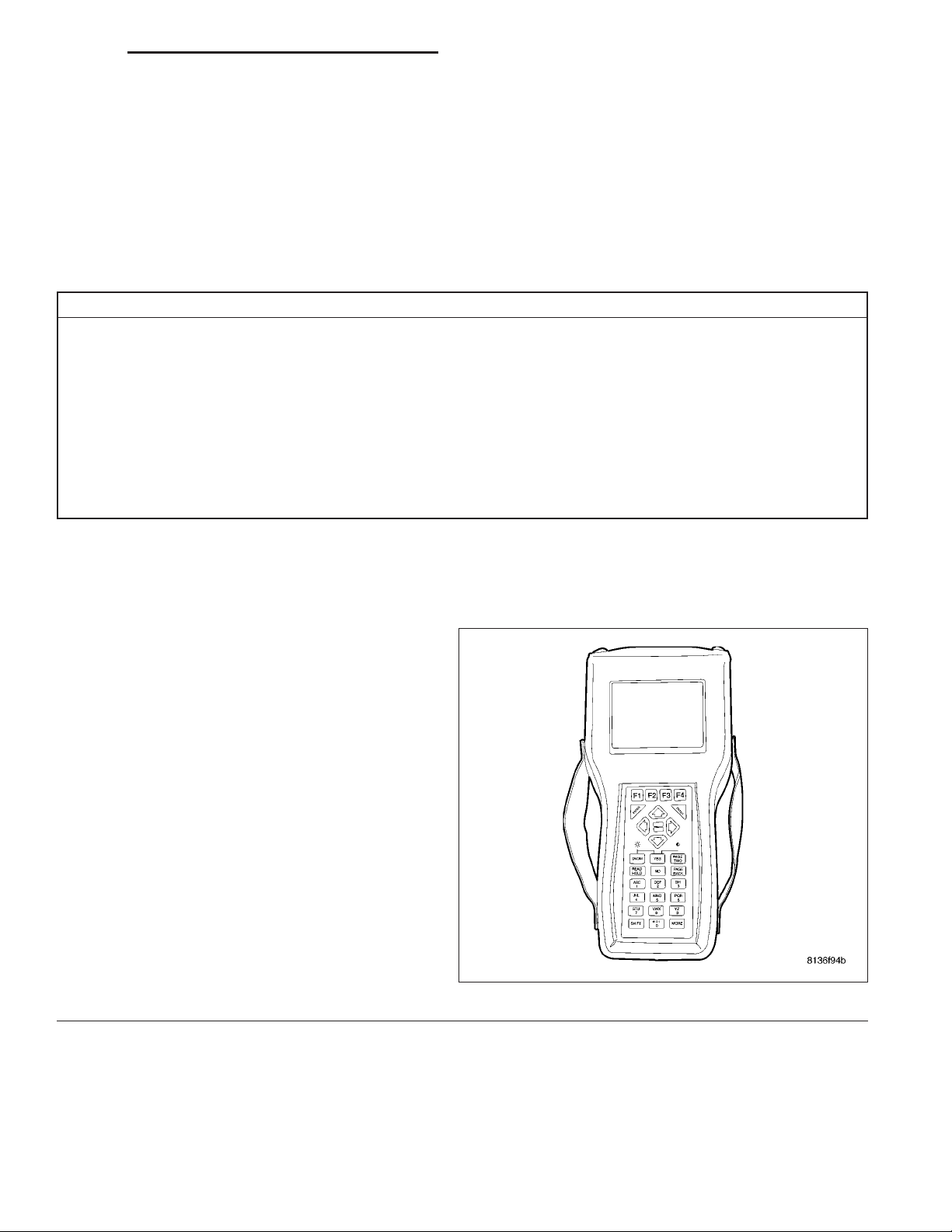

(P392) DOOR LOCK DRIVER RIGHT DOORS SHORTED TO (G778) DOOR UNLOCK DRIVER RIGHT

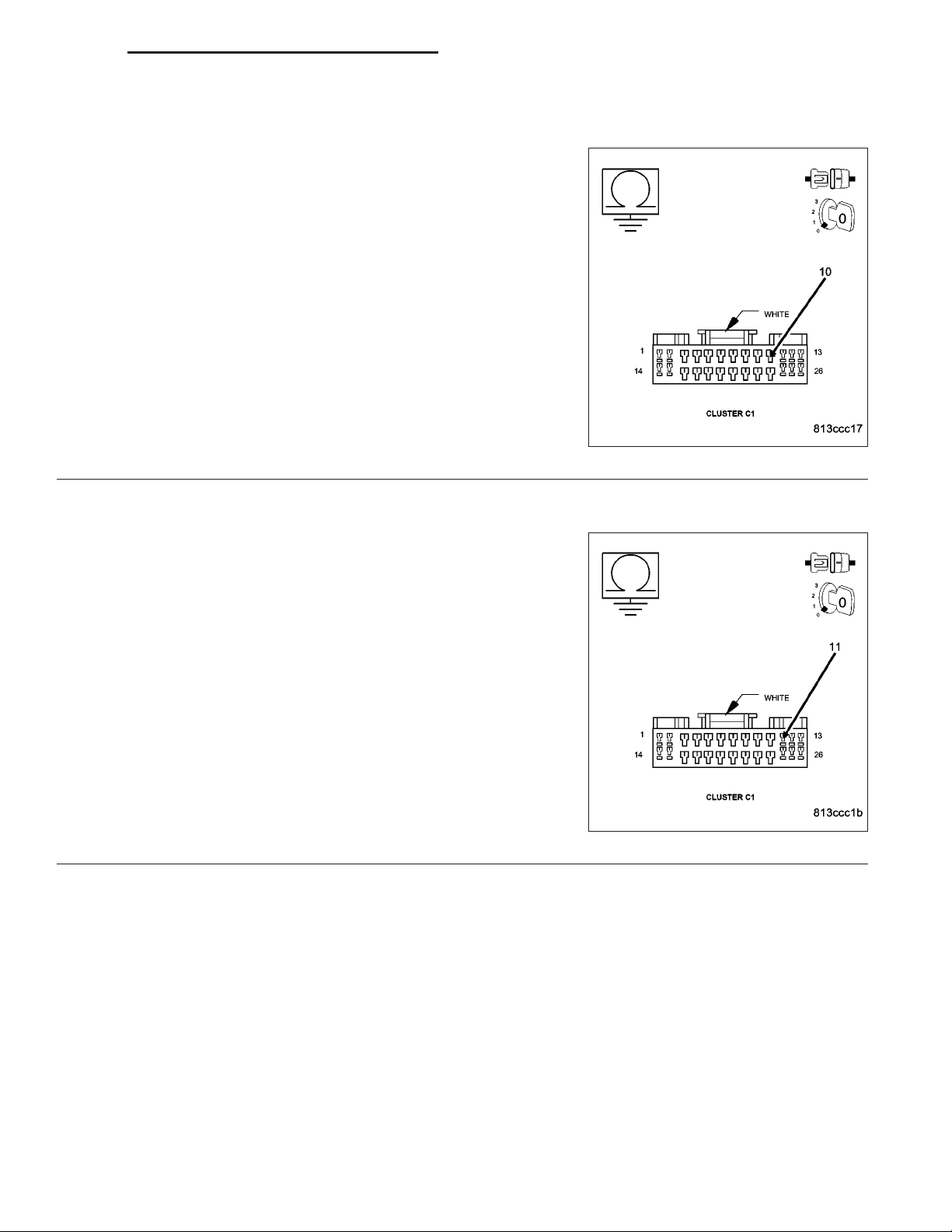

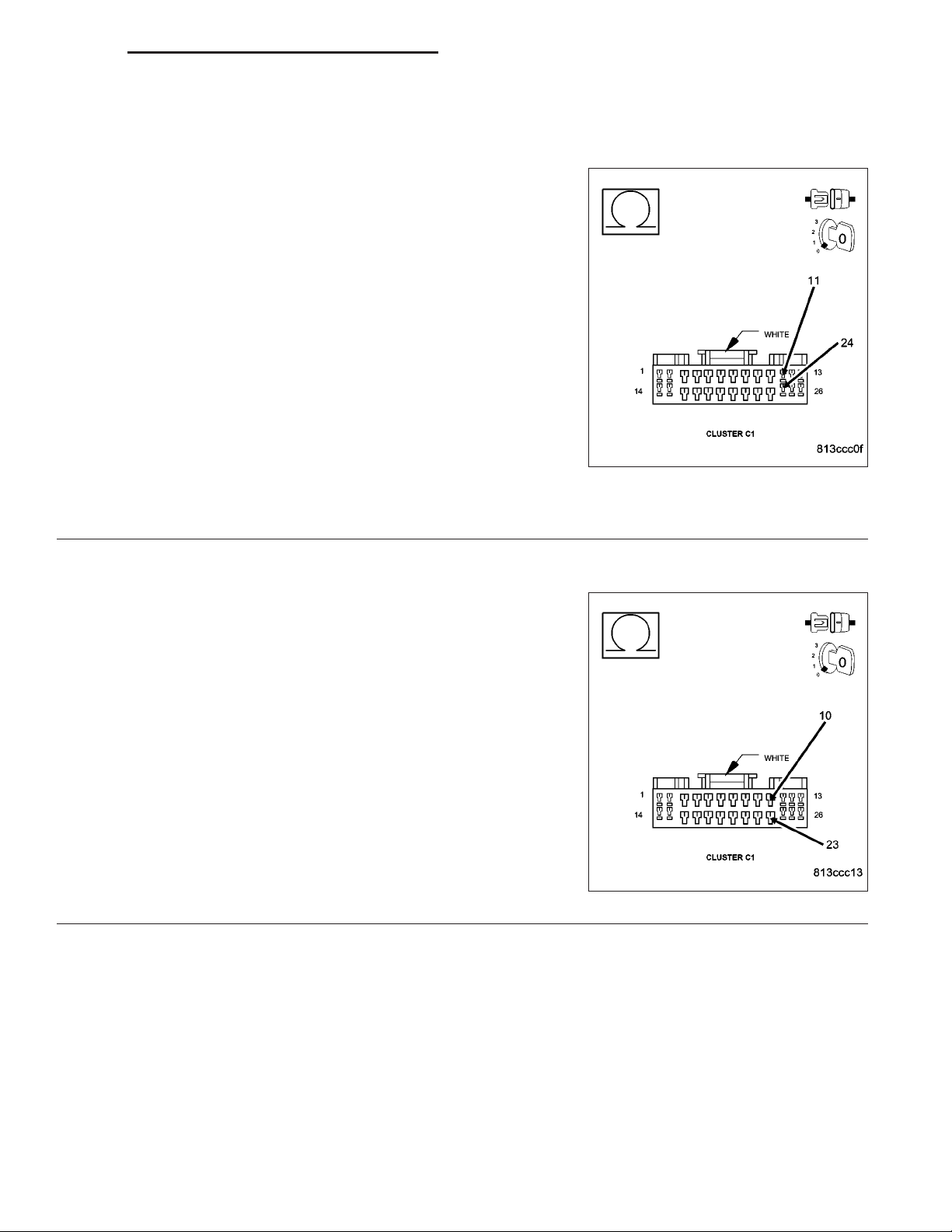

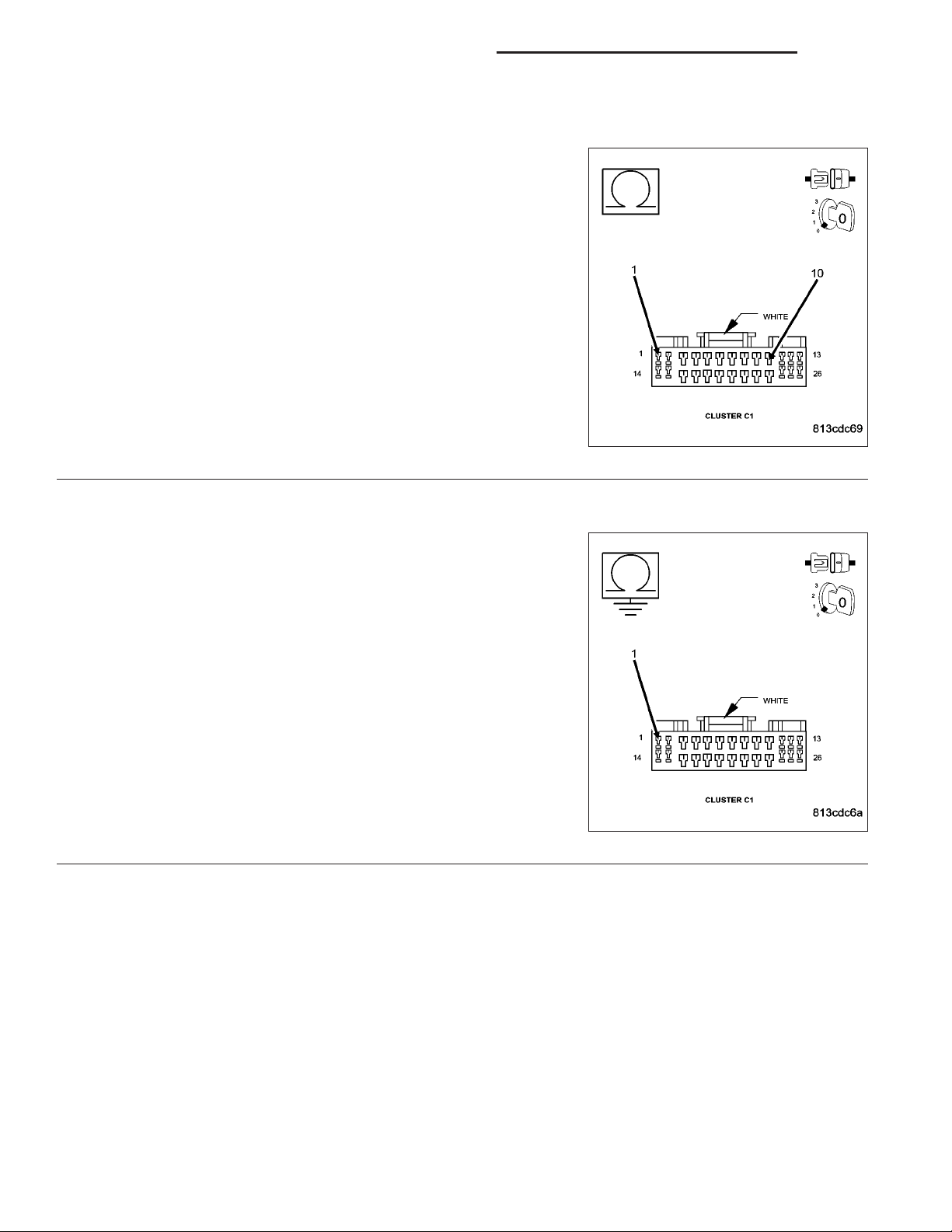

2.

DOORS

NOTE: If only one door motor is inoperative when the door locks

are actuated, disconnect that door latch connector and retest to

see if the DTC is still active. If it is not, replace that door latch.

Turn the ignition off.

Disconnect the Instrument Cluster C1 connector.

Measure the resistance between the (P392) Door Lock Driver Right

Doors circuit and the (G778) Door Unlock Driver Right Doors circuit in

the Instrument Cluster connector.

Is the resistance below 1.6 ohms?

Yes >>

No >>

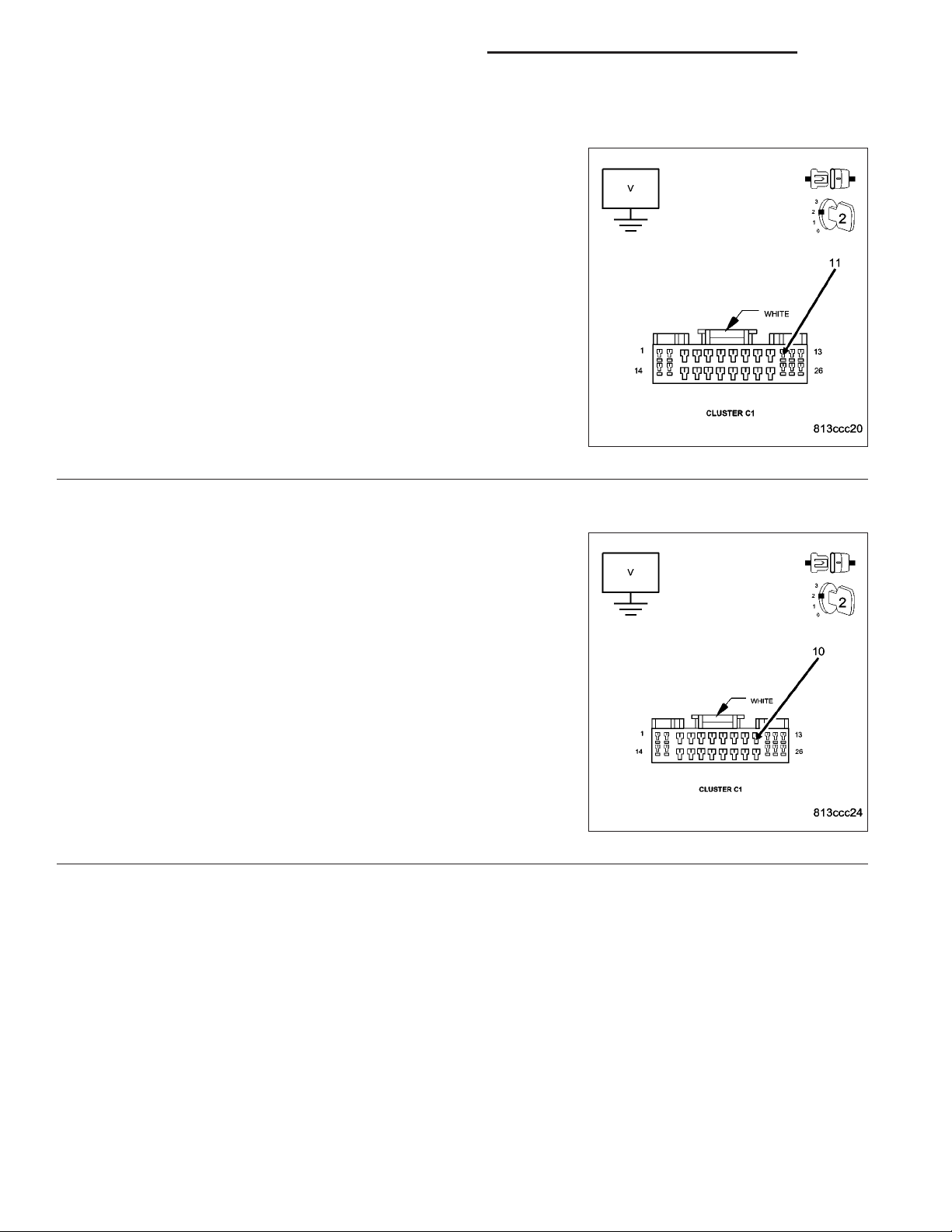

(P393) DOOR LOCK DRIVER LEFT DOORS SHORTED TO THE (P5) DOOR UNLOCK DRIVER LEFT REAR

3.

NOTE: If this is a 2 door vehicle, answer NO to the question and

continue.

Measure the resistance between the (P393) Door Lock Driver Left

Doors circuit and the (P5) Door Unlock Driver Left Rear circuit in the

Instrument Cluster connector.

Is the resistance below 2.5 ohms?

Yes >>

No >>

Repair the (P392) Door Lock Driver Right Doors circuit for

a short to the (G778) Door Unlock Driver Right Doors circuit (could be a shorted motor).

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 3

Repair the (P393) Door Lock Driver Left Doors circuit for a

short to the (P5) Door Unlock Driver Left Rear circuit

(could be a shorted motor).

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 4

Page 5

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 5

ALL DOOR LOCK OUTPUT CIRCUIT SHORT TO GROUND OR VOLTAGE (CONTINUED)

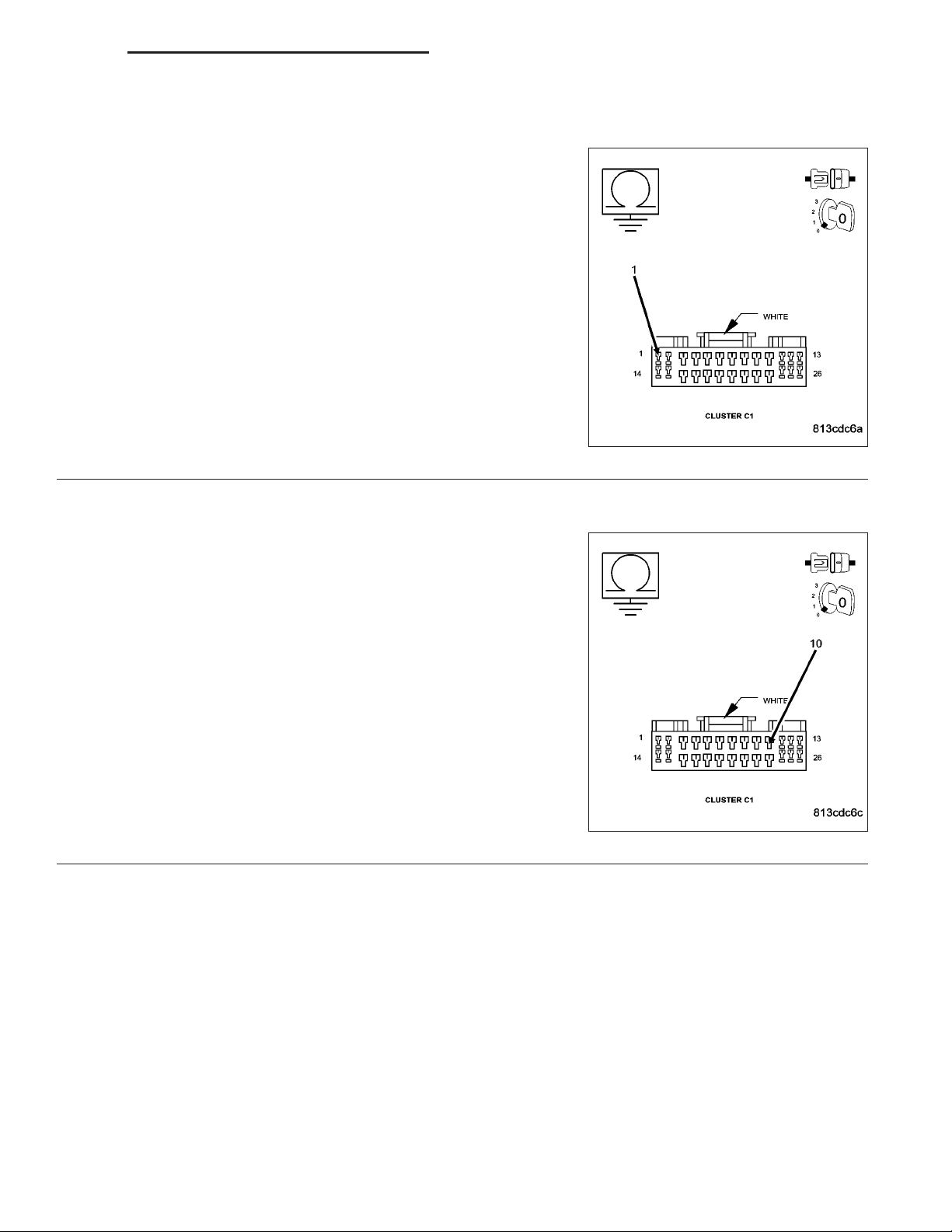

(P393) DOOR LOCK DRIVER LEFT DOORS SHORT TO GROUND

4.

Measure the resistance between ground and the (P393) Door Lock

Driver Left Doors circuit in the Instrument Cluster C1 connector.

Is the resistance below 1000.0 ohms?

Yes >>

No >>

(P392) DOOR LOCK DRIVER RIGHT DOORS SHORT TO GROUND

5.

Measure the resistance between ground and the (P392) Door Lock

Driver Right Doors circuit in the Instrument Cluster C1 connector.

Is the resistance below 1000.0 ohms?

Yes >>

No >>

Repair the (P393) Door Lock Driver Left Doors circuit for a

short to ground. The short may be in the (P393) Door

Lock Driver Left Doors wire, the (P5) Door Unlock Driver

Left Rear Wire, instrument panel wiring or one of the left

side motors.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 5

Repair the (P392) Door Lock Driver Right Doors circuit for

a short to ground. The short may be in the (P392) Door

Lock Driver Right Doors wire, the (G778) Door Unlock

Driver Right Doors wire or in a right side motor.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 6

Page 6

8N - 6 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

ALL DOOR LOCK OUTPUT CIRCUIT SHORT TO GROUND OR VOLTAGE (CONTINUED)

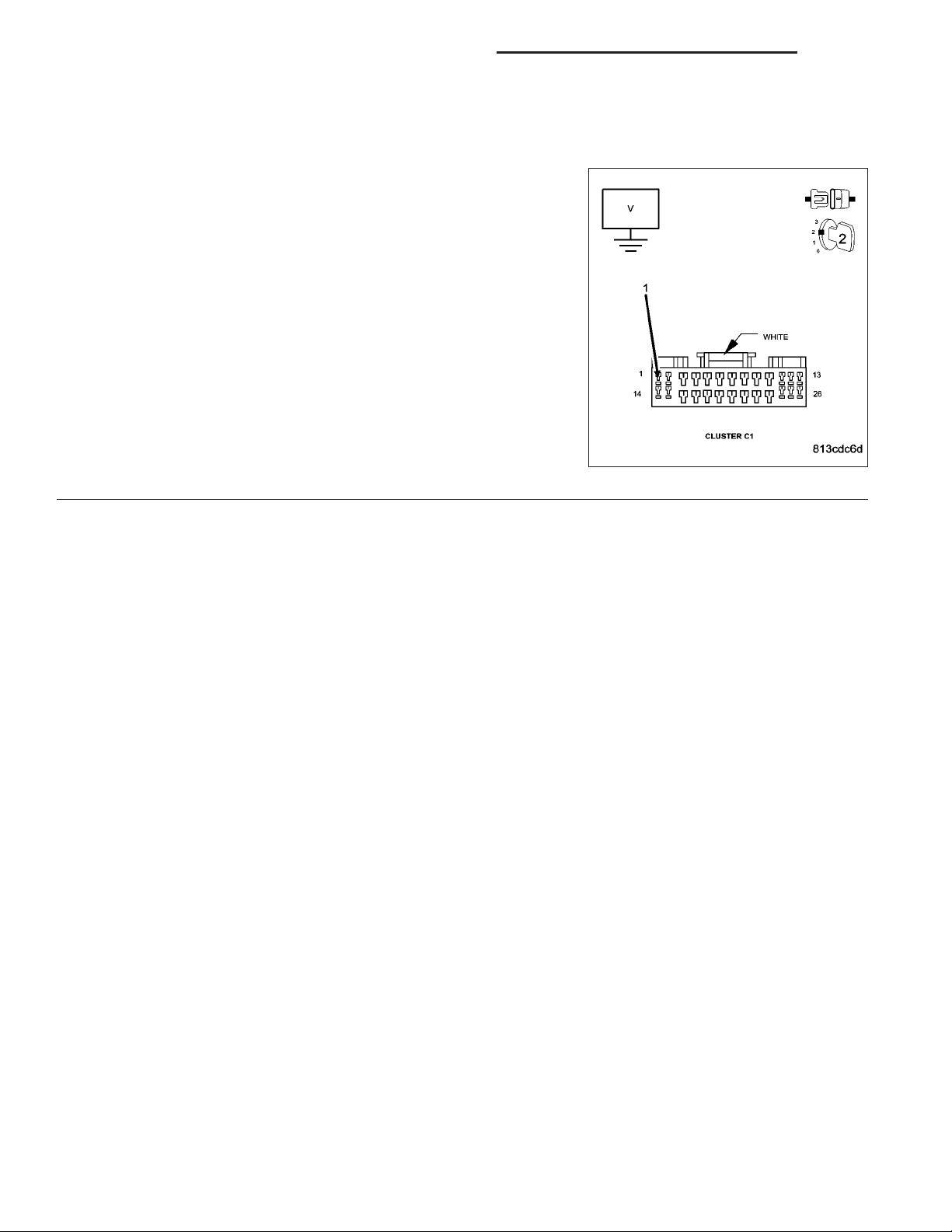

(P392) DOOR LOCK DRIVER RIGHT DOORS SHORT TO VOLTAGE

6.

Turn the ignition on.

Measure the voltage between ground and the (P392) Door Lock Driver

Right Doors circuit.

Is there any voltage present?

Yes >>

No >>

(P393) DOOR LOCK DRIVER LEFT DOORS SHORT TO VOLTAGE

7.

Measure the voltage between ground and the (P393) Door Lock Driver

Left Doors circuit.

Is there any voltage present?

Yes >>

No >>

Repair the (P392) Door Lock or (G778) Unlock Driver

Right Doors circuit for a short to voltage.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 7

Repair the (P393) Door Lock or (P5) Door Unlock Driver

Left Rear or (P1) Door Unlock Driver Left Front circuit for

a short to voltage.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Replace the Instrument Cluster.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 7

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 7

ALL DOOR UNLOCK OUTPUT CIRCUIT SHORT TO GROUND OR VOLTAGE

Page 8

8N - 8 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

ALL DOOR UNLOCK OUTPUT CIRCUIT SHORT TO GROUND OR VOLTAGE (CONTINUED)

For the Power Door Lock circuit diagram (Refer to 8 - ELECTRICAL/POWER LOCKS - SCHEMATICS AND DIAGRAMS).

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Whenever the instrument cluster is awake.

• Set Condition:

The instrument cluster monitors the door unlock output circuits and when one of them is shorted to ground or

to voltage, this code will set. This code will only set when the door locks are actuated.

Possible Causes

(P392) DOOR LOCK DRIVER RIGHT DOORS SHORTED TO (G778) DOOR UNLOCK DRIVER RIGHT DOORS

(P393) DOOR LOCK DRIVER LEFT DOORS SHORTED TO (P5) DOOR UNLOCK DRIVER LEFT REAR

DOOR UNLOCK DRIVER RIGHT DOORS CIRCUIT SHORT TO GROUND

DOOR UNLOCK DRIVER LEFT REAR CIRCUIT SHORT TO GROUND

DOOR UNLOCK DRIVER RIGHT DOORS SHORT TO VOLTAGE

DOOR UNLOCK DRIVER LEFT REAR SHORT TO VOLTAGE

DOOR LATCH

INSTRUMENT CLUSTER

Diagnostic Test

DTC PRESENT

1.

Turn the ignition on.

With the DRBIIIT, record and erase DTC’s.

With the DRBIIIT, read DTC’s.

Operate the door locks several times from a door lock

switch while monitoring the DRBIIIT.

Does the DRBIIIT display ALL DOOR UNLOCK

OUTPUT SHORT TO GROUND OR VOLTAGE?

Yes >>

No >>

Go To 2

Using the wiring diagram/schematic as a

guide, inspect the wiring and connectors.

Check for any possible shorted conditions

between the instrument cluster and the

door lock motors.

Perform BODY VERIFICATION TEST VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES/FRONT

CONTROL MODULE - DIAGNOSIS AND

TESTING)

Page 9

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 9

ALL DOOR UNLOCK OUTPUT CIRCUIT SHORT TO GROUND OR VOLTAGE (CONTINUED)

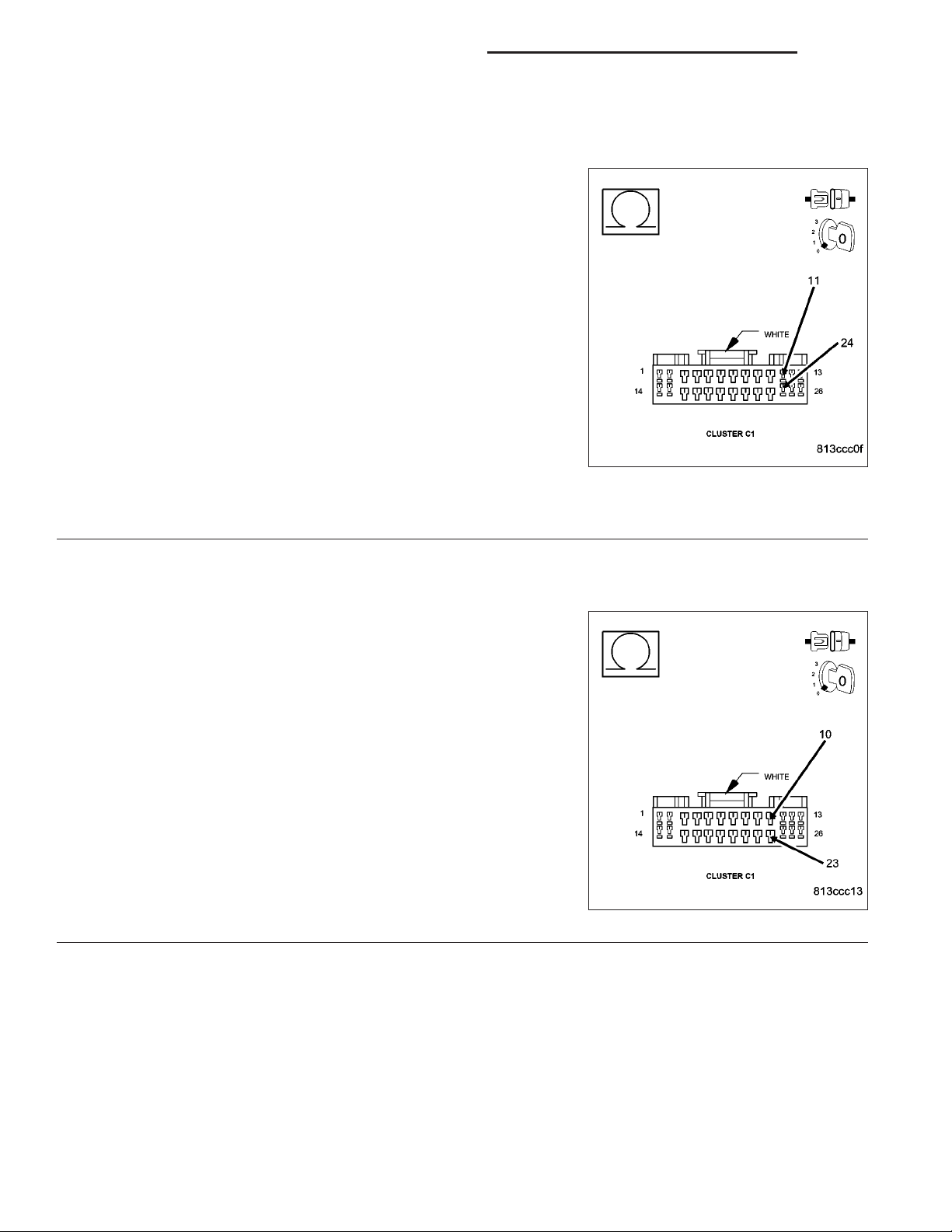

(P392) DOOR LOCK DRIVER RIGHT DOORS SHORTED TO (G778) DOOR UNLOCK DRIVER RIGHT

2.

DOORS

NOTE: If only one motor is inoperative when the door locks are

actuated, disconnect that door latch connector and retest to see

if the DTC is still present. If it is not, replace that door latch.

Turn the ignition off.

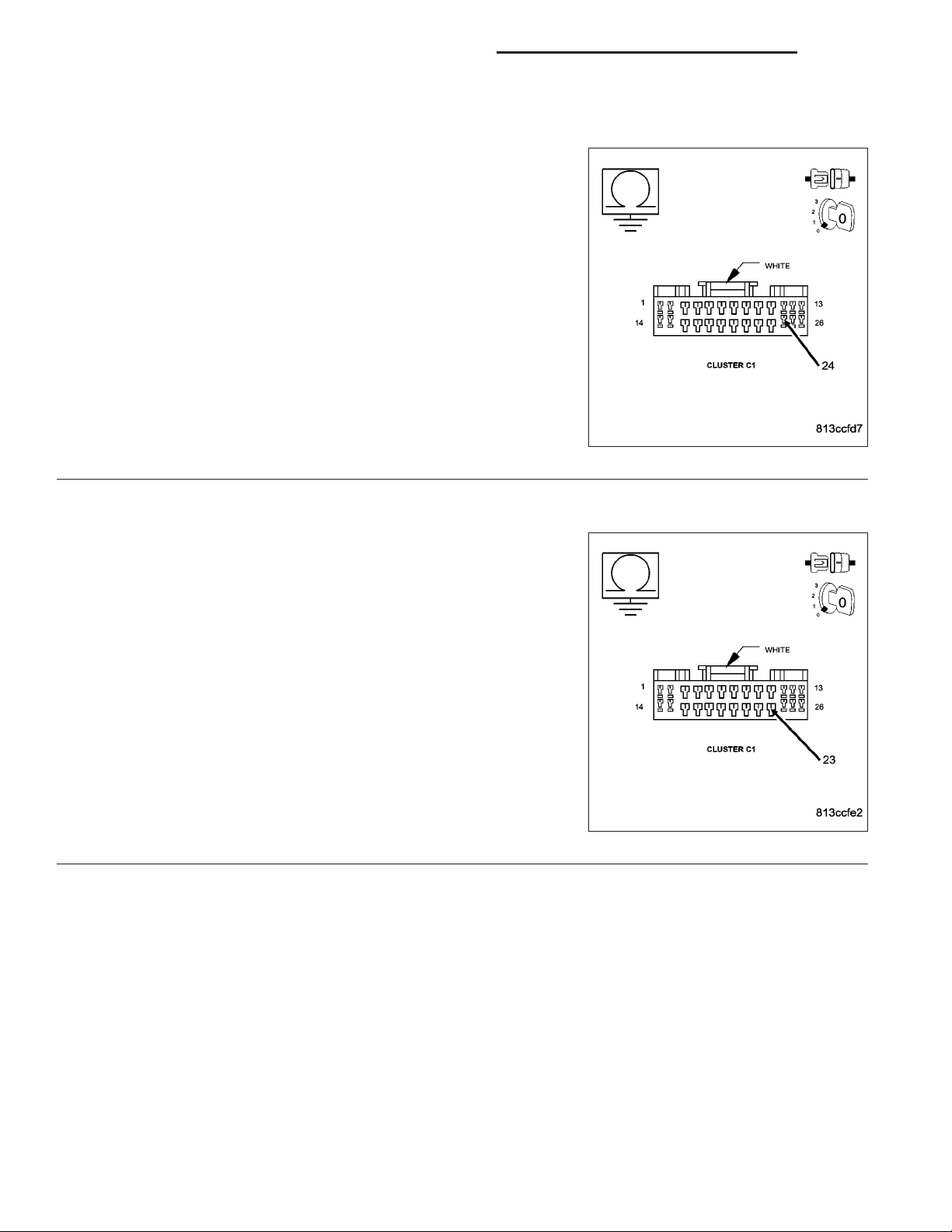

Disconnect the Instrument Cluster C1 connector.

Measure the resistance between the (P392) Door Lock Driver Right

Doors circuit and the (G778) Door Unlock Driver Right Doors circuit in

the Instrument Cluster connector.

Is the resistance below 1.6 ohms?

Yes >>

No >>

(P393) DOOR LOCK DRIVER LEFT DOORS SHORTED TO (P5) DOOR UNLOCK DRIVER LEFT REAR

3.

NOTE: If this is a 2 door vehicle, answer NO to the question and

continue.

Measure the resistance between the (P393) Door Lock Driver Left

Doors circuit and the (P5) Door Unlock Driver Left Rear circuit in the

Instrument Cluster connector.

Is the resistance below 2.5 ohms?

Yes >>

No >>

Repair the (P392) Door Lock Driver Right Doors circuit for

a short to the (G778) Door Unlock Driver Right Doors circuit (could be a shorted motor).

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 3

Repair the (P393) Door Lock Driver Left Doors circuit for a

short to the (P5) Door Unlock Driver Left Rear or the (P1)

Door Unlock Driver Left Front circuit (could be a shorted

motor).

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 4

Page 10

8N - 10 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

ALL DOOR UNLOCK OUTPUT CIRCUIT SHORT TO GROUND OR VOLTAGE (CONTINUED)

(G778) DOOR UNLOCK DRIVER RIGHT DOORS CIRCUIT SHORT TO GROUND

4.

Measure the resistance between ground and the (G778) Door Unlock

Driver Right Doors circuit in the Instrument Cluster C1 connector.

Is the resistance below 1000.0 ohms?

Yes >>

No >>

(P5) DOOR UNLOCK DRIVER LEFT REAR CIRCUIT SHORT TO GROUND

5.

NOTE: If this is a 2 door vehicle, answer NO to the question and

continue.

Measure the resistance between ground and the (P5) Door Unlock

Driver Left Rear circuit in the Instrument Cluster C1 connector.

Is the resistance below 1000.0 ohms?

Yes >>

No >>

Repair the (G778) Door Unlock Driver Right Doors circuit

for a short to ground. The short may be in the (G778)

Door Unlock Driver Right Doors wire, the (P392) Door

Lock Driver Right Doors wire or a right side door lock

motor.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 5

Repair the (P5) Door Unlock Driver Left Rear circuit for a

short to ground. The short may be in the (P5) Door Unlock

Driver Left Rear wire, the (P393) Door Lock Driver Left

Doors wire or in a left side door lock motor.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 6

Page 11

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 11

ALL DOOR UNLOCK OUTPUT CIRCUIT SHORT TO GROUND OR VOLTAGE (CONTINUED)

(G778) DOOR UNLOCK DRIVER RIGHT DOORS SHORT TO VOLTAGE

6.

Turn the ignition on.

Measure the voltage between ground and the (G778) Door Unlock

Driver Right Doors circuit.

Is there any voltage present?

Yes >>

No >>

(P5) DOOR UNLOCK DRIVER LEFT REAR SHORT TO VOLTAGE

7.

NOTE: If this a 2 Door vehicle, answer NO to the question and

continue.

Measure the voltage between ground and the (P5) Door Unlock Driver

Left Rear circuit.

Is there any voltage present?

Yes >>

No >>

Repair the (P392) Door Lock or (G778) Door Unlock

Driver Right Doors circuit for a short to voltage.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 7

Repair the (P393) Door Lock Driver Left Doors or the (P5)

Door Unlock Driver Left Rear circuit for a short to voltage.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING).

Replace the Instrument Cluster.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 12

8N - 12 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

DRIVER DOOR UNLOCK OUTPUT CIRCUIT SHORT TO GROUND OR VOLTAGE

Page 13

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 13

DRIVER DOOR UNLOCK OUTPUT CIRCUIT SHORT TO GROUND OR VOLTAGE (CONTINUED)

For the Power Door Lock circuit diagram (Refer to 8 - ELECTRICAL/POWER LOCKS - SCHEMATICS AND DIAGRAMS)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Whenever the instrument cluster is awake.

• Set Condition:

The instrument cluster monitors the driver door unlock output circuit and when it is shorted to ground or to

voltage, this code will set. This code will only set when the door locks are actuated.

Possible Causes

(P393) DOOR LOCK DRIVER LEFT DOORS SHORTED TO (P1) DOOR UNLOCK DRIVER LEFT FRONT

(P1) DOOR UNLOCK DRIVER LEFT FRONT WIRE SHORT TO GROUND

(P393) DOOR LOCK DRIVER LEFT DOORS WIRE SHORT TO GROUND

(P393) DOOR LOCK DRIVER LEFT DOORS WIRE SHORTED TO VOLTAGE

(P1) DOOR LOCK DRIVER LEFT FRONT WIRE SHORTED TO VOLTAGE

DRIVER DOOR LATCH

INSTRUMENT CLUSTER

Diagnostic Test

DTC PRESENT

1.

Turn the ignition on.

With the DRBIIIT, record and erase DTC’s.

With the DRBIIIT, read DTC’s.

Operate the door locks several times from a door lock

switch while monitoring the DRBIIIT.

Does the DRBIIIT display DRIVER DOOR

UNLOCK OUTPUT CIRCUIT SHORT TO GROUND

OR VOLTAGE?

Yes >>

No >>

Go To 2

Using the wiring diagram/schematic as a

guide, inspect the wiring and connectors.

Check for any possible shorted conditions

between the instrument cluster and the

driver door lock motor.

Perform BODY VERIFICATION TEST VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES/FRONT

CONTROL MODULE - DIAGNOSIS AND

TESTING)

Page 14

8N - 14 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

DRIVER DOOR UNLOCK OUTPUT CIRCUIT SHORT TO GROUND OR VOLTAGE (CONTINUED)

(P393) DOOR LOCK DRIVER LEFT DOORS SHORTED TO (P1) DOOR UNLOCK DRIVER LEFT FRONT

2.

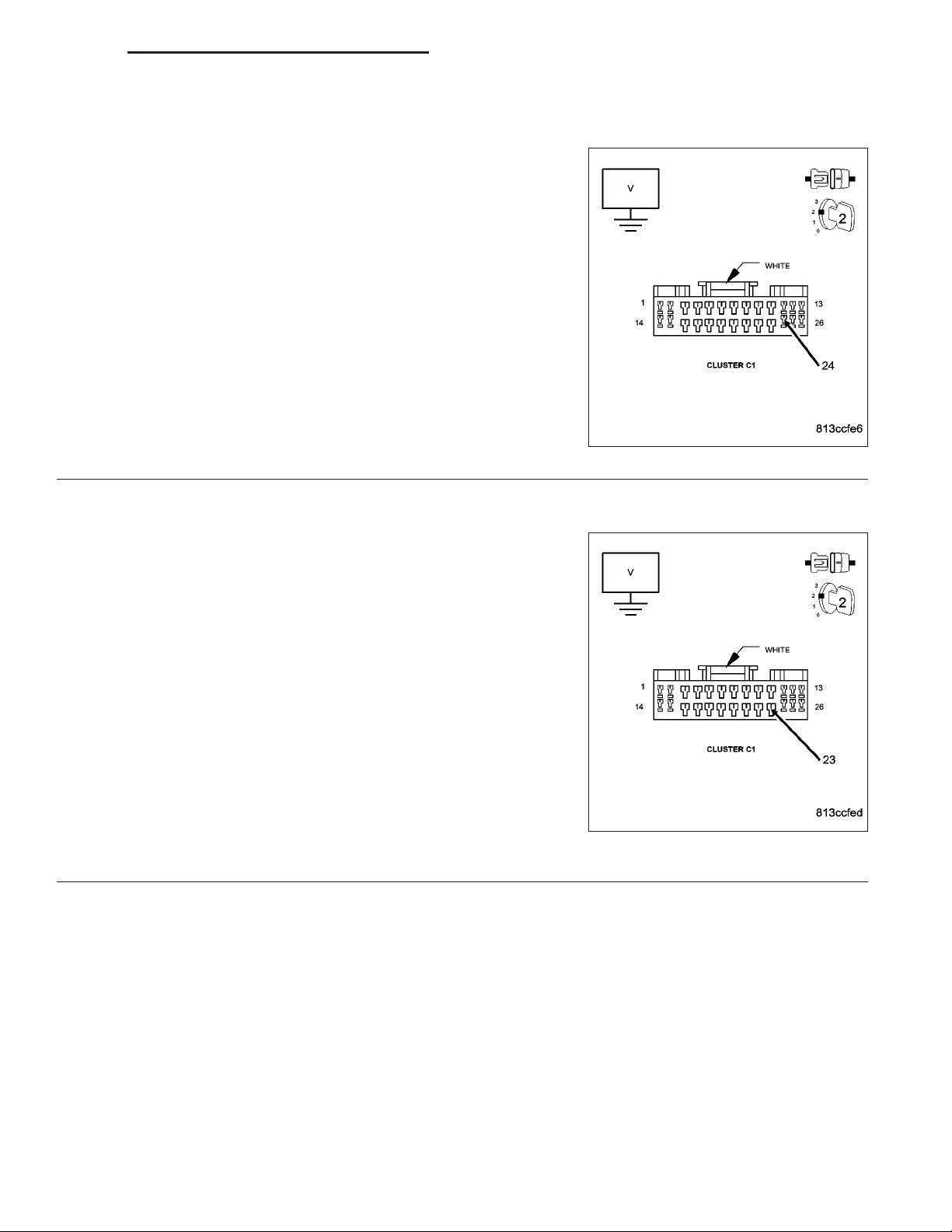

Turn the ignition off.

Disconnect the Instrument Cluster C1 connector.

Measure the resistance between the (P1) Door Unlock Driver Left

Front circuit and the (P393) Door Lock Driver Left Doors circuit in the

Instrument Cluster C1 connector.

Is the resistance below 3.0 ohms?

Yes >>

No >>

(P1) DOOR UNLOCK DRIVER LEFT FRONT CIRCUIT SHORTED TO GROUND

3.

Measure the resistance between ground and the (P1) Door Unlock

Driver Left Front circuit in the Instrument Cluster C1 connector.

Is the resistance below 1000.0 ohms?

No >>

Yes >>

Repair the (P393) Door Lock Driver Left Doors circuit for a

short to the (P1) Door Unlock Driver Left Front circuit

(could be a shorted motor).

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 3

Go To 6

Go To 4

Page 15

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 15

DRIVER DOOR UNLOCK OUTPUT CIRCUIT SHORT TO GROUND OR VOLTAGE (CONTINUED)

(P1) DOOR UNLOCK DRIVER LEFT FRONT WIRE SHORT TO GROUND

4.

Disconnect the Driver Door Lock Motor connector.

Measure the resistance between ground and the (P1) Door Unlock

Driver Left Front wire in the Instrument Cluster C1 connector.

Is the resistance below 1000.0 ohms?

Yes >>

No >>

(P393) DOOR LOCK DRIVER LEFT DOORS WIRE SHORT TO GROUND

5.

Measure the resistance between ground and the (P393) Door Lock

Driver Left Doors circuit in the Instrument Cluster C1 connector.

Is the resistance below 1000.0 ohms?

Yes >>

No >>

Repair the (P1) Door Unlock Driver Left Front wire for a

short to ground.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 5

Repair the (P393) Door Lock Driver Left Doors wire for a

short to ground.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Replace the Driver Door Latch.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 16

8N - 16 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

DRIVER DOOR UNLOCK OUTPUT CIRCUIT SHORT TO GROUND OR VOLTAGE (CONTINUED)

(P1) DOOR UNLOCK DRIVER LEFT FRONT OR (P393) DOOR LOCK DRIVER LEFT DOORS SHORTED TO

6.

VOLTAGE

Turn the ignition on.

Measure the voltage between ground and the (P1) Door Unlock Driver

Left Front circuit.

Is there any voltage present?

Yes >>

No >>

Repair the (P393) Door Lock Driver Left Doors or (P1)

Door Unlock Driver Left Front circuit for a short to voltage.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Replace the Instrument Cluster.

Perform BODY VERIFICATION TEST - VER 1 (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 17

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 17

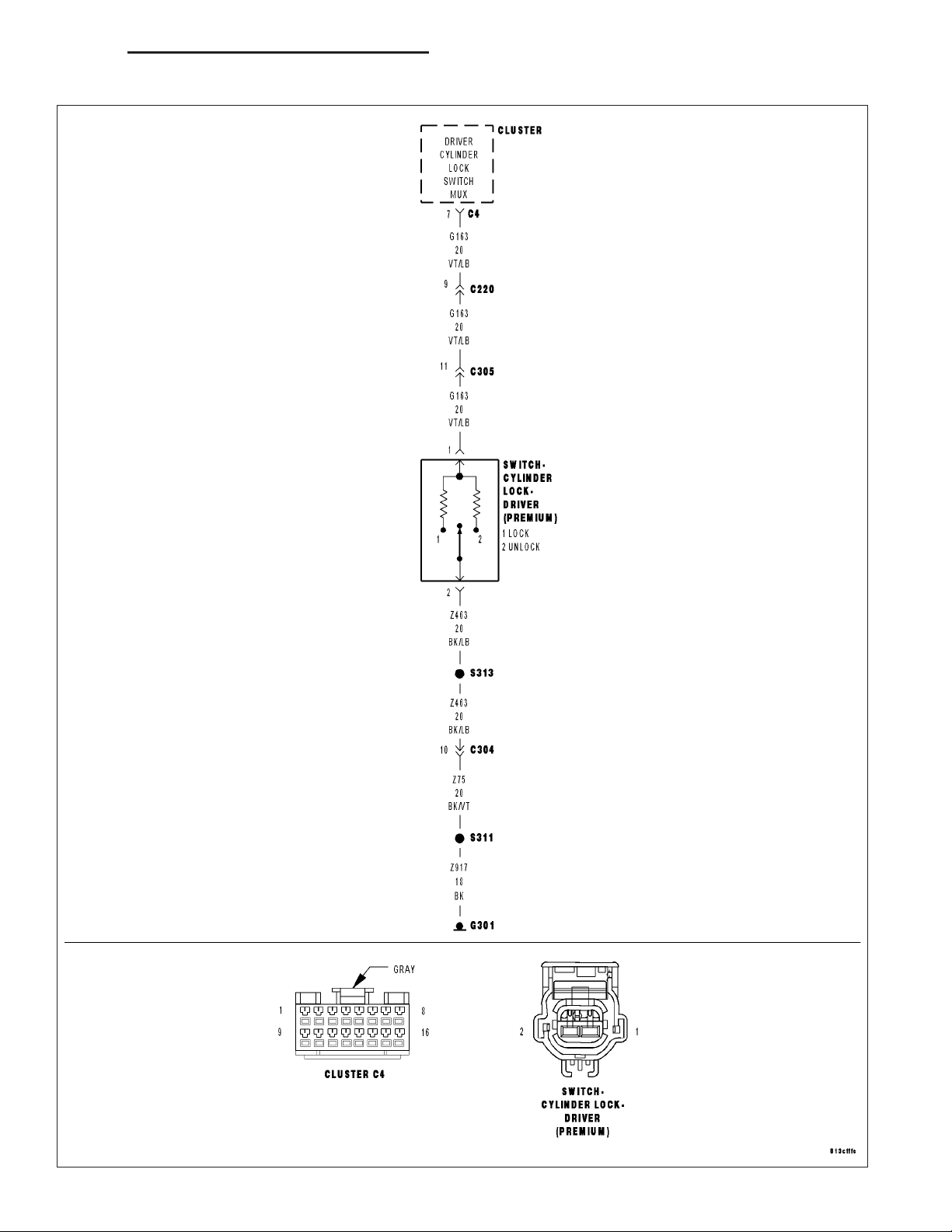

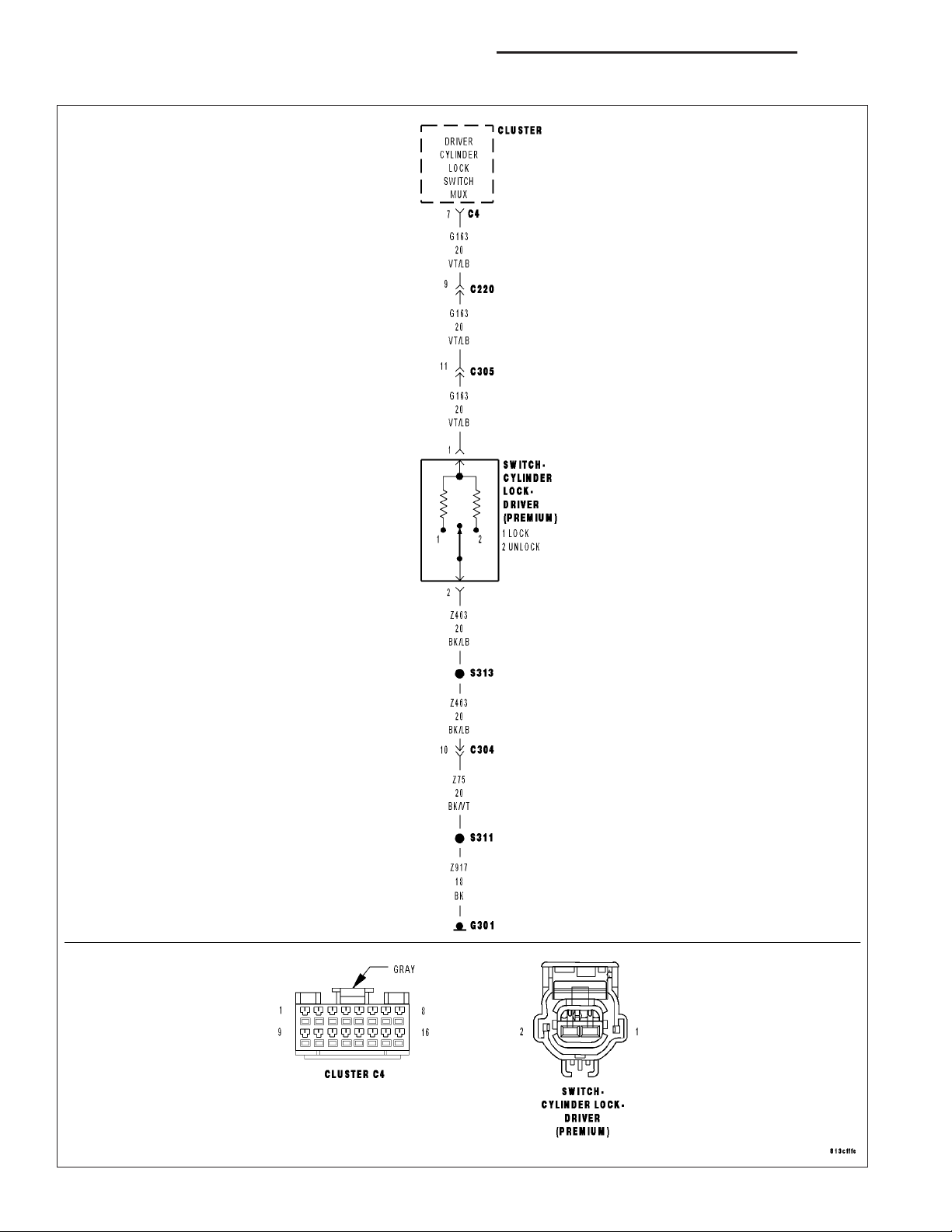

DRIVER CYLINDER LOCK SWITCH INPUT CIRCUIT SHORTED (WITH VTSS ONLY)

Page 18

8N - 18 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

DRIVER CYLINDER LOCK SWITCH INPUT CIRCUIT SHORTED (WITH VTSS ONLY) (CONTINUED)

For the Power Door Locks circuit diagram (Refer to 8 - ELECTRICAL/POWER LOCKS - SCHEMATICS AND DIAGRAMS).

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

At all times when battery power is supplied to the Instrument Cluster.

• Set Condition:

When the Instrument Cluster senses voltage to the driver cylinder lock switch below 0.25 volts for over 10

seconds.

Possible Causes

(G163) DRIVER CYLINDER LOCK SWITCH MUX CIRCUIT SHORT TO GROUND

CYLINDER LOCK SWITCH SHORTED

INSTRUMENT CLUSTER

Diagnostic Test

DTC PRESENT

1.

Turn the ignition on.

With the DRBIIIT, record and erase DTC’s.

With the DRBIIIT, read DTC’s.

Operate the door locks several times from the Driver

Cylinder Lock Switch by cycling the key clockwise

while monitoring the DRBIIIT.

Does the DRBIIIT display DRIVER CYL LOCK SW

INPUT CIRCUIT SHORTED?

Yes >>

No >>

Go To 2

Using the wiring diagram/schematic as a

guide, inspect the wiring and connectors.

Perform BODY VERIFICATION TEST -

VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES/FRONT

CONTROL MODULE - DIAGNOSIS AND

TESTING)

Page 19

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 19

DRIVER CYLINDER LOCK SWITCH INPUT CIRCUIT SHORTED (WITH VTSS ONLY) (CONTINUED)

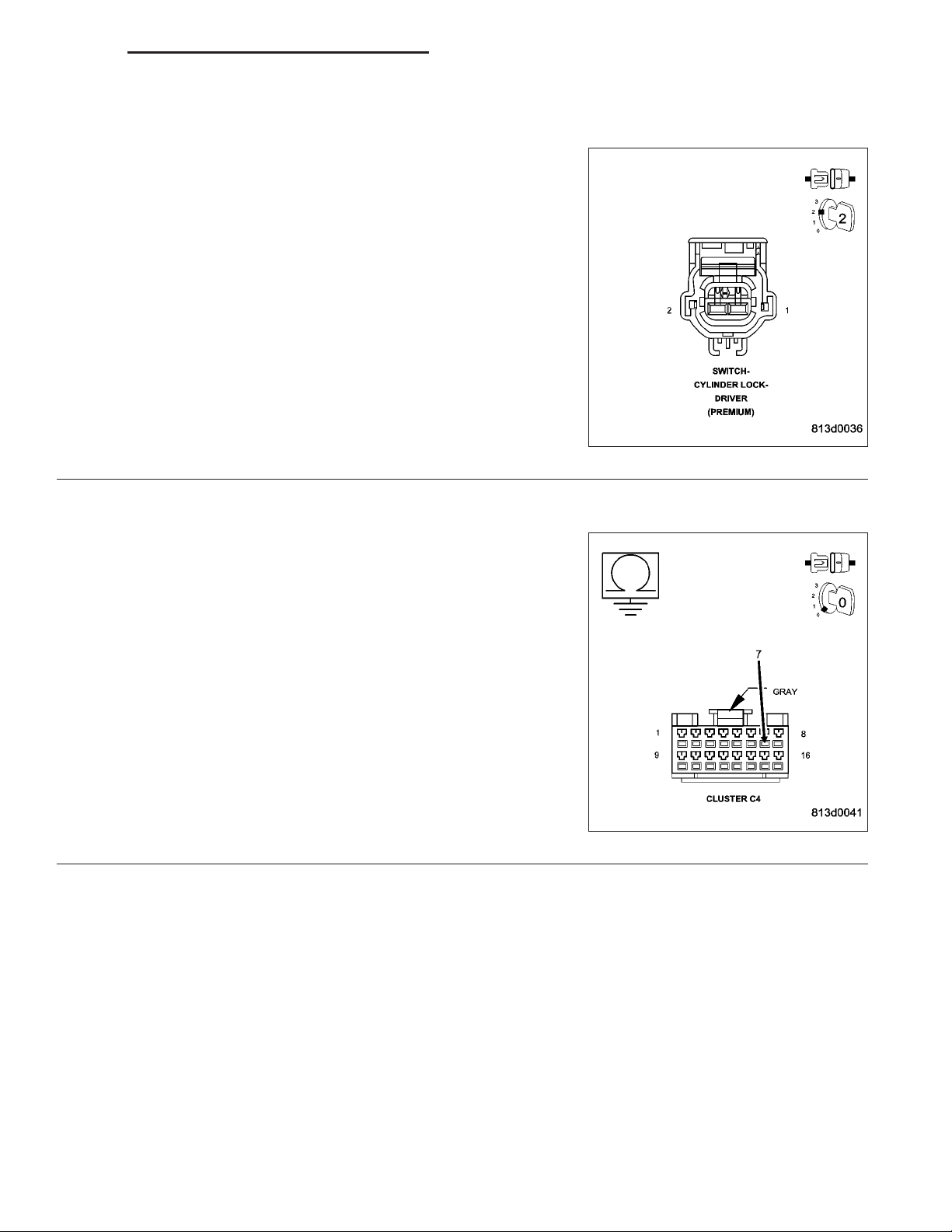

CYLINDER LOCK SWITCH SHORTED

2.

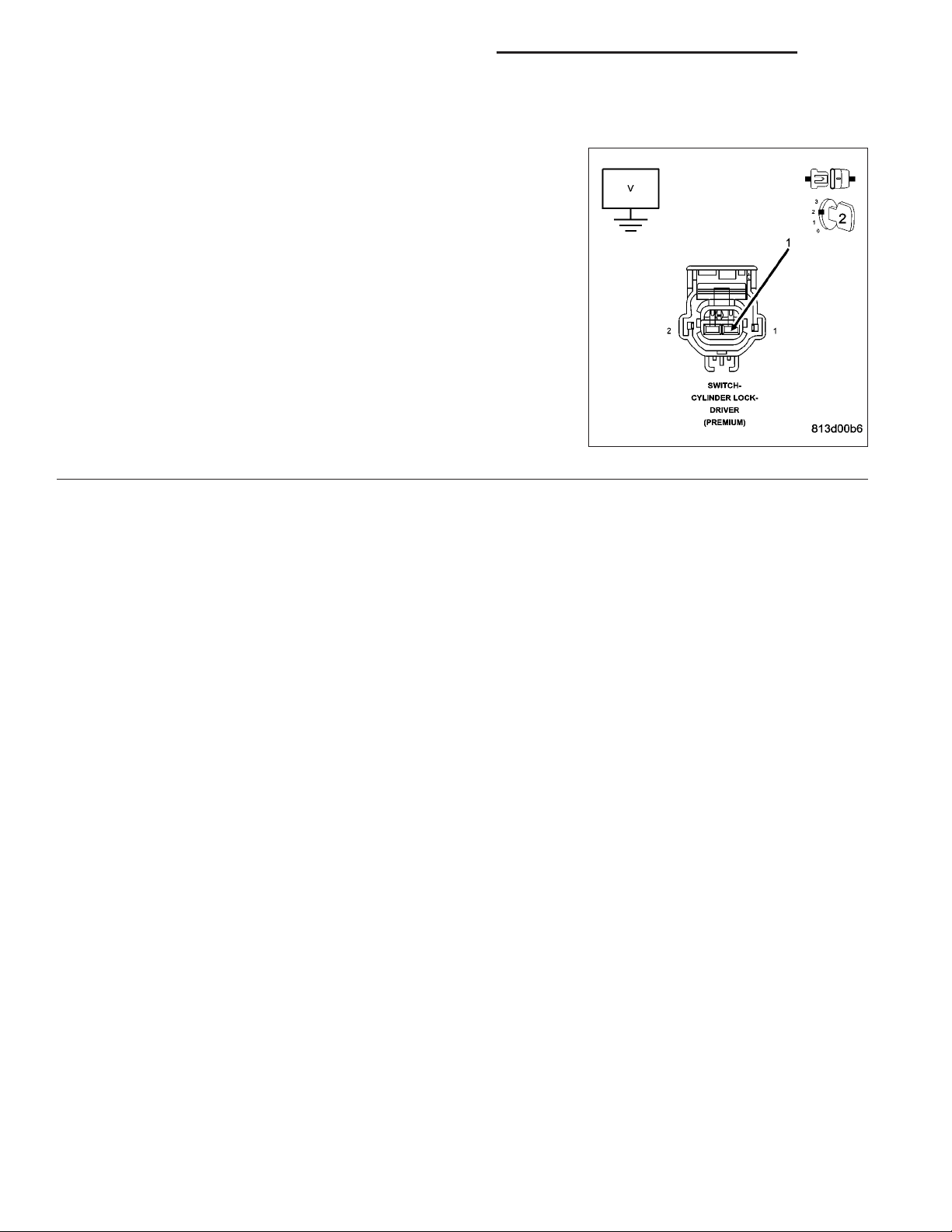

Disconnect the Driver Cylinder Lock Switch connector.

With the DRBIIIT in Sensors, read the DRV CYL LOCK SW MUX cir-

cuit

Is the voltage above 4.8 volts?

Yes >>

No >>

(G163) DRIVER CYLINDER LOCK SWITCH MUX SHORTED

3.

Disconnect the Driver Cylinder Lock Switch connector.

Disconnect the Instrument Cluster C2. connector.

Measure the resistance between (G163) Driver Cylinder Lock Switch

Mux circuit and ground.

Is the resistance below 1000.0 ohms?

Yes >>

No >>

Replace the Cylinder Lock Switch.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 3

Repair the (G163) Driver Cylinder Lock Switch Mux circuit

for a short to ground.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Replace the Instrument Cluster. Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES/FRONT CONTROL

MODULE - DIAGNOSIS AND TESTING)

Page 20

8N - 20 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

DRIVER CYLINDER LOCK SWITCH INPUT STUCK (WITH VTSS ONLY)

Page 21

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 21

DRIVER CYLINDER LOCK SWITCH INPUT STUCK (WITH VTSS ONLY) (CONTINUED)

For the Power Door Locks circuit diagram. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES/FRONT

CONTROL MODULE - DIAGNOSIS AND TESTING)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

At all times when battery power is supplied to the Instrument Cluster.

• Set Condition:

When the Instrument Cluster senses voltage to the driver cylinder lock switch between 1.3 and 3.75 volts for

over 10 seconds.

Possible Causes

DRIVER CYLINDER LOCK SWITCH MUX CIRCUIT PARTIAL SHORT TO GROUND

CYLINDER LOCK SWITCH STUCK

INSTRUMENTT CLUSTER

Diagnosttic Test

DTC PRESENT

1.

Turn the ignition on.

With the DRBIIIT, record and erase DTC’s.

With the DRBIIIT, read DTC’s.

Operate the door locks several times from the Driver

Cylinder Lock Switch by cycling the key in both directions while monitoring the DRBIIIT.

Does the DRBIIIT display DRV CYL LOCK SW

INPUT CIRCUIT STUCK?

Yes >>

No >>

CYLINDER LOCK SWITCH SHORTED

2.

With the DRBIIIT in Sensors, read the DRV CYL LOCK SW MUX circuit

Does the DRBIIIT display voltage between 1.3 and 4.15 volts?

No >>

Yes >>

Go To 2

Using the wiring diagram/schematic as a

guide, inspect the wiring and connectors.

Perform BODY VERIFICATION TEST -

VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES/FRONT

CONTROL MODULE - DIAGNOSIS AND

TESTING)

Replace the Instrument Cluster.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 3

Page 22

8N - 22 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

DRIVER CYLINDER LOCK SWITCH INPUT STUCK (WITH VTSS ONLY) (CONTINUED)

(G164) DRIVER CYLINDER LOCK SWITCH MUX SHORTED

3.

Disconnect the Driver Cylinder Lock Switch connector.

Measure the voltage between (G163) Driver Cylinder Lock Switch Mux

circuit and ground.

Is the voltage above 4.9 volts?

No >>

Yes >>

Repair the (G163) Driver Cylinder Lock Switch Mux circuit

for a partial short to ground.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Replace the Cylinder Lock Switch. Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES/FRONT CONTROL

MODULE - DIAGNOSIS AND TESTING)

Page 23

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 23

DRIVER DOOR LOCK SWITCH INPUT CIRCUIT OPEN OR SHORT TO VOLTAGE

Page 24

8N - 24 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

DRIVER DOOR LOCK SWITCH INPUT CIRCUIT OPEN OR SHORT TO VOLTAGE (CONTINUED)

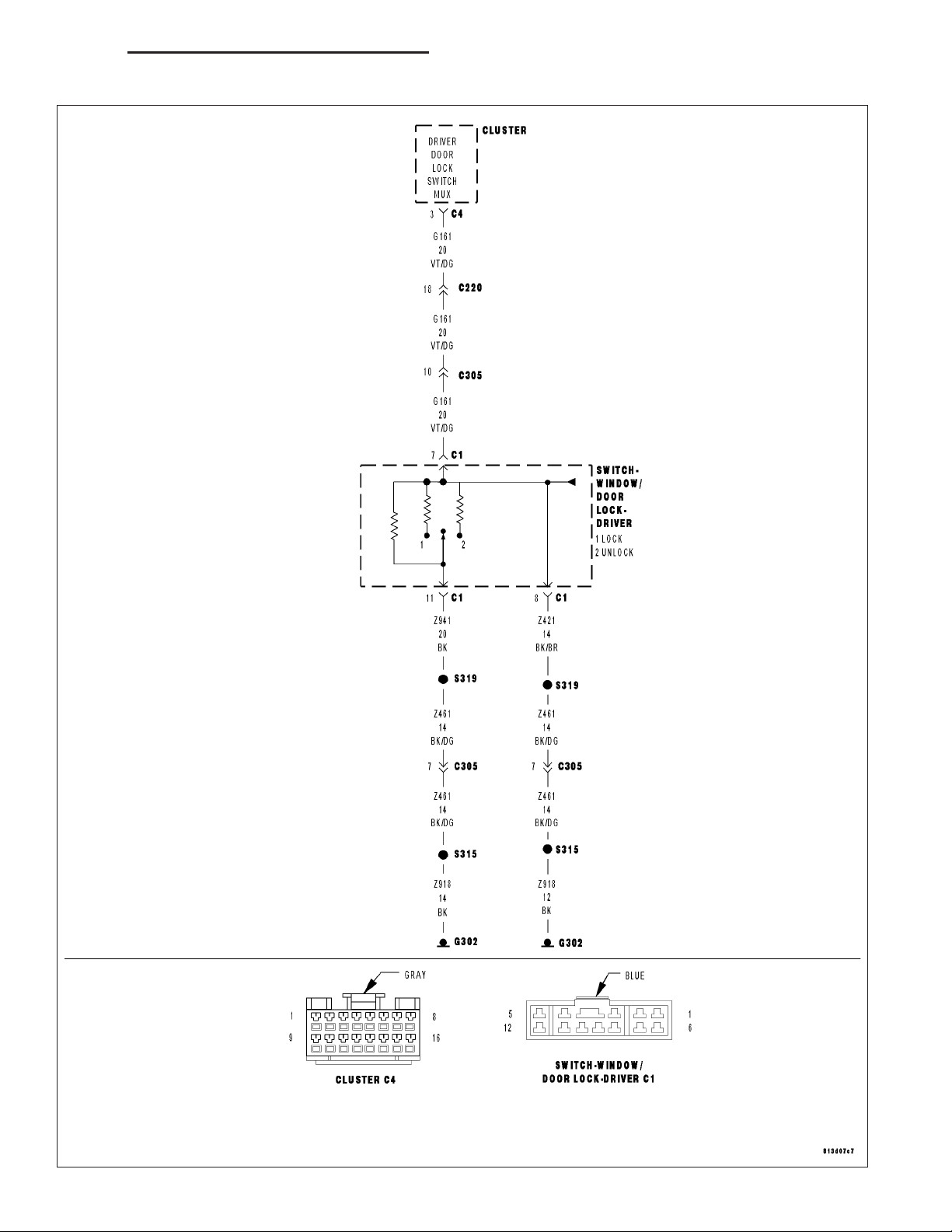

For the Power Door Lock circuit diagram (Refer to 8 - ELECTRICAL/POWER LOCKS - SCHEMATICS AND DIAGRAMS) (Refer to ).

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

At all times when battery power is supplied to the Instrument Cluster.

• Set Condition:

When the Instrument Cluster senses voltage to the driver door lock switch above 4.85 volts.

Possible Causes

(G161) DRIVER DOOR LOCK SWITCH WIRE SHORT TO VOLTAGE

(G161) DRIVER DOOR LOCK SWITCH MUX CIRCUIT OPEN

DOOR LOCK SWITCH GROUND OPEN

DOOR LOCK SWITCH SHORT TO VOLTAGE

DOOR LOCK SWITCH OPEN

INSTRUMENT CLUSTER - VOLTAGE TO HIGH

INSTRUMENT CLUSTER - DRIVER DOOR LOCK SWITCH VOLTAGE LOW

Diagnostic Test

DTC PRESENT

1.

Turn the ignition on.

With the DRBIIIT, record and erase DTC’s.

With the DRBIIIT, read DTC’s.

Operate the door locks from the Driver Door Lock

Switch while monitoring the DRBIIIT.

Does the DRBIIIT display DRIVER DOOR LOCK

SWITCH INPUT CIRCUIT OPEN OR SHORT TO

VOLTAGE?

Yes >>

No >>

Go To 2

Using the wiring diagram/schematic as a

guide, inspect the wiring and connectors.

Check for any possible loose connections

at the instrument cluster and the door lock

switch.

Perform BODY VERIFICATION TEST VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES/FRONT

CONTROL MODULE - DIAGNOSIS AND

TESTING)

Page 25

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 25

DRIVER DOOR LOCK SWITCH INPUT CIRCUIT OPEN OR SHORT TO VOLTAGE (CONTINUED)

INSTRUMENT CLUSTER - DRIVER DOOR LOCK SWITCH VOLTAGE LOW

2.

With the DRBIIIT in Sensors, read the DRV DOOR LOCK SW voltage.

Voltage reading is:

Above 5.2 volts

Go To 3

Between 4.9 and 5.1 volts

Go To 5

Below 4.8 volts

Replace the Instrument Cluster.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

INSTRUMENT CLUSTER - VOLTAGE TO HIGH

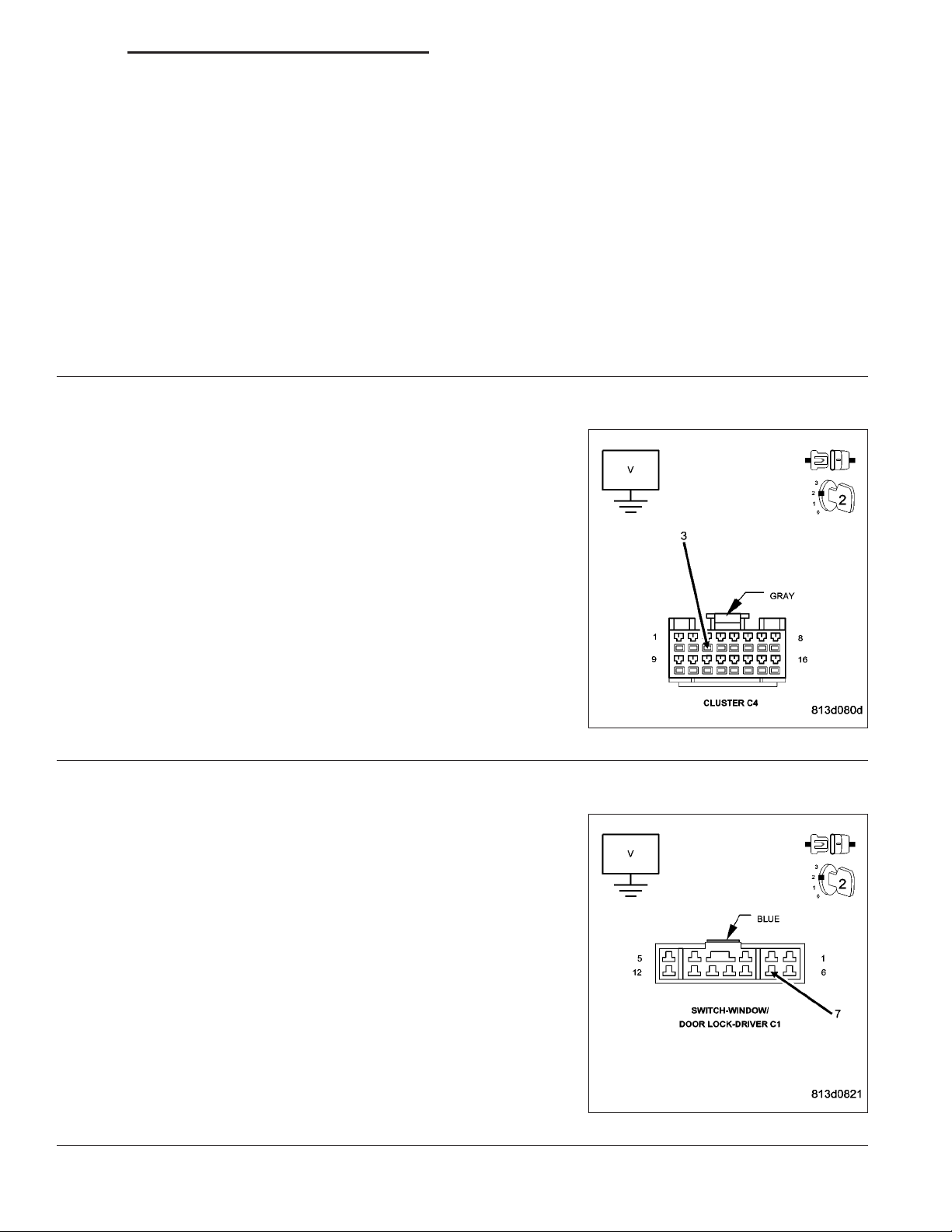

3.

Turn the ignition off.

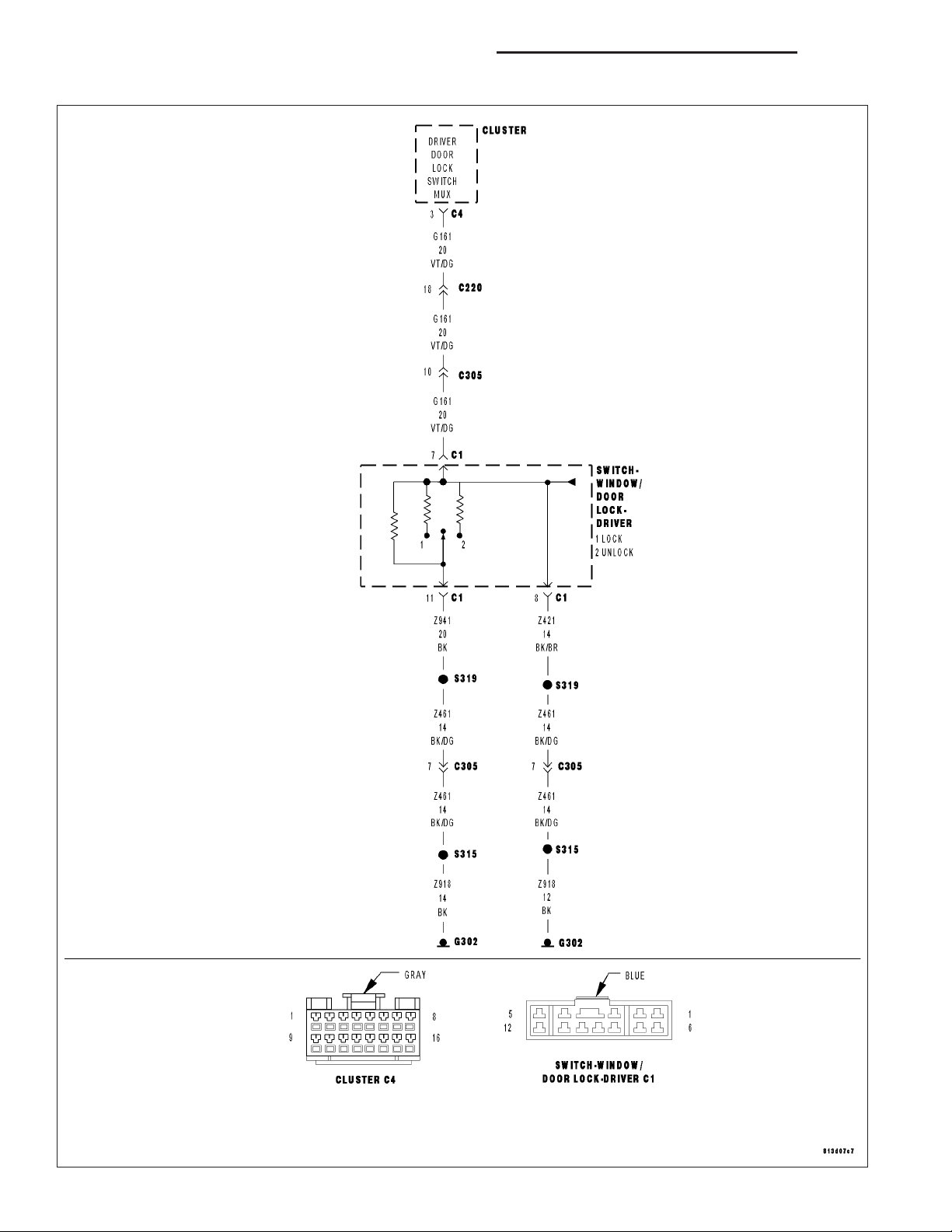

Disconnect the Instrument Cluster C4 connector.

Turn the ignition on.

Measure the voltage between (G161) Driver Door Lock Switch Mux

circuit and ground.

Is there any voltage present?

Yes >>

No >>

(G161) DRIVER DOOR LOCK SWITCH WIRE SHORT TO VOLTAGE

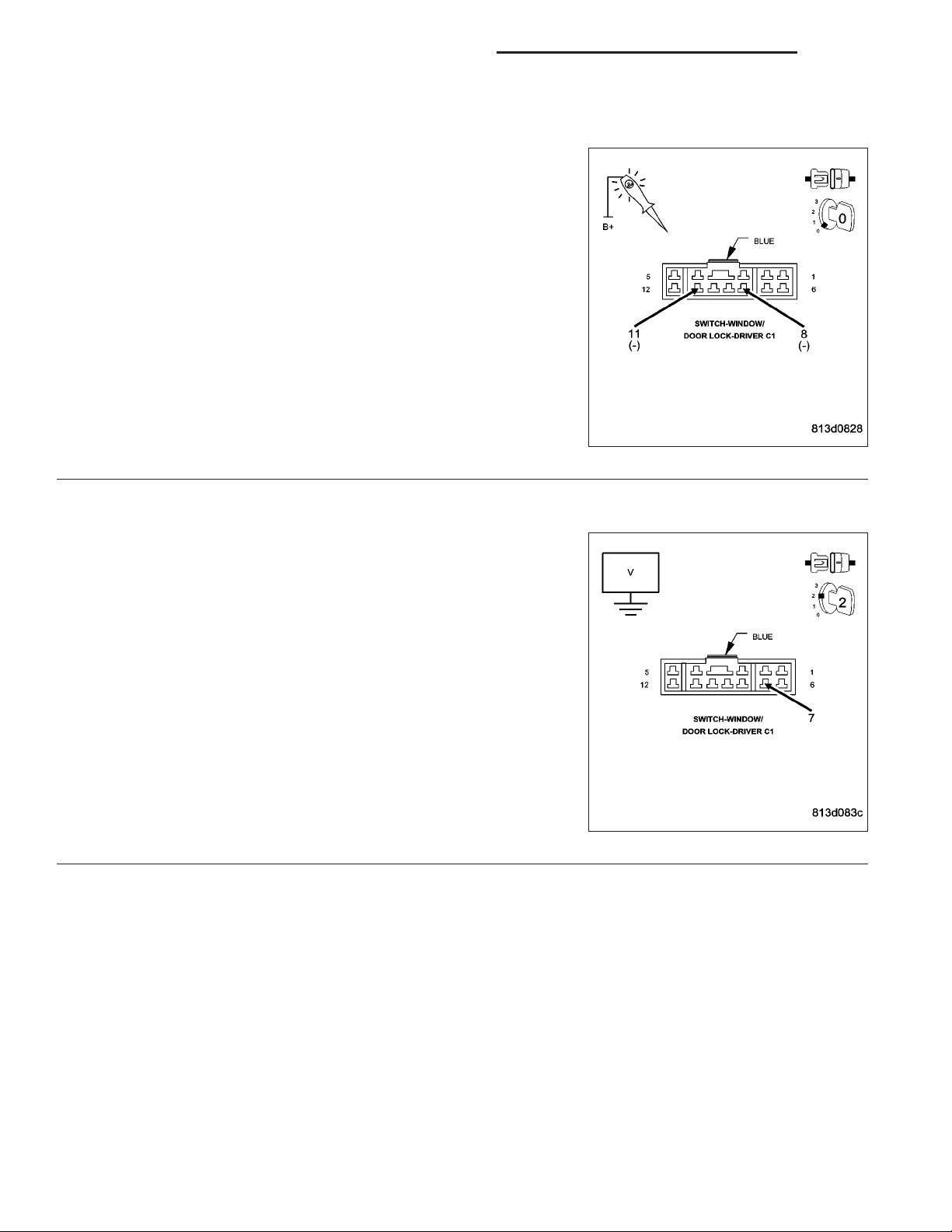

4.

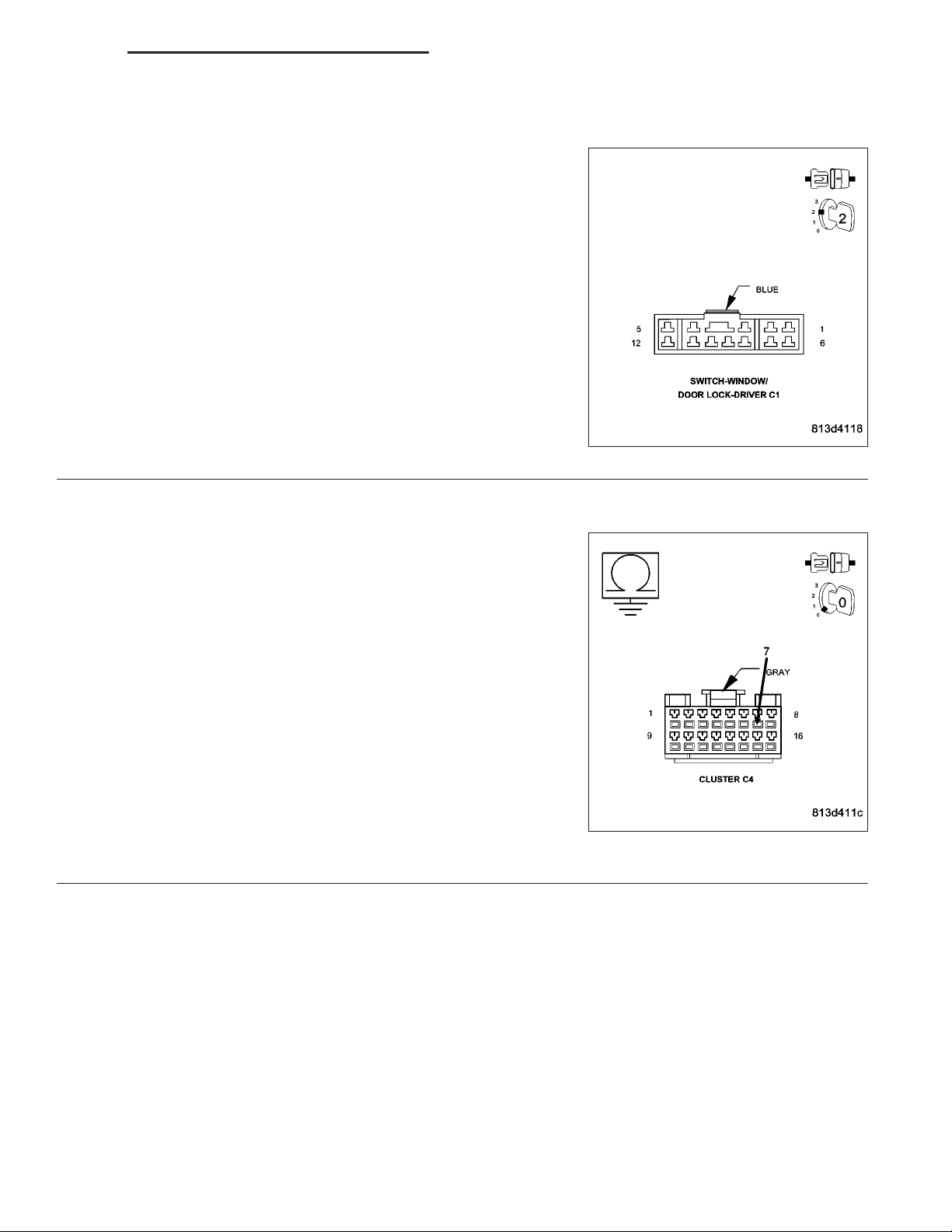

Disconnect the Driver Window/Door Lock Switch C1 connector.

Measure the voltage between the (G161) Driver Door Lock Switch

Mux circuit and ground.

Is there any voltage present?

Yes >>

No >>

Go To 4

Replace the Instrument Cluster.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Repair the (G161) Driver Door Lock Switch Mux circuit for

a short to voltage.

Perform BODY VERIFICATION TEST - VER 1 (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING).

Replace the Window/Door Lock Switch.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 26

8N - 26 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

DRIVER DOOR LOCK SWITCH INPUT CIRCUIT OPEN OR SHORT TO VOLTAGE (CONTINUED)

(Z421) and (Z941) DOOR LOCK SWITCH GROUND OPEN

5.

Turn the ignition off.

Disconnect the Driver Window/Door Lock Switch C1 connector.

Using a 12-volt test light connected to 12-volts, check both Ground cir-

cuits in the Door Module C1 connector.

Does the test light illuminate brightly in both terminals?

Yes >>

No >>

(G161) DRIVER DOOR LOCK SWITCH MUX OPEN

6.

Turn the ignition on.

Measure the voltage between the (G161) Driver Door Lock Switch

Mux circuit and ground.

Is the voltage above 4.6 volts?

Yes >>

No >>

Go To 6

Repair the (Z421) or (Z941) Ground circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Replace the Driver Window/Door Lock Switch.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Repair the (G161) Driver Door Lock Switch Mux circuit for

an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 27

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 27

DRIVER DOOR LOCK SWITCH INPUT CIRCUIT SHORTED

Page 28

8N - 28 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

DRIVER DOOR LOCK SWITCH INPUT CIRCUIT SHORTED (CONTINUED)

For the Power Door Lock circuit diagram (Refer to 8 - ELECTRICAL/POWER LOCKS - SCHEMATICS AND DIAGRAMS).

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

At all times when battery power is supplied to the Instrument Cluster.

• Set Condition:

When the Instrument Cluster senses voltage to the driver door lock switch below .25 volts, the input circuit is

not valid and this code will set.

Possible Causes

(G161) DRIVER DOOR LOCK SWITCH MUX CIRCUIT SHORTED TO GROUND

DOOR LOCK SWITCH SHORTED

INSTRUMENT CLUSTER

Diagnostic Test

DTC PRESENT

1.

Turn the ignition on.

With the DRBIIIT, record and erase DTC’s.

With the DRBIIIT, read DTC’s.

Operate the door locks several times from the Driver

Door Lock Switch while monitoring the DRBIIIT.

Does the DRBIIIT display DRIVER DOOR LOCK

SW INPUT CIRCUIT SHORTED?

Yes >>

No >>

Go To 2

Using the wiring diagram/schematic as a

guide, inspect the wiring and connectors.

Perform BODY VERIFICATION TEST -

VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES/FRONT

CONTROL MODULE - DIAGNOSIS AND

TESTING)

Page 29

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 29

DRIVER DOOR LOCK SWITCH INPUT CIRCUIT SHORTED (CONTINUED)

DOOR LOCK SWITCH SHORTED

2.

Disconnect the Driver Window/Door Lock Switch C1 connector.

With the DRBIIIT in sensors, read the DRV DOOR LOCK SW MUX

circuit.

Is the voltage above 4.6 volts?

Yes >>

No >>

(G161) DRIVER DOOR LOCK SWITCH MUX CIRCUIT SHORTED

3.

Turn the ignition off.

Disconnect the Instrument Cluster C4 connector.

Measure the resistance between the (G161) Driver Door Lock Switch

Mux circuit and ground.

Is the resistance below 1000.0 ohms?

Yes >>

No >>

Replace the Driver Window/Door Lock Switch.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 3

Repair the (G161) Driver Door Lock Switch Mux circuit for

a short to ground.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Replace the Instrument Cluster.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 30

8N - 30 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

DRIVER DOOR LOCK SWITCH INPUT CIRCUIT STUCK

Page 31

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 31

DRIVER DOOR LOCK SWITCH INPUT CIRCUIT STUCK (CONTINUED)

For the Power Door Lock circuit diagram (Refer to 8 - ELECTRICAL/POWER LOCKS - SCHEMATICS AND DIAGRAMS).

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

At all times when battery power is supplied to the Instrument Cluster.

• Set Condition:

When the Instrument Cluster senses voltage to the driver door lock switch between 1.3 and 3.75 volts for over

20 seconds, this code will set.

Possible Causes

(G161) DRIVER DOOR LOCK SWITCH MUX CIRCUIT PARTIALLY SHORTED TO GROUND

DOOR LOCK SWITCH SHORTED

INSTRUMENT CLUSTER

Diagnostic Test

DTC PRESENT

1.

Turn the ignition on.

With the DRBIIIT, record and erase DTC’s.

With the DRBIIIT, read DTC’s.

Operate the door locks several times from the Driver

Door Lock Switch while monitoring the DRBIIIT.

Does the DRBIIIT display DRIVER DOOR LOCK

SWITCH INPUT CIRCUIT STUCK?

Yes >>

No >>

Go To 2

Using the wiring diagram/schematic as a

guide, inspect the wiring and connectors.

Operate the switch several times and

check for an occasional sticking problem.

Perform BODY VERIFICATION TEST VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES/FRONT

CONTROL MODULE - DIAGNOSIS AND

TESTING)

Page 32

8N - 32 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

DRIVER DOOR LOCK SWITCH INPUT CIRCUIT STUCK (CONTINUED)

DOOR LOCK SWITCH STUCK

2.

Disconnect the Driver Window/Door Lock Switch C1 connector.

With the DRBIIIT in sensors, read the DRV DOOR LOCK SW MUX

circuit.

Is the voltage above 4.6 volts?

Yes >>

No >>

(G161) DRIVER DOOR LOCK SWITCH MUX CIRCUIT SHORTED

3.

Turn the ignition off.

Disconnect the Instrument Cluster C4 connector.

Measure the resistance between the (G161) Driver Door Lock Switch

Mux circuit and ground.

Is the resistance below 10000.0 ohms?

Yes >>

No >>

Replace the Driver Window/Door Lock Switch.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 3

Repair the (G161) Driver Door Lock Switch Mux circuit for

a partial short to ground.

Perform BODY VERIFICATION TEST - VER 1 (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Replace the Instrument Cluster

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 33

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 33

PASSENGER DOOR LOCK SWITCH INPUT CIRCUIT OPEN OR SHORT TO

VOLTAGE

Page 34

8N - 34 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

PASSENGER DOOR LOCK SWITCH INPUT CIRCUIT OPEN OR SHORT TO VOLTAGE (CONTINUED)

For the Power Door Lock circuit diagram (Refer to 8 - ELECTRICAL/POWER LOCKS - SCHEMATICS AND DIAGRAMS) (Refer to ).

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

At all times when battery power is supplied to the Instrument Cluster.

• Set Condition:

When the Instrument Cluster senses voltage on the passenger door lock switch circuit above 4.85 volts, this

will set and the input will not be valid.

Possible Causes

(G160) PASSENGER DOOR LOCK SWITCH WIRE SHORT TO VOLTAGE

(G160) PASSENGER DOOR LOCK SWITCH MUX CIRCUIT OPEN

(Z461) DOOR LOCK SWITCH GROUND OPEN

DOOR LOCK SWITCH SHORT TO VOLTAGE

DOOR LOCK SWITCH OPEN

INSTRUMENT CLUSTER - VOLTAGE TO HIGH

INSTRUMENT CLUSTER - PASSENGER DOOR LOCK SWITCH VOLTAGE LOW

Diagnostic Test

DTC PRESENT

1.

With the DRBIIIT, record and erase DTC’s.

With the DRBIIIT, read DTC’s.

Operate the door locks from the Passenger Door Lock

Switch while monitoring the DRBIIIT.

Does the DRBIIIT display PASSENGER DOOR

LOCK SWITCH INPUT CIRCUIT OPEN OR SHORT

TO VOLTAGE?

Yes >>

No >>

Go To 2

Using the wiring diagram/schematic as a

guide, inspect the wiring and connectors.

Check for any possible loose connections

at the instrument cluster and the door lock

switch.

Perform BODY VERIFICATION TEST VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES/FRONT

CONTROL MODULE - DIAGNOSIS AND

TESTING)

Page 35

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 35

PASSENGER DOOR LOCK SWITCH INPUT CIRCUIT OPEN OR SHORT TO VOLTAGE (CONTINUED)

INSTRUMENT CLUSTER - PASSENGER DOOR LOCK SWITCH VOLTAGE LOW

2.

With the DRBIIIT in Sensors, read the PASS DOOR LOCK SW voltage.

Voltage reading is:

Above 5.2 volts

Go To 3

Between 4.9 and 5.1 volts

Go To 5

Below 4.8 volts

Replace the Instrument Cluster.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

INSTRUMENT CLUSTER - VOLTAGE TO HIGH

3.

Turn ignition off.

Disconnect the Instrument Cluster C4 connector.

Turn ignition on.

Measure the voltage between (G160) Passenger Door Lock Switch

Mux circuit and ground.

Is there any voltage present?

Yes >>

No >>

(G160) PASSENGER DOOR LOCK SWITCH WIRE SHORT TO VOLTAGE

4.

Disconnect the Passenger Door Lock Switch connector.

Measure the voltage between the (G160) Passenger Door Lock Switch

Mux circuit and ground.

Is there any voltage present?

Yes >>

No >>

Go To 4

Replace the Instrument Cluster.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Repair the (G160) Passenger Door Lock Switch Mux circuit for a short to voltage.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Replace the Door Lock Switch.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 36

8N - 36 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

PASSENGER DOOR LOCK SWITCH INPUT CIRCUIT OPEN OR SHORT TO VOLTAGE (CONTINUED)

(Z461) DOOR LOCK SWITCH GROUND OPEN

5.

Turn ignition off.

Disconnect the Passenger Door Lock Switch connector.

Using a 12-volt test light connected to 12-volts, check the (Z461)

Ground circuit in the Door Lock Switch connector.

Does the test light illuminate brightly?

Yes >>

No >>

(G160) PASSENGER DOOR LOCK SWITCH MUX OPEN

6.

Turn ignition on.

Measure the voltage between the (G160) Passenger Door Lock Switch

Mux circuit and ground.

Is the voltage above 4.6 volts?

Yes >>

No >>

Go To 6

Repair the (Z461) Ground circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Replace the Passenger Door Lock Switch.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Repair the (G160) Passenger Door Lock Switch Mux circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 37

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 37

PASSENGER DOOR LOCK SWITCH INPUT CIRCUIT SHORTED

Page 38

8N - 38 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

PASSENGER DOOR LOCK SWITCH INPUT CIRCUIT SHORTED (CONTINUED)

For the Power Door Lock circuit diagram (Refer to 8 - ELECTRICAL/POWER LOCKS - SCHEMATICS AND DIAGRAMS).

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

At all times when battery power is supplied to the Instrument Cluster.

• Set Condition:

When the Instrument Cluster senses voltage to the passenger door lock switch below .25 volts, the input circuit

is not valid and this code will set.

Possible Causes

(G160) PASSENGER DOOR LOCK SWITCH MUX CIRCUIT SHORTED TO GROUND

DOOR LOCK SWITCH SHORTED

INSTRUMENT CLUSTER

Diagnostic Test

DTC PRESENT

1.

Turn the ignition on.

With the DRBIIIT, record and erase DTC’s.

With the DRBIIIT, read DTC’s.

Operate the door locks several times from the Driver

Door Lock Switch while monitoring the DRBIIIT.

Does the DRBIIIT display PASSENGER DOOR

LOCK SW INPUT CIRCUIT SHORTED?

Yes >>

No >>

Go To 2

Using the wiring diagram/schematic as a

guide, inspect the wiring and connectors.

Perform BODY VERIFICATION TEST -

VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES/FRONT

CONTROL MODULE - DIAGNOSIS AND

TESTING)

Page 39

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 39

PASSENGER DOOR LOCK SWITCH INPUT CIRCUIT SHORTED (CONTINUED)

DOOR LOCK SWITCH SHORTED

2.

Disconnect the Passenger Door Lock Switch connector.

With the DRBIIIT in sensors, read the PASS DOOR LOCK SW MUX

circuit.

Is the voltage above 4.6 volts?

Yes >>

No >>

(G160) PASSENGER DOOR LOCK SWITCH MUX CIRCUIT SHORTED

3.

Turn the ignition off.

Disconnect the Instrument Cluster C4 connector.

Measure the resistance between the (G160) Passenger Door Lock

Switch Mux circuit and ground.

Is the resistance below 1000.0 ohms?

Yes >>

No >>

Replace the Passenger Door Lock Switch.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 3

Repair the (G160) Passenger Door Lock Switch Mux circuit for a short to ground.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Replace the Instrument Cluster.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 40

8N - 40 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

PASSENGER DOOR LOCK SWITCH INPUT CIRCUIT STUCK

Page 41

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 41

PASSENGER DOOR LOCK SWITCH INPUT CIRCUIT STUCK (CONTINUED)

For the Power Door Lock circuit diagram (Refer to 8 - ELECTRICAL/POWER LOCKS - SCHEMATICS AND DIAGRAMS).

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

At all times when battery power is supplied to the Instrument Cluster.

• Set Condition:

When the Instrument Cluster senses voltage to the passenger door lock switch between 1.3 and 3.95 volts for

over 20 seconds, this code will set.

Possible Causes

(G160) PASSENGER DOOR LOCK SWITCH MUX CIRCUIT PARTIALLY SHORTED TO GROUND

DOOR LOCK SWITCH SHORTED

INSTRUMENT CLUSTER

Diagnostic Test

DTC PRESENT

1.

Turn the ignition on.

With the DRBIIIT, record and erase DTC’s.

With the DRBIIIT, read DTC’s.

Operate the door locks several times from the Passen-

ger Door Lock Switch while monitoring the DRBIIIT.

Does the DRBIIIT display PASSENGER DOOR

LOCK SWITCH INPUT CIRCUIT STUCK?

Yes >>

No >>

Go To 2

Using the wiring diagram/schematic as a

guide, inspect the wiring and connectors.

Operate the switch several times and

check for an occasional sticking problem.

Perform BODY VERIFICATION TEST VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES/FRONT

CONTROL MODULE - DIAGNOSIS AND

TESTING)

Page 42

8N - 42 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

PASSENGER DOOR LOCK SWITCH INPUT CIRCUIT STUCK (CONTINUED)

DOOR LOCK SWITCH STUCK

2.

Disconnect the Passenger Door Lock Switch connector.

With the DRBIIIT in sensors, read the PASS DOOR LOCK SW MUX

circuit.

Is the voltage above 4.6 volts?

Yes >>

No >>

(G160) PASSENGER DOOR LOCK SWITCH MUX CIRCUIT SHORTED

3.

Turn the ignition off.

Disconnect the Instrument Cluster C4 connector.

Measure the resistance between the (G160) Passenger Door Lock

Switch Mux circuit and ground.

Is the resistance below 10000.0 ohms?

Yes >>

No >>

Replace the Passenger Door Lock Switch.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 3

Repair the (G160) Passenger Door Lock Switch Mux circuit for a partial short to ground.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Replace the Instrument Cluster.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 43

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 43

RKE FOB BATTERY LOW

For the Power Door Lock circuit diagram. (Refer to 8 - ELECTRICAL/POWER LOCKS - SCHEMATICS AND DIAGRAMS)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Upon activation of any button on the Remote Keyless Entry transmitter (fob).

• Set Condition:

The RKE module monitors the input from the fobs and determines if the voltage is within tolerance. If the

battery voltage of the RKE fob falls between 2.0 and 3.5 volts the RKE module will communicates this to the

Instrument Cluster which in turn will set this code.

Possible Causes

BATTERIES LOW

RKE TTRANSMITER - LOW VOLAGE OUTPUT

Diagnosttic Test

CHECK TROUBLE CODE

1.

Turn the ignition on.

Using the RKE transmitter, press the UNLOCK button

six times or more.

With the DRBIIIT, read DTCs.

Does the DRBIIIT display RKE KEY FOB BATTERY LOW?

Yes >>

No >>

BATTERIES LOW

2.

Test the voltage of each battery in the RKE transmitter.

Is the voltage at or above 2.9 in each battery?

Yes >>

No >>

Go To 2

Problem is intermittent and not present at

this time. Check the other transmitters

used with this vehicle to determine which

one set the code. Check the voltage of

each battery in FOB and ensure they

above 2.9 volts each.

Perform BODY VERIFICATION TEST VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES/FRONT

CONTROL MODULE - DIAGNOSIS AND

TESTING)

Replace the RKE Transmitter.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Replace the batteries and press the unlock button on the transmitter six times to clear the DTC.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 44

8N - 44 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

RKE MODULE COMMUNICATION LINK

For the Power Door Lock circuit diagram. (Refer to 8 - ELECTRICAL/POWER LOCKS - SCHEMATICS AND DIAGRAMS)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Whenever battery power is applied the Instrument Cluster.

• Set Condition:

The Instrument Cluster has learned that the vehicle is equipped with Remote Keyless Entry, but then is unable

to communicate with that module, this code will set. The Instrument Cluster provides power for the RKE module and communicates by the PCI bus.

Possible Causes

RKE MODULE OPEN

IJNSTRUMENT CLUSTER

Diagnostic Test

DTC PRESENT

1.

Turn the ignition on.

With the DRBIIIT, record and erase DTC’s.

With the DRBIIIT, read DTC’s.

Operate the door locks several times from the RKE

transmitter while observing the DRBIIIT.

Does the DRBIIIT display RKE MODULE COMM

LINK?

Yes >>

No >>

Go To 2

Using the wiring diagram/schematic as a

guide, inspect the wiring and connectors.

Perform BODY VERIFICATION TEST -

VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES/FRONT

CONTROL MODULE - DIAGNOSIS AND

TESTING)

Page 45

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 45

RKE MODULE COMMUNICATION LINK (CONTINUED)

RKE MODULE OPEN

2.

Turn the ignition off.

Remove the Instrument Cluster.

Replace the RKE module with a known good module.

Connect all Cluster connectors.

With the DRBIIIT, Program the RKE transmitter.

Operate the door locks using the RKE transmitter.

Do the door locks respond correctly with the RKE transmitter?

Yes >>

No >>

Replace the original RKE module.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Replace the Instrument Cluster.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 46

8N - 46 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

*ALL DOOR LOCKS INOPERATIVE

Page 47

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 47

*ALL DOOR LOCKS INOPERATIVE (CONTINUED)

For the Power Door Locks circuit diagram (Refer to 8 - ELECTRICAL/POWER LOCKS - SCHEMATICS AND DIAGRAMS).

For a complete wiring diagram Refer to Section 8W.

Possible Causes

DTC PRESENT

FUSE #22 OPEN

(A941) FUSE B+ CIRCUIT OPEN

INSTRUMENT CLUSTER

Diagnostic Test

DTC PRESENT

1.

Turn the ignition on.

With the DRBIIIT, read DTC’s.

Does the DRBIIIT display any Door Lock or Cluster related DTC’s?

Yes >>

No >>

FUSE #22 OPEN

2.

Test both sides of fuse #22 in the PDC.

Is there 12 volts on both sides of fuse #22?

Yes >>

No >>

Refer to the Table of Contents in this section.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 2

Go To 3

Replace the fuse if open and retry the system. If the fuse

blows, locate and repair a short to the Instrument Cluster.

The 12 volt supply to the fuse is a bus bar in the PDC.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 48

8N - 48 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

*ALL DOOR LOCKS INOPERATIVE (CONTINUED)

(A941) FUSED B+ CIRCUIT OPEN

3.

Turn the ignition off.

Remove the instrument cluster.

Measure the voltage between the (A941) Fused B+ circuit and ground

(cavity 2 in the C1 connector to ground).

Is the voltage above 10.0 volts on the Fused B+ circuit?

Yes >>

No >>

Replace the Instrument Cluster.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Repair the Fused B+ circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 49

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 49

*AUTO (ROLLING) DOOR LOCKS INOPERATIVE

For the Power Door Lock circuit diagram (Refer to 8 - ELECTRICAL/POWER LOCKS - SCHEMATICS AND DIAGRAMS).

For a complete wiring diagram Refer to Section 8W.

Possible Causes

DOOR AJAR SWITCH STATUS INCORRECT

TPS OR VSS DTC’s

AUTO DOOR LOCKS NOT ENABLED

INSTRUMENT CLUSTER

Diagnostic Test

CHECK THE DOOR AJAR SWITCH STATUS

1.

Ensure all doors are closed.

With the DRBIII, enter 9Electro/Mech Cluster9 then

9Input/Output9 and observe all of the Door Ajar states.

Does the DRBIII display CLOSED for any door

ajar state?

Yes >>

No >>

ANY TPS OR VSS RELATED DTC’s

2.

With the DRBIII read 9Engine9 and “Anti-Lock Brakes” DTC’s.

Does the DRBIII display any Throttle Position Sensor or Vehicle Speed Sensor related DTC’s?

Yes >>

No >>

Select the appropriate Door Ajar Circuit

Shorted: (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - INTERIOR - DIAGNOSIS AND TESTING).

Go To 2

Diagnose and repair the DTC’s. For gas engines (Refer to 9 - ENGINE - ELECTRICAL DIAGNOSTICS).

For diesel engines (Refer to 9 - ENGINE - ELECTRICAL DIAGNOSTICS). For Anti-Lock Brake (Refer to

5 - BRAKES - DIAGNOSIS AND TESTING)

Go To 3

Page 50

8N - 50 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

*AUTO (ROLLING) DOOR LOCKS INOPERATIVE (CONTINUED)

ENABLE AUTO DOOR LOCKS

3.

With the DRBIII, enter 9Electron/Mech Cluster9 then 9Miscellaneous9 and observe the rolling door lock status.

Does the DRBIII display ROLLING DOOR LOCKS: ENABLED

Yes >>

No >>

Replace the Instrument Cluster.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

With the DRBIII, enable the Auto Door Locks.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 51

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 51

*CYLINDER LOCK SWITCH INOPERATIVE

Page 52

8N - 52 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

*CYLINDER LOCK SWITCH INOPERATIVE (CONTINUED)

For the Power Door Lock circuit diagram (Refer to 8 - ELECTRICAL/POWER LOCKS - SCHEMATICS AND DIAGRAMS).

For a complete wiring diagram Refer to Section 8W.

Possible Causes

DTC PRESENT

(Z463) CYLINDER LOCK SWITCH GROUND OPEN

(G163) CYLINDER LOCK SWITCH MUX CIRCUIT OPEN

(G163) CYLINDER LOCK SWITCH MUX WIRE SHORT TO GROUND

CYLINDER LOCK SWITCH

INSTRUMENT CLUSTER

Diagnostic Test

DTC PRESENT

1.

Turn the ignition on.

With the DRBIIIT, read DTC’s.

Are there any Power Door Lock related trouble

codes?

Yes >>

No >>

Refer to symptom list for problems related

to Power Door Locks.

Perform BODY VERIFICATION TEST VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES/FRONT

CONTROL MODULE - DIAGNOSIS AND

TESTING)

Go To 2

Page 53

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 53

*CYLINDER LOCK SWITCH INOPERATIVE (CONTINUED)

CYLINDER LOCK SWITCH VOLTAGE LOW

2.

Turn the ignition off.

Disconnect the Cylinder Lock Switch connector.

Turn the ignition on.

Measure the voltage between (G163) Cylinder Lock Switch Mux circuit

and ground.

Is the voltage between 4.6 and 5.2 volts?

Yes >>

No >>

(Z463) CYLINDER LOCK SWITCH GROUND OPEN

3.

Using a 12-volt test light connected to 12-volts, check the (Z463)

Ground circuit.

Does the test light illuminate brightly?

Yes >>

No >>

Go To 3

Go To 4

Replace the Cylinder Lock Switch.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Repair the (Z463) Ground circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND

TESTING)

Page 54

8N - 54 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

*CYLINDER LOCK SWITCH INOPERATIVE (CONTINUED)

(G163) CYLINDER LOCK SWITCH MUX OPEN

4.

Turn the ignition off.

Disconnect the Instrument Cluster C4 connector.

Measure the resistance of the (G163) Cylinder Lock Switch Mux circuit

between the Switch connector and the Instrument Cluster connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

(G163) CYLINDER LOCK SWITCH MUX WIRE SHORT TO GROUND

5.

Measure the resistance between Ground and the (G163) Cylinder

Lock Switch Mux circuit in the Cluster C4 connector.

Is the resistance below 1000.0 ohms?

No >>

Yes >>

Go To 5

Repair the (G163) Cylinder Lock Switch Mux circuit for an

open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Replace the Instrument Cluster.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Repair the (G163) Cylinder Lock Switch Mux circuit for a

short to ground.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 55

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 55

*DOOR LOCK INHIBIT INOPERATIVE

For a complete wiring diagram Refer to Section 8W.

Possible Causes

CHIME INOPERATIVE

INSTRUMENT CLUSTER

Diagnostic Test

CHIME INOPERATIVE

1.

Turn the ignition off but leave the key in the ignition.

Open the drivers door.

Does the chime sound?

Yes >>

No >>

Replace the Instrument Cluster.Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Perform the test “*KEY IN IGNITION AND DRIVER’S DOOR OPEN CHIME INOPERATIVE”. (Refer to 8

- ELECTRICAL/CHIME/BUZZER - DIAGNOSIS AND TESTING).

Page 56

8N - 56 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

*LEFT REAR DOOR FAILS TO LOCK AND UNLOCK

Page 57

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 57

*LEFT REAR DOOR FAILS TO LOCK AND UNLOCK (CONTINUED)

For the Power Door Lock circuit diagram (Refer to 8 - ELECTRICAL/POWER LOCKS - SCHEMATICS AND DIAGRAMS)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

DTC PRESENT

(P393) DOOR LOCK DRIVER LEFT DOORS WIRE OPEN

(P5) DOOR UNLOCK DRIVER LEFT REAR WIRE OPEN

DOOR LATCH

INSTRUMENT CLUSTER

Diagnostic Test

DTC PRESENT

1.

Turn the ignition on.

With the DRBIIIT, read DTC’s.

Does the DRBIIIT display any Door Lock related

DTC’s?

Yes >>

No >>

Refer to symptom list for problems related

to Power Door Locks to diagnose and

repair DTC’s.

Go To 2

Page 58

8N - 58 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

*LEFT REAR DOOR FAILS TO LOCK AND UNLOCK (CONTINUED)

INSTRUMENT CLUSTER

2.

Turn the ignition off.

Disconnect the Instrument Cluster C1 connector.

Connect a jumper wire between the (P5) Door Unlock Driver Left Rear

circuit in the Instrument Cluster C1 connector and ground.

Momentarily connect a fused jumper wire between the Fused B+ cir-

cuit and the (P393) Door Lock Driver Left Doors circuit in the Instrument Cluster C1 connector.

Reverse the jumper wires to drive the motor in the opposite direction.

Did the left doors lock and unlock?

Yes >>

No >>

(P393) DOOR LOCK DRIVER LEFT DOORS WIRE OPEN

3.

Disconnect the Left Rear Door Latch connector.

Measure the resistance of the (P393) Door Lock Driver Left Doors cir-

cuit between the Instrument Cluster C1 connector and the Door Latch

connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Replace the Instrument Cluster.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 3

Go To 4

Repair the (P393) Door Lock Driver Left Doors wire for an

open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 59

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 59

*LEFT REAR DOOR FAILS TO LOCK AND UNLOCK (CONTINUED)

(P5) DOOR UNLOCK DRIVER LEFT REAR WIRE OPEN

4.

Measure the resistance of the (P5) Door Unlock Driver Left Rear circuit between the Instrument Cluster C1 connector and the Door Latch

connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Replace the Door Latch.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Repair the (P5) Door Unlock Driver Left Rear wire for an

open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 60

8N - 60 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

*DRIVER DOOR FAILS TO LOCK AND UNLOCK

Page 61

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 61

*DRIVER DOOR FAILS TO LOCK AND UNLOCK (CONTINUED)

For the Power Door Lock circuit diagram (Refer to 8 - ELECTRICAL/POWER LOCKS - SCHEMATICS AND DIAGRAMS)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

DTC PRESENT

(P393) DOOR LOCK DRIVER LEFT DOORS WIRE OPEN

(P1) DOOR UNLOCK DRIVER LEFT FRONT WIRE OPEN

DOOR LATCH

INSTRUMENT CLUSTER

Diagnostic Test

DTC PRESENT

1.

Turn the ignition on.

With the DRBIIIT, read DTC’s.

Does the DRBIIIT display any Door Lock related

DTC’s?

Yes >>

No >>

Refer to symptom list for problems related

to Power Door Locks and diagnose and

repair DTC’s.

Go To 2

Page 62

8N - 62 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

*DRIVER DOOR FAILS TO LOCK AND UNLOCK (CONTINUED)

INSTRUMENT CLUSTER

2.

Turn the ignition off.

Disconnect the Instrument Cluster C1 connector.

Connect a jumper wire between the (P1) Door Unlock Driver Left Front

circuit in the Instrument Cluster C1 connector and ground.

Momentarily connect a fused jumper wire between the Fused B+ cir-

cuit and the (P393) Door Lock Driver Left Doors circuit in the Instrument Cluster C1 connector.

Reverse the jumper wires to drive the motor in the opposite direction.

Did the Driver Door lock and unlock?

Yes >>

No >>

(P393) DOOR LOCK DRIVER LEFT DOORS WIRE OPEN

3.

Disconnect the Driver Door Latch connector.

Measure the resistance of the (P393) Door Lock Driver Left Doors cir-

cuit between the Instrument Cluster C1 connector and the Door Latch

connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Replace the Instrument Cluster.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 3

Go To 4

Repair the (P393) Door Lock Driver Left Doors wire for an

open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 63

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 63

*DRIVER DOOR FAILS TO LOCK AND UNLOCK (CONTINUED)

(P1) DOOR UNLOCK DRIVER LEFT FRONT WIRE OPEN

4.

Measure the resistance of the (P1) Door Unlock Driver Left Front circuit between the Instrument Cluster C1 connector and the Door Latch

connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Replace the Door Latch.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Repair the (P1) Door Unlock Driver Left Front wire for an

open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 64

8N - 64 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

*ONE DOOR LOCK MOTOR INOPERATIVE

For the Power Door Lock circuit diagram (Refer to 8 - ELECTRICAL/POWER LOCKS - SCHEMATICS AND DIAGRAMS).

For a complete wiring diagram Refer to Section 8W.

Possible Causes

DTC’s PRESENT

DOOR LOCK DRIVER OR DOOR UNLOCK DRIVER CIRCUIT OPEN

DOOR LATCH

Diagnostic Test

CHECK DOOR LOCK MOTOR CIRCUIT

1.

With the DRBIIIT, read DTCs. If there are any door lock related DTC’s,

refer to symptom list for problems related to Power Door Locks and

diagnose and repair the DTC’s..

Disconnect the inoperative Door Latch connector.

Connect a 12 volt test light between the Door Lock Driver and the

Door Unlock Driver circuits in the latch connector.

NOTE: Graphic shows Passenger Latch – all others similar.

Operate the door locks several time in the lock and unlock positions

from a door lock switch and observe the test light.

Does the test light illuminate brightly when the locks are actuated in both directions?

Yes >>

No >>

Replace the Door latch.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Repair the appropriate Door Lock Driver or Door Unlock Driver circuit for an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 65

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 65

*RIGHT DOORS FAIL TO LOCK AND UNLOCK – QUAD CAB

Page 66

8N - 66 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

*RIGHT DOORS FAIL TO LOCK AND UNLOCK – QUAD CAB (CONTINUED)

For the Power Door Lock circuit diagram (Refer to 8 - ELECTRICAL/POWER LOCKS - SCHEMATICS AND DIAGRAMS)

For a complete wiring diagram Refer to Section 8W.

Possible Causes

DTC PRESENT

(P392) DOOR LOCK DRIVER RIGHT DOORS WIRE OPEN

(G778) DOOR UNLOCK DRIVER RIGHT DOORS WIRE OPEN

DOOR LATCH

INSTRUMENT CLUSTER

Diagnostic Test

DTC PRESENT

1.

Turn the ignition on.

With the DRBIIIT, read DTC’s.

Does the DRBIIIT display any Door Lock related

DTC’s?

Yes >>

No >>

Refer to symptom list for problems related

to Power Door Locks and diagnose and

repair DTC’s.

Go To 2

Page 67

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 67

*RIGHT DOORS FAIL TO LOCK AND UNLOCK – QUAD CAB (CONTINUED)

INSTRUMENT CLUSTER

2.

Turn the ignition off.

Disconnect the Instrument Cluster C1 connector.

Connect a jumper wire between the (G778) Door Unlock Driver Right

Doors circuit in the Instrument Cluster C1 connector and ground.

Momentarily connect a fused jumper wire between the Fused B+ cir-

cuit and the (P392) Door Lock Driver Right Doors circuit in the Instrument Cluster C1 connector.

Reverse the jumper wires to drive the motor in the opposite direction.

Did the Right Doors lock and unlock?

Yes >>

No >>

(P392) DOOR LOCK DRIVER RIGHT DOORS WIRE OPEN

3.

Disconnect the Passenger Door Latch connector.

Measure the resistance of the (P392) Door Lock Driver Right Doors

circuit between the Instrument Cluster C1 connector and the Passenger Door Latch connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Replace the Instrument Cluster.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 3

Go To 4

Repair the (P392) Door Lock Driver Right Doors wire for

an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 68

8N - 68 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

*RIGHT DOORS FAIL TO LOCK AND UNLOCK – QUAD CAB (CONTINUED)

(G778) DOOR UNLOCK DRIVER RIGHT DOORS WIRE OPEN

4.

Measure the resistance of the (G778) Door Unlock Driver Right Doors

circuit between the Instrument Cluster C1 connector and the Passenger Door Latch connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Replace the Door Latch.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Repair the (G778) Door Unlock Driver Right Doors wire for

an open.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES/

FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 69

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 69

*RKE INOPERATIVE

For the Power Door Lock circuit diagram (Refer to 8 - ELECTRICAL/POWER LOCKS - SCHEMATICS AND DIAGRAMS).

For a complete wiring diagram Refer to Section 8W.

Possible Causes

DTC PRESENT

TRANSMITTER NOT PROGRAMMED

RKE TRANSMITTER

REMOTE KEYLESS ENTRY MODULE

Diagnostic Test

DTC PRESENT

1.

With the DRBIIIT, read DTCs.

Attempt to operate the door locks with the RKE trans-

mitter.

Does the DRBIIIT display RKE FOB BATTERY

LOW?

Yes >>

No >>

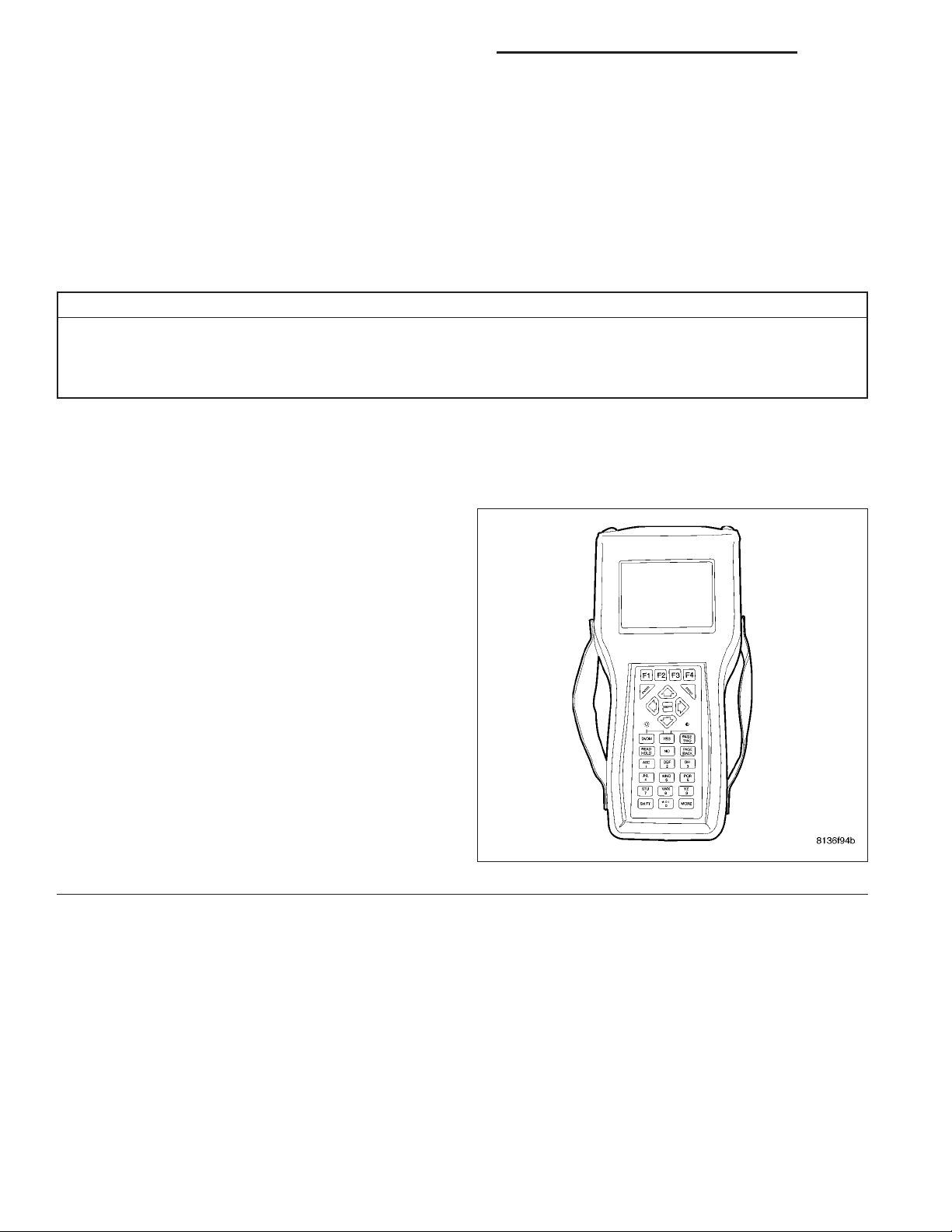

9001 TESTER AVAILABLE

2.

Do you have access to the Miller Special Tool (9001 RF DETECTOR(?

No >>

Yes >>

Refer to symptom RKE FOB BATTERY

LOW in this category.

Go To 2

Go To 3

Go To 5

Page 70

8N - 70 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

*RKE INOPERATIVE (CONTINUED)

TRANSMITTER NOT PROGRAMMED

3.

Turn the ignition on.

Place transmission in the Park position.

Ensure Vehicle Theft Security System (if equipped) is in Disarmed Mode.

With the DRBIIIT, select ELECTRO/MECH CLUSTER, MISCELLANEOUS, PROGRAM New Fob.

Follow the instructions on the DRBIII screen

Programming mode will last for 30 seconds. To get out of Programming Mode sooner, press PAGE BACK.

Try the door locks using the Transmitter.

Does the RKE System operate properly?

Yes >>

No >>

SUBSTITUTE A KNOWN GOOD TRANSMITTER

4.

Secure a known good transmitter.

With the DRBIIIT, select ELECTRO/MECH CLUSTER, MISCELLANEOUS, PROGRAM New Fob.

Follow the instructions on the DRBIII screen.

Programming mode will last for 30 seconds. To get out of Programming Mode sooner, press PAGE BACK.

Lock and Unlock the vehicle using the transmitter.

Does the RKE System operate properly?

Yes >>

No >>

Repair complete. Check with the customer to see if the other transmitter(s) are operating properly. They

may have to be programmed also.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Go To 4

Replace the original transmitter and program all transmitters that will be used with this vehicle.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Replace the Remote Keyless Entry Module and reprogram all transmitters used with this vehicle.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

TEST TRANSMITTER WITH TESTER

5.

Using the 9001 RF Detector, follow the instructions on the back of the tester and test the transmitter several times.

Does the signal strength measure (STRONG(?

Yes >>

No >>

Go To 6

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Replace the transmitter and program all transmitters that will be used with this vehicle.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 71

DR/DH POWER LOCKS - ELECTRICAL DIAGNOSTICS 8N - 71

*RKE INOPERATIVE (CONTINUED)

PROGRAM RKE TRANSMITTER WITH THE DRBIIIT

6.

Turn the ignition on

Place transmission in the Park position.

Ensure Vehicle Theft Security System (if equipped) is in Disarm Mode.

With the DRBIIIT, select ELECTRO/MECH CLUSTER, MISCELLANEOUS, then PROGRAM New Fob. Follow the

instructions on the screen.

Exit PROGRAM RKE.

Activate the Door Locks using the RKE Transmitter.

NOTE: When repairs are complete, ensure all transmitters used with the vehicle have been programmed.

Did the door locks respond properly to the RKE transmitter commands?

Yes >>

No >>

Repair complete.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Replace the Remote Keyless Entry Module and reprogram all transmitters used with this vehicle.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 72

8N - 72 POWER LOCKS - ELECTRICAL DIAGNOSTICS DR/DH

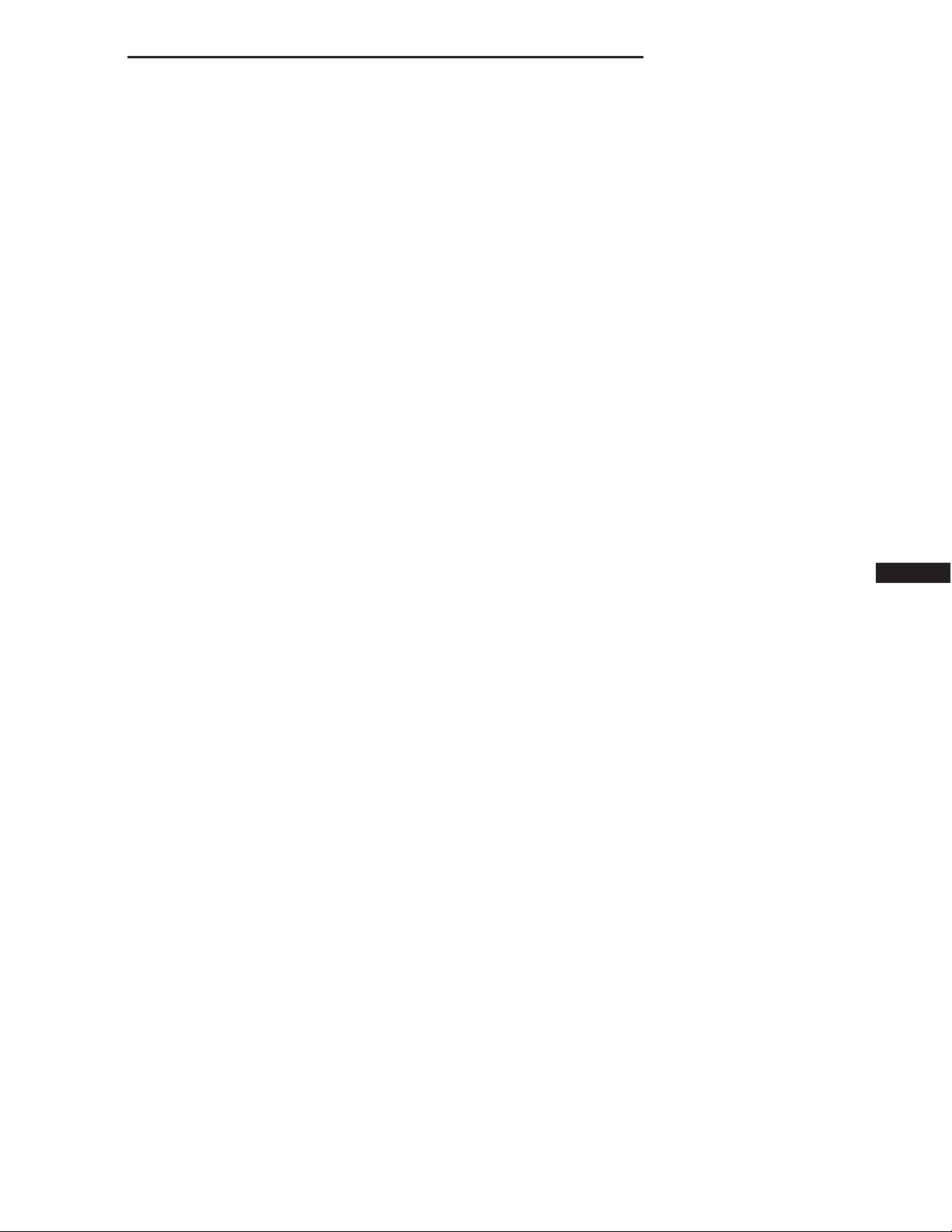

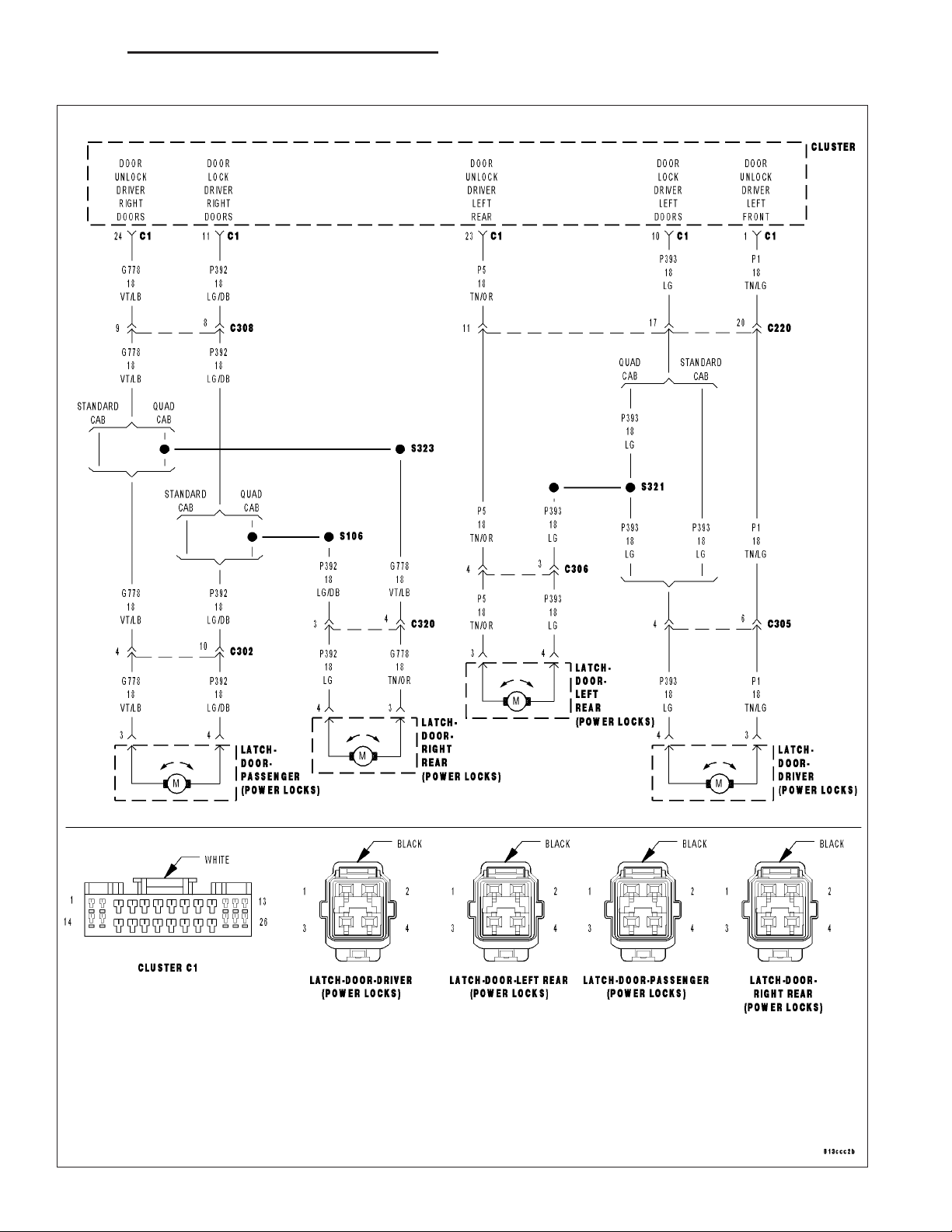

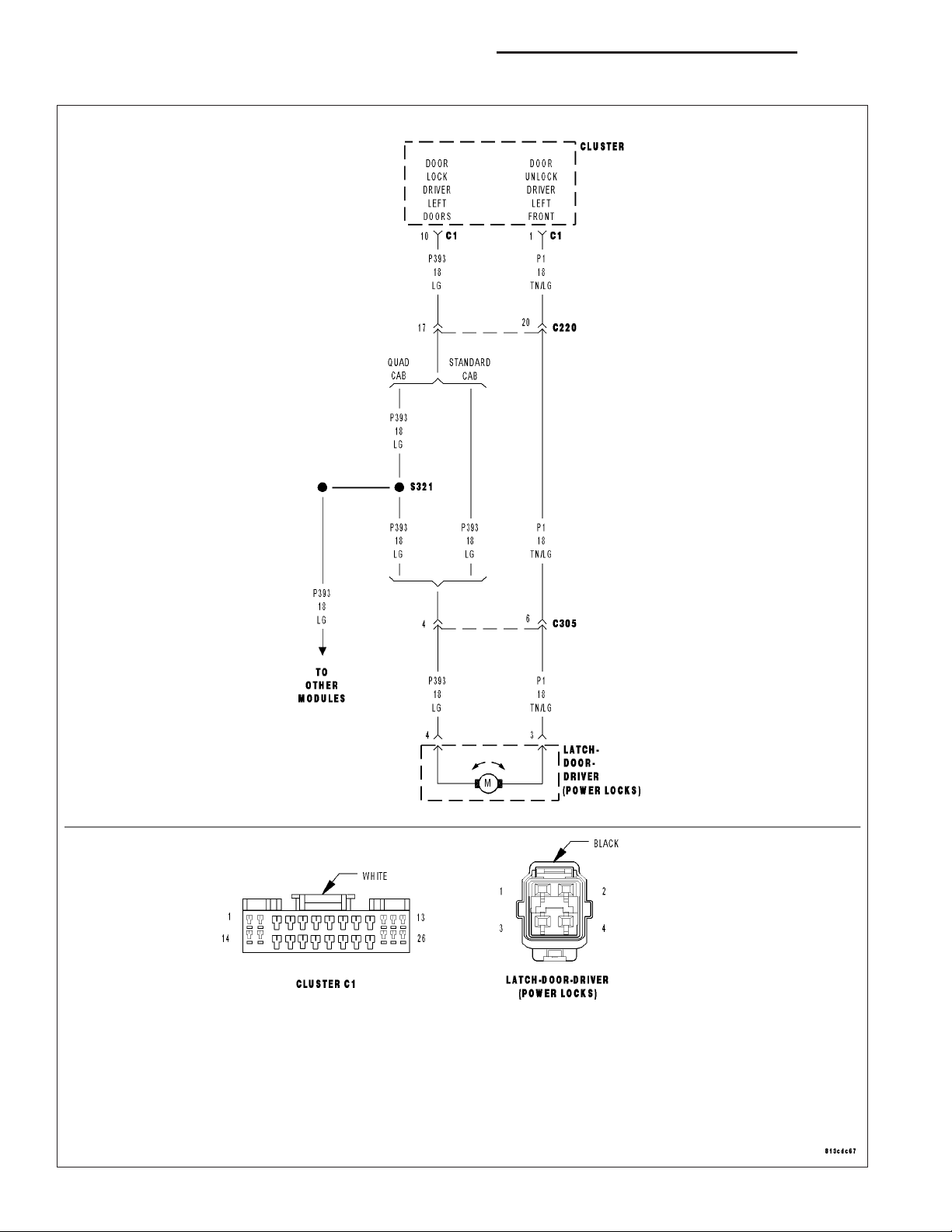

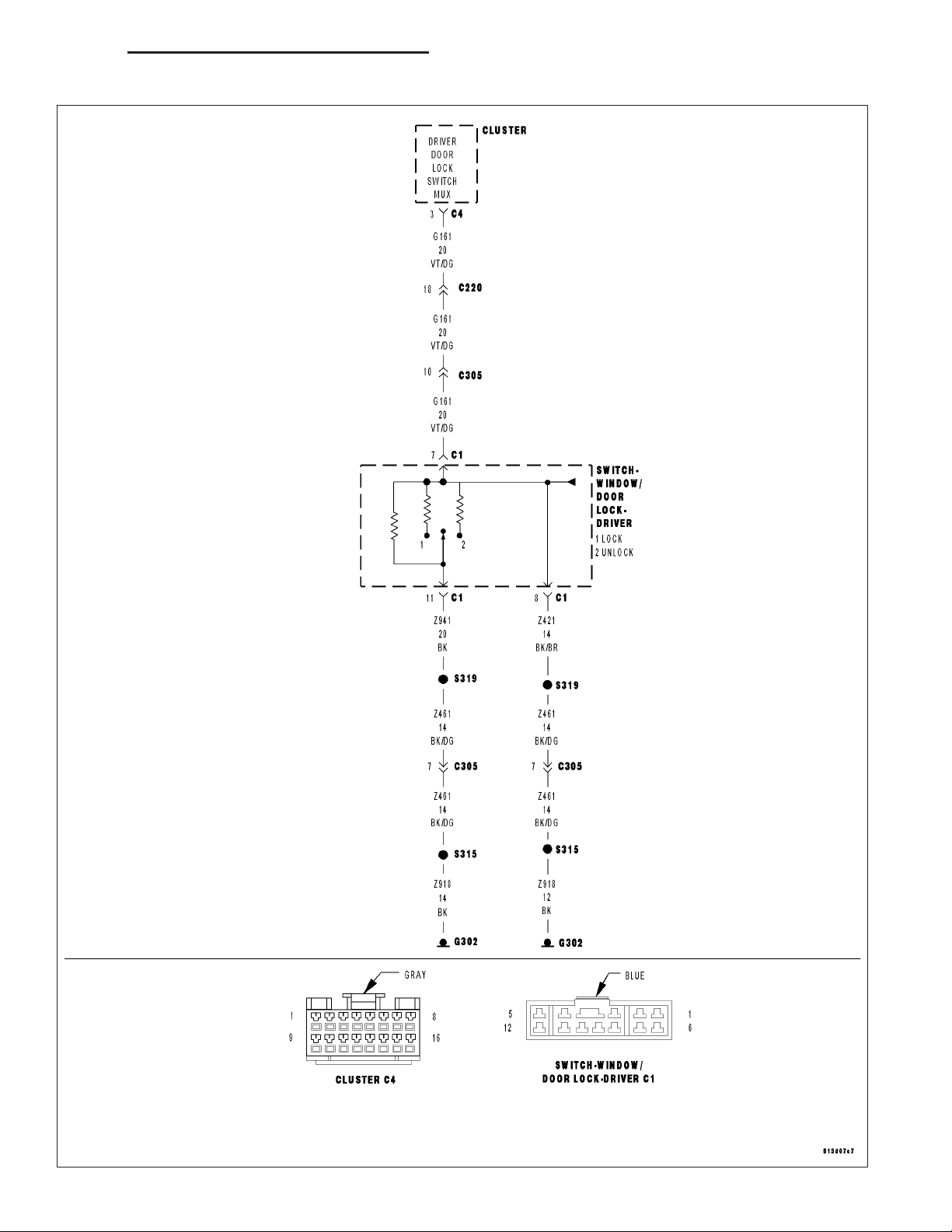

SCHEMATICS AND DIAGRAMS

POWER DOOR LOCK SYSTEM

Page 73

DR/DH POWER LOCKS - SERVICE INFORMATION 8N - 73

POWER LOCKS - SERVICE INFORMATION

TABLE OF CONTENTS

page page

POWER LOCKS - SERVICE INFORMATION

DESCRIPTION .........................73

OPERATION ...........................74

DIAGNOSIS AND TESTING

POWER LOCKS ......................75

MOTOR - DOOR LOCK

DESCRIPTION .........................76

OPERATION ...........................76