Page 1

DR IGNITION CONTROL 8I - 1

IGNITION CONTROL

TABLE OF CONTENTS

page page

IGNITION CONTROL

DESCRIPTION ..........................1

SPECIFICATIONS

SPECIFICATIONS - TORQUE - IGNITION ....3

ENGINE FIRING ORDER - 3.7L V-6 .........4

ENGINE FIRING ORDER – 4.7L V-8 ........4

FIRING ORDER / CABLE ROUTING – 5.7L

V-8 ENGINE...........................4

ENGINE FIRING ORDER - 5.9L V-8 .........4

SPARK PLUG CABLE ORDER – 8.0L V-10

ENGINE..............................5

SPARK PLUG CABLE RESISTANCE ........5

SPARK PLUGS ........................5

IGNITION COIL RESISTANCE - 3.7L V-6 .....6

IGNITION COIL RESISTANCE - 4.7L V-8 .....6

IGNITION COIL RESISTANCE - 5.7L V-8 .....6

IGNITION COIL RESISTANCE - 5.9L ........6

IGNITION COIL RESISTANCE – 8.0L V-10

ENGINE..............................6

IGNITION TIMING ......................6

AUTOMATIC SHUT DOWN RELAY

DESCRIPTION - PCM OUTPUT .............6

OPERATION

OPERATION - PCM OUTPUT .............6

OPERATION - ASD SENSE - PCM INPUT ....6

DIAGNOSIS AND TESTING - ASD AND FUEL

PUMP RELAYS ........................7

REMOVAL .............................7

INSTALLATION ..........................8

CAMSHAFT POSITION SENSOR

DESCRIPTION ..........................8

OPERATION ............................8

REMOVAL .............................11

INSTALLATION .........................14

DISTRIBUTOR

DESCRIPTION .........................16

OPERATION ...........................16

REMOVAL .............................17

INSTALLATION .........................18

DISTRIBUTOR CAP

DIAGNOSIS AND TESTING - DISTRIBUTOR

CAP - 5.9L V-8 ........................18

DISTRIBUTOR ROTOR

DIAGNOSIS AND TESTING - DISTRIBUTOR

ROTOR - 5.9L V-8 .....................19

IGNITION COIL

DESCRIPTION .........................19

OPERATION ...........................20

REMOVAL .............................23

INSTALLATION .........................24

KNOCK SENSOR

DESCRIPTION .........................25

OPERATION ...........................25

REMOVAL .............................25

INSTALLATION .........................26

SPARK PLUG

DESCRIPTION .........................27

DIAGNOSIS AND TESTING - SPARK PLUG

CONDITIONS .........................27

REMOVAL .............................30

CLEANING

CLEANING AND ADJUSTMENT ...........31

INSTALLATION .........................31

IGNITION COIL CAPACITOR

DESCRIPTION .........................33

OPERATION ...........................33

REMOVAL .............................33

INSTALLATION .........................33

SPARK PLUG CABLE

DESCRIPTION .........................33

OPERATION ...........................33

DIAGNOSIS AND TESTING - SPARK PLUG

CABLES ............................33

REMOVAL .............................34

INSTALLATION .........................35

IGNITION CONTROL

DESCRIPTION

The ignition system is controlled by the Powertrain

Control Module (PCM) on all engines.

3.7L V-6 ENGINE

The 3.7L V-6 engine uses a separate ignition coil

for each cylinder. The one-piece coil bolts directly to

the cylinder head. Rubber boots seal the secondary

terminal ends of the coils to the top of all 6 spark

plugs. A separate electrical connector is used for each

coil.

Because of coil design, spark plug cables (secondary cables) are not used. A distributor is not used

with the 3.7L engine.

Two knock sensors (one for each cylinder bank) are

used to help control spark knock.

Page 2

8I - 2 IGNITION CONTROL DR

IGNITION CONTROL (Continued)

The Auto Shutdown (ASD) relay provides battery

voltage to each ignition coil.

The ignition system consists of:

• 6 Spark Plugs

• 6 Separate Ignition Coils

• 2 Knock Sensors

• Powertrain Control Module (PCM)

• Also to be considered part of the ignition system

are certain inputs from the Crankshaft Position,

Camshaft Position, Throttle Position, 2 knock and

MAP Sensors

4.7L V-8 ENGINE

The 4.7L V-8 engine uses a separate ignition coil for

each cylinder. The one-piece coil bolts directly to the

cylinder head. Rubber boots seal the secondary terminal ends of the coils to the top of all 8 spark plugs. A

separate electrical connector is used for each coil.

Because of coil design, spark plug cables (secondary cables) are not used. A distributor is not used

with the 4.7L engine.

Two knock sensors (one for each cylinder bank) are

used to help control spark knock.

The Auto Shutdown (ASD) relay provides battery

voltage to each ignition coil.

The ignition system consists of:

• 8 Spark Plugs

• 8 Separate Ignition Coils

• 2 Knock Sensors

• Powertrain Control Module (PCM)

• Also to be considered part of the ignition system

are certain inputs from the Crankshaft Position,

Camshaft Position, Throttle Position, 2 knock and

MAP Sensors

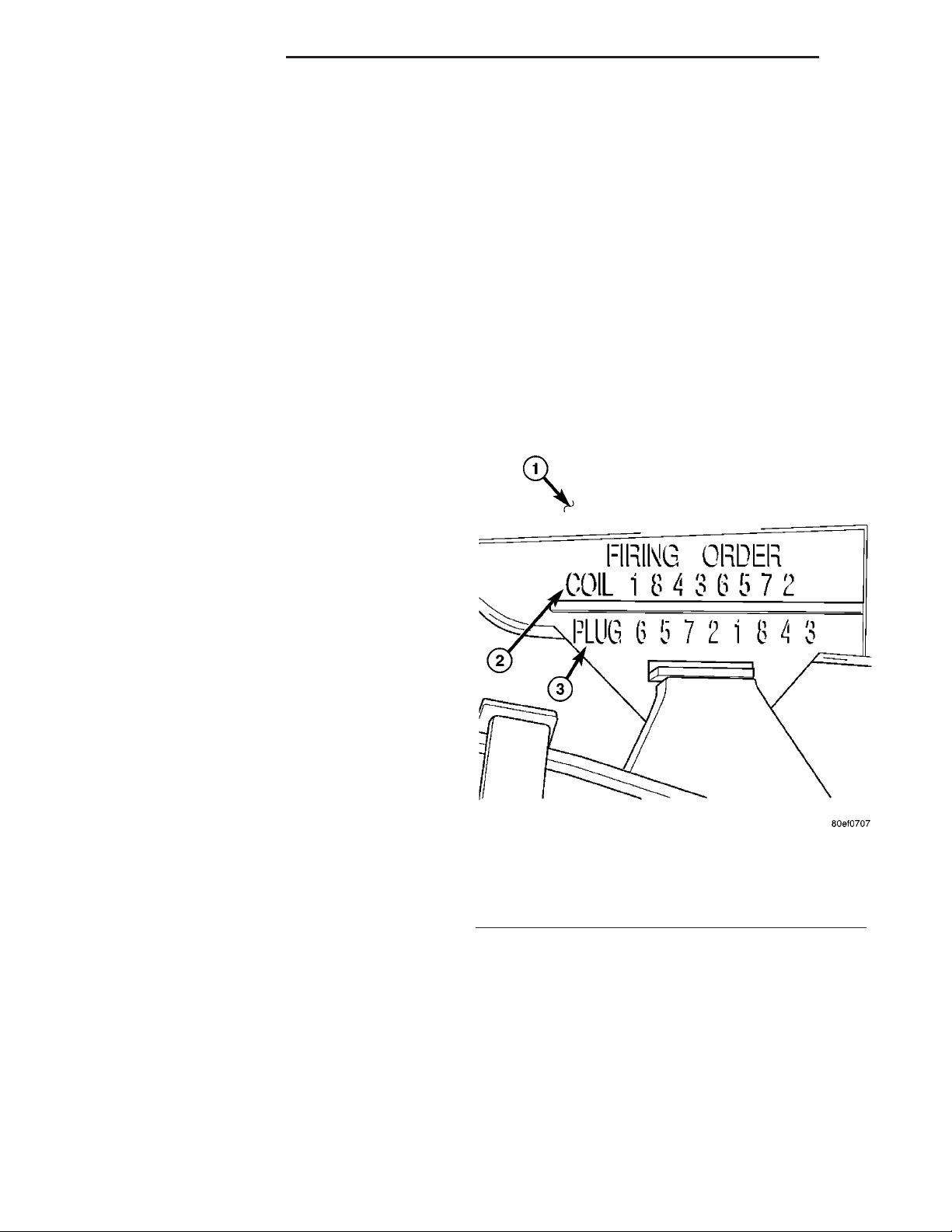

and 5/8. These numbers can also be found on the top

of the intake manifold to the right of the throttle

body (Fig. 1).

Two knock sensors (one for each cylinder bank) are

used to help control spark knock.

The 5.7L engine will not use a conventional distrib-

utor.

The ignition system consists of:

• 16 Spark Plugs (2 per cylinder)

•

8 Separate, Dual-Secondary Output, Ignition Coils

• 2 Knock Sensors

• 8 Secondary Ignition Cables

• Powertrain Control Module (PCM)

• Also to be considered part of the ignition system

are certain inputs from the Crankshaft Position,

Camshaft Position, Throttle Position, 2 knock and

MAP Sensors

5.7L V-8 ENGINE

For additional information, also refer to Ignition Coil Description and Operation.

The 5.7L V-8 engine is equipped with 16 spark

plugs. Two plugs are used for each cylinder. The 5.7L

is also equipped with 8 separate and independent

ignition coils. The one-piece coil bolts directly to the

cylinder head cover and attaches the coils secondary

output terminal directly to a spark plug using a rubber boot seal. Each coil is also equipped with a second output terminal. This second terminal connects a

conventional spark plug cable directly to a spark

plug on the opposite cylinder bank. A separate primary electrical connector is used for each coil.

Eight conventional spark plug cables are used with

the 5.7L. These cables connect a coil on one cylinder

bank, directly to a spark plug on the opposite cylinder bank. The cables are placed and routed in a special plastic loom to keep them separated. This loom is

clipped to the intake manifold. To prevent a missmatch of cables, a corresponding spark plug / coil

number is displayed on each plug cable: 1/6, 2/3, 4/7

Fig. 1 FIRING ORDER / CABLE ROUTING - 5.7L V-8

ENGINE

1 - TOP OF INTAKE MANIFOLD

2 - CYLINDER FIRING ORDER (IGNITION COIL NUMBER)

3 - CORRESPONDING SPARK PLUG NUMBER

5.9L V-8 ENGINE

The 5.9L V-8 ignition system will use a conventional distributor and 1 remotely mounted coil. Conventional spark plug cables are used with the 5.9L.

Knock sensors are not used with the 5.9L engine.

The ignition system consists of:

• 8 Spark Plugs

• 1 Ignition Coil

• Secondary Ignition Cables

• Distributor (contains rotor and camshaft position

sensor)

• Powertrain Control Module (PCM)

Page 3

DR IGNITION CONTROL 8I - 3

IGNITION CONTROL (Continued)

•

Also to be considered part of the ignition system

are certain inputs from the Crankshaft Position, Camshaft Position, Throttle Position and MAP Sensors

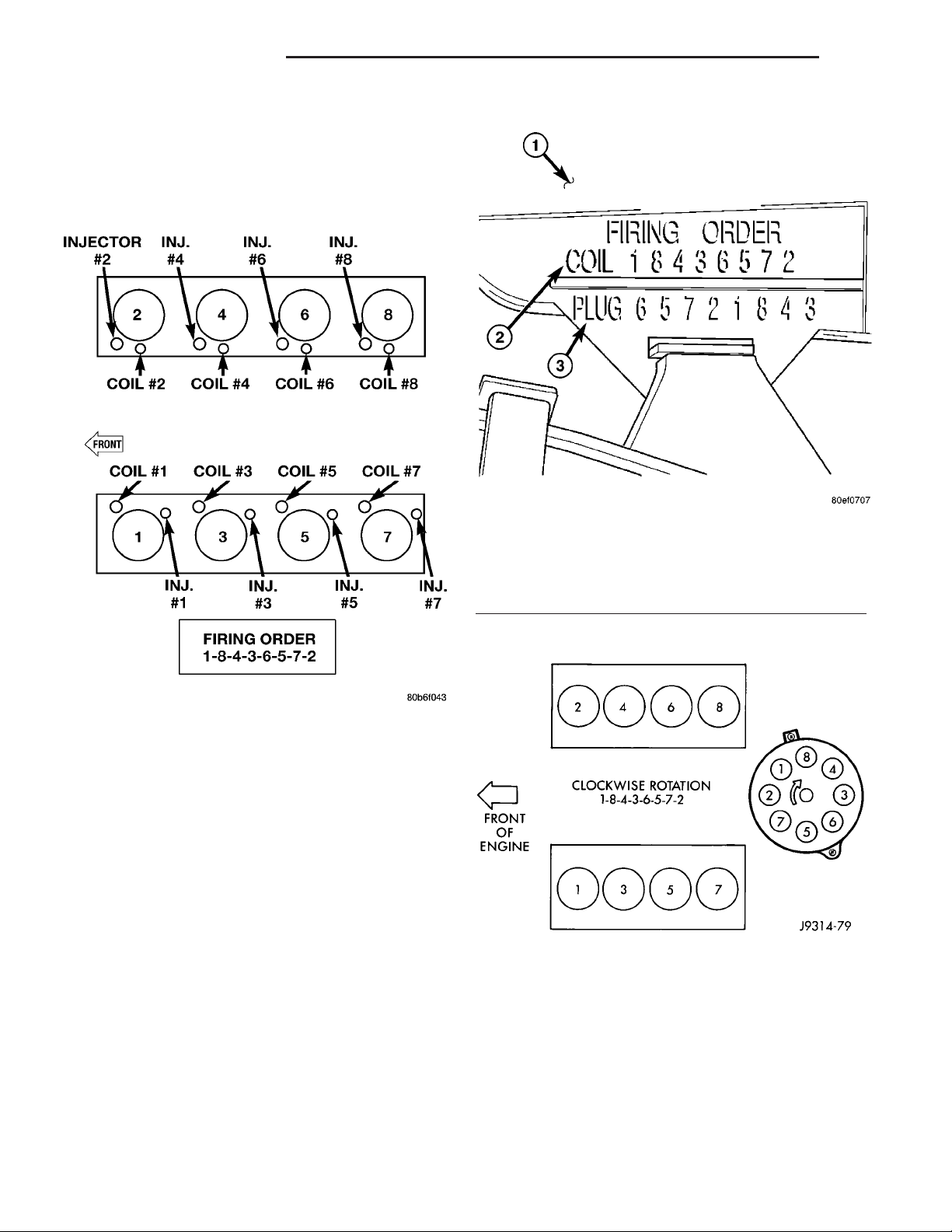

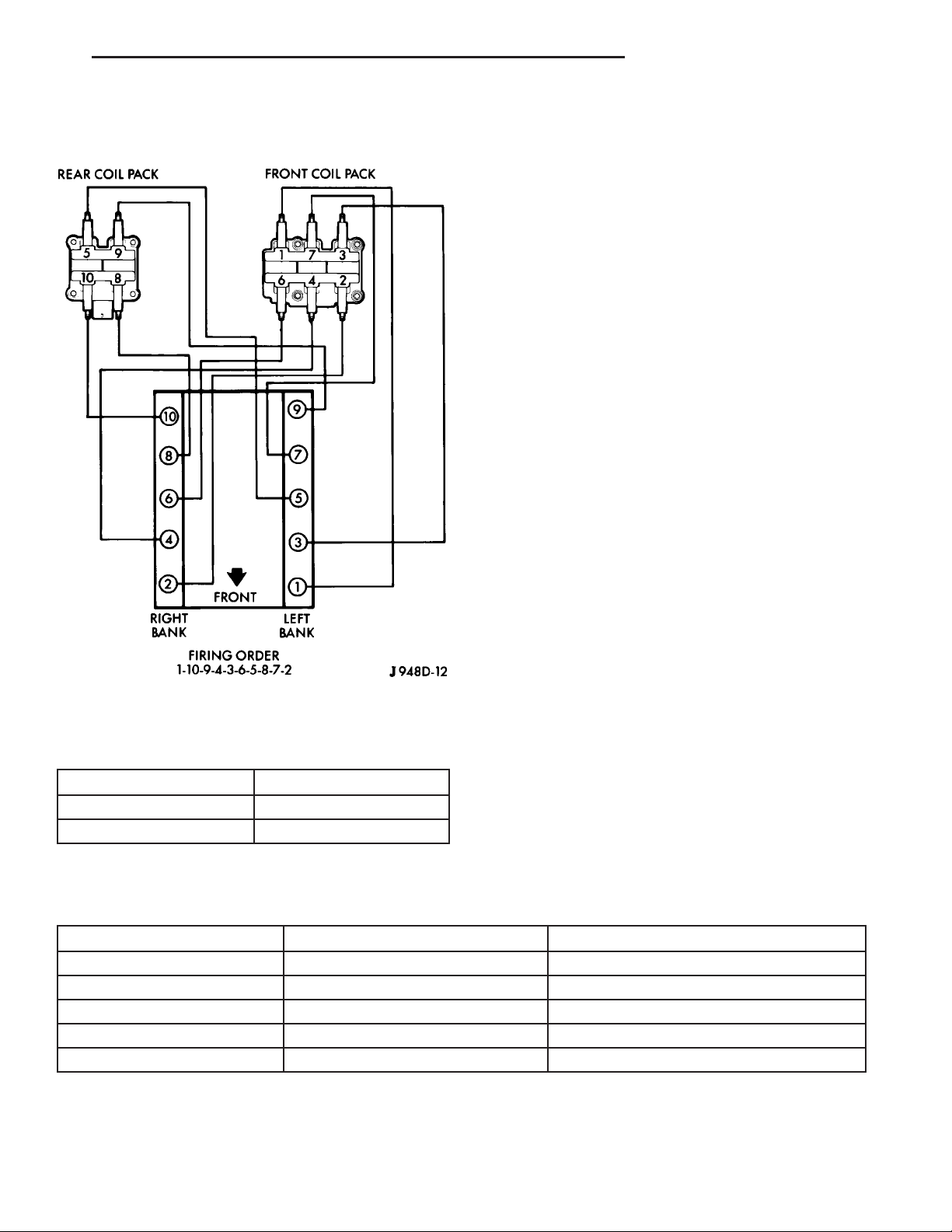

8.0L V-10 ENGINE

. The 8.0L V-10 engine is equipped with 2 remote

coil packs. Conventional spark plug cables are used

with the 8.0L engine. The 8.0L engine will not use a

conventional distributor

The ignition coils are individually fired, but each

coil is a dual output. Refer to Ignition Coil for additional information.

Knock sensors are not used with the 8.0L engine.

The ignition system consists of:

• 10 Spark Plugs

• 2 Ignition Coil packs containing 10 individual

coils

• 10 Secondary Ignition Cables

• Powertrain Control Module (PCM)

• Also to be considered part of the ignition system

are certain inputs from the Crankshaft Position,

Camshaft Position, Throttle Position and MAP Sensors

SPECIFICATIONS

SPECIFICATIONS - TORQUE - IGNITION

DESCRIPTION N·m Ft. Lbs. In. Lbs.

Camshaft Position Sensor - 3.7L V-6 Engine 12 - 106

Camshaft Position Sensor - 4.7L V-8 Engine 12 - 106

Camshaft Position Sensor - 5.7L V-8 Engine 12 9 105

Camshaft Position Sensor - 8.0L V-10 Engine 6 - 50

Crankshaft Position Sensor - 3.7L V-6 Engine 28 21 205

Crankshaft Position Sensor - 4.7L V-8 Engine 28 21 205

Crankshaft Position Sensor - 5.7L V-8 Engine 12 9 105

Crankshaft Position Sensor - 5.9L V-8 Engine 8 - 70

Crankshaft Position Sensor - 8.0L V-10 Engine 8 - 70

Distributor Hold Down Bolt - 5.9L V-8 Engine 23 17 -

Ignition Coil Mounting - 5.9L V-8 Engine

(if tapped bolts are used)

Ignition Coil Mounting - 5.9L V-8 Engine

(if nuts/bolts are used)

Ignition Coil Mounting - 3.7L V-6 Engine 8 - 70

Ignition Coil Mounting - 4.7L V-8 Engine 8 - 70

Ignition Coil Mounting - 5.7L V-8 Engine 12 9 105 (± 20)

Ignition Coil Mounting - 8.0L V-10 Engine 10 - 90

* Knock Sensor - 3.7L V-6 Engine 20 15 176

* Knock Sensor - 4.7L V-8 Engine 20 15 176

* Knock Sensor - 5.7L V-8 Engine 20 15 176

Spark Plugs - 3.7L V-6 Engine 27 20 Spark Plugs - 4.7L V-8 Engine 27 20 -

** Spark Plugs - 5.7L V-8 Engine 18 (± 3) 13 (± 2) -

Spark Plugs - 5.9L V-8 Engine 41 30 -

Spark Plugs - 8.0L V-10 Engine 41 30 -

* Do not apply any sealant, thread-locker or adhesive

to bolts. Poor sensor performance may result.

** Torque critical tapered design. Do not exceed 15 ft.

lbs.

5-50

11 - 100

Page 4

8I - 4 IGNITION CONTROL DR

IGNITION CONTROL (Continued)

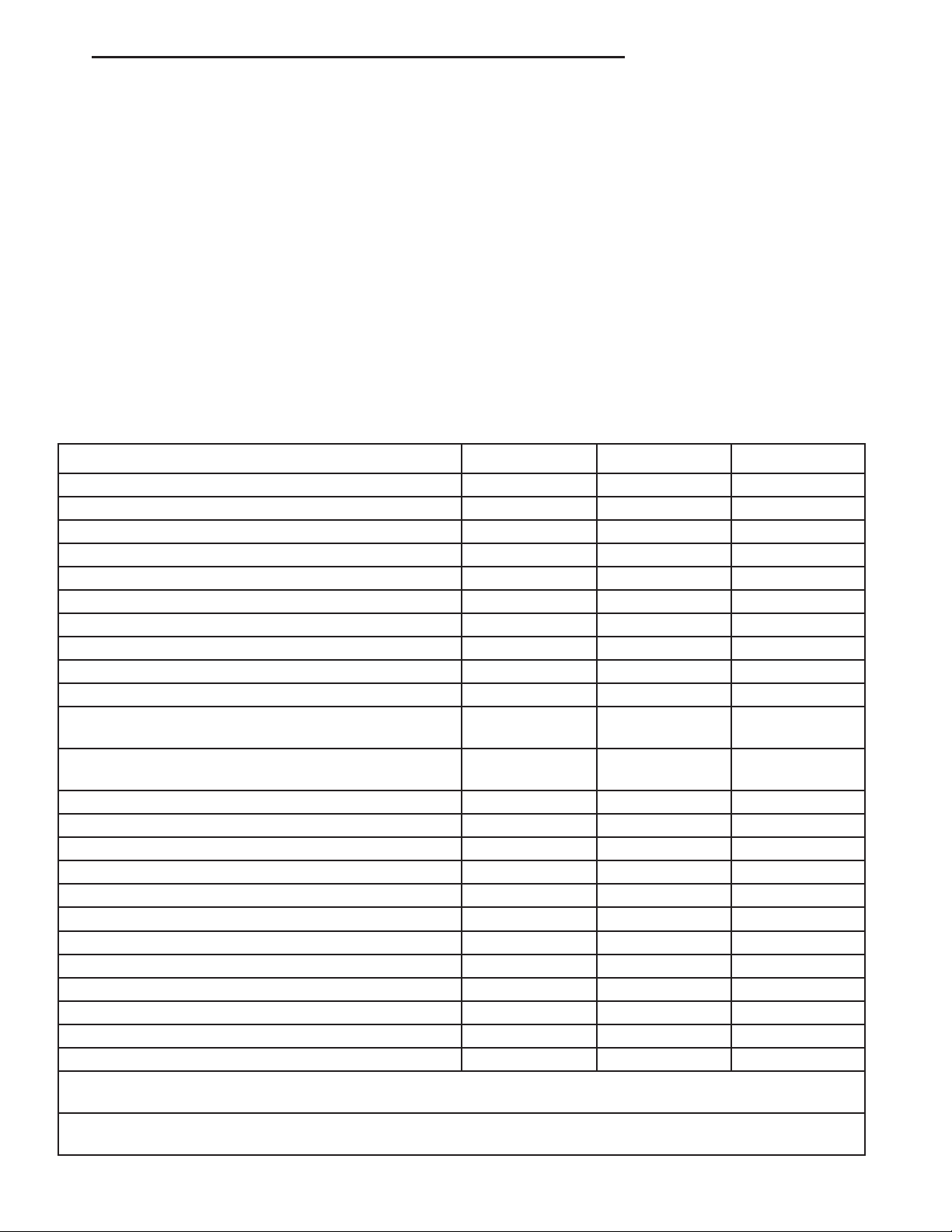

ENGINE FIRING ORDER - 3.7L V-6

1-6-5-4-3-2

ENGINE FIRING ORDER – 4.7L V-8

FIRING ORDER / CABLE ROUTING – 5.7L V-8

ENGINE

Eight conventional spark plug cables are used with

the 5.7L. These cables connect a coil on one cylinder

bank, directly to a spark plug on the opposite cylinder bank. The cables are placed and routed in a special plastic loom to keep them separated. This loom is

clipped to the intake manifold. To prevent a missmatch of cables, a corresponding spark plug / coil

number is displayed on each plug cable: 1/6, 2/3, 4/7

and 5/8. These numbers can also be found on the top

of the intake manifold to the right of the throttle

body (Fig. 2).

Fig. 2 FIRING ORDER / CABLE ROUTING - 5.7L V-8

ENGINE

1 - TOP OF INTAKE MANIFOLD

2 - CYLINDER FIRING ORDER (IGNITION COIL NUMBER)

3 - CORRESPONDING SPARK PLUG NUMBER

ENGINE FIRING ORDER - 5.9L V-8

Page 5

DR IGNITION CONTROL 8I - 5

IGNITION CONTROL (Continued)

SPARK PLUG CABLE ORDER – 8.0L V-10

ENGINE

SPARK PLUG CABLE ORDER – 8.0L V-10 ENGINE

SPARK PLUG CABLE RESISTANCE

MINIMUM MAXIMUM

250 Ohms Per Inch 1000 Ohms Per Inch

3000 Ohms Per Foot 12,000 Ohms Per Foot

SPARK PLUGS

ENGINE PLUG TYPE ELECTRODE GAP

3.7L V-6 ZFR6F - 11G (NGK) 1.1 (0.042 in.)

4.7L V-8 RC12MCC4 1.01 mm (.040 in.)

5.7L V-8 Champion - RE14MCC4 1.14 mm (.045 in.)

5.9L V-8 RC12LC4 1.01 mm (.040 in.)

8.0L V-10 QC9MC4 1.14 mm (.045 in.)

Page 6

8I - 6 IGNITION CONTROL DR

IGNITION CONTROL (Continued)

IGNITION COIL RESISTANCE - 3.7L V-6

PRIMARY RESISTANCE

21-27°C (70-80°F)

0.6 - 0.9 Ohms 6,000 - 9,000 Ohms

SECONDARY

RESISTANCE 21-27°C

(70-80°F)

IGNITION COIL RESISTANCE - 4.7L V-8

PRIMARY

RESISTANCE 21-27°C

(70-80°F)

0.6 - 0.9 Ohms 6,000 - 9,000 Ohms

SECONDARY

RESISTANCE 21-27°C

(70-80°F)

IGNITION COIL RESISTANCE - 5.9L

COIL MANUFACTURER

Diamond 0.97 - 1.18 Ohms 11,300 - 15,300 Ohms

Toyodenso 0.95 - 1.20 Ohms 11,300 - 13,300 Ohms

PRIMARY RESISTANCE

21-27°C (70-80°F)

IGNITION COIL RESISTANCE - 5.7L V-8

PRIMARY RESISTANCE @ 21-27°C (70-80°F)

0.558 - 0.682 Ohms

(Plus or Minus 10% @ 70-80° F)

SECONDARY RESISTANCE 21-27°C

(70-80°F)

IGNITION COIL RESISTANCE – 8.0L V-10

ENGINE

Primary Resistance: 0.53-0.65 Ohms. Test across the

primary connector. Refer to text for test procedures.

Secondary Resistance: 10.9-14.7K Ohms. Test across

the individual coil towers. Refer to text for test

procedures.

IGNITION TIMING

Ignition timing is not adjustable on any engine.

AUTOMATIC SHUT DOWN

RELAY

DESCRIPTION - PCM OUTPUT

The 5–pin, 12–volt, Automatic Shutdown (ASD)

relay is located in the Power Distribution Center

(PDC). Refer to label on PDC cover for relay location.

OPERATION

The ground circuit for the coil within the ASD

relay is controlled by the Powertrain Control Module

(PCM). The PCM operates the ASD relay by switching its ground circuit on and off.

The ASD relay will be shut–down, meaning the

12–volt power supply to the ASD relay will be de-activated by the PCM if:

• the ignition key is left in the ON position. This

is if the engine has not been running for approximately 1.8 seconds.

• there is a crankshaft position sensor signal to

the PCM that is lower than pre-determined values.

OPERATION - ASD SENSE - PCM INPUT

A 12 volt signal at this input indicates to the PCM

that the ASD has been activated. The relay is used to

connect the oxygen sensor heater element, ignition

coil and fuel injectors to 12 volt + power supply.

This input is used only to sense that the ASD relay

is energized. If the Powertrain Control Module

(PCM) does not see 12 volts at this input when the

ASD should be activated, it will set a Diagnostic

Trouble Code (DTC).

OPERATION - PCM OUTPUT

The ASD relay supplies battery voltage (12+ volts)

to the fuel injectors and ignition coil(s). With certain

emissions packages it also supplies 12–volts to the

oxygen sensor heating elements.

Page 7

DR IGNITION CONTROL 8I - 7

AUTOMATIC SHUT DOWN RELAY (Continued)

DIAGNOSIS AND TESTING - ASD AND FUEL

PUMP RELAYS

The following description of operation and

tests apply only to the Automatic Shutdown

(ASD) and fuel pump relays. The terminals on the

bottom of each relay are numbered. Two different

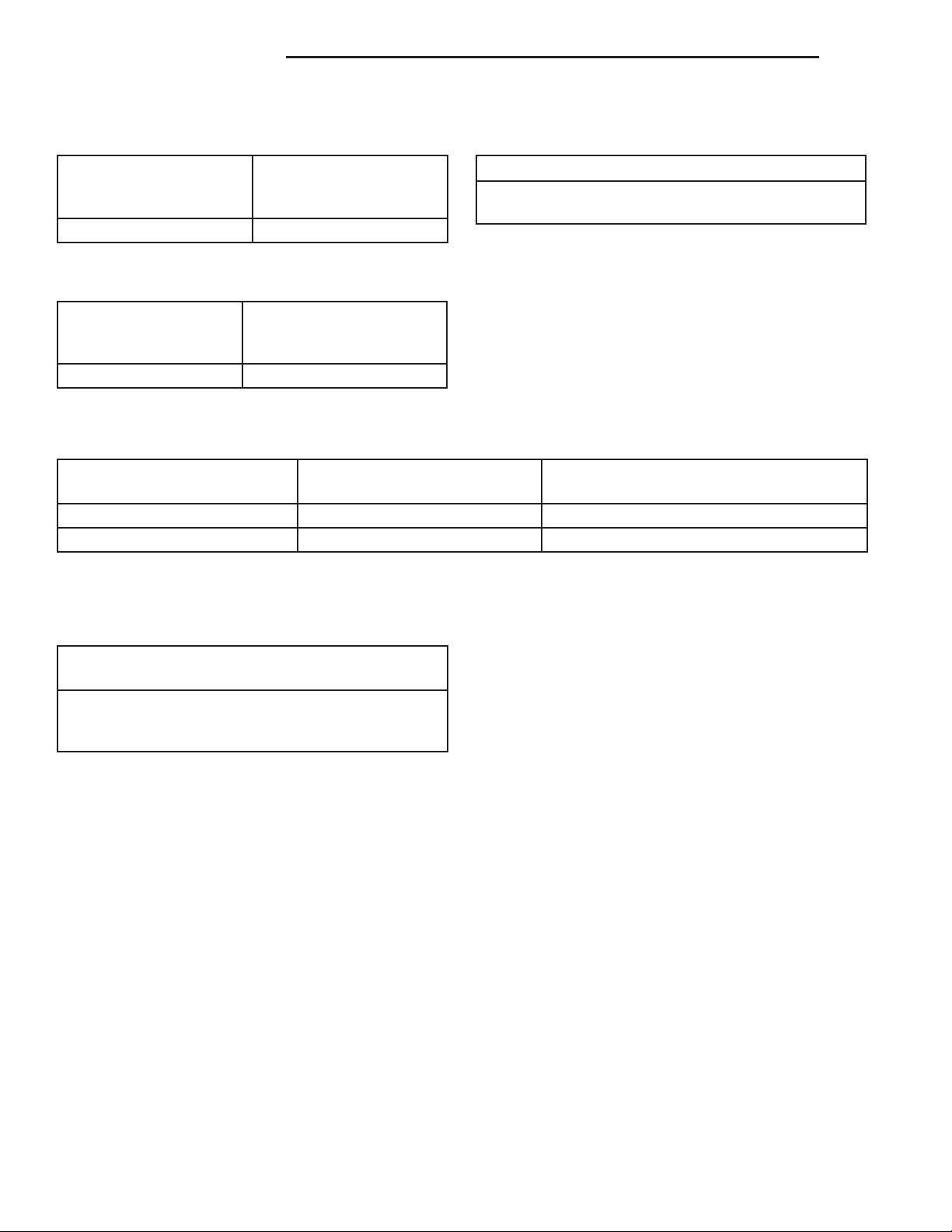

types of relays may be used, (Fig. 3) or (Fig. 4).

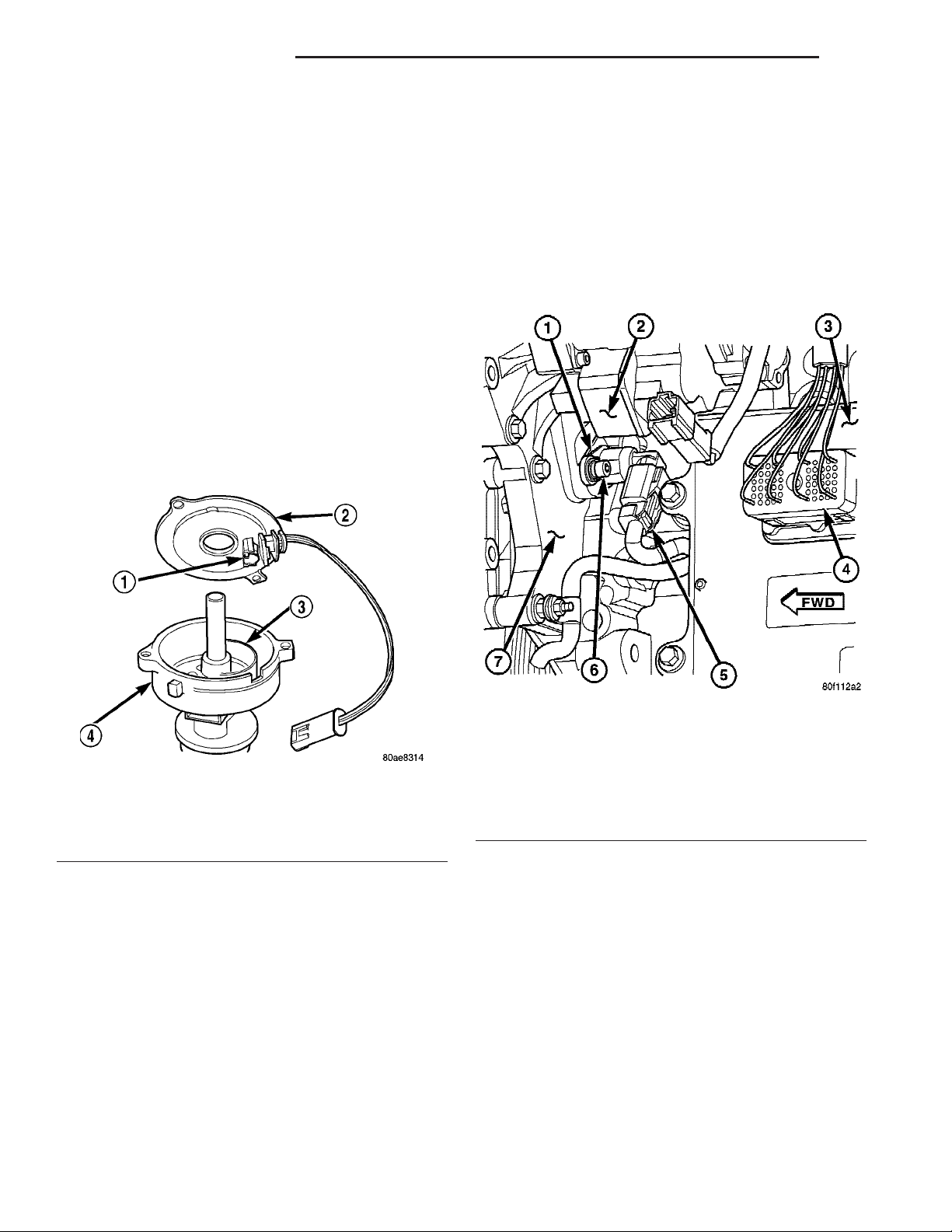

Fig. 3 TYPE 1 RELAY (ISO MICRO RELAY)

• Terminal number 86 supplies voltage to the coil

side of the relay.

• When the PCM de-energizes the ASD and fuel

pump relays, terminal number 87A connects to terminal 30. This is the Off position. In the off position,

voltage is not supplied to the rest of the circuit. Terminal 87A is the center terminal on the relay.

• When the PCM energizes the ASD and fuel

pump relays, terminal 87 connects to terminal 30.

This is the On position. Terminal 87 supplies voltage

to the rest of the circuit.

The following procedure applies to the ASD and

fuel pump relays.

(1) Remove relay from connector before testing.

(2) With the relay removed from the vehicle, use

an ohmmeter to check the resistance between terminals 85 and 86. The resistance should be 75 ohms +/5 ohms.

(3) Connect the ohmmeter between terminals 30

and 87A. The ohmmeter should show continuity

between terminals 30 and 87A.

(4) Connect the ohmmeter between terminals 87

and 30. The ohmmeter should not show continuity at

this time.

(5) Connect one end of a jumper wire (16 gauge or

smaller) to relay terminal 85. Connect the other end

of the jumper wire to the ground side of a 12 volt

power source.

(6) Connect one end of another jumper wire (16

gauge or smaller) to the power side of the 12 volt

power source. Do not attach the other end of the

jumper wire to the relay at this time.

Fig. 4 ASD AND FUEL PUMP RELAY TERMINALS—

TYPE 2

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

• Terminal number 30 is connected to battery voltage. For both the ASD and fuel pump relays, terminal 30 is connected to battery voltage at all times.

• The PCM grounds the coil side of the relay

through terminal number 85.

WARNING: DO NOT ALLOW OHMMETER TO CONTACT TERMINALS 85 OR 86 DURING THIS TEST.

DAMAGE TO OHMMETER MAY RESULT.

(7) Attach the other end of the jumper wire to

relay terminal 86. This activates the relay. The ohmmeter should now show continuity between relay terminals 87 and 30. The ohmmeter should not show

continuity between relay terminals 87A and 30.

(8) Disconnect jumper wires.

(9) Replace the relay if it did not pass the continuity and resistance tests. If the relay passed the tests,

it operates properly. Check the remainder of the ASD

and fuel pump relay circuits. Refer to 8, Wiring Diagrams.

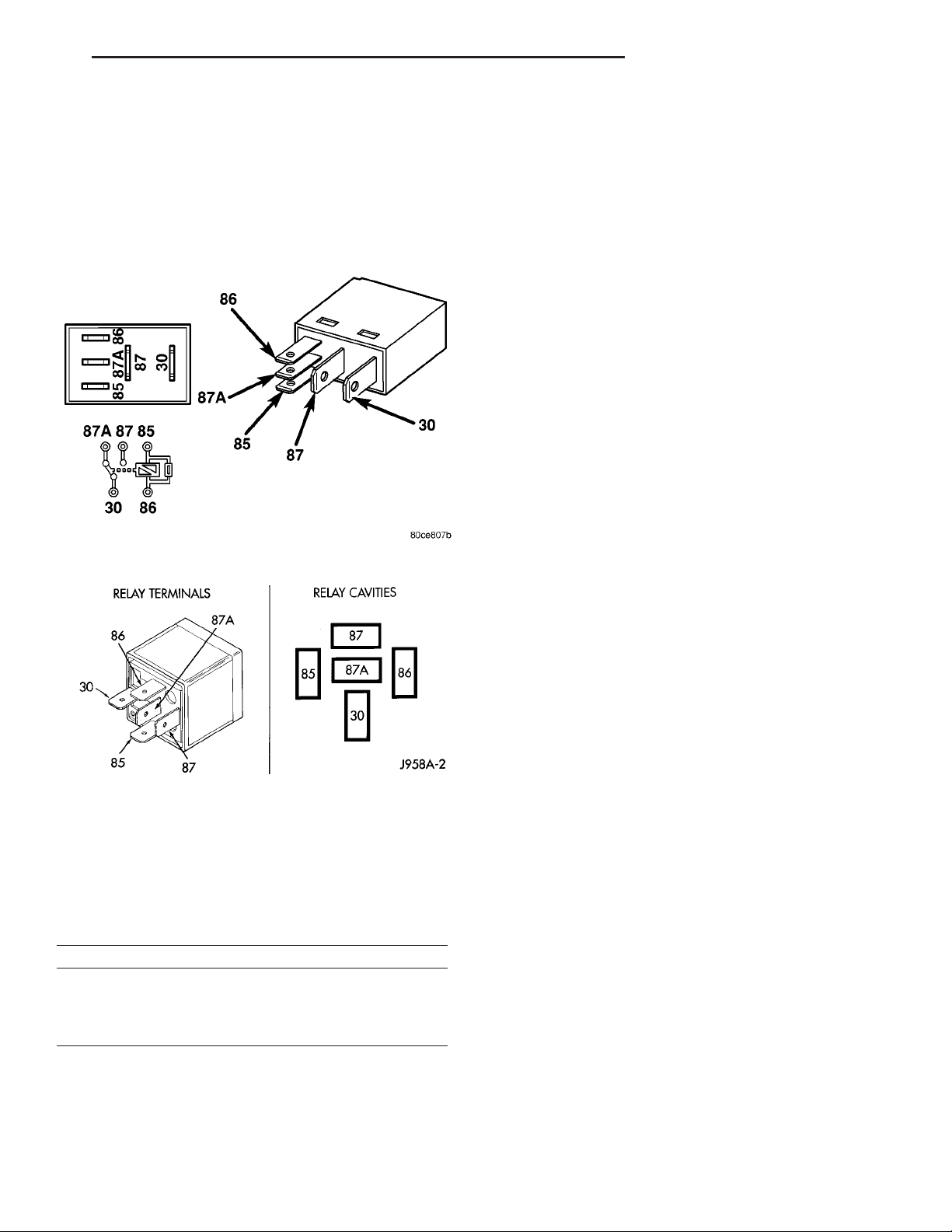

REMOVAL

The ASD relay is located in the Power Distribution

Center (PDC) (Fig. 5). Refer to label on PDC cover

for relay location.

(1) Remove PDC cover.

(2) Remove relay from PDC.

Page 8

8I - 8 IGNITION CONTROL DR

AUTOMATIC SHUT DOWN RELAY (Continued)

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

Fig. 5 PDC LOCATION

1 - BATTERY

2 - PDC (POWER DISTRIBUTION CENTER)

INSTALLATION

The ASD relay is located in the Power Distribution

Center (PDC) (Fig. 5). Refer to label on PDC cover

for relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

CAMSHAFT POSITION

SENSOR

DESCRIPTION

5.7L V-8

The Camshaft Position Sensor (CMP) on the 5.7L

V-8 engine is located below the generator on the timing chain / case cover on the right/front side of

engine.

5.9L Diesel

The Camshaft Position Sensor (CMP) on the 5.9L

diesel engine is located below the fuel injection

pump. It is bolted to the back of the timing gear

cover.

5.9L V-8 Gas

The Camshaft Position Sensor (CMP) on the 5.9L

V-8 engine is located inside the distributor.

8.0L V–10

The Camshaft Position Sensor (CMP) on the 8.0L

V-10 engine is located on the timing chain / case

cover on the left/front side of engine.

OPERATION

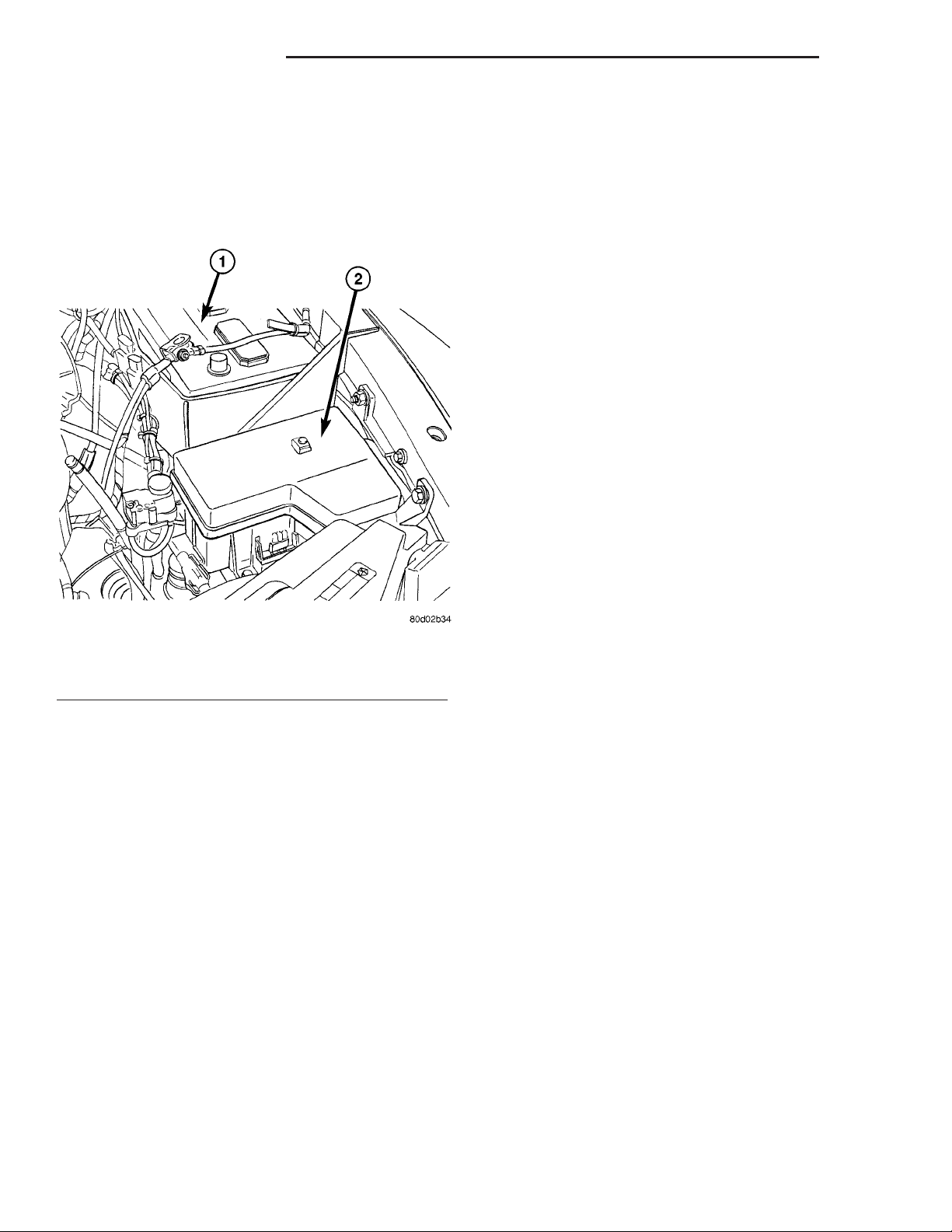

3.7L V-6

The Camshaft Position Sensor (CMP) sensor on the

3.7L V-6 engine contains a hall effect device referred

to as a sync signal generator. A rotating target wheel

(tonewheel) for the CMP is located at the front of the

camshaft for the right cylinder head (Fig. 6). This

sync signal generator detects notches located on a

tonewheel. As the tonewheel rotates, the notches

pass through the sync signal generator. The signal

from the CMP sensor is used in conjunction with the

Crankshaft Position Sensor (CKP) to differentiate

between fuel injection and spark events. It is also

used to synchronize the fuel injectors with their

respective cylinders.

When the leading edge of the tonewheel notch

enters the tip of the CMP, the interruption of magnetic field causes the voltage to switch high, resulting in a sync signal of approximately 5 volts.

When the trailing edge of the tonewheel notch

leaves then tip of the CMP, the change of the magnetic field causes the sync signal voltage to switch

low to 0 volts.

3.7L V-6

The Camshaft Position Sensor (CMP) on the 3.7L

6-cylinder engine is bolted to the right-front side of

the right cylinder head.

4.7L V-8

The Camshaft Position Sensor (CMP) on the 4.7L

V-8 engine is bolted to the right-front side of the

right cylinder head.

4.7L V-8

The CMP sensor on the 4.7L engine contains a hall

effect device called a sync signal generator to generate a fuel sync signal. This sync signal generator

detects notches located on a tonewheel. The tonewheel is located at the front of the camshaft for the

right cylinder head (Fig. 7). As the tonewheel rotates,

the notches pass through the sync signal generator.

The pattern of the notches (viewed counter-clockwise

from front of engine) is: 1 notch, 2 notches, 3 notches,

Page 9

DR IGNITION CONTROL 8I - 9

CAMSHAFT POSITION SENSOR (Continued)

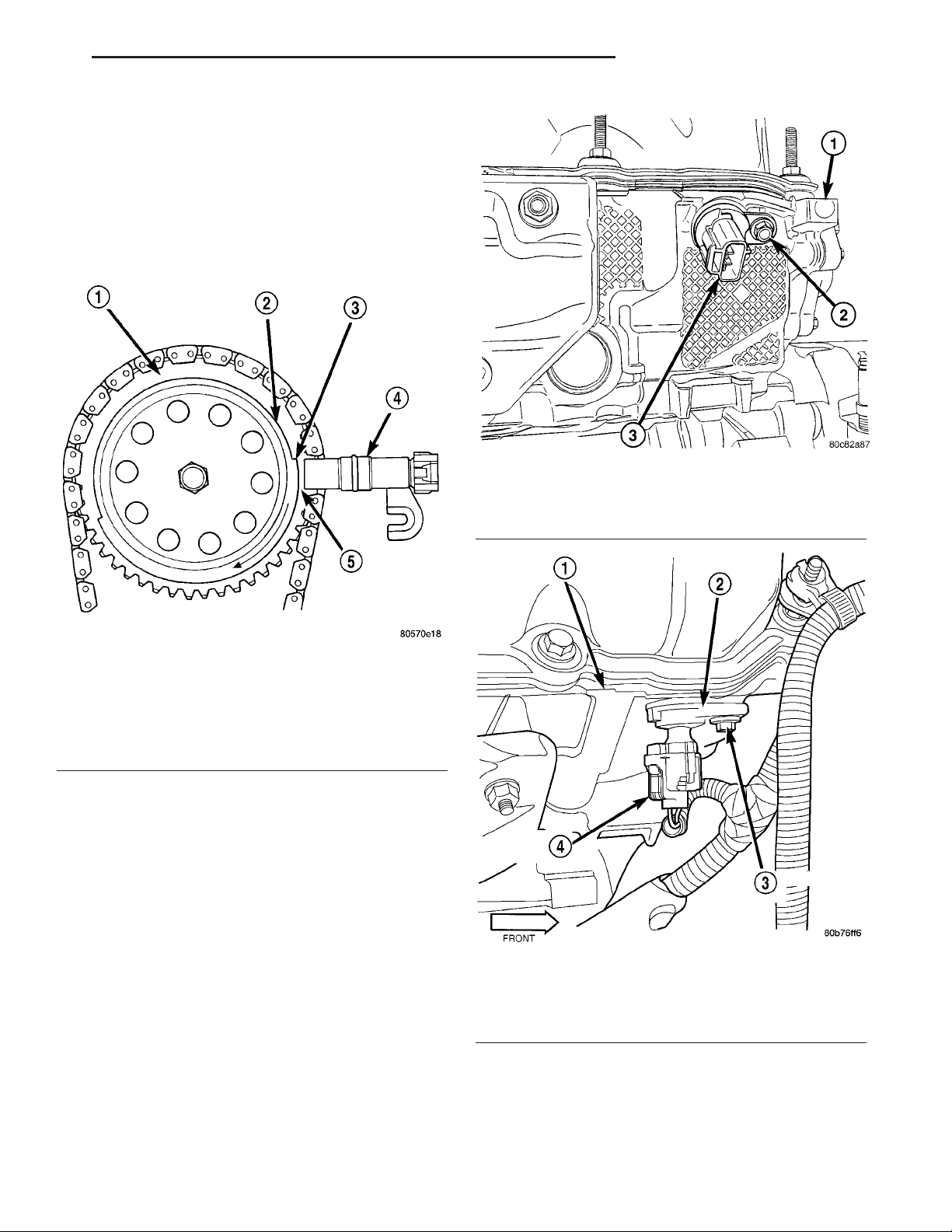

Fig. 6 CMP OPERATION- 3.7L V-6

1 - NOTCHES

2 - RIGHT CYLINDER HEAD

3 - CMP

4 - TONEWHEEL (TARGET WHEEL)

3 notches, 2 notches 1 notch, 3 notches and 1 notch.

The signal from the CMP sensor is used in conjunction with the crankshaft position sensor to differentiate between fuel injection and spark events. It is also

used to synchronize the fuel injectors with their

respective cylinders.

Fig. 7 CMP AND TONEWHEEL OPERATION - 4.7L

V-8

1 - NOTCHES

2 - RIGHT CYLINDER HEAD

3 - CAMSHAFT POSITION SENSOR

4 - TONEWHEEL

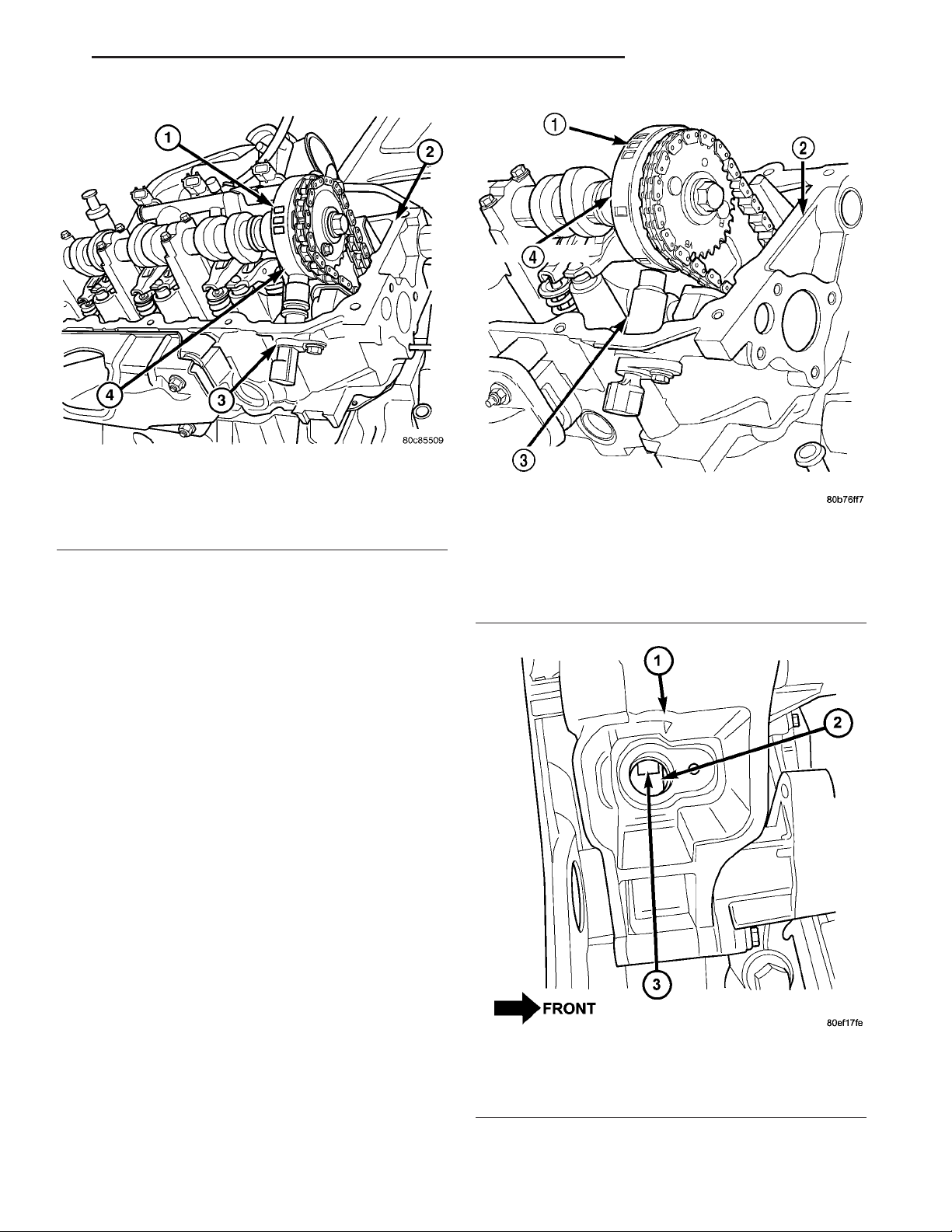

5.7L V-8

The CMP sensor is used in conjunction with the

crankshaft position sensor to differentiate between

fuel injection and spark events. It is also used to synchronize the fuel injectors with their respective cylinders. The sensor generates electrical pulses. These

pulses (signals) are sent to the Powertrain Control

Module (PCM). The PCM will then determine crankshaft position from both the camshaft position sensor

and crankshaft position sensor.

The tonewheel is located at the front of the camshaft (Fig. 8). As the tonewheel rotates, notches (Fig.

8) pass through the sync signal generator.

When the cam gear is rotating, the sensor will

detect the notches. Input voltage from the sensor to

the PCM will then switch from a low (approximately

0.3 volts) to a high (approximately 5 volts). When the

sensor detects a notch has passed, the input voltage

switches back low to approximately 0.3 volts.

Fig. 8 CMP OPERATION - 5.7L ENGINE

1 - TIMING CHAIN COVER

2 - TONEWHEEL

3 - NOTCHES

Page 10

8I - 10 IGNITION CONTROL DR

CAMSHAFT POSITION SENSOR (Continued)

5.9L V-8 Gas

The CMP sensor on the 5.9L V-8 engine contains a

hall effect device called a sync signal generator to

generate a fuel sync signal. This sync signal generator detects a rotating pulse ring (shutter) (Fig. 9) on

the distributor shaft. The pulse ring rotates 180

degrees through the sync signal generator. Its signal

is used in conjunction with the Crankshaft Position

(CKP) sensor to differentiate between fuel injection

and spark events. It is also used to synchronize the

fuel injectors with their respective cylinders.

When the leading edge of the pulse ring (shutter)

enters the sync signal generator, the following occurs:

The interruption of magnetic field causes the voltage

to switch high resulting in a sync signal of approximately 5 volts.

When the trailing edge of the pulse ring (shutter)

leaves the sync signal generator, the following occurs:

The change of the magnetic field causes the sync signal voltage to switch low to 0 volts.

change of the magnetic field causes the signal voltage

to switch low to 0 volts.

The CMP (Fig. 10) provides a signal to the Engine

Control Module (ECM) at all times when the engine

is running. The ECM uses the CMP information primarily on engine start-up. Once the engine is running, the ECM uses the CMP as a backup sensor for

engine speed. The Crankshaft Position Sensor (CKP)

is the primary engine speed indicator for the engine

after the engine is running.

Fig. 9 CMP / PULSE RING - 5.9L GAS ENGINE

1 - SYNC SIGNAL GENERATOR

2 - CAMSHAFT POSITION SENSOR

3 - PULSE RING

4 - DISTRIBUTOR ASSEMBLY

5.9L Diesel

The Camshaft Position Sensor (CMP) contains a

hall effect device. A rotating target wheel (tonewheel)

for the CMP is located on the front timing gear. This

hall effect device detects notches located on the tonewheel. As the tonewheel rotates, the notches pass the

tip of the CMP.

When the leading edge of the tonewheel notch

passes the tip of the CMP, the following occurs: The

interruption of magnetic field causes the voltage to

switch high resulting in a signal of approximately 5

volts.

When the trailing edge of the tonewheel notch

passes the tip of the CMP, the following occurs: The

Fig. 10 5.9L DIESEL CMP

1 - CMP

2 - FUEL INJECTION PUMP (BOTTOM)

3 - ELECTRONIC CONTROL MODULE (ECM)

4 - ECM ELEC. CONNECTOR

5 - CMP ELEC. CONNECTOR

6 - CMP MOUNTING BOLT

7 - BACK OF TIMING GEAR COVER

8.0L V-10

The CMP sensor is used in conjunction with the

crankshaft position sensor to differentiate between

fuel injection and spark events. It is also used to synchronize the fuel injectors with their respective cylinders. The sensor generates electrical pulses. These

pulses (signals) are sent to the Powertrain Control

Module (PCM). The PCM will then determine crankshaft position from both the camshaft position sensor

and crankshaft position sensor.

A low and high area are machined into the camshaft drive gear (Fig. 11). The sensor is positioned in

the timing gear cover so that a small air gap (Fig. 11)

exists between the face of sensor and the high

machined area of cam gear.

Page 11

DR IGNITION CONTROL 8I - 11

CAMSHAFT POSITION SENSOR (Continued)

When the cam gear is rotating, the sensor will

detect the machined low area. Input voltage from the

sensor to the PCM will then switch from a low

(approximately 0.3 volts) to a high (approximately 5

volts). When the sensor detects the high machined

area, the input voltage switches back low to approximately 0.3 volts.

Fig. 12 CMP LOCATION - 3.7L

1 - RIGHT/FRONT OF RIGHT CYLINDER HEAD

2 - CMP MOUNTING BOLT

3 - CMP LOCATION

Fig. 11 CMP SENSOR OPERATION – 8.0L V-10

ENGINE

1 - CAM DRIVE GEAR

2 - LOW MACHINED AREA

3 - HIGH MACHINED AREA

4 - CAMSHAFT POSITION SENSOR

5 - AIR GAP

REMOVAL

3.7L V-6

The Camshaft Position Sensor (CMP) on the 3.7L

V-6 engine is bolted to the front/top of the right cylinder head (Fig. 12).

(1) Disconnect electrical connector at CMP sensor.

(2) Remove sensor mounting bolt (Fig. 12).

(3) Carefully twist sensor from cylinder head.

(4) Check condition of sensor o-ring.

4.7L V-8

The Camshaft Position Sensor (CMP) on the 4.7L

V–8 engine is bolted to the front/top of the right cylinder head (Fig. 13).

(1) Raise and support vehicle.

(2) Disconnect electrical connector at CMP sensor

(Fig. 13).

Fig. 13 CMP LOCATION - 4.7L

1 - RIGHT CYLINDER HEAD

2 - CAMSHAFT POSITION SENSOR

3 - MOUNTING BOLT

4 - ELEC. CONNECTOR

(3) Remove sensor mounting bolt (Fig. 13).

(4) Carefully twist sensor from cylinder head.

(5) Check condition of sensor o-ring.

Page 12

8I - 12 IGNITION CONTROL DR

CAMSHAFT POSITION SENSOR (Continued)

5.7L V-8

The Camshaft Position Sensor (CMP) on the 5.7L

V-8 engine is located on right side of timing chain

cover below generator (Fig. 14).

(1) Disconnect electrical connector at CMP sensor.

(2) Remove sensor mounting bolt (Fig. 15).

(3) Carefully twist sensor from cylinder head.

(4) Check condition of sensor o-ring.

Fig. 14 CMP LOCATION – 5.7L

1 - GENERATOR

2 - CMP LOCATION

3 - ELECTRICAL CONNECTOR

5.9L Diesel

The Camshaft Position Sensor (CMP) on the 5.9L

diesel engine is located below the fuel injection

pump. It is bolted to the back of the timing gear

cover (Fig. 16).

(1) Disconnect electrical connector at CMP sensor

(Fig. 16).

(2) Remove sensor mounting bolt.

(3) Carefully twist sensor from timing gear cover.

(4) Check condition of sensor o-ring.

5.9L V-8 Gas

The Camshaft Position Sensor (CMP) is located

inside the distributor (Fig. 17).

Distributor removal is not necessary to remove

camshaft position sensor.

(1) Disconnect negative cable from battery.

(2) Remove air cleaner tubing at throttle body, and

at air filter housing.

(3) Remove distributor cap from distributor (two

screws).

Fig. 15 CMP REMOVAL / INSTALLATION – 5.7L V-8

1 - TIMING CHAIN COVER (RIGHT/FRONT)

2 - CMP SENSOR

3 - MOUNTING BOLT

Fig. 16 5.9L DIESEL CMP

1 - CMP

2 - FUEL INJECTION PUMP (BOTTOM)

3 - ELECTRONIC CONTROL MODULE (ECM)

4 - ECM ELEC. CONNECTOR

5 - CMP ELEC. CONNECTOR

6 - CMP MOUNTING BOLT

7 - BACK OF TIMING GEAR COVER

Page 13

DR IGNITION CONTROL 8I - 13

CAMSHAFT POSITION SENSOR (Continued)

(4) Disconnect camshaft position sensor wiring

harness from main engine wiring harness.

(5) Remove distributor rotor from distributor shaft.

(6) Lift camshaft position sensor assembly from

distributor housing (Fig. 17).

Fig. 17 DISTRIBUTOR AND CMP LOCATION - 5.9L

1 - SYNC SIGNAL GENERATOR

2 - CAMSHAFT POSITION SENSOR

3 - PULSE RING

4 - DISTRIBUTOR ASSEMBLY

8.0L V–10

The camshaft position sensor is located on the timing chain case/cover on the left-front side of the

engine (Fig. 18).

the engine has been operated, part of this rib may be

sheared (ground) off. Depending on parts tolerances,

some of the rib material may still be observed after

removal.

Fig. 19 SENSOR DEPTH POSITIONING RIB – 8.0L

V-10 ENGINE

1 - CAMSHAFT POSITION SENSOR

2 - PAPER SPACER

3 - RIB MATERIAL (FOR SENSOR DEPTH POSITIONING)

Refer to either of the following procedures; Replacing Old Sensor With Original, or Replacing With

New Sensor:

REPLACING OLD SENSOR WITH ORIGINAL

If the original camshaft position sensor is to be

removed and installed, such as when servicing the

timing chain, timing gears or timing chain cover, use

this procedure.

(1) Disconnect sensor harness connector from sensor.

(2) Remove sensor mounting bolt (Fig. 18).

(3) Carefully pry sensor from timing chain case/

cover in a rocking action with two small screwdrivers.

(4) Remove sensor from vehicle.

(5) Check condition of sensor o-ring (Fig. 20).

Fig. 18 CMP LOCATION - 8.0L

1 - CAMSHAFT POSITION SENSOR

2 - MOUNTING BOLT

3 - TIMING CHAIN CASE/COVER

A thin plastic rib is molded into the face of the sensor (Fig. 19) to position the depth of sensor to the

upper cam gear (sprocket). This rib can be found on

both the new replacement sensors and sensors that

were originally installed to the engine. The first time

REPLACING WITH NEW SENSOR

If a new replacement camshaft position sensor is to

be installed, use this procedure.

(1) Disconnect sensor wiring harness connector

from sensor.

(2) Remove sensor mounting bolt (Fig. 18).

(3) Carefully pry sensor from timing chain case/

cover in a rocking action with two small screwdrivers.

(4) Remove sensor from vehicle.

Page 14

8I - 14 IGNITION CONTROL DR

CAMSHAFT POSITION SENSOR (Continued)

(4) Install mounting bolt and tighten. Refer to

Torque Specifications.

(5) Connect electrical connector to sensor.

5.7L V-8

The Camshaft Position Sensor (CMP) on the 5.7L

V-8 engine is bolted to the right / front side of the

timing chain cover (Fig. 14) or (Fig. 15).

(1) Clean out machined hole in cylinder head.

(2) Apply a small amount of engine oil to sensor

o-ring.

(3) Install sensor into cylinder head with a slight

rocking action. Do not twist sensor into position as

damage to o-ring may result.

Fig. 20 CAMSHAFT SENSOR O-RING – 8.0L

1 - SLOTTED MOUNTING HOLE

2 - SCRIBE LINE

3 - CAMSHAFT POSITION SENSOR O-RING

INSTALLATION

3.7L V-6

The Camshaft Position Sensor (CMP) on the 3.7L

V-6 engine is bolted to the front/top of the right cylinder head (Fig. 12).

(1) Clean out machined hole in cylinder head.

(2) Apply a small amount of engine oil to sensor

o-ring.

(3) Install sensor into cylinder head with a slight

rocking and twisting action.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder head.

If sensor is not flush, damage to sensor mounting

tang may result.

(4) Install mounting bolt and tighten. Refer to

torque specifications.

(5) Connect electrical connector to sensor.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to timing chain

cover. If sensor is not flush, damage to sensor

mounting tang may result.

(4) Install mounting bolt and tighten. Refer to

Torque Specifications.

(5) Connect electrical connector to sensor.

5.9L Diesel

The CMP is located on the back of the timing gear

cover (Fig. 16).

(1) Clean out machined hole in back of timing gear

cover.

(2) Apply a small amount of engine oil to sensor

o-ring.

(3) Install sensor into timing gear cover with a

slight rocking action. Do not twist sensor into position as damage to o-ring may result.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to back of timing

chain cover. If sensor is not flush, damage to sensor mounting tang may result.

4.7L V-8

The Camshaft Position Sensor (CMP) on the 4.7L

V-8 engine is bolted to the front/top of the right cylinder head (Fig. 13).

(1) Clean out machined hole in cylinder head.

(2) Apply a small amount of engine oil to sensor

o-ring.

(3) Install sensor into cylinder head with a slight

rocking action. Do not twist sensor into position as

damage to o-ring may result.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder head.

If sensor is not flush, damage to sensor mounting

tang may result.

(4) Install mounting bolt and tighten. Refer to

Torque Specifications.

(5) Connect electrical connector to sensor.

5.9L Gas

The camshaft position sensor is located inside the

distributor (Fig. 17).

(1) Install camshaft position sensor to distributor.

Align sensor into notch on distributor housing.

(2) Connect engine wiring harness to sensor pigtail

harness.

(3) Install rotor.

(4) Install distributor cap. Tighten 2 mounting

screws.

(5) Install air filter tubing.

(6) Connect battery cable.

Page 15

DR IGNITION CONTROL 8I - 15

CAMSHAFT POSITION SENSOR (Continued)

8.0L V–10

If Replacing Old Sensor With Original

The camshaft position sensor is located on the timing chain case/cover on the left-front side of the

engine (Fig. 18).

When installing a used camshaft position sensor,

the sensor depth must be adjusted to prevent contact

with the camshaft gear (sprocket).

(1) Observe the face of the sensor. If any of the

original rib material remains (Fig. 19), it must be cut

down flush to the face of the sensor with a razor

knife. Remove only enough of the rib material until

the face of the sensor is flat. Do not remove more

material than necessary as damage to sensor may

result. Due to a high magnetic field and possible electrical damage to the sensor, never use an electric

grinder to remove material from sensor.

(2) From the parts department, obtain a peel-andstick paper spacer (Fig. 19). These special paper

spacers are of a certain thickness and are to be used

as a tool to set sensor depth.

(3) Clean the face of sensor and apply paper

spacer (Fig. 19).

(4) Apply a small amount of engine oil to the sensor o-ring (Fig. 20).

A low and high area are machined into the camshaft drive gear (Fig. 21). The sensor is positioned in

the timing gear cover so that a small air gap (Fig.

21) exists between the face of sensor and the high

machined area of cam gear.

Before the sensor is installed, the cam gear may

have to be rotated. This is to allow the high

machined area on the gear to be directly in front of

the sensor mounting hole opening on the timing gear

cover.

Do not install sensor with gear positioned at

low area (Fig. 22) or (Fig. 21). When the engine

is started, the sensor will be broken.

(5) Using a 1/2 in. wide metal ruler, measure the

distance from the cam gear to the face of the sensor

mounting hole opening on the timing gear cover (Fig.

22).

(6) If the dimension is approximately 1.818 inches,

it is OK to install sensor. Proceed to step Step 9.

(7) If the dimension is approximately 2.018 inches,

the cam gear will have to be rotated.

(8) Attach a socket to the vibration damper mounting bolt and rotate engine until the 1.818 inch

dimension is attained.

(9) Install the sensor into the timing case/cover

with a slight rocking action until the paper spacer

contacts the camshaft gear. Do not install the sensor

mounting bolt. Do not twist the sensor into position

as damage to the o-ring or tearing of the paper

spacer may result.

Fig. 21 SENSOR OPERATION – 8.0L V-10 ENGINE

1 - CAM DRIVE GEAR

2 - LOW MACHINED AREA

3 - HIGH MACHINED AREA

4 - CAMSHAFT POSITION SENSOR

5 - AIR GAP

(10) Scratch a scribe line into the timing chain

case/cover to indicate depth of sensor (Fig. 20).

(11) Remove the sensor from timing chain case/

cover.

(12) Remove paper spacer from sensor. This step

must be followed to prevent the paper spacer from

getting into the engine lubrication system.

(13) Again, apply a small amount of engine oil to

sensor o-ring.

(14) Again, install the sensor into the timing case/

cover with a slight rocking action until the sensor is

aligned to scribe line.

(15) Install sensor mounting bolt and tighten to 6

N·m (50 in. lbs.) torque.

(16) Connect engine wiring harness to sensor.

Replacing With a New Sensor

(1) Apply a small amount of engine oil to the sensor o-ring (Fig. 20).

A low and high area are machined into the camshaft drive gear (Fig. 21). The sensor is positioned in

the timing gear cover so that a small air gap (Fig.

21) exists between the face of sensor and the high

machined area of cam gear.

Before the sensor is installed, the cam gear may

have to be rotated. This is to allow the high

machined area on the gear to be directly in front of

the sensor mounting hole opening on the timing gear

cover.

Page 16

8I - 16 IGNITION CONTROL DR

CAMSHAFT POSITION SENSOR (Continued)

When the engine is started, the rib material will be

sheared off the face of sensor. This will automatically

set sensor air gap.

DISTRIBUTOR

DESCRIPTION

All 5.9L V-8 engines are equipped with a camshaft

driven mechanical distributor (Fig. 23) containing a

shaft driven distributor rotor. All distributors are

equipped with an internal camshaft position (fuel

sync) sensor (Fig. 23).

Fig. 22 SENSOR DEPTH DIMENSIONS – 8.0L V-10

ENGINE

1 - 2.01888 DO NOT INSTALL SENSOR

2 - SENSOR MOUNTING HOLE OPENING

3 - SENSOR CENTER LINE

4 - TIMING CHAIN COVER

5 - 1.81888 OK TO INSTALL SENSOR

6 - CAM DRIVE GEAR

7 - HIGH MACHINED AREA

8 - LOW MACHINED AREA

Do not install sensor with gear positioned at

low area (Fig. 22) or (Fig. 21). When the engine

is started, the sensor will be broken.

(2) Using a 1/2 in. wide metal ruler, measure the

distance from the cam gear to the face of the sensor

mounting hole opening on the timing gear cover (Fig.

22).

(3) If the dimension is approximately 1.818 inches,

it is OK to install sensor. Proceed to step Step 9.

(4) If the dimension is approximately 2.018 inches,

the cam gear will have to be rotated.

(5) Attach a socket to the vibration damper mounting bolt and rotate engine until the 1.818 inch

dimension is attained.

(6) Install the sensor into the timing case/cover

with a slight rocking action. Do not twist the sensor

into position as damage to the o-ring may result.

Push the sensor all the way into the cover until the

rib material on the sensor (Fig. 19) contacts the camshaft gear.

(7) Install the mounting bolt and tighten to 6 N·m

(50 in. lbs.) torque.

(8) Connect sensor wiring harness to engine harness.

Fig. 23 DISTRIBUTOR AND CAMSHAFT POSITION

SENSOR - 5.9L

1 - SYNC SIGNAL GENERATOR

2 - CAMSHAFT POSITION SENSOR

3 - PULSE RING

4 - DISTRIBUTOR ASSEMBLY

OPERATION

The distributor does not have built in centrifugal

or vacuum assisted advance. Base ignition timing

and all timing advance is controlled by the Powertrain Control Module (PCM). Because ignition timing

is controlled by the PCM, base ignition timing is

not adjustable.

The distributor is held to the engine in the conventional method using a holddown clamp and bolt.

Although the distributor can be rotated, it will

have no effect on ignition timing.

All distributors contain an internal oil seal that

prevents oil from entering the distributor housing.

The seal is not serviceable.

Page 17

DR IGNITION CONTROL 8I - 17

DISTRIBUTOR (Continued)

REMOVAL

CAUTION: Base ignition timing is not adjustable on

any engine. Distributors do not have built in centrifugal or vacuum assisted advance. Base ignition

timing and timing advance are controlled by the

Powertrain Control Module (PCM). Because a conventional timing light can not be used to adjust distributor position after installation, note position of

distributor before removal.

(1) Disconnect negative cable from battery.

(2) Remove air cleaner tubing.

(3) Remove distributor cap from distributor (two

screws).

(4) Mark the position of distributor housing in

relationship to engine or dash panel. This is done to

aid in installation.

(5) Before distributor is removed, the number one

cylinder must be brought to the Top Dead Center

(TDC) firing position.

(6) Attach a socket to the Crankshaft Vibration

Damper mounting bolt.

(7) Slowly rotate engine clockwise, as viewed from

front, until indicating mark on crankshaft vibration

damper is aligned to 0 degree (TDC) mark on timing

chain cover (Fig. 24).

1 - CAMSHAFT POSITION SENSOR ALIGNMENT MARK

2 - ROTOR

3 - DISTRIBUTOR

(9) Disconnect camshaft position sensor wiring

harness from main engine wiring harness.

(10) Remove distributor rotor from distributor

shaft.

(11) Remove distributor holddown clamp bolt and

clamp (Fig. 26). Remove distributor from vehicle.

Fig. 25 ROTOR ALIGNMENT MARK

Fig. 24 DAMPER-TO-COVER ALIGNMENT MARKS —

TYPICAL

1 - ALIGNMENT MARK

2 - TIMING CHAIN COVER MARKS

3 - CRANKSHAFT VIBRATION DAMPER

(8) The distributor rotor should now be aligned to

the CYL. NO. 1 alignment mark (stamped) into the

camshaft position sensor (Fig. 25). If not, rotate the

crankshaft through another complete 360 degree

turn. Note the position of the number one cylinder

spark plug cable (on the cap) in relation to rotor.

Rotor should now be aligned to this position.

Fig. 26 DISTRIBUTOR HOLDDOWN CLAMP

1 - CLAMP BOLT

2 - HOLDDOWN CLAMP

3 - DISTRIBUTOR HOUSING

CAUTION: Do not crank engine with distributor

removed. Distributor/crankshaft relationship will be

lost.

Page 18

8I - 18 IGNITION CONTROL DR

DISTRIBUTOR (Continued)

INSTALLATION

If engine has been cranked while distributor is

removed, establish the relationship between distributor shaft and number one piston position as follows:

Rotate crankshaft in a clockwise direction, as

viewed from front, until number one cylinder piston

is at top of compression stroke (compression should

be felt on finger with number one spark plug

removed). Then continue to slowly rotate engine

clockwise until indicating mark (Fig. 24) is aligned to

0 degree (TDC) mark on timing chain cover.

(1) Clean top of cylinder block for a good seal

between distributor base and block.

(2) Lightly oil the rubber o-ring seal on the distributor housing.

(3) Install rotor to distributor shaft.

(4) Position distributor into engine to its original

position. Engage tongue of distributor shaft with slot

in distributor oil pump drive gear. Position rotor to

the number one spark plug cable position.

(5) Install distributor holddown clamp and clamp

bolt. Do not tighten bolt at this time.

(6) Rotate the distributor housing until rotor is

aligned to CYL. NO. 1 alignment mark on the camshaft position sensor (Fig. 25).

(7) Tighten clamp holddown bolt (Fig. 26) to 22.5

N·m (200 in. lbs.) torque.

(8) Connect camshaft position sensor wiring harness to main engine harness.

(9) Install distributor cap. Tighten mounting

screws.

(10) Refer to the following, Checking Distributor

Position.

(5) If a plus (+) or a minus (-) is displayed next to

degree number, and/or the degree displayed is not

zero, loosen but do not remove distributor holddown

clamp bolt. Rotate distributor until IN RANGE

appears on screen. Continue to rotate distributor

until achieving as close to 0° as possible. After

adjustment, tighten clamp bolt to 22.5 N·m (200 in.

lbs.) torque.

Do not attempt to adjust ignition timing using this

method. Rotating distributor will have no effect on

ignition timing. All ignition timing values are controlled by Powertrain Control Module (PCM).

After testing, install air cleaner tubing.

DISTRIBUTOR CAP

DIAGNOSIS AND TESTING - DISTRIBUTOR

CAP - 5.9L V-8

Remove the distributor cap and wipe it clean with

a dry lint free cloth. Visually inspect the cap for

cracks, carbon paths, broken towers or damaged

rotor button (Fig. 27) or (Fig. 28). Also check for

white deposits on the inside (caused by condensation

entering the cap through cracks). Replace any cap

that displays charred or eroded terminals. The

machined surface of a terminal end (faces toward

rotor) will indicate some evidence of erosion from

normal operation. Examine the terminal ends for evidence of mechanical interference with the rotor tip.

Checking Distributor Position

To verify correct distributor rotational position, the

DRB scan tool must be used.

WARNING: WHEN PERFORMING THE FOLLOWING

TEST, THE ENGINE WILL BE RUNNING. BE CAREFUL NOT TO STAND IN LINE WITH THE FAN

BLADES OR FAN BELT. DO NOT WEAR LOOSE

CLOTHING.

(1) Connect DRB scan tool to data link connector.

The data link connector is located in passenger compartment, below and to left of steering column.

(2) Gain access to SET SYNC screen on DRB.

(3) Follow directions on DRB screen and start

engine. Bring to operating temperature (engine must

be in “closed loop” mode).

(4) With engine running at idle speed, the words

IN RANGE should appear on screen along with 0°.

This indicates correct distributor position.

Fig. 27 CAP INSPECTION—EXTERNAL—TYPICAL

1 - BROKEN TOWER

2 - DISTRIBUTOR CAP

3 - CARBON PATH

4 - CRACK

Page 19

DR IGNITION CONTROL 8I - 19

DISTRIBUTOR CAP (Continued)

IGNITION COIL

DESCRIPTION

3.7L V-6

The 3.7L V-6 engine uses 6 dedicated, and individually fired coil for each spark plug (Fig. 30). Each

coil is mounted directly into the cylinder head and

onto the top of each spark plug (Fig. 31).

Fig. 28 CAP INSPECTION—INTERNAL—TYPICAL

1 - CHARRED OR ERODED TERMINALS

2 - WORN OR DAMAGED ROTOR BUTTON

3 - CARBON PATH

DISTRIBUTOR ROTOR

DIAGNOSIS AND TESTING - DISTRIBUTOR

ROTOR - 5.9L V-8

Visually inspect the rotor (Fig. 29) for cracks, evidence of corrosion or the effects of arcing on the metal

tip. Also check for evidence of mechanical interference

with the cap. Some charring is normal on the end of

the metal tip. The silicone-dielectric-varnish-compound

applied to the rotor tip for radio interference noise suppression, will appear charred. This is normal. Do not

remove the charred compound.

insufficient tension. Replace a rotor that displays any

of these adverse conditions.

Test the spring for

Fig. 30 IGNITION COIL - 3.7L V-6/ 4.7L V-8

1 - O-RING

2 - IGNITION COIL

3 - ELECTRICAL CONNECTOR

Fig. 29 ROTOR INSPECTION—TYPICAL

1 - INSUFFICIENT SPRING TENSION

2 - CRACKS

3 - EVIDENCE OF PHYSICAL CONTACT WITH CAP

4 - ROTOR TIP CORRODED

Fig. 31 IGNITION COIL LOCATION - 3.7L V-6

1 - IGNITION COIL

2 - COIL MOUNTING NUT

Page 20

8I - 20 IGNITION CONTROL DR

IGNITION COIL (Continued)

4.7L V-8

The 4.7L V–8 engine uses 8 dedicated, and individually fired coil (Fig. 30) for each spark plug. Each

coil is mounted directly to the top of each spark plug

(Fig. 32).

Fig. 32 IGNITION COIL LOCATION - 4.7L V-8

1 - IGNITION COIL

2 - COIL ELECTRICAL CONNECTOR

3 - COIL MOUNTING STUD/NUT

5.7L V-8

The 5.7L V–8 engine uses 8 dedicated, and individually fired coil (Fig. 33) for each pair of spark plugs.

Each coil is mounted directly to the top of each spark

plug (Fig. 34). Each coil is bolted to the valve cover.

5.9L V-8

A single ignition coil is used (Fig. 35) or (Fig. 36).

The coil is not oil filled. The coil windings are embedded in an epoxy compound. This provides heat and

vibration resistance that allows the coil to be

mounted on the engine.

8.0L V-10

Two separate coil packs containing a total of five

independent coils are attached to a common mounting bracket. They are located above the right engine

valve cover (Fig. 37). The coil packs are not oil filled.

The front coil pack contains three independent epoxy

filled coils. The rear coil pack contains two independent epoxy filled coils.

Fig. 33 IGNITION COIL - 5.7L V-8

1 - IGNITION COIL

2 - MOUNTING BOLTS (2)

3 - BOOT TO SPARK PLUG

OPERATION

3.7L V-6

Battery voltage is supplied to the 6 individual ignition coils from the ASD relay. The Powertrain Control Module (PCM) opens and closes each ignition coil

ground circuit at a determined time for ignition coil

operation.

Base ignition timing is not adjustable. By controlling the coil ground circuit, the PCM is able to set

the base timing and adjust the ignition timing

advance. This is done to meet changing engine operating conditions.

The ignition coil is not oil filled. The windings are

embedded in an epoxy compound. This provides heat

and vibration resistance that allows the ignition coil

to be mounted on the engine.

Because of coil design, spark plug cables (secondary cables) are not used with the 3.7L V-6 engine.

Page 21

DR IGNITION CONTROL 8I - 21

IGNITION COIL (Continued)

Fig. 36 IGNITION COIL LOCATION – 5.9L HDC V-8

1 - COIL MOUNTING BOLTS

2 - IGNITION COIL

3 - COIL ELEC. CONNECTOR

Fig. 34 IGNITION COIL R/I — 5.7L V-8

1 - SLIDE LOCK (SLIDE OUTWARD TO UNLOCK)

2 - SPARK PLUG CABLE (TO OPPOSITE CYLINDER BANK

SPARK PLUG)

3 - RELEASE LOCK / TAB (PUSH HERE)

4 - ELEC. CONNECTOR

5 - IGNITION COIL

6 - COIL MOUNTING BOLTS (2)

7 - SPARK PLUG CABLE (TO OPPOSITE CYLINDER BANK

IGNITION COIL)

4 - SECONDARY CABLE

Fig. 35 IGNITION COIL LOCATION - 5.9L V-8

(EXCEPT HDC)

1 - ACCESSORY DRIVE BELT TENSIONER

2 - COIL CONNECTOR

3 - IGNITION COIL

4 - COIL MOUNTING BOLTS

Fig. 37 8.0L V-10 COIL PACKS

1 - IGNTITION COILS

2 - COIL MOUNTING BOLTS (8)

3 - ENGINE CYLINDER NUMBER

Page 22

8I - 22 IGNITION CONTROL DR

IGNITION COIL (Continued)

4.7L V-8

Battery voltage is supplied to the 8 individual ignition coils from the ASD relay. The Powertrain Control Module (PCM) opens and closes each ignition coil

ground circuit at a determined time for ignition coil

operation.

Base ignition timing is not adjustable. By controlling the coil ground circuit, the PCM is able to set

the base timing and adjust the ignition timing

advance. This is done to meet changing engine operating conditions.

The ignition coil is not oil filled. The windings are

embedded in an epoxy compound. This provides heat

and vibration resistance that allows the ignition coil

to be mounted on the engine.

Because of coil design, spark plug cables (secondary cables) are not used with the 4.7L V-8 engine.

5.7L V-8

The ignition system is controlled by the Powertrain

Control Module (PCM) on all engines.

A “wasted spark” system is used on the 5.7L

engine combining paired, or dual-firing coils, and 2

spark plugs per cylinder. The coils and spark plugs

are connected with paired, secondary high-voltage

cables.

Each cylinder is equipped with 1 dual-output coil.

Meaning one coil mounts directly over one of the

dual spark plugs for 1 high-voltage output. A second

high-voltage output is supplied directly from the

same coil (using a plug cable) to one of the dual

spark plugs on a corresponding (paired) cylinder on

the opposite cylinder bank.

Each coil fires 2 spark plugs simultaneously on

each of the cylinder banks (one cylinder on compression stroke and one cylinder on exhaust stroke).

EXAMPLE : When the #1 cylinder is on compression

stroke and ready for spark, the #1 coil will fire one of

the dual spark plugs on the #1 cylinder (directly

below the coil). The other dual spark plug on the #1

cylinder will be fired by the #6 coil. At the same

time, the #1 coil will fire a “wasted spark” to one of

the dual spark plugs at the #6 cylinder as coil #6 also

fires a “wasted spark” to one of the dual spark plugs

at the #6 cylinder.

The firing order is paired at cylinders 1/6, 2/3, 4/7,

5/8. Basic cylinder firing order is 1–8–4–3–6–5–7–2.

Battery voltage is supplied to all of the ignition

coils positive terminals from the ASD relay. If the

PCM does not see a signal from the crankshaft and

camshaft sensors (indicating the ignition key is ON

but the engine is not running), it will shut down the

ASD circuit.

Base ignition timing is not adjustable on the

5.7L V-8 engine. By controlling the coil ground cir-

cuits, the PCM is able to set the base timing and

adjust the ignition timing advance. This is done to

meet changing engine operating conditions.

The PCM adjusts ignition timing based on inputs it

receives from:

• The engine coolant temperature sensor

• The crankshaft position sensor (engine speed)

• The camshaft position sensor (crankshaft posi-

tion)

• The manifold absolute pressure (MAP) sensor

• The throttle position sensor

• Transmission gear selection

5.9L V-8

A single ignition coil is used. The Powertrain Control Module (PCM) opens and closes the ignition coil

ground circuit for ignition coil operation.

Battery voltage is supplied to the ignition coil positive terminal from the ASD relay. If the PCM does

not see a signal from the crankshaft and camshaft

sensors (indicating the ignition key is ON but the

engine is not running), it will shut down the ASD circuit.

Base ignition timing is not adjustable on any

engine. By controlling the coil ground circuit, the

PCM is able to set the base timing and adjust the

ignition timing advance. This is done to meet changing engine operating conditions.

Conventional spark plug cables (secondary cables)

are used with the 5.9L V-8 engine.

8.0L V-10

When one of the 5 independent coils discharges, it

fires two paired cylinders at the same time (one cylinder on compression stroke and the other cylinder

on exhaust stroke).

Coil firing is paired together on cylinders:

• Number 5 and 10

• Number 9 and 8

• Number 1 and 6

• Number 7 and 4

• Number 3 and 2

The ignition system is controlled by the Powertrain

Control Module (PCM) on all engines.

Battery voltage is supplied to all of the ignition

coils positive terminals from the ASD relay. If the

PCM does not see a signal from the crankshaft and

camshaft sensors (indicating the ignition key is ON

but the engine is not running), it will shut down the

ASD circuit.

Conventional spark plug cables (secondary cables)

are used with the 8.0L V-10 engine.

Base ignition timing is not adjustable on the

8.0L V-10 engine. By controlling the coil ground cir-

cuits, the PCM is able to set the base timing and

adjust the ignition timing advance. This is done to

meet changing engine operating conditions.

Page 23

DR IGNITION CONTROL 8I - 23

IGNITION COIL (Continued)

The PCM adjusts ignition timing based on inputs it

receives from:

• The engine coolant temperature sensor

• The crankshaft position sensor (engine speed)

• The camshaft position sensor (crankshaft posi-

tion)

• The manifold absolute pressure (MAP) sensor

• The throttle position sensor

• Transmission gear selection

REMOVAL

3.7L V-6

An individual ignition coil is used for each spark

plug (Fig. 30). The coil fits into machined holes in the

cylinder head. A mounting stud/nut secures each coil

to the top of the intake manifold (Fig. 31). The bottom of the coil is equipped with a rubber boot to seal

the spark plug to the coil. Inside each rubber boot is

a spring. The spring is used for a mechanical contact

between the coil and the top of the spark plug. These

rubber boots and springs are a permanent part of the

coil and are not serviced separately. An o-ring (Fig.

30) is used to seal the coil at the opening into the cylinder head.

(1) Depending on which coil is being removed, the

throttle body air intake tube or intake box may need

to be removed to gain access to coil.

(2) Disconnect electrical connector from coil by

pushing downward on release lock on top of connector and pull connector from coil.

(3) Clean area at base of coil with compressed air

before removal.

(4) Remove coil mounting nut from mounting stud

(Fig. 31).

(5) Carefully pull up coil from cylinder head opening with a slight twisting action.

(6) Remove coil from vehicle.

4.7L V-8

An individual ignition coil is used for each spark

plug (Fig. 30). The coil fits into machined holes in the

cylinder head. A mounting stud/nut secures each coil

to the top of the intake manifold (Fig. 32). The bottom of the coil is equipped with a rubber boot to seal

the spark plug to the coil. Inside each rubber boot is

a spring. The spring is used for a mechanical contact

between the coil and the top of the spark plug. These

rubber boots and springs are a permanent part of the

coil and are not serviced separately. An o-ring (Fig.

30) is used to seal the coil at the opening into the cylinder head.

(1) Depending on which coil is being removed, the

throttle body air intake tube or intake box may need

to be removed to gain access to coil.

(2) Disconnect electrical connector (Fig. 32) from

coil by pushing downward on release lock on top of

connector and pull connector from coil.

(3) Clean area at base of coil with compressed air

before removal.

(4) Remove coil mounting nut from mounting stud

(Fig. 32).

(5) Carefully pull up coil from cylinder head opening with a slight twisting action.

(6) Remove coil from vehicle.

5.7L V-8

Before removing or disconnecting any spark plug

cables, note their original position. Remove cables

one-at-a-time. To prevent ignition crossfire, spark

plug cables MUST be placed in cable tray (routing

loom) into their original position.

An individual ignition coil (Fig. 33) is used at each

cylinder. The coil mounts to the top of the valve cover

with 2 bolts (Fig. 34). The bottom of the coil is

equipped with a rubber boot to seal the spark plug to

the coil. Inside each rubber boot is a spring. The

spring is used for a mechanical contact between the

coil and the top of the spark plug.

(1) Depending on which coil is being removed, the

throttle body air intake tube or intake box may need

to be removed to gain access to coil.

(2) Unlock electrical connector (Fig. 34) by moving

slide lock first. Press on release lock (Fig. 34) while

pulling electrical connector from coil.

(3) Disconnect secondary high-voltage cable from

coil with a twisting action.

(4) Clean area at base of coil with compressed air

before removal.

(5) Remove 2 mounting bolts (note that mounting

bolts are retained to coil).

(6) Carefully pull up coil from cylinder head opening with a slight twisting action.

(7) Remove coil from vehicle.

(8) Before installing spark plug cables to either the

spark plugs or coils, or before installing a coil to a

spark plug, apply dielectric grease to inside of boots.

5.9L V-8

The coil is not oil filled. The coil windings are

embedded in an epoxy compound. This provides heat

and vibration resistance that allows the coil to be

mounted on the engine. If the coil is replaced, it must

be replaced with the same type.

5.9L V-8 LDC-Gas Engines: The coil is mounted to

a bracket that is bolted to the front of the right

engine cylinder head (Fig. 35). This bracket is

mounted on top of the automatic belt tensioner

bracket using common bolts.

Page 24

8I - 24 IGNITION CONTROL DR

IGNITION COIL (Continued)

WARNING: 5.9L V-8 LDC-GAS ENGINES: DO NOT

REMOVE THE COIL MOUNTING BRACKET-TO-CYLINDER HEAD MOUNTING BOLTS. THE COIL

MOUNTING BRACKET IS UNDER ACCESSORY

DRIVE BELT TENSION. IF THIS BRACKET IS TO BE

REMOVED FOR ANY REASON, ALL BELT TENSION

MUST FIRST BE RELIEVED. REFER TO THE BELT

SECTION OF GROUP 7, COOLING SYSTEM.

5.9L V-8 HDC-Gas Engine: The coil is mounted to

a bracket that is bolted to the air injection pump

(AIR pump) mounting bracket (Fig. 36).

(1) Disconnect primary coil connector from ignition

coil.

(2) Disconnect secondary cable from ignition coil.

(3) Remove ignition coil from coil mounting

bracket (two bolts).

8.0L V-10

Two separate coil packs containing a total of five

independent coils are attached to a common mounting bracket located above the right engine valve

cover (Fig. 37). The front and rear coil packs can be

serviced separately.

(1) Depending on which coil is being removed, the

throttle body air intake tube or intake box may need

to be removed to gain access to coils.

(2) Remove secondary spark plug cables from coil

packs. Note position of cables before removal.

(3) Disconnect primary wiring harness connectors

at coil packs.

(4) Remove four (4) coil pack-to-coil mounting

bracket bolts for coil pack being serviced (Fig. 37).

(5) Remove coil(s) from mounting bracket.

INSTALLATION

3.7L V-6

(1) Using compressed air, blow out any dirt or contaminants from around top of spark plug.

(2) Check condition of coil o-ring and replace as

necessary. To aid in coil installation, apply silicone to

coil o-ring.

(3) Position ignition coil into cylinder head opening

and push onto spark plug. Do this while guiding coil

base over mounting stud.

(4) Install coil mounting stud nut. Refer to torque

specifications.

(5) Connect electrical connector to coil by snapping

into position.

(6) If necessary, install throttle body air tube.

4.7L V-8

(1) Using compressed air, blow out any dirt or con-

taminants from around top of spark plug.

(2) Check condition of coil o-ring and replace as

necessary. To aid in coil installation, apply silicone to

coil o-ring.

(3) Position ignition coil into cylinder head opening

and push onto spark plug. Do this while guiding coil

base over mounting stud.

(4) Install coil mounting stud nut. Refer to torque

specifications.

(5) Connect electrical connector to coil by snapping

into position.

(6) If necessary, install throttle body air tube.

5.7L V-8

(1) Using compressed air, blow out any dirt or contaminants from around top of spark plug.

(2) Before installing spark plug cables to either the

spark plugs or coils, or before installing a coil to a

spark plug, apply dielectric grease to inside of boots.

(3) Position ignition coil into cylinder head opening

and push onto spark plug. Twist coil into position.

(4) Install 2 coil mounting bolts. Refer to torque

specifications.

(5) Connect electrical connector to coil by snapping

into position.

(6) Install cable to coil. To prevent ignition crossfire, spark plug cables MUST be placed in cable tray

(routing loom) into their original position. Refer to

Spark Plug Cable Removal for a graphic.

(7) If necessary, install throttle body air tube.

5.9L V-8

The ignition coil is an epoxy filled type. If the coil

is replaced, it must be replaced with the same type.

(1) Install ignition coil to coil bracket. If nuts and

bolts are used to secure coil to coil bracket, tighten to

11 N·m (100 in. lbs.) torque. If coil mounting bracket

has been tapped for coil mounting bolts, tighten bolts

to 5 N·m (50 in. lbs.) torque.

(2) Connect all wiring to ignition coil.

8.0L V-10

(1) Position coil packs to mounting bracket (primary wiring connectors face downward).

(2) Install coil pack mounting bolts. Tighten bolts

to 10 N·m (90 in. lbs.) torque.

(3) Install coil pack-to-engine mounting bracket (if

necessary).

(4) Connect primary wiring connectors to coil

packs (four wire connector to front coil pack and

three wire connector to rear coil pack).

(5) Connect secondary spark plug cables to coil

packs. Refer to (Fig. 38) for correct cable order.

Page 25

DR IGNITION CONTROL 8I - 25

IGNITION COIL (Continued)

(6)

If necessary, install throttle body air tube or box.

The voltage signal produced by the knock sensor

increases with the amplitude of vibration. The PCM

receives the knock sensor voltage signal as an input.

If the signal rises above a predetermined level, the

PCM will store that value in memory and retard

ignition timing to reduce engine knock. If the knock

sensor voltage exceeds a preset value, the PCM

retards ignition timing for all cylinders. It is not a

selective cylinder retard.

The PCM ignores knock sensor input during engine

idle conditions. Once the engine speed exceeds a

specified value, knock retard is allowed.

Knock retard uses its own short term and long

term memory program.

Long term memory stores previous detonation

information in its battery-backed RAM. The maximum authority that long term memory has over timing retard can be calibrated.

Short term memory is allowed to retard timing up

to a preset amount under all operating conditions (as

long as rpm is above the minimum rpm) except at

Wide Open Throttle (WOT). The PCM, using short

term memory, can respond quickly to retard timing

when engine knock is detected. Short term memory

is lost any time the ignition key is turned off.

Fig. 38 SPARK PLUG CABLE ORDER - 8.0L V-10

KNOCK SENSOR

DESCRIPTION

The sensors are used only with 3.7L V-6, 4.7L V-8

and 5.7L V-8 engines. On 3.7L V-6 and 4.7L V-8

engines, the 2 knock sensors are bolted into the cylinder block under the intake manifold.

On 5.7L V-8 engines, 2 knock sensors are also

used. These are bolted into each side of the cylinder

block (outside) under the exhaust manifold.

OPERATION

3.7L V-6 / 4.7L V-8 / 5.7L V-8 Engines Only

Two knock sensors are used; one for each cylinder

bank. When the knock sensor detects a knock in one

of the cylinders on the corresponding bank, it sends

an input signal to the Powertrain Control Module

(PCM). In response, the PCM retards ignition timing

for all cylinders by a scheduled amount.

Knock sensors contain a piezoelectric material

which constantly vibrates and sends an input voltage

(signal) to the PCM while the engine operates. As the

intensity of the crystal’s vibration increases, the

knock sensor output voltage also increases.

NOTE: Over or under tightening the sensor mounting bolts will affect knock sensor performance, possibly causing improper spark control. Always use

the specified torque when installing the knock sensors.

REMOVAL

3.7L V-6 / 4.7L V-8

The 2 knock sensors are bolted into the cylinder

block under the intake manifold (Fig. 39). or (Fig.

40).

NOTE: The left sensor is identified by an identification tag (LEFT). It is also identified by a larger bolt

head. The Powertrain Control Module (PCM) must

have and know the correct sensor left/right positions. Do not mix the sensor locations.

(1) Disconnect knock sensor dual pigtail harness

from engine wiring harness. This connection is made

near rear of engine.

(2) Remove intake manifold. Refer to Engine section.

(3) Remove sensor mounting bolts (Fig. 39), or

(Fig. 40). Note foam strip on bolt threads. This foam

is used only to retain the bolts to sensors for plant

assembly. It is not used as a sealant. Do not apply

any adhesive, sealant or thread locking compound to

these bolts.

Page 26

8I - 26 IGNITION CONTROL DR

KNOCK SENSOR (Continued)

(4) Remove sensors from engine. 5.7L V8

Two sensors are used. Each sensor is bolted into

the outside of cylinder block below the exhaust manifold (Fig. 41).

(1) Raise vehicle.

(2) Disconnect knock sensor electrical connector.

(3) Remove sensor mounting bolt (Fig. 41). Note

foam strip on bolt threads. This foam is used only to

retain the bolts to sensors for plant assembly. It is

not used as a sealant. Do not apply any adhesive,

sealant or thread locking compound to these bolts.

(4) Remove sensor from engine.

Fig. 39 KNOCK SENSOR — 3.7L V-6

1 - KNOCK SENSORS (2)

2 - MOUNTING BOLTS

Fig. 40 KNOCK SENSOR — 4.7L V-8

1 - KNOCK SENSORS (2)

2 - MOUNTING BOLTS

3 - INTAKE MANIFOLD (CUTAWAY)

4 - PIGTAIL CONNECTOR

Fig. 41 5.7L KNOCK SENSOR (RIGHT SENSOR

SHOWN)

1 - KNOCK SENSOR (RIGHT SENSOR SHOWN)

2 - MOUNTING BOLT

3 - EXHAUST MANIFOLD

4 - RIGHT ENGINE MOUNT

5 - ELEC. CONNECTOR

INSTALLATION

3.7L V-6 / 4.7L V-8

NOTE: The left sensor is identified by an identification tag (LEFT). It is also identified by a larger bolt

head. The Powertrain Control Module (PCM) must

have and know the correct sensor left/right positions. Do not mix the sensor locations.

(1) Thoroughly clean knock sensor mounting holes.

(2) Install sensors into cylinder block.

Page 27

DR IGNITION CONTROL 8I - 27

KNOCK SENSOR (Continued)

NOTE: Over or under tightening the sensor mounting bolts will affect knock sensor performance, possibly causing improper spark control. Always use

the specified torque when installing the knock sensors. The torque for the knock senor bolt is relatively light for an 8mm bolt.

NOTE: Note foam strip on bolt threads. This foam is

used only to retain the bolts to sensors for plant

assembly. It is not used as a sealant. Do not apply

any adhesive, sealant or thread locking compound

to these bolts.

(3) Install and tighten mounting bolts. Refer to

torque specification.

(4) Install intake manifold. Refer to Engine sec-

tion.

(5) Connect knock sensor wiring harness to engine

harness at rear of intake manifold.

5.7L V-8

(1) Thoroughly clean knock sensor mounting hole.

(2) Install sensor into cylinder block.

NOTE: Over or under tightening the sensor mounting bolts will affect knock sensor performance, possibly causing improper spark control. Always use

the specified torque when installing the knock sensors. The torque for the knock senor bolt is relatively light for an 8mm bolt.

NOTE: Note foam strip on bolt threads. This foam is

used only to retain the bolts to sensors for plant

assembly. It is not used as a sealant. Do not apply

any adhesive, sealant or thread locking compound

to these bolts.

(3) Install and tighten mounting bolt. Refer to

torque specification.

(4) Install electrical connector to sensor.

SPARK PLUG

DESCRIPTION

Resistor type spark plugs are used on all engines.

Sixteen spark plugs (2 per cylinder) are used with

5.7L V-8 engines.

DIAGNOSIS AND TESTING - SPARK PLUG

CONDITIONS

To prevent possible pre-ignition and/or mechanical

engine damage, the correct type/heat range/number

spark plug must be used.

Always use the recommended torque when tightening spark plugs. Incorrect torque can distort the

spark plug and change plug gap. It can also pull the

plug threads and do possible damage to both the

spark plug and the cylinder head.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken porcelain insulators. Keep plugs arranged in the order

in which they were removed from the engine. A single plug displaying an abnormal condition indicates

that a problem exists in the corresponding cylinder.

Replace spark plugs at the intervals recommended in

the Lubrication and Maintenance section.

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective, carbon or oil

fouled.

CAUTION: Never use a motorized wire wheel brush

to clean the spark plugs. Metallic deposits will

remain on the spark plug insulator and will cause

plug misfire.

Spark plug resistance values range from 6,000 to

20,000 ohms (when checked with at least a 1000 volt

spark plug tester). Do not use an ohmmeter to

check the resistance values of the spark plugs.

Inaccurate readings will result.

NORMAL OPERATING

The few deposits present on the spark plug will

probably be light tan or slightly gray in color. This is

evident with most grades of commercial gasoline

(Fig. 42). There will not be evidence of electrode

burning. Gap growth will not average more than

approximately 0.025 mm (.001 in) per 3200 km (2000

miles) of operation. Spark plugs that have normal

wear can usually be cleaned, have the electrodes

filed, have the gap set and then be installed.

Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)