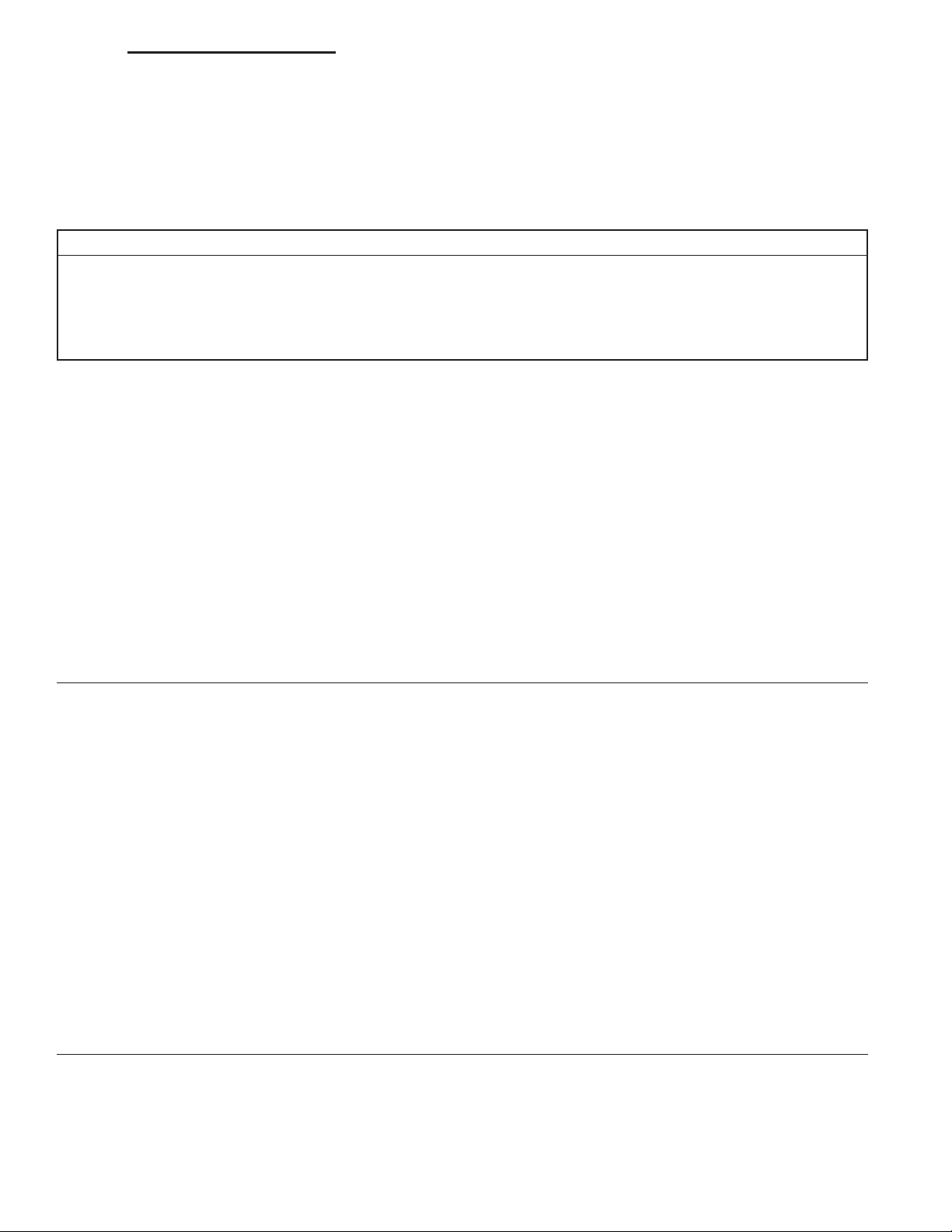

Dodge Differential Driveline 3500 2005, Differential Driveline 2500 2005, Differential Driveline 1500 2005 Service Manual

DR/DH DIFFERENTIAL & DRIVELINE 3 - 1

DIFFERENTIAL & DRIVELINE

TABLE OF CONTENTS

page page

DIFFERENTIAL & DRIVELINE - ELECTRICAL

DIAGNOSTICS ........................... 1

DIFFERENTIAL & DRIVELINE - SERVICE

INFORMATION.......................... 98

DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS

TABLE OF CONTENTS

page page

DIFFERENTIAL & DRIVELINE - ELECTRICAL

DIAGNOSTICS

DIAGNOSIS AND TESTING

C143A - DIFFERENTIAL/LOCKER SELECT

SWITCH PERFORMANCE ................2

C143B-DIFFERENTIAL/LOCKER SELECT

SWITCH CIRCUIT LOW ..................6

C143C-DIFFERENTIAL/LOCKER SELECT

SWITCH CIRCUIT HIGH.................10

C1418–FRONT DIFFERENTIAL CONTROL

CIRCUIT HIGH ........................14

C1419–FRONT DIFFERENTIAL CONTROL

CIRCUIT OPEN .......................18

C141E–REAR DIFFERENTIAL CONTROL

CIRCUIT HIGH ........................21

C141F–REAR DIFFERENTIAL CONTROL

CIRCUIT OPEN .......................25

C1446-FRONT DIFFERENTIAL RETURN

CIRCUIT LOW ........................28

C1447-FRONT DIFFERENTIAL RETURN

CIRCUIT HIGH ........................31

C144A-REAR DIFFERENTIAL RETURN

CIRCUIT LOW ........................35

C144B-REAR DIFFERENTIAL RETURN

CIRCUIT HIGH ........................38

C144E-FRONT DIFFERENTIAL POSITION

SENSOR PERFORMANCE...............42

C1450-FRONT DIFFERENTIAL POSITION

SENSOR CIRCUIT HIGH ................46

C144F-FRONT DIFFERENTIAL POSITION

SENSOR LOW ........................50

C1452-REAR DIFFERENTIAL POSITION

SENSOR PERFORMANCE...............53

C1453-REAR DIFFERENTIAL POSITION

SENSOR LOW ........................57

C1454-REAR DIFFERENTIAL POSITION

SENSOR CIRCUIT HIGH ................60

C2111- DIFFERENTIAL POSITION SENSOR

SUPPLY VOLTAGE CIRCUIT LOW .........64

C2112-DIFFERENTIAL POSITION SENSOR

SUPPLY VOLTAGE CIRCUIT HIGH.........68

C230F-LOCKER/DIFFERENTIAL INDICATOR

SUPPLY CIRCUIT PREFORMANCE ........72

C2310-STABILIZER/DIFFERENTIAL

INDICATOR SUPPLY CIRCUIT LOW........76

C2311-STABILIZER/DIFFERENTIAL

INDICATOR SUPPLY CIRCUIT HIGH .......80

C2314-DIFFERENTIAL INDICATOR

CONTROL CIRCUIT ....................85

CHECKING FRONT LOCKER SOLENOID

OPERATION .........................89

CHECKING REAR LOCKER SOLENOID

OPERATION .........................93

FDCM VERIFICATION TEST .............97

DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS

DIAGNOSIS AND TESTING

3 - 2 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR/DH

C143A - DIFFERENTIAL/LOCKER SELECT SWITCH PERFORMANCE

DR/DH DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 3

C143A - DIFFERENTIAL/LOCKER SELECT SWITCH PERFORMANCE (CONTINUED)

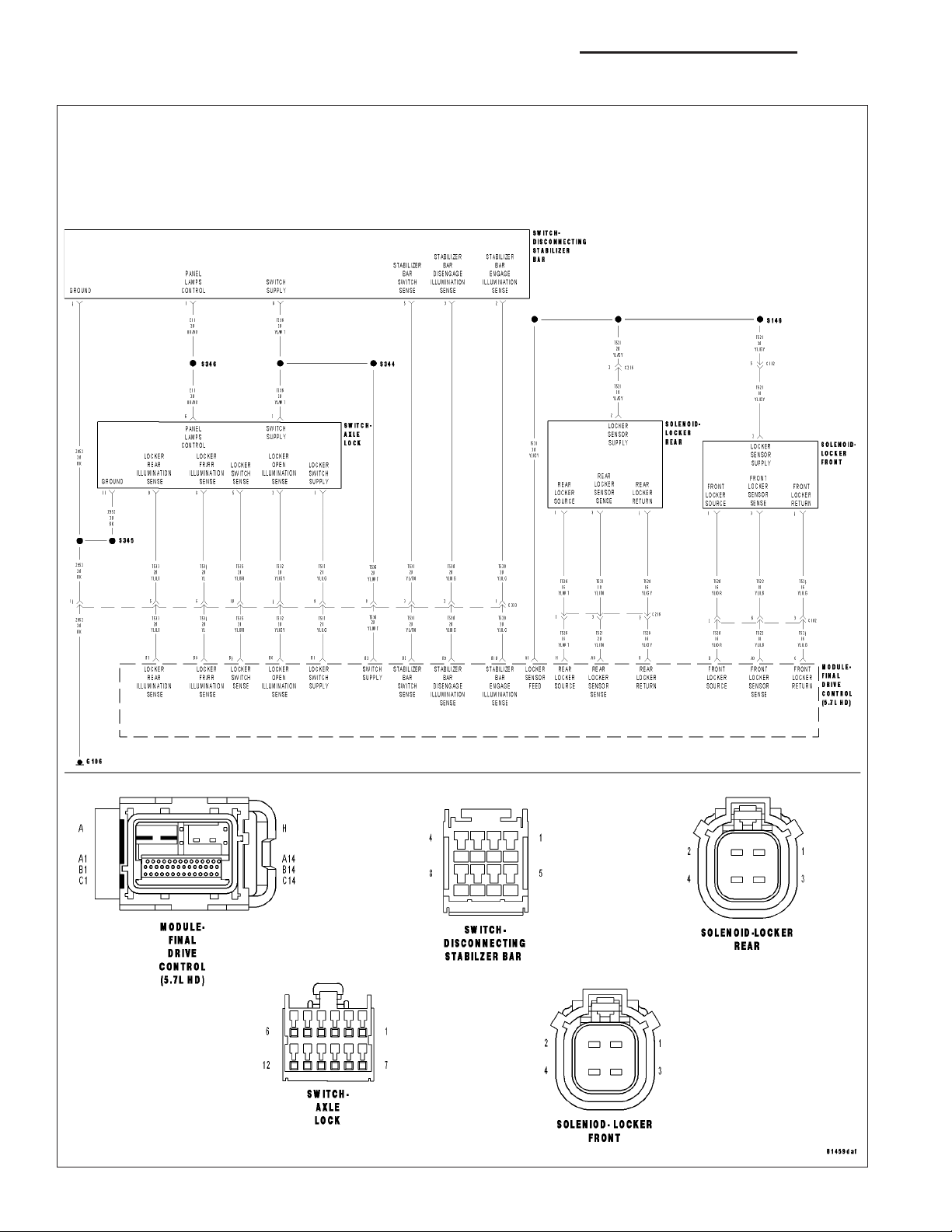

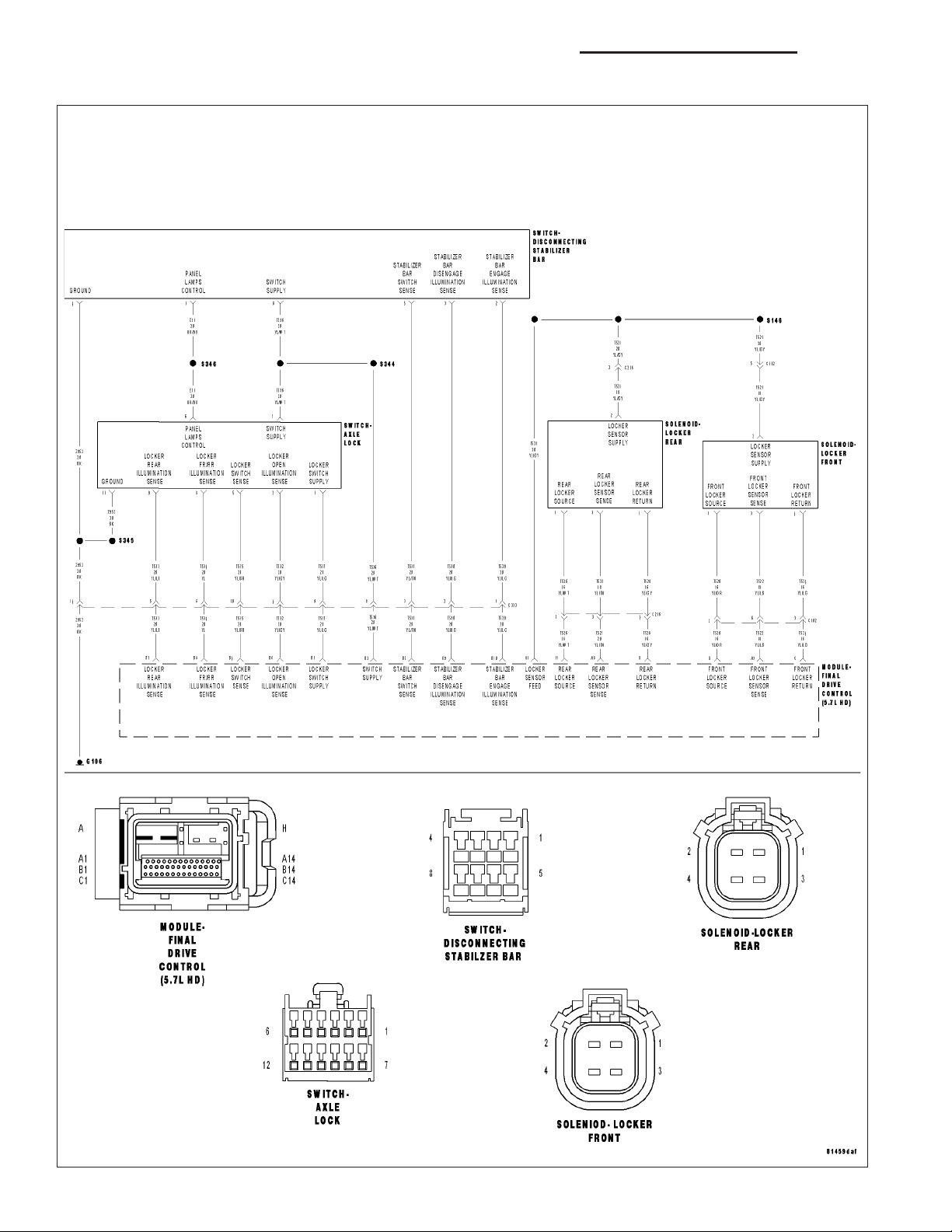

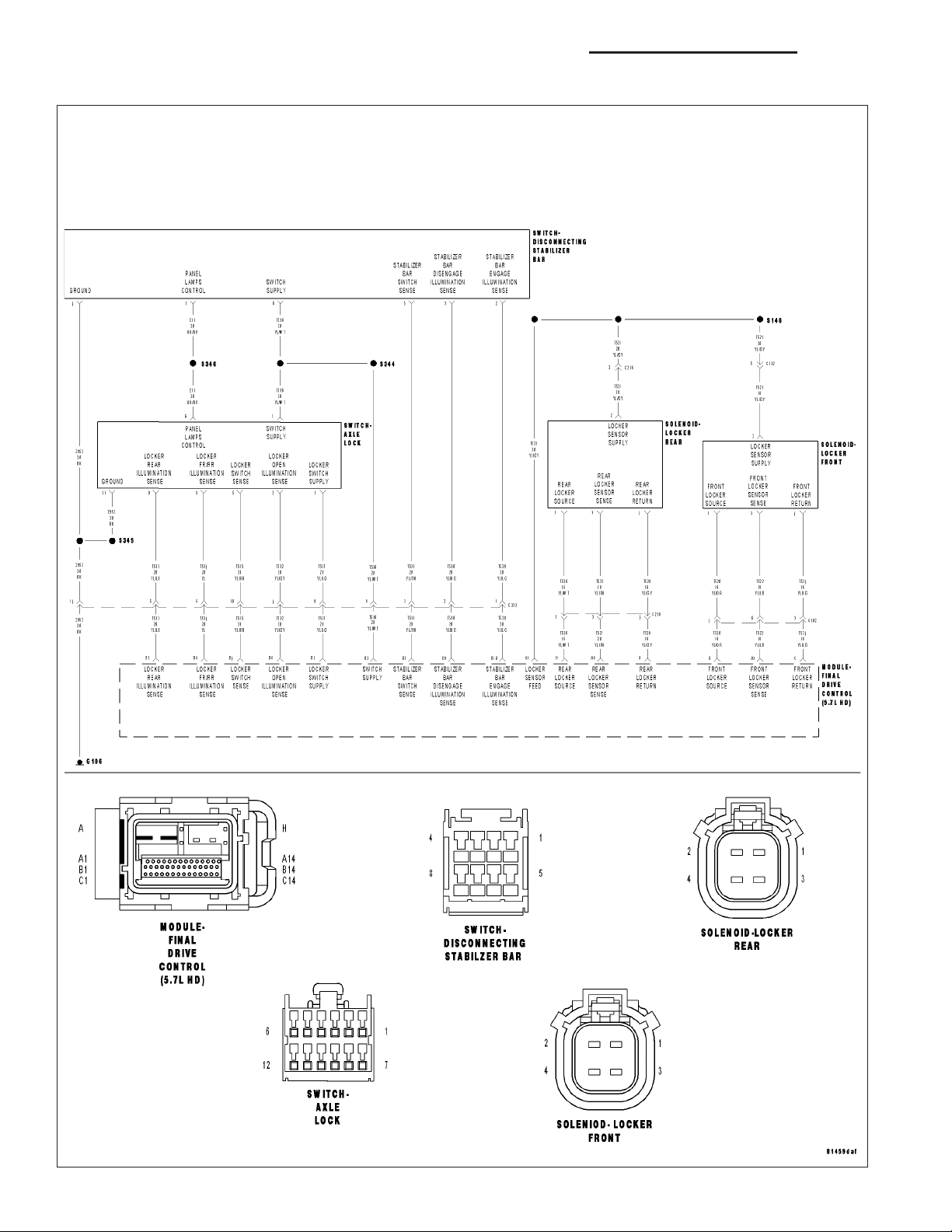

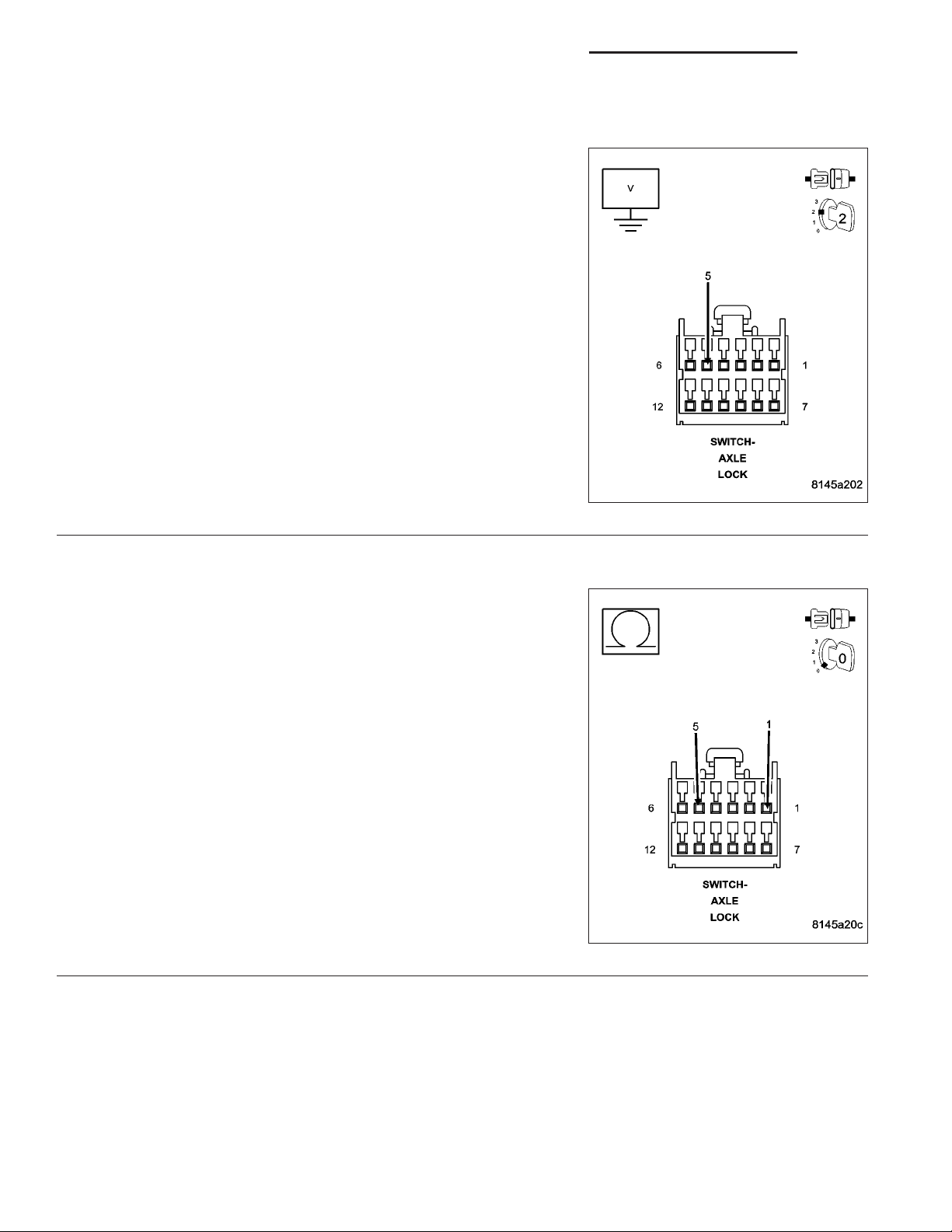

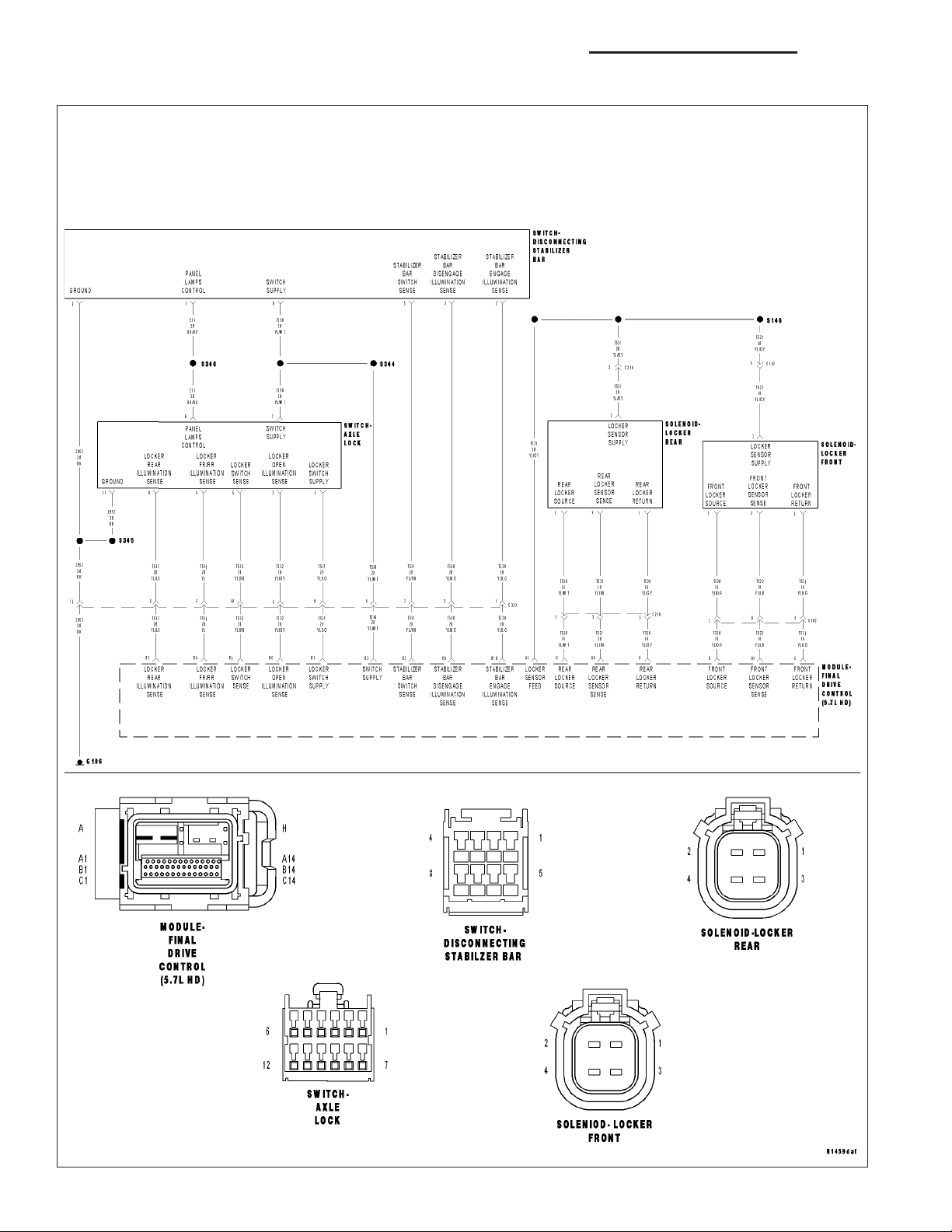

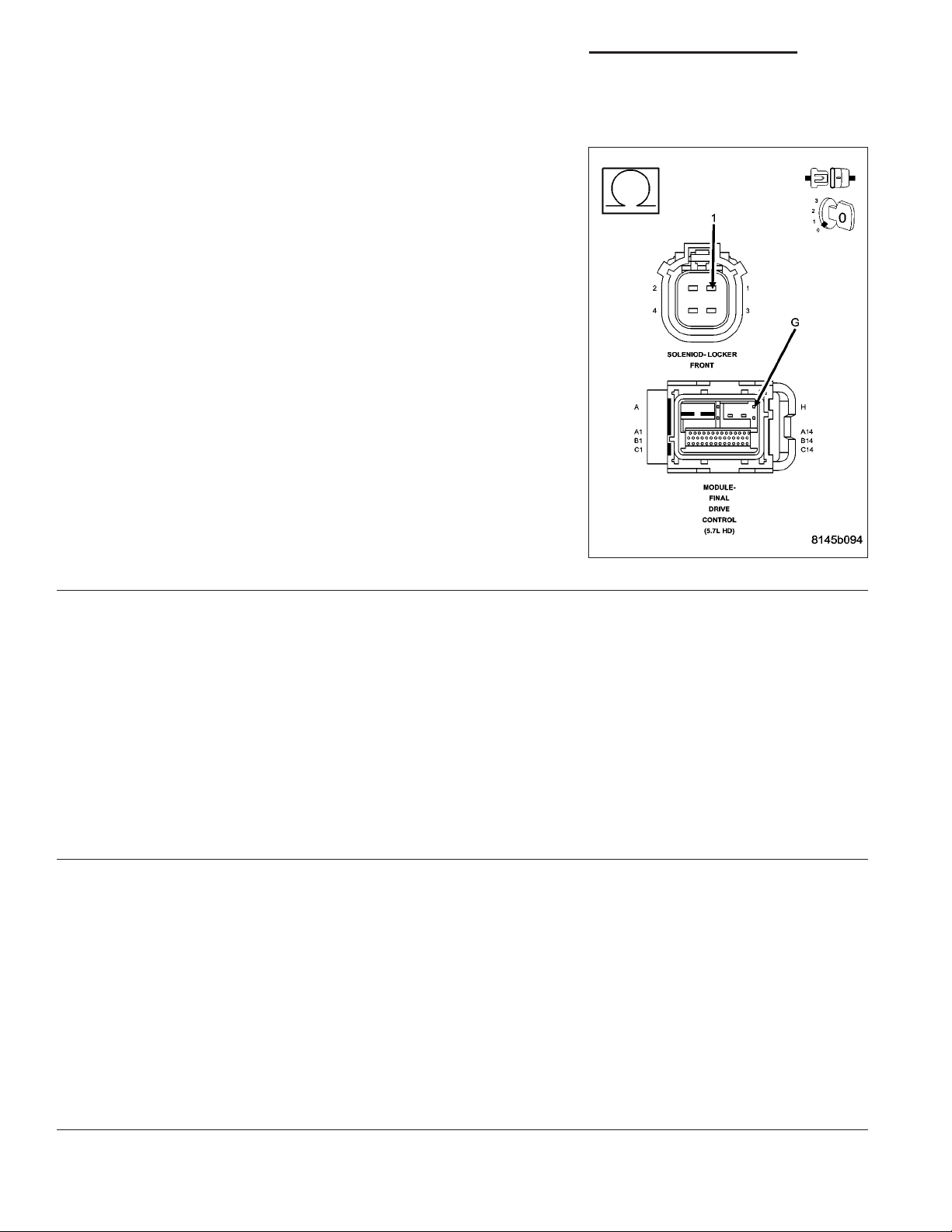

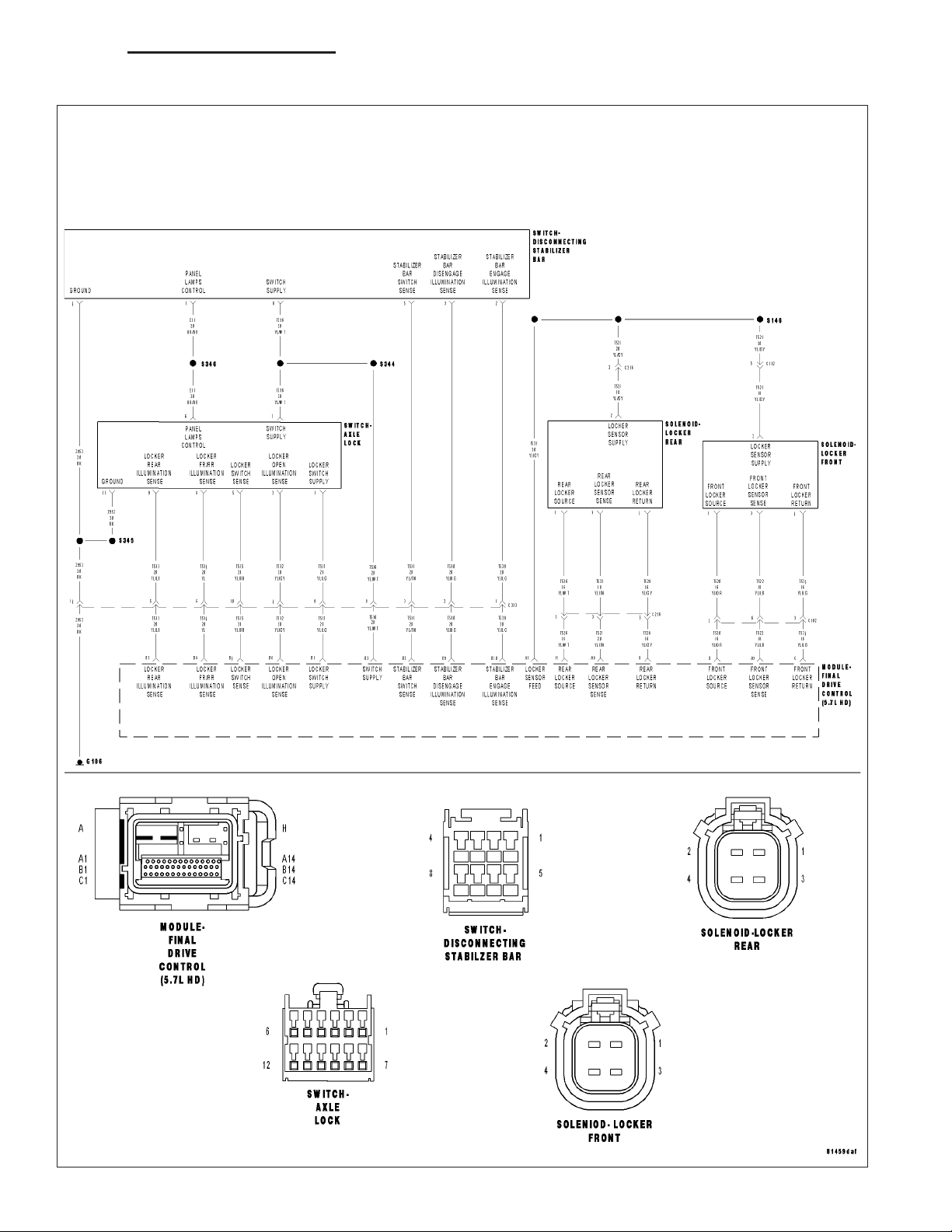

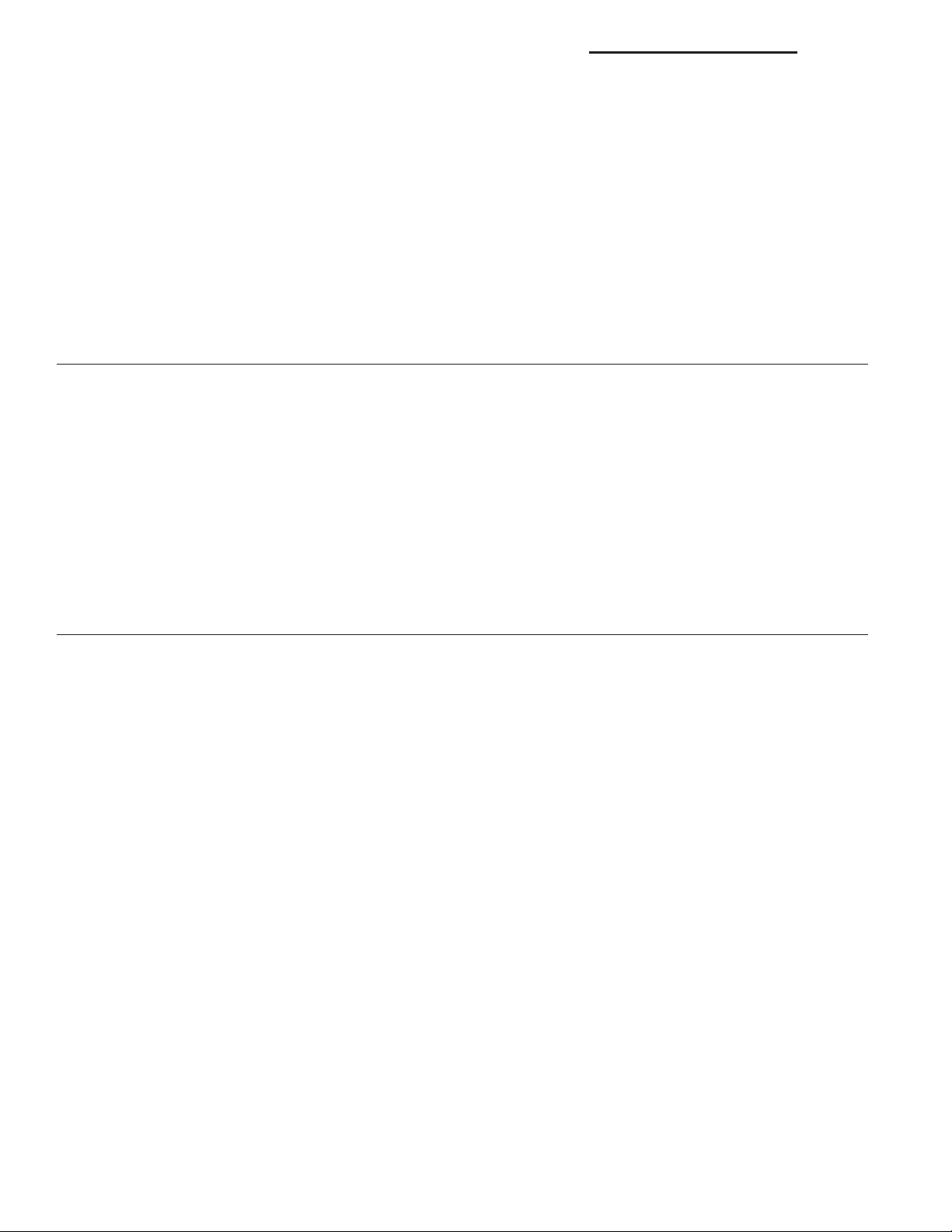

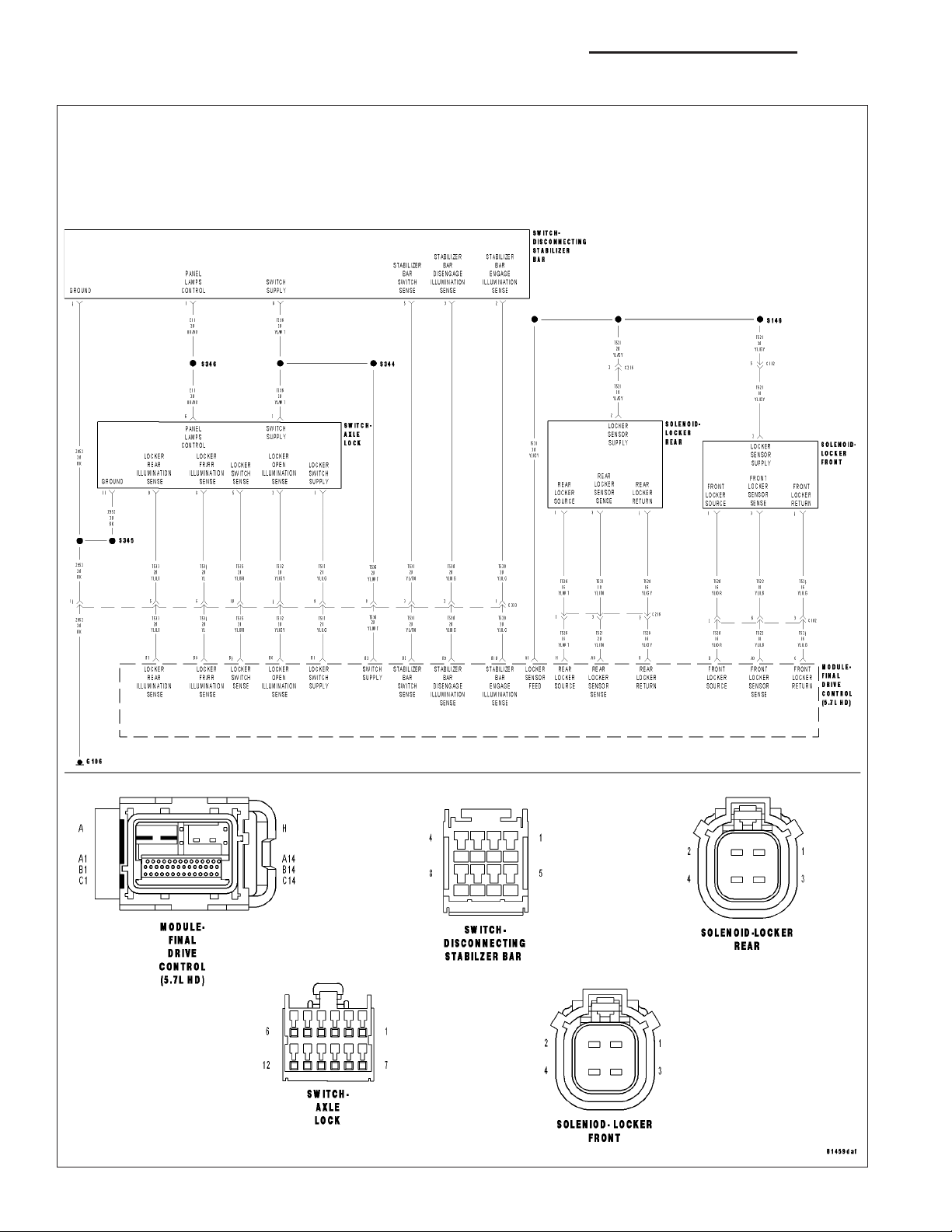

For a complete wiring diagram Refer to Section 8W

• When Monitored:

Ignition on.

• Set Condition:

During switch operation, the FDCM senses the Axle Locker Switch resistance is out of specification.

Possible Causes

SWITCH INTERMITTENT

ALXE LOCKER SWITCH

(T537) LOCKER SWITCH SUPPLY CIRCUIT

(T535) LOCKER SWITCH SENSE CIRCUIT OPEN/HIGH RESISTANCE

FDCM

DTC ACTIVE

1.

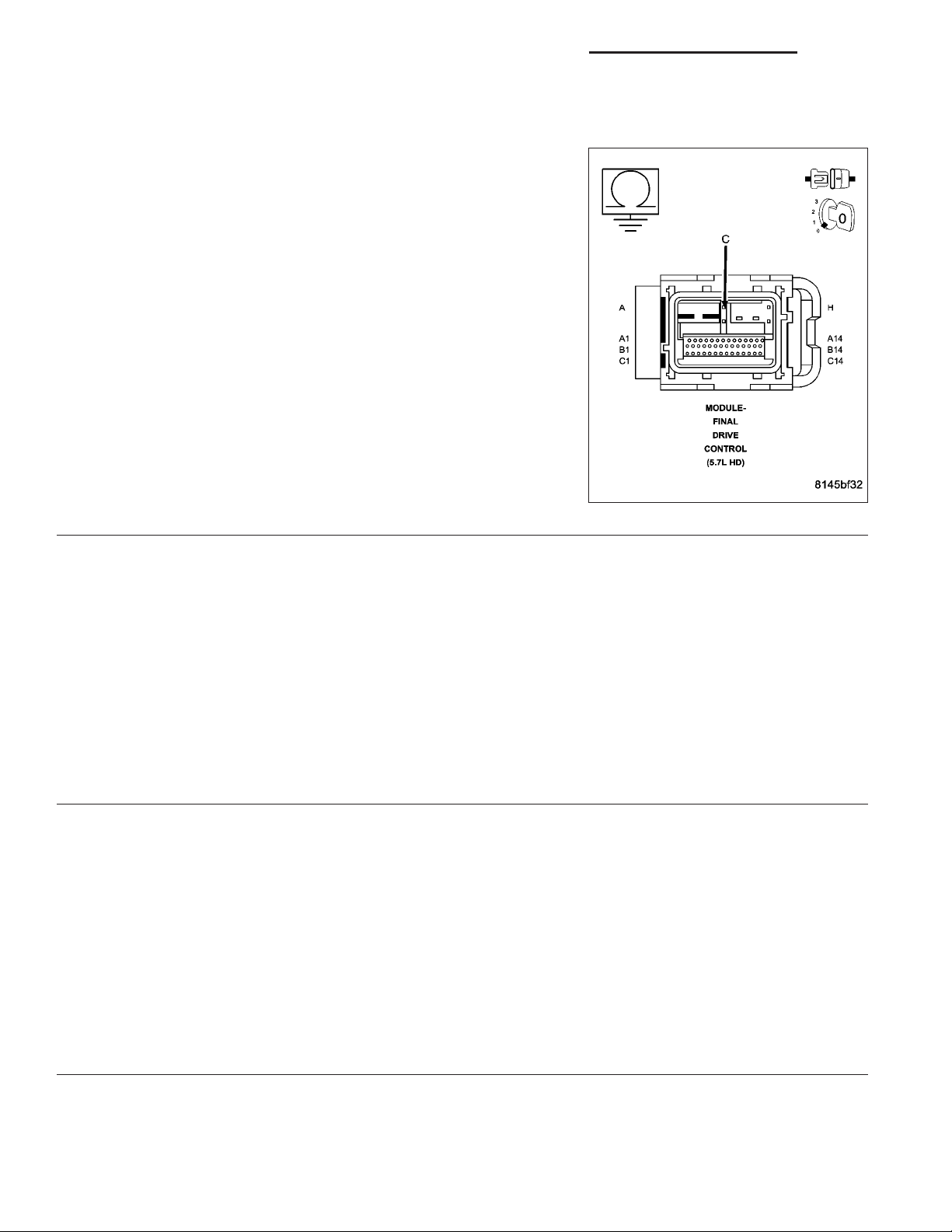

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Turn the ignition on, engine not running

With the DRBIIIT, read FDCM DTC(s).

Is the DTC active at this time?

Yes >>

No >>

AXLE LOCKER SWITCH OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

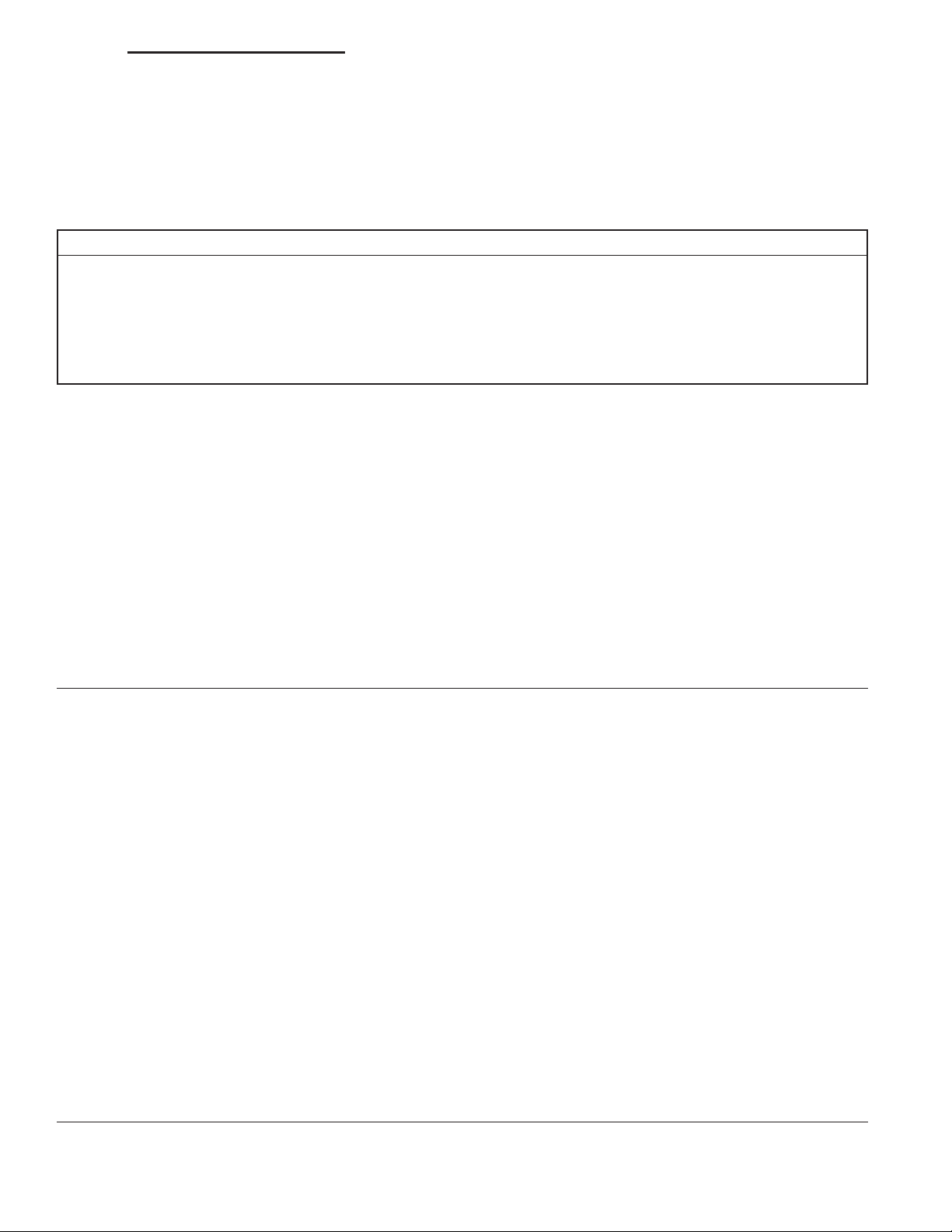

Disconnect the Axle Locker Switch harness connector.

Remove the Axle Locker Switch.

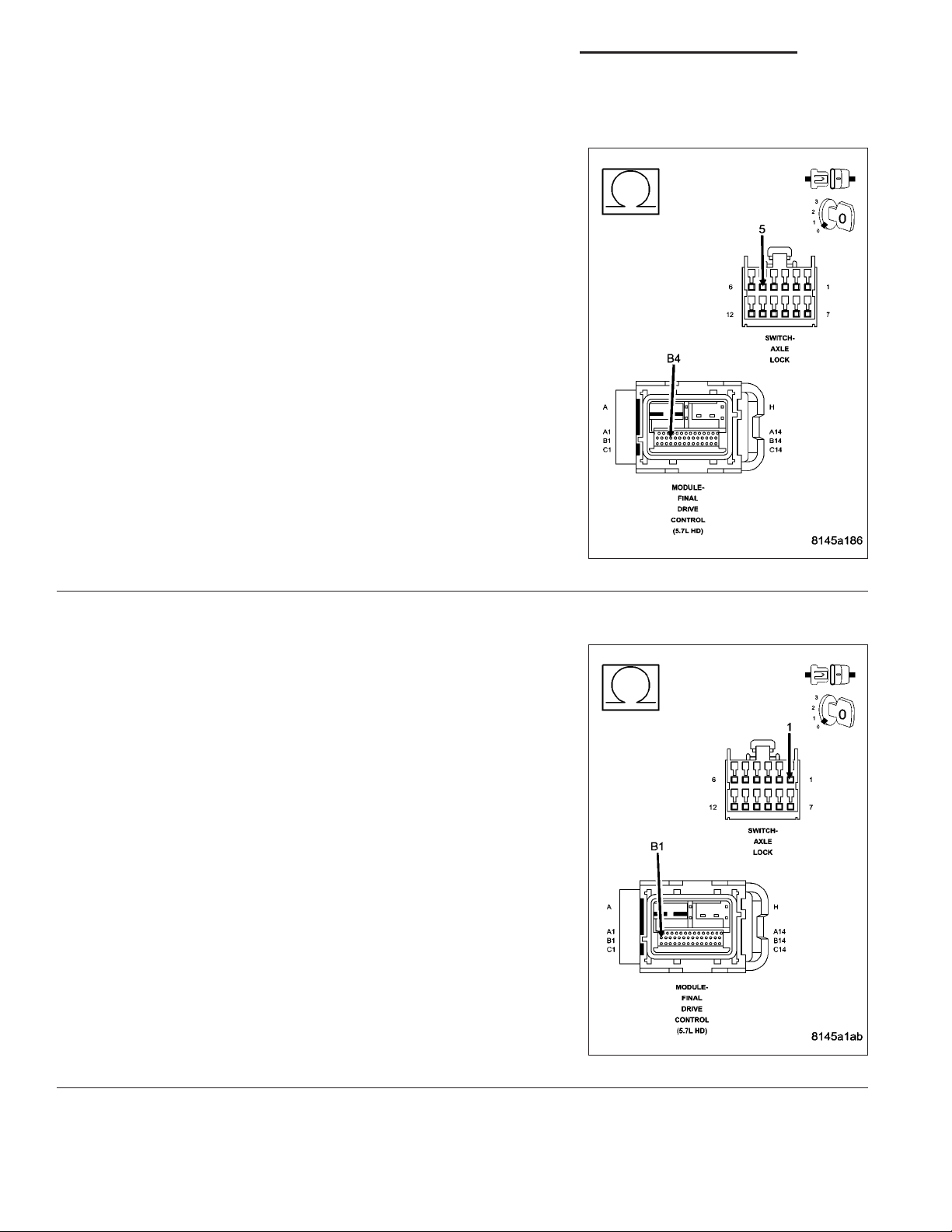

Measure the resistance on the Axle Locker Switch between the Locker Switch Supply terminal and the Locker

Switch Sense terminal.

The resistance must read as follows for each position of the switch.

• UNLOCK: 5454 ohms +/- 5%

• RR: 1940 ohms +/- 5%

• FR/RR: 1075 ohms +/- 5%

Does the ohmmeter read correctly for each position of the Axle Locker Switch

Yes >>

Go To 2

Go To 5

Go To 3

No >>

Replace the Axle Locker Switch.

Perform FDCM VERIFICATION TEST.

3 - 4 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR/DH

C143A - DIFFERENTIAL/LOCKER SELECT SWITCH PERFORMANCE (CONTINUED)

(T535) LOCKER SWITCH SENSE CIRCUIT OPEN

3.

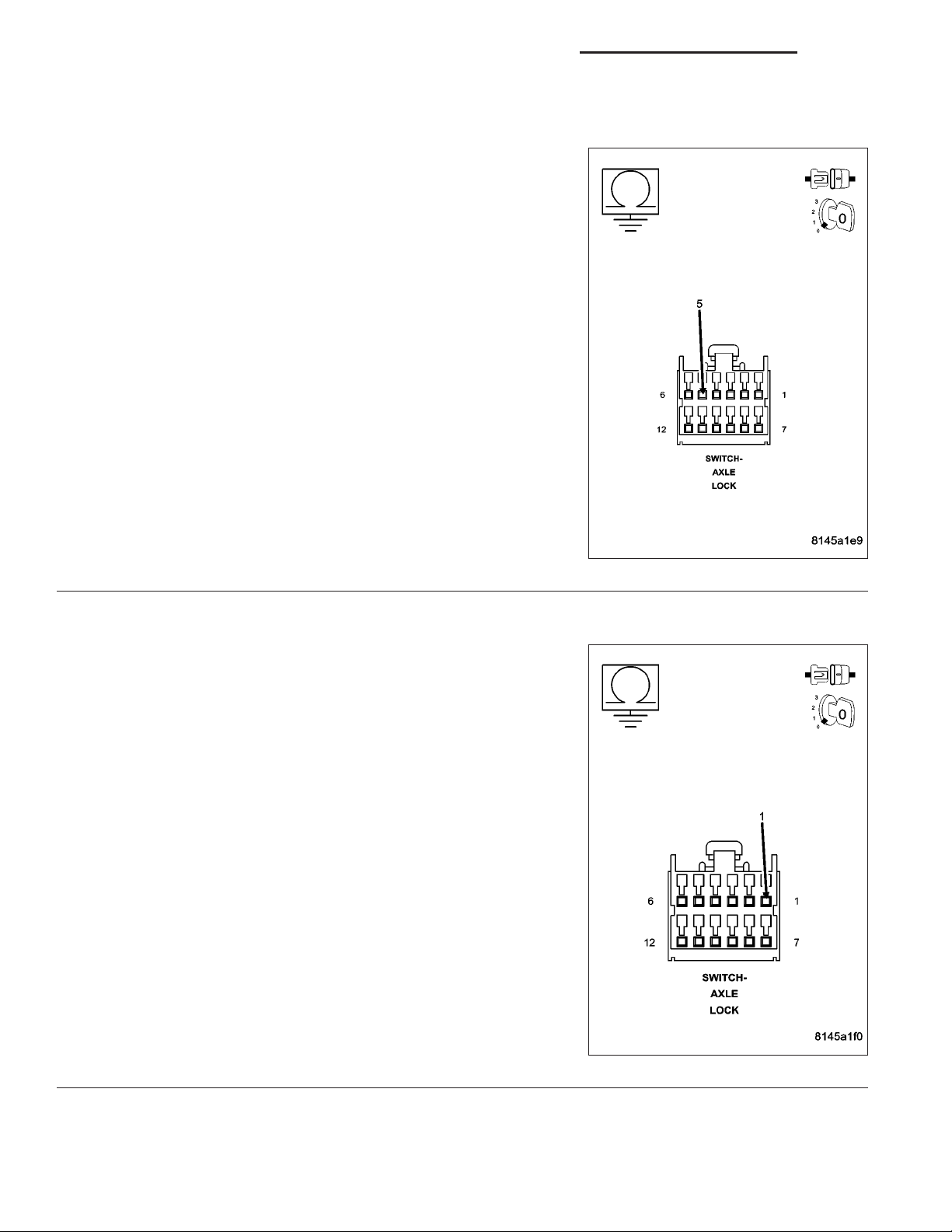

Disconnect the FDCM harness connector.

Measure the resistance of the (T535) Locker Switch Sense circuit

between the Axle Locker Switch and the FDCM harness connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

(537) LOCKER SWITCH SUPPLY CIRCUIT OPEN

4.

Measure the resistance of the (T537) Locker Switch Supply circuit

between the Axle Locker Switch and the FDCM harness connector.

Is the resistance below 5.0 ohms?

Go To 4

Repair the open or high resistance in the (T535) Locker

Switch Sense circuit.

Perform FDCM VERIFICATION TEST.

Yes >>

No >>

Replace the FDCM in accordance with the Service Information

Perform FDCM VERIFICATION TEST.

Repair the open or high resistance in the (T537) Locker

Switch Supply circuit.

Perform FDCM VERIFICATION TEST.

DR/DH DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 5

C143A - DIFFERENTIAL/LOCKER SELECT SWITCH PERFORMANCE (CONTINUED)

INTERMITTENT WIRING AND CONNECTORS

5.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the DRBIIIT, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

While monitoring the TRAC State on the DRBIIIT, move the switch to each position. The DRBIIIT display must

match the position on the actual switch.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform TRANSFER CASE VERIFICATION TEST.

Test Complete.

3 - 6 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR/DH

C143B-DIFFERENTIAL/LOCKER SELECT SWITCH CIRCUIT LOW

DR/DH DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 7

C143B-DIFFERENTIAL/LOCKER SELECT SWITCH CIRCUIT LOW (CONTINUED)

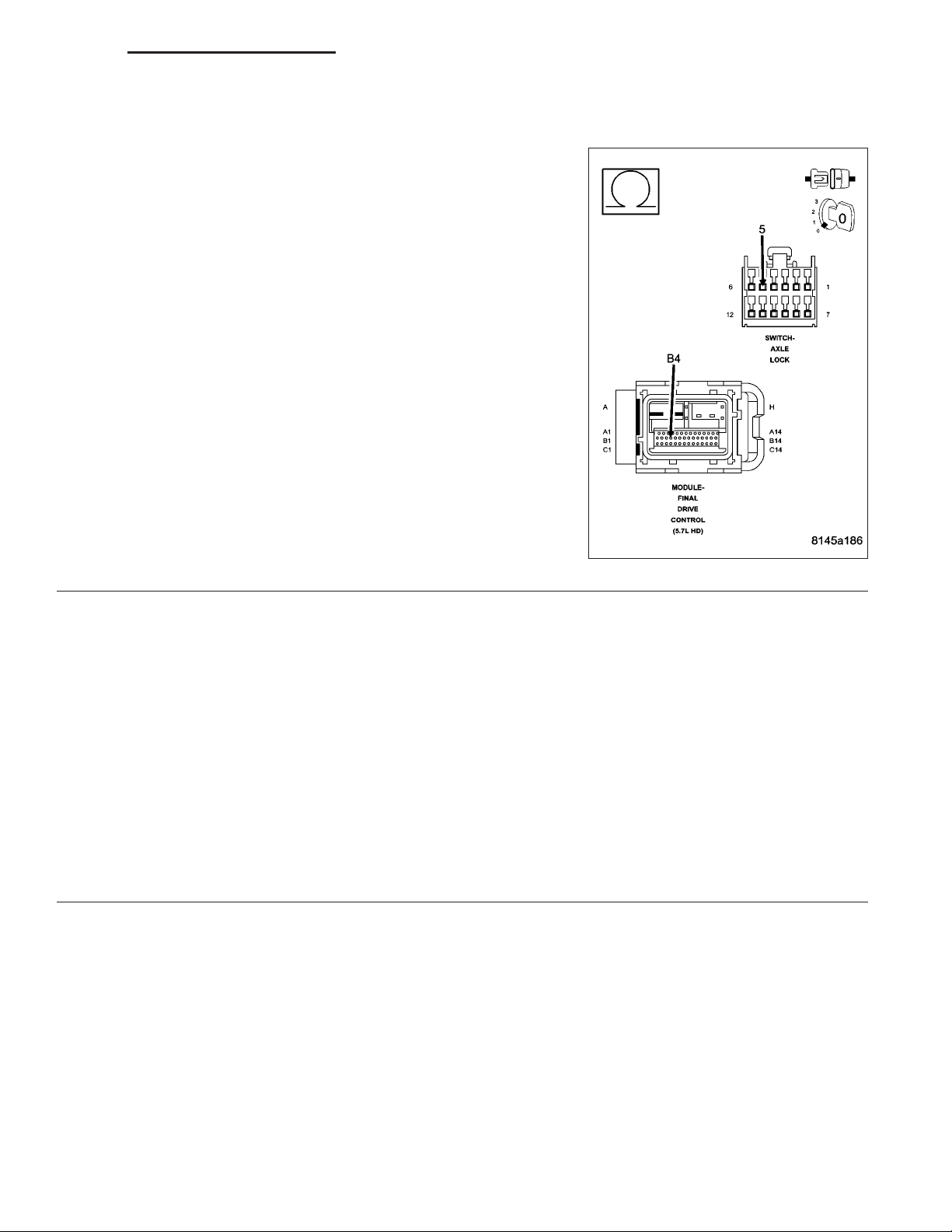

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Ignition on.

• Set Condition:

During switch operation, the FDCM senses the Axle Locker Switch sense is below 0.25 volt.

Possible Causes

SWITCH INTERMITTENT

ALXE LOCKER SWITCH

(T537) LOCKER SWITCH SUPPLY CIRCUIT SHORTED TO GROUND

(T535) LOCKER SWITCH SENSE CIRCUIT SHORT TO GROUND

FDCM

DTC ACTIVE

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Turn the ignition on, engine not running

With the DRBIIIT, read FDCM DTC(s).

Is the DTC active at this time?

Yes >>

No >>

AXLE LOCKER SWITCH OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Axle Locker Switch harness connector.

Remove the Axle Locker Switch.

Measure the resistance on the Axle Locker Switch between the Locker Switch Supply terminal and the Locker

Switch Sense terminal.

The resistance must read as follows for each position of the switch.

• UNLOCK: 5454 ohms +/- 5%

• RR: 1940 ohms +/- 5%

• FR/RR: 1075 ohms +/- 5%

Does the ohmmeter read correctly for each position of the Axle Locker Switch

Yes >>

Go To 2

Go To 5

Go To 3

No >>

Replace the Axle Locker Switch.

Perform FDCM VERIFICATION TEST.

3 - 8 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR/DH

C143B-DIFFERENTIAL/LOCKER SELECT SWITCH CIRCUIT LOW (CONTINUED)

(T535) LOCKER SWITCH SENSE CIRCUIT SHORTED TO GROUND

3.

Disconnect the FDCM harness connector.

Measure the resistance of the (T535) Locker Switch Sense circuit in

the Axle Locker Switch harness connector to ground.

Is the resistance below 100 ohms?

Yes >>

No >>

(T537) LOCKER SWITCH SUPPLY CIRCUIT SHORT TO GROUND

4.

Measure the resistance of the (T537) Locker Switch Supply circuit in

the Axle Locker Switch harness connector to ground.

Is the resistance below 100 ohms?

Repair the short to ground in the (T535) Locker Switch

Sense circuit.

Perform FDCM VERIFICATION TEST.

Go To 4

Yes >>

No >>

Repair the short to ground in the (T537) Locker Switch

Supply circuit.

Perform FDCM VERIFICATION TEST.

Replace the FDCM in accordance with the Service Infor-

mation

Perform FDCM VERIFICATION TEST.

DR/DH DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 9

C143B-DIFFERENTIAL/LOCKER SELECT SWITCH CIRCUIT LOW (CONTINUED)

INTERMITTENT WIRING AND CONNECTORS

5.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the DRBIIIT, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

While monitoring the TRAC State on the DRBIIIT, move the switch to each position. The DRBIIIT display must

match the position on the actual switch.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform TRANSFER CASE VERIFICATION TEST.

Test Complete.

3 - 10 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR/DH

C143C-DIFFERENTIAL/LOCKER SELECT SWITCH CIRCUIT HIGH

DR/DH DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 11

C143C-DIFFERENTIAL/LOCKER SELECT SWITCH CIRCUIT HIGH (CONTINUED)

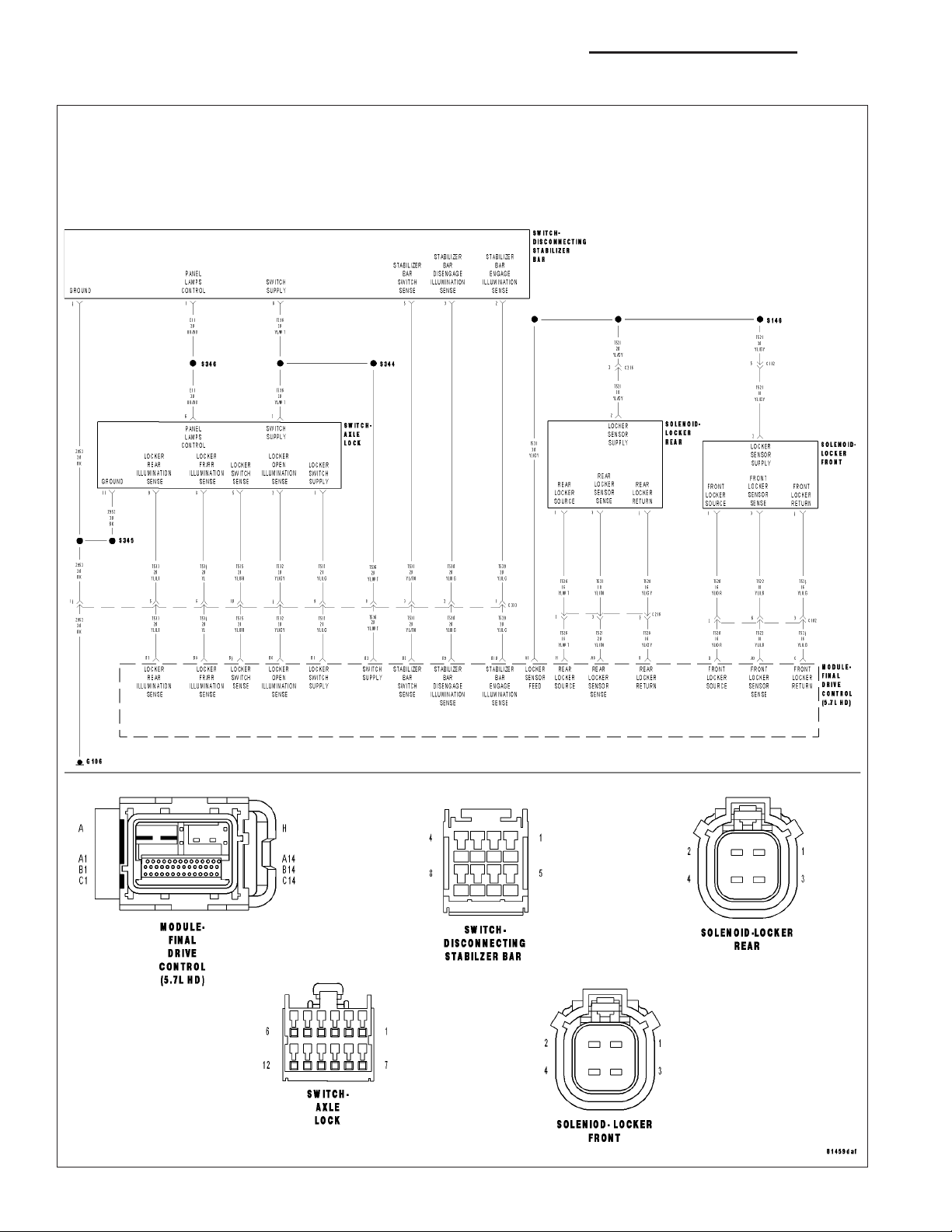

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Ignition on.

• Set Condition:

During switch operation, the FDCM senses the Axle Locker Switch Sense circuit is above 4.5 volts.

Possible Causes

SWITCH INTERMITTENT

ALXE LOCKER SWITCH

(T535) LOCKER SWITCH SENSE CIRCUIT SHORT TO VOLTAGE

(T537) LOCKER SWITCH SUPPLY CIRCUIT SHORTED TO (T535) LOCKER SWITCH SENSE CIRCUIT

(T535) LOCKER SWITCH SENSE CIRCUIT OPEN

FDCM

DTC ACTIVE

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Turn the ignition on, engine not running

With the DRBIIIT, read FDCM DTC(s).

Is the DTC active at this time?

Yes >>

No >>

AXLE LOCKER SWITCH OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Axle Locker Switch harness connector.

Remove the Axle Locker Switch.

Measure the resistance on the Axle Locker Switch between the Locker Switch Supply terminal and the Locker

Switch Sense terminal.

The resistance must read as follows for each position of the switch.

• UNLOCK: 5454 ohms +/- 5%

• RR: 1940 ohms +/- 5%

• FR/RR: 1075 ohms +/- 5%

Does the ohmmeter read correctly for each position of the Axle Locker Switch

Yes >>

Go To 2

Go To 6

Go To 5

No >>

Replace the Axle Locker Switch.

Perform FDCM VERIFICATION TEST.

3 - 12 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR/DH

C143C-DIFFERENTIAL/LOCKER SELECT SWITCH CIRCUIT HIGH (CONTINUED)

(T535) LOCKER SWITCH SENSE CIRCUIT SHORTED TO VOLTAGE

3.

Disconnect the FDCM harness connector.

Turn the ignition on.

Measure the voltage of the (T535) Locker Switch Sense circuit in the

Axle Locker Switch harness connector.

Does the voltmeter indicate voltage present?

Yes >>

No >>

(T537) LOCKER SWITCH SUPPLY CIRCUIT SHORTED TO (T535) LOCKER SWITCH SENSE CIRCUIT

4.

Measure the resistance between (T537) Locker Switch Supply circuit

and the (T535) Locker Switch Sense circuit in the Axle Locker Switch

harness connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Repair the short to voltage in the (T535) Locker Switch

Sense circuit.

Perform FDCM VERIFICATION TEST.

Go To 4

Repair the short between (T537) Locker Switch Supply circuit and the (T535) Locker Switch Sense circuit.

Perform FDCM VERIFICATION TEST.

Go To 5

DR/DH DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 13

C143C-DIFFERENTIAL/LOCKER SELECT SWITCH CIRCUIT HIGH (CONTINUED)

(T535) LOCKER SWITCH SENSE CIRCUIT OPEN

5.

Measure the resistance of the (T535) Locker Switch Sense circuit

between the Axle Locker Switch and the FDCM harness connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

INTERMITTENT WIRING AND CONNECTORS

6.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the DRBIIIT, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

While monitoring the TRAC State on the DRBIIIT, move the switch to each position. The DRBIIIT display must

match the position on the actual switch.

Replace the FDCM in accordance with the Service Information.

Perform FDCM VERIFICATION TEST.

Repair the open in the (T535) Locker Switch Sense circuit.

Perform FDCM VERIFICATION TEST.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform TRANSFER CASE VERIFICATION TEST.

Test Complete.

3 - 14 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR/DH

C1418–FRONT DIFFERENTIAL CONTROL CIRCUIT HIGH

DR/DH DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 15

C1418–FRONT DIFFERENTIAL CONTROL CIRCUIT HIGH (CONTINUED)

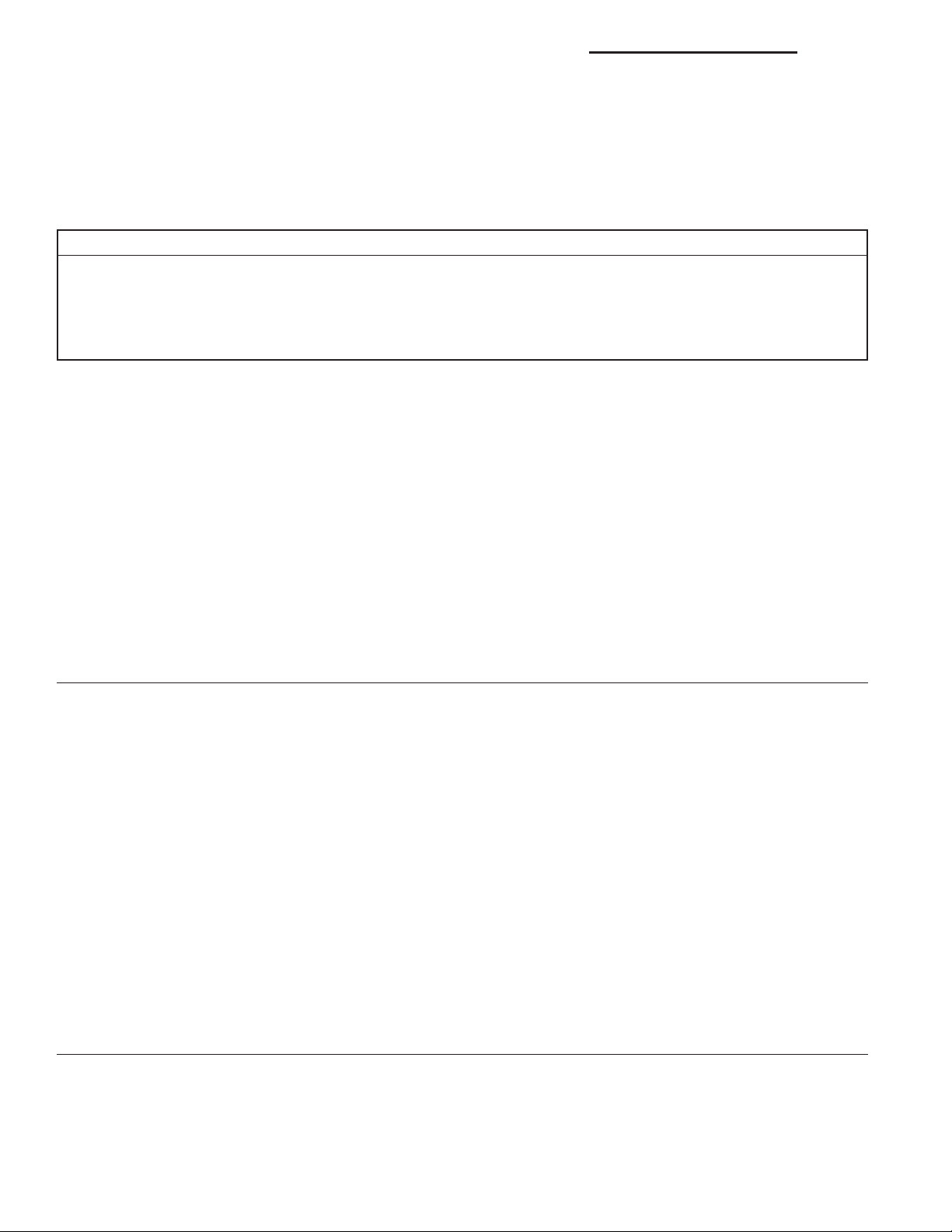

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Ignition on. Axle Locker Switch in the FR/RR position.

• Set Condition:

The FDCM detects the Front Locker Source circuit is shorted high.

Possible Causes

FRONT LOCKER SOLENOID

(T520) FRONT LOCKER SOURCE CIRCUIT SHORTED TO BATTERY VOLTAGE

(T524) FRONT LOCKER RETURN CIRCUIT OPEN

FDCM

Diagnostic Test

ACTIVE DTC

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Ignition on, engine not running.

With the DRBIIIT, read DTCs.

Is the DTC active at this time?

Yes >>

No >>

FRONT LOCKER SOLENOID OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Front Locker Solenoid harness connector.

Ignition on, engine not running.

Using a 12-volt test light, jump across from the (T520) Front Locker Source circuit and the (T524) Front Locker

Return circuit in the Front Locker harness connector.

With a DRBIIIT, actuate the Front Locker Solenoid.

Does the test light flash on and off?

Yes >>

No >>

Go To 2

Go To 6

Inspect the Front Locker Solenoid terminals and connectors for corrosion and/or dirty that may compromise the connection. If OK, replace the Front Locker Solenoid.

Perform FDCM VERIFICATION TEST.

Go To 3

3 - 16 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR/DH

C1418–FRONT DIFFERENTIAL CONTROL CIRCUIT HIGH (CONTINUED)

(T520) FRONT LOCKER SOURCE CIRCUIT SHORTED TO BATTERY VOLTAGE

3.

Turn the ignition off.

Disconnect the FDCM harness connector.

Turn the ignition on.

Measure the voltage on the (T520) Front Locker Source circuit at the

FDCM harness connector.

Does the voltmeter indicate voltage present?

Yes >>

No >>

(T524) FRONT LOCKER RETURN CIRCUIT OPEN

4.

Measure the resistance of the (T524) Front Locker Return circuit form

the in the Front Locker Solenoid harness connector and the FDCM

harness connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Repair the short to voltage in the (T520) Front Locker

Source circuit.

Perform FDCM VERIFICATION TEST.

Go To 4

Go To 5

Repair the open in the (T524) Front Locker Return circuit.

Perform FDCM VERIFICATION TEST

DR/DH DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 17

C1418–FRONT DIFFERENTIAL CONTROL CIRCUIT HIGH (CONTINUED)

FDCM

5.

NOTE: Before continuing, check the FDCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Yes >>

No >>

INTERMITTENT WIRING AND CONNECTORS

6.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the DRBIIIT, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST

Replace and program the Final Drive Control Module in accordance with Service Information.

Perform FDCM VERIFICATION TEST.

Repair as necessary.

Perform FDCM VERIFICATION TEST.

Test Complete.

3 - 18 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR/DH

C1419–FRONT DIFFERENTIAL CONTROL CIRCUIT OPEN

DR/DH DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 19

C1419–FRONT DIFFERENTIAL CONTROL CIRCUIT OPEN (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Ignition on. Axle Locker Switch in the FR/RR position.

• Set Condition:

The FDCM detects the Front Locker Source circuit is open.

Possible Causes

FRONT LOCKER SOLENOID

(T520) FRONT LOCKER SOURCE CIRCUIT OPEN

FDCM

Diagnostic Test

ACTIVE DTC

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Ignition on, engine not running.

With the DRBIIIT, read DTCs.

Is the DTC active at this time?

Yes >>

No >>

FRONT LOCKER SOLENOID OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Front Locker Solenoid harness connector.

Ignition on, engine not running.

Using a 12-volt test light, jump across from the (T520) Front Locker Source circuit and the (T524) Front Locker

Return circuit in the Front Locker harness connector.

With a DRBIIIT, actuate the Front Locker Solenoid.

Does the test light flash on and off?

Yes >>

No >>

Go To 2

Go To 5

Inspect the Front Locker Solenoid terminals and connectors for corrosion and/or dirty that may compromise the connection. If OK, replace the Front Locker Solenoid.

Perform FDCM VERIFICATION TEST.

Go To 3

3 - 20 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR/DH

C1419–FRONT DIFFERENTIAL CONTROL CIRCUIT OPEN (CONTINUED)

(T520) FRONT LOCKER SOURCE CIRCUIT OPEN

3.

Turn the ignition off.

Disconnect the FDCM harness connector.

Turn the ignition on.

Measure the resistance of the (T520) Front Locker Source circuit from

the FDCM harness connector and the Front Locker Solenoid harness

connector.

Is the resistances below 5.0 ohms?

Yes >>

No >>

FDCM

4.

NOTE: Before continuing, check the FDCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Go To 4

Repair the open in the Front Locker Source circuit.

Perform FDCM VERIFICATION TEST.

Yes >>

No >>

INTERMITTENT WIRING AND CONNECTORS

5.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the DRBIIIT, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST

Replace and program the Final Drive Control Module in accordance with Service Information.

Perform FDCM VERIFICATION TEST.

Repair as necessary.

Perform FDCM VERIFICATION TEST.

Test Complete.

DR/DH DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 21

C141E–REAR DIFFERENTIAL CONTROL CIRCUIT HIGH

3 - 22 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR/DH

C141E–REAR DIFFERENTIAL CONTROL CIRCUIT HIGH (CONTINUED)

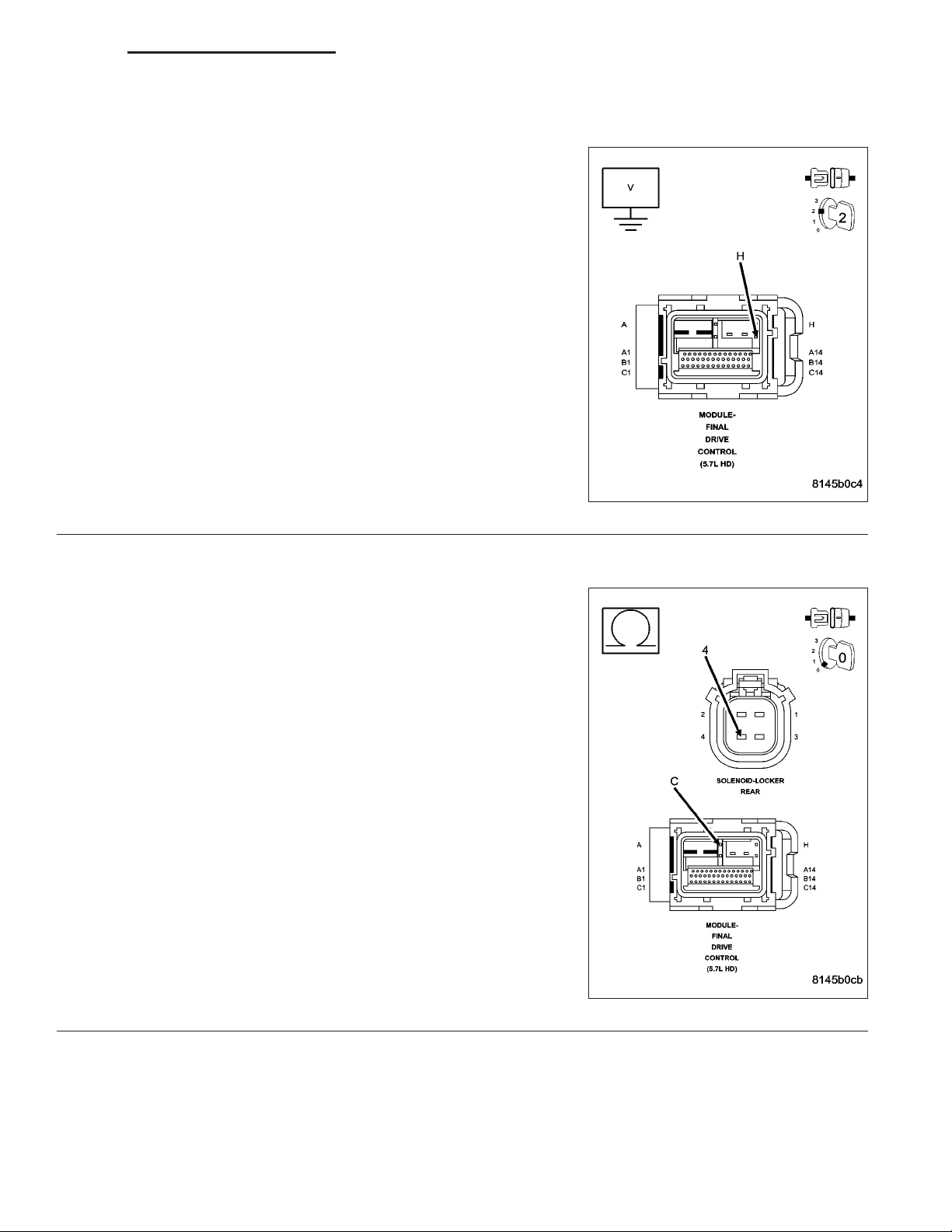

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Ignition on. Axle Locker Switch in the FR/RR position.

• Set Condition:

The FDCM detects the Rear Locker Source circuit is shorted high.

Possible Causes

REAR LOCKER SOLENOID

(T526) REAR LOCKER SOURCE CIRCUIT SHORTED TO BATTERY VOLTAGE

(T528) REAR LOCKER RETURN CIRCUIT OPEN

FDCM

Diagnostic Test

ACTIVE DTC

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Ignition on, engine not running.

With the DRBIIIT, read DTCs.

Is the DTC active at this time?

Yes >>

No >>

REAR LOCKER SOLENOID OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Rear Locker Solenoid harness connector.

Ignition on, engine not running.

Using a 12-volt test light, jump across from the (T526) Rear Locker Source circuit and the (T528) Rear Locker

Return circuit in the Rear Locker harness connector.

With a DRBIIIT, actuate the Rear Locker Solenoid.

Does the test light flash on and off?

Yes >>

No >>

Go To 2

Go To 6

Inspect the Rear Locker Solenoid terminals and connectors for corrosion and/or dirty that may compromise the connection. If OK, replace the Rear Locker Solenoid.

Perform FDCM VERIFICATION TEST.

Go To 3

DR/DH DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 23

C141E–REAR DIFFERENTIAL CONTROL CIRCUIT HIGH (CONTINUED)

(T526) REAR LOCKER SOURCE CIRCUIT SHORTED TO BATTERY VOLTAGE

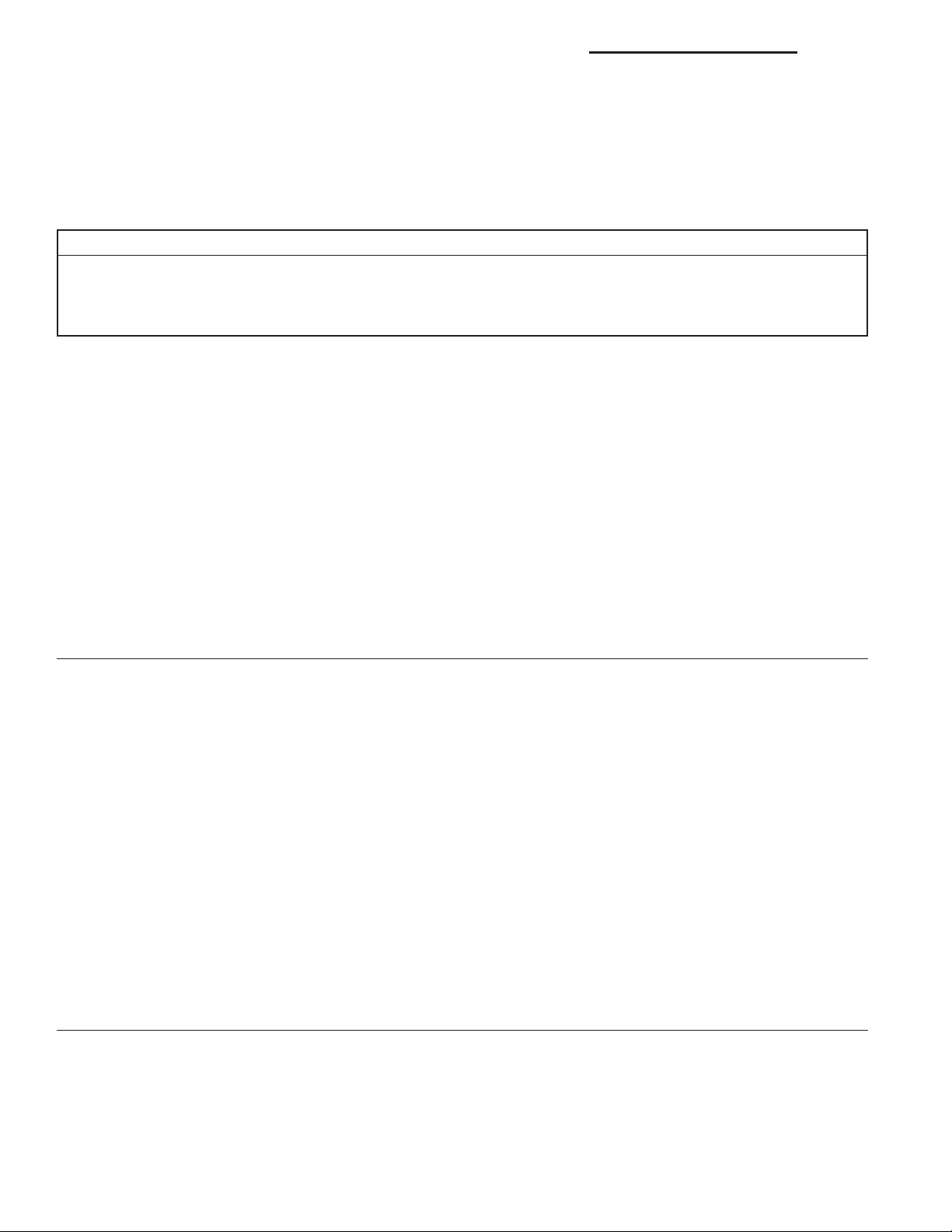

3.

Turn the ignition off.

Disconnect the FDCM harness connector.

Turn the ignition on.

Measure the voltage on the (T526) Rear Locker Source circuit at the

FDCM harness connector.

Does the voltmeter indicate voltage present?

Yes >>

No >>

(T528) REAR LOCKER RETURN CIRCUIT OPEN

4.

Measure the resistance of the (T528) Rear Locker Return circuit form

the in the Rear Locker Solenoid harness connector and the FDCM

harness connector.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Repair the short to voltage in the Rear Locker Source circuit.

Perform FDCM VERIFICATION TEST.

Go To 4

Go To 5

Repair the open in the (T528) Rear Locker Return circuit.

Perform FDCM VERIFICATION TEST

3 - 24 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR/DH

C141E–REAR DIFFERENTIAL CONTROL CIRCUIT HIGH (CONTINUED)

FDCM

5.

NOTE: Before continuing, check the FDCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Yes >>

No >>

INTERMITTENT WIRING AND CONNECTORS

6.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the DRBIIIT, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST

Replace and program the Final Drive Control Module in accordance with Service Information.

Perform FDCM VERIFICATION TEST.

Repair as necessary.

Perform FDCM VERIFICATION TEST.

Test Complete.

DR/DH DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 25

C141F–REAR DIFFERENTIAL CONTROL CIRCUIT OPEN

3 - 26 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR/DH

C141F–REAR DIFFERENTIAL CONTROL CIRCUIT OPEN (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Ignition on. Axle Locker Switch in the FR/RR position.

• Set Condition:

The FDCM detects the Rear Locker Source circuit is open.

Possible Causes

REAR LOCKER SOLENOID

(T526) REAR LOCKER SOURCE CIRCUIT OPEN

FDCM

Diagnostic Test

ACTIVE DTC

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Ignition on, engine not running.

With the DRBIIIT, read DTCs.

Is the DTC active at this time?

Yes >>

No >>

REAR LOCKER SOLENOID OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Rear Locker Solenoid harness connector.

Ignition on, engine not running.

Using a 12-volt test light, jump across from the (T526) Rear Locker Source circuit and the (T528) Rear Locker

Return circuit in the Rear Locker harness connector.

With a DRBIIIT, actuate the Rear Locker Solenoid.

Does the test light flash on and off?

Yes >>

No >>

Go To 2

Go To 5

Inspect the Rear Locker Solenoid terminals and connectors for corrosion and/or dirty that may compromise the connection. If OK, replace the Rear Locker Solenoid.

Perform FDCM VERIFICATION TEST.

Go To 3

DR/DH DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 27

C141F–REAR DIFFERENTIAL CONTROL CIRCUIT OPEN (CONTINUED)

(T526) REAR LOCKER SOURCE CIRCUIT OPEN

3.

Turn the ignition off.

Disconnect the FDCM harness connector.

Turn the ignition on.

Measure the resistance of the (T526) Rear Locker Source circuit from

the FDCM harness connector and the Rear Locker Solenoid harness

connector.

Is the resistances below 5.0 ohms?

Yes >>

No >>

FDCM

4.

NOTE: Before continuing, check the FDCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Go To 4

Repair the open in the Rear Locker Source circuit.

Perform FDCM VERIFICATION TEST.

Yes >>

No >>

INTERMITTENT WIRING AND CONNECTORS

5.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the DRBIIIT, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST

Replace and program the Final Drive Control Module in accordance with Service Information.

Perform FDCM VERIFICATION TEST.

Repair as necessary.

Perform FDCM VERIFICATION TEST.

Test Complete.

3 - 28 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR/DH

C1446-FRONT DIFFERENTIAL RETURN CIRCUIT LOW

DR/DH DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS 3 - 29

C1446-FRONT DIFFERENTIAL RETURN CIRCUIT LOW (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Ignition on. Axle Locker Switch in the FR/RR position.

• Set Condition:

The FDCM detects the Front Locker Source circuit is shorted low.

Possible Causes

FRONT LOCKER SOLENOID

(T526) FRONT LOCKER RETURN CIRCUIT SHORTED TO GROUND

FDCM

Diagnostic Test

ACTIVE DTC

1.

CAUTION: Before removing the FDCM harness connector, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasing or installing the harness connector.

Ignition on, engine not running.

With the DRBIIIT, read DTCs.

Is the DTC active at this time?

Yes >>

No >>

FRONT LOCKER SOLENOID OPERATION

2.

NOTE: Before continuing with the below diagnostic test, ensure the FDCM harness connector seal is

installed correctly. Inspect the terminals on both harness connector and the module for damage. Failure to

do so can result in misdiagnoses of the system.

Turn the ignition off.

Disconnect the Front Locker Solenoid harness connector.

Ignition on, engine not running.

Using a 12-volt test light, jump across from the (T520) Front Locker Source circuit and the (T524) Front Locker

Return circuit in the Front Locker harness connector.

With a DRBIIIT, actuate the Front Locker Solenoid.

Does the test light flash on and off?

Yes >>

No >>

Go To 2

Go To 5

Inspect the Front Locker Solenoid terminals and connectors for corrosion and/or dirty that may compromise the connection. If OK, replace the Front Locker Solenoid.

Perform FDCM VERIFICATION TEST.

Go To 3

3 - 30 DIFFERENTIAL & DRIVELINE - ELECTRICAL DIAGNOSTICS DR/DH

C1446-FRONT DIFFERENTIAL RETURN CIRCUIT LOW (CONTINUED)

(T524) FRONT LOCKER RETURN CIRCUIT SHORTED TO GROUND

3.

Turn the ignition off.

Disconnect the FDCM harness connector.

Measure the resistance of the (T524) Front Locker Return circuit in the

FDCM harness connector to ground.

Is the resistance below 100 ohms?

Yes >>

No >>

FDCM

4.

NOTE: Before continuing, check the FDCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Yes >>

No >>

Repair the short to ground in (T524) Front Locker Return

circuit.

Perform FDCM VERIFICATION TEST

Go To 4

Repair as necessary.

Perform FDCM VERIFICATION TEST

Replace and program the Final Drive Control Module in accordance with Service Information.

Perform FDCM VERIFICATION TEST.

INTERMITTENT WIRING AND CONNECTORS

5.

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this circuit.

Wiggle test the wiring harness and connectors while checking for shorted and open circuits.

Using the DRBIIIT, monitor the data related to this circuit while performing the wiggle test. Look for the data to

change or for the DTC to reset.

Were there any problems found?

Yes >>

No >>

Repair as necessary.

Perform FDCM VERIFICATION TEST.

Test Complete.

Loading...

Loading...