Page 1

DR DIFFERENTIAL & DRIVELINE 3 - 1

DIFFERENTIAL & DRIVELINE

TABLE OF CONTENTS

page page

PROPELLER SHAFT ......................1

HALF SHAFT ...........................11

FRONT AXLE - C205F ....................18

FRONT AXLE - 9 1/4 AA ...................45

PROPELLER SHAFT

TABLE OF CONTENTS

page page

PROPELLER SHAFT

DIAGNOSIS AND TESTING ................1

STANDARD PROCEDURE .................3

SPECIFICATIONS ........................6

SPECIAL TOOLS ........................6

FRONT PROPELLER SHAFT

REMOVAL .............................6

INSTALLATION ..........................7

REAR PROPELLER SHAFT

REMOVAL .............................7

REAR AXLE-91/4 .......................69

REAR AXLE - 10 1/2 AA ..................100

REAR AXLE - 11 1/2 AA ..................127

INSTALLATION ..........................8

CENTER BEARING

REMOVAL .............................8

INSTALLATION ..........................8

ADJUSTMENTS .........................8

SINGLE CARDAN UNIVERSAL JOINTS

DISASSEMBLY ..........................9

ASSEMBLY .............................9

PROPELLER SHAFT

DIAGNOSIS AND TESTING

PROPELLER SHAFT VIBRATION

Tires that are out-of-round or wheels that are

unbalanced, will cause a low frequency vibration.

Brake drums that are unbalanced will cause a

harsh, low frequency vibration.

Driveline vibration can also result from loose or

damaged engine mounts.

Propeller shaft vibration increases as the vehicle

speed is increased. A vibration that occurs within a

specific speed range is not usually caused by a propeller shaft being unbalanced. Defective universal

joints or an incorrect propeller shaft angle are usually the cause of such a vibration.

Page 2

3 - 2 PROPELLER SHAFT DR

PROPELLER SHAFT (Continued)

DRIVELINE VIBRATION

Drive Condition Possible Cause Correction

Propeller Shaft Noise 1) Undercoating or other foreign

material on shaft.

2) Loose U-joint clamp screws. 2) Install new clamps and screws

3) Loose or bent U-joint yoke or

excessive runout.

4) Incorrect driveline angularity. 4) Measure and correct driveline

5) Rear spring center bolt not in

seat.

6) Worn U-joint bearings. 6) Install new U-joint.

7) Propeller shaft damaged or out

of balance.

8) Broken rear spring. 8) Install new rear spring.

9) Excessive runout or unbalanced

condition.

10) Excessive drive pinion gear

shaft runout.

11) Excessive axle yoke deflection. 11) Inspect and replace yoke if

12) Excessive transfer case runout. 12) Inspect and repair as necessary.

1) Clean exterior of shaft and wash

with solvent.

and tighten to proper torque.

3) Install new yoke.

angles.

5) Loosen spring u-bolts and seat

center bolt.

7) Installl new propeller shaft.

9) Re-index propeller shaft, test,

and evaluate.

10) Re-index propeller shaft and

evaluate.

necessary.

Universal Joint Noise 1) Loose U-joint clamp screws. 1) Install new clamps and screws

and tighten to proper torque.

2) Lack of lubrication. 2) Replace as U-joints as

necessary.

PROPELLER SHAFT BALANCE

NOTE: Removing and re-indexing the propeller

shaft 180° relative to the yoke may eliminate some

vibrations.

If propeller shaft is suspected of being unbalanced,

it can be verified with the following procedure:

(1) Raise the vehicle.

(2) Clean all the foreign material from the propel-

ler shaft and the universal joints.

(3) Inspect the propeller shaft for missing balance

weights, broken welds, and bent areas. If the pro-

peller shaft is bent, it must be replaced.

(4) Inspect the universal joints to ensure that they

are not worn, are properly installed, and are correctly aligned with the shaft.

(5) Check the universal joint clamp screws torque.

(6) Remove the wheels and tires. Install the wheel

lug nuts to retain the brake drums or rotors.

(7) Mark and number the shaft six inches from the

yoke end at four positions 90° apart.

(8) Run and accelerate the vehicle until vibration

occurs. Note the intensity and speed the vibration

occurred. Stop the engine.

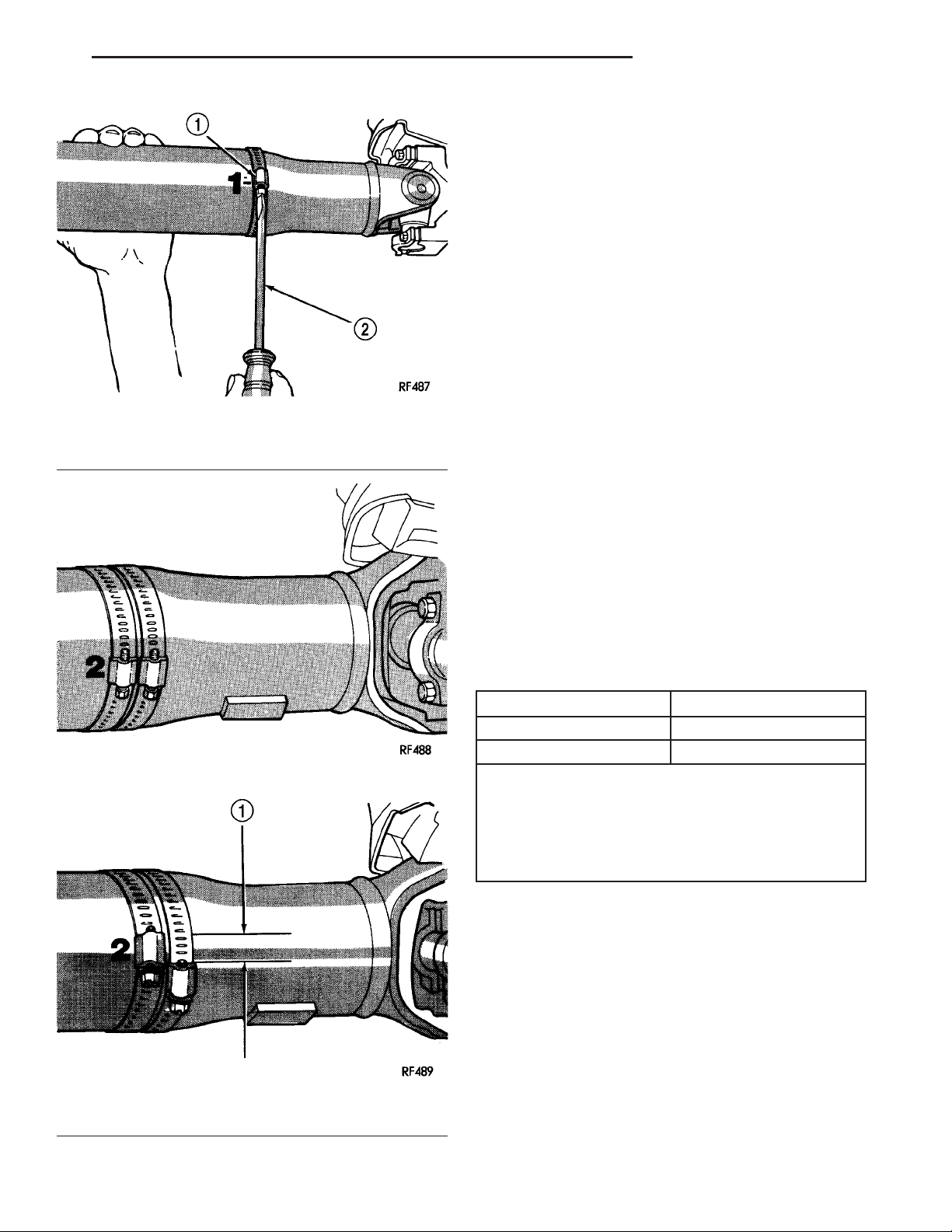

(9) Install a screw clamp at position 1 (Fig. 1).

(10) Start the engine and re-check for vibration. If

there is little or no change in vibration, move the

clamp to one of the other three positions. Repeat the

vibration test.

(11) If there is no difference in vibration at the

other positions, the source of the vibration may not

be propeller shaft.

(12) If the vibration decreased, install a second

clamp (Fig. 2) and repeat the test.

(13) If the additional clamp causes an additional

vibration, separate the clamps (1/2 inch above and

below the mark). Repeat the vibration test (Fig. 3).

(14) Increase distance between the clamp screws

and repeat the test until the amount of vibration is

at the lowest level. Bend the slack end of the clamps

so the screws will not loosen.

Page 3

DR PROPELLER SHAFT 3 - 3

PROPELLER SHAFT (Continued)

(15) If the vibration remains unacceptable, apply

the same steps to the front end of the propeller shaft.

(16) Install the wheel and tires. Lower the vehicle.

PROPELLER SHAFT RUNOUT

(1) Remove dirt, rust, paint and undercoating from

the propeller shaft surface where the dial indicator

will contact the shaft.

(2) The dial indicator must be installed perpendicular to the shaft surface.

(3) Measure runout at the center and ends of the

shaft sufficiently far away from weld areas to ensure

that the effects of the weld process will not enter into

the measurements.

(4) Refer to Runout Specifications chart.

(5) If the propeller shaft runout is out of specifica-

Fig. 1 CLAMP SCREW AT POSITION 1

1 - CLAMP

2 - SCREWDRIVER

tion, remove the propeller shaft, index the shaft 180°,

and re-install the propeller shaft. Measure shaft

runout again.

(6) If the propeller shaft runout is now within

specifications, mark the shaft and yokes for proper

orientation.

(7) If the propeller shaft runout is not within specifications, verify that the runout of the transmission/

transfer case and axle are within specifications.

Correct as necessary and re-measure propeller shaft

runout.

(8) Replace the propeller shaft if the runout still

exceeds the limits.

RUNOUT SPECIFICATIONS

1-1⁄2INCH

Fig. 2 TWO CLAMP SCREWS

Fig. 3 CLAMP SCREWS SEPARATED

Front of Shaft 0.020 in. (0.50 mm)

Center of Shaft 0.025 in. (0.63 mm)

Rear of Shaft 0.020 in. (0.50 mm)

note:

Measure front/rear runout approximately 3 inches (76

mm) from the weld seam at each end of the shaft

tube for tube lengths over 30 inches. For tube lengths

under 30 inches, the maximum allowed runout is

0.020 in. (0.50 mm) for the full length of the tube.

STANDARD PROCEDURE

PROPELLER SHAFT ANGLE

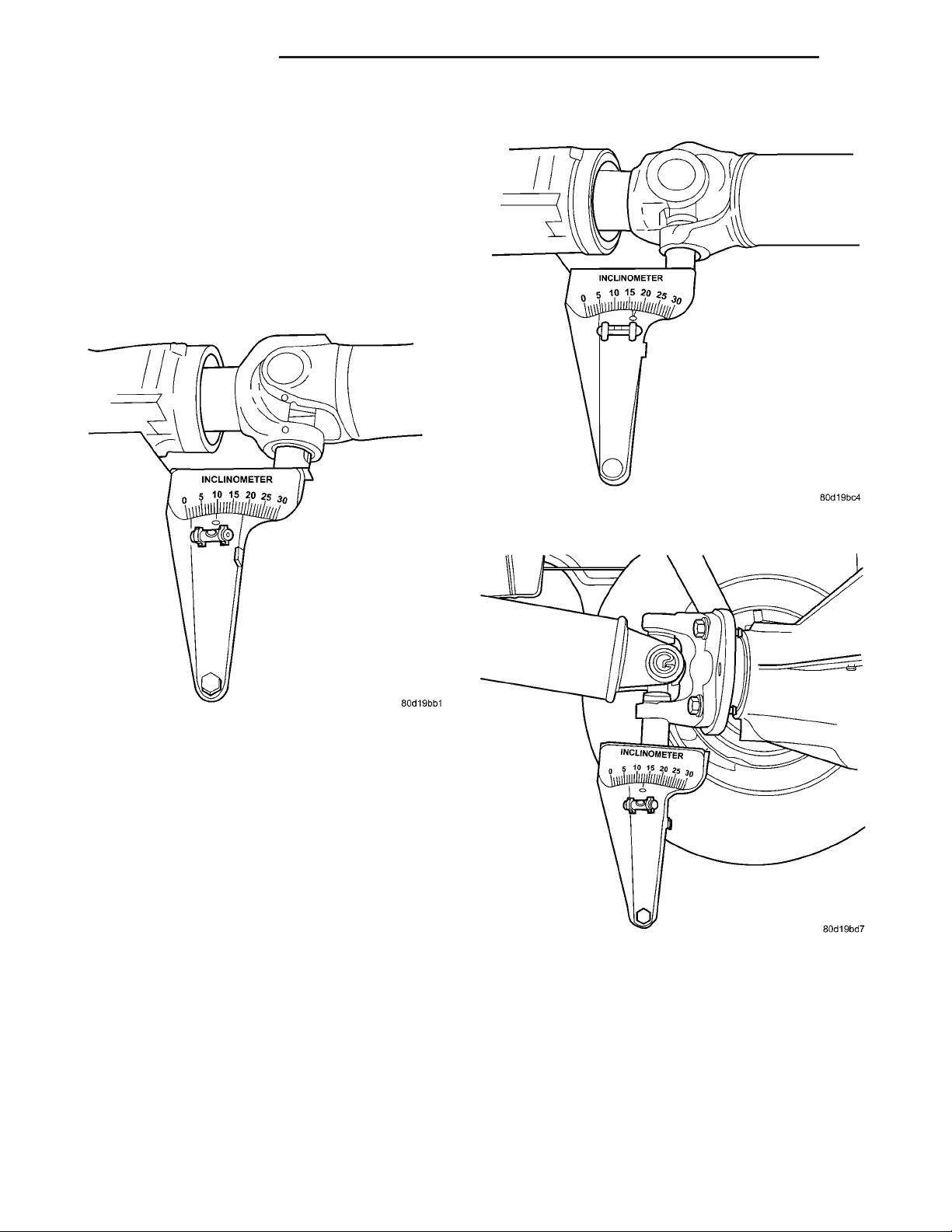

This procedure applies to both the front/rear propeller shafts. To obtain the front output angle (A) on

the front propeller shaft, place the inclinometer the

machined surface of the C/V joint.

(1) To check driveline alignment, raise and support

the vehicle at the axles as level as possible. Allow the

wheels and propeller shaft to turn.

(2) Remove any external bearing snap rings, if

equipped from universal joint so protractor base sits

flat.

Page 4

3 - 4 PROPELLER SHAFT DR

PROPELLER SHAFT (Continued)

(3) Rotate the shaft until transmission/transfer

case output yoke bearing is facing downward.

NOTE: Always make measurements from front to

rear and from the same side of the vehicle.

(4) Place Inclinometer 7663 on yoke bearing (A)

parallel to the shaft (Fig. 4). Center bubble in sight

glass and record measurement.

This measurement will give you the transmission yoke Output Angle (A).

Fig. 4 OUTPUT ANGLE (A)

(5) Rotate propeller shaft 90 degrees and place

Inclinometer on yoke bearing parallel to the shaft

(Fig. 5). Center bubble in sight glass and record measurement. This measurement can also be taken at

the rear end of the shaft.

This measurement will give you the Propeller

Shaft Angle (C).

(6) Rotate propeller shaft 90 degrees and place

Inclinometer on companion flange yoke bearing parallel to the shaft (Fig. 6). Center bubble in sight glass

and record measurement.

This measurement will give you the pinion

Companion Flange Input Angle (B).

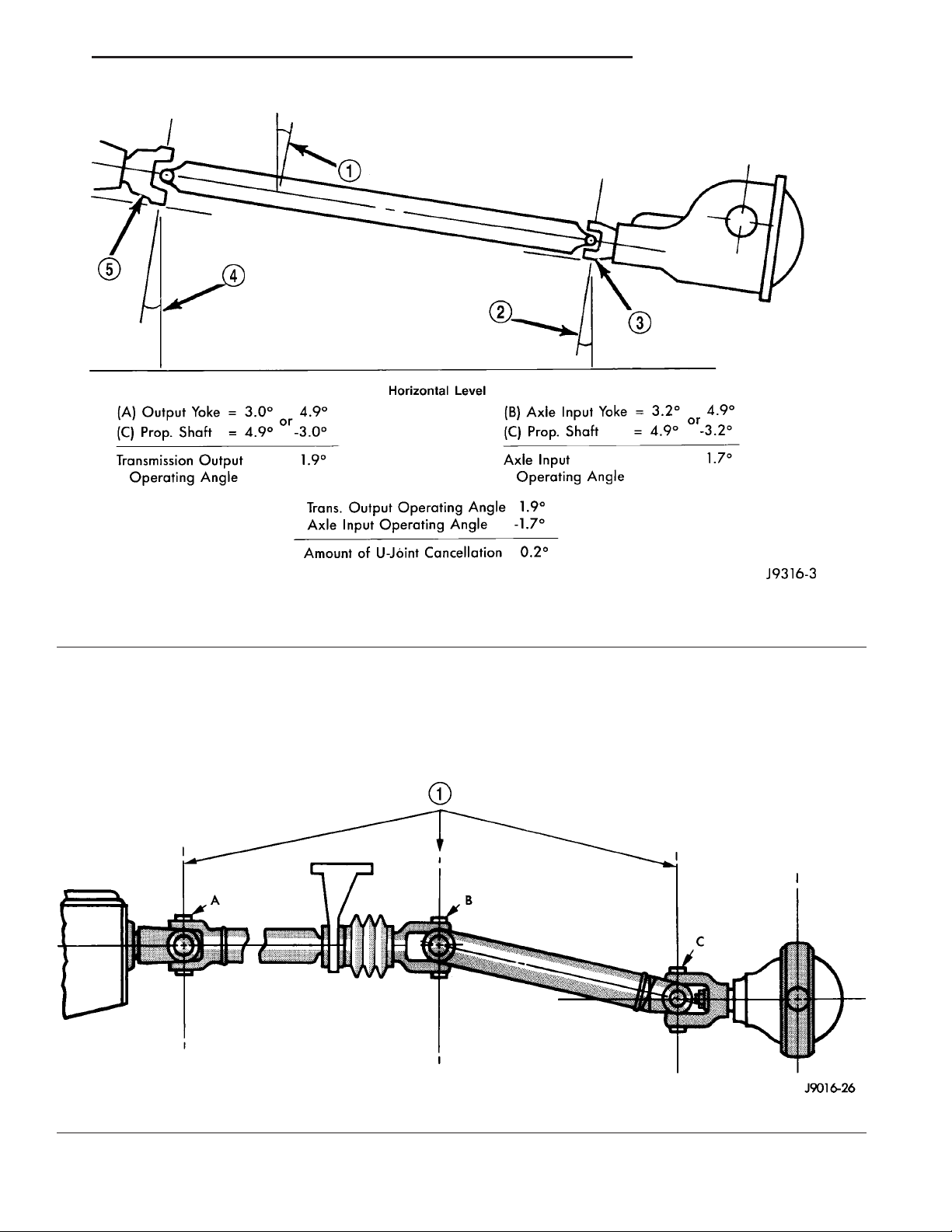

(7) Subtract smaller figure from larger (C minus

A) to obtain Transmission/Transfer Case Output

Operating Angle.

(8) Subtract smaller figure from larger (C minus

B) to obtain axle Input Operating Angle.

Fig. 5 PROPELLER SHAFT ANGLE (C)

Fig. 6 INPUT ANGLE (B)

Refer to rules given below and the example in (Fig.

7) for additional information.

• Good cancellation of U-joint operating angles

should be within 1°.

• Operating angles should be less than 3°.

• At least 1/2 of one degree continuous operating

(propeller shaft) angle.

Page 5

DR PROPELLER SHAFT 3 - 5

PROPELLER SHAFT (Continued)

Fig. 7 UNIVERSAL JOINT ANGLE EXAMPLE

1 - 4.9°Angle (C)

2 - 3.2°Angle (B)

3 - Input Yoke

TWO-PIECE PROPELLER SHAFT

The procedure to measure the propeller shaft

angles involved with a two-piece (Fig. 8) propeller

shaft is the same as those for a one-piece propeller

shaft.

4 - 3.0°Angle (A)

5 - Output Yoke

1 - YOKES MUST BE IN SAME PLANE

Fig. 8 UNIVERSAL JOINT ANGLE

Page 6

3 - 6 PROPELLER SHAFT DR

PROPELLER SHAFT (Continued)

SPECIFICATIONS

TORQUE SPECIFICATIONS

DESCRIPTION N·m Ft. Lbs. In. Lbs.

Center Bearing Bolts 54 40 -

Front Pinion Flange Bolts 115 85 -

Rear Pinion Flange Bolts 115 85 -

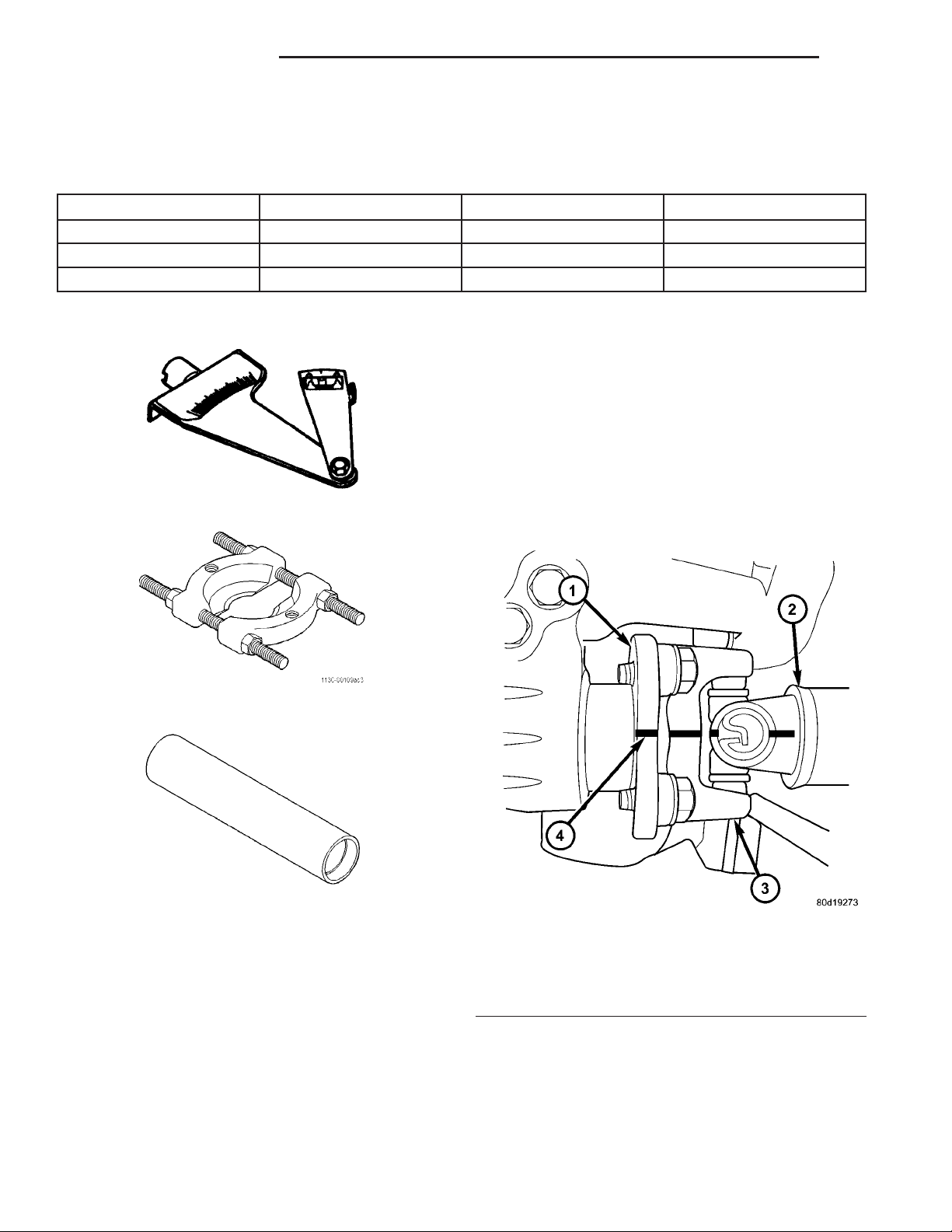

SPECIAL TOOLS

INCLINOMETER 7663

Bearing Splitter 1130

FRONT PROPELLER SHAFT

REMOVAL

(1) Position transmission and transfer case into

neutral.

(2) Raise and support vehicle.

(3) Remove exhaust crossover pipe.

(4) Mark a line across the axle companion flange

and propeller shaft flange yoke (Fig. 9) for installation reference.

INSTALLER 6052

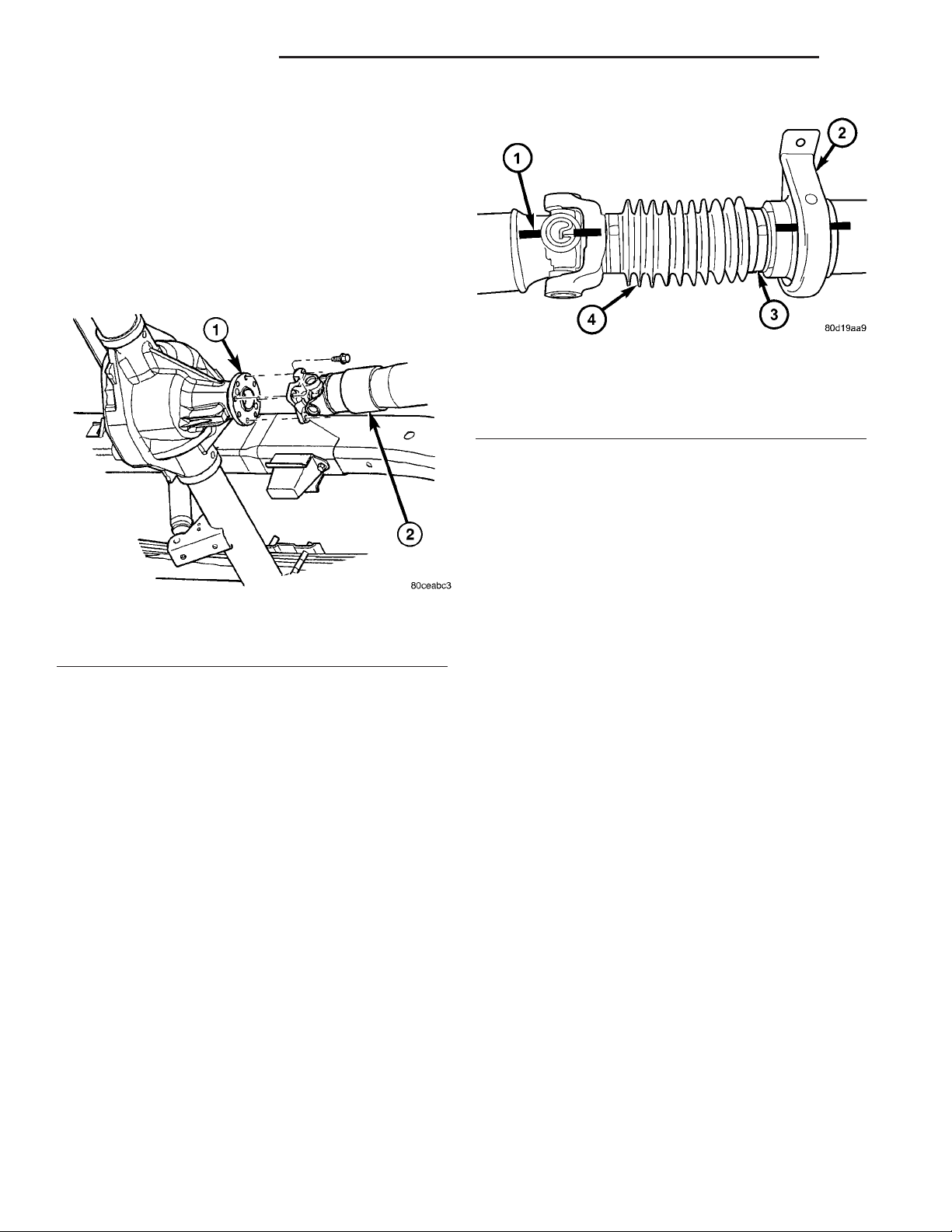

Fig. 9 COMPANION FLANGE

1 - COMPANION FLANGE

2 - PROPELLER SHAFT

3 - FLANGE YOKE

4 - REFERENCE MARK

(5) Remove companion flange bolts.

(6) Remove dust boot clamp (Fig. 10) from the C/V

jonit end of the shaft.

(7) Remove propeller shaft.

Page 7

DR PROPELLER SHAFT 3 - 7

FRONT PROPELLER SHAFT (Continued)

Fig. 10 DUST BOOT

1 - C/V JOINT

2 - TRANSFER CASE

3 - BOOT CLAMP

4 - PROPELLER SHAFT

INSTALLATION

(1) Install propeller shaft with with all reference

marks aligned.

(2) Install transfer case companion flange bolts

and tighten to 30.5 N·m (22.5 ft. lbs.).

(3) Install axle companion flange bolts and tighten

to 108 N·m (80 ft. lbs.).

(4) Install skid plate, if equipped.

(5) Lower vehicle and road test to verify repair.

REAR PROPELLER SHAFT

REMOVAL

(1) Shift transmission into Neutral.

(2) Raise and support vehicle.

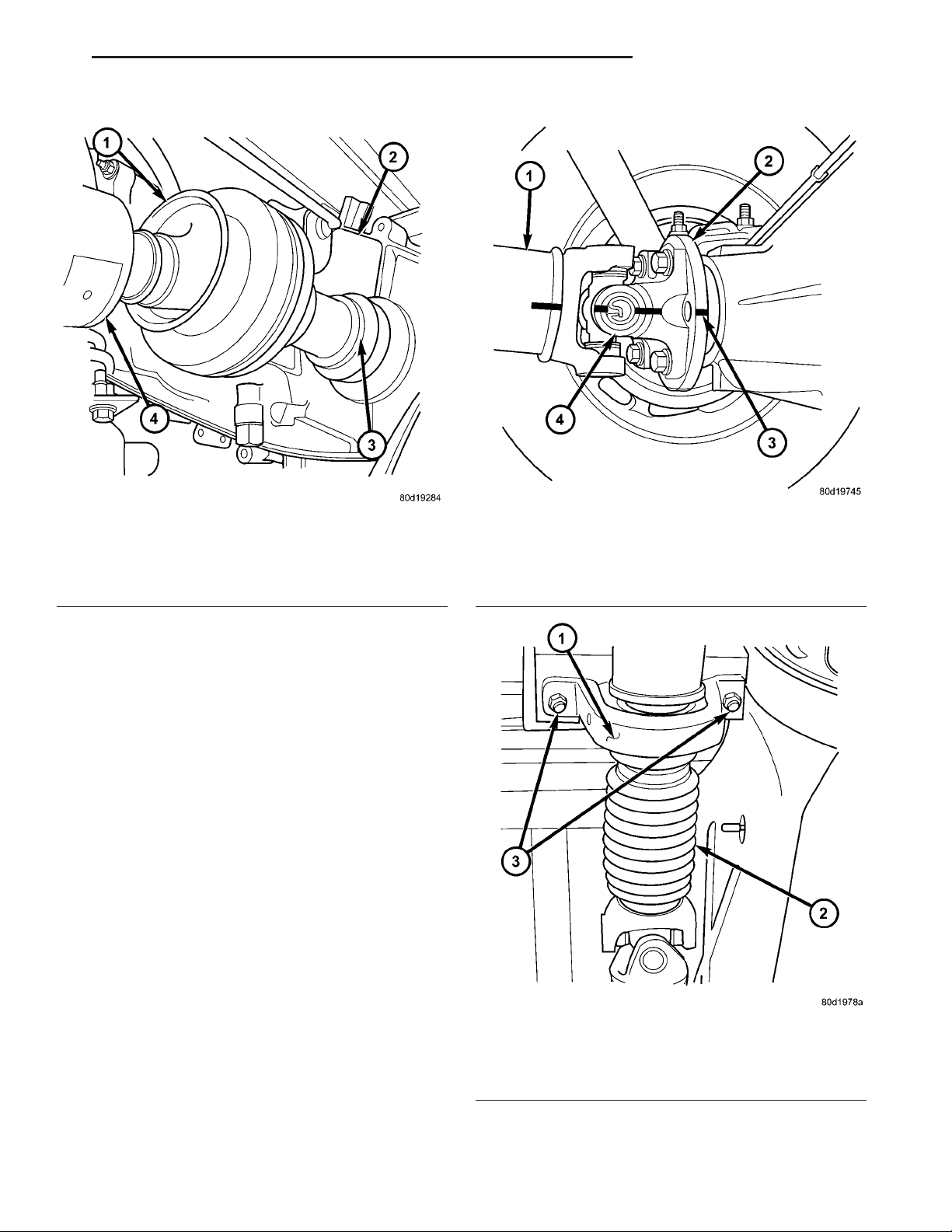

(3) Mark a line across the pinion companion flange

and propeller shaft flange yoke (Fig. 11) for installation reference.

(4) Mark the outline of the center bearing (Fig. 12)

on the crossmember for installation reference, if

equipped.

(5) Remove center bearing mounting nuts, if

equipped.

(6) Remove pinion yoke companion flange bolts.

(7) Slide slip yoke off of the transmission or transfer case output shaft and remove propeller shaft.

Fig. 11 COMPANION FLANGE

1 - PROPELLER SHAFT

2 - COMPANION FLANGE

3 - REFERENCE MARK

4 - SHAFT FLANGE YOKE

Fig. 12 CENTER BEARING

1 - CENTER BEARING

2 - DUST BOOT

3 - MOUNTING NUTS

Page 8

3 - 8 PROPELLER SHAFT DR

REAR PROPELLER SHAFT (Continued)

INSTALLATION

(1) Slide the slip yoke onto the transmission/transfer case output shaft.

(2) Align and install center bearing on crossmember, if necessary and tighten nutts to 54 N·m (40 ft.

lbs.).

(3) Align reference marks on the propeller shaft

yoke and pinion companion flange (Fig. 13).

(4) Tighten pinion companion flange bolts to 115

N·m (85 ft. lbs.).

Fig. 14 REFERENCE MARKS

1 - REFERENCE MARK

2 - CENTER BEARING

3 - BOOT CLAMP

4 - DUST BOOT

INSTALLATION

NOTE: Two types of center bearings are used and

are not interchangeable. Install the same type as

the vehicle was built with.

Fig. 13 REAR PROPELLER SHAFT

1 - COMPANION FLANGE

2 - PROPELLER SHAFT

(5) Lower the vehicle.

CENTER BEARING

REMOVAL

(1) Remove rear propeller shaft.

(2) Mark the two shafts (Fig. 14) for installation

reference.

(3) Remove slip joint boot clamp and separate the

two shafts.

(4) Use hammer and punch to tap slinger away

from shaft to provide room for bearing splitter.

(5) Position Bearing Splitter Tool 1130 between

slinger and shaft.

CAUTION: Do not damage shaft spline during

removal of center bearing.

(6) Set shaft in press and press bearing off the

shaft.

(1) Install new slinger on shaft and drive into posi-

tion with appropriate installer tool.

(2) Install new center bearing on shaft with Bearing Installer Tool 6052. Drive on shaft with hammer

until bearing is seated.

(3) Clean shaft splines and apply a coat of multipurpose grease.

(4) Align master splines and slide front and rear

half-shafts together. Reposition slip yoke boot and

install new clamp.

(5) Install propeller shaft in vehicle.

ADJUSTMENTS

CENTER BEARING

Launch shudder is a vibration that occurs at first

acceleration from a stop. Shudder vibration usually

peaks at the engines highest torque output. Shudder

is a symptom associated with vehicles using a twopiece propeller shaft. To decrease shudder, lower the

center bearing in 1/8 inch increments. Use shim

stock or fabricated plates. Plate stock must be used

to maintain compression of the rubber insulator

around the bearing. Do not use washers. Replace the

original bolts with the appropriate increased length

bolts.

Page 9

DR PROPELLER SHAFT 3 - 9

SINGLE CARDAN UNIVERSAL

JOINTS

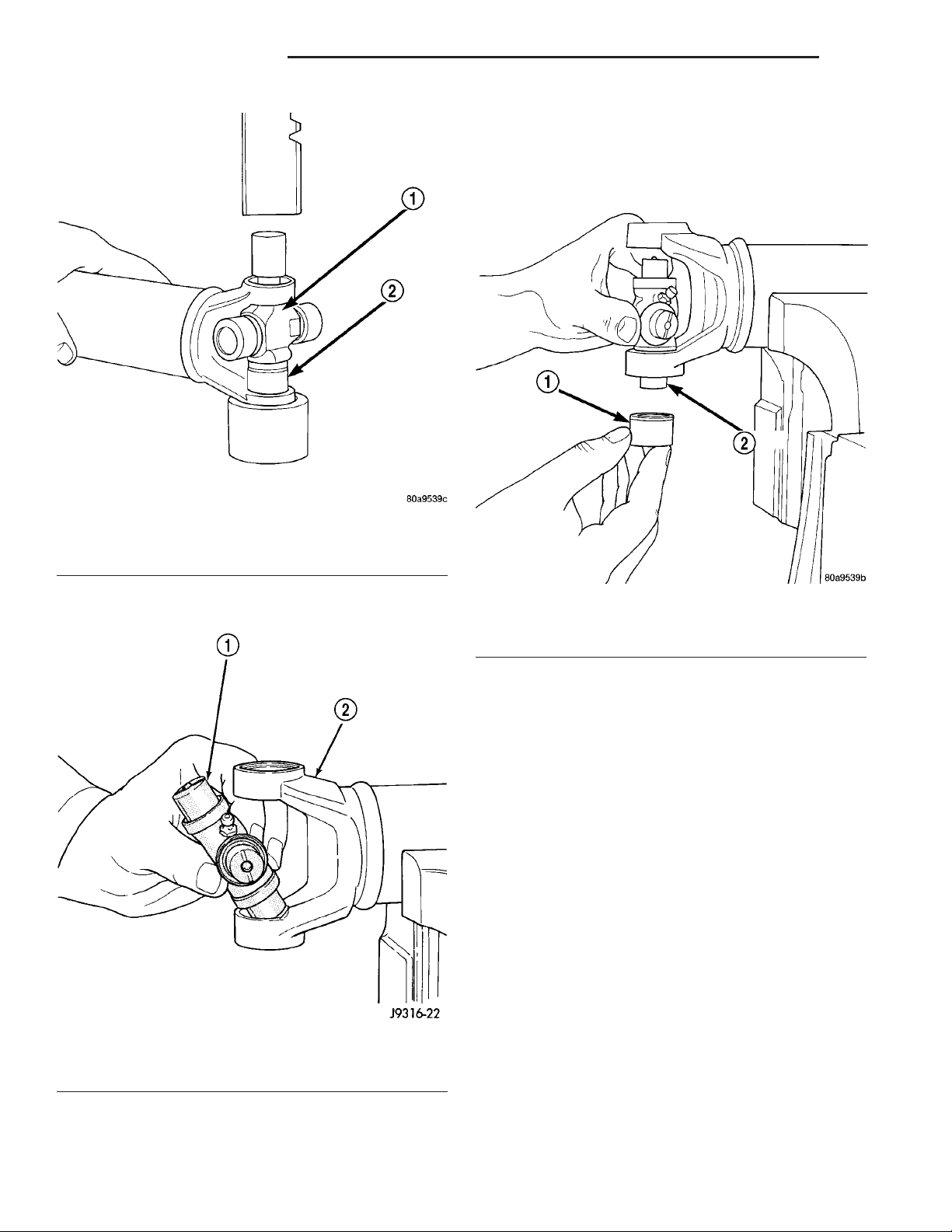

DISASSEMBLY

NOTE: The following procedure is described for a

propeller shaft equipped with only a cardan joint in

the tube yoke. If the propeller shaft is equipped

with a companion yoke, simply repeat the following

steps to remove the cardan joint from the companion yoke after removing the cardan joint from the

tube yoke.

Individual components of cardan universal joints

are not serviceable. If worn or leaking, they must be

replaced as an assembly.

(1) Remove the propeller shaft.

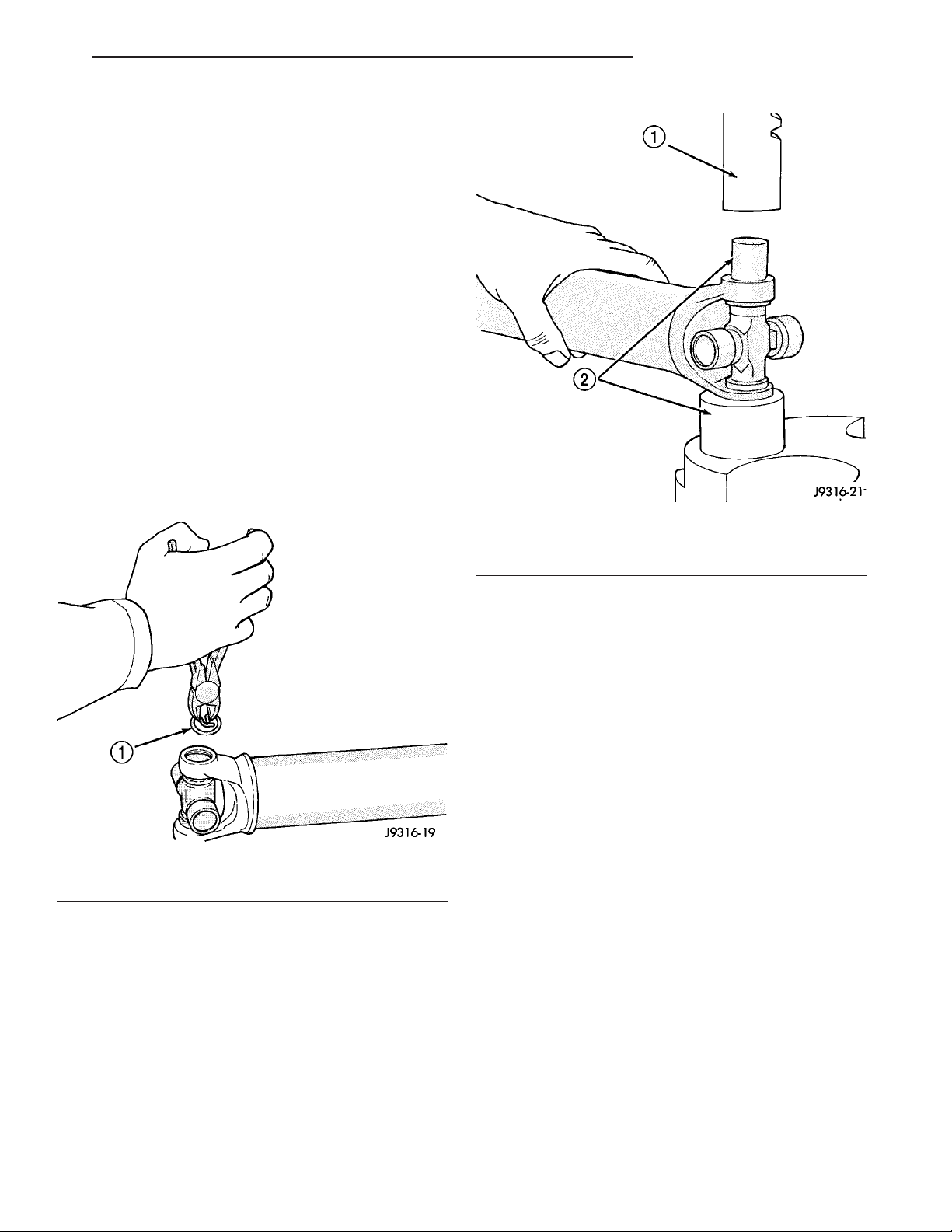

(2) Using a soft drift, tap the outside of the bearing cap assembly to loosen snap ring.

(3) Remove snap rings from both sides of yoke

(Fig. 15).

Fig. 16 Press Out Bearing

1 - PRESS

2 - SOCKET

Fig. 15 Snap Ring

1 - SNAP RING

(4) Set the yoke in an arbor press or vise with a

socket whose inside diameter is large enough to

receive the bearing cap positioned beneath the yoke.

(5) Position the yoke with the grease fitting, if

equipped, pointing up.

(6) Place a socket with an outside diameter

smaller than the upper bearing cap on the upper

bearing cap and press the cap through the yoke to

release the lower bearing cap (Fig. 16).

(7) If the bearing cap will not pull out of the yoke

by hand after pressing, tap the yoke ear near the

bearing cap to dislodge the cap.

(8) To remove the opposite bearing cap, turn the

yoke over and straighten the cross in the open hole.

Then, carefully press the end of the cross until the

remaining bearing cap can be removed (Fig. 17).

CAUTION: If the cross or bearing cap are not

straight during installation, the bearing cap will

score the walls of the yoke bore and damage can

occur.

ASSEMBLY

NOTE: The following procedure is described for a

propeller shaft equipped with only a cardan joint in

the tube yoke. If the propeller shaft is equipped

with a companion yoke, simply repeat the following

steps to remove the cardan joint from the companion yoke after removing the cardan joint from the

tube yoke.

(1) Apply extreme pressure (EP) N.L.G.I. Grade 1

or 2 grease to inside of yoke bores to aid in installation.

Page 10

3 - 10 PROPELLER SHAFT DR

SINGLE CARDAN UNIVERSAL JOINTS (Continued)

(3) Place a bearing cap over the trunnion and

align the cap with the yoke bore (Fig. 19). Keep the

needle bearings upright in the bearing assembly. A

needle bearing lying at the bottom of the cap will

prevent proper assembly.

Fig. 17 Press Out Remaining Bearing

1 - CROSS

2 - BEARING CAP

(2) Position the cross in the yoke with its lube fit-

ting, if equipped, pointing up (Fig. 18).

Fig. 19 Install Bearing On Trunnion

1 - BEARING CAP

2 - TRUNNION

(4) Press the bearing cap into the yoke bore

enough to install a snap ring.

(5) Install a snap ring.

(6) Repeat Step 3 and Step 4to install the opposite

bearing cap. If the joint is stiff or binding, strike the

yoke with a soft hammer to seat the needle bearings.

(7) Add grease to lube fitting, if equipped.

(8) Install the propeller shaft.

1 - CROSS

2 - YOKE

Fig. 18 Cross In Yoke

Page 11

DR HALF SHAFT 3 - 11

HALF SHAFT

TABLE OF CONTENTS

page page

HALF SHAFT

CAUTION .............................11

DIAGNOSIS AND TESTING ................11

REMOVAL .............................11

INSTALLATION .........................12

SPECIFICATIONS .......................12

SPECIAL TOOLS .......................12

HALF SHAFT

CAUTION

CAUTION:: Never grasp half shaft assembly by the

boots. This may cause the boot to pucker or crease

and reduce the service life of the boot.

Avoid over angulating or stroking the C/V joints

when handling the half shaft.

Half shafts exposed to battery acid, transmission

fluid, brake fluid, differential fluid or gasoline may

cause the boots to deteriorate.

DIAGNOSIS AND TESTING

Check for grease at the inboard and outboard C/V

joint. This is a sign of boot or boot clamp damage.

NOISE/VIBRATION IN TURNS

A clicking noise or a vibration in turns could be

caused by a damaged outer C/V or inner tripod joint

seal boot or seal boot clamps. This will result in the

loss/contamination of the joint grease, resulting in

inadequate lubrication of the joint. Noise could also

be caused by another component of the vehicle coming in contact with the half shafts.

CV JOINT-OUTER

REMOVAL .............................13

INSTALLATION .........................13

CV JOINT-INNER

REMOVAL .............................16

INSTALLATION .........................16

VIBRATION AT HIGHWAY SPEEDS

This problem could be a result of out of balance

front tires or tire/wheel runout. Foreign material

(mud, etc.) packed on the backside of the wheel(s)

will also cause a vibration.

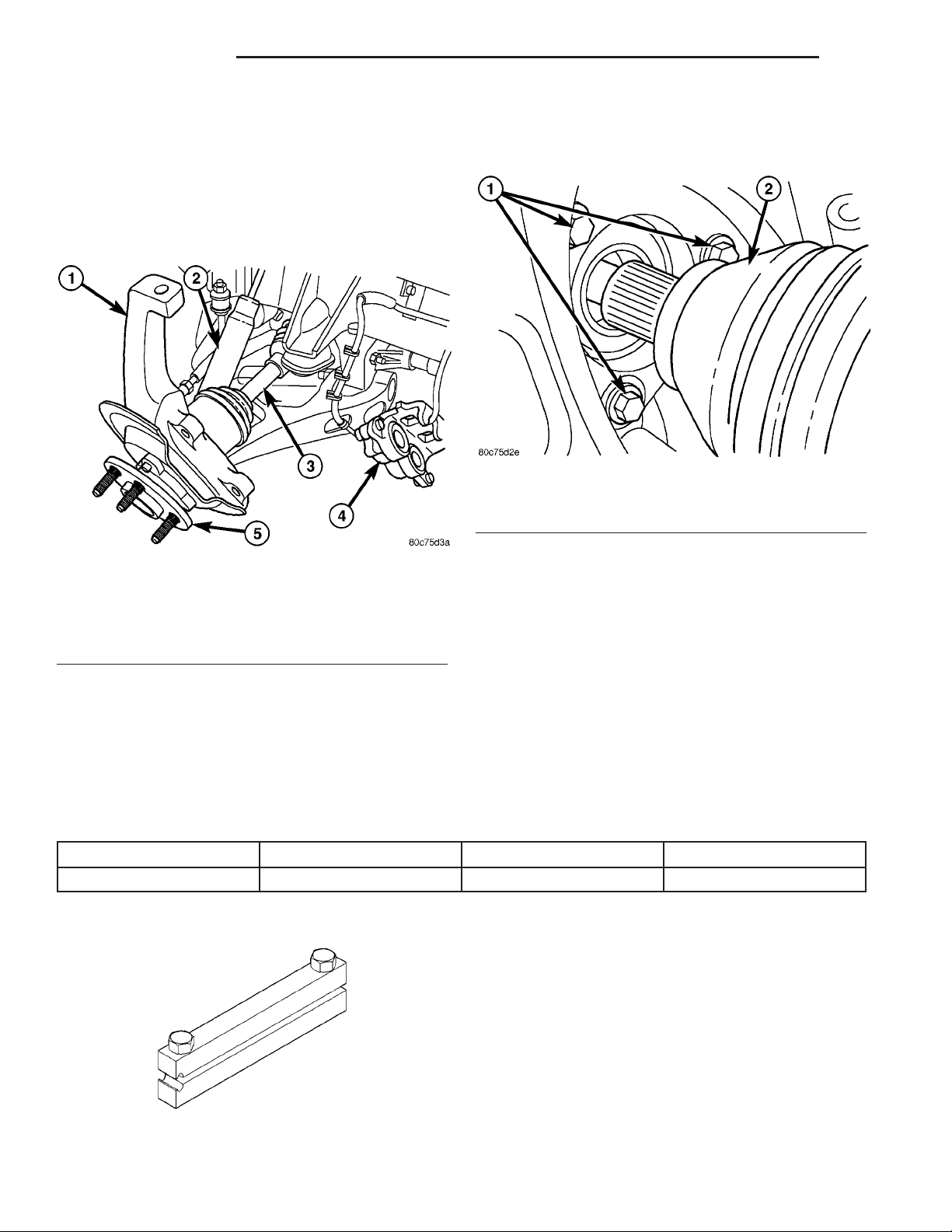

REMOVAL

(1) Loosen lug nuts and hub nut while the with

the vehicle brakes applied.

(2) Raise and support the vehicle.

(3) Remove wheel and tire assembly

(4) Remove half shaft hub nut.

(5) Remove brake caliper and rotor.

(6) Position hydraulic jack under lower suspension

arm and raise jack to unload rebound bumper.

(7) Remove lower shock absorber bolt.

(8) Remove upper ball joint nut and seperate ball

with Remover 8677 (Fig. 1).

CLUNKING NOISE DURING ACCELERATION

This noise may be a result of a damaged or worn

C/V joint. A torn boot or loose/missing clamp on the

inner/outer joint which has allowed the grease to be

lost will damage the C/V joint.

SHUDDER/VIBRATION DURING ACCELERATION

This problem could be a result of a worn/damaged

inner tripod joint or a sticking tripod joint. Improper

wheel alignment may also cause a shudder or vibration.

Fig. 1 UPPER BALL JOINT SEPARATION

1 - UPPER CONTROL ARM

2 - REMOVER

3 - STEERING KNUCKLE

Page 12

3 - 12 HALF SHAFT DR

HALF SHAFT (Continued)

(9) Disengage inner C/V joint from the axle shaft

snap-ring by apply pressure with two pry bars

between the C/V housing and axle housing.

(10) Tilt the knuckle out and push the half shaft

out of the knuckle (Fig. 2).

CAUTION: Do not damage outer C/V threads while

removing half shaft.

Fig. 2 STEERING KNUCKLE

1 - STEERING KNUCKLE

2 - SHOCK

3 - HALFSHAFT

4 - DISC BRAKE CALIPER

5 - HUB/BEARING

(11) Remove the half shaft from the vehicle.

INSTALLATION

(1) Clean hub bearing bore, hub bearing mating

surface and half shaft splines.

(2) Apply a light coating of grease to the front axle

shaft output splines.

(3) Install half shaft into the knuckle (Fig. 3).

Fig. 3 HALF SHAFT AND HUB/BEARING

1 - HUB/BEARING MOUNTING NUTS

2 - HALF SHAFT

(4) Install half shaft on the axle output shaft.

Push firmly to engage the axle output shaft snap

ring into the inner C/V housing.

(5) Install upper ball joint into the knuckle.

(6) Install upper ball joint nut and tighten to specification.

(7) Install lower shock absorber bolt and tighten to

specification.

(8) Install brake rotor and caliper.

(9) Install half shaft hub nut and tighten to 251

N·m (185 ft. lbs.).

(10) Install the wheel and tire assembly.

SPECIFICATIONS

DESCRIPTION N·m Ft. Lbs. In. Lbs.

Half Shaft Nut 251 185 -

SPECIAL TOOLS

CLAMP INSTALLER C-4975A

TORQUE SPECIFICATIONS

Page 13

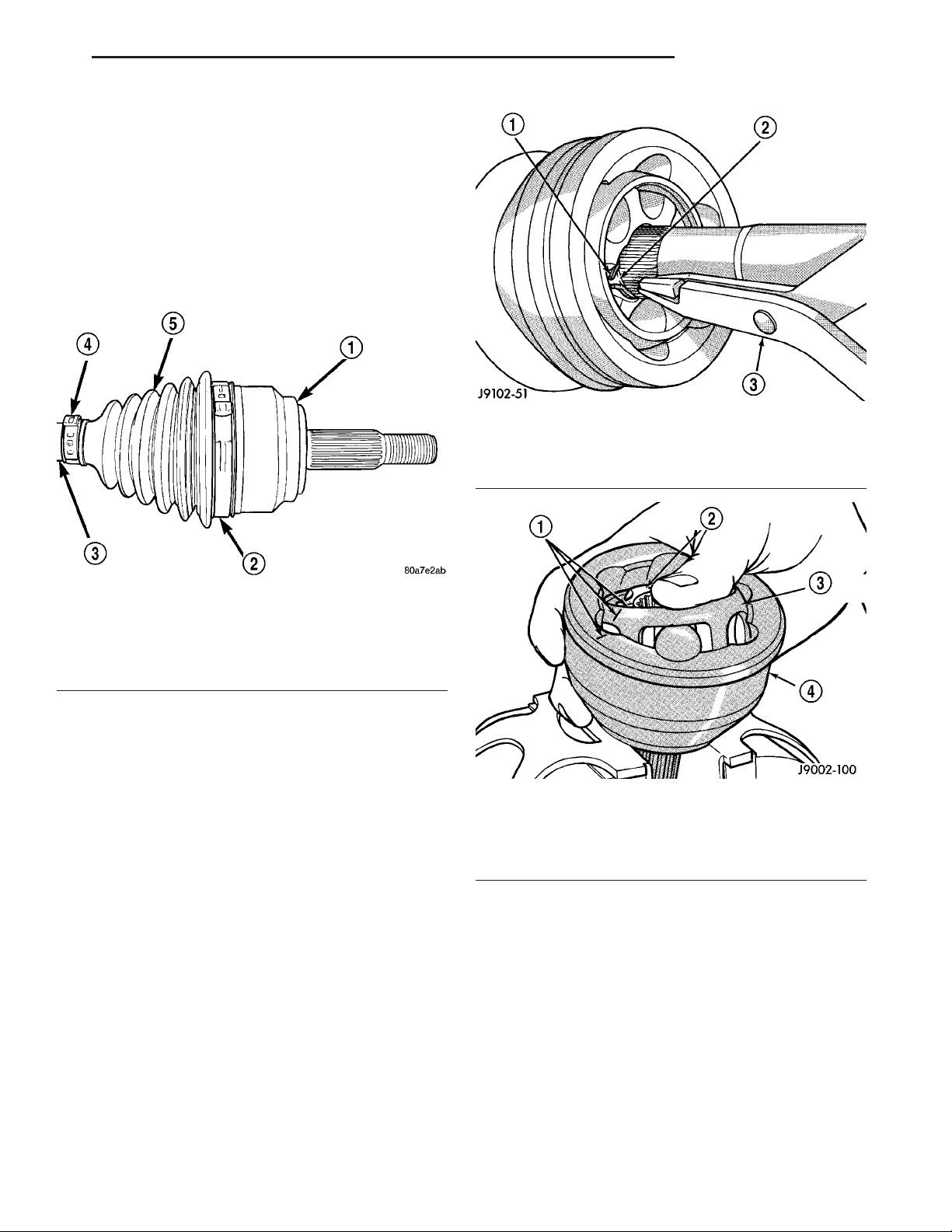

DR HALF SHAFT 3 - 13

CV JOINT-OUTER

REMOVAL

(1) Clamp shaft in a vise (with soft jaws) and sup-

port C/V joint.

(2) Remove clamps with a cut-off wheel or grinder

(Fig. 4).

CAUTION: Do not damage C/V housing or half

shaft.

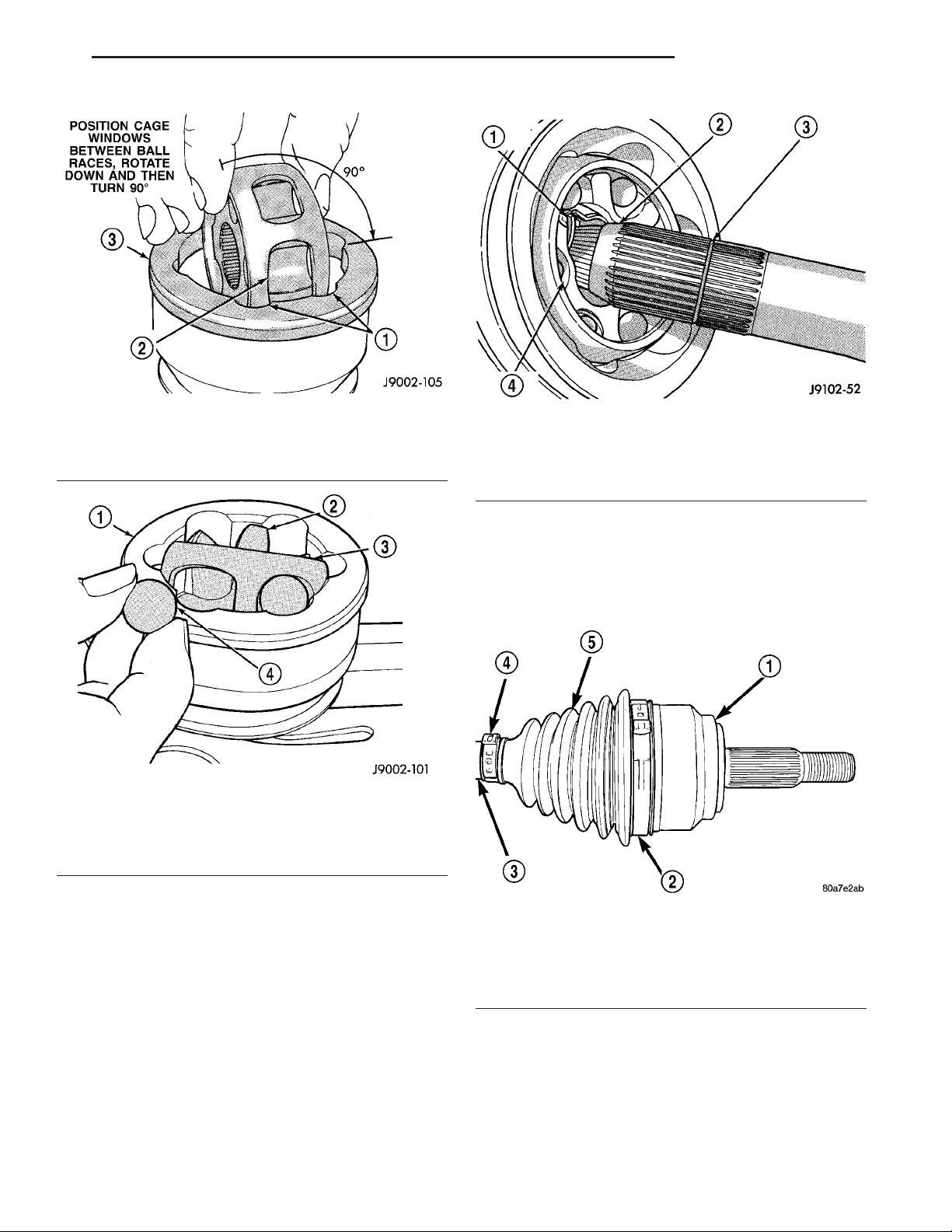

Fig. 5 OUTER C/V JOINT

1 - SNAP RING

2 - SNAP RING GROVE

3 - SNAP RING PLIERS

Fig. 4 BOOT CLAMP LOCATIONS

1 - C/V HOUSING

2 - CLAMP

3 - HALF SHAFT

4 - CLAMP

5 - C/V BOOT

(3) Slide the boot down the shaft.

(4) Remove lubricant to expose the C/V joint snap

ring.

(5) Spread snap ring and slide the joint off the

shaft (Fig. 5).

(6) Slide boot off the shaft and discard old boot.

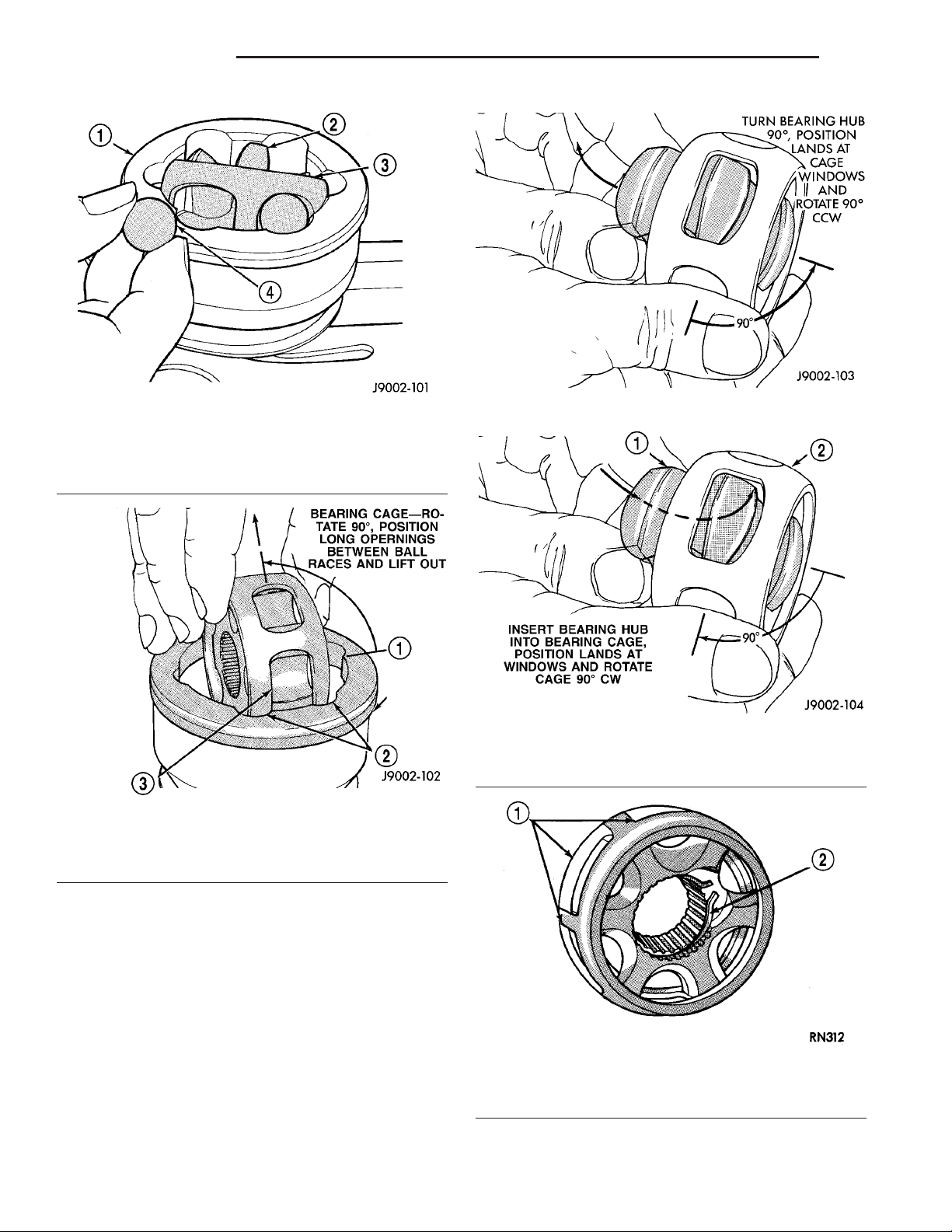

(7) Mark alignment marks on the inner race/hub,

bearing cage and housing with dabs of paint (Fig. 6).

(8) Clamp C/V joint in a vertical position in a soft

jawed vise.

(9) Press down one side of the bearing cage to gain

access to the ball at the opposite side.

NOTE: If joint is tight, use a hammer and brass drift

to loosen the bearing hub. Do not contact the bearing cage with the drift.

(10) Remove ball from the bearing cage (Fig. 7).

(11) Repeat step above until all six balls are

removed from the bearing cage.

(12) Lift cage and inner race upward and out from

the housing (Fig. 8).

(13) Turn inner race 90° in the cage and rotate the

inner race/hub out of the cage (Fig. 9).

Fig. 6 BEARING ACCESS

1 - ALIGNMENT MARKS

2 - BEARING HUB

3 - BEARING CAGE

4 - HOUSING

INSTALLATION

NOTE: If C/V joint is worn, replace entire C/V joint

and boot.

(1) Clean all C/V joint components and shaft.

(2) Apply a light coat of grease supplied with the

joint/boot to the C/V joint components before assembling them.

(3) Align the inner race, cage and housing according to the alignment reference marks.

(4) Insert the inner race into the cage (Fig. 10) and

rotate race into the cage.

(5) Rotate the inner race/hub in the cage (Fig. 11).

Page 14

3 - 14 HALF SHAFT DR

CV JOINT-OUTER (Continued)

1 - HOUSING

2 - INNER RACE/HUB

3 - BEARING CAGE

4 - BALL

Fig. 8 CAGE AND INNER RACE/HUB

1 - HOUSING

2 - INNER RACE

3 - CAGE WINDOW

Fig. 7 BEARING

Fig. 9 INNER RACE/HUB

Fig. 10 INNER RACE/HUB

1 - INNER RACE/HUB

2 - BEARING CAGE

(6) Insert cage into the housing (Fig. 12). Rotate

the cage 90° into the housing so the large bearing

hub counterbore is facing outwards.

(7) Apply the grease supplied with the joint/boot to

the ball races. Spread the grease equally between all

the races.

(8) Tilt inner race/hub and cage and install the

balls (Fig. 13).

(9) Place new clamps onto new boot and slide boot

onto the shaft to it’s original position.

(10) Apply the rest of grease to the C/V joint and

boot.

Fig. 11 CAGE AND INNER RACE/HUB

1 - CAGE WINDOWS

2 - SNAP RING

Page 15

DR HALF SHAFT 3 - 15

CV JOINT-OUTER (Continued)

Fig. 12 BEARING CAGE AND HOUSING

1 - OUTER RACE

2 - BEARING CAGE WINDOW

3 - CV JOINT HOUSING

Fig. 13 BALL BEARING

1 - C/V HOUSING

2 - INNER RACE/HUB

3 - BEARING CAGE

4 - BEARING

Fig. 14 OUTER C/V JOINT

1 - SNAP RING

2 - SHAFT TAPER

3 - SNAP RING GROVE

4 - BEARING HUB

NOTE: Verify boot is not twisted and remove any

excess air.

(13) Secure both boot clamps (Fig. 15) with Clamp

Installer C-4975A. Place tool on clamp bridge and

tighten tool until jaws of the tool are closed.

(11) Install the joint onto the shaft. Push the joint

onto the shaft until the snap ring seats in the groove

(Fig. 14).

NOTE: Pull on the joint to verify the span ring has

engaged.

(12) Position the boot on the joint in it’s original

position.

Fig. 15 BOOT CLAMP LOCATIONS

1 - C/V HOUSING

2 - CLAMP

3 - HALF SHAFT

4 - CLAMP

5 - C/V BOOT

Page 16

3 - 16 HALF SHAFT DR

CV JOINT-INNER

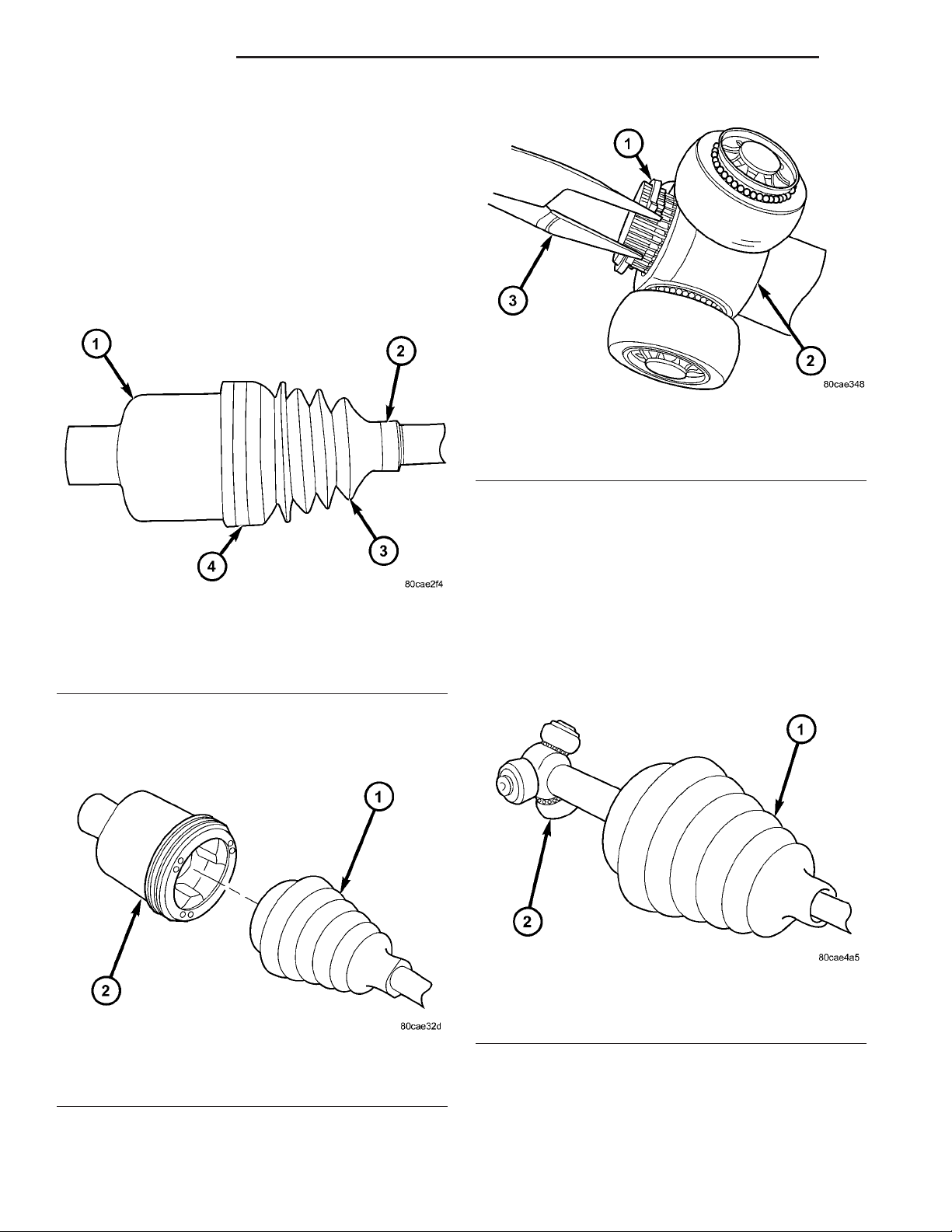

REMOVAL

(1) Clamp shaft in a vise (with soft jaws) and support C/V joint.

(2) Remove clamps with a cut-off wheel or grinder

(Fig. 16).

CAUTION: Do not damage C/V housing or half shaft

with cut-off wheel or grinder.

Fig. 18 TRIPOD SNAP RING

1 - SNAP RING

2 - TRIPOD

3 - PLIERS

(6) Remove tripod and boot from the half shaft.

(7) Clean and inspect C/V components for excessive wear and damage. Replace the tripod as a unit

only if necessary.

Fig. 16 BOOT CLAMP LOCATION

1 - C/V HOUSING

2 - CLAMP

3 - BOOT

4 - CLAMP

(3) Remove housing from the half shaft (Fig. 17)

and slide boot down shaft.

INSTALLATION

(1) Clean all C/V joint components and shaft.

(2) Slide new boot down the half shaft.

(3) Install tripod and tripod snap ring on the half

shaft (Fig. 19).

Fig. 19 C/V TRIPOD

1 - BOOT

2 - TRIPOD

Fig. 17 C/V HOUSING

1 - BOOT

2 - HOUSING

(4) Remove housing bushing from the housing.

(5) Remove tripod snap ring (Fig. 18).

(4) Pack grease supplied with the joint/boot into

the housing and boot.

(5) Coat tripod with supplied grease.

(6) Install new bushing (Fig. 20) onto the housing.

(7) Insert the tripod and shaft in the housing.

Page 17

DR HALF SHAFT 3 - 17

CV JOINT-INNER (Continued)

Fig. 20 HOUSING BUSHING

1 - BUSHING

2 - HOUSING

(8) Position the boot on the joint and shaft in it’s

original position (Fig. 21).

NOTE: Verify boot is not twisted and remove any

excess air.

(9) Measure the distance from the end of the housing to the end of the boot on the shaft. This measurement should be 260 mm (10.25 in.).

Fig. 21 INNER C/V BOOT

1 - CLAMP

2 - BOOT

3 - CLAMP

4 - SHAFT

5 - HOUSING

NOTE: If measurement is not correct, allow more or

less air into the boot.

(10) Secure both boot clamps with Clamp Installer

C-4975A. Place tool on clamp bridge and tighten tool

until the jaws of the tool are closed.

Page 18

3 - 18 FRONT AXLE - C205F DR

FRONT AXLE - C205F

TABLE OF CONTENTS

page page

FRONT AXLE - C205F

DESCRIPTION .........................18

OPERATION ...........................18

DIAGNOSIS AND TESTING ................18

REMOVAL .............................21

INSTALLATION .........................21

ADJUSTMENTS ........................21

SPECIFICATIONS .......................29

SPECIAL TOOLS .......................30

AXLE SHAFTS

REMOVAL .............................33

INSTALLATION .........................33

AXLE SHAFT SEALS

REMOVAL .............................33

INSTALLATION .........................33

AXLE BEARINGS

REMOVAL .............................33

FRONT AXLE - C205F

DESCRIPTION

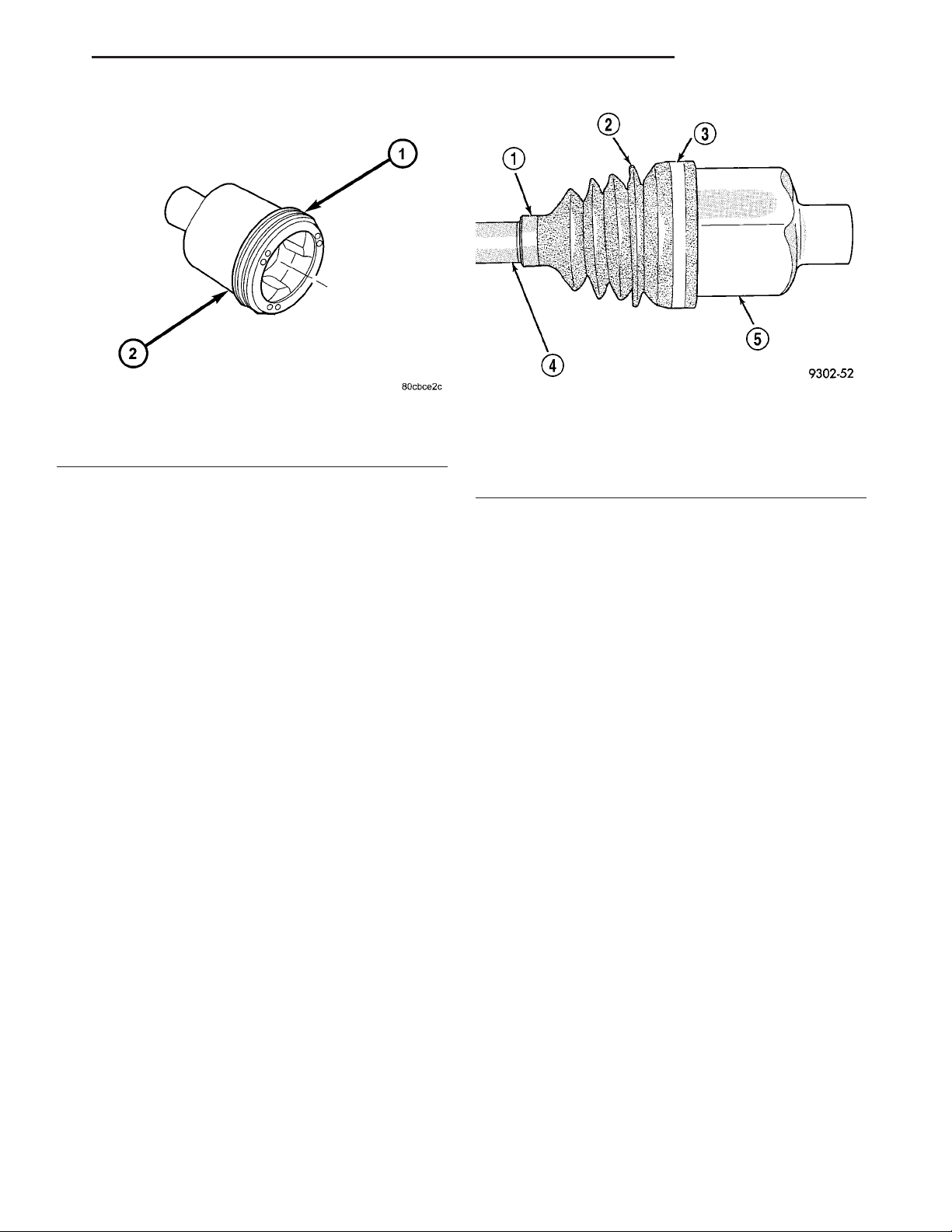

The axle consists of an alumunum center section

with an axle tube extending from one side. The tube

is pressed into the differential housing. The power is

transferred from the axle through two constant velocity (C/V) drive shafts to the wheel hubs. The drive

shafts are identical and interchangeable.

OPERATION

The axle receives power from the propeller shaft.

The propeller shaft is connected to the pinion gear

which rotates the differential through the gear mesh

with the ring gear bolted to the differential case. The

engine power is transmitted to the axle shafts

through the pinion mate and side gears. The side

gears are splined to the axle shafts.

DIAGNOSIS AND TESTING

GEAR NOISE

Axle gear noise can be caused by insufficient lubricant, incorrect backlash, tooth contact, worn/damaged

gears or the carrier housing not having the proper

offset and squareness.

Gear noise usually happens at a specific speed

range. The noise can also occur during a specific type

of driving condition. These conditions are acceleration, deceleration, coast, or constant load.

INSTALLATION .........................34

PINION SEAL

REMOVAL .............................34

INSTALLATION .........................35

DIFFERENTIAL

DESCRIPTION .........................36

OPERATION ...........................36

REMOVAL .............................36

DISASSEMBLY .........................37

ASSEMBLY ............................38

INSTALLATION .........................38

DIFFERENTIAL CASE BEARINGS

REMOVAL .............................39

INSTALLATION .........................39

PINION GEAR/RING GEAR

REMOVAL .............................40

INSTALLATION .........................42

When road testing, first warm-up the axle fluid by

driving the vehicle at least 5 miles and then accelerate the vehicle to the speed range where the noise is

the greatest. Shift out-of-gear and coast through the

peak-noise range. If the noise stops or changes

greatly:

• Check for insufficient lubricant.

• Incorrect ring gear backlash.

• Gear damage.

Differential side gears and pinions can be checked

by turning the vehicle. They usually do not cause

noise during straight-ahead driving when the gears

are unloaded. The side gears are loaded during vehicle turns. A worn pinion mate shaft can also cause a

snapping or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining, or a growling sound.

Pinion bearings have a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differential. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

heard during a coast, the front pinion bearing is the

source.

Worn or damaged differential bearings usually produce a low pitch noise. Differential bearing noise is

similar to pinion bearing noise. The pitch of differen-

Page 19

DR FRONT AXLE - C205F 3 - 19

FRONT AXLE - C205F (Continued)

tial bearing noise is also constant and varies only

with vehicle speed.

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side-gear thrust washers. A worn

pinion shaft bore will also cause low speed knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by:

• Damaged drive shaft.

• Missing drive shaft balance weight(s).

• Worn or out of balance wheels.

• Loose wheel lug nuts.

• Worn U-joint(s).

• Loose/broken springs.

• Damaged axle shaft bearing(s).

• Loose pinion gear nut.

• Excessive pinion yoke run out.

• Bent axle shaft(s).

Check for loose or damaged front end components

or engine/transmission mounts. These components

can contribute to what appears to be a rear end

vibration. Do not overlook engine accessories, brackets and drive belts.

All driveline components should be examined

before starting any repair.

(Refer to 22 - TIRES/WHEELS - DIAGNOSIS AND

TESTING)

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged) can be caused by:

• High engine idle speed.

• Transmission shift operation.

• Loose engine/transmission/transfer case mounts.

• Worn U-joints.

• Loose spring mounts.

• Loose pinion gear nut and yoke.

• Excessive ring gear backlash.

• Excessive side gear to case clearance.

The source of a snap or a clunk noise can be determined with the assistance of a helper. Raise the vehicle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear. Listen

for the noise, a mechanics stethoscope is helpful in

isolating the source of a noise.

DIAGNOSTIC CHART

Condition Possible Causes Correction

Wheel Noise 1. Wheel loose. 1. Tighten loose nuts.

2. Faulty, brinelled wheel bearing. 2. Replace bearing.

Axle Shaft Noise 1. Misaligned axle tube. 1. Inspect axle tube alignment.

Correct as necessary.

2. Bent or sprung axle shaft. 2. Inspect and correct as necessary.

3. End-play in pinion bearings. 3. Refer to pinion pre-load

information and correct as

necessary.

4. Excessive gear backlash

between the ring gear and pinion.

5. Improper adjustment of pinion

gear bearings.

6. Loose pinion yoke nut. 6. Tighten the pinion yoke nut.

7. Scuffed gear tooth contact

surfaces.

4. Check adjustment of the ring

gear and pinion backlash. Correct

as necessary.

5. Adjust the pinion bearings

pre-load.

7. Inspect and replace as

necessary.

Page 20

3 - 20 FRONT AXLE - C205F DR

FRONT AXLE - C205F (Continued)

Condition Possible Causes Correction

Axle Shaft Broke 1. Misaligned axle tube. 1. Replace the broken shaft after

correcting tube mis-alignment.

2 Vehicle overloaded. 2. Replace broken shaft and avoid

excessive weight on vehicle.

3. Erratic clutch operation. 3. Replace broken shaft and avoid

or correct erratic clutch operation.

4. Grabbing clutch. 4. Replace broken shaft and inspect

and repair clutch as necessary.

Differential Cracked 1. Improper adjustment of the

differential bearings.

2. Excessive ring gear backlash. 2. Replace case and inspect gears

3. Vehicle overloaded. 3. Replace case and inspect gears

4. Erratic clutch operation. 4. Replace case and inspect gears

Differential Gears Scored 1. Insufficient lubrication. 1. Replace scored gears. Fill

2. Improper grade of lubricant. 2. Replace scored gears. Fill

3. Excessive spinning of one

wheel/tire.

1. Replace case and inspect gears

and bearings for further damage.

Set differential bearing pre-load

properly.

and bearings for further damage.

Set ring gear backlash properly.

and bearings for further damage.

Avoid excessive vehicle weight.

and bearings for further damage.

Avoid erratic use of clutch.

differential with the correct fluid type

and quantity.

differential with the correct fluid type

and quantity.

3. Replace scored gears. Inspect all

gears, pinion bores, and shaft for

damage. Service as necessary.

Loss Of Lubricant 1. Lubricant level too high. 1. Drain lubricant to the correct

level.

2. Worn axle shaft seals. 2. Replace seals.

3. Cracked differential housing. 3. Repair as necessary.

4. Worn pinion seal. 4. Replace seal.

5. Worn/scored yoke. 5. Replace yoke and seal.

6. Axle cover not properly sealed. 6. Remove, clean, and re-seal

cover.

Axle Overheating 1. Lubricant level low. 1. Fill differential to correct level.

2. Improper grade of lubricant. 2. Fill differential with the correct

fluid type and quantity.

3. Bearing pre-loads too high. 3. Re-adjust bearing pre-loads.

4. Insufficient ring gear backlash. 4. Re-adjust ring gear backlash.

Page 21

DR FRONT AXLE - C205F 3 - 21

FRONT AXLE - C205F (Continued)

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

4. Worn teeth on ring gear and/or

pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

8. Loose differential bearing cap

bolts.

9. Housing not machined properly. 9. Replace housing.

2. Check ring gear and pinion

contact pattern.

ring gear and pinion.

4. Replace ring gear and pinion.

pre-load.

Replace components as necessary.

8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

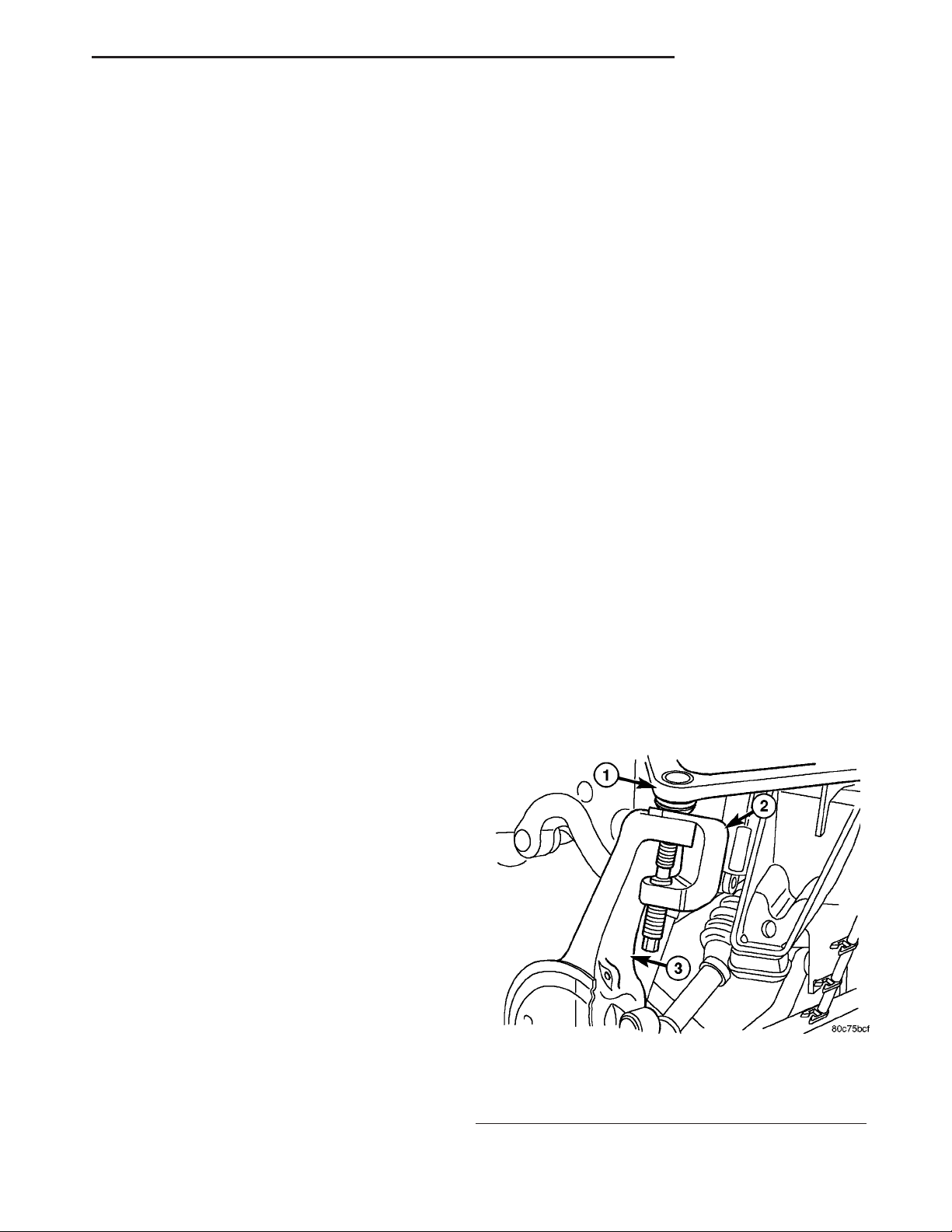

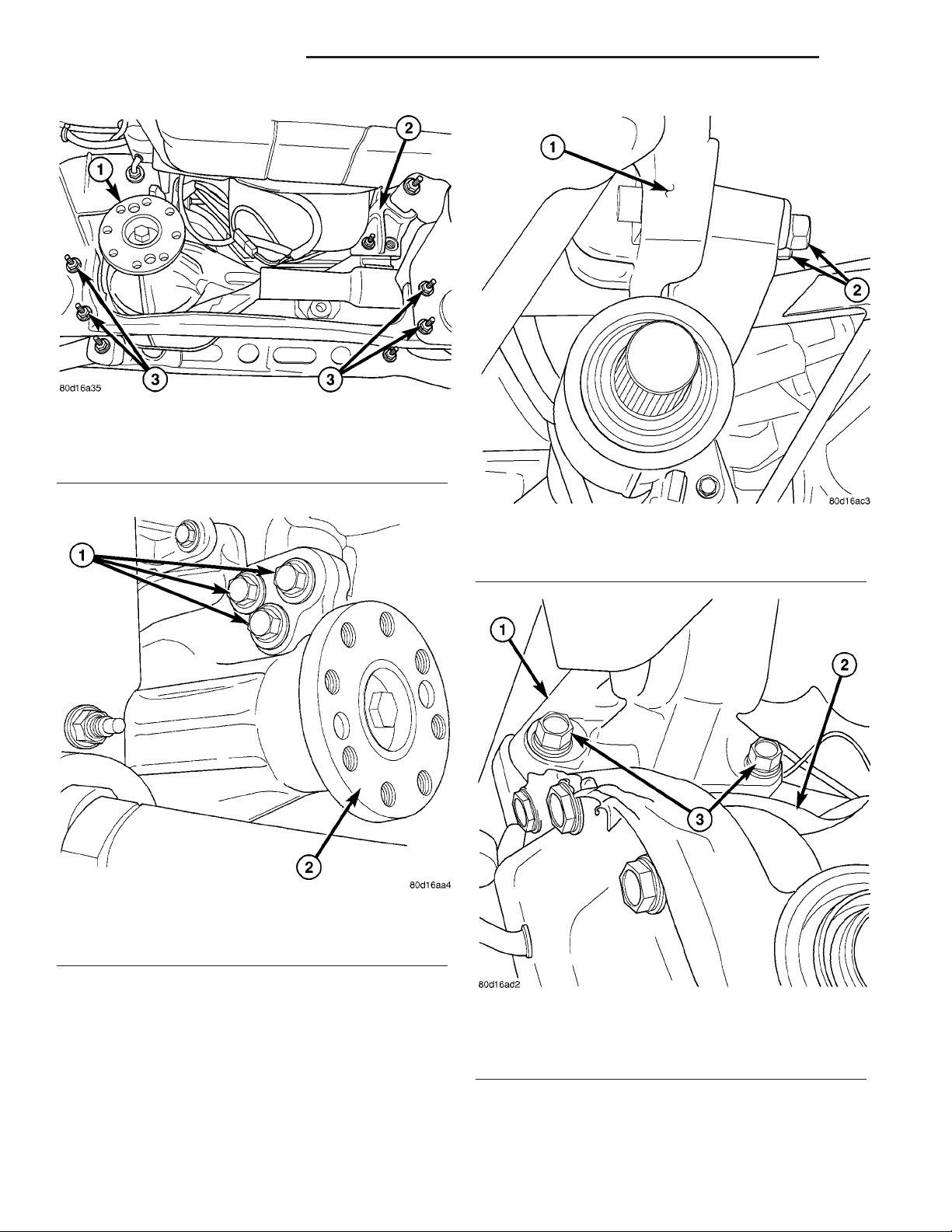

REMOVAL

(1) Place transmission in netural.

(2) Raise and support the vehicle.

(3) Remove tire and wheel assemblies.

(4) Remove axle half shafts.

(5) Remove exhaust crossover.

(6) Mark front propeller shaft and remove shaft.

(7) Remove suspension crossmember mounting

bolts (Fig. 1) and remove crossmember.

(8) Support axle with hydraulic jack.

(9) Remove axle housing pinion mounting bolts

(Fig. 2).

(10) Remove axle shaft tube mounting bolts (Fig.

3).

(11) Remove differential housing mounting bolts

(Fig. 4).

(12) Lower axle from the vehicle.

INSTALLATION

(1) Raise axle into position.

(2) Install axle mounting bolts and tighten nuts to

95 N·m (70 ft. lbs.).

(3) Install suspension crossmember and bolts.

Tighten crossmember nuts to 102 N·m (75 ft. lbs.).

(4) Install front propeller shaft with reference

marks aligned (Fig. 5) and tighten bolts to 115 N·m

(85 ft. lbs.).

(5) Install exhaust crossover.

(6) Install axle half shafts.

(7) Check the differential fluid level and add fluid

if necessary.

(8) Install tire and wheel assemblies.

(9) Remove support lower the vehicle.

ADJUSTMENTS

Ring gear and pinion are supplied as matched sets

only. The identifying numbers for the ring gear and

Page 22

3 - 22 FRONT AXLE - C205F DR

FRONT AXLE - C205F (Continued)

Fig. 1 SUSPENSION CROSSMEMBER

1 - PINION FLANGE

2 - AXLE TUBE MOUNTING BRACKET

3 - CROSSMEMBER BOLTS

Fig. 2 HOUSING PINION MOUNTING BOLTS

1 - MOUNTING BOLTS

2 - PINION FLANGE

Fig. 3 AXLE TUBE MOUNT

1 - MOUNTING BOLTS

2 - BOLTS

pinion are painted onto the pinion gear shaft and the

side of the ring gear. A plus (+) number, minus (–)

number or zero (0) along with the gear set sequence

number (01 to 99) is on each gear. This first number

is the amount (in thousandths of an inch) the depth

varies from the standard depth setting of a pinion

marked with a (0). The next two numbers are the

sequence number of the gear set. The standard setting from the center line of the ring gear to the back

Fig. 4 DIFFERENTIAL MOUNT

1 - DIFFERENTIAL MOUNT

2 - DIFFERENTIAL HOUSING

3 - MOUNTING BOLTS

face of the pinion is 99.690 mm (3.925 in.). The standard depth provides the best teeth contact pattern.

Compensation for pinion depth variance is

achieved with select shims. The shims are placed

Page 23

DR FRONT AXLE - C205F 3 - 23

FRONT AXLE - C205F (Continued)

Fig. 6 ADJUSTMENT SHIM

1 - PINION GEAR DEPTH SHIM

2 - DIFFERENTIAL BEARING PRELOAD SHIM

3 - RING GEAR

4 - DIFFERENTIAL BEARING PRELOAD SHIM

5 - COLLAPSIBLE SPACER

Fig. 5 COMPANION FLANGE

1 - COMPANION FLANGE

2 - PROPELLER SHAFT

3 - FLANGE YOKE

4 - REFERENCE MARK

between the rear pinion bearing cone and the pinion

gear head. (Fig. 6).

If a new gear set is being installed, note the depth

variance marked on both the original and replacement pinion. Add or subtract the thickness of the

original depth shims to compensate for the difference

in the depth variances. Refer to the Pinion Gear

PINION GEAR DEPTH VARIANCE

Original Pinion

New Pinion Gear Depth Variance

Gear Depth

Variance

24 23 22 21 0 +1 +2 +3 +4

+4 +0.008 +0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 0

+3 +0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 0 20.001

+2 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 0 20.001 20.002

+1 +0.005 +0.004 +0.003 +0.002 +0.001 0 20.001 20.002 20.003

0 +0.004 +0.003 +0.002 +0.001 0 20.001 20.002 20.003 20.004

21 +0.003 +0.002 +0.001 0 20.001 20.002 20.003 20.004 20.005

22 +0.002 +0.001 0 20.001 20.002 20.003 20.004 20.005 20.006

23 +0.001 0 20.001 20.002 20.003 20.004 20.005 20.006 20.007

24 0 20.001 20.002 20.003 20.004 20.005 20.006 20.007 20.008

Depth Variance charts. Note where Old and New

Pinion Marking columns intersect. Intersecting figure

represents plus or minus amount needed.

Note the painted number on the shaft of the drive

pinion (–1, –2, 0, +1, +2, etc.). The numbers represent thousands of an inch deviation from the standard. If the number is negative, add that value to the

required thickness of the depth shim(s). If the number is positive, subtract that value from the thickness

of the depth shim(s). If the number is 0 no change is

necessary.

Page 24

3 - 24 FRONT AXLE - C205F DR

FRONT AXLE - C205F (Continued)

PINION DEPTH MEASUREMENT AND ADJUSTMENT

Measurements are taken with pinion cups and pinion bearings installed in housing. Take measurements with a Pinion Gauge Set, Pinion Block 8177,

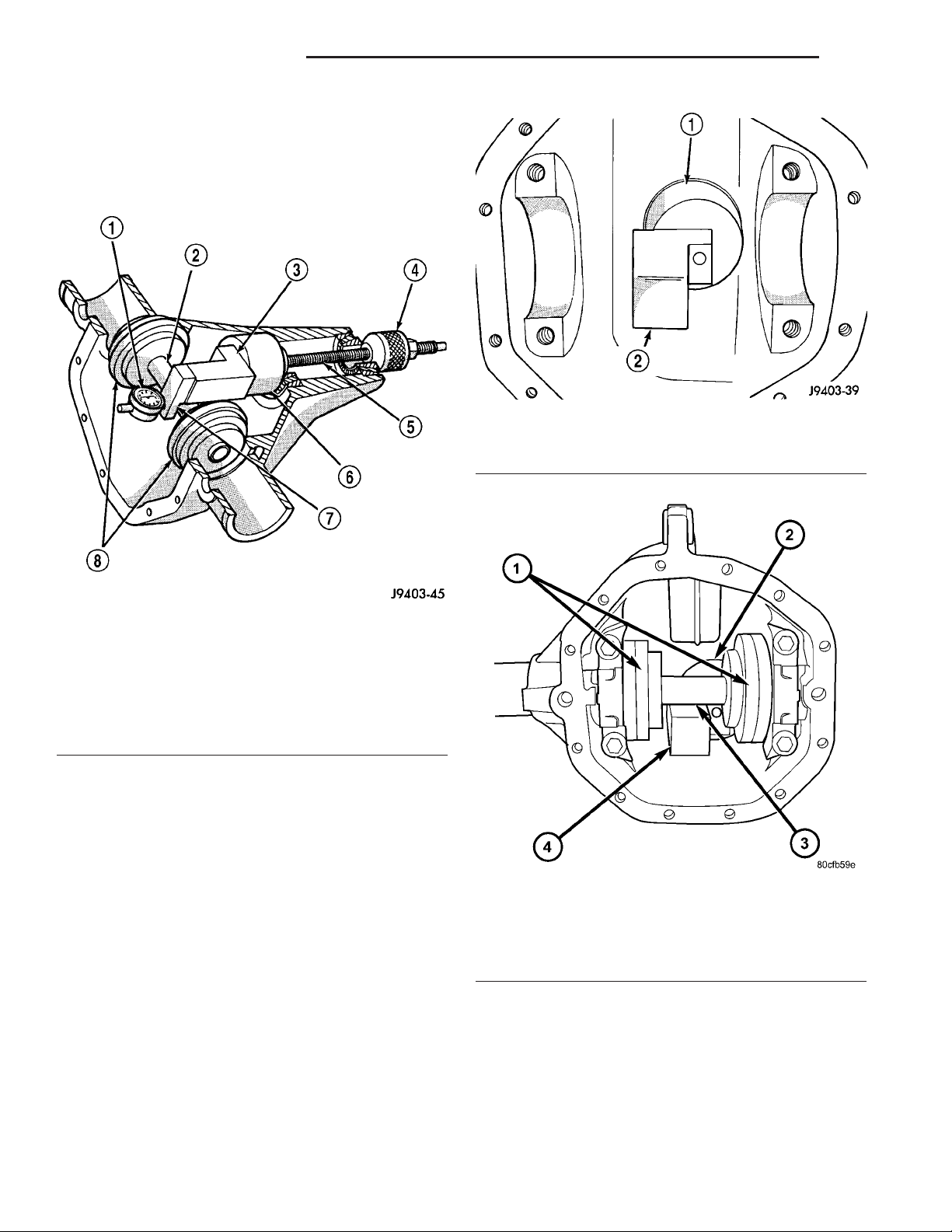

Arbor Discs 8541 and Dial Indicator C-3339 (Fig. 7).

Fig. 8 PINION HEIGHT BLOCK

1 - PINION BLOCK

2 - PINION HEIGHT BLOCK

Fig. 7 PINION GEAR DEPTH GAUGE

1 - DIAL INDICATOR

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

(1) Assemble Pinion Height Block 6739, Pinion

Block 8177 and rear pinion bearing onto Screw 6741

(Fig. 7).

(2) Insert assembled height gauge components,

rear bearing and screw into the housing through the

pinion bearing cups (Fig. 8).

(3) Install front pinion bearing and Cone 6740 onto

the screw hand tight (Fig. 7).

(4) Place Arbor Discs 8541 on Arbor D-115-3 in

position in the housing side bearing cradles (Fig. 9).

Install differential bearing caps on arbor discs and

tighten cap bolts to specification.

(5) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(6) Place Scooter Block/Dial Indicator in position

in the housing so dial probe and scooter block are

flush against the surface of the pinion height block.

Hold scooter block in place and zero the dial indicator. Tighten dial indicator face lock screw.

(7) Slide the dial indicator probe across the gap

between the pinion height block and the arbor bar

Fig. 9 PINION GAUGE TOOLS

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

with the scooter block against the pinion height block

(Fig. 10). Slide the dial probe to the crest of the arbor

bar and record the highest reading.

(8) Select a shim equal to the dial indicator reading plus the drive pinion gear depth variance number

marked on the shaft of the pinion gear using the

opposite sign on the variance number. For example, if

the depth variance is –2, add +0.002 in. to the dial

indicator reading.

Page 25

DR FRONT AXLE - C205F 3 - 25

FRONT AXLE - C205F (Continued)

Fig. 10 PINION GEAR DEPTH MEASUREMENT

1 - ARBOR

2 - SCOOTER BLOCK

3 - DIAL INDICATOR

(9) Remove the pinion depth gauge components

from the housing

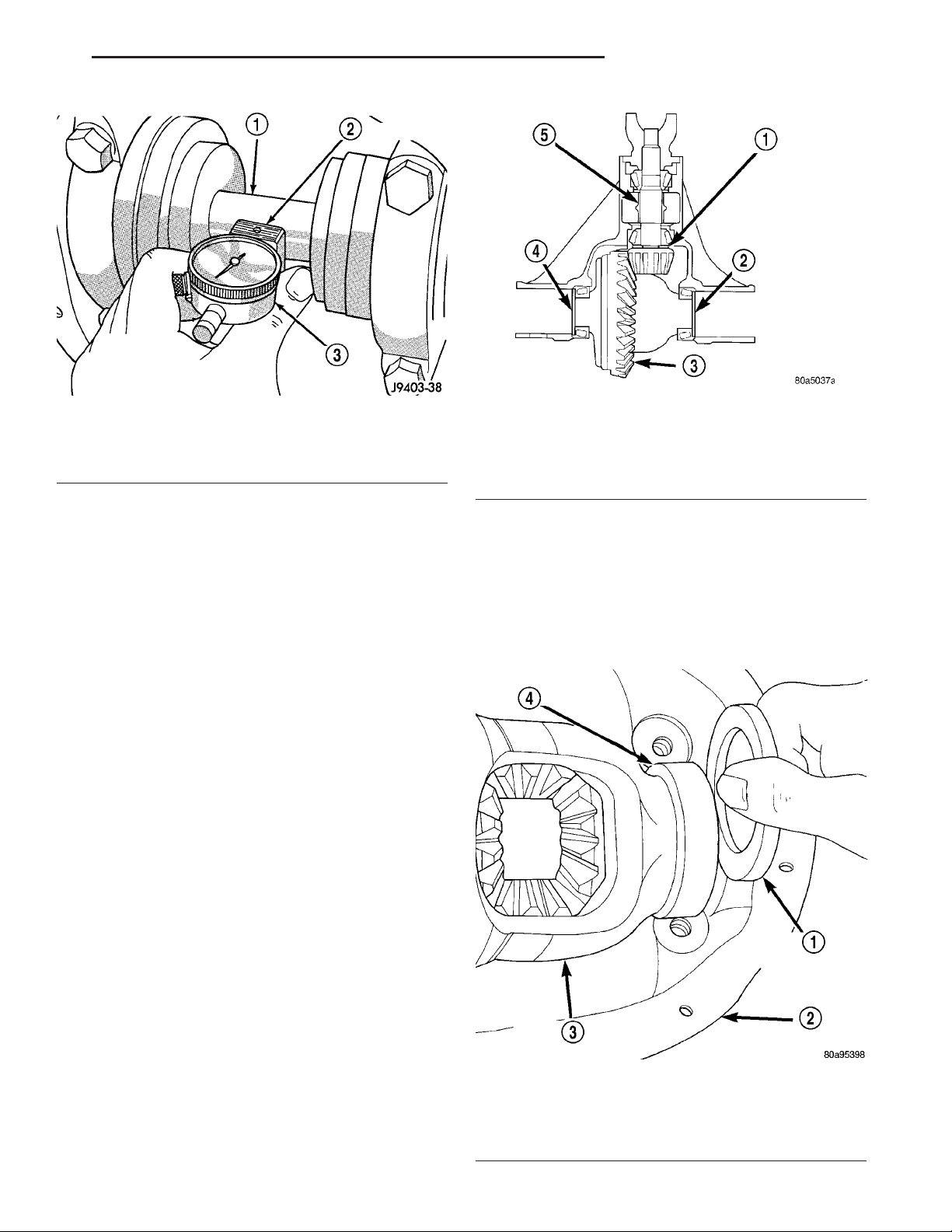

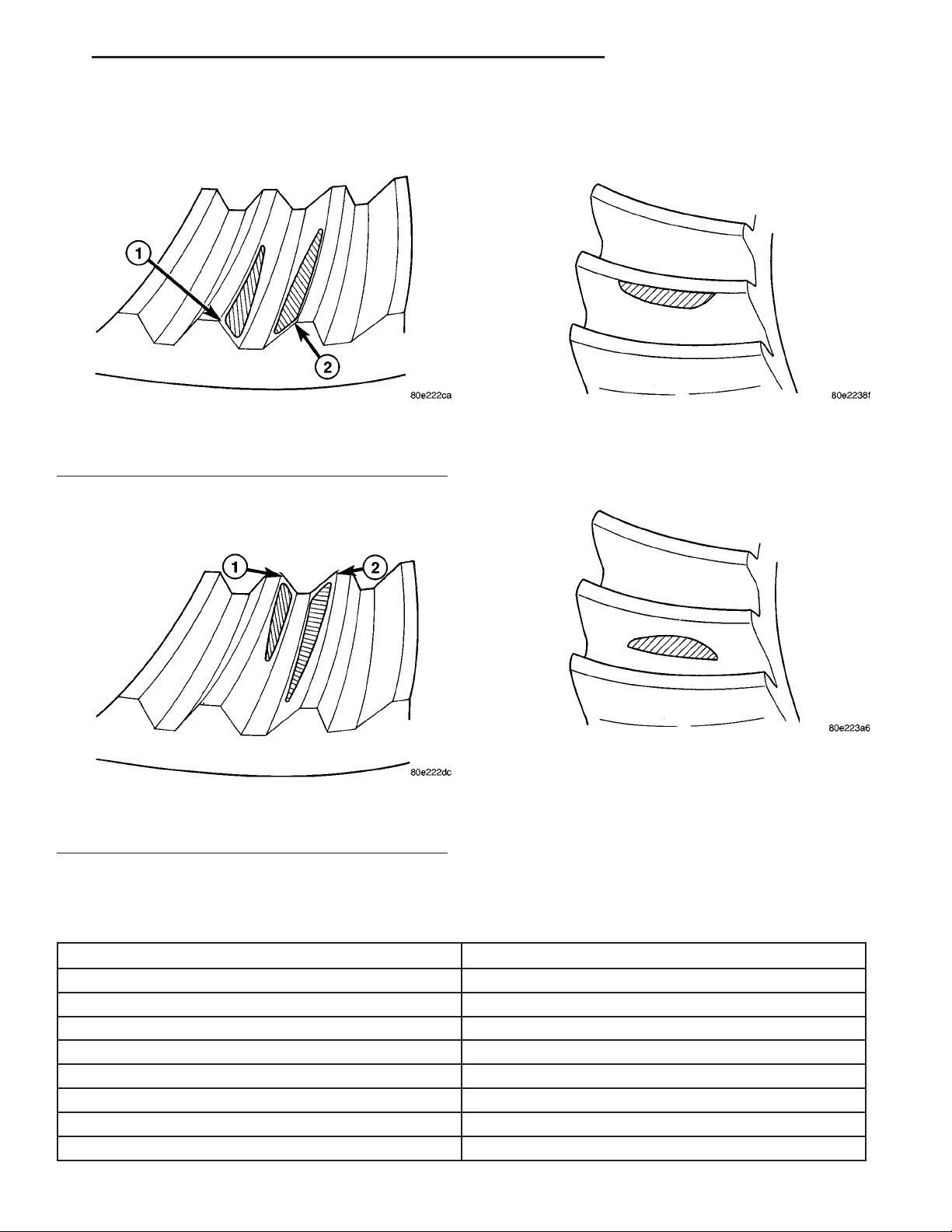

DIFFERENTIAL BEARING PRELOAD AND GEAR

BACKLASH

Differential side bearing preload and gear backlash

is achieved by selective shims inserted between the

bearing cup and the housing. The proper shim thickness can be determined using slip-fit Dummy Bearings 8398 in place of the differential side bearings

and a Dial Indicator C-3339. Before proceeding with

the differential bearing preload and gear backlash

measurements, measure the pinion gear depth and

prepare the pinion for installation. Establishing

proper pinion gear depth is essential to establishing

gear backlash and tooth contact patterns. After the

overall shim thickness to take up differential side

play is measured, the pinion is installed, and the

gear backlash shim thickness is measured. The overall shim thickness is the total of the dial indicator

reading, starting point shim thicknesses, and the

preload specification added together. The gear backlash measurement determines the thickness of the

shim used on the ring gear side of the differential

case. Subtract the gear backlash shim thickness from

the total overall shim thickness and select that

amount for the pinion side of the differential (Fig.

11).

Fig. 11 ADJUSTMENT SHIM

1 - PINION GEAR DEPTH SHIM

2 - DIFFERENTIAL BEARING PRELOAD SHIM

3 - RING GEAR

4 - DIFFERENTIAL BEARING PRELOAD SHIM

5 - COLLAPSIBLE SPACER

(2) Install ring gear if necessary, on differential

case and tighten bolts to specification.

(3) Install Dummy Bearings 8398 on differential

case.

(4) Install differential case in the housing.

(5) Insert Dummy Shims 8107 3.0 mm (0.118 in.)

starting point shims between both dummy bearings

and the housing (Fig. 12).

SHIM SELECTION

NOTE: It is difficult to salvage the differential side

bearings during the removal procedure. Install

replacement bearings if necessary.

(1) Remove side bearings from differential case.

Fig. 12 DUMMY SHIM

1 - DUMMY SHIM

2 - DIFFERENTIAL HOUSING

3 - DIFFERENTIAL CASE

4 - DUMMY BEARINGS

Page 26

3 - 26 FRONT AXLE - C205F DR

FRONT AXLE - C205F (Continued)

(6) Install the marked bearing caps in their correct

positions. Install and snug the bolts.

(7) Using a dead-blow hammer to seat the differential dummy bearings to each side of the differential

housing (Fig. 13) and (Fig. 14).

Fig. 13 SEAT PINION GEAR SIDE

1 - DEAD-BLOW HAMMER

2 - HOUSING

3 - PINION GEAR SIDE

(8) Install Pilot Stud C-3288-B in cover bolt hole

below ring gear.

(9) Attach Dial Indicator C-3339 to post and position dial indicator plunger on a flat surface on a ring

gear bolt head (Fig. 15).

(10) Push and hold differential to the pinion gear

side of the housing (Fig. 16) and zero dial indicator.

(11) Push and hold differential case to the ring

gear side and record dial indicator reading (Fig. 17).

(12) Add the dial indicator reading to the starting

point shim thicknesses to determine the total shim

thickness necessary to achieve zero differential end

play.

(13) Add 0.2 mm (0.008 in) to the zero end play

total. This new total represents the shims needed to

preload the new differential case bearings.

(14) Rotate dial indicator out of the way on pilot

stud.

(15) Remove differential case, dummy bearings

and dummy shims from the housing.

(16) Install the pinion gear in the housing. Install

the companion flange and establish the correct pinion

rotating torque.

Fig. 14 SEAT RING GEAR SIDE

1 - HOUSING

2 - DEAD-BLOW HAMMER

3 - RING GEAR SIDE

Fig. 15 DIFFERENTIAL SIDE PLAY

1 - DIFFERENTIAL

2 - PILOT STUD

3 - DIAL INDICATOR

4 - HOUSING

(17) Install differential case and Dummy Bearings

in the housing with a single dummy shim on the ring

gear side of the axle and tighten retaining cap bolts.

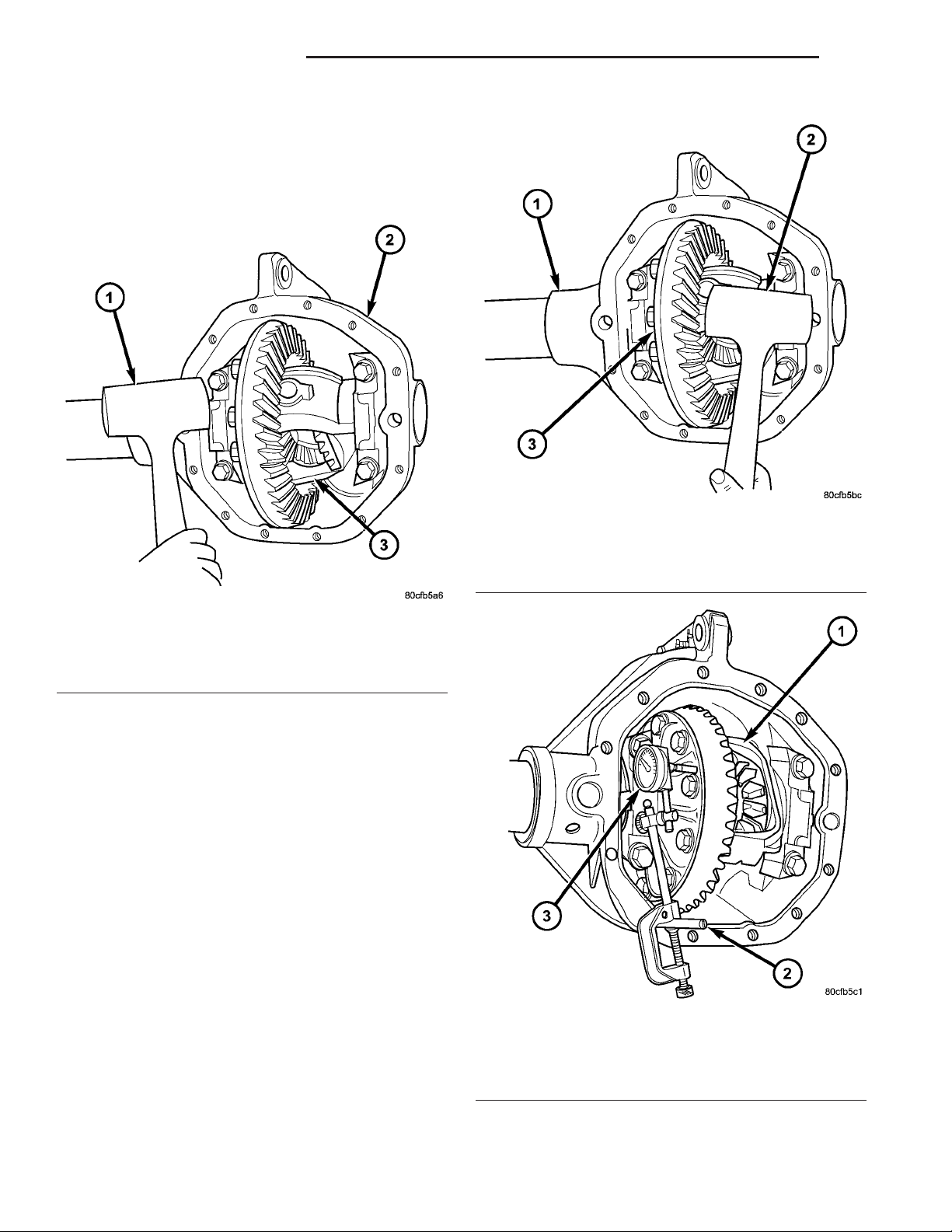

Page 27

DR FRONT AXLE - C205F 3 - 27

FRONT AXLE - C205F (Continued)

(20) Zero dial indicator face to pointer.

(21) Push and hold differential case to ring gear

side of the housing.

(22) Record dial indicator reading.

(23) Subtract 0.05 mm (0.002 in.) from the dial

indicator reading to compensate for backlash between

ring and pinion gears. Add the resulting measurement to the thickness of the single dummy shim.

This is the thickness of shim required to achieve

proper backlash.

(24) Subtract the backlash shim thickness from

the total preload shim thickness. The remainder is

the shim thickness required on the pinion side of the

housing.

(25) Rotate dial indicator out of the way on pilot

stud.

(26) Remove differential case, dummy bearings

and dummy shim from the housing.

(27) Install new side bearing cones and cups on

differential case.

(28) Install Spreader W-129-B and Adapter Plates

8142-A on the housing and spread open enough to

Fig. 16 ZERO DIAL INDICATOR

1 - PINION GEAR SIDE

2 - PILOT STUD

3 - DIAL INDICATOR

receive differential case.

CAUTION: Never spread over 0.50 mm (0.020 in). If

the housing is over-spread, it could be distorted or

damaged.

Fig. 17 RECORD DIAL INDICATOR

1 - DIAL INDICATOR

2 - HOUSING

3 - RING GEAR SIDE

(18) Position the dial indicator plunger on a flat

surface between the ring gear bolt heads (Fig. 15).

(19) Push and hold differential case toward pinion.

(29) Place the side bearing shims in the differential housing against the housing shoulder.

(30) Install the differential case in the housing.

(31) Rotate the differential case several times to

seat the side bearings.

(32) Position the dial indicator plunger against a

ring gear tooth (Fig. 18).

Fig. 18 RING GEAR BACKLASH

1 - RING GEAR

2 - DIAL INDICATOR

(33) Push and hold ring gear upward while not

allowing the pinion gear to rotate.

Page 28

3 - 28 FRONT AXLE - C205F DR

FRONT AXLE - C205F (Continued)

(34) Zero dial indicator face to pointer.

(35) Push and hold ring gear downward while not

allowing the pinion gear to rotate. Dial indicator

reading should be between 0.12 mm (0.005 in.) and

0.20 mm (0.008 in.). If backlash is not within specifications transfer the necessary amount of shim thickness from one side of the differential housing to the

other (Fig. 19).

(36) Verify differential case and ring gear runout

by measuring ring to pinion gear backlash at eight

locations around the ring gear. Readings should not

vary more than 0.05 mm (0.002 in.). If readings vary

more than specified, the ring gear or the differential

case is defective.

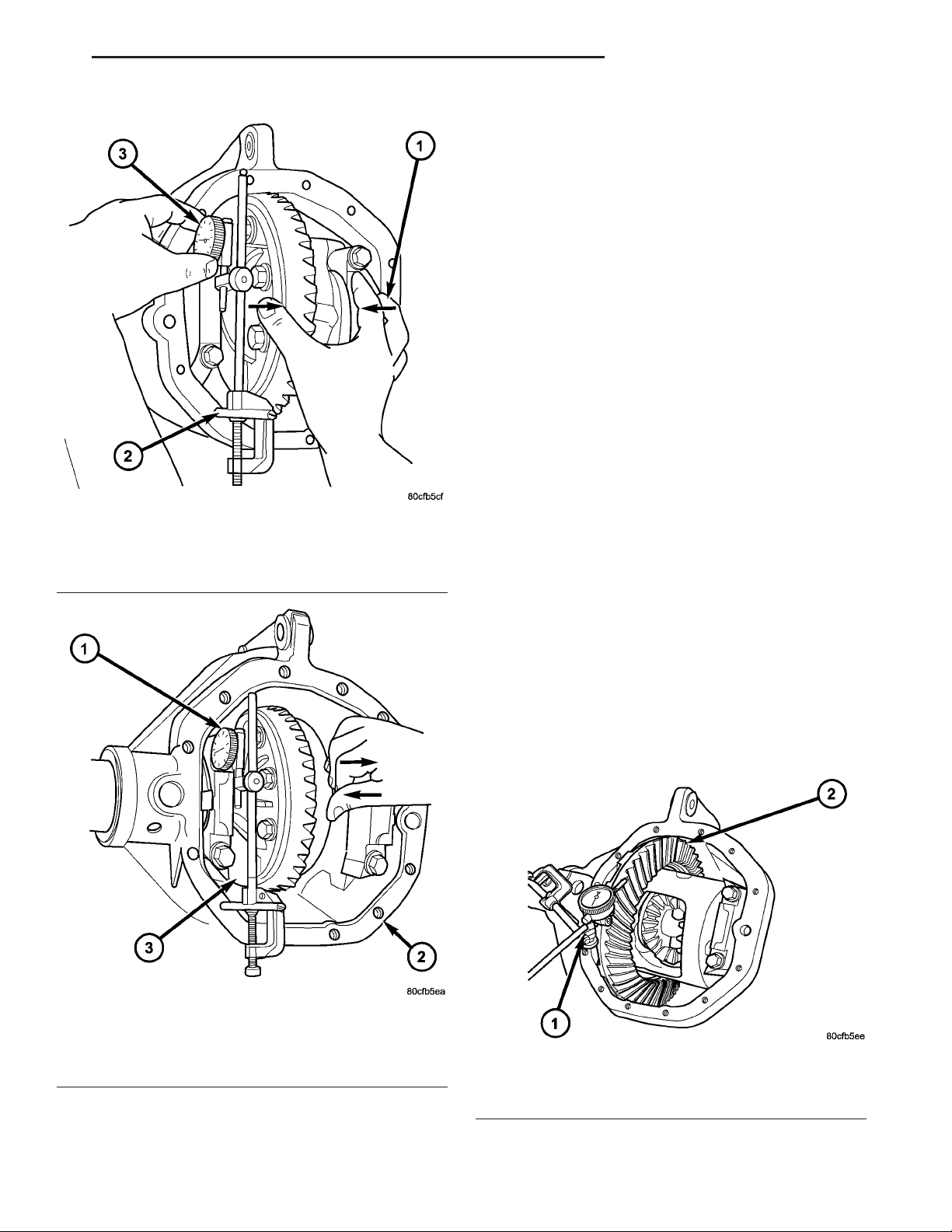

After the proper backlash is achieved, perform the

Gear Contact Pattern procedure.

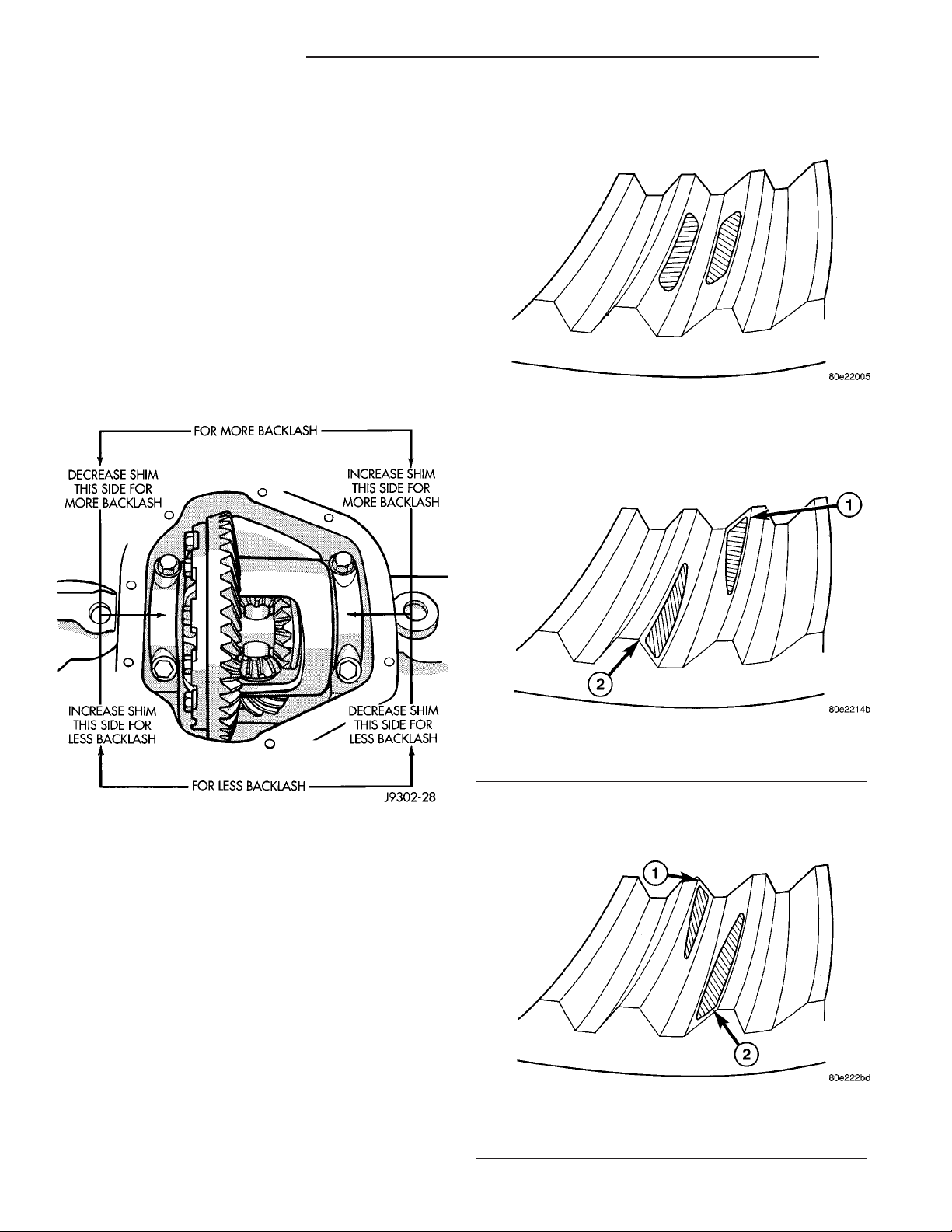

• Gear contact pattern correct (Fig. 20). Backlash

and pinion depth is correct.

Fig. 20 CORRECT CONTACT PATTERN

• Ring gear too far away from pinion gear (Fig.

21). Decrease backlash by moving the ring closer to

the pinion gear.

Fig. 19 BACKLASH SHIM ADJUSTMENT

GEAR CONTACT PATTERN

Gear tooth contact pattern is used to verify the correct running position of the ring and pinion gears.

This will produce low noise and long gear life. Gears

which are not positioned properly may be noisy and

have shorten gear life.

(1) Wipe clean each tooth of the ring gear.

(2) Apply gear marking compound to all of the ring

gear teeth.

(3) Verify bearing cap bolts are torque specification.

(4) Apply the brakes lightly to create at 14 N·m

(10 ft. lbs.) pinion rotating torque.

(5) Rotate the pinion/pinion yoke 4 full revolutions

in each directions.

(6) Read gear tooth contact pattern:

Fig. 21 INCORRECT BACKLASH

1 - COAST SIDE TOE

2 - DRIVE SIDE HEEL

• Ring gear too close to pinion gear (Fig. 22).

Increase backlash, by moving the ring away from the

pinion gear.

Fig. 22 INCORRECT BACKLASH

1 - DRIVE SIDE TOE

2 - COAST SIDE HEEL

Page 29

DR FRONT AXLE - C205F 3 - 29

FRONT AXLE - C205F (Continued)

• Ring gear too far away from pinion gear (Fig.

23). Decrease backlash, by moving the ring closer to

the pinion gear.

Fig. 23 INCORRECT BACKLASH

1 - DRIVE SIDE HEEL

2 - COAST SIDE HEEL

• Ring gear too close to pinion gear (Fig. 24).

Increase backlash, by moving the ring away from the

pinion gear.

• Pinion gear set too low (Fig. 25). Increase pinion

gear height, by increasing the pinion depth shim

thickness.

Fig. 25 LOW PINION HEIGHT

• Pinion gear set too high (Fig. 26). Decrease pinion depth, by decreasing the pinion depth shim thickness.

Fig. 24 INCORRECT BACKLASH

1 - DRIVE SIDE TOE

2 - COAST SIDE TOE

SPECIFICATIONS

Differential Case Flange Runout 0.076 mm (0.003 in.)

Differential Side Gear Clearance 0-0.15 mm (0-0.006 in.)

Pinion Bearing Preload - New Bearings 2.0-2.8 N·m (18-25 in. lbs.)

Pinion Bearing Preload - Original Bearings 1-2 N·m (10-20 in. lbs.)

Fig. 26 HIGH PINION HEIGHT

AXLE SPECIFICATIONS

DESCRIPTION SPECIFICATION

Axle Ratio 3.55, 3.92

Ring Gear Diameter 205 mm (8.0 in.)

Ring Gear Backlash 0.12-0.20 mm (0.005-0.008 in.)

Ring Gear Runout 0.12 mm (0.005 in.)

Page 30

3 - 30 FRONT AXLE - C205F DR

FRONT AXLE - C205F (Continued)

TORQUE SPECIFICATIONS

DESCRIPTION N·m Ft. Lbs. In. Lbs.

Mounting Nuts 95 70 -

Differential Fill Hole Plug 34 25 -

Differential Cover Bolts 22 15 -

Bearing Cap Bolts 61 45 -

Ring Gear Bolts 108 80 -

Pinion Nut 271-475 200-350 -

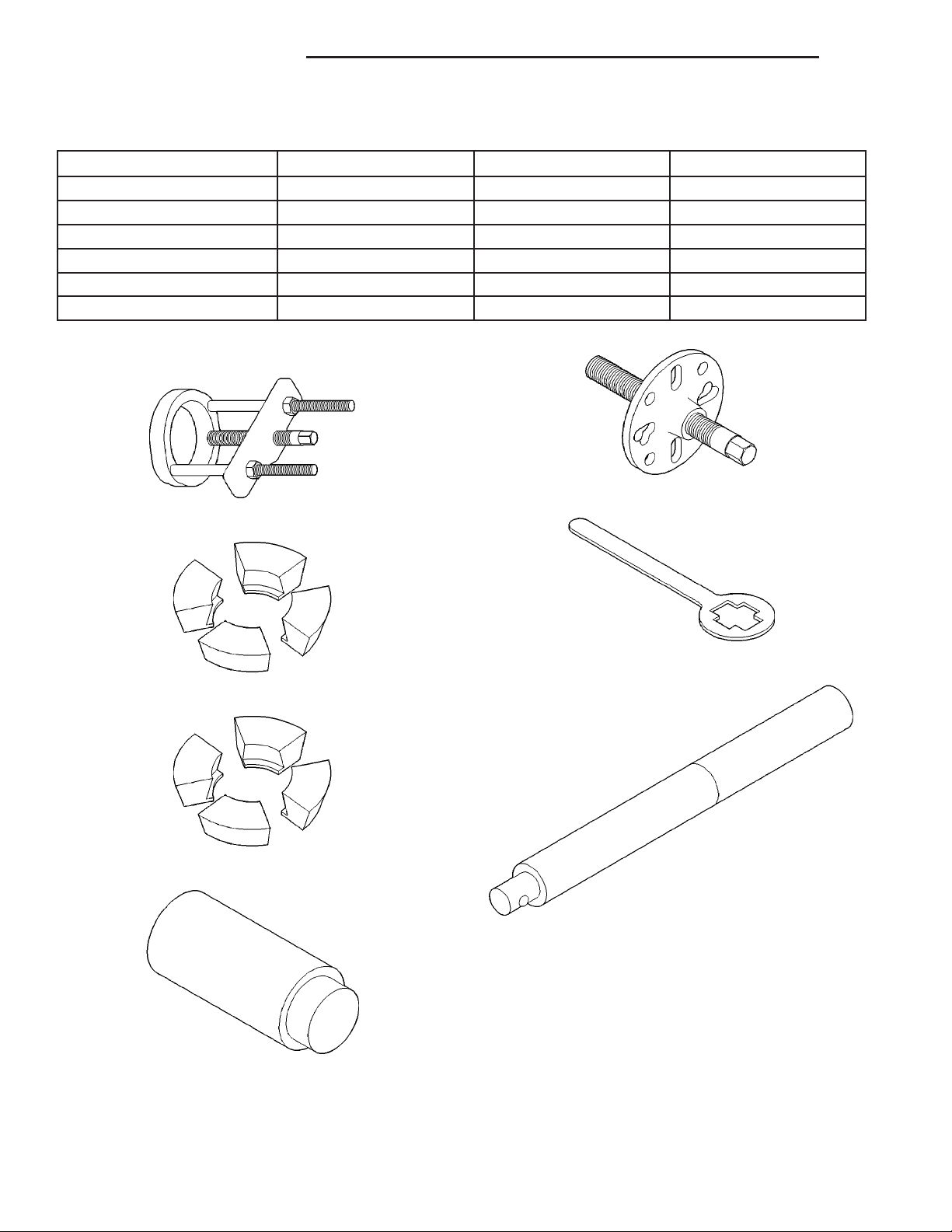

SPECIAL TOOLS

PULLER C-452

PULLER C-293-PA

ADAPTER C-293-42

ADAPTER C-293-48

PLUG C-293-3

HOLDER 6719A

HANDLE C-4171

Page 31

DR FRONT AXLE - C205F 3 - 31

FRONT AXLE - C205F (Continued)

REMOVER 8401

INSTALLER 8693

REMOVER 8831

INSTALLER 8695

INSTALLER 8692

INSTALLER 6448

REMOVER C-4660-A

INSTALLER 8694

CUP 8150

Page 32

3 - 32 FRONT AXLE - C205F DR

FRONT AXLE - C205F (Continued)

INSTALLER 5063

PINION BLOCK 8177

PINION DEPTH SET 6775

DIAL INDICATOR C-3339

DUMMY SHIM 8107

DUMMY BEARING 8398

SPREADER W-129-B

PILOTS C-3288-B

INSTALLER C-3718

ADAPTER PLATES 8142A

Page 33

DR FRONT AXLE - C205F 3 - 33

AXLE SHAFTS

REMOVAL

(1) Remove half shaft from vehicle.

(2) Remove skid plate, if equipped.

(3) Clean axle seal area.

(4) Remove snap ring from the axle shaft.

(5) Remove axle with Remove 8420A Collar 8420-3

and Slide Hammer C-3752 (Fig. 27).

Fig. 27 AXLE SHAFT PULLER

1 - SNAP RING GROVE

2 - SLID HAMMER THREADS

3 - REMOVER BLOCKS

4 - REMOVER COLLAR

INSTALLATION

INSTALLATION

(1) Clean axle shaft bore clean.

(2) Install a new axle shaft seal with Installer

8694 and Handle C-4171.

(3) Lubricate seal lip with gear lubricant.

(4) Insert axle shaft through seal, bearing, and

engage it into side gear splines. Push firmly on the

axle shaft to engage the snap-ring.

NOTE: Use care to prevent shaft splines from damaging axle shaft seal lip.

(5) Install axle shaft O-ring.

(6) Check the differential fluid level and add fluid

if necessary.

(7) Install skid plate, if necessary.

(8) Install half shaft.

AXLE BEARINGS

REMOVAL

(1) Remove half shaft from vehicle.

(2) Remove skid plate, if equipped.

(3) Clean axle seal area.

(4) Remove axle shaft O-ring.

(5) Remove axle shaft.

(6) Remove axle shaft seal.

(7) Install axle shaft bearing Remover C-4660-A in

the bearing (Fig. 28). Then tighten the nut to spread

the remover in the bearing.

NOTE: Use care to prevent shaft splines from damaging axle shaft seal lip.

(1) Lubricate bearing bore and seal lip with gear

lubricant.

(2) Insert axle shaft through seal, bearing, and

engage it into side gear splines. Push firmly on the

axle shaft to engage the snap-ring.

(3) Check the differential fluid level and add fluid

if necessary.

(4) Install skid plate, if necessary.

(5) Install half shaft.

AXLE SHAFT SEALS

REMOVAL

(1) Remove half shaft from vehicle.

(2) Remove skid plate, if equipped.

(3) Clean axle seal area.

(4) Remove axle shaft O-ring.

(5) Remove axle shaft.

(6) Remove axle shaft seal with a small pry bar.

Fig. 28 BEARING REMOVER

1 - AXLE BEARING

2 - NUT

3 - REMOVER

(8) Install the bearing remove cup, bearing and

nut (Fig. 29). Then tighten the nut to draw the bearing out.

Page 34

3 - 34 FRONT AXLE - C205F DR

AXLE BEARINGS (Continued)

(6) Install axle shaft O-ring.

(7) Check the differential fluid level and add fluid

if necessary.

(8) Install skid plate, if necessary.

(9) Install half shaft.

PINION SEAL

REMOVAL

(1) Remove skid plate, if equipped.

(2) Remove both half shafts.

(3) Mark the propeller shaft and pinion companion

flange (Fig. 31) for installation reference.

Fig. 29 BEARING REMOVER CUP

1 - REMOVER CUP

2 - BEARING

3 - NUT

(9) Inspect the axle shaft tube bore for roughness

and burrs. Remove as necessary.

INSTALLATION

(1) Wipe the axle shaft tube bore clean.

(2) Install axle shaft bearing with Installer 5063

and Handle C-4171 (Fig. 30).

Fig. 30 BEARING INSTALLER

1 - INSTALLER

2 - HANDLE

(3) Install a new axle shaft seal with Installer

8694 and Handle C-4171.

(4) Lubricate seal lip with gear lubricant.

(5) Insert axle shaft through seal, bearing and

engage it into side gear splines. Push firmly on the

axle shaft to engage the snap-ring.

NOTE: Use care to prevent shaft splines from damaging axle shaft seal lip.

Fig. 31 COMPANION FLANGE

1 - COMPANION FLANGE

2 - PROPELLER SHAFT

3 - FLANGE YOKE

4 - REFERENCE MARK

(4) Remove the front propeller shaft.

(5) Rotate the pinion gear three or four times and

verify pinion rotates smoothly.

(6) Record pinion rotating torque with an inch

pound torque wrench, for installation reference (Fig.

32).

(7) Position Holder 6719 against the companion

flange and install a four bolts and washers into the

threaded holes and tighten the bolts.

(8) Remove the pinion nut.

(9) Remove the companion flange with Remover

C-452 (Fig. 33).

(10) Remove pinion seal with a pry tool or a slide

hammer mounted screw.

Page 35

DR FRONT AXLE - C205F 3 - 35

PINION SEAL (Continued)

Fig. 34 PINION SEAL INSTALLER

1 - HANDLE

2 - INSTALLER

(4) Position holder against the companion flange

and install four bolts and washers into the threaded

holes. Tighten the bolt and washer so that the holder

is held to the flange.

Fig. 32 PINION ROTATING TORQUE

1 - COMPANION FLANGE

2 - INCH POUND TORQUE WRENCH

(5) Install a new pinion nut onto the pinion shaft

and tighten the pinion nut until there is zero bearing

end-play (Fig. 35).

Fig. 33 COMPANION FLANGE REMOVER

1 - COMPANION FLANGE

2 - PULLER TOOL

CAUTION: Do not exceed 271 N·m (200 ft. lbs.) the

minimum tightening torque when installing the

companion flange at this point. Damage to the collapsible spacer or bearings may result.

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal.

(2) Install seal with Installer 8695 and Handle

C-4171 (Fig. 34).

(3) Install companion flange onto the pinion with

Installer C-3718 and Holder 6719A.

Fig. 35 COMPANION FLANGE HOLDER

1 - DIFFERENTIAL HOUSING

2 - COMPANION FLANGE HOLDER

3 - TORQUE WRENCH

Page 36

3 - 36 FRONT AXLE - C205F DR

PINION SEAL (Continued)

CAUTION: Never loosen pinion nut to decrease pinion bearing rotating torque and never exceed specified preload torque. If preload torque or rotating

torque is exceeded a new collapsible spacer must

be installed.

(6) Record pinion rotating torque using an inch

pound torque wrench. The rotating torque should be

equal to the reading recorded during removal plus an

additional 0.56 N·m (5 in. lbs.) (Fig. 36).

DIFFERENTIAL

DESCRIPTION

The differential case is a one-piece design. The differential pinion shaft is retained with a snap ring.

Differential bearing preload and ring gear backlash

is adjusted by the use of adjusters. The adjuster are

between the differential bearings and the differential

housing. Pinion bearing preload is set and maintained by the use of a collapsible spacer. The

stamped steel cover provides a means for inspection

and servicing the differential.

OPERATION

During straight-ahead driving, the differential pinion gears do not rotate on the pinion mate shaft. This

occurs because input torque applied to the gears is

divided and distributed equally between the two side

gears. As a result, the pinion gears revolve with the

pinion mate shaft but do not rotate around it (Fig.

37).

Fig. 36 PINION ROTATION TORQUE

1 - COMPANION FLANGE

2 - INCH POUND TORQUE WRENCH

(7) If rotating torque is low, tighten the pinion nut

in 6.8 N·m (5 ft. lbs.) increments until the proper

rotating torque is achieved.

CAUTION: If maximum tightening torque 475 N·m

(350 ft. lbs.) is reached prior to reaching the

required rotating torque, the collapsible spacer may

have been damaged. Replace the collapsible

spacer.

(8) Install propeller shaft with reference marks

aligned.

(9) Add gear lubricant to differential housing if

necessary.

(10) Install half shafts and skid plate if equipped.

Fig. 37 DIFFERENTIAL-STRAIGHT AHEAD DRIVING

1 - IN STRAIGHT AHEAD DRIVING EACH WHEEL ROTATES AT

100% OF CASE SPEED

2 - PINION GEAR

3 - SIDE GEAR

4 - PINION GEARS ROTATE WITH CASE

When turning corners, the outside wheel must

travel a greater distance than the inside wheel to

complete a turn. To accomplish this, the differential

allows the axle shafts to turn at unequal speeds (Fig.

38). In this instance, the input torque applied to the

pinion gears is not divided equally. The pinion gears

now rotate around the pinion mate shaft in opposite

directions. This allows the side gear and axle shaft

attached to the outside wheel to rotate at a faster

speed.

REMOVAL

(1) Remove differential housing cover and drain

fluid.

Page 37

DR FRONT AXLE - C205F 3 - 37

DIFFERENTIAL (Continued)

(6) Install a Pilot Stud L-4438 at the left side of

the differential housing. Attach Dial Indicator C-3339

to pilot stud. Load the indicator plunger against the

opposite side of the housing and zero the indicator.

(7) Spread the housing to remove the differential

case from the housing (Fig. 40). Measure the distance

with the dial indicator.

CAUTION: Never spread over 0.50 mm (0.020 in). If

the housing is over-spread, it could be distorted or

damaged.

Fig. 38 DIFFERENTIAL-ON TURNS

1 - PINION GEARS ROTATE ON PINION SHAFT

(2) Remove axle shafts.

(3) Loosen bearing cap bolts.

NOTE: Differential bearing cap reference numbers

are stamped on caps and machined flat on the

housing. If reference numbers cannot be found,

make new marks for later reference.

(4) Install Adapter Plates 8142-A onto the housing.

(5) Install Spreader W-129-B onto the adapter

plates (Fig. 39) and tighten the turnbuckle fingertight.

Fig. 40 DIAL INDICATOR LOCATION

1 - DIAL INDICATOR

2 - SPREADER

(8) Remove dial indicator.

(9) While holding the differential case in position,

remove bearing cap bolts and caps.

(10) Remove differential from the housing (Fig.

41). Ensure differential bearing cups and shims

remain in position on the differential bearings.

(11) Tag differential bearing cups and shims to

indicate their location.

(12) Remove spreader from housing.

Fig. 39 ADAPTER PLATES AND SPREADER

1 - ADAPTER PLATE

2 - SPREADER

DISASSEMBLY

(1) Remove ring gear.

(2) Remove roll-pin holding mate shaft in housing.

(3) Remove pinion gear mate shaft.

(4) Rotate differential side gears and remove the

pinion mate gears and thrust washers (Fig. 42).

(5) Remove the differential side gears and thrust

washers.

Page 38

3 - 38 FRONT AXLE - C205F DR

DIFFERENTIAL (Continued)

ASSEMBLY

(1) Install differential side gears and thrust wash-

ers.

(2) Install pinion mate gears and thrust washers.

(3) Install pinion gear mate shaft.

(4) Align the hole in the pinion gear mate shaft

with the hole in the differential case.

(5) Install the roll-pin in the differential case a

punch and hammer (Fig. 43). Peen the edge of the

roll-pin hole in the differential case in two places

180° apart.

(6) Lubricate all differential components with

hypoid gear lubricant.

(7) Install ring gear.

1 - HOUSING

2 - DIFFERENTIAL

3 - BEARING CUPS

Fig. 41 DIFFERENTIAL

Fig. 43 PINION MATE SHAFT ROLL-PIN

1 - PUNCH

2 - PINION MATE SHAFT

3 - MATE SHAFT LOCKPIN

INSTALLATION

NOTE: If replacement differential bearings or differential case are replaced, Refer to adjustments for

Differential Bearing Preload and Gear Backlash procedures.

Fig. 42 PINION MATE GEAR

1 - THRUST WASHER

2 - SIDE GEAR

3 - PINION MATE GEAR

(1) Install Spreader W-129-B with the Adapter

Plates 8142-A and install the safety holddown

clamps. Tighten the tool turnbuckle finger-tight.

(2) Install a Pilot Stud L-4438 at the left side of

the differential housing. Attach Dial Indicator C-3339

to pilot stud. Load indicator plunger against the

opposite side of the housing and zero the indicator.

Page 39

DR FRONT AXLE - C205F 3 - 39

DIFFERENTIAL (Continued)

(3) Spread housing and measure the distance with

the dial indicator.

CAUTION: Never spread over 0.50 mm (0.020 in). If

the housing is over-spread, it could be distorted or

damaged.

(4) Remove dial indicator.

(5) Install differential case in the housing. Ensure

differential bearing cups remain in position on the

bearings and the differential preload shims are

seated in the housing. Tap differential case to ensure

bearings cups are seated in the housing.

(6) Install bearing caps to their original locations

and loosely install cap bolts.

(7) Remove housing spreader.

(8) Tighten the bearing cap bolts to 61 N·m (45 ft.

lbs.).

(9) Install axle shafts.

(10) Apply a bead of red Mopar Silicone Sealant or

equivalent to the housing cover.

CAUTION: If cover is not installed within 3 to 5 minutes, the cover must be cleaned and new RTV

applied or adhesion quality will be compromised.

(11) Install cover and tighten bolts in a criss-cross

pattern to 22 N·m (15 ft. lbs.).

(12) Fill differential with lubricant.

DIFFERENTIAL CASE

BEARINGS

REMOVAL

(1) Remove differential from housing.

(2) Remove bearings from the differential case

with Puller/Press C-293-PA, Adapters C-293-48 and

Plug C-293-3 (Fig. 44).

INSTALLATION

(1) Install differential case bearings with Installer

C-3716-A and Handle C-4171 (Fig. 45).

(2) Install differential into the housing.

Fig. 44 DIFFERENTIAL CASE BEARING PULLER

1 - PULLER

2 - ADAPTERS

3 - BEARING

4 - DIFFERENTIAL

5 - PLUG

Fig. 45 DIFFERENTIAL CASE BEARINGS

1 - HANDLE

2 - DIFFERENTIAL

3 - BEARING

4 - INSTALLER

Page 40

3 - 40 FRONT AXLE - C205F DR

PINION GEAR/RING GEAR

REMOVAL

NOTE: The ring gear and pinion are serviced in a

matched set. Never replace one without replacing

the other.

(1) Remove differential from housing.

(2) Place differential case in a vise with soft jaw

(Fig. 46).

(3) Remove bolts holding ring gear to differential

case.

(4) Drive ring gear from differential case with a

soft hammer (Fig. 46).

Fig. 46 RING GEAR

1 - DIFFERENTIAL CASE

2 - RING GEAR

3 - RAWHIDE HAMMER

(5) Mark the companion yoke and companion

flange for installation reference.

(6) Remove companion flange bolts and tie the propeller shaft to the vehicle underbody.

(7) Rotate companion flange three or four times

and verify flange rotates smoothly.

(8) Record pinion rotating torque an inch pound

torque wrench for installation reference (Fig. 47).

(9) Install bolts into two of the threaded holes in

the companion flange 180° apart.

(10) Position Holder 6719 against the companion

flange and install a bolt and washer into one of the

remaining threaded holes. Tighten the bolts so that

the Holder 6719 is held to the flange.

(11) Remove the pinion nut.

(12) Remove the companion flange with Remover

C-452 (Fig. 48).

(13) Remove pinion from differential housing.

(14) Remove pinion seal with a pry tool or a slide

hammer mounted screw.

Fig. 47 PINION ROTATING TORQUE

1 - PINION COMPANION FLANGE

2 - TORQUE WRENCH

Fig. 48 COMPANION FLANGE REMOVER

1 - COMPANION FLANGE

2 - PULLER TOOL

(15) Remove oil slinger, if equipped and front pin-

ion bearing.

(16) Remove front pinion bearing cup with

Remover 8831 and Handle C-4171 (Fig. 49).

(17) Remove rear pinion bearing cup from housing

(Fig. 50) with Remover 8401 and Handle C-4171.

Page 41

DR FRONT AXLE - C205F 3 - 41

PINION GEAR/RING GEAR (Continued)

Fig. 49 FRONT PINION BEARING CUP

1 - HOUSING

2 - REMOVER

3 - HANDLE

Fig. 51 COLLAPSIBLE SPACER

1 - COLLAPSIBLE SPACER

2 - REAR PINION BEARING

3 - PINION DEPTH SHIM

Fig. 50 REAR PINION BEARING CUP

1 - HOUSING

2 - REMOVER

3 - HANDLE

(18) Remove collapsible preload spacer (Fig. 51).

(19) Remove rear pinion bearing with Puller/Press

C-293-PA and Adapters C-293-42 (Fig. 52).

Fig. 52 REAR PINION BEARING

1 - PULLER

2 - VISE

3 - ADAPTERS

4 - DRIVE PINION GEAR SHAFT

(20) Remove depth shims from the pinion shaft

and record thickness of shims.

Page 42

3 - 42 FRONT AXLE - C205F DR

PINION GEAR/RING GEAR (Continued)

INSTALLATION

NOTE: The ring gear and pinion are serviced in a

matched set. Never replace one gear without replacing the other matching gear. If ring and pinion

gears or bearings are replaced, Refer to Adjustments for Pinion Gear Depth Setting.

(1) Apply Mopar Door Ease or equivalent lubricant

to outside surface of the bearing cups.

(2) Install rear pinion bearing cup with Installer

8692 and Driver Handle C-4171 (Fig. 53) and verify

cup is seated.

(3) Install front pinion bearing cup with Installer

8693 and Handle C-4171 (Fig. 54) and verify cup is

seated.

Fig. 53 REAR PINION BEARING CUP

1 - HOUSING

2 - INSTALLER

3 - HANDLE

Fig. 54 FRONT PINION BEARING CUP

1 - HOUSING

2 - INSTALLER

3 - HANDLE

(4) Lubricate front pinion bearing and install bearing in the housing.

(5) Apply a light coating of gear lubricant on the

lip of pinion seal.

(6) Install pinion seal with Installer 8695 and

Handle C-4171 (Fig. 55).

Fig. 55 PINION SEAL

1 - HANDLE

2 - INSTALLER

Page 43

DR FRONT AXLE - C205F 3 - 43

PINION GEAR/RING GEAR (Continued)

(7) Place pinion depth shim (Fig. 56) on the pinion

shaft.

(9) Install new collapsible spacer onto the pinion

shaft (Fig. 58).

Fig. 56 PINION DEPTH SHIM

1 - PINION DEPTH SHIM

2 - PINION GEAR

(8) Install rear pinion bearing onto the pinion

shaft with Installer 6448 and a press (Fig. 57).

Fig. 57 REAR PINION BEARING

1 - PRESS

2 - INSTALLER

3 - PINION GEAR

4 - REAR PINION BEARING

Fig. 58 COLLAPSIBLE SPACER

1 - COLLAPSIBLE SPACER

2 - REAR PINION BEARING

3 - PINION DEPTH SHIM

(10) Lubricate rear pinion bearing and install the

pinion gear in the housing.

(11) Install companion flange with Installer

C-3718 and Holder 6719.

(12) Install new pinion nut and tighten to 271

N·m (200 ft. lbs.) (Fig. 59).

(13) Using Holder 6719 and a torque wrench set at

475 N·m (350 ft. lbs.). Tighten pinion nut until bearing end play is taken up.

(14) Slowly tighten the nut in 6.8 N·m (5 ft. lbs.)

increments until desired rotating torque is achieved.

Measure rotating torque frequently to avoid overcrushing the collapsible spacer (Fig. 60). The pinion

rotating torque should be:

• Original Bearings: 1 to 2.5 N·m (10 to 20 in.

lbs.)