Page 1

DODGE PLUG IN MODEL 250 POWER SUPPLY

DESCRIPTION:

INSTALLATION MANUAL FOR

Specifications:

Input voltage: 115 VAC 50-60 Hz

Output voltage: 15-100 VDC Nominal

Output current: 0.5 Amp Maximum

Output wattage: 50 Watts Maximum

Dimensions: 2.88” H, 2.38” W, 1.75” D

Installation and Operating Instructions

Model 250 is an octal-base power supply that

converts 115 VAC, 50-60 Hz to a DC voltage. It

provides one fixed 100 VDC output and one

adjustable (15 to 100 VDC) output. The Model 250 is

capable of providing DC operating voltage to 1 or 2

clutches or brakes (each with 50 watts or less power

consumption). If two units are operated with the Model

250 power supply, only one unit should be energized

at a time. Note: Switches Furnished By User.

WARNING

Only qualified electrical personnel familiar with the

construction and operation of this equipment and the

hazards involved should install, adjust, and/or service

this precaution can result in bodily injury.

DANGER

Subsequent steps require rotating parts and/or

electrical circuits to be exposed. Stay clear if unit must

be running or disconnect and lockout or tag power

source if contact must be made. Failure to observe

these precautions could result in severe bodily injury or

loss of life.

DANGER

The user is responsible for conforming to the National

Electrical Code and all other applicable local codes in

respect to wiring practices, grounding, disconnects, and

overcurrent protection. Installation of an approved

disconnecting means in the line side of the controller is of

particular importance. Failure to observe these

precautions could result in severe bodily injury or loss of

life.

1. Be sure power is locked off when wiring a power

supply installation.

2. Use adequate sized wire. No. 18 gauge is

recommend-ed for runs less than 25 feet. No. 16

gauge is recommended for runs 25 feet or longer.

3. The neutral or grounded side of the 115 VAC line

must be connected to terminal 5 on the octal socket.

A voltmeter connected between the neutral line and

line ground will read 0 volts. The hot side of the 115

VAC line must be connected to terminal 1.

Note 1: Connect switches per diagrams. Do not connect

switch for the clutch or brake in coil circuit.

Note 2: Output voltage under load of the power supply

is approximately 100 VDC with 115 VAC input. This is

suitable for clutches and brakes rated 90 VDC.

Note 3: Output voltage without load is about 160 VDC.

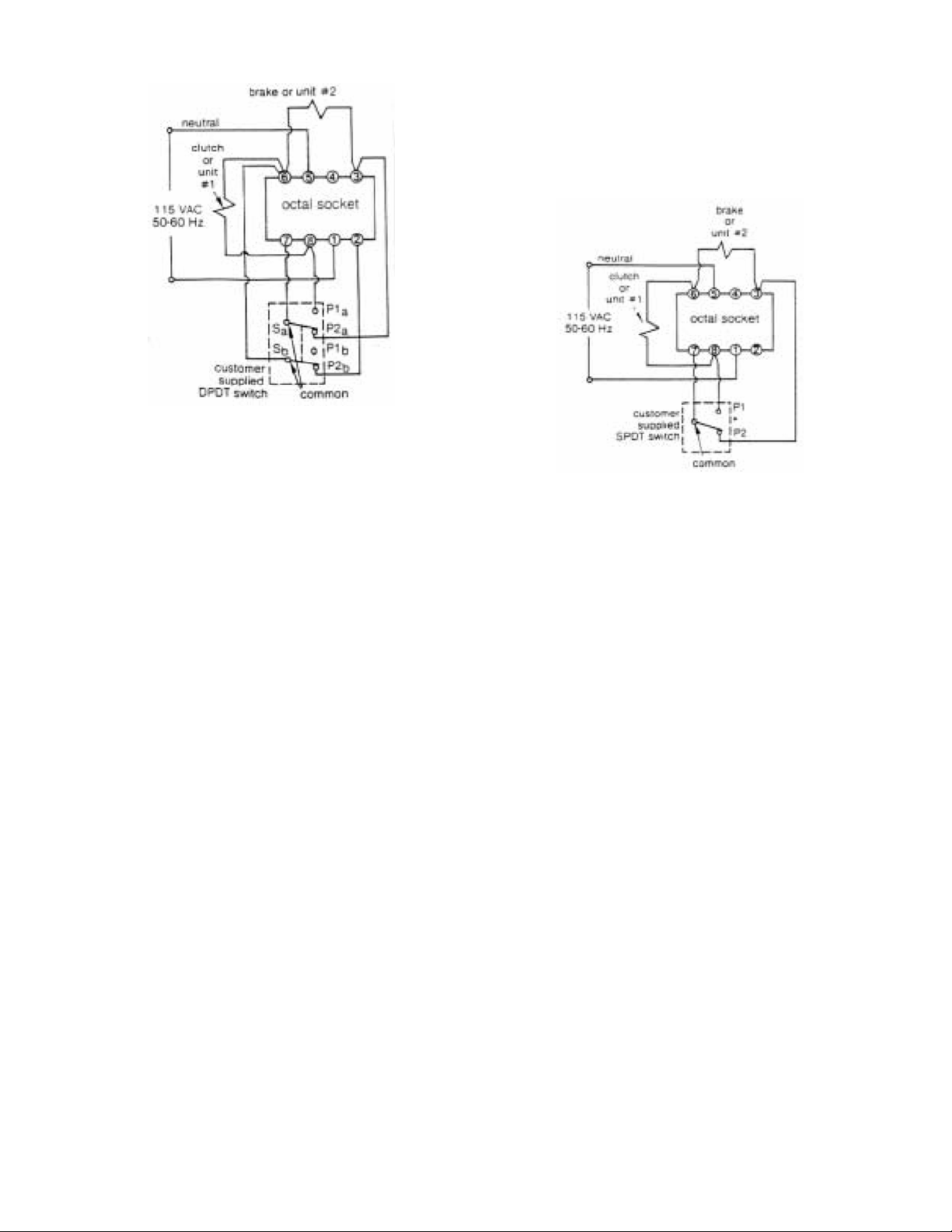

Model 250 used with 2 units - adjustable voltage on

unit #1, fixed 100 VDC on unit #2. Connection

Instructions (See Figure 1):

1. All connections are made to terminals on octal

socket.

2. Connect unit #1 to terminals 6 and 8.

3. Connect unit #2 to terminals 3 and 6.

4. Connect side S

(DPDT) switch to terminals 3, 7, and 8; the switch

common must be connected to terminal 7.

5. Connect side S

the switch common must be connected to terminal

6.

6. Connect 115 VAC, 50-60 Hz to terminals 1 and 5.

Warning: The neutral or grounded side must be

connected to terminal 5.

a of a double-pole, double-throw

b of the switch to terminals 6 and 2;

1

Page 2

Figure 1

the switch common must be connected to terminal

7. A maintained-contact type SPDT switch should

be used.

5. Connect 115 VAC, 50-60 Hz to terminals 1 and 5.

Warning: The neutral or grounded side must be

connected to terminal 5.

Wiring 2 units (adjustable voltage on unit #1)

Operation:

1. Plug power supply into octal socket.

2. Turn on power source.

3. Voltage adjustments are made by removing plug

button on top of power supply case. This will

expose a screwdriver slotted adjustment. Turn the

adjustment clockwise to increase voltage, or

counterclockwise to decrease voltage. When wired

as described above, the adjusted voltage will be

applied across unit #1.

4. With switch in position P1, unit #1 is energized with

adjusted voltage and unit #2 is de-energized.

5. With switch in position P2 (normally closed), unit

#2 is energized with 100 VDC and unit #1 is deenergized.

6. If unit fails to operate, refer to the Troubleshooting

section.

Note: If unit #1 is energized with fixed 100 VDC, and

unit #2 with adjustable DC voltage, remove lead

between terminal 2 of octal socket and P2

Add lead between terminal 2 of octal socket and P1

switch.

b of switch.

b of

Model 250 used with 2 units – adjustable voltage

on both units.Connection Instructions (See Figure

2):

1. All connections are made to terminals on octal

socket.

2. Connect unit #1 to terminals 6 and 8.

3. Connect unit #2 to terminals 3 and 6.

4. Connect a SPDT switch to terminals 3, 7, and 8;

Figure 2

Wiring 2 units (adjustable voltage on both units)

Operation:

1. Plug power supply into octal socket.

2. Turn on power source.

3. Voltage adjustments are made by removing plug

button on top of power supply case. This will

expose a screwdriver slotted adjustment. Turn the

adjustment clockwise to increase voltage, or

counterclockwise to decrease voltage. When wired

as described above, this same adjusted voltage

will be applied across both unit #1 and unit #2.

4. With switch in position P1, unit #1 is energized with

adjusted voltage and unit #2 is de-energized.

5. With switch in position P2 (normally closed), unit

#2 is energized with adjusted voltage and unit #1 is

de-ener-gized.

6. If unit fails to operate, refer to the Troubleshooting

section.

Model 250 used with 1 unit. Connection

Instructions (See Figure 3):

1. All connections are made to terminals on octal

socket.

2. Connect unit (clutch or brake) to terminals 6 and 8.

3. Connect switch to terminals 7 and 8; the switch

common should be connected to terminal 7. Use a

maintained contact SPDT (shown in Figure 3) or

SPST switch.

4. Connect 115 VAC, 50-60 Hz to terminals 1 and 5.

Warning: The neutral or grounded side must be

connected to terminal 5.

2

Page 3

Figure 4

Fuse Location

Figure 3

Wiring for 1 unit

Operation:

1. Plug power supply into octal socket.

2. Turn on power source.

3. Voltage adjustments are made by removing plug

button on top of power supply case. This will

expose a screwdriver slotted adjustment. Turn the

adjustment clockwise to increase voltage, or

counterclockwise to decrease voltage.

4. With switch in position P1 (or switch closed when

usingSPST) the clutch or brake is energized.

5. With switch in position P2 (or switch open when

usingSPST) the clutch or brake is de-energized.

6. If unit fails to operate, refer to the Troubleshooting

section.

Maintenance

Fuse location and access

Model 250 has an internal fuse. The fuse can be

checked without removing the power supply cover.

First remove the power supply from the octal socket.

An ohmmeter connected between pins 1 and 4 on the

module will read near infinity if the fuse has burned

out. If blown then replace with type 3AG 0.6 amp fuse.

Caution: Do not use slow-blow type fuse.

To replace the fuse, remove four fasteners holding

cover of base plug. Carefully remove the cover. The

fuse is located as shown in Figure 4. Visually check

the fuse. If the fuse is burned out, remove it, and

replace with a new fuse of proper size and type.

Carefully replace the cover and fasteners.

Troubleshooting

If the unit fails to operate or operates in an improper

manner, use the following procedure to identify and

resolve the problem.

1. Check the power source (115 VAC, 50-60 Hz line

voltage). Is it turned on? Using an AC voltmeter,

check the voltage between terminals 1 and 5. The

voltage should be between 110 and 120 VAC.

2. Check actual wiring against the wiring diagram.

Check tosee if voltage adjustment is turned up

high enough to operate clutch or brake.

3. Check fuse. If the fuse is burned out, replace it with

oneof the same type and rating. Review entire

troubleshooting procedure to identify reason for

blown fuse.

4. Disconnect clutch and/or brake from power supply.

Check resistance of clutch and/or brake coils. If

coil is shorted or open it should be replaced.

5. Check the connections between the power supply

and theclutch and/or brake to be operated. If the

connections are loose or the wires damaged or

grounded, correct the problem.

6. If the above corrective actions do not restore

normal oper-ation, the power supply should be

replaced with a new one.

Accessory Requirements

The following accessories are required for installation,

but are not supplied with the Model 250 power supply.

1. Octal socket - DODGE part number 032401.

2. Switch - One switch (SPST, SPDT, or DPDT

depending upon applications). Switch should be

contact type. A minimum of 6A, 120VAC is

recommended.

3. Hook-up wire - as required.

3

Page 4

WARNING: Because of the possible danger to persons(s) or property from accidents which may result from the improper use of products, it is important that

correct procedures be followed. Products must be used in accordance with the engineering information specified in the catalog. Proper installation,

maintenance and operation procedures must be observed. The instructions in the instruction manuals must be followed. Inspections should be made as

necessary to assure safe operation under prevailing conditions. Proper guards and other suitable safety devices or procedures as may be desirable or as may

be specified in safety codes should be provided, and are neither provided by Baldor Electric Company nor are the responsibility of Baldor Elec tric Com pany.

This unit and its associated equipment must be installed, adjusted and maintained by qualified personnel who are familiar with the construction and operation

of all equipment in the system and the potential hazards involved. When risk to persons or property may be involved, a failsafe device must be an inegral part

of the driven equipment beyond the speed reducer output shaft.

www.baldor.com www.ptplace.com www.dodge-pt.com www.reliance.com

Baldor Electric Company Headquarters

P.O. Box 2400, Fort Smith, AR 72902-2400 U.S.A., Ph: (1) 479.648.5792, Fax (1) 479.648.5792, International Fax (1) 479.648.5895

DODGE/Reliance Division

6040 Ponders Court, Greenville, SC 29615-4617 U.S.A., Ph: (1) 864.297.4800, FAX: (1) 864.281.2433

Copyright © 2007 Baldor Electric Company All Rights Reserved. Printed in USA.

04/07

3C-K

This material is not intended to provide operational instructions. Appropriate instruction

manuals and precautions should be studied prior to installation, operation or maintenance

of equipment.

4

Loading...

Loading...