Page 1

Spreading Wings S800 EVO

User Manual

V 1.10

February 07, 2014 Revision

www.dji.com

Page 2

Disclaimer

Thank you for purchasing this DJI product. Please regularly visit the S800 EVO web page at www.dji.com, which is

updated regularly. Product information, technical updates and manual corrections will be available on this web page.

Due to unforeseen changes or product upgrades, the information contained in the manual is subject to change

without notice.

Read this disclaimer carefully before using this product. By using this product, you hereby agree to this disclaimer

and signify that you have read them fully. Please strictly follow the manual to assemble and use the product. The

manufacturer and seller assume no liability for any resulting damage or injury arising from the operation or use of

this product.

DJI is registered trademark of DJI Innovations. Names of product, brand, etc., appearing in this manual are

trademarks or registered trademarks of their respective owner companies. This product and manual are copyrighted

by DJI Innovations with all rights reserved. No part of this product or manual shall be reproduced in any form

without the prior written consent or authorization of DJI Innovations. No patent liability is assumed with respect to

the use of the product or information contained herein.

Page 3

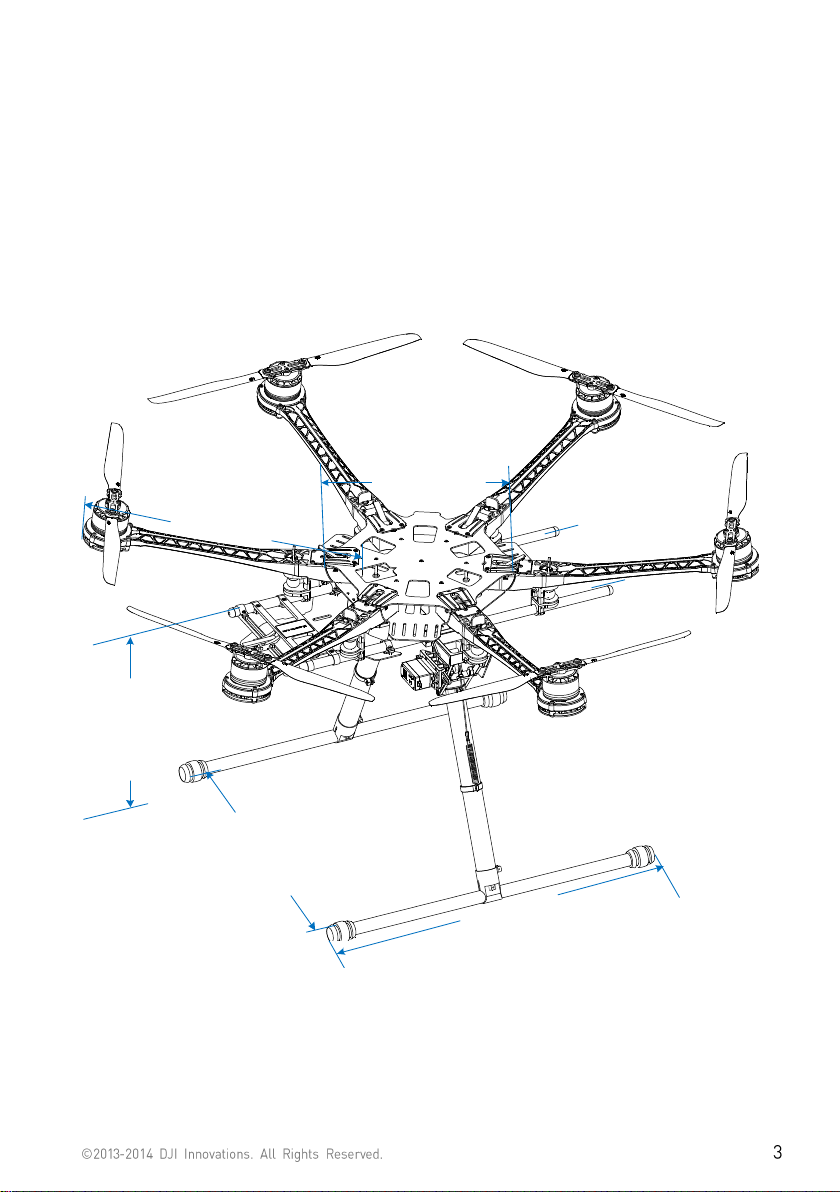

Profile

460

mm

(

Length

)

425

mm

(

Width

)

320

mm

(

Heigth

)

155

mm

(

Top

Width

)

350

mm

(

Length

)

240mm(Diameter)

S800 EVO is a multi-rotor designed for aerial photograph which integrates reinforced mechanical structures,

stabilized dynamical system and high-efficiency power supply. Integrated designs make assembly and configuration

become especially easy and fast; retractable landing gear, foldable propellers and collapsible GPS Mount are

conveniently portable for optimal user experiences. Retractable landing gears and vibration dampers coordinate to

create omnidirectional aerial view and high quality photograph. Combined with professional DJI multi-rotor

autopilot system S800 EVO will achieve hovering, cruising and other steady flight elements, which can be applied

for aerial photography and other aero-modeling activities.

Page 4

Contents

Disclaimer ................................................................................................................................................................................................................ 2

Profile ....................................................................................................................................................................................................................... 3

Contents .................................................................................................................................................................................................................. 4

Product Usage Cautions ................................................................................................................................................................................... 5

In The Box ............................................................................................................................................................................................................... 6

Tools Needed ........................................................................................................................................................................................................ 6

Center Frame Wiring ......................................................................................................................................................................................... 7

Attach Electric Equipment to Center Frame ............................................................................................................................................. 8

Mount Frame Arms ............................................................................................................................................................................................ 10

Mount Landing Gear .......................................................................................................................................................................................... 12

1 Assembly & Connection ....................................................................................................................................................................... 12

2 Travel Calibration .................................................................................................................................................................................. 13

3 Transmitter Setting ............................................................................................................................................................................... 14

4 Usage ......................................................................................................................................................................................................... 14

5 Mount Battery Bracket ........................................................................................................................................................................ 16

Assembly ................................................................................................................................................................................................................ 17

Install the IMU Mount (Optional) .................................................................................................................................................................. 18

Appendix ................................................................................................................................................................................................................ 19

ESC Sound ................................................................................................................................................................................................... 19

ESC LED ....................................................................................................................................................................................................... 19

Specifications ............................................................................................................................................................................................ 20

FAQ (Trouble Shooting) ................................................................................................................................................................................... 21

Solder ESC ................................................................................................................................................................................................... 21

Assemble the Vibration Absorber of Motors .................................................................................................................................. 21

Spare Parts Listing ............................................................................................................................................................................................. 22

Page 5

Product Usage Cautions

Assembly Cautions

(1) Mount the GPS Module with a bracket, to avoid interference with the power board of center frame.

(2) For IMU mounting, make sure the arrow direction marking on the IMU is pointing to the aircraft nose.

(3) The receiver is strongly recommended to be attached under the bottom board of center frame, and the

head of antenna is downward without any obstacle. Otherwise the aircraft may be out of control, since

the wireless signal may be lost.

(4) Mount the arms correctly.

a) Center frame Arm

b) Center frame Arm

(5) For removing screws in the bottom board, please proceed with cautious, avoiding damages. Do not

remove any other screws fixed with glue.

(6) Notice matching the indications is very important, please pay attention to them.

Flight Cautions

(1) With DJI WKM autopilot system, make sure the output signal of WKM F1~F2 and M1~M6 are all normal,

to avoid serious damages and injuries.

(2) Keep flying the multi-rotor a distance from people, building, high-voltage lines, tall trees, water, etc.

(3) Make sure to use 6S LiPo battery for power supply.

(4) Do not get close to or touch the working motors and propellers, which will cause serious injury.

(5) Do not over load the multi-rotor.

(6) Make sure the propellers and the motors are installed correctly and firmly before flying.

(7) Make sure all parts of product are in good condition before each flight. Do not fly with wore or broken

parts.

(8) Strongly recommend you to use DJI parts as much as possible.

Others

(1) If you have any problem you cannot solve, please contact your dealer or DJI customer service.

When flying, the fast rotating propellers may cause serious damage(s) and injuries. Therefore, please fly with a high

safety in mind at all time.

Page 6

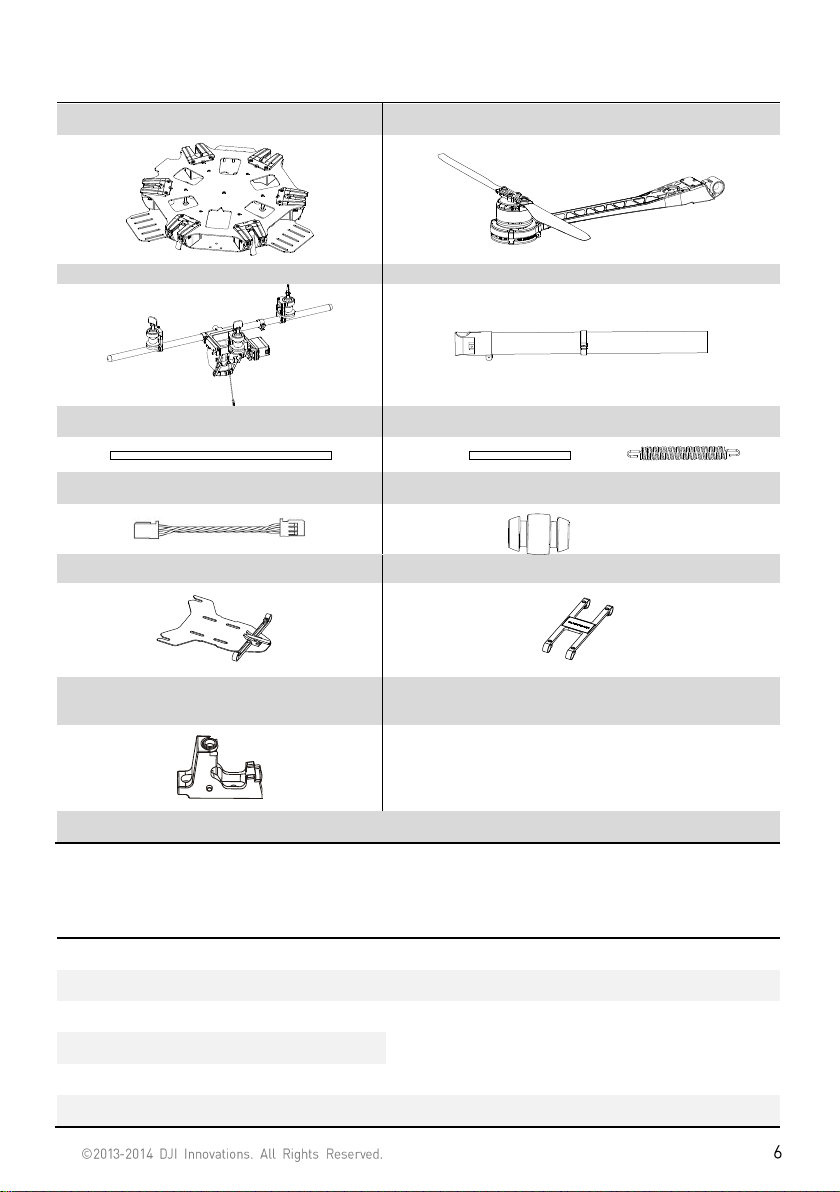

In The Box

Center Frame×1

Frame Arm×6

Retracting Mechanism×2

Landing Gear Support Tube ×2

Base Pipe×2

H Frame Connection Pipe×1、Spring×2

Package of 3-PIN Servo Cable ×1

Silicone Rubber Damper ×4

Package of Battery Tray×1

Package of IMU Mount×1

GPS Fixed Seat×1

Screw Package for Frame×1

Screw Package for Landing Gear×1

Out of The Box Guidance ×2

2.0mm Hex Wrench, 2.5mm Hex Wrench

For mounting screws.

Thread Locker

For fastening screws.

Nylon Cable Tie

For binding devices and wires.

Scissors

Diagonal Cutting Pliers

Foam Double Sided Adhesive Tape

For fixing receiver, controller and other modules.

Tools Needed

Page 7

Center Frame Wiring

Top Board

Bottom Board

Buckle

Slot

M

1

M

2

M3

M

4

M6

M

5

BATT

PM

GIMBAL

IMU Front

Aircraft Nose

To Battery

To PMU

XT60 Male

XT60 Female

XT60 Female

To Gimbal

M

1

M

2

M

3

M

4

M

5

M

6

Motor clock-wise

ESC signal outlet

To main controller

Mark

IMU mount position

Circuit line

Parallel Circuit

Motor number

Mark

Motor counter clock-wise

Mark

Top Board

Notes:

(1) For IMU mounting, make sure the arrow direction marking on the IMU is pointing to the aircraft nose.

(2) Connect the 3-pin connectors (M1~M6) of servo cable from WKM M.C. to ESC signal socket (M1~M6) on

center frame markings accordingly.

(WKM M.C. M1 ESC signal socket M1, …… , WKM M.C. M6 ESC signal socket M6)

Tips:

(1) The main battery power leads, gimbal and PMU leads are on the bottom surface of the top board.

(2) Markings and stand for the propeller rotation direction. means clock-wise, and means

counter clock-wise.

(3) If other lead connector is required, please cut the original connector and solder on the new one. (But NOT

Recommend.)

The top board is a power distribution board, and the bottom board is for loading autopilot system components.

Page 8

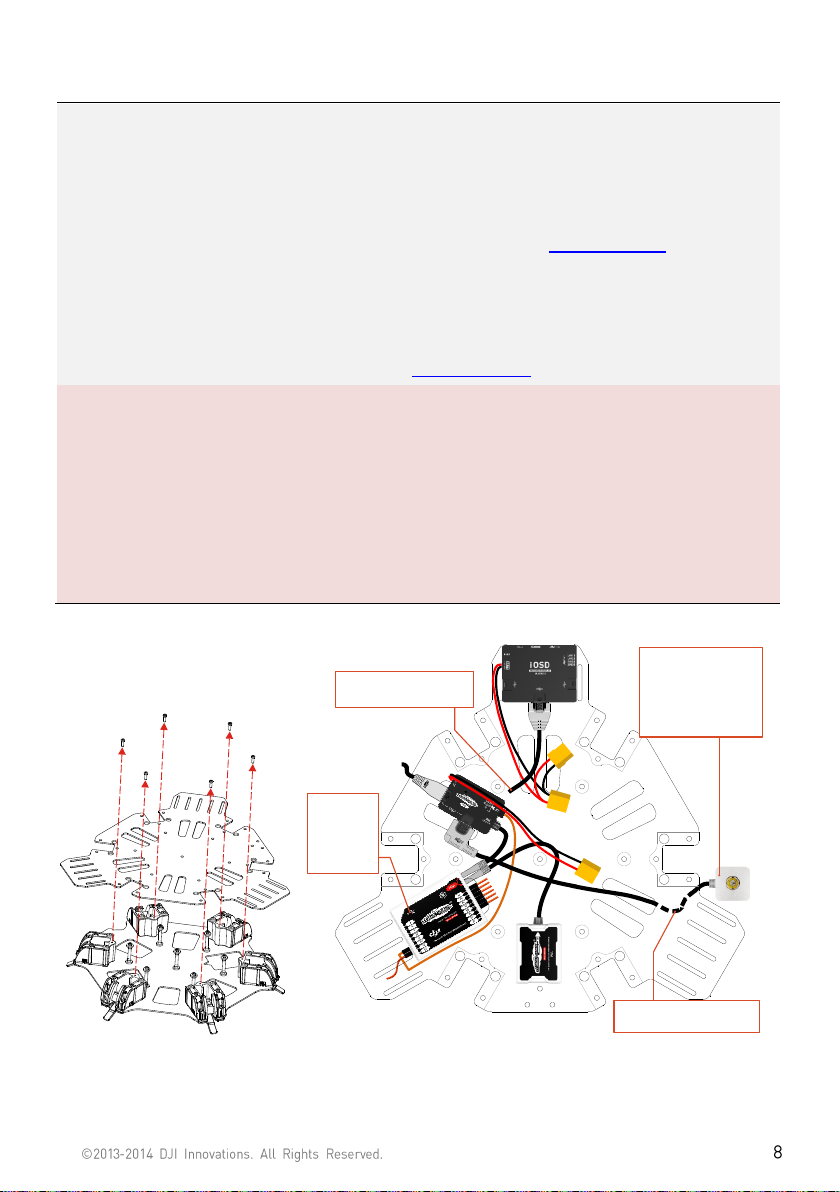

Attach Electric Equipment to Center Frame

1. (Fig.1)Remove the screws in the bottom board.

2. (Fig.2)Attach the IMU module into IMU position in the center frame. Ensure the IMU casing is out of

touching the top board edge, as vibration can cause IMU mal-function.

3. (Fig.2)Please attach DJI Autopilot System parts onto the bottom board (not including GPS modules.

4. (Fig.2)Connect the Autopilot System and receiver. Please refer to DJI

WKM User Manual

for details.

5. (Fig.3)Please fix all the screws to bottom board, and use adequate thread locker.

6. (Fig.4)Attach the GPS Fixed Seat to the top board (near to the M3), then mount the GPS Module to the

GPS Fixed Seat with a bracket.

7. Configure Autopilot System. Please refer to DJI

WKM User Manual

.

Note:

(1) Make sure to mount the IMU module at the IMU position first, and the mount orientation is correct.

(2) Mount the GPS with a bracket, to avoid interference from center frame power board.

(3) Make sure the USB port of the M.C. is pointing outwards for easy access.

(4) Please wire neatly. Make sure the wires will not be cut by the edge of frames.

(5) Install the screws with appropriate strength to prevent damage threads.

(6) Watch out clamping fingers when folding the GPS Bracket.

To GIMBAL Lead

To the CAN Port of

GPS/Compass Module

You can attach the LED

Module to the support

tube.

Note: Risk of wire cut

off by the Retracting

Mechanism.

GPS/Compass

Module

Micro-USB

Port faces

outwards for

connection

convenience

Receiver

(D-BUS)

You can wire the LED

through the bottom board

To PM Lead

Fig.1 Remove the screws Fig.2 Attach the Autopilot System

Page 9

Fig.3 Fix the screws

Note: for DJI A2 user,

please use the

component in red; for

WKM user, it is not

required.

Fig.4 Mount the GPS Fixed Seat and GPS module

Mind You Fingers

Fig.5 Note of folding the GPS Bracket

Page 10

Mount Frame Arms

Step 1

Step 2

Motor rotation direction

Clock-wise

Counter clock-wise

Motor

ESC

LED

Copper contacts

Screw

Propeller

Cover

(1)

Step 3

Step 4

Step 5

(2)

35

o

Horizontal

Vertical

Horizontal

Step1: Check the arms.

(1) Make sure the copper contacts are in good condition without bend or severe wear.

(2) Make sure the propellers are without crack, and screws in propeller cover tight.

(3) Make sure the motors are mounted firmly, and rotate freely.

(4) We recommend you to mount the arms with red propeller cover to M1 and M2 to indicate the nose

of aircraft.

(5) Distinguish the marks and on the arms.

Arm Center frame

Arm Center frame

Step2: Insert the frame arm into center frame vertically.

Step3: Slowly rotate the frame arm upward until positioned completely.

Step4: Press down the buckle to lock the arm. Make sure the arm does not move.

Step5: Make sure the buckle is pressed down correctly, about 35o under normal circumstances.

Notes:

(1) Please add some lubricant at the position (1) if it is hard to press down the buckle.

(2) Slowly rotate the frame arm to prevent from breaking the copper contacts.

©2012 DJI Innovations. All Rights Reserved. 10

Page 11

(3) Please refer to (2) to make sure the arm is perfectly positioned.

(4) Make sure to use appropriate strength to press down the buckle correctly.

(5) Do not hot plug arms.

Tips:

(1) LED is on after motor start.

Step 6 Double Check

Arms①②are aircraft nose, arms④⑤ are aircraft tail. See from top, motors on arms①③⑤ rotate counter

clockwise; motors on arms②④⑥ rotate clockwise.

Aircraft Nose

①

②

③

④

⑤

⑥

Page 12

Mount Landing Gear

R

IN

L

Con tr ol B oar d

Ser vo

Arm

Cen ter L ine

Ser vo

Ser vo A rm Ins ta llati on

Fin is hed

Ser vo A ss emb ly

Rig ht art o f th e

and in g e ar

P

LG

Left Serv o

Right S ervo

Lef t Servo

Rig ht Ser vo

SET B utt on

LED

Rec eiver C han nel

ADircra f t os e N ire ct ion

Lef t art of

the

PLGand in g e ar

DANGE R!!!

DO N OT T OUCH !

step1: Servo Installation

(If the servos have already been installed, please skip this step.)

1. (Shown in the Fig) Define and mark the two HS-7954SH servos from Hitec as left servo and right servo.

2. Connect the left servo to the [L] port on the control board, and the right servo to the [R] port.

3. Keep pressing the SET button with aid of a small tool, and then power on. You will see the yellow LED

beside SET button flashes quickly, and then wait until the servos have finished their position initialization.

4. Make sure the servo arm is parallel to the servo’s center line.

5. Power off, assemble the left and right servos to the left and the right parts of the landing gear.

Tips: If you use your own servos, it is recommended to use the dedicated programmer from Hitec to enlarge the

servo travel from 120° to 150°, and then install servos by the above steps. Servos from DJI have been enlarged

servo travel.

step2: Mechanical Assembly

By using a 2-position switch of R/C transmitter, you can control the landing gear to retract remotely.

1 Assembly & Connection

The part with the control board attached is defined as left, and the other part is right. Make sure to make a

distinction between the left and the right servos.

Page 13

1. Assemble the left and right parts respectively, and then fix the screws at the joints with appropriate

thread locker.

2. Connect the left and right parts with connecting rod.

3. For safety reasons, make sure to connect the springs to both parts.

step3: Electrical Connections

1. Plug the cables from the servos into the correct ports on the control board. Make sure the right servo is

connected to the [R] port, and the left servo to the [L] port.

2. Connect the required 2-position switch of R/C receiver to the [IN] port.

1. For safety reasons, please keep your hands away from any link mechanism to avoid injury.

2. Make sure the [R], [L] and [IN] connections are correct and firmly connected.

3. Hang the Landing Gear in the air during calibration, as the landing gear will move.

4. Keep pressing the SET button using a small tool and power on. You can see the LED flashes YELLOW

quickly, and then press the SET button once again. The system begins auto calibration with the indication

of the LED flashing YELLOW slowly. DO NOT obstruct any moving part during auto calibration.

5. The left-part is calibrated, the left link mechanism first moves up then moves down automatically. Then

the right-part is calibrated, the right link mechanism first moves up then moves down automatically.

6. After calibration, both left and right parts are in the [Lower] position, and the LED is solid GREEN on.

Then the landing gear will work normally.

Notes:

(1) If the LED is solid YELLOW on during calibrating, it means that there is something wrong with the

calibration, please re-do the Servo Installation of the Assembly & Connection section, since the servo arm

might be installed with a wrong angle.

(2) Please avoid any obstruction during calibrating. If the landing gear is blocked from moving, please

recalibrate the landing gear by the above steps.

(3) If the [R] and [L] servo cables are reversed, the travel will not be measured correctly. Please connect

correctly and recalibrate the landing gear using the above steps.

2 Travel Calibration

If the Landing Gear you got has been installed with the servos, please skip this step. Otherwise, calibrate the system

using the following procedures.

Page 14

3 Transmitter Setting

Select a 2-position switch (default setting is OK) of

Transmitter as the control input of the landing gear, and

then make sure the corresponding port of receiver is

connected to the [IN] port on control board.

Fig. 1

Fig. 2

1. Make sure the transmitter & receiver batteries are fully charged.

2. Toggle the switch to the [Lower] position, and then turn on the transmitter.

3. Make sure the [R], [L] and [IN] connections are correct and firmly connected.

4. Make sure the Landing Gear is at the [Lower] position, and then power on the system. If the green LED is

solid on, then this is a normal start. If the LED flashes GREEN slowly, please re-calibrate the system

according to the procedure of Travel Calibration.

5. Make sure to toggle the switch to the [Retracted] position ONLY AFTER you takeoff the aircraft.

6. When the aircraft is landing, please toggle the switch to the [Lower] position for a safe landing.

Retracted:Toggle the switch to

this position to retract the

landing gear (Fig.1)

Lower:Toggle the switch to this

position to lower the landing

gear (Fig. 2)

Tips:

(1) If the switch of Transmitter has FailSafe function,

set the FailSafe value to the [Lower] position, so

that the landing gear will be in [Lower] status when

the receiver enters FailSafe mode, to land the

aircraft safely.

(2) To avoid false switch triggering, you can use the

slide lever or other trim as the landing gear’s

control switch.

4 Usage

The landing gear can be used by following the steps below after assembly & connection.

Page 15

Tips

(1) The system will turn off the servo power temporarily within 3 seconds after the landing gear has reached

the target position.

(2) When powering on the system, if the Transmitter switch is at the [Retracted] position, which is the unsafe

signal for the landing gear, the LED will quickly flash RED. Toggle the switch to the [Lower] position.

(3) If there is an abnormal signal or no signal input into the [IN] port the LED will slowly flash RED. Please

check the receiver and the connections.

(4) If the power consumption of servos is too large during usage, the LED will be solid RED on. If this status

lasts more than 4 seconds, the landing gear will lower and the LED will flash GREEN slowly. Please

re-calibrate the system.

System works normally

Hasn’t been calibrated

Need re-calibration

Wrong calibration

Enter the calibration mode

System is calibrating

Motor stall

Input signal is unsafe when power on the Transmitter

Input signal is abnormal

Parameter

Range

Parameter

Range

Working Voltage

3S~6S (LiPo)

Input Signal

PWM (High-Pulse Width 800us~2200us)

Working Current

Max 1A@6S

Output Signal

PWM(Mid Position is 1520us) in 90Hz

Working Temperature

-20~70oC

Output Voltage

6V

Total Weight

875g

Servo Travel

150 o (Minimum120 o)

LED Indicator

Specifications

Page 16

5 Mount Battery Bracket

Step1: Mount the retaining clip and the bracket, fix screws (but not tighten).

M2.5X5

Retaining Clips

Chamfer Outwards

Bracket

Notch Outwards

Step2: Place the battery mounting board and adjust its position, and then tighten all screws.

Ensure to align

90

o

Parallel

Correct

Parallel Parallel

Battery Mounting Board

About

131

mm

Page 17

Assembly

Assembly

(2)

①

②

③

④

⑤

⑥

(1)

Vibration Absorber

Coaxial Align

Not

Coaxial

Align knob to mark

Insert knob into arm Rotate knob

Aircraft

Nose

Mark

Knob

Vibration Damper Mount

Vibration Damper Mount Details

Not

Coaxial

1. Align all knobs on H frame to the marks; refer to fig (1).

2. Lie frame and Landing Gear horizontally, insert knobs into arms ③ and ⑥ first, and then adjust to

insert the others into the arms.

3. Make sure the Vibration Damper Mount is correct, and then rotate the knob to the end, as fig (2) shown.

Notes:

Ensure all knobs on the H frame aligned to the marks, and they would go through the arms successfully.

Page 18

Install the IMU Mount (Optional)

1. (Fig.1) Remove the screws to dismount the Battery Bracket.

2. (Fig.2) Fix the IMU Mount and remount the Battery Bracket.

3. (Fig.3) Adjust the IMU Mount and the Battery Bracket, and then fix all the screws.

4. (Fig.4) Attach the IMU Module; make sure that the arrow on LOGO is pointing to the aircraft nose.

Fig.1 Fig.2

Aircraft Nose

Arrow on

IMU LOGO

Fig.3 Fig.4

If you wish to achieve a smooth and steady fight, carry out the following procedures to install the IMU Mount.

Page 19

Appendix

ESC State

Sound

Ready

♪1234567--B--B

Throttle stick is not at bottom

BBBBBB…

Input signal abnormal

B--------B--------B…

Input voltage abnormal

BB---BB---BB---BB…

ESC State

LED

Standby

Off

Motor rotating

Solid Red or Green On

Motor rotating at full throttle position

Solid Yellow On

Tips:

DJI ESCs are specially designed for multi-rotors. When use with DJI autopilot systems, you do not have to setup

any parameters or calibrate travel range.

ESC Sound

ESC LED

Page 20

Specifications

Frame

Diagonal Wheelbase

800mm

Frame Arm Length

350mm

Frame Arm Weight

(with Motor, ESC, Propeller )

356g

Center Frame Diameter

240mm

Center Frame Weight

550g

Landing Gear Size

460mm(Length)×425mm(Width)×320mm(Height)

(Top width: 155mm)

Retractable Landing Gear Weight

(Including Battery Tray)

1050g

Motor

Stator Size

41×14mm

KV

400rpm/V

Max Power

500W

Weight (with Cooling Fan)

158g

ESC

Current

40A OPTO

Voltage

6S LiPo

Signal Frequency

30Hz ~ 450Hz

Drive PWM Frequency

8KHz

Weight (with Radiators)

35g

Foldable Propeller (1552)

Material

Engineering plastic

Size

15×5.2 inch

Weight

13g

Flight Parameters

Takeoff Weight

6.0Kg ~ 8.0Kg

Total Weight

3.7Kg

Power Battery

LiPo (6S、10000mAh~15000mAh、15C(Min))

Max Power Consumption

3000W

Hover Power Consumption

800W(@ Takeoff Weight 6.7Kg)

Hover Time

Max: 20 min (@15000mAh&6.7KgTakeoff Weight)

Working Environment Temperature

-10 ~ +40 oC

Page 21

FAQ (Trouble Shooting)

For arms

For arms

G V

G P

G V

G P

Blue

Solder pad

Fine wire

Thick wire

Black

Red

Blue

Black

Red

Thick wire

Fine wire

Propeller CCW

Propeller CW

A

B

C

D

Solder ESC

Make sure to solder the thick wires and fine wires correctly, when solder ESC to frame arm.

Clockwise and counter clockwise motor should be soldered to ESC correctly by different color order.

Assemble the Vibration Absorber of Motors

The soft gasket is a part of the Vibration Absorber and it has a thick end and a thin end, it’s important to assemble

the soft gaskets in correct approach adhere to the diagram below.

Propeller CCW: the thick ends of the gaskets (A) are upwards, the thick ends of the gaskets (B) are downwards.

Propeller CW: the thick ends of the gaskets (C) are downwards, the thick ends of the gaskets (D) are upwards.

Page 22

Spare Parts Listing

SE010101CCW

CW-Clockwise CCW-Counter clockwise; ;

;;

Parts NO.

Package NO.

01Arm Frame 02Center Frame

03Landing Gear

;;

S800 EVO

Frame Arm

M2x 9(3pc s)

SE0 10102 CCW

SE0 10102

SE0 10103

M3x 10.5( 2pcs)

M2. 5(4pc s)

SE0 10301 B/

SE0 10401 R

SE0 10302

SE0 14401

SE0 10303

M3x 4.5(2 pcs)

SE0 10501 R/

M2. 5x11( 4pcs)

SE0 10601 G

SE0 11001

SE0 10702 (4pcs )

SE0 10701 CW/

M3 (3 pcs )x4. 5

SE0 10101 CW/

SE0 10801 CCW

S 01 4402E

Package NO.

Name

Components Number

1

Frame Arm (Counter Clockwise)

SE010101CCW、SE010102、SE010103、M2x9

2

Frame Arm (Clockwise)

SE010102CW、SE010102、SE010103、M2x9

3

Motor with black Prop cover

SE010301B、SE010302、SE014402、SE014401 、

SE010303 、M2.5x5、M3x4.5

4

Motor with red Prop cover

SE010401R、SE010302、SE014402、SE014401 、

SE010303 、M2.5x5、M3x4.5

5

ESC with Red Led

SE010501R

6

ESC with Green Led

SE010601G

45

1552 Folding Propellers(both

CW&CCW)

SE010701CCW、SE010801CW、SE010702、M3x10.5

9

Washer for Propeller

SE010702

10

ESC Heat Sink

SE011001

If S800 EVO needs component replaced, please refer to the following diagram to identify the component NO., and

then make a purchase of corresponding package. Each package includes screws needed. The Components Number

is defined as bellow.

Page 23

Center Frame

M2.5x 5( 25pcs)

M2x9( 12 pcs)

SE021 40 1( 6pcs)

SE021 20 1

SE021 60 1( 7pcs)

SE021 50 1

SE021 50 2

SE021 50 3

SE021 30 1SE021 30 1

M2.5x 5( 25pcs)

Package NO.

Name

Components Number

11

Center Frame

SE021201、SE021301、SE021401、SE021501、

SE021502 、SE021503、SE021601、M2x9、M2.5x5

12

Center Frame Top Board

SE021201、M2x9、M2.5x5

13

Center Frame Bottom Board

SE021301、M2.5x5

14

Top Board Cover

SE021401、M2x9

15

Arm Mounting Bracket

SE021501、SE021502、SE021503、 M2x9、M2.5x5

16

Aluminum Brace for Center Frame

SE021601、M2.5x5

Page 24

Landing Gear

SE0 31701

SE0 31702

SE0 31801

SE0 31901

HC_ M2 5x 10 4p cs. ( )

SE0 32001

PM2 5 x4.x3

SE0 32901

SE0 32201

SE0 32202

SE0 32204

M2 5x5 4 pcs. ( )

SE0 32301

SE0 32302

M3x 8

SE0 32501

SE0 32502

HC_ M2.5x 8

HC_ M3x22

SE0 32401

SE0 32402

SE0 32601

SE0 32701 (4pcs )

SE0 32101

SE0 33001

SE0 32801

SE0 32802

SE0 32803

SE0 32803

SE0 32802

SE0 32804

HC_ M3x8()2pc s

SE0 33102

SE0 32801

SE0 33103

SE0 33104

M3x 5 2pc s()

M2. 5x5 2 pc s()

M3x 8()4pcs

SE8032802

SE8032801 SE8032803

(2)

SE8032502

SE8032402

(1)

SE0 33301

SE0 33201

SE0 33201

SE0 33202

SE0 33401 7pcs()

M2. 5x8

SE0 33203

Package NO.

Name

Components Number

17

Retract Module(Left)

SE031701、SE031702

18

Retract Module(Right)

SE031801、SE031702

19

HITEC Servo (Right)

SE031901、HC_M2.5x10

20

HITEC Servo (Left)

SE032001、HC_M2.5x10

21

Carbon Tube of H-Frame

SE032101、HC_M2.5x8

22

Control Board

SE032201、SE032202、SE032203、SE032204、M2.5x5

23

Spring

SE032301、SE032302、SE031702、M3x8

24

Support Tube (Right)

SE032401、SE032402、M3x8、HC_M2.5x8、HC_M3x8

25

Support Tube (Left)

SE032501、SE032502、M3x8、HC_M2.5x8、HC_M3x8

Note1: (1) Left Support Tube right Support Tube are different; (2) Left set, middle set and right set of Damping Unit

are different.

Page 25

26

Base Tube

SE032601、SE032701

27

Silicone Rubber Damper

SE032701

28

Damping Unit (Set)

SE032801、SE032802、SE032803、SE032804、HC_M3x8

29

Aluminum Tube of H-Frame

SE032901

30

Silicone Rubber of H-Frame

SE033001

31

Battery Tray

SE033101、SE033102、SE033103、SE033104、M2.5x5、M3x5

32

Control arm of Retractable

Module(Left)

SE033201、SE033202、SE033203、M2.5x8

33

Control Arm of Retractable

Module(Right)

SE033301、SE033202、SE033203、M2.5x8

34

Shaft Sleeve of Retract

Module

SE033401

35

IMU Mount

SE033501 、M3x8

Others

SE033 60 1

SE0 33801

Package NO.

Name

Components Number

36

GPS Holder

SE033601

37

Screws Package

M3x8(10pcs)、HC_M2.5x10(10pcs)、M2.5x5(30pcs)、M2x9(10pcs)、

M3x4.5(10pcs)、M2.5x8(5pcs)、M2.5x11(10pcs)、M3x 10.5(15pcs)、

HC_M3x8(10pcs)、HC_M2.5x8(10pcs)、HC_M3x22(5pcs)

38

Blade Holder

SE033801

Package NO.

Name

Components Number

39

Battery Mount Board

SE033104、Velcro straps

40

Frame Arm with Prop CCW &Red LED

Package NO. 1、4、5、7、10

41

Frame Arm with Prop CW &Red LED

Package NO. 2、4、5、8、10

42

Frame Arm with Prop CCW &Green LED

Package NO. 1、3、6、7、10

43

Frame Arm with Prop CW &Green LED

Package NO. 2、3、6、8、10

Page 26

M2. 5( 4pcs)

SE0 14 401

S 0144 02E

Package NO.

Name

Components Number

44

Vibration absorber of Motor

SE014401、SE014402、M2.5

Loading...

Loading...