Page 1

2000 Operator's Manual

5000

SERIES

1Page

Page 2

IMPORTANT - READ CAREFULLY

The Dixon® ZTR® Mower is both easy and fun to operate. However, any

power mower must be operated properly to be safe. It is not a toy or a

recreational vehicle. Before you start to use the mower, read the

operator's manual carefully and become completely familiar with the

controls.

The information in this operator's manual applies to all Dixon® ZTR® 5000

Series Commercial Mowers. Your Dixon dealer will gladly answer any

questions.

See your dealer for warranty service, parts and repairs.

Page 2

DIXON INDUSTRIES, INC.

A BLOUNT International Inc. Co.

PO BOX 1569

COFFEYVILLE KS 67337 0945

316 251 2000

Page 3

INDEX

SAFETY..........................................................Pages 2 - 7

WARRANTY POLICY .....................................Page 8

SPECIFICATIONS ..........................................Pages 9 - 11

SEAT ADJUSTMENT.....................................Page 12

CONTROLS....................................................Pages 13 - 16

OPERATION INSTRUCTIONS.......................Pages 17 - 23

CARE AND MAINTENANCE ..........................Pages 24 - 39

STANDARD SERVICE PARTS LIST .............Pages 40 - 41

TROUBLESHOOTING ...................................Pages 42 - 44

5000 Series

Part No. 1858-0599

3Page

Page 4

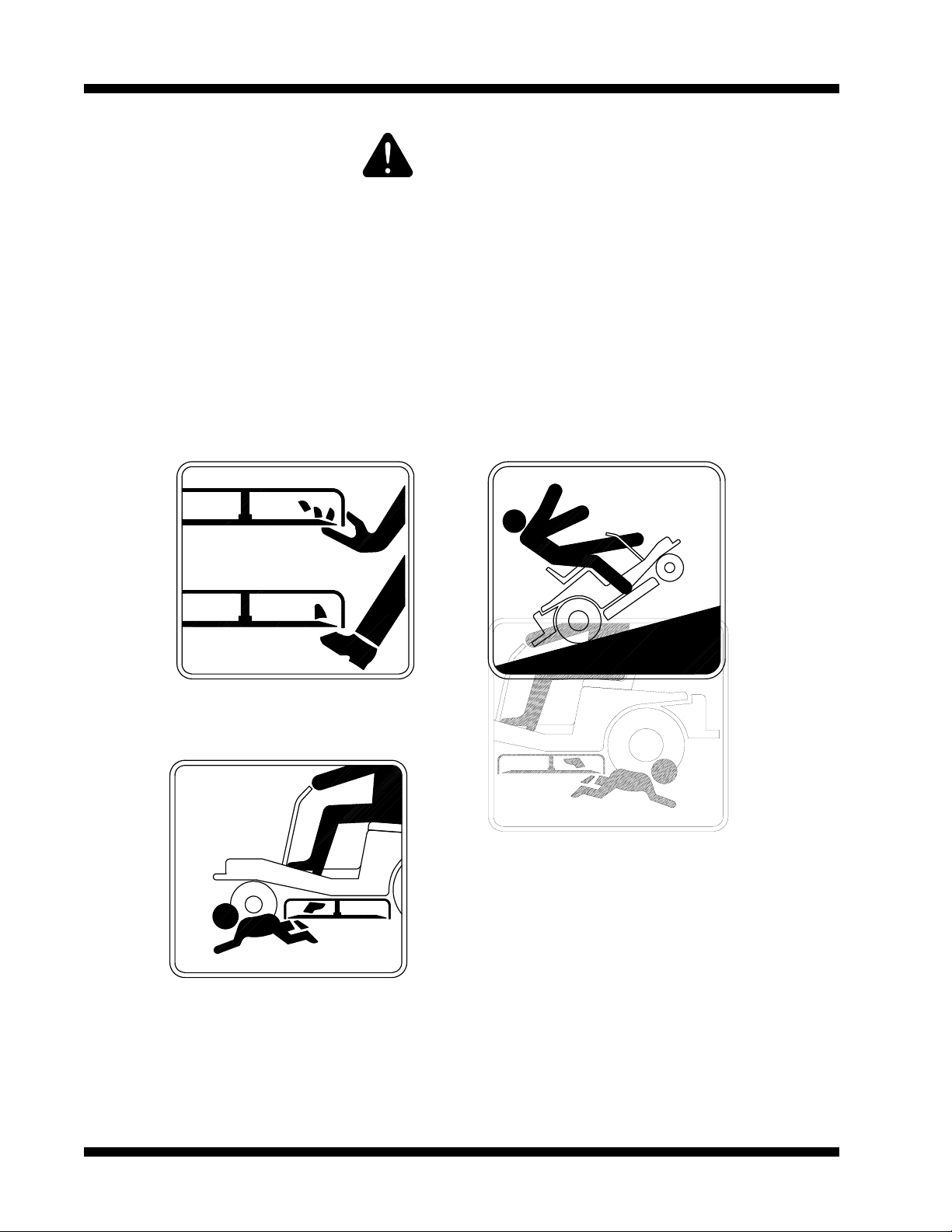

SAFETY

RIDING LAWNMOWERS, IF IMPROPERLY OPERATED,

CAN CAUSE SERIOUS INJURY OR DEATH

The most common causes of injury to the operator or bystander...

BLADE CONTACT

RUN-OVER

...read and understand this manual to prevent injuries.

TIP-OVER

BACK-OVER

Page 4

Page 5

SAFETY

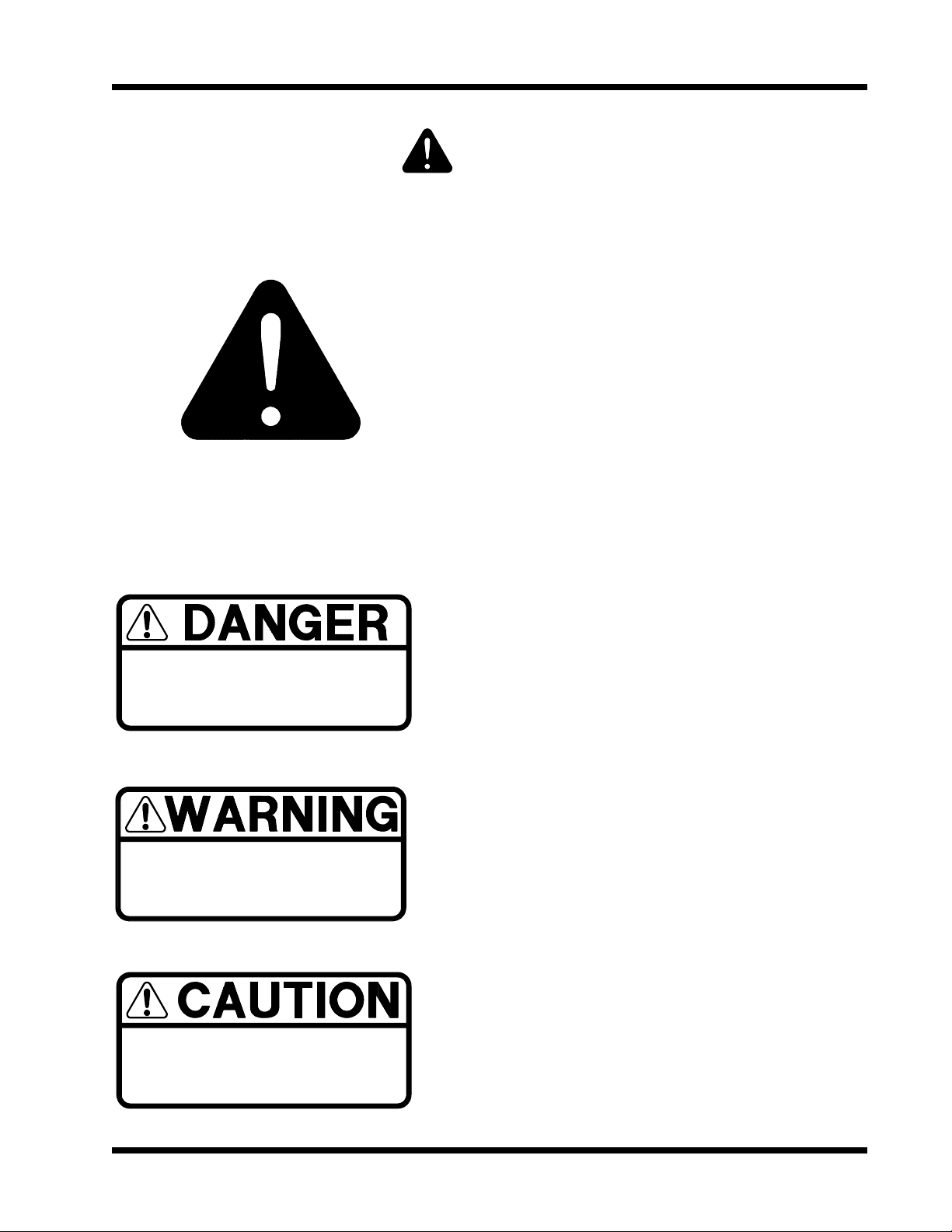

SAFETY SYMBOLS

Safety Alert Symbol

When you see this symbol,

BE ALERT to the potential for injury.

Follow recommended safety precautions and safe

operating practices.

Danger

indicates an imminently hazardous situation

which, if not avoided, will result in death or

serious injury.

Warning

indicates a potentially hazardous situation

which, if not avoided, could result in death

or serious injury.

Caution

indicates a potentially hazardous situation

which, if not avoided, may result in minor or

moderate injury. It may also be used to alert

against unsafe practices.

5Page

Page 6

SAFETY

This cutting mower is capable of amputating hands & feet, and throwing objects.

Failure to observe the following safety instructions could result in

serious injury or death.

GENERAL OPERA TION:

• Read, understand, and follow all instructions in the manual and on the mower before

starting.

• Only allow responsible adults, who are familiar with the instructions, to operate the mower.

• Clear the area of objects such as rocks, toys, wire, etc., which could be picked up and thrown

by the blade.

• Be sure the area is clear of other people before mowing. Stop mower if anyone enters the

area.

• Never carry passengers.

• Do not mow in reverse unless absolutely necessary. Always look down and behind before

and while backing.

• Be aware of the mower discharge direction and do not point it at anyone. Do not operate

the mower without either the entire grass catcher or the deflector in place.

• Slow down before turning.

• Never leave a running mower unattended. Always turn off blades, set parking brake, stop

engine, and remove key before dismounting.

• Turn off blades when not mowing.

• Stop engine before removing grass catcher or unclogging chute.

• Mow only in daylight or good artificial light.

• Do not operate the mower while under the influence of alcohol or drugs.

• Watch for traffic when operating near or crossing roadways.

• Use extra care when loading or unloading the mower into a trailer or truck.

Do not ride the mower when loading & unloading.

• Always wear safety goggles or safety glasses with side shields when operating mower.

• Data indicates that operators, age 60 years and above, are involved in a large percentage

of riding mower-related injuries. These operators should evaluate their ability to operate

the riding mower safely enough to protect themselves and others from serious injury.

• Follow the manufacturer's recommendation for wheel weights or counterweights.

W ARNING:

Page 6

The engine exhaust from this product contains chemicals known to the

State of California to cause cancer, birth defects or other reproductive harm.

Page 7

SAFETY

SLOPE OPERATION:

Slopes are a major factor related to loss-of-control and tip-over accidents,

which can result in severe injury or death.

All slopes require extra caution.

If you cannot back up the slope or if you feel uneasy on it, do not mow it.

DO

Mow across the slope with your Dixon ZTR - never up or down.

Remove obstacles such as rocks, tree limbs, etc.

Watch for holes, ruts or bumps. Uneven terrain could overturn the mower. Tall

grass can hide obstacles.

Use slow speed. Tires may lose traction on slopes even though the brakes are

functioning properly.

Use extra care with grass catchers or other attachments. These can change the

stability of the mower.

Keep all movement on the slopes slow and gradual. Do not make sudden changes

in speed or direction.

Avoid starting or stopping on a slope. If tires lose traction, disengage the blades and

proceed slowly down the slope.

If front wheels lift off the ground, pull the levers back to stabilize the mower.

DO NOT

Do not turn on slopes unless necessary, and then, turn slowly and gradually

downhill, if possible.

Do not mow near drop-offs, ditches, or embankments. The mower could suddenly

turn over if a wheel is over the edge of a cliff or ditch, or if an edge caves in.

Do not mow on wet grass. Reduced traction could cause sliding.

Do not try to stabilize the mower by putting your foot on the ground.

Do not use grass catcher on steep slopes.

7Page

Page 8

SAFETY

CHILDREN:

Tragic accidents can occur if the operator is not alert to the

presence of children.

Children are attracted to lawn mowers and the mowing activity.

NEVER assume children will stay where they were last seen.

Be alert to avoid accidents.

• Keep children out of the mowing area and under the watchful care of another

responsible adult.

• Be alert and turn mower off if a child enters the area.

• Before and during backing, look behind and DOWN for small children.

• Never carry children. They may fall off and be seriously injured or interfere with

safe mower operation.

• Never allow children to operate the mower.

• Use extra care when approaching blind corners, shrubs, trees, or other objects

that may obscure vision.

12 VOLT UTILITY OUTLET

A utility outlet is provided for use with 12 volt DC attachments. It is located just

ahead of the instrument panel.

Output is limited to 5 amps.

We do not recommend the use of sound equipment (such as CD players with

earphones) that could interfere with the operators hearing. The operator may not hear

impending hazards and could be distracted from the safe operation of the mower.

Page 8

Page 9

SAFETY

SERVICE:

• Use extra care in handling gasoline and other fuels. They are flammable and vapors are

explosive.

Use only an approved container.

Never remove gas cap or add fuel with the engine running. Allow engine to cool before

refueling. Do not smoke.

Never refuel the mower indoors.

Never store the mower or fuel container inside a building where there is an open flame.

Never fill containers inside a vehicle or on a truck or trailer bed with a plastic liner. Always

place containers on the ground away from your vehicle before filling.

When practical, remove gas-powered equipment from the truck or trailer and refuel it on the

ground. If this is not possible, then refuel such equipment on a trailer with a portable

container, rather than from a gasoline dispenser nozzle.

If a gasoline dispenser nozzle must be used, keep the nozzle in contact with the rim of the

fuel tank or container opening at all times until fueling is complete. Do not use a nozzle

lock-open device.

• Never run a mower inside a closed area. The exhaust fumes are toxic.

• Keep nuts and bolts tight, especially blade attachment bolts, and keep equipment in good

condition.

• Never tamper with safety devices. Check their proper operation regularly.

• Keep mower free of grass, leaves, or other debris buildup. Clean up oil or fuel spillage. Allow

mower to cool before storing.

• Stop and inspect the equipment if you strike an object. Repair, if necessary, before restarting.

• Never make adjustments or repairs with the engine running.

• Grass catcher components are subject to wear, damage, and deterioration, which could expose

moving parts or allow objects to be thrown. Frequently check components and replace with

original equipment parts, when necessary.

• Mower blades are sharp and can cut. Wrap the blade(s) or wear gloves, and use extra caution

when servicing them.

• Batteries contain sulfuric acid. To prevent burns avoid contact with skin, eyes and clothing. To

prevent a fire or explosion keep sparks and open flames away from battery.

Before disconnecting the negative (-) ground cable, make sure all switches are OFF.

9Page

Page 10

DIXON LIMITED W ARRANTY POLICY -- EST ATE MODELS

This warranty policy applies to all Estate Mowers purchased on or after September 1, 1997.

WARRANTY:

Commercial Applications: Dixon Estate Models used in any commercial application are warranted for a period of six

(6) months from date of purchase. Commercial applications or use is defined as any use other than at owners primary

place of residence.

are warranted for a period of two (2) years from date of purchase. DIXON ZTR MOWERS ARE WARRANTED

AGAINST DEFECTS IN MATERIALS AND WORKMANSHIP AND PROVIDES FOR REPLACEMENT OR REPAIR OF

PARTS INCLUDING LABOR COSTS. THIS WARRANTY IS SUBJECT TO THE FOLLOWING CONDITIONS AND

LIMITATIONS:

1. Warranty applies only to original retail purchaser of new and unused mowers and accessories.

2. All Dixon warranty must be accomplished by authorized Dixon dealers and in accordance with Dixon warranty policy and

allowances. All warranty claims must be approved by Dixon Industries, Inc.

3. Battery warranty: Limited to 90 days from date of purchase.

4. Accessories Warranty (Grass Catchers, Snow Blades, Tine Rakes, Covers, etc.): Limited to 90 days from date of purchase.

5. Warranty does not apply to damage in transit or incidents of misuse, negligence, accidents, or alteration. The use of parts

or components other than those supplied by Dixon Industries, Inc. VOIDS ALL WARRANTY.

Home Owner Applications: Dixon Estate Models used primarily at the owner’s place of residence

6. The following items are not covered by this warranty policy:

(a) Pick up and delivery charges for transportation of mower to and from an Authorized Dixon Dealer's place of business.

(b) Routine maintenance or adjustments.

(c) Belts / cutting blades / HydroGear Filters.

(d) Engines -- All engines used on Dixon ZTR mowers are warranted by each individual engine manufacturer.

(e) Any costs or expense of providing substitute equipment while repair work is being performed on a warranted mower.

7. There is no other express warranty. Implied warranties, including those of merchantability and fitness for a particular

purpose, are limited to the same duration of the express warranty, and to the extent permitted by law any and all implied

warranties are excluded. Liabilities for consequential damages under any and all warranties are excluded.

WARRANTY VALIDATION: At the time of sale, selling dealer must review each portion of this warranty document, complete the

information section below, secure customer's signature and send copy to Dixon Industries, Inc.

DATE OF PURCHASE__________________________Model ____________________ S/N______________________

(Owner's Name)

(Address)

(Dealership)

(Dealership)

(Address)

Page 10

(Dealer's Signature) (Owner's Signature)

SEE DEALER FOR DETAILS

Page 11

SPECIFICATIONS

Model ZTR 5020

CHASSIS: 11 G A - rectangular tube

BODY: Two piece - made of rotational molded polyethylene. Front body

contains access panels for battery service and engine to mower deck

belt removal. Rear body tilts up to allow service on the entire drive

system.

SEAT: Designed for operator comfort by use of high density closed cell foam

padded back rest and arm rests, upholstered with Cordura

repellent fabric. Seat is adjustable fore and aft.

MOWER DECK: 2 Decks are available. 60" is made of stamped steel. 50" is made of

11 GA fabricated welded construction with external reinforcement

ribs. 3 blades combine for either a 50" or 60" cut width.

Cut height approximately 1.5" to 4.5" via 7 position lift handle.

BLADE DRIVE: Electric clutch

DRIVE SYSTEM: Each rear wheel is independently driven by a HydroGear BDU-10L

Series 70 hydrostatic transmission. The hydrostatic transmissions, in

turn, power a fully enclosed HydroGear gearbox.

ENGINE: 20HP Briggs & Stratton Intek, overhead valves, replaceable oil filter,

full pressure lube system, dual element air cleaner, integral fuel pump.

STARTING SYSTEM: Electric by key switch operation with safety interlocks on parking brake

and blade drive clutch.

TIRES: Front 11 X 4 X 5 smooth profile

Rear 20 X 10 X 8 Multi Trac

RECOMMENDED Front 16 - 21 lbs.

TIRE PRESSURE: Rear 8 - 14 lbs.

TM

water-

CAPACITIES: Fuel - 4.8 gallons total (dual tanks)

Hydrostat oil tank - 3 quart with in-line 40 micron filter

Hydrostat oil recommendation, refer to page 36

Engine - 2 qts. SAE 30 (with filter)

DIMENSIONS: Width 60"(50" Deck), 73"(60"Deck)

Height 45"

Length 72"

Weight 668 lbs. (50" Deck), 685 lbs. (60" Deck)

NOTE: Additional information provided in service instructions under the

individual component.

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

11Page

Page 12

SPECIFICATIONS

Model ZTR 5023

CHASSIS: 11 GA - rectangular tube

BODY: Two piece - made of high-density polyethylene. Front body contains

access panels for battery service and engine to mower deck belt

removal. Rear body tilts up to allow service on the entire drive system.

SEAT: Designed for operator comfort by use of high density closed cell foam

padded back and arm rests, upholstered with Cordura

fabric. Seat is adjustable fore and aft.

MOWER DECK: 2 Decks are available. 60" is made of stamped steel. 50" is made of

11 GA fabricated welded construction with external reinforcement

ribs. 3 blades combine for either a 50" or 60" cut width. Cut height

approximately 1.5" to 4.5" via 7 position lift handle.

BLADE DRIVE: Electric clutch

DRIVE SYSTEM: Each rear wheel is independently driven by a HydroGear BDU-10L

Series 70 hydrostatic transmission. The hydrostatic transmissions, in

turn, power a fully enclosed HydroGear gearbox.

ENGINE: 23HP Kohler Command, 4-Cycle, V-Configuration, Overhead Valve, Air-

Cooled, Gasoline, Vertical Shaft, Aluminum Head, and Crankcase with

Cast Iron Liners, Full Pressure Lubrication/Full Flow Filter, Pulse-type

Fuel Pump, Fixed Jet Carburetor w/Smart-Choke, Electronic Ignition,

In-Line Fuel Filter, Dual Element Air Cleaner.

STARTING SYSTEM: Electric by key switch operation with safety interlocks on parking brake

and blade drive clutch.

TIRES: Front 11 X 4 X 5 ribbed tread

Re a r 20 X 10 X 8 Multi Trac

TM

water-repellent

RECOMMENDED Front 16 - 21 lbs.

TIRE PRESSURE: Rear 8 - 14 lbs.

CAPACITIES: Fuel - 4.8 gallons total (dual tanks)

Hydrostat oil tank - 3 quart with in-line 40 micron filter

Hydrostat oil recommendation, refer to page 36

Engine - 2 qts. SAE 10W30 (with filter)

DIMENSIONS: Width 60"(50" Deck), 72"(60" Deck)

Height 45"

Length 72"

Weight 680 lbs.(50" Deck), 685 lbs.(60" Deck)

NOTE:

Additional information provided in service instructions under the individual

component.

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

Page 12

Page 13

SPECIFICATIONS

Model ZTR 5425

CHASSIS: 11 G A - rectangular tube

BODY: Two piece - made of rotational molded polyethylene. Front body

contains access panels for battery service and engine to mower deck

belt removal. Rear body tilts up to allow service on the entire drive

system.

SEAT: Designed for operator comfort by use of high density closed cell foam

padded back rest and arm rests, upholstered with Cordura

repellent fabric. Seat is adjustable fore and aft.

MOWER DECK: 13 ga stamped steel construction. 3 blades combine for a 42" cut width.

Cut height approximately 1.5" to 4.5" via 7 position lift handle.

BLADE DRIVE: Electric clutch

DRIVE SYSTEM: Each rear wheel is independently driven by a HydroGear BDU-10L

Series 70 hydrostatic transmission. The hydrostatic transmissions, in

turn, power a fully enclosed HydroGear gearbox.

ENGINE: 17HP Briggs & Stratton Intek, overhead valves, replaceable oil filter,

full pressure lube system, dual element air cleaner, integral fuel pump.

STARTING SYSTEM: Electric by key switch operation with safety interlocks on parking brake

and blade drive clutch.

TIRES: Front 11 X 4 X 5 smooth profile

Rear 18 X 9.5 X 8 Multi Trac

RECOMMENDED Front 16 - 21 lbs.

TIRE PRESSURE: Rear 8 - 14 lbs.

CAPACITIES: Fuel - 4.8 gallons total (dual tanks)

Hydrostat oil tank - 3 quart with in-line 40 micron filter

Hydrostat oil recommendation, refer to page 36

Engine - 2 qts. SAE 30 (with filter)

TM

water-

DIMENSIONS: Width 54"

Height 45"

Length 72"

Weight 615 lbs

NOTE: Additional information provided in service instructions under the

individual component.

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

13Page

Page 14

SEAT ADJUSTMENT

INSTRUCTIONS

5000 Series Models

1. Grasp seat slide adjuster and move it into adjustment position.

2. Slide seat forward or backward.

3. Release seat slide adjuster.

Page 14

Page 15

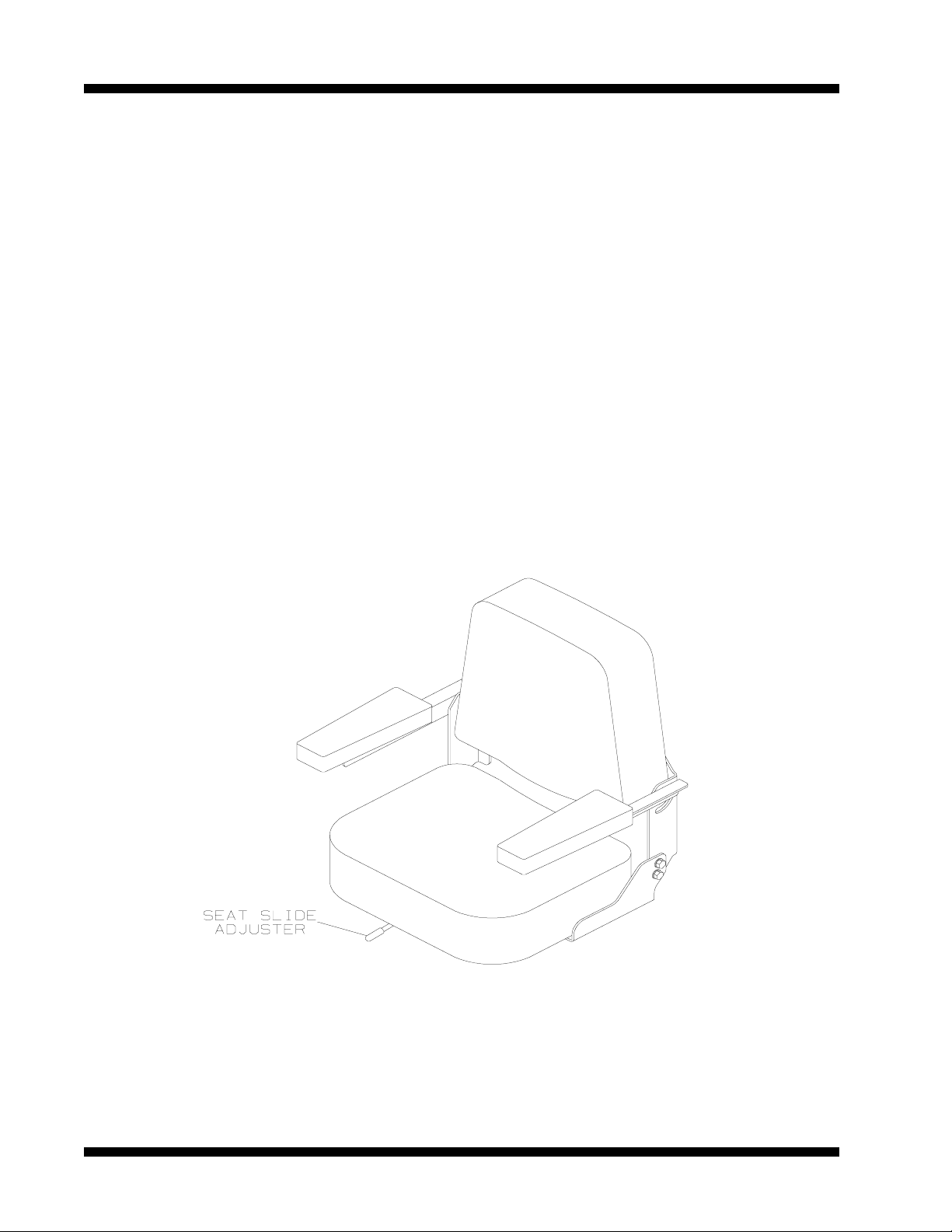

CONTROLS

15Page

Page 16

PARKING BRAKE:

The parking brake is designed to hold the mower from

moving and is not intended for use in stopping the mower

while it is in motion.

CONTROLS

CAUTION

Engage parking brake before starting engine

TO SET PARKING BRAKE:

The hand operated parking brake is located at

left hand side of mower.

To engage brake, pull lever up (to the rear).

To release brake, move lever forward (down).

NOTE: Always set parking brake before dismounting.

Release parking brake before moving mower.

HYDRO-GEAR DRIVE SYSTEM:

Allows the mower to turn on its own axis (zero turning radius).

Each lever controls one side of the mower.

NOTE: The pressure required to operate the mower is very light.

Page 16

Page 17

TO GO FORWARD:

From neutral position, gently push both drive levers forward.

To increase speed, move levers farther forward.

TO GO BACKWARD:

From neutral position, gently pull both drive levers toward you.

CONTROLS

(left turn opposite)

TURNING:

Turning is controlled by moving one drive lever slightly forward or rearward of

the other.

To turn left, move left lever rearward of the right lever.

To turn "square corners" move lever of desired direction to neutral.

To turn on mower's own axis (zero turning radius) stop and move one lever to

reverse position and the other to forward position.

BRAKING:

To brake mower, move both levers in direction opposite of travel, release levers

to neutral, set parking brake. Park only on level surfaces.

CHOKE CONTROL LEVER:

Located on control panel to operator's right.

Used to start a cold engine.

THROTTLE CONTROL LEVER:

Located on control panel to operator's right.

Controls engine speed, slow to maximum.

While mowing, throttle control should be set to the MAXIMUM or wide open

setting to insure adequate cooling of the engine and to maintain mower deck

blade speed.

17Page

Page 18

BLADE DRIVE:

Located on control panel, on operator's right.

To engage blades: Pull up on the switch.

To disengage blades: Push down.

CIRCUIT BREAKER:

Located on control panel, on operator's right.

Protection of the electrical system is by

(1) 15 amp circuit breaker.

If circuit breaker trips, push button to reset.

If this condition repeats, consult dealer for

inspection and repair.

CONTROLS

MOWER DECK CUT HEIGHT LIFT LEVER:

Located to the right and front of operator.

Controls the cutting height.

Seven positions of adjustment.

Depress trigger and move lever forward to

lower deck.

Depress trigger and pull lever back to raise

deck.

NOTE: Always use high position for transport.

Page 18

Page 19

OPERATION INSTRUCTIONS

Safe and successful operation will depend upon the operator having the correct

knowledge of all controls used on the mower and making good judgements about the

terrain to be mowed.

NEVER allow anyone to operate the mower without complete knowledge of all controls

and their functions.

During initial operation, "learning to drive", set throttle at slow speed.

Sound judgement by the operator will prevent accidents.

DRINK/CUP HOLDER located on left rear fender is for transport or carrying ONLY!

Mower usage requires that both hands be free to control individual levers.

DO NOT ATTEMPT operation of mower with any type of

container or other object in either hand.

TOWING

Towing a trailer or other attachment that is too heavy could damage the drive or cause

the mower to become unstable. Limit loads to 500 pounds or less on this mower.

BEFORE OPERATING MOWER:

1. Read engine manufacturer's operating and maintenance instructions.

2. Discuss proper maintenance with your dealer.

3. Read and observe all safety instructions on your mower and in the

manual.

4. Check engine oil.

5. Be sure gas cap is in place.

6. Be sure parking brake is on.

7. Be sure mower blade drive is off.

8. Know how to stop engine. (Turn key to off position)

19Page

Page 20

OPERATION INSTRUCTIONS

TESTING OF SAFETY INTERLOCK SYSTEMS:

PARKING BRAKE SWITCH TEST: a) Place Parking Brake in OFF position

b) Turn ignition switch to START

Engine should not turn over or attempt to start.

BLADE DRIVE SWITCH TEST: a) Place Parking Brake in ON position

b) Engage blade drive switch

c) Turn ignition switch to START

Engine should not turn over or attempt to start.

SEAT SWITCH TEST: a) In a SAFE AREA away from bystanders,

start the engine

b) Engage blade drive switch

c) Raise slightly off seat

ENGINE SHOULD STOP

If Any Safety Check F AILS: Do Not Operate The Mower until

the system has been checked and repaired

by an Authorized Dixon ZTR Dealer

Page 20

Page 21

OPERATION INSTRUCTIONS

STARTING INSTRUCTIONS: Cold Engine

1. Position choke control in ON position.

2. Position throttle control at 1/2 speed setting.

3. Insert ignition key and turn to "Start"

position.

When engine starts, release ignition key.

Key will return to "Run" position.

4. Once engine starts to warm up, slowly move

choke control to OFF position.

5. Move throttle control to the FAST position.

6. Engine must be operated with throttle

control in the FAST position, or maximum

setting to insure adequate lubrication and

cooling of the engine, and cut quality of the

mower deck.

STARTING INSTRUCTIONS: Engine has been operated.

1. Move throttle control to 1/4 to 1/2 setting.

2. Insert ignition key and turn to "Start" position. When engine starts, release

ignition key. Key will return to "Run" position.

3. Move throttle control to FAST position.

NOTE:Model ZTR 5023 may require partial choke setting to start even if the

engine has been operated for a period of time.

4. Engine must be operated with throttle control in the FAST position, or

maximum setting to insure adequate lubrication and cooling of the engine,

and cut quality of the mower deck.

CAUTION DO NOT operate the engine in an enclosed area. The exhaust

fumes are toxic.

21Page

Page 22

OPERATION INSTRUCTIONS

MOWING WITH A MULCHING ATT ACHMENT:

Mulching or recycling the grass clippings requires a totally different mowing approach

than would be normal when side discharging or bagging the grass. There may be

instances or conditions where it is not possible to hide all of the recycled or mulched

clippings.

In order to achieve the best results, please read and follow the mulching tips listed below:

1. Set the engine speed control to the wide open or full setting.

2. Place the mower deck cut height selector in either the top or second notch. Never

cut more than 3/4" to 1" off the grass at any one time. Attempting to cut more grass

will result in the deck plugging and cause the engine to stall.

3. It may be necessary to cut the lawn twice to achieve acceptable mulching

performance especially on first cuttings or if the lawn is heavily fertilized.

4. Do Not Attempt To Cut Grass When It Is Wet. Mulching performance will be very

poor under wet grass conditions.

5. Maintain Sharp Blades Throughout The Cutting Season. This is very important.

Optimal mulching performance cannot be obtained with dull or nicked blades.

6. Keep The Underside Of The Mower Deck Clean. Remove all grass and dirt buildup

from the underside of the pan, the baffles and deflectors after each use.

7. Alternate mower direction. This will evenly disperse the mulched grass clippings

over the lawn for even fertilization.

If the mulching quality of the mower does not seem to be satisfactory, try one or more

of the following tips:

1. Raise the height-of-cut setting on your mower.

2. It may be necessary to cut your grass more frequently.

3. Operate the mower at a slower ground speed.

4. Overlap cutting swaths instead of cutting a full swath with each pass.

5. Mow across the marginal areas a second time.

Page 22

6. CUT HIGH - MOW OFTEN!

Page 23

OPERATION INSTRUCTIONS

MOWING WITH A GRASS CATCHER ATT ACHMENT :

In order to achieve optimum performance when mowing with a grass catching attachment,

please read and follow the tips listed below:

1. Set engine speed control to the wide open or full setting.

2. Do Not Attempt To Cut Grass When It Is Wet. Wet grass will clog both the underside

of the deck and the attachment chutes. Empty bags often to prevent plugging.

3. If the grass is tall, place the mower deck cut height selector in the top or second

notch. Initially overlap cutting swaths instead of a full swath with each pass.

4. Keep The Underside Of The Mower Deck Clean. Frequent removal of dried grass

and dirt will greatly assist in bagging of the clippings.

5. Use only the correct blades. Some grass catching attachments require a "high-lift"

blade. See your dealer for advice on the type of blades needed for your mower.

6. Maintain Sharp Blades Throughout The Cutting Season.

7. Operate the mower at a slower ground speed than when mowing without a grass

catching attachment.

CAUTION

• Watch for low hanging branches or other obstacles which might hit the catcher top

while turning or backing the mower.

• Use care when backing to avoid pushing the grass bags into the frame or hot

exhaust muffler of the engine.

• Disengage blade and stop engine prior to clearing grass from either the discharge

chute or grass catcher components.

• Keep all attachment bolts tight.

• Do Not operate the mower with the grass catching attachment partially removed.

• Important:

• Do not leave clippings in the bags while the mower is stored.

• Damp grass clippings are a fire hazard if left in the bags.

23Page

Page 24

OPERATION INSTRUCTIONS

SIDE DISCHARGE OF THE CLIPPINGS:

In order to achieve optimum performance when side discharging the grass clippings,

please read and follow the tips listed below.

Additional information can be found in the troubleshooting guide.

CAUTION

Be sure that deflector is properly installed

on the discharge chute.

1. Set engine speed control to the wide open or full setting.

2. Do Not Attempt To Cut Grass When It Is Wet. Wet grass will clog the underside of

the deck and discharge area.

3. If the grass is tall, place the mower deck cut height lever in the top or second

notch. Initially overlap cutting swaths instead of a full swath with each pass.

Some applications may require a second cutting.

4. Keep The Underside Of The Mower Deck Clean. Frequent removal of dried grass

and dirt will allow the clippings to discharge correctly.

5. Maintain Sharp Blades Throughout The Cutting Season.

GRASS HEIGHT SUGGESTIONS:

Correct mowing height can reduce weeds and disease by 50% to 80%

The following grass cut heights are based on adequate moisture conditions and normal

thatch buildup in a healthy lawn. Some locations and applications may require slightly

different cut heights. If in doubt, consult your local lawn professional for assistance.

Page 24

Grass Types: Best Cut Heights:

Zoysia 2" - 2 1/2"

Blue Grass 1 1/2" - 3"

Fescue Blends 1 1/2" - 3"

St. Augustine (Mid South) 1 1/2" - 2"

St. Augustine (Deep South) 3" - 4"

Tifton Bermuda 1 1/2"

Centipede 1 1/2" - 2"

Common Bermuda 1 1/2" - 2"

Bahia/Argentina/Pensacola 2"

Page 25

OPERATION INSTRUCTIONS

DECK ROLLERS: 60" Deck

Purpose: The spring loaded deck rollers located at the front corners of the 60"

mower deck are designed as an aid to limit turf scalping when mowing on

uneven ground.

Height: Normal height settings as installed at the factory allows each roller to ride

slightly above the turf. This setting should prove ideal under most

mowing conditions.

Adjustment: Some mowing applications may require lowering of each front roller. To

lower the roller, remove the pin, spring, washers and spacer P/N 9789 from

the top of roller bracket tube. Remove roller bracket from tube. Slide

spacer P/N 9789 on roller bracket shaft and reassemble using washer,

spring and pin at the top.

Lubrication: The use of a penetrating oil or light grease on the roller bracket shafts will

keep roller moving freely.

25Page

Page 26

CARE AND MAINTENANCE

This portion of the owner's manual deals with normal service items which can be performed by

the owner. Please remember that if you are in doubt as to the correct service procedures to

be followed, these and other service situations can be handled by a Dixon ZTR dealer who is

familiar with the service of your mower.

MAINTENANCE SCHEDULE:

To insure a long and trouble free service life of all components, a regular and

thorough maintenance schedule should be followed. The following items should

be checked after the first (10) hours of operation and on a weekly basis, or each

(40) hours of use:

(Items marked with an asterisk * require more frequent attention)

1. Drive system, belts and controls.

2. Mower deck belts.

3. Tire pressures.

4. HydroGear oil tank.

5. Tightness of all nuts and bolts.

6. Battery fluid level.

7. * Engine oil. (Before each use or every 8 hours)

8. Electric blade clutch air gap setting.

CAUTION

Before performing any maintenance, shut off engine,

allow to cool.

ENGINE: For engine operating and maintenance information, refer to the engine

operating and maintenance instructions furnished by the engine

manufacturer, supplied with each mower.

BATTERY:Check the fluid in the battery at frequent intervals.

Keep fluid level above the plates in each cell, using distilled water.

OFF-SEASON BATTERY STORAGE:

Identify each cable so cables can be reconnected to correct

terminals.

Disconnect cables from terminals.

ALWAYS disconnect ground cable first and reconnect last.

Charge battery.

DO NOT remove battery from mower.

Clean top of battery and terminals with baking soda and water.

Page 26

Page 27

CARE AND MAINTENANCE

MOWER BLADE MAINTENANCE:

NOTE: Observe proper blade position prior to removal.

1. Safely raise front of mower.

2. Hold or block blade from turning.

3. Loosen blade nut and remove blade.

4. When replacing blade, tighten blade nut securely. Refer to diagram.

CAUTION

NOTE:

Be sure blade is centered on pilot before tightening nut to 60 ft. lbs. torque.

Wear heavy, thick gloves when holding onto mower blade,

avoid the sharp edge of the blade.

27Page

Page 28

CARE AND MAINTENANCE

BELT TENSION

ENGINE TO MOWER DECK BELT:

42" and 50" P/N 6111

60" P/N 6938

The engine to mower deck drive belts are automatically held in proper

tension by springs which push the deck assembly forward and do not

require any additional adjustment to be made.

MOWER DECK SERPENTINE BELT:

REAR

HANGER

PIN

42" P/N 6109

50" P/N 1300

60" P/N 6939

Refer to illustration for adjustment procedure.

TIGHTEN OR LOOSEN

HEX NUT TO ACHIEVE

THIS DIMENSION

NOTE: Belt deflection or movement should be approximately 1/4" when

measured at mid-point between pulleys.

Periodically inspect both belt and idler systems.

50" & 60" 5/8"

42" 3/4"

Page 28

Page 29

CARE AND MAINTENANCE

FUEL SHUT OFF VALVE:

A fuel shut off valve is located at the bottom rear of each fuel tank.

Always turn the valve to the "OFF" position when the mower is stored or

not in use.

LUBRICATION

CHASSIS: Number of grease zerks used: (5)

LOCATIONS: (1) each front wheel caster tube

(1) each mower deck hub

SERVICE INTERVALS: Every 50 hours of operation

RECOMMENDED GREASE: Name brand wheel bearing or multi-purpose grease

Adequate lubrication of the caster tubes and

mower deck hubs will help dispel moisture from

within the bearing retention areas. Bearings are

of a sealed design.

29Page

Page 30

CARE AND MAINTENANCE

REAR WHEELS:

The rear wheels of all 5000 Series models are of an "offset" center design to allow

"reversed" installation for using snow chains or to gain increased stability when

mowing on sloped ground.

Slopes are a major factor related to loss-of-control and tip-over accidents, which

can result in severe injury or death. All slopes require extra caution. If you cannot

back up the slope or if you feel uneasy on it, do not mow it.

WHEEL REVERSAL:

* Installation instructions marked with an * asterisk are particularly important.

1. Raise rear of mower and place suitable supports at the rear of the chassis.

2. Remove rear wheel lug nuts and rear wheels.

3. Reinstall rear wheels with valve stems inward.

4.* Install lug nuts with "flat" side of nut against wheel.

5.* Tighten lug nuts to a minimum torque factor of 50 ft. lbs.

Page 30

Page 31

CARE AND MAINTENANCE

CAUTION

HOT oil may cause burns.

Allow engine to cool before draining oil.

CHANGING THE ENGINE OIL:

1. The "snap lock" oil drain valve is located on the left side of the engine

crankcase.

2. Place a suitable container under the drain valve. The short piece of

hose will help direct the oil.

3. Push the valve body in and twist to clear the detent notch.

4. Pulling the valve body outward will start the flow of oil.

NOTE:

Refer to engine manufacturers recommendations for frequency

of oil changes.

OIL FILL:

1. Push the valve body in and twist into the detent notch.

2. Clean any spilled oil from engine and chassis.

3. Refill engine with type, and quantity of oil recommended by the

engine manufacturer in engine literature.

NOTE:

Engine oil changes on the 5000 Series Models will require

replacement of the oil filter. These filters can be obtained from

any authorized Kohler or Briggs & Stratton engine dealer.

PROTECT YOUR INVESTMENT:

The use of non-original oil or air filters may result in damage to the

engine and a loss of warranty. Listed on Page 41 are the correct part

numbers for each engine in the 5000 Commercial Series.

PLEASE DISPOSE OF USED OILS AT PROPER COLLECTION CENTERS

PROTECT YOUR ENVIRONMENT

CLOSED OPEN

31Page

Page 32

CARE AND MAINTENANCE

MOWER DECK REMOVAL:

1. Remove mower deck drive belt. To relieve belt tension, insert 5283

link (at front of lift frame) into tab illustrated below. Move lift handle

into the lowest cut position. Belt can now be removed from

mower deck pulley.

5283

LINK

FRONT

OF LIFT

FRAME

2. Remove front and rear deck hanger pins, as illustrated below.

INSERT END OF

LINK HERE

Page 32

3. Slide deck from beneath chassis.

4. Reverse procedure to reinstall deck to chassis.

Page 33

CARE AND MAINTENANCE

MOWER DECK LEVELING PROCEDURE:

There are a total of (4) threaded adjusters which will control the attitude or pitch of the mower deck. The adjusters

have lock nuts on the bottom which can be turned up or down to raise or lower the front and rear of the mower

deck. Deck should be level or pitched slightly higher in rear.

A . Place the mower on a smooth level surface, check tire pressures to insure the mower has

a correct stance. Inflate tires as required:

Front: 16 - 21 lbs maximum

Rear : 8 -14 lbs maximum

B . Turn each outer blade tip to align with the deck or in a side to side manner.

C. Measure from the floor surface up to the bottom of the blade tip on the discharge side of the

mower deck. Retain this measurement. Move to the opposite side, check that measurement

is the same. If adjustment is required, turn the nut on the bottom of the front threaded adjuster

up or down until both side to side measurements are equal. Retain measurement.

D. Turn both outer blades to align with the deck in front to rear manner. Turn left rear adjuster

nut up or down until rear of mower deck is positioned level to 1/8th of an inch higher in the

rear than the side to side measurement. At this time, the mower deck will be suspended on

(3) points (both front adjusters and the left rear adjuster). Move the right rear adjuster and

take out the slack which will be present by turning adjuster lock nut up.

E . Confirm measurements once again. Blade tips should be level in a side to side manner. In

the rear, blade tips should be level to 1/8" higher than side to side measurement. In the front,

blade tips should be level to 1/8" lower than side to side measurement.

NOTE: This will place the mower deck in a base measurement position. Additional

adjustment may be required to achieve desired cut for the type of grass or conditions

being mowed.

FRONT

ADJUSTERS

LEFT REAR

ADJUSTER

DECK LEVELING ADJUSTMENT POINTS

33Page

Page 34

CARE AND MAINTENANCE

Adjustment of the drive system is limited to the actual function of the hydrostatic

transmissions as outlined below.

T-BOX TO HYDROSTAT BELT ADJUSTMENT:

Tighten the (2) J-bolts on the T-box mounting plate until each belt has 1/8th

to 1/4th of an inch free play or movement at a mid-point between the pulleys

on the hydrostats and T-Box.

ADJUSTMENT POINTS FOR

T-BOX BELT TENSION

Page 34

Å Bypass Relief Pin

Each hydrostat has a bypass relief pin located at the rear of the

hydrostatic unit. A bypass keeper is provided to allow the mower to be

rolled around without engine running. To accomplish this, the bypass

keeper springs must be positioned to depress the bypass relief pins.

Remove bypass keeper springs prior to actual operation of the mower.

Page 35

CARE AND MAINTENANCE

PARKING BRAKE CABLE ADJUSTMENT:

Make necessary adjustments to the T-Box to Hydrostat belt, as shown on page 32.

Position parking brake lever in the off or disengaged position.

This will allow the belt idler used on the engine to T-box to swing fully and apply

tension to the belt.

At this time, check that the cable has approximately 1-1 /2 to 2 inches of free play.

If adjustment is required, turn the lock nut illustrated below to achieve a

recommended 1-1/2 to 2 inches of free play.

ADJUST HERE FOR PROPER

FREE PLAY OF CABLE WITH

BRAKE LEVER OFF

NOTE: Cable must have the recommended 1-1/2 to 2 inches of free play with parking

brake released or drive belt may slip, causing loss of power.

35Page

Page 36

CARE AND MAINTENANCE

NEUTRAL ADJUSTMENT:

1. Engage parking brake and raise rear of frame with jack or blocks so that rear tires do not

contact the ground.

2. Swing out the control levers, start the engine, and release the paking brake.

3. Raise the upper body to access hydro control linkage. If right wheel creeps, adjust right

side linkage and vice-versa. Use procedure below.

a. loosen, but do not remove, the bolt in the control tube (5540)

b. loosen jam nuts on ends of the control rod (9067)

c. turn control rod in or out until neutral is achieved

d. tighten jam nuts on control rod

9067 CONTROL ROD

e. tighten bolt in control tube

5540 CONTROL

ADJUST IN STEP C

TUBE

JAM NUTS

LOOSEN IN STEP B

TIGHTEN IN STEP D

CONTROL TUBE BOLT

LOOSEN IN STEP A

TIGHTEN IN STEP E

4. Engage parking brake and lower the body.

Release parking brake and swing control levers in. If wheel

creeps, repeat step 3.

5. Stop engine and remove rear of machine from jack or blocks.

6. Drive machine with both levers in top speed position. If one side now drives slightly faster than

the other adjust forward speed bolt in to contact stop sooner.

If levers are now uneven at top speed, loosen control lever mounting nut. Rotate lever to be even

with other side and tighten nut.

Page 36

Page 37

CARE AND MAINTENANCE

FORWARD TRAVEL SPEED ADJUSTMENT:

1. Drive machine on a smooth, level surface with both levers in top speed position.

2. If one side drives slightly faster than the other, adjust forward speed bolt in to contact stop

sooner. If levers are now uneven at top speed, loosen control lever mounting nut. Rotate lever

to be even with other side and tighten nut.

37Page

Page 38

CARE AND MAINTENANCE

PROCEDURE FOR ELECTRIC CLUTCH ADJUSTMENT

Electric clutches require periodic Air Gap adjustments for extended life. Listed below is

both an Air Gap adjustment procedure and an Ohms test to check for a faulty coil within the

clutch. No replacement parts are available to repair a faulty assembly. The entire clutch

must be replaced.

A. AIR GAP ADJUSTMENT

1.

It is not necessary to remove the clutch from the motor.

2. Locate the three holes in the brake plate, one

near each adjustment nut. (Figure 1)

3. Insert a .012 inch feeler gauge into one of the

three windows. Be careful to position the

feeler gauge between the rotor and armature

faces. (Figure 2)

4. Tighten the adjusting nut adjacent to the

window with the feeler gauge inserted until the

gauge fits snugly between the rotor and armature.

The gap should not be so tight that the feeler gauge

cannot be reinserted after removal.

Figure 1

5. Repeat Steps 5 and 6 at the other two windows.

6. Recheck the air gap at each window and make minor adjustments

as necessary to achieve a consistent .012 inch air gap.

B. OHMS TEST

1. Disconnect clutch from mower wiring

harness.

2. Attach the two leads on multi-meter to

the two wires coming from the electric

clutch.

3.

The reading you receive should be

between2.4 to 2.9 OHMS.

4.

If the resistance is outside this range

the clutch coil is faulty.

5. If the clutch coil is faulty, the clutch must be

replaced.

Figure 2

Page 38

Page 39

CARE AND MAINTENANCE

HYDROSTATIC TRANSMISSION OIL AND FILTER SERVICE

SERVICE INTERVALS: 1. Initial oil and filter service - 50 hours.

2. Every 250 hours thereafter.

OIL REQUIREMENTS: Any high quality engine oil with an API classification

of SG/CD is recommended.

RECOMMENDED OIL WEIGHT: Normal operation temperatures - 20 W 50

Cold climate usage - 10 W 40

Another alternative that will provide excellent all

climate performance and extended time between oil

changes is a 15 W 50 synthetic engine oil.

OIL FILTER: P/N 7252- IMPORTANT

The oil filter is a special

design for use on "vacuum

or suction" oil flow systems.

DO NOT: Use automotive engine oil

filters. These filters require

a "pressure" to allow oil

flow. Usage will result in an

"air-lock" condition with

possible damage.

39Page

Page 40

CARE AND MAINTENANCE

HYDROSTATIC TRANSMISSION OIL & FILTER SERVICE

If transmission is to be serviced, proper air purging procedures must be followed, or

damage will occur. Proceed as follows:

1. Remove oil filter from chassis, allowing oil to drain into container. Clean impurities

from inside of reservoir, if necessary.

2. Install new oil filter to chassis. Use only genuine Dixon replacement oil filter.

3. Put fresh oil in reservoir. Fill reservoir to the full mark.

4. Remove two oil return hoses from top of oil reservoir and direct these hoses into a

container for oil draining.

5. Depress by-pass valve on both hydros.

6. Start engine and move throttle to mid-range setting.

7. Release parking brake.

8. Dirty oil, filled with air bubbles, will start to drain from oil return hoses into container.

When oil flowing from hoses is clear and contains no bubbles, stop the engine.

9. Reattach oil return hoses to top of reservoir.

10. Release by-pass valve on both hydros.

11. Add sufficient oil to reservoir to return oil level to the full mark.

Page 40

Page 41

CARE AND MAINTENANCE

WHEELS AND TIRES: Correct tire pressure is important for correct operation of

mower.

Front Tires 11 x 4 x 5 16-21 lbs.

Rear Tires(5020&5023) 20 x 10.5 x 8 8-14 lbs.

Rear Tire (5425) 18 x 9.5 x 8 8-14 lbs.

NOTE: Check lug nuts periodically for tightness.

ELECTRICAL SYSTEMS: Keep all connections clean and tight.

CLEANING THE MOWER: Wash mower periodically.

Clean above and below deck.

NOTE: Allow mower to cool before washing. If bearings

are hot, they will draw moisture inside as they dry

and cause corrosion.

SERIAL NUMBERS: The serial number is located on frame at rear of engine.

WARRANTY : Refer to Warranty Registration Form.

PARTS/SERVICE: See your Dixon dealer for replacement parts, warranty or

service.

PLEASE HELP PROTECT THE ENVIRONMENT BY AVOIDING ALL

CHEMICALS WHICH MAY DAMAGE OR CAUSE HARM TO PLANTS

AND ANIMALS IN YOUR AREA

41Page

Page 42

STANDARD SERVICE PARTS LIST

42" DECK

BLADES: Lo Lift P/N 6236

Standard Hi-Lift P/N 8688

BELTS: Engine to Mower Deck P/N 6111

Serpentine Belt P/N 6109

Engine to T-Box P/N 7253

T-Box to Hydros P/N 1765

Grass Blower Belt P/N 4983

50" DECK

BLADES: Lo-Lift P/N 9443

Standard Hi-Lift P/N 9444

BELTS: Engine to Mower Deck P/N 6111

60 " DECK

BLADES: Hi-Lift P/N 9445

BELTS: Engine to Mower Deck P/N 6938

Serpentine Belt P/N 1300

Engine to T-Box P/N 7253

T-Box to Hydros P/N 1765

Grass Blower Belt P/N 4983

Serpentine Belt P/N 6939

Engine to T-Box P/N 7253

T-Box to Hydros P/N 1765

Page 42

Page 43

STANDARD SERVICE PARTS LIST

KOHLER AND BRIGGS & STRA TTON AIR AND OIL FILTER PART NUMBERS:

Refer to engine manufacturers manual for recommendations regarding frequency of

service required for engine oil changes and air filter maintenance.

Protect your engine investment, use only original equipment filters.

Kohler 23HP Pre-Cleaner Foam Element 45083-01

Cartridge Air Cleaner 45083-02

Engine Oil Filter 12050-01

Briggs & Stratton 17 & 20HP Pre-Cleaner Foam Element 273638

Cartridge Air Cleaner 499486

Engine Oil Filter 492932

43Page

Page 44

TROUBLESHOOTING

MOWER CUT QUALITY:

There are many variables that can affect the cut quality of any riding mower. Type and conditions

of grass, cut height setting, engine RPM and ground speed are some of the variables that interact

creating differences in cut quality. Examination of one or more of the above will generally produce

a quality cut.

The Troubleshooting Chart suggests practices and adjustments that may be helpful in improving

cut quality. Your Dixon ZTR dealer is also available to provide assistance to you.

SITUATION CAUSES REMEDY

Poor cut quality Ground speed Reduce mowing speed.

Poor cut quality Incorrect engine to Refer to page 40 for part numbers.

mower deck belt

Poor cut quality Engine RPM too low Increase engine RPM to maximum.

Poor cut quality Dull or bent blade Sharpen or replace as required.

Poor cut quality Un-level mower deck Refer to page 31 for deck leveling

procedure.

Poor cut quality Grass buildup under Clean out undersideofmowerdeck.

mower deck

Poor cut quality Improper blades Refer to page 40 for part numbers.

Poor cut quality Uneven tire pressures Refer to page 39 for correct tire

pressures.

Page 44

Page 45

TROUBLESHOOTING

DRIVE SYSTEM:

SITUATION CAUSES REMEDY

Mower pulls to one Forward travel Refer to page 35 for procedure

side or the other speed adjustment or consult your dealer for repair.

Drive system will not function

on either side after changing

hydrostatic transmission oil

and filter

Drive system functions on

one side only

Loss of power and speed on

both hydrostatic

transmissions

Incorrect oil filter installed on

system.

Hydrostatic transmissions are

"air locked", low or no oil

return to tank.

Loss of set screw tension on

hydrostatic transmission

pulley.

Incorrect parking brake cable

adjustment

Incorrect or worn drive

belt

Replace with correct Dixon filter.

Consult your dealer for repairs.

Continued attempted operation may result

in damage to the system.

Consult your dealer for repairs.

Refer to adjustment procedure page 33 or

consult your dealer for repair.

Replace with correct belt.

Mower creeps in

neutral position

Neutral Adjustment

Refer to adjustment procedure page 34 or

consult your dealer for repair.

45Page

Page 46

TROUBLESHOOTING

ELECTRICAL SYSTEM:

SITUATION CAUSES REMEDY

Starter will not Circuit breaker Push button to reset

turn engine over disengaged Consult your dealer for repair

Starter will not Dead battery Charge battery

turn engine over

Battery discharge Poor battery connections Tighten or replace as required

Battery water low

Wrong battery installed

in mower

Battery discharge Engine electrical system Have electrical system checked by

not functioning correctly your dealer

Battery discharge Engine being operated Increase engine RPM

at too low an RPM Contact your dealer for information

NOTE: Electrical system failures are generally simple in nature, always check the obvious

first and then move onto the more complicated parts used. Poor battery service, loose

connections, corrosion, frayed or broken wiring, are more likely than component

failure.

Page 46

Page 47

NOTES

47Page

Page 48

DIXON INDUSTRIES, INC.

A BLOUNT International Inc. Co.

PO BOX 1569

COFFEYVILLE KS 67337 0945

316 251 2000

FAX 316 251 4117

OWNER

INFORMATION

DATE PURCHASED MOWER MODEL NUMBER

PURCHASED FROM

Name

Address

MOWER SERIAL NUMBER

DM-

DATE OIL CHANGED: DATE ENGINE TUNED:

Page 48

Page 49

WARNING:

Dixon® and ZTR® are registered trademarks of Dixon Industries, Inc.

California to cause cancer, birth defects or other reproductive harm.

The engine exhaust from this product contains chemicals known to the State of

DIXON INDUSTRIES, INC.

A BLOUNT INTERNATIONAL INC. CO.

PO BOX 1569

COFFEYVILLE KS 67337 0945

316 251 2000

5000Series

5020,5023&5425

Part No. 1858-0599

49Page

Loading...

Loading...