Page 1

1592009760 XW60VS GB Rel 1.1 .09.11.2011 XW60VS 1/4

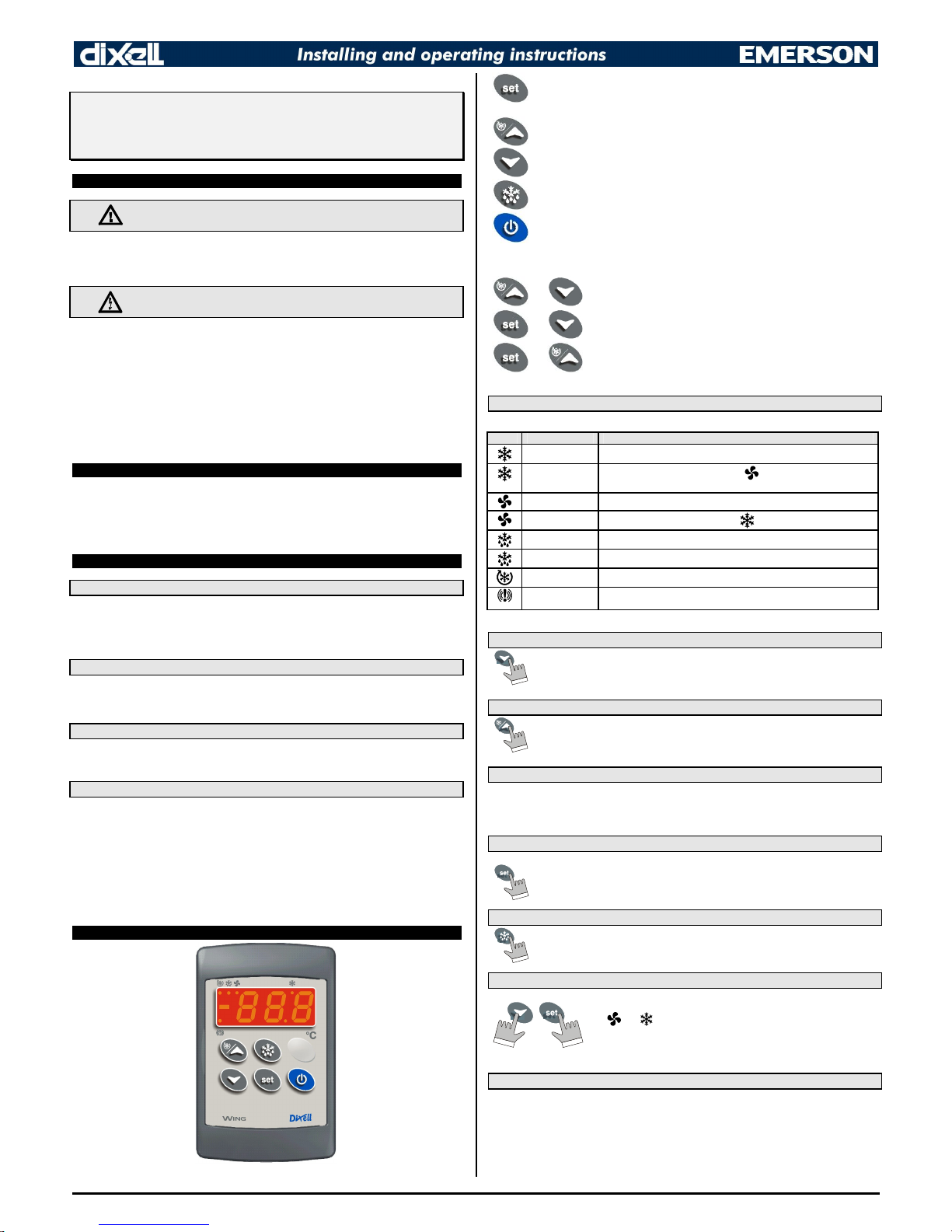

WING

XW60VS

1. GENERAL WARNING

1.1 PLEASE READ BEFORE USING THIS MANUAL

This manual is part of the product and should be kept near the instrument for easy and quick reference.

The instrument shall not be used for purposes different from those described hereunder. It cannot be used

as a safety device.

Check the application limits before proceeding.

1.2

SAFETY PRECAUTIONS

Check the supply voltage is correct before connecting the instrument.

Do not expose to water or moisture: use the controller only within the operating limits avoiding sudden

temperature changes with high atmospheric humidity to prevent formation of condensation

Warning: disconnect all electrical connections before any kind of maintenance.

Fit the probe where it is not accessible by the End User. The instrument must not be opened.

In case of failure or faulty operation send the instrument back to the distributor or to “Dixell S.r.l.” (see

address) with a detailed description of the fault.

Consider the maximum current which can be applied to each relay (see Technical Data).

Ensure that the wires for probes, loads and the power supply are separated and far enough from each other,

without crossing or intertwining.

In case of applications in industrial environments, the use of mains filters (our mod. FT1) in parallel with

inductive loads could be useful.

2. GENERAL DESCRIPTION

Model XW60VS, 100x64 format, is microprocessor based controller suitable for applications on medium or low

temperature refrigerating units. It is provided with 3 relay outputs to control compressor, defrost - which can be

either electrical or hot gas - and the evaporator fans. It is also provided with 3 NTC or PTC probe inputs, one for

temperature control, one to control the defrost end temperature of the evaporator. There is 1 digital input (free

contact) configurable by parameter. An output allows the user to programme the parameter list with the “Hot

Key”.

3. CONTROLLING LOADS

3.1 THE COMPRESSOR

The regulation is performed according to the temperature measured by the thermostat probe with a positive

differential from the set point: if the temperature increases and reaches set point plus differential the compressor is

started and then turned off when the temperature reaches the set point value again.

In case of fault in the thermostat probe the start and stop of the compressor are timed through parameters “COn”

and “COF”.

3.2 FAST FREEZING

When defrost is not in progress, it can be activated the keypad by holding the o key pressed for about 3

seconds. The compressor operates in continuous mode for the time set through the “CCt” parameter. The cycle

can be terminated before the end of the set time using the same activation key, o for about 3 seconds.

3.3 DEFROST

Two defrost modes are available through the “tdF” parameter: defrost with electrical heater or hot gas. The defrost

interval is control by means of parameter “EdF”: (EdF=in) the defrost is made every “IdF” time, (EdF=Sd) the

interval “IdF” is calculate through Smart Defrost algorithm (only when the compressor is ON).

3.4 CONTROL OF EVAPORATOR FANS

The fan control mode is selected by means of the “FnC” parameter:

FnC=C-n fans will switch ON and OFF with the compressor and not run during defrost:;

FnC= O-n fans will run continuously, but not during defrost

After defrost, there is a timed fan delay allowing for drip time, set by means of the “Fnd” parameter.

FnC=C-y fans will switch ON and OFF with the compressor and run during defrost;

FnC=O-y fans will run continuously also during defrost

An additional parameter “FSt” provides the setting of temperature, detected by the evaporator probe, above which

the fans are always OFF. This can be used to make sure circulation of air only if his temperature is lower than set

in “FSt”.

4. KEYBOARD

To display and modify target set point; in programming mode it selects a parameter or confirm an

operation.

By holding it pressed for 3s when max or min temperature is displayed it will be erased.

To see the max. stored temperature; in programming mode it browses the parameter codes or

increases the displayed value. By holding it pressed for 3s the fast freezing cycle is started.

To see the min stored temperature; in programming mode it browses the parameter codes or

decreases the displayed value.

By holding it pressed for 3s the defrost is started.

Switch ON and OFF the instrument.

KEY COMBINATIONS

+

To lock and unlock the keyboard.

+

To enter the programming mode.

+

To exit the programming mode.

4.1 USE OF LEDS

Each LED function is described in the following table.

LED MODE Function

ON The compressor is running

FLASHING

- Programming Phase (flashing with LED )

- Anti-short cycle delay enabled

ON The fan is running

FLASHING

Programming Phase (flashing with LED )

ON The defrost is enabled

FLASHING Drip time in progress

ON The Fast Freezing cycle is enabled

ON - ALARM signal

- In “Pr2” indicates that the parameter is also present in “Pr1”

4.2 HOW TO SEE THE MIN TEMPERATURE

1. Press and release the n key.

2. The “Lo” message will be displayed followed by the minimum temperature recorded.

3. By pressing the n key or waiting for 5s the normal display will be restored.

4.3 HOW TO SEE THE MAX TEMPERATURE

1. Press and release the o key.

2. The “Hi” message will be displayed followed by the maximum temperature recorded.

3. By pressing the o key or waiting for 5s the normal display will be restored.

4.4 HOW TO RESET THE MAX AND MIN TEMPERATURE RECORDED

To reset the stored temperature, when max or min temperature is displayed :

1. Press SET key until “rST” label starts blinking.

N.B. After the installation RESET the temperature stored .

4.5 HOW TO SEE AND MODIFY THE SET POINT

1. Push and immediately release the SET key: the display will show the Set point value;

2. The SET LED start blinking;

3. To change the Set value push the o or n arrows within 10s.

4. To memorise the new set point value push the SET key again or wait 10s.

4.6 TO START A MANUAL DEFROST

1. Push the DEF key for more than 2 seconds and a manual defrost will start.

4.7 TO ENTER IN PARAMETERS LIST “PR1”

To enter the parameter list “Pr1” (user accessible parameters) operate as follows:

1. Enter the Programming mode by pressing the Set and DOWN key for few seconds

( and start blinking).

2. The instrument will show the first parameter present in “Pr1”

4.8 TO ENTER IN PARAMETERS LIST “PR2”

To access parameters in “Pr2”:

1. Enter the “Pr1” level.

2. Select “Pr2” parameter and press the “SET” key.

3. The “PAS” flashing message is displayed, shortly followed by “0 - -” with a flashing zero.

4. Use o or n to input the security code in the flashing digit; confirm the figure by pressing “SET”. The

security code is “321“.

5. If the security code is correct the access to “Pr2” is enabled by pressing “SET” on the last digit.

Page 2

1592009760 XW60VS GB Rel 1.1 .09.11.2011 XW60VS 2/4

Another possibility is the following: after switching ON the instrument the user can push Set and DOWN keys

within 30 seconds.

NOTE: each parameter in “Pr2” can be removed or put into “Pr1” (user level) by pressing “SET” + n. When a

parameter is present in “Pr1” LED is on.

4.9 HOW TO CHANGE THE PARAMETER VALUE

1. Enter the Programming mode.

2. Select the required parameter with o or n.

3. Press the “SET” key to display its value ( and LED starts blinking).

4. Use o or n to change its value.

5. Press “SET” to store the new value and move to the following parameter.

To exit: Press SET + UP or wait 15s without pressing a key.

NOTE: the new programming is stored even when the procedure is exited by waiting the time-out.

4.10 HOW TO LOCK THE KEYBOARD

1. Keep the o and n keys pressed together for more than 3 s the o and n keys.

2. The “POF” message will be displayed and the keyboard is locked. At this point it is only

possible the viewing of the set point or the MAX o Min temperature stored and to switch ON

and OFF the light, the auxiliary output and the instrument.

TO UNLOCK THE KEYBOARD

Keep the o and n keys pressed together for more than 3s.

4.11 ON/OFF FUNCTION

By pushing the ON/OFF key, the instrument shows “OFF” for 5 sec. and the ON/OFF LED is

switched ON.

During the OFF status, all the relays are switched OFF and the regulations are stopped;

N.B. During the OFF status the Light button is active.

4.12 TO SEE THE PROBE VALUES

1. Enter in “Pr2” level.

2. Select “Prd” parameter with o or n.

3. Press the “SET” key to display “Pb1” label alternate with Pb1 value.

4. Use o and n keys to display the other probe values.

5. Press “SET” to move to the following parameter.

5. PARAMETER LIST

REGULATION

Hy Differential: (0,1÷25,5°C; 1÷45°F): Intervention differential for set point, always positive. Compressor Cut

IN is Set Point Plus Differential (Hy). Compressor Cut OUT is when the temperature reaches the set point.

LS Minimum set point limit: (-50,0°CSET; -58°F÷SET) Sets the minimum acceptable value for the set

point.

US Maximum set point limit: (SET110°C; SET÷230°F) Set the maximum acceptable value for set point.

OdS Outputs activation delay at start up: (0÷255 min) This function is enabled at the initial start up of the

instrument and inhibits any output activation for the period of time set in the parameter. (Light can work)

AC Anti-short cycle delay: (0÷30 min) interval between the compressor stop and the following restart.

CCt Thermostat override: (0min ÷23h 50min) allows to set the length of the continuous cycle. Can be used, for

instance, when the room is filled with new products.

Con Compressor ON time with faulty probe: (0÷255 min) time during which the compressor is active in case

of faulty thermostat probe. With COn=0 compressor is always OFF.

COF Compressor OFF time with faulty probe: (0÷255 min) time during which the compressor is off in case of

faulty thermostat probe. With COF=0 compressor is always active.

DISPLAY

CF Temperature measurement unit: °C = Celsius; °F = Fahrenheit. When the measurement unit is changed

the SET point and the values of some parameters have to be modified.

rES Resolution (for °C): (in = 1°C; de = 0,1°C) allows decimal point display.

dE = 0,1°C; in = 1 °C

Lod Local display : select which probe is displayed by the instrument:

P1 = Room probe

P2 = Evaporator probe

P3 = Display probe

1r2 = difference between P1 and P2 (P1-P2)

DEFROST

tdF Defrost type:

rE = electrical heater (Compressor OFF)

in = hot gas (Compressor and defrost relays ON)

EdF Defrost mode:

in = interval mode. The defrost starts when the time “Idf” is expired.

Sd = Smartfrost mode. The time IdF (interval between defrosts) is increased only when the compressor is

running (even non consecutively).

SdF Set point for SMARTFROST: (-3030 °C/ -2286 °F) evaporator temperature which allows the IdF

counting (interval between defrosts) in SMARTFROST mode.

dtE Defrost termination temperature: (-50,0÷110,0°C; -58÷230°F) (Enabled only when the evaporator probe

is present) sets the temperature measured by the evaporator probe which causes the end of defrost.

IdF Interval between defrosts: (1÷120h) Determines the time interval between the beginning of two defrost

cycles.

MdF (Maximum) duration of defrost: (0÷255 min) When P2P = n, no evaporator probe, it sets the defrost

duration, when P2P = y, defrost end based on temperature, it sets the maximum length for defrost.

dFd Display during defrost:

rt = real temperature; it = temperature reading at the defrost start;

Set = set point; dEF = “dEF” label; dEG = “dEG” label;

dAd Defrost display time out: (0255 min) Sets the maximum time between the end of defrost and the

restarting of the real room temperature display.

dSd Start defrost delay: ( 0÷99min) This is useful when different defrost start times are necessary to avoid

overloading the plant.

Fdt Drain down time: (0÷60 min.) time interval between reaching defrost termination temperature and the

restoring of the control’s normal operation. This time allows the evaporator to eliminate water drops that

might have formed due to defrost.

dPO First defrost after start-up:

y = Immediately; n = after the IdF time

dAF Defrost delay after fast freezing: (0min÷23h 50min) after a Fast Freezing cycle, the first defrost will be

delayed for this time.

FANS

FnC Fan operating mode:

C-n = running with the compressor, OFF during the defrost;

C-y = running with the compressor, ON during the defrost;

O-n = continuous mode, OFF during the defrost;

O-y = continuous mode, ON during the defrost;

Fnd Fan delay after defrost: (0÷255 min) The time interval between the defrost end and evaporator fans start.

FSt Fan stop temperature: (-50÷110°C; -58÷230°F) setting of temperature, detected by evaporator probe,

above which the fan is always OFF.

ALARMS

ALC Temperature alarm configuration

rE = High and Low alarms related to Set Point

Ab = High and low alarms related to the absolute temperature.

ALU High temperature alarm setting:

ALC= rE, 0 50°C or 90°F

ALC= Ab, ALL 110°C or 230°F

when this temperature is reached and after the ALd delay time the HA alarm is enabled.

ALL Low temperature alarm setting:

ALC = rE , 0 50 °C or 90°F

ALC = Ab , - 50°C or -58°F ALU

when this temperature is reached and after the ALd delay time, the LA alarm is enabled,.

AFH Temperature alarm and fan differential: (0,1÷25,5°C; 1÷45°F) Intervention differential for temperature

alarm set point and fan regulation set point, always positive.

ALd Temperature alarm delay: (0÷255 min) time interval between the detection of an alarm condition and the

corresponding alarm signalling.

dAO Delay of temperature alarm at start-up: (0min÷23h 50min) time interval between the detection of the

temperature alarm condition after the instrument power on and the alarm signalling.

EdA Alarm delay at the end of defrost: (0255 min) Time interval between the detection of the temperature

alarm condition at the end of defrost and the alarm signalling.

doA Open door alarm delay:(0÷255 min) delay between the detection of the open door condition and its alarm

signalling: the flashing message “dA” is displayed.

nPS Pressure switch number: (0 15) Number of activation of the pressure switch, during the “did” interval,

before signalling the alarm event (I2F= PAL).

If the nPS activation in the did time is reached, switch off and on the instrument to restart normal

regulation.

PROBE INPUTS

Ot Thermostat probe calibration: (-12.012.0°C/ -21 21°F) allows to adjust possible offset of the

thermostat probe.

OE Evaporator probe calibration: (-12.012.0°C/ -2121°F) allows to adjust possible offsets of the

evaporator probe.

O3 Display probe calibration: (-12.012.0°C/ -2121°F) allows to adjust possible offsets of the display

probe.

P2P Evaporator probe presence: n= not present: the defrost stops only by time; y= present: the defrost stops

by temperature and time.

P3P Display probe presence: n= not present:; y= present:.

HES Temperature increase during the Energy Saving cycle : (-30,0°C 30,0°C / -22÷86°F) sets the

increasing value of the set point during the Energy Saving cycle.

DIGITAL INPUTS

odc Compressor and fan status when open door:

no = normal; Fan = Fan OFF; CPr = Compressor OFF; F_C = Compressor and fan OFF.

I2P Configurable digital input polarity:

CL : the digital input is activated by closing the contact;

OP : the digital input is activated by opening the contact

I2F Digital input operating mode: configure the digital input function:

EAL = generic alarm; bAL = serious alarm mode; PAL = Pressure switch; dFr = Start defrost;

AUS = Not used; Es = Energy Saving; onF = remote On/OFF; dor = door switch

did Time interval/delay for digital input alarm:(0255 min.) If I2F=EAL or bAL (external alarms), “did”

parameter defines the time delay between the detection and the successive signalling of the alarm.

OTHER

Adr RS485 serial address (1÷247): Identifies the instrument address when connected to a ModBUS

compatible monitoring system.

PbC Type of probe: it allows to set the kind of probe used by the instrument:

PbC = PBC probe, ntC = NTC probe.

rEL Release software: (read only) Software version of the microprocessor.

Ptb Parameter table: (read only) it shows the original code of the dIXEL parameter map.

Prd Probes display: (read only) display the temperature values of the evaporator probe Pb2.

Pr2 Access to the protected parameter list (read only).

6. DIGITAL INPUT

The XW60VS has 1 free contact digital input. It is programmable in seven different configurations by the “I2F”

parameter.

6.1 DOOR SWITCH INPUT (I2F = dor)

It signals the door status and the corresponding relay output status through the “odc” parameter:

no = normal (any change);

Fan = Fan OFF;

CPr = Compressor OFF;

F_C = Compressor and fan OFF.

Since the door is opened, after the delay time set through parameter “dOA”, the alarm output is enabled and the

display shows the message “dA”. The alarm stops as soon as the external digital input is disabled again. During

this time and then for the delay “dot” after closing the door, the high and low temperature alarms are disabled.

6.2 GENERIC ALARM (I2F = EAL)

As soon as the digital input is activated the unit will wait for “did” time delay before signalling the “EAL” alarm

message. The outputs status don’t change. The alarm stops just after the digital input is de-activated.

6.3 SERIOUS ALARM MODE (I2F = BAL)

When the digital input is activated, the unit will wait for “did” delay before signalling the “BAL” alarm message.

The relay outputs are switched OFF. The alarm will stop as soon as the digital input is de-activated.

Page 3

1592009760 XW60VS GB Rel 1.1 .09.11.2011 XW60VS 3/4

6.4 PRESSURE SWITCH (I2F = PAL)

If during the interval time set by “did” parameter, the pressure switch has reached the number of activation of the

“nPS” parameter, the “PAL” pressure alarm message will be displayed. The compressor and the regulation are

stopped. When the digital input is ON the compressor is always OFF.

If the nPS activation in the did time is reached, switch off and on the instrument to restart normal

regulation.

6.5 START DEFROST (I2F = DFR)

It executes a defrost if there are the right conditions. After the defrost is finished, the normal regulation will restart

only if the digital input is disabled otherwise the instrument will wait until the “Mdf” safety time is expired.

6.6 ENERGY SAVING (I2F = ES)

The Energy Saving function allows to change the set point value as the result of the SET+ HES (parmeter) sum.

This function is enabled until the digital input is activated.

6.7 REMOTE ON/OFF (I2F = ONF)

This function allows to switch ON and OFF the instrument.

6.8 DIGITAL INPUTS POLARITY

The digital input polarity depends on the “I2P” parameters.

CL : the digital input is activated by closing the contact.

OP : the digital input is activated by opening the contact

7. INSTALLATION AND MOUNTING

Instruments XW60VS shall be mounted on vertical panel, in a 72x56 mm hole, and fixed using screws 3 x 2mm.

To obtain an IP65 protection grade use the front panel rubber gasket (mod. RGW-V).

The temperature range allowed for correct operation is 0 - 60 °C (32÷120°F). Avoid places subject to strong

vibrations, corrosive gases, excessive dirt or humidity. The same recommendations apply to probes. Let the air

circulate by the cooling holes.

7.1 XW60VS: CUT OUT

56

7

2

40

8

3

,

5

8. ELECTRICAL CONNECTIONS

The instrument is provided with faston connections (6,3mm). Heat-resistant cables have to be used. Before

connecting cables make sure the power supply complies with the instrument’s requirements. Separate the probe

cables from the power supply cables, from the outputs and the power connections. Do not exceed the maximum

current allowed on each relay, in case of heavier loads use a suitable external relay.

N.B. Maximum current allowed for all the loads is 20A.

8.1 PROBE CONNECTIONS

The probes shall be mounted with the bulb upwards to prevent damages due to casual liquid infiltration. It is

recommended to place the thermostat probe away from air streams to correctly measure the average room

temperature. Place the defrost termination probe among the evaporator fins in the coldest place, where most ice is

formed, far from heaters or from the warmest place during defrost, to prevent premature defrost termination.

9. USE OF THE PROGRAMMING “HOT KEY “

The XW60VS unit can UPLOAD or DOWNLOAD the parameter list from its own E2 internal memory to the “Hot

Key” and vice-versa.

Note: You must first program one controller with the front keypad. Double check the parameters that you want to

duplicate. Label the HOT KEY with a code for that program.

9.1 UPLOAD (FROM THE INSTRUMENT TO THE “HOT KEY”)

1. When the Controller is ON, insert the “Hot key” and push UP key; the "uPL" message appears followed

a by flashing “End”

2. Push “SET” key and the End will stop flashing;

3. Turn OFF the instrument remove the “Hot Key”, then turn it ON again.

(At the end of the data transfer phase the instrument displays the following messages:)

“End “ for right programming.

“Err” for failed programming. In this case push “SET” key if you want to restart the programming again or remove

the not programmed “Hot key”.

9.2 DOWNLOAD (FROM THE “HOT KEY” TO THE INSTRUMENT)

1. Turn OFF the instrument by means of the ON/OFF key (or un-plug the appliance), insert the “Hot Key” into

the 5 PIN receptacle and then turn the Controller ON.

2. Automatically the parameter list of the “Hot Key” is downloaded into the Controller memory, the “DoL”

message is blinking. After 10 seconds the instrument will restart working with the new parameters.

3. Turn OFF the instrument remove the “Hot Key”, then turn it ON again.

At the end of the data transfer phase the instrument displays the following messages:

“End “ for right programming. The instrument starts regularly with the new programming.

“Err” for failed programming. In this case turn the unit off and then on if you want to restart the download again or

remove the “Hot key” to abort the operation.

10. ALARM SIGNALS

Message Cause Outputs

“P1” Thermostat probe failure

Alarm output ON; Compressor output according to

parameters “COn” and “COF”

“P2” Evaporator probe failure Alarm output ON; Other outputs unchanged

“P3” Display probe failure Alarm output ON; Other outputs unchanged

“HA” Maximum temperature alarm Alarm output ON; Other outputs unchanged

“LA” Minimum temperature alarm Alarm output ON; Other outputs unchanged

“EE” Data or memory failure Alarm output ON; Other outputs unchanged

“dA” Door switch alarm Alarm output ON; Other outputs unchanged

“EAL” External alarm Alarm output ON; Other outputs unchanged

“bAL” Serious external alarm Alarm output ON; Other outputs OFF

“PAL” Pressure switch alarm Alarm output ON; Other outputs OFF

The alarm message is displayed until the alarm condition is recovery.

All the alarm messages are showed alternating with the room temperature except for the “P1” which is flashing. To

reset the “EE” alarm and restart the normal functioning press any key, the “rSt” message is displayed for about 3s.

10.1 “EE” ALARM

The dIXEL instruments are provided with an internal check for the data integrity. Alarm “EE” flashes when a

failure in the memory data occurs. In such cases the alarm output is enabled.

10.2 ALARM RECOVERY

Probe alarms : “P1” (probe1 faulty), “P2” and “P3”; they automatically stop 10s after the probe restarts normal

operation. Check connections before replacing the probe.

Temperature alarms “HA” and “LA” automatically stop as soon as the thermostat temperature returns to normal

values or when the defrost starts.

Door switch alarm “dA” stop as soon as the door is closed.

External alarms “EAL”, “BAL” stop as soon as the external digital input is disabled

Pressure switch alarm “PAL” alarm is recovered by switching OFF the instrument.

11. TECHNICAL DATA

Housing: self extinguishing ABS.

Case: facia 100x64 mm; depth 40mm

Mounting : panel mounting in a 56x72 mm panel cut-out with two screws. 3x2mm. Distance between the holes

40mm

Protection: IP20.

Frontal protection: IP65 with optional frontal gasket; RGW-V (XW60VS).

Connections: heat-resistant wiring and 6,3mm Faston for loads and power supply

Power supply: 230Vac 10% or 120Vac or 24Vac

Power absorption: 3VA max.

Display: 3 digits, red LED, 14,2 mm high.

Inputs: 3 NTC or PTC probes

Digital input: 1 free voltage

Relay outputs: Total current on loads MAX. 10A

compressor: relay SPST 16(6) A, 250Vac

fans: relay SPST 8(3) A, 250Vac

defrost: relay SPDT 16(6) A, 250Vac

Data storing: on the non-volatile memory (EEPROM).

Kind of action: 1B.

Pollution grade: normal

Software class: A.

Operating temperature: 0÷60 °C.

Storage temperature: -25÷60 °C.

Relative humidity: 2085% (no condensing)

Measuring and regulation range:

PTC probe: -50÷150°C (-58÷302°F)

NTC probe: -40÷110°C (-58÷230°F)

Resolution: 0,1 °C or 1°C or 1 °F (selectable).

Accuracy (ambient temp. 25°C): ±0,5 °C ±1 digit

12. CONNECTIONS

Defrost

Power supply: use terminal 3-4; according to the model 230Vac or 120Vac or 24Vac

Page 4

1592009760 XW60VS GB Rel 1.1 .09.11.2011 XW60VS 4/4

13. DEFAULT SETTING VALUES

Label Name Range Default Level

REGULATION

Set Set point LS÷US

-5.0 ---

Hy Differential 0,1÷25,5 °C / 1÷45°F

2.0 Pr1

LS Minimum set point -50,0°C÷SET / -58°F÷SET

-30.0 Pr2

US Maximum set point SET ÷ 110°C / SET ÷ 230°F

20.0 Pr2

OdS Outputs activation delay at start up 0÷255 min.

0 Pr2

AC Anti-short cycle delay 0÷30 min.

1 Pr1

CCt Compressor ON time during fast freezing 0 ÷ 23h 50 min.

0.0 Pr2

COn Compressor ON time with faulty probe 0÷255 min.

15 Pr2

COF Compressor OFF time with faulty probe 0÷255 min.

30 Pr2

DISPLAY

CF Temperature measurement unit °C ÷ °F

°C Pr2

rES Resolution (integer/decimal point) in ÷ de

dE Pr1

Lod Local display P1 ÷ 1r2

P1 Pr2

DEFROST

tdF Defrost type rE, rT, in

rE Pr2

EdF Defrost mode In, Sd

in Pr2

SdF Set point for SMART DEFROST -30 ÷ +30°C / -22÷+86°F

0 Pr2

dtE Defrost termination temperature -50,0÷110°C/ -58÷230°F

8.0 Pr1

IdF Interval between defrost cycles 1÷120h

6 Pr1

MdF (Maximum) length for 1° defrost 0÷255 min.

30 Pr1

dFd Displaying during defrost rt, it, SEt, dEF, dEG

it Pr2

dAd MAX display delay after defrost 0÷255 min.

30 Pr2

dSd Delay before defrost 0÷255 min.

0 Pr2

Fdt Draining time 0÷60 min.

0 Pr2

dPO First defrost after start up n ÷ y

n Pr2

dAF Defrost delay after fast freezing 0 ÷ 23h 50 min.

0.0 Pr2

FANS

FnC Fans operating mode C-n, C-y, O-n, O-y

O-n Pr2

Fnd Fans delay after defrost 0÷255 min.

10 Pr2

FSt Fans stop temperature -50,0÷110°C/ -58÷230°F

2.0 Pr2

ALARMS

ALC Temperature alarms configuration rE÷Ab

Ab Pr2

ALU MAXIMUM temperature alarm -50,0÷110°C/ -58÷230°F

110 Pr1

ALL minimum temperature alarm -50,0÷110°C/ -58÷230°F

-40.0 Pr1

AFH Temperature alarm differential 0,1÷25,5 °C / 1÷45°F

2.0 Pr2

ALd Temperature alarm delay 0÷255 min.

15 Pr2

dAO Delay of temperature alarm at start up 0 ÷ 23h 50 min.

1.3 Pr2

EdA Alarm delay at the end of defrost 0÷255 min.

30 Pr2

dot Delay of temperature alarm after closing the door 0÷255 min.

15 Pr2

dOA Open door alarm delay 0÷255 min.

15 Pr2

nPS Pressure switch number 0÷15

0 Pr2

ANALOGUE INPUTS

Ot Thermostat probe calibration -12,0÷12,0°C / -21÷21°F

0 Pr1

OE Evaporator probe calibration -12,0÷12,0°C / -21÷21°F

0 Pr1

O3 Display probe calibration -12,0÷12,0°C / -21÷21°F

0 Pr1

P2P Evaporator probe presence n ÷ y

y Pr2

P3P Display probe presence n ÷ y

y Pr2

HES

Temperature increasing during the Energy Saving

cycle

-30÷30°F/-54÷54°F

0 Pr2

DIGITAL INPUTS

Odc Open door control no, Fan, CPr, F_C

FAn Pr2

I2P Configurable digital input polarity CL÷OP

cL Pr2

i2F Digital input configuration dor, EAL, bAL, PAL, dFr,

AUS, ES, OnF

dor Pr2

dId Digital input alarm delay 0÷255 min.

5 Pr2

OTHER

Adr Serial address 0÷247

1 Pr2

Pbc Kind of probe PbC, ntc

ntc Pr2

rEL Software release - - - 2.0 Pr2

Ptb Map code - - - - - - Pr2

Prd Probes display Pb1÷Pb3 - - - Pr2

Pr2 Access parameter list - - - - - - Pr1

Loading...

Loading...