Page 1

UNIVERSAL–XR Unit of Measure Change Instructions

STEP 1

Install the new Universal-XR per the installation instructions included with the controller.

STEP 2

Turn on power,

THEN WITHIN 1 MINUTE COMPLETE STEPS 3, 4 AND 5.

STEP 3

+

Press the “SET” and “DOWN” key for 3 seconds and the controller will automatically recognise and

adjust itself to the type of probes connected. (The display briefly shows tPd followed by ntC or PtC).

STEP 4

Press the “AUX/tC” key for 3 seconds and the setting of parameter tC is displayed. Use the UP or

DOWN keys to adjust to required setting then confirm by pressing SET (see table 1 below).

STEP 5

Press SET for 3 seconds until the °C or °F icon starts to flash, then adjust the SET POINT using the UP

or DOWN keys, then press SET again to confirm.

1. GENERAL DESCRIPTION

Model Universal-XR is a 71x29 mm format microprocessor based controller, it is available in 12/24Vac/dc, 120Vac or

230Vac,and is suitable for applications on high, medium or low temperature refrigeration units. It is provided with three relay

outputs to control compressor, defrost - which can be both electrical or hot gas - and evaporator fans. It can work with PTC

or NTC probes. Where defrost is being terminated by time, it can operate with just one thermostat probe. Where defrost is

being terminated by temperature, it has an input for an evaporator probe(s).

The Universal-XR is equipped with a flashing visual alarm and buzzer.

Each instrument is fully configurable through special parameters that can be easily programmed through the keypad.

2. QUICK START UP PROCEDURE – Up and running in 5 easy steps

This Quick Start Up section is designed to get you up and running with the minimum of fuss. Just follow these 5 simple steps.

Notes:

1. All probes must be of the same type, either PTC or NTC.

2. Probes must be at between --58 to 140°F for auto recognition to work;

3. If 1 minute expires before you have completed quick set up, either cycle the power OFF then ON to start the set up again or

enter Pr2 as per the instructions and adjust your parameter settings manually (see Section 9).

Universal-XR 1/15 UXR10012015_REV1.4mm

Page 2

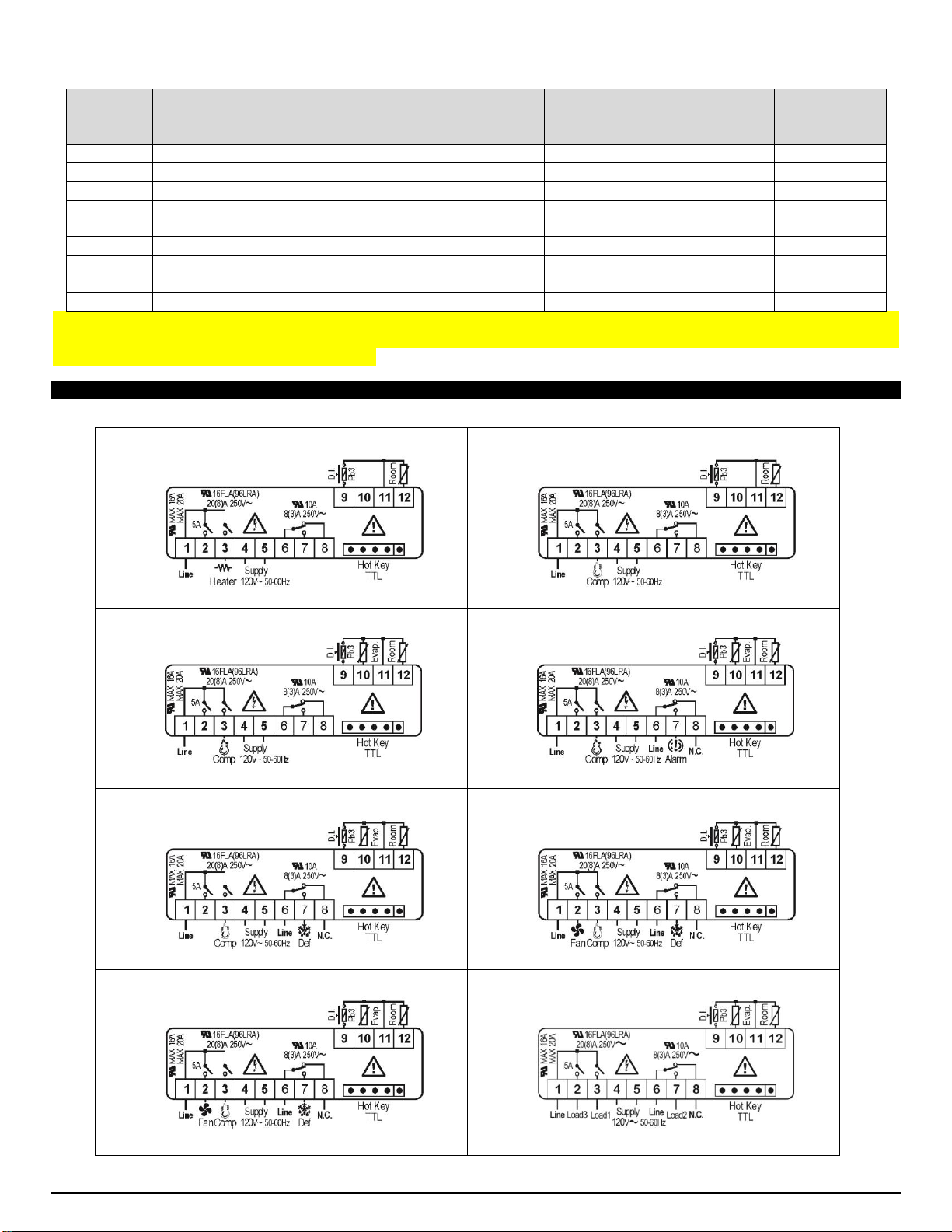

Table 1: parameter “tC” settings

TC=1 Heating

12/24Vac/dc use Terminals 4 & 5 for power supply

TC=2 Cooling, Off Cycle Defrost, Time Ended

12/24Vac/dc use Terminals 4 & 5 for power supply

TC=3 Cooling, Off Cycle Defrost, Temperature Ended

12/24Vac/dc use Terminals 4 & 5 for power supply

TC=4 Cooling, Off Cycle Defrost, Temperature Ended, Alarm Relay

12/24Vac/dc use Terminals 4 & 5 for power supply

TC=5 Cooling, Electric or Hot Gas Defrost Temperature Ended

12/24Vac/dc use Terminals 4 & 5 for power supply

TC6= Low Temp, Elec. Or Hot Gas Defrost, Temp. Ended, Fan

Control

12/24Vac/dc use Terminals 4 & 5 for power supply

TC7= Open Map to be Configured for any application

12/24Vac/dc use Terminals 4 & 5 for power supply

Actual Label on The Control in the Box.

Load1 is always Comp, or Heat.

Load2 is OAA and Load3 is OAb.

Parameter

tC

Type of Control

Models Replaced

Required

probes

1

On / Off thermostat – Heating

XR110C, XR01CX, XR10C, XR10CX

x 1

2

Off cycle defrost (timed)

XR120C, XR02CX, XR20C, XR20CX

x 1

3

Off Cycle defrost time initiated / temperature terminated

XR120C, XR02CX, XR20C-E

x 2

4

Off Cycle defrost time initiated / temperature terminated, Alarm

Relay

XR130C, XR03CX, XR30CX

x 2

5

Electrical / Hot Gas defrost, time initiated / temperature terminated

XR140C, XR04CX, XR40CX

x 2

6

Electrical / Hot Gas defrost, time initiated / temperature terminated

+ evap. Fan delay and control

XR160C, XR06CX, XR60CX

x 2

7

Full open map of parameters configure your own control

Your determination

1 to 3

Note: As you change parameter tC, defaults change and should be approximately correct for that application but we strongly recommend you check

all parameter default values listed in these instructions to ensure they suit your particular application and make further adjustments if necessary. Read

the following sections for information about programming.

3. TYPICAL CONNECTIONS - FOR GENERAL GUIDANCE ONLY

Table 2: typical connections

Universal-XR 2/15 UXR10012015_REV1.4mm

Page 3

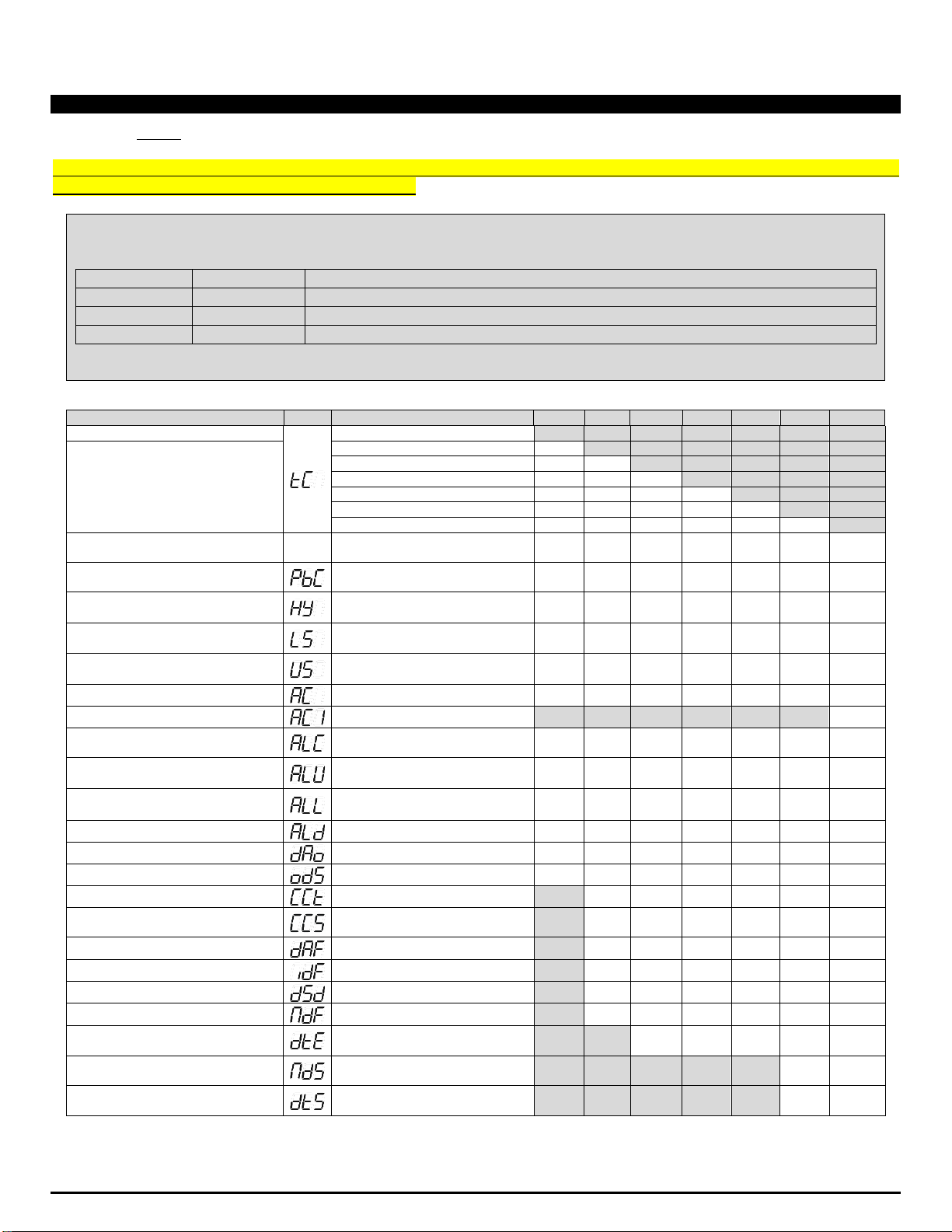

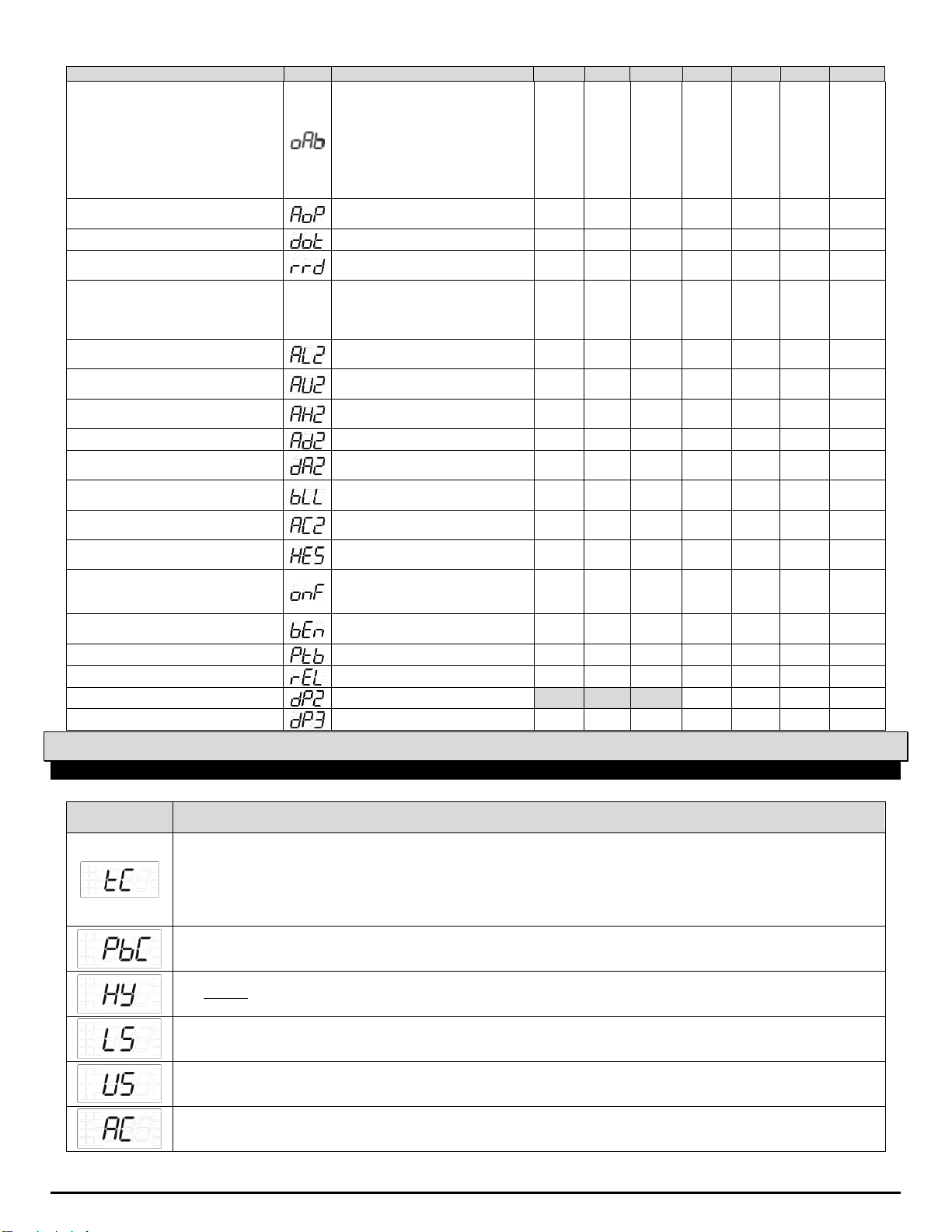

4. PARAMETER TABLE and factory default settings

WARNING!!

Always switch the power OFF and then ON at the end of programming to update any parameter changes.

Make sure you connect the correct number of probes to suit the setting of parameter tC. Failure to do this will cause probe alarms

tC setting

No. Probes

Type

1, 2

1

Room only

3, 4, 5, 6

2

Room + Evaporator 1

7

3

Room + Evaporator 1 + Display or AUX

Any probe alarms can be cleared by turning off / on the power

Description

Label

Adjustment Range

tC1

tC2

tC3

tC4

tC5

tC6

tC7

Type (category) of controller

1 = On / Off Thermostat

1

2 = Off cycle defrost

2

3 = Time / time defrost

3

4 = Time / temp defrost + alarm

4

5 = Time / temp defrost

5

6 = Time / temp defrost + fan delay

6

7 = Full Open Map Configurable

7

Set Point

LS to US

40.0°C;

104°F

2.0°C;

36°F

2.0°C;

36°F

2.0°C;

36°F

2.0°C;

36°F

2.0°C;

36°F

2.0°C;

36°F

Probe type

PTC=0

NTC=1

1 1 1 1 1 1 1

Differential

0.1 to 25.5C;

1 to 45°F

2.0°C;

2°F

2.0°C;

2°F

2.0°C;

2°F

2.0°C;

2°F

2.0°C;

2°F

2.0°C;

2°F

2.0°C;

2°F

Minimum Set Point limit

-55C to Set Point;

-67°F to Set Point

-50.0°C;

-58°F

-50.0°C;

-58°F

-50.0°C;

-58°F

-50.0°C;

-58°F

-50.0°C;

-58°F

-50.0°C;

-58°F

-50.0°C;

-58°F

Maximum Set Point limit

Set Point to 150C;

Set Point to 302°F

50.0°C;

122°F

50.0°C;

122°F

50.0°C;

122°F

50.0°C;

122°F

50.0°C;

122°F

50.0°C;

122°F

50.0°C;

122°F

Anti-short cycle delay

0 to 50 min

1 1 1 1 1 1 0

Second compressor start delay

0 to 255 sec

0

Temperature alarm configuration

rE (0)= Relative to Set Point;

Ab (1) = Absolute

1 1 1 1 1 1 1

High temperature alarm

0 to 50C (Rel); ALL to 150C (Abs);

0 to 90F (Rel); ALL to 302C (Abs)

50.0°C;

122°F

50.0°C;

122°F

50.0°C;

122°F

50.0°C;

122°F

50.0°C;

122°F

50.0°C;

122°F

50.0°C;

122°F

Low temperature alarm

0 to 50C (Rel); -55C to ALU (Abs);

0 to 90C (Rel); -67C to ALU (Abs)

-50.0°C;

-58°F

-50.0°C;

-58°F

-50.0°C;

-58°F

-50.0°C;

-58°F

-50.0°C;

-58°F

-50.0°C;

-58°F

-50.0°C;

-58°F

Temperature alarm delay

0 to 255 min

15

15

15

15

15

15

15

Delay of temperature alarm at start up

0 to 720 min

90

90

90

90

90

90

90

Outputs activation delay at start up

0 to 255 min

0 0 0 0 0 0 0

Thermostat override

0 to 990 min

0 0 0 0 0

0

Set point for continuous cycle

-55 to 150°C;

-67 to 302°F

2.0°C;

36°F

2.0°C;

36°F

2.0°C;

36°F

2.0°C;

36°F

2.0°C;

36°F

2.0°C;

36°F

Defrost delay after thermostat override

0 to 255 min

2 2 2 2 2

2

Interval between defrosts

1 to 250 hours

4 6 6 6 4 4 Delay start of defrost

0 to 255 min

0 0 0 0 0 0 Maximum duration of defrost

0 to 255 min

15

15

30

30

30

30

Defrost termination temperature

-55 to 50C;

-67 to 122°F

8.0°C

46°F

8.0°C

46°F

8.0°C

46°F

8.0°C

46°F

8.0°C

46°F

Maximum duration of defrost

(second evaporator)

0 to 255 min

30

30

Defrost termination temperature (second

evaporator)

-55 to 50C;

-67 to 122°F

8.0°C

46°F

8.0°C

46°F

IMPORTANT: Always set parameter “tC” first. As you move “tC” between settings 1 to 7, all non-relevant parameters will be masked. After setting

“tC”, it will be possible to modify all the other relevant parameters.

Once the program is completed you may want to save the parameter map to a Hot Key. If the “tC” is changed after final programming the

parameters will be changed back to the default listed below.

Table 3: default controller parameters

Universal-XR 3/15 UXR10012015_REV1.4mm

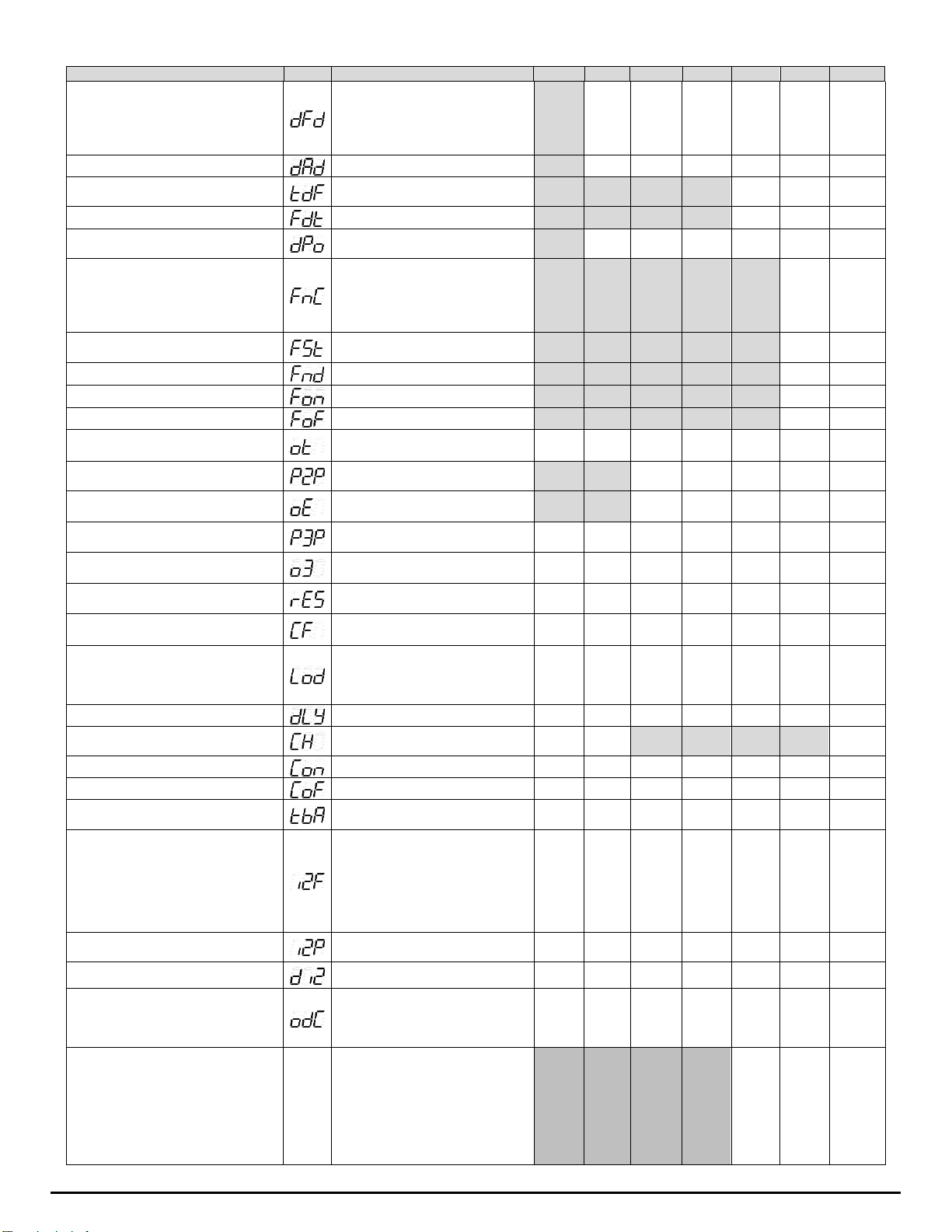

Page 4

Description

Label

Adjustment Range

tC1

tC2

tC3

tC4

tC5

tC6

tC7

Display during defrost

Rt (0) = Real temp.

it (1) = Temp. at defrost start

sEt (2) = Set Point

dEF (3) = “DEF” label

dEG (4) = “DEG” label

3 3 3 3 3

3

Defrost display time out

0 to 255 min

10

10

10

10

10

10

Defrost type (forced)

El (0) = Electrical

rE (1) = Hot Gas

0 0 0

Drain down time

0 to 255 min

0 2 2

First defrost after power on

Y (0) = Immediate

N (1) = After normal interval

1 1 1 1 1

1

Evaporator fan operating mode

C_n (0) =On with Comp, off with defrost

O_n (1) =On regardless of comp, off w/

defrost

C_y (2) =On with comp, on with defrost

O_y (3) =Always on

1

1

Evaporator fan stop temperature

-55 to 50C;

-67 to 122°F

8°C;

46°F

8°C;

46°F

Evaporator fan delay after defrost

0 to 255 min

7

7

Fan ON time

0 to 15 min

0

0

Fan Off time

0 to 15 min

0

0

Thermostat probe calibration

-12.0 to 12.0C;

-21 to 21F

0.0°C;

0°F

0.0°C;

0°F

0.0°C;

0°F

0.0°C;

0°F

0.0°C;

0°F

0.0°C;

0°F

0.0°C;

0°F

Evaporator probe presence

N (0) = evaporator probe not present

Y (1) = evaporator probe present

1 1 1 1 1

Evaporator probe calibration

-12.0 to 12.0C;

-21 to 21F

0.0°C;

0°F

0.0°C;

0°F

0.0°C;

0°F

0.0°C;

0°F

0.0°C;

0°F

Third probe presence

n (0) = third probe not present,

Y (1) = third probe present.

1 1 1 1 1 1 1

Third probe calibration

-12.0 to 12.0C;

-21 to 21F

0.0°C;

0°F

0.0°C;

0°F

0.0°C;

0°F

0.0°C;

0°F

0.0°C;

0°F

0.0°C;

0°F

0.0°C;

0°F

Display Resolution

Y (0) = With decimal point in C only

N (1) = No decimal point

1 1 1 1 1 1 1

Temperature measurement unit (°C/°F)

C (0) = Celsius

F (1) = Fahrenheit

1 1 1 1 1 1 1

Instrument display

P1 (0)= Thermostat probe

P2 (1) = Evaporator probe

P3 (2) = Third probe

sEt (3) = SET-POINT

0 0 0 0 0 0 0

Display delay

0 to 20min0sec, res. 10sec

0 0 0 0 0 0 0

Type of action

Cl (0) = cooling

Ht (1) = heating

1 0 0

Compressor ON time with faulty probe

0 to 255 min

15

15

15

15

15

15

15

Compressor OFF time with faulty probe

0 to 255 min

30

30

30

30

30

30

30

Alarm muting configuration for

buzzer & relay

n (0) = Mute buzzer only

Y (1) = Mute buzzer & relay

1 1 1 1 1 1 1

Second Digital input configuration

dEF(0) = Start defrost

dor (1)= Door switch

AUS (2) = Auxiliary relay

ES (3) = Energy saving

onF (4) = Remote On/OFF

EAl (5) = Generic alarm

bAl (6) = Serious alarm

5 5 5 5 5 5 5

Second Digital input polarity

Cl (0) = Closed circuit

oP (1) = Open circuit

0 0 0 0 0 0 0

Digital input 2 delay

0 to 255 min

0 0 0 0 0 0 0

Door open – compressor / fan status

No (0) = No change

FAn (1) = Fan off

CPr (2) = Compressor off

F_C (3) = Compressor & Fan off

0 0 0 0 0 0 0

Defrost relay configuration

OAA

Alr (0) = Alarm;

db (1) = Dead Band;

AUS (2) = Auxiliary;

CP2 (3) = Second compressor output;

liG (4) = Light output;

dF2 (5) = Second defrost output.

dEF (6) =1st Defrost output

Fan (7) =Fan output

6 6 6

Universal-XR 4/15 UXR10012015_REV1.4mm

Page 5

Description

Label

Adjustment Range

tC1

tC2

tC3

tC4

tC5

tC6

tC7

Auxiliary relay configuration

Alr (0) = Alarm;

db (1) = Dead Band;

AUS (2) = Auxiliary;

CP2 (3) = Second compressor output;

liG (4) = Light output;

dF2 (5) = Second defrost output.

dEF (6) =1st Defrost output

Fan (7) =Fan output

0 0 0 0 7 7 7

Alarm relay polarity

Cl (0)= [11 -12] closed with alarm

oP (1) = [11 -12] open with alarm

0 0 0 0 0 0 0

Exclude temperature alarm - door open

0 to 255 min

20

20

20

20

20

20

20

Restart regulation with door open alarm

n (0) = No

Y (1) = Yes

0 0 0 0 0 0 0

Probe selection for Condenser Alarm

AP2

nP (0) =No Probe selected

P1 (1) =Probe 1

P2 (2) =Probe 2

P3 (3) =Probe3

0 0 0 0 0 0 0

Low temperature alarm of condenser

-55 to 150°C;

-67 to 302°F

-40°C;

-40°F

-40°C;

-40°F

-40°C;

-40°F

-40°C;

-40°F

-40°C;

-40°F

-40°C;

-40°F

-40°C;

-40°F

High temperature alarm of condenser

-55 to 150°C;

-67 to 302°F

110°C;

230°F

110°C;

230°F

110°C;

230°F

110°C;

230°F

110°C;

230°F

110°C;

230°F

110°C;

230°F

Differential for temperature condenser

alarm recovery

0.1 to 25.5°C;

1 to 45°F

5°C;

5°F

5°C;

5°F

5°C;

5°F

5°C;

5°F

5°C;

5°F

5°C;

5°F

5°C;

5°F

Condenser temperature alarm delay

0 to 254 min, 255 = nU

15

15

15

15

15

15

15

Condenser temperature alarm exclusion at

start up

0 to 720 min, res.10min

90

90

90

90

90

90

90

Compressor off with low temperature alarm

of condenser

n (0) = No

y (1) = Yes

0 0 0 0 0 0 0

Compressor off with high temperature

alarm of condenser

n (0) = No

y (1) = Yes

0 0 0 0 0 0 0

Temperature deviation from normal

Set Point during Energy Saving

-30.0 to 30°C;

-54 to 54°F

0°C;

0°F

0°C;

0°F

0°C;

0°F

0°C;

0°F

0°C;

0°F

0°C;

0°F

0°C;

0°F

ON / OFF key enabling

nU (0) = Disabled

OFF(1) = Enabled

ES (2) = Energy saving

0 0 0 0 0 0 0

Buzzer enabling

n (0) = Disabled

Y (1) = Enabled

1 1 1 1 1 1 1

Parameter table

For factory use only

- - - - - - -

Software release number

Read only

- - - - - - -

Evaporator probe temperature

Read only

- - -

-

Third probe temperature

Read only

- - - - - - -

READ ON IF YOU NEED MORE DETAIL

Display visualisation

Description

Type of Controller: tells the Universal-XR which type of controller it will be operating as.

1 = on/off Heating thermostat – 1 relay & 1 probe;

2 = Combined thermostat with off cycle defrost timer – 1 relay & 1 probe;

3 = Combined thermostat with time initiated & time terminated defrost – 2 relays & 2 probe;

4 = Combined thermostat with time initiated & temperature terminated defrost – 2 relays & 2 probes; alarm

5 = Combined thermostat with time initiated, temperature terminated defrost + 2 relays & 2 probes; defrost

6 = Combined thermostat with time initiated, temperatures terminated defrost + evaporator fans control with delay after defrost – 3 relays & 3 probes;

7 = Combined thermostat with time initiated, temperatures terminated defrost + evaporator fans control with delay after defrost – 3 relays & 3 probes. Fully open map

Probe Type: configures the controller to work with PTC or NTC probes.

0= ptC = PTC,

1= ntC = NTC.

Differential: (1 to 50) sets the degrees above Set Point at which the compressor cuts in.

Note: when tC = 1 (heating applications) the tC value is automatically set below the Set Point. If the temperature decreases and reaches set point minus differential the regulation output is activated and

then turned off when the temperature reaches the set point value again.

Minimum set point limit: (-55°C to SET or -67°F to SET) sets the lower limit of set point adjustment.

Maximum set point limit: (SET to 150°C or SET to 302°F) sets the upper limit of set point adjustment.

Anti-short cycle delay: (0 to 50min) minimum interval between the compressor stop and the next possible restart.

5. PARAMETERS – THEIR FUNCTIONS IN DETAIL

Table 4: controller parameters in detail

Universal-XR 5/15 UXR10012015_REV1.4mm

Page 6

Second compressor start delay: (0 to 255sec)

Temperature alarm configuration:

rE = Related to Set Point;

Ab = Absolute.

Note: Relative means alarms are linked to the Set Point and will follow it if it is adjusted. In this case ALU & ALL set the temp over & under Set Point for alarm. Absolute means ALU & ALL are fixed alarm

temperatures, which are not affected by any Set Point adjustment.

High temperature alarm:

ALC = rE→ [0 to 50°C] or [0 to 90°F];

ALC = Ab → [ALL to 150°C] or [ALL to 302°F].

Low temperature alarm:

ALC = rE → [0 to 50°C] or [0 to 90°F];

ALC = Ab → [-55°C to ALU] or [-67 to ALU].

Temperature alarm delay: (0 to 255min) time interval between an alarm condition occurring and the alarm is signalling.

Delay of temperature alarm at start-up: (from 0 to 720min; res. 10min) time delay of any temperature alarm during pull down following “power on”.

Outputs activation delay at start up: (0 to 255min) time delay before any output relay activates following “power on”.

Thermostat override: (0 to 990min; res. 10min) period during which the compressor will run continuously, regardless of temperature. Setting this parameter to 0 disables this function.

Set point for continuous cycle: (-55 to 150 °C or -67 to 302°F) it sets the set point used during the continuous cycle.

Defrost delay after fast freezing: (0 to 255min) time interval between the end of the thermostat override period and the start of the following defrost related to it.

Interval between defrosts: (0 to 255hours) time interval between the beginning of two consecutive defrosts.

Delay start of defrost: (0 to 255min) delay between reaching the defrost interval time (as defined by parameter idF) and when a defrost cycle actually starts. Used to stagger defrosts between multiple

systems.

(Maximum) duration of defrost: (0 to 255min) time duration of a defrost cycle when only one probe is in use, or defrost time out override when second (evaporator) probe is in use. Set it to zero to disable

defrost cycles.

Defrost termination temperature: (-55 to 50°C or -67 to 122°F) sets the defrost termination temperature. Measured by the evaporator probe.

(Maximum) length for second defrost: (0 to 255min) when P3P = 0, (not evaporator probe: timed defrost) it sets the defrost duration, when P3P = 1 (defrost end based on temperature) it sets the

maximum length for defrost. *** Only if being used with tC7***

Note: The P3 probe will be automatically set as second evaporator probe by the tC parameter.

Second termination temperature: (-55 to 50°C or -67 to 122°F) sets the temperature measured by the second evaporator probe (P3), which causes the end of defrost.

Display during defrost:

0= rt = real temperature;

1= it = temperature at defrost start;

2= sEt = set point;

3= dEF = dEF label;

4= dEG = dEG label.

Defrost display time out: (0 to 250min) after a defrost, the controller will revert to current temperature display when the temperature is back down within its normal working range, or after the time set in

this parameter, whichever is the sooner.

Defrost type:

0= El= electrical heater;

1= rE = hot gas, compressor runs during defrost.

Drain down time: (0 to 255min) drain down time. Runs concurrently with Fnd (Fan delay after defrost time).Both fan and compressor are off during this time period.

First defrost after power-on:

0= Y = immediately;

1= n = after the idF interval time.

Fan operating mode:

0= C_n = cycles on/off with the compressor, OFF during defrost;

1= O_n= continuous mode, OFF during defrost;

2= C_Y = cycles on/off with the compressor, ON during defrost;

3= O_Y = continuous mode, ON during defrost;

Fan stop temperature: (-55 to 50°C or -67 to 122°F) temperature above which the evaporator fan stops (during the normal refrigerat ion cycle).

Universal-XR 6/15 UXR10012015_REV1.4mm

Page 7

Fan delay after defrost: (0 to 255min) the time interval between the end of a defrost cycle and evaporator fans starting. Runs concurrently with Fdt (Drain down time). Always keep Fnd longer that Fdt.

Fan ON time: (0 to 15min) used to set an On/Off cycle of the evaporator fans while the compressor is off. With FnC = 0 or FnC = 2, it sets the evaporator fan ON cycling time when the compressor is OFF.

With Fon = 0 and FoF ≠ 0, the fans are always off. With Fon = 0 and FoF = 0 the fans are always off.

Fan OFF time: (0 to 15min) used to set an On/Off cycle of the evaporator fans while the compressor is off. With FnC = 0 or FnC = 2, it sets the evaporator fan OFF cycling time when the compressor is

OFF. With Fon = 0 and FoF ≠ 0, the fans are always off. With Fon = 0 and FoF = 0 the fans are always off.

Thermostat probe calibration: (-12.0 to 12.0°C or -21 to 21°F) adjustment for thermostat probe (Room) offset.

Evaporator probe presence (Evap on the label):

0= n = not present;

1= Y = present.

Evaporator probe calibration: (-12.0 to 12.0°C or -21 to 21°F) adjustment for evaporator probe offset.

Third probe presence (probe named Evap.2 on the label):

0= n = not present, the third input (the one signed with label “D.I. / Pb3”) Input operates as digital input;

1= Y = present, the third input (the one signed with label “D.I. / Pb3”) Input operates as third probe.

Third probe calibration: (-12.0 to 12.0°C or -21 to 21°F) adjustment for third probe offset.

Display resolution (Only available in Celsius):

0= dE = with decimal point;

1= in = without decimal point.

Temperature measurement unit:

0= °C = Celsius;

1= °F = Fahrenheit.

Warning: If you alter the setting of parameter rES ( decimal point on/off ) re-check the settings of all temperature related parameters Set Point, HY, LS, US, ALU, ALL, dtE, FSt, ot & oE, as they can be

effected.

Probe for Display:

0= P1 = Thermostat probe;

1= P2 = Evaporator probe;

2= P3 = Third probe;

3= sEt = DISPLAY ONLY SHOWS THE SET-POINT. THE ACTUAL TEMPERATURE CAN BE SEEN BY PRESSING THE SET BUTTON.

Display delay: (0 ÷ 20min0sec; resolution 10 sec) when the temperature increases, the display is updated of 1°C or 1°F after this time.

Type of action: 0= Cl = cooling; 1= Ht = heating.

Compressor ON time with faulty probe: (0 to 255min) If there is a P1 probe failure the controller will automatically cycle the compressor on/off according to Con & CoF to maintain basic cooling. Con is

the compressor “ON” time.

Compressor OFF time with faulty probe: (0 to 255min) If there is a P1 probe failure the controller will automatically cycle the compressor on/off according to Con & CoF to maintain basic cooling. CoF is

the compressor “OFF” time.

Alarm muting:

0= n = Alarm relay remains active when alarm buzzer is muted;

1= Y = Alarm relay is cancelled when alarm buzzer is muted.

Second digital input operating mode: configures the second digital input function:

0 = Starts a defrost;

1 = Input from a door switch (see parameter odC);

2 = Activates the auxiliary relay;

3 = Starts Energy Saving (Control Point becomes Set Point +/- value in HES);

4 = Remote On/OFF (puts the controller into standby);

5 = Generic external alarm (normal regulation continues);

6 = Serious external alarm (regulation is stopped).

Configurable second digital input polarity:

0 = the digital input is activated by closing the circuit;

1 = the digital input is activated by opening the circuit.

Time interval/delay for digital input 2 alarm: (0 to 255min) it defines the time delay between the detection and the subsequent signalling of the alarm.

Compressor and fan status when open door:

0= no = normal;

1= FAn = Fan OFF;

2= CPr= Compressor OFF;

3= F_C = Compressor and fan OFF.

Universal-XR 7/15 UXR10012015_REV1.4mm

Page 8

Defrost relay configuration: Only on tC=7

0= Alr = Alarm;

1= db = Dead Band;

2= AUS = Auxiliary;

3= Cp2 = Second compressor output;

4= LIG = Light output;

5= dF2 = Second defrost output.

Auxiliary relay configuration:

1= Alr = Alarm;

2= db = Dead Band;

3= AUS = Auxiliary;

4= Cp2 = Second compressor output;

5= LIG = Light output;

6= dF2 = Second defrost output.

Alarm relay polarity:

0= CL= contact [13 – 14] closed with alarm;

1= oP = contact [13 – 14] open with alarm.

Temperature alarm exclusion with door open: 0 to 255min.

Regulation restart with door open alarm:

0= n = no;

1= Y = yes, regulation will restart after “door open” alarms.

Probe selection for Condenser Alarm :

0= nP=No Probe selected

1= P1=Probe 1

2= P2=Probe 2

3= P3=Probe3 *normally P3 would be used*

Low temperature alarm of condenser: (-55 to 150°C or -67 to 302°F) when this temperature is reached, the HA2 alarm will be raised (after the Ad2 delay time has expired).

High temperature alarm of condenser: (-55 to 150°C or -67 to 302°F) when this temperature is reached, the LA2 alarm will be raised (after the Ad2 delay time has expired).

Differential for temperature condenser alarm recovery: 0.1 to 25.5°C or 1 to 45°F.

Condenser temperature alarm delay: (0 to 255min) time interval between the detection of an alarm condition at the condenser and the relative alarm signalling.

Condenser temperature alarm exclusion during start-up: (0 to 720min, resolution 10min).

Compressor off when a low temperature alarm of the condenser is active:

0= n = the compressor keeps on working if a low temperature alarm at the condenser is active;

1= Y = the compressor is switched off while the low temperature alarm is active. The regulation will restart after elapsing AC delay time.

Compressor off when an high temperature alarm of the condenser is active:

0= n = the compressor keeps on working if a low temperature alarm at the condenser is active;

1= Y = the compressor is switched off while the low temperature alarm is active. The regulation will restart after elapsing AC delay time.

Temperature set point change during the Energy Saving cycle: (-30.0 to 30.0°C or -54 to 54°F) sets the deviation from the normal set point during the Energy Saving cycle.

ON / OFF key enabling:

0= nu= key functionality disabled;

1= OFF = On Off function enabled;

2= ES = Energy Saving function enabled.

Buzzer enabling:

0= n = disabled;

1= Y = enabled.

Parameter table: read only – for factory use.

Software release: read only – shows the software release.

Evaporator probe: shows the current temperature sensed by the evaporator probe.

Third probe temperature: shows the current temperature sensed by the third probe.

Universal-XR 8/15 UXR10012015_REV1.4mm

Page 9

6. BUTTONS AND THEIR FUNCTIONS

BUTTON

FUNCTION

Type Controller menu: keep this button pressed for at least 3 sec within 1 min after power on to enter the “Type Controller Menu” (tC).

AUX output control: Switches the AUX relay output (if enabled as such).

Manual Defrost: keep this button pressed for 3 s to start a manual defrost cycle. The defrost icon will illuminate.

(Not possible if parameter tC = 1 ).

Display current set point: after pressing and releasing this button, the set point will be displayed for 5 sec. This will not allow the set point to

be altered.

Changing set point value: keep this button pressed for at least 2 sec. Set point change mode is entered indicated by the small led’s flashing.

Change the set point using the UP and DOWN buttons. The new value can be stored either by pressing SET button (the instrument restores

temperature display) or by waiting the exit time-out to expire (15 sec).

(UP): to see the max stored temperature; in programming mode it browses the parameter codes or increases the displayed value.

(DOWN): to see the min stored temperature; in programming mode it browses the parameter codes or decreases the displayed value.

Keep press 3sec just after powering on the device (and within the first 60sec) to start automatic probe recognising.

Energy Saving: Allows the control to use the HES offset parameter to change the set point.

COMBINATION

FUNCTION

+

Lock & unlock the keyboard: keeping both buttons pressed for 3 sec will lock or unlock the keyboard. The display

will flash PoF or Pon for a few seconds to confirm locking or unlocking respectively.

+

Enter programming mode: keep both buttons pressed for 3 sec, release them and then press them again for 8 sec.

The first label of Pr2 level will be displayed.

+

Exit programming mode: press together to return to normal display.

As well as the main digital display, there are some small icons on the front

panel. These are used to indicate the status of the loads controlled by the

instrument. Each icon function is described in the following table.

6.1 SINGLE BUTTON FUNCTIONS

Table 5: single button functions

6.2 BUTTON COMBINATION FUNCTIONS

Table 6: button combination functions

7. PROGRAMMING MODE

7.1 USER PROGRAMMING LEVEL – PR1

To enter programming level Pr1 (user programming level), keep both SET and DOWN buttons pressed for 3 sec. The first parameter label will

appear. Browse parameter list by using the UP or DOWN keys. Press SET to see a parameter’s current value and UP or DOWN keys to alter its

value. Press SET to confirm change (the display will blink for 3 sec and then the next parameter will appear) or by waiting for the menu timeout to

expire (15 sec). If no parameter is available for changes in Pr1 level, a noP label will be show.

7.2 PROTECTED PROGRAMMING LEVEL – PR2 (ALL VISIBLE PARAMETERS CAN BE FOUND HERE)

First enter Pr1 level (as described above) then with any parameter label displayed keep both SET and DOWN buttons pressed for 8 sec. The first

parameter label will appear. Browse parameter list by using the UP or DOWN keys. Press SET to see a parameter’s current value and UP or

DOWN keys to alter its value. Press SET to confirm change (the display will blink for 3 sec and then the next parameter will appear) or by waiting

for the menu timeout to expire (15 sec).

From Pr2 level it is also possible to add or remove any parameter to / from Pr1 by pressing both SET & DOWN while its label is displayed.

Accessibility of any particular parameter via Pr1 level is confirmed by the alarm LED lighting up while its label is displayed

WARNING: if no button is pressed for 15 sec, any modified value will be stored into memory and the controller will return to the normal display mode.

8. OTHER FEATURES OF THE UNIVERSAL-XR

Universal-XR 9/15 UXR10012015_REV1.4mm

Page 10

Table 7: display signalling description

ICON

FUNCTION

MEANING

ON

Light (AUX) output enabled.

ON

Cooling enabled.

FLASHING

Anti-short cycle delay in progress.

ON

Fan enabled.

FLASHING

Delay time on fan activation is running (Fnd > 0)

ON

Defrost in progress.

FLASHING

Drip time in progress (Fdt > 0) or delay on start defrosting is running (dSd > 0).

ON

Auxiliary output activated.

ON

Energy Saving activated.

ON

Thermostat override enabled.

ON

ALARM signal: when in programming mode and in Pr2 level, this icon lights up notifying

this parameter is also accessible in the Pr1 level.

ON

All measurement units are in Celsius degrees.

FLASHING

Programming mode.

ON

All measurement units are in Fahrenheit degrees.

FLASHING

Programming mode.

tC parameter value

Action

1

No defrost

2 or 3

Off cycle defrost by timer

4, 5, 6 or 7

Forced type of defrost: Electrical or Hot Gas

FnC

parameter

Action

C_n

Fans will cycle ON and OFF with the compressor and be off during defrost cycle.

O_n

Fans will run continuously, but be off during defrost cycle.

C_Y

Will switch ON and OFF with the compressor and be on during defrost cycle (*).

O_Y

Fans will run continuously and be on during defrost cycle (*).

9. THERMOSTAT OVERRIDE ( not available when parameter tC = 1)

For rapid chilling or freezing, the thermostat can be overridden by pressing the UP button until the icon lights up. The compressor will run in

continuous mode, for the time period set in parameter CCt. Normal operation will then resume automatically after the CCt is exhausted or when the

CCS is exhausted (Continuous Cycle Set Point). The cycle can also be terminated manually by pressing the UP button again for about 3 seconds.

10. DEFROST TYPES

- tdF = 0: defrost is electrical;

- tdF = 1: defrost is by hot gas.

11. EVAPORATOR FAN CONTROL (only when parameter tC = 6 or 7)

The fan control mode is selected by means of the “FnC” parameter:

(*) Note: Fans will stop if the temperature value set in parameter “FSt” is exceeded.

Parameter FSt sets the fan stop temperature. This is the maximum temperature, detected by the evaporator probe, above which the evaporator fans

will stop.

Leave FSt above ambient temperature during commissioning to avoid fan short cycle.

After finishing the defrost phase, there is a stand still drain time, set by parameter Fdt. When this period has expired, the refrigeration cycle

commence but the evaporator fans remain off until Fnd (fan delay) times out.

12. SPECIAL APPLICATIONS – DEAD BAND CONTROL

12.1 DEAD BAND CONTROL (COOLING & HEATING) tc=7

With [oAb = db], the compressor relay controls cooling as normal but the 3rd (auxiliary/ fan) relay is used to control a heater. The value entered in

parameter HY will now be set equal on both sides of the SET POINT. Example: if [HY = 1°C] that will create a 2°C Dead Band.

At [SET POINT + HY], cooling switches on. At [SET POINT – HY], heating switches on. Either cooling or heating switch off when temperature returns

to SET POINT.

Universal-XR 10/15 UXR10012015_REV1.4mm

Page 11

13. ALARMS

Message

Message – Mode

Cause

Outputs

EE

Flashing

Data or memory failure

Alarm output ON; Other outputs unchanged.

P1

Flashing

Thermostat probe failure

Alarm output ON; Compressor output according to parameters Con and CoF.

P2

Alternating with

room temperature

Evaporator probe failure

Alarm output ON; Other outputs unchanged; End defrost is timed.

P3

Alternating with

room temperature

Second evaporator probe

failure

Alarm output ON; Other outputs unchanged; End defrost is timed.

HA

Alternating with

room temperature

High temperature alarm

Alarm output ON; Other outputs unchanged.

LA

Alternating with

room temperature

Minimum temperature

alarm

Alarm output ON; Other outputs unchanged.

HA2

Alternating with

room temperature

Condenser max temp

alarm

Alarm output ON; Other outputs unchanged.

LA2

Alternating with

room temperature

Condenser max temp

alarm

Alarm output ON; Other outputs unchanged.

dA

Alternating with

room temperature

Door open alarm

Alarm output ON: Outputs re-start if parameter rrd = 1.

EA

Alternating with

room temperature

Generic external alarm

Alarm output ON; Other outputs unchanged.

bAL

Alternating with

room temperature

Serious external alarm

Alarm output ON; Other outputs OFF.

13.1 MUTING ALARM BUZZER & RELAY

The alarm buzzer can be muted, by pressing any button. The controller will briefly show the reset “rES” label. Parameter tbA defines how the alarm

relay will respond to the muting of the buzzer.

- tbA = n: the alarm relay will remain active until the alarm condition is rectified;

- tbA = Y: the alarm relay de-activates when the buzzer is muted.

In either case, the display will flash an alarm label until the condition is rectified.

13.2 ALARM “EE”

The Dixell Universal-XR is provided with an internal watchdog verifying data and memory integrity. Alarm “EE” will flash after detecting a failure in data

or in the internal memory. In this case, the alarm output is enabled.

WHAT TO DO

1. Cancel the alarm by pressing a key.

2. Check the value of all parameters and restore correct values when wrong.

3. Check the correct instrument operation and in case of further errors replace it.

13.3 ALARM RECOVERY

Probe alarms “P1”, “P2” and “P3” start 30 seconds after a fault in probe is detected; they automatically stop 30 seconds after the probe restarts normal operation. Check

connections before replacing the probe.

Temperature alarms “HA” and “LA” automatically stop as soon as the thermostat temperature returns to normal values and when defrost starts. Temperature alarms

“HA2” and “LA2” automatically stop as soon as the condenser temperature returns to normal values.

14. REMOVING SECURITY LEVEL PROTECTION

It is possible to allow access to any parameter from Pr1 level. To do this, go into Pr2 as previously described. Scroll to the label of the parameter you require and then

press the SET and DOWN buttons in quick succession. The decimal point LED will be on indicating that access to this particular parameter is now possible from Pr1

level. Its label will now appear when in Pr1 programming level and its value can be altered. To restore security level protection, use the same procedure (the decimal

point LED will go out after pressing both buttons).

15. MOUNTING

The Universal-XR should be mounted in a panel, in a 29mm (1.14”) x 71mm (2.8”) hole, and fixed using the special brackets supplied. Ambient temperature for correct

operation is 32 to 140°F. Avoid places subject to strong vibrations, corrosive gases, excessive dirt or humidity (20 to 85% non-condensing RH is the recommended

working range). Make sure air can freely circulate through the cooling holes slots at the rear side of the controller.

16. ELECTRICAL CONNECTIONS

The instrument is provided with screw terminal block to connect cables with a cross section up to 2.5 mm2. Before connecting cables make sure the

power supply complies with the instrument’s requirements. Separate the probe cables from the power supply cables, from the outputs and from the

power connections. Do not exceed the maximum current rating for each relay; in case of heavier loads use a suitable external relay.

Universal-XR 11/15 UXR10012015_REV1.4mm

Page 12

17. PROBES

Problem

Possible reason

Notes

Display flashing HA

Temperature too high.

Check cooling system.

Check alarm settings.

Display flashing LA

Temperature too low.

Check cooling system.

Check alarm settings.

Display flashing

HA2

Condenser temperature too high.

Check condenser cooling system.

Check alarm settings.

Display flashing

LA2

Condenser temperature too low.

Check condenser cooling system.

Check alarm settings.

Display flashing P1

Fault with thermostat probe.

Wrong type of probe fitted

(NTC/PTC).

Check probe connections and resistance value.

Change probe type or alter parameter PbC.

Display flashing P2

Fault with evaporator probe.

Wrong type of probe fitted

(NTC/PTC).

Parameter tC has been set to 4, 5

or 6 without evaporator probe

fitted.

Check probe connections and resistance value.

Change probe type or alter parameter PbC.

Fit evaporator probe or alter parameter tC.

Display flashing P3

Fault with third probe.

Wrong type of probe fitted

(NTC/PTC).

Parameter tC has been set to 6

without third probe fitted.

Check probe connections and resistance value.

Change probe type or alter parameter PbC.

Fit evaporator probe or alter parameter tC.

Display flashing EE

Data corruption.

Check for electrical spikes and interference. Fit filters DIXL930 & DIXL932.

Ensure probe cables are separated from power cables. Re-check all parameter

settings. Replace controller if still not working.

Display flashing dA

Door has been left open too long.

Shut the door.

Display flashing EA

A non-serious external alarm has been

detected by the digital input.

Trace and rectify the external problem.

Display flashing

bAL

A serious external alarm has been

detected by the digital input.

Trace and rectify the external problem.

Buttons will not

work

Buttons have been locked.

Unlock buttons by pressing both UP & DOWN buttons until display flashes Pon.

It is recommended to place the thermostat probe away from rapid air streams to correctly measure the average room temperature. Place the defrost

termination probe among the evaporator fins in the coldest place, where most ice is formed, far from heaters or from the warmest place during defrost,

to prevent premature defrost termination.

18. TECHNICAL DATA

Housing: Self-extinguishing ABS

Size: Frontal 32x74 mm; depth 70mm

Mounting: Panel mounting in a 71x29 mm panel cut-out

Frontal protection: IP65

Connections: Screw terminal block 2.5 mm2 wiring

Power supply: 120Vac, -10% +15% or 230Vac, -10% +15%

Power absorption: 4 VA max

Display: 3 digits, red LED, 14.2mm high

Inputs: a maximum of 3 temperature probes, PTC or NTC type.

Probes (supplied): 2 x NTC, range-50 TO 110°C (-58 to 230°F) with 1.5 meter (4.98’) cables

Relay outputs: Amps Resistive

Compressor: SPST relay 16FLA / 96LRA, 250Vac

Defrost: SPDT relay 10A, 250Vac

Fans: SPST relay 5A, 250Vac

Other output: Buzzer for acoustic signalling of alarms

Data storing: Non-volatile memory (EEPROM)

Ambient temperature: 0 to 60°C (32 to 140°F)

Ambient humidity: 20 to 85% (non condensing)

Storage temperature: -30 to 85°C (-22 to 185°F)

Operating range: PTC: -50 to 150°C (-58 to 302°F); NTC: -50 to 110°C (-40 to 230°F)

Resolution: 0.1°C or 1°F (selectable)

Accuracy at 25°C: (range -40 to 50°C) 0.5 °C 1 digit

19. TROUBLESHOOTING

Universal-XR 12/15 UXR10012015_REV1.4mm

Page 13

Parameter cannot

be adjusted over its

full range

Some other parameter is conflicting and

preventing further adjustment.

Check other parameter settings.

Power on but no

output operates

Small LED’s

flashing

Anti-short cycle delay in progress, all

relays being held off until it expires.

Wait or adjust parameters AC or odS.

Evaporator fan short

cycling

Parameter FSt set too low.

Adjust FSt to a higher setting. During commissioning, set it above ambient until

pull down is complete, then re-set to a more suitable temperature.

20. CHANGE OVER FROM F TO C OR VIS-VERSA

Label

Description

Edit

Original

Vis.

Level

Min

Max

Comment

tC

Parameter map selection

7

Pr2 1 7

PbC

Kind of probe

ntC

Pr2

Hy

Differential

4

Pr1 1 45

LS

Minimum set point value

-50

Pr2

-67

75

US

Maximum set point value

230

Pr2

75

302

AC

Anti-short cycle delay

1

Pr2 0 50

AC1

Second compressor start delay

0

Pr2 0 255

ALP

Probe selection for temperature alarms

0

Pr2

ALC

Temperature alarm configuration

Ab

Pr2

ALU

High temperature alarm

230

Pr1

-50

302

ALL

Low temperature alarm

-50

Pr1

-67

230

AFH

Differential for temperature alarm recovery

1

Pr1 1 45

ALd

Temperature alarm delay

15

Pr2 0 255

dAo

Delay before activating a temperature alarm at

start up

90

Pr2 0 720

odS

Delay before activating outputs at start up

0

Pr2 0 255

CCt

Continuous cycle duration

0

Pr2 0 990

CCS

Set point for continuous cycle

0

Pr2

-67

302

dAF

Defrost delay after fast freezing

2

Pr2 0 255

idF

Interval between defrost cycles

6

Pr1 0 250

dSd

Start defrost delay

0

Pr2 0 255

dFP

Probe selection for first defrost

3

Pr2

MdF

(Maximum) length for first defrost

30

Pr1 0 255

1. Hold the Set & Down (n) buttons, until HY is displayed, release both buttons then hold the Set and Down (n) buttons until Pr2 is

displayed. Release the buttons.

2. Scroll with the up button to CF, then press and release Set. Change the 1 to 0, then press and release Set.

3. Scroll down and adjust the ALL, ALU, FST, AFH, ALH, LS, US, rES as well as the HY.

4. Let the control time out to the temp display.

Adjust the Set temp by holding the Set until the C or F starts to flash, adjust the set point.

21. ENTER YOUR SETTINGS HERE FOR FUTURE REFERENCE (tC=7 SET UP AS DEAD BAND CONTROL)

Universal-XR 13/15 UXR10012015_REV1.4mm

Page 14

Universal-XR 14/15 UXR10012015_REV1.4mm

Label

Description

Edit

Original

Vis.

Level

Min

Max

Comment

dtE

Defrost termination temperature (first evaporator)

46

Pr1

-67

122

dSP

Probe selection for second defrost

0

Pr2

MdS

(Maximum) length for second defrost

0

Pr2 0 255

dtS

Defrost termination temperature (second

evaporator)

0

Pr2

-67

122

dFd

Display during defrost

3

Pr2

dAd

Max display delay after defrost

10

Pr2 0 255

tdF

Defrost type

0

Pr2

Fdt

Drain down time

2

Pr1 0 255

dPo

First defrost after start-up

0

Pr2

FnC

Fan operating mode

1

Pr2

FSt

Fan stop temperature

46

Pr1

-67

122

Fnd

Fan delay after defrost

5

Pr1 0 255

Fon

Fan on time with compressor off

0

Pr2 0 15

FoF

Fan off time with compressor off

0

Pr2 0 15

FAP

Probe selection for fan management

1

Pr2

FCt

Differential of temperature to force fan activation

5

Pr2 0 90

FSU

Fan management

0

Pr2

ot

Thermostat probe calibration

0

Pr2

-21

21

P2P

Evaporator probe presence

1

Pr2

oE

Evaporator probe calibration

0

Pr2

-21

21

P3P

Third probe presence

0

Pr2

o3

Third probe calibration

0

Pr2

-21

21

rES

Display resolution

1

Pr2

CF

Temperature measurement unit

1

Pr2

Lod

Display visualization

0

Pr2

dLy

Delay before updating the displayed temperature

0.00

Pr2

CH

Kind of action: heating or cooling

0

Pr2

Con

Compressor ON time with faulty probe

15

Pr2 0 255

CoF

Compressor OFF time with faulty probe

310

Pr2 0 255

tbA

Alarm output disabling by pushing any button

0

Pr2

i2F

Digital input 2 configuration

5

Pr2

i2P

Digital input 2 polarity

0

Pr2

di2

Digital input 2 alarm delay

0

Pr2 0 255

Page 15

odC

Compressor and fan status when the door is open

0

Pr2

oAA

First output configuration

0

Pr2

oAb

Second output configuration

3

Pr2

Label

Description

Edit

Original

Vis.

Level

Min

Max

Comment

AoP

Alarm relay polarity

0

Pr2

dot

Temperature alarm exclusion with door open

20

Pr2 0 255

rrd

Regulation restart with door open alarm

0

Pr2

AP2

Probe selection for condenser temperature

alarms

0

Pr2

AL2

Condenser low temperature alarm

0

Pr2

-67

302

AU2

Condenser high temperature alarm

0

Pr2

-67

302

AH2

Differ. for condenser temp. alarm recovery

1

Pr2 1 45

Ad2

Condenser temperature alarm delay

0

Pr2

dA2

Delay of condenser temper. alarm at start up

0

Pr2 0 720

bLL

Compressor off for condenser low temperature

alarm

0

Pr2

AC2

Compressor off for condenser high temperature

alarm

0

Pr2

HES

Differential for Energy Saving

0

Pr2

-54

54

onF

On/off key configuration

2

Pr2

bEn

Buzzer enabling

1

Pr2

Ptb

Map code READ ONLY

Pr2

0

655

35

Adr

Serial address

1

Pr2 1 247

SEt

Set point

75

-50

230

NOTES:

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

Climate.Emerson.com

Universal-XR 15/15 UXR10012015_REV1.4mm

Loading...

Loading...