dixell iPRO Operation Manual

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 1 -

iPRO

PROGRAMMABLE CONTROLLER

OPERATION MANUAL iPRO.GENIUS

Vers. 1.0

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 2 -

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 3 -

1. lNDEX

2. WARNING

3. INTRODUCTION

3.1 Main Features

3.2 Technical data

3.3 Alarm Management

3.4 Plant Status Display

3.5 ISaGRAF

3.6 Why ISaGRAF

3.7 Development tools

3.8 Upgrade programs from previous version of ISaGRAF (3.x)

3.9 Minimum system requirement for PC

3.10 Inside the packaging

4. BASIC Input/Output CONFIGURATION

4.1 Power Supply

4.2 Analog Inputs (Probes PTC - NTC)

4.3 Analog Inputs (Pressure transducers 4÷20mA, Probes 0÷20mA)

4.4 Analog Inputs (Pressure transducers 0÷1V, Ratiometric 0÷5V - 0÷10V)

4.5 Analog Inputs (Probes 0÷1V - 0÷10V)

4.6 Analog Outputs (0÷10V - 4÷20mA signal for condenser controls)

4.7 Analog Outputs (PWM signal for fan speed module)

4.8 Analog Outputs (proportional signal 0÷10V - 4÷20mA for actuators and servomotors)

4.9 Analog Outputs (configured to control remote relay)

4.10 Digital Inputs

4.11 Digital Outputs

4.12 Visograph connection

4.13 Expansion module (specifications and connections)

4.14 Other connections

5. HOW TO START

5.1 Ethernet 10/100 connection

5.2 Direct connection (between iPRO and PC with a cable)

5.3 Intranet/Ethernet connection (Local Area Network)

5.4 Port forwarding

5.5 Modem connection

6. ISAGRAF INSTALLATION AND SET-UP

6.1 Requirements

6.2 How to install the ISaGRAF software

6.3 How to download the software from ISaGRAF website

6.4 How to set-up the ISaGRAF program

6.5 Start with the new project

7. THE ISAGRAF WORKBENCH

7.1 Definitions

7.2 How to make a regulator ON-OFF

7.3 Debug Step by Step

7.4 The ISaGRAF instruction manual

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 4 -

8. PROGRAMMING LANGUAGES

8.1 ST language – General concepts

8.2 FBD language – General concepts

8.2.1 FBD example – ON/OFF regulator

8.3 FB function block

8.3.1 Introduction of Function Block FB

8.3.2 How to create the FB

8.3.3 How to use the FB inside the programs

8.3.4 Exportation and Importation of FB

8.4 Configuration files

8.4.1 File CONF

8.4.2 File BIN

8.4.3 File PARAM

8.4.4 File SPALT

9. SECURITY

9.1 How to protect your application/program

9.2 How to transfer or copy the application

9.3 How to protect the function blocks FB

10. HOW TO USE THE USB

11. VISOPROG INSTALLATION AND SET-UP

11.1 How to install VISOPROG software

11.2 License Activation

11.3 How to set-up the VISOPROG program

11.3.1 Environment Language

11.3.2 Environment Connection

11.3.3 Project Options

12. VISOGRAPH

13. THE VISOPROG WORKBENCH

13.1 Introduction

13.2 The VISOPROG environment

13.3 The STAGE area

13.4 The STAGE EDITOR area

13.5 The INFORMATION area

13.5.1 Object Properties

13.5.2 Main View

13.5.3 Variables

13.5.4 Vocabulary

13.5.5 View State

13.6 How to create a new project

13.6.1 Fine tuning of your project

13.7 Features included

13.7.1 Buttons combination and actions

13.7.2 Disabled property unchecked (active elements)

13.7.3 Controls visibility

13.7.4 Automatic Stages

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 5 -

14. CONNECTIVITY

14.1 Ethernet 10/100 and Serial bus

14.2 How to configure the bus and variables

14.2.1 Define the BUS (GENLINE board)

14.2.2 Define the I/O (GENAI, GENAO, GENDI, GENDO boards)

14.2.3 Define the new variable(s) in the dictionary

14.2.4 Link between variables and boards

15. ADMINISTRATOR SITE

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 6 -

2. WARNING

WARNING: TO PREVENT FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS

APPLIANCE TO RAIN OR MOISTURE.

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK). NO USERSERVICEABLE PARTS INSIDE, REFER SERVICING TO

QUALIFIED SERVICE PERSONNEL.

THE LIGHTNING FLASH WITH ARROWHEAD SYMBOL,

WITHIN AN EQUILATERAL TRIANGLE, IS INTENDED TO

ALERT THE USER TO THE PRESENCE OF UNINSULATED

“DANGEROUS VOLTAGE” WITHIN THE PRODUCT’S

ENCLOSURE THAT MAY BE OF SUFFICIENT

MAGNITUDE TO CONSTITUTE A RISK OF ELECTRIC

SHOCK TO PERSONS.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL

TRIANGLE IS INTENDED TO ALERT THE USER TO THE

PRESENCE OF IMPORTANT OPERATING AND

MAINTENANCE (SERVICING) INSTRUCTIONS IN THE

LITERATURE ACCOMPANYING THE APPLIANCE.

WARNING:

Dixell Spa can accept no responsibility for any possible damage due the usage of

not supported modems.

Dixell Spa. reserves itself the right to modify this manual without notice. The

last version available can be downloaded from the website.

This controller is compliant with standard EN 12830 if it is used together with

probes that are compliant with standard EN 13485

WARNING:

This manual is part of the product and should be kept near the instrument to

easy and quick reference.

The instrument shall not be used for different purpose from those described in

this manual. It cannot be used as a safety device.

Check the application limits before proceeding.

WARNING:

Check the supply voltage is correct before connecting the instrument.

Do not expose to water or moisture: use the controller only within the operating

limits avoiding sudden temperature changes with high atmospheric humidity to

prevent formation of condensation.

Warning: disconnect all electrical connections before any kind of maintenance.

Fit the probe where it is not accessible by the End User.

The instrument must not be opened.

Consider the maximum current which can be applied to each relay (see

Technical Data).

Ensure that the wires for the probes, loads and the power supply are separated

and far enough from each other, without crossing or intertwining.

In case of applications in industrial environments, the use of mains filters (our

mod. FT1) in parallel with inductive loads could be useful.

DIXELL reserves the right to modify or change its products without prior warning.

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 7 -

3. INTRODUCTION

3.1 Main Features

iPRO family, dedicated whether for HVAC units (iPRO Chill and Domo) or for general

purposes and refrigeration (iPRO Genius), is characterized by the most advanced

technology in connectivity and processing speed.

It is based on a powerful platform that includes one hardware configuration that is able to

expand the actual solution in the market, and a software that, thanks to the ISaGRAF®

development environment allows the development through standard programming

languages.

An easy and useful HMI is also guaranteed through the VISOGRAPH graphic display, as

the expandability and the solution to many applications are satisfied with a complete range

of accessories, among which, I/O expansion modules and proportional electronic valve

management, modem, wiring…

The iPRO Genius family satisfy all requirements regarding the controlling and management

of refrigeration, heating, ventilation, electric power and all building automation services.

They are suited for all applications in the PLC world and they find applications in many

shopping centres, hospitals, airports, boatyards, energy management plants, and so on…

These controllers provide a high level of technology for ease of external connectivity and

programmability providing simple answers to every application’s needs, while ensuring a

complete local or remote monitoring.

• Fully programmable controllers and high connectivity.

• VISOGRAPH programmable graphic display (LCD – 240x96 pixels).

• Ethernet for connection to an intranet-internet network and to others programmable

controllers for a distributed application management.

• USB (host) that allows the download of applications, parameters, data/alarm logger

and the applications and parameters upload. It is possible also to upgrade the BIOS

of microprocessor.

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 8 -

• CANBus digital communication serial protocol for the connection to other

programmable controllers, to I/O expansion modules.

• Two master and slave RS485 serial output.

• ModBUS-RTU standard communication protocol that allows connection to Dixell

digital controllers, to XWEB supervising and controlling systems or to applications

developed by third Party Systems.

• BACnet communications allows the system to have easy and immediate integration

with different manufactures ensuring a complete collaboration.

• The possibility to have a connection to the expansion modules in order to increase

system capacity.

• 20VA max power absorption.

3.2 Technical data

LINUX Operative System

200MHz CPU

32bit processor

32MB RAM memory

128MB flash memory capacity (80MB free)

10 configurable Analog Inputs (configurable as Digital Inputs)

6 Analog Outputs (configurable as Digital Outputs)

20 Digital Inputs (free contacts)

15 Digital Outputs (Relay 5A)

Ethernet 10/100

Modem (Internal and External)

2 Master bus (RS485 and Can-bus)

1 Slave bus (RS485 MODBUS RTU)

1 USB

1 VISOGRAPH connection

Power Supply: 24 Vac-dc

Operating temperature: -10 ÷ 60 °C

Storage temperature: -20 ÷ 70 °C

Relative humidity: < 90% (no condensing)

Power consumption: 10W

Protection: IP20 (IP40 for VISOGRAPH)

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 9 -

3.3 Alarm Management

The alarm management system is the fundamental element that increases the plant

efficiency, ensuring an immediate identification of plant problems and activates automatic

strategies to prevent possible damages. The following possible options are available with

iPro GENIUS.

• Alarm sending management by e-mail or sms

• Direct internet connection

• Point-to-point connection via modem, GSM and PDA modem

• Remote command sending via sms

• Possibility of updating the (iPro) on-board software via e-mail

3.4 Plant Status Display

The plant maintenance staff can easily have a report of application status in order to decide

how and when to intervene. The report contains all of the most important values, the plant

status and operating set point.

3.5 ISaGRAF

In order to create programs that will be uploaded into the iPro series Dixell has selected

ISaGRAF®; a software environment that enables you to create local or distributed control

systems. ISaGRAF® offers a combination of a highly portable, robust management engine

(Virtual Machine) and an intuitive application development environment (Workbench). The

output of the development environment is selectable as either portable “C” source code or

TIC (target independent code). The ISaGRAF® Virtual Machine is a powerful, optimized

and very fast control engine that executes the TIC. Virtual Machine and all options are

offered ready to use on NT, Linux, CE 3.0 and QNX. Additionally, this control engine has

been designed such that the source code of the Virtual Machine is available in a toolkit

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 10 -

format, providing portability to any OS on any hardware platform. The Enhanced options for

ISaGRAF® transform this outstanding controller into a top of the line PLC, DCS or RTU.

3.6 Why ISaGRAF ?

• This development environment is international, complete, standard

• Is ideal for small applications but it can manage several I/O points

• It is the most used (more than 40.000 developers in the world and more than

500.000 applications in the last 10 years)

• It includes 5 different programming languages coded according to IEC61131

• It integrates the best system for simulation and remote debugging

• It is supported all over the world (essential for training and assistance)

The ISaGRAF® Application development Workbench supports all the standard IEC 61131

control program languages plus Flow Chart.

• SFC: Sequencial Function Chart

• ST: Structured Text

• FBD: Function Block Diagram

• IL: Instruction List

• FC: Flow Chart

• LD: Ladder Diagram

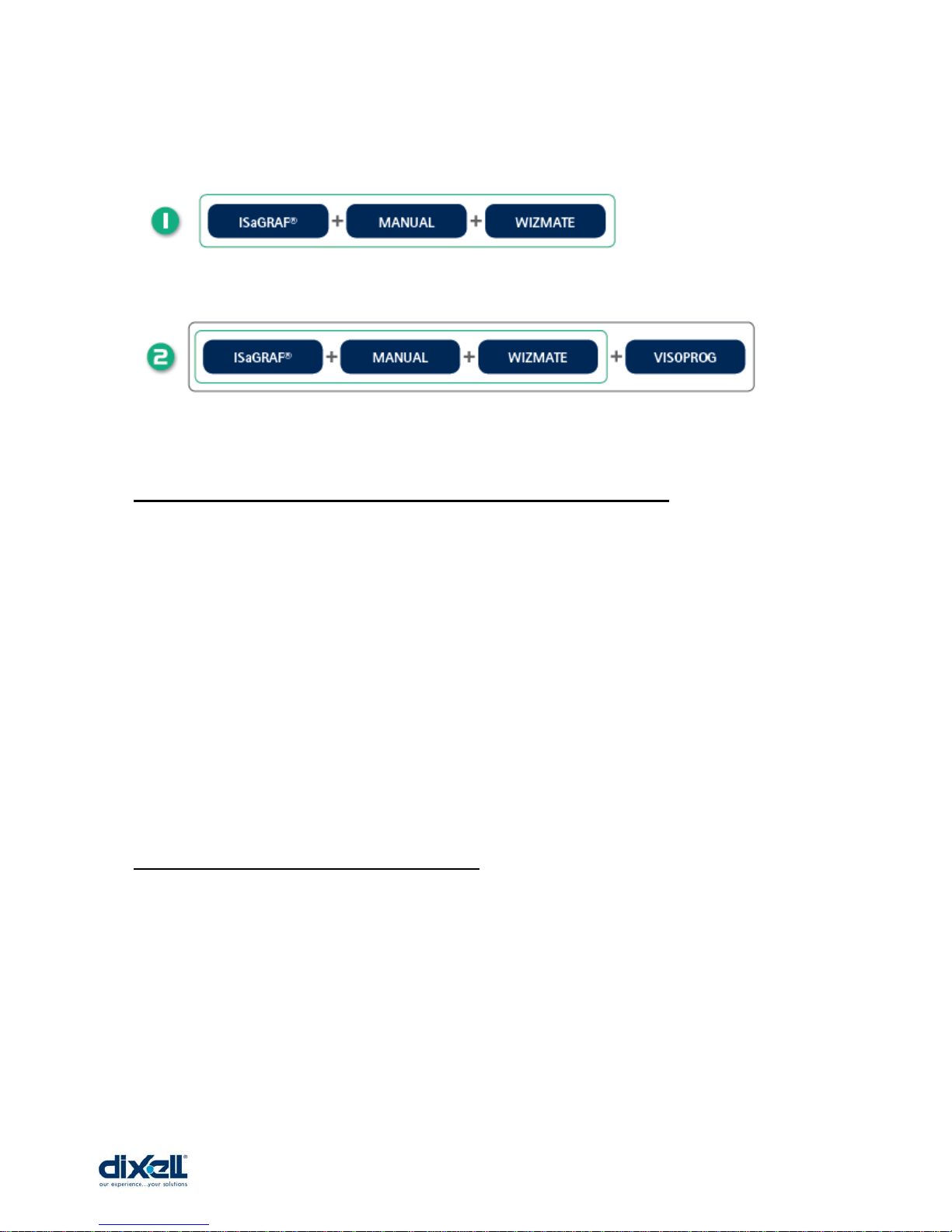

3.7 Development tools

IPRO-TOOL is a complete tool, provided by Dixell, that allows the final user to work

independently to create programs for iPRO controllers, taking advantage of all the

programmable series potential. The package includes manuals and the WIZMATE software,

a useful instrument that allows a simple iPRO controllers programming mode. Another utility

provided by Dixell is the VISOPROG software for the graphic interfaces creation of

VISOGRAPH displays.

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 11 -

The user can choose between two options:

3.8 Upgrade programs from previous version of ISaGRAF (3.x)

For iPRO is possible to manage programs that have been developed with ISaGRAF 3.x

version; it is not possible the opposite.

If the program contains ISaGRAF standard function block, they can be converted

automatically.

If the program contains ISaGRAF custom functional block (for example blocks made from

other company), it will be necessary to codify and rewrite them for the new version.

3.9 Minimum system requirement for PC

When connecting through the LAN, the PC client computer must have installed these

components:

• Windows 98®, Windows 2000, WindowsXP.

• Pentium II 300MHz with 64Mb ram or higher

• Java Virtual Machine

• Explorer 5.5 or higher, Firefox

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 12 -

If necessary, inside the CD-ROM you will find the Java Virtual Machine program distributed

by Sun® Microsystems.

Dixell S.p.a. is not responsible for any kind of damage occurring after the loading of the

Java Virtual Machine program into the user’s PC.

3.10 Inside the packaging

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 13 -

4. BASIC Input/Output CONFIGURATION

Configurable means that every inputs or output can be configured different each other.

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 14 -

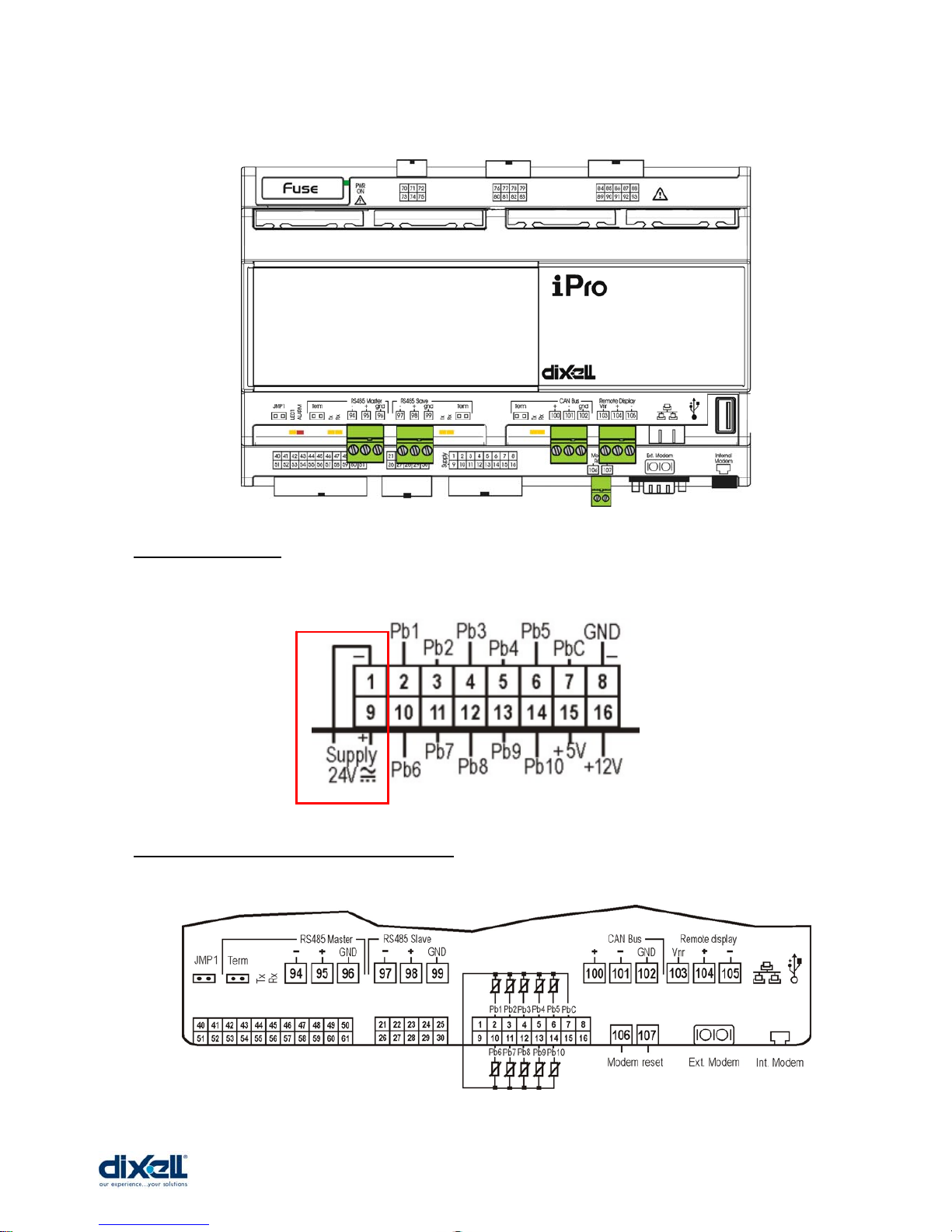

4.1 Power Supply

4.2 Analog Inputs (Probes PTC-NTC)

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 15 -

4.3 Analog Inputs (Pressure transducers 4÷20mA, probes 0÷20mA)

4.4 Analog Inputs (Pressure transducers 0÷1V, Ratiometric 0÷5V - 0÷10V)

4.5 Analog Inputs (Probes 0÷1V - 0÷10V)

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 16 -

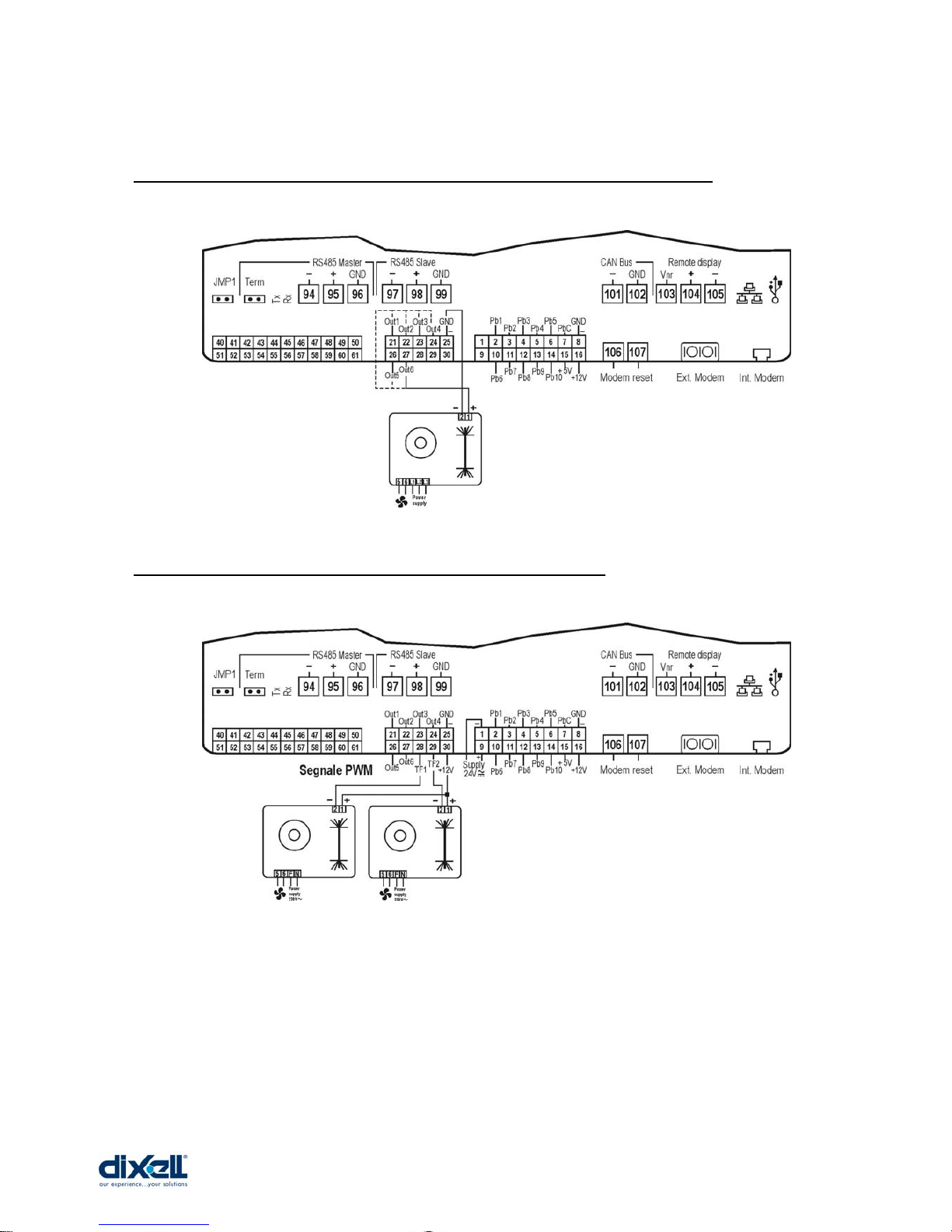

4.6 Analog Outputs (0÷10V - 4÷20mA signal for condenser controls)

4.7 Analog Outputs (PWM signal for fan speed module)

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 17 -

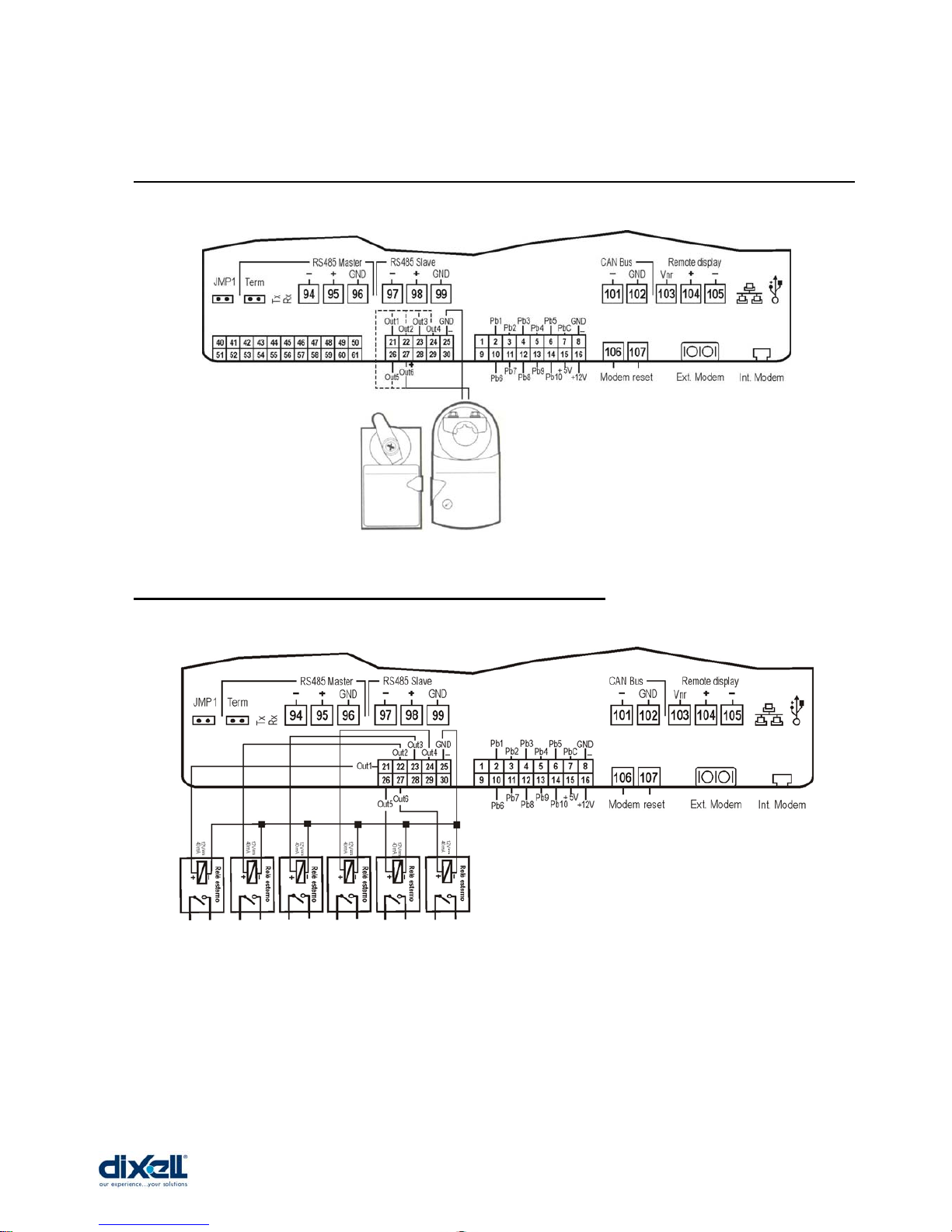

4.8 Analog Outputs (proportional signal 0÷10V, 4÷20mA for actuators/ servo-motors)

4.9 Analog Outputs (configured to control remote relay)

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 18 -

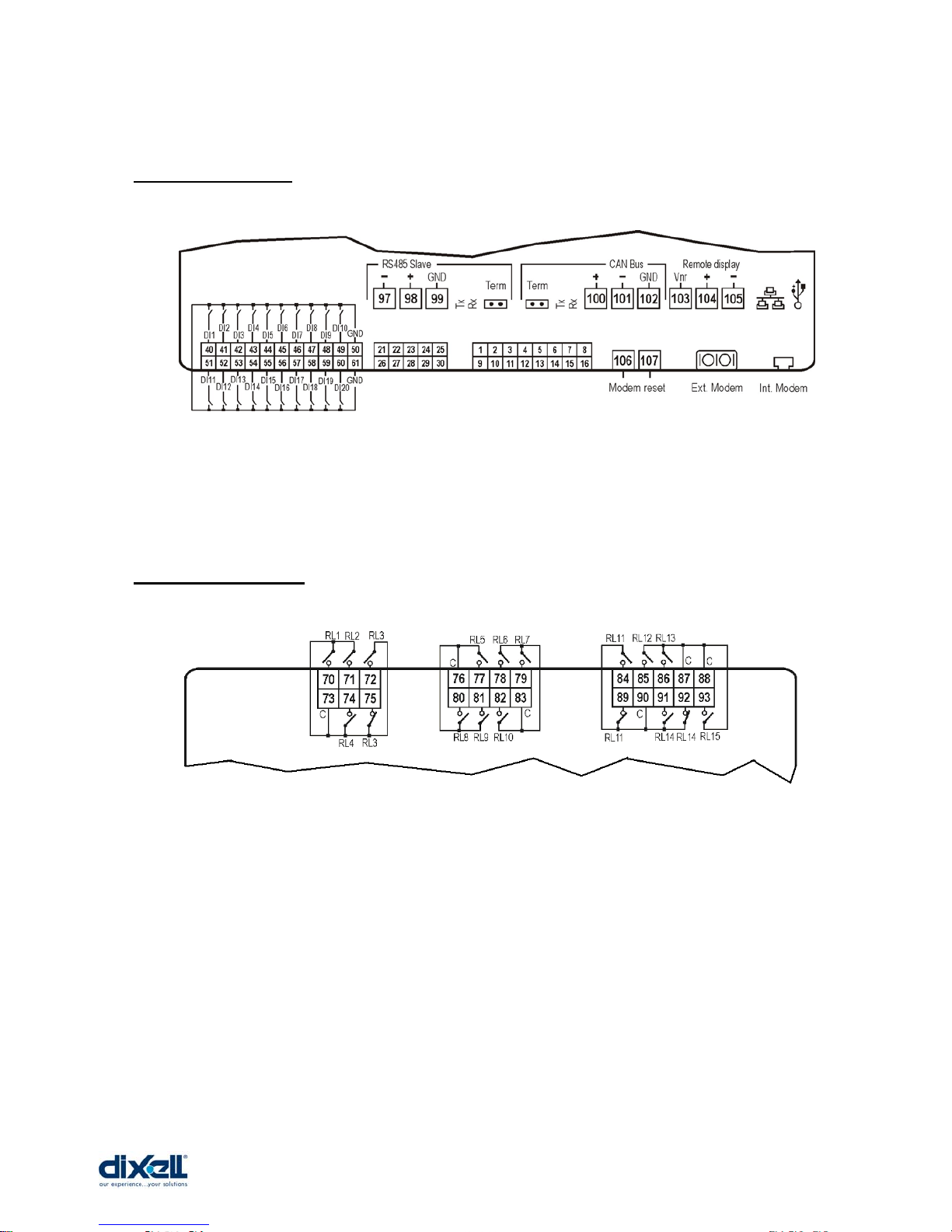

4.10 Digital Inputs

4.11 Digital Outputs

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 19 -

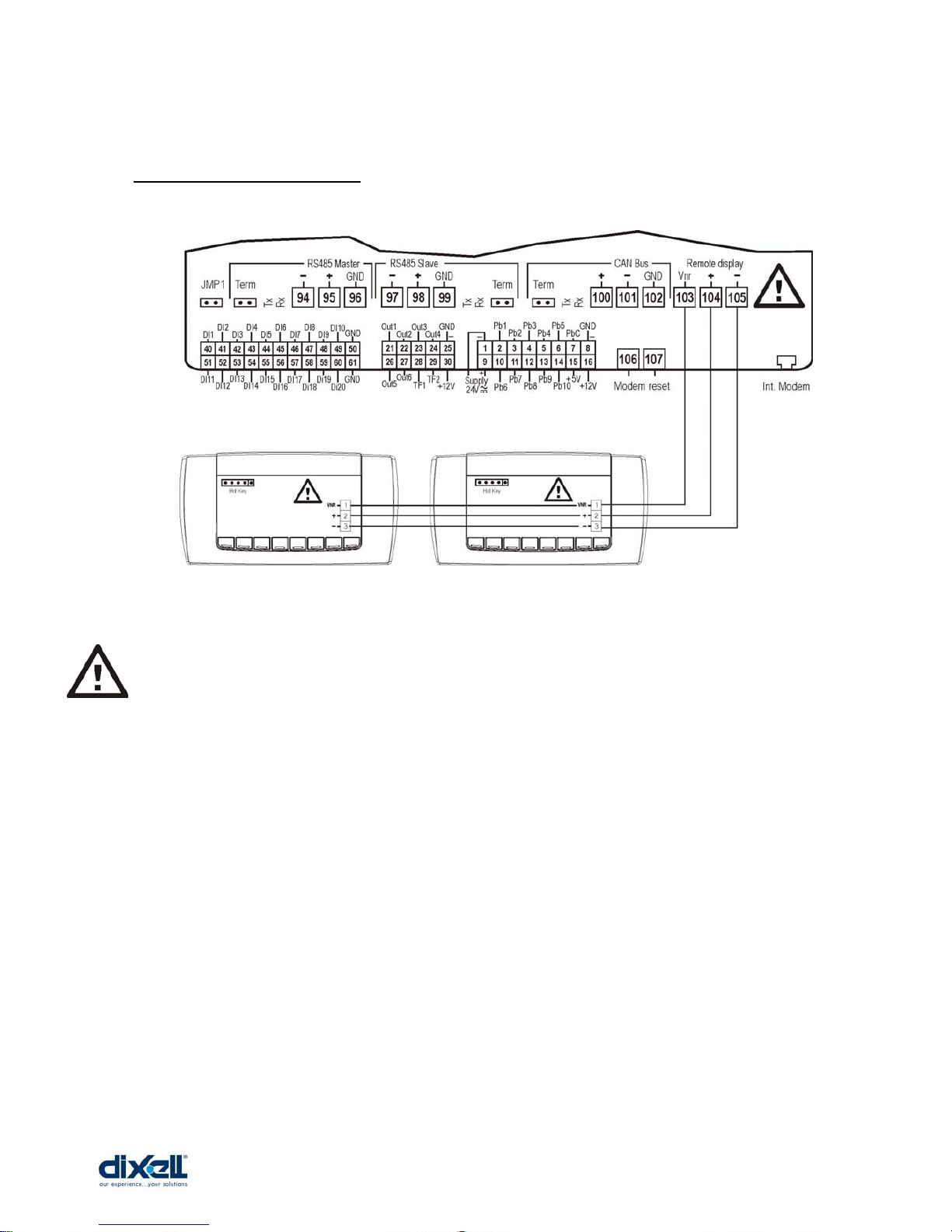

4.12 Visograph connection

IT IS VERY IMPORTANT TO RESPECT THE POLARITY OF CONNECTIONS TO AVOID

THE DAMAGING OF THE VISOGRAPH.

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 20 -

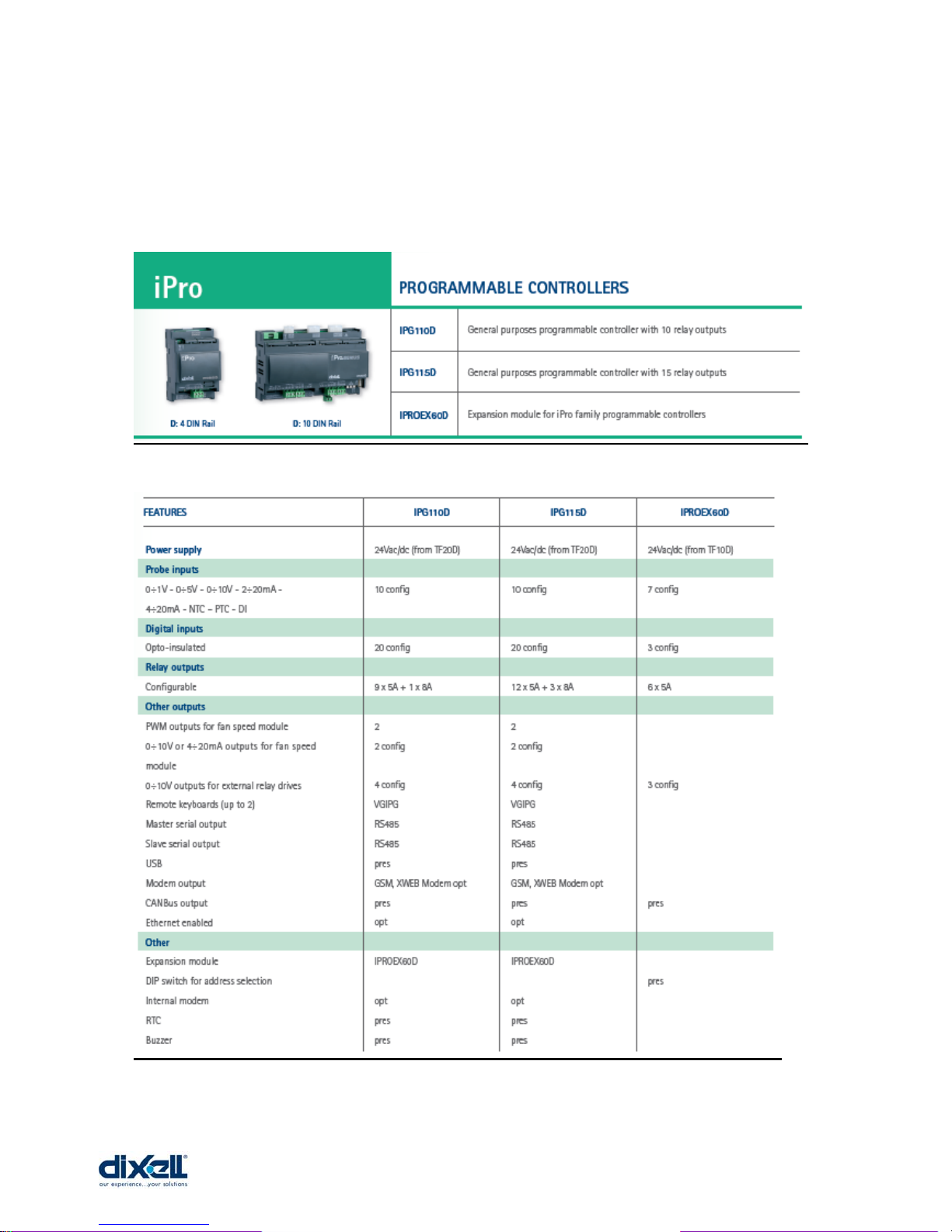

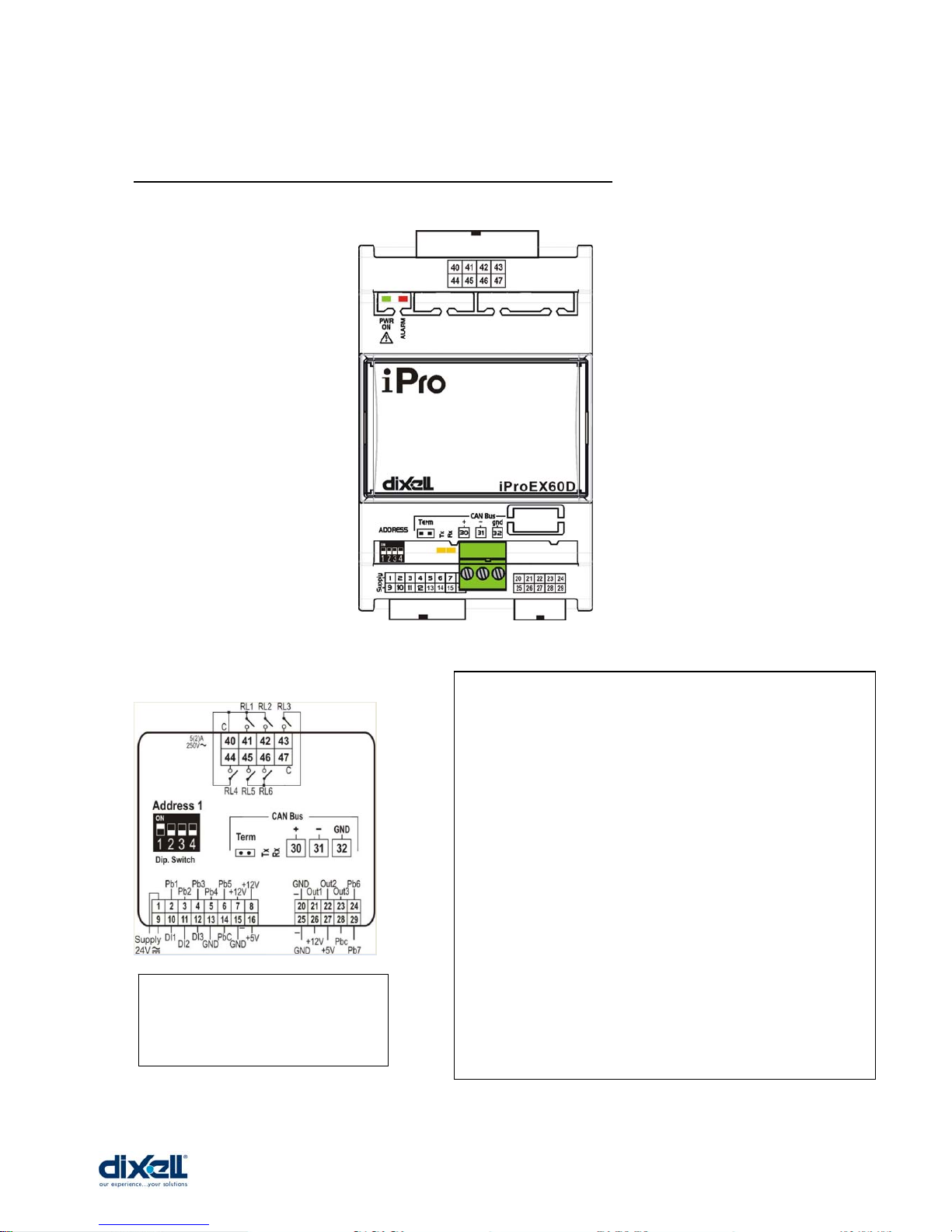

4.13 Expansion Module (specifications and connections)

Power supply: 24V Vac/dc

Analog Inputs: 7 configurable

0÷1V, 0÷5V, 0÷10V,

0÷20mA, 4÷20mA, NTC, PTC, DI

Analog Outputs: 3 configurable

0÷10V ( or DO for relay)

Digital Inputs: 3 (free contacts)

Digital Output: 6 relay 5A 250V

Connection: 1 CANBus

Address: Dip switch 4 positions

Can bitrate = 100Kbit/s

(set-up this value

through the browser

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 21 -

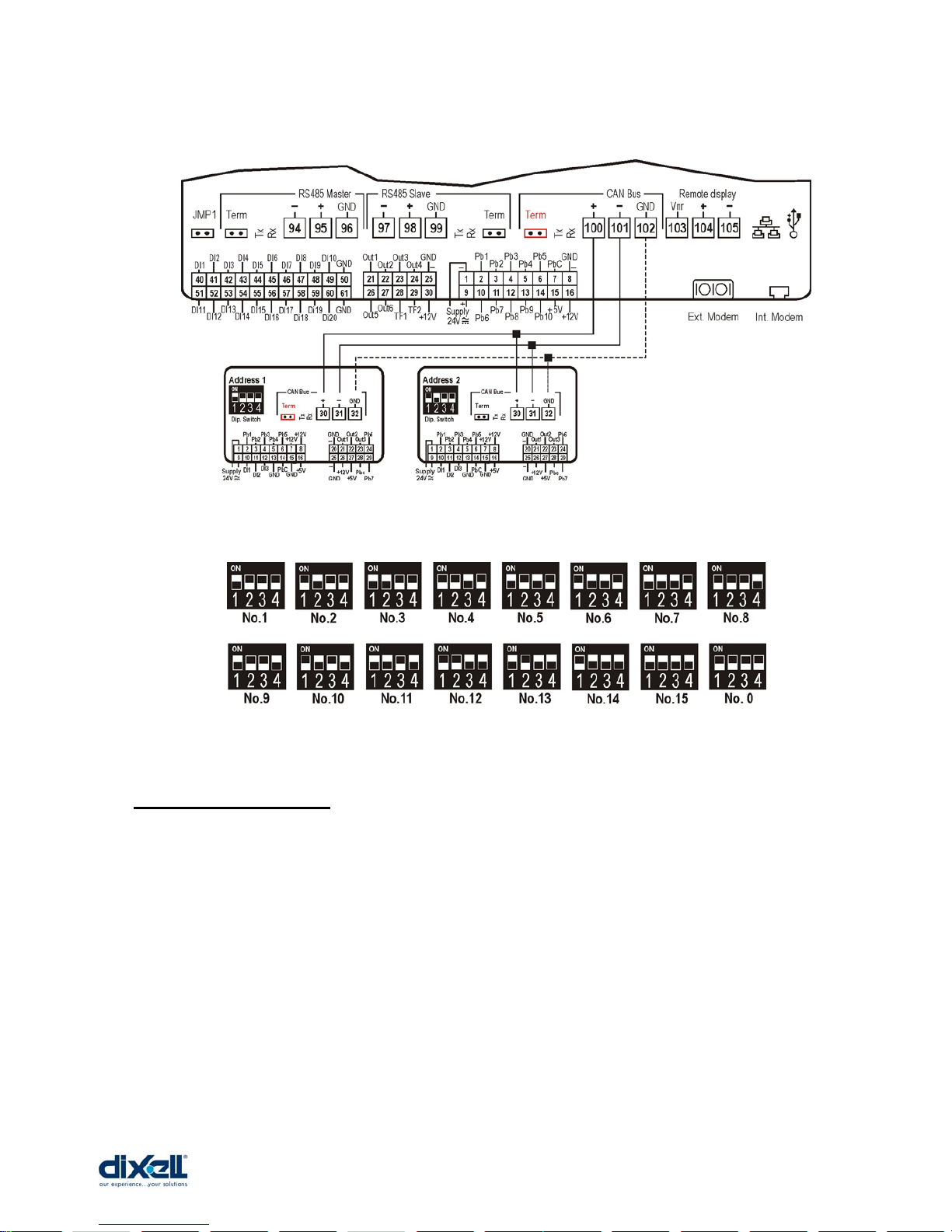

4.14 Other connections

For all the other connections, please refer to the section No. 14.

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 22 -

5. HOW TO START

5.1 Ethernet 10/100 connection

With this connection is possible:

• To connect the iPRO with the personal computer; through ISaGRAF workbench you

download and debug the application.

• To connect more iPRO; different applications on different iPRO to exchanges

variables.

• To send mail and sms; you can program your iPRO so that it can sends mail/sms on

time or on demand.

• To visit your own website; you can program iPRO with your own web site. With a

standard browser, a user can read/write variables.

5.2 Direct connection (between iPRO and PC with a cable)

With this kind of connection is possible to connect directly your personal computer with the

programmable controller iPRO. In this case, you need a standard “Crossover Cable” (cod.

Dixell CAB/WEB/PC). The PC can communicate with the iPRO only if the settings in the

devices are aligned; this means that the PC and the iPRO have to work in the same

network.

The procedure is the following:

Cable

(Crossover)

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 23 -

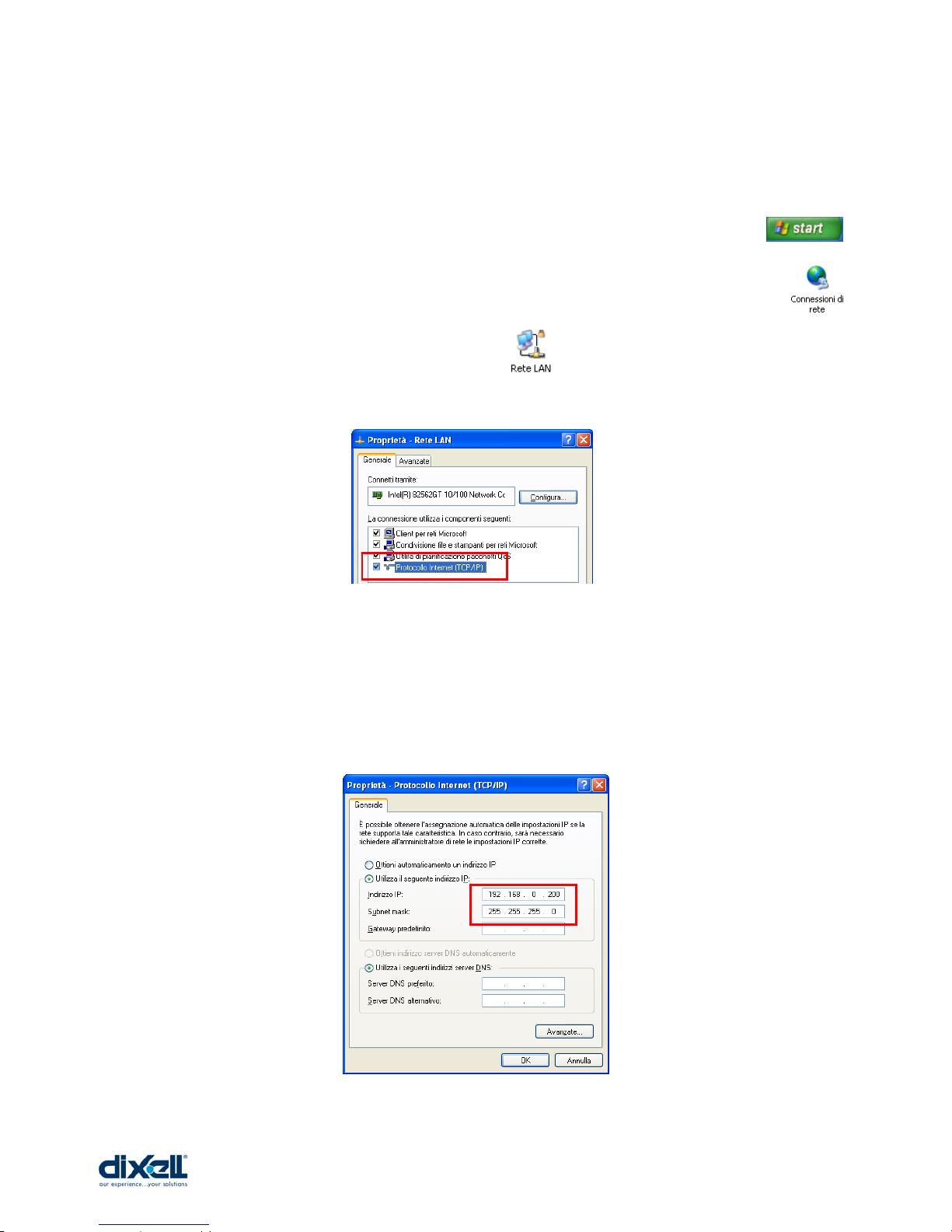

• Disconnect your computer from the data network of your company and connect the

PC with the iPRO through the Crossover cable.

• The personal computer has to be set in the same network of the iPRO.

o In the windows environment click with the mouse on “start” button .

o Choose “Control Panel” and selec t “Network and dial-up connections” .

o Choose “Local area connection” .

o Choose “Properties” and double click on “Internet Protocol (TCP/IP)”.

o In this window set the following parameters (as showed in the picture):

IP address: 192.168.0.200

Subnet Mask: 255.255.255.0

o Click “OK” to confirm.

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 24 -

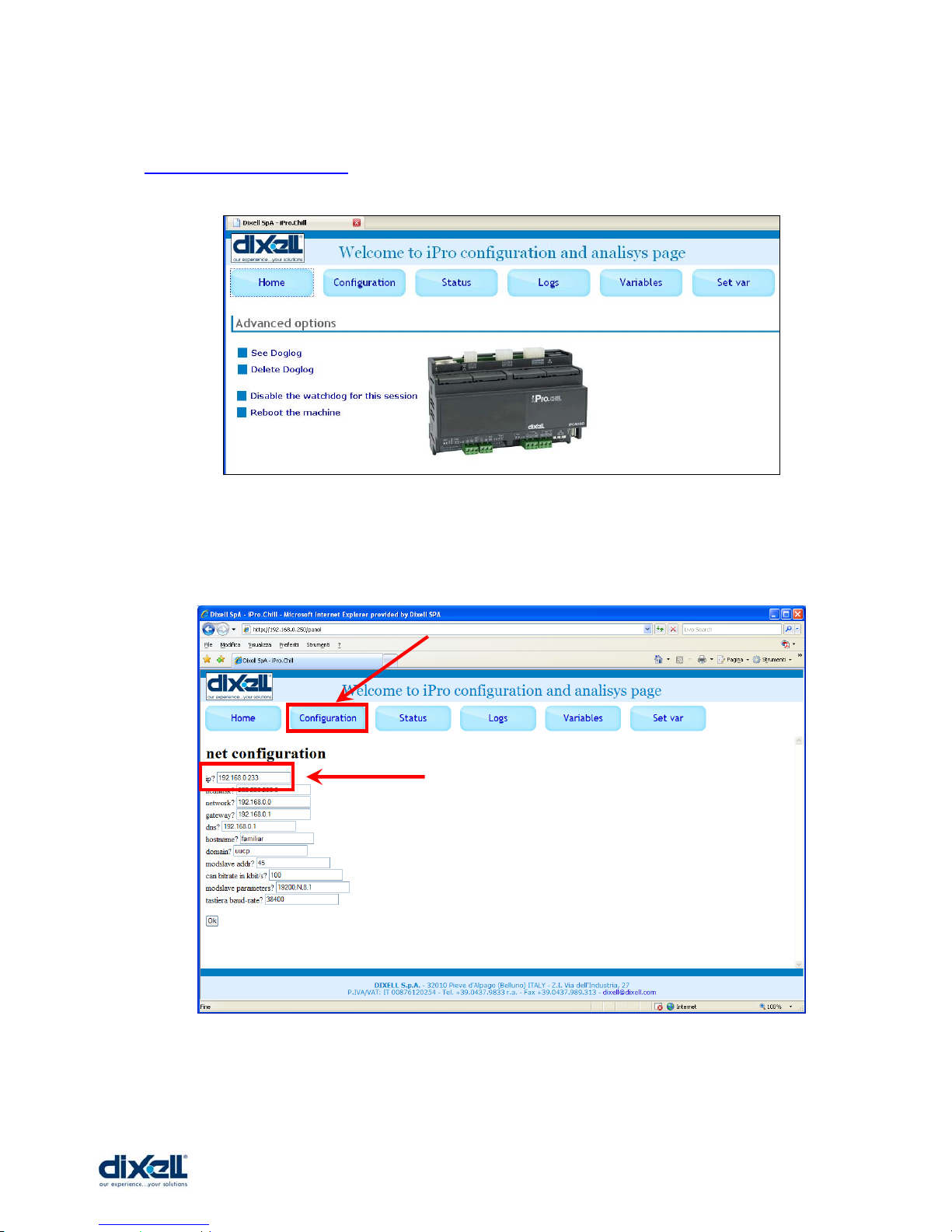

Launch the browser in your computer and write the following web site address:

http://192.168.0.250/panel (if your IP is different, write the correct one):

If necessary is possible to change the IP address; click the Configuration button and in the

IP box write the new address (for example if your IP address is: 192.168.0.233).

Click “OK” to confirm the operation.

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 25 -

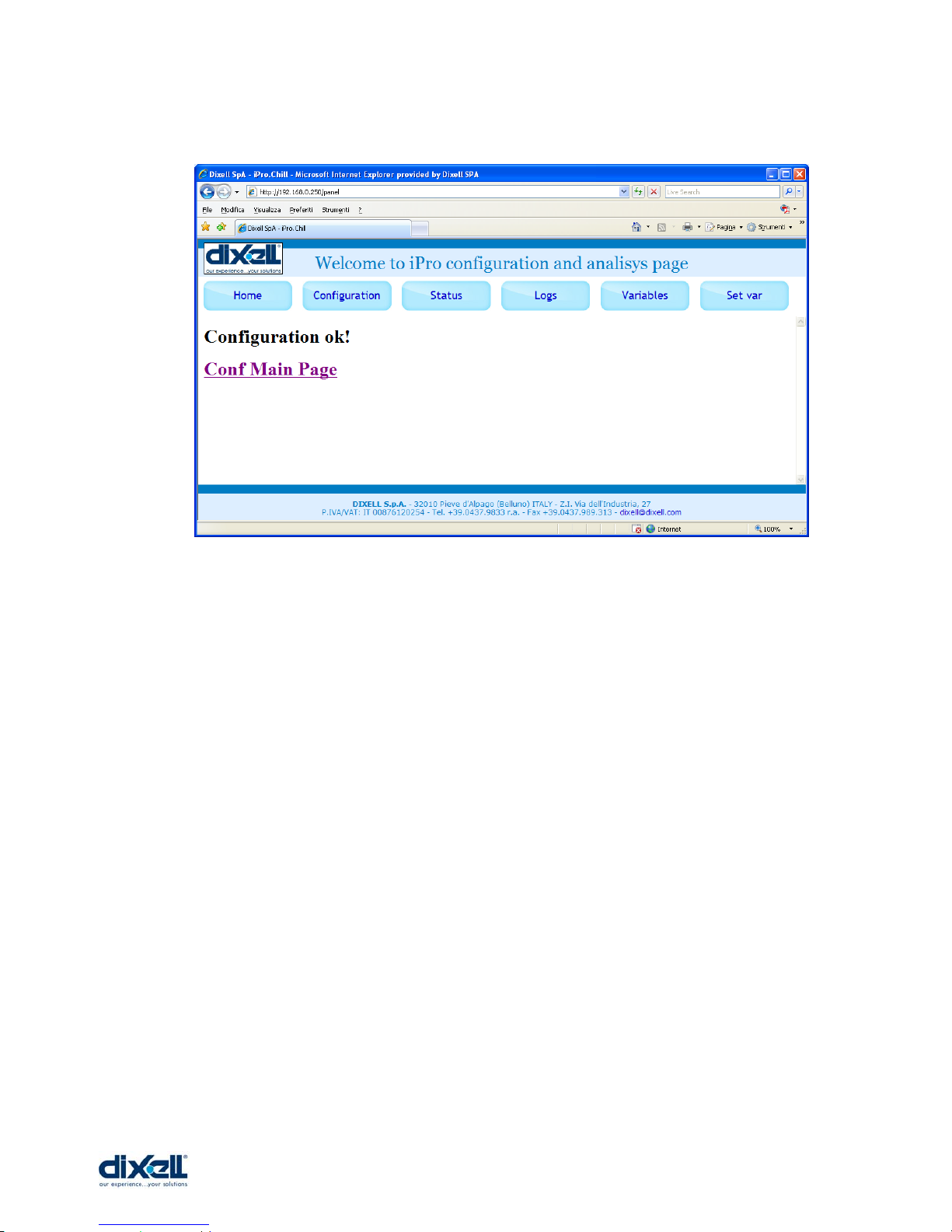

If everything is ok, the message will be:

Now it is necessary to restart the iPRO.

To test the connection follows the procedure in the chapter 5.3.

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 26 -

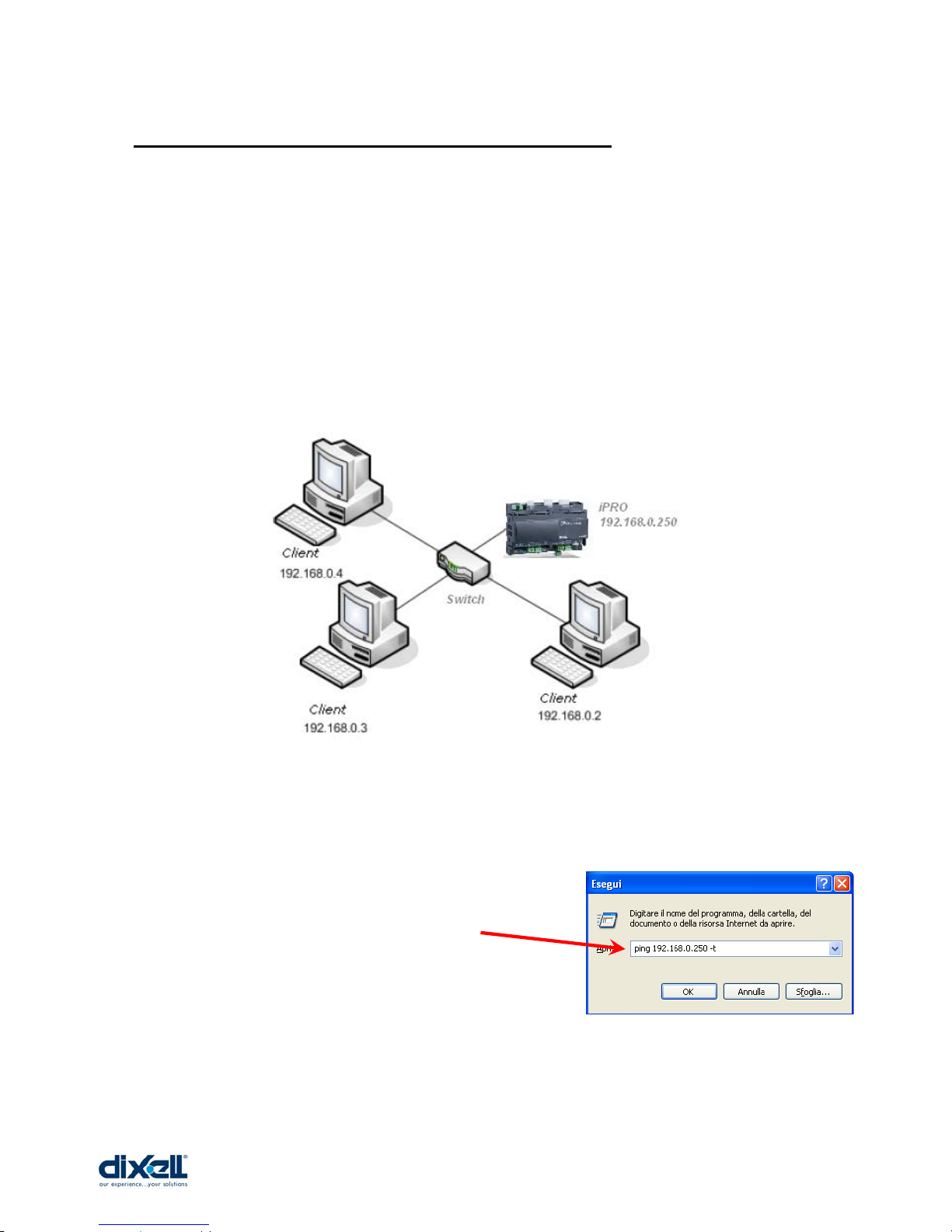

5.3 Intranet / Ethernet connection (Local Area Network)

The Intranet or Ethernet connection should be initially managed by the net administrator

that will assign one free IP address to reach the iPRO. This number is an example of what

you should expect with the default IP of the iPRO: 192.168.0.250.

After receiving the address from your network Administrator the iPRO must be set with this

number (through the procedure described in the chapter 5.2).

Use a standard RJ45 network cable to connect the unit to your existing LAN.

The Intranet method allows the connection to interact with iPRO from all the PC Clients.

To check if the connection has been established try in this way:

• From your computer launch: start -Æ run

• In the box write the following string:

• Then click OK.

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 27 -

If the connection is OK, in this window you will see the following information:

5.4 Port forwarding

Port forwarding allows remote computers (e.g. public machines on the Internet) to connect

to a specific computer within a private LAN.

The ports that have to be opened are:

• 22 for SSH protocol

• 80 for browser (internet explorer, firefox, …)

• 1131 for ISaGRAF WorkBench

• 6666 used for remote update

5.5 Modem connection

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 28 -

6. ISAGRAF INSTALLATION AND SET-UP

6.1 Requirements

To develop the software with ISaGRAF are necessary:

• Software (it is possible to install the program from the CD or download it from the

ISaGRAF Website).

• To have the ISaGRAF USB KEY

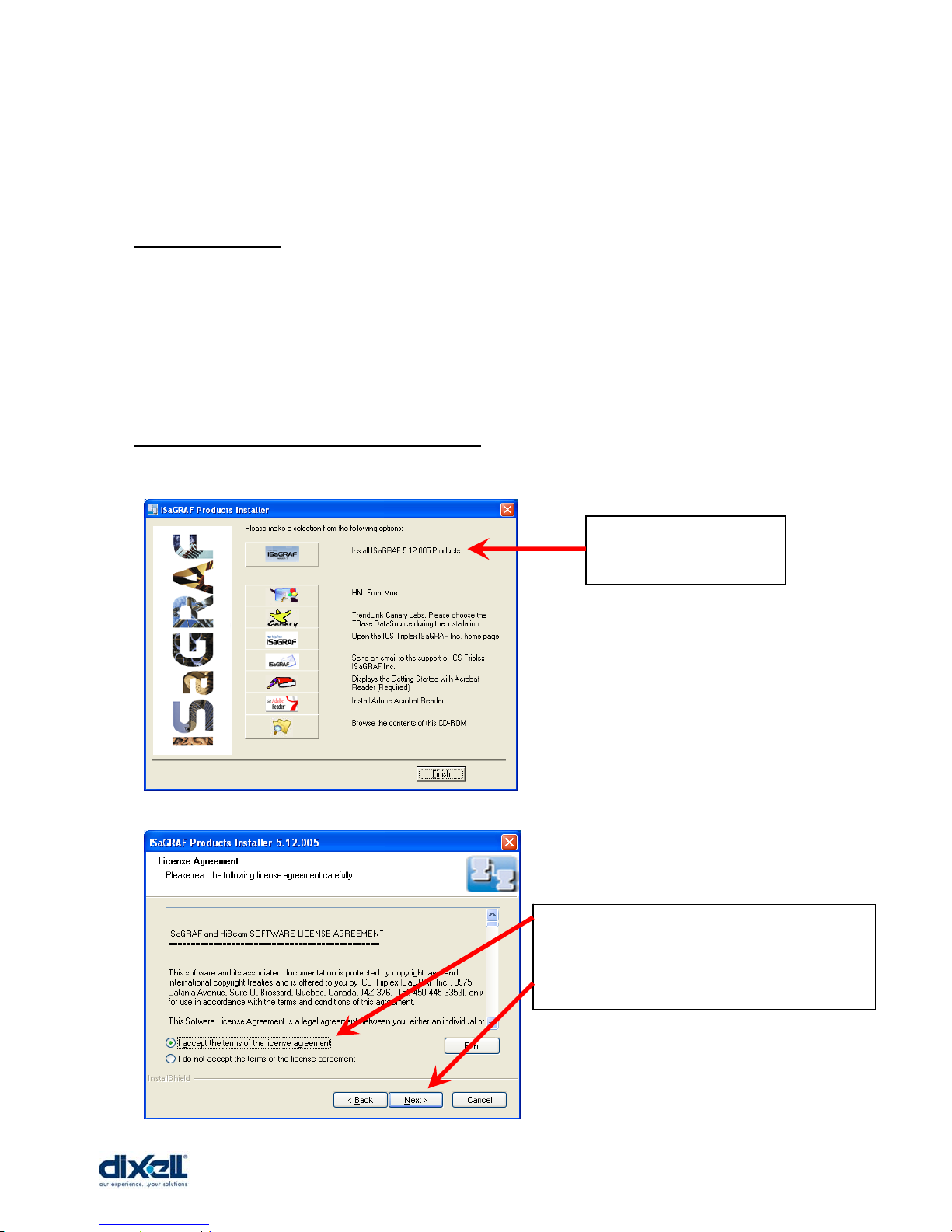

6.2 How to install the ISaGRAF software

Insert the CD in your computer; the CD will start automatically.

You have to choose

the first option.

You have to select: “ I accept the terms”

…and then: “Next”

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 29 -

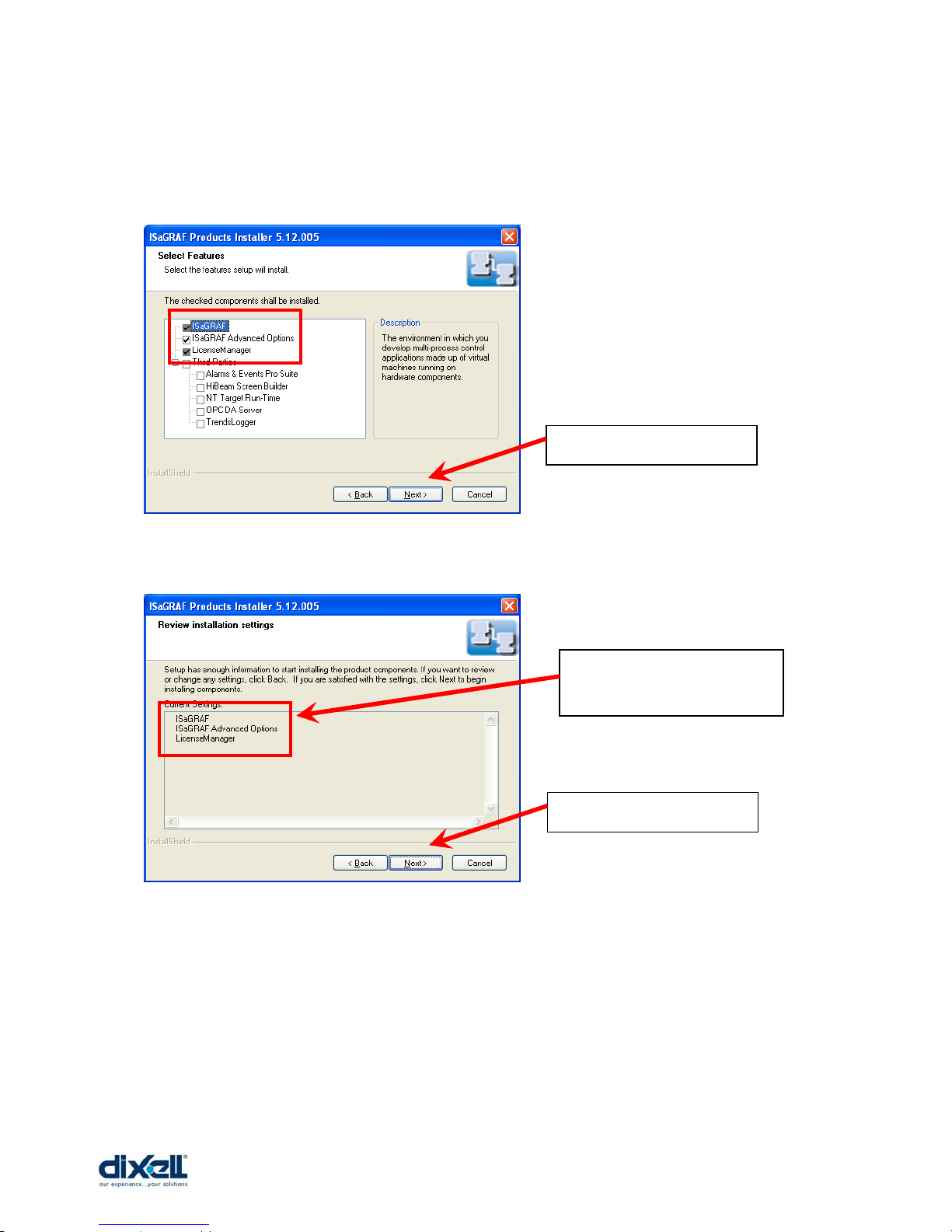

Please install ONLY the programs selected as showed here below:

…and then: “Next”

…and then: “Next”

These are the programs

that you are installing…

________________________________________________________________________________________________________

1592025400 – Vers. 1.0 - 30 -

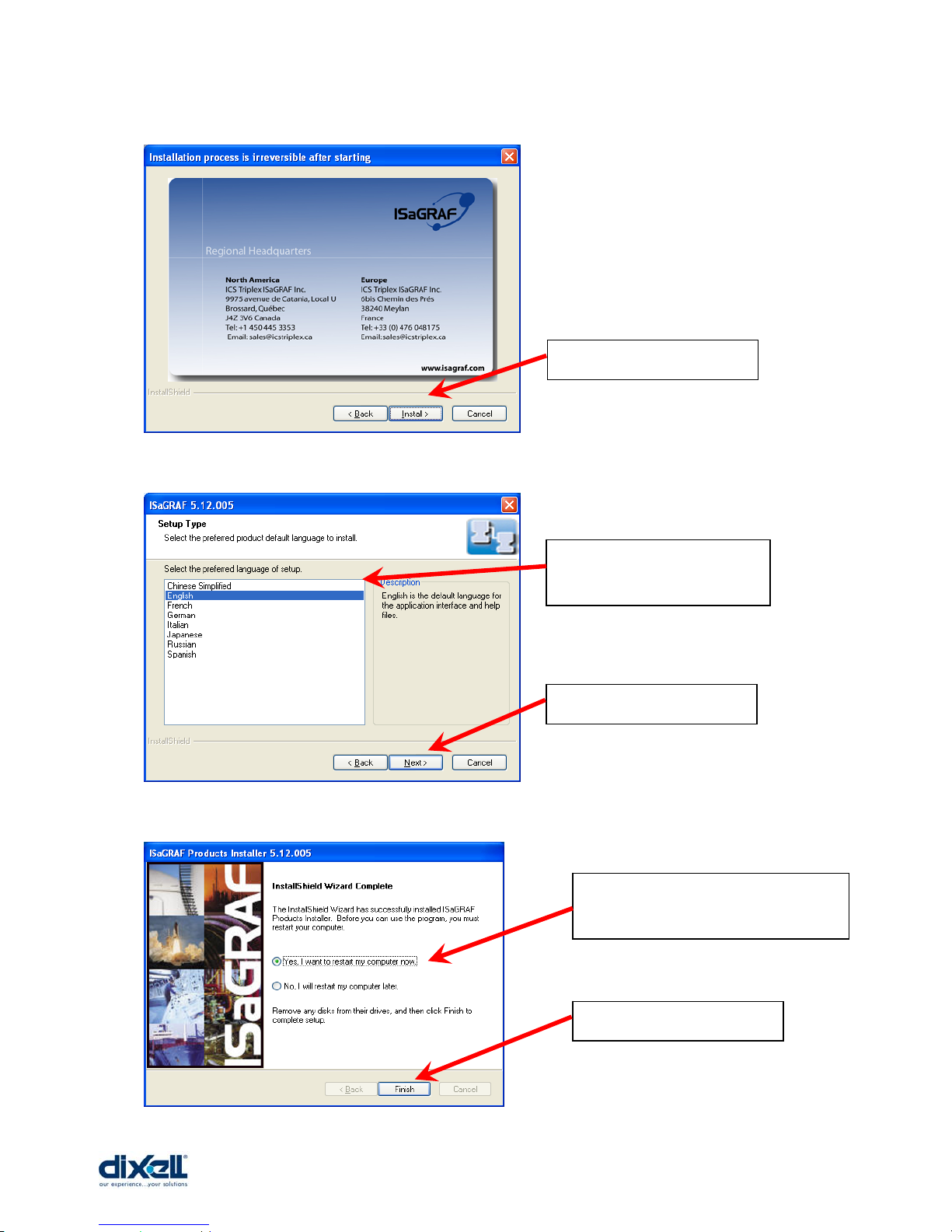

…select: “Install”

Choose the languages…

…select: “Next”

At the end of the installation,

please restart the computer

…select: “Finish”

Loading...

Loading...