dixell IPX125D, IPX225D, IPX115D, IPX215D, IPG108D Installing And Operating Insructions

...Page 1

iPro SERIES

(V.3.2)

Page 2

Page 3

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 3/72

INDEX

1. IMPORTANT RECOMMENDATIONS 5

1.1 PRODUCT DISPOSAL (WEEE) 6

2. INTRODUCTION 7

3. GENERAL SPECIFICATIONS 8

3.1 PROCESSING ENVIRONMENT 8

3.1.1 Fields of application ................................................................................................................................................................ 8

3.1.2 Hardware architecture ............................................................................................................................................................ 8

4. VERSIONS OF THE PROGRAMMABLE CONTROLLERS 10

4.1 IPRO.GENIUS AND IPRO.CHILL (IPG100D – IPC100D RANGES) 11

4.1.1 Description of the connections ............................................................................................................................................. 12

4.1.2 Description of the inputs and outputs ................................................................................................................................... 13

4.1.3 Technical specifications ....................................................................................................................................................... 16

4.1.3.1 Analogue inputs ........................................................................................................................................................... 16

4.1.3.2 Digital inputs ................................................................................................................................................................ 16

4.1.3.3 Analogue outputs ........................................................................................................................................................ 16

4.1.3.4 Standard Digital outputs .............................................................................................................................................. 17

4.1.3.5 SSR Digital outputs version ......................................................................................................................................... 17

4.1.3.6 Wiring diagrams .......................................................................................................................................................... 18

4.1.3.7 Mechanical specifications ............................................................................................................................................ 19

4.1.3.8 Electrical specifications ............................................................................................................................................... 19

4.1.3.9 Plastic container .......................................................................................................................................................... 19

4.1.3.10 Product certifications ................................................................................................................................................... 19

4.2 IPRO.GENIUS (IPG200D RANGE) 20

4.2.1 Description of the connections ............................................................................................................................................. 21

4.2.2 Description of the inputs and outputs ................................................................................................................................... 22

4.2.3 Technical specifications ....................................................................................................................................................... 24

4.2.3.1 Analogue inputs ........................................................................................................................................................... 24

4.2.3.2 Digital inputs ................................................................................................................................................................ 24

4.2.3.3 Analogue outputs ........................................................................................................................................................ 24

4.2.3.4 Digital outputs .............................................................................................................................................................. 24

4.2.3.5 Wiring diagrams .......................................................................................................................................................... 25

4.2.3.6 Mechanical specifications ............................................................................................................................................ 25

4.2.3.7 Electrical specifications ............................................................................................................................................... 25

4.2.3.8 Plastic container .......................................................................................................................................................... 26

4.2.3.9 Product certifications ................................................................................................................................................... 26

4.3 IPRO 4 DIN (IPG100D – IPG200D – IPC100E RANGES) 27

4.3.1 Description of the connections ............................................................................................................................................. 27

4.3.2 Description of the inputs and outputs ................................................................................................................................... 28

4.3.3 Technical specifications ....................................................................................................................................................... 29

4.3.3.1 Analogue inputs ........................................................................................................................................................... 29

4.3.3.2 Digital inputs ................................................................................................................................................................ 29

4.3.3.3 Analogue outputs ........................................................................................................................................................ 30

4.3.3.4 Digital outputs .............................................................................................................................................................. 30

4.3.3.5 Wiring diagrams .......................................................................................................................................................... 30

4.3.3.6 Mechanical specifications ............................................................................................................................................ 31

4.3.3.7 Electrical specifications ............................................................................................................................................... 31

4.3.3.8 Plastic container .......................................................................................................................................................... 31

4.3.3.9 USB-ETHERNET Adapter ........................................................................................................................................... 31

4.4 IPRO.LINK (IPL500D) 32

4.4.1 Description of the connections ............................................................................................................................................. 32

4.4.2 Description of the inputs and outputs ................................................................................................................................... 33

4.4.3 Technical specifications ....................................................................................................................................................... 33

4.4.3.1 Wiring diagrams .......................................................................................................................................................... 33

4.4.3.2 Mechanical specifications ............................................................................................................................................ 34

4.4.3.3 Electrical specifications ............................................................................................................................................... 34

4.4.3.4 Plastic container .......................................................................................................................................................... 34

4.5 IPX106D 35

4.5.1 Description of the connections ............................................................................................................................................. 35

4.5.2 Description of the inputs and outputs ................................................................................................................................... 36

4.5.3 Technical specifications ....................................................................................................................................................... 37

4.5.3.1 Analogue inputs ........................................................................................................................................................... 37

4.5.3.2 Digital inputs ................................................................................................................................................................ 37

4.5.3.3 Analogue outputs ........................................................................................................................................................ 37

4.5.3.4 Digital outputs .............................................................................................................................................................. 37

4.5.3.5 Wiring diagrams .......................................................................................................................................................... 38

4.5.3.6 Mechanical specifications ............................................................................................................................................ 38

4.5.3.7 Electrical specifications ............................................................................................................................................... 38

Page 4

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 4/72

4.5.3.8 Plastic container .......................................................................................................................................................... 39

4.5.3.9 Setting the address of the device ................................................................................................................................ 39

4.6 IPX125D – IPX115D 40

4.6.1 Description of the connections ............................................................................................................................................. 40

4.6.2 Description of the inputs and outputs ................................................................................................................................... 41

4.6.3 Technical specifications ....................................................................................................................................................... 43

4.6.3.1 Analogue inputs ........................................................................................................................................................... 43

4.6.3.2 Digital inputs ................................................................................................................................................................ 43

4.6.3.3 Analogue outputs ........................................................................................................................................................ 43

4.6.3.4 Digital outputs .............................................................................................................................................................. 44

4.6.3.5 Wiring diagrams .......................................................................................................................................................... 44

4.6.3.6 Mechanical specifications ............................................................................................................................................ 45

4.6.3.7 Electrical specifications ............................................................................................................................................... 45

4.6.3.8 Plastic container .......................................................................................................................................................... 45

4.6.3.9 Setting the address of the device ................................................................................................................................ 45

4.7 IPX225D – IPX215D 46

4.7.1 Description of the connections ............................................................................................................................................. 46

4.7.2 Description of the inputs and outputs ................................................................................................................................... 47

4.7.3 Technical specifications ....................................................................................................................................................... 49

4.7.3.1 Analogue inputs ........................................................................................................................................................... 49

4.7.3.2 Digital inputs ................................................................................................................................................................ 49

4.7.3.3 Analogue outputs ........................................................................................................................................................ 49

4.7.3.4 Digital outputs .............................................................................................................................................................. 50

4.7.3.5 Wiring diagrams .......................................................................................................................................................... 50

4.7.3.6 Mechanical specifications ............................................................................................................................................ 51

4.7.3.7 Electrical specifications ............................................................................................................................................... 51

4.7.3.8 Plastic container .......................................................................................................................................................... 51

4.7.3.9 Setting the address of the device ................................................................................................................................ 51

5. INTERFACE 52

5.1 VISOGRAPH 52

5.1.1 Specifications ....................................................................................................................................................................... 52

5.1.2 Connections ......................................................................................................................................................................... 53

5.1.3 Options menu ....................................................................................................................................................................... 53

5.1.4 Dimensions ........................................................................................................................................................................... 54

6. MEANING OF THE LEDS AND JUMPERS IN THE VARIOUS DEVICES 55

6.1 PROGRAMMABLE CONTROLLERS 55

6.2 EXPANSION MODULES 55

7. INSTALLATION 56

7.1 GENERAL RULES 56

7.2 POWER SUPPLY 56

7.3 CONNECTION OF THE ANALOGUE INPUTS 57

7.3.1 Temperature probes (NTC and PTC) ................................................................................................................................... 57

7.3.2 Pressure transducers and current probes (0 - 20mA, 4 - 20mA) ......................................................................................... 57

7.3.3 Pressure transducers and ratiometric pressure transducers (0 - 5V) ................................................................................... 58

7.3.4 Live probes (0 - 1V, 0 - 5V, 0 - 10V) ..................................................................................................................................... 58

7.3.5 Probes and transducers with 24Vac/dc power supply .......................................................................................................... 59

7.4 CONNECTION OF THE DIGITAL INPUTS 60

7.4.1 Potential-free digital inputs ................................................................................................................................................... 60

7.4.2 Live digital inputs (24Vac/dc) ............................................................................................................................................... 61

7.5 CONNECTION OF THE ANALOGUE OUTPUTS 61

7.5.1 0 - 10V, 4 - 20mA Analogue output for condensation control .............................................................................................. 62

7.5.2 PWM analogue output for condensation control .................................................................................................................. 63

7.5.3 0 - 10V, 4 - 20mA Proportional analogue output for servomotors/actuators ........................................................................ 63

7.5.4 Devices with 24Vac/dc power supply ................................................................................................................................... 64

7.5.5 Analogue output for relays (coil power supply 12Vdc) ......................................................................................................... 65

7.6 CONNECTION OF THE DIGITAL OUTPUTS 65

7.7 CANBUS CONNECTION 66

7.8 RS485 SLAVE CONNECTIONS 67

7.9 RS485 MASTER CONNECTION 68

Page 5

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 5/72

1. IMPORTANT RECOMMENDATIONS

¾ The symbol alerts the user of non-insulated “dangerous voltage” within the product area that

is sufficiently high to constitute a risk of electric shock to persons.

¾ The

symbol alerts the user of important operating and maintenance (assistance) instructions

found in the documentation attached to the device.

¾ Dixell Srl cannot accept any liability for damages caused by modems that are not supported. Dixell

Srl reserves the right to modify this manual without prior notice. The documentation can be

downloaded from www.dixell.com even prior to purchase.

¾ This manual forms part of the product and must always be kept near the device for easy and quick

reference. The device cannot be used as a safety device. Verify the limits of application before using

the device.

¾ Verify that the power supply voltage is correct before connecting the device. Do not expose it to

water or humidity: use the controller only within the operating limits, avoiding sudden changes in

temperature and high atmospheric humidity in order to prevent condensation from forming.

Recommendation: disconnect all the electric connections before performing any maintenance. Insert

the probe where it cannot be reached by the End User. The device must not be opened. Consider

the maximum current that can be applied to each relay. Make sure that the wires for the probes, the

loads and the electrical power supply are separated and sufficiently distant from each other, without

crossing or intertwining with each other. In the case of applications in industrial environments, it may

be useful to use the main filters (our mod. FT1) in parallel to the inductive loads.

¾ The customer shall bear full responsibility and risk for product configuration in order to achieve the

results pertaining to installation and/or final equipment/system. Upon the customer's request and

following a specific agreement, Dixell s.r.l. may be present during the start-up of the final

machine/application, as a consultant, however, under no circumstances can the company be held

responsible for the correct operation of the final equipment/system.

¾ Since Dixell products form part of a very high level of technology, a

qualification/configuration/programming/commissioning stage is required to use them as best as

possible. Otherwise, these products may malfunction and Dixell cannot be held responsible. The

product must not be used in any way that differs from that stipulated in the documentation.

• The device must always be inserted inside an electrical panel that can only be accessed by

authorised personnel. For safety purposes, the keyboard must be the only part that can be reached.

• The device must never be hand-held while being used.

¾ It is good practice to bear the following in mind for all Dixell products:

o Prevent the electronic circuits from getting wet as contact made with water, humidity or any

other type of liquid can damage them. Comply with the temperature and humidity limits

specified in the manual in order to store the product correctly.

o The device must not be installed in particularly hot environments as high temperatures can

damage it (electronic circuits and/or plastic components forming part of the casing). Comply

with the temperature and humidity limits specified in the manual in order to store the product

correctly.

Page 6

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 6/72

o Under no circumstances is the device to be opened - the user does not require the internal

components. Please contact qualified service personnel for any assistance.

o Prevent the device from being dropped, knocked or shaken as either can cause irreparable

damage.

o Do not clean the device with corrosive chemical products, solvents or aggressive detergents.

o The device must not be used in applications that differ from that specified in the following

material.

¾ Separate the power of the device from the rest of the electrical devices connec ted inside the

electrical panel. The secondary of the transformer must never be connected to the earth.

¾ Dixell Srl reserves the right to change the composition of its products, even without notice,

ensuring the same and unchanged functionality."

1.1 PRODUCT DISPOSAL (WEEE)

With reference to Directive 2002/96/EC of the European Parliament and of the Council of 27 January

2003 and to the relative national legislation, please note that:

¾ There lies the obligation not to dispose of electrical and electronic waste as municipal waste but to

separate the waste.

¾ Public or private collection points must be used to dispose of the goods in accordance with local

laws. Furthermore, at the end of the product's life, it is also possible to return this to the retailer when

a new purchase is made.

¾ This equipment may contain hazardous substances. Improper use or incorrect disposal can have

adverse effects on human health and the environment.

¾ The symbol shown on the product or the package indicates that the product has been placed on the

market after 13 August 2005 and must be disposed of as separated waste.

¾ Should the product be disposed of incorrectly, sanctions may be applied as stipulated in applicable

local regulations regarding waste disposal.

Page 7

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 7/72

2. INTRODUCTION

iPRO is the range of programmable controllers manufactured by Dixell.

The range consists of programmable controllers, I/O expansions, drivers for electronic valves and graphical

interfaces adapted to cover any type of application in the air-conditioning sector, cooling sector and any

relative area. As the system is one of the most technologically advanced, it is flexible and can be customised

for it to be adapted to the user’s particular requirements.

Page 8

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 8/72

3. GENERAL SPECIFICATIONS

The Dixell programmable controllers are all powered at 24Vac/dc and use a high speed performance 32-bit

ARM9 (200 MHz) microprocessor. The models differ in size (10 DIN or 4 DIN) and number of inputs and

outputs (analogue and digital).

One of the features that distinguishes the iPRO controllers is the vast range of connection options with

external devices, Dixell as well as other brands. CANBus, RS485 Master and Slave, and an Ethernet and

USB port provide maximum flexibility of integration with the outside world. MODBUS RTU protocol, one of

the most popular in the world, is used for serial communication.

Up to 80 MB of flash memory are entirely available to the user, according to the model. All the inputs and

outputs are fully configurable.

3.1 PROCESSING ENVIRONMENT

All Dixell programmable controllers use the following software as a processing environment:

¾ ISaGRAF® to process the iPRO application.

¾ VISOPROG to process the LCD graphic interface application (VISOGRAPH)

ISaGRAF® software is used worldwide and allows those with no programming experience to build

applications ranging from the simplest to the more sophisticated. The vast range of the most popular

programming languages (Structured Text, Function Block Diagram, Ladder Diagram, Instruction List,

Sequential Function Chart, Flow Chart, FBD IEC 61499) provides all programmers with access to the

processing environment. Thanks also to the extensive libraries of blocks already developed by Dixell, the

processing and debug times are reduced.

The SIMULATION (verification of the application without using the controller) and DEBUG options

(verification of the actual application within the controller), allow the user to block and force the value of the

variables to speed up the testing times.

3.1.1 Fields of application

The possibility of all-round configuration allows the Dixell iPRO programmable controller to be used for any

type of application. The same applications can be downloaded in the various models available (obviously

adapting the number of inputs and outputs).

The hardware has already been used for the following applications:

¾ Chillers and heat pumps

¾ Air treatment units

¾ Air-conditioners

¾ Roof-tops

¾ Cooling systems

¾ Energy saving management in systems

¾ Climatic chamber control

¾ Cold rooms and seasoner cabinets

3.1.2 Hardware architecture

The iPRO programmable controller is structured as follows:

• 32-bit microprocessor used to run the application

• Removable connectors (Molex) or bayonet connectors (Phoenix)

• The programme and parameters are stored in a permanent flash memory. No data is lost in case of

power failure.

• Internal web server with the Dixell website as default with the option of downloading a customised

website for reading and writing variables with synoptic creation (via HTML).

• Ethernet port.

• USB port.

• Connection to the dedicated remote LCD display.

• CANBus.

Page 9

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 9/72

• RS485 Master.

• RS485 Slave.

The remote LCD display has the following features:

• 240x96 pixel LCD graphic display.

• 32-bit processor.

• Multilingual in ASCII or UNICODE version.

• 8 fully programmable keys.

• Panel or wall mounted.

The LED display (only for the IPS versions) has the following features:

• Configurable digits and icons

• 6 fully programmable keys

Page 10

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 10/72

4. VERSIONS OF THE PROGRAMMABLE CONTROLLERS

10 DIN versions:

• IPRO.GENIUS

o IPG115D (15 relays, no application, disconnectable connectors)

o IPG215D (15 relays, no application, spring connectors)

• IPRO.CHILL

o IPC115D (15 relays, with application chiller/heatpump, disconnectable connectors )

o IPC115D SSR (15 relays, with application chiller/heatpump, disconnectable connectors)

• EXPANSION

o IPX125D (25 relay, disconnectable connectors)

o IPX225D (25 relay, spring connectors)

o IPX115D (15 relay, disconnectable connectors)

o IPX215D (15 relay, spring connectors)

4 DIN versions:

• IPRO.GENIUS

o IPG108D (8 relays, no application, disconnectable+screw connectors)

o IPG208D (8 relays, no application, spring+screw connectors)

o IPG108E (8 relays, LED display, without application, diconnectable+screw connectors)

o IPG208E (8 relays, LED display, without application, spring+screw connectors)

• IPRO.CHILL

o IPC108E (8 relays, LED display, with application chiller/heatpump, diconnectable+screw

connectors)

• IPRO.LINK

o IPL500D (connectivity module)

• EXPANSION

o IPX106D (6 relay, disconnectable connectors)

o IPX206D (6 relay, spring+screw connectors)

o IPX306D (6 relay, disconnectable+screw connectors)

• ELECTRONIC VALVE DRIVER

o XEV20D (driver for electronic valve – up to 2 valves per driver)

Page 11

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 11/72

4.1 IPRO.GENIUS AND IPRO.CHILL (IPG100D – IPC100D RANGES)

Page 12

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 12/72

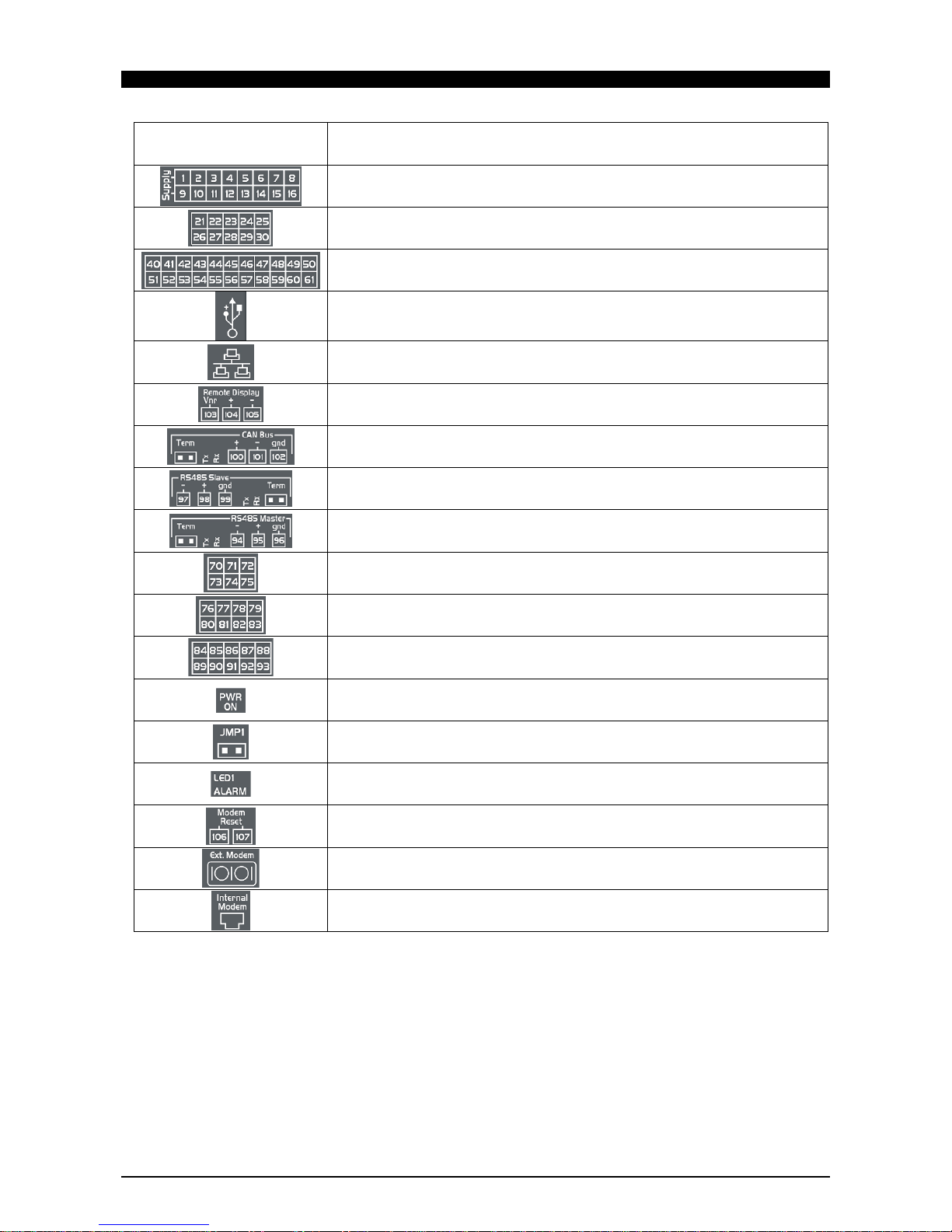

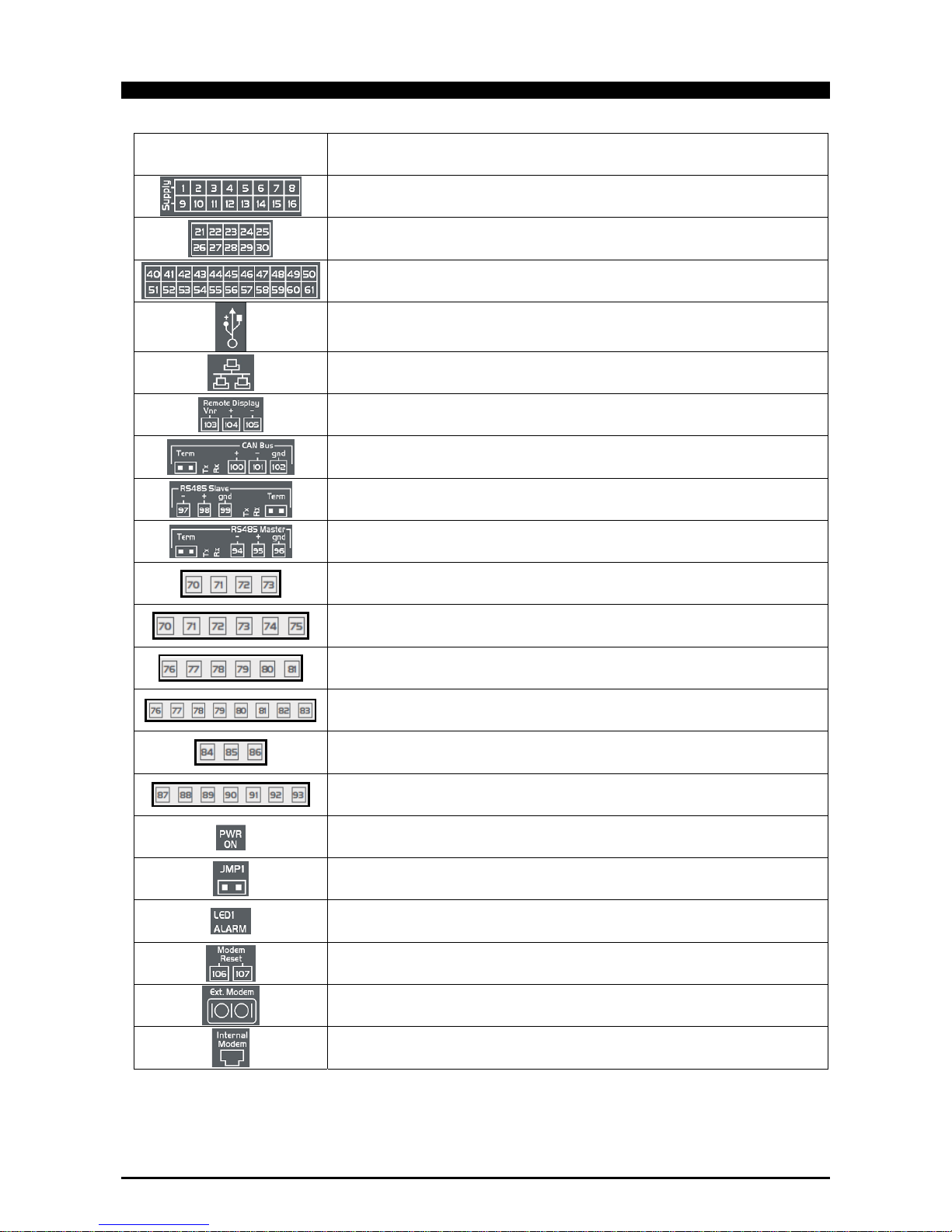

4.1.1 Description of the connections

Connector Description

Connector for 24Vac/dc power supply

Analogue inputs (Pb1 - Pb10, PbC)

Additional power (+5Vdc, +12Vdc, GND)

Analogue outputs (Out1 - Out6, TF1 - T2)

Additional power (+12Vdc, GND)

Potential free opto-insulated digital inputs (DI1 - DI20, DIC)

USB port for downloads (BIOS, ISaGRAF® application, maps of parameters, remote display

applications, network configuration, website) and uploads (log files)

TCP/IP Ethernet port

Connector for remote terminal (VISOGRAPH), maximum 2 terminals per iPRO.

CANBUS connector for expansions (IPEXx0D) and drivers for electronic valves (XEVx0D

Rx and Tx LED to indicate that communication is active

Closed circuit terminal (Term)

RS485 Slave connector

Rx and Tx LED to indicate that communication is active

Closed circuit terminal (Term)

RS485 Master connector

Rx and Tx LED to indicate that communication is active

Closed circuit terminal (Term)

Digital relay outputs (115D, 110D, 415D, 410D versions)

3 NO relays + 1 changeover relay, 1 common

Digital relay outputs (115D, 110D, 415D, 410D versions)

6 NO relays, 2 common

Digital relay outputs (only for 115D and 415D versions)

3 NO relays + 2 changeover relays, 3 common (for 115D and 415D versions)

5 relays SSR (for 415D SSR version) *** different connection ***

Green LED to indicate the presence of power

Jumper to activate the RESCUE MODE

Yellow status LEDs (LED1) and red LED (ALARM)

See relative paragraph

Connector for NC contact to reset an external modem

RS232 connector for an external GSM modem connection (SIEMENS TC35)

Connector for an internal analogue modem

Page 13

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 13/72

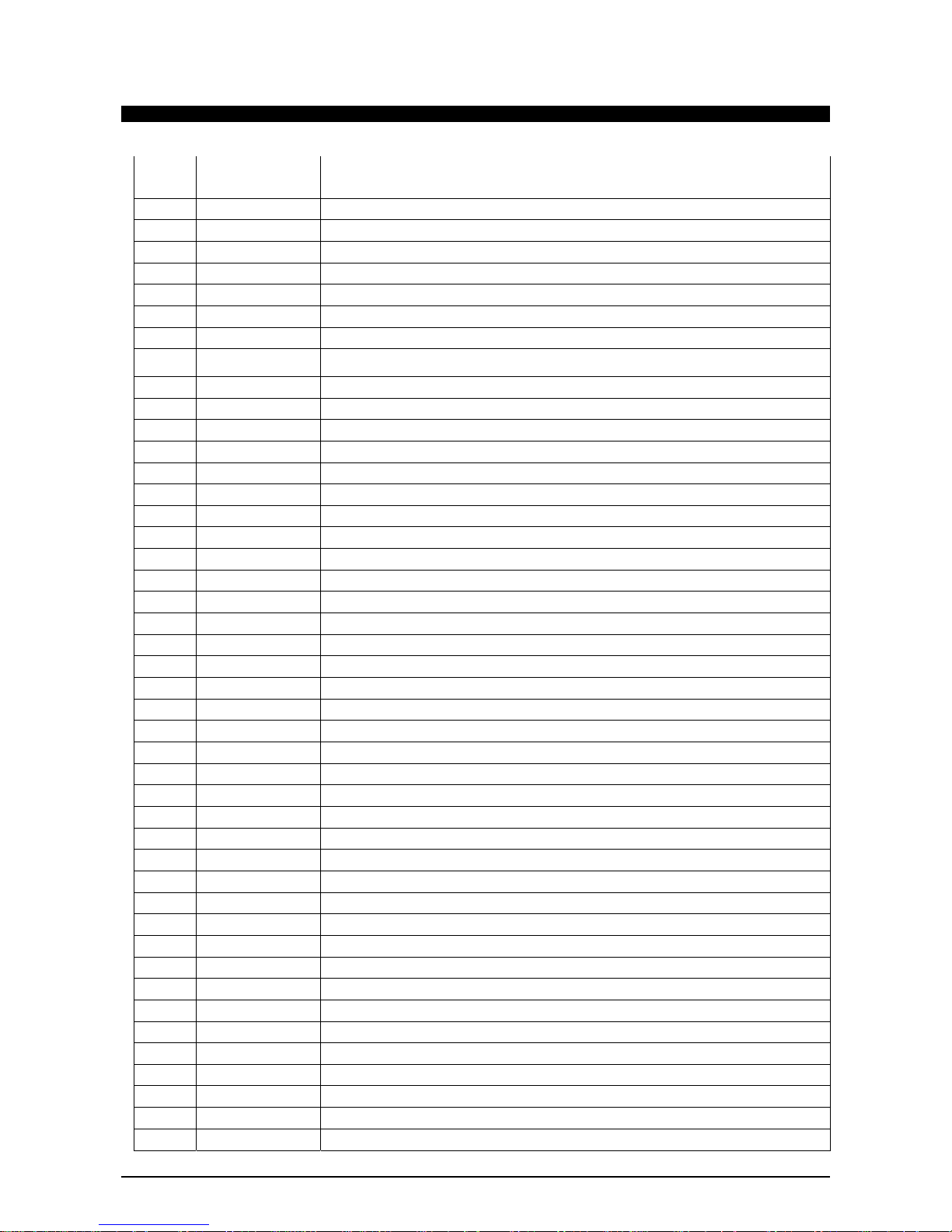

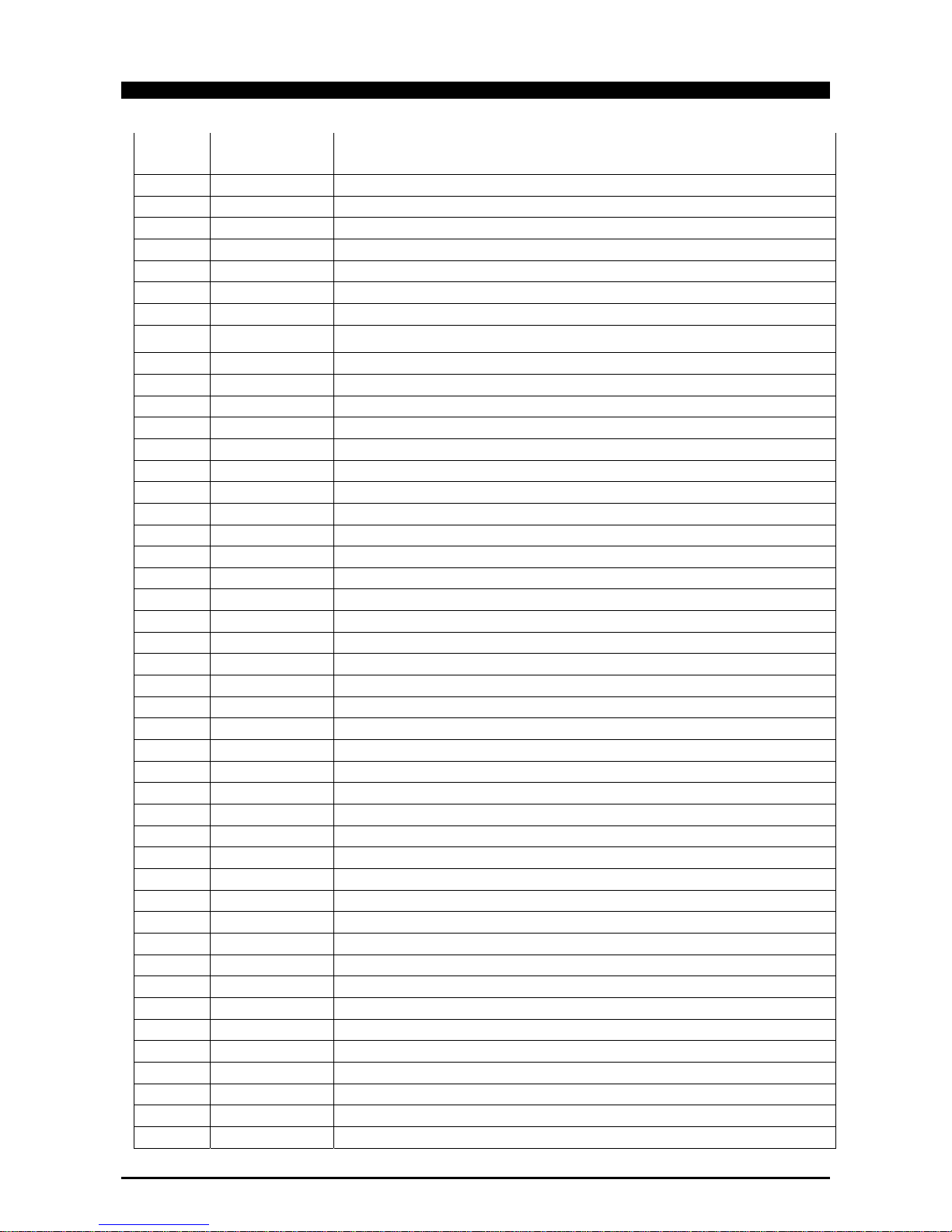

4.1.2 Description of the inputs and outputs

Input

No.

Type of Input Description

1 Supply Reference “-“/GND power (24Vac or 24Vdc)

2 Pb1 Configurable analogue input 1 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

3 Pb2 Configurable analogue input 2 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

4 Pb3 Configurable analogue input 3 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

5 Pb4 Configurable analogue input 4 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

6 Pb5 Configurable analogue input 5 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

7 PbC Common analogue inputs (NTC, PTC, DI)

8 GND (-)

Additional power reference 5Vdc and 12Vdc and analogue inputs (0 - 20mA, 4 - 20mA, 0 - 10V,

0 - 1V, 0 - 5V)

9 Supply Reference “+“ power supply (24Vac or 24Vdc)

10 Pb6 Configurable analogue input 6 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

11 Pb7 Configurable analogue input 7 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

12 Pb8 Configurable analogue input 8 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

13 Pb9 Configurable analogue input 9 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

14 Pb10 Configurable analogue input 10 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

15 +5V Additional power +5Vdc

16 +12V Additional power +12Vdc

21 Out1 Analogue output 1 0 - 10V

22 Out2 Analogue output 2 0 - 10V

23 Out3 Analogue output 3 0 - 10V

24 Out4 Analogue output 4 0 - 10V

25 GND(-) Additional power reference 12Vdc and analogue outputs

26 Out5 Analogue output 5 0 - 10V, 4 - 20mA, Relay (if TF1 is not used)

27 Out6 Analogue output 6 0 - 10V, 4 - 20mA, Relay (if TF2 is not used)

28 TF1 Analogue output TF1 PWM (if Out5 is not used)

29 TF2 Analogue output TF2 PWM (if Out6 is not used)

30 +12V Additional power +12Vdc

40 DI1 Opto-insulated digital input 1 (potential free contact)

41 DI2 Opto-insulated digital input 2 (potential free contact)

42 DI3 Opto-insulated digital input 3 (potential free contact)

43 DI4 Opto-insulated digital input 4 (potential free contact)

44 DI5 Opto-insulated digital input 5 (potential free contact)

45 DI6 Opto-insulated digital input 6 (potential free contact)

46 DI7 Opto-insulated digital input 7 (potential free contact)

47 DI8 Opto-insulated digital input 8 (potential free contact)

48 DI9 Opto-insulated digital input 9 (potential free contact)

49 DI10 Opto-insulated digital input 10 (potential free contact)

50 DIC Common opto-insulated digital inputs 1 to 20

51 DI11 Opto-insulated digital input 11 (potential free contact)

52 DI12 Opto-insulated digital input 12 (potential free contact)

53 DI13 Opto-insulated digital input 13 (potential free contact)

54 DI14 Opto-insulated digital input 14 (potential free contact)

55 DI15 Opto-insulated digital input 15 (potential free contact)

56 DI16 Opto-insulated digital input 16 (potential free contact)

57 DI17 Opto-insulated digital input 17 (potential free contact)

Page 14

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 14/72

58 DI18 Opto-insulated digital input 18 (potential free contact)

59 DI19 Opto-insulated digital input 19 (potential free contact)

60 DI20 Opto-insulated digital input 20 (potential free contact)

61 DIC Common digital inputs 1 to 20

70 RL1 Relay 1 normally open contact

71 RL2 Relay 2 normally open contact

72 RL3 Relay 3 normally open contact

73 C Common relays 1, 2, 3 and 4 (MAX 6A)

74 RL4 Relay 4 normally open contact

75 RL3 Relay 3 normally closed contact

76 C Common relays 5, 8 and 9 (MAX 6A)

77 RL5 Relay 5 normally open contact

78 RL6 Relay 6 normally open contact

79 RL7 Relay 7 normally open contact

80 RL8 Relay 8 normally open contact

81 RL9 Relay 9 normally open contact

82 RL10 Relay 10 normally open contact

83 C Common relays 6, 7 and 10 (MAX 6A)

84 RL11 Relay 11 normally open contact

85 RL12 Relay 12 normally open contact

86 RL13 Relay 13 normally open contact

87 C Common relays 12, 13 and 15 (MAX 6A)

88 C Common relays 12, 13 and 15 (MAX 6A)

89 RL11 Relay 11 normally closed contact

90 C Common relays 11 and 14 (MAX 6A)

91 RL14 Relay 14 normally open contact

92 RL14 Relay 14 normally closed contact

93 RL15 Relay 15 normally open contact

94 RS485 Master RS485 Master connection (-)

95 RS485 Master RS485 Master connection (+)

96 RS485 Master RS485 Master connection (insulated gnd)

97 RS485 Slave RS485 Slave connection (-)

98 RS485 Slave RS485 Slave connection (+)

99 RS485 Slave RS485 Slave connection (insulated gnd)

100 CAN Bus CAN Bus connection (+), not open

101 CAN Bus CAN Bus connection (-), not open

102 CAN Bus CAN Bus connection (insulated gnd), not open

103 Remote Display Connection for VISOGRAPH remote terminal (Vnr)

104 Remote Display Connection for VISOGRAPH remote terminal (+)

105 Remote Display Connection for VISOGRAPH remote terminal (-)

106 Modem Reset NC relay input to reset an external modem (24Vac/dc)

107 Modem Reset NC relay output to reset an external modem (24Vac/dc)

Version with SSR relay

84 RL11 Relay 11 normally open contact

85 RL11 Common relays 11

86 RL12 Relay 12 normally open contact

87 RL12 Common relays 12

88 RL13 Common relays 13

Page 15

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 15/72

89 RL14 Relay 14 normally open contact

90 RL14 Common relays 14

91 RL15 Relay 15 normally open contact

92 RL15 Common relays 15

93 RL13 Relay 13 normally open contact

Page 16

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 16/72

4.1.3 Technical specifications

4.1.3.1 Analogue inputs

Analogue conversion type: 10-bit A/D converter

Number of inputs: 10

Type of analogue input:

(configurable via software parameter)

NTC Dixell (-50T110°C; 10KΩ±1% at 25°C)

PTC Dixell(-55T115°C; 990Ω±1% at 25°C)

Digital input (potential free contact)

Voltage: 0 - V, 0 - 5V, 0 - 10V (input resistance 3.7KΩ )

Current: 0 - 20mA, 4 - 20mA (input resistance 100Ω)

Digital input status variation detection time: 100ms (in any case it depends on the cycle time set by the user in the

given application)

Accuracy: NTC, PTC: ±1°C

0-1V: ±20mV

0-5V: ±100mV

0-10V: ±200mV

2-20mA, 4-20mA: ±0.30mA

Additional power: +12V: 200mA in total (between +12V and analogue outputs)

+5v: 100mA

Notes: Any inputs that are powered with a voltage that differs from that supplied

by the device (+12V or +5V) must be powered separately with another

transformer (do not use the same secondary of the controller's power) in

order to prevent the inputs from malfunctioning or being damaged.

4.1.3.2 Digital inputs

Type:

(configurable via software parameter)

Opto-insulated potential free contact

Number of inputs: 20

Digital input status variation detection time: 100ms (in any case it depends on the cycle time set by the user in the

given application)

Notes: Do not use live contacts in order to prevent the inputs from being

damaged.

4.1.3.3 Analogue outputs

Type: Non opto-insulated internal power

Number of outputs: 6

Type of analogue output:

(configurable via software parameter)

4 fixed outputs 0-10Vdc (Out1 - Out4)

2 configurable outputs (alternative):

- 0-10Vdc, 4-20mA (Out5 and Out6)

- PWM to be used with Dixell XV modules (TF1 and TF2)

Maximum load: 40mA (Out1 - Out4)

20mA (Out5 and Out6) max with configured outputs 0-10Vdc

400Ω max with configured outputs 4-20mA

22Ω per live analogue output

Accuracy: Out1 - Out4: ±2% full scale

Out5 – Out6: ±2% full scale

Resolution: 8bit

Notes: The electrical devices controlled by these analogue outputs must be

powered separately with another transformer (do not use the same

secondary of the controller's power) in order to prevent the outputs from

malfunctioning or being damaged.

Page 17

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 17/72

4.1.3.4 Standard Digital outputs

Type: Relays with NO or NC contacts, depending on the model

Number of outputs: 10 or 15, depending on the model

Type of output:

(configurable via software parameter)

Relays with normally open contact:

- RL1, RL2, RL4, RL5, RL6, RL7, RL8, RL9, RL10, RL12, RL13, RL15

Relays with changeover contact:

- RL3, RL11, RL14

Maximum load: Relays with normally open contact: 5A(250Vac) SPST 5(2)A

Relays with changeover contact: 8A(250Vac) SPDT 8(3)A

Notes: Verify the capacity of the output used. There is double insulation between

the digital outputs and the low voltage of the rest of the circuit.

Do not use different voltages for the various groups of relays nor within

each group.

4.1.3.5 SSR Digital outputs version

Type: Relays with NO or NC contacts, depending on the model

Number of outputs: 10 or 15, depending on the model

Type of output:

(configurable via software parameter)

Relays with normally open contact:

- RL1, RL2, RL4, RL5, RL6, RL7, RL8, RL9, RL10, RL11, RL12, RL13,

RL14, RL15

Relays with changeover contact:

- RL3

Maximum load: Relays with normally open contact: 5A(250Vac) SPST 5(2)A

Relays with changeover contact: 8A(250Vac) SPDT 8(3)A

SSR relays with normally open contact 1A(12 - 250Vac):

- only in AC load

- minimum current is 50mA (equivalent to 12W - 250Vac)

- internal impedance 300KΩ (current 0.2mA at 250Vac with an open

contact)

Notes: Verify the capacity of the output used. There is double insulation between

the digital outputs and the low voltage of the rest of the circuit.

Do not use different voltages for the various groups of relays nor within

each group.

Page 18

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 18/72

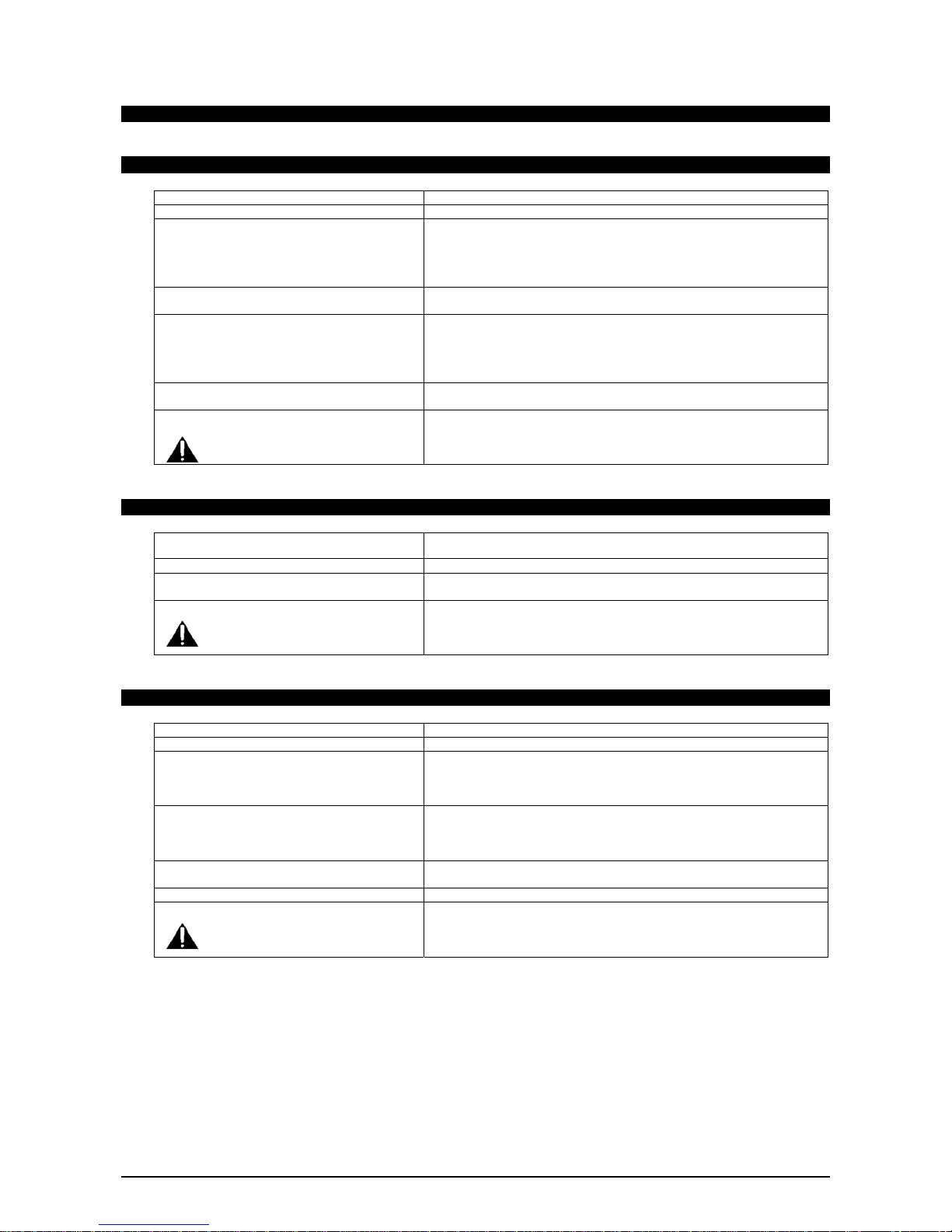

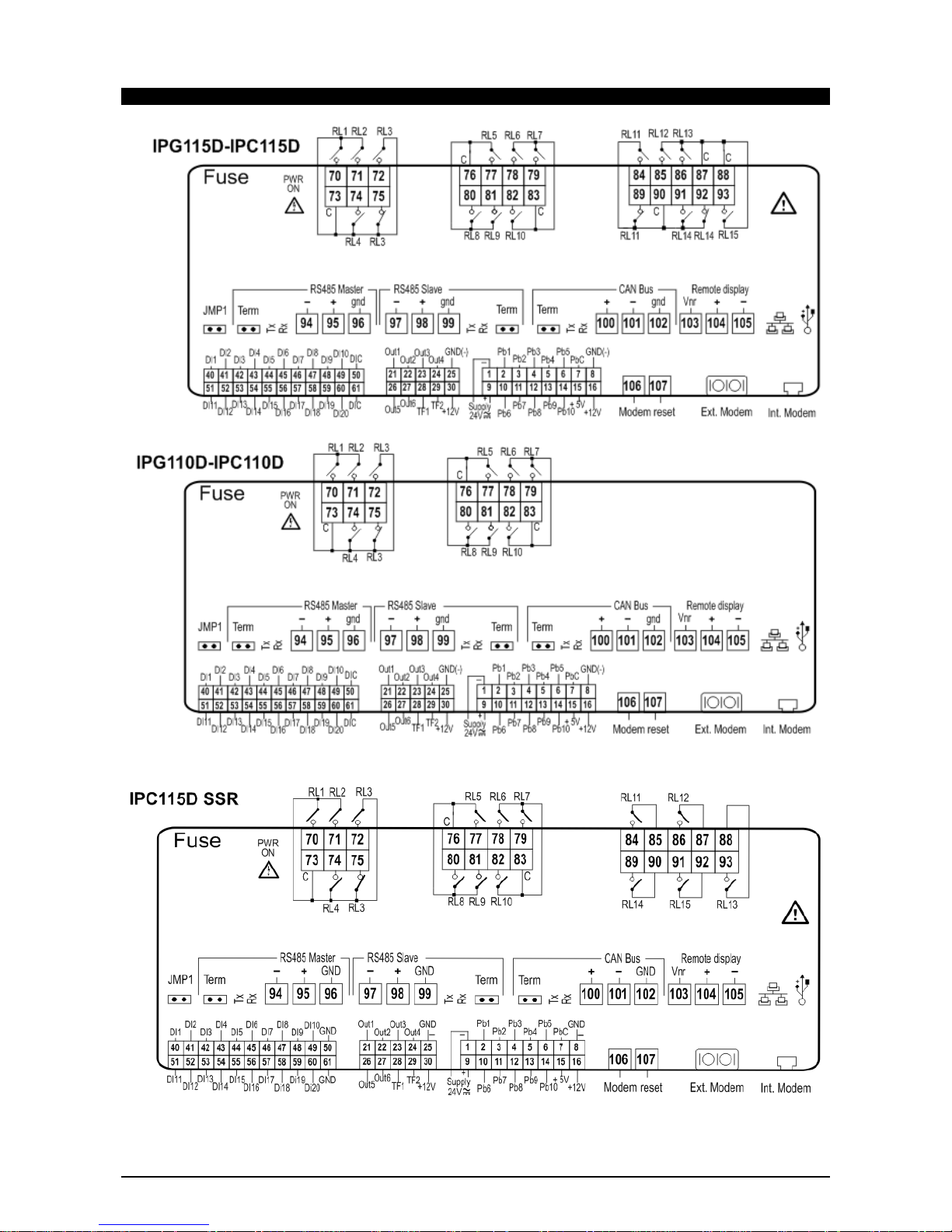

4.1.3.6 Wiring diagrams

Page 19

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 19/72

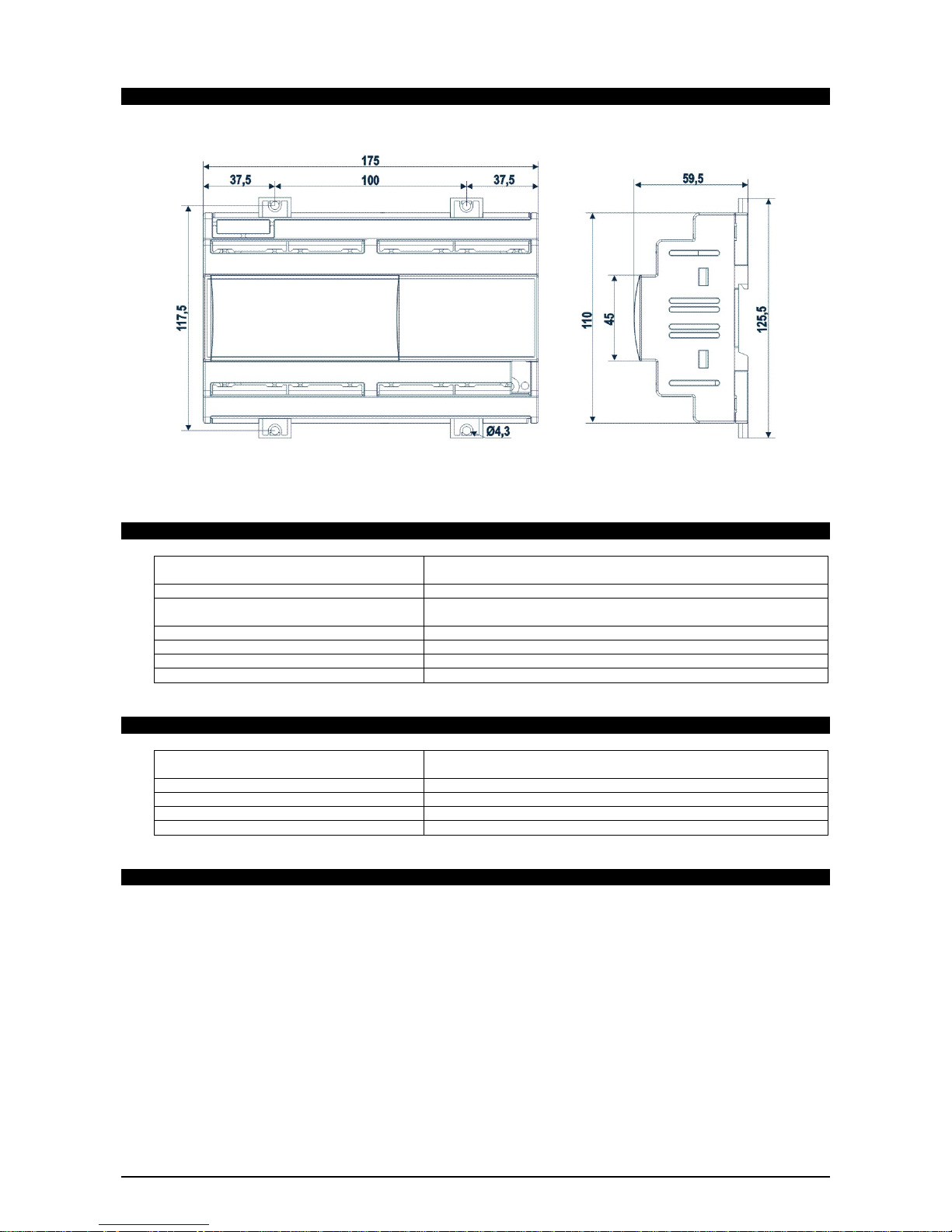

4.1.3.7 Mechanical specifications

10 DIN module

4.1.3.8 Electrical specifications

Power Supply: 24Vac +10/-15%, 50/60Hz

20 - 36Vdc

Consumption: 20VA (Vac), 15W (Vdc)

Connectors: Molex connectors with low voltage wiring

SELECOM/CIVILUX connectors for digital outputs (250Vac, 6A max)

Microprocessor: AT91RM9200 32-bit 200Mhz

Permanent FLASH memory: 128MB, in 8-bit

RAM: 32MB or 64MB, in 16-bit

Internal clock: standard

4.1.3.9 Plastic container

Mount: On a DIN rail (EN 50022, DIN 43880)

Fastened with screws via the removable plastic flaps.

Material: PC-ABS Thermoplastic

Self-extinguishing: V0 (UL94)

Comparative Tracking Index (CTI): 300V

Colour: Black

4.1.3.10 Product certifications

Control to classify with the definitions 2.5.1 e 2.5.2 mentioned in the section 2.5 of the general

requirements EN60730-1 (2.5.1 = integrated control, 2.5.2 = incorporated control).

Electrical safety:

• EN60730-1

Electromagnetic compatibility:

• EN61000-4-2, EN61000-4-3, EN61000-4-4, EN61000-4-5, EN61000-4-6, EN61000-4-8,

EN61000-4-11

Page 20

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 20/72

4.2 IPRO.GENIUS (IPG200D RANGE)

Page 21

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 21/72

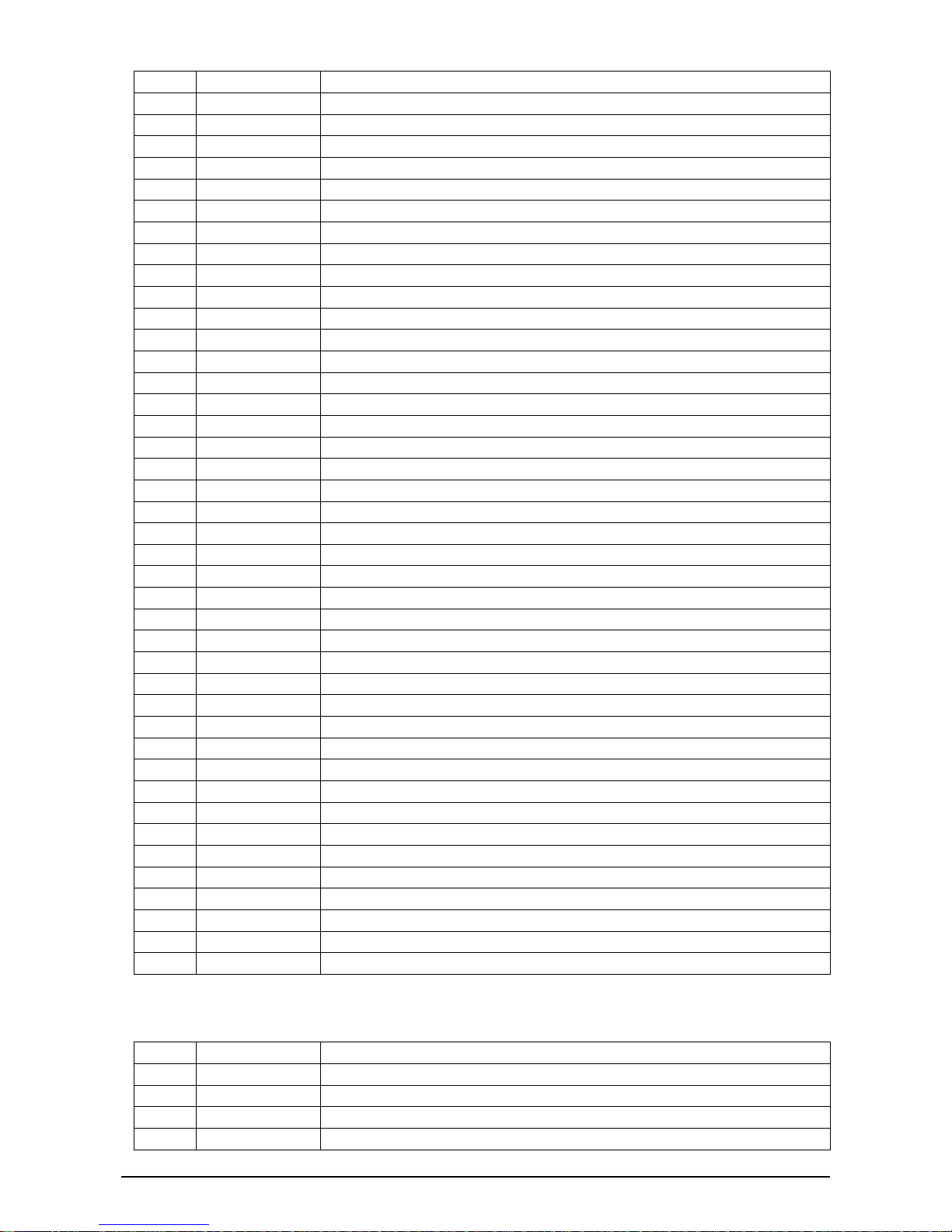

4.2.1 Description of the connections

Connector Description

Connector for 24Vac/dc power supply

Analogue inputs (Pb1 - Pb10, PbC)

Additional power (+5Vdc, +12Vdc, GND)

Opto-insulated analogue outputs (Out1 - Out6, GND)

24Vac/dc power supply for the opto-insulated analogue output

Potential free opto-insulated digital inputs (DI1 - DI20, DIC)

Opto-insulated 24Vac/dc digital inputs (DI1 - DI20, GND)

USB port for downloads (BIOS, ISaGRAF® application, maps of parameters, remote display

applications, network configuration, website) and uploads (log files)

TCP/IP Ethernet port

Connector for remote terminal (VISOGRAPH), maximum 2 terminals per iPRO.

CANBUS connector for expansions (IPEXx0D) and drivers for electronic valves (XEVx0D

Rx and Tx LED to indicate that communication is active

Closed circuit terminal (Term)

RS485 Slave connector

Rx and Tx LED to indicate that communication is active

Closed circuit terminal (Term)

RS485 Master connector

Rx and Tx LED to indicate that communication is active

Closed circuit terminal (Term)

Digital relay outputs (for digital outputs with potential free contacts)

3 NO relays, 1 common

Digital relay outputs (for digital outputs with live contacts)

3 NO relays, 1 common and 2 potential free (Neutral)

Digital relay outputs (for digital outputs with potential free contacts)

5 NO relays, 1 common

Digital relay outputs (for digital outputs with live contacts)

5 NO relays, 1 common and 2 potential free (Neutral)

Digital relay outputs

2 NO relays, 1 common

Digital relay outputs (only for 215D versions)

5 NO relays, 1 common and 1 potential free (Neutral)

Green LED to indicate the presence of power

Jumper to activate the RESCUE MODE

Yellow status LEDs (LED1) and red LED (ALARM)

See relative paragraph

Connector for NC contact to reset an external modem

RS232 connector for an external GSM modem connection (SIEMENS TC35)

Connector for an internal analogue modem

Page 22

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 22/72

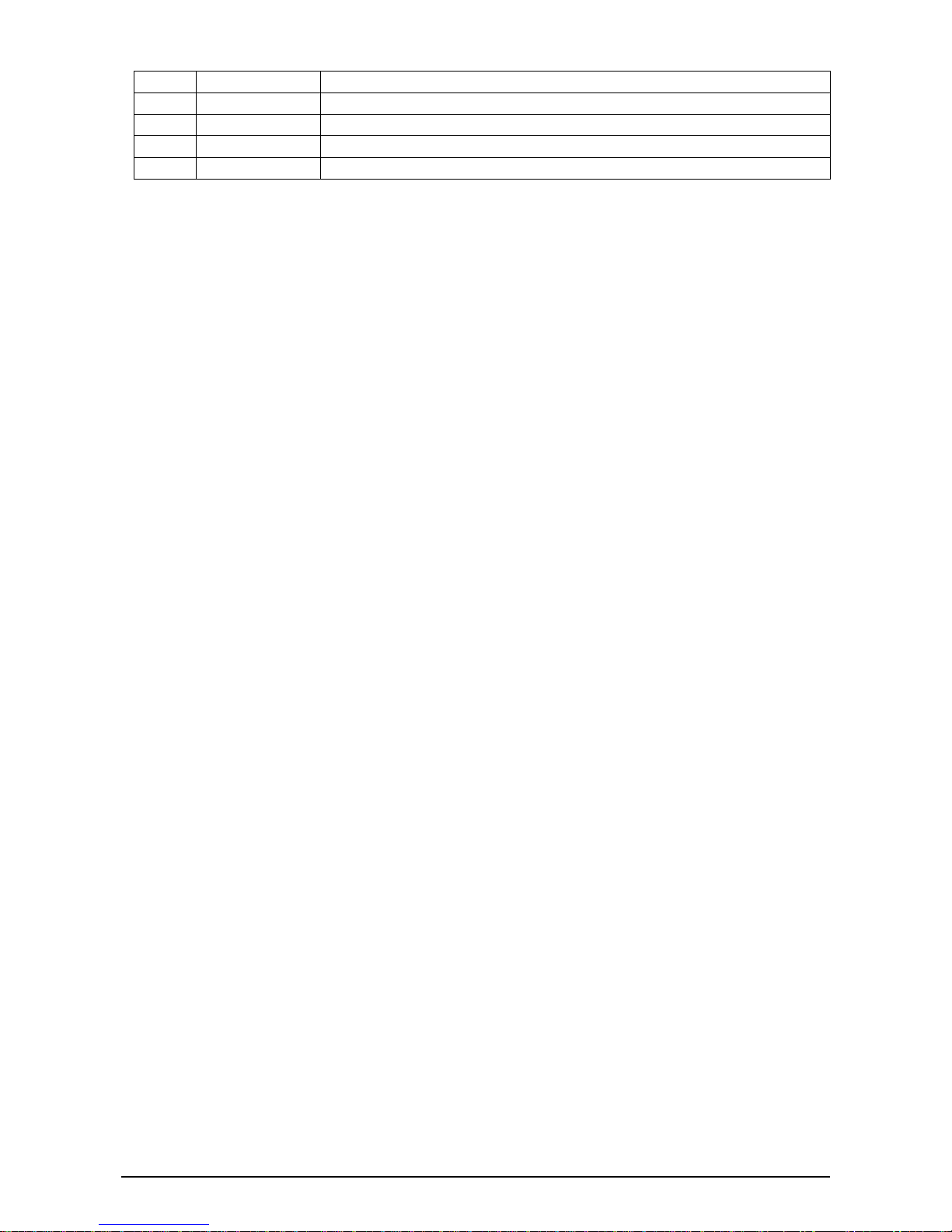

4.2.2 Description of the inputs and outputs

Input

No.

Type of Input Description

1 Supply Reference “-“/GND power (24Vac or 24Vdc)

2 Pb1 Configurable analogue input 1 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

3 Pb2 Configurable analogue input 2 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

4 Pb3 Configurable analogue input 3 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

5 Pb4 Configurable analogue input 4 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

6 Pb5 Configurable analogue input 5 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

7 PbC Common analogue inputs (NTC, PTC, DI)

8 GND(-)

Additional power reference 5Vdc and 12Vdc and analogue inputs (0 - 20mA, 4 - 20mA, 0 10V, 0 - 1V, 0 - 5V)

9 Supply Reference “+“ power supply (24Vac or 24Vdc)

10 Pb6 Configurable analogue input 6 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

11 Pb7 Configurable analogue input 7 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

12 Pb8 Configurable analogue input 8 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

13 Pb9 Configurable analogue input 9 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

14 Pb10 Configurable analogue input 10 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

15 +5V Additional power +5Vdc

16 +12V Additional power +12Vdc

21 Out1 Opto-insulated analogue output 1 0 - 10V

22 Out2 Opto-insulated analogue output 2 0 - 10V

23 Out3 Opto-insulated analogue output 3 0 - 10V

24 Out4 Opto-insulated analogue output 4 0 - 10V

25 GND(-) Common opto-insulated analogue output

26 Out5 Analogue output 5 0 - 10V, 4 - 20mA, Opto-insulated relay

27 Out6 Analogue output 6 0 - 10V, 4 - 20mA, Opto-insulated relay

28 Supply Power for opto-insulated analogue outputs at 24Vac or 24Vdc(-)

29 Supply Power for opto-insulated analogue outputs at 24Vac or 24Vdc(+)

30 GND(-) Common opto-insulated analogue output

40 DI1 Opto-insulated digital input 1

41 DI2 Opto-insulated digital input 2

42 DI3 Opto-insulated digital input 3

43 DI4 Opto-insulated digital input 4

44 DI5 Opto-insulated digital input 5

45 DI6 Opto-insulated digital input 6

46 DI7 Opto-insulated digital input 7

47 DI8 Opto-insulated digital input 8

48 DI9 Opto-insulated digital input 9

49 DI10 Opto-insulated digital input 10

50 GND(-) Reference “-“ for opto-insulated digital inputs 1 to 20 (if inputs 24Vac or 24Vdc)

51 DI11 Opto-insulated digital input 11

52 DI12 Opto-insulated digital input 12

53 DI13 Opto-insulated digital input 13

54 DI14 Opto-insulated digital input 14

55 DI15 Opto-insulated digital input 15

56 DI16 Opto-insulated digital input 16

57 DI17 Opto-insulated digital input 17

58 DI18 Opto-insulated digital input 18

Page 23

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 23/72

59 DI19 Opto-insulated digital input 19

60 DI20 Opto-insulated digital input 20

61 IDC Common opto-insulated digital inputs 1 to 20 (if potential free inputs)

70 RL1 Relay 1 normally open contact

71 C Common relays 1, 2 and 3 (MAX 6A)

72 RL2 Relay 2 normally open contact

73 RL3 Relay 3 normally open contact

74 C Potential free contact (MAX 6A)

75 C Potential free contact (MAX 6A)

76 RL4 Relay 4 normally open contact

77 RL5 Relay 5 normally open contact

78 RL6 Relay 6 normally open contact

79 RL7 Relay 7 normally open contact

80 C Common relays 4, 5, 6, 7 and 8 (MAX 6A)

81 RL8 Relay 8 normally open contact

82 C Potential free contact (MAX 6A)

83 C Potential free contact (MAX 6A)

84 RL9 Relay 9 normally open contact

85 RL10 Relay 10 normally open contact

86 C Common relays 9 and 10 (MAX 6A)

87 RL11 Relay 11 normally open contact

88 RL12 Relay 12 normally open contact

89 RL13 Relay 13 normally open contact

90 C Common relays 11, 12, 13, 14 and 15 (MAX 6A)

91 RL14 Relay 14 normally open contact

92 RL15 Relay 15 normally open contact

93 C Potential free contact (MAX 6A)

94 RS485 Master RS485 Master connection (-)

95 RS485 Master RS485 Master connection (+)

96 RS485 Master RS485 Master connection (insulated gnd)

97 RS485 Slave RS485 Slave connection (-)

98 RS485 Slave RS485 Slave connection (+)

99 RS485 Slave RS485 Slave connection (insulated gnd)

100 CAN Bus CAN Bus connection (+), not open

101 CAN Bus CAN Bus connection (-), not open

102 CAN Bus CAN Bus connection (insulated gnd), not open

103 Remote Display Connection for VISOGRAPH remote terminal (Vnr)

104 Remote Display Connection for VISOGRAPH remote terminal (+)

105 Remote Display Connection for VISOGRAPH remote terminal (-)

106 Modem Reset NC relay input to reset an external modem (24Vac/dc)

107 Modem Reset NC relay output to reset an external modem (24Vac/dc)

Page 24

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 24/72

4.2.3 Technical specifications

4.2.3.1 Analogue inputs

Analogue conversion type: 10-bit A/D converter

Number of inputs: 10

Type of analogue input:

(configurable via software parameter)

NTC Dixell (-50T110°C; 10KΩ±1% at 25°C)

PTC Dixell(-55T115°C; 990Ω±1% at 25°C)

Digital input (potential free contact)

Voltage: 0 - V, 0 - 5V, 0 - 10V (input resistance 3.7KΩ )

Current: 0 - 20mA, 4 - 20mA (input resistance 100Ω)

Digital input status variation detection time: 100ms (in any case it depends on the cycle time set by the user in the

given application)

Accuracy: NTC, PTC: ±1

0-1V: ±20mV

0-5V: ±100mV

0-10V:±200mV

2-20mA, 4-20mA: ±0.30mA

Additional power: +12V: 200mA in total

+5v: 100mA

Notes: Any inputs that are powered with a voltage that differs from that supplied

by the device (+12V or +5V) must be powered separately with another

transformer (do not use the same secondary of the controller's power) in

order to prevent the inputs from malfunctioning or being damaged.

4.2.3.2 Digital inputs

Type:

(configurable via software parameter)

Opto-insulated potential free or live contact (24Vac/dc)

External power 24Vac/dc ±20%

Number of inputs: 20

Digital input status variation detection time: 100ms (in any case it depends on the cycle time set by the user in the

given application)

Notes:

If the digital inputs are used with voltage, use another transformer (do not

use the same secondary of the controller's power) in order to prevent the

inputs from malfunctioning or being damaged.

4.2.3.3 Analogue outputs

Type: Opto-insulated with separate 24Vac/dc power supply

Number of outputs: 6

Type of analogue output:

(configurable via software parameter)

4 fixed outputs 0-10Vdc (Out1 - Out4)

2 configurable outputs 0-10Vdc, 4-20mA (Out5 and Out6)

Maximum load: 40mA (Out1 - Out4)

20mA (Out5 and Out6) max with configured outputs 0-10Vdc

400Ω max with configured outputs 4-20Ma

22Ω per live analogue output

Accuracy: Out1 - Out4: ±2% full scale

Out5 – Out6: ±2% full scale

Resolution: 8bit

Notes: The electrical devices controlled by these analogue outputs must be

powered separately with another transformer (do not use the same

secondary of the controller's power) in order to prevent the outputs from

malfunctioning or being damaged.

4.2.3.4 Digital outputs

Type: Relays with NO contacts

Number of outputs: 10 or 15, depending on the model

Type of output:

(configurable via software parameter)

Relays with normally open contact

Maximum load: 5A(250Vac) SPST 5(2)A

Notes: Verify the capacity of the output used. There is double insulation between

the digital outputs and the low voltage of the rest of the circuit.

Do not use different voltages for the various groups of relays nor within

each group.

Page 25

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 25/72

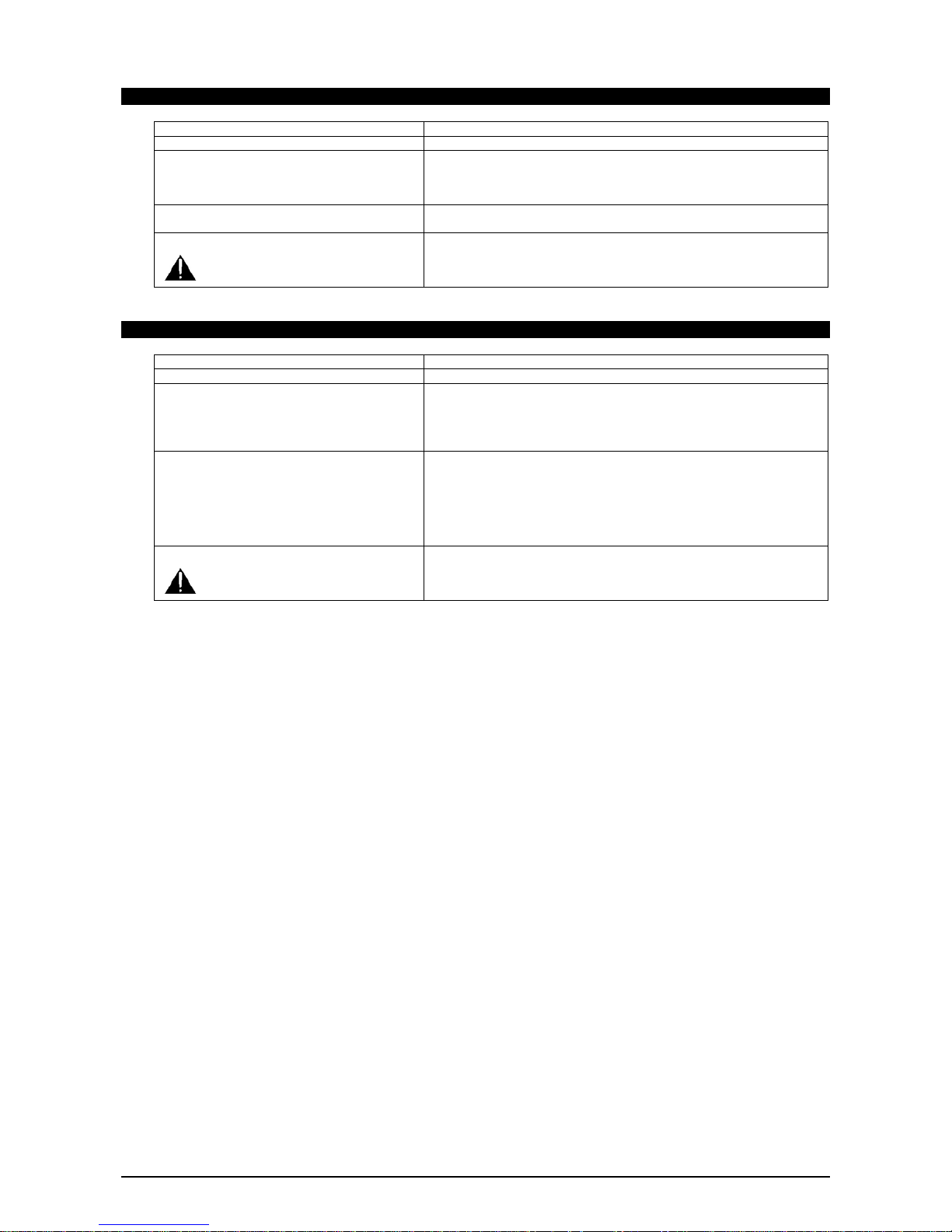

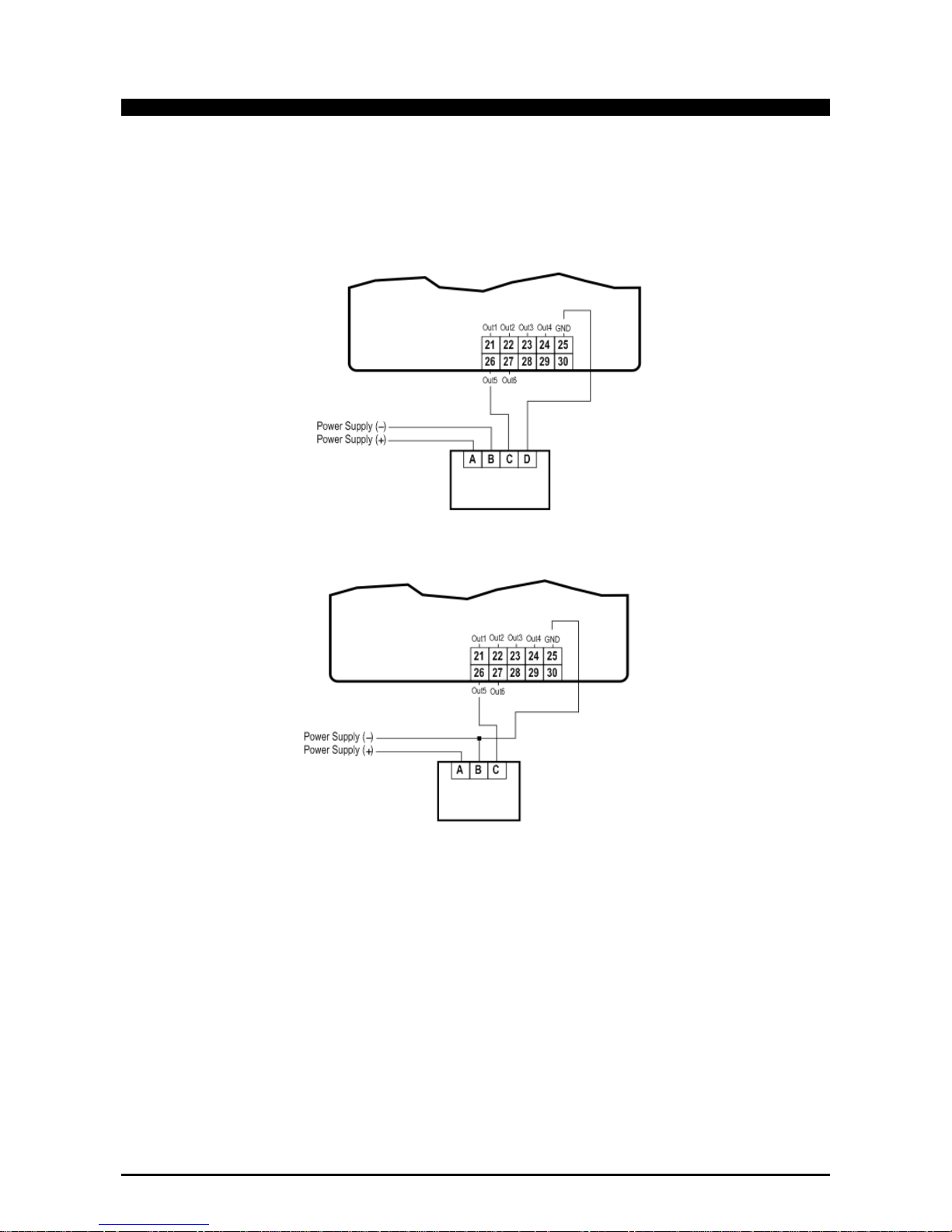

4.2.3.5 Wiring diagrams

4.2.3.6 Mechanical specifications

10 DIN module

4.2.3.7 Electrical specifications

Power Supply: 24Vac +10/-15%, 50/60Hz

20 - 36Vdc

Consumption: 20VA (Vac), 15W (Vdc)

Connectors: Phoenix quick coupling connectors for low voltage

STELVIO 90° screw connectors for digital outputs (250Vac, 6A max)

Microprocessor: AT91RM9200 32-bit 200Mhz

Permanent FLASH memory: 128MB, in 8-bit

RAM: 32MB o 64MB, in 16-bit

Internal clock: standard

Page 26

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 26/72

4.2.3.8 Plastic container

Mount: On a DIN rail (EN 50022, DIN 43880)

Fastened with screws via the removable plastic flaps.

Material: PC-ABS Thermoplastic

Self-extinguishing: V0 (UL94)

Comparative Tracking Index (CTI): 300V

Colour: White

4.2.3.9 Product certifications

Control to classify with the definitions 2.5.1 e 2.5.2 mentioned in the section 2.5 of the general

requirements EN60730-1 (2.5.1 = integrated control, 2.5.2 = incorporated control).

Electrical safety:

• EN60730-1

Electromagnetic compatibility:

• EN61000-4-2, EN61000-4-3, EN61000-4-4, EN61000-4-5, EN61000-4-6, EN61000-4-8,

EN61000-4-11

Page 27

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 27/72

4.3 IPRO 4 DIN (IPG100D – IPG200D – IPC100E RANGES)

4.3.1 Description of the connections

Connector Description

Connector for 24Vac/dc power supply

Analogue inputs (Pb1 - Pb6, PbC)

Additional power (+5Vdc, +12Vdc, GND)

Analogue outputs (Out1 - Out4, GND)

Page 28

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 28/72

24Vac/dc digital inputs (DI1 - DI11, GND)

Connector for remote terminal (VISOGRAPH), maximum 1 terminal per iPRO.

RS485 Slave connector

Serial port connector (LAN or RS485)

USB port for downloads (BIOS, ISaGRAF® application, maps of parameters, remote display

applications, network configuration, website) and uploads (log files)

Connection with the computer via a USB-ETH converter

Digital relay outputs

4 NO relays, 2 common

Digital relay outputs

4 NO relays, 2 common

4.3.2 Description of the inputs and outputs

Input

No.

Type of Input Description

1 Supply Reference “-“/GND power (24Vac or 24Vdc)

2 Pb1 Configurable analogue input 1 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

3 Pb2 Configurable analogue input 2 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

4 Pb3 Configurable analogue input 3 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

5 +12V Additional power +12Vdc

6 +5V Additional power +5Vdc

7 Out1 Analogue output 1 0 - 10V, 4 - 20mA, Relay

8 Out2 Analogue output 2 0 - 10V, 4 - 20mA, Relay

9 Supply Reference “+“ power supply (24Vac or 24Vdc)

10 Pb4 Configurable analogue input 4 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

11 Pb5 Configurable analogue input 5 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

12 Pb6 Configurable analogue input 6 (NTC, PTC, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 - 5V, DI)

13 PbC Common analogue inputs (NTC, PTC, DI)

14 GND(-)

Additional power reference 5Vdc and 12Vdc, analogue inputs (0 - 20mA, 4 - 20mA, 0 - 10V, 0

- 1V, 0 - 5V), analogue outputs

15 Out3 Analogue output 3 0 - 10V, 4 - 20mA, Relay

16 Out4 Analogue output 4 0 - 10V, 4 - 20mA, Relay

20 DI1 Digital input 1 24Vac/dc

21 DI2 Digital input 2 24Vac/dc

22 DI3 Digital input 3 24Vac/dc

23 DI4 Digital input 4 24Vac/dc

24 DI5 Digital input 5 24Vac/dc

25 DI6 Digital input 6 24Vac/dc

26 DI7 Digital input 7 24Vac/dc

27 DI8 Digital input 8 24Vac/dc

28 DI9 Digital input 9 24Vac/dc

29 DI10 Digital input 10 24Vac/dc

30 DI11 Digital input 11 24Vac/dc

31 GND(-)

Reference “-“ for digital inputs from1 to 11 (if version with dry contacts, this input has

to be used only as common for the digital inputs)

40 C Common relays 1, 2, 3 and 4 (MAX 10A)

41 C Common relays 1, 2, 3 and 4 (MAX 10A)

42 RL1 Relay 1 normally open contact

43 RL2 Relay 2 normally open contact

Page 29

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 29/72

44 RL3 Relay 3 normally open contact

45 RL4 Relay 4 normally open contact

46 RL5 Relay 5 normally open contact

47 C Common relays 5, 6, 7 and 8 (MAX 10A)

48 C Common relays 5, 6, 7 and 8 (MAX 10A)

49 RL6 Relay 6 normally open contact

50 RL7 Relay 7 normally open contact

51 RL8 Relay 8 normally open contact

60 Remote Display Connection for VISOGRAPH remote terminal (Vnr)

61 Remote Display Connection for VISOGRAPH remote terminal (+)

62 Remote Display Connection for VISOGRAPH remote terminal (-)

63 RS485 Slave RS485 Slave connection (-)

64 RS485 Slave RS485 Slave connection (+)

65 LAN LAN Connection (-)

66 LAN LAN Connection (+)

4.3.3 Technical specifications

4.3.3.1 Analogue inputs

Analogue conversion type: 10-bit A/D converter

Number of inputs: 6

Type of analogue input:

(configurable via software parameter)

NTC Dixell (-50T110°C; 10KΩ±1% at 25°C)

PTC Dixell(-55T115°C; 990Ω±1% at 25°C)

Digital input (potential free contact)

Voltage: 0 - V, 0 - 5V, 0 - 10V (input resistance 3.7KΩ )

Current: 0 - 20mA, 4 - 20mA (input resistance 100Ω)

Digital input status variation detection time: 100ms (in any case it depends on the cycle time set by the user in the

given application)

Accuracy: NTC, PTC: ±1

0-1V: ±20mV

0-5V: ±100mV

0-10V:±200mV

2-20mA, 4-20mA: ±0.30mA

Additional power: +12V: 200mA in total (between +12V and analogue outputs)

+5v: 100mA

Notes: Any inputs that are powered with a voltage that differs from that supplied

by the device (+12V or +5V) must be powered separately with another

transformer (do not use the same secondary of the controller's power) in

order to prevent the inputs from malfunctioning or being damaged.

4.3.3.2 Digital inputs

Type:

(configurable via software parameter)

Opto-insulated live contact (24Vac/dc)

External power 24Vac/dc ±20%

Number of inputs: 11

Digital input status variation detection time: 100ms (in any case it depends on the cycle time set by the user in the

given application)

Notes: Use another transformer (do not use the same secondary of the

controller's power) in order to prevent the inputs from malfunctioning or

being damaged.

Note: the digital inputs as dry contacts are available on request.

Page 30

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 30/72

4.3.3.3 Analogue outputs

Type: Non opto-insulated internal power

Number of outputs: 4

Type of analogue output:

(configurable via software parameter)

4 configurable outputs 0-10Vdc 4-20mA (Out1 - Out4)

Maximum load: 40mA (Out1 - Out4) max with configured outputs 0-10Vdc

400Ω max with configured outputs 4-20mA

22Ω per live analogue output

Accuracy: Out1 - Out4: ±2% full scale

Resolution: 8bit

Notes: The electrical devices controlled by these analogue outputs must be

powered separately with another transformer (do not use the same

secondary of the controller's power) in order to prevent the outputs from

malfunctioning or being damaged.

4.3.3.4 Digital outputs

Type: Relays with NO contacts

Number of outputs: 8

Type of output:

(configurable via software parameter)

Relays with normally open contact

Maximum load: 5A(250Vac) SPST 5(2)A

Notes: Verify the capacity of the output used. There is double insulation between

the digital outputs and the low voltage of the rest of the circuit.

Do not use different voltages for the various groups of relays nor within

each group.

4.3.3.5 Wiring diagrams

Page 31

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 31/72

4.3.3.6 Mechanical specifications

4 DIN module

4.3.3.7 Electrical specifications

Power Supply: 24Vac +10/-15%, 50/60Hz

20 - 36Vdc

Consumption: from 30VA (Vac), from 25W (Vdc)

Connectors: Molex connectors with low voltage wiring (for IPS100D and IPS400D)

Phoenix quick coupling connectors for low voltage (for IPS200D)

STELVIO 90° screw connectors for digital outputs (250Vac, 6A max)

Microprocessor: AT91SAM9260 32-bit 200Mhz

Permanent FLASH memory: 32MB, in 8-bit

RAM: 32MB, in 16

Internal clock: standard

4.3.3.8 Plastic container

Mount: On a DIN rail (EN 50022, DIN 43880)

Fastened with screws via the removable plastic flaps.

Material: PC-ABS Thermoplastic

Self-extinguishing: V0 (UL94)

Comparative Tracking Index (CTI): 300V

Colour: Black or White, depending on the model

4.3.3.9 USB-ETHERNET Adapter

The IPS range of programmable controllers can be connected to a computer via an external adapter. This

adapter must be used in the processing environment for the application download in the ipro. This

adapter is not set up for fixed or continuous connection. If the adapter should be kept connected

continuously, the room temperature must not exceed 50°C.

Page 32

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 32/72

4.4 IPRO.LINK (IPL500D)

4.4.1 Description of the connections

Connector Description

Connector for 24Vac/dc power supply

Connector for remote terminal (VISOGRAPH), maximum 1 terminal per iPRO.

RS485 Slave connector

Serial port connector (LAN or RS485)

CANBUS connector (for expansion and driver for electroni expansion valve)

Communication leds

USB port for downloads (BIOS, ISaGRAF® application, maps of parameters, remote

display applications, network configuration, website) and uploads (log files)

Ethernet port for TCP/IP connections

SIM CARD slot (only for version with GPRS modem)

Connection for GPRS modem antenna

Page 33

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 33/72

4.4.2 Description of the inputs and outputs

Input

No.

Type of Input Description

1 Supply Reference “-“/GND power (24Vac or 24Vdc)

2 Supply Reference “+“ power supply (24Vac or 24Vdc)

3 Remote Display Connection for VISOGRAPH remote terminal (Vnr)

4 Remote Display Connection for VISOGRAPH remote terminal (+)

5 Remote Display Connection for VISOGRAPH remote terminal (-)

6 RS485 Slave RS485 Slave connection (-)

7 RS485 Slave RS485 Slave connection (+)

8 Serial Port LAN or RS485 MASTER Connection (-) – depend on the model

9 Serial Port LAN or RS485 MASTER Connection (+) – depend on the model

10 CAN CANBUS connection (-)

11 CAN CANBUS connection (+)

4.4.3 Technical specifications

4.4.3.1 Wiring diagrams

Page 34

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 34/72

4.4.3.2 Mechanical specifications

4 DIN module

4.4.3.3 Electrical specifications

Power Supply: 24Vac +10/-15%, 50/60Hz

20 - 36Vdc

Consumption: from 20VA (Vac), from 15W (Vdc)

Connectors: STELVIO 90° screw connectors for digital outputs (250Vac, 6A max)

Microprocessor: AT91SAM9260 32-bit 200Mhz

Permanent FLASH memory: 128MB, in 8

RAM: 32MB, in 16

Internal clock: standard

4.4.3.4 Plastic container

Mount: On a DIN rail (EN 50022, DIN 43880)

Fastened with screws via the removable plastic flaps.

Material: PC-ABS Thermoplastic

Self-extinguishing: V0 (UL94)

Comparative Tracking Index (CTI): 300V

Colour: Black or White, depending on the model

Page 35

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 35/72

4.5 IPX106D

4.5.1 Description of the connections

Connector Description

Connector for 24Vac/dc power supply

Analogue inputs (Pb1 - Pb5, PbC)

Potential free digital inputs (DI1 - DI3, DIC)

Additional power (+5Vdc, +12Vdc, GND)

Analogue outputs (Out1..Out3, GND)

Analogue inputs (Pb6 - Pb7, PbC)

Additional power (+5Vdc, +12Vdc, GND)

Digital relay outputs

6 NO relays, 2 common

CANBUS Connector

Rx and Tx LED to indicate that communication is active

Closed circuit terminal (Term)

LAN serial port connector

Dip-switch to set the address of the device.

Green LED to indicate the presence of power

Red status LED (ALARM)

See relative paragraph

Page 36

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 36/72

4.5.2 Description of the inputs and outputs

Input

No.

Type of Input Description

1 Supply Reference “-“/GND power (24Vac or 24Vdc)

2 Pb1

Configurable analogue input 1 (NTC, PTC, PT1000, 0 - 20mA, 4 - 20mA, 0 - 5V, 0 - 1V, 0 10V, DI, not used)

3 Pb2

Configurable analogue input 1 (NTC, PTC, PT1000, 0 - 20mA, 4 - 20mA, 0 - 5V, 0 - 1V, 0 10V, DI, not used)

4 Pb3

Configurable analogue input 1 (NTC, PTC, PT1000, 0 - 20mA, 4 - 20mA, 0 - 5V, 0 - 1V, 0 10V, DI, not used)

5 Pb4

Configurable analogue input 1 (NTC, PTC, PT1000, 0 - 20mA, 4 - 20mA, 0 - 5V, 0 - 1V, 0 10V, DI, not used)

6 Pb5

Configurable analogue input 1 (NTC, PTC, PT1000, 0 - 20mA, 4 - 20mA, 0 - 5V, 0 - 1V, 0 10V, DI, not used)

7 +12V Additional power +12Vdc

8 +12V Additional power +12Vdc

9 Supply Reference “+“ power supply (24Vac or 24Vdc)

10 DI1 Digital input 1 (potential free contact)

11 DI2 Digital input 2 (potential free contact)

12 DI3 Digital input 3 (potential free contact)

13 DIC Common digital inputs 1 to 3

14 Pbc Common analogue inputs (NTC, PTC, PT1000, DI)

15 GND(-)

Additional power reference 5Vdc and 12Vdc and analogue inputs (0 - 20mA, 4 - 20mA, 0 10V, 0 - 1V, 0 - 5V)

16 +5V Additional power +5Vdc

20 GND(-) Additional power reference 5Vdc, 12Vdc and analogue outputs

21 Out1 Analogue output 1 0 - 10V

22 Out2 Analogue output 2 0 - 10V

23 Out3 Analogue output 3 0 - 10V

24 Pb6

Configurable analogue input 1 (NTC, PTC, PT1000, 0 - 20mA, 4 - 20mA, 0 - 5V, 0 - 1V, 0 10V, DI, not used)

25 GND(-) Additional power reference 5Vdc, 12Vdc and analogue outputs

26 +12V Additional power +12Vdc

27 +5V Additional power +5Vdc

28 Pbc Common analogue inputs (NTC, PTC, PT1000, DI)

29 Pb7

Configurable analogue input 1 (NTC, PTC, PT1000, 0 - 20mA, 4 - 20mA, 0 - 5V, 0 - 1V, 0 10V, DI, not used)

30 CAN Bus CAN Bus connection (+), not open

32 CAN Bus CAN Bus connection (-), not open

33 CAN Bus CAN Bus connection (insulated gnd), not open

40 RL4 Relay 4 normally open contact

41 RL5 Relay 5 normally open contact

42 RL6 Relay 6 normally open contact

43 C Common relays 5, 6 and 3 (MAX 6A)

44 C Common relays 1, 2 and 4 (MAX 6A)

45 RL1 Relay 1 normally open contact

46 RL2 Relay 2 normally closed contact

47 RL3 Relay 3 normally closed contact

Page 37

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 37/72

4.5.3 Technical specifications

4.5.3.1 Analogue inputs

Analogue conversion type: 10-bit A/D converter

Number of inputs: 7

Type of analogue input:

(configurable via software parameter)

NTC Dixell (-50T110°C; 10KΩ±1% at 25°C)

PTC Dixell(-55T115°C; 990Ω±1% at 25°C)

PT1000 Dixell (-100T150°C; 1KΩ at 0°C)

Digital input (potential free contact)

Voltage: 0 - V, 0 - 5V, 0 - 10V (input resistance 3.7KΩ )

Current: 0 - 20mA, 4 - 20mA (input resistance 100Ω)

Digital input status variation detection time: 100ms (in any case it depends on the cycle time set by the user in the

given application)

Accuracy: NTC, PTC, PT1000: ±1°C

0-1V: ±20mV

0-5V: ±100mV

0-10V:±200mV

2-20mA, 4-20mA: ±0.30mA

Additional power: +12V: 40mA max per terminal

+5v: 100mA

Notes: Any inputs that are powered with a voltage that differs from that supplied

by the device (+12V or +5V) must be powered separately with another

transformer (do not use the same secondary of the controller's power) in

order to prevent the inputs from malfunctioning or being damaged.

4.5.3.2 Digital inputs

Type:

(configurable via software parameter)

Opto-insulated potential free contact

Number of inputs: 3

Digital input status variation detection time: 100ms (in any case it depends on the cycle time set by the user in the

given application)

Notes: Do not use live contacts in order to prevent the inputs from being

damaged.

4.5.3.3 Analogue outputs

Type: Non opto-insulated internal power

Number of outputs: 3

Type of analogue output:

(configurable via software parameter)

3 fixed outputs 0-10Vdc (Out1 - Out3)

Maximum load: 40mA (Out1 - Out3)

22Ω per live analogue output

Accuracy: Out1 - Out3: ±2% full scale

Resolution: 8bit

Notes: The electrical devices controlled by these analogue outputs must be

powered separately with another transformer (do not use the same

secondary of the controller's power) in order to prevent the outputs from

malfunctioning or being damaged.

4.5.3.4 Digital outputs

Type: Relays with NO contacts

Number of outputs: 6

Type of output:

(configurable via software parameter)

Relays with normally open contact:

Maximum load: 5A(250Vac) SPST 5(2)A

Notes: Verify the capacity of the output used. There is double insulation between

the digital outputs and the low voltage of the rest of the circuit.

The common relays of the outputs are separate and split into groups.

Different voltages can be used for different groups of relays but the same

voltage must be used within each group.

Page 38

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 38/72

4.5.3.5 Wiring diagrams

4.5.3.6 Mechanical specifications

4 DIN module

4.5.3.7 Electrical specifications

Power Supply: 24Vac +10/-15%, 50/60Hz

20 - 36Vdc

Consumption: 10VA (Vac), 10W (Vdc)

Connectors: Molex connectors with low voltage wiring

SELECOM/CIVILUX connectors for digital outputs (250Vac, 6A max) or

with a different order code:

Phoenix quick coupling connectors for low voltage

STELVIO 90° screw connectors for digital outputs (250Vac, 6A max)

Page 39

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 39/72

4.5.3.8 Plastic container

Mount: On a DIN rail (EN 50022, DIN 43880)

Fastened with screws via the removable plastic flaps.

Material: PC-ABS Thermoplastic

Self-extinguishing: V0 (UL94)

Comparative Tracking Index (CTI): 300V

Colour: Black

4.5.3.9 Setting the address of the device

The address of the device is set via a dip-switch and numbering is binary as shown in the table

below:

If the address is changed while the device is switched on, to confirm the new address

remember to switch off and switch on again the device.

Notused

Page 40

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 40/72

4.6 IPX125D – IPX115D

4.6.1 Description of the connections

Connector Description

Connector for 24Vac/dc power supply

Analogue inputs (Pb1 - Pb10, PbC)

Additional power (+5Vdc, +12Vdc, GND)

Opto-insulated analogue outputs (Out1 - Out6, GND)

24Vac/dc power supply for the opto-insulated analogue output

Potential free opto-insulated digital inputs (DI1 - DI20, DIC)

Opto-insulated 24Vac/dc digital inputs (DI1 - DI20, GND)

LAN serial port connector

Rx and Tx LED to indicate that communication is active

CANBUS Connector

Rx and Tx LED to indicate that communication is active

Closed circuit terminal (Term)

Dip-switch to set the address of the device.

Digital relay outputs

3 NO relays + 1 changeover relay, 1 common

Digital relay outputs

6 NO relays, 2 common

Digital relay outputs

3 NO relays + 2 changeover relays, 3 common

Page 41

1592025700 IPROFAMILY stp GB 2012.08.08.doc iPro Series 41/72

Digital outputs with SSR relays (IPX125D)

4 NO relays, 2 common

Digital relay outputs (IPX125D)

6 NO relays, 2 common

Green power LEDs (PWR ON) and red alarm signal LED (ALARM)

See relative paragraph

4.6.2 Description of the inputs and outputs

Input

No.

Type of Input Description

1 Supply Reference “-“/GND power (24Vac or 24Vdc)

2 Pb1

Configurable analogue input 1 (NTC, PTC, PT1000, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 5V, DI)

3 Pb2

Configurable analogue input 2 (NTC, PTC, PT1000, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 5V, DI)

4 Pb3

Configurable analogue input 3 (NTC, PTC, PT1000, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 5V, DI)

5 Pb4

Configurable analogue input 4 (NTC, PTC, PT1000, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 5V, DI)

6 Pb5

Configurable analogue input 5 (NTC, PTC, PT1000, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 5V, DI)

7 PbC Common analogue inputs (NTC, PTC, PT1000, DI)

8 GND(-)

Additional power reference 5Vdc and 12Vdc and analogue inputs (0 - 20mA, 4 - 20mA, 0 10V, 0 - 1V, 0 - 5V)

9 Supply Reference “+“ power supply (24Vac or 24Vdc)

10 Pb6

Configurable analogue input 6 (NTC, PTC, PT1000, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 5V, DI)

11 Pb7

Configurable analogue input 7 (NTC, PTC, PT1000, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 5V, DI)

12 Pb8

Configurable analogue input 8 (NTC, PTC, PT1000, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 5V, DI)

13 Pb9

Configurable analogue input 9 (NTC, PTC, PT1000, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 5V, DI)

14 Pb10

Configurable analogue input 10 (NTC, PTC, PT1000, 0 - 20mA, 4 - 20mA, 0 - 10V, 0 - 1V, 0 5V, DI)

15 +5V Additional power +5Vdc

16 +12V Additional power +12Vdc

21 Out1 Opto-insulated analogue output 1 0 - 10V

22 Out2 Opto-insulated analogue output 2 0 - 10V

23 Out3 Opto-insulated analogue output 3 0 - 10V

24 Out4 Opto-insulated analogue output 4 0 - 10V

25 GND(-) Common opto-insulated analogue output

26 Out5 Analogue output 5 0 - 10V, 4 - 20mA, Opto-insulated relay

27 Out6 Analogue output 6 0 - 10V, 4 - 20mA, Opto-insulated relay

28 Supply Power for opto-insulated analogue outputs at 24Vac or 24Vdc(-)

29 Supply Power for opto-insulated analogue outputs at 24Vac or 24Vdc(+)

30 GND(-) Common opto-insulated analogue output