Page 1

QUICK REFERENCE GUIDE

IC200CX (v. 1.0)

Page 2

Page 3

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 3/40

INDEX

1 GENERAL WARNING ................................................................................................ 5

1.1 PLEASE READ BEFORE USING THIS MANUAL ........................................................ 5

1.2 SAFETY PRECAUTIONS ............................................................................................. 5

1.3 PRODUCT DISPOSAL (WEEE)............................................................................................. 6

2 USING THE QUICK REFERENCE GUIDE ................................................................ 6

3 IC200 CX TABLE OF THE FEATURES ..................................................................... 7

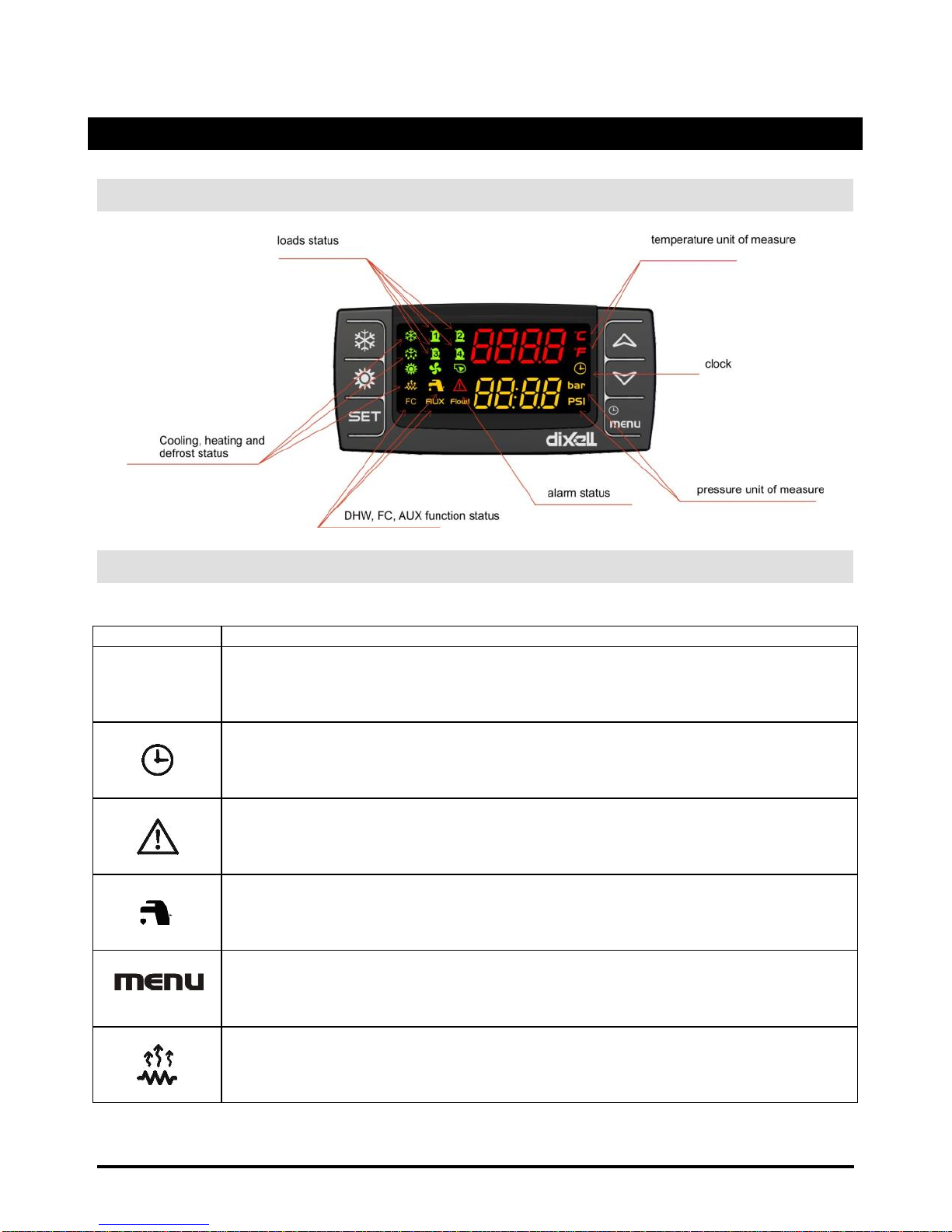

4 USER INTERFACE .................................................................................................... 8

4.1 MEANING OF THE LEDS ...................................................................................................... 8

4.2 DISPLAY AND ICONS ........................................................................................................... 8

5 DISPLAY LAYOUT ..................................................................................................... 9

6 OTHER DISPLAY INFORMATION ........................................................................... 10

6.1 READ THE SET POINT VALUE .......................................................................................... 10

6.2 MODIFY THE SET POINT ................................................................................................... 10

7 KEY FUNCTION ....................................................................................................... 11

7.1 KEY COMBINANTION ......................................................................................................... 12

8 FIRST INSTALLING ................................................................................................. 12

8.1 ON BOARD CLOCK (OPTIONAL) ................................ ....................................................... 12

8.2 RTC SETUP ........................................................................................................................ 12

9 PARAMETERS PROGRAMMING WITH THE “HOT KEY 64” ............................... 13

9.1 HOW TO PROGRAM AN INSTRUMENT WITH AN ALREADY PROGRAMMED “HOT KEY”

(DOWNLOAD) ................................ ................................................................................................ ... 13

9.2 HOW TO COPY THE PARAMETER MAP INTO THE “HOT KEY” (UPLOAD)..................... 13

10 PROGRAMMING USING LOCAL USER INTERFACE ............................................ 13

10.1 ENTER THE PROGRAMMING LEVEL PR1 ........................................................................ 13

10.2 ENTER THE PROGRAMMING LEVEL PR2 ........................................................................ 14

10.3 ENTER THE PROGRAMMING LEVEL PR3 ........................................................................ 14

11 MENU ( MENU KEY) ................................................................................................ 14

11.1 ALARM LIST: READ AND RESET ....................................................................................... 15

11.2 ALARM LOG LIST ............................................................................................................... 15

12 REMOTE KEYBOARD VICX620 EVO ..................................................................... 16

13 REMOTE KEYBOARD V2I820 ................................................................................. 16

13.1 PROBES VISUALIZATION .................................................................................................. 18

13.2 VISUALIZZAZIONE / MODIFICA SET POINT ...................................................................... 18

13.3 ALARM VISUALIZATION ..................................................................................................... 19

14 TABLE OF THE OUTPUT STATUS IN ALARM CONDITION ................................. 20

14.1 ALARM: “A” TYPE AND STATUS OF THE LOADS IN CASE OF ALARM ........................... 20

14.2 ALARM: “B” TYPE AND STATUS OF THE LOADS IN CASE OF ALARM ........................... 22

14.3 ALARM: “C” TYPE AND STATUS OF THE LOADS IN CASE OF ALARM ........................... 23

14.1 WARNING ........................................................................................................................... 24

15 BLACK-OUT............................................................................................................. 24

16 WIRING CONNECTIONS ......................................................................................... 24

16.1 IC206CX CONNECTIONS ................................................................................................... 24

16.2 208CX CONNECTIONS ...................................................................................................... 25

16.1 REMOTE KEYBOARD CONNECTION ................................................................................ 26

16.2 ANALOG INPUTS NTC – PTC PROBES ............................................................................. 28

Page 4

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 4/40

16.3 DIGITAL INPUTS ................................................................................................................. 29

16.4 ANALOG INPUT FOR PRESSURE TRANSDUCER PP30 (4 ÷ 20MA SIGNAL) .................. 30

16.5 ANALOG INPUT FOR PRESSURE RATIOMETRIC TRANSDUCER PPR30 (0 ÷ 5V SIGNAL)

31

16.6 PWM OUTPUT FOR CONDENSING FAN SPEED CONTROL ............................................ 32

16.7 PROPORTIONAL OUTPUT FOR FAN CONDENSING CONTROL OR FOR COMPRESSOR

INVERTER CONTROLLED OR FOR AUXILIARY OUTPUTS ............................................................ 33

16.8 PROPORTIONAL OUTPUT 0..10V TO CONTROL DUMPER MOTORS ............................. 34

16.9 PROPORTIONAL OUTPUTS CONFIGURED FOR AUX RELAY CONTROL ....................... 36

17 INSTALLING AND MOUNTING ............................................................................... 37

17.1 PANEL CUT- OUT ............................................................................................................... 37

17.2 VERTICAL BOARDS VI620CX PANEL CUT-OUT ............................................................... 37

17.1 V2I820 PANEL CUT-OUT .................................................................................................... 38

18 ELECTRICAL CONNECTIONS ................................................................................ 38

19 TECHNICAL DATA .................................................................................................. 39

Page 5

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 5/40

1 GENERAL WARNING

1.1 PLEASE READ BEFORE USING THIS MANUAL

This manual is part of the product and should be kept near the instrument for easy and

quick reference.

The instrument shall not be used for purposes different from those described

hereunder. It cannot be used as a safety device.

Check the application limits before proceeding.

Dixell Srl reserves the right to change the composition of its products, even without

notice, ensuring the same and unchanged functionality.

1.2 SAFETY PRECAUTIONS

Check the supply voltage is correct before connecting the instrument.

Do not expose to water or moisture: use the controller only within the operating limits

avoiding sudden temperature changes with high atmospheric humidity to prevent

formation of condensation

Warning: disconnect all electrical connections before any kind of maintenance.

The instrument must not be opened.

In case of failure or faulty operation send the instrument back to the distributor or to

“Dixell S.r.l.” with a detailed description of the fault.

Consider the maximum current which can be applied to each relay (see Technical

Data).

Ensure that the wires for probes, loads and the power supply are separated and far

enough from each other, without crossing or intertwining; do not use the same electrical

conduit to install high voltage cabling and low voltage cabling.

The ground connection of the secondary coil of the transformer that powers the device

can result in a bad performance; where possible, this connection should be avoided.

Fit the probe where it is not accessible by the end user.

In case of applications in industrial environments, the use of mains filters (our mod.

FT1) in parallel with inductive loads could be useful.

The symbol alerts the user of non-insulated “dangerous voltage” within the

product area that is sufficiently high to constitute a risk of electric shock to persons.

The symbol alerts the user of important operating and maintenance

(assistance) instructions found in the documentation attached to the device.

Page 6

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 6/40

1.3 PRODUCT DISPOSAL (WEEE)

With reference to Directive 2002/96/EC of the European Parliament and of the Council

of 27 January 2003 and to the relative national legislation, please note that:

There lies the obligation not to dispose of electrical and electronic waste as

municipal waste but to separate the waste.

Public or private collection points must be used to dispose of the goods in

accordance with local laws. Furthermore, at the end of the product's life, it is

also possible to return this to the retailer when a new purchase is made.

This equipment may contain hazardous substances. Improper use or

incorrect disposal can have adverse effects on human health and the

environment.

The symbol shown on the product or the package indicates that the product

has been placed on the market after 13 August 2005 and must be disposed

of as separated waste.

Should the product be disposed of incorrectly, sanctions may be applied as

stipulated in applicable local regulations regarding waste disposal.

2 USING THE QUICK REFERENCE GUIDE

In this guide, there are some general guidelines regarding the product; more details are in

the full manual, to be requested from the Dixell Customer Service department.

Page 7

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 7/40

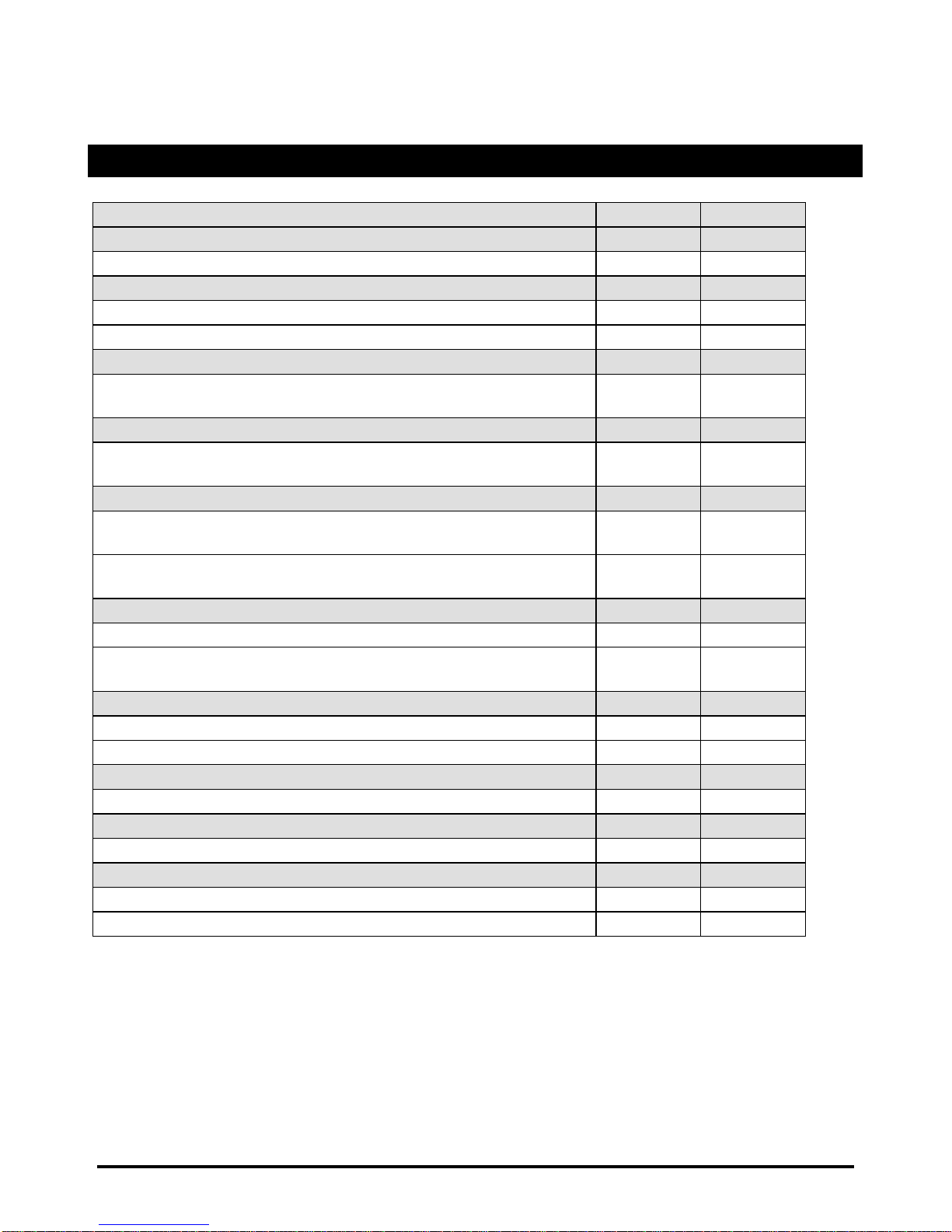

3 IC200 CX TABLE OF THE FEATURES

CHARACTERISTICS

IC206CX

IC208CX

N° KEYS

6

RELAYS

6 8

DIGITAL INPUTS

11

Configura

ble

Configura

ble

ANALOG INPUTS

4 NTC – PTC

2 NTC - PTC - 4÷20mA - 0 ÷ 5Volt

Configura

ble

Configura

ble

PROPORTIONAL OUTPUTS

2 configurables (signal 0÷10V)

Configura

ble

Configura

ble

2 configurables (signal 0÷10V, PWM)

Configura

ble

Configura

ble

SERIAL OUTPUTS

TTL with Mod-BusRtu protocol

Remote Keyboard VICX620 (up to 2 remote keyboards

with probe on board)

POWER SUPPLY

12 Vac/dc (+15%;-10%)

24 Vac/dc (± 10%)

Opt

Opt

MAIN DISPLAY (UPPER DISPLAY)

± 4 digits with decimal point

SECONDARY DISPLAY (LOWER DISPLAY)

± 4 digits with decimal point

OTHER

Clock on board

Opt

Opt

Buzzer

Opt

Opt

Opt = optional

= default

Page 8

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 8/40

4 USER INTERFACE

4.1 MEANING OF THE LEDS

4.2 DISPLAY AND ICONS

ICON

MEANING / FUNCTIONNING

°C

°F BAR

PSI

Lighted when the display shows a temperature or pressure

Lighted when the bottom display shows the clock

Lighted during the programming parameters if it is time based

Lighted in function menu when the display shows the defrost delay

Alarm: blinking in case of alarm

Lighted when sanitary hot water function is active

Lighted after pressing menu button

Lighted if anti freeze heaters/ integration heating / boiler are activated

Page 9

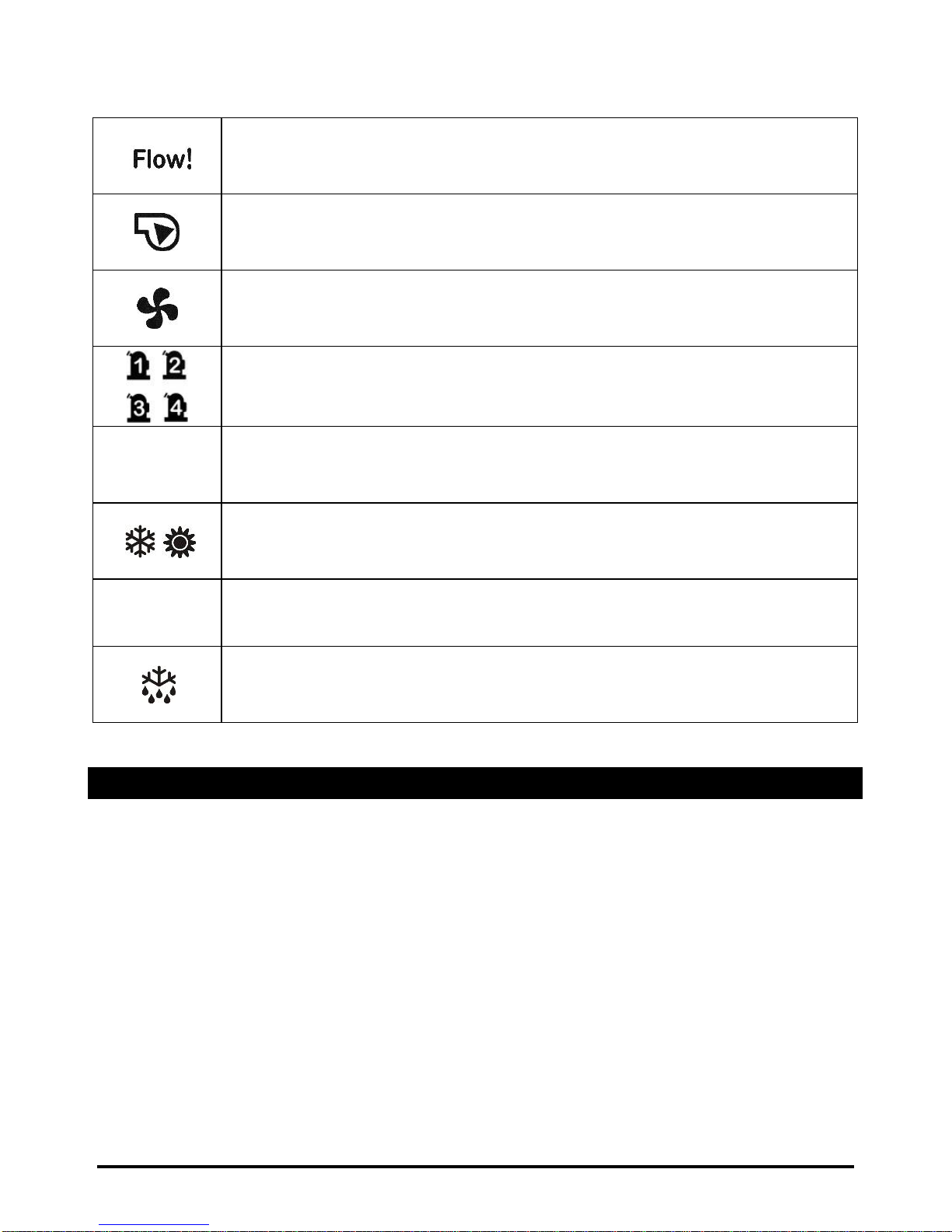

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 9/40

Flow switch alarm / supply fan overload (air / air unit)

Water pump: lighted if at least one pump is ON

Condenser fan: lighted if at least one fan is ON

Lighted when a compressor is ON

Blinking = when the delay of activation is running

AUX

Lighted when auxiliary function is active

Lighted when the controller is ON in cooling or heating

FC

Lighted when the Free cooling is active

Lighted when the defrost is activated

Blinking when the delay to activate the defrost is active

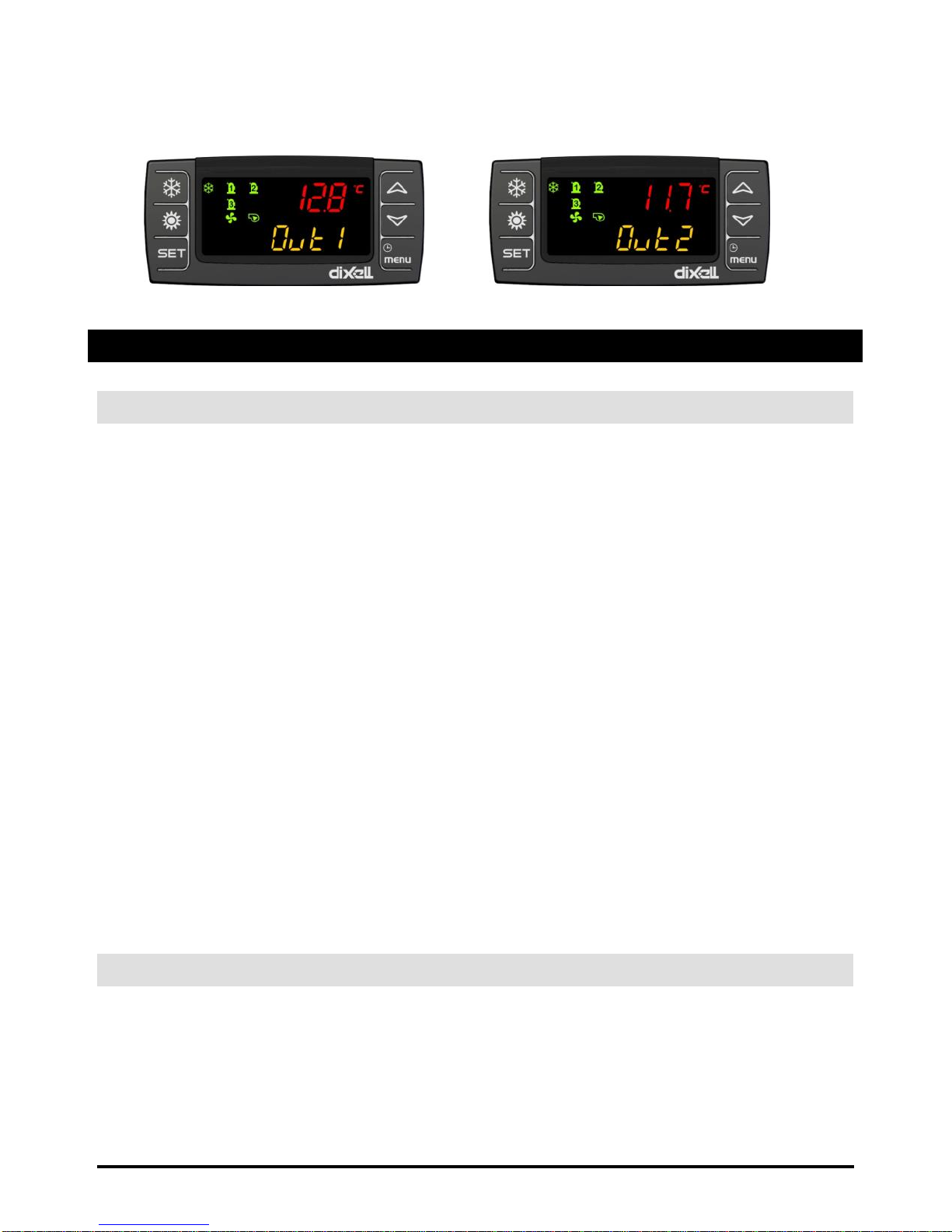

5 DISPLAY LAYOUT

Pressing Up or Down button the display shows the temperature or pressure of the main

probes configured in the instrument.

The lower display shows the label of the selected probe while the upper display shows its

value.

If the machine is configured with two gas circuits, when on the display is visualized the

condenser pressure/temperature or evaporation pressure of circuit 1, pressing SET button

the display shows condenser pressure/temperature or evaporation pressure of circuit 2.

Page 10

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 10/40

Fig.1 Fig.2

6 OTHER DISPLAY INFORMATION

6.1 READ THE SET POINT VALUE

Press and release the SET key:

If the unit is on standby:

lower display shows SEtC (set chiller);

press SET key again, lower display shows SEtH (set heat pump, if it is enabled);

press SET key again, lower display shows SEtr (set real of operation, in the case

where the Energy Saving and / or function dynamic set point are active);

press SET key again, lower display shows SEtS (set sanitary circuit, in case it is

enabled)

If the instrument is in chiller operation:

lower display shows SEtC (set chiller);

press SET key again, lower display shows SEtr (set real of operation, in the case

where the Energy Saving and / or function dynamic set point are active);

press SET key again, lower display shows SEtS (set sanitary circuit, in case it is

enabled)

If the instrument is in chiller operation:

lower display shows SetH (set heat pump);

press SET key again, lower display shows SEtr (set real of operation, in the case

where the Energy Saving and / or function dynamic set point are active);

press SET key again, lower display shows SEtS (set sanitary circuit, in case it is

enabled)

6.2 MODIFY THE SET POINT

push SET key for at least 3 seconds

use the UP or DOWN key to modify the setpoint. In chiller it is possible to modify the chiller

set point, in heat pump it is possible to modify the heat pump set point, in std-by it is

possible to modify both the set point.

push SET to confirm or wait the timeout (15seconds).

Page 11

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 11/40

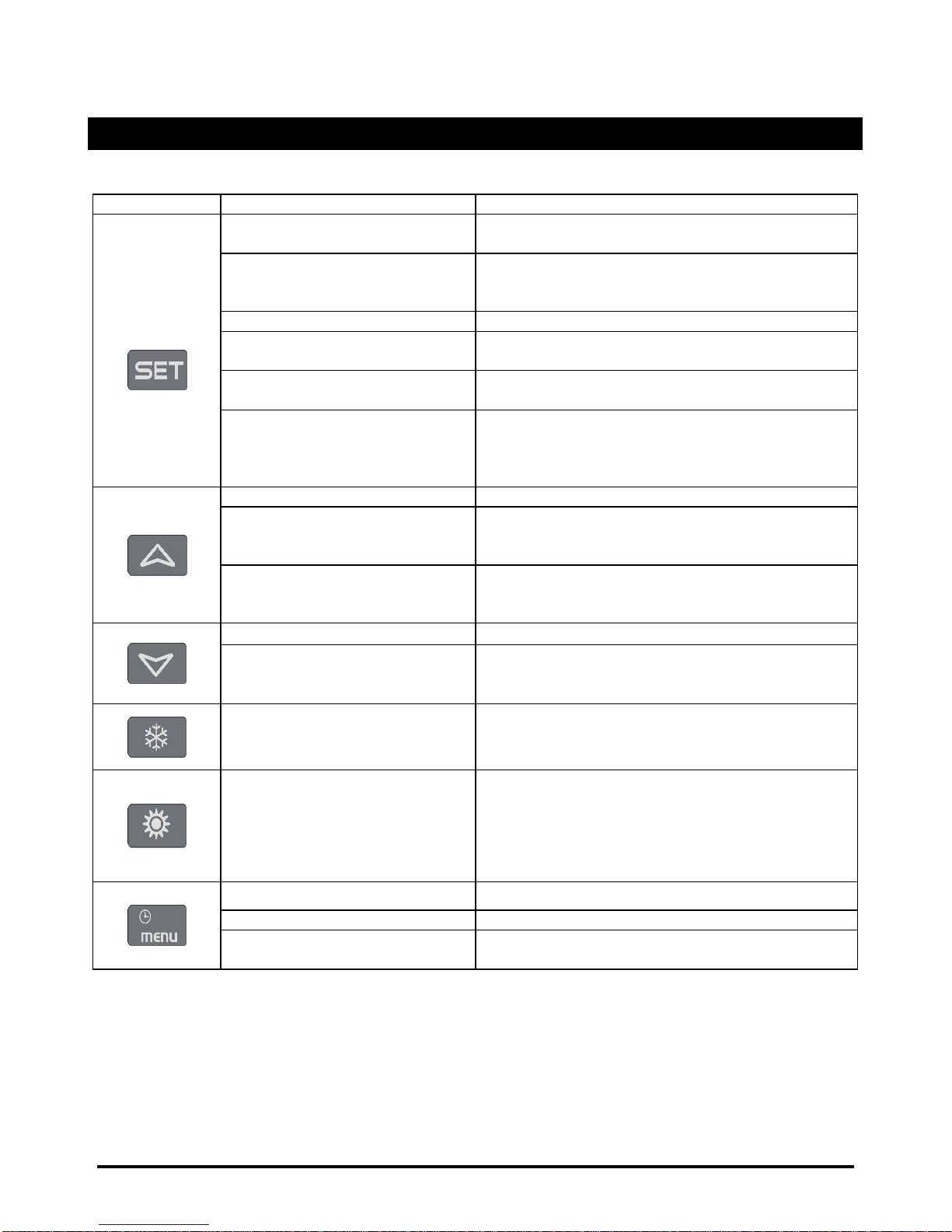

7 KEY FUNCTION

KEY

ACTION

FUNCTION

Push and release

Show chiller set point SetC, heat pump set point

SetH, sanitay water set point SetS

Push once again

In chiller or heat pump if the Energy saving or the

Dynamic setpoint are enabled it shows the real

setpoint Setr.

Push for 3 seconds

Set point modification

During the programming: push

once

To enter parameter modification or confirm a

value

Push when an alarm is showed

in menù ALrM

To reset the alarm

Push once with probe label

showed on the bottom display

(press up or down starting from

default visualization)

To read probes values of circuit 1 or circuit 2

Push once

To read probes value

Pushing once during the

programming

To change the group of parameters, to change

the parameter, to change the value of the

parameter

Push for 1 second during the

programming when the display

visualize Pr1 or Pr2 or Pr3

1 time shows the Pr2 programming level

2 times shows the Pr3 programming level

Push once

To read probes value

Pushing once during the

programming

To change the group of parameters, to change

the parameter, to change the value of the

parameter

Push once

To turn ON or turn OFF the controller (in chiller or

heat pump depending from CF58 parameter)

Push once

To turn ON or turn OFF the controller (in chiller or

heat pump depending from CF58 parameter)

Push once

To enter the function Menu

Push for 3 seconds

To set the clock (controller with clock on board)

Pushing once during the

programming

To exit from a group of parameter

Page 12

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 12/40

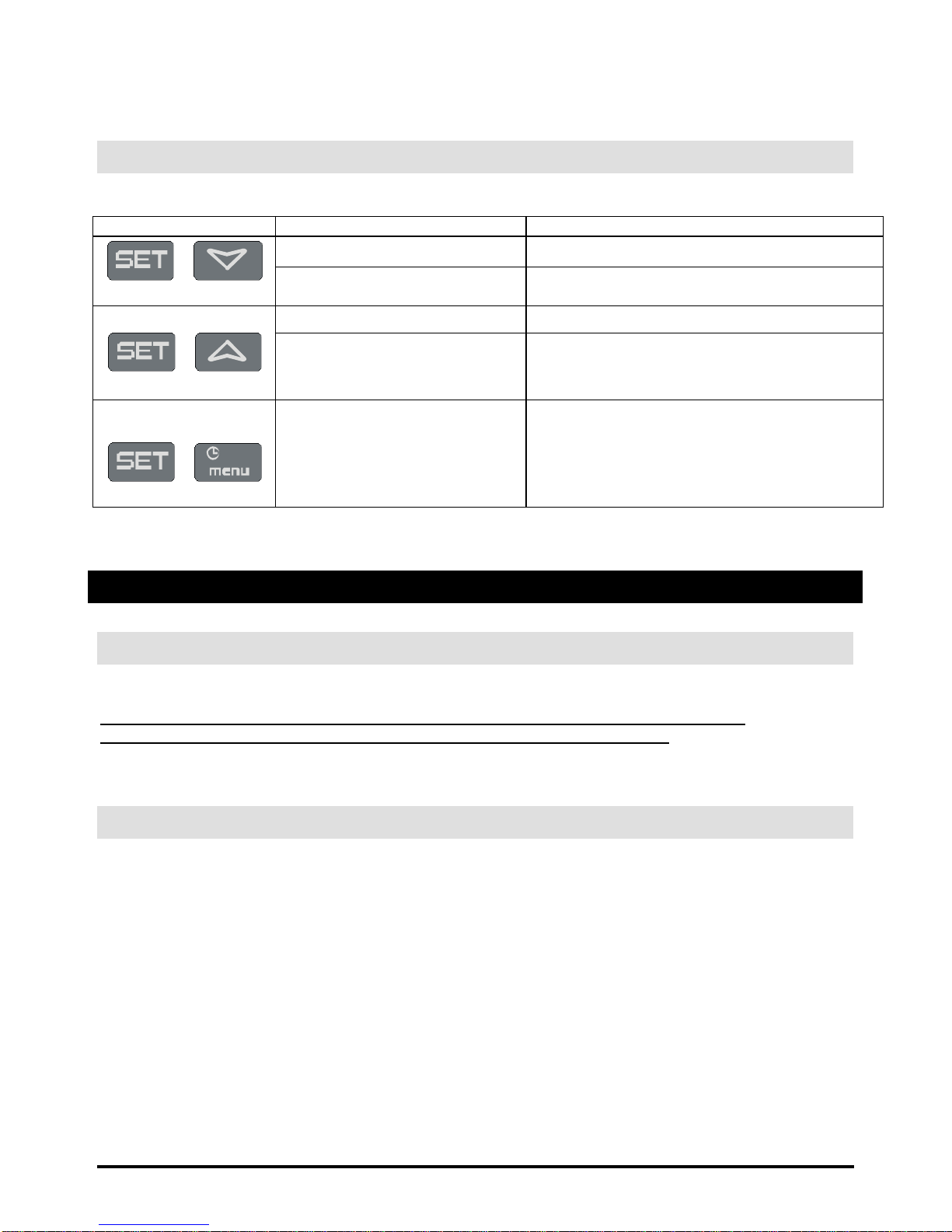

7.1 KEY COMBINANTION

KEY

ACTION

FUNCTION

+

Push for 3 seconds together

Enter the programming parameters

Only in Pr3 level: push SET and

DOWN key

Select the parameter level visibility Pr1 / Pr2 /

Pr3

+

Push once together

Exit the programming parameters

Push 5 seconds in heat pump

mode

Manual defrost

+

Only in Pr3 programming level:

push SET and then the MENU

key

In Pr3 defines if the parameter can be

modified or not in the other levels.

8 FIRST INSTALLING

8.1 ON BOARD CLOCK (OPTIONAL)

If giving power supply the bottom display shows “rtC” alternated to a temperature or pressure value, It

is necessary to set the RTC (Real time clock).

The internal clock is an option of the instrument and it is not possible to update it.

It is necessary to order the instrument already complete of this features.

If the instrument is disconnected to the power supply for more than 3 days, it is necessary to setup the

clock.

8.2 RTC SETUP

1. Push Menu key continuously for 3 seconds until the bottom display shows “Hour” and the top

display shows its value.

2. Push SET one time: the value is blinking.

3. Use the Up and Down keys to adjust it. Push SET one time to confirm.

4. Push up or down keys and repeat the operations 2. 3. and 4. for all the RTC parameters:

- Min: minutes (0÷60)

- UdAy: day of the week (Sun = Sunday, Mon =Monday, tuE =Tuesday, UEd = Wednesday, tHu

= Thursday, Fri =Friday, SAt =Saturday)

- dAy: day of the month (0÷31)

- MntH: month (1÷12)

- yEAr: year (00÷99)

Page 13

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 13/40

9 PARAMETERS PROGRAMMING WITH THE “HOT KEY 64”

9.1 HOW TO PROGRAM AN INSTRUMENT WITH AN ALREADY

PROGRAMMED “HOT KEY” (DOWNLOAD)

1. Power off the instrument

2. Insert the hot key already programmed (by software Wizmate or other instrument)

3. Power on the instrument

4. Automatically the parameters are downloaded

During the download the regulation is locked and the top display shows the “doL” blinking label. At the

end of the download will appear:

“End” if the programming procedure is completely OK, after 30seconds the regulation starts

automatically.

“Err” if the programming procedure has found an error and the parameter have not been transferred.

In this case turn off and then on the instrument supply to repeat the operation or remove the hot key,

with power supply off, to restart the regulation.

9.2 HOW TO COPY THE PARAMETER MAP INTO THE “HOT KEY”

(UPLOAD)

1. Power on the instrument

2. Insert the hot key

3. Enter the function Menu

4. Select the UPL function (on the bottom display)

5. Push SET key and immediately the instrument starts transfer the parameters into the Hot key.

During the upload the regulation is locked and the top display shows the “UPL” blinking label. At the

end of the UPLOAD will appear:

“End” if the programming procedure is completely OK, after 30seconds the regulation starts

automatically.

“Err” if the programming procedure has found an error and the parameter have not been transferred.

Repeat the procedure.

To exit the UPL function push the MENU key or wait the time-out (15 sec).

10 PROGRAMMING USING LOCAL USER INTERFACE

Though the keyboard it is possible to modify the values of the parameters and set for each

one of them the visibility and editability; each parameter can be made visible at different

levels of users:

Pr1 User level (default Password = 1)

Pr2 Maintenance level (default Password = 2)

Pr3 OEM level (default Password = 3)

10.1 ENTER THE PROGRAMMING LEVEL PR1

Enter the Pr1 “User level”:

1. Push SET + DOWN keys together for 3 seconds. The top display shows “PAS” and the bottom

display shows “Pr1”.

Page 14

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 14/40

2. Push SET key and the top display shows “0” blinking

3. Push UP or DOWN to select Pr1 password

4. Push SET and, if the value is correct, the top display shows the first family of parameters “ALL”

5. Push UP or DOWN to select the parameter family

6. Push SET to enter; the bottom display shows the first available parameter while the top display

shows its value.

7. Push UP or DOWN to modify its value

8. Push SET to confirm the new value

9. If necessary modify others parameter

10. Push SET + UP keys together to exit parameters programming

10.2 ENTER THE PROGRAMMING LEVEL PR2

Enter the Pr2 “service level”:

1. Push SET + DOWN keys together for 3 seconds. The top display shows “PAS” and the bottom

display shows “Pr1”

2. Push UP key for 2 seconds and the top display will show Pr2

3. Push SET key and the top display shows “0” blinking

4. Push UP or DOWN to select Pr2 password

5. Push SET and, if the value is correct, the top display shows the first family of parameters “ALL”

6. Push UP or DOWN to select the parameter family

7. Push SET to enter, the bottom display shows the first available parameter label while the top

display shows its value

8. Push UP or DOWN to modify its value

9. Push SET to confirm the new value

10. If necessary modify others parameter

11. Push SET + UP keys together to exit parameters programming

10.3 ENTER THE PROGRAMMING LEVEL PR3

Enter Pr3 “OEM level ”:

1. Push SET + DOWN keys together for 3 seconds. The top display shows PAS and the bottom

display shows Pr1

2. Push UP key for 2 seconds and the top display shows Pr2

3. Push UP key again for 2 seconds and the top display will show Pr3

4. Push SET key and the top display shows “0” blinking

5. Push UP or DOWN to select Pr3 password

6. Push SET and, if the value is correct, the top display shows the first family of parameters “ALL”

7. Push UP or DOWN to select the parameter family

8. Push SET to enter; the bottom display shows the first available parameter label while the top

display shows its value

9. Push UP or DOWN to modify its value

10. Push SET to confirm the new value

11. If necessary modify others parameter

12. Push SET + UP keys together to exit parameters programming

11 MENU ( MENU KEY)

Enter the menu:

• press the menu button;

Page 15

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 15/40

• press the UP or DOWN button to select the submenu;

• press the SET to enter the submenu.

Exit menu functions:

• Press the menu button or wait the time-out.

Entering the menu, it is possbile to:

1. Read and reset the alarms (ALrM)

2. Read and reset the alarm log (ALOG)

3. Upload the parameter into the Hot Key (UPL)

4. Enable – disable a gas circuit (CrEn)

5. Enable – disable a compressors (COEn)

6. Read and reset the number of compressor running hour (Hour)

7. Read and reset the number of compressor starts-up (COSn)

8. Read dynamic set point probe value (PbdS)

9. Read compressor discharge temperature (COdt)

10. Read condensing fan speed percentage of the proportional output (Cond)

11. Read the percentage of the proportional output 0 ÷ 10 Vdc Pout

12. Enable – disable one of the pumps POEn

13. Read the delay time between two defrost cycles (dF)

14. Read auxiliary output probe value (uS)

15. Read the temperature measured by internal sensor of the remote keyboards (trEM)

16. Read the temperature, the set point and the output status of the Free cooling (FC)

17. Read the temperature, the set point and the output status of the Solar panel (SoL)

18. Read temperature, pressure and status of the electronic expansion valve 1 (Et1)

19. Read temperature, pressure and status of the electronic expansion valve 2 (Et2)

11.1 ALARM LIST: READ AND RESET

ALrM FUNCTION

1. Push MENU key

2. The display shows AlrM label

3. Push SET key (Nothing happens if there are not alarms)

4. The bottom display shows the alarm code and the top display shows the label rSt, if it is possible

to reset the alarm, or NO if it is not possible to reset the alarm

5. Push UP or DOWN to scroll the alarm list (if more than one alarm is active)

6. Repeat the reset procedure for each alarm

7. To exit the ALrM reset, push MENU or wait the timeout.

11.2 ALARM LOG LIST

ALOG FUNCTION

1. Push MENU key

2. Push UP or DOWN to select ALOG

3. Push SET key

4. The bottom display shows the alarm label, the top display shows a number in the range 00 to 99.

5. Use the UP or DOWN keys to scroll the list.

6. To exit the ALOG function push MENU or wait the timeout.

Page 16

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 16/40

Erase the Alarm log list

1. Push MENU key

2. Push UP or DOWN to select ALOG

3. Push the SET key

4. Push UP or DOWN keys and search the ArSt label on the bottom display; the top display shows

PAS.

5. Push SET; the bottom display shows PAS and the top display shows “0” blinking

6. Push UP or DOWN to set the password

7. If the password is OK the label ArST blinks for 5 seconds then the display returns to normal

condition read-out

8. If the password is not correct the display shows PAS again

9. To exit, push the MENU key or wait the timeout.

The standard password to reset the alarm log is “4”.

12 REMOTE KEYBOARD VICX620 EVO

The display visualization and the button functions are the same of the Ichill, then refer to previous

chapters of the quick reference guide.

13 REMOTE KEYBOARD V2I820

The main window shows the temperature / pressure measured by the main probe of the

machine.

Some icons indicate the activation of the main loads (compressors, water pumps, fans,

heaters), the status of the machine (production of hot water, defrost, unloading, energy

saving and alarm):

• unit status: ON/OFF status and operating mode (cooling, heating, .......)

• time and date, if the iCHILL 200D is equipped with on-board clock

• the value of 4 sensors can be configured as desired through the parameters

Page 17

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 17/40

dP06..dP09

• the load status

Compressor/s

(blinking during the start up

delay)

Economy function

/

Water pump / Supply fan

Unloading function

Condenser fan

Economy or ON/OFF by

timetable

Electric heater

Defrost

Sanitary water

Alarm

Recovery enabled

Meaning of the keys:

Allows to read the value of the

probes configured in the Ichill

Allows to read/modify the set point

Allows to switch on the Ichill in

heating or cooling mode (see

parameter CF78)

Allows to read the alarms

Allows to switch on the Ichill in

heating or cooling mode (see

parameter CF78)

Allows to enter the SERVICE

menù

Allows to put the Ichill in STD-BY

Allows to read the main

information of the circuits

(compressor status, water pump

status, pressure probe value,…)

Note:

in case of alarm, press any key to silence the buzzer.

Page 18

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 18/40

13.1 PROBES VISUALIZATION

Press key to visualize the value of the probes configured in the Ichill and I/O

expansion (press or to visualize all the probes).

13.2 VISUALIZZAZIONE / MODIFICA SET POINT

Press key to read the value of the set point (cooling set point if the Ichill is in cooling mode,

heating set point if the Ichill is in heating mode, cooling and hating set point if the Ichill is in STD_BY or

remote OFF, Sanitary water when enabled).

It is also possible to read the status of the Energy saving, the status of the Dynamic set point and the

real value of the set point if the Energy saving or Dinamic set point are active.

To modify the set point (Cooling, Heating or Sanitary water):

press or to select the value of the set point

press

press o to modify the value

Page 19

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 19/40

press to confirm the operation

13.3 ALARM VISUALIZATION

Press key to read the alarm status; the alarm status can be:

o Active: the alarm is still active and it is not possible to reset it

o Reset: the alarm is not active and it is possible to reset it

Manual reset procedure:

o press or to select the alarm;

o press to reset the alarm

In case of compressor overload alarm when the password is requested, follow this step:

o press o to select the compressor overload alarm

o press

o press

o press or to insert the password value (parameter AL46)

o press to confirm the operation

Note:

in caso of alarm, first key pressure silence internal buzzer (if enabled).

Page 20

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 20/40

14 TABLE OF THE OUTPUT STATUS IN ALARM CONDITION

14.1 ALARM: “A” TYPE AND STATUS OF THE LOADS IN CASE OF

ALARM

Alarm

Code

Alarm

description

Compressor

Anti

freeze

heaters

Boiler

Support

heaters

Evap.

Pump.

Supply

fan

Condenser

Pump

Cond.

Fan

Cir1

Cir2

Auxili

ary

relay

ACF1

..

ACF12

Configuration

alarm

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ACFL

Condenser

flow alarm

OFF

OFF (3)

OFF

AEE

Eeprom

alarm

OFF

OFF

OFF

OFF

OFF

AEFL

Evaporator

flow alarm

OFF

OFF

(boiler)

OFF

(3)

OFF

AEht

High water

temperature

inlat

evaporator

OFF

AELt

Low

temperature

of the

evaporator

inlet in Heat

Pump mode

OFF

AHFL

Sanitary

water pump

flow alarm

OFF (6)

/ / / / /

/

ALc1

Generic

alarm n°1

OFF

OFF

OFF

OFF

OFF

Page 21

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 21/40

ALc2

Generic

alarm n°2

and AL56=0

ALSF

Phase

sequence

alarm

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ALti

Low air

temperature

of the

evaporator

inlet (air / air

unit) Alarm

Ap1 ..

Ap6

Probe failure

(7)

Yes (6)

(7)

(7)

(7)

(7)

Spent

o (2)

APE1

...

APE8

I/O

expansion

probes

(7)

(7)

(7)

(7)

(7)

(7)

(7)

APFL

Solar panel

water pump

flow alarm

/ / / / / / /

APr1

APr2

Remote

terminals

probe

(7)

(7)

(7)

(7)

(7)

(7)

(7)

APU1

...

APU4

IEV

Electronic

expansion

valve probes

(8)

(8)

(8)

(8)

(8)

(8)

(8)

ASLA

Serial

communicati

on failure

with I/O

expansion

OFF

OFF

OFF

OFF

OFF

OFF

OFF

AtAS

Sanitary

water pump

overload

OFF (6)

/ / / / /

/

AtC1

Condenser

water pump 1

overload

alarm

OFF (4)

OFF

OFF

AtC2

Condenser

water pump 2

overload

alarm

OFF (4)

OFF

OFF

AtE1

Evaporator

water pump 1

overload

alarm

OFF (4)

OFF

(boiler)

(5)

OFF

OFF

AtE2

Evaporator

water pump 2

overload

alarm

OFF (4)

OFF

(boiler)

(5)

OFF

OFF

Page 22

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 22/40

AtHS

Sanitary

heater

overload

/ / / / / / /

AtSF

Supply fan

overload

alarm

OFF

OFF

OFF OFF

AUAL

Serial

communicati

on failure

with

expansion

valve driver

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Err

Contemporar

y activation of

cooling and

heating

request on

condensing

unit

OFF

OFF

OFF

OFF

OFF

OFF

OFF

(1) = if probe configured as anti-freeze / boiler control and Ar10 = 0

(2) = if probe configured to control the auxiliary output

(3) = if the alarm is manual reset

(4) = compressors off if only 1 water pump configured or if 2 water pumps and both in alarm

(5) = boiler heaters off if only 1 water pump configured or if 2 water pumps and both in alarm (in this

case boiler heaters are used only for anti-freeze)

(6) = if enabled the only sanitary water function, or if the chiller and heat pump set point are reached

(7) = load switching off depends on the probe on error; regulation probe alarm switch off main loads,

external probe alarm disable only dynamic set point function

(8) = in case of electronic expansion valve probe alarm, all the loads of gas circuits where the valve

is mounted are switched off

14.2 ALARM: “B” TYPE AND STATUS OF THE LOADS IN CASE OF

ALARM

Alarm

Code

Alarm description

Compressors

of the circuit

(n)

Compressors

of the other

circuit

Fan

condensing

of the

circuit (n)

Fan

condensing

of the other

circuit

b(n)AC

Anti-freeze in chiller circuit (n)

OFF

OFF

b(n)Ac

Anti-freeze circuit (n) warning

in chiller

b(n)AH

Anti-freeze in heat pump

circuit (n)

OFF

OFF

b(n)Ah

Anti-freeze circuit (n) warning

in heat pump

b(n)dF

End defrost warning circuit

(n)

Page 23

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 23/40

b(n)ds

Circuit (n) disabled from

keyboard

OFF

OFF

b(n)Eu

Unloading from evaporator

low temp/press of the circuit

(n)

OFF

OFF

b(n)HP

High pressure switch circuit

(n)

OFF

OFF after

60 seconds

b(n)hP

High condensing pressure of

the circuit (n)

OFF

OFF after

60 seconds

b(n)hP

High condensing temperature

from NTC of the circuit (n)

OFF

OFF after

60 seconds

b(n)LP

Low pressure switch circuit (n)

OFF

OFF

b(n)LP

Low condensing pressure (evaporating with low

pressure transducer) with

transducer of the circuit of the

(n)

OFF

OFF

b(n)lP

Low condensing temperature

NTC circuit (n)

OFF

OFF

b(n)PH

Pump down alarm in stop

regulation of the circuit (n)

OFF

OFF

b(n)PL

Pump down in regulation

start-up of the circuit (n)

OFF

OFF

b(n)rC

Recovery function disabled in

circuit (n)

b(n)tF

Fan overload circuit (n)

OFF

OFF

b(n)UA

IEV electronic expansion

valve driver alarm circuit (n)

OFF

/

OFF

/

(n) identifies the circuit 1 or 2

14.3 ALARM: “C” TYPE AND STATUS OF THE LOADS IN CASE OF

ALARM

Alarm

Code

Alarm description

Compressor

(n)

Compressors not

involved

C(n)dS

Compressor (n) disabled from keyboard

OFF

C(n)dt

Compressor high discharge temperature

OFF

C(n)HP

Compressor(n) high pressure switch

OFF

C(n)Mn

Compressor(n) maintenance

C(n)oP

Compressor(n) oil pressure switch / Oil

level switch

OFF

C(n)tr

Compressor(n) overload

OFF

(n) identifies the compressor 1, 2 , 3 , 4

Page 24

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 24/40

14.1 WARNING

Alarm

Code

Alarm description

ACP1

Condenser water pump 1 maintenance

ACP2

Condenser water pump 2 maintenance

AEP1

Evaporator water pump 1 maintenance

AEP2

Evaporator water pump 2 maintenance

AEUn

Unloading caused by evaporator high temp.

ArtC

Clock setting

ArtF

Clock failure

ASAn

Sanitary water pump maintenance

ASun

Solar panel water pump maintenance

Atr1

Remote terminal n° 1 configured but not connected

Atr2

Remote terminal n° 2 configured but not connected

b(n)Cu

Unloading caused by condenser high temp/press circuit (n)

b(n)Eu

Unloading from evaporator low temp/press of the circuit (n)

noL

Communication problem with Ichill and remote keyboard

15 BLACK-OUT

After the black-out, when the power supply is restored:

1. the instrument restores the same operating mode lost after the supply failure.

2. if active at the power off, the defrost is aborted

3. All the timers are reloaded

4. The alarm, if actives in manual mode at the power down, is not reset

16 WIRING CONNECTIONS

16.1 IC206CX CONNECTIONS

6 digital outputs (relays)

o MAX. current on the relay contacts 5(2)A 250V

o MAX. Current on the coomon line (C1R and, C2R) 10A 250V

11 digital inputs (free of voltage)

6 analogue inputs:

4 NTC / PTC probes

2 NTC / PTC / pressure transducer 4÷20 mA / pressure transducer ratio-metric 0÷ 5Volt

4 modulating outputs:

2 0 ÷ 10 Volt

2 0 ÷ 10.0 Volt or cut of phase (for modulating condenser fan)

1 LAN output to connect the I/O expansion and IEV electronic expansion valve

1 output to connect a remote keyboard (max. 2 VICX620 EVO or 1 VGI820)

1 TTL output for “Hot Key 64” or for XJ485CX (interface module for monitoring system)

Page 25

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 25/40

16.2 IC208CX CONNECTIONS

8 digital outputs (relays)

o MAX. current on the relay contacts 5(2)A 250V

o MAX. Current on the coomon line (C1R and, C2R) 10A 250V

11 digital inputs (free of voltage)

6 analogue inputs:

4 NTC / PTC probes

2 NTC / PTC / pressure transducer 4÷20 mA / pressure transducer ratio-metric 0÷ 5Volt

4 modulating outputs:

2 0 ÷ 10 Volt

2 0 ÷ 10.0 Volt or cut of phase (for modulating condenser fan)

1 LAN output to connect the I/O expansion and IEV electronic expansion valve

1 output to connect a remote keyboard (max. 2 VICX620 EVO or 1 V2I820)

1 TTL output for “Hot Key 64” or for XJ485CX (interface module for monitoring system)

Page 26

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 26/40

16.1 REMOTE KEYBOARD CONNECTION

It is possible to connect to the instrument up to two remote terminals VICX620 EVO, available with /

without temperature probe on board, or an LCD keyboard Visograph 2.0 (V2I820 without probes on

board); the use of keyboards VICX620 EVO exclude the possibility of use of the keyboard Visograph

and vice versa.

If the remote terminal VICX620 EVO is provided with temperature sensor on board, the temperature

adjustment can be performed with the probe at the edge of the terminal.

To enable the remote keyboard is necessary to configure the following parameters (in the Ichill

parameter map):

• CF54 Enable remote terminal 1 (VICX620 EVO)

• CF55 Enable remote terminal 2 (VICX620 EVO)

• CF84 Enable remote terminal Visograph (V2I820)

The connection of the remote terminals must be performed using a shielded / twisted (such as Belden

8772, wires 1 mm2 minimum); the maximum distance is 100M (maximum length of the connection,

both if using one or two keyboards).

In case of lack of communication between the device and the keyboard (wrong connection, wrong

configuration parameters), the display shows the message "noL" (no link).

When using two keyboards VICX620 EVO you must configure the dip switches on the rear of the

same, giving to the first keyboard address 1 and to the second keyboard address 2.

Page 27

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 27/40

Page 28

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 28/40

16.2 ANALOG INPUTS NTC – PTC PROBES

PbC = common terminal

Pb1…Pb6 = probe inputs

Page 29

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 29/40

16.3 DIGITAL INPUTS

GND = common terminal

ID1…ID11 = digital inputs

Page 30

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 30/40

16.4 ANALOG INPUT FOR PRESSURE TRANSDUCER PP30 (4 ÷ 20MA

SIGNAL)

12V = power supply for pressure transducers

Pb3 and Pb4 = pressure transducer inputs

Page 31

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 31/40

16.5 ANALOG INPUT FOR PRESSURE RATIOMETRIC TRANSDUCER PPR30 (0

÷ 5V SIGNAL)

+5V = power supply for pressure transducers

GND = ground for pressure transducers

Pb3 and Pb4 = pressure transducer inputs

Page 32

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 32/40

16.6 PWM OUTPUT FOR CONDENSING FAN SPEED CONTROL

OUT3 and OUT4 = signals for the modulation of the condenser fan

GND = ground for pressure transducers

The compatible modules are the following:

XV05PK mono-phase 500 Watt (2A)

XV10PK mono-phase 1000 Watt (4A)

XV22PK mono-phase 2200 Watt (9A)

Page 33

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 33/40

16.7 PROPORTIONAL OUTPUT FOR FAN CONDENSING CONTROL OR FOR

COMPRESSOR INVERTER CONTROLLED OR FOR AUXILIARY OUTPUTS

OUT1…OUT4 = signals for the modulation of the condenser fan

GND = ground for pressure transducers

Page 34

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 34/40

16.8 PROPORTIONAL OUTPUT 0..10V TO CONTROL DUMPER MOTORS

OUT1…OUT4 = signals for the modulation of the dumper motor

GND = ground

If the dumper motor has a common line between a pole of the power supply and the “–“ pole of the

0..10V signal, it is necessary to use two transformers for the power supply of the controller Ichill and

the power supply of the dumper motor.

Page 35

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 35/40

Page 36

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 36/40

16.9 PROPORTIONAL OUTPUTS CONFIGURED FOR AUX RELAY CONTROL

OUT1…OUT4 = signals for relays

GND = ground

Page 37

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 37/40

17 INSTALLING AND MOUNTING

17.1 PANEL CUT- OUT

The instrument must be mounted on vertical panel with cut-out 71x29mm, and fixed using the special

supplied bracket.

Avoid locations subject to heavy vibration, corrosive gases or excessive dirt. Ensure ventilation around

the instrument.

17.2 VERTICAL BOARDS VI620CX PANEL CUT-OUT

The keyboard must be mounted on vertical panel with cut-out 72x56 mm, and screwed with two

screws.

The IP65 can be reached with the gasket RGW-V (optional).

Page 38

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 38/40

WALL MOUNTING: use the vertical V-KIT (black, white and grey) as described in the following

scheme:

17.1 V2I820 PANEL CUT-OUT

18 ELECTRICAL CONNECTIONS

The instrument is provided with:

2 removable terminal blocks MOLEX MICROFIT 14 and 18 ways for power supplay / digital and

analogue inputs and modulating outputs

1 removable terminal blocks AMP 12 ways for the relay outputs

5 ways connector for TTL RS485 interface outputs.

Page 39

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 39/40

Wire size:

signal cable AWG 24

power supply cable AWG 22

relay output AWG 17

General notes:

Keep low voltage cables, such as analogue/digital inputs/outputs and probes, away from power

cables.

Respect the minimum load current of each relay output, in case of power loads use filtered

contactors.

19 TECHNICAL DATA

Material: Housing PC + ABS, frontal panel PC

Case: 32x74 mm; depth 60mm

Mounting: panel mounting in a 29 x71mm panel cut-out

Frontal protection: IP65

Power supply:

12Vac -10%÷+15% or

24 Vac/dc ±10% 50/60 Hz

Power consumption: 10VA max.

Analog Inputs:

4 configurable (NTC/PTC/dig. input)

2 configurable (NTC/PTC/4÷20ma/0÷5Volt/dig. input)

Digital inputs: 11 (free voltage, don’t supply voltage)

Relay outputs:

IC206CX: 6 relays SPDT 5(2) A, 250Vac

IC208CX: 8 relays SPDT 5(2) A, 250Vac

Max. current on common line: 10A

Data storing: on the non-volatile memory (EEPROM).

Operating temperature: -10÷55 °C

Storage temperature: -30÷85 °C

Relative humidity: 20÷85% (not condensing)

Measuring range:

- 50÷110 °C / - 58 ÷ 230 °F NTC probes

-50.0÷150 °C / -58÷302 °F PTC probes

0÷ 50 bar / 0÷725 psi 4..20mA and 0..5V probes

Resolution: 0,1 °C or 1 °F

Page 40

1592022760 Quick reference guide iCHILL 200CX EVO rel. 1.0 40/40

Loading...

Loading...