Page 1

F

IC200CX Series

User manual

Page 2

INDEX

1 GENERAL ADVICE 6

2 GENERAL FEATURES 6

2.1 MAIN FUNCTION 6

3 IC200 CX TABLE OF THE FEATURES 8

4 USER INTERFACE 9

4.1 DISPLAY CONFIGURATION 9

4.2 FORCED READ - OUT OF THE TOP AND BOTTOM DISPLAY 11

4.3 ICONS MEANING 12

4.4 MEANING / FUNCTIONNING OF THE BOTTOM DISPLAY LED 13

5 DISPLAY LAYOUT 13

5.1 HOW TO READ THE MEASUREMENT LIST 13

5.2 READ PROBE VALUES OF CIRCUIT 1 OR 2 13

6 DISPLAY INFORMATION 14

6.1 READ THE SET POINT VALUE 14

6.2 MODIFY THE SET POINT 14

6.3 READ THE ACTIVE SETPOINT DURING ENERGY SAVING OR DYNAMIC SETPOINT 14

6.4 DISPLAY VISUALIZATION IN REMOTE OFF 14

6.5 DISPLAY VISUALIZATION IN STD-BY 15

6.6 DISPLAY IN CONDENSING UNIT 15

6.7 KEY FUNCTION 16

6.8 KEY COMBINANTION 16

7 REMOTE TERMINAL 17

8 FIRST INSTALLING 17

8.1 ON BOARD CLOCK (OPTIONAL) 17

8.2 RTC SETUP 17

9 ANALOG AND DIGITAL OUTPUT CONFIGURATION 18

9.1 ANALOG INPUT PB1 - PB2 – PB5 – PB6 18

9.2 ANALOG INPUT CONFIGURATION PB3 - PB4 18

9.3 DIGITAL INPUT CONFIGURATION ID1 – ID18 18

9.4 DIGITAL OUTPUT (RELAY) CONFIGURATION RL1- RL8 19

9.5 ANALOG OUTPUT CONFIGURATION 0 ÷ 10 VOLT (OUT1 E OUT2) 20

9.6 CONFIGURAZIONE N° 2 USCITE ANALOGICHE 0 ÷ 10 VOLT / TAGLIO DI FASE (OUT3 E OUT4) 20

10 PROGRAMMING WITH THE “HOT KEY 64” 21

10.1 DOWNLOAD: HOW TO PROGRAM AN INSTRUMENT WITH A PROGRAMMED “HOT KEY” 21

10.2 UPLOAD: HOW TO PROGRAM A “HOT KEY” WITH THE PARAMETERS OF THE INSTRUMENT 21

11 PROGRAMMING USING THE KEYBOARD 21

11.1 PASSWORD DEFAULT VALUES 21

11.2 ENTER THE PR1 - PR2 - PR3 PROGRAMMING LEVELS 21

11.3 HOW TO CHANGE A PARAMETER VALUE 21

11.4 CHANGE THE PASSWORD VALUE 22

11.5 ENTER THE PROGRAMMING LEVEL PR1 22

11.6 ENTER THE PROGRAMMING LEVEL PR2 22

11.7 ENTER THE PROGRAMMING LEVEL PR3 23

11.8 MOVE A PARAMETER LEVEL FROM PR2 TO PR1 23

11.9 MOVE A PARAMETER FROM PR3 TO PR2 TO PR1 24

11.10 VISIBILITY AND PARAMETER VALUE LOCKED 24

11.11 PROGRAMMING: DIGITAL INPUT AND OUTPUT POLARITY 24

11.12 CHANGE THE POLARITY OF THE DIGITAL INPUTS-OUTPUTS 25

Page 3

12 FUNCTION MENU “ M” KEY 25

12.1 ALARM LIST: SHOW AND RESET 25

12.2 COMPRESSOR OVERLOAD ALARM RESET 25

12.3 COMPRESSOR OVERLOAD PASSWORD. 26

12.4 ALARM LOG LIST 26

12.5 ERASE THE ALARM LOG LIST 26

12.6 PASSWORD VALUE OF THE ALARM LIST 26

12.7 DISABLE – ENABLE A SINGLE CIRCUIT 26

12.8 READ-OUT OF A CIRCUIT NOT ENABLED 26

12.9 ENABLE OR DISABLE A SINGLE COMPRESSOR 26

12.10 READ-OUT OF A COMPRESSOR NOT ENABLED 27

12.11 READ-OUT OF THE COMPRESSOR DISCHARGE TEMPERATURE PROBE 27

12.12 READ-OUT OF THE RUNNING HOURS 27

12.13 RESET THE RUNNING HOUR 27

12.14 READ-OUT OF THE COMPRESSOR STARTS-UP 27

12.15 RESET THE STARTS-UP NUMBER 27

12.16 READ-OUT OF THE PROPORTIONAL OUTPUT PERCENTAGE OF THE CONDENSER FAN CONTROL 27

12.17 READ-OUT OF THE FOUR PROPORTIONAL OUTPUT 28

12.18 READ-OUT OF THE TIME COUNTING TO THE NEXT DEFROST 28

12.19 READ-OUT OF THE PROBES CONFIGURED TO CONTROL AN AUXILIARY OUTPUT RELAY 28

12.20 HOW TO DISPLAY THE TEMPERATURE OF THE REMOTE KEYBOARD 1 OR 2 28

13 CHILLER / HEAT PUMP SELECTION 29

14 UNIT START - STOP 30

14.1 START – STOP AND STAND- BY FROM KEYBOARD 30

14.2 UNIT START- STOP FROM DIGITAL INPUT 30

14.3 MOTOCONDENSING UNIT START- STOP FROM DIGITAL INPUT 30

14.4 MODE WITH DIGITAL INPUT CONFIGURED AS THERMOREGULATION REQUEST 30

14.5 MODE WITH DIGITAL INPUT CONFIGURED AS CHILLER REQUEST 30

14.6 MODE WITH DIGITAL INPUT CONFIGURATED AS HEAT PUMP REQUEST 31

15 COMPRESSOR THERMOREGULATION 31

15.1 THERMOREGULATION PARAMETER DESCRIPTION 31

16 THERMOREGULATION: PROPORTIONAL OR NEUTRAL ZONE 32

16.1 GRAPH OF THE COMPRESSOR THERMOREGULATION IN CHILLER 32

16.2 GRAPH OF THE COMPRESSOR THERMOREGULATION IN HEAT PUMP 32

16.3 GRAPH NEUTRAL ZONE COMPRESSOR CONTROL 32

17 COMPRESSOR STATUS INTO THE NEUTRAL ZONE 33

17.1 MAXIMUM TIME OF NEUTRAL ZONE STAY WITHOUT INSERTION OF RESOURCES WITH AT LEAS ONE

RESOURCE INSERTED 34

17.2 MAXIMUM TIME OF NEUTRAL ZONE STAY WITHOUT THE RESOURCES ROTATION 34

17.3 THERMOREGULATION OF THE COMPRESSOR INVERTER CONTROLLED 34

18 THERMOREGULATION AND COMPRESSORS ROTATION 37

19 SATURATION - CIRCUIT BALANCING 37

20 COMPRESSORS START-UP 37

20.1 COMPRESSORS START- UP 37

20.2 DIRECT START- UP 37

20.3 DIRECT START- UP OF A CAPACITY COMPRESSOR 37

20.4 PART WINDING 38

20.5 PART WINDING START- UP OF COMPRESSORS OR CAPACITY COMPRESSORS 38

21 CAPACITY CONTROL 38

21.1 MINIMUM LOAD START- UP 39

21.2 BY- PASS GAS VALVE DURING COMPRESSOR START- UP 40

21.3 SOLENOID VALVE INTERMITTENT FOR SCREW COMPRESSOR 40

22 THERMOREGULATION OF THE COMPRESSORS WITH DIFFERENT SIZE 40

Page 4

23 PUMP DOWN 40

23.1 OFF UNIT WITH PUMP DOWN AND WITH LOW PRESSURE SWITCH CONTROL 40

23.2 PUMP DOWN WITH DEDICATED PRESSURE SWITCH 41

23.3 PUMP DOWN FUNCTION WITH DEDICATED PRESSURE PROBE 41

23.4 PUMP DOWN ALARM DURING COMPRESSORS START- UP 42

23.5 PUMP DOWN ALARM DURING COMPRESSORS SWITCHING OFF 42

23.6 PUMP DOWN BY DELAY TIME 42

24 UNLOADING 43

24.1 HIGH TEMPERATURE OF THE EVAPORATOR WATER INLET 43

24.2 UNLOADING DESCRIPTION 43

24.3 UNLOADING INFORMATION 43

24.4 UNLOADING WITH PRESSURE / CONDENSING TEMPERATURE OR EVAPORATING PRESSURE CONTROL 43

24.5 REGULATION IN CHILLER MODE 43

24.6 REGULATION IN HEAT PUMP MODE 44

24.7 LOW TEMPERATURE OF THE EVAPORATOR WATER OUTLET 44

25 SOLENOID VALVE FOR LIQUID INJECTION 44

25.1 FUNCTIONNING 44

26 WATER PUMP OF THE EVAPORATOR / SUPPLY FAN 44

26.1 WATER PUMP OF THE EVAPORATOR / SUPPLY FAN (AIR/AIR UNIT) 44

26.2 HOT START (SUPPLY FAN) ONLY FOR AIR / AIR UNIT IN HEAT PUMP MODE 45

26.3 SUPPLY FAN OPERATION WITH DIGITAL INPUT AND RTC 45

27 EVAPORATOR PUMP GROUP 45

27.1 EVAPORATOR WATER PUMP ROTATION 45

27.2 EVAPORATOR WATER PUMP ROTATION THROUGH DIGITAL INPUT CONTROL 45

28 WATER PUMP OF THE CONDENSER 46

28.1 CONDENSER WATER PUMP CONTROL 46

29 PUMP GROUP OF THE CONDENSER 46

29.1 CONDENSER WATER PUMP ROTATION 46

29.2 CONDENSER WATER PUMP ROTATION THROUGH DIGITAL INPUT CONTROL 47

30 MODULATING OPERATION OF THE PUMPS 47

31 CONDENSER FAN REGULATION 48

31.1 ON/OFF CONDENSER FAN 49

31.2 PROPORTIONAL FAN CONTROL (PWM OR 0..10V) 49

31.3 CONDENSING UNIT: COMMON OR SEPARATE 49

31.4 GRAPH: PROPORTIONAL REGULATION OF CONDENSER FANS 50

31.5 GRAPH: ON / OFF REGULATION OF THE CONDENSER FAN IN CHILLER MODE 50

31.6 GRAPH: ON / OFF REGULATION OF THE CONDENSER FAN IN HEAT PUMP MODE 50

32 THERMOREGULATION OF THE ANTI FREEZE, INTEGRATION HEATING

OR BOILER 51

32.1 THERMOREGULATION OF THE HEATERS IN CHILLER 51

32.2 THERMOREGULATION OF THE HEATERS IN HEAT PUMP 51

32.3 THERMOREGULATION OF THE SUPPORT HEATERS FOR AIR/AIR UNIT 51

32.4 CONDENSER ANTI-FREEZE HEATERS REGULATION 51

32.5 GRAPH OF THE ANTI-FREEZE- INTEGRATION HEATING - BOILER HEATER RELAYS 52

32.6 BOILER FUNCTION 52

33 DEFROST CYCLE 53

33.1 FORCED DEFROST 53

33.2 COMBINED DEFROST 53

33.3 MANUAL DEFROST 53

33.4 DEFROST START CONDITION WITH TWO CIRCUIT UNIT 53

33.5 START/STOP DEFROST IN A TWO CIRCUITS UNIT WITH ONE CONDENSING FAN CONTROL UNIT 53

33.6 START/STOP DEFROST IN A TWO CIRCUITS UNIT WITH TWO CONDENSING FAN CONTROL UNIT 53

33.7 AUTOMATIC DEFROST PROCEDURE 54

33.8 OTHER INFORMATION ABOUT THE DEFROST 55

33.9 DEFROST BY CONDENSER FAN 55

Page 5

33.10 END DEFROST BY LOW WATER OUTLET EVAPORATOR TEMPERATURE 55

33.11 DEFROST PARAMETER DESCRIPTION 55

34 ENERGY SAVING 57

34.1 ENERGY SAVING: DIGITAL INPUT ACTIVATION 57

34.2 ENERGY SAVING TIME TABLE WITH RTC 57

34.3 RTC DAILY TIME TABLE PROGRAMMING 57

34.4 ENERGY SAVING OR UNIT ON/OFF ACTIVATION WITH RTC PROGRAMMING 57

34.5 UNIT ON/OFF ACTIVATION WITH RTC PROGRAMMING AND DIGITAL INPUT 58

35 DYNAMIC SETPOINT 59

35.1 DYNAMIC SETPOINT GRAPH 59

36 GEOTHERMAL FUNCTION 60

37 AUXILIARY FUNCTION 61

37.1 AUXILIARY FUNCTION ON RELAY OUTPUT 61

37.1.1 Auxiliary relay on Direct action .....................................................................................................................................61

37.1.2 Auxiliary relay on reverse action...................................................................................................................................62

37.2 AUXILIARY FUNCTION ON ANALOG OUTPUTS 62

38 LOAD MAINTENANCE 63

38.1 LOAD MAINTENANCE RESQUESTS 63

39 MESSAGES - ALARM CODES 64

39.1 AP1 - AP2 - AP3 - AP4 - AP5 - AP6 - AP7 - AP8 PROBE FAILURE 64

39.2 AEFL: EVAPORATOR FLOW ALARM (DIFFERENTIAL PRESSURE SWITCH) 64

39.3 ACFL: CONDENSER FLOW ALARM (DIFFERENTIAL PRESSURE SWITCH) 64

39.4 ATSF: OVERLOAD ALARM OF THE SUPPLY FAN 65

39.5 ATE1 - ATE2 EVAPORATOR PUMP OVERLOAD ALARM 65

39.6 ATC1 - ATC2 CONDENSER PUMP OVERLOAD ALARM 65

39.7 AEE EEPROM ALARM 65

39.8 AFR: POWER SUPPLY FREQUENCY ALARM 66

39.9 ALC1: GENERIC ALARM WITH STOP REGULATION 66

39.10 ALC2: GENERIC SIGNAL ALARM 66

39.11 ALC2: GENERIC ALARM WITH STOP REGULATION 66

39.12 ACF1 - ACF2 - ACF3 - ACF4 - ACF5 - ACF6 - ACF7 - ACF8 - ACF9 – ACF10 – ACF11 CONFIGURATION ALARM

OF THE UNIT 67

39.13 ARTF CLOCK FAILURE 69

39.14 ARTC CLOCK ALARM 69

39.15 AEUN: UNLOADING FROM HIGH TEMPERATURE OF THE EVAPORATOR WATER INLET 69

39.16 AEHT: ALARM FROM HIGH TEMPERATURE OF THE EVAPORATOR WATER INLET 69

39.17 AELT LOW WATER TEMPERATURE INLET (ONLY HEAT PUMP) 69

39.18 AEDT DIFFERENTIAL ALARM EVAPORATOR WATER INLET – OUTLET TEMPERATURE 70

39.19 ALTI: LOW AIR AMBIENT TEMPERATURE (AIR / AIR UNIT ONLY) 70

39.20 AEP1 - AEP2 EVAPORATOR PUMPS / SUPPLY FAN MAINTENANCE REQUEST 71

39.21 ACP1 - ACP12 CONDENSER PUMPS MAINTENANCE REQUEST 71

39.22 B1HP - B2HP HIGH PRESSURE SWITCH CIRCUIT 1 AND 2 71

39.23 B1LP - B2LP LOW TEMPERATURE / LOW CONDENSING PRESSURE OF THE CIRCUIT 72

39.24 B1AC - B2AC - B1AC - B2AC ANTIFREEZE ALARM / LOW OUTLET TEMPERATURE (AIR / AIR UNIT IN CHILLER

MODE) 72

39.25 B1AH - B2AH ANTI-FREEZE ALARM / LOW OUTLET AIR TEMPERAURE(AIR/AIR UNIT ONLY) ON HEAT PUMP

MODE 72

39.26 B1HP - B2HP HIGH CONDENSING PRESSURE / TEMPERATURE OF THE CIRCUIT 73

39.27 B1LP - B2LP LOW PRESSURE SWITCH CIRCUIT #1 OR 2 73

39.28 B1LP - B2LP LOW EVAPORATING PRESSURE OF THE CIRCUIT (WITH PRESSURE TRANSDUCERS ONLY) 73

39.29 B1TF- B2TF CONDENSER FAN OVERLOAD ALARM 73

39.30 B1EU – B2EU: UNLOADING FROM LOW TEMPERATURE OF THE EVAPORATOR WATER OUTLET 74

39.31 C1HP - C2HP COMPRESSOR HIGH PRESSURE ALARMS 74

39.32 C1OP - C2OP PRESSURE SWITCH ALARM / COMPRESSOR OIL 74

39.33 C1DT - C2DT HIGH COMPRESSOR DISCHARGE TEMPERATURE ALARM 74

39.34 C1TR - C2TR COMPRESSOR OVERLOAD ALARM 75

39.35 B1DF – B2DF DEFROST ALARM 75

39.36 B1CU – B2CU UNLOADING: HIGH CONDENSING TEMPERATURE / PRESSURE IN CHILLER 75

39.37 B1CU – B2CU: UNLOADING: LOW CONDENSING TEMPERATURE / PRESSURE IN HEAT PUMP 75

39.38 B1PH - B2PH: PUMP DOWN STOP ALARM FROM PRESSURE SWITCH / LOW PRESSURE SWITCH 76

39.39 B1PL - B2PL ALARM DURING THE PUMP DOWN START-UP FROM PUMP DOWN PRESSURE SWITCH / LOW

PRESSURE TRANSDUCER 76

39.40 C1MN - C2MN COMPRESSOR MAINTENANCE 76

39.41 ALARM RELAY AND BUZZER 77

Page 6

39.42 KEYABOARD ALARM 77

40 AUTOMATIC TO MANUAL ALARM PROCEDURE 77

41 TABLE OF THE OUTPUT STATUS IN ALARM CONDITION 78

41.1 ALARM: “A” TYPE AND STATUS OF THE LOADS IN CASE OF ALARM 78

41.2 ALARM: “B” TYPE AND STATUS OF THE LOADS IN CASE OF ALARM 79

41.3 ALARM: “C” TYPE AND STATUS OF THE LOADS IN CASE OF ALARM 79

42 TABLE OF THE PARAMETERS 81

43 BLACK-OUT 99

44 WIRING CONNECTIONS 99

44.1 HARDWARE RESOURCES FOR IC206CX MODEL 99

44.2 HARDWARE RESOURCES FOR 208CX MODELS 100

44.3 ANALOG INPUTS NTC – PTC PROBES 100

44.4 DIGITAL INPUTS 101

44.5 ANALOG INPUT FOR PRESSURE TRANSDUCER PP30 (4 ÷ 20MA SIGNAL) 101

44.6 ANALOG INPUT FOR PRESSURE RATIOMETRIC TRANSDUCER PPR30 (0 ÷ 5V SIGNAL) 102

45 PWM OUTPUT FOR CONDENSING FAN SPEED CONTROL 103

45.1 PROPORTIONAL OUTPUT FOR FAN CONDENSING CONTROL OR FOR COMPRESSOR INVERTER

CONTROLLED OR FOR AUXILIARY OUTPUTS 103

45.2 PROPORTIONAL OUTPUTS CONFIGURED FOR AUX RELAY CONTROL 104

45.3 HOT KEY 64 CONNECTION 104

45.4 XJ485CX CONNECTION 105

45.5 REMOTE KEYBOARD VI620CX 106

46 INSTALLING AND MOUNTING 106

46.1 PANEL CUT- OUT 106

46.2 VERTICAL BOARDS VI620CX PANEL CUT-OUT 107

47 ELECTRICAL CONNECTIONS 108

48 ACCESSORIES 108

48.1 MONOPHASE FAN CONTROL: 230VAC AND CUT PHASE CONTROL 108

48.2 WIRING KIT 109

48.3 TRANSFORMER 109

48.4 XJ485CX 109

48.5 RT314 KIT 109

48.6 HOT KEY: 109

49 TECHNICAL DATA 110

Page 7

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

Pg.6/114

1 GENERAL ADVICE

PLEASE READ BEFORE USING THIS MANUAL

• This manual is part of the product and should be kept near the instrument for easy and quick reference.

• The instrument shall not be used for purposes different from those described hereunder. It cannot be used as a safety device.

• Check the application limits before proceeding.

SAFETY PRECAUTIONS

• Check the supply voltage is correct before connecting the instrument.

• Do not expose to water or moisture: use the controller only within the operating limits avoiding sudden temperature changes with

high atmospheric humidity to prevent formation of condensation

• Warning: disconnect all electrical connections before any kind of maintenance.

• The instrument must not be opened.

• In case of failure or faulty operation send the instrument back to the distributor or to “Dixell s.r.l.” (see address) with a detailed

description of the fault.

• Consider the maximum current which can be applied to each relay (see thechnical Data).

• Ensure that the wires for probes, loads and the power supply are separated and far enough from each other, without crossing or

intertwining.

• Fit the probe where it is not accessible by the end user.

• In case of applications in industrial environments, the use of mains filters (our mod. FT1) in parallel with inductive loads could be

useful.

Page 8

Page 9

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

Pg.6/114

2 GENERAL FEATURES

iCHILL IC200CX is an electronic controller for chiller unit applications having one or two circuits:

• Air/air

• Air/water

• Water/water

• Motocondensing

Additional features:

• Heat pump with gas reversibility

• Free cooling function

• Recovery function

2.1 MAIN FUNCTION

Chiller management:

• One circuit up to 2 compressors (max 1 capacity step per compressor)

• Two circuits with 1 compressor per circuit (max 1 capacity step per compressor)

• Screw compressors

• Compressor inverter controlled

Compressor start up:

• Direct

• Part winding

Compressor Soft start:

• With step valve

• Automatic start-unloading (without load)

• External by-pass gas valve

Capacity step control:

• Continuous control

• Step control

• Modulation control (screw compressors)

Thermoregulation of the compressors

• Time running hours

• Number of start-up per hour

Cooling liquid injection

• With dedicated PTC probe (for compressor one only)

High temperature alarm of the compressor discharge side

• With dedicated PTC probe (for compressor one only)

Complete management of two pump groups of the water side

• 2 pumps evaporator side

• 2 pumps condenser side

Display layout customizable

• Temperature

• Pressure

• Time / RTC in real time

Other display readings

• Safety digital inputs

• Compressors running hours

• Number of compressor start-up

• Pump running hours

• Delay counting to the next defrost

• Proportional output percentage status

• Compressors discharge temperature

Alarm reset with custom password

• Alarm list

• Compressor thermal protection alarm

Pump down management

• With dedicated pressure switch

• With low pressure switch

• With low pressure transducer

Unloading circuit

• High temperature of the evaporator inlet water

• High temperature of the condenser inlet water (unit with recovery)

• High condensing pressure

• Low evaporating pressure

Maintenance messages

• Compressors

• Evaporator pumps

• Condenser pumps

Weekly Energy saving

Page 10

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

• Three different time bands per day (only for controller with RTC onboard)

• From digital input

Weekly ON/OFF:

• Three different time bands per day (only with RTC onboard)

Dynamic setpoint:

• Determined by analogue NTC input or 4÷20mA current input.

Change over :

• Automatic chiller or heat pump functioning depending from NTC analogue input

Remote OFF:

• From configurable digital input

Remote change over:

• From configurable digital input

Hot start :

• Only for air / air unit

Defrost management:

• Combined control with temperature and pressure

• Forced defrost with low temperature of external air

• From configurable digital input

• Manual from keyboard

Boiler:

• For electrical integration heating or anti-freeze heaters

Proportional signal for condensing fan speed control (inverter or cut of phase):

• PWM

• 0÷10Volt

• 4÷20mA

Proportional outputs 0÷10V or ON/OFF

• To control the dumper in geothermal application or for auxiliary outputs

• To control an external relay

Complete alarm management

• Internal Data logger up to 100 events

Supervisor / tele assistance/ monitoring

• TTL output for XJ485CX interface (ModBus protocol) for Dixell monitoring system for local and remote control

Up to 2 remote terminals

• With NTC ambient temperature probe

Page 11

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

Pg.8/114

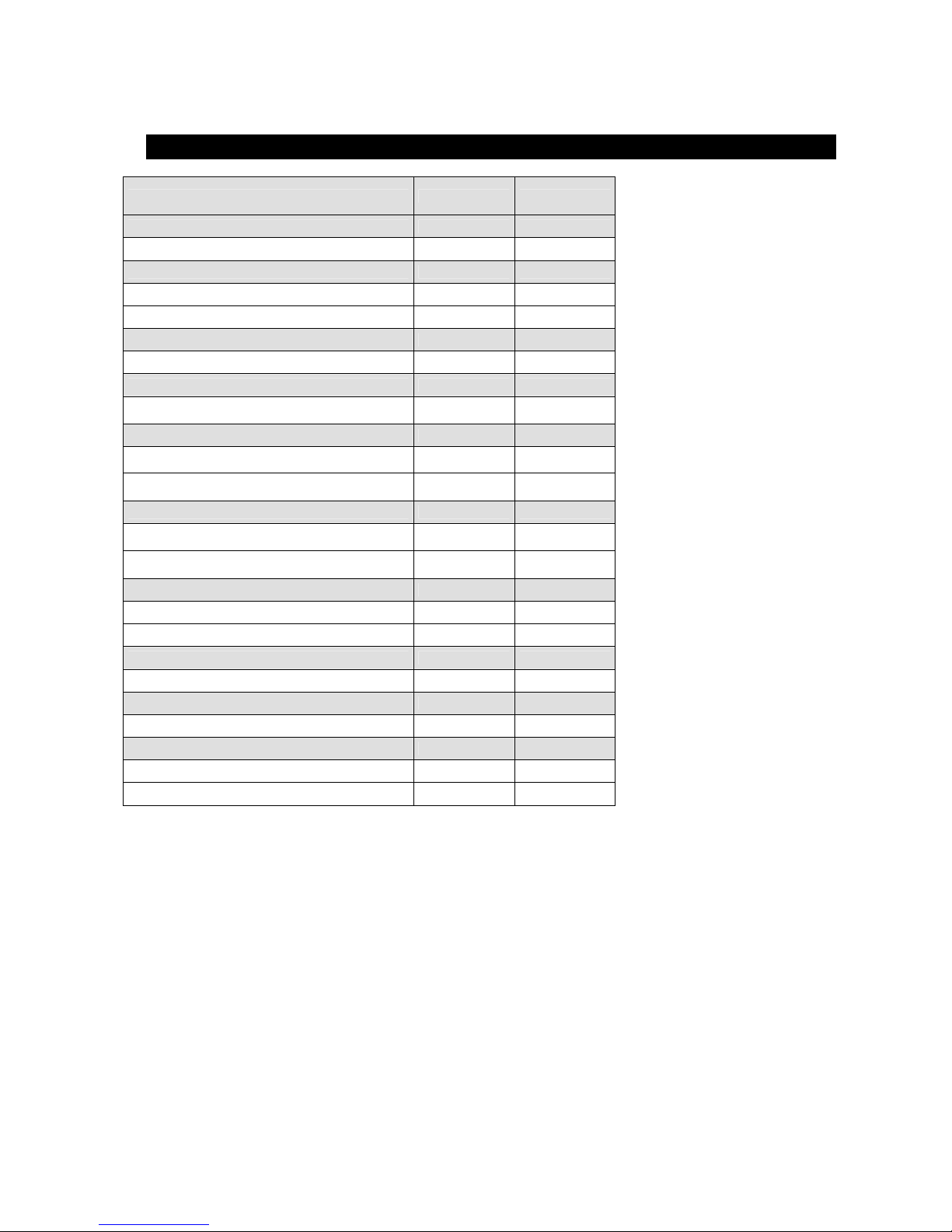

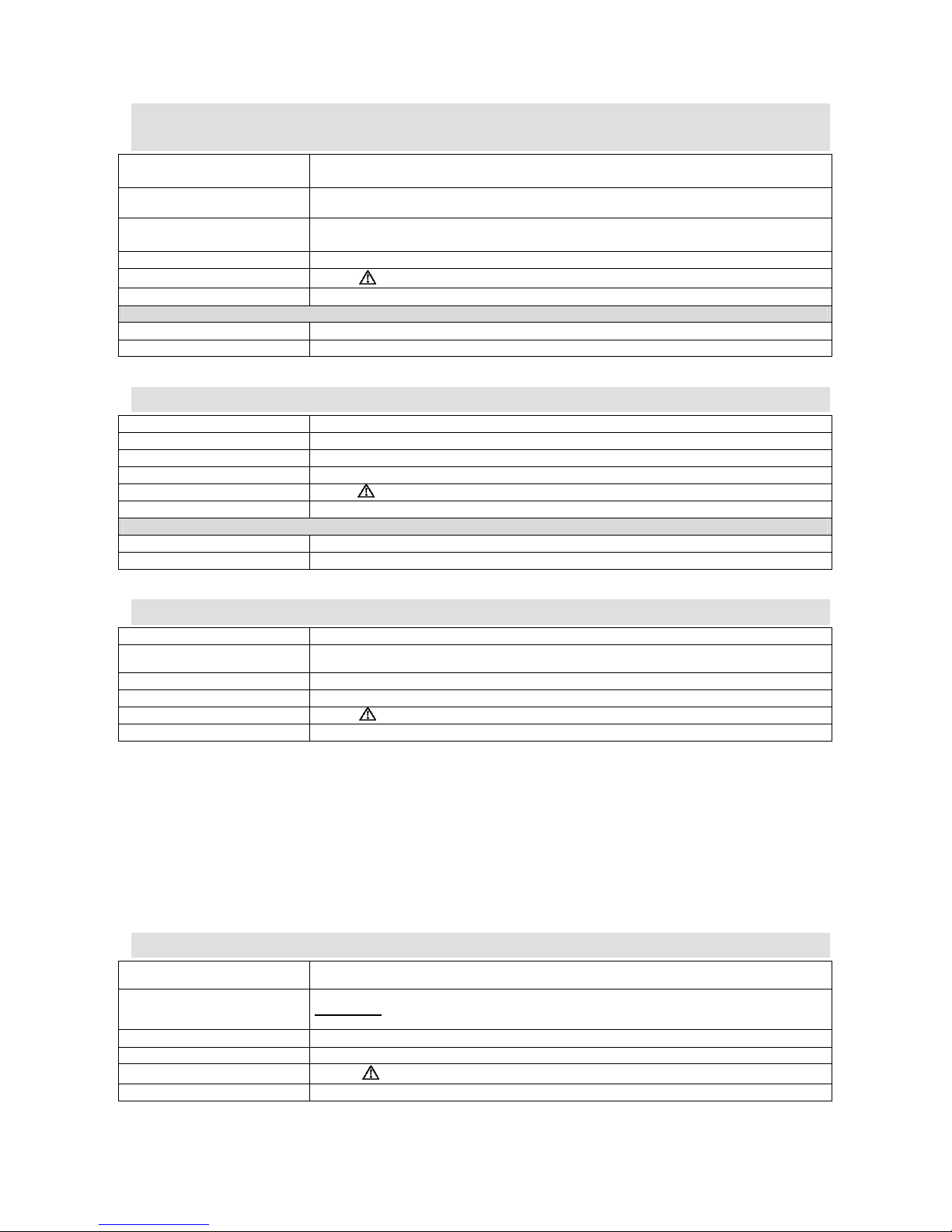

3 IC200 CX TABLE OF THE FEATURES

CHARACTERISTICS IC206CX IC208CX

N° KEYS

6

n n

RELAYS

6

n

8

n

DIGITAL INPUTS

11 Config Config

ANALOG INPUTS

4 NTC – PTC

2 NTC - PTC - 4÷20mA - 0 ÷ 5Volt

Config Config

PROPORTIONAL OUTPUTS

2 configurables (signal 0÷10V) Config Config

2 configurables (signal 0÷10V, PWM) Config Config

SERIAL OUTPUTS

TTL with Mod-BusRtu protocol

n n

Remote Keyboard VICX620 (up to 2 remote

keyboards with probe on board)

n n

POWER SUPPLY

12 Vac/dc (+15%;-10%)

n n

24 Vac/dc (± 10%) Opt Opt

MAIN DISPLAY (UPPER DISPLAY)

± 4 digits with decimal point

n n

SECONDARY DISPLAY (LOWER DISPLAY)

± 4 digits with decimal point

n n

OTHER

Clock on board Opt Opt

Buzzer Opt Opt

configurable = configurable through parameter

opt = optional

n = default

Page 12

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

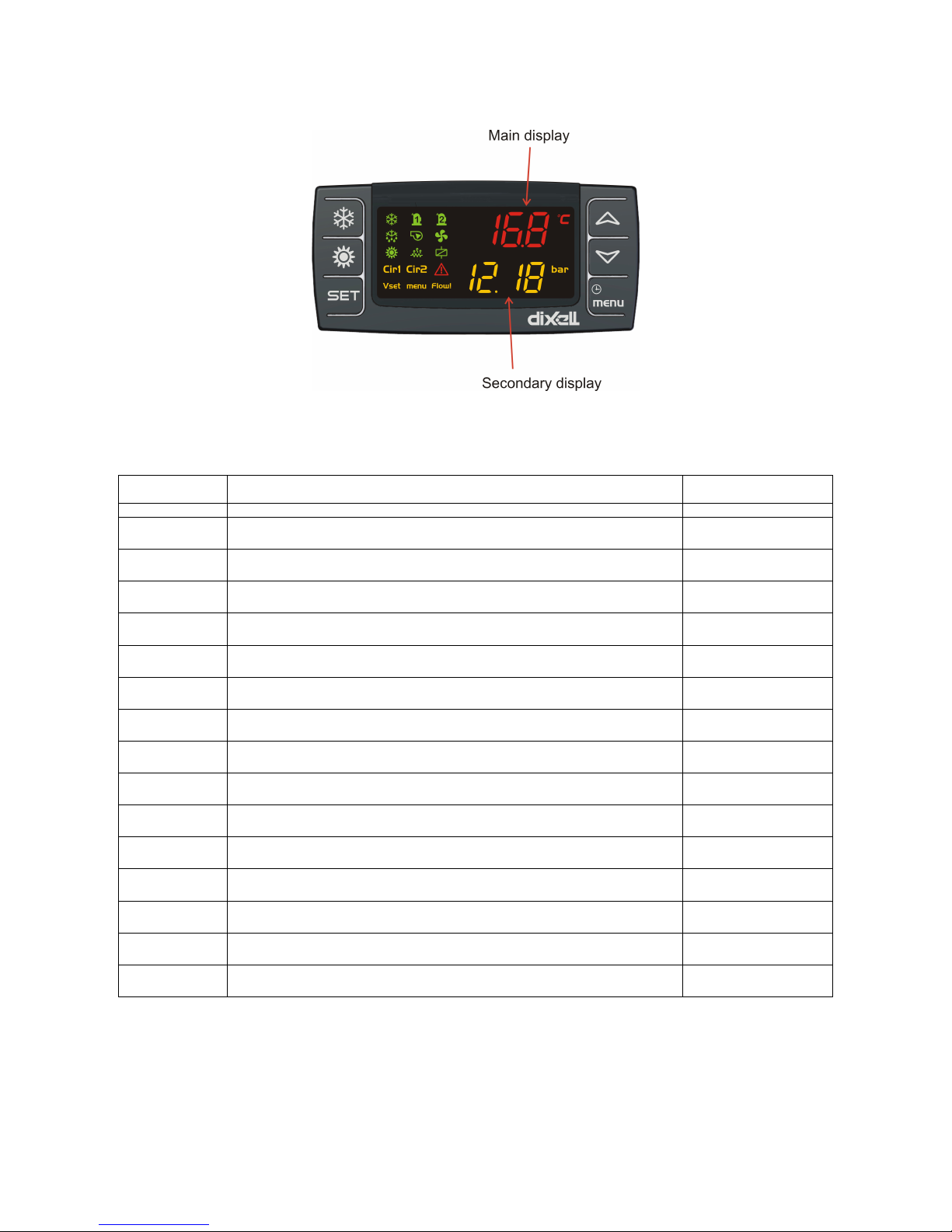

4 USER INTERFACE

4.1 DISPLAY CONFIGURATION

IC 206CX / IC 208CX

Remote keyboard

Page 13

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

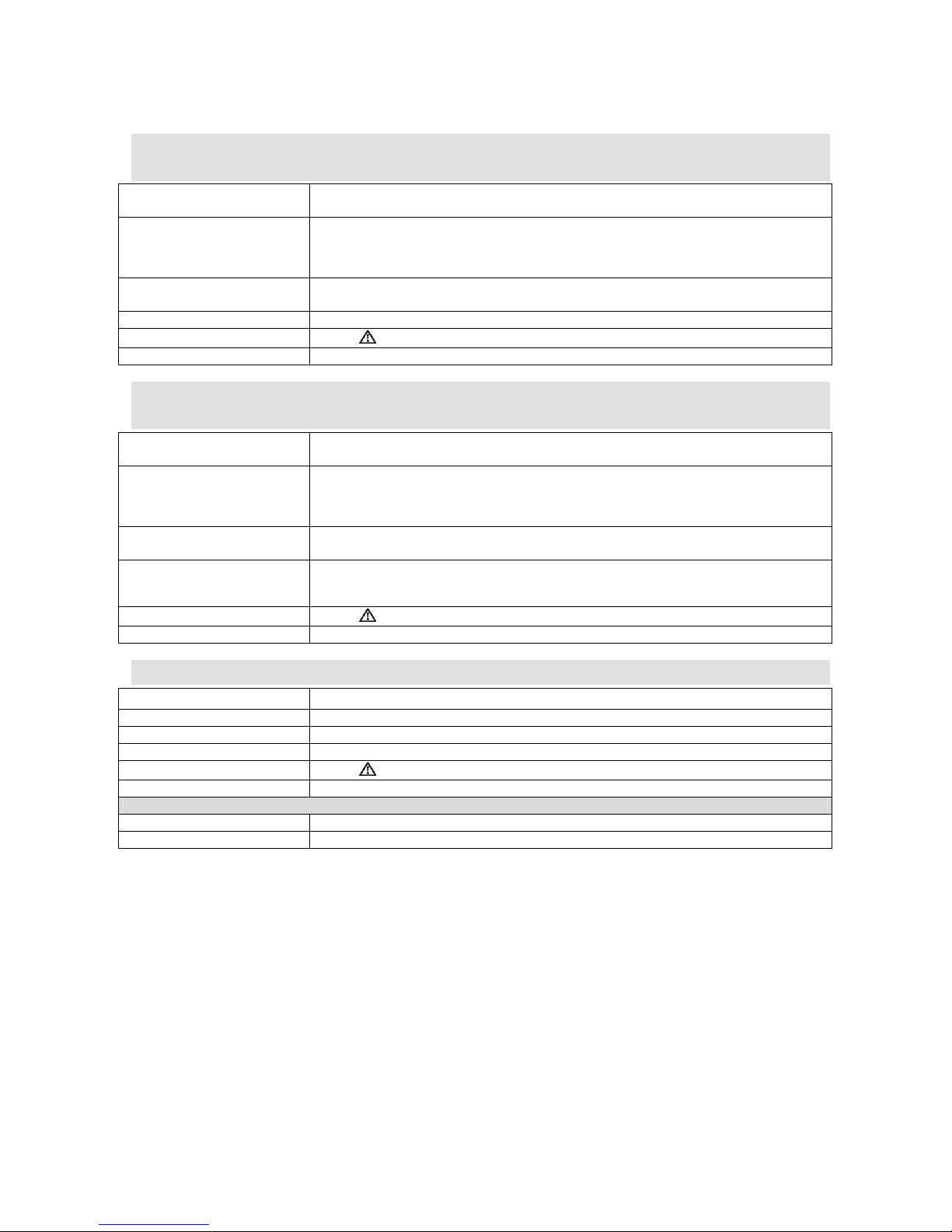

Pg.10/114

Main display (upper display)

Parameters dP01 (IC200CX), dP05 (remote keyboard n°1), dP07 (remote keyboard n°2)

PARAMETER

VALUE

DESCRIPTION

CORRESPONDING

LABEL

0

No display read out

No label

1

NTC temperature probe of the evaporator water inlet

Ein

2

NTC temperature probe of the evaporator water outlet 1 and 2

Out1 circuit 1

Out2 circuit 2

3

NTC temperature probe of the common evaporator water outlet

Eout

4

NTC temperature probe of the condenser water inlet

CIn1 circuit 1

CIn2 circuit 2

5

NTC temperature probe of the common condenser water inlet

Cin

6

NTC temperature probe of the condenser water outlet

Cou1 circuit 1

Cou2 circuit 2

7

NTC temperature probe of the common condenser water outlet

Cout

8

NTC temperature probe of the dynamic setpoint

Et

9

NTC temperature probe of the remote terminal 1

trE1

10

NTC temperature probe of the remote terminal 2

trE2

11

NTC temperature probe for the combined defrost

dEF1 circuit 1

dEF2 circuit 2

12

NTC temperature probe of the condenser

Cdt1 circuit 1

Cdt2 circuit 2

13

Set point (set point chiller or set point heat pump when the controller is ON; “OFF”

when the controller is OFF or STD-BY)

14

Differential of regulation in chiller or heat pump

15

Machine status (OFF / OnC=ON chiller / OnH=ON heat pump)

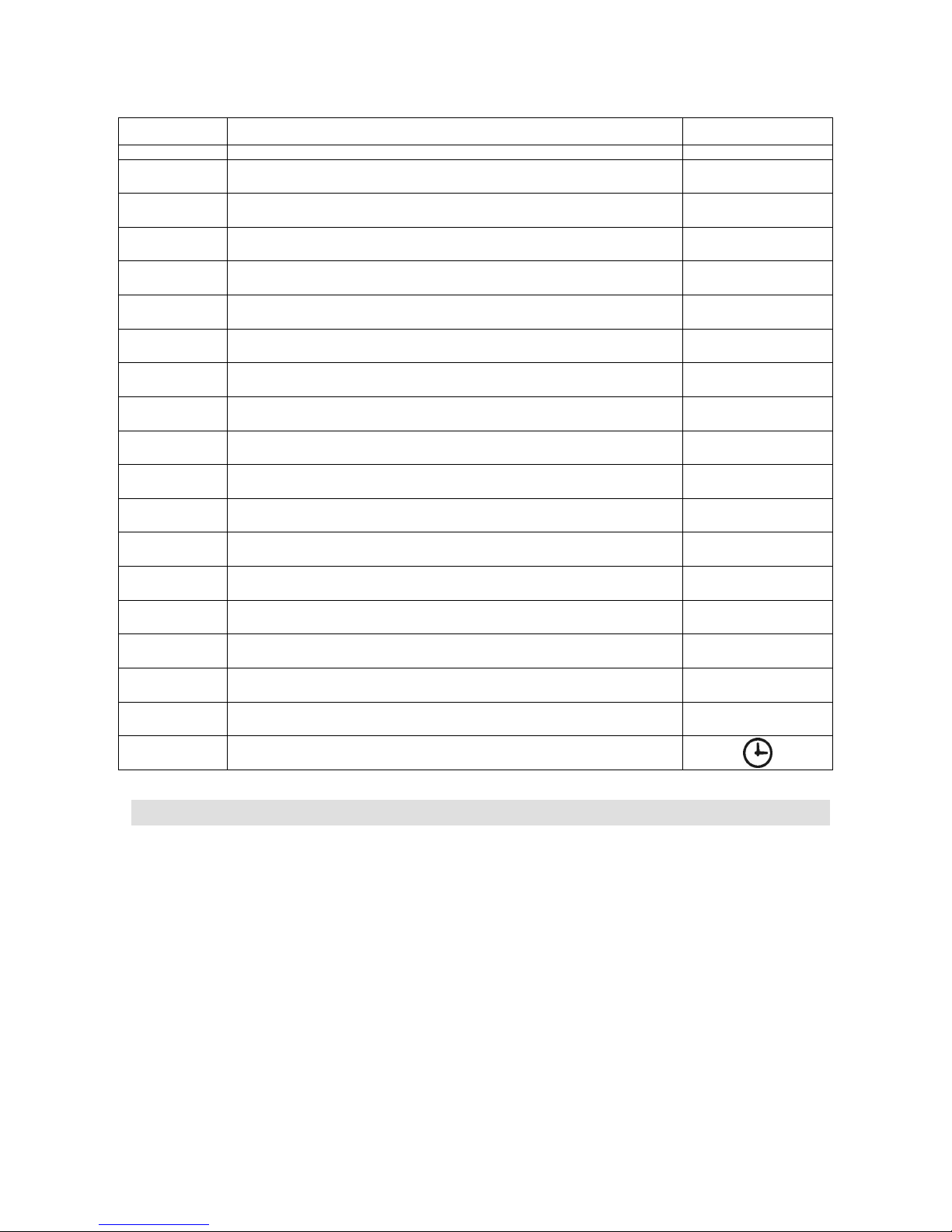

Secondary display (lower display)

Parameters dP02 (IC200CX), dP06 (remote keyboard n°1), dP08 (remote keyboard n°2)

Page 14

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

PARAMETER

VALUE

DESCRIPTION

CORRESPONDING

LABEL

0

No display read out

No label

1

NTC temperature probe of the evaporator water inlet

Ein

2

NTC temperature probe of the evaporator water outlet 1 and 2

Out1 circuit 1

Out2 circuit 2

3

NTC temperature probe of the common evaporator water outlet

Eout

4

NTC temperature probe of the condenser water inlet

CIn1 circuit 1

CIn2 circuit 2

5

NTC temperature probe of the common condenser water inlet

Cin

6

NTC temperature probe of the condenser water outlet

Cou1 circuit 1

Cou2 circuit 2

7

NTC temperature probe of the common condenser water outlet

Cout

8

NTC temperature probe of the dynamic setpoint

Et

9

NTC temperature probe of the remote terminal 1

trE1

10

NTC temperature probe of the remote terminal 2

trE2

11

NTC temperature probe for the combined defrost

dEF1 circuit 1

dEF2 circuit 2

12

NTC temperature probe of the condenser

Cdt1 circuit 1

Cdt2 circuit 2

13

Set point (set point chiller or set point heat pump when the controller is ON; “OFF”

when the controller is OFF or STD-BY)

14

Differential of regulation in chiller or heat pump

15

Machine status (OFF / OnC=ON chiller / OnH=ON heat pump)

16

Pressure probe of the condenser

CdP1 circuit 1

CdP2 circuit 2

17

Pressure probe of the evaporator

LP1 circuit 1

LP2 circuit 2

18

Clock

4.2 FORCED READ - OUT OF THE TOP AND BOTTOM DISPLAY

To force the display read-out:

1. Set the dP03 parameter different to 0

2. Select the value range 1..3

These configurations allow to show together two temperatures or two pressures of the same circuit in order to have an easier reading of

the measurements:

Par. dP03 = 1

Top display: for both the circuits 1,2:

• Evaporator water inlet, with the Ein label.

Bottom display: circuit 1:

• Evaporator 1 water outlet, with the label OuT1

Bottom display: circuit 2:

• Evaporator 2 water outlet, with the label OuT2.

Par. dP03 = 2

Top display of the circuit 1:

• Condenser 1 water inlet temperature with the label CIn1

Bottom display of the circuit 1

• Condenser 1water outlet with the label COu1.

Top display of the circuit 2:

Condenser 2 water inlet temperature with the label Cin2

Bottom display of the circuit 2

• Condenser 2water outlet with the label Cou2.

Par. dP03 = 3

Top display of the circuit 1:

Page 15

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

Pg.12/114

• Condenser probe temperature Cdt1 / pressure CdP1

Bottom display of the circuit 1

• Evaporator pressure probe LP1

Top display of the circuit 2:

Condenser probe temperature Cdt2 / pressure CdP2

Bottom display of the circuit 2

Evaporator pressure probe LP2

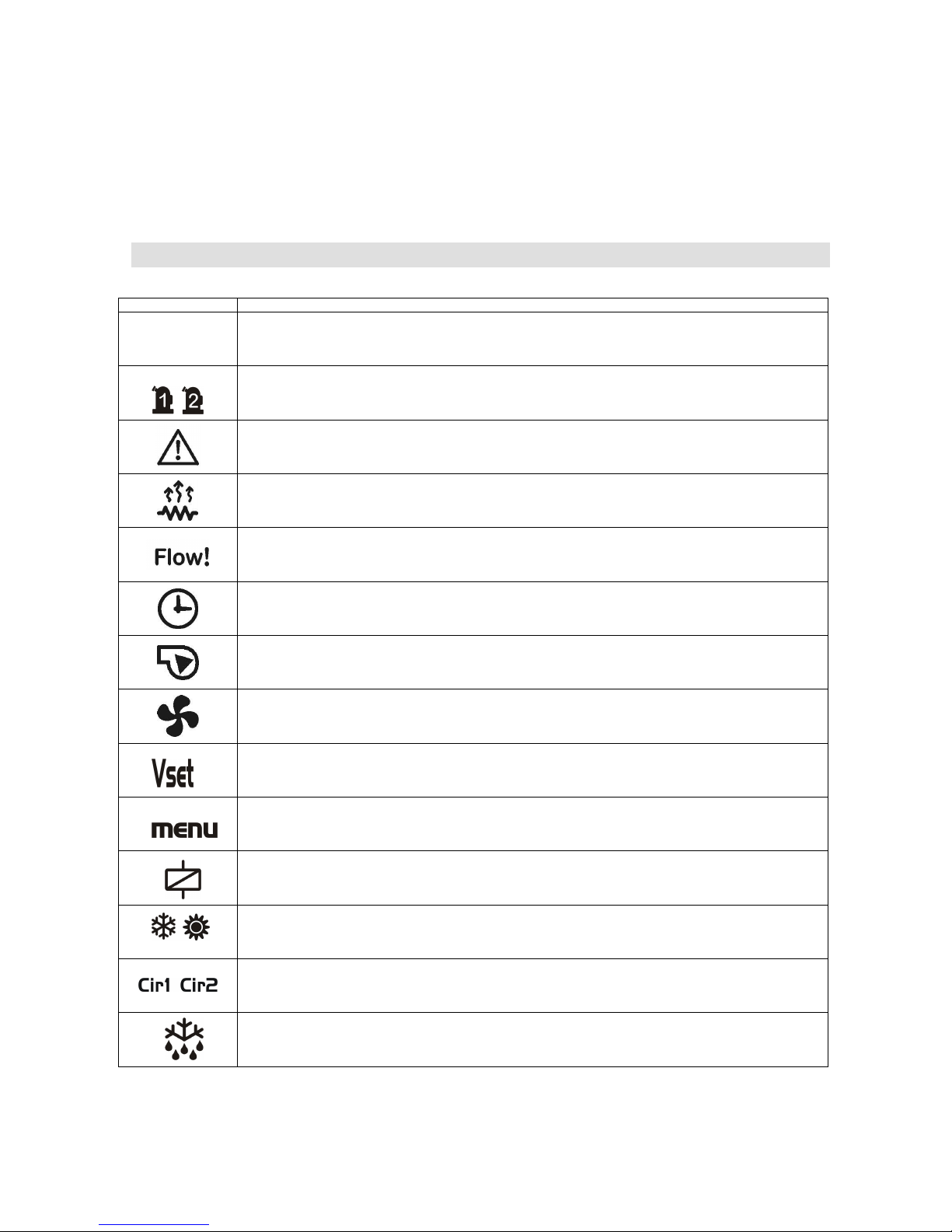

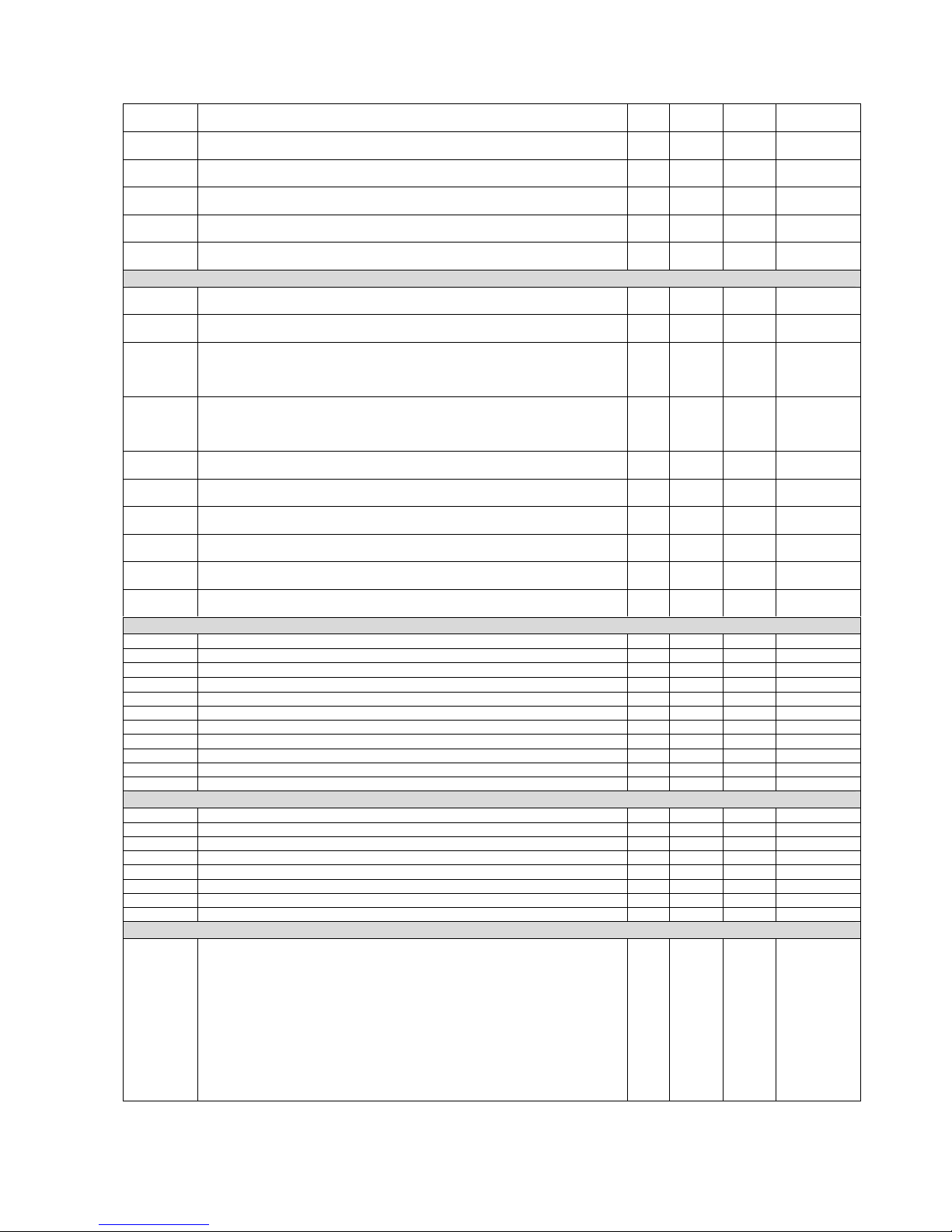

4.3 ICONS MEANING

ICON MEANING / FUNCTIONNING

°C -°F

BAR-PSI

Lighted when the display shows a temperature or pressure

Lighted when a compressor is activated

Blinking = when the delay of activation is running

Alarm: blinking in case of alarm

Lighted if anti freeze heaters/ integration heating / boiler are activated

Flow alarm/ (differential) pressure switch / supply fan thermal (air / air unit): is blinking if the configuration of the

digital input is active

Lighted when the bottom display shows the RTC

Lighted during the programming parameters if it is time based

Lighted in function menu when the display shows the defrost delay

Water pump: lighted if at least one pump is activated

Condenser fan: lighted if at least one fan is active

Lighted if Dynamic set point or Energy saving are active

Lighted during menu navigation

Lighted if auxiliary ouput is active

Lighted when the controller is ON

Lighted when the display shows probes values of circuit 1 or circuit 2

Lighted when the defrost is activated

Blinking during the counting of the interval between defrost

Page 16

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

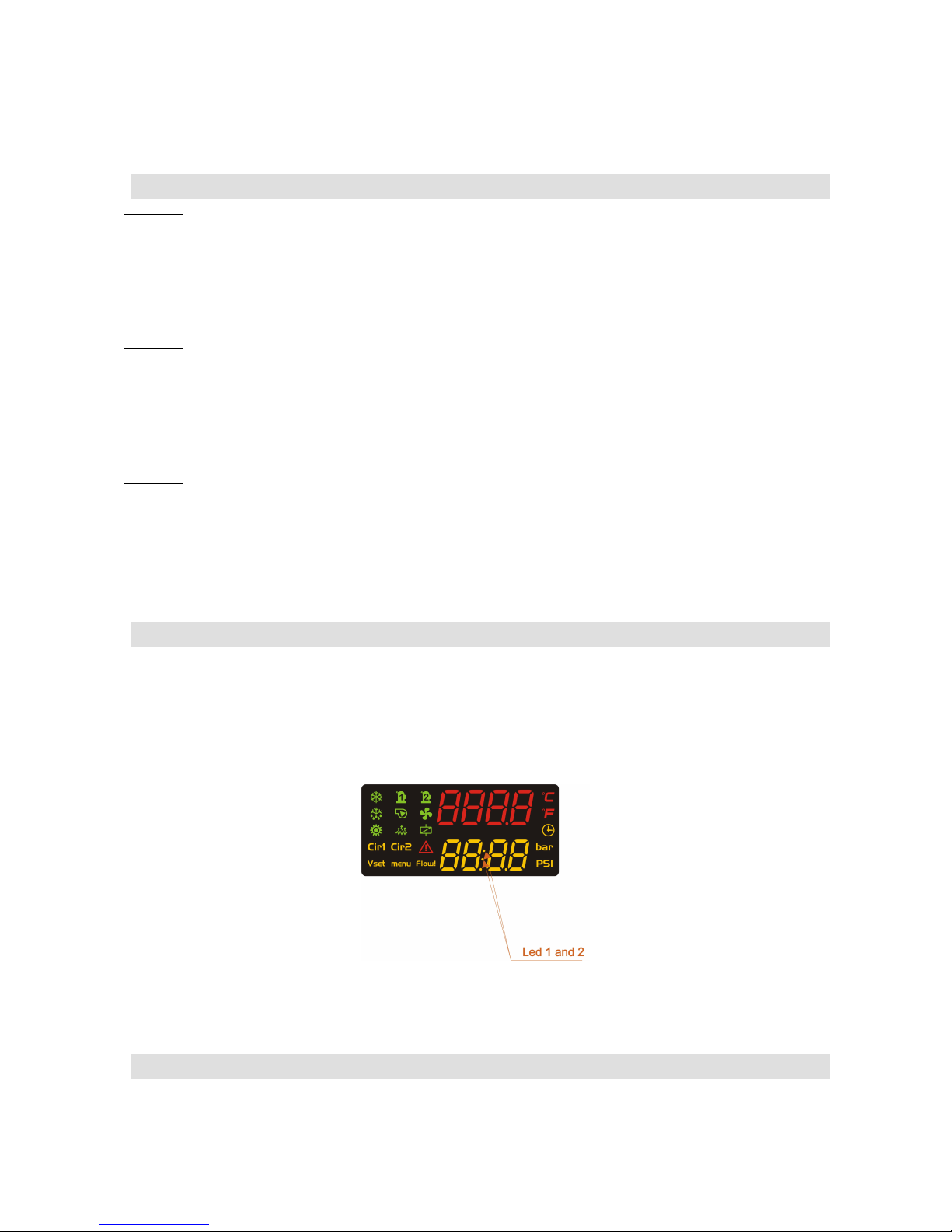

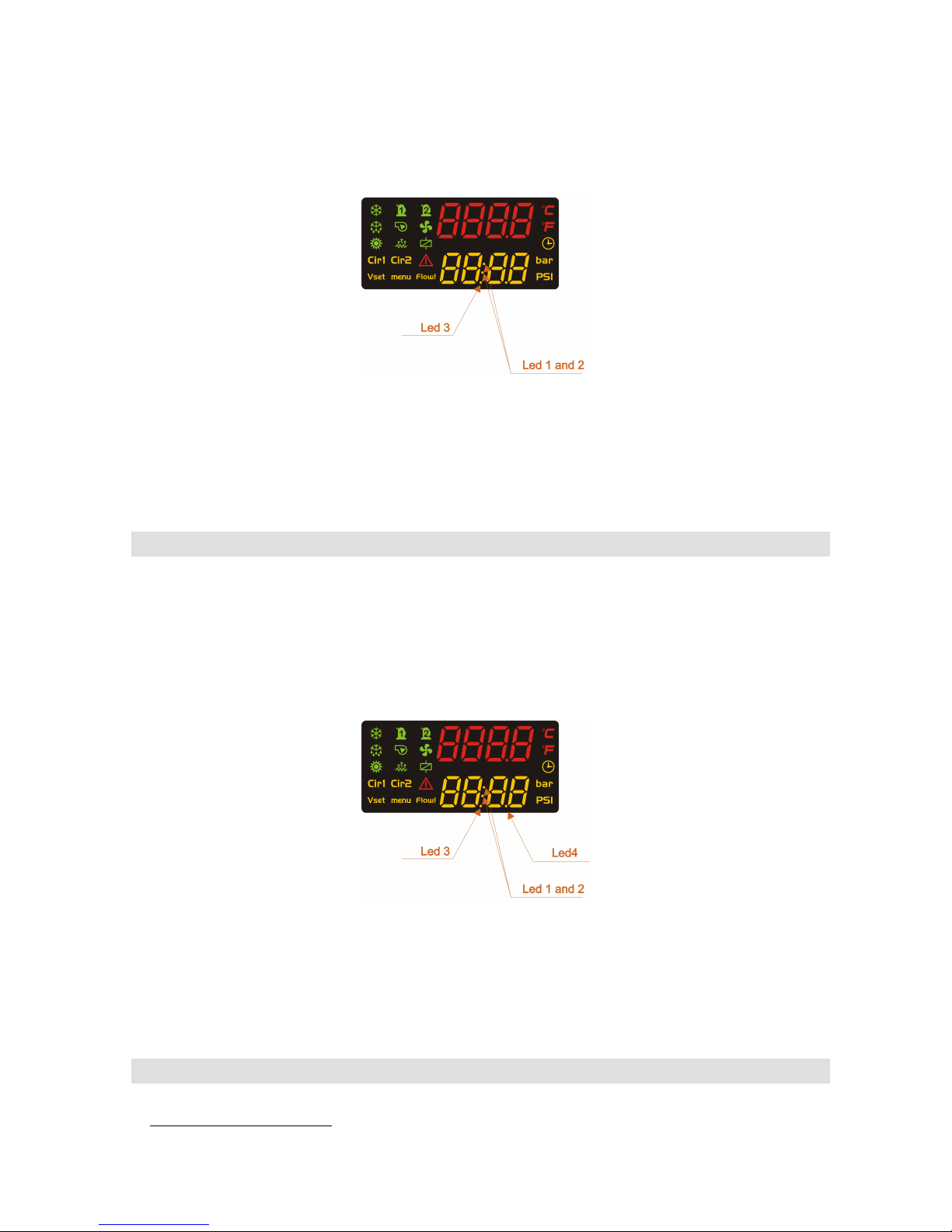

4.4 MEANING / FUNCTIONNING OF THE BOTTOM DISPLAY LED

Led # 1 – 2 (With RTC)

If the bottom display shows the RTC the leds are both blinking.

Led # 1 – 2 In function Menu

During the time counting to the next defrost for one or both circuits the leds are both blinking.

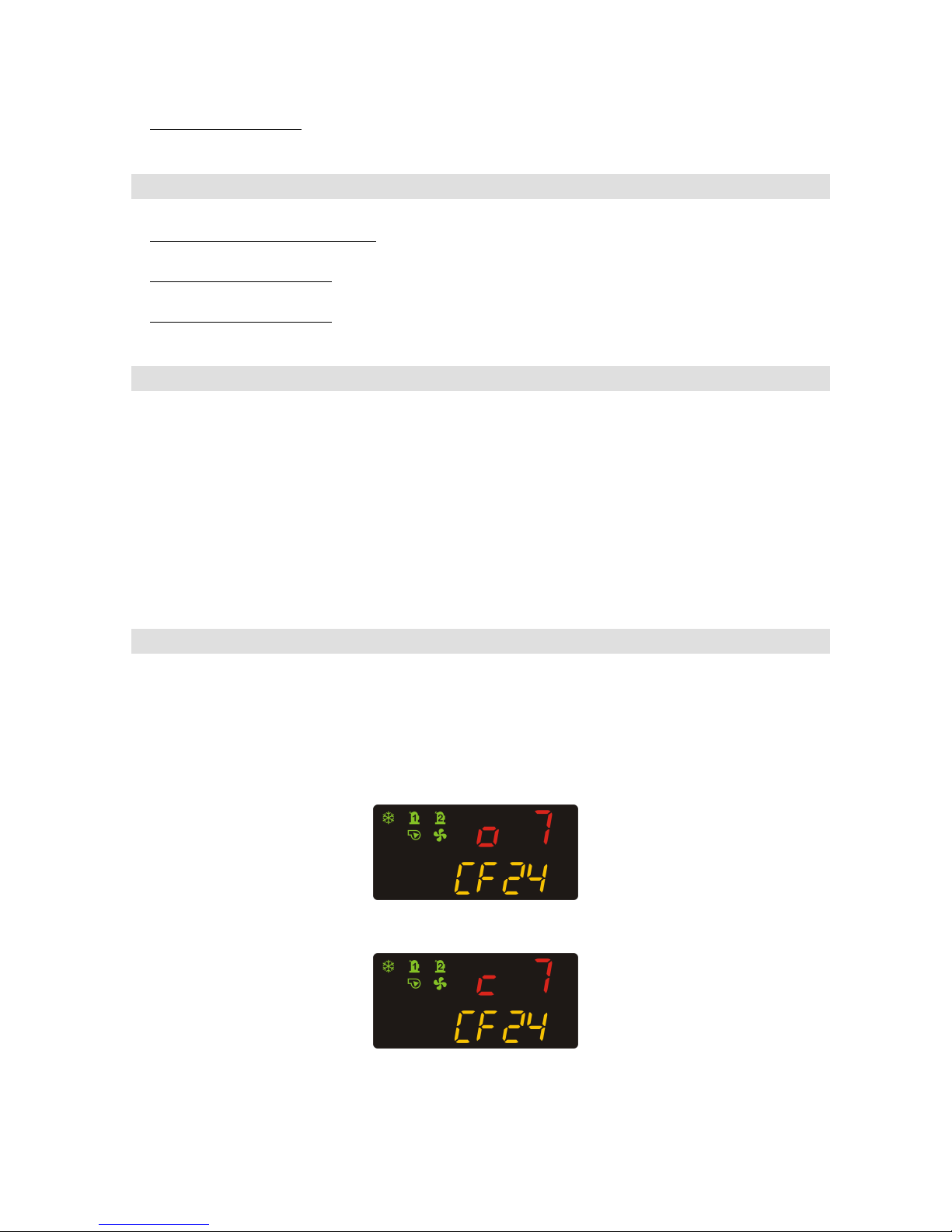

LED during parameters programming

In Pr2 level: led #3 indicates the visibility of the parameter; the led #1 and #2 show if the parameter can be modified or not.

In Pr3 level: led #3 and #4 indicate the visibility of the parameter; the led #1 and #2 show if the parameter can be modified or not.

5 DISPLAY LAYOUT

5.1 HOW TO READ THE MEASUREMENT LIST

With the icon Cir1 on, push UP or Down keys to display the labels of the information of the circuit 1.

With the icon Cir2 on, push UP or Down keys to display the labels of the information of the circuit 2.

Each measurement is defined by a label that indicates which if it is a pressure a temperature or a time.

5.2 READ PROBE VALUES OF CIRCUIT 1 OR 2

To swap between the information of the two circuits use the UP and DOWN key to select a label then push SET, check the led.

Example in fig.1

Icon Cir1 is on: the top display shows the value of the output evaporator temperature (12.8°C) of the circuit 1; the bottom display

shows Out 1 (outlet temperature evaporator 1). Push SET key to swap to the circuit 2. Fig2

Icon Cir2 is on: the top display shows the value of the output evaporator temperature (11.7°C) of the circuit 2, the bottom display

shows Out 2.

Fig.1

Fig.2

Page 17

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

Pg.14/114

6 DISPLAY INFORMATION

6.1 READ THE SET POINT VALUE

Push and release the SET key, the set value is displayed.

In stand-by the bottom display shows SetC (set chiller), by pushing SET again the next label is SetH (set heat pump).

If the unit is running the only set displayed is related to the running mode.

6.2 MODIFY THE SET POINT

1) Push SET key for at least 3 seconds

2) Use the UP or DOWN key to modify the setpoint. In chiller it is possible to modify the chiller set point, in heat pump it is possible to

modify the heat pump set point, in std-by it is possible to modify both the set point.

3) Push SET to confirm or wait the timeout (15seconds).

6.3 READ THE ACTIVE SETPOINT DURING ENERGY SAVING OR DYNAMIC SETPOINT

If the unit is running in chiller or heat pump, the Energy Saving or the Dinamic Setpoint activity is signalled by the blinking of the Vset

icon.

Chiller mode: push SET one time, the bottom display shows the SEtC (set chiller) while the top display shows the set value. Only if the

Energy saving or the Dynamic Setpoint are active, pushing another time the SET key, the bottom display shows “SEtr” (real setpoint),

and the top display shows the setpoint that the unit is really using for the thermoregulation.

Heat pump mode: push SET one time, the bottom display shows the SEtH (set Heat pump) while the top display shows the set value.

Only if the Energy saving or the Dynamic Setpoint are active, pushing another time the SET key, the bottom display shows “SEtr” (real

setpoint), and the top diplay shows the setpoint that the unit is really using for the thermoregulation.

6.4 DISPLAY VISUALIZATION IN REMOTE OFF

Digital input configured as remote ON/OFF: the active input sets the unit in OFF (even when the unit is a condensing unit).

The upper display shows “OF.F ”, the led of the decimal point is blinking.

Page 18

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

6.5 DISPLAY VISUALIZATION IN STD-BY

It is possible to customise the visualization of the display when the unit is in STD-BY:

Parameter dP4:

0= the display shows "STD-BY"

1= the display shows what defined by parameters dP1 and dP2

2= the display shows “OFF”

dP4=0

dP4=1

The display shows what defined by parameters dP1 and dP2

dP4=2

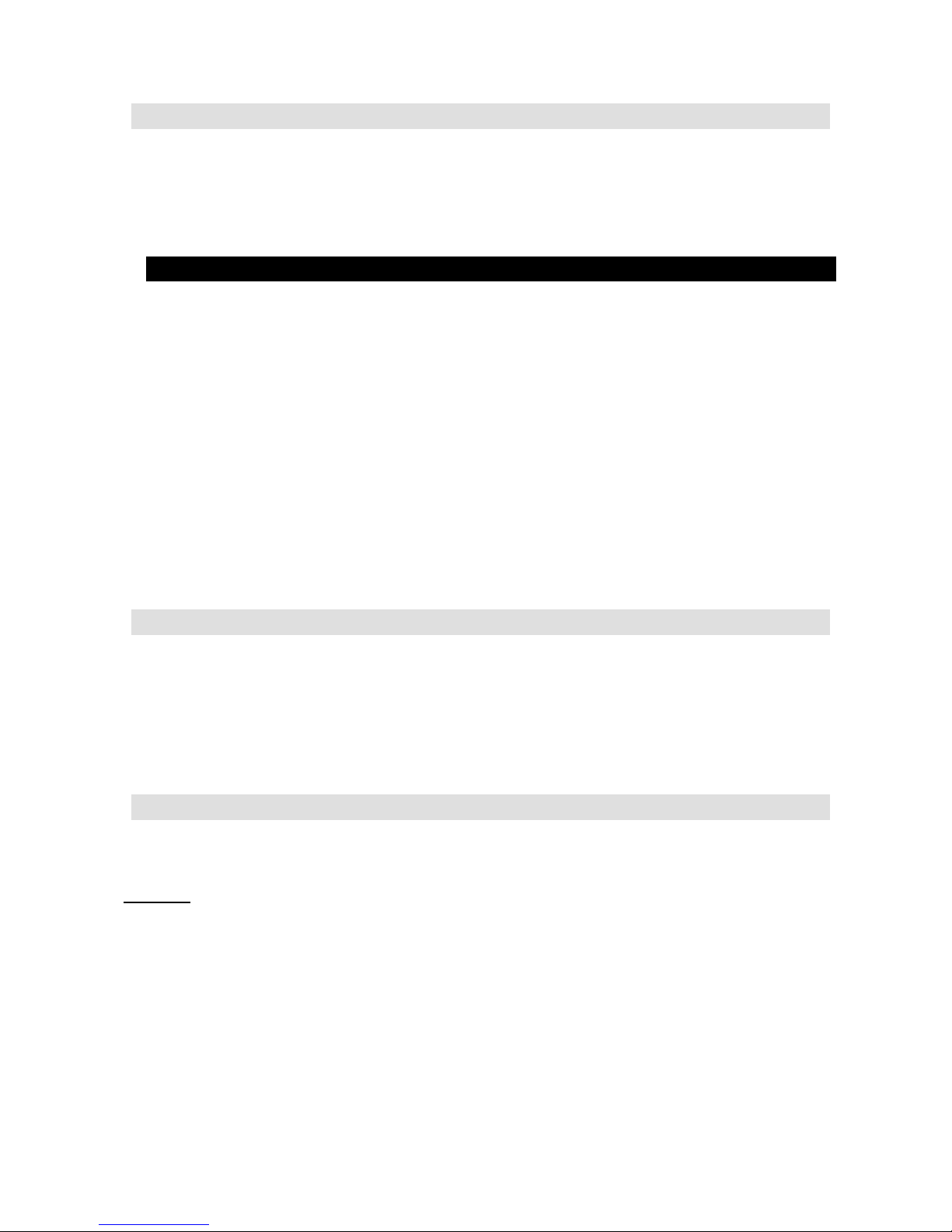

6.6 DISPLAY IN CONDENSING UNIT

If the controller is configured to manage a condensing unit (CF03=1):

• one digital input has to be configured as “chiller request”; if the digital input is active the unit works in chiller mode and

the display visualizes OnC

• one digital input can be configured as “heat pump request”; if the digital input is active the unit works in heat pump mode

and the display visualizes OnH

Another possibility is to configure the controller to manage a motorcondensing unit (CF03=1) and one digital input is configured as

“thermoregulation request”:

• if the digital input is active:

o by keyboard it is possible to switch on the unit in chiller mode and the display shows OnC; by keyboard it is possible

to select the STD-By mode and the display shows On

o by keyboard it is possible to switch on the unit in heat pump mode and the display shows OnH; by keyboard it is

possible to select the STD-By mode and the display shows On

• if the digital input is not active the unit is OFF and the display visualizes OFF

Page 19

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

Pg.16/114

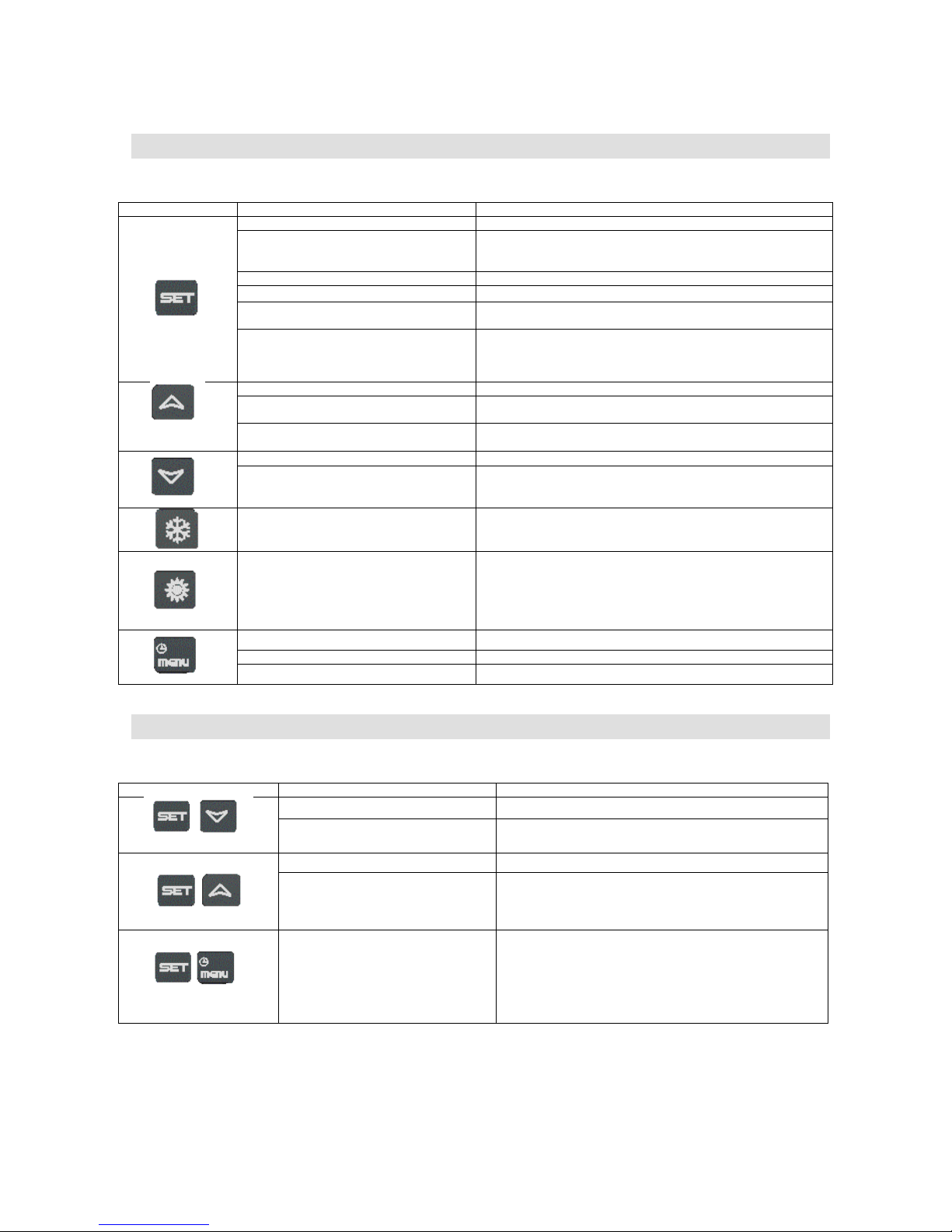

6.7 KEY FUNCTION

KEY ACTION FUNCTION

Push and release

Show chiller set point SetC and heat pump SetH

Push once again

In chiller or heat pump if the Energy saving or the Dynamic

setpoint are enabled it shows the real setpoint Setr, the led is

blinking.

Push for 3 seconds Set point modification

During the programming: push once To enter parameter modification or confirm a value

Push when an alarm is showed in menù

ALrM

To reset the alarm

Push once with probe label showed on the

bottom display (press up or down starting

from default visualization)

To read probes values of circuit 1 or circuit 2

Push once To read probes value

Pushing once during the programming

To change the group of parameters, to change the parameter, to

change the value of the parameter

Push for 1 second during the programming

when the display visualize Pr1 or Pr2

1 time shows the Pr2 programming level

2 times shows the Pr3 programming level

Push once To read probes value

Pushing once during the programming

To change the group of parameters, to change the parameter, to

change the value of the parameter

Push once

To turn ON or turn OFF the controller (in chiller or heat pump

depending from CF51 parameter)

Push once

To turn ON or turn OFF the controller (in chiller or heat pump

depending from CF51 parameter)

Push once To enter the function Menu

Push for 3 seconds To set the clock (controller with clock on board)

Pushing once during the programming To exit from a group of parameter

6.8 KEY COMBINANTION

KEY ACTION FUNCTION

Push for 3 seconds together Enter the programming parameters

Only in Pr3 level: push SET and DOWN

key

Select the parameter level visibility Pr1 / Pr2 / Pr3

Push once together Exit the programming parameters

Push 5 seconds in heat pump mode Manual defrost

Only in Pr3 programming level: push

SET and then the MENU key

In Pr3 defines if the parameter can be modified or not in the

other levels.

Page 20

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

7 REMOTE TERMINAL

The iCHILL can be connected to a remote keyboard (max 2 remote keyboards).

The remote keyboard with probe on board can be used for the regulation of the machine.

The maximum length of the cable is 150mt (shielded cable is recommended).

Use the connection cable CAB/CJ30 (2x0.2 mm2) to interface the ichill connector to the shielded wire.

In case of communication problems (hardware problems or bad connection) the upper display shows “noL” (no link).

8 FIRST INSTALLING

8.1 ON BOARD CLOCK (OPTIONAL)

Giving power supply the bottom display shows “rtC” alternated to a temperature or pressure value: It is necessary to set the RTC

(Real time clock).

ATTENTION

The RTC function is an option and it is not possible to update the instrument It is necessary to order the instrument already

complete of this features.

With a prolunged power failure (several days) it is necessary to setup the clock again.

8.2 RTC SETUP

1. Push Menu key for 3 seconds until the bottom display shows “Hour” and the top display shows its value.

2. Push SET one time: the value is blinking.

3. Use the Up and Down keys to adjust it. Push SET one time to confirm.

4. Push up or down keys and repeat the operations 2. 3. and 4. for all the RTC parameters:

- Min: minutes (0÷60)

- UdAy: day of the week (Sun = Sunday, Mon =Monday, tuE =Tuesday, UEd = Wednesday, tHu = Thursday, Fri =Friday, SAt

=Saturday)

- dAy: day of the month (0÷31)

- MntH: month (1÷12)

- yEAr: year (00÷99)

Page 21

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

Pg.18/114

9 ANALOG AND DIGITAL OUTPUT CONFIGURATION

9.1 ANALOG INPUT PB1 - PB2 – PB5 – PB6

Parameters involved:

CF08 = Configuration PB1

CF09 = Configuration PB2

CF12 = Configuration PB5

CF13 = Configuration PB6

0. Not enabled

1. Temperature probe PTC for compressor #1 discharge

2. Temperature probe NTC for evaporator inlet

3. Temperature probe NTC for evaporator #1 outlet

4. Temperature probe NTC for evaporator #2 outlet

5. Temperature probe NTC for common evaporator outlet

6. Temperature probe NTC for common hot water condenser inlet

7. Temperature probe NTC for hot water of the condenser circuit #1 inlet

8. Temperature probe NTC for hot water of the condenser circuit #2 inlet

9. Temperature probe NTC for hot water of the condenser circuit #1 outlet

10. Temperature probe NTC for hot water of the condenser circuit #2 outlet

11. Temperature probe NTC for hot water of the condenser common outlet

12. Temperature probe NTC (external temperature) for dynamic setpoint / boiler / change over

13. Temperature probe NTC for combined defrost circuit #1

14. Temperature probe NTC for combined defrost circuit #2

15. Temperature probe NTC for auxiliary output #1

16. Temperature probe NTC for auxiliary output #2

17. Temperature probe NTC for condensing circuit #1

18. Temperature probe NTC for condensing circuit #2

Every analogue input can be configured as digital input; after the number 18, the values o 1 … c38 allow the configuration of the

analogue input as digital inputs with the same meaning (o 1= remote ON/OFF, o 2= Remote chiller / heat pump, …..).

9.2 ANALOG INPUT CONFIGURATION PB3 - PB4

Parameter involved:

CF10 = Configuration PB3

CF11 = Configuration PB4

0 Not enabled

1 Temperature probe PTC for compressor #1 discharge

2 Temperature probe NTC for evaporator inlet

3 Temperature probe NTC for evaporator #1 outlet

4 Temperature probe NTC for evaporator #2 outlet

5 Temperature probe NTC for common evaporator outlet

6 Temperature probe NTC for common hot water condenser inlet

7 Temperature probe NTC for hot water of the condenser circuit #1 inlet

8 Temperature probe NTC for hot water of the condenser circuit #2 inlet

9 Temperature probe NTC for hot water of the condenser circuit #1 outlet

10 Temperature probe NTC for hot water of the condenser circuit #2 outlet

11 Temperature probe NTC for hot water of the condenser common outlet

12 Temperature probe NTC (external temperature) for dynamic setpoint / boiler / change over

13 Temperature probe NTC for combined defrost circuit #1

14 Temperature probe NTC for combined defrost circuit #2

15 Temperature probe NTC for auxiliary output #1

16 Temperature probe NTC for auxiliary output #2

17 Condenser probe circuit 1 ( temperature NTC / pressure 4÷20 mA / ratio-metric 0÷ 5Volt )

18 Condenser probe circuit 2 ( temperature NTC / pressure 4÷20 mA / ratio-metric 0÷ 5Volt )

19 Evaporator pressure probe circuit 1 (pressure 4÷20 mA / ratio-metric 0÷ 5Volt )

20 Evaporator pressure probe circuit 1 (pressure 4÷20 mA / ratio-metric 0÷ 5Volt )

21 Auxiliary output 1 pressure probe control (4÷20 mA / ratio-metric 0÷ 5Volt).

22 Auxiliary output 2 pressure probe control (4÷20 mA / ratio-metric 0÷ 5Volt).

23 Dynamic setpoint pressure probe (4÷20 mA)

Every analogue input can be configured as digital input; after the number 18, the values o 1 … c38 allow the configuration of the

analogue input as digital inputs with the same meaning (o 1= remote ON/OFF, o 2= Remote chiller / heat pump, …..).

9.3 DIGITAL INPUT CONFIGURATION ID1 – ID18

Parameters involved:

CF24 = Configuration ID1…CF34 = Configuration ID18

0. Not enabled

1. Remote ON / OFF

2. Remote chiller / heat pump

Page 22

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

3. Flow switch evaporator pump / supply fan overload

4. Flow switch condenser pump

5. Antifreeze heater circuit 1

6. Antifreeze heater circuit 2

7. High pressure switch circuit 1

8. High pressure switch circuit 2

9. Low pressure switch circuit 1

10. Low pressure switch circuit 2

11. Compressor 1 high pressure

12. Compressor 2 high pressure

13. Compressor 1 overload

14. Compressor 2 overload

15. Condenser fan overload of circuit 1

16. Condenser fan overload of circuit 2

17. Condenser fan overload of circuit 1 and 2 (common condenser)

18. Evaporator water pump overload

19. Support evaporator water pump overload

20. Condenser water pump overload

21. Support condenser water pump overload

22. End defrost of circuit 1

23. End defrost of circuit 2

24. Energy Saving

25. Pressure switch / compressor 1 oil

26. Pressure switch / compressor 2 oil

27. Pump down pressure switch of circuit 1

28. Pump down pressure switch of circuit 2

29. Generic alarm n°1

30. Generic alarm n°2

31. RTC disabled

32. Supplay fan enabled (the unit works only with the supplay fan)

33. Thermoregulation request (motocondensing unit)

34. Cooling request (motocondensing unit)

35. Heating request (motocondensing unit)

36. Request step 2 (motocondensing unit)

37. Request step 3 (motocondensing unit)

38. Request step 4 (motocondensing unit)

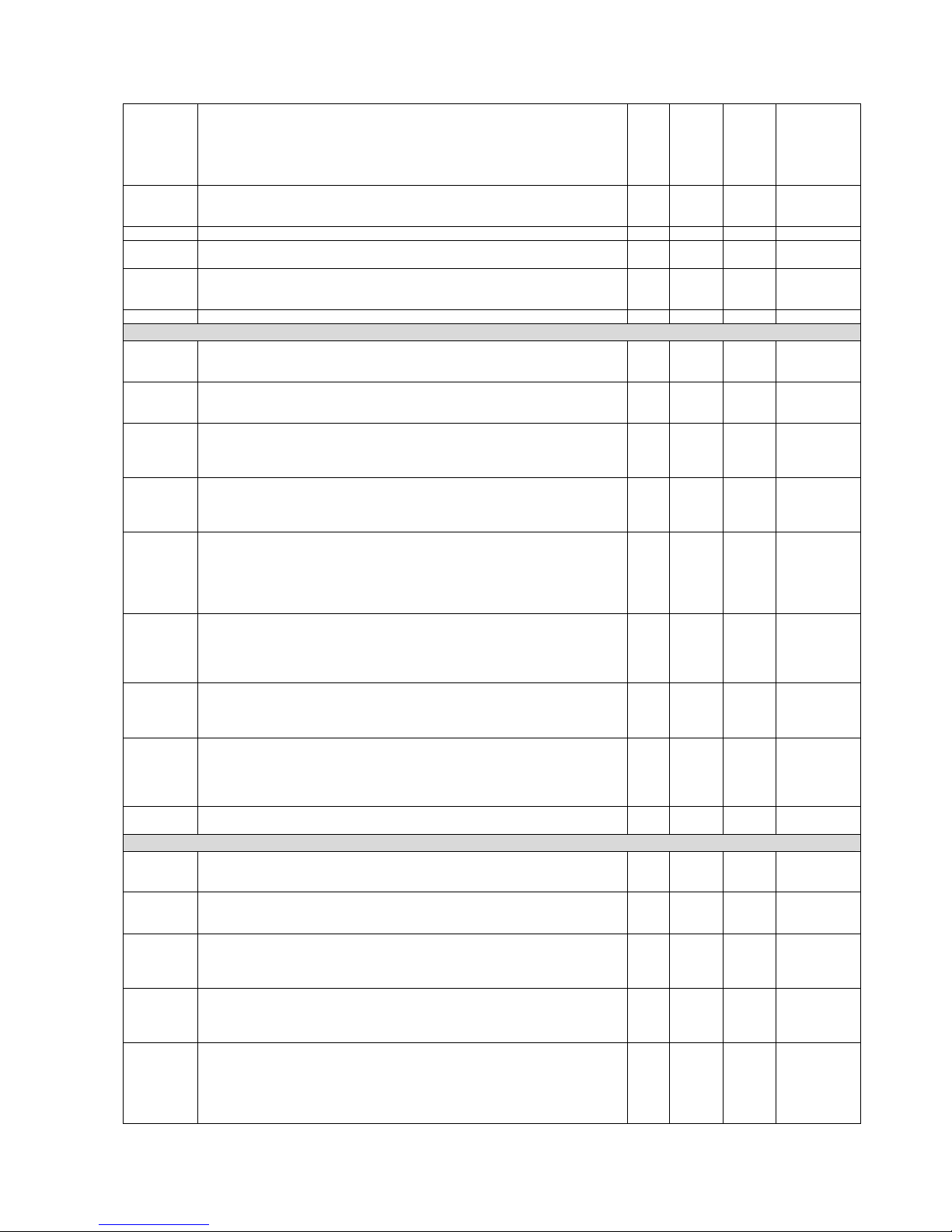

9.4 DIGITAL OUTPUT (RELAY) CONFIGURATION RL1- RL8

Parameter involved:

CF35= Configuration RL1…CF42= Configuration RL8

0. Not enabled

1. Alarm

2. Evaporator water pump / Supply fan

3. Evaporator support water pump

4. Anti-freeze heater / integration heating / boiler circuit 1

5. Anti-freeze heater / integration heating / boiler circuit 2

6. Condenser water pump

7. Condenser support water pump

8. 4-way valve for chiller / heat pump inversion of the circuit 1

9. 4-way valve for chiller / heat pump inversion of the circuit 2

10. 1° condenser fan step ON/OFF control of the circuit 1

11. 2° condenser fan step ON/OFF control of the circuit 1

12. 3° condenser fan step ON/OFF control of the circuit 1

13. 1° condenser fan step ON/OFF control of the circuit 2

14. 2° condenser fan step ON/OFF control of the circuit 2

15. 3° condenser fan step ON/OFF control of the circuit 2

16. Solenoid valve of the pump-down circuit 1

17. Solenoid valve of the pump-down circuit 2

18. Auxiliary output circuit 1

19. Auxiliary output circuit 2

20. Solenoid valve Intermittent for screw compressor 1

21. Solenoid valve of the liquid injection for compressor 1

22. Soleniod valve water side for chiller and heat pump circuit 1

23. Soleniod valve water side for heat pump circuit 1

24. Soleniod valve water side for chiller and heat pump circuit 2

25. Soleniod valve water side for heat pump circuit 2

26. Valve for geothermal function

27. Direct start-up : compressor 1 relay

Part Winding 1 of the compressor 1

28. Part Winding 2 of the compressor 1

29. Capacity step valve 1 compressor 1

30. Capacity step valve 2 compressor 1

31. Capacity step valve 3 compressor 1

32. By-pass gas valve compressor 1start

33. Direct start: compressor 2 start

Page 23

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

Pg.20/114

Part Winding 1 of the compressor 2

34. Part Winding 2 of the compressor 2

35. Capacity step valve 1 compressor 2

36. By-pass gas valve compressor 2 start

9.5 ANALOG OUTPUT CONFIGURATION 0 ÷ 10 VOLT (OUT1 E OUT2)

Parametri:

CF43 = Analog output OUT1 configuration

CF44 = Analog output OUT2 configuration

0 = output disabled

1 = 0..10V output for compressor 1 inverter controlled

2 = 0..10V output for compressor 2 inverter controlled

3 = 0..10V output for auxiliary output 1

4 = 0..10V output for auxiliary output 2

5 = 0..10V output for geothermal function

6 = 0..10V output for condenser fan circuit 1

7 = 0..10V output for condenser fan circuit 2

8 = 0..10V output for modulating evaporator pump

9 = 0..10V output for modulating condenser pump

o1..c26 = ON / OFF output for external relay management (same meaning of relays configuration)

9.6 CONFIGURAZIONE N° 2 USCITE ANALOGICHE 0 ÷ 10 VOLT / TAGLIO DI FASE (OUT3 E

OUT4)

Parametri:

CF45 = Configurazione uscita analogica n° 3

CF46 = Configurazione uscita analogica n° 4

0 = output disabled

1 = 0..10V output for compressor 1 inverter controlled

2 = 0..10V output for compressor 2 inverter controlled

3 = 0..10V output for auxiliary output 1

4 = 0..10V output for auxiliary output 2

5 = 0..10V output for geothermal function

6 = 0..10V output for condenser fan circuit 1

7 = 0..10V output for condenser fan circuit 2

8 = PWM output for condenser fan circuit 1

9 = PWM output for condenser fan circuit 2

o1..c26 = OFF output for external relay management (same meaning of relays configuration)

Page 24

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

10 PROGRAMMING WITH THE “HOT KEY 64”

10.1 DOWNLOAD: HOW TO PROGRAM AN INSTRUMENT WITH A PROGRAMMED “HOT KEY”

1. Turn off the instrument supply

2. Insert the hot key.

3. Turn on the power supply.

4. Immediately the parameters are downloaded.

During the download the regulation is locked and the top display shows the “doL” blinking label. At the end of the download will appear:

“End” if the programming procedure is completely OK, after 30seconds the regulation starts automatically.

“Err” if the programming procedure has found an error and the parameter have not been transferred. In this case turn off and then on

the instrument supply to repeat the operation or remove the hot key, with power supply off, to restart the regulation.

10.2 UPLOAD: HOW TO PROGRAM A “HOT KEY” WITH THE PARAMETERS OF THE INSTRUMENT

1. Turn on the power supply.

2. Insert the hot key.

3. Enter the function Menu.

4. Select the UPL function (on the bottom display).

5. Push SET key and immediately the instrument starts transfer the parameters into the Hot key.

During the upload the regulation is locked and the top display shows the “UPL” blinking label. At the end of the UPLOAD will appear:

“End” if the programming procedure is completely OK, after 30seconds the regulation starts automatically.

“Err” if the programming procedure has found an error and the parameter have not been transferred. Repeat the procedure.

To exit the UPL function push the MENU key or wait the time-out.

11 PROGRAMMING USING THE KEYBOARD

Through the instrument keyboard it is possible to enter the programming. In all the three accessible levels the user can show and modify

both value and visibility of the parameters. To ensure an easy navigation through the different levels the common parameters have been

named and grouped under a family name.

The three levels of programming:

• Pr1 User level

• Pr2 Maintenance level

• Pr3 OEM level

11.1 PASSWORD DEFAULT VALUES

• Password level Pr1 = 1

• Password level Pr2 = 2

• Password level Pr3 = 3

Each password can be changed, the range is from 0 to 999.

11.2 ENTER THE PR1 - PR2 - PR3 PROGRAMMING LEVELS

Pr1 LEVEL:

Push SET + DOWN together for 3 seconds, the top display shows the PAS label and the bottom display shows the Pr1 label. The leds

Cir1 and Cir2 are blinking to inform that you now are in PR1 programming level.

Pr2 LEVEL:

Starting from Pr1 level push the UP key for 2 seconds and the bottom display will show Pr2. The top display still shows PAS.

Push the SET key and the top display will show the 0 blinking value; set the password level using the UP and DOWN keys then confirm

with SET key.

Pr3 LEVEL:

Starting from the Pr2 level push the UP key for 2 seconds and the bottom display will show Pr3. The top display still shows PAS.

After selecting the level push the SET key and the top display will show the 0 blinking value where to insert the password.

Set the password level using the UP and DOWN keys then confirm with SET key.

Dependening on the password value there will be the different level access, if the password is wrong the instrument shows the

password value again.

ATTENTION:

For all the programming levels Pr1, 2, 3: the CF family (or configuration parameters) can not be changed if the unit is running

in chiller or heat pump. To change this parameters is necessary to set the unit in stand-by and then enter the programming

again.

During the defrost the dF family can’t be programmed.

11.3 HOW TO CHANGE A PARAMETER VALUE

Enter the programming

1. Push the SET + DOWN keys together for 3 seconds;

2. Select the parameter label with up and down keys;

3. Push SET to enter the parameter value;

Page 25

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

Pg.22/114

4. Change the value with UP or DOWN keys;

5. Push “SET” to confirm, after some seconds the display shows the next parameter;

6. Exit: Push SET + UP together when a parameter label is displayed or wait 15seconds without pushing a key.

NOTE: a new parameter value is confirmed also after the 15 seconds of timeout is expired (without pushing SET key to confirm).

11.4 CHANGE THE PASSWORD VALUE

Pr1 LEVEL

Remember that it is necessary to know the old password value.

1) Enter the Pr1 level

2) Select a parameter family.

3) Select “Pr1” on the bottom display; the current password value is on the top display. Push the SET key to change the value that

now is blinking.

4) Use the UP or DOWN key to insert the NEW PASSWORD value, then push SET to confirm the new value.

5) The top display blinks for some seconds and then shows the next parameter.

6) Exit the programming pushing SET + UP together or wait the timeout.

Pr2 LEVEL

Remember that it is necessary to know the old password value.

1. Enter the Pr2 level

2. Select a parameter family.

3. Select the “Pr2” on the bottom display; the current password value on the top display. Push the SET key to change the value that

now is blinking.

4. Use the UP or DOWN key to insert the NEW PASSWORD value, then push SET to confirm the new value.

5. The top display blinks for some seconds and then shows the next parameter

6. Exit the programming pushing SET + UP together or wait the timeout.

Inside the Pr2 level it is possible to change also the Pr1 password.

Pr3 LEVEL

Remember that it is necessary to know the old password value.

1. Enter the Pr3 level

2. Select a parameter family.

3. Select the “Pr3” on the bottom display; the current password value on the top display. Push the SET key to change the value that

now is blinking.

4. Use the UP or DOWN key to insert the NEW PASSWORD value, then push SET to confirm the new value.

5. The top display blinks for some seconds and then shows the next parameter

6. Exit the programming pushing SET + UP together or wait the timeout.

Inside the Pr3 level it is possible to change also the Pr1 and Pr2 passwords.

11.5 ENTER THE PROGRAMMING LEVEL PR1

Enter the Pr1 “User level ”:

1. Push the SET + DOWN keys together for 3 seconds. The top display shows PAS while the bottom display shows Pr1 labels.

2. Push SET key and the top display shows a blinking 0, with UP or DOWN insert the Pr1 password. Push SET and, if the value is

correct, the top display will show the first family of parameters “ALL”. Otherwise set the password again.

3. Select a parameter family with DOWN or UP keys.

4. Push SET to enter, the bottom display shows the first available parameter label while the top display shows its value.

The user can shows and modify all the parameters belonging to this family.

Parameter status, leds and bottom display in Pr1

• If the selected parameter can not be changed the leds 1 and 2 are blinking.

• In Pr1 level the user can not see and change any parameter of Pr2 and Pr3.

• The MENU key allows to exit from a family to reselect another without exit the Pr1 level.

• To exit completely the programming push SET + UP.

11.6 ENTER THE PROGRAMMING LEVEL PR2

Enter the Pr2 “maintenance level ”:

1. Push the SET + DOWN keys together for 3 seconds. The top display shows PAS while the bottom display shows Pr1 labels.

2. Push UP key for 2 seconds and the top display will show Pr2.

Page 26

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

3. Push SET key and the top display shows a blinking 0, with UP or DOWN insert the Pr2 password. Push SET and, if the value is

correct, top display will show the first family of parameters “ALL”. Otherwise set the password again.

4. Select a parameter family with DOWN or UP keys.

5. Push SET to enter, the bottom display shows the first available parameter label while the top display shows its value.

The user can shows and modify all the paramters belonging to this family.

Parameter status, leds and bottom display in Pr2

• Leds 1 / 2 are blinking: the parameter can not be changed.

• All the leds are off: the parameter ca not be seen in Pr1 level.

• Led 3 is on: the parameter can be seen in Pr1 level.

• Led 3 blinking: the parameter can be showed and changed in Pr2, showed but not changed in Pr1.

• Leds 1 / 2 / 3 are blinking: the parameter can’t be showed and changed in Pr2 and in Pr1.

• In Pr2 level the user can not see and change any parameter of Pr3 level.

• The MENU key allows to exit from a family to reselect another without exit the Pr2 level.

• The MENU key allows to pass to Pr1 starting from a family label.

• To exit completely the programming push SET + UP.

11.7 ENTER THE PROGRAMMING LEVEL PR3

Enter the Pr3 “OEM level ”:

1. Push the SET + DOWN keys together for 3 seconds. The top display shows PAS while the bottom display shows Pr1 labels.

2. Push UP key for 2 seconds and the top display will show Pr2.

1. Push UP key again for 2 seconds and the top display will show Pr3

3. Push SET key and the top display shows a blinking 0, with UP or DOWN insert the Pr3 password. Push SET and, if the value is

correct, top display will show the first family of parameters “ALL”. Otherwise set the password again.

4. Select a parameter family with DOWN or UP keys.

5. Push SET to enter, the bottom display shows the first available parameter label while the top display shows its value.

The user can shows and modify all the paramters belonging to this family.

Parameter status, leds and bottom display in Pr3

• Leds 1 / 2 are blinking: the parameter can not be changed in Pr1 and Pr2 level.

• All the leds are off: the parameter is available only in Pr3.

• Led 4 on: the parameter can be changed also in Pr2.

• Led 4 blinking: the parameter is visible but not modifiable in Pr2.

• Leds 3 / 4 on: the parameter is visible and modifiable in Pr2 and in Pr1.

• Leds 3 / 4 blinking: the parameter is visible but not modifiable in Pr1 and in Pr2.

• The MENU key allows to exit from a family to reselect another without exit the Pr2 level.

• The MENU key allows to pass to Pr1 starting from a family label.

• To exit completely the programming push SET + UP.

11.8 MOVE A PARAMETER LEVEL FROM PR2 TO PR1

Enter Pr2 programming level

Select the parameter and if the led n° 3 is off: the parameter is available only in Pr2.

To show the parameter also in Pr1:

1. Keep pushed SET key;

Page 27

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

Pg.24/114

2. Push 1 time the DOWN key and the led 3 should be on, the parameter is now available in Pr1.

To hide the parameter in Pr1:

1. Keep pushed SET key;

2. Push 1 time the DOWN key and the led 3 should be off, the parameter is now removed from Pr1.

11.9 MOVE A PARAMETER FROM PR3 TO PR2 TO PR1

Enter Pr3 programming level, here the parameter are all visible:

Select the parameter, if all the leds are off the parameter is available only in Pr3.

To show the parameter also in Pr2 and Pr1:

1. Keep pushed SET key;

2. Push 1 time the DOWN key and the leds 3 and 4 should be on, the parameter is now available also in Pr2 / Pr1.

To show the parameter only in Pr2:

1. Keep pushed SET key;

2. Push 1 time the DOWN key and the led 3 is off and the led 4 is on, the parameter is now available also in Pr2.

To show the parameter only in Pr3:

1. Keep pushed SET key

2. Push 1 time the DOWN key and the leds 3 and 4 are off, the parameter is now available only in Pr3.

11.10 VISIBILITY AND PARAMETER VALUE LOCKED

To set the only visibility and lock the parameter value it is necessary enter Pr3 programming level.

Pr1 PARAMETER VISIBILITY

Enter the Pr3 level

1. Select the parameter;

2. Keep pushed the SET key;

3. Push 1 time the MENU key and the led 3 change from on to blinking: the parameter is visible in Pr1 but can’t be changed.

Pr2 PARAMETER VISIBILITY

Enter the Pr3 level

1. Select the parameter;

2. Keep pushed the SET key;

3. Push 1 time the MENU key and the led 4 change from on to blinking the parameter is visible in Pr2 but can’t be changed.

Leds 3 / 4 blinking: the parameter is visible in Pr1 and in Pr2 but in those levels now they can’t be changed.

TO SET THE ORIGINAL TAG FOR THE PARAMETER Pr1 / Pr2

1. Keep pushed the SET key;

2. Push one time the MENU key, the leds 3 / 4 turn on, the parameter can be seen and modified in Pr1 and Pr2.

11.11 PROGRAMMING: DIGITAL INPUT AND OUTPUT POLARITY

The parameters that allow to configure different options such as:

1. Digital inputs

2. Digital outputs (relay)

3. Proportional output configured as ON/OFF

4. Analogue input configured as digital input

have a different parameter description that allows to configure the operating mode and the corresponding polarity.

Example of programming:

The bottom display shows the parameter label (CF24) Digital input ID1 configuration;

Note that the top display shows “c” or “o” before the configuration number.

The selection 7 for the digital input ID1 (CF24) means that it is the “high pressure switch of circuit 1”.

The label “o” means that the digital input is active for open contact.

Otherwise if the selection is 7 for the digital input ID1 (CF36) = “high pressure switch of circuit 1”.

The label “c” means that the digital input is active for closed contact.

Page 28

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

11.12 CHANGE THE POLARITY OF THE DIGITAL INPUTS-OUTPUTS

Enter the programming:

1. Select a parameter with digital input/output value, the top display shows the label o before the configuration number while the

bottom display shows the parameter label.

2. Push SET key: the o label and the configuration number are blinking, use the UP or DOWN key and select the proper polarity ( o /

c ) of the function, then push SET key to confirm it all.

3. The top display blinks for some seconds and then it will shows the next parameter.

4. To exit the programming push SET + UP together or wait the timeout (15seconds).

12 FUNCTION MENU “ M” KEY

The function Menu is composed of the following items:

1) Show and reset the alarms ALrM

2) Compressor overload alarm reset COtr

3) Show and reset the alarm log ALOG

4) Upload the parameter into the Hot Key UPL

5) Enable – disable one or the two circuits CrEn

6) Enable – disable one of the compressors COEn

7) Enable – disable one of the pumps POEn

8) Display the compressor discharge temperature COdt

9) Show and reset the number of compressor running hour Hour

10) Show and reset the number of compressor starts-up COSn

11) Show the condensing fan speed percentage of the proportional output Cond

12) Show the percentage of the proportional output 0 ÷ 10 Vdc Pout

13) Time counting to next defrost cycle, under heat pump mode, dF

14) Show the probe temperatures that enabled to control the auxiliary output uS

15) Show the probe the temperature of the remote panels trEM

MENU FUNCTION ACCESS: Push and release the M key.

MENU FUNCTION ACCESS: Push and release the M key or wait the 15seconds timeout limit.

With the UP or DOWN keys move inside the label list.

12.1 ALARM LIST: SHOW AND RESET

ALrM FUNCTION

Enter the function MENU pushing M key one time

1) Use the UP or DOWN to select the AlrM label

2) Push SET key (Nothing happens if there are no active alarm events)

3) Bottom display: alarm label code. Top display: label rSt to reset or NO if it is not possible.

4) Use the UP or DOWN to scroll the alarm list.

5) Pushing SET when the rSt label is displayed the corresponding alarm will be reset, then the display shows next alarm in the list,

pushing SET again the alarm is reset and the display shows next alarm etc. Nothing happens by pushing SET when the label NO

is displayed, in this case push UP or DOWN to move to another alarm label.

6) To exit the ALrM reset function push MENU one time or wait the timeout.

12.2 COMPRESSOR OVERLOAD ALARM RESET

COtr function resets the compressor overload alarm event.

Within the COtr function all the active compressor overload alarms are displayed in a list.

Labels involved in COtr: CO1r = compressor 1 overload reset … CO2r = compressor 2 overload reset. Labels CO1r – CO2r are

available if the digital inputs have been previously configured.

ATTENTION

The COtr menù is displayed only if the compressor overload alarm is at manual reset (after AL25 alarm events per hour the alarm is at

manual reset).

MANUAL ALARM RESET PROCEDURE

Enter Menu function

1. Use UP or DOWN key and select the COtr on the bottom display.

2. Push SET one time, if there are active alarms the bottom display shows the alarm label eg. CO1r (for compressor 1) while the top

display shows the label rSt to reset the alarm or NO if the alarm can not be reset. Use the UP or DOWN keys to scroll all the alrm

list.

3. Nothing happens by pushing SET when the label NO is displayed.

4. Pushing SET when the rSt label is displayed the corresponding alarm will be reset after the password: bottom display = ArSt while

the top display = PAS.

5. Push SET and the top display blinks 0 while the bottom shows PAS. Insert the password using UP or DOWN key (see AL60

parameter). If the password is OK the ArSt blinks for per 3seconds, if the password value is not correct the top display blinks 0

while the bottom shows PAS. If within 5 seconds no value is inserted the display label come back to CO1r function.

6. To exit the COtr function push MENU or wait the timeout.

Page 29

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

Pg.26/114

12.3 COMPRESSOR OVERLOAD PASSWORD.

The default value is 0; to change this value enter Pr3 level, search AL60 parameter and modify its value.

12.4 ALARM LOG LIST

ALOG FUNCTION TO SEE THE ALARM LOG

The function and the alarm codes are visible only if there are alarm events. If many events are active at the same time the list displayed

by increasing order.

Enter the function Menu

1. Select ALOG

2. Push SET one time. Nothing happens if there are no active alarm events.

3. The bottom display shows the alarm label, the top display shows a number in the range 00 to 99.

4. Use the UP or DOWN keys to scroll the list.

5. To exit the ALOG function push MENU or wait the timeout.

12.5 ERASE THE ALARM LOG LIST

ALOG FUNCTION TO ERASE THE LOG LIST

1. Enter the function Menu.

2. Use the UP or DOWN keys to select ALOG on the bottom display.

3. Push the SET key.

4. Push UP or DOWN keys and search the ArSt label on the bottom display; the top display shows PAS.

5. Push SET: the bottom display shows PAS and the top display shows 0 value blinking.

6. Insert the password

7. If the password is OK the label ArST blinks for 5 seconds then the display returns to normal condition read-out (probes).

8. If the password is not correct the display shows PAS again. in any case is possible to scroll the list with UP or DOWN

9. To exit push the M key one time or wait the timeout.

12.6 PASSWORD VALUE OF THE ALARM LIST

The default value is 0 to change this value enter Pr3 level under the AL parameter family.

THE ALARM LIST CONTAINS 100 EVENTS IN A FIFO STRUCTURE. WHEN THE MEMORY IS FULL ANY NEW ALARM WILL

ERASE THE OLDEST.

12.7 DISABLE – ENABLE A SINGLE CIRCUIT

Through the instruments keyboard is possible to completely disable a single circuit for maintenance or to use just a cooling part of of the

unit.

CrEn FUNCTION enables – disables a circuit from keyboard.

Label involved with CrEn function: Cr1E = circuit 1, Cr2E = circuit 2

HOW TO DISABLE A CIRCUIT

Enter the function Menu

1. Use UP or DOWN keys to select CrEn on the bottom display

2. Push SET key: the bottom display = Cr1E, top display = En.

3. Select the circuit 1 or 2 with UP or DOWN key (Cr1E or Cr2E).

4. Push SET key for 3 seconds when; the top display shows the En blinking label. Using UP or DOWN key, choose the label diS

(Disabled) or En (Enabled), then push SET key to confirm the new selection. The display shows next circuit status.

5. To exit the CrEn function push MENU key or wait the timeout.

12.8 READ-OUT OF A CIRCUIT NOT ENABLED

If one circuit is disabled the bottom display shows diS alternated with the label name of the measurement selected.

Circuit 1 = diS the bottom display shows b1dS = circuit 1 disabled.

Circuit 2 = diS the bottom display shows b2dS = circuit 2 disabled.

The b2dS label appears only if the 2nd circuit is configured,

12.9 ENABLE OR DISABLE A SINGLE COMPRESSOR

Through the instruments keyboard is possible to disable a single compressor for maintenance or to lock it when malfunctioning.

COEn FUNCTION compressors running status.

Label involved in COEn function: CO1E = Compressor 1 status… CO6E = Compressor 6 status

The COEn function uses only the compressors configured by the corresponding output parameters.

Enter the function Menu

1. Use the UP or DOWN keys to select COEn.

2. Push SET key; the bottom display shows CO1E, and the top display shows En

3. Select the compressor using UP or DOWN key

4. Push SET for 3 seconds; the top display shows the En label blinking. Using UP or DOWN key change the label diS (Compressor

disabled) or En (compressor enabled) then push SET to confirm.

5. To exit the COEn function push MENU key or wait the timeout.

Page 30

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

12.10 READ-OUT OF A COMPRESSOR NOT ENABLED

During the normal running condition a disabled compressor is displayed with a blinking label alternated with the measurement value of

the display.

If the compressor is disabled these the corresponding labels: C1dS = compressor 1 disabled, C2dS = compressor 2 disabled

The label C1dS…C2dS are available only if the corresponding compressor is configured.

12.11 READ-OUT OF THE COMPRESSOR DISCHARGE TEMPERATURE PROBE

The menu function allows to read-out the compressor temperature probes.

COdt FUNCTION shows the discharge temperatures

Label involved in Codt function: CO1t Compressor 1 discharge temperature (only for compressor 1 is possible to configure the

discharge probe)

1. Use the UP or DOWN keys to select COdt

2. Push SET key: bottom display = CO1t, top display = temperature value of that probe.

3. To exit the COEn function push MENU key or wait the timeout

ATTENZIONE

The labels Codt are available only if the compressor probe is configured.

The display resolution is 0.1°C until the read-out is 99.9, over 100°C it is 1°C.

12.12 READ-OUT OF THE RUNNING HOURS

This menu allows to shows all the time running hours of the compressors, supply fan and pumps.

Hour FUNCTION to show the controlled load consumption

Label involved in the Hour function:

CO1H Compressor 1 running hours .. CO2H Compressor 2 running hours.

EP1H Evaporator water pump or Supply fan running hours (air/air)

EP2H Support evaporator water pump running hours

CP1H Condenser water pump running hours

CP2H Support condenser water pump running hours

The labels are displayed only if the corresponding output is present and configured.

The running hours is displayed on the top display, the resolution is x 10 hours (eg 2 means 20 hours, 20 means 200hours)

Enter the function Menu

1. Use the UP or DOWN keys to select Hour

2. Push SET key: bottom display = above labels, top display = hours x10. The time is on.

3. Use the UP or DOWN keys to scroll the list.

4. To exit the Hour function push MENU key or wait the timeout

12.13 RESET THE RUNNING HOUR

Enter the function Menu

1. Within the Hour function select, with UP or DOWN, the interested label: CO1H, CO2H, EP1H, EP2H, CP1H, CP2H.

2. Push the SET keys for 3seconds: the top display shows the running hours blinking value, then it shows 0 to confirm the reset. The

next load label is automatically loaded.

To exit the Hour function push MENU key or wait the timeout

12.14 READ-OUT OF THE COMPRESSOR STARTS-UP

For each compressor is possible to show the number of starts-up.

COSn FUNCTION: number of starts-up of the compressor

Label involved in COSn function: C1S number of compressor 1 starts-up .. C2S number of compressor 2 starts-up

The labels are displayed only if the corresponding output is present and configured

The number of starts-up is displayed on the top display, the resolution is x 10 (eg 2 means 20 starts, 20 means 200starts)

Enter the function Menu

1. Use the UP or DOWN keys to select COSn.

2. Push SET one time: the label of the first load C1S is showed on the top display, the bottom display shows the number x10.

3. With UP or DOWN scroll the compressor list.

4. To exit the Hour function push MENU key or wait the timeout

12.15 RESET THE STARTS-UP NUMBER

Enter the function Menu

1. Use the UP or DOWN keys to select COSn.

2. Push SET one time: the label of the first load C1S is showed on the top display, the bottom display shows the number x10.

3. With UP or DOWN scroll the compressor list and select one of them

4. Push the SET keys for 3seconds: the top display shows the running hours blinking value, then it shows 0 to confirm the reset. The

next load label is automatically loaded.

5. To exit the Hour function push MENU key or wait the timeout.

12.16 READ-OUT OF THE PROPORTIONAL OUTPUT PERCENTAGE OF THE CONDENSER FAN

CONTROL

The proportional outputs of the two circuits, that control the fan speed, can be showed in the menu function.

Page 31

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

Pg.28/114

Cond FUNCTION selects the proportional output 1 and 2.

Label involved in Cond function.

Cnd1 Proportional output status of the condenser fan of the circuit 1.

Cnd2 Proportional output status of the condenser fan of the circuit 2.

TO SEE THE OUTPUT PERCENTAGE:

Enter the function menu

1. Use the UP or DOWN keys to select Cond.

2. Push SET key: the bottom display shows Cnd1, the top display shows the output percentage.

3. Use the UP or DOWN keys to select Cnd1 or Cnd2, the top display always shows the value, between 0% and 100%, of the

proportional output of the selected circuit.

4. To exit the Hour function push MENU key or wait the timeout.

12.17 READ-OUT OF THE FOUR PROPORTIONAL OUTPUT

The four proportional outputs 0-10V, can be showed in the menu function.

Pout FUNCTION selects the proportional outputs.

Label involved in Cond function:

Pou1 Proportional output or signal to drive the external relay 1

Pou2 Proportional output or signal to drive the external relay 2

Pou3 Proportional output or signal to drive the external relay 3

Pou4 Proportional output or signal r to drive the external relay 4

The labels are displayed only if the corresponding output is present and configured.

TO SEE THE FOUR OUTPUT PERCENTAGE:

Enter the function menu

1. Use the UP or DOWN keys to select Pout.

2. Push SET key: the bottom display shows Pou1, the top display shows the output percentage.

3. Use the UP or DOWN keys to select Pou1, Pou2, Pou3 or Pou4 the top display always shows the value, between 0% and 100%, of

the proportional output of the selected circuit.

4. To exit the Hour function push MENU key or wait the timeout.

ATTENTION:

If the proportional output Pou1 - Pou2 - Pou3 - Pou4 are configured to drive an external relay the display will show 0=relay off

and 100=relay on.

12.18 READ-OUT OF THE TIME COUNTING TO THE NEXT DEFROST

The time delay between two defrosts can be showed in the menu function.

dF FUNCTION time to next defrost.

Label involved in dF function:

dF1 delay time to next defrost of the circuit 1

dF2 delay time to next defrost of the circuit 2

The labels apperas on if the heat pump configuration is enabled.

Enter the function menu :

1. Use the UP or DOWN keys to select dF

2. Push SET key: the dF1 label is showed on the top display, the bottom display shows the time delay to next defrost in minutes /

seconds. The icon is on.

3. Use the UP or DOWN keys to select dF1 or dF2.

4. To exit push MENU key or wait the timeout.

12.19 READ-OUT OF THE PROBES CONFIGURED TO CONTROL AN AUXILIARY OUTPUT

RELAY

uS FUNCTION temperature/pressure value of the control probe for auxiliary output.

Label involved in uS function:

uSt1 auxiliary probe value of the circuit 1

uSt2 auxiliary probe value of the circuit 2

Enter the function menu

1. Use the UP or DOWN keys to select uS.

2. Push SET key: the label uSt1 (temperature probe ) or uSP1 (Pressure probe) is showed on bottom display, the top display shows

the the temperature or pressure value.

3. Use the UP or DOWN keys to select uSt1 auxiliary probe for circuit 1or uSt2 auxiliary probe for circuit 2.

4. To exit the Hour function push MENU key or wait the timeout.

12.20 HOW TO DISPLAY THE TEMPERATURE OF THE REMOTE KEYBOARD 1 OR 2

Inside the funcion menu it is possible to see the ambient temperature detected by the NTC sensor mounted in the remote keyboard

(availabel only for model with internal probe)

FUNCTION trEM to show the temperature of the remote panels

Identification label trEM.

trE1 value of the NTC probe of the remote 1

trE2 value of the NTC probe of the remote 2

Page 32

1592022700 User manual iCHILL 200CX Rel. 1.0 22/04/2009

Select with UP or DOWN the trEM function

Push SET the trE1 or trE2 label is shown on the bottom display, the top display shows the probe value.

Use the UP or DOWN arrow to change beteween trE1 or trE2 read-out.

To exit to the normal display read-out push MENU or wait the time – out time.

ATTENTION:

THE trEm function and the labels trE1 or trE2 appear only if the CF47=1 (remote panel 1 configuration) or if the parameter CF48 = 1

(remote panel 2 configuration).

13 CHILLER / HEAT PUMP SELECTION

The CF52 parameter allows to select and enable the running mode:

Par. CF52= 0: Through keyboard; the user can start and stop the unit using the keys of the front panel.

Par. CF52 = 1: Through digital input programmed as start/stop the unit from remote control.

• this selection is enabled if there is one digital input configured as start/stop from remote (remote chiller / heat pump). If any of the

digital input is not configured as “remote chiller/heat pump”, the unit remains in stand–by.

• if a digital input is configured as “o2” (“remote chiller/heat pump” active if the contact is open) when the digital input is open the unit

works in chiller mode, when the digital input is closed the unit works in heat pump mode

• if a digital input is configured as “c2” (“remote chiller/heat pump” active if the contact is closed) when the digital input is open the

unit works in heat pump mode, when the digital input is closed the unit works in chiller mode

• the working mode selection (chiller / heat pump) from keyboard is disabled; it is possible to switch-off the unit (std-by mode) or

switch-on the unit in the working mode selected by digital input

Par. CF52 =2: Automatic selection of the Chiller - Heat Pump through analogue input

The analogue input selection or change over function overrides the selection of the working mode (chiller / heat pump) by digital input. If

the external air temperature are within the ST13 differential, the user can change the running mode from the keyboard.

If the unit is running with CF52 = 1 or CF52=2, and it is requested a running mode change, the controller turns off all the outputs, starts

a fixed delay time signalled by the chiller or heat pump blinking led. This blinking led indicates which running mode will be activated after

the compressor delay time protection.

To change the running status the following condition must be respected otherwise the unit remains in stand - by:

1. CF02=3 (chiller and heat pump unit)

2. CF52=2 and a NTC probe configured as NTC external air temperature for dynamic setpoint/ boiler / change over

3. This probe is working properly.

Parameters involved with the change over function: