Page 1

1592015820 User Manual IC200L/D DUO rel 1.0

Pag. 1 of 149

User Manual

Ichill 260L_D DUO

Ichill 261L_D DUO

(Firmware version 1.9)

Page 2

1592015820 User Manual IC200L/D DUO rel 1.0

Pag. 2 of 149

INDEX

1. GENERAL FEATURES .............................................................................................. 8

1.1 Main Function ................................................................................................................................................ 8

2. ICHILL 260/261L_D FEATURES ............................................................................. 10

3. USER INTERFACE .................................................................................................. 11

4. REMOTE KEYBOARD ............................................................................................. 15

5. FIRST INSTALLING ................................................................................................. 15

6. WIRING CONNECTIONS ......................................................................................... 16

7. ANALOG AND DIGITAL OUTPUT CONFIGURATION ........................................... 26

8. PROGRAMMING WITH THE “HOT KEY 64” ......................................................... 31

9. PROGRAMMING USING THE KEYBOARD ............................................................ 31

10. CHILLER / HEAT PUMP SELECTION ..................................................................... 36

11. HOW TO SWITCH ON / SWITCH OFF THE UNIT ................................................... 37

12. SWITCH ON / SWITCH OFF THE CONDENSING UNIT BY DIGITAL INPUT ......... 37

13. DISPLAY LAYOUT ................................................................................................... 38

14. DISPLAY CONFIGURATION ................................................................................... 39

15. DISPLAY INFORMATION ........................................................................................ 41

16. FUNCTION MENU “ M” KEY ................................................................................... 42

16.1.1 Compressor overload alarm; manual reset ................................................................................................43

16.1.2 Compressor overload alarm; manual reset with password .........................................................................43

17. ENERGY SAVING .................................................................................................... 48

17.1 Energy Saving Activation By Digital Input ..................................................................................................48

17.2 Energy Saving Time Table With Rtc ............................................................................................................48

18. DYNAMIC SETPOINT .............................................................................................. 49

Page 3

1592015820 User Manual IC200L/D DUO rel 1.0

Pag. 3 of 149

19. COMPRESSOR REGULATION ............................................................................... 51

19.1 Compressor Security Time ...........................................................................................................................51

20. CHILLER / HEAT PUMP REGULATION .................................................................. 51

20.1 Parameter Description ..................................................................................................................................51

20.2 Proportional Regulation ...............................................................................................................................52

20.3 Neutral Zone Regulation...............................................................................................................................53

21. COMPRESSORS MANAGEMENT ........................................................................... 54

21.1 Compressors Start- Up .................................................................................................................................54

22. COMPRESSORS ROTATION .................................................................................. 56

23. CAPACITY STEP CONTROL................................................................................... 56

23.1 Minimum Load Start- Up .............................................................................................................................58

23.2 Intermittent Solenoid Valve for Screw Compressor ....................................................................................58

24. COMPRESSOR INVERTER CONTROLLED ........................................................... 58

24.1 Inverter Compressor In Heat Pump And External Temperature ...............................................................62

25. COMPRESSOR RACK ............................................................................................. 62

26. COMPRESSORS WITH DIFFERENT CAPACITY ................................................... 63

27. CIRCUIT MANAGEMENT: SATURATION OR BALANCING .................................. 64

28. PUMP DOWN ........................................................................................................... 64

29. UNLOADING ............................................................................................................ 66

29.1 High Temperature Of The Evaporator Water Inlet ....................................................................................66

29.2 Condenser High Pressure, Condenser High Temperature Or Evaporator Low Pressure ..........................66

29.3 Low Temperature Of The Evaporator Water Outlet...................................................................................67

30. SOLENOID VALVE FOR LIQUID INJECTION......................................................... 67

31. EVAPORATOR WATER PUMP / SUPPLY FAN (AIR/AIR UNIT) ............................ 67

31.1 Evaporator Pump Group ..............................................................................................................................68

31.2 Modulating Evaporator Water Pump ..........................................................................................................68

Page 4

1592015820 User Manual IC200L/D DUO rel 1.0

Pag. 4 of 149

32. WATER PUMP OF THE CONDENSER ................................................................... 69

32.1 Condenser Pump Group ...............................................................................................................................70

33. CYCLIC OPERATION OF THE WATER PUMPS .................................................... 70

34. HOT START ............................................................................................................. 71

35. LOAD MAINTENANCE ............................................................................................ 71

36. CONDENSER FAN REGULATION .......................................................................... 71

36.1 Output Step Rele’ Condenser Fan ................................................................................................................72

36.2 Pwm Output For Fan Control ......................................................................................................................73

36.3 Condensing Unit: Common Or Separate Condenser ...................................................................................73

36.4 Proportional Regulation Of Condenser Fans ...............................................................................................73

36.5 On/Off Regulation Of Condenser Fans ........................................................................................................74

36.6 Pre-Ventilation And Post-Ventilation...........................................................................................................74

37. ANTI FREEZE HEATERS, INTEGRATION HEATING OR BOILER ........................ 75

38. AUXILIARY RELAYS ............................................................................................... 77

39. AUXILIARY PROPORTIONAL OUTPUTS ............................................................... 78

40. DEFROST CYCLE .................................................................................................... 81

40.1 Automatic Defrost Procedure .......................................................................................................................81

40.2 Other Information About The Defrost .........................................................................................................82

40.3 Forced Defrost ..............................................................................................................................................83

40.4 Combined Defrost .........................................................................................................................................83

40.5 Manual Defrost .............................................................................................................................................83

40.6 Defrost In Unit With Two Circuits ...............................................................................................................83

40.6.1 Start defrost in unit with common condenser ............................................................................................83

40.6.2 End defrost in unit with two condenser ....................................................................................................83

40.7 Defrost With Condenser Fan Procedure ......................................................................................................84

40.8 Defrost Parameter Description .....................................................................................................................84

40.9 Defrost Dynamic Set Point ............................................................................................................................86

41. PRODUCTION OF SANITARY HOT WATER .......................................................... 87

Page 5

1592015820 User Manual IC200L/D DUO rel 1.0

Pag. 5 of 149

41.1 Anti-Legionella Function ..............................................................................................................................89

41.2 Water Pumps Management ..........................................................................................................................90

41.3 Sanitary Water Second Set Point .................................................................................................................91

41.4 Sanitary Hot Water Production: Valves In Water Circuit ___ Fs01=1 (Air/Water, Water/Water Unit) ...91

41.4.1 - Sanitary hot water operation when the unit is producing hot water .........................................................91

41.4.2 - Sanitary hot water operation when the unit is producing cold water ........................................................92

41.5 Sanitary Hot Water Production: Valves In Gas Circuit ___ Fs01=2 (Air/Water, Water/Water Unit) .......92

41.5.1 Sanitary hot water operation when the unit is producing hot water ............................................................92

41.5.2 - Sanitary hot water operation when the unit is producing cold water ........................................................92

42. SOLAR PANEL MANAGEMENT ............................................................................. 94

42.1 Solar Panel In Sanitary Hot Water ..............................................................................................................94

42.2 Solar Panel In Heating Mode ........................................................................................................................94

43. UNIT WITH HYBRID EXCHANGERS (AIR / WATER UNIT).................................... 95

44. GEOTHERMAL FREE COOLING ............................................................................ 96

44.1 Fan speed control if compressors and free cooling are used for cooling (CF97=3)......................................98

45. RECOVERY FUNCTION .......................................................................................... 98

45.1 Unit With Two Separate Idraulic Circuits ...................................................................................................98

45.2 Unit With Two Idraulic Circuit Working In Parallel ..................................................................................99

46. CONDENSER TEMPERAURE / PRESURE CONDITION TO ENABLE/DISABLE

THE RECOVERY CYCLE ............................................................................................... 100

46.1 Recovery Disabled....................................................................................................................................... 100

46.2 Recovery Enabled ....................................................................................................................................... 101

46.3 Note About Recovery Enabled/Disabled .................................................................................................... 101

47. OPERATION RELATED TO THE REAL TIME CLOCK ......................................... 101

47.1 Real Time Clock Disabled By Digital Input ............................................................................................... 101

47.2 “Only supply fan” working mode” ............................................................................................................. 101

48. MESSAGES - ALARM CODES ............................................................................. 101

48.1 Automatic / Manual Alarm Description ..................................................................................................... 101

C1Pd - C2Pd – compressor oil differential pressure.............................................................................................. 115

49. AUTOMATIC TO MANUAL ALARM PROCEDURE .............................................. 120

Page 6

1592015820 User Manual IC200L/D DUO rel 1.0

Pag. 6 of 149

49.1 Alarm .......................................................................................................................................................... 121

49.2 Alarm: Circuit Alarm ................................................................................................................................. 122

49.3 Alarm: Compressor Alarm ......................................................................................................................... 123

50. TABLE OF THE PARAMETERS ............................................................................ 124

51. BLACK-OUT........................................................................................................... 145

52. INSTALLING AND MOUNTING ............................................................................. 145

52.1 ICHILL 200 L FORMAT: Panel cut- out .................................................................................................. 145

52.2 ICHILL 200 L FORMAT: metal front frame ............................................................................................ 145

52.3 Ichill 200 Din Format SERIES ................................................................................................................... 146

52.4 Vertical boards Vi620 – panel cut-out ........................................................................................................ 146

53. ELECTRICAL CONNECTIONS .............................................................................. 147

54. ACCESSORIES ...................................................................................................... 147

55. TECHNICAL DATA ................................................................................................ 149

Page 7

1592015820 User Manual IC200L/D DUO rel 1.0

Pag. 7 of 149

General advice

PLEASE READ BEFORE USING THIS MANUAL

This manual is part of the product and should be kept near the instrument for easy and quick reference.

The instrument shall not be used for purposes different from those described hereunder. It cannot be

used as a safety device.

Check the application limits before proceeding

The technical data and information in the user manual could change without obligation to notice.

SAFETY PRECAUTIONS

Check the supply voltage is correct before connecting the instrument.

Do not expose to water or moisture: use the controller only within the operating limits avoiding sudden

temperature changes with high atmospheric humidity to prevent formation of condensation

Warning: disconnect all electrical connections before any kind of maintenance.

The instrument must not be opened.

In case of failure or faulty operation send the instrument back to the distributor or to “Dixell company with

a detailed description of the fault.

Consider the maximum current which can be applied to each relay (see Technical Data).

Ensure that the wires for probes, loads and the power supply are separated and far enough from each

other, without crossing or intertwining.

Fit the probe where it is not accessible by the end user.

In case of applications in industrial environments, the use of mains filters (our mod. FT1) in parallel with

inductive loads could be useful.

Page 8

1592015820 User Manual IC200L/D DUO rel 1.0

Pag. 8 of 149

1. GENERAL FEATURES

IC260L_D/261L_D is an electronic controller for chiller unit applications having one or two circuits:

Air/air

Air/water

Water/water

Condensing unit

Additional features :

Heat pump with gas reversibility

1.1 MAIN FUNCTION

Chiller management:

One circuit up to 4 compressors

Double circuit up to 6 compressors

Screw compressors

Compressor start up:

Direct

Part winding

Star - delta

Capacity step control:

Continuous control

Step control

Modulation control (screw compressors)

Regulation of the compressors

Working hour trade-off

Start-up trade-off

Management of two pump groups

2 pumps evaporator side

2 pumps condenser side

Pump down management

With dedicated pressure switch

Low pressure switch

Low pressure transducer

Unloading circuit

High temperature of the evaporator inlet water

High temperature of the condenser inlet water (unit with recovery)

High condensing pressure

Low evaporating pressure

Maintenance messages

Compressors

Evaporator pumps

Condenser pumps

Auxiliary relays

It is possible to configure two relays with indipendent regulation

Weekly Energy saving

Three different time bands per day (only if RTC onboard)

Energy saving enabled by digital input

Weekly ON/OFF:

Three different time bands per day (only if RTC onboard)

Dynamic setpoint:

It is possible to modify the set point according to outside temperature or a dedicated 4..20mA probe

Change over :

Automatic operative mode selection (chiller / heat pump) maccording to outside temperature

Defrost management:

Combined control temperature / pressure

Page 9

1592015820 User Manual IC200L/D DUO rel 1.0

Pag. 9 of 149

Forced defrost

Different way to enable the defrost (temperature / pressure / digital input)

Boiler:

For heating integration

Two proportional outputs for condensing fan speed control (inverter or phase cut) with configurable

signal:

PWM

0÷10Volt

4÷20mA

Four proportional control outputs 0÷10V or ON/OFF

To control the dumper

To control an external relay

Complete alarm management

Internal Data logger up to 100 events

Supervisor / monitoring

TTL output for XJ485 interface (ModBus protocol) for XWEB Dixell monitoring system

Page 10

1592015820 User Manual IC200L/D DUO rel 1.0

Pag. 10 of 149

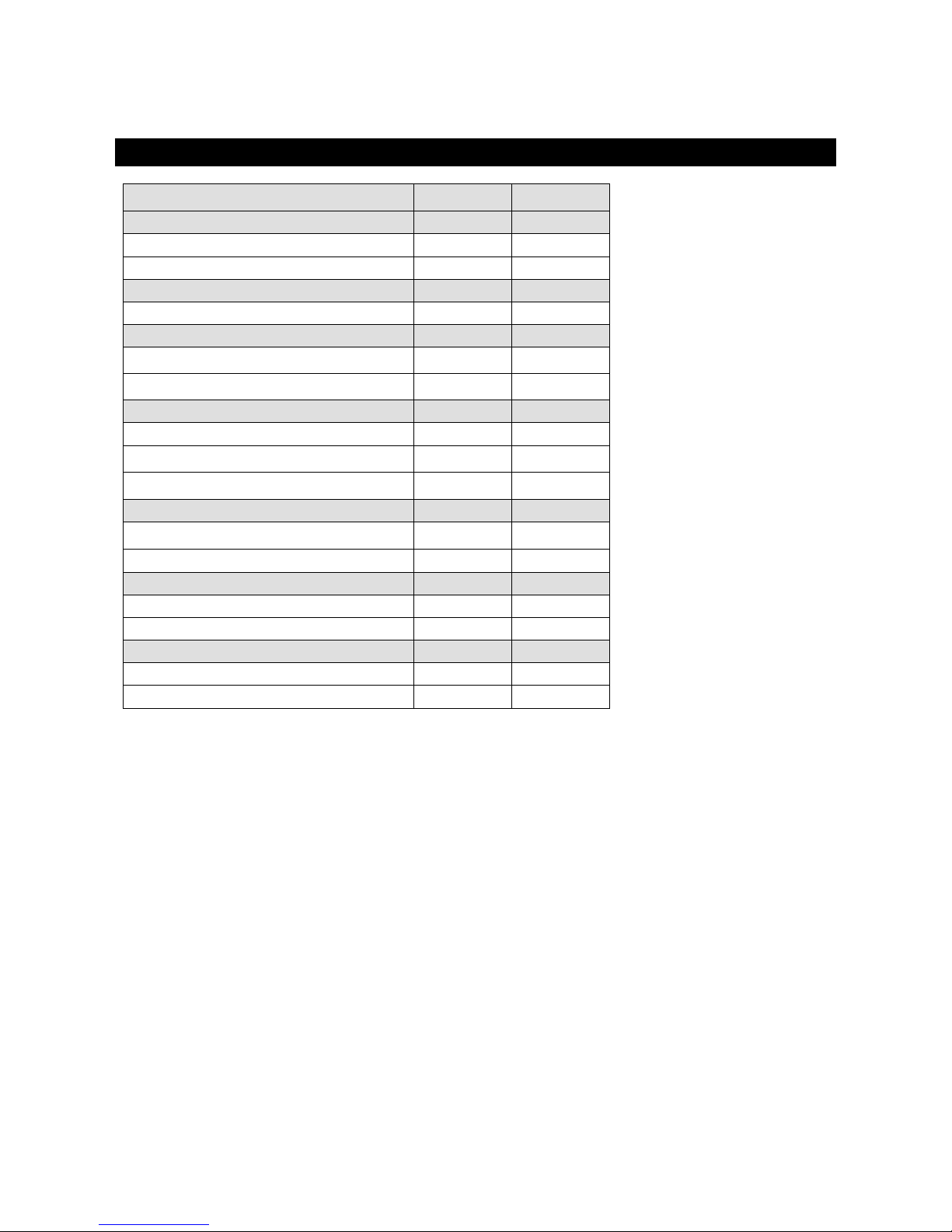

2. ICHILL 260/261L_D FEATURES

FEATURES IC290D IC291D

OUTPUT RELAYS

10

14

DIGITAL INPUTS

18 configurable configurable

PROBE INPUTS

6 (NTC/PTC) configurable configurable

4 (NTC/PTC/0..5V/4..20mA) configurable configurable

PROPORTIONAL OUTPUTS

2 PWM outputs for condensing fan

2 0÷10V or 4÷20mA for condensing fan configurable configurable

4 0÷10V configurable configurable

OTHER OUTPUTS

TTL

Output for remote keyboard VGI890

POWER SUPPLY

12 Vac/dc (+15%;-10%)

24 Vac/dc (± 10%) opt opt

OTHERS

Internal RTC opt opt

Buzzer opt opt

configurable = configurable by parameter

opt = optional

= default

Page 11

1592015820 User Manual IC200L/D DUO rel 1.0

Pag. 11 of 149

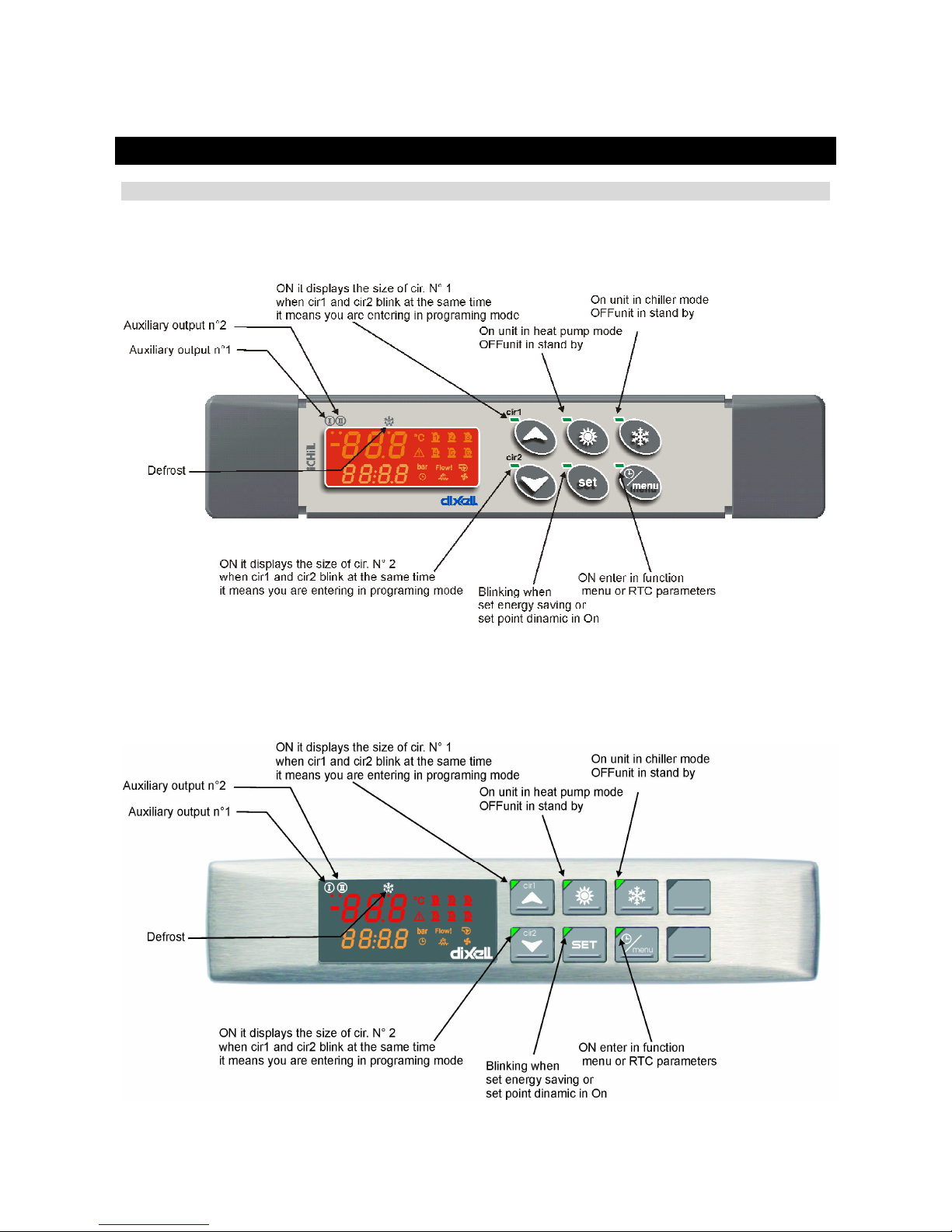

3. USER INTERFACE

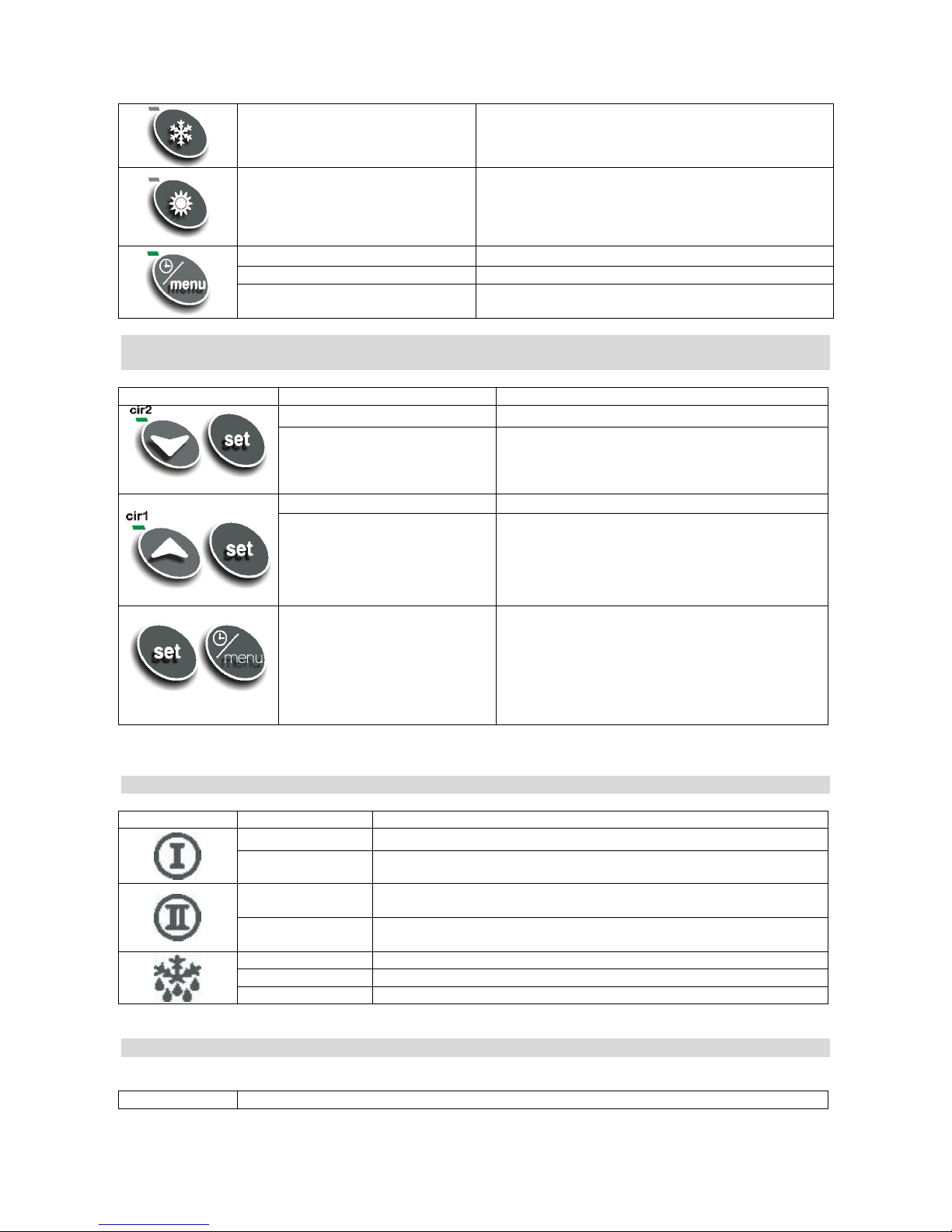

Meaning of the LEDs

IC260L / IC261L models

IC260L / IC261L metal front panel

Page 12

1592015820 User Manual IC200L/D DUO rel 1.0

Pag. 12 of 149

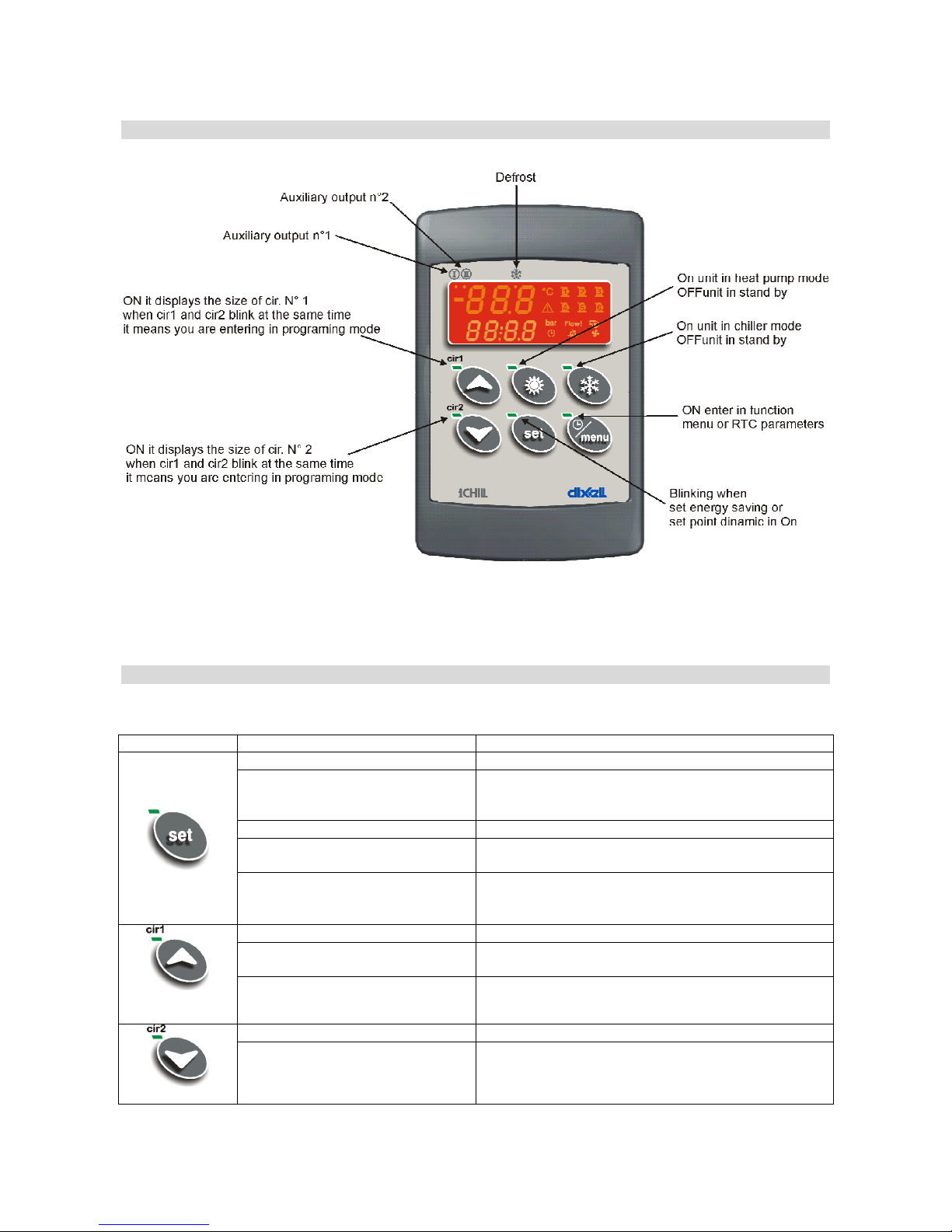

Meaning of the leds on the models VI620 - VI620S remote keyboard

KEY FUNCTION

KEY ACTION

FUNCTION

Push and release

Show chiller set point

SetC

and heat pump

SetH

Push once

In chiller or heat pump if the Energy saving or the

Dynamic setpoint are enabled it shows the real

setpoint Setr, the led is blinking.

Push for 3 seconds the release Change between chiller / heat pump

During the programming: push one

time

Select a parameter or confirm a value

Push once with probe label

showed on the bottom display

Change between the read-out of the circuit 1 and the

circuit 2 and viceversa

UP KEY

Push once Select the readings of the first circuit

Pushing once during the

programming

To change the parameter code or value

Push for 1 second during the

programming

1 time shows the Pr2 programming level

2 time shows the Pr3 programming level

TASTO DOWN

Push once Select the readings of the second circuit

Pushing one time during the

programming

To change the parameter code or value

Page 13

1592015820 User Manual IC200L/D DUO rel 1.0

Pag. 13 of 149

Push once

Turn the chiller on, if the unit is on led is on

The led is blinking if there is a power on delay or

during the pump down

Push once

Turn the heat pump on, if the unit is on led is on

The led is blinking if there is a power on delay or

during the pump down

Push once enter the function Menu

Push for 3 seconds To set RTC parameters (if the RTC is inside)

Pushing once during the

programming

To exit from a group of parameter

KEY COMBINANTION

KEY ACTION

FUNCTION

Push for 3 seconds together Enter the programming

In Pr3 level: push SET and the

push DOWN key

Select the parameter level visibility Pr1 / Pr2 / Pr3

Push once together

Exit the programming

Push 5 seconds (heat pump

with ok condition)

Manual defrost

In Pr3 programming level Push

SET and then the MENU key

In Pr3 defines if the parameter can be changed

or not in the other levels.

LED and ICONS

ICON

LED FUNCTION

ON Auxiliary relay #1 active

OFF Auxiliary relay #1 not active

ON Auxiliary relay #2 active

OFF Auxiliary relay #2 not active

BLINKING

Defrost delay counting active

ON

Defrost

OFF

Defrost end

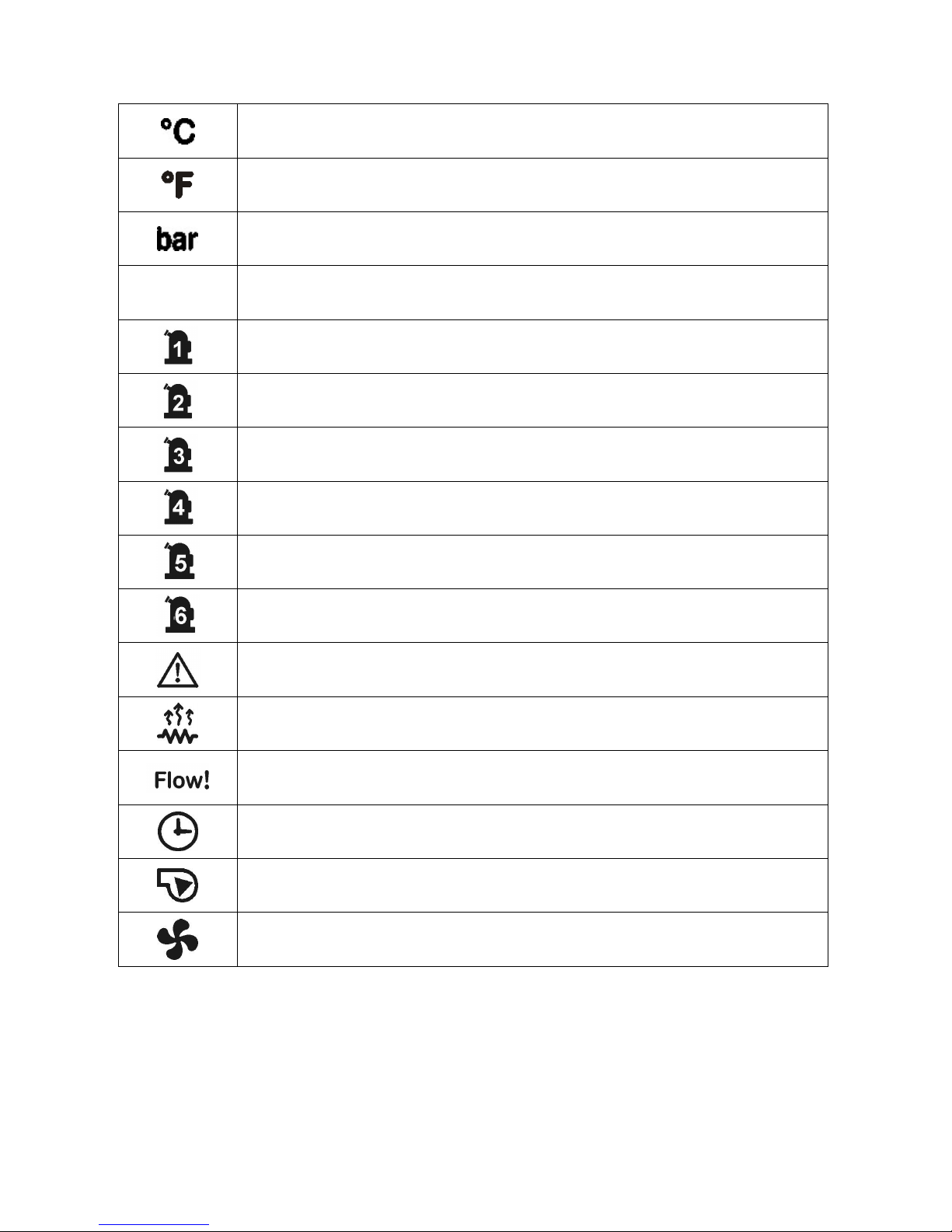

Display and Icons

ICON

MEANING / FUNCTIONNING

Page 14

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 14 of 149

Celsius degrees: ON for temperature measurements of probe values or parameters

Fahrenheit degrees: ON for temperature measurements of probe values or parameters

Bar: ON for pressure measurements of probe values, setpoint or parameters

PSI

Psi: ON for pressure measurements of probe values, setpoint or parameters

ON = compressor 1 active

Blinking = compressor 1 delay counting

ON = compressor 2 active

Blinking = compressor 2 delay counting

ON = compressor 3 active

Blinking = compressor 3 delay counting

ON = compressor 4 active

Blinking = compressor 4 delay counting

ON = compressor 5 active

Blinking = compressor 5 delay counting

ON = compressor 6 active

Blinking = compressor 6 delay counting

General alarm: blinking if there is an alarm not identified by an icon

Anti freeze heaters/ integration heating / boiler: ON if the output is on

Flow alarm/ (differential) pressure switch / supply fan thermal (air / air unit) : is blinking if

the configuration of the digital input is active

Real time clock: On when the bottom display show the RTC

ON during the programming with time based parameter value

In function menu indicates the defrost delay counting

Water pump: On if at least one of the four configurable pump group is on

Condenser fan: ON if at least one of the PWM or relay outputs for fan control is active

Page 15

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 15 of 149

Meaningg of the bottom display led

Led # 1 – 2 (With RTC)

If the bottom display shows the RTC the 1 and 2 leds are blinking.

Led # 1 – 2 In function Menu

During the time counting to the next defrost for one or both circuits the led 1 and 2 are blinking.

LED Parameter programming

In Pr2 level: led #3 indicates the visibility while the #1 and #2 show if the parameter can be modified or not.

In Pr3 level: led #3 and #4 indicate the visibility while the #1 and #2 show if the parameter can be modified or

not.

4. REMOTE KEYBOARD

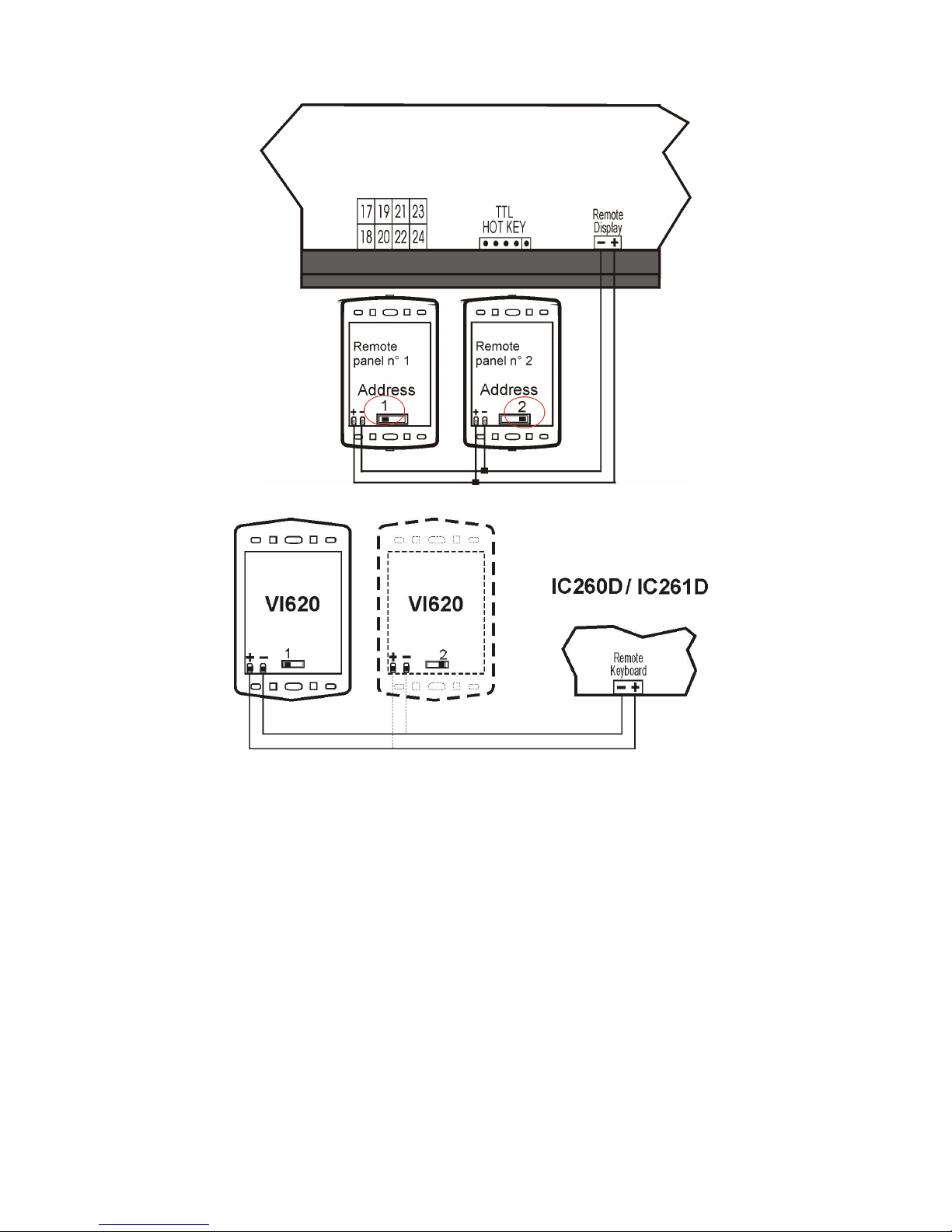

The IC200L/D can be connected with 2 remote keyboard.

The remote keyboard can have the NTC probe on board that is used to show the room temperature and also

to control the temperature regulation.

To connect the remote keyboard it is necessary to use shielded cable for a maximum lenght of 150mt. In

case of no communication between the instrument and the remote keyboard the display shows “noL” (no

link).

Mod. VI620 – standard keyboard

Mod VI620S – keyboard with internal temperature probe

Use the connection cable CAB/CJ30 (2x0.2 mm2) to interface the IC connector to the shielded wire.

5. FIRST INSTALLING

On Board Clock (Optional)

Giving power supply the bottom display shows “rtC” alternated with a temperature or pressure value: It is

necessary to set the RTC.

If the probes are not connected the display shows the corresponding probe alarm messages. In this situation

the RTC setup and the programming are available.

ATTENTION

The RTC function is an optional and it is not possible to update the instrument but it is necessary to

order the instrument already complete of this features.

With power failure the RTC back-up battery maximum duration is 1 week. After this period it is necessary to

setup the clock again.

Real Time Clock Setup

1. Push M key for 3 seconds until the bottom display shows “Hour” and the top display shows its value.

2. Push SET one time: the value is blinking.

3. Use the Up and Down keys to adjust it. Push SET one time to confirm; automatically the display shows

next parameter.

4. Repeat the operations 2. 3. and 4. for all the RTC parameters:

- Min: minutes (0÷60)

- UdAy: day of the week (Sun = Sunday, Mon =Monday, tuE =Tuesday, UEd = Wednesday, tHu =

Thursday, Fri =Friday, SAt =Saturday)

Page 16

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 16 of 149

- dAy: day of the month (0÷31)

- MntH: month (1÷12)

- yEAr: year (00÷99)

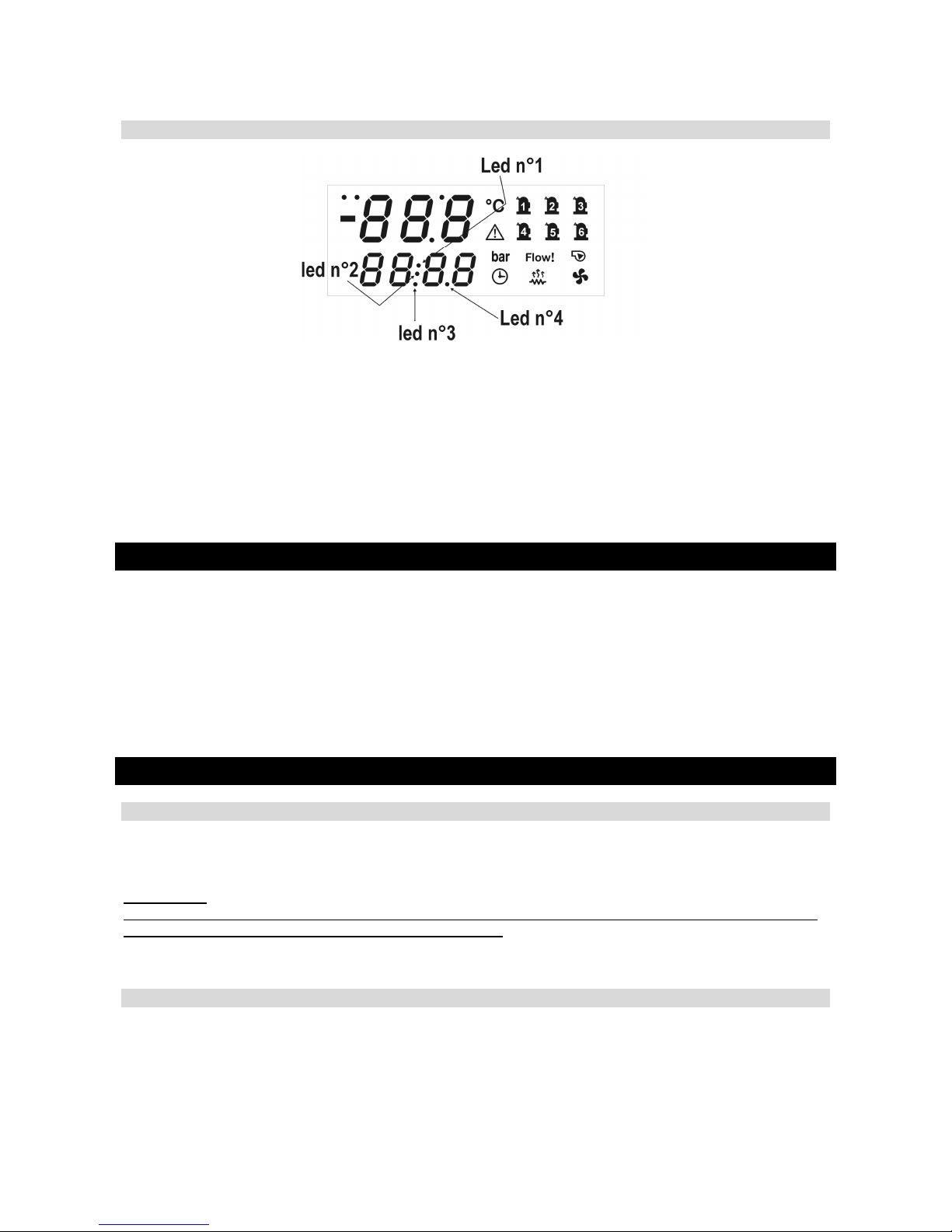

6. WIRING CONNECTIONS

Ichill 260L

10 relays

18 digital inputs (free of voltage)

10 analogue inputs: NTC probes or through configuration 6 NTC / PTC and 4 pressure transducer 4÷20mA

or ratio-metric 0÷ 5.0Volt

6 modulating outputs

1 output for remote panel (max 2 remote panels)

1 TTL output for “Hot Key 64” connection or for XJ485, interface module for monitoring system, connection.

MAX current on the relay contacts relè 5(2)A 250V - MAX common current 12A 250V

Ichill 261L

14 relays

18 digital inputs (free of voltage)

10 analogue inputs: NTC probes or through configuration 6 NTC / PTC and 4 pressure transducer 4÷20mA

or ratio-metric 0÷ 5.0Volt

6 modulating outputs

1 output for remote panel (max 2 remote panels)

1 TTL output for “Hot Key 64” connection or for XJ485, interface module for monitoring system, connection.

MAX current on the relay contacts relè 5(2)A 250V - MAX common current 12A 250V

Page 17

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 17 of 149

Ichill 260D

10 digital outputs (relays)

18 digital inputs (free of voltage)

10 analogue inputs: NTC probes or through configuration 6 NTC / PTC and 4 pressure transducer 4÷20mA

or ratio-metric 0÷ 5.0Volt

6 modulating outputs

1 output for remote panel (max 2 remote panels)

1 TTL output for “Hot Key 64” connection

1 RS485 output with modbus RTU protocol for monitoring system, connection.

MAX current on the relay contacts relè 5(2)A 250V - MAX common current 12A 250V

Ichill 261D

14 digital outputs (relays)

18 digital inputs (free of voltage)

10 analogue inputs: NTC probes or through configuration 6 NTC / PTC and 4 pressure transducer 4÷20mA

or ratio-metric 0÷ 5.0Volt

6 modulating outputs

1 output for remote panel (max 2 remote panels)

1 TTL output for “Hot Key 64” connection

1 RS485 output with modbus RTU protocol for monitoring system.

MAX current on the relay contacts relè 5(2)A 250V - MAX common current 12A 250V

Page 18

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 18 of 149

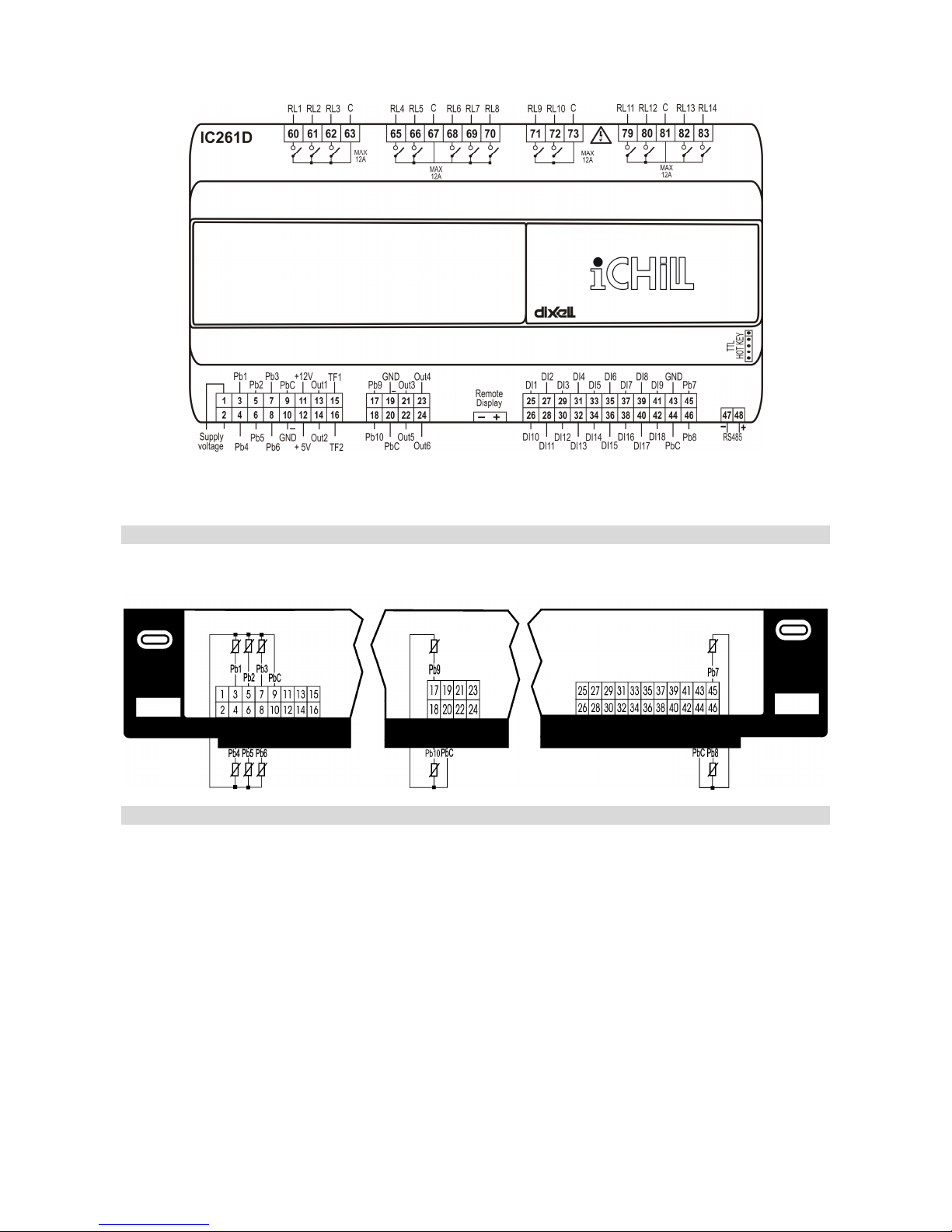

Temperature probes connection (NTC – PTC Probes)

Connection diagram for IC260L / IC261L / IC260D and IC261D.

PbC = Probes common terminal

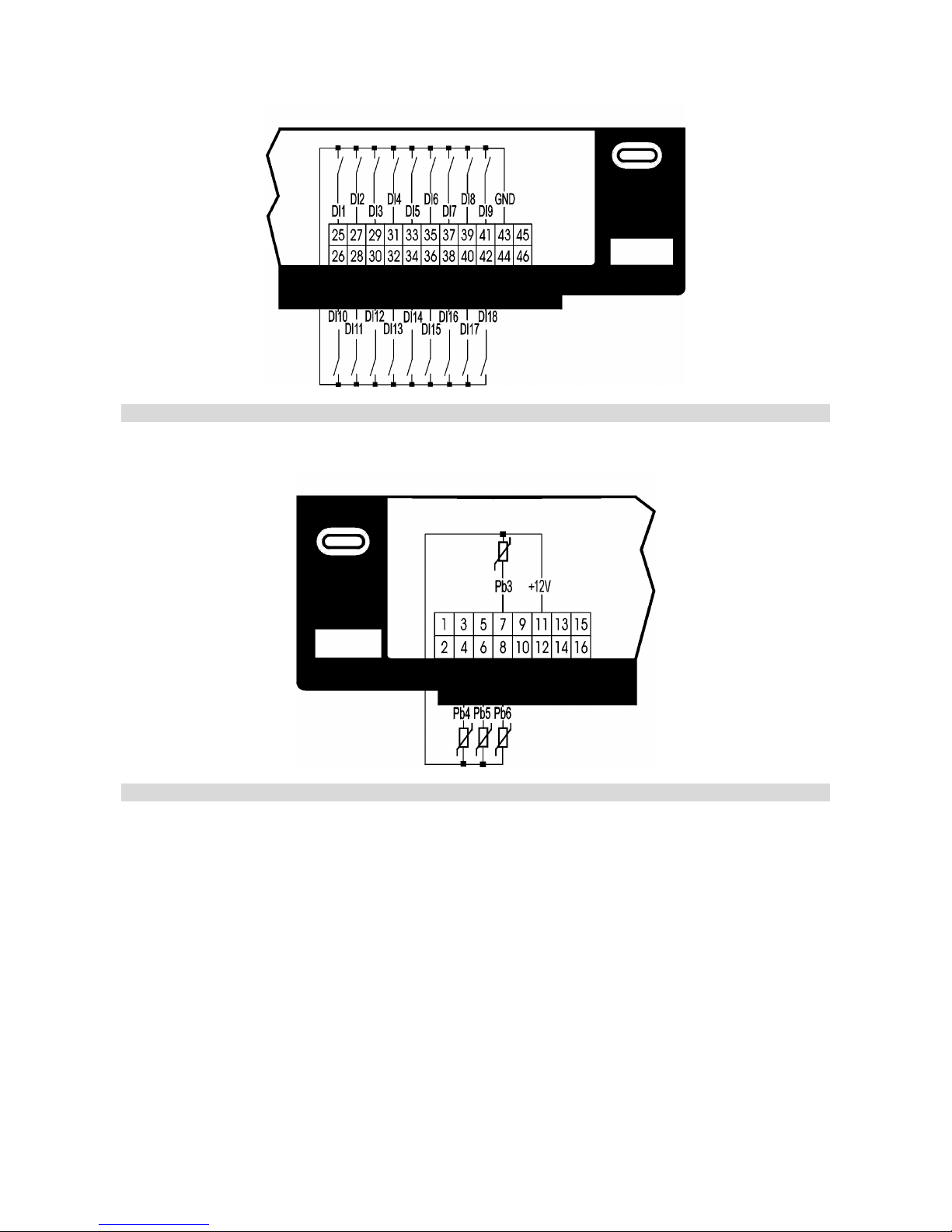

Digital Inputs

Connection diagram for IC260L / IC261L / IC260D and IC261D.

GND = Digital inputs common terminal

Page 19

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 19 of 149

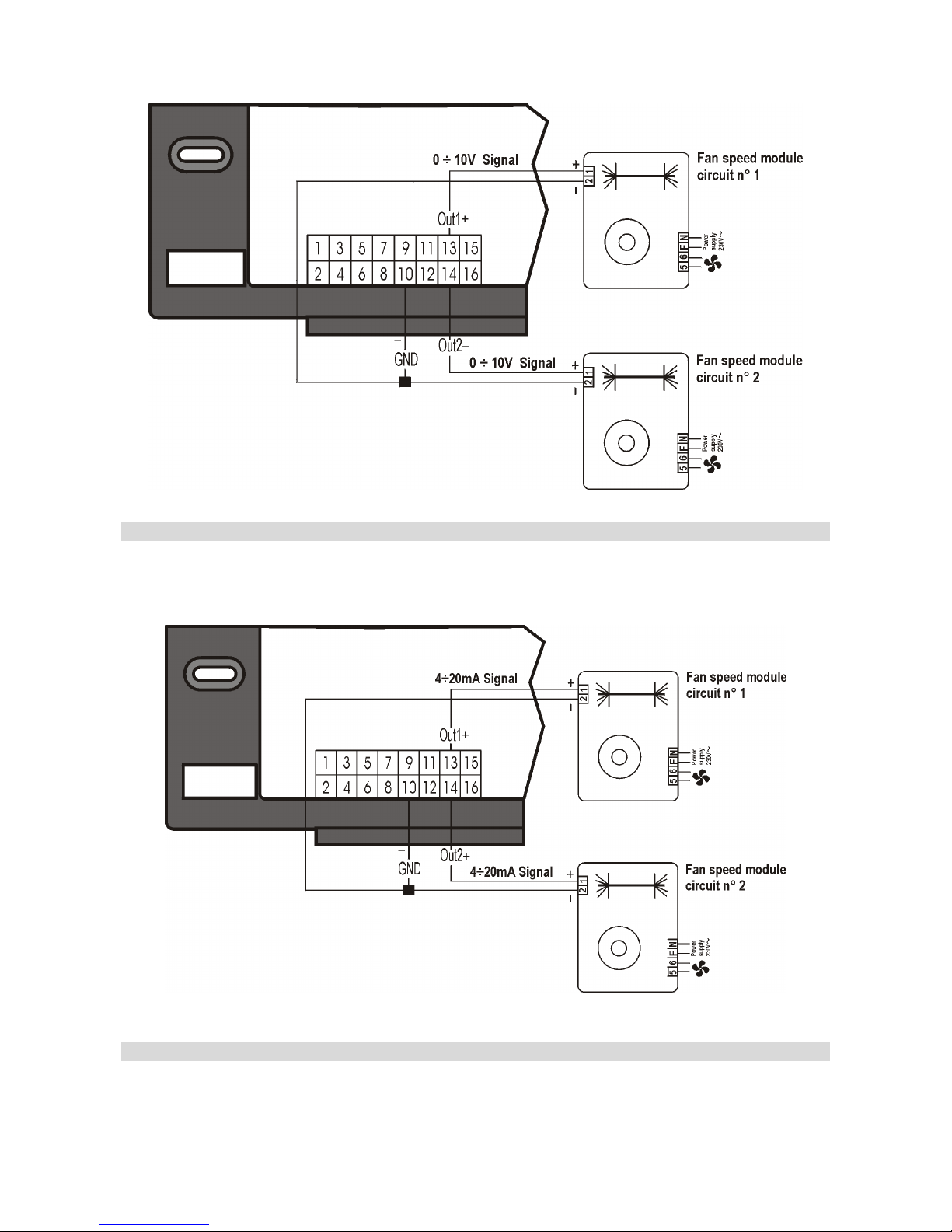

Pressure Transducer connection (4 ÷ 20mA signal)

Connection diagram for IC260L / IC261L / IC260D and IC261D.

12V = Pressure trasducers common terminal

Ratiometric Transducer connection (0 ÷ 5V signal)

Connection diagram for IC260L / IC261L / IC260D and IC261D.

Page 20

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 20 of 149

PWM Output for Condensing Fan Speed Control

Connection diagram for IC260L / IC261L / IC260D and IC261D.

The PWM signal has to be connected to the cut of phase controller:

Mod. XV05PK mono-phase , cut phase control 500 Watt (2A)

Mod. XV10PK mono-phase , cut phase control 1000 Watt (4A)

Mod. XV22PK mono-phase , cut phase control 2200 Watt (9A)

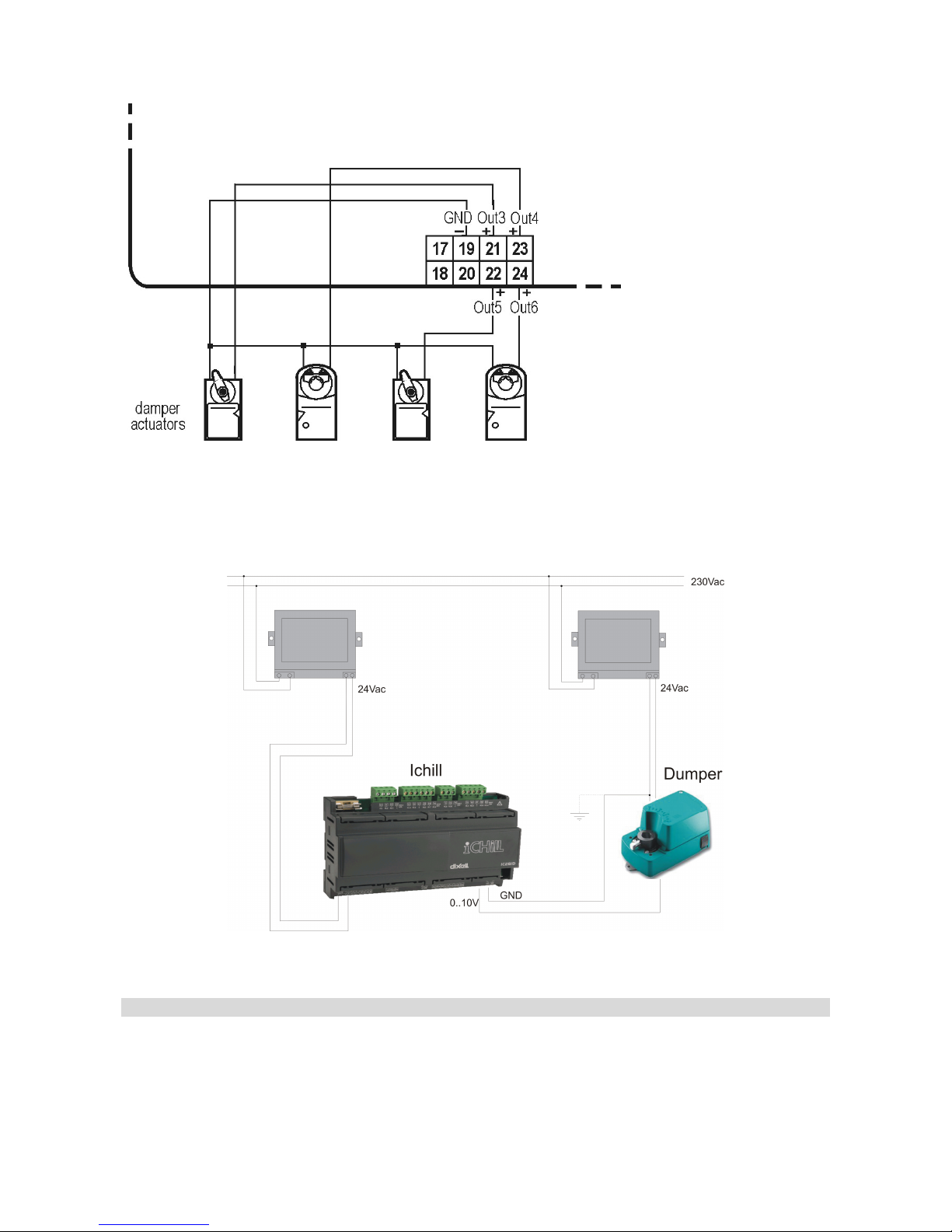

Condensing Fan control: 0 ÷ 10Vdc signal

Connection diagram for IC260L / IC261L / IC260D and IC261D.

In case of only one condensing circuit configured, the Out1 / Out2 outputs work together giving the same

signal.

Page 21

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 21 of 149

Condensing Fan Control: 4÷20mA signal

Connection diagram for IC260L / IC261L / IC260D and IC261D.

In case of only one condensing circuit configured, the Out1 / Out2 outputs work together giving the same

signal.

Proportional outputs 0 ÷ 10V dumper control

Connection diagram for IC260L / IC261L / IC260D and IC261D.

Page 22

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 22 of 149

If the dumper motor has a common pole for the 0..10V and the power supply, the connection has to be done

as showed below.

Ground connection has to be evaluated case per case.

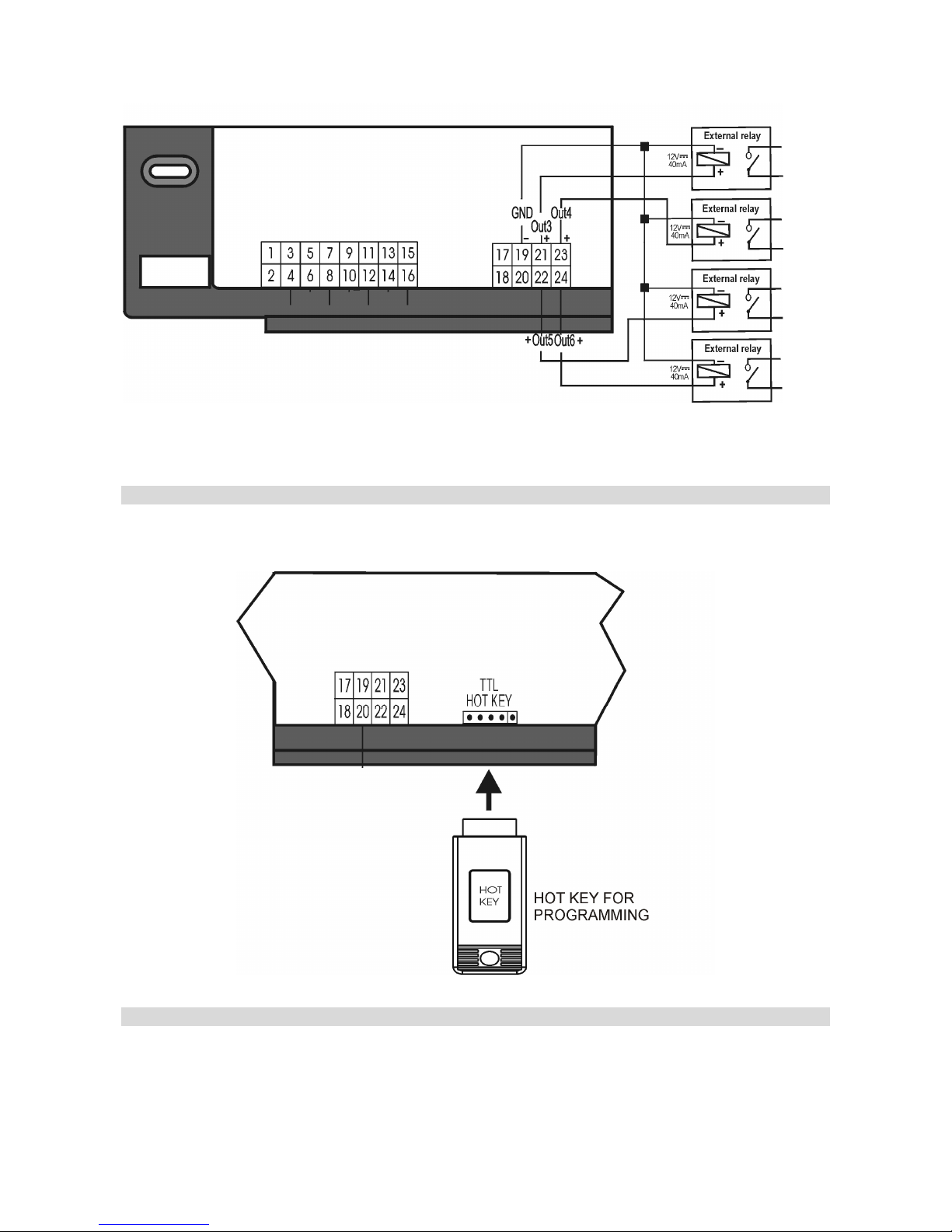

Proportional outputs configured to manage an external relay

Connection diagram for IC260L / IC261L / IC260D and IC261D.

Page 23

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 23 of 149

Hot Key 64 Connection

Connection diagram for IC260L / IC261L / IC260D and IC261D.

The programming HOT KEY 64 allows to upload or download a copy of the parameters of the instrument

(see HOT KEY paragraph).

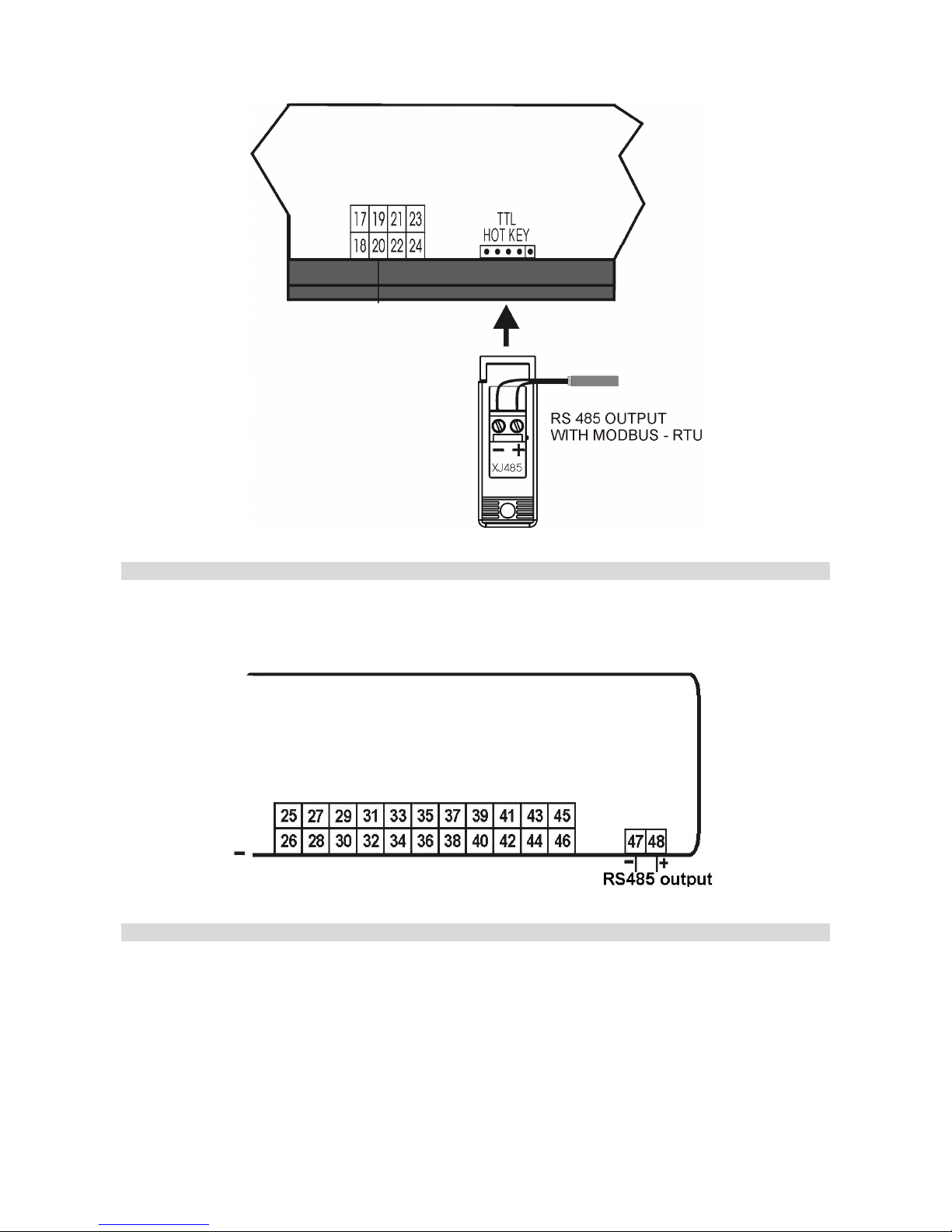

XJ485 Connection

Connection diagram for IC260L / IC261L .

The XJ485 interface is a converter between the RS485 and the TTL connector output. The RS485 uses two

terminals (+) and (-) that must be connected respecting the polarity to build the serial line. Use the

CAB/RS02 to connect the XJ485 interface to the TTL connector.

Page 24

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 24 of 149

RS485 connection (IC260D / IC261D)

The Ichill 260D and Ichill 261D have a RS 485 output to connect the controller to the ProgTool or a XWEB

(monitoring, controlling and supervising system).

Make attention to the polarity of the RS 485 signal.

Remote keyboard VI620

Connection diagram for IC260L / IC261L / IC260D and IC261D.

Using the remote panels provided with the ambient NTC probe the display measurement, and the control can

be managed directly by this probe.

Use shielded cable for the connection up to 150mt maximum. In case of communication failure the upper

display shows “noL” (no link).

Use the CAB/CJ30 to interface the ichill connector to the shielded cable.

It is possible to connect maximu 2 remote keyboard.

Page 25

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 25 of 149

Page 26

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 26 of 149

7. ANALOG AND DIGITAL OUTPUT CONFIGURATION

Analog input Pb1 - Pb2 - Pb7 - Pb8 - Pb9 - Pb10

Parameters involved:

CF08 = Configuration PB1

CF09 = Configuration PB2

CF14 = Configuration PB7

CF15 = Configuration PB8

CF16 = Configuration PB9

CF17 = Configuration PB10

0. Not enabled

1. Temperature probe PTC for compressor 1 discharge

2. Temperature probe PTC for compressor 2 discharge

3. Temperature probe PTC for compressor 3 discharge

4. Temperature probe PTC for compressor 4 discharge

5. Temperature probe PTC for compressor 5 discharge

6. Temperature probe PTC for compressor 6 discharge

7. Temperature probe PTC for solar panel

8. Temperature probe NTC for evaporator inlet

9. Temperature probe NTC for evaporator 1 outlet

10. Temperature probe NTC for evaporator 2 outlet

11. Temperature probe NTC for common evaporator outlet

12. Temperature probe NTC for common hot water condenser / recovery inlet

13. Temperature probe NTC for hot water of the condenser / recovery circuit 1 inlet

14. Temperature probe NTC for hot water of the condenser / recovery circuit 2 inlet

15. Temperature probe NTC for hot water of the condenser / recovery circuit 1 outlet

16. Temperature probe NTC for hot water of the condenser / recovery circuit 2 outlet

17. Temperature probe NTC for hot water of the condenser / recovery common outlet

18. Temperature probe NTC for free cooling water inlet circuit

19. Temperature probe NTC for dynamic setpoint external air / boiler / change over

20. Temperature probe NTC for combined defrost circuit 1

21. Temperature probe NTC for combined defrost circuit 2

22. Temperature probe NTC for auxiliary output 1

23. Temperature probe NTC for auxiliary output 2

24. Temperature probe NTC sanitary water 1

25. Temperature probe NTC sanitary water 1

26. Temperature probe NTC solar panel

27. Temperature probe NTC for condensing circuit 1

28. Temperature probe NTC for condensing circuit 2

After the number 28 the configuration can be selected from o 1 to c73 that allows to set an analogue input as

digital input (see polarity of the digital input/outputs).

Analog input Configuration Pb3 - Pb4 - Pb5 - Pb6

Parameter involved:

CF10 = Configuration PB3

CF11 = Configuration PB4

CF12 = Configuration PB5

CF13 = Configuration PB6

0 Not enabled

1 Temperature probe PTC for compressor 1 discharge

2 Temperature probe PTC for compressor 2 discharge

3 Temperature probe PTC for compressor 3 discharge

4 Temperature probe PTC for compressor 4 discharge

5 Temperature probe PTC for compressor 5 discharge

6 Temperature probe PTC for compressor 6 discharge

7 Temperature probe PTC for solar panel

8 Temperature probe NTC for evaporator inlet

9 Temperature probe NTC for evaporator outlet 1

Page 27

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 27 of 149

10 Temperature probe NTC for evaporator outlet 2

11 Temperature probe NTC for common evaporator outlet

12 Temperature probe NTC for common hot water condenser / recovery inlet

13 Temperature probe NTC for hot water condenser / recovery inlet circuit 1

14 Temperature probe NTC for hot water condenser / recovery inlet circuit 2

15 Temperature probe NTC for hot water condenser / recovery outlet circuit 1

16 Temperature probe NTC for hot water condenser / recovery outlet circuit 2

17 Temperature probe NTC for hot water condenser / recovery common outlet circuit

18 Temperature probe NTC for free cooling water inlet

19 Temperature probe NTC for external air dynamic setpoint/ boiler / change over

20 Temperature probe NTC for combined defrost circuit 1

21 Temperature probe NTC for free cooling water inlet 2

22 Temperature probe NTC for auxiliary output 1

23 Temperature probe NTC for auxiliary output 2

24 Temperature probe NTC sanitary water 1

25 Temperature probe NTC sanitary water 2

26 Temperature probe NTC solar panel

27 Condenser probe circuit 1 ( temperature NTC / pressure 4÷20 mA / ratio-metric 0÷ 5Volt )

28 Condenser probe circuit 2 ( temperature NTC / pressure 4÷20 mA / ratio-metric 0÷ 5Volt )

29 Evaporator pressure probe circuit 1 (pressure 4÷20 mA / ratio-metric 0÷ 5Volt )

30 Evaporator pressure probe circuit 1 (pressure 4÷20 mA / ratio-metric 0÷ 5Volt )

31 Aux 1 output probe control (4÷20 mA / ratio-metric 0÷ 5Volt)

32 Aux 2 output probe control (4÷20 mA / ratio-metric 0÷ 5Volt)

33 Dynamic setpoint probe (4÷20 mA)

34 Compressor 1 or circuit 1 pressure probe

35 Compressor 2 or circuit 2 pressure probe

After the number 35 the display read-out goes from “o 1” to “c73 that allows to set an analogue input as

digital input (see polarity input of digital inputs).

Digital Input Configuration Id1 – Id18

Parameters involved:

CF36 = Configuration ID1…CF53 = Configuration ID18

0. Not enabled

1. Remote ON / OFF

2. Remote chiller / heat pump

3. Flow switch/ Supply fan overload

4. Flow switch of heated side

5. Antifreeze heater circuit 1

6. Antifreeze heater circuit 2

7. High pressure switch circuit 1

8. High pressure switch circuit 2

9. Low pressure switch circuit 1

10. Low pressure switch circuit 2

11. Compressor 1 high pressure

12. Compressor 2 high pressure

13. Compressor 3 high pressure

14. Compressor 4 high pressure

15. Compressor 5 high pressure

16. Compressor 6 high pressure

17. Compressor 1 overload

18. Compressor 2 overload

19. Compressor 3 overload

20. Compressor 4 overload

21. Compressor 5 overload

22. Compressor 6 overload

23. Condenser fan overload of circuit 1

24. Condenser fan overload of circuit 2

25. Condenser fan overload of circuit 1 and 2 (comun)

26. Water pump overload of evaporator 1

27. Water support pump overload of evaporator

28. Water pump overload of condenser 1

29. Water support pump overload of condenser

Page 28

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 28 of 149

30. Recovery request circuit 1

31. Recovery request circuit 2

32. Start/End defrost circuit 1

33. Start/End defrost circuit 2

34. Energy Saving

35. Pressure switch / compressor 1 oil

36. Pressure switch / compressor 2 oil

37. Pressure switch / compressor 3 oil

38. Pressure switch / compressor 4 oil

39. Pressure switch / compressor 5 oil

40. Pressure switch / compressor 6 oil

41. Pump down pressure switch of circuit 1

42. Pump down pressure switch of circuit 2

43. Generic alarm from digital input with stop regulation n° 1

44. Generic alarm from digital input with stop or signal regulation n° 2

45. Operation working mode: by RTC or keyboard

46. Operation mode with supplay fan only

47. Digital input of thermoregulation request (condensing unit)

48. Digital input of cooling request (condensing unit)

49. Digital input of heating request (condensing unit)

50. Request step 2 (condensing unit)

51. Request step 3 (condensing unit)

52. Request step 4 (condensing unit)

53. Request step 5 (condensing unit)

54. Request step 6 (condensing unit)

55. Request step 7 (condensing unit)

56. Request step 8 (condensing unit)

57. Request step 9 (condensing unit)

58. Request step 10 (condensing unit)

59. Request step 11 (condensing unit)

60. Request step 12 (condensing unit)

61. Request step 13 (condensing unit)

62. Request step 14 (condensing unit)

63. Request step 15 (condensing unit)

64. Request step 16 (condensing unit)

65. Sanitary water flow switch

66. Solar panel flow switch

67. Only sanitary water

68. Sanitary water heaters overload

69. Sanitary water pump overload

70. Sanitary water second set point

71. Phase sequence alarm

72. Sanitary water priority

73. Free cooling water pump flow switch

Digital Output (relay) Configuration RL1- RL14

Parameter involved:

CF54= Configuration RL1…CF67= Configuration RL14

0. Not enabled

1. Alarm

2. Evaporator water pump / Supply fan

3. Support water pump of the evaporator

4. Anti-freeze heater / integration heating / boiler circuit 1

5. Anti-freeze heater / integration heating / boiler circuit 2

6. Water pump of the condenser recovery circuit

7. Support water pump of the condenser recovery circuit

8. 4-way valve for chiller / heat pump inversion of the circuit 1

9. 4-way valve for chiller / heat pump inversion of the circuit 2

10. 1° condenser fan step ON/OFF control of the circuit 1

11. 2° condenser fan step ON/OFF control of the circuit 1

12. 3° condenser fan step ON/OFF control of the circuit 1

13. 4° condenser fan step ON/OFF control of the circuit 1

Page 29

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 29 of 149

14. 1° condenser fan step ON/OFF control of the circuit 2

15. 2° condenser fan step ON/OFF control of the circuit 2

16. 3° condenser fan step ON/OFF control of the circuit 2

17. 4° condenser fan step ON/OFF control of the circuit 2

18. Solenoid valve of the pump-down circuit 1

19. Solenoid valve of the pump-down circuit 2

20. Recovery valve circuit 1

21. Recovery valve circuit 2

22. Free cooling ON/OFF valve

23. Auxiliary output circuit 1

24. Auxiliary output circuit 2

25. Solenoid valve Intermittent for screw compressor 1

26. Solenoid valve Intermittent for screw compressor 2

27. Solenoid valve of the liquid injection for compressor 1

28. Solenoid valve of the liquid injection for compressor 2

29. Sanitary valve 1

30. Sanitary valve 2

31. Sanitary heater 1

32. Sanitary heater 2

33. Sanitary heater 3

34. Solar panel water pump

35. Solar panel valve

36. Sanitary water pump

37. Hybrid exchanger 1 circuit 1

38. Hybrid exchanger 2 circuit 1

39. Hybrid exchanger 1 circuit 2

40. Hybrid exchanger 2 circuit 2

41. Defrost status

42. Chiller status

43. Heat pump status

44. Sanitary water status

45. STD-By status

46. Solenoid water valve circuit 1

47. Solenoid water valve circuit 2

48. Direct start-up : compressor 1 relay

PW start: relay PW 1 of the compressor 1

Star-delta start: relay line 1 of the compressor 1

49. PW start: relay PW 2 of the compressor 1

Star-delta start: relay linea 2 compressor 1

50. Star centre of the Star-delta start of the compressor 1

51. Capacity step valve 1 compressor 1

52. Capacity step valve 2 compressor 1

53. Capacity step valve 3 compressor 1

54. By-pass gas valve compressor 1start

55. Direct start: compressor 2 start

PW start: relay 1 of the compressor 2

Star-delta start: relay line 1 of the compressor 2

56. PW start: relay PW 2 of the compressor 2

Star-delta start: relay line 2 of the compressor 2

57. Star centre of the Star-delta start of the compressor 2

58. Capacity step valve 1 compressor 2

59. Capacity step valve 2 compressor 2

60. Capacity step valve 3 compressor 2

61. By-pass gas valve compressor 2 start

62. Direct start: compressor 3 relay

PW start: relay PW 1 of the compressor3

Star-delta start: relay line 1 of the compressor 3

63. PW start: relay PW 2 of the compressor 3

Star-delta start: relay line 1 of the compressor 3

64. Star centre of the Star-delta start of the compressor 3

65. Capacity step valve 1 compressor 3

66. Capacity step valve 2 compressor 3

Page 30

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 30 of 149

67. Capacity step valve 3 compressor 3

68. By-pass gas valve compressor 3 start

69. Direct start: compressor 4 relay

PW start: PW 1 of the compressor 4

Star-delta start: relay line 1 of the compressor 4

70. PW start: relay PW 2 of the compressor 4

Star-delta start: relay line 1 of the compressor 4

71. Star centre of the Star-delta start of the compressor 4

72. Capacity step valve 1 of the compressor 4

73. Capacity step valve 2 of the compressor 4

74. Capacity step valve 3 of the compressor 4

75. By-pass gas valve compressor 4 start

76. Compressor 5 relay

77. Compressor 6 relay

Condenser proportional control configuration (2 outputs)

Proportional outputs used to configure a proportional output signal to condenser fan control

Parameters involved:

CF68 = Condenser control configuration for circuit 1

CF69 = Condenser control configuration for circuit 2

0= 0 ÷ 10Vdc (for external mono or three-phase fan control board)

1= 4÷20mA (for external mono or three-phase fan control board)

2= PWM (only for external mono-phase fan control board with cut phase control)

Proportional output configuration 0 ÷ 10 Vdc (4 outputs)

Parameters involved:

CF70 = Proportional output 1 configuration

CF71 = Proportional output 2 configuration

CF72 = Proportional output 3 configuration

CF73 = Proportional output 4 configuration

0 Not enabled

1 Modulated evaporator water pump

2 Modulated Free cooling valve

3 not used

4 Auxiliary output 0÷10V n° 1

5 Auxiliary output 0÷10V n° 2

6 Proportional output for modulating compressor 1

7 Proportional output for modulating compressor 2

After the read-out number 4 the display goes from the label “o 1” to “c47 (see input/output polarity), that

allow to configure the output as digital output to control an external relay.

Page 31

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 31 of 149

8. PROGRAMMING WITH THE “HOT KEY 64”

Download: how to program an instrument with a programmed “Hot Key”

1. Turn off the instrument supply

2. Insert the hot key.

3. Turn on the power supply.

4. Immediately the parameters are downloaded.

During the download the regulation is locked and the top display shows the “doL” blinking label. At the end of

the download will appear:

“End” if the programming procedure is completely OK, after 30seconds the regulation starts automatically.

“Err” if the programming procedure has found an error and the parameter have not been transferred. In this

case turn off and then on the instrument supply to repeat the operation or remove the hot key, with power

supply off, to restart the regulation.

Upload: How to program a “Hot Key” with the parameters of the instrument

1. Turn on the power supply.

2. Insert the hot key.

3. Enter the function Menu.

4. Select the UPL function (on the bottom display).

5. Push SET key and immediately the instrument starts transfer the parameters into the Hot key.

During the upload the regulation is locked and the top display shows the “UPL” blinking label. At the end of

the UPLOAD will appear:

“End” if the programming procedure is completely OK, after 30seconds the regulation starts automatically.

“Err” if the programming procedure has found an error and the parameter have not been transferred.

Repeat the procedure.

To exit the UPL function push the MENU key or wait the time-out (15 sec).

9. PROGRAMMING USING THE KEYBOARD

Through the instrument keyboard it is possible to enter the programming. In all the three accessible levels

the user can show and modify both value and visibility of the parameters. To ensure an easy navigation

through the different levels the common parameters have been named and grouped under a family name.

The three levels of programming:

Pr1 User level

Pr2 Maintenance level

Pr3 OEM level

Password default values

Password level Pr1 = 1

Password level Pr2 = 2

Password level Pr3 = 3

Under the function Menu (to reset the Alarm Log or the Compressor Overload) the password is 0 (see

parameter AL46)

Each password can be changed, the range is from 0 to 999.

Each parameter has two level: visibility and modify. Therefore it can be configured as follow:

The parameter can be showed and changed.

The parameter can be showed but not changed.

Enter the Pr1 - Pr2 - Pr3 programming levels

Pr1 LEVEL:

Push SET + DOWN together for 3 seconds, the top display shows the PAS label and the bottom display

shows the Pr1 label. The leds cir1/cir2 are blinking (up and down leds) to inform that you now are in PR1

programming level.

Pr2 LEVEL:

From the Pr1 level push the UP key for 2 seconds and the bottom display will show Pr2. The top display still

shows PAS.

Pr3 LEVEL:

Page 32

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 32 of 149

From the Pr2 level push the UP key for 2 seconds and the bottom display will show Pr3. The top display still

shows PAS.

After selecting the level push the SET key and the top display will show the 0 blinking value where to insert

the password .

Set the password level using the UP and DOWN keys then confirm with SET key.

Dependening on the password value there will be the different level access, if the password is wrong the

instrument shows the password value again.

ATTENTION:

For all the programming levels Pr1,2,3: the CF family (or configuration parameters) can not be

changed if the unit is running in chiller, heat pump. The user can check the leds #1 and #2 and if they

are blinking it is not possible to change this parameters but it is necessary to set the unit in stand-by

and then enter the programming again.

During the defrost the dF family can’t be programmed.

How to change a parameter value

Enter the programming

1. Push the SET + DOWN keys together for 3 seconds;

2. Select the parameter label with up and down keys;

3. Push SET to enter the parameter value;

4. Change the value with UP or DOWN keys;

5. Push “SET” to confirm, after some seconds the display shows the next parameter;

6. Exit: Push SET + UP together when a parameter label is displayed or wait 15seconds without pushing a

key.

NOTE: a new parameter value is confirmed also after the 15 seconds of timeout is expired (without pushing

SET key to confirm).

Change the Password value

Pr1 LEVEL

Remember that it is necessary to know the old password value.

1) Enter the Pr1 level

2) Select a parameter family.

3) Inside the family select the “Pr1 - 1”, Pr1 on the bottom display, the current password value 1 on the top

display. Push the SET key to change the value that now is blinking.

4) Use the UP or DOWN key to insert the NEW PASSWORD value, then push SET to confirm the new

value.

5) The top display blinks for some seconds and then shows the next parameter.

6) Exit the programming pushing SET + UP together or wait the timeout.

Pr2 LEVEL

Remember that it is necessary to know the old password value.

1. Enter the Pr2 level

2. Select a parameter family.

3. Inside the family select the “Pr2 - 2”, Pr2 on the bottom display, the current password value 2 on the top

display. Push the SET key to change the value that now is blinking.

4. Use the UP or DOWN key to insert the NEW PASSWORD value, then push SET to confirm the new

value.

5. The top display blinks for some seconds and then shows the next parameter

6. Exit the programming pushing SET + UP together or wait the timeout.

Inside the Pr2 level it is possible to change also the Pr1 password.

Pr3 LEVEL

Remember that it is necessary to know the old password value.

1. Enter the Pr3 level

2. Select a parameter family.

3. Inside the family select the “Pr3 - 3”, Pr3 on the bottom display, the current password value “3” on the

top display. Push the SET key to change the value that now is blinking.

4. Use the UP or DOWN key to insert the NEW PASSWORD value, then push SET to confirm the new

value.

5. The top display blinks for some seconds and then shows the next parameter

6. Exit the programming pushing SET + UP together or wait the timeout.

Inside the Pr3 level it is possible to change also the Pr1 and Pr2 passwords.

Page 33

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 33 of 149

Enter the programming level Pr1

Enter the Pr1 “User level ”:

1. Push the SET + DOWN keys together for 3 seconds. The top display shows PAS while the bottom

display shows Pr1 labels.

2. Push SET key and the top display shows a blinking 0, with UP or DOWN insert the Pr1 password. Push

SET and, if the value is correct, top display will show the first family of parameters “ALL”. Otherwise set

the password again.

3. Select a parameter family with DOWN or UP keys.

4. Push SET to enter, the bottom display shows the first available parameter label while the top display

shows its value.

The user can shows and modify all the parameters belonging to this family.

Parameter status, leds and bottom display in Pr1

If the selected parameter can not be changed the leds 1 and 2 are blinking.

In Pr1 level the user can not see and change any parameter of Pr2 and Pr3.

The MENU key allows to exit from a family to reselect another without exit the Pr1 level.

To exit completely the programming push SET + UP.

Enter the programming level Pr2

Enter the Pr2 “maintenance level ”:

1. Push the SET + DOWN keys together for 3 seconds. The top display shows PAS while the bottom

display shows Pr1 labels.

2. Push UP key for 2 seconds and the top display will show Pr2.

3. Push SET key and the top display shows a blinking 0, with UP or DOWN insert the Pr2 password. Push

SET and, if the value is correct, top display will show the first family of parameters “ALL”. Otherwise set

the password again.

4. Select a parameter family with DOWN or UP keys.

5. Push SET to enter, the bottom display shows the first available parameter label while the top display

shows its value.

The user can shows and modify all the paramters belonging to this family.

Parameter status, leds and bottom display in Pr2

Leds 1 / 2 are blinking: the parameter can not be changed.

All the leds are off: the parameter ca not be seen in Pr1 level.

Led 3 is on: the parameter can be seen in Pr1 level.

Leds 1 / 2 are blinking and led 3 is on: the parameter can be showed and changed in Pr2, showed but

not changed in Pr1.

Leds 1 / 2 / 3 are blinking: the parameter can be showed and changed in Pr2 and in Pr21.

In Pr2 level the user can not see and change any parameter of Pr3 level.

Page 34

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 34 of 149

The MENU key allows to exit from a family to reselect another without exit the Pr2 level.

The MENU key allows to pass to Pr1 starting from a family label.

To exit completely the programming push SET + UP.

Enter the programming level Pr3

Enter the Pr3 “OEM level ”:

1. Push the SET + DOWN keys together for 3 seconds. The top display shows PAS while the bottom

display shows Pr1 labels.

2. Push UP key for 2 seconds and the top display will show Pr2.

1. Push UP key again for 2 seconds and the top display will show Pr3

3. Push SET key and the top display shows a blinking 0, with UP or DOWN insert the Pr3 password. Push

SET and, if the value is correct, top display will show the first family of parameters “ALL”. Otherwise set

the password again.

4. Select a parameter family with DOWN or UP keys.

5. Push SET to enter, the bottom display shows the first available parameter label while the top display

shows its value.

The user can shows and modify all the paramters belonging to this family.

Parameter status, leds and bottom display in Pr3

Leds 1 / 2 are blinking: the parameter can not be changed.

All the leds are off: the parameter is available only in Pr3.

Led 4 on: the parameter can be changed also in Pr2.

Led 4 blinking: the parameter is visible also in Pr2 .

Leds 3 / 4 on: the parameter is available in Pr2 and in Pr1.

Leds 3 / 4 blinking: the parameter is visible in Pr1 and in Pr2.

The MENU key allows to exit from a family to reselect another without exit the Pr2 level.

The MENU key allows to pass to Pr1 starting from a family label.

To exit completely the programming push SET + UP.

Move a parameter level from Pr2 to Pr1

Enter Pr2 programming level

Select the parameter and if the led # 3 is off: the parameter is available only in Pr2.

To show the parameter also in Pr1:

1. Keep pushed SET key;

2. Push 1 time the DOWN key and the led 3 should be on, the parameter is now available in Pr1.

To hide the parameter in Pr1:

1. Keep pushed SET key;

2. Push 1 time the DOWN key and the led 3 should be off, the parameter is now removed from Pr1.

Move a parameter from Pr3 to Pr2 to Pr1

Enter Pr3 programming level, here the parameter are all visible:

Select the parameter, if all the leds are off the parameter is available only in Pr3.

To show the parameter also in Pr2 and Pr1:

1. Keep pushed SET key;

2. Push 1 time the DOWN key and the leds 3 and 4 should be on, the parameter is now available also in

Pr2 / Pr1.

To show the parameter only in Pr2:

Page 35

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 35 of 149

1. Keep pushed SET key;

2. Push 1 time the DOWN key and the leds 3 is off, the parameter is now available also in Pr2.

To show the parameter only in Pr3:

1. Keep pushed SET key

2. Push 1 time the DOWN key and the leds 3 and 4 are off, the parameter is now available only in Pr3.

Visibility and Parameter value locked

To set the only visibility and lock the parameter value it is necessary enter Pr3 programming level.

Pr1 PARAMETER VISIBILITY

Enter the Pr3 level

1. Select the parameter;

2. Keep pushed the SET key;

3. Push 1 time the MENU key and the led 3 change from on to blinking: the parameter is visible in Pr1 but

can’t be changed.

Pr2 PARAMETER VISIBILITY

Enter the Pr3 level

1. Select the parameter;

2. Keep pushed the SET key;

3. Push 1 time the MENU key and the led 4 change from on to blinking the parameter is visible in Pr2 but

can’t be changed.

Leds 3 / 4 blinking: the parameter is visible in Pr1 and in Pr2 but in those levels now they can’t be

changed.

TO SET THE ORIGINAL TAG FOR THE PARAMETER Pr1 / Pr2

1. Keep pushed the SET key;

2. Push one time the MENU key, the leds 3 / 4 turn on, the parameter can be seen and modified in Pr1 and Pr2.

Programming: digital input and output polarity

The parameters that allow to configure different options such as:

1. Digital inputs

2. Digital outputs (relay)

3. Proportional output configured as ON/OFF

4. Analogue input configured as digital input

have a different parameter description that allows to configure the operating mode and the corresponding

polarity.

Example of programming:

The bottom display shows the parameter label (CF36) Digital input ID1 configuration;

Note that the top display shows “c” or “o” before the configuration number.

The selection 7 for the digital input ID1 (CF36) means that it is the “high pressure switch of circuit 1”.

The label “o” means that the digital input is active for open contact.

Otherwise if the selection is 7 for the digital input ID1 (CF36) = “high pressure switch of circuit 1”.

The label “c” means that the digital input is active for closed contact.

Change the polarity of the digital Inputs-Outputs

Enter the programming:

1. Select a parameter with digital input/output value, The top display shows the label o before the

configuration number while the bottom display shows the parameter label.

Page 36

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 36 of 149

2. Push SET key: the o label and the configuration number are blinking, use the UP or DOWN key and

select the proper polarity ( o / c ) of the function, then push SET key to confirm it all.

3. The top display blinks for some seconds and then it will shows the next parameter.

4. To exit the programming push SET + UP together or wait the timeout (15seconds).

10. CHILLER / HEAT PUMP SELECTION

Select the Chiller or the Heat pump mode

The CF79 parameter allows to select and enable the running mode:

Par. CF79 = 0: Through keyboard

The user can start and stop the unit using the keys of the front panel.

Par. CF79 = 1: Through digital input programmed to start/stop the unit from remote control.

This selection is enabled if there is one digital input configured as start/stop from remote (remote chiller /

heat pump). I non of the digital input are configure the unit remains in stand–by.

The “open” status of the input forces the chiller running mode.

The “closed” status of the input forces the heat pump running mode.

The keyboard selection is disabled.

The key on the front panel can start/stop the unit only with the digital input selection

Par. CF79 =2: Automatic selection of the Chiller - Heat Pump through analogue input

The analogue input selection or change over function overrides the digital input C-HP function. If the external

air temperature are within the CF81 differential, the user can change the running mode from the keyboard.

If the unit is running with CF79 = 1 or CF79=2, and it is requested a running mode change, the controller

turns off all the outputs, starts a fixed delay time signalled by the chiller or heat pump blinking led. This

blinking led indicates which running mode will be activated after the compressor delay time protection.

Change Over

To change the running status the following condition must be respected otherwise the unit remains in stand by:

1. CF02=3 (heat pump selected)

2. CF79=2 and a NTC probe configured as NTC external air temperature for dynamic setpoint/ boiler /

change over

3. This probe is working properly

Parameters involved with the change over function:

CF80 Change over Setpoint. If the analogue input control (from probe) function is enabled, it represents the

limit temperature of the probe value under which the unit runs the Heat Pump mode.

CF81 Change over Differential. If the analogue input control (from probe) function is enabled, it represents

the limit differential temperature of the probe value to restart in the Chiller mode.

For external air temperature within CF81 the user can manually change the status from keyboard.

GRAPH: AUTOMATIC CHANGE OVER

Keyboard selection

CF78 = 0: pushing key the unit starts in chiller, pushing key the unit starts in heat pump

CF78 = 1: pushing key the unit starts in heat pump, pushing key the unit starts in chiller

Page 37

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 37 of 149

Analog input selection

CF78 = 0 NTC, External air temperature probe > CF80+ CF81 the unit starts in chiller, NTC, External air

temperature probe < CF80 the unit starts in heat pump.

CF78 = 1 NTC, External air temperature probe > CF80+ CF81 the unit starts in chiller, NTC, External air

temperature probe < CF80 the unit starts in heat pump.

11. HOW TO SWITCH ON / SWITCH OFF THE UNIT

SWITCH ON / SWITCH OFF THE ICHILL BY KEYBOARD

Push and release the key allows to start in chiller mode if CF78 =0, in heat pump if CF78 =1. When

the unit is running the corresponding led is on.

INPORTANT: To change from chiller to heat pump and viceversa the unit must be set in stand-by before

continuing.

Push and release the key allows to start in heat pump mode if CF78 =0, in chiller if CF78 =1er. When

the unit is running the corresponding led is on.

INPORTANT: To change from chiller to heat pump and viceversa the unit must be set in stand-by before

continuing.

STAND- BY ( OR UNIT OFF, NOT RUNNING)

The unit is considered in stand by when the leds and are both off. The stand-by is reached

each time the Chiller or the Heat Pump are turned off. During the stand by the user can:

Show all the probe measurements

Detect and reset the alarm events.

SWITCH ON / SWITCH OFF THE ICHILL DIGITAL INPUT

Turn on or off the unit from digital input

Set the digital input as remote ON/OFF, depending on the input polarity it can generate the unit off

The digital input overrides the keyboard command.

The keyboard can run only if the digital input is not active.

When the digital input is not active the instrument restore its status (had before the digital input

activation).

12. SWITCH ON / SWITCH OFF THE CONDENSING UNIT BY DIGITAL

INPUT

DIGITAL INPUT CONFIGURED AS REGULATION REQUEST

Unit configured as condensing unit CF03 = 1.

Digital input thermoregulation request (condensing unit)

With contact OFF unit on stand-by , the top display shows OFF

With contact ON unit on stand-by , the top display shows On

With active contact select the chiller mode from the keyboard (the top display shows OnC) or heat pump (the

top display shows OnH), with the funcioning mode active the step is activated, the others, if availables, will

be requested by configured digital input as resources on circuits.

Page 38

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 38 of 149

With active contact if the unit is being switched off by keyboard it can be switched on by keyboard. If the unit

is being switched off by keyboard, in order to switch on the unit from digital input it must be deactivated and

activated.

DIGITAL INPUT CONFIGURED AS CHILLER REQUEST

Unit configured as condensing unit CF03 = 1

Digital input chiller request (condensing unit)

With contact OFF unit on stand-by , the top display shows OFF

With contact ON unit on stand-by , the top display shows OnC

With active contact unit on chiller mode is activated also a step, the others, if availables, will be requested by

configured digital input as as resources on circuits.

With active contact if the unit is being switched off by keyboard it can be switched on by keyboard. If the unit

is being switched off by keyboard, in order to switch on the unit from digital input it must be deactivated and

activated.

DIGITAL INPUT CONFIGURATED AS HEAT PUMP REQUEST

Unit configured as condensing unit CF03 = 1

Digital input heat pump request (condensing unit)

With contact OFF unit on stand-by , the top display shows OFF

With contact ON unit on stand-by , the top display shows OnH

With active contact unit on chiller mode is activated also a step, the others, if availables, will be requested by

configured digital input as as resources on circuits.

With active contact if the unit is being switched off by keyboard it can be switched on by keyboard. If the unit

is being switched off by keyboard, in order to switch on the unit from digital input it must be deactivated and

activated.

13. DISPLAY LAYOUT

As default, in normal condition, the display shows the circuit 1 information.

The displayed circuit is indicated from the corresponding led Cir1 on (UP key), or Cir2 (circuit 2, DOWN

key).

How to show the measurement list

With the led Cir1 on, push UP or Down keys to display the labels of the information of the circuit 1.

With the led Cir2 on, push UP or Down keys to display the labels of the information of the circuit 2.

Each measurement is defined by a label that indicates which if it is a pressure a temperature or a time.

How to read the circuit 1 or 2 probe temperature or pressure

To swap between the probe value of the two circuits push SET button; the led “cir1” or “cir2” is lighted to

indicate the probe of the circuit 1 or circuit 2.

Example in fig.1

Led cir1 is on: the top display shows the value of the output evaporator temperature ( 7.8°C) of the circuit 1,

The bottom display shows Out 1. Push SET key to swap to the circuit 2. Fig2

Led cir2 is on: the top display shows the value of the output evaporator temperature ( 7.9°C) of the circuit 2,

the bottom display shows Out 2.

Fig.1

Page 39

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 39 of 149

Fig.2

14. DISPLAY CONFIGURATION

The dP family of parameters allows to set a custom display read-out. The user can change the default readout (both for instrument and remote terminals) of the measurements depending on the application.

Top Display

Bottom display

Default read - out of the top display

To set the default value displayed on the top display:

1. Set the parameter dP03 = 0, it means configurable;

2. Select the dP01 parameter into the range 0..14 descripted here below:

PARAMETER

VALUE

DESCRIPTION

CORRESPONDING

LABEL

dP01=0

No label

No label

dP01=1

temperature probe of the evaporator water inlet

Ein

dP01=2

temperature probe of the evaporator water outlet 1 and 2

Out1

circuit 1

Out2 circuit 2

dP01=3

temperature probe of the uscita common evaporator water outlet

Eout

dP01=4

temperature probe of the condenser water inlet

CIn1

circuit 1

CIn2 circuit 2

dP01=5

temperature probe of the common condenser water inlet

Cin

Page 40

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 40 of 149

dP01=6

temperature probe of the condenser water outlet

Cou1

circuit 1

Cou2 circuit 2

dP01=7

temperature probe of the common condenser water outlet

Cout

dP01=8

temperature probe of the dynamic external air setpoint

Et

dP01=9

temperature probe of the free cooling water inlet

FCIn

dP01=10

temperature probe of the free cooling external air value

FCEt

dP01=11

temperature probe of the remote terminal 1

trt1

dP01=12

temperature probe of the remote terminal 2

trt2

dP01=13

temperature probe of the combined defrost

dEF1

circuit 1

dEF2 circuit 2

dP01=14

sanitary water temperature 1

San1

dP01=1

5

sanitary water temperature 2

San2

dP01=1

6

solar panel water temperature

SoLE

dP01=17

temperature probe of the condenser

Cdt1

circuit 1

Cdt2 circuit 2

Default read - out of the bottom display

To set the default value displayed on the bottom display:

1. Set the parameter dP03 = 0, it means configurable;

2. Select the dP02 parameter into the range 0..17 descripted here below:

PARAMETER

VALUE

DESCRIPTION

CORRESPONDING

LABEL

dP02=0

No label

No label

dP02=1

temperature probe of the evaporator water inlet

Ein

dP02=2

temperature probe of the evaporator water outlet 1 and 2

Out1

circuit 1

Out2 circuit 2

dP02=3

temperature probe of the common evaporator water outlet

Eout

dP02=4

temperature probe of the condenser water inlet

CIn1

circuit 1

CIn2 circuit 2

dP02=5

temperature probe of the common condenser water inlet

Cin

dP02=6

temperature probe of the condenser water outlet

Cou1

circuit 1

Cou2 circuit 2

dP01=7

temperature probe of the common condenser water outlet

Cout

dP02=8

temperature probe of the dynamic external air setpoint

Et

dP02=9

temperature probe of the free cooling water inlet

FCIn

dP02=10

temperature probe of the free cooling external air value

FCEt

dP02=11

temperature probe of the remote terminal 1

trt1

dP02=12

temperature probe of the remote terminal 2

trt2

dP02=13

temperature probe of the combined defrost

dEF1

circuit 1

dEF2 circuit 2

dP02=14

sanitary water temperature 1

San1

Page 41

1592015820 User manual IC260_261L_D DUO FW1.9 rel. 1.0

Pag. 41 of 149

dP02=15

sanitary water temperature 2

San2

dP02=16

solar panel water temperature

SoLE

dP02=17

temperature probe of the condenser

Cdt1

circuit 1

Cdt2 circuit 2

dP02=18

pressure probe of the condenser 4÷20mA - 0.5V

Cdt1

circuit 1

Cdt2 circuit 2

dP02=19

pressure probe of the evaporator 4÷20mA - 0.5V

LP1

circuit 1

LP2 circuit 2

dP02=20

pressure probe of the compressor oil differential

OIL

1

comp 1

OIL2 comp 2

dP02=21

Clock

Forced read - out of the top and bottom display

To force the display read-out:

1. Set the dP03 parameter not equal to 0

2. Select the value range 1..3

These configurations allow to show together two temperatures or two pressures of the same circuit in order

to have an easier reading of the measurements:

Par. dP03 = 1

Top display: for both the circuits 1,2:

Evaporator water inlet, with the Ein label.

Bottom display: circuit 1:

Evaporator 1 water outlet, with the label OuT1

Bottom display: circuit 2:

Evaporator 2 water outlet, with the label OuT2.

Par. dP03 = 2

Top display of the circuit 1:

Condenser 1 water inlet temperature with the label CIn1

Bottom display of the circuit 1

Condenser 1water outlet with the label COu1.

Top display of the circuit 2:

Condenser 2 water inlet temperature with the label Cin2

Bottom display of the circuit 2

Condenser 2water outlet with the label Cou2.

Par. dP03 = 3

Top display of the circuit 1:

Condenser probe temperature Cdt1 / pressure CdP1

Bottom display of the circuit 1

Evaporator pressure probe LP1

Top display of the circuit 2:

Condenser probe temperature Cdt2 / pressure CdP2

Bottom display of the circuit 2

Evaporator pressure probe LP2

Default display read - out of the remote panels VI620S